SERVICE MANUAL

FULLY AUTOMATIC

WASHING MACHINE

AW–6'6%2

AW–S'6%$

FILE NO. %-

PRINTED IN THAILAND, -XQ., 20 S

– 1 –

CONTENTS

1. SPECIFICATIONS .................................................................................................................. 1

2. CAUTIONS FOR SAFETY ..................................................................................................... 2

3. CAUTIONS FOR MICROCOMPUTER OPERATION ............................................................. 4

4. TECHNICAL POINT ............................................................................................................... 5

5. INSTALLATION ....................................................................................................................... 8

6. SCHEMATIC DIAGRAM ......................................................................................................... 9

7. CHECKING PROCEDURES ................................................................................................ 10

8. DISASSEMBLY INSTRUCTIONS ......................................................................................... 22

9. CHECK POINTS AFTER REPAIRING ................................................................................. 35

10. EXPLODED VIEWS AND PARTS LIST ................................................................................ 38

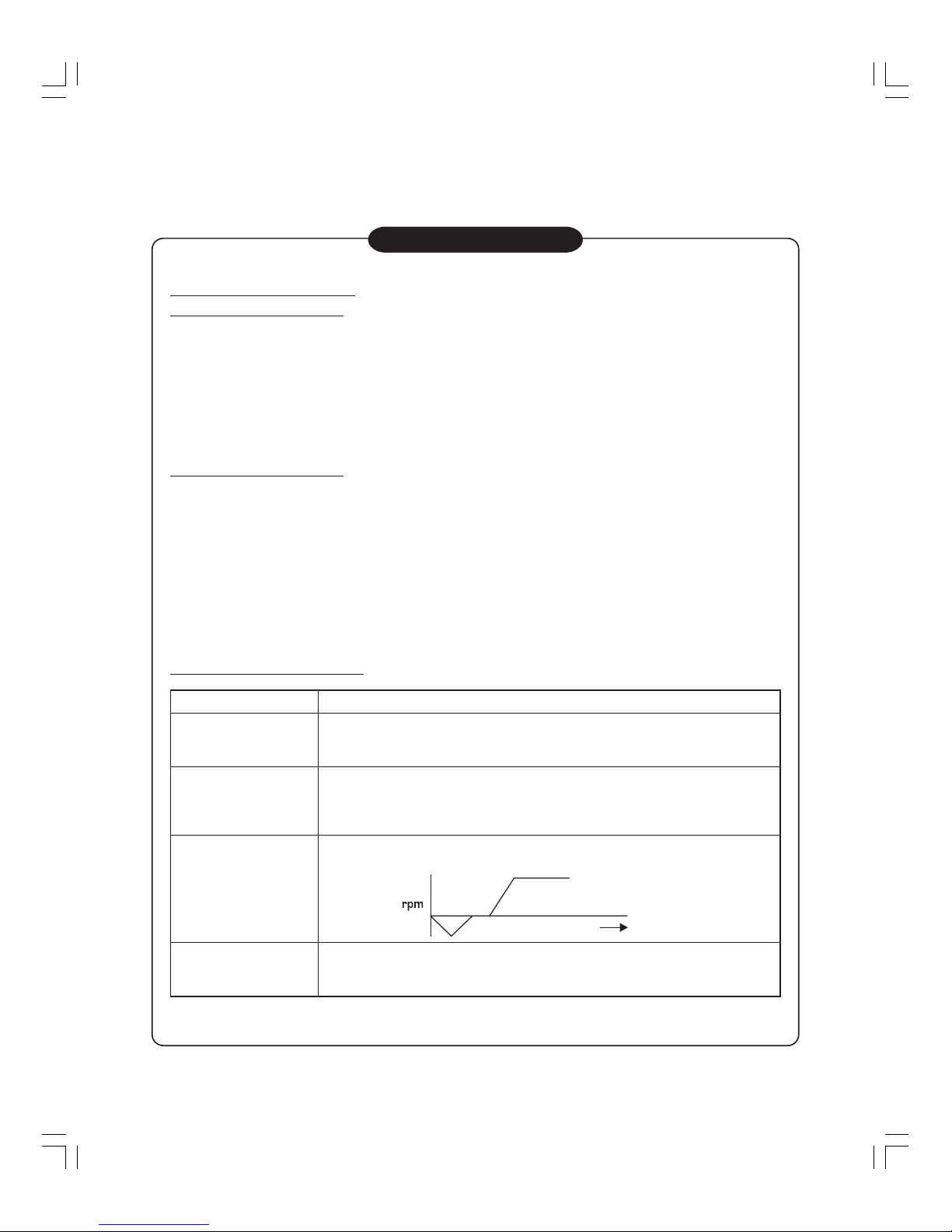

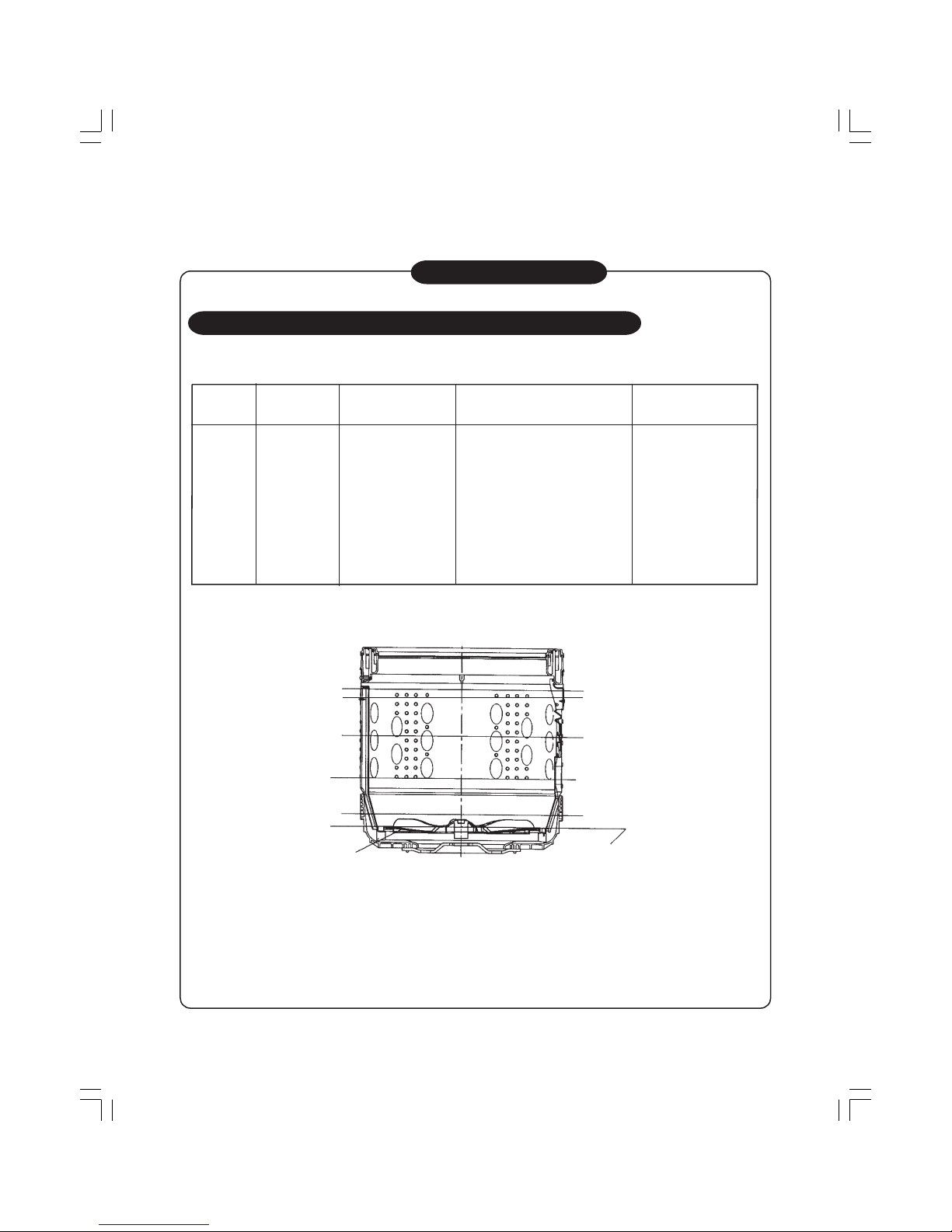

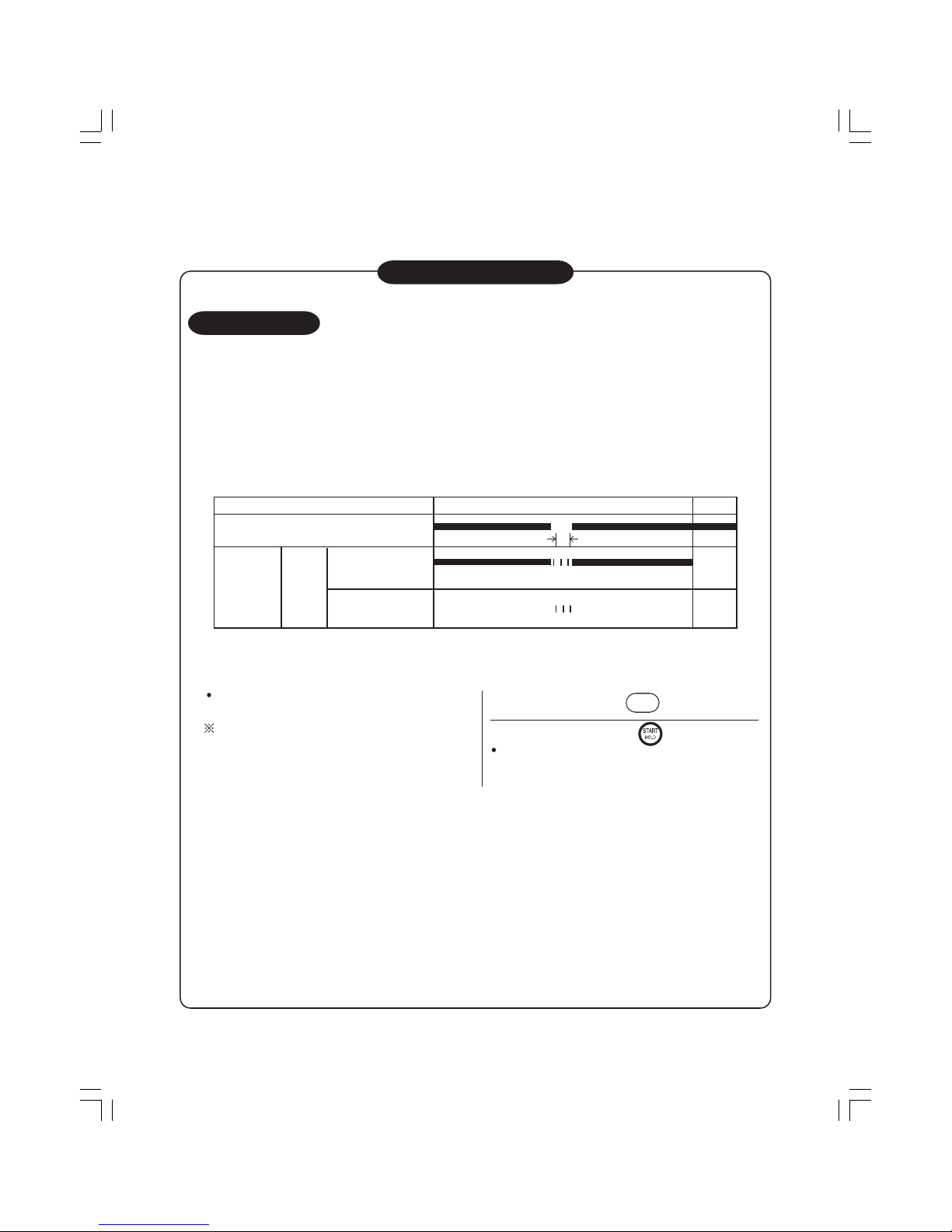

1. SPECIFICATIONS

Model

Wash

Spin

Water Level

Water Consumption

Motor Type

Water Pressure

Hot Water

Overall Dimension

Net Weight

Wash

Spin

AW-SD150SBA

50Hz : 70 - 150 rpm

50Hz : 760 rpm

High : 105 L, LOW : L

Regular cycle : 250 L

Capacitor Motor

0.03 ~ 1 Mpa

50 degrees C or less

W: 685 mm x D: 685 mm x H: 1088 mm

50 kg

1.0 kg

Power Source

Plug Type

Wash

Spin

Destination

Specifications are subject to change without notice.

230 - 240 V, 50Hz

33

W

W

Oman

Power Consumption

Revolution

Capacity

AW-SD150SBO

220 V, 50Hz

W

:

UAE

3P

– 2 –

2. CAUTIONS FOR SAFETY

• Please observe the following important notes on safety.

• The notes mean as follows.

Symbol Meaning

Indicates possibility of death or serious injury of a repair technician and a person

nearby through the misconducted work, or of a user by a defect of the product after

the work performed by the technician.

Indicates possibility of injury or physical damages* of a repair technician and a

person nearby through the misconducted work, or of a user by a defect of the

product after the work performed by the technician.

WARNING

CAUTION

∗ Means secondary damages of property, furniture, domestic animal and pet.

Graphic symbols

Graphic Symbol Meaning

indicates a caution (including a warning).

Specific instruction is followed by a graphic or characters in or near

.

Symbol left warns an electric shock.

indicated prohibition (act must not be conducted).

Specific instruction is followed by a graphic or characters in or near

.

Symbol left warns not to disassemble.

indicates a forcing (act must be conducted).

Specific instruction is followed by a graphic or characters in or near

.

Symbol left warns to unplug the power cord.

ELECTRIC SHOCK

DO NOT

DISASSEMBLE

UNPLUG

L Advise the customer to keep children out of the work place.

Children may be injured with a tool or a disassembled part.

L

Unplug the power cord for the work unnecessary to power on like disassembling.

Do not hold the plug by a wet hand.

Failing to unplug may cause an electric shock.

L Use the specified repair parts when repairing the product.

Otherwise, a malfunction or a defect may occur. Also, a short circuit, ignition or

other danger to the customer may occur.

WARNING

OUT OF CHILD

UNPLUG POWER

USE

REPAIR PARTS

– 3 –

WARNING

L

After the end of working, measure insulation resistance between the charging part

(power cord plug) and the non-charging metallic part (ground) with an insulation

resistance meter (500 V) and check the resistance is 10 MΩ or more.

Failing to check the insulation resistance may cause a short circuit, an electric

shock or other diseases to the customer.

L Do not modify the product.

An electric shock or ignition may occur.

L Only a repair technician can disassemble and repair.

An electric shock, ignition or malfunction may cause injury.

L

Use an exclusive 220 VAC/17 A socket for the washing machine.

Otherwise, an electric shock or ignition may cause. Sharing the same socket with

other instrument causes heating of a branch socket and result in a fire.

L Connect the grounding wire.

Failing to do so may cause an electric shock when a short circuit occurs.

Consult an electric work shop or a sales shop.

L Do not install in a bath room or a place exposed to wind or rain.

An electric shock or a short circuit may cause a fire.

L Do not pour or immerse the electrical parts.

An electric shock or ignition may occur.

L Wipe off the dust adhered to the plug of the power cord.

Dust may cause a fire.

L Do not put inflammable into the washing tub.

Do not put cloths stained with kerosene, gasoline, benzene, thinner, alcohol. etc. It may

causea a fire or explosion.

L Do not touch the laundry before the spin basket stops completely.

The laundry entangles your hand causing an injury even if the basket rotates slowly.

Pay special attention to children.

CHECK INSULATION

RESISTANCE

DO NOT MODIFY

DO NOT

DISASSEMBLE

AND REPAIR

USE EXCLUSIVE

SOCKET

CONNECT

GROUNDING WIRE

DO NOT USE

WET PLACE

DO NOT SPLASH

WATER

REMOVE DUST

DO NOT TOUCH

AVOID INFLAM-

MABLE

– 4 –

CAUTION

L Ask an electric work shop to install the product.

Install the product securely and safely according to the electrical equipment

technical standard and the wiring standard.

Incorrect work causes an electric shock and a fire.

L Do not pull the power cord when unplugging.

Hold the power plug to unplug.

An electric shock or short circuit may cause a fire.

L Do not insert your hand under the washing machine during operation.

There is a rotary part under the machine which may cause an injury.

L Before starting washing, open the faucet and check that the water supply hose

joint is not loose and no water leaks.

The loose screw or hose joint may cause water leakage resulting in an unexpected damage.

INSTALL

CAREFULLY

DO NOT PULL

DANGER HAND

WATER LEAKAGE

3. CAUTIONS FOR MICROCOMPUTER OPERATION

When changing the cycles or procedures of the operation on the way, the operation will not be changed even if

the START/HOLD button is pushed.

When changing the cycles or the procedures of the operation, please turn off the power switch and set them

again.

When the power switch is not turned on, the operation is not performed even if the clock display appears.

(When the clock display appears on the display panel, it may lead misunderstanding to control the operation.

But the operation is not performed in this condition.)

