Page 1

FILE NO : A09-01P

Quick reference

AIR TO WATER HEAT PUMP

Page 2

Quick Reference Guide - Page 2

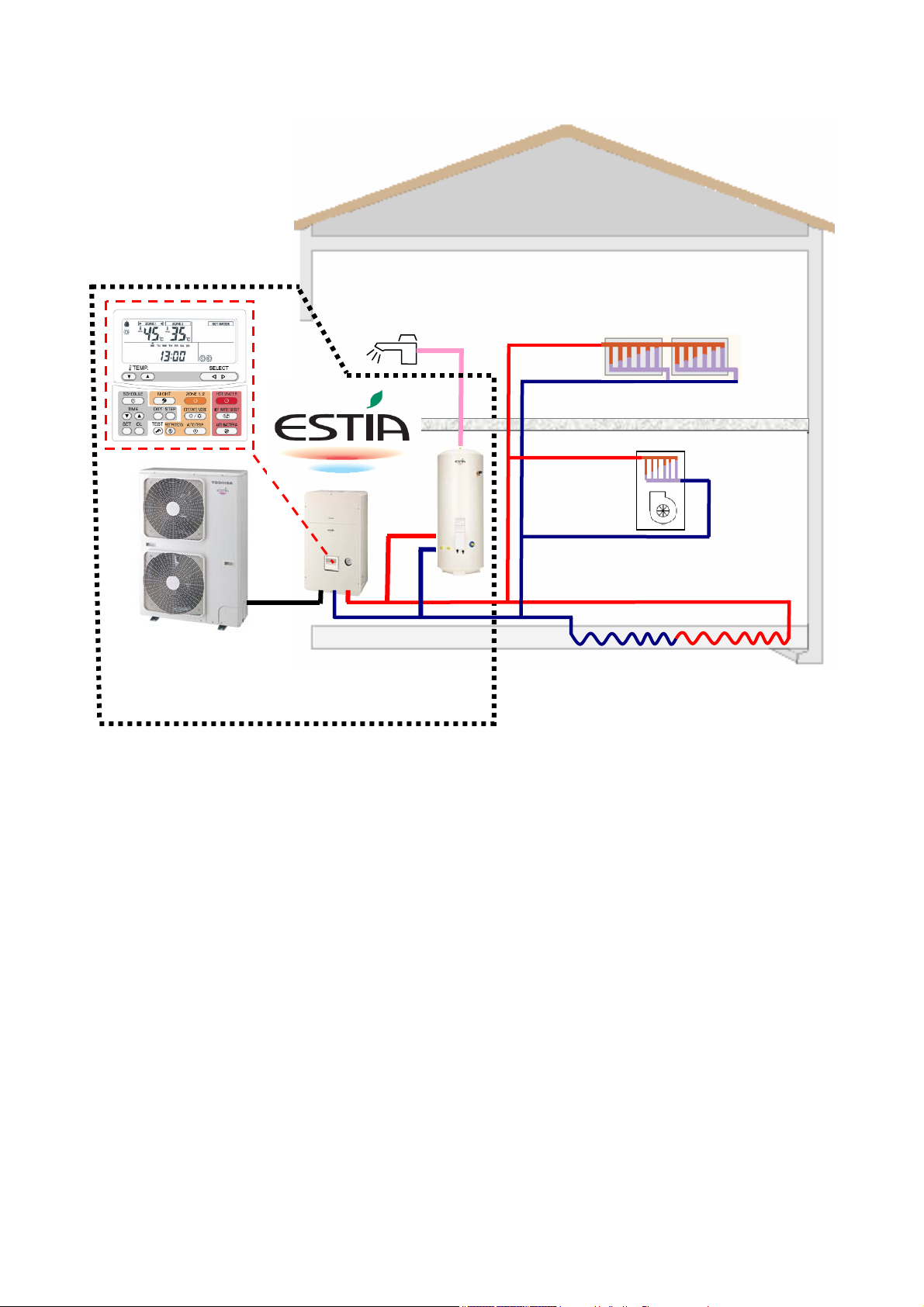

Estia System

Estia Outdoor Unit

HWS-802H-E 8.0kW Inverter (use Hydro Unit: HWS-802XWH**-E)

HWS-1102H-E 11.2kW Inverter (use Hydro Unit: HWS-1402XWH**-E)

HWS-1402H-E 14.0kW Inverter (use Hydro Unit: HWS-1402XWH**-E)

Estia Hydro Unit

HWS-802XWHM3-E Plate Heat exchanger and 3kW Backup Heater

HWS-802XWHT6-E Plate Heat exchanger and 6kW Backup Heater

HWS-1402XWHM3-E Plate Heat exchanger and 3kW Backup Heater

HWS-1402XWHT6-E Plate Heat exchanger and 6kW Backup Heater

HWS-1402XWHT9-E Plate Heat exchanger and 9kW Backup Heater

Estia Hot Water Cylinder (EU)

HWS-1501CSHM3-E 150L Stainless Steel Tank (with EU Accessories)

HWS-2101CSHM3-E 210L Stainless Steel Tank (with EU Accessories)

HWS-3001CSHM3-E 300L Stainless Steel Tank (with EU Accessories)

Estia Hot Water Cylinder (UK)

HWS-1501CSHM3-UK 150L Stainless Steel Tank (with UK Accessories)

HWS-2101CSHM3-UK 210L Stainless Steel Tank (with UK Accessories)

HWS-3001CSHM3-UK 300L Stainless Steel Tank (with UK Accessories)

Note:

Under floor heating, Fan Coil units, Radiators, valves and Hot Water Piping are procured locally.

Outdoor unit

Hydro unit

Domestic Hot Water

Hot water

cylinder

Space Conditioning

Radiator

Fan coil unit

(Heating or Cooling)

Under floor heating

(Zone Control)

Page 3

Quick Reference Guide - Page 3

Notes on System Design

• The input water temperature to the Hydro Unit must be 55°C or less.

Especially, be careful when there is an external heating source such as a boiler.

When hot water over 55°C returns, it may result in a failure of the unit or water leakage.

• The flow rate of the circulating water must meet the following range:-

11 and 14 kW 17.5 L/minute or more

8 kW 13 L/minute or more

If the flow rate becomes less than the minimum, the protective device is activated to stop operation.

Ensure the flow rate with a bypass valve, etc. when you use a flow rate valve for the Hydro Unit.

• Do not drive water by power other than the pump built in the Hydro Unit.

• The backup heater operates supplementary to exert a prescribed capacity when the heat pump

cannot exert its capacity at a low outside temperature.

• Install the Hydro Unit and water pipes in a place in which they do not freeze.

• Make the water circuit closed. Never use it as an open circuit.

• To prevent damage to the system during outdoor defrost the circulating water must be 20 litres

or more. If total water amount is not enough, the unit may not function fully due to protective

operation.

Options required for each function

Purpose

Space Heating - -

Space Heating &

Space Cooling

(All Rooms)

Space Heating &

Space Cooling

(partly heating only)

150L Hot water cylinder HWS-1501CSHM3-E

150L Hot water cylinder HWS-1501CSHM3-UK

Domestic Hot Water

2-zone control - -

Interlocking with

boiler

Interlocking with

booster heater

210L Hot water cylinder HWS-2101CSHM3-E

210L Hot water cylinder HWS-2101CSHM3-UK

300L Hot water cylinder HWS-3001CSHM3-E

300L Hot water cylinder HWS-3001CSHM3-UK

Output control board kit

Part name Model code Part name

(1)

Toshiba Supply Procure locally

- - Fan coil(s) only

- -

- - Electric heater

Radiator(s),

Fan coil(s),

Under floor heating

Fan coil(s) plus

Radiator(s)

