TOSHIBA 6560 SERVICE HANDBOOK

SERVICE HANDBOOK

PLAIN PAPER COPIER

Click the Page Only button to close the overview area of the window.

Click the Bookmarks and Page button to open the Contents and

65/5560

display bookmarks created for the document. Click a bookmark’s name

to go to the Page marked by that bookmark.

Click the Thumbnails and Page button to open the overview area and

display thumbnail images of each document page. Click a thumbnail to

go to the page marked by that thumbnail.

Copyright TOSHIBA CORPORATION 1995

ALL RIGHTS RESERVED

GENERAL PRECAUTIONS REGARDING THE INSTALLATION AND THE SERVICE OF THE 6560

1. Transportation/Installation

• When transporting the copier, move it by the casters while lifting the stoppers.

The copier is quite heavy and weighs approximately 230 kg (507 lb); therefore, pay full attention

when handling it.

2. Installation

• Be sure to use a dedicated outlet with AC 115V/15A (220V, 230V, 240V/10A) or more for the

power source.

• The copier must be grounded for safety.

Never ground it to a gas pipe or a water pipe.

• Select a suitable place for installation.

Avoid excessive heat, high humidity, dust, vibration and direct sunlight.

Also provide proper ventilation as the copier emits a slight amount of ozone.

• To insure adequate working space for copying operations, keep a minimum clearance of 80 cm

(32") on the left, 80 cm (32") on the right and 10 cm (4") in the rear.

3. Service of Machines

• Basically, be sure to turn the main switch off and unplug the power cord during service.

• Be sure not to touch high temperature sections such as the exposure lamp, the fuser unit, the

damp heater and their periphery.

• Be sure not to touch high-voltages sections such as the chargers and the high-voltage transformer.

• Be sure not to touch rotating/operating sections such as gears, belts, pulleys,etc.

• When servicing the machines with the main switch turned on, be sure not to touch live sections

such as the lamp terminal etc.

• Use suitable measuring instruments and tools.

65/5560 PRECAUTIONS

1

MAY.1997 © TOSHIBA CORP.

4. Main Service Parts for Safety

• The thermofuse,thermistor,fuse,breaker and door switches,thermostat etc. are particularly important

for safety.Be sure to handle/install them properly.

5. Notice Labels

• Be sure to check the rating plate and the notice labels such as "Unplug the power cord during

service" ,"Hot area" ,etc. to see if there is any dirt on their surface or if they are properly stuck to

the copier during servicing.

6. Disposition of Consumable Parts/Packing Materials

• Regarding the recovery and disposal of the copier, supplies, consumable parts and packing

materials, it is recommended to follow the relevant local regulations or rules.

7. When parts are disassembled, reassembly is basically the reverse of disassembly unless otherwise

noted in this manual or other related documents. Be careful not to reassemble small parts such as

screws, washers, pins, E-rings, toothed washers in the wrong places.

8. Basically, the machine should not be operated with any parts removed or disassembled.

9. Precautions Against Static Electricity

• The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband,

because the ICs on it may be damaged due to static electricity.

2

65/5560 PRECAUTIONSMAY.1997 © TOSHIBA CORP.

1. SPECIFICATIONS, ACCESSORIES AND OPTIONS

1.1 Specifications

1.2 Accessories

1.3 Options

1.4 System List

COSMOS

Texts from 1-1 to 1-5 in the

6560 Service Handbook

are the same as texts from 1-1 to 1-5 in the

Service Manual

Do you refer to the

.

6560 Service Manual

SkipOK Cancel

?

6560

65/5560 SPECIFICATIONS 1-1 MAY.1997 © TOSHIBA CORP

2. ADJUSTMENT

2.1 TOSHIBA Supplies List

COSMOS

Text 2-1 in the

text 20-2 in the

65/5560 Service Handbook

65/5560 Service Manual

Do you refer to the

is same as

.

65/5560 Service Manual

SkipOK Cancel

?

65/5560 ADJUSTMENT MAY.1997 © TOSHIBA CORP.2-1

2.2 List of Adjustment Jigs Used

COSMOS

Text 2-2 in the

text 20-1in the

65/5560 Service Handbook

65/5560 Service Manual

Do you refer to the

is same as

.

65/5560 Service Manual

SkipOK Cancel

?

65/5560 ADJUSTMENTMAY.1997 © TOSHIBA CORP. 2-2

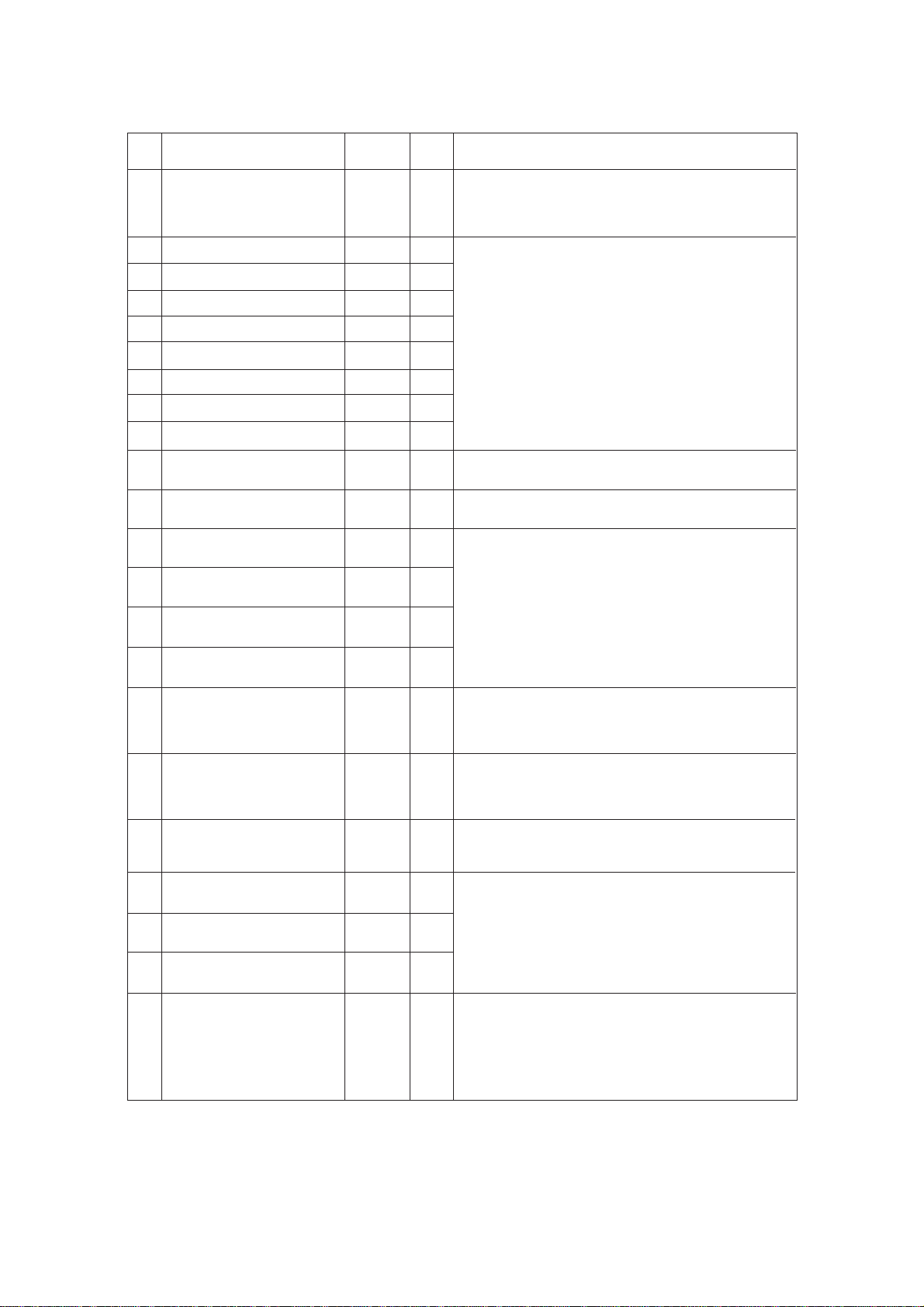

2.3 Error Codes

When either the CLEAR PAPER( )or CALL SERVICE( ) symbol appears,press the CLEAR/

STOP and "8"keys simuitaneously and the corresponding error code will be displayed.To clear the

error code,turn off the power.

Code Machine status

E1 Paper jam inside thr copier

E2 Paper jam near fuser unit

E3 Paper remaining inside the copier when the main switch is turned on

E4 The front cover is opened during copying

E5 Paper misfeed in LCF and manual feeding and paper jam in front of the aligning roller

E8 Paper misfeed (ADD)

E9 Paper misfeed (pedestal)

EC Paper misfeed (ADF)