– 5 –

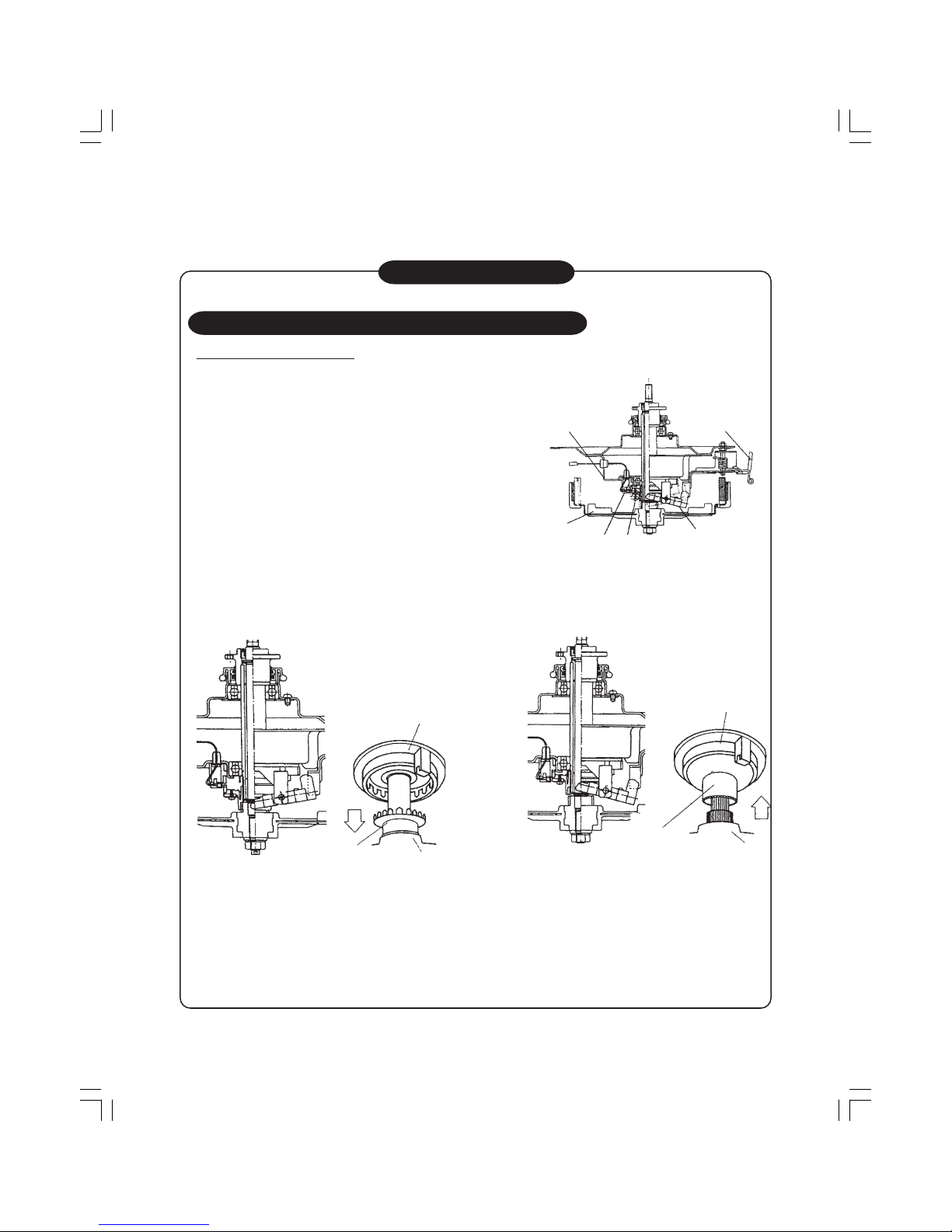

4. Technical Points

One-Point Information

About operation switching by clutch mechanism

1. About Clutch Mechanism

Switch washing operation and spinning operation by

a sliding clutch mechanism. The sliding clutch is

operated by pulling and pushing back the clutch lever.

1) When washing operation is performed, the teeth

on the top of the clutch fit into the teeth of the

lock gear on the upper part of the product

(on cup assy side). Fig.3

2) When spinning operation is performed, the

teeth on the bottom of the clutch fit into the teeth

of the boss on the lower part of the product

(on rotor side). Fig.2

Cup assy Clutch lever

Rotor

Lock gear

Clutch

Switching lever

Fig.1 Clutch mechanism

Lock gear

Clutch

Rotor

Lock gear

Clutch

Rotor

Fig.2 Clutch condition during spinning operation Fig.3 Clutch condition during washing operation

– 6 –

One-Point Information

2. About Operation Switching

Wash A Spin clutch switching

1 Pull the drain valve. (Pull the clutch lever.)

2 The pulsator rotates forwards while repeating small forward and reverse rotations.

3 Clutch switching is completed when both the wash tub and the pulsator start rotating.

In the case where the clutch is not switched even after the clutch switching is attempted 4 times, fill the

wash tub with water again and fluff the laundry, then perform the same switching operation. If the clutch is

still not switched, the error Ec6 is displayed.

Sometimes, clutch switching operation is performed by filling the wash tub with water at the start of

spinning.

(See Page 2 for details of Ec errors.)

Spin A Wash clutch switching

1 The drain valve returns. (The lever returns.)

2 Spin tub makes small forward and reverse rotations.

3 The spin tub makes large forward and reverse rotations at a low speed.

4 Clutch switching is completed when only the pulsator starts rotating.

In the case where the clutch is not switched even after the clutch switching is attempted 6 times, fill the

wash tub with water and let it stand for 3 minutes, then perform the switching operation again. If the

clutch is still not switched, rotate the wash tub by 180 degrees and perform the same switching operation.

If the clutch is still not switched, the error Ec5 is displayed. (See Page 2 for details of Ec errors.)

Note) If the washing operation was originally being performed, the clutch switching is not performed but

the washing operation starts immediately.

3. About operation of wash tub

When the power is

turned off during spin

process

Operation

Just as the current models, the wash tub does not rotate even if it is not turned

clockwise or counterclockwise direction. The wash tub stops at multiple

positions (at one of the 18 points for every 20 degrees)

Just as the current models, the wash tub rotates freely both in clockwise or

counterclockwise direction. When a long time (30 minutes) has elapsed, the

machine is switched to the clutch switching standby status.

After rotating in the reverse direction at the start of spinning, the main spinning

is performed. (This control is adopted from E-series.)

Just as the current models, brake is applied to stop rotation. When the rotation

stops, the clutch lever returns and the machine is switched to the clutch

switching standby status.

Process

Wash process & when

wash process is stopped

When spin process is

suspended.

(When the lid is opened

during spin process)

At the start of spinning

Forward rotation

Reverse rotation

Time

– 7 –

One-Point Information

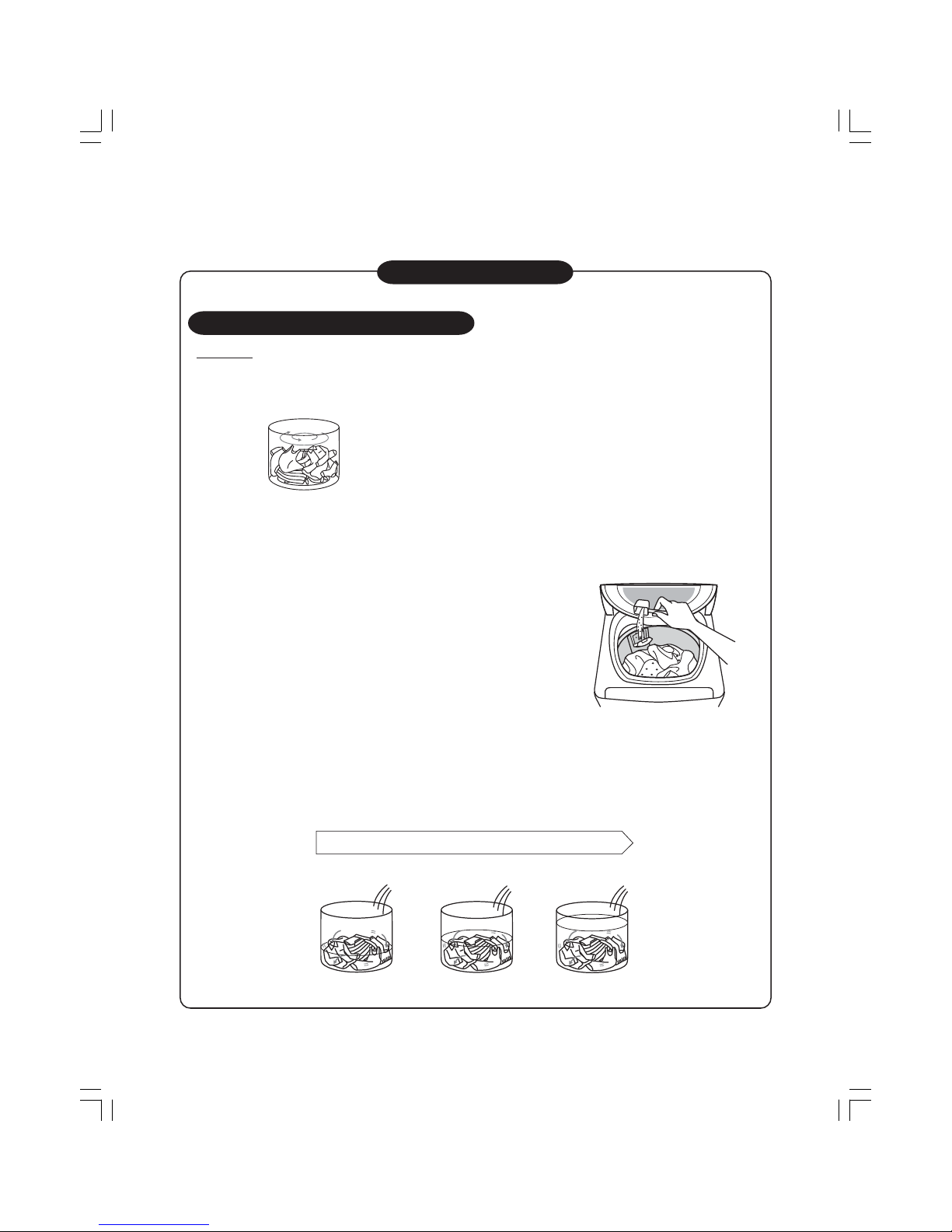

About Concentrated Bubble Wash

1. Outline

Put the laundry in the basket and start the machine. The sensor will weigh clothes and begin flowing water.

1

The pulsator begins to revolve 6 seconds after startup under none-water situation, and clothes are

weighed.

2

)ORwing water starts. Put in detergent accorGLQJWRWKHUHIHUHQFHYDOXHWKURXJKHQWU\JDWHRI

"Washing Spinning Tub", followed by softening agent. Close the lid. Display of detergent amount.

■ How to put detergent

Referring to the indicated detergent amount, put the

detergent into the detergent dispenser of the wash/spin tub.

Excessive detergent may lead to excessive suds or

insufficient rinsing.

If the water level is set to too low, some detergent may be

left in the dispenser.

In this case, put the detergent inside the wash/spin tub

around its peripheral.

∗ There are 2 dispensers.

Choose more convenient one to put in the detergent.

• When changing the dispenser position

Turn on the power, set spin only while the lid is open, and then start the machine.

After “E21” is displayed, rotate the wash/spin tub manually to adjust the dispenser position. Then,

turn off the power.

3

The water level indicator will be lighted when flowing water ends by reaching the preset water level.

• When a chemical fiber, blending fiber or spreadsheet is washed, the water level may be a little bit low.

Adjust the water level by "WATER LEVEL" button.

Stirring starts during flowing water while washing and flowing water are executed simultaneously.

Times of flowing water differ depending onFORWKHVZHLJKWDQGULQVLQJIUHTXHQF\

Washinging

Stirring during

flowing water

Stirring during

flowing water

Stirring during

flowing water

– 8 –

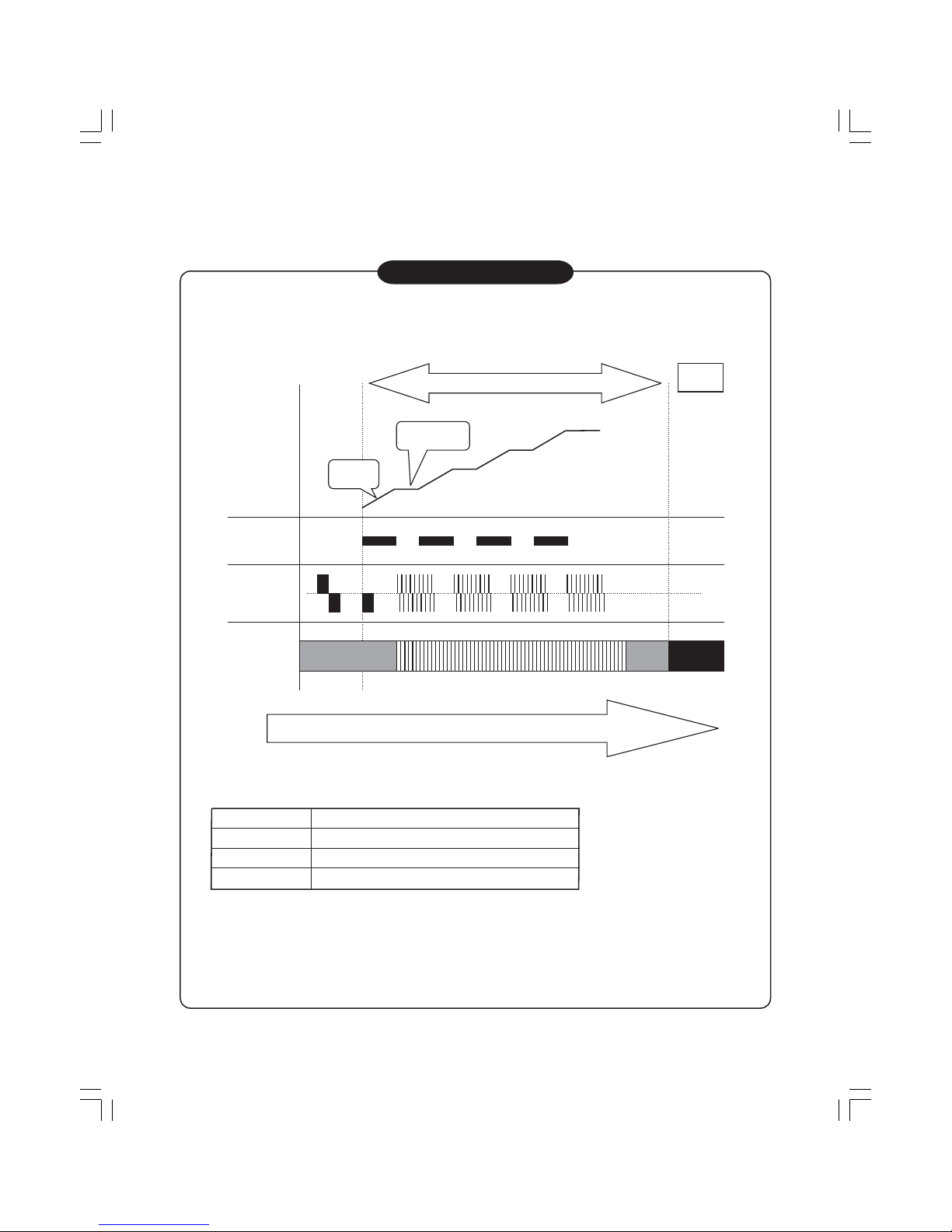

One-Point Information

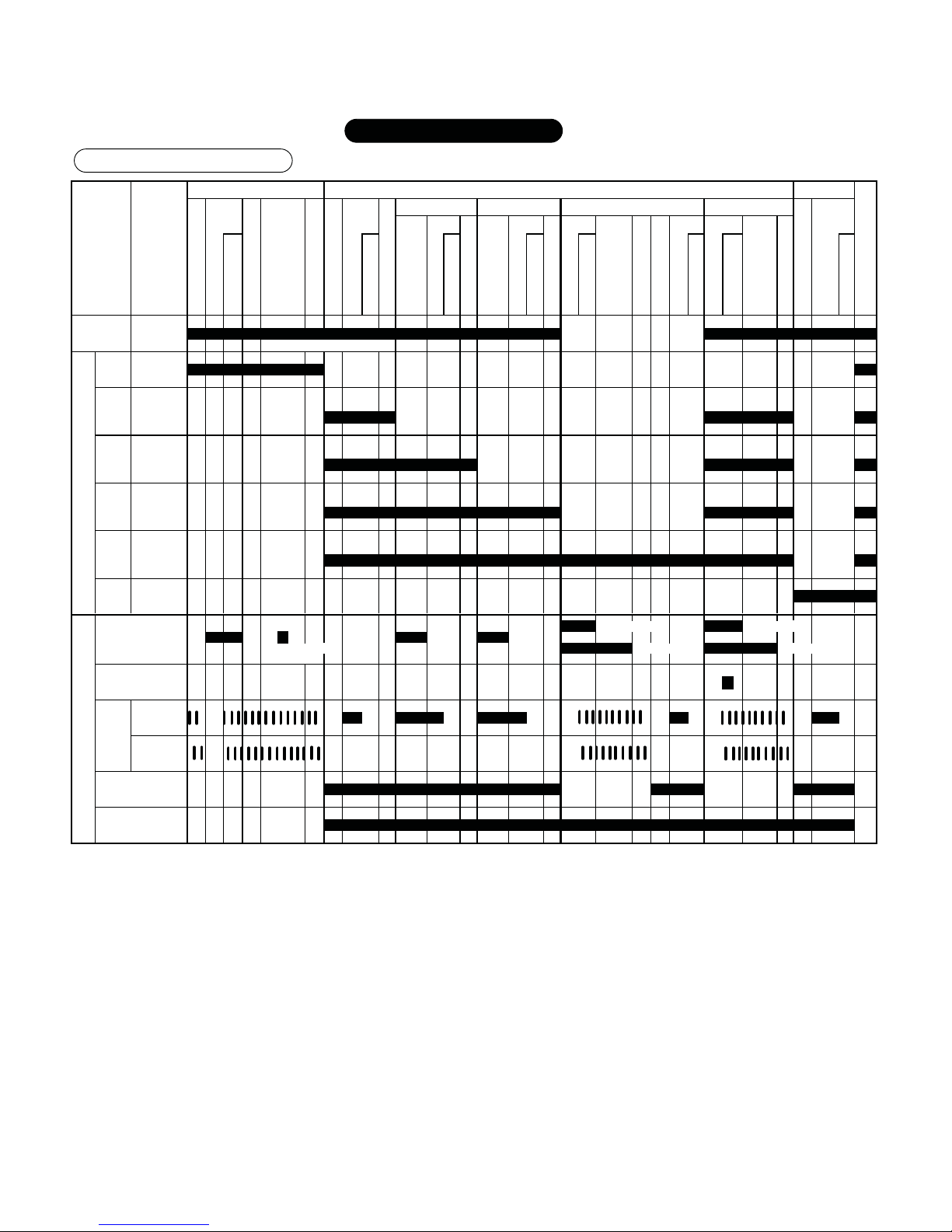

2. Operation Cycle

Example : At high water level

High

Water level

Low

Water

supply valve

Motor

Concentrated

Bubble

Cleaning

Indicator

Weight

sensor

Wash Process

Drain

Agitation

Water

supply

Light Flash Light Off

Time scale

Washing load Number of levels of water supply and agitation

8.1 kg and above

1.1 ~ 8.0 kg 3 levels

Below 1.0 kg 2 levels

Number of levels of water supply and agitation vary depending on the washing load.