or Under floor heating

Motorized 2-way

valve

Motorized 3-way

valve

Earth leakage breaker

Motorized mixing

valve

Circulator pump

Buffer tank

TBC-PCIN3E Boiler

Page 4

Quick Reference Guide - Page 4

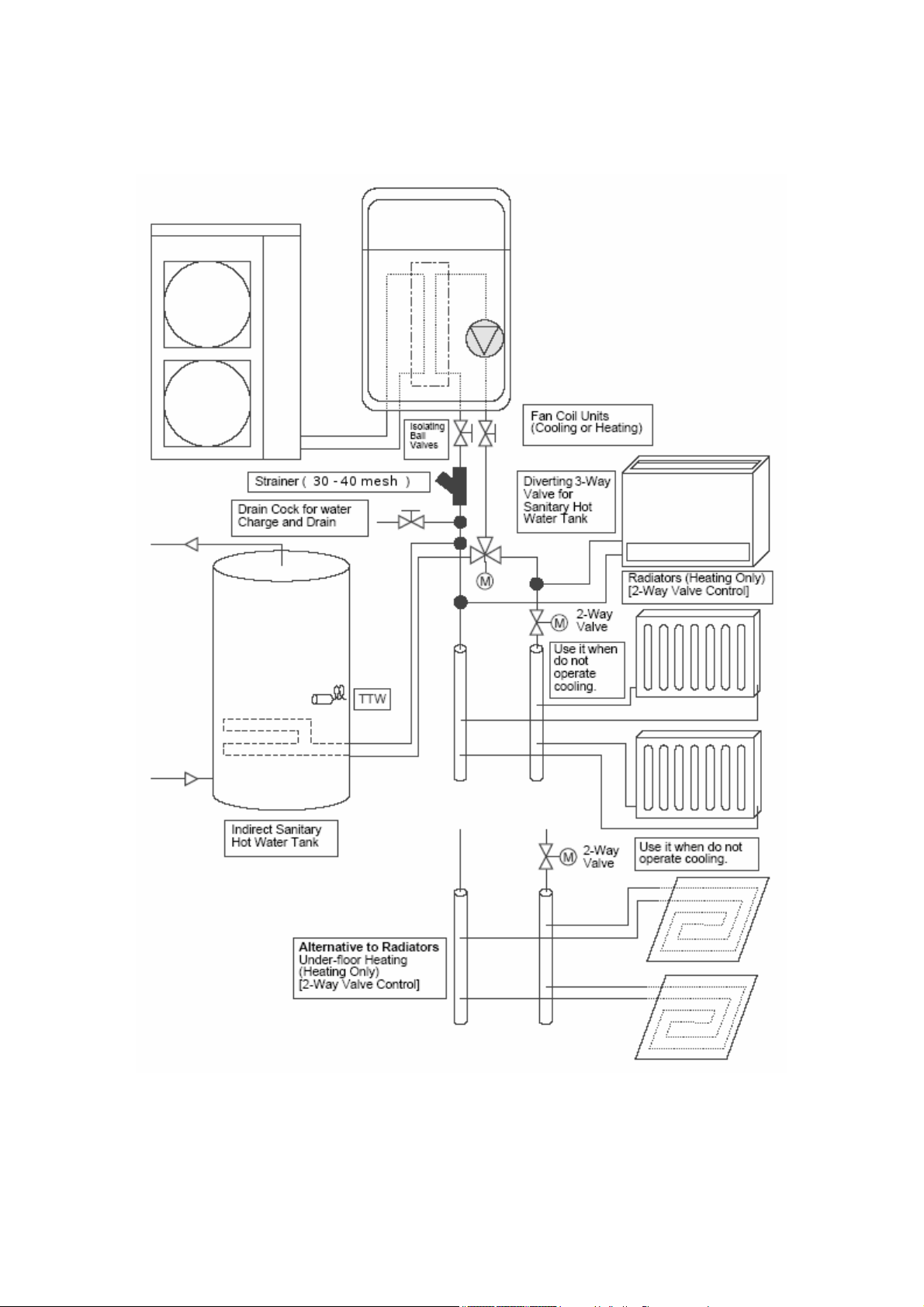

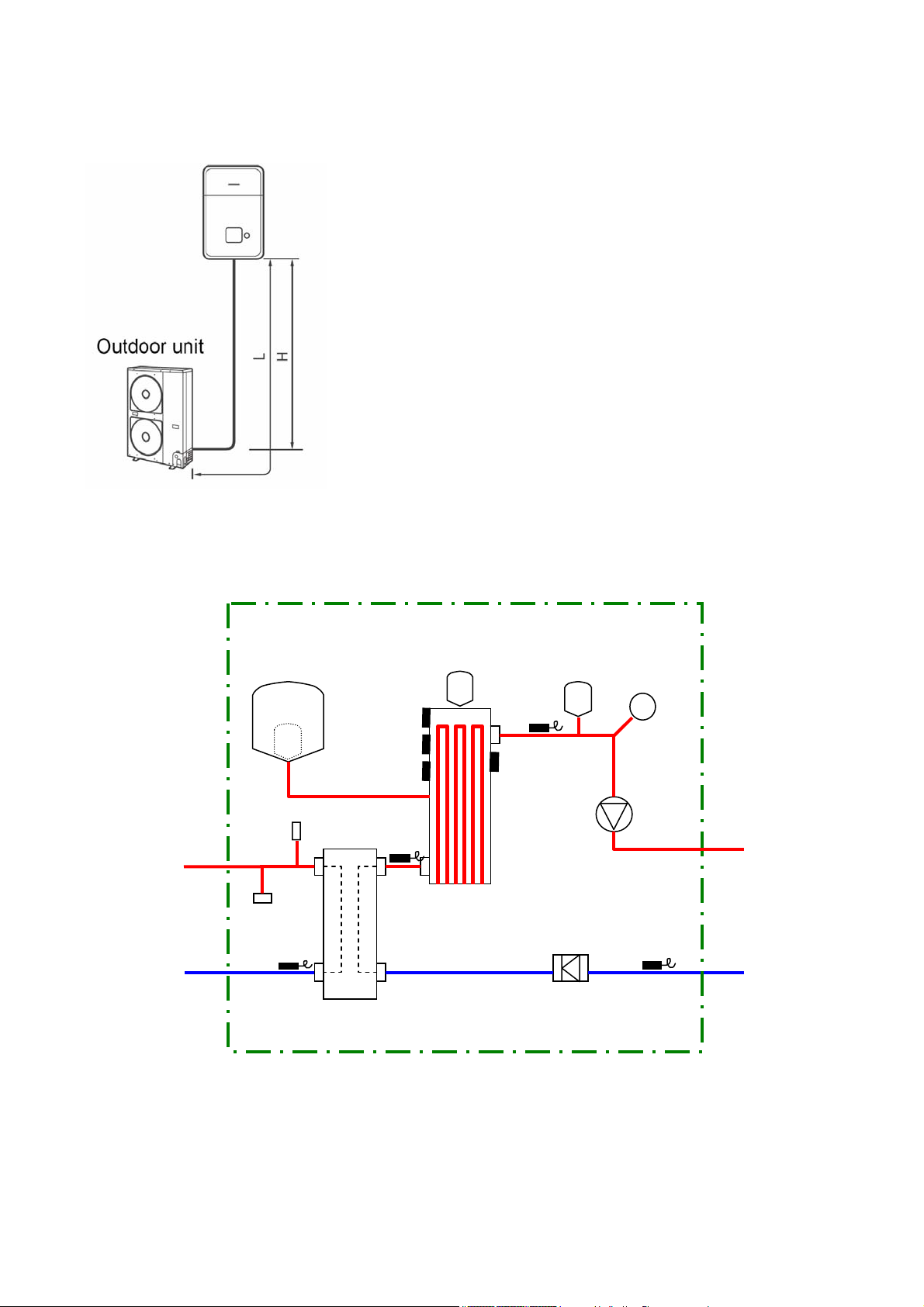

Installation Examples

Space Cooling and Space Heating with Domestic Hot Water

When both cooling and heating are used, install a 2-way valve (for cooling) to the pipe to the room

for heating only.

Page 5

Quick Reference Guide - Page 5

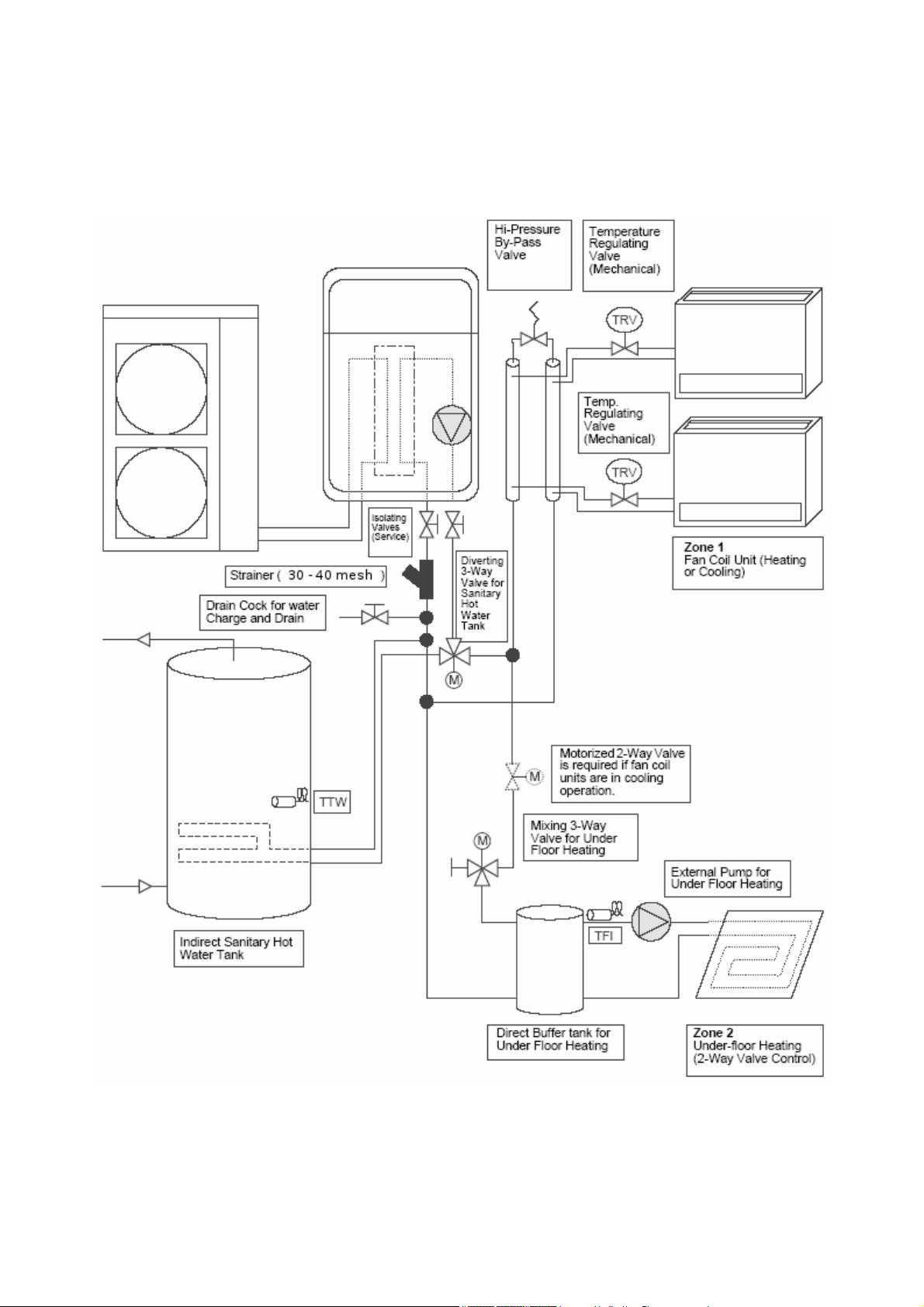

Installation Examples (cont.)

2-Zone Space Heating with Domestic Hot Water

The following shows an example of the 2-zone temperature control.

A buffer tank and a water pump are required for the 2-zone temperature control. This example is

Heating only, if the Fan Coils are to be used for Cooling then a 2-Way valve must be fitted.