ED Paper misfeed in ADF transport unit

EE Paper misfeed in ADF exit/reverse unit

C3 Abnormal serial transmission between main CPU and sub-CPU

C5 The optical system will not initialise;the optical system is locked

C7 Heat roller thermistor is open-circuited,

CB ADF feed motor locked

CC ADF transport motor locked

A0 Abnormal signal transmission in PFC interface

A1 Faulty charger wire cleaning operation

A2 ADD malfunction

A3 PFC (paper feed controller) malfunction

A4 Sorter malfunction

A5 Abnormal signal transmission between main CPU and IPC

A6 Abnormal signal transmission in sorter interface

A7 Abnormal signal transmission in ADF interface

A9 Blown exposure lamp or defective AES

65/5560 ADJUSTMENT MAY.1997 © TOSHIBA CORP.2-3

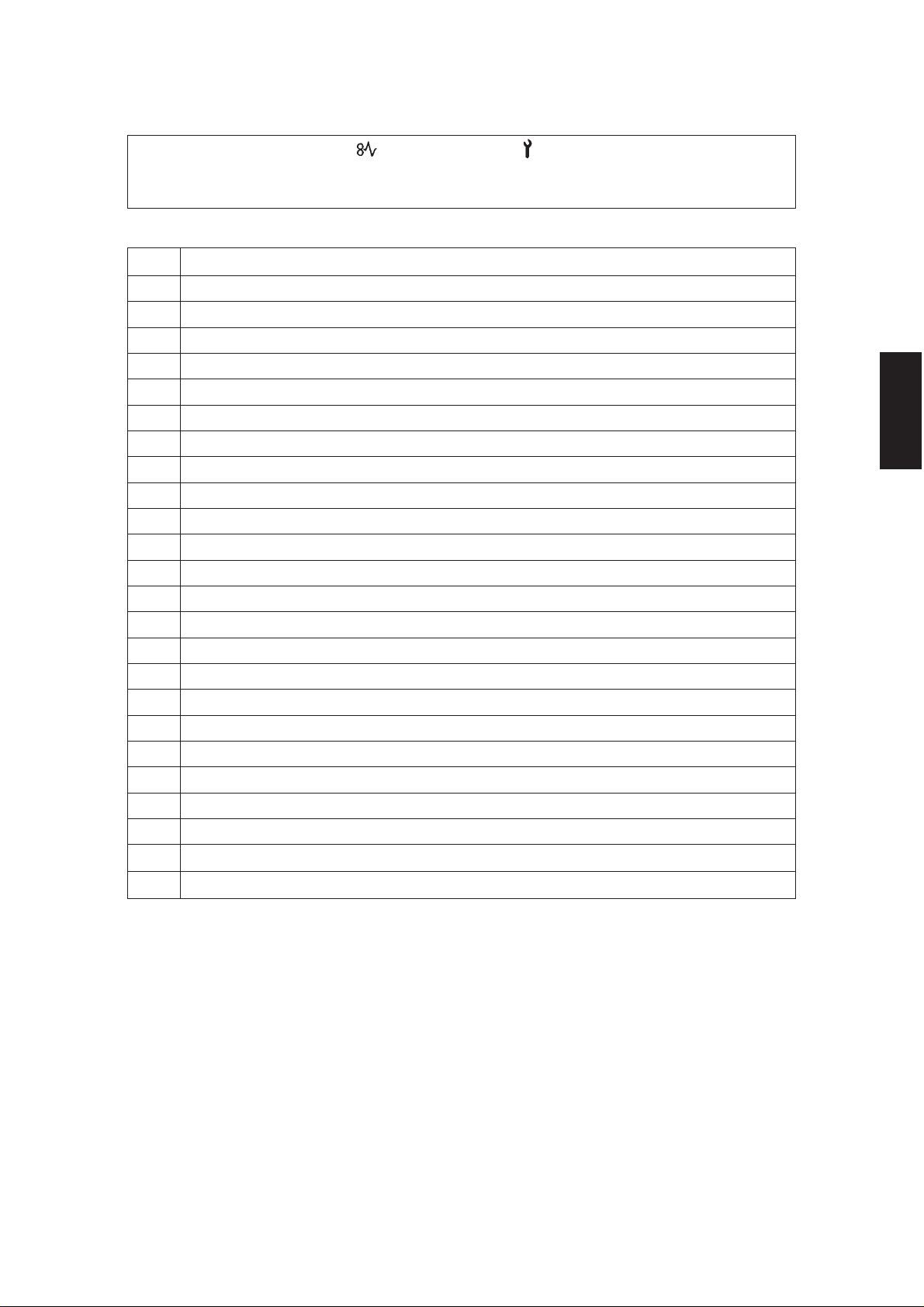

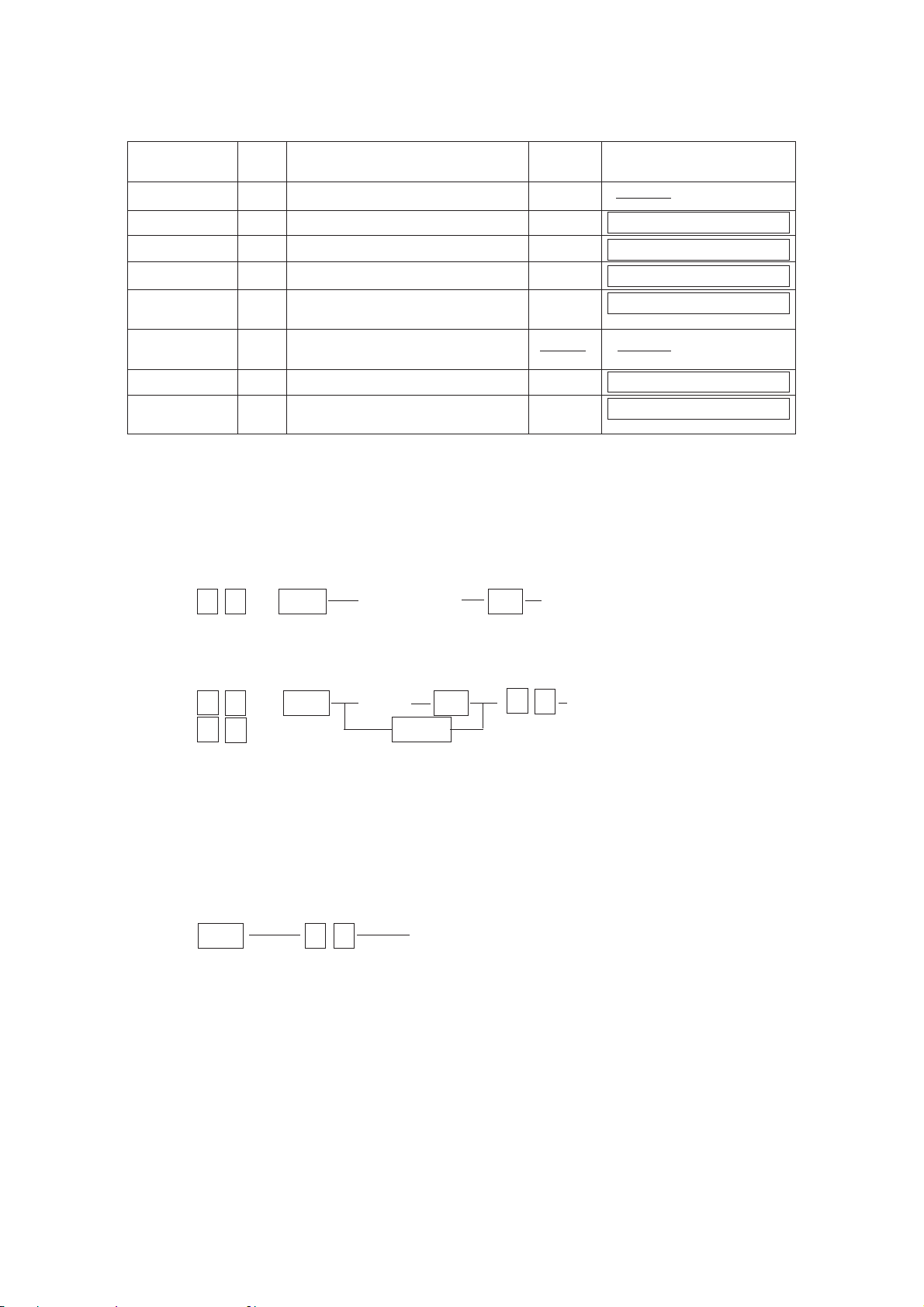

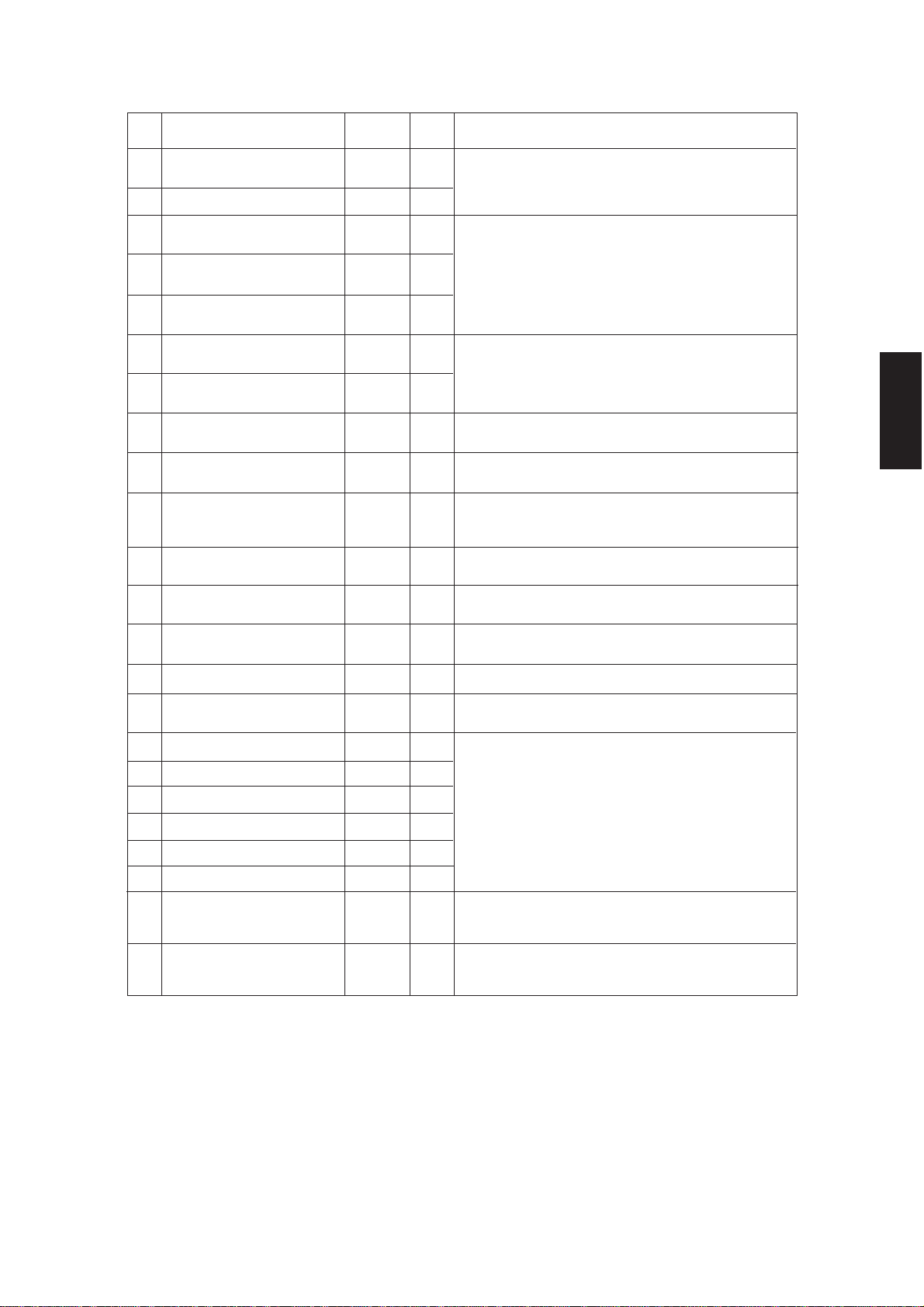

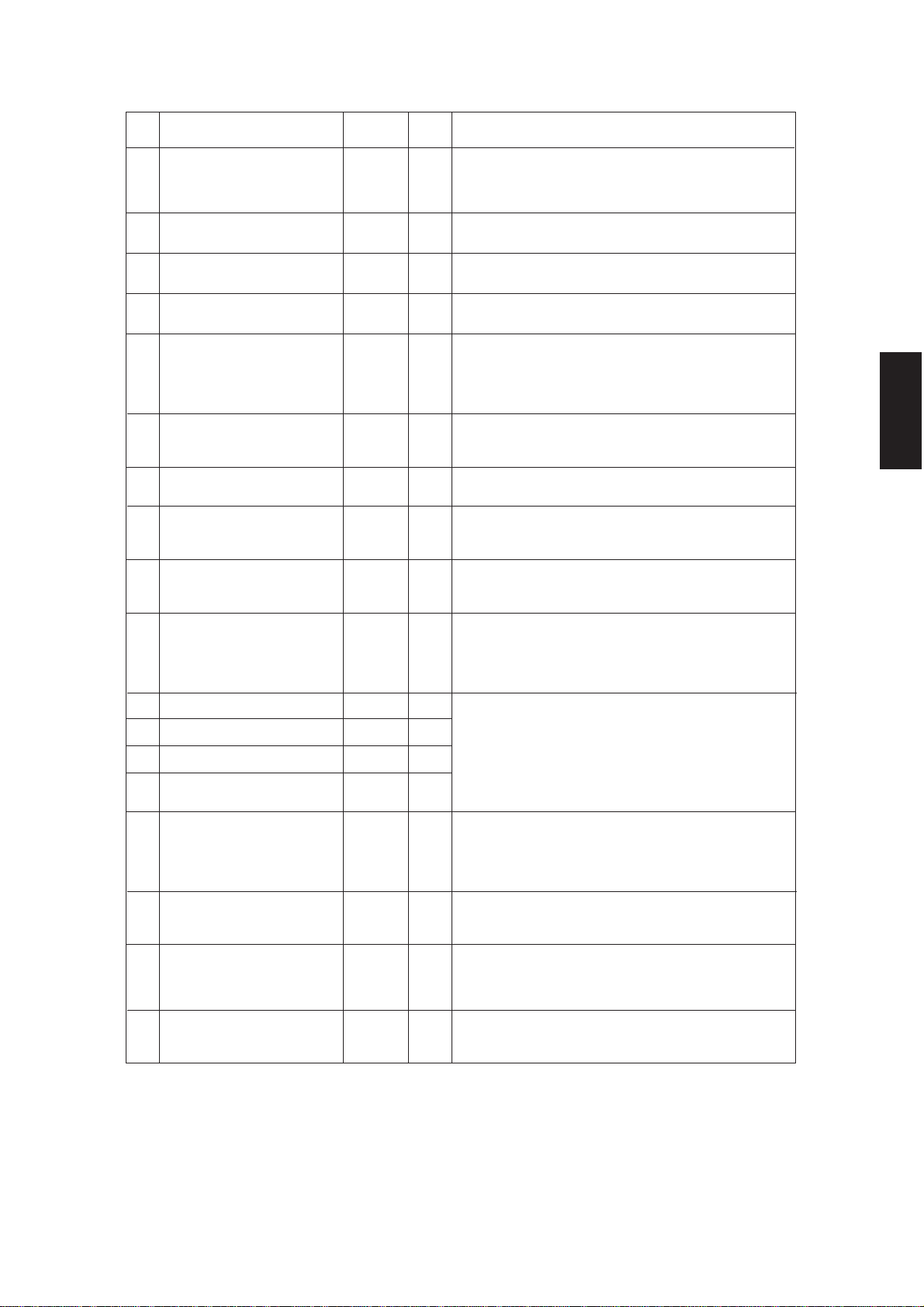

2.4 DIP Switch/Jumper/VR Functions