∗ When increasing the number of rinsing for the reason that the tub has already been filled with water,

the above number of levels may become less.

∗ Agitation varies depending on the washing load

∗ If washing time (preset: 15 minutes) is changed in the midst of wash process, agitating time in each level

becomes shorter.

4 levels

– 9 –

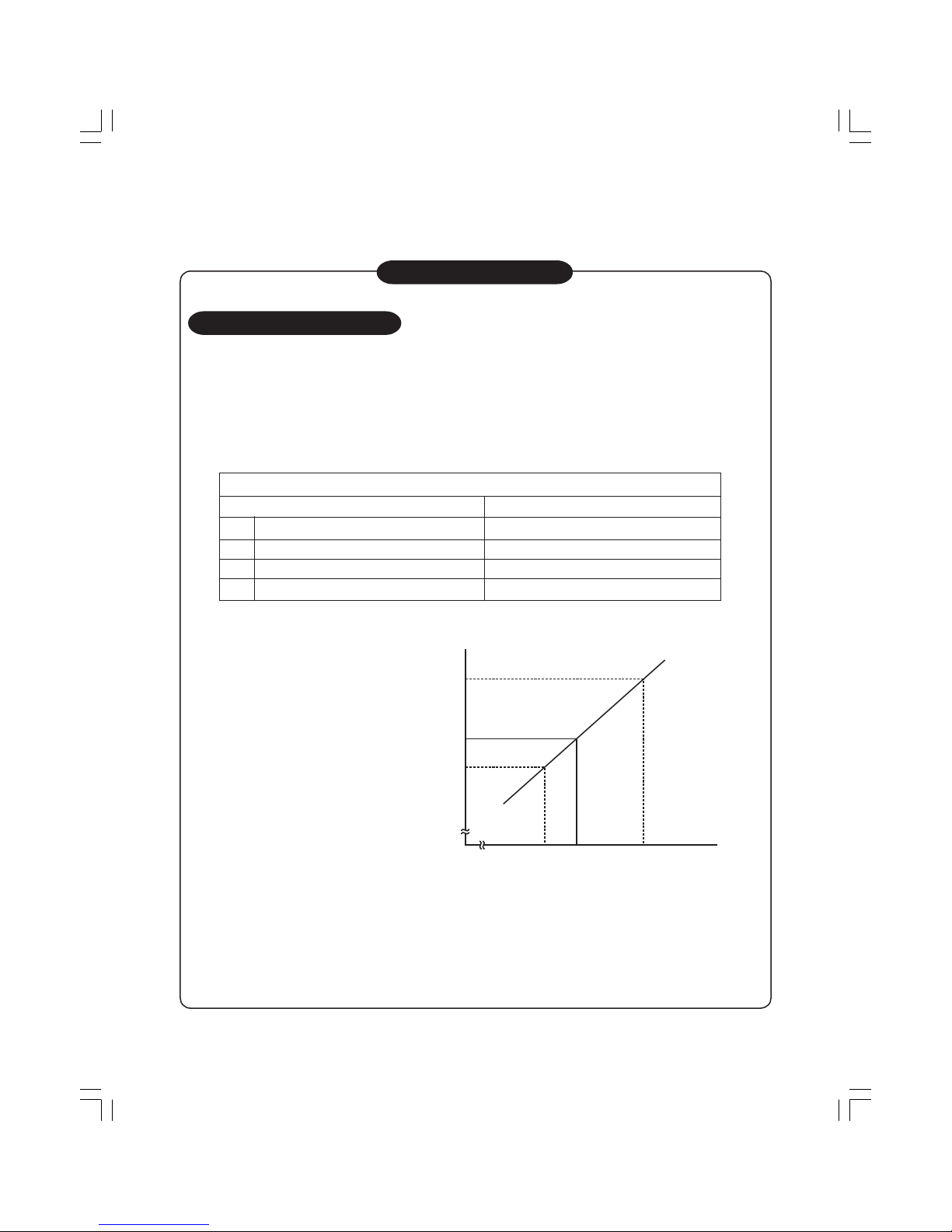

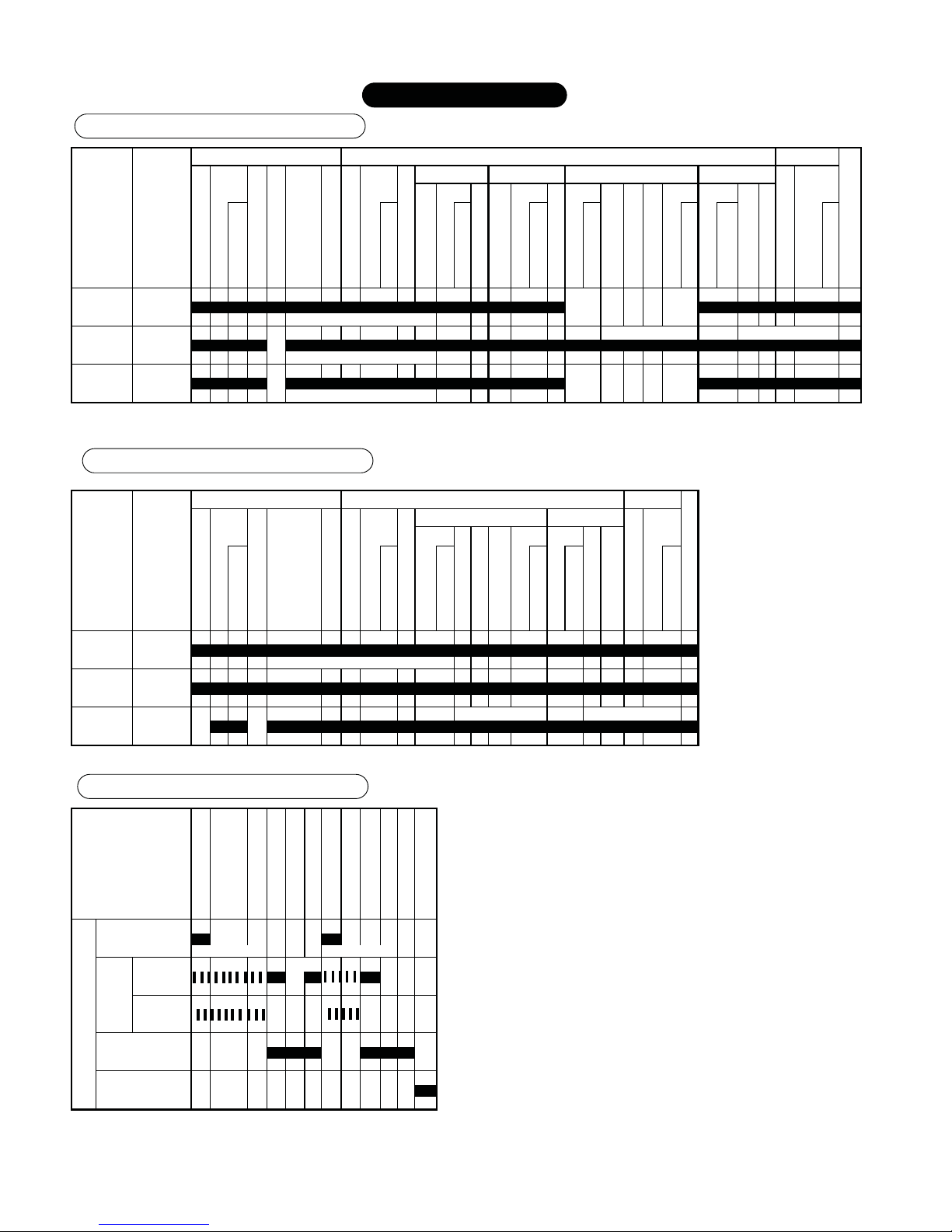

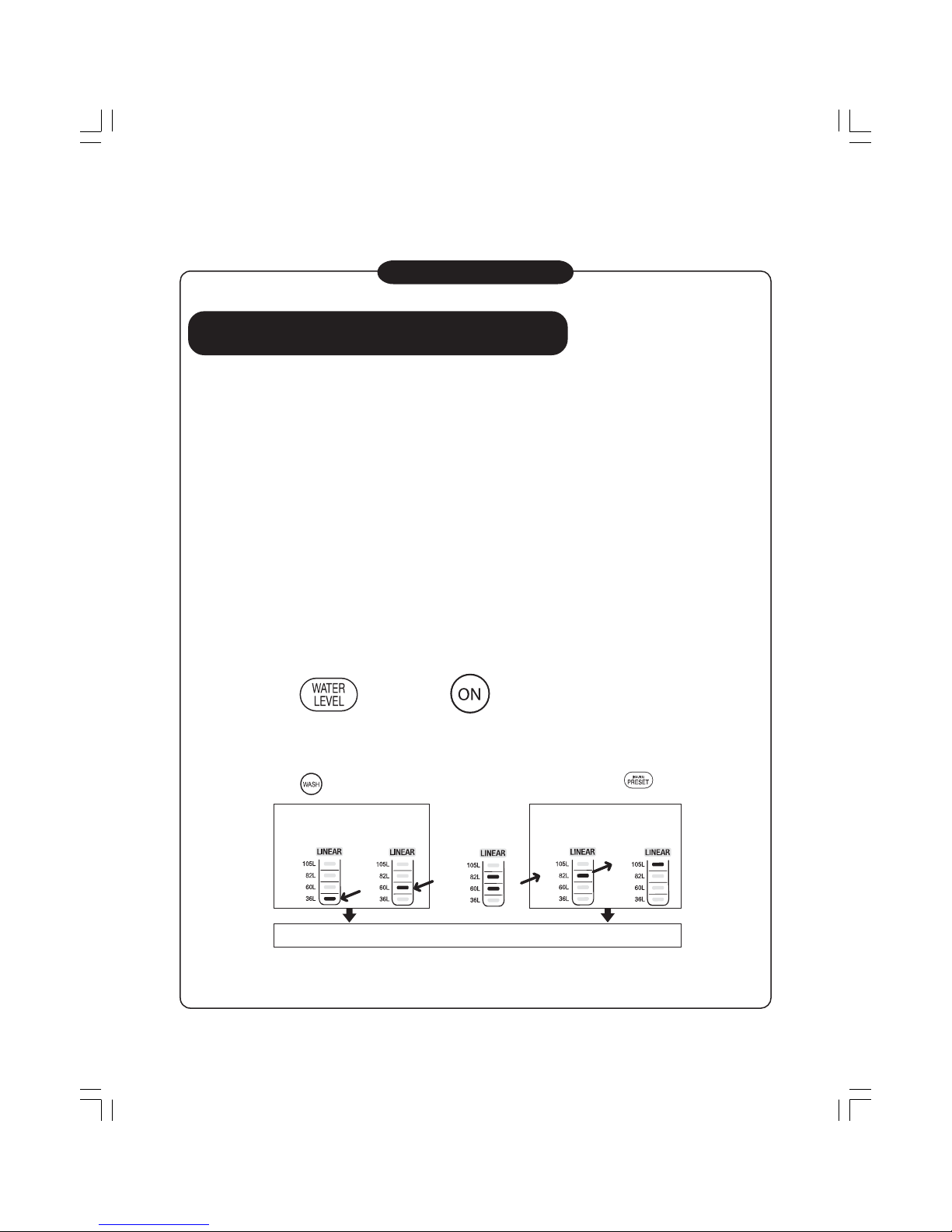

One-Point Information

About Linear Water Level

When “Standard”, “Soak” , “Memory”,"Heavy","Delicate" or "Softener" is set, the weight sensor automatically

sets the most suitable water level for the washing load on a linear basis to save water.

Setting is made based on the 4-levelled water level for manual setting. For example, when the detected

washing load is 5.0kg, the most suitable water level of 67.3L is automatically set by proportional calculation

between the first level of 82L for washing load of 7.0kg and the second level of 60L for washing load of

4.0kg. The display indicator for the lower water level, i.e., 60L for this example, turns on.

Manually set water level

1

2

82L

7.0Kg

3

60L

4.0Kg

4

36L

1.0Kg

2

.

4.0

5..

(L)

(KL)

Water level

Washing load

Water level of 36L is very low as the blade of the pulsator is not fully covered with water. However, this water

level is suitable for washing the washing load of 1.0kg or below.

It is not an abnormal level.

AW-SD1567\SH

1.0Kg

105L

Washing load

– 10 –

One-Point Information

Relation between oscillation frequency and water level

The table below shows the relation between oscillation frequency and water level.

Water level Water amount Oscillation frequency

Distance from the top edge of the

Reference water level

outer periphery of the pulsator

–

26.40kHz and above

––

– 26.05kHz – –

36L 25.10kHz 100±30 mm

60L 23.80kHz

82L 23.00kHz

100L 22.05kHz

No water

reset

Low 60L

Pulsator

High 105L

Med 82L

Very little 36L

End of the outer

periphery of the pulsator

<Reference Water Level>

105L 22.00kHz

High 100L

±

30 mm

±

30 mm

5HIHUWRWKHILJXUHEHORZ

±

15 mm

±

15 mm

㩷㩷㪚㫆㫌㫉㫊㪼

㪮㪸㫋㪼㫉

㫃㪼㫍㪼㫃

㪁㪥㫆㫋㪼㪈

㪮㪼㫀㪾㪿㫋㩷㪻㪼㫋㪼㪺㫋㫀㫆㫅

㪮㪸㫋㪼㫉㩷㫊㫌㫇㫇㫃㫐

㪧㫉㪼㪄㪸㪾㫀㫋㪸㫋㫀㫆㫅

㪮㪸㫊㪿

㪩㪸㫍㪼㫃

㪛㫉㪸㫀㫅

㪪㫇㫀㫅

㪪㫋㫆㫇

㪙㫉㪸㫂㪼

㪮㪸㫋㪼㫉㩷㪽㫀㫃㫃㫀㫅㪾

㪪㫇㫀㫅

㪪㫋㫆㫇

㪙㫉㪸㫂㪼

㪮㪸㫋㪼㫉㩷㪽㫀㫃㫃㫀㫅㪾

㪪㫇㫀㫅

㪪㫋㫆㫇

㪙㫉㪸㫂㪼

㪮㪸㫋㪼㫉㩷㫊㫌㫇㫇㫃㫐

㪧㫉㪼㪄㪸㪾㫀㫋㪸㫋㫀㫆㫅

㪩㫀㫅㫊㪼

㪩㪸㫍㪼㫃

㪛㫉㪸㫀㫅

㪪㫇㫀㫅

㪪㫋㫆㫇

㪮㪸㫋㪼㫉㩷㫊㫌㫇㫇㫃㫐

㪧㫉㪼㪄㪸㪾㫀㫋㪸㫋㫀㫆㫅

㪩㫀㫅㫊㪼

㪩㪸㫍㪼㫃

㪛㫉㪸㫀㫅

㪪㫇㫀㫅

㪪㫋㫆㫇

㪙㫌㫑㫑㪼㫉

㪣㫀㫅㪼㪸㫉

㪸㫌㫋㫆㩷㫊㪼㫋㫋㫀㫅㪾

㩿㪊㪍㪣䌾㪈㪇㪌㪣㪀

䋨㪟㫀㪾㪿㩷㫎㪸㫋㪼㫉㩷㫃㪼㫍㪼㫃㩷㪺㫆㫅㪻㫀㫋㫀㫆㫅㩷㪀

㪣㫀㫅㪼㪸㫉

㪮㪸㫊㪿

㪸㫌㫋㫆㩷㫊㪼㫋㫋㫀㫅㪾

㩿㪊㪍㪣䌾㪈㪇㪌㪣㪀

㪣㫀㫅㪼㪸㫉

㪩㫀㫅㫊㪼

㪸㫌㫋㫆㩷㫊㪼㫋㫋㫀㫅㪾

㫆㫅㪼

㩿㪊㪍㪣䌾㪈㪇㪌㪣㪀

㫋㫀㫄㪼 㪁㪥㫆㫋㪼㪉

㪣㫀㫅㪼㪸㫉

㪩㫀㫅㫊㪼

㪸㫌㫋㫆㩷㫊㪼㫋㫋㫀㫅㪾

㫋㫎㫆

㩿㪊㪍㪣䌾㪈㪇㪌㪣㪀

㫋㫀㫄㪼㫊 㪁㪥㫆㫋㪼㪉

㪣㫀㫅㪼㪸㫉

㪩㫀㫅㫊㪼

㪸㫌㫋㫆㩷㫊㪼㫋㫋㫀㫅㪾

㫋㪿㫉㪼㪼

㩿㪊㪍㪣䌾㪈㪇㪌㪣㪀

㫋㫀㫄㪼㫊 㪁㪥㫆㫋㪼㪉

㪣㫀㫅㪼㪸㫉

㪩㫀㫅㫊㪼

㪸㫌㫋㫆㩷㫊㪼㫋㫋㫀㫅㪾

㪽㫆㫌㫉

㩿㪊㪍㪣䌾㪈㪇㪌㪣㪀

㫋㫀㫄㪼㫊 㪁㪥㫆㫋㪼㪉

㪪㫇㫀㫅 㫅㫀㫃

㫊㫋㪸㫋㫀㪺㩷㫉㫀㫅㫊㪼㩷 㩷㫊㫋㪸㫋㫀㪺㩷㫉㫀㫅㫊㪼㩷

㩿㫊㫌㫇㫇㫃㪼㫄㪼㫅㫋㪸㫃㫐㩷 㫆㫍㪼㫉㩷㪽㫃㫆㫎㩷㫉㫀㫅㫊㪼 㫆㫍㪼㫉㩷㪽㫃㫆㫎㩷㫉㫀㫅㫊㪼

㩷㩷㫎㪸㫋㪼㫉㩷㪽㫀㫃㫃㫀㫅㪾㪀

㪝㫆㫉㫎㪸㫉㪻

㫉㫆㫋㪸㫋㫀㫆㫅

㩿㩷㪚㪚㪮㪀

㪩㪼㫍㪼㫉㫊㪼

㫉㫆㫋㪸㫋㫀㫆㫅

㩿㩷㪚㪮㪀

㪥㫆㫋㪼㪈㩷㪑

㪥㫆㫋㪼䋲㩷㪑 㪮㪿㪼㫅㩷㩹㪮㪸㫊㪿㩹㩷㫀㫊㩷㫅㫆㫋㩷㫊㪼㫋㩷㪃㩷㫋㪿㪼㩷㫎㪸㫋㪼㫉㩷㫃㪼㫍㪼㫃㩷㫎㫀㫃㫃㩷㪸㫌㫋㫆㫄㪸㫋㫀㪺㪸㫃㫃㫐㩷㪹㪼㩷㫊㪼㫋㩷㫋㫆㩷㪿㫀㪾㪿㪅