Page 6

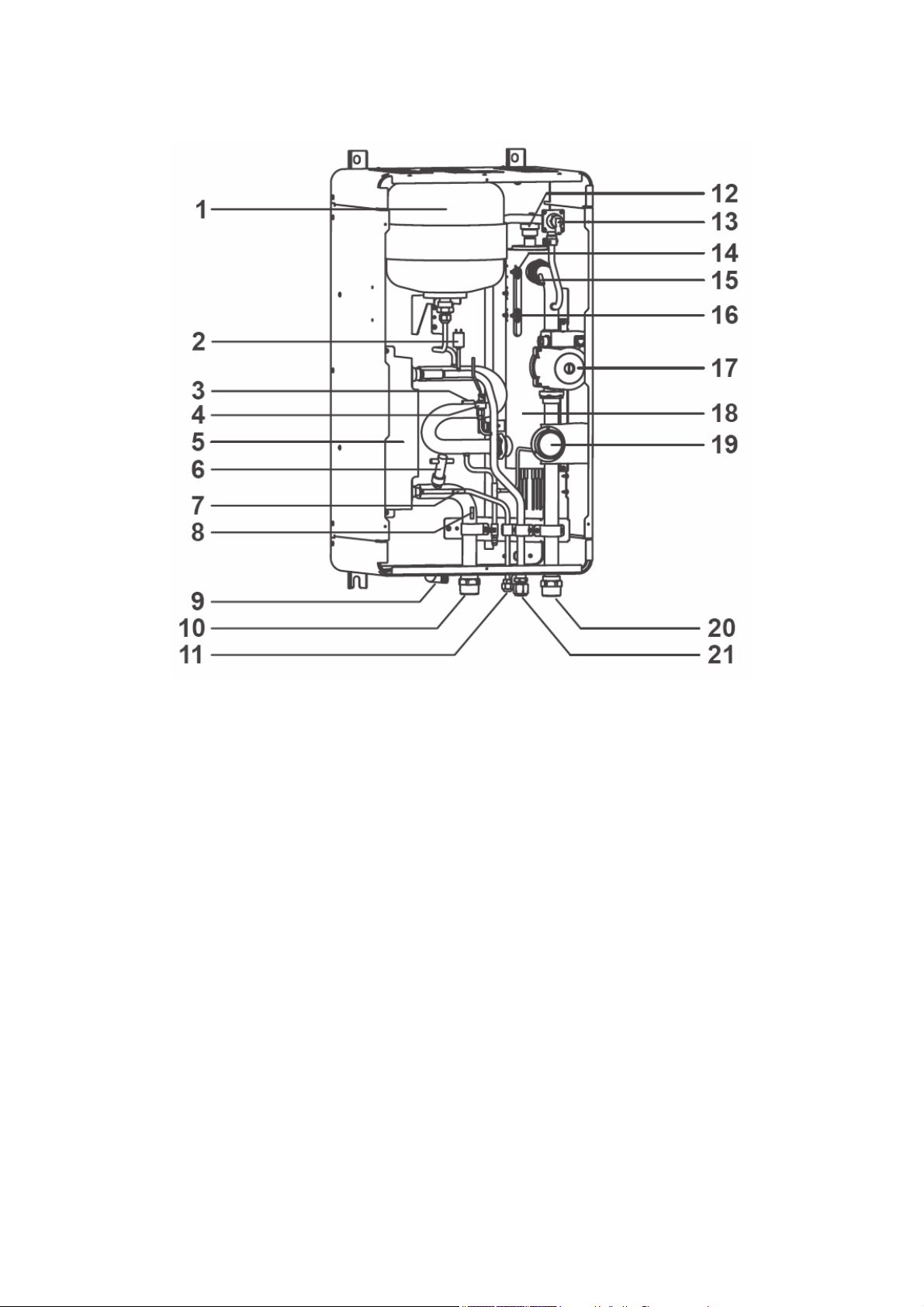

Hydro Unit – Exploded View

Quick Reference Guide - Page 6

1 : Expansion vessel

2 : Hi pressure switch (4.15 MPa)

3 : Temperature sensor (for Heat pump outlet -TWO)

4 : Pressure sensor

5 : Heat exchanger

6 : Flow switch (13.0 L/min 17.5 L/min)

7 : Temperature sensor (for refrigerant -TC)

8 : Temperature sensor (for water inlet -TWI)

9 : Drain nipple

10 : Water inlet connection

11 : Refrigerant liquid connection

12 : Air relief valve

13 : Pressure relief valve (0.3 MPa (3 bar))

14 : Thermal protector (auto)

15 : Temperature sensor (for water outlet THO)

16 : Thermal protector (Single operation)

17 : Water pump

18 : Backup heater (3 kW, 3 kW x 2, 3 kW x 3)

19 : Manometer

20 : Water outlet connection

21 : Refrigerant gas connection

Page 7

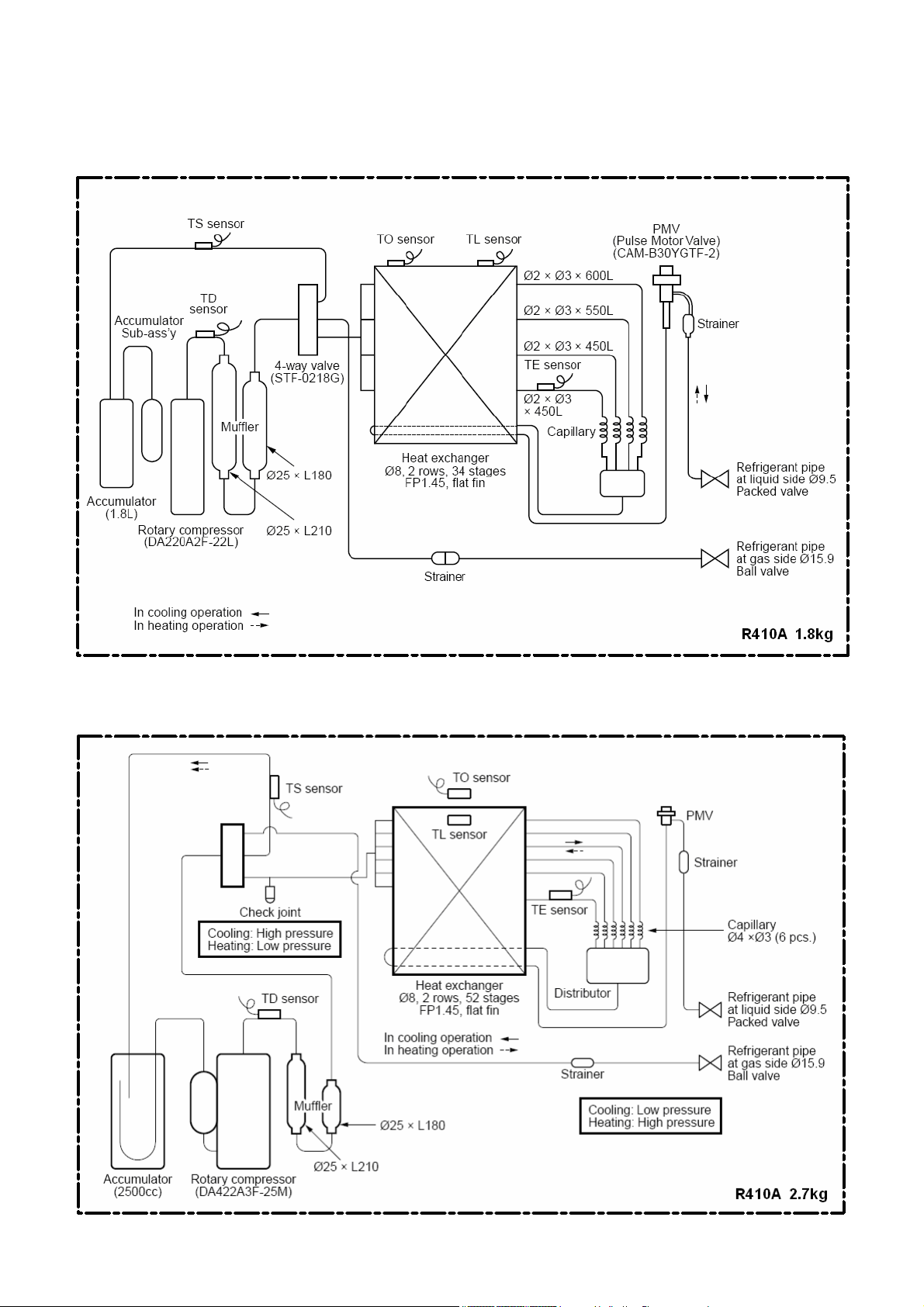

Quick Reference Guide - Page 7

Refrigerant Piping

Refrigerant Pipe Lengths and Height

The length and height of the refrigeration pipe must be within the following values.

Minimum Pipe Length

HWS-802H-E : 5 m

HWS-1102H-E : 3 m

HWS-1402H-E : 3 m

Maximum Pipe Length and Height

H: Max. ±30 m (above or below)

L: Max. 30 m

Note

The maximum pipe length cannot be increased using additional

refrigerant.

Refrigeration and Water Cycle Diagrams

Hydro Unit

Refrigerant pipe

at gas side

(Outer ø15.88)

Refrigerant pipe

at liquid side

(Outer ø9.52)

Expansion vessel

Hi_P_Switch

P_Sensor

TC

Sensor

Water Heat exchanger

Thermal

Protector

TWO

Sensor

Air vent valve

Backup heater

Pressure

relief

valve

THO

Sensor

Flow_Switch

Pressure

Gauge

Pump

Water Out

(1 1/4")

TWI

Sensor

Water IN

(1 1/4")