(1) Logic PC board

JP1

ì

PWA-F-LGC-154/155

(2) Paper feed control PC board

í

í

R60

PWA-F-PFC-154/155

Note: Adjustoment procedure

Plus terminal of the tester Minus COM terminal of the tester Adjustment value VR

Jumper Name When shipped Remarks

JP1 UNT No jumper Jumper:Factory adjustment mode

Note: Replacement PC boards are supplied with the jumper

installed.

Be sure to cut it when replacing the PC boards.

JP3

(TP-SG)

VR1

R61

VR2

(open) No jumper:Normal mode

VR FUNCTION

VR2 For adjustment ofthe paper width guide position of the

stack guide unit.

Aroow side of R60 JP3(TP-SG) 0~0.1V VR2

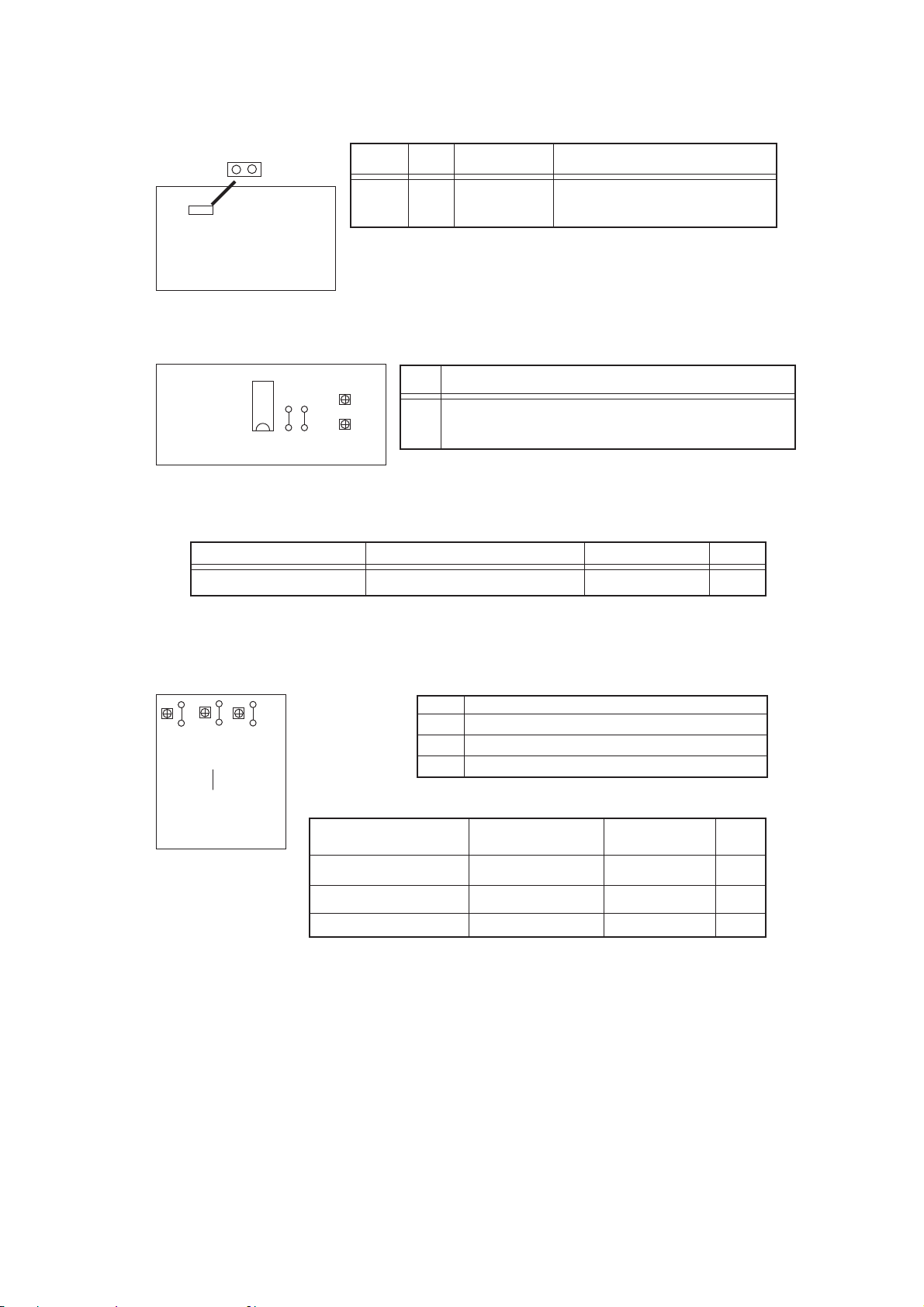

(3) Paper feed drive PC board

R19

R39

VR1

ëë

(TP-SG)

JP25

VR3

R40

VR2

ë

Note: Adjustment procedure

PWA-F-PFD-152

VR Function

VR1 For adjustment of the PFP lower aligning value.

VR2 For adjustment of the PFP middle aligning value.

VR3 For adjustment of the PFP upper aligning value.