䊶䇭㪠㫅㩷㫋㪿㪼㩷㪺㪸㫊㪼㩷㫎㪿㪼㫉㪼㩷㫋㪿㪼㩷㫇㫆㫎㪼㫉㩷㫀㫊㩷㫋㫌㫉㫅㪼㪻㩷㫆㫅㩷㩿㩷㫋㪿㪼㩷㫇㫆㫎㪼㫉㩷㪹㫌㫋㫋㫆㫅㩷㫀㫊㩷㫇㫉㪼㫊㫊㪼㪻㩷㪀㩷㪹㫌㫋㩷㫅㫆㩷㫆 㫇㪼㫉㪽㫆㫉㫄㪼㪻㪃㩷㫋㪿㪼㩷㫇㫆㫎㪼㫉㩷㫀㫊㩷㫋㫌㫉㫅㪼㪻㩷㫆㪽㪽㩷㫀㫅㩷㪈㪇㩷㫄㫀㫅㫌㫋㪼㫊㪅

㪣㫀㪻㩷㪣㫆㪺㫂

㪦㫌㫋㫆㫌㫋

㪪㫆㪽㫋㪼㫅㪼㫉㩷㫎㪸㫋㪼㫉

㫊㫌㫇㫇㫃㫐㩷㫍㪸㫃㫍㪼

㪤㫆㫋㫆㫉

㪛㫉㪸㫀㫅㩷㫍㪸㫃㫍㪼

㪪㫋㪸㫋㫀㪺㩷㫉㫀㫅㫊㪼㩷㪈 㪪㫋㪸㫋㫀㪺㩷㫉㫀㫅㫊㪼㩷㪉

㪩㫀㫅㫊㪼 㪪㫇㫀㫅

㪮㪸㫋㪼㫉㩷㪽㫃㫆㫎㩷㪻㪼㫋㪼㪺㫋㫀㫆㫅

㪮㪸㫊㪿

㪪㪿㫆㫎㪼㫉㩷㫉㫀㫅㫊㪼㩷㪈 㪪㪿㫆㫎㪼㫉㩷㫉㫀㫅㫊㪼㩷㪉

㪚㫆㫅㪻㪼㫅㫊㪼㪻

㪩㪼㪾㫌㫃㪸㫉

㪤㪼㫄㫆㫉㫐

㪮㪸㫋㪼㫉㩷㫊㫌㫇㫇㫃㫐㩷㫍㪸㫃㫍㪼

㪦㫅㪼㪄㪧㫆㫀㫅㫋㩷㩷㪠㫅㪽㫆㫉㫄㪸㫋㫀㫆㫅

㪮㪸㫊㪿㫀㫅㪾㩷㪧㫉㫆㪺㪼㫊㫊㩷㪚㪿㪸㫉㫋

– 11 –

AW-SD150S Type 36L ~ 105L

peration is

㩷㩷㪚㫆㫌㫉㫊㪼

㪮㪸㫋㪼㫉

㫃㪼㫍㪼㫃

㪮㪼㫀㪾㪿㫋㩷㪻㪼㫋㪼㪺㫋㫀㫆㫅

㪮㪸㫋㪼㫉㩷㫊㫌㫇㫇㫃㫐

㪧㫉㪼㪄㪸㪾㫀㫋㪸㫋㫀㫆㫅

㪪㫆㪸㫂

㪩㪸㫍㪼㫃

㪛㫉㪸㫀㫅

㪪㫇㫀㫅

㪪㫋㫆㫇

㪙㫉㪸㫂㪼

㪮㪸㫋㪼㫉㩷㪽㫀㫃㫃㫀㫅㪾

㪪㫇㫀㫅

㪪㫋㫆㫇

㪙㫉㪸㫂㪼

㪮㪸㫋㪼㫉㩷㪽㫀㫃㫃㫀㫅㪾

㪪㫇㫀㫅

㪪㫋㫆㫇

㪙㫉㪸㫂㪼

㪮㪸㫋㪼㫉㩷㫊㫌㫇㫇㫃㫐

㪧㫉㪼㪄㪸㪾㫀㫋㪸㫋㫀㫆㫅

㪩㫀㫅㫊㪼

㪩㪸㫍㪼㫃

㪛㫉㪸㫀㫅

㪪㫇㫀㫅

㪪㫋㫆㫇

㪮㪸㫋㪼㫉㩷㫊㫌㫇㫇㫃㫐

㪧㫉㪼㪄㪸㪾㫀㫋㪸㫋㫀㫆㫅

㪩㫀㫅㫊㪼

㪩㪸㫍㪼㫃

㪛㫉㪸㫀㫅

㪪㫇㫀㫅

㪪㫋㫆㫇

㪙㫌㫑㫑㪼㫉

㪣㫀㫅㪼㪸㫉

㪸㫌㫋㫆㩷㫊㪼㫋㫋㫀㫅㪾

㩿㪊㪍㪣䌾㪈㪇㪌㪣㪀

䋨㪟㫀㪾㪿㩷㫎㪸㫋㪼㫉㩷㫃㪼㫍㪼㫃㩷㪺㫆㫅㪻㫀㫋㫀㫆㫅㩷㪀

㪣㫀㫅㪼㪸㫉

㩿㫆㫍㪼㫉㩷㪽㫃㫆㫎㩷㫉㫀㫅㫊㪼㪀 㩿㫆㫍㪼㫉㩷㪽㫃㫆㫎㩷㫉㫀㫅㫊㪼㪀

㪸㫌㫋㫆㩷㫊㪼㫋㫋㫀㫅㪾

㩿㪊㪍㪣䌾㪈㪇㪌㪣㪀

䋨㪟㫀㪾㪿㩷㫎㪸㫋㪼㫉㩷㫃㪼㫍㪼㫃㩷㪺㫆㫅㪻㫀㫋㫀㫆㫅㩷㪀

㪣㫀㫅㪼㪸㫉

㩿㪍㩷㫄㫀㫅㪀 㩿㪌㩷㫄㫀㫅㪀

㪸㫌㫋㫆㩷㫊㪼㫋㫋㫀㫅㪾

㩿㪊㪍㪣䌾㪈㪇㪌㪣㪀

䋨㪟㫀㪾㪿㩷㫎㪸㫋㪼㫉㩷㫃㪼㫍㪼㫃㩷㪺㫆㫅㪻㫀㫋㫀㫆㫅㩷㪀

㩷㩷㪚㫆㫌㫉㫊㪼

㪮㪸㫋㪼㫉

㫃㪼㫍㪼㫃

㪮㪼㫀㪾㪿㫋㩷㪻㪼㫋㪼㪺㫋㫀㫆㫅

㪮㪸㫋㪼㫉㩷㫊㫌㫇㫇㫃㫐

㪧㫉㪼㪄㪸㪾㫀㫋㪸㫋㫀㫆㫅

㪮㪸㫊㪿

㪩㪸㫍㪼㫃

㪛㫉㪸㫀㫅

㪪㫇㫀㫅

㪪㫋㫆㫇

㪙㫉㪸㫂㪼

㪮㪸㫋㪼㫉㩷㫊㫌㫇㫇㫃㫐

㪧㫉㪼㪄㪸㪾㫀㫋㪸㫋㫀㫆㫅

㪩㫀㫅㫊㪼

㪩㪸㫍㪼㫃

㪛㫉㪸㫀㫅

㪪㫇㫀㫅

㪪㫋㫆㫇

㪮㪸㫋㪼㫉㩷㫊㫌㫇㫇㫃㫐

㪧㫉㪼㪄㪸㪾㫀㫋㪸㫋㫀㫆㫅

㪩㫀㫅㫊㪼

㪩㪸㫍㪼㫃

㪛㫉㪸㫀㫅

㪪㫇㫀㫅

㪪㫋㫆㫇

㪙㫌㫑㫑㪼㫉

㪣㫀㫅㪼㪸㫉

㪸㫌㫋㫆㩷㫊㪼㫋㫋㫀㫅㪾

㩿㪊㪍㪣䌾㪈㪇㪌㪣㪀

䋨㪟㫀㪾㪿㩷㫎㪸㫋㪼㫉㩷㫃㪼㫍㪼㫃㩷㪺㫆㫅㪻㫀㫋㫀㫆㫅㩷㪀

㪣㫀㫅㪼㪸㫉

㩿㪍㩷㫄㫀㫅㪀 㩿㪊㩷㫄㫀㫅㪀

㪸㫌㫋㫆㩷㫊㪼㫋㫋㫀㫅㪾

㩿㪊㪍㪣䌾㪍㪇㪣㪀

㩿㫆㫍㪼㫉㩷㪽㫃㫆㫎㩷㫉㫀㫅㫊㪼㪀 㩿㫆㫍㪼㫉㩷㪽㫃㫆㫎㩷㫉㫀㫅㫊㪼㪀

㪈㪇㪌㪣

㪮㪸㫋㪼㫉㩷㫊㫌㫇㫇㫃㫐

㪮㪸㫊㪿

㪪㫇㫀㫅㩷㩷㩷㫉㪼㫄㪸㫀㫅㫀㫅㪾㩷㫎㪸㫋㪼㫉

㪛㫉㪸㫀㫅

㪪㫇㫀㫅

㪮㪸㫋㪼㫉㩷㫊㫌㫇㫇㫃㫐

㪩㫀㫅㫊㪼

㪪㫇㫀㫅㩷㩷㩷㫉㪼㫄㪸㫀㫅㫀㫅㪾㩷㫎㪸㫋㪼㫉

㪛㫉㪸㫀㫅

㪪㫇㫀㫅

㪙㫌㫑㫑㪼㫉

㪮㪸㫋㪼㫉㩷㫊㫌㫇㫇㫃㫐㩷㫍㪸㫃㫍㪼

㩿㪟㫀㪾㪿㩷㪂㩷㪊㪇㩷㫊㪼㪺㪀 㩿㪟㫀㪾㪿㩷㪂㩷㪊㪇㩷㫊㪼㪺㪀

㪝㫆㫉㫎㪸㫉㪻 㩿㪍㩷㫄㫀㫅㪀

㫉㫆㫋㪸㫋㫀㫆㫅

㩿㩷㪚㪚㪮㪀

㪩㪼㫍㪼㫉㫊㪼

㫉㫆㫋㪸㫋㫀㫆㫅

㩿㩷㪚㪮㪀

㪛㫉㪸㫀㫅㩷㫍㪸㫃㫍㪼

㪘㫌㫋㫆㩷

㫇

㫆㫎㪼㫉㩷㫆㪽㪽

㪪㫋㪸㫋㫀㪺㩷㫉㫀㫅㫊㪼㩷㪈 㪪㫋㪸㫋㫀㪺㩷㫉㫀㫅㫊㪼㩷㪉

㪩㫀㫅㫊㪼 㪪㫇㫀㫅㪮㪸㫊㪿

㪪㪿㫆㫎㪼㫉㩷㫉㫀㫅㫊㪼㩷㪈 㪪㪿㫆㫎㪼㫉㩷㫉㫀㫅㫊㪼㩷㪉

㪮㪸㫊㪿

㪛㪼㫃㫀㪺㪸㫋㪼

㪪㫇㪼㪼㪻

㪮㪸㫋㪼㫉㩷㪽㫃㫆㫎㩷㪻㪼㫋㪼㪺㫋㫀㫆㫅

㪪㫆㪸㫂

㪟㪼㪸㫍㫐㩷㫎㪸㫊㪿

㪮㪸㫊㪿 㪪㫇㫀㫅

㪪㫋㪸㫋㫀㪺㩷㫉㫀㫅㫊㪼㩷㪈 㪪㫋㪸㫋㫀㪺㩷㫉㫀㫅㫊㪼㩷㪉

㪤㫆㫋㫆㫉

㪪㫆㪸㫂

㪦㫌㫋㫇㫌㫋

㪩㫀㫅㫊㪼

㪙㫃㪸㫅㫂㪼㫋

㪮㪸㫋㪼㫉㩷㪽㫃㫆㫎㩷㪻㪼㫋㪼㪺㫋㫀㫆㫅

㪪㫆㪽㫋㪼㫅㪼㫉

㪦㫅㪼㪄㪧㫆㫀㫅㫋㩷㩷㪠㫅㪽㫆㫉㫄㪸㫋㫀㫆㫅

㪪㫆㪸㫂㩷䊶㩷㪟㪼㪸㫍㫐㩷㫎㪸㫊㪿㩷䊶㩷㪛㪼㫃㫀㪺㪸㫋㪼㩷㩷㪚㫆㫌㫉㫊㪼

㪪㫆㪽㫋㪼㫅㪼㫉㩷䊶㩷㪪㫇㪼㪼㪻㩷䊶㩷㪙㫃㪸㫅㫂㪼㫋㩷㪚㫆㫌㫉㫊㪼

㪫㫌㪹㩷㪚㫃㪼㪸㫅㫀㫅㪾㩷㩷㪚㫆㫌㫉㫊㪼

– 12 –

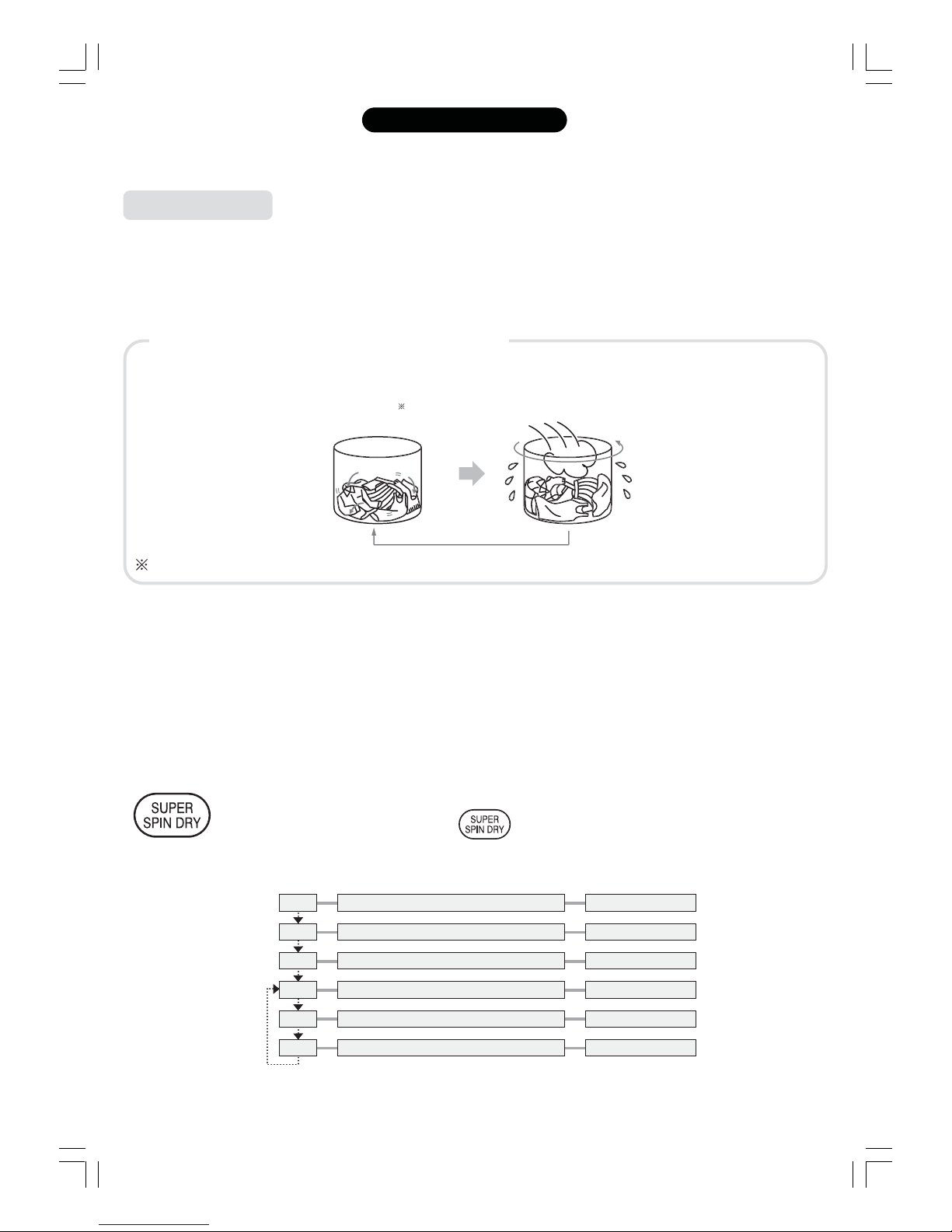

Through setting of the SUPER SPIN DRY for 30 minutes, you can vapor the water contained in clothes, thus shorten

their indoor drying time. In addition, you can basically dry sports wear, chemical fiber or blending fiber by setting

SUPER SPIN DRY for 60 minutes (less than 3 kg).