Page 8

Outdoor Unit

HWS-802H-E

Quick Reference Guide - Page 8

HWS-1102H-E, 1402H-E

Page 9

Quick Reference Guide - Page 9

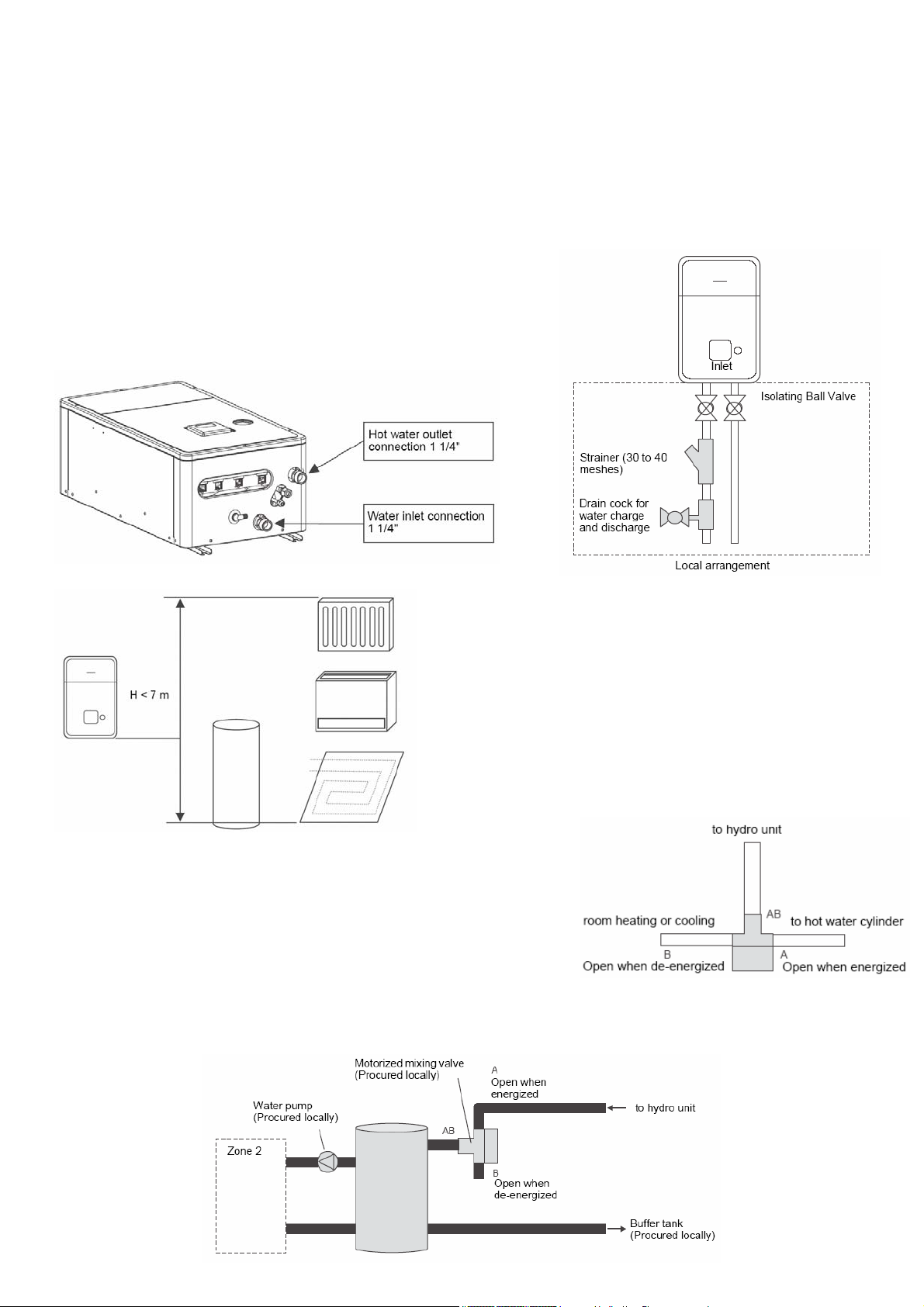

Water Piping

• Install water pipes according to the regulations of respective countries.

• Install water pipes in a freeze-free place.

• Make sure that water pipes have sufficient pressure resistance (The setting value of the pressure

relief valve is 0.3 MPa).

• Do not use zinc plated water pipes. When steel pipes are used, insulate both ends of the pipes.

Water Connections

• Install a strainer with 30 to 40 meshes (procure locally) at

the water inlet of the Hydro Unit.

• Install drain cocks (procure locally) for water charge and

discharge at the lower part of the Hydro Unit.

Water Piping Limitations

Design the water pipe length within the QH

characteristics of the pump (flow-rate and pump

head).

The maximum height difference for the water pipes i

7 metres.

Piping to hot water tank (option

Water supplied to the hot water cylinder is branched by a

motorized 3-way valve (procured locally).

Connect the hot water cylinder to port A (open when

energized) of the valve.

)

Piping to 2-zone operation (option)

To perform 2-zone temperature control circulate water using another pump (procured locally)

through a motorized mixing valve (procured locally) and a buffer tank (procured locally).

s

Page 10

Quick Reference Guide - Page 10

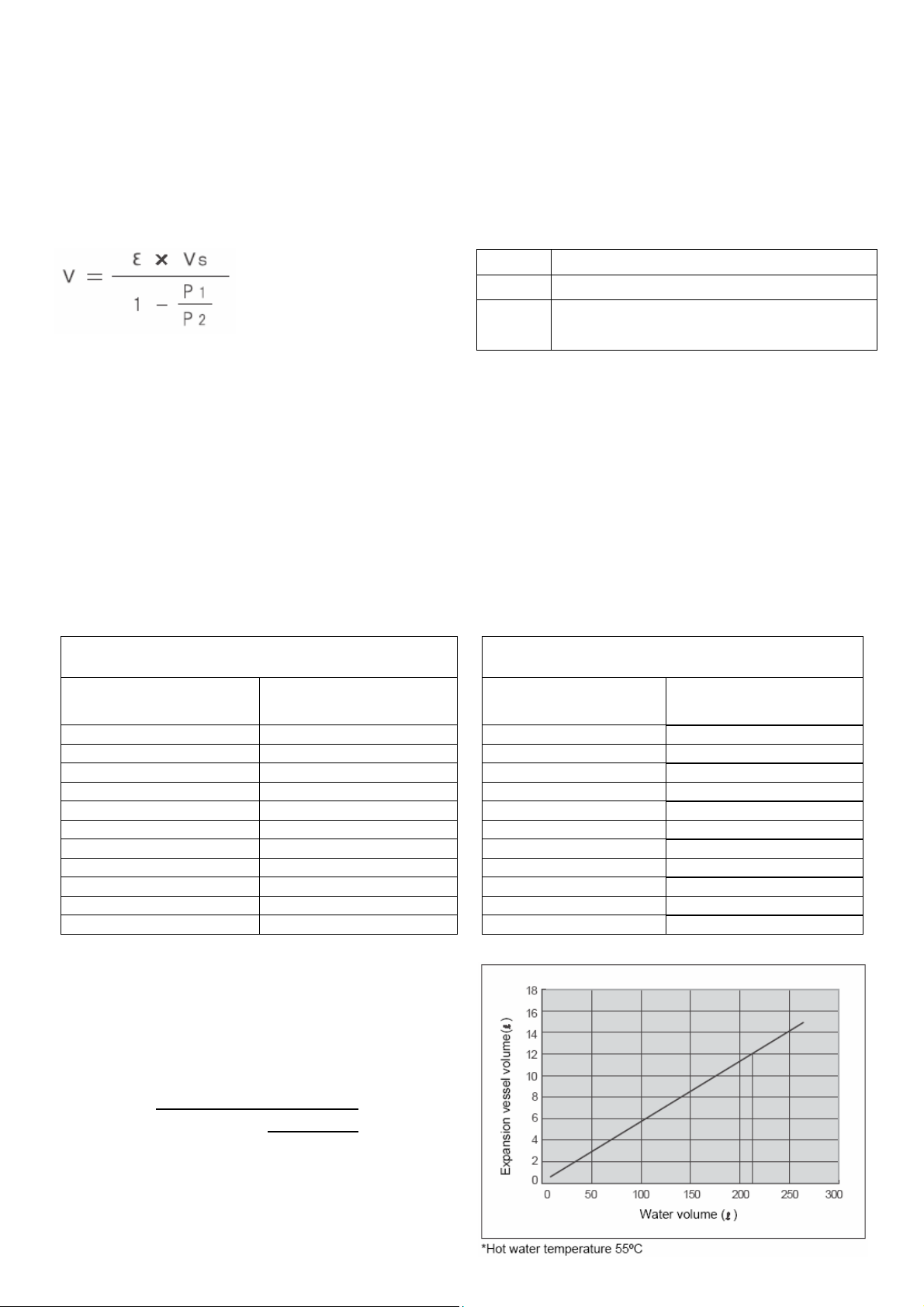

Checking water volume and initial pressure of expansion vessel

The expansion vessel of the Hydro Unit has a capacity of 12 litres.

The initial pressure of the expansion vessel is 0.1 MPa (1 bar).

The suggested initial water charge is 0.2MPa (2 bar).

The pressure of the safety valve is 0.3 MPa (3 bar).

Verify whether the capacity of the expansion vessel is sufficient using the following expression. If

the volume is insufficient, install an appropriate external expansion vessel.

V Action

< 12 L Internal Expansion Vessel Size OK

> 12 L

Internal Expansion Vessel Size too small.

Install appropriate external expansion vessel

V: Necessary total vessel capacity (L)

Ɛ: Water expansion coefficient at average hot water temperature

Vs: Total water volume in the closed system (Do not include Hot Water Cylinder)

P1: System pressure at tank setting position (Mpa_abs*).

(Pipe inner pressure during pump operation before heating device operates = water supply

pressure)

P2: Maximum pressure used during operation at tank setting position (MPa_abs*).

(= safety valve setting pressure)

* The absolute pressure value (abs.) is obtained by adding the atmospheric pressure (0.1 MPa (1

bar)) to the gauge pressure.

Water temperature and expansion coefficient (Ɛ)

Hot water temperature

(°C)

0 0.0002 50 0.0121

4 0.0000 55 0.0145

5 0.0000 60 0.0171

10 0.0003 65 0.0198

15 0.0008 70 0.0229

20 0.0017 75 0.0258

25 0.0029 80 0.0292

30 0.0043 85 0.0324

35 0.0050 90 0.0961

40 0.0078 95 0.0967

45 0.0100 - -

Expansion rate

(Ɛ)

Water temperature and expansion coefficient (Ɛ)

Hot water temperature

(°C)

Expansion rate

(Ɛ)

Example

Maximum Hot Water temperature: 55°C, initial

water charge: 0.2MPa and system volume: 200 L.

The calculated Vessel capacity (V) is 11.6 L:-

11.6

=

0.0145

1

x

-

In this case V < 12 L therefore the internal

expansion vessel is sufficient.

There is no need to install an external expansion

vessel.

200

(0.2+0.1)

(0.3+0.1)

Page 11

Quick Reference Guide - Page 11

Pump operation / configuration

Change Pump speed, so that water flow is always greater than the minimum flow rate. If water flow

is lower than the minimum rate during operation, the unit detects error.

Water charging

Charge water until the pressure gauge shows 0.2 MPa (2 bar).

Hydraulic pressure may drop when the trial run begins. In that case, add water.

Air may enter if the charged hydraulic pressure is low.

Loosen the purge valve cap by two turns to release air.

Loosen the cap of the pressure relief valve to release air.

Water may come out of the pressure relief valve.

Release the air completely from the water circuit. Failure to do so

may disable correct operation.

Water quality

The water used must satisfy EN directive 98/83 EC.

Piping insulation

It is recommended that insulation treatment be applied to all pipes. To perform optional cooling

operation, apply insulation treatment of 20 t or more to all pipes.