Plus teminal of the tester Minus COM terminal Adjustment value VR

of the tester

Arrow side of R19 JP25(TP-SG) 0~0.1V VR1

Arrow side of R39 JP25(TP-SG) 0~0.1V VR2

Arrow side of R40 JP25(TP-SG) 0~0.1V VR3

65/5560 ADJUSTMENTMAY.1997 © TOSHIBA CORP. 2-4

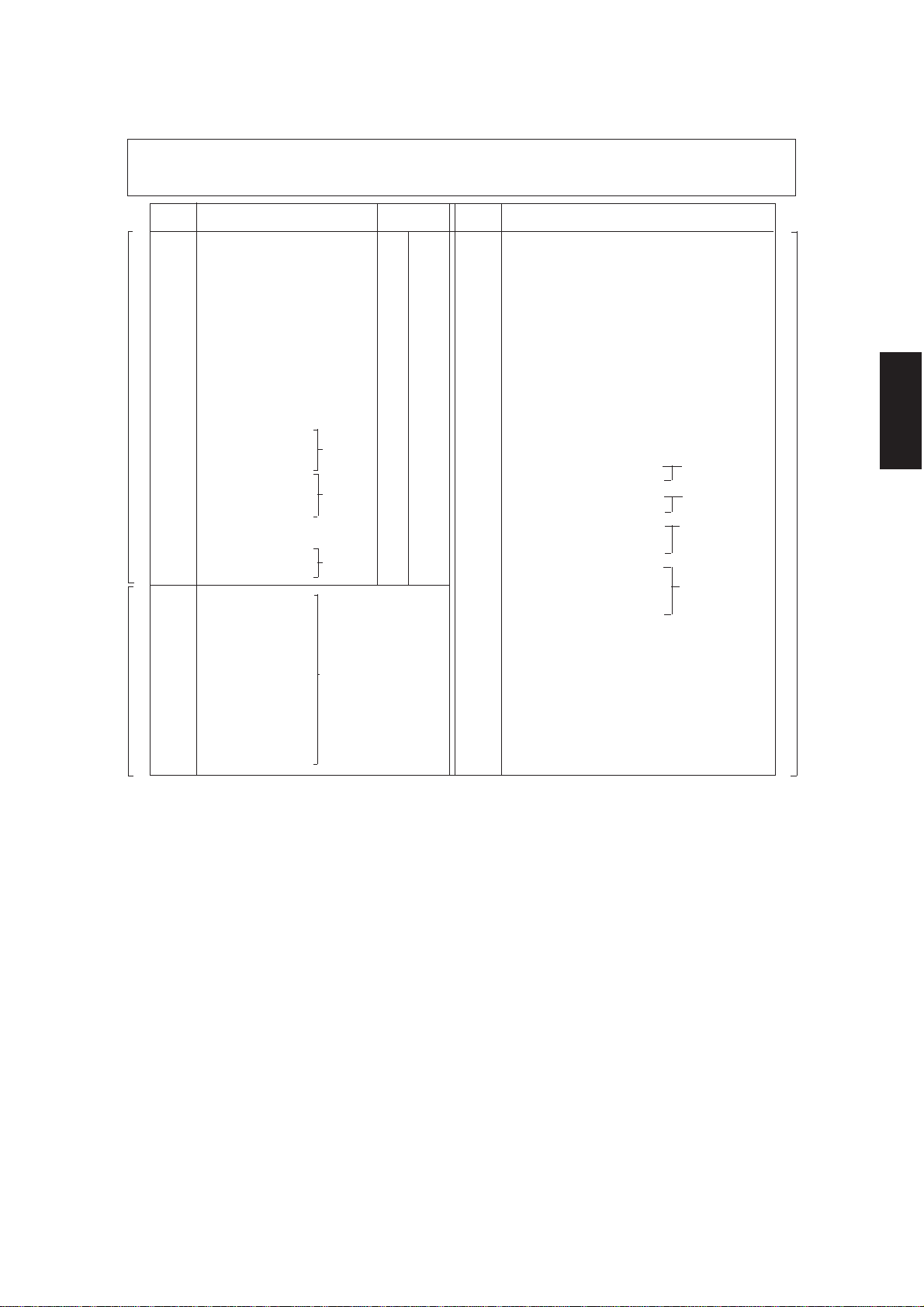

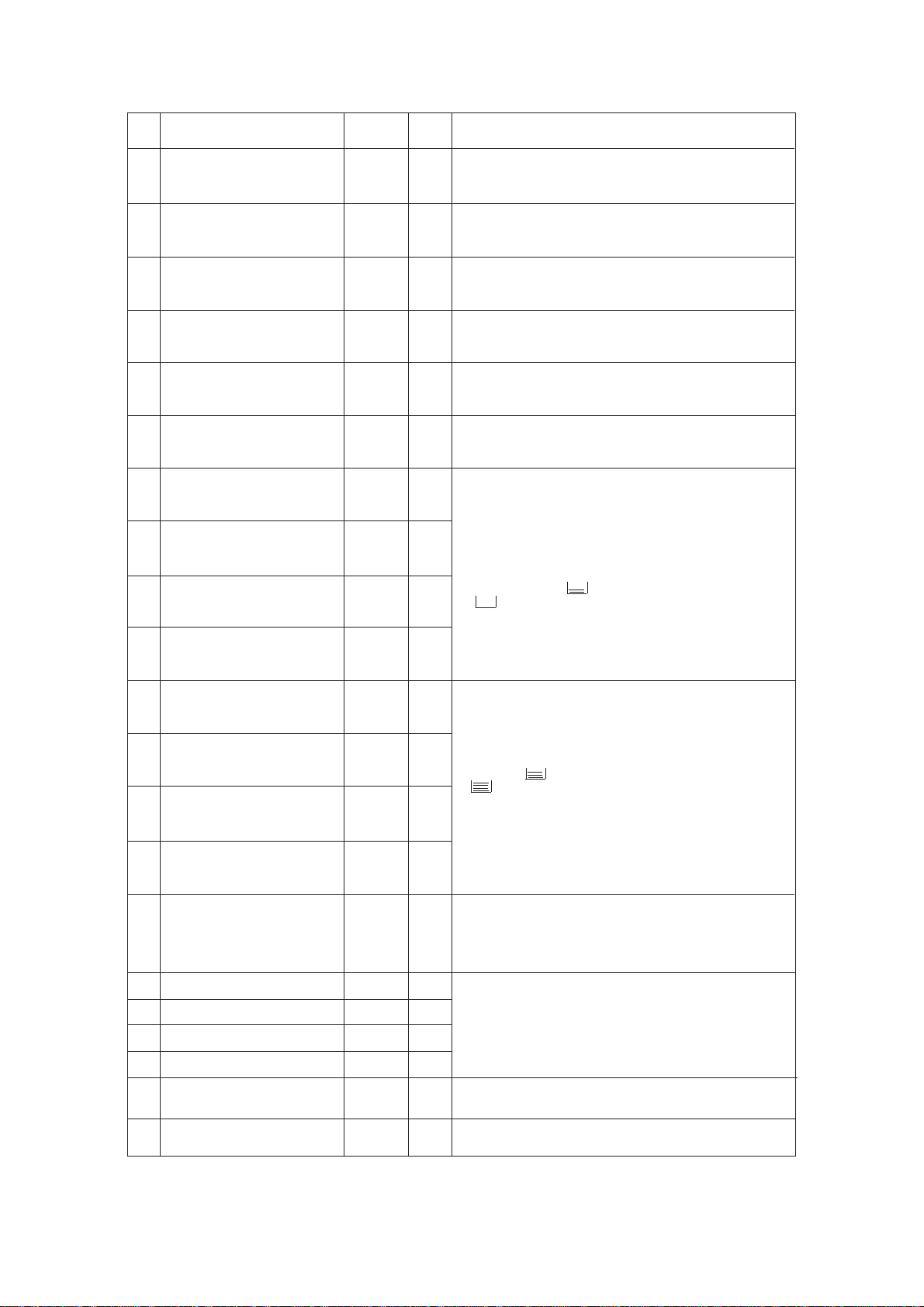

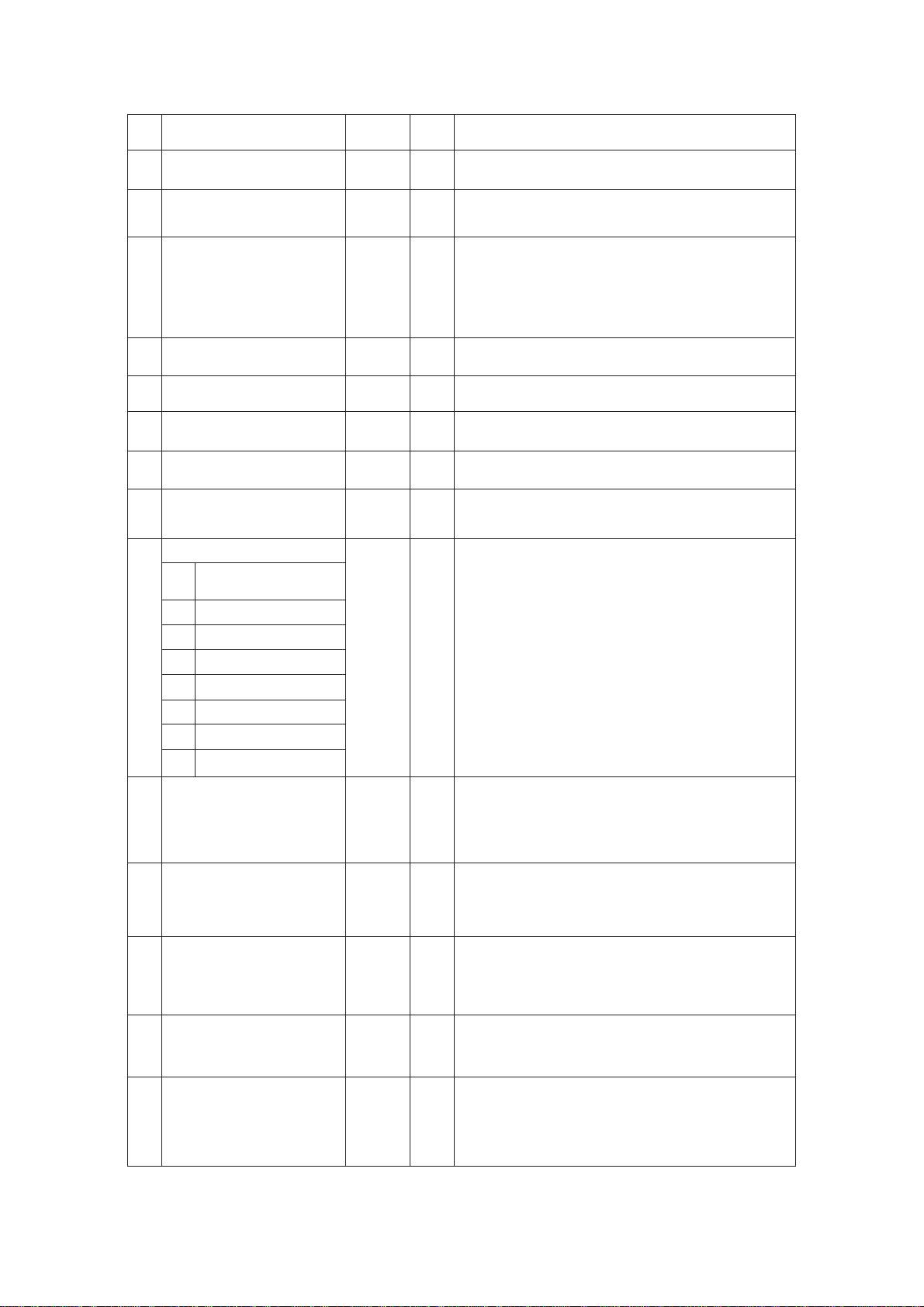

(4) ADF logic PC board

PWA-F-LGC-758

↑

1 2 3 4 5

DIP switch

1 Independent Normal mode Feeding mode Drive system

2 Original set Original set Duplex Single-sided

by switchback by direct feeding mode feeding mode

3 USA/Canada Europe Aging mode Multifeeding

4 E2PROM Normal mode Not used Not used

5 Not used Normal mode 2 in 1 mode OFF

At power on

ON OFF ON OFF

operation check mode

mode

version version without paper mode

initialigation

Duning independent operation mode

stopping

Note: The independent operation mode is performed as in the following procedure;set the DIP switch 1

to its ON position and turn on the power.Select the menu of the independent operation mode and

then open and close the jam release cover or the ADF cover.