• The hand touch differs depending on the type, weight of clothes, room temperature and moisture. Clothes will be cold due to air

drying process, so they may produce a hand touch feeling like the wet ones.

When you need to dry clothes or shorten their indoor drying time.

SUPER SPIN DRY

1 time

2 times

3 times

4 times

5 times

6 times

“REGULAR” course for CONDENSED BUBBLE

“REGULAR” course for CONDENSED BUBBLE

“REGULAR” course for CONDENSED BUBBLE

None

None

None

30 minutes

60 minutes

90 minutes

30 minutes

60 minutes

90 minutes

Washing SUPER SPIN DRY

What is the SUPER SPIN DRY?

This is a course which discharge wet air through the high-speed revolving of the washing-spinning tub, thus

vapor the water carried by the clothes.

Stirring High-speed revolving

Repeatedly

: Stir for every 15 minutes to unravel the clothes. Stirring may not be necessary, depending on the weight of the clothes.

LClothes prohibited for the SUPER SPIN DRY

• Since the SUPER SPIN DRY needs a long time for high-speed revolving, and unravel clothes every 15 minutes,

the following articles are not allowed for the process:

• Clothes with unstable color

• Creasing-prone clothes (such as frock, or 100% cotton shirt)

• Deformation-prone clothes

• Water-tight clothes

• Quilt and blanket

LMethod of using SUPER SPIN DRY button

(Ex.) When the “REGULAR” course of the “CONDENSED BUBBLE” is being executed

Press the “SUPER SPIN DRY” to select processing time according to the following sequence or select

SUPER SPIN DRY only. Please press the

button for at least 4 times, when you select

SUPER SPIN DRY only.

SUPER SPIN DRY

– 13 –

One-Point Information

About Tub Dry

1. O utline

B y pe rforming "tub dry" ope ra tion after w as hing is c omple ted, humidity inside the was h/spin tub ca n be

removed a nd growth of black mold c a n be reduced.

2. P rocess

Dry u p th e rema ini ng wa te r by high- s pee d ro ta tion of wa s h/s pin tub for a pp roxima te ly 3 0 minute s .

P e rfor m this o pe r a tion a fte r re mo ving a ll the c lo the s in the tub to e mpty the tub.

3. P a ne l ope ra tion

Tub rota tion a t h ig h s peed(30 min)

Forward

ro ta tion

Motor

Reverse

ro ta tion

(30 min)

1 minute

Operation time is 30 minutes, which ca nnot be cha nged.

Tub dry

Buzzer

(CCW)

(CW)

Output

Run "TUB DRY" a fter wa s hing is finis hed, to preve nt

mil de w by rem ov in g th e mois ture of the tub. P lea s e run

the course once a week.

P lea s e do not add c lothes during the course .

1

Power on, and press the

SUPER

SPIN DRY

butto n 4 time s .

2

Clos e the lid and press the butto n.

H igh -s pe e d revolving for a bo ut 3 0 mi nu tes c a n d ry th e

was hing-s pinning tub through air intaking a nd revolving

the pu ls ato r.

Tips

Mildew of Was hing-S pinning tank occ urs depending on the e nvironment.

Once mildew occurs, it can not be removed by "TUB DR Y " process. Therefore, it is recommended to run "TUB DR Y"

and "TUB CLE AN" regularly.

– 14 –

One-Point Information

About Weight Sensor and S uitable Detergent

Amount Guide

( It is described as "Washing load

sens or" in the instruction ma nua l.)

B e fore the wa te r s u pply, rota te the puls ator for a pproxi ma tely 6 s ec onds to de te c t the loa d on to the moto r

by the num be r of rota tion of the motor. T h is is pe rfor me d to judge the wa sh in g load to de c i de wa te r leve l

a nd dis pla y the mos t s uita ble deterge nt a mount to be put.

Dete rg e nt a mo unt is dis playe d by how ma ny s poons of c ompa ct de terg e nt to be us ed when us ing the

spoon provided.

(T h e c a lcula tio n is bas ed on the as su mptio n th a t 1 s poonful of de te rge n t is for 5 5 L of wa te r. )

Dete rg e nt a mo unt fo r " Dry" course will be dis played by how ma ny c a ps of ne utral detergent to be put.

(T h e c a lcula tio n is bas ed on the as su mptio n th a t 2 c a ps of ne u tral dete rg e nt is for 3 0L of wa ter. )

T h e wa te r leve l is auto matic a lly s et a c c o rdin g to the de te r gent a m ount. H o we ver, the wate r le vel may b e

a djus ted by the fo llowing metho d if the us er fe e ls tha t a u toma tic a lly s e t wa te r le ve l is too high or to o low.

When adjus ting a u tomatic ally s et water lev el

T h e wa te r leve l is auto matic a lly s et a c c o rdin g to the de te r gent a m ount. H o we ver, the wate r le vel may b e

a djus ted by the fo llowing metho d if the us er fe e ls tha t a u toma tic a lly s e t wa te r le ve l is too high or to o low.

Once a s etting is ma de, it will be s tored in the me mory.

While pres sing the

press the powe r . B uz z er bee ps . W a ter level indic a tor turns on.

(Auto power ON/OFF)

To lowe r the wa ter leve l

Press

to a dju s t

To raise the water level

Press

to a dju s t

Press twice. Press once.

(Decrease approx. 20L.) (Decrease approx. 10L.)

Press once. Press twice.

(Increase approx. 10L.)(Increase approx. 20L.)

Turn the P OWE R off. (F inis hed adjus ting)

– 15 –

– 16 –

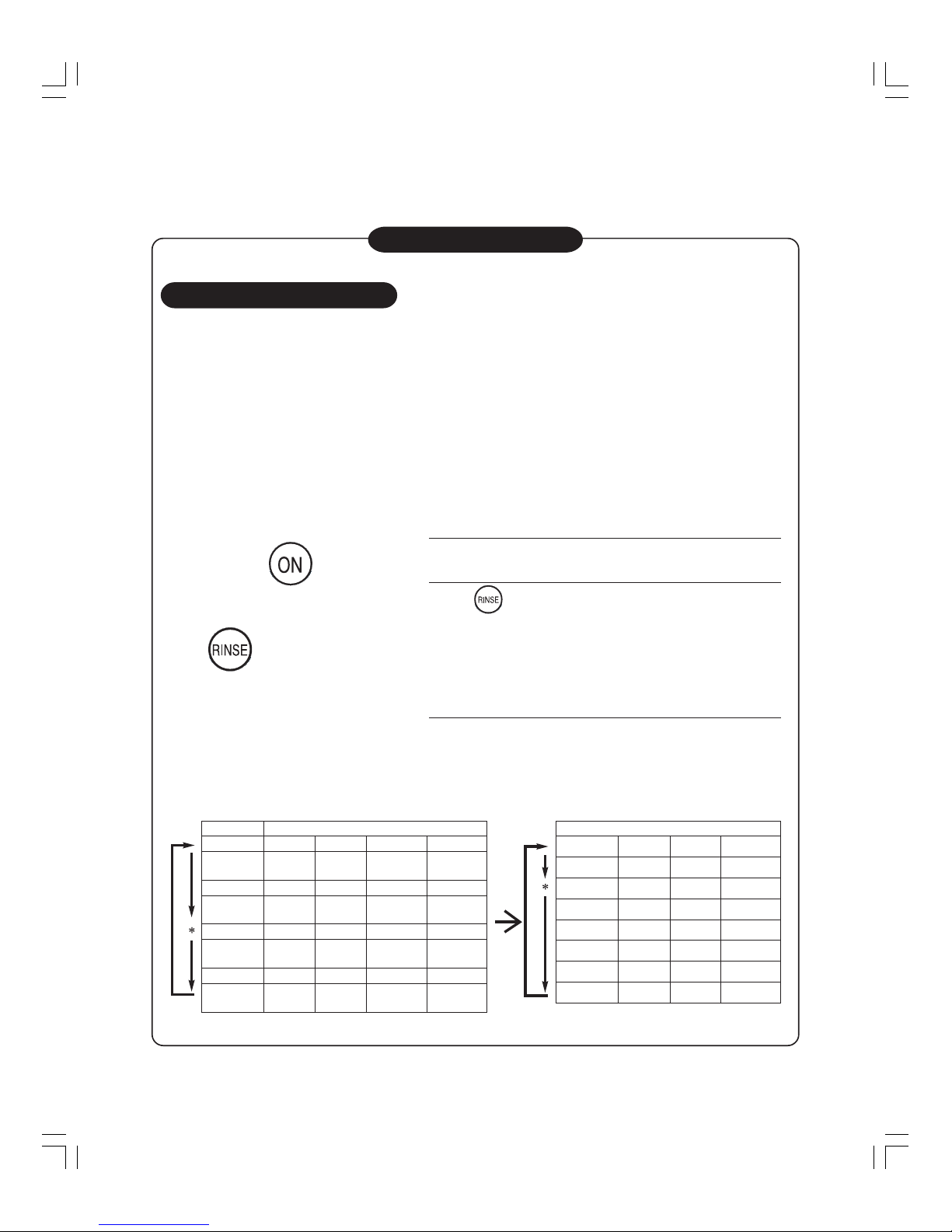

One-Point Information

About Static Rinse Mode

1. “Static rinse” mode

There is a mode to change from “shower rinse” to “static rinse” mode by invisible button operation.

Use this mode for users who have a problem in “white rinsing water” or those who want longer rinsing.

(1) Applicable course

Concentrated standard, standard, soak and memory

(2) Mode setting method

1 of shower rinse becomes 1 of static rinse.

Rinse cycle becomes same as the case where bath water is used until rinse process.

1

Turn on the power.

2

Press button for 3 seconds. The setting completes

in approximately 5 seconds when the buzzer beeps.

Turn off the power.

• To return to shower rinse mode, perform the above

operation again. When the setting to shower rinse

completes, the buzzer beeps.

• Once the setting is made, it will be stored in the memory.

• The setting method for the past models, i.e., turn on the power while pressing “RINSE” + “COURSE”

can also be used.

(3) Rinse cycle

“Shower rinse” becomes “Static rinse” as shown in the table below.

Press the power

button, then

Press

for 3 seconds.

Display Rinse Cycle

1 rinse

Static

1 rinse + overflow

overflow rinse

Static

2 rinse + Shower overflow

overflow rinse

3 rinse Shower Shower

Static

3 rinse + Shower Shower overflow

overflow rinse

4 rinse Shower Shower

Static

4 rinse + Shower Shower overflow overflow

overflow rinse

Static Rinse Cycle

Static

overflow

Static

overflow

Static

overflow

Static

Static

overflow overflow

Static

Static

Static

Static

Static

Static

Static

Static

Static

Static

Static

2 rinse Shower

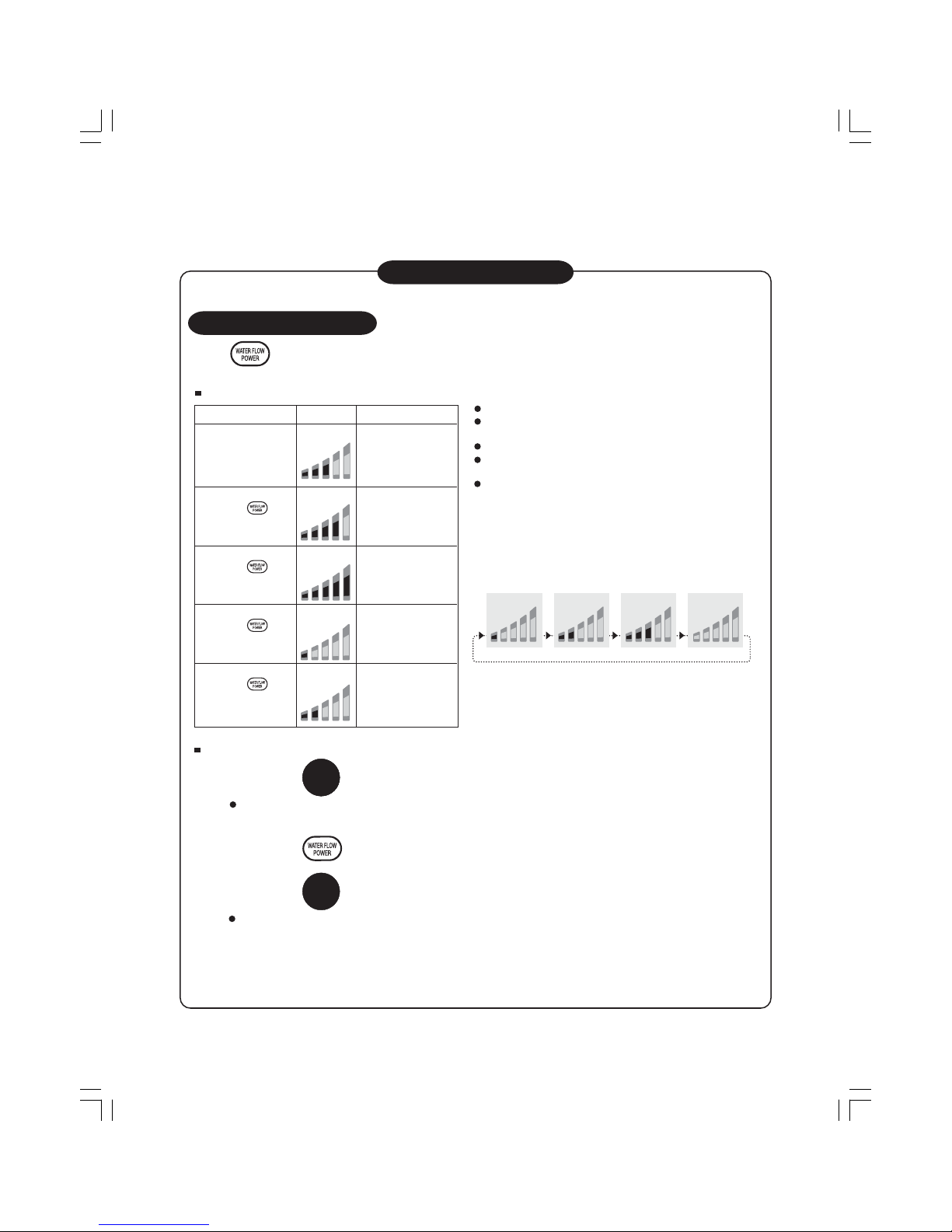

One-Point Information

Water Flow Power

How to choos e the water flow power

The water flow power during rins ing ca nnot be cha nged.

The water flow power can be adjus ted only any of

"REGULAR" and "MEMERY" is selected.

Clothes should not be washed by strong water flow power.

with the wate r flow po we r pre s et.

When the water le vel rea che s to a des igna ted leve l, the

water flow power will be indica ted. S uc h indic ation will be

repe a ted in the following order. T his me ans the operation is

being done under the water flow power pres et.

E xample (S tandard water flow power)

Ke y ope ra tion Dis play S ituation

Tur n on th e power. S ta nda rd wa te r flow

(Default)

Press the When you need to

button once. wa sh rather s trongly.

Press the When you need to

butto n twi c e. wa sh str on gl y.

Press the When you need to

butto n thre e tim e s . wa s h so ftly.

Press the When you need to

butto n fo ur times . was h ra ther s oftly.

HI

LO

HI

LO

HI

LO

HI

LO

HI

LO

HI

LO

HI

LO

HI

LO

HI

LO

Press button to cho os e the wa ter flow power a c c ordi ng to your ne eds su c h a s what to be

was hed or dirtines s level.

When you need to change the water flow power during operation

Press the button to hold the operation.

T he wa ter flow powe r will be gradually incre a s ed, a nd then be dec reas ed. Whe n you nee d to was h sensitive

clothes s oftly, hold the opera tion. Otherwis e, s uch c lothes may be da ma ged.

Press the butto n to choo s e the water flow power.

Press the

button again.

T he wa ter flow powe r will be cha nge d during the operation whe n you s elec t more tha n one leve ls of water.

1

2

3

When the "MEMORY" mode is set, the operation will start

– 17 –

– 18 –

One-Point Information

CHILD PROOF mode

This model is equipped with CHILD PROOF mode. After this mode is set to ON, the lid can be locked so that children should

not fall into washing-spining tub during washing or drying. If you find the accident such as children’s falling into the wash tub,

please take necessary safety action urgently.

If there are small children who require attention, set this mode ON.

WARNING: Pay attention to small children. Do not leave the lid open. Do not leave the washer filled with water. Never allow

children to look into the basket or play around the washer. Do not place the stand or box etc. near the washer.

HOW TO USE CHILD PROOF MODE

Press the button, then the washing machine begins operating, follow the instruction below:

Hold down the

button, press the button once again.

•

A buzzer will sound and the CHILD PROOF mode indicator will be activated.

Once the CHILD PROOF mode is set, it is stored in memory.

Canceling the CHILD PROOF mode

Hold down the button, press the button once again.

•

A buzzer will sound and the CHILD PROOF mode indicator will be canceled.

Once the CHILD PROOF mode can be canceled even during the operation.

L Cannot add detergent while child proof mode. The lid lock is activated.

L If accident occur when strongly pull up lid when lid lock in child proof mode operate. The buzzer will be sound and operation

will stop. Subsequently if that state persists about 5 seconds, it will be detected as an alarm and water will be drained.

CHILD PROOF MODE (if you have small children)

LID LOCK

Instruction: Do not open the lid while lights up. (The lid may be damaged.)

At the end of washing, the lid will be automatically locked.

When you need to cancel the lid lock

L During operation

Press the button to hold the operation.

When

lights out, the lid can be open.

L While the power is off

Turn the power on. When lights out, the lid can be open.

(When the power is turned off or shut down during operation, the lid will be automatically locked.)