Page 12

Electrical Connections

E Box layout

Quick Reference Guide - Page 12

Terminal Block Connections

Page 13

Power Lines Schematic

Quick Reference Guide - Page 13

Control Lines Schematic

Page 14

Electrical supply / cable specifications

Wiring specifications (power line)

Quick Reference Guide - Page 14

Description

POWER

SUPPLY

Maximum

current

Installation

fuse rating

Cable size

14 kW 230 V ~ 50 Hz 22.8 A 25 A 2.5 mm² or more

Outdoor unit power

11 kW 230 V ~ 50 Hz 22.8 A 25 A 2.5 mm² or more

8 kW 230 V ~ 50 Hz 20.8 A 25 A 2.5 mm² or more

Outdoor-Hydro – – 1.5 mm² or more

3 kW 230 V ~ 50 Hz 13 A 16 A 1.5 mm² or more

Hydro inlet heater

power

6 kW 400 V 3N ~ 50 Hz 15 A (13 A x 2P) 25 A 2.5 mm² or more

9 kW 400 V 3N ~ 50 Hz 23 A (13 A x 3P) 25 A 2.5 mm² or more

Hydro cylinder heater power 230 V ~ 50 Hz 12 A 16 A 1.5 mm² or more

Hydro - cylinder – 12 A – 1.5 mm² or more

Wiring specification (control line)

Description

Line spec

Maximum

current

3-way valve control 2 line or 3 line 100 mA 12 m 0.75 mm² or more

Mixing valve control 3 line 100 mA 12 m 0.75 mm² or more

2-zone thermo sensor 2 line 100 mA 5 m 0.75 mm² or more

Cylinder thermo sensor

2+GND (shield

wire)

100 mA 5 m 0.75 mm² or more

Second remote controller 2 line 50 mA 50 m 0.75 mm² or more

Maximum

length

Cable Size

Control parts specifications

Maximum

Description Power

current

Type

Connection

destination

L

, N

1

, 2 , 3

L

, N (TB02)

L1

, L2 , L3

N

(TB02)

L

1

TB03)

, N (

, 2 (TB03)

Connection

destination

7

, 8 , 9

(TB05)

1

, 2 , 3

or

2

, 3 , 4

(TB04)

C

, D (TB06)

A

, B (TB06)

1

, 2 (TB07)

Motorized 3-way valve (for

hot water)

Motorized 2-way valve (for

cooling)

Motorized mixing valve type

1 (for 2-zone)

AC 230 V 100 mA

AC 230 V 100 mA spring return type (normally open )

AC 230 V 100 mA

Spring return type Note: 3-wire SPST and SPDT type can be

used by changing the function code.

60 sec 90º. SPDT type Note: SPST and 20 to 240 sec type

can be used by changing the function code.

Output line specifications

Description

Output

Maximum

current

External pump No. 1 AC230V 1 A – 12 m

External booster heater AC230V 1 A – 12 m

Boiler control

ALARM Output

Operation Output

Defrost Output

Nonvoltage

contacts

Nonvoltage

contacts

Nonvoltage

contacts

Nonvoltage

contacts

0.5 A AC230 V 12 m

1 A DC24 V 12 m

0.5 A AC230 V 12 m

1 A DC24 V 12 m

0.5 A AC230 V 12 m

1 A DC24 V 12 m

0.5 A AC230 V 12 m

1 A DC24 V 12 m

Max

voltage

Maximum

length

Interlocked with the Hydro Unit

pump

Output as required when outdoor

air temperature is -20°C or less

Output as required when outdoor

air temperature is -10°C or less

Page 15

Quick Reference Guide - Page 15

Input line specifications

Description

Emergency stop control Non-voltage 12 m

Cylinder thermostat input Non-voltage 12 m

Cooling thermostat input Non-voltage 12 m

Heating thermostat input Non-voltage 12 m

Input

Maximum length

CAUTION

Earthing arrangements

The Hydro Unit and related equipment must be earthed in accordance with your local and national

electrical regulations.

It is essential that the equipment is earthed to prevent the electric shock and damage to the

equipment.

Electrical connection to hydro unit

• Remove the front cover and the electrical box cover from the Hydro Unit.

• The Hydro Unit power cable must be sized in accordance with refer to “Electrical supply/cable

specifications”.

• Connect the Hydro Unit power cable to Terminal 02 as shown below.

Single Phase Units: Live conductor – Terminal L1

Neutral conductor – Terminal L2

Earth conductor – Earth terminal

Three Phase Units: Phase 1 conductor – Terminal L1

Phase 2 conductor – Terminal L2

Phase 3 conductor – Terminal L3

Neutral conductor – Terminal N

Earth conductor – Earth

• Ensure the Hydro Unit power cable is secured using the cable clamp fitted in the electrical box.

• Ensure the Hydro Unit power cable connection terminals are tight.

Outdoor unit to hydro unit electrical connection

• Ensure electrical circuits are isolated before commencing work.

• The Outdoor Unit to Hydro Unit interconnecting cable must be sized in accordance with refer to

“Electrical supply/cable specifications”.

• Connect the Outdoor Unit to Hydro Unit interconnecting cable as shown in the diagram above.

• Ensure the Outdoor Unit to Hydro Unit interconnecting cable is secured using the cable clamp

fitted in the electrical box.

• Ensure the Outdoor Unit to Hydro Unit interconnecting cable connection terminals are tight.

Page 16

Quick Reference Guide - Page 16

Electrical connection for external booster heater

CAUTION

The maximum current available from the booster heater output is 1 A. Do not connect the

booster heater directly to Terminal Block 05 on the Hydro Unit. The AC230 V 1 A output

from the Hydro Unit must only be used to energize an external contactor (Supplied locally).

• The booster heater can be installed only for room heating and cannot be used for hot water

supply.

• Install the booster heater downstream of the 3-way valve on the indoor unit side.

• The booster heater is an external heater, supplied locally, used to assist the Hydro Unit during

low ambient conditions.

• The output from the Hydro Unit is only enabled when the outdoor air temperature is less than -

20°C.

• Ensure the external booster heater is installed and set up in accordance with all Local, National

and International regulations.

• Connect the coil, of the field supplied contactor, to terminals 5 & 6 on Terminal Block 05. The

contactor will energize in the event of low ambient conditions.

• A separate dedicated electrical supply must be used for the external booster heater. This must

be connected through the contacts on the field supplied contactor (see diagram below):-

Electrical connection for external additional pump (P2)

CAUTION

The maximum current available from the additional pump output is 1 A. Do not connect the

additional pump directly to Terminal Block 05 on the Hydro Unit. The AC230 V 1 A output

from the Hydro Unit must only be used to energize an external contactor (Supplied locally).

• The Hydro Unit has the facility to connect an additional circulating pump, if required, into the

heating or cooling system.

• Install the external pump so that its motive power does not affect the internal pump.

• The output for the pump is synchronized with the operation of the main circulating pump (P1)

inside the Hydro Unit.

• Connect the coil, of the field supply contactor, to terminals 1 & 2 on Terminal Block 05.

• A separate dedicated electrical supply must be used for the additional pump. This must be

connected through the contacts on the field supplied contactor (see diagram below):-

Page 17

Quick Reference Guide - Page 17

2-way valve (for cooling) connection

Required Valve Specification:

Electrical Specification: 230 V; 50 Hz; <100 mA

Return Mechanism: 2-wire spring return.

• The Hydro Unit has the facility to connect a 2-way valve to

isolate Space Conditioning Units that do not perform cooling,

when Cooling Mode is selected.

• Connect the 2-way valve in accordance with the diagram

(opposite):-

3-way valve (diverter) connection

Required Valve Specification:

Electrical Specification: 230 V; 50 Hz; <100 mA

Valve Diameters: Port A, Port B: Ø 1 1/4"

Return Mechanism: 3 types of 3-way valve (diverter) can be used.

Set the 3-way valve in use with the DIP switch SW13-1 on the Hydro Unit board.

Diverter Valve Description

Type 1 2-wire spring return OFF

Type 2 3-wire SPST OFF

Type 3 3-wire SPDT ON

Continuous operation of the valve motor at the fully open position is not recommended.

• The 3-way diverter valve is used to select either domestic hot water or space heating.

• Connect the 3-way diverter valve in accordance with the diagram below:-

SW13-1

Page 18

Quick Reference Guide - Page 18

3-way mixing valve connection

Required Actuator Specification

Electrical Specification:230 V; 50 Hz; <100 mA

The 3-way mixing valve is used to achieve the temperature differential needed in a 2-zone heating

system.

• Connect the 3-way mixing valve in accordance with the diagrams below:-

Hot water cylinder connection (optional)

• Please refer to “Electrical supply/cable specifications” for fuse/cable size and for

connection details.

Electrical Connection (Hot Water Cylinder Electric Heater)

• The electric heater, incorporated in the hot water cylinder, requires a separate supply to Hydro

Unit.

• Connect the hot water cylinder heater electrical supply in accordance with shown below:

Live conductor: Terminal L on Terminal Block 03

Neutral conductor: Terminal N on Terminal Block 03

Earth Conductor: Earth terminal on Terminal Block 03

• Connect the hot water cylinder heater to the Hydro Unit as shown below:

Live conductor to hot water cylinder: Terminal 1 on Terminal Block 03

Neutral conductor to hot water cylinder: Terminal 2 on Terminal Block 03

Earth conductor to hot water cylinder: Earth terminal on Terminal Block 03

Electrical Connection (Hot Water Cylinder temperature Sensor)

• Connect the hot water cylinder temperature sensor as shown below to terminals A & B on

Terminal Block 06 in the Hydro Unit.

• Please ensure that the interconnecting cable, between the Hydro Unit and the hot water cylinder,

is connected to earth at both ends of the cable using the shield wire.

Page 19

Setting DIP Switches on the Board

in the Hydro Unit

• Detach the front cover and the electric parts box cover of

the Hydro Unit.

• Set the DIP switches on the main board.

Quick Reference Guide - Page 19

SW10 Description

1

3 External P2 pump operation Continuous operation OFF ON

SW11 Description

1

2

3 Booster heater operation Operate

SW12 Description

1 Hot water supply operation Valid

2 Zone 1 operation Valid

3 Zone 2 operation Invalid

SW13 Description

1 Type of motorized 3-way valve

2 Interlocking with boiler Invalid

3 Auto restart for power failure Auto restart

SW02 Description

4 Room thermostat Invalid

Internal pump P1 operating

mode

Internal backup heater

operation

Hot water cylinder heater

operation

Continuous operation OFF ON HP synchronized

Operate

Operate

• 2-wire spring return type

• 3-wire SPST type

Default setting Alternate

Default setting Alternate

Default setting Alternate

Default setting Alternate

Default setting Alternate

Switch mode

Switch mode

OFF ON Not operate

OFF ON Not operate

OFF ON Not operate

Switch mode

OFF ON Invalid

OFF ON Invalid

OFF ON Valid

Switch mode

OFF ON 3-wire SPDT type

OFF ON Valid

OFF ON Manual restart

Switch mode

OFF ON Valid

Interlocked with the

internal pump

synchronized with P1.