65/5560 ADJUSTMENT MAY.1997 © TOSHIBA CORP.2-5

2.5 Self-Diagnosis Modes

Mode Input Definition Cleaning Display after selection

All-LEDs-lit "01" All LEDs on the control panel are lit. C/S

Aging mode "02" Aging (ADF does not operate) "09" AGING 100% 0

Test mode "03" Motor test and input/output check "09" TEST MODE C 100% C

Test mode "04" Motor test and input/output check "09" TEST MODE C 100% C

Adjustment "05" Adjustment of items "09" TEST MODE A 100% A

mode

Forced ready "06" Forced entry of ready mode

mode

Aging mode "07" Aging (includes ADF) "09" AGING 100% 0

Setting mode "08" System switchover and setting of each "09" TEST MODE D 100% D

Code method

priority mode,PM counter,etc.

Note: To access the desired diagnostic mode,turn on the power switch while pressing the appropriate

keys.

<Procedure>

•All-LEDs-lit mode(01):

0 1 / PWR All LEDs light C/S Exit

→

→

→

•Aging mode(02 or 07):

0 2 / PWR Aging C/S Exit

→

↑

( 0 7 ) PRINT

→→

←

0 9

→

•Test mode(03 or 04)

For these test modes,refer to 2.5.1 and 2.5.2.

•Adjustment mode(05):

For this mode,refer to"2.5.3 Adjustment Mode".

•Forced ready mode(06):

PWR 0 6 Forced ready

→→

Note:This mode is for checking the paper feeding operation only.

•Setting mode(08):

For this mode,refer to"2.5.4 Setting mode".

Note: C/S : Press the CLEAR/STOP key

PWR: Turn on the power switch

INT : Press the INTERRUPT key

E/S : Press the ENERGY SAVER key

65/5560 ADJUSTMENTMAY.1997 © TOSHIBA CORP. 2-6

Warming up

Quick reference chart for self-diagnostic mode

Power On

"07"

"C"

All the displays on

the control panel llt

"01"

*2

"02"

(With ADF)

Aging

"03/04"

Test mode

"05"

Adjustment

mode

"08"

Setting mode

"06"

Standby

"C""P"

Stops momentarily

"09"

"09"

"09"

"05"

*1

*1: In case of "05"+

"P":PRINT key on.

"C":CLEAR/STOP key on.

power on only

*2: Copies cannot be made

65/5560 ADJUSTMENT MAY.1997 © TOSHIBA CORP.2-7

2.5.1 Input Signal Check (03/04)

In the "03" or "04" test mode, the following input signal conditions can be checked by pressing the

appropriate keys.

lWhen automatic exposure is selected

Indicator

Operation

(1)key

(2)key

(3)key

(4)key

(5)key

(6)key

(7)key

(8)key

(9)key

(0)key

LEDkey

A4/LD A3/LG B4/LT A5/ST A4/LD A3/LG B4/LT A5/ST

TNR-HOP-SW

Opened

TNR-EMP-SW

Toner empty

ADD-PEM-SW

Paper

loaded

EMP2-SW

Paper

loaded

EMP3-SW

Paper

loaded

EMP4-SW

Paper

loaded

LCF-EMP-SW

Paper loaded

BVD1

Battery

living

CLN-T-SW

On

GUIDE-HOME-SW

Home

position

TUP2-SW

Top

position

TUP3-SW

Top

position

TUP4-SW

Top

position

T-UP-SW

Top position

ADD-STR-SW

Paper loaded

BVD2

∗

Battery's

life

CNT(JPI)

Connected

APS-C

Paper loaded

ADD-STP-SW

Paper

loaded

PSTP2-SW

Paper

loaded

PSTP3-SW

Paper

loaded

PSTP4-SW

Paper

loaded

P-STP-SW

Paper

loaded

LCF-FEED-SW

Paper

loaded

WP

∗∗

Write

protect

R-DOOR-SW

Opened

APS-F

Paper loaded

STP-HOME-SW

Home

position

FEED2-SW

Paper loaded

FEED3-SW

Paper loaded

FEED4-SW

Paper loaded

T-DWN-SW

Bottom

position

ADD-JAM-SW

Paper

loaded

UNIVERSAL/

OTHER

CD

∗

IC card

DEV-SW

Connected

CTRSIG

Connected

HOME-SW

Home

position

CST2-SW

Cassette

loaded

LCF

LCF loaded

CLN-M-SW

ON

EXIT-SW

Paper

loaded

DF-CNT

Connected

LNS-SW

Home

position

LCFDOOR

Closed

CST3-SW

Cassette

loaded

LCFKEY

On

Original-size LEDCopy-size LED

T-FUL-SW

Toner full

APS-STR-SW

Closed

CST4-SW

Cassette

loaded

M-FEED-SW

Paper

loaded

L-DOOR-SW

Opened

MRR-SW

On

UNIVERSAL/

OTHER

lWhen manual exposure is selected

Indicator

Operation

(1)key

LEDkey

A4/LD A3/LG B4/LT A5/ST A4/LD A3/LG B4/LT A5/ST

DF-OPN-SW

COVER-SW

Opened

UNIVERSAL/

OTHER

TURN-SNS

Paper

loaded

SIZE-SNS

Paper

loaded

Original-size LEDCopy-size LED

UNIVERSAL/

EMP-SNS

Paper

loaded

REG-SNS

Paper

loaded

OTHER

Note:*:Only for machines which have an optional IC card installed

<Procedure>

0 3 PRINT EXP Digital key PWR OFF 0 9

→→

↑

→

→

→

PWR (To clear)

Note: 03 →With initialization before test mode is entered

(

04 →Without initialization

ORIGINAL COPY

A4

(LD)

A3

(LG)

B4

(LT)

A5

(ST)

UNIVERSAL

(OTHER)

•

means that when the particular key is pressed and the

condition shown exists,the LED will light.(Input signal is "H" level)

•

means that the LED does not light if the condition shown

exists.(Input signal is "L"level)

65/5560 ADJUSTMENTMAY.1997 © TOSHIBA CORP. 2-8

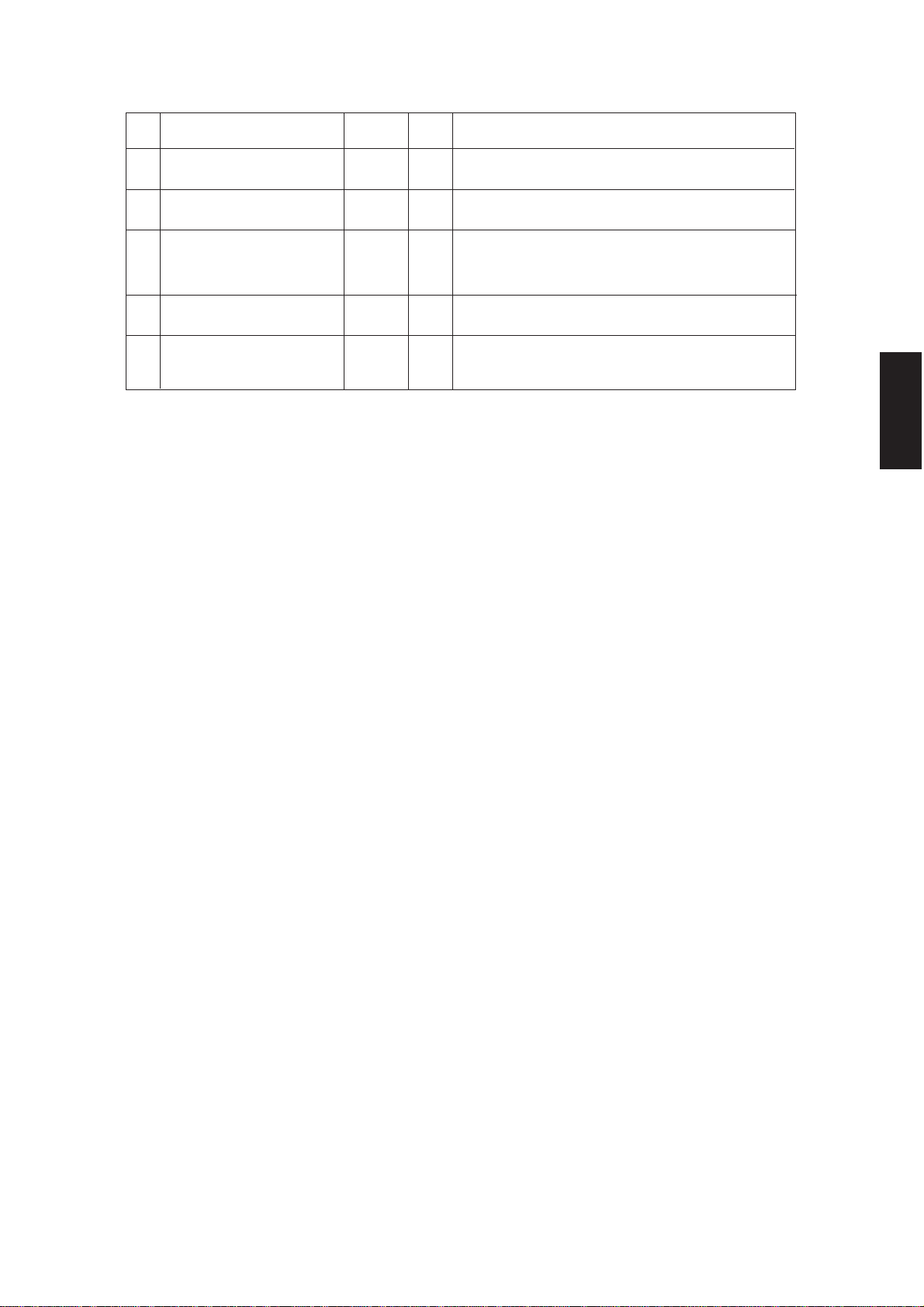

2.5.2 Output Signal check (03/04)

In the "03"or"04"test mode,the folloeing output signal conditions can be checked by entering appropiate

codes.