ON

OFF

– 1–

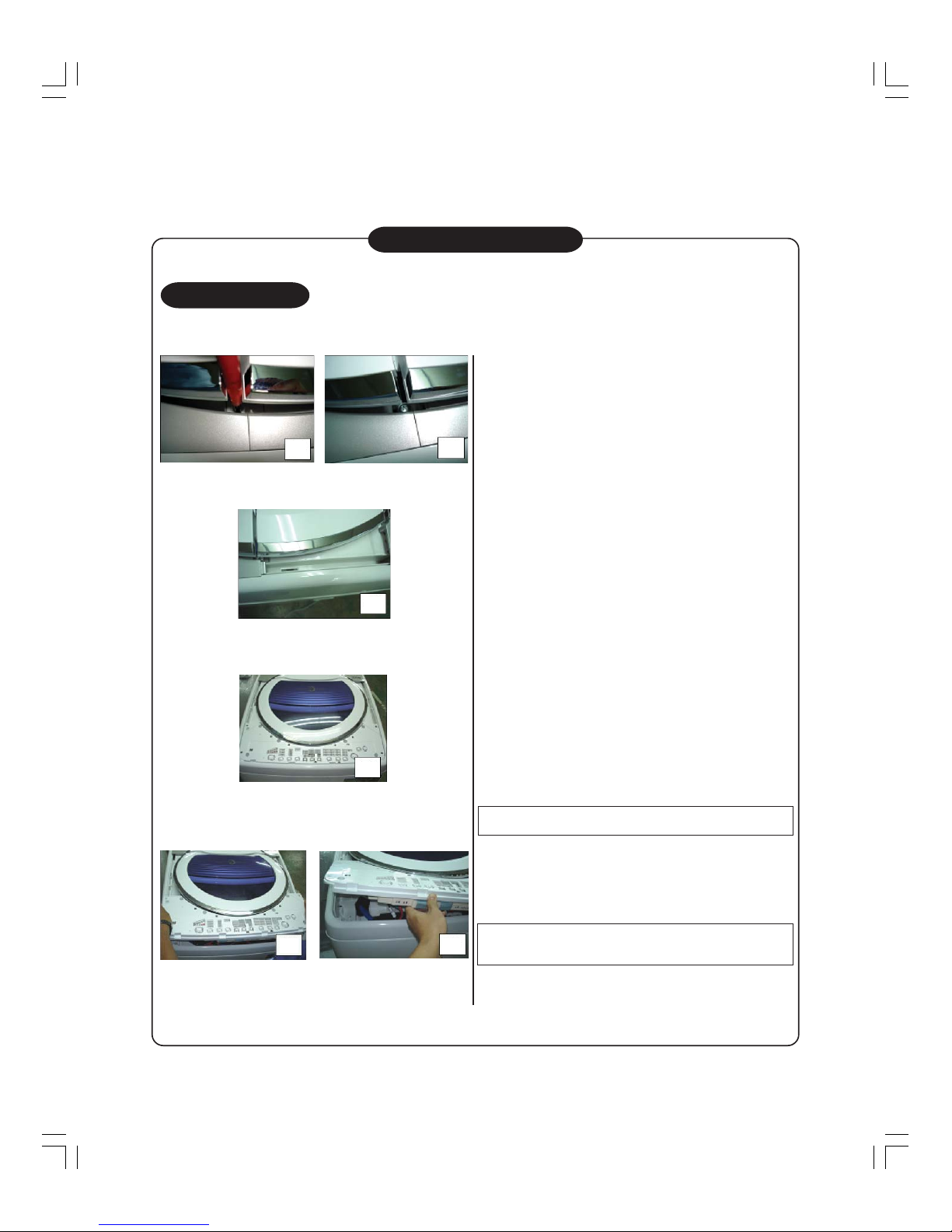

: If Lid Lock problem, wash lid assy cannot open.

One-Point Information

About Lid Lock

How to do?

1) Take off top cover cap of both side by lift up of

lid 1 & lid 2 at center position and use small minus

driver for open cap.

(Photo. 1 and Photo. 2)

2) Take off screw and then remove top cover deco

of both side(Right & Left side).

(Photo. 3)

3) Take off panel deco by pushing slide-up by hand.

(Photo. 4)

4) Take off 4 screws on control panel and then lift-up

(Photo. 5)

5) Move control panel assy to left side for lid lock

(Photo. 6)

move out from lid hook.

1

2

3

4

5

6

Note 1) Becareful lead wire unit.

Caution : Before take off must beUnplug for prevent

electric shock.

– –

2. Functions during each process

Process in which the lid is opened

1 During weight sensing

2 During water supply

3 During wash, rinse & agitation

4 During drain

5 During spin

6 During shower rinse

7 Before starting operation

(When the power is ON)

8 After course completes

(When the power is ON.)

9 When the power switch is OFF

Functions while the child proof is set

• No child proof function

•

No child proof function until the water reaches the reset level.

However, the child proof functions when the lid is opened

after the status of “lid closed” is detected during water supply.

Child proof functions.

• Basically, the child proof is to be set after star ting operation.

If the child proof is set and the lid is opened before starting,

the child proof functions as follows;-

1 When there is no water: No child proof function

2 When there is water: Child proof functions.

1 When there is no water: No child proof function even if the

lid is opened.

2 When there is water: Child proof functions when the lid is

opened.

(When the child proof is set, the power is not automatically

turned off after wash only or rinse only completes.)

Others • When the child proof is set, it functions when the lid is opened even when the start/stop

button is pressed to suspend the operation.

• If the operation is started while the lid is open, water is supplied just for a while and the

child proof functions once the water level reaches a certain level (reset level).

About Cancellation of Memory Data

This machine has data which will remain in the memory even if the power cord is unplugged or a power

failure occurs.

To initialize the memory data, turn on the power while pressing (Super Spin Dry). If this is carried out, the

buzzer sounds and all the settings are cancelled.

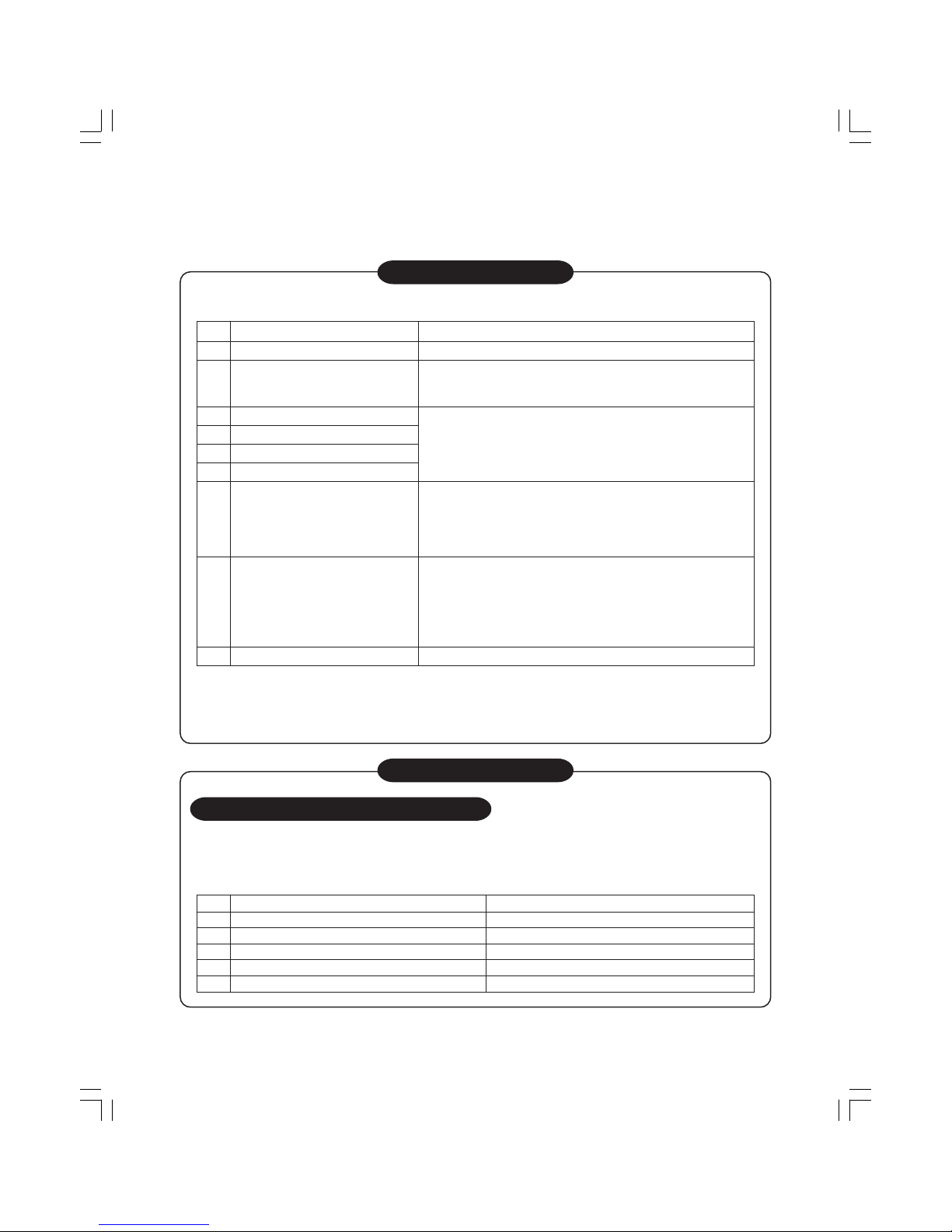

No. Memory Data Items Initialized Status

1 Buzzer for standard and other courses Sounds

2 Course button memory “Standard” turns on.

3 Description of memory course

“Standard” Wash: 8 min, Rinse: 2 times, Spin: 4 min

4 Water volume adjustment by the weight sensor Standard

5 Child proof setting No

One-Point Information

One-Point Information

– 2 –

One-Point Information

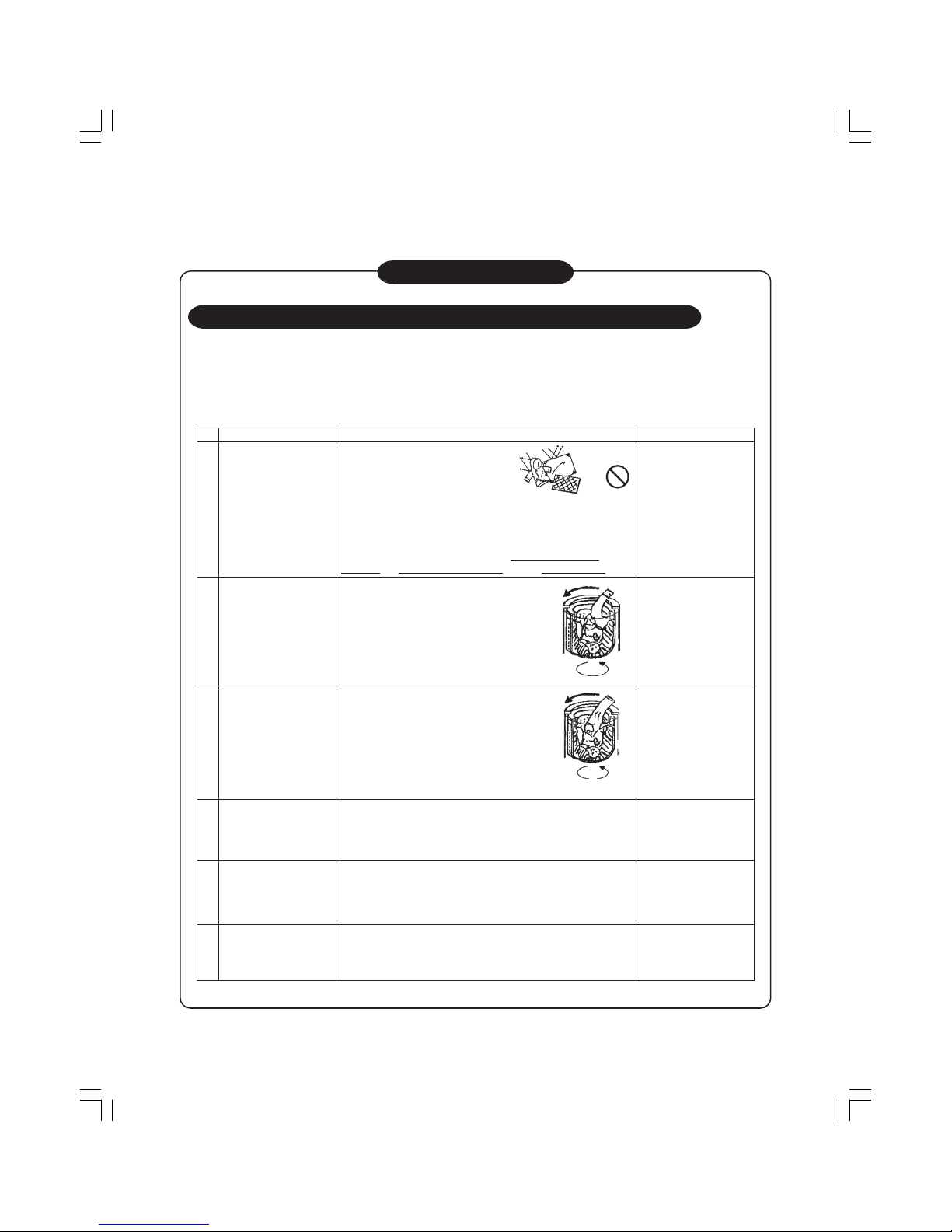

About Clothes for Which Care Should be Taken When Washing

Recently, more users think, in this environment where clothes types are diversified, that anything can be

washed with a fully automatic washing machine and actually wash various types of clothes in a washing

machine.

However, a fully automatic washing machine cannot wash every type of cloth that is said to be washable.

Please be reminded of the followings, which are also noted in the owner’s manual.

No.

1

2

3

4

5

6

Clothes

Waterproof type sheets,

mats and clothing

Ex. Cover for cars, sauna

suits, rain coat, ski wear,

sleeping bag, etc.

Clothing made of

synthetic fabric such as

polyester and nylon

Ex. Wind breaker, shirt,

etc.

Clothing made of thick

fabric

Clothes that is hard to

absorb water

Ex. Pillow, doll, cushion,

etc.

Clothing which carries a

laundry symbol denoting

hand wash or gentle

machine wash

Large item

Ex. Blanket, curtain, etc.

Symptoms

Injury hazard due to abnormal vibration

during spin process.

If waterproof clothes are spun, the water

in the clothes cannot be removed as this

type of cloth does not absorb water and thus

water starts rotating in the wash tub. If spinning by high-speed

rotation is performed in such a condition, the balance may be lost or

great vibration is applied to the tub itself because of sudden removal

of water. Abnormal vibration (impact) thus occurs on the washing

machine and this could result in not only

damage on washing

machine and tear and wear of clothing but also personal injury.

Clothing made of synthetic fabric may come

out of the tub due to centrifugal force during

spinning and this could damage the clothing.

<Symptom where the tub cover is damaged

may also occur.>

As clothing made of thick fabric becomes bulky,

it has a tendency to become difficult to be

agitated compared to other types of clothing.

Particularly when it is washed together with

other types of clothes, it becomes further

difficult to be agitated and could be damaged

by coming out of the tub during spin process

due to centrifugal force.

<Symptom where the tub cover is damaged may also occur.>

Items that still float even if pressed by hand cannot be washed.

Such items may come out of the tub during spin process and the

clothes, water tub cover or inner lid could be damaged.

In the case where this type of clothing is washed in heavy water flow,

i.e., standard course, it may shrink or be damaged even if it is put

inside the laundry net.

Blanket

Unless otherwise stated, this type of item may come out the tub and

be damaged if a blanket net is not used.

<Symptom where the tub cover is damaged may also occur.>

Notes on clothes

No washing of waterproof

type sheets, mats and

clothing.

Warning stated on the

owner’s manual.

(Hand wash or seeking

laundry service by a

specialist is recommended.)

If there is a large amount

to be washed, reduce the

amount.

Push a small amount

inside the tub to wash.

Do not wash together with

other types of clothes.

(It is recommended to

wash thick clothes alone

without mixing other

types.)

Do not wash items that

still float if pressed by

hand.(Hand wash is

recommended.)

Select a course with

gentle water flow (such

as gentle course)

following the laundry

symbol or instruction.

Wash a large item using

the blanket course.

Use a blanket net unless

otherwise stated.

No washing

– 2 –

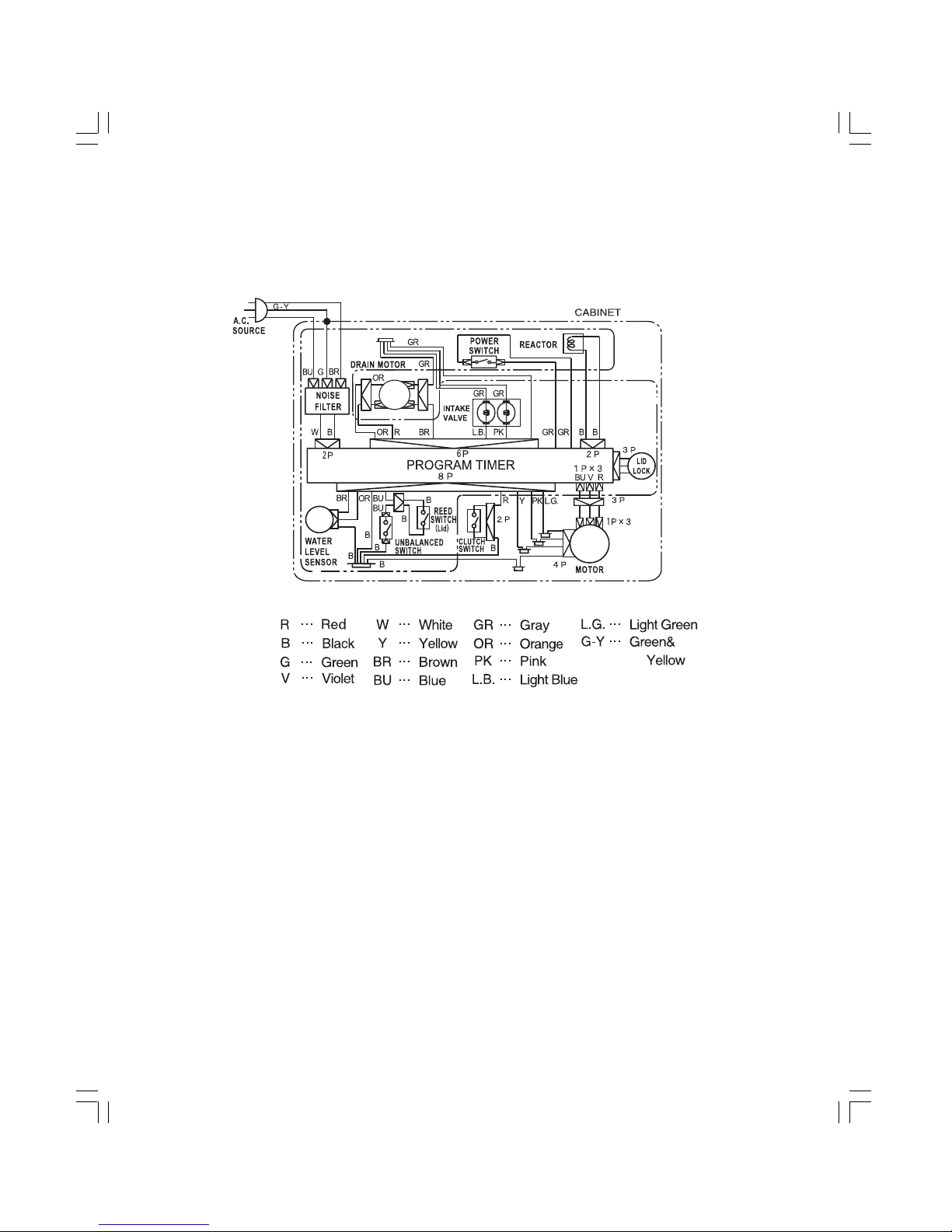

5. SCHEMATIC DIAGRAM

– 2 –

About operation check during installation

Notes on Installation

1. Wash operation check

• Plug in the power cord and press the “POWER” button. Then, press the “START” button.