Page 20

Hydro Unit Remote Control

Buttons and Functions

1. TEMP. button:

2. SCHEDULE

button:

3. TIME button:

4. SET button:

Changes the set temperature for

each operation mode (ZONE1/2 hot

water) by 1°C step.

Sets the current time and

scheduled weekly operation.

Changes time for current time

setting and scheduled weekly

operation setting with ▼ and ▲

buttons.

Determines the entered current

time setting and scheduled weekly

operation setting.

10. NIGHT button:

11. AUTO TEMP.

button:

12. OPERATE

MODE button:

13. ZONE1, 2

button:

Quick Reference Guide - Page 20

Controls the night set back

operation.

Switches setting temperature

automatically according to outside

temperature. (Pressing this button

long changes the mode to data

setting mode).

Selects ZONE1/2 operation mode

(heating or cooling).

Turns on/off the zone (floor

heating/radiator/FCU) operation.

5. CL button:

6. DAY button:

7. STEP button:

8. TEST button:

9. FROST

PROTECTION

button:

Clears settings for the current time

and scheduled weekly operation.

Sets days of the week for current

time setting and scheduled weekly

operation setting.

Specifies switching STEP number

in a day for weekly schedule.

Used for test run or service.

Controls minimum operation for

unused period (going out,

absence,etc.) for anti freezing.

14. ANTI BACTERIA

button:

15. HOT WATER

BOOST button:

16. HOT WATER

button:

17. SELECT button:

Regularly increases the hot water

temperature in the tank for

sterilization. (Pressing this button

long changes the mode to data

setting mode).

Boosts boiling when high tapping

temperature is required temporarily.

Turns on/off hot water operation.

Selects an operation mode when

changing the set temperature of

each operation mode.

NOTE

Some functions are not provided depending on the system specification in use.

Page 21

Display Explanation

Quick Reference Guide - Page 21

18: ZONE1, ZONE2

Display Description Display Description

Lights when floor heater or radiator

is connected (when the system has

floor heater or radiator).

ZONE1 selected for Temperature

to be changed.

Lights when system configured to

have 2 zones.

ZONE2 selected for Temperature

to be changed.

Lights during heating or cooling

operation using the heat pump.

Lights when the internal heater is

energized during heating

operation.

Lights when heating is selected.

20: HOT WATER

Lights when hot water supply system is

connected (when the system has hot

water supply).

HOT WATER selected for Temperature

Lights when hot water supply operation

Lights when the internal heater is

energized during hot water supply

Lights during hot water supply operation.

to be changed.

is performed by heat pump.

operation.

Lights while hot water boost is activated.

Lights when the ANTI BACTERIA button

is pressed and goes out when the button

is pressed again.

Lights when unit enters the data set

mode.

Displays hot water set temperature.

(40 to 80°C, factory setting: 65°C)

Lights when the set temperature or

sensor's water temperature is displayed

with the 7-segment indicator.

°C

Lights when cooling is selected.

Lights when the FROST

PROTECTION button is pressed

and goes out when the button is

pressed again.

Lights when Auto operation is

selected.

Displays heating/cooling set

temperature. (Heating: 20 to 55°C,

factory setting: Auto, cooling: 10 to

30°C) Goes out when Auto

operation is selected.

Lights when the set temperature or

sensor's water temperature is

displayed with the 7-segment

indicator.

°C

Page 22

Quick Reference Guide - Page 22

Display Explanation (cont.)

19: TIMER

Display Description Display Description

21: OPERATION

Clock: Displays the current time

(AM or PM).

Displays days of the week (Sunday

to Saturday).

Lights when the NIGHT button is

pressed and goes out when the

button is pressed again.

Lights when night time quiet

operation is set.

Indicates scheduled operation 1

status (including setting time).

Displays the scheduled operation

step when the scheduled operation

STEP1-5 program is set.

Lights during time setting and

scheduled operation setting.

Lights while internal pump (P1) or

external pump (P2) is driven.

Lights during backup operation only by

the heater.

Lights when the unit enters the data set

mode and goes out when the unit exits

the data set mode.

Lights when the unit enters the service

mode and goes out when the unit exits

the service mode.

Lights when an error occurs and goes

out when the error is cleared.

Lights for two seconds when settings are

completed.

Lights for two seconds when settings

failed.

Function Code Access

Set function codes for various operation modes, input using the remote controller.

There are 2 types of settings:-

1) Hydro Unit function code setting.

2) Remote controller function code setting.

Setting procedure for Hydro Unit function code

1. Press the TEST + SET + SELECT buttons

for four seconds or more to enter the hydro unit function code setting mode.

2. Set the function code number with the TEMP. buttons

(CODE No.: 01 to 91).

3. Set data (DATA) with the TIME buttons .

4. Press the SET button to confirm the settings.

5. The CL button is enabled only before the SET button is

pressed and the function code is changed.

6. Press the TEST button to finish the settings.

Setting procedure for Remote Controller function code

1. Press the TEST + CL TEMP. ▼ buttons for four seconds

or more to enter the ote controller function code setting mode.

2. Set the function code number with the TEMP. buttons

(CODE No.: 01 to 13).

3. Set data (DATA) with .

4. Press the SET button to determine the settings.

rem

the TIME buttons

+

5. The CL button is enabled only before the SET button is

pressed and the function code is changed.

6. Press the TEST button to end the settings.

Page 23

Quick Reference Guide - Page 23

Main setting items

) Setting Hot Water Temperature Range (functi on code 18 to 1F)

(1

• Set the temperature range for heating (zone 1, zone 2), cooling, and h

• The upper-limit and lower-limit temperatures of each mode can be set.

) Setting Heat Pump Operation Conditions for Hot Water Supply (func(2

• Set the heat pump start water temperature and heat pump stop water temperature.

is recommended that the default value be used.

3) Compensating Hot Water Temperature (fun(

• Compensate the target temperature from the remote controller set tempe

temperature lowers below the set outside air temperature.

4) Setting Hot Water Boost (function code 08 and 09) (

• Set the control time and target temperature when the HO

controller is pressed.

5) Setting Anti-Bacte(

• Set the control for the hot

• Set the target temperature, control period, start time (24-hour not nd target temperature retention

period.

this control setting according to regulations and rules of respective countries. • Make

6) Setting Priority Mode Temperature (

• Set the outside air temperature that change

• Hot Water - Heating Switching Temperature

• Boiler HP Switching Temperature

made.

7) Sett(

• Compensate the target temperature when Auto is set for temperature set

• The outside air temperature can be set to one of three points (T1, T2, and T3) within a range of -20 to 2

• The target temperature can be set to a value from 20 to 55°C.

• However, A > B > C > D > E.

ing Heating Auto Mode Temperature (function code 27 to 31)

ria

water cylinder when ANTI BACTERIA

t temperature, the HP operation stops and the external bWhen the temperature lowers the se

ction code 24 and 25)

T WATER BOOST

s the preferred operation mode.

temperature lowers the set tempeHeating operation takes precedence when the

ot water.

ation), a

tion code 20 and 21)

rt water tempe• The heat pump starts working when the water temperature lowers below the set sta

rature when the hot water

button on the remote

is set with the remote controller.

rature.

ting on the remote controller.

rature. It

oiler output is

0°C.

• The entire curve can be adjusted plus and minus 5°C by function code 27.

) Setting Frost Protection Temperature (function code 3A to 3B) (8

• Set the function when the FROST PROTECTION

• Set enabling/disabling of this function and the targe ater temperature.

• If disabling is set, the frost protection operation is not performed even wh

is pressed.

(9) Setting

• The increase/decrease time is used to set the response time.

10)Setting Night Setback (function code 26. remote control(

• Set the function when the NIGHT

• If disabling is set, the night setback operation is not performed even when the NIGHT

Frequency of Output to Internal Heater (function code 33 to 34)

button on the remote controller is pressed.

ion, re e. • Set enabling/disabling of this funct duction temperature, start time, and end tim

button on the remote controller is pressed.

t w

en the FROST PROTECTION

ler function code 0F to 11)

button is pressed.

button

Page 24

Quick Reference Guide - Page 24

Main setting item (cont.)

1)Setting 2-Way Valve (for Cooling) Operation (function code 3C)

(1

• When using both cooling and heating operations and there is an indoor

heating), install the 2-way valve and set this function code.

2)Setting 3-Way Valve Operation (function code 54)

(1

• This setting is not necessary for normal installation. Make

A and B of the 3-way valve are wrongly attached and it cannot be rectified on site.

(1

3)Mixing valve types and setting

• Set the time period from full close to

the actual time.

(1

4)Setting Heating/Hot Water Switching when Boiler Is Used (function code 3E)

• When boiler is used, make this setting to operate the Hydro Unit by the instruction from

(1

5)Setting Heat Pump Operating Time for Hot Water Supply Operation

• Set the time period from the start of heat pump run to the start of heater ene

water supply operation. If a long period is set, it takes long time for heating water.

(1

6)Setting Cooling ON/OFF

• Set this function when perform

(1

7)Remote controller time indication

• 24-hour or 12-hour notation is selected for the timer.

(1

8)Setting Nighttimes Quiet Operation

• Issue an instruction for low-noise mode op

time, and end time can be set.

(1

9)Setting Alarm Tone

• The remote controller ala

rm tone can be set.

full open of the 2-zone control mixing valve. Set a value that is 1/10 of

ing cooling operation.

eration to the outdoor unit. Enabling/disabling of this function, start

this setting to invert the logic circuit in case ports

unit only for heating (such as floor

rgization at the beginning of hot

Function Code List

Zone 1 - heating upper temperature limit °C

Zone 1 - heating lower temperature limit °C

Setting

mperatu

Te re

Range

Hot Water

Operation

Hot Water

T

emperature

Compensation

Hot Water Boost

Anti - Bacteria

Priority Mode

Zone 2 - heating upper limit temperature °C

Zone 2 - heating lower limit temperature °C

Cooling mode - upper temperature limit °C

Cooling mode - lower temperature limit °C

Hot water - upper temperature limit °C

Hot water - lower temperature limit °C

Heat pump start temperature °C

Heat pump stop temperature °C

Temperature compensation - start outside air

temperature °C

Compensation te

Operation time x 10 min

Setting temperature °C

Setting temperature °C

Start cycle (day)

Start time (hour)

Operation time (m

Hot water and heating switching

temperature °C

Boiler and heat p

temperature °C

Function

mperature °C

in)

ump switching

Function Code

Number

o Rem

Hydr ote

Unit ontroller

1A - 37 ~55 55

1B - 20 ~ 37 20

1C - 37 ~55 55

1D - 20 ~ 37 20

18 - 18 ~ 30 25

19 - 10 ~ 18 10

1E - 50 ~ 75 75

1F - 40 ~ 60 40

20 - 20 ~ 45 38

21 - 40 ~ 50 45

24 - -20 ~ 10 0

25 - 0 ~ 15 3

08 - 3 ~ 18 6

09 - 40 ~ 75 75

0A - 70 ~ 75 75

- 0D 0 ~ 10 7

- 0C 0 ~ 23 22

0B

22 - ~ 20 0

23 - -20 ~ 20 -10

C

the boiler.