Code Function Stop code

1 DRM-MOT ON 11 OFF

2 FED-MOT ON 12 OFF

*1

3 RGT-MOT ON 13 OFF

4 HTR-MOT ON 14 OFF

5 DEV-MOT ON 15 OFF

6 TNR-MOT ON 16 OFF

7 OPT-FAN-MOT HIGH 17 LOW

8 EXIT-FAN-MOT HIGH 18 LOW

9 AUG-MOT ON 19 OFF

41 ADD-FED-MOT ON 51 OFF

42 ADD-RGT-MOT(Stack) ON 52 OFF

43 ADD-RGT-MOT(Feed) ON 53 OFF

61 PD-MOT ON 71 OFF

62 FD2-CLT

*2

Group1

*2

*3

*4

*5

Group2

*6

*7

FD3-CLT ON 72 OFF

FD4-CLT

63 RGT2-CLT

RGT3-CLT ON 73 OFF

RGT4-CLT

65 DEV-FAN ON 75 OFF

67 BTM-FAN HIGH 77 LOW

68 CH-FAN

HTR-FAN

20 SCN-MOT

21 LNS-MOT

22 MRR-MOT

23 CLN-MOT

24 DCM-MOT

25 CLN-TR-MOT

26 TRAY-MOT(LCF)

45 STOP-MOT

46 GUIDE-MOT

64 TR2-MOT(PFP)

TR3-MOT(PFP)

TR4-MOT(PFP)

ON 78 OFF

Changes direction

each time the PRINT

key is pressed

Code Function

30 HV-M ON/OFF

(Main charger output)

31 HV-TR ON/OFF

(Transfer charger output)

32 HV/AC ON/OFF

(Transfer charger output)

33 EXP-LAMP ON/OFF

34 GBIAS ON/OFF

(Transfer bias output)

35 PRE-TR-C4 ON/OFF

37 SCRP-SOL ON/OFF

38 MANUAL-SOL ON/OFF

48 ADD-SOL ON/OFF

49 GATE-SOL ON/OFF

81 ADF-FEED-MOT(CW) ON/OFF

82 ADF-FEED-MOT(CCW) ON/OFF

83 ADF-CLU ON/OFF

ADF-BELT-MOT(CW)

84 ADF-CLU ON/OFF

ADF-BELT-MOT(CCW)

85 ADF-FEED-MOT(CCW) ON/OFF

ADF-BELT-MOT(CW)

ADF-CLU

86 STP-SOL

FLP-SOL ON/OFF

ADF-CLU

BRKE

.

*8

Group3

*1 The feed motor will rotate in the direction appropriate for the cassette loaded at the time of the output signal

check.

*2 For FD2~4-CLT and RGT2~4-CLT,the clutch appro priate for the cassette loaded at the time of the output signal

check will be driven.

*3 The scanning motor will run at the correct speed for the reproduction ratio selected(and displayed)at the time of

the output signal check.

*4 The tray motor moves the tray up when the PRINT key is pressed once,and is turned off when the tray-up switch

is turned on.When the PRINT key is pressed a second time,it moves the tray down and is turned off when the

tray-down switch is turned on.

*5 The length guide motor performs initalisation when the PRINT key is pressed once.When the PRINT key is

pressed a second time, it moves the paper length guide to the widest setting position and then is turned off.When

the PRINT key is pressed a third time,it moves the paper length guide in for a narrow setting and is turned off

when the length guide home switch is turned on.

*6 The width guide motor widens the paper width guide when the PRINT key is pressed once and is turned off when

the width guide home switch is turned on.When the PRINT key is pressed a second time,it narrows the paper

width guide until the A4-R size position and then is turned off.When the PRINT key is pressed a third time,it,widens

the guide until the A3 size position and is turned off.

*7 For TR2 to 4-MOT,the motor appropriate for the cassette loaded at the time of output signal check is chosen.When

the PRINT key is pressed once, the motor moves the tray up and is turned off when TUP2 to 4-SW is turned

on.When the PRINT key is pressed a second time,it moves the tray down and is turned off after a set time lag.

*8 The exposure lamp stays on for 5 sec.and then goes off automatically.

65/5560 ADJUSTMENT MAY.1997 © TOSHIBA CORP.2-9

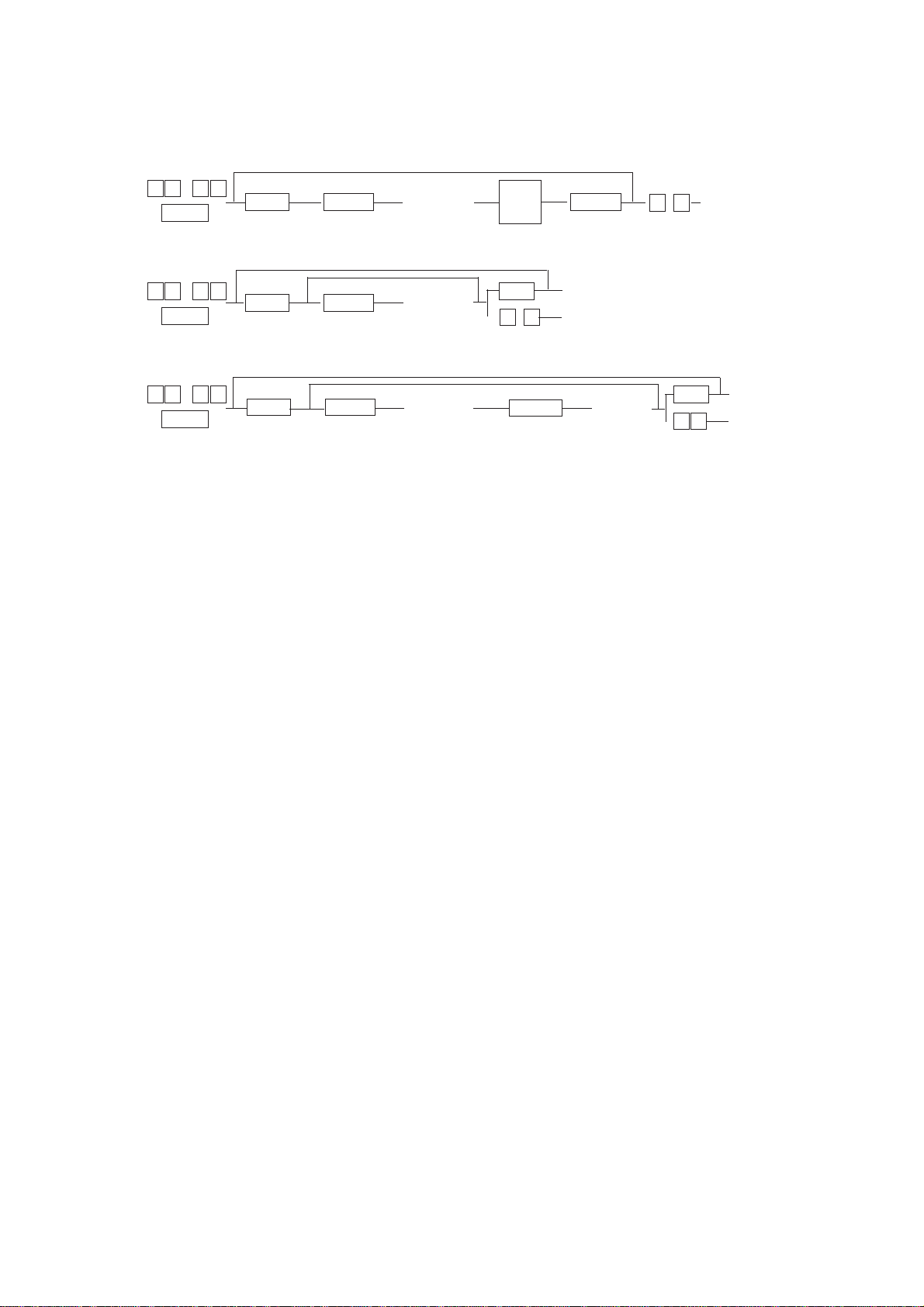

<Procedure>

Group(1)

0 3 / 0 4 Operation Stop

PWR (ON) Code

↓

→→→ →

Code PRINT PRINT 0 9 Warm-UP

→

→→

Group(2)

0 3 / 0 4 Operation C/S Test mode standby

↓↓

→→ →

Code PRINT

PWR (one-way) 0 9 Warm-up

→

→

→

→

Group(3)

0 3 / 0 4 Operation Operation C/S

PWR (ON) (OFF) 0 9 Warm-up

↓

→

Code PRINT PRINT

↓

→

→→

→

→

→

Test mode

→

standby

→

65/5560 ADJUSTMENTMAY.1997 © TOSHIBA CORP. 2-10

2.5.3 Adjustment Mode (05)

In this mode,the following adjustment items can be corrected or changed(see the Adjustment Code

List for "05"Mode). To access this code,turn on the power while pressing the "0"and"5"keys.

Adjustment item Code Keys to adjust with keys to store with Remarks

Auto-toner sensor 0 Zoom keys INTERRUPT See 2.6 for details.

Exposure 1~10 Digital keys/ INTERRUPT See 2.7 for details.

14~17 ZOOM keys

*Automatic adjustment 49 Not needed Not needed See 2.7 for details.

for exposure

HVT output 38~40,41,44 ZOOM keys INTERRUPT See 2.10 for details.

Registration 53~58 Digotsl keys INTERRUPT See 2.8.5 for details.

Other adjustment Except for Digital keys INTERRUPT Refer to Adjustment

above codes code list

<Procedure>

0 5

PWR

0 5

∗

PWR

↓

→

Code PRINT ADJUST INT E/S 0 9

→

→→→

Memory set

Automatic adjustment

49 PRINT 0 9

→→→→

for automatic exposure

Test copy

Exit

→

↑

Exit

65/5560 ADJUSTMENT MAY.1997 © TOSHIBA CORP.2-11

Adjustment Code List ("05")

Code

Name

No.

0 Auto-toner sensor 0~255 128

Allowable Initial

Input values Value*

Contents

•The larger the value,the larger the sensor output,

•About 3 minutes after this mode has been started,this

value changes automatically to make the sensor output

2.45V~2.55V.