• Pulsator rotates clockwise and counterclockwise direction. Detergent amount 0.2 cup is displayed.

∗ Knocking sound is heard when plugging in. However, it is not abnormal.

2. Spin operation check

• Close the lid and press the “POWER”, “SPIN” and “START” buttons in this sequence.

∗ Before spinning starts, the wash tub rotates slowly and a clicking operation sound is heard because

the clutch is switched from washing to spinning.

∗ The brake works at the completion of spinning. Then the wash tub rotates and the clutch switching

from spinning to washing is performed.

∗ For the course operation, the clutch switching from washing to spinning and vise versa will be

performed automatically.

NOTE Never do as shown in the drawing below.

Direct insertion of the drain hose from

interior of the washing machine into the

drain hole could result in water leakage

or abnormal noise.

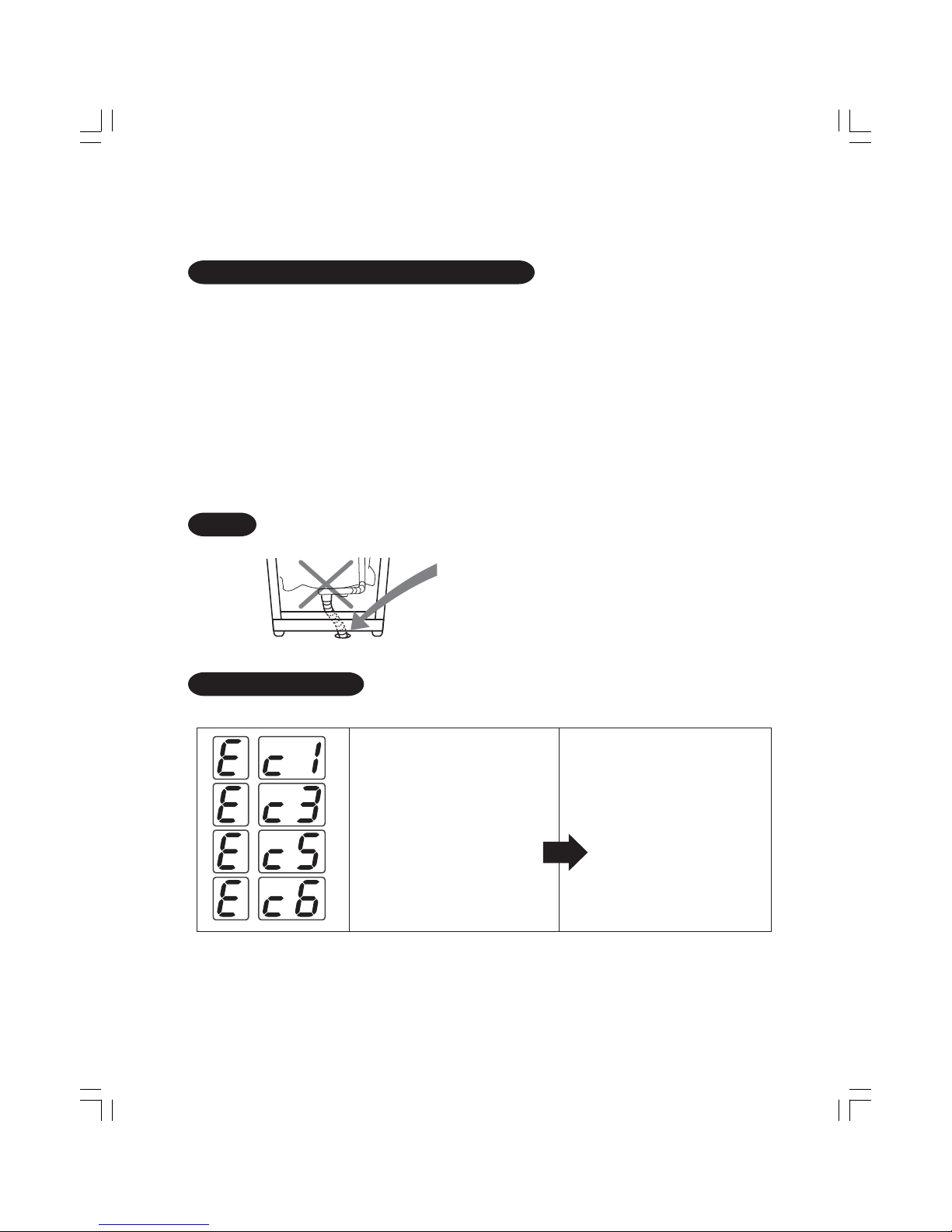

About Error Display

When the following errors are displayed, carry out the inspection stated below.

• Is too much laundry put into the

tub?

• Is the water level set to too low for

the laundry load?

∗ If the error is not solved even after the above inspection, please request repair service.

• Turn off and on the power. Reduce

the laundry or reset the water level

and then press the start button

again.

6. CHECKING PROCEDURES

– 2 –

Abnormality Alarm

(1) Error display and description of abnormality alarm

• In case of abnormality or failure such as incorrect operation and faulty drainage or spinning, the operation is

stopped by error display and abnormality report (buzzer alarm).

Error Display

Abnormal

drainage

Abnormal

open lid

Abnormal

unbalance

E31, E32

Abnormal

water supply

Abnormal

motor current

E61, E63~66

Description of Detected Error

• After starting draining in wash or spin process, the water level does not

go down below the reset level even after the specified time has elapsed.

(To be detected by the water level sensor) [7 mins 30 secs]

• Occurred by drain hose that was not put down or flattened hose, etc.

• The lid is open or opened during spin in rinse and spin process or during

shower rinse operation. (To be detected by the lid switch)

(E21):The lid is opened, while spining or switching of clutch.

• Unbalance occurred by uneven laundry load during the final spinning.

(Unbalance detected t rectifying operation was repeated but the

unbalance was not rectified.)

(Abnormality alarm) When an unbalance was detected 3 times during the

same spin process. In dry course, however, abnormality alarm sounds at

the first abnormality detection.

(E31): When abnormality was detected by the lid switch unbalance. (To be

detected by the lid switch)

(E32): When abnormality alarm was detected by the vibration sensor. (To

be detected by the rotation sensor.)

• When the water level reaches the following water level during water supply

in wash and rinse process or while rectifying an unbalance, the water does

not rise up to the water level of one-level higher even after a specified time

has elapsed. (To be detected by the water sensor)

• Occurred by a tap which was not turned on or water supply valve failure,

etc.

• Overcurrent flows through the motor while the motor is running (for all

processes).

(Current value flowing through the motor drive circuit is detected by the

program timer assy.)

• Occurred by excessive laundry load, too low water level, defective wiring

between the motor and the program timer assy, motor drive circuit failure,

etc.

(E61): While washing (E63): Abnormality occurred while spinning and there

was no problem during washing.

(E64): Occurred when spin only is set. (E65): When clutch is switched to

washing.

(E66): When clutch is switched to spinning.

How to Cancel

After opening and closing

the lid, press the start

button. The operation

resumes from the stopped

state.

Open and close the lid.

The operation resumes

from the stopped state.

Tu r n o ff and on the power

(OFF/ON) button.

Operation will not

continue. Start back the

operation from the

beginning again.

Detected water level Detected time

97 ~ 105L 16 minutes

91 ~ 97L 12 minutes

82 ~ 91L 18 minutes

76 ~ 82L 12 minutes

69 ~ 76L 14 minutes

60 ~ 69L 18 minutes

55 ~ 60L 10 minutes

46 ~ 55L 18 minutes

36 ~ 46L 20 minutes

0 ~ 36L 52 minutes

E21, E23

After opening and closing

the lid, press the start

button. The operation

resumes from the stopped

state.

(E23):The lid lock is not locked or is not released.

(E21):Close the lid. The

operation resumes from

WKHstopped state.

(7XUQoff and on the

SRZHU2))ON)button.

Operation will not continue.

Start back the operation

from the begining again.

– 2 –

Error Display

Abnormal

motor current

E71, E73~74

Abnormal

motor voltage

E81, E83~86

Abnormal

water leakage

Abnormal

DC voltage

Abnormality

in the clutch

EC1, EC3

EC5, EC6

Leakage

current

detected

Abnormal water

(During air

drying)

During air

drying

Abnormal

overload alarm

Description of Detected Error

• Abnormality occurred in the sensor signal which detects motor rotation while the

motor is running (for all processes).

• Occurred by excessive laundry load, too low water level, defective wiring

between motor and program timer assy, motor drive circuit failure, etc.

(E71): While washing (E73): Abnormality occurred while spinning and

there was no problem during washing.

(E74): Occurred when spin only is set. (E75): When clutch is switched to

washing.

(E76): When clutch is switched to spinning.

• Excessive voltage was added to the program timer assy by the motor while the

motor is running (for all processes).

(Voltage value applied to the motor drive circuit is detected by the program

timer assy.)

•

Occurred by excessive laundry load or motor program timer assy failure, etc.

(E81): While washing (E83): Abnormality occurred while spinning and there

was no problem during washing.

(E84): Occurred when spin only is set. (E85): When clutch is switched to

washing.

(E86): When clutch is switched to spinning.

• The water level of the water tub became lower than the reset level during

agitation ( in wash and rinse process). (To be detected by the water level

sensor)

• Occurred by crack on the tub, foreign matters stuck in the drain valve, water

level sensor failure, etc.

•

DC voltage of the motor drive power circuit is too low while the motor is stopped.

(Voltage value applied to the motor drive circuit is detected by the program

timer assy.)

• Occurred by defective wiring in the machine or motor program timer assy

failure, etc.

• Clutch switching was not performed correctly (wash t spin, spin t wash) for

all processes. (To be detected by the clutch sensor)

• Occurred by excessive laundry load, clutch failure or clutch sensor circuit

failure, etc.

(Ec1) When the clutch is released during washing (Ec3) When the clutch

is applied during spinning (Ec5) When the clutch was not switched to washing.

(EC6) When clutch was not switched to spinning.

• Leakage current occurred on the main unit of the washing machine. (To be

detected by the leakage current detection sensor inside the program timer assy

after turning on the power and before pressing the start switch)

(Detectable leakage current is 1mA or below.)

• Occurred by submerged electrical components on the bottom part, freezing or

water splashing, etc.

• Water level sensor output is above the reset level when drying starts.

(To be detected by the water level sensor)

• Occurred by drying operation started while there is water in the tub.

• Occurred by excessive laundry load, etc.

• Occurred by tangled laundry.

How to Cancel

Tu r n o ff and on the

power (OFF/ON)

button.

Operation will not

continue. Start back

the operation from the

beginning again.

Unplug the po

wer

cord.

Tu r n o ff and on the

power (ON/OFF)

button, operate spin

only and drain water.

Turn on the power

again and perform

drying operation.

Reduce laundry

amount or fluff the

laundry, then press

the start button.

Abnormal

water level

sensor

Water level sensor output is out of normal area.

Occured by detective connector of water level sensor, detective

connector of air tube.

Occured by program timer assy failure, water level sensor failure,etc.

•

•

•

Turn off and on the

power(OFF/ON)

button. Operation will

not continue. Start

back the operation

from the begining

again.

– 2 –

Detailed Description of E6, E7, E8 and Ec Errors

On the above error table, error description is classified and stated.

The table below shows how to identify, with the last number of the error display, the process where the error

had occurred.

Check the laundry overload when E6, E7, E8 or Ec occurred.

Overload: Laundry more than the rated load is put in the washing machine,

The water level is set to extremely too low for laundry load, etc.

Error Display

E6 E7 E8 Ec

1 In wash process In wash & rinse process

2 NIL NIL

3 There is no problem in wash process but In spin process

abnormality occurred in a subsequent

process

4 When spin only or rinse only is set When spin only or rinse only is set

5 At the clutch switching from spin to wash At the clutch switching from spin to wash

6 At the clutch switching from spin to wash At the clutch switching from spin to wash

Last number

(2) Actions to be taken against error alarm, etc.

Error Display

Abnormal

drainage

Abnormal

open lid

Abnormal

unbalance

E31, E32

Abnormal

water supply

Check Items & Description t Actions to be Taken in Case of Abnormality

• Check around the drain hose (Forgot to put down the hose, flattened hose,

hose tip submerged in the water, a sleeve installed, extension of hose, etc.)

<Most of the water in the wash tub has been drained>

• Check the water level sensor and air tube.

<Most of the water in the wash tub has not been drained>

• Check the drain valve operation.

• The lid is open t Close the lid.

• Error is displayed even if the lid is closed.

t (1) Check the safety lever distance.

(2) Check the operation of the lid switch.

• Is the laundry load uneven? t Make it even.

• Is the washing machine installed on an uneven or inclined floor surface?

t Rectify the unevenness to secure levelness. (Check with a level.)

• Check the installation of the drain hose. (Perform the same check as E1)

• Check the lifting rod. t Replace the rod.

• Check the operation of the cover switch. (Perform the same check as E2)

• Is the tap not turned on? (When a bath water pump is used, this error may

be displayed during rinsing.) t Turn on the tap.

• Is dust or rubbish accumulated on the net of the water supply port?

t Clean the net of the water supply valve.

• Check the operation of the water supply valve.

Relevant Places

• Around the drain hose

• Water level sensor

• Air tube

• Drain valve

• Junction lead wire

• Program timer assy

• Lid

• Lid switch

• Junction lead wire

• Program timer assy

• Uneven laundry load

• Installed place

(Unevenness,

inclination)

• Around the drain hose

• Lifting rod

• Around lid switch

• Forgot to turn on the tap.

• Dust or rubbish on the

net of the water supply

valve

• Water supply valve

• Junction lead wire

• Program timer assy

Safety lever distance

59±4mm

E21, E23

(3) Check the operation of the lid lock.

Lid lock

Around safety lever

•

•

– 2 –

Error Display

Abnormal

motor current

E61, E63~66

Abnormal

motor rotation

E71, E73~76

Abnormal

motor voltage

E81, E83~86

Abnormal

water leakage

Abnormal

DC voltage

Abnormality

in the clutch

Ec1, Ec3

Ec5, Ec6

Leakage

current detected

Abnormal water

(During air

drying)

During air drying

Abnormal

overload alarm

Check Items & Description t Actions to be Taken in Case of Abnormality

• Laundry load exceeds the rated load. t Reduce the laundry amount.

• Water level is extremely too low than laundry load.

t

Make the set water level higher.

∗ It can be thought that the load on the pulsator became too large and the pulsator due

to excessive laundry load thus became locked. This could be a cause of an overcurrent

flowing in the motor.

• Check the operation of the motor.

∗ The followings are thought to be other factors (including occasional factors) of this error.

(1) Current is not correctly switched to the motor due to defective wiring, etc.

(2) The motor become locked due to the stuck or suspended clutch.

(3) Current is not correctly switched to the motor due to influence of external noise, etc

• Perform the same check as E6.

∗ It can be thought that the load on the pulsator became too large due to excessive laundry

load and the pulsator thus became locked. This could be a cause of interruption of the

motor signal.

∗ The followings are thought to be other factors (including occasional factors) of this error.

(1) Defective wiring between the motor and the program timer assy

(2) The motor become locked due to the stuck or suspended clutch.

• Perform the same check as E6.

∗ It can be thought that the load on the pulsator became too large due to excessive laundry

load and the pulsator thus became locked. This could be a cause of counter electromotive

current generated from the motor.

∗ The followings are thought to be other factors (including occasional factors) of this error.

(1) Program timer assy failure (detection circuit or microcomputer surrounding circuit failure)

(2)

Defective wiring inside the machine (disconnection or poor contact at the connector)

NOTE: The state where the circuit voltage becomes highest is when the lid is

opened during spin top rotation. To perform reproduction for checking, carry it out at

the abovementioned operation status.

• Fill the water inside the water tub and check water leakage from the tub or drain valve.

t Repair the water leaking part or replace the component.

• Check the operation of the water level sensor.

• Check AC supply voltage. (Reduced up to approx. AC35V or exceeds AC160V)

t Check the power supply wiring.

∗ The followings are thought to be other factors (including occasional factors) of this error.

(1) Defective wiring inside the machine (disconnection or poor contact at the connector)

(2) Program timer assy failure (detection circuit or microcomputer surrounding circuit failure)

• Perform the same check as E6.