Range Default

- 0 ~ 60 30

-20

Page 25

Function Code List (cont.)

Function Hydro Unit

Outside temperature T1 °C

Outside temperature T2 °C

Outside air temperature T3 °C

Setting temperature A at -20 °C

Heating

Auto Curve

Settings

Frost Protection

Back Up Heater

Control

Setting temperature B at T1°C

Setting temperature C at T2°C

Setting temperature D at T3°C

Setting temperature E at +20°C

Ratio of Zone 2 in Zone 1 Auto mode (%)

Temperature shift of entire Auto curve (°C)

Function 0 = Valid; 1 = Invalid

Setting temperature °C

Back up heater downtime. 0=5min; 1=10min;

2=15min; 3=20min

Back up heater uptim

2=30min; 3=40min

e. 0=10min; 1=20min;

Quick Reference Guide - Page 25

Function Code Number

Remote

C

ontroller

29 - -15 ~ 0 -10

- - 0 0

2B 0 ~ 15

2C - 20 ~ 55 40

2D - 20 ~ 55 35

2E - 20 ~ 55 30

2F - 20 ~ 55 25

30 - 20 ~ 55 20

31 - 0 ~ 100 80

27 - -5 ~ 5 0

3A - 0 ~ 1 1

3B - 8 ~ 20 15

33 - 0 ~ 3 1

34 - 0 ~ 3 0

- 10

Range Default

Night Setback

Room Temperature

Setting

2 Way Valve

peration Contro

O l

3 Way valve

Op ol

eration Contr

2 Zone Mixing

V

alve Drive Time

Boiler & Heat

Pump

hronisa

Sync tion

Zone Selection: 0=Zones 1 and Zone 2;

1=Zone 1 Only

Change Setback temperature °C

Start time (hour)

End time (hour) - 0F 0 ~ 23 06

Room temperature control adjustment. 0=Valid;

1=Invalid

Compensation for temperature °C 35 - 1 ~ 5 1

Downtime Zone B (x 5min) 36 -

Uptime Zone C (x5min) 37 -

2 way valve activation for cooling.

0=activated during cooling;

1=not activated during coolin

3 way valve activation.

0=activated during hot w

1=not activated during hot water operatio

Specified Drive Time for Mixing Valve to 90°

open (x 10 sec)

Boiler synchronisation with

0=synchronised; 1=not synchronised

g

ater operation;

n

heat pump.

58 - 0 ~ 1 0

26 - 5

- 0E 0 ~ 23 22

- 02 0 ~ 1 0

3C - 0 ~ 1 0

54 - 0 ~ 1 0

0C - 3 ~ 24 6

3E - 0 ~ 1 0

3 ~ 20

1 ~ 24

(5 ~ s) 120min

1 ~ 24

(5 ~ s)

120min

6

6

Maximum

Ope of

ration Time

Hot Water Heat

Pump

Cooling Operation

Maximum heat pump operation time in hot

water operation priority mode (minutes)

Activate cooling mode.

e; 02 - 0 ~ 1 1 0=cooling & heating mod

1=heating mode only

07 - 1 ~ 120 30

Page 26

Quick Reference Guide - Page 26

Function Code List (cont.)

Function Hydro Unit

Remote Controller

Indication

Outdoor Night Time

Low Noise

Operation

Alarm Tone Tone Switching 0: OFF, 1: ON 11 0 ~ 1 1

Pump P2 remote

controller Display

Outdoor Forced

Defrost Mode

Optional ON/OFF

Command

Outdoor Night Time

Mode Button

Control Logic for

Room Thermostat

24 hour or 12 hour remote control display.

0=24hr; 1=12hr

0 = Function invalid

1 = Function valid

Start time (hour) - 0A 0 ~ 23 22

End time (hour) - 0B 0 ~ 23 06

0 = Not Shown;

1 = Shown

0 = Forced Defrost OFF;

1 = Forced Defrost ON

0 = a contact “ON” = Forced stop

1 = b contact “OFF” = Forced stop

2 = ON/OFF = Start / Stop

3= HA Specification

0 = Symbol displayed when mode is valid

(controlled by Function Code Only);

1 = Symbol displayed when mode is activated

(controlled by Function Code and Button)

0 = Cooling thermo on – contact open;

1 = Cooling thermo on – contact close

Function Code Number

Remote

Controller

- 05 0 ~ 1 0

- 09 0 ~ 1 0

42 - 0 ~ 1 0

46 - 0 ~ 1 0

52 - 0 ~ 3 0

56 - 0 ~ 1 0

57 - 0 ~ 1 0

Range Default

Settings by Purpose

Settings when hot water supply function is not used

• When the hot water supply function is not used, set DIP SW12-1 on the Hydro Unit board to ON.

Setting for cooling

• For Space Conditioning Units that do not perform cooling (radiators and Under floor heating, etc.), procure a

motorized 2-way valve (for cooling) locally and attach it to the water pipe that is not used for cooling. Connect the

valve cables (as described in Electrical section).

• Press long the TEST + SET + SELECT switches on the remote controller to change the

Hydro Unit function code, and change address 02 to 0, and then press the SET button to enable the function.

Press the TEST button to exit the setting mode.

• Stick the optional insulator for cooling to the bottom of the Hydro Unit.

Settings for hot water supply

• Prepare the optional hot water cylinder.

• Procure a motorized 3-way (diverter) valve locally and perform piping. Connect the valve cables (as described in

Electrical section).

• Set DIP SW12-1 on the Hydro Unit board to OFF.

• Connect the power supply unit for the hot water cylinder heater to terminals TB03 L and N of the Hydro Unit.

• Connect cables between the Hydro Unit and the hot water cylinder as follows:

Hydro Unit terminals TB03 (1), (2), and earth — Hot water cylinder (1), (2), and earth

TB06 A, B, and earth — Hot water cylinder A, B, and earth

Page 27

Quick Reference Guide - Page 27

Settings by Purpose (cont)

Settings for 2-zone temperature control

• Procure a motorized mixing valve locally and perform piping. Connect the valve cables (as described in Electrical

section).

• Procure a buffer tank locally.

• Procure a water pump locally, and connect its cables (as described in Electrical section).

To inhibit interlocking the water pump with the internal pump of the Hydro Unit, set DIP SW10-3 on the Hydro

Unit board to OFF.

• Set DIP SW12-3 on the Hydro Unit board to ON.

Attach the temperature sensor (TFI) connected to terminals TB06 C and D of the Hydro Unit near the hot water

inlet of the Hydro Unit.

• Contact the temperature sensor closely with the pipe, fix it with aluminium tape or the like, and then perform

insulation treatment for the sensor.

• Fix TFI sensor on the room heating supply pipe by using the connector procured in locally.

• Cover the cables with insulation tube (minimum 1 mm) or conduit so that the user cannot touch them directly.

• Connect the functional earth wire of TFI sensor in the tank unit.

• Cover the TFI sensor's cables and sensor with insulation tube (minimum 1 mm) shown in the diagram on the

right.

Test Run

Use operation buttons usually to conduct a test run.

If the outside air temperature or water temperature is outside the setting value range, press the TEST button on

the remote controller and then start a test run. Since the protection setting is disabled in the TEST mode, do not

continue a test run longer than 10 minutes.

• Press the TEST button on the remote controller. An indication “TEST” appears on the remote controller.

• Press the ZONE1, 2

The pump is activated in 30 seconds.

If air is not released completely, the flow rate switch is activated to stop operation. Release air again according to the

piping procedure. Little air bite is discharged from the purge valve.

• Check that the air bite sound disappears.

• Check that the hydraulic pressure has become the predetermined pressure 0.1 to 0.2 MPa (1 to 2 bar). If the

hydraulic pressure is insufficient, replenish water.

• Heating operation starts. Check that the hydro unit starts heating.

• Press the OPERATE MODE

• Cooling operation starts. Check that the hydro unit starts cooling and that the floor heating system is not cooled.

• Press the ZONE1, 2

• Press the HOT WATER

• Check that there is no air bite.

• Check that hot water is present at the connection port of the hot water cylinder.

button and select “heating” with the OPERATE MODE button.

button and select “cooling.”

button to stop operation.

button to start hot water supply operation.

• Press the HOT WATER

• Press the TEST button to exit the test mode.

button to stop the hot water supply operation.

Page 28

Quick Reference Guide - Page 28

Sensor Temperature Monitoring Function

The sensor sensing temperature is displayed on the remote controller. This function allows you to make sure whether

the sensor is installed properly.

1) Press the TEST + CL buttons for four seconds or more.

2) Select the Code No. with the TEMP. buttons.

3) Press the TEST button to exit the test mode.

Code No. Location Indication

06

08

09 Hydro unit 2-zone sensor temperature °C

0A

0B

60

61

62 Outdoor unit Refrigerant discharge temperature °C

63

6A

70

F4

F5 Operating hours Hot water cylinder heater total operating hours x100 hours

F6

Return water temperature °C

Hot water temperature °C

Hot water cylinder temperature sensor °C

Motorized mixing valve position

Heat exchanger temperature °C

Outside air temperature °C

Refrigerant intake temperature °C

Current value (in the inverter) A

Compressor operating frequency

Hydro unit AC pump total operating hours x100 hours

Hydro unit heater total operating hours x100 hours

Fault Symptoms

Symptom Possible cause Corrective action

Room is not heated or

cooled. Water is not hot

enough.

Nothing is displayed on

the remote controller.

Flow rate switch is

activated. Error code

[A01]

Hot water leaks from

pressure relief valve.

Incorrect remote controller setting

Incorrect function code setting

Backup heater disconnected Check backup heater and bimetal thermostat.