1 Manual exposure(100%) 0~255 128

2 Manual exposure(154%) 0~255 128

3 Manual exposure(50%) 0~255 128

4 Manual exposure(200%) 0~255 128

5 Manual exposure(100%) 0~255 128

6 Manual exposure(154%) 0~255 128

7 Manual exposure(50%) 0~255 128

8 Manual exposure(200%) 0~255 128

9 Allowable exposure step 0~255 12 8

range(light)

10 Allowable exposure step 0~255 12 8

range(dark)

14 Manual photo exposure 0~255 128

(100%)

15 Manual photo exposure 0~255 128

(154%)

16 Manual photo exposure 0~255 128

(50%)

17 Manual photo exposure 0~255 128

(200%)

20 Aligning roller speed 0~15 10

adjustment

21 Drum speed adjustment 0~15 12

22 Heat roller speed adjustment 0~15 8

25 Leading edge of image shift 0~15 8

(100%)

26 Leading edge of image shift 0~15 8

(200%)

27 Leading edge of image shift 0~15 8

(50%)

•The larger the value,the lighter the image.

•The adjustment sequence must be

1→2→3→4→5→6→7→8→9→10.

The larger the value,the lighter the light range.

The smaller the value,the darker the dark range.

•The larger the value,the lighter the image.

•The adjustment sequence must be 14→15→16→17.

Each time the numerical value is increased by "1",the

reproduction ratio in the movement direction increases

by approximately 0.15%.

Range;-1.17%(reduction)to +1.05%(enlargement)

Each time the numerical value is increased by"1",the

reproduction ratio in the movement direction increases

by approximately 0.10.

Range:-0.77%(reduction)to +0.69%(enlargement)

Each time the numerical value is increased by"1",the

heat roller motor speed increases by 0.06%.

Range:-0.75%(reduction)to +0.71%(enlargement)

Each time the numerical value is increased by "1",the

image shift moves 0.5mm toward the trailing edge of

the paper without changing the position of the image

relative to the paper.

28 PFP motor speed 0~15 8

*The initial value means the one that is set by the BC-RAM initialize program, and does not mean the one set at the

factory before shipment.

Motor ratings can be adjusted by the following ranges:

0:-1.19% 1:-1.03%

2:-0.88% 3:-0.73%

---------- ----------

---------- 13:+0.76%

14:+0.91% 15:+1.06%

65/5560 ADJUSTMENTMAY.1997 © TOSHIBA CORP. 2-12

Code

Name

No.

Allowable Initial

Input values Value

30 Leading edge of edge 0~15 8

erasing

31 Trailing edge of edge erasing 0~15 8

32 Editing position adjustment 0~15 8

(100%)

33 Editing position adjustment 0~15 8

(200%)

34 Editing position adjustment 0~15 8

(50%)

35 Leading-edge void adjust- 0~15 8

ment

36 Trailing-edge void adjust- 0~15 8

ment

38 Main charger output 0~255 128

Contents

Each increase by "1" will move the edge erasing position

or the leading (trailing) edge of the paper 0.5mm toward

the trailing edge of the paper.

Each increase by"1"will move the editing position 0.5mm

toward the trailing edge of the paper(feed

side).Adjustment should be made in the order of

32→33→34.

Each time the numerical value is increased by"1",only

the void moves 0.5mm toward the trailing edge of the

paper.

The larger the value,the higher the output.(Not

necessary to adjust)

39 High-voltage transformer 0~255 128

(transfer)output

40 High-voltage transformer 0~255 128

(separation/developer bias)

output

41 Pre-transfer discharger 0~255 128

transformer output

42 Main charger output 0~255 205

(photo mode)

44 Separation DC output 0~255 185

45 LCD contrast adjustment 0~255 150

49 Automatic adjustment for - -

automatic exposure

53 Registration(LCF/100%) 0~15 8

54 Registration(LCF/200%) 0~15 8

55 Registration(LCF/50%) 0~15 8

56 Registration(manual/100%) 0~15 8

57 Registration(PFP/100%) 0~15 8

58 Registration(ADD/100%) 0~15 8

60 Lens position(100%) 0~99 50

61 Mirror position(100%) 0~99 50

The larger the value,the higher the output.

The larger the value,the higher the output.

The larger the value, the higher the output.

When the numerical value is increased, the output

increases

The lager the value, the higher the separation DC

welghted output.

The larger the value, the brighter the LCD panel.

Automatically adjusts the automatic exposure based on

the manual exposure.

Each time the unmerical value is increased by "1",the

image advances approximately 0.8mm toward the

leading edge.The adjustment sequence is

53→54→55→56→57→58.

Each time the numerical value is increased by "1",the

lens moves approximately 0.2mm toward the

enlargement direction.

Each time the numerical value is increased by "1",the

lens moves approximately 0.1mm toward the

enlargement direction.

65/5560 ADJUSTMENT MAY.1997 © TOSHIBA CORP.2-13

Code

Name

No.

Allowable Initial

Input values Value

62 Lens position(200%) 0~99 50

63 Mirror position(200%) 0~99 50

64 Lens position(50%) 0~99 50

65 Mirror position(50%) 0~99 50

Contents

Each time the numerical value is increased by "1",the

lens moves approximately 0.2mm toward the

enlargement direction.

Each time the numerical value is increased by "1",the

lens moves approximately 0.1mm toward the

enlargement direction.

Each time the numerical value is increased by "1",the

lens moves approximately 0.2mm toward the

enlargement direction.

Each time the numerical value is increased by "1",the

lens moves approximately 0.1mm toward the

enlargement direction.

68 Automatic adjustment of – –

remaining paper quantity

indication(no paper loaded)

69 Automatic adjustment of – –

remaining paper quantity

indication( paper loaded)

70 Remaining paper quantity 0~31 3

indication(LCF/no paper

loaded)

71 Remaining paper quantity 0~31 2

indication(upper cassette

/no paper loaded)

72 Remaining paper quantity 0~31 2

indication(middle cassette/

no paper loaded)

73 Remaining paper quantity 0~31 2

indication(lower cassette/

no paper loaded)

74 Remaining paper quantity 0~31 4/3**

indication(LCF/ paper

loaded)

75 Remaining paper quantity 0~31 2/3**

indication(upper cassette

/paper loaded)

76 Remaining paper quantity 0~31 4/8**

indication(middle cassette/

paper loaded)

Remove all of the paper from the LCF and PFP cassettes

when the adjustment is performed.

Install 4,000 sheets of paper in the LCF and the 500

sheets of paper in each of the PFP cassettes when the

adjustment is performed.

These adjustments are made manually when the

remaining paper quantity becomes down to half or less.

After the adjustment of code 68 is performed,conduct

these adjustments if necessary.

In case the variational ratio of the remaining paper

quantity indication is slower than the decrease ratio of

the actual quantity of sheets of paper,increase the

numerical value.

(Example)When" "symbol suddenly changes to

" "symbol.

These adjustments are made manually when more than

half of the paper remains.After the adjustment of code

69 is perfomed,conduct these adjustments if necessary.

In case the remaining paper quantity indication is

displayed as greater than the actual quantity of sheets

of paper,increase the numerical value.

(Example)" "symbol should be actually displayed,but

" "symbol is displayed.

**LT series/A4 series

77 Remaining paper quantity 0~31 7/3**

indication(lower cassette/

paper loaded)

79 Carriage control of the 0~2 –

leading edge of the image

80 Aligning value(LCF) 0~15 8

81 Aligning value(manual) 0~15 8

82 Aligning value(PFP) 0~15 7

83 Aligning value(ADD) 0~15 7

84 ADF aligning value(1st 0~15 8

page)

85 ADF aligning value(2nd 0~15 8

page)

**Europe (A4 series) / U.S.A. and Canada (LT series)

0:Normal control

1:To slow down the acceleration to the leading edge of

the image.

2:To increase the pre-scanning amount to the leading

edge of the image.

Each time the numerical value is increased by"1",the

amount of slack increases by approximately 1.9 mm.

Each time the numerical value is increased,the original

moves toward the paper feed side.

Each time the numerical value is increased,the original

moves toward the exit side(original stopper side).

65/5560 ADJUSTMENTMAY.1997 © TOSHIBA CORP. 2-14

Code

Name

No.

Allowable Initial

Input values Value

86 Aligning value 0~15 7

(long size paper/upper cassetle)

87 ADF aligning value 0~15 8

(2in1 original gap)

88 ADF leading edge position 0~15 8

(in 2in1 mode)

90 Auto-toner sensor 0~255 128

adjustment value

99 Real-time clock adjustment 0~63 0

Contents

Each time the numerical value is increased by "1", the

amount of slack increases by approximately 1.9 mm.

Each time the numerical value is increased, the gap

between originals increases.

Each time the numerical value is increased, the original

shifts to the paper supply side on the copier (that is,

moves away from the original stopper). This is carried

out after adjustment "87"(ADF aligning value).

The auto-toner adjustment value is indicated.

This value can be changed.