∗ It can be thought that the load on the pulsator became too large due to excessive laundry

load and the pulsator thus became locked. This could be a cause of the clutch that cannot

be switched.

∗ The followings are thought to be other factors (including occasional factors) of this error.

(1) Defective operation of the clutch mechanism

(2) Clutch sensor failure (including defective wiring)

• Is the bottom part of the washing machine submerged in the water due to clogging of the

waterproof pan, etc.?

t Clean the clogging.

• Check if dew condensation occurred on the motor, etc. in cold morning.

t Dry up well. (Insulation resistance 3MΩ and above)

• Leakage current from other electrical components than motor could occur.

t Check the insulation resistance of each electrical component.

• Is water left in the machine?

t Drain the water.

• “A” may be displayed even when there is the same symptom as “E1”.

t Take the same actions as in case of “E1”.

• Is too much laundry put in the machine?

t Reduce the laundry.

• Is the laundry tangled?

t Fluff the laundry and put it again.

Relevant Places

•

Excessive laundry load

• Too low water level

• Junction lead wire

• Clutch

• Clutch sensor

• Program timer assy

•

Excessive laundry load

• Too low water level

• Junction lead wire

• Clutch

• Program timer assy

•

Excessive laundry load

• Junction lead wire

• Program timer assy

• Water tub

• Drain valve

• Water level sensor

• Junction lead wire

• Program timer assy

• Power supply wiring

• Junction lead wire

• Program timer assy

•

Excessive laundry load

• Too low water level

• Clutch mechanism

• Clutch sensor

• Junction lead wire

• Program timer assy

• Submerge

• Dew condensation

• Water splashing

• Program timer assy

• Water left in the

machine

• Same places as in

“E1”, such as water

level sensor and drain

valve

• Excessive laundry to

be dried

Abnormal

water level

sensor

Check connector of water level sensor, connector of program timer assy.

Check connection of air tube.

Program timer assy failure, water level sensor failure,etc.

•

•

•

Water level sensor

Air tube

Junction lead wire

Program timer assy

•

•

•

•

Detailed Failure Diagnos is Method

(1) Setting method of inspection mode and description of inspection

In the inspection mode, failure diagnosis of each electrical part can easily be checked on the control panel. If an

abnorma l a la rm s ounds a nd there is a problem in the was hing ma c hine, ide ntify the faulty e lectric al part by this

inspection mode and ca rry out the failure diagnos is of eac h elec trical part (Page 29).

If the connector is disconnected and reconnected, carry out the checks under this inspection mode again after

the r e pa ir c om pl e te s and ma ke su re tha t th e motor s tar ts rota tion w he n s tar tin g s pinn in g a nd tha t no a bno r ma l

ala rm s ounds when the s pinning operation is performed for 1 minute.

Wa ter level indica tor

Process indicator

Course indicator

1. While pres sing down the

butto n, pre s s the button. (The buzzer beeps.)

2. Press the

button. ( T he was hing ma chine will be in s tandby mode. ) (P res et time: 10 minutes )

3. A fter the ins pe c tio n c o mple tes , ca rry o ut a uto ma tic power o ff with the

butto n.

The power is then turned off.

No.

1

2

3

4

5

6

7

8

9

Chec k Items

Motor forward

ro tati on

Motor forward

ro ta tion ( H igh

speed)

R o tati on

sensor

function

Function of

water supply

valve (on the

ta p s ide)

Function of

water supply

valve (on the

softener side)

Drain valve

function

Clutch sensor

input

Water level

input

Lid switch

input

Operation under Normal C ondition

By pressing the

butto n, the m oto r rota tes

forwards after the clutch is switched to washing.

T he motor ro ta te s forwa rds ( a t hig h s peed ) a fte r

the clutch is switched to washing by pressing the

butto n wh il e p re ss ing th e button .

Ac cor di ng to the motor s pee d, outpu t of 2 r ota tion

sensors is displayed on the digital LE D.

P ink lea d sens or: Wa s h LE D

Yellow gree n lea d sens or: S pin LE D

The water supply valve (on the tap side) works for

15 seconds by pressing the

butto n.

The water supply valve (on the tap side) works for

15 seconds by pressing the

butto n.

Drain valve motor works for 15 seconds and then

clutch is switched to s pinning by pres sing the

butto n.

According to the clutch status, the process

ind ic a tor tur ns on/o ff.

Spin side: OFF, Wash side: ON

Wa ter level in the wa ter tub is dire ctly dis played

on the wa ter leve l indic ator.

C ours e i ndi c a tor tur ns on/of f a ccordin g to ope n/

clos e of the lid.

Lid open: O F F, lid clos ed: O N

Chec k Items in C as e of Abnormality

(Normal Value)

R esistance between CN4 blue - CN6 red (10 ~ 20 )

R esistance between CN4 blue - CN5 purple (10 ~ 20 )

R esistance between CN6 red - CN5 purple (10 ~ 20 )

* Measured value when unplugged and CN4-6 is removed.

R esistance between CN4 blue - CN6 red (10 ~ 20 )

R esistance between CN4 blue - CN5 purple (10 ~ 20 )

R esistance between CN6 red - CN5 purple (10 ~ 20 )

* Measured value when unplugged and CN4-6 is removed.

CN7

Voltage between black - yellow (5V)

Voltage between black - pink (5V 0V

...

)

Voltage between black - yellow green (5V 0V

...

)

Voltage between CN1 black - CN9 pink

(S tandby state: AC 220-240V

, during operation:

0V)

Voltage between CN1 black - CN9 light

blue

(S tandby state: AC 220-240V, during operation:

0V)

Voltage between CN1 black - CN9 brown

(S tandby state: AC 220-240V) (During

operation:

0V

Voltage betwee n C N9 re d-ora nge

(S tandby state : AC 0V

during latch opera tion : a bout DC300~330V)

Voltage between CN7 black - red

(Lid open, clutch on spin side: DC5V )

(Lid closed, clutch on spin side: DC 3.3 ~ 4.2V)

(Lid open, clutch on wash side: 0V)

(Lid closed, clutch on wash side: 0V)

Ac cording to (4) Wa ter level s ensor failure

diagnosis method

Voltage between CN7 black - blue

(Lid open, clutch on spin side: DC5V )

(Lid open, clutch on wash side: DC2.7 ~ 3.3V)

(Lid closed, clutch on spin side: 0V)

(Lid closed, clutch on wash side: 0V)

Failur e

Diagnosis

of Electrical

Parts

1

2

3

4

5

6

Inspection

mode s etting

(P rocedures )

Motor

Water

s upply

valve

Drain

valve

motor

Clutch

sensor

(cup assy)

Water

leve l

sensor

Lid

switch

operation time : about 1 second

Lid

Lock

10

Lid lock

input

Lid lock locks by pres sing the ( W ater leve l) bu tton.

Lid lock releases by pressing the (Water flow

power) button.

(L id lock)L ED turns on by locked c ondition.

(L id lock)L ED turns off by re leas ed condition.

Voltage between CN10 black-white

stanby state(release or lock position) : about

0V, during operation (release lock, lock

relea s e) AC 220-240V

7

– 2 –

– 2 –

(2) Failure Diagnosis of Each Electrical Part

No.

1

2

Part

Program

timer motor

Clutch

sensor

(Cup assy)

• Water

supply

valve

• Lid Lock

Failure Diagnosis Method

• Inspection mode 123 (Make sure that there is no problem in common check items stated on Page 2.)

The motor does not rotate.

Does the rotation indicator

change when the pulsator is

turned manually after setting to

the inspection mode?

Changes

No change

Is the voltage between CN7

black – yellow DC5V?

Ye s

No

Short or open

Unplug the power cord,

remove the CN4 ~ 6 of the

program timer and measure

the resistance between

(red) – (purple), (red) – (blue)

and (blue) – (purple) on the

main unit lead wire side.

When rotated, does the voltage

between CN7 black – yellow

green and between CN7 black –

pink change from DC5V to 0V?

All approximately

10 ~ 20Ω

Program timer failure

No change

Changes

Motor failure, disconnected lead wire

unit connector or wire disconnection

Ec5 error is displayed but the

clutch is on the wash side.

Is CN7 black – red shorted when

unplugged and CN7 is removed?

Open

Disconnected lead wire unit

connector, wire disconnection or

cup assy failure

Short

Program timer failure

• Inspection mode

4~5

,

Is the voltage at the checked point AC220V

in standby status?

No

Failure of each electrical part,

disconnected lead wire unit

connector, or wire

disconnection

Ye s

Does the voltage at the checked point change

from AC220V to 0V when operated?

Changes

No change

Program timer failure

Each electrical part failure

– –

No.

3

4

Part

1 Drain

valve motor

2 Drain

valve

Latch signal

Clutch

sensor

(Cup assy)

Clutch

sensor

(Mechanical

part)

Failure Diagnosis Method

• Inspection mode

Check the voltage between CN1 (black) –

CN9 (brown) in the standby status. Is it

AC220V?

No

Drain valve motor failure,

disconnected lead wire unit

connector or disconnected wire

Ye s

Check the above voltage when winding completes.

Does it change from AC220V to 0V?

(Check the voltage during winding.)

Changes

No Changes

Drain valve motor failure

Program timer failure

Check the voltage between CN9 red – gray

in the standby status. Is it about DC 0V?

No

Drain valve motor failure,

disconnected lead wire unit

connector or disconnected wire

Changes

No Changes

Program timer failure

Lid Lock failure

The clutch is on the spin side but

the clutch sensor does not judge

that it is on the spin side.

Is between CN7 black – red

open when plugged and CN7

is removed?

Short

Lead wire unit connector short or

cup assy failure

Open

Program timer failure

• Check in the inspection mode 1236

L atch of Drain valve does not work.

Check the voltage between CN9 red-RraQJH

during latch operation. Is it about DC0aV?

during latch operation :

press [Power ON] ,and press [start]

during about 1 second.

6

3

– 3 –

No.

5

6

Part

Water level

sensor

Lid switch

Failure Diagnosis Method

• Inspection mode 8

Are all the water level indicators

turned off when there is no water

in the water tub?

All turned off

What is the indicated water level

when water is supplied into the

water tub? (Refer to the table

below)

Lower level is

indicated.

Water level for each water level indicator

Any of them is

turned on.

Higher level is

indicated.

Is the 3P connector of

the water level sensor

disconnected?

Disconnected

Connect

Not disconnected

Water level sensor

failure or program

timer failure

Higher level

is indicated.

Check disconnection of or tear on the air

tube, foreign matter stuck inside or water

gone inside the air trap, etc.

Auto

Display Water volume Water level height

1

2 82L Approx. 280mm

3 60L Approx. 200mm

4 36L

Appr

ox. 100mm

• Inspection mode

Check the voltage between CN7 black – yellow.

Is it DC5V?

Ye s

No

Program timer failure

Does the voltage between CN7 black – blue

change from DC3V to 2.5V when the lid is

opened and closed while the clutch is on the

wash side?

Changes

No changes

Connector of the lid switch or lead

wire unit is disconnected or the lid

switch or lead wire unit is

disconnected.

7

Lid Lock

sensor

• Inspection mode

Lid Lock sensor can not detect

Iock or release condition.

Check connection of lead wire unit

connector of Lid Lock.

Does the voltage between CN10

white-black change?

Lid Lock : standby state about 0V

release position

lock position

release lock

Lid Lock : during operation AC0V

rlock release

10

Program timer failure

Lid lock failure

AW-SD1567\SH

No changes

Changes

10L Approx. 410mm

9

– 3 –

Common check items when a DD

motor-related error occurred

(Applicable error display: E6, E7, E8 & Ec)

E6, E7, E8 & Ec errors are the errors occurred by excessive washing load, too low water level for the washing load,

rotation sensor failure, clutch sensor failure, defective operation or failure of clutch mechanism, drain valve motor

failure, electronic unit failure, incomplete contact of in-machine wiring and wire disconnection.

Depending on the detecting situation, error display may not always be the same even when a deficiency occurred on

the same place. Please check the operation of the motor and clutch following the procedures shown below.

Are clothes more than the rated load put in the machine?

Within the rating

Is water level set lower for the washing load?

Appropriate water level

Turn off the power and take clothes out of the machine.

More

Lower

Reduce the clothes up to the rating.

Raise the water level.

Check the clutch sensor position according to the detailed failure diagnosis method. (Page 2)

Wash side Spin side

Check if the spin tub is rotated manually and locked.

Manually rotate the spin tub in clockwise and

counterclockwise direction.

(Switch the clutch to the wash side manually.)

Locked (wash side)

Check <A>

Rotate the pulsator by hand

to check the input of the

rotation sensor signal.

Free (spin side)

Clutch sensor failure

Electronic unit failure

Was the clutch input switched to the wash side?

It still remains at the spin side.

The input changes synchro-

nizing with the rotation.

Check the forward rotation

(according to the failure

diagnosis method)

It rotates smoothly.

Turn off the power and

check the spinning

operation.

Normal

(To the next page)

Does not change

synchronizing with rotation.

Rotation sensor failure

Incomplete contact of

wiring, disconnected wire,

electronic unit failure

It does not rotate smoothly,

or

It does not rotate.

Incomplete contact of

wiring, disconnected wire,

Electronic unit failure

Motor failure

Spinning operation cannot

be performed.

Electronic unit failure

Clutch mechanism failure

The spin tub is

locked and the input

was also switched

to the wash side.

To Check <A>

The spin tub is locked

but the input is still at

the spin side

Clutch sensor failure,

disconnected wiring,

incomplete contact,

electronic unit failure

The clutch is still at the

spin side.

Clutch mechanism

failure

Drain valve motor failure

– 3 –

Actions to be taken when the motor and

clutch switching were judged to be normal

If the motor and clutch switching were judged to be normal, check whether or not there is no abnormality on

wiring connection (incomplete connection of connector or incomplete contact etc.) again.

When an abnormality cannot be identified due to the reason of occasional abnormal occurrence, etc., check

the number of abnormality occurrence and observe the situation for a certain period of time.

(It is suspected that the abnormality is due to certain usage condition including excessive washing load or

condition of clothes.)

∗ How to check the number of abnormality occurrence: Refer to Page 3

Simple checking method in case of abnormal motor operation

Failure of drive circuit inside the electronic unit, abnormal motor coil, disconnected wiring and incomplete

contact, etc. are suspected to be a cause of abnormal motor operation. Carry out the check by the following

methods.

The motor does not rotate or the rotation is not smooth.

Remove 3 of 1P connectors CN4 – 6 (red, blue, purple) of the electronic unit.

Check the resistance value among 3 removed connectors. (Resistance value: 10 ~ 20Ω)

Abnormal

Electronic unit failure

Resistance value: Larger

Resistance value: Smaller

Remove the rear lid and remove 3 of 1P

connectors (red, blue, purple).

Then check the resistance value among

3 terminals on the motor terminal.

Remove the rear lid and remove 3 of 1P

connectors (red, blue, purple). Then

check the resistance value among 3

terminals on the motor terminal.

(ex: Between red and blue)

10 ~ 20Ω

20Ω and above No continuity

There is continuity

Disconnected wiring or

incomplete contact

Motor failure

Defective wiring insulation

Normal

– 3 –

White : AC 220-240V

AC 220-240V

White and Black : AC 220-240V

Orange : Drain valve

Gray : AC 220-240V

Brown : AC 220-240V

Blue : AC 220-240V

Displaying Method of the Number of Error

Occurrence and Its Clearing Method

(1) Displaying method of the number of error occurrence and its clearing method

The number of past error occurrence is kept in the memory and can be displayed on the control panel.

Memoriz ed number of error occurrence can a ls o be cleared. U s e this function to check the failure for any

repa ir work or to che ck the c onditions a fter repair.

Digital LED display

T I M E R button

WAS H butto n

R IN S E button

C OU R S E button

S TAR T butto n

Dis pla y S ample on B utton Des cription

Number LE D Display

[S etting of dis play mode]

W ith in 3 min ute s a fter tur ning on the powe r button, pre s s th e WA S H

and R INSE button for approximately 1 second.

E rror number is displayed on the number LE D.

(The buzzer beeps.)

(T he power is au toma tically turn e d o ff in 1 0 min ute s. )

(S ubse que ntly, operations will be in dis play mode.)

[C hange error numbe r (increment)]

E rror number increments. Every time TIMER button is pressed, the

display cha nge s as follows: E 1 E 2 E 3 E 5 E 6 E 7 E 8 E 9

EP Ec EL EA AF

[Change error number (decrement)]

E rror number decrements. E very time WASH button is pressed, the

display cha nge s as follows :

EP E9 E8 E7 E6 E5 E3 E2

[Dis play the number of error occurrenc e]

After selecting the error number by the above method using TIME R or

WAS H button, press S TART button. The number of past occurrence of

that error will be displaye d.

(Displayed in 3-digit number. Max. displayed number: 255 times)

(Display "000" means the number of error occurrence is 0.)

[C lea r the me morized number of errors ]

Memoriz ed number of errors can be cleare d.

(The buzzer beeps.)

(Memor ize d numbe r of a ll the e rrors will be cle ared. )

Use it when necess ary after repair.

(To c heck the completed re pa ir works on a later day, etc. )

WAS H

and

RINSE

TIME R

WAS H

START

START

and

COURSE

(T his ca n be us ed for any

displayed error number.)

(E x: E 2 error occ urred

9 ti me s in the pa s t.)

E1 E95 E23 E- FA EA EL Ec

E- E23 E95

– 3 –

– 3 –

Symptoms That Are Easily Suspected As a

Failure

Symptom Check Points Actions to be Taken

(1) Error is displayed

on the timer display

and electronic

buzzer sounds.

(2) Operation stops

in the midst of a

process.

(3) “WASH, RINSE

and SPIN” buttons

do not work when

a process is under

way.

(4) “START/STOP”

button does not

work.

(5) Water cannot be

drained effectively.

Water cannot be

drained.

It is difficult to

drain the water.

(E1 is displayed.)

Check following “Abnormality Alarm” on Page 2 ~ 2.