Insufficient capacity Check selection of equipment.

Sensor defect

Power is not supplied. Check power supply wiring.

Incorrect setting

Air bite in the pump Release air completely according to the procedure.

Low hydraulic pressure

Strainer is clogged. Clean the strainer.

Large resistance on the hydro side

Malfunction of motorized 3-way

valve for hot water supply

Excessive hydraulic pressure

Insufficient capacity of expansion

tank

Expansion tank failure Check the air pressure.

Check remote controller operation and temperature

setting

Check function code setting with the function code

table.

Check whether temperature sensor is installed at

the normal position.

Check DIP switch setting on the Hydro Unit board.

Check the setting with the function code table.

Set hydraulic pressure considering pipe height, and

replenish water until manometer shows a value of

set hydraulic pressure or more.

Widen water path to the hydro unit or adopt a

bypass valve.

Check wiring and parts.

Set hydraulic pressure considering pipe height, and

replenish water until manometer shows a value of

set hydraulic pressure or more.

Check expansion tank capacity compared to total

water amount. If it is insufficient, install another

expansion tank.

Page 29

Alarm Indications

Quick Reference Guide - Page 29

Alarm

indication

Regular communication error between hydro unit and remote controller (system controller) If there is no

E03

E04

F03 If short-circuit or open-circuit state continues for two seconds, an alarm occurs.

Auto-reset: When normal value is confirmed

F10 If short-circuit or open-circuit state continues for two seconds, an alarm occurs.

Auto-reset: When normal value is confirmed

F11 If short-circuit or open-circuit state continues for two seconds, an alarm occurs.

Auto-reset: When normal value is confirmed

F14 If short-circuit or open-circuit state continues for two seconds, an alarm occurs.

Auto-reset: When normal value is confirmed

F17 If short-circuit or open-circuit state continues for two seconds, an alarm occurs.

Auto-reset: When normal value is confirmed

F18 If short-circuit or open-circuit state continues for two seconds, an alarm occurs.

Auto-reset: When normal value is confirmed

F23 If open-circuit state continues for two seconds, an alarm occurs.

Auto-reset: When normal value is confirmed

F29

(When EEPROM1K is mounted, this alarm cannot be reset.)

F20

regular communication from the remote controller for three minutes, the hydro unit regards it as no

remote controller. If there is no communication from both sides, alarm E03 occurs. Auto-reset: When

successful regular communication is made

Regular communication error between hydro unit and outdoor unit When serial signal from the outdoor

unit cannot be received though normal serial signal is sent to the outdoor unit 1) When serial signal

cannot be received continuously for 60 seconds (S code communication) 2) Communication is still not

successful for 80 seconds through three retries if serial signal cannot be received for 20 seconds after

new communication (f code) starts When the remote controller starts operation, serial transmission

starts with the new communication format. Auto-reset: When successful regular communication is

made

Condensing temperature TC sensor defect

Hydraulic heat exchanger inlet temperature TWI sensor defect

Hydraulic heat exchanger outlet temperature TWO sensor defect

Hot water cylinder temperature TTW sensor defect

Floor inlet temperature TFI sensor defect

Internal heater outlet temperature TWO sensor defect

Low-pressure sensor defect

Hydraulic heat exchanger EEPROM defect

One mismatch is detected if there is no verification ACK after data write to the EEPROM Reset

condition: This alarm is inhibited while the unit is not working.

Floor inlet temperature TFI sensor disconnection or wrong installation (This alarm is reset by stopping

operation and is checked again.)

Alarm description and generation/reset conditions

F30 Onboard expansion IC defect This alarm is not reset automatically.

L07

This alarm is not reset automatically. (This alarm is inhibited while the unit is not working, but occurs

L09

A01 Pump defect or abnormal flow rate This alarm is not reset automatically.

A02 Excessive water temperature increase by the heating heater Auto-reset:

A03 Excessive water temperature increase in the hot water cylinder

A04 Freezing is detected. Auto-reset:

A07 High-pressure switch malfunction This alarm is not reset automatically.

A08 Low-pressure sensor malfunction This alarm is not reset automatically.

Group line in an hydro unit

This alarm is checked during initial communication immediately after power-on. This alarm occurs

immediately after operation start.

again after the unit operates.)

Hydro unit capacity has not been set.

This alarm is checked immediately after power-on. This alarm is not reset automatically. (This alarm is

inhibited while the unit is not working, but occurs again after the unit operates.)

Page 30

Quick Reference Guide - Page 30

Alarm Indications (cont)

A09 Overheat preventive operation malfunction Auto-reset: When operation mode is changed

A11

P31

Release preventive operation malfunction This alarm occurs when the Hydro Unit enters the forcedstop zone 10 times.

Self-hydro unit is stopped due to alarm of other hydro unit. When alarm occurs in an hydro unit in the

group, other hydro units must also be stopped with refrigerant control.

When alarm E03, L03 or L07 occurs in the header unit in the group, other hydro units must also be

stopped

because they do not know which header unit (remote controller) to follow.

Auto-reset: When the first alarm is reset

Outdoor Alarm indication

Alarm

indication

F04

F06

F08

H01 Compressor breakdown

H02 Compressor locked When compressor lock is detected

H03 Current detector defect

H06 Low-pressure system defect Ps pressure sensor defect or low-pressure protective operation

L29 Other outdoor unit faults

L31 Phase sequence error, etc.

P03

P04

P22 Outdoor unit fan defect When over current or lock in outdoor unit fan drive circuit is detected

P26 Inverter Idc operation

P29 Position detection error When compressor motor position detection error is detected

Main failure part Description

Outdoor unit discharge

temperature sensor TD

defect

Outdoor unit temperature

sensor TE or TS defect

Outdoor unit outside air

temperature sensor TO

defect

Abnormal outdoor unit

discharge temperature

High-pressure system

defect

When open- or short-circuit of discharge temperature sensor TD is

detected

When open- or short-circuit of heat exchanger temperature sensor

TE or TS is detected

When open- or short-circuit of outside air temperature sensor TO is

detected

When min-Hz is reached by current release control or when shortcircuit current (Idc) is detected after direct current excitation

When abnormal current is detected in AC-CT or phase loss is

detected

Other outdoor unit faults: 1) Inter-MCU communication error between

IPDU and CDB 2) abnormal GBT heat sink temperature

When phase sequence of 3-phase power supply is incorrect

(thermostat OFF operation continued), etc.

When abnormal temperature is detected by discharge temperature

release control

When high-pressure switch , IOL is activated or when abnormality is

detected by high-pressure release control by TE

When short-circuit protection is activated for compressor driver

devices (G-Tr, IGBT)

Page 31

Quick Reference Guide - Page 31

A

Outdoor Fault Diagnosis

You can perform fault diagnosis of the outdoor unit with the LED's on the P.C. board of the outdoor unit in addition

to check codes displayed on the wired remote controller of the hydro unit.

Use the LED’s and check codes for various checks.

Check of the current abnormal status

1. Check that DIP switch SW803 is set to all OFF.

2. Jot down the states of LED800 to LED804. (Display mode 1)

3. Press SW800 for at least one second. The LED status changes to

display mode 2.

4. Check the code whose display mode 1 equals the jotted LED status and

display mode 2 equals the current flashing status of LED800 to LED804

from the following table to identify the cause.

Check of the abnormal status in the

past although the abnormal status is

not occurred now.

1. Set bit 1 of DIP switch SW803 to ON.

2. Jot down the states of LED800 to

LED804. (Display mode 1)

3. Press SW800 for at least one second.

The LED status changes to display

mode 2.

4. Find an error whose display mode 1

equals the jotted LED status and display

mode 2 equals the current flashing

status of LED800 to LED804 from the

following table to identify the error.

• An outside air temperature (TO)

sensor error can be checked only while

an error occurs.

DISPLAY MODE 1 DISPLAY MODE 2

No. Cause D800 D801 D802 D803 D804 D800 D801 D802 D803 D804

1 Normal

2 Discharge sensor (TD) error

3 Heat exchanger sensor (TE) error

4 Heat exchanger sensor (TL) error

Outside air temperature sensor (TO)

5

error

6 Suction sensor (TS) error

7 Heat sink sensor (TH) error

Outdoor temperature sensor (TE/TS)

8

connection error

9 Outdoor EEPROM error

10 Compressor lock

11 Compressor lock

12 Current detect circuit error

13 Thermostat for compressor activated

Model data not set (on the service P.C.

14

board)

15 MCU-MCU communication error

16 Discharge temperature error

bnormal power (open phase detected

17

or abnormal voltage)

18 Heat sink overheat

19 refrigerant leak detected

20 4-way valve reverse error

21 High pressure release operation

22 Outdoor fan motor error

Compressor driver short circuit

23

protection

Position detect circuit error in one-line

24

display

● ● ● ● ● ● ● ● ● ●

○ ○ ● ● ○ ● ● ◎ ● ●

○ ○ ● ● ○ ● ◎ ◎ ● ●

○ ○ ● ● ○ ◎ ◎ ◎ ● ●

○ ○ ● ● ○ ● ● ● ◎ ●

○ ○ ● ● ○ ● ● ◎ ◎ ●

○ ○ ● ● ○ ◎ ● ◎ ◎ ●

○ ○ ● ● ○ ◎ ◎ ◎ ◎ ●

○ ○ ● ● ○ ◎ ◎ ◎ ◎ ◎

● ● ○ ● ○ ◎ ● ● ● ●

● ● ○ ● ○ ● ◎ ● ● ●

● ● ○ ● ○ ◎ ◎ ● ● ●

● ● ○ ● ○ ● ● ◎ ● ●

● ○ ○ ● ○ ● ◎ ● ◎ ●

● ○ ○ ● ○ ◎ ● ◎ ◎ ◎

○ ○ ○ ● ○ ◎ ◎ ● ● ●

○ ○ ○ ● ○ ◎ ● ◎ ● ●

○ ○ ○ ● ○ ◎ ◎ ◎ ● ●

○ ○ ○ ● ○ ◎ ◎ ◎ ◎ ●

○ ○ ○ ● ○ ◎ ◎ ● ● ◎

○ ○ ○ ● ○ ● ● ◎ ● ◎

○ ○ ○ ● ○ ● ◎ ◎ ● ◎

○ ○ ○ ● ○ ● ◎ ● ◎ ◎

○ ○ ○ ● ○ ◎ ● ◎ ◎ ◎

○

: ON

●

: OFF

◎

: FLASHING

Loading...

Loading...