0~31 :Negative calibration:Max.-5.35sec./month/step

32~63:Positive calibration:Max.+10.7sec./month/step

0,32 :Correction deactivated

65/5560 ADJUSTMENT MAY.1997 © TOSHIBA CORP.2-15

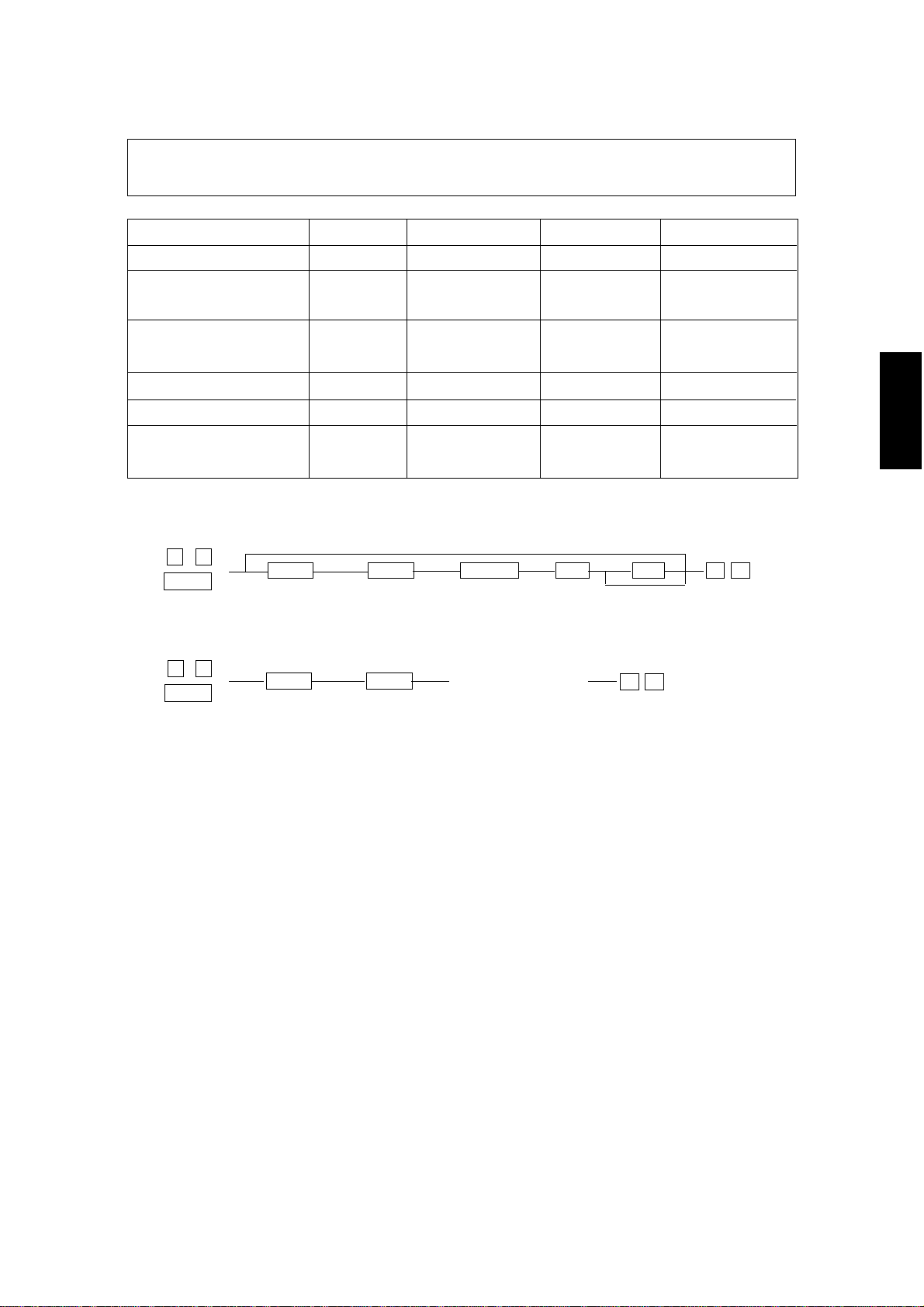

2.5.4 Setting Mode (08)

In thismode, the various special modes listed in the Setting Code List can be set or changed.

<Procedure>

0 8

PWR

Code

Name

No.

↓

→→→ →

Code PRINT INT 0 9

Allowable Initial

Input values Value*

0 Date/time input 13digits 1 Date indication 0~3 2

2 Time indication 0,1 0/1**

4 Auto sort mode 0~3 0

5 Automatic duplex mode 0~3 0/1**

Ste/change

a value

Memorize

→

Clear

Contents

Year/month/date/day/hour/minute/second

(Example)0:5/25 1:25/5 2:25.May 3:25.May

(Example)0:15:30 1:PM 3:30

The sort mode is selected automatically when the

original is placed on the ADF.

0: Deactivated

1: Staple sort

2: Sort

3: Group

The duplex mode is selected automatically when the

original is placed on the ADF.

0: Deactivated

1: (single-sided to dual-sided) is selected

2: (dual-sided to dual-sided) is selected

3: (dual-sided to single-sided) or (single-sided to dual sided) is selected according to the message.

6 Setting temperature of the 0~15 0

heat-roller surface

0:200°C 1:197°C 2:199°C 3:200°C 4:202°C 5:204°C

6:206°C 7:208°C 8:210°C 9:212°C 10:214°C 11:216°C

12:218°C 13:221°C 14:223°C 15:224°C

∗Never set to a value of 8 or more.

7 Access control mode active 0~2 0

0: Access control mode deactivated

1: Access control mode activated(copier)

2: Access control mode activated(IC card)

8 Version change 0~2 0/1**

0: EUR(A4/A3/FOLIO),1:UC(LT/LD)

2: JPN(A4/B4)

9 Actual-size reproduction 0 , 1 0

0: 100%,1:101%

ratio

10 Timer mode 0~10 3

If there is no control panel operation during the ready

status for a certain length of time as shown below,the

copy-mode automatic resetting function is performed.

Resetting operation start time is:

1: 15 sec.,2: 30 sec.,3: 45 sec.,4: 60 sec.,----10: 150 sec.

0: Deactivates the copy-mode automatic resetting.

11 Auto power saving 0~12 0/3**

Auto power saving operates n minutes after ready status

is reached.The functions are:

0: Deactivated

1: After 5 minutes

2: After 10 minutes

n: After n ×5 minutes

12 MAX9 0~2 0

Copy quantity

0: max.999,1:max.9,2:max.99

13 Paper-feed retrial 0,1 0

0: Feed-retrial mode

1: No-feed-retrial mode

14 Cassette priority selection 0~4 1

***

0: A4/LT priority

1: LCF priority

2: Upper cassette priority

3: Middle cassette priority

4: Lower cassette priority

*The initial value means the one that is set by the BC-RAM initialize program, and does not meaus the one set at the factory

before shipment.

**Europe(A4 series)/U.S.A.and Canada(LT series)

***This selection is made only when the FC key is pressed or when auto-resetting works.

65/5560 ADJUSTMENTMAY.1997 © TOSHIBA CORP. 2-16

Code

Name

No.

Allowable Initial

Input values Value

15 Exposure priority selection 0~2 0

16 A3 double count 0,1 0

17 Manual-feed auto-start 0,1 0

Contents

0: Auto exposure priority

1: Manual exposure priority

2: Photo exposure priority

3: Toner save priority

0: Single count

1: Double count

0: PRINT key starting

1: Auto-start

18 ADF mode selection 0,1 0

19 Sort mode selection 0~3 0

20 Edge erasing priority 0~2 0

selection

21 Automatic cassette 0,1 1

selection

22 APS priority selection 0,1,2 1

23 Detection of manually placed 0,1 0

original

24 APS start timing 0~15 5

27 ADF¥APS mode 0,1 0

31 Paper size(LCF) 0~15 3/4**

32 Paper size(upper cassette) 0~15 6/7**

33 Paper size(middle cassette) 0~15 11/14**

34 Paper size(lower cassette) 0~15 13/4**

0: ADF mode

1: SDF mode

The mode selected when power is turned ON

0: Non sort

1: Staple sort

2: Sort

3: Group

0: Deactivated

1: Edge erasing priority

2: Automatic edge erasing priority

0: Deactivated

1: Activated

0: Deactivated

1: APS priority

2: AMS priority

Detects manually placed original

0: Deactivated

1: Activated

0: 0 sec.,1: 100 msec,2: 200 msec

n: n×100 msec

0: Detection of every sheet of paper

1: Detection of only the first sheet

1: A5-R 2: ST-R/B5

3: LT 4: A4

5: B5-R 6: LT-R

7: A4-R 8: Sheet insertion

9: Cover seet 10: COM/FOLIO

11:LG 12: B4

13: LD 14: A3

**LT series/A4 series

38 Upper heater setting during 0~9 0

energy saving

39 Selection of paper size

enabled by cassette key 0~2 0

43 Resettable counter display, 0~3 0

original counter display

46 Toner save mode 0.1 1

**Europe(A4 series)/U.S.A.and Canada(LT series)

65/5560 ADJUSTMENT MAY.1997 © TOSHIBA CORP.2-17

0: 190°C 5: 160°C

1: Heater off 6: 170°C

2: 130°C 7: 180°C

3: 140°C 8: 190°C

4: 150°C 9: 200°C

0: Enabled

1: Not allowed

2: Cover sheet and sheet insertion only enabled

0: Deactivated

1: Resettable counter only displayed

2: Original counter only displayed

3: Resettable counter and original counter displayed

0: Deactivated

1: Selectable with IMAGE/PHOTO Key

2: Activated

Code

Name

No.

50 Paper retry counter

Allowable Initial

Input values Value

0~999,999 000000

Contents

53 Exposure burnout detection 0~2 0

56 Auto shut-off 16/12**

0~16/0~15**

69 PM counter setting value

(Total)

79 Current PM counter value

(Total)

80 Telephone number 14 digits 0

86 LCF tray lock counter 0.1 0

89 C7 counter 0~3 0

91

Copy counter of unit

~97

Code

Unit name

NO.

91 ADD

92 ADF

93 SBF

94 LCF

95 Upper cassetle(PFP)

96 Middle cassetle(PFP)

97 Lower cassetle(PFP)

98 The setting value of the drum ∗1 0~15

surface potential

108 Error alarm 0~2 0

109 Universal paper 0~14 1/9**

134 TOSHIBA Rogo Display. 0~1 0

135 Front access sorter 0~1 0

unloading mode

(MG-2011)

**Europe(A4 series)/U.S.A.and Canada(LT series)

0~999,999

0~999,999

0~999,999 000000

0: Activated at all times

1: Activated only at automatic exposure

2: Deactivated

Auto shut-off to force when it was left for a following

contorol time (Same OFF state as weekly Timer)

0:3 1:5 2:10 3:15 4:20 5:25

6:30 7:40 8:50 9:60 10:70

11:80 12:90 13:100 14:110 15:20

16:150 17:180 18:210 19:240(min)

∞

20:

0

Other than 0: PM call when set value ≤ Copy count

(code"79")

0

Current copy quantity

Telephone numbers of up to 14 digits can be

entered.Use the HELP key to enter hyphens(min.).

0: Normal

1: LCF forced paper OFF state (LCF tray does not move)

Heat-roller thermistor breakdown counter

0~2:Normal operation

3:Copier does not operate

0:800V 1:830V 2:840V 3:850V

4:860V 5:870V 6:880V 7:890V

8:900V 9:910V 10:920V 11:930V

12:940V 13:950V 14:960V 15:970V

∗Never set to a value of 5 or more.

Changing the number of alarm sounds when an error

occurs

0: No sound

1: 5 times

∞

2:

1 A5-R 6 FOL10 11 LT-R

2B5 7B4 12LG

3 B5-R 8 A3 13 COMP

4 A4 9 ST-R 14 LD

5 A4-R 10 LT

Turning on the power supply Rogo is displayed on the

Message display.

0: Display

1: No Display

After the end of copying the stacked copy paper is

pushed out into each bin.

(When the MG-2011 is connected and a mode other

than the multi-stacking mode is selected)

0: Function

1: No Function

65/5560 ADJUSTMENTMAY.1997 © TOSHIBA CORP. 2-18

2.5.5 How to Register/Change ID Codes (access control mode)

COSMOS

Text 2-19 in the

65/5560 Service Handbook

as text 2-19 in the

Do you refer to the

is same

76/7550 Service Handbook

76/7550 Service Handbook

SkipOK

Cancel

.

?

65/5560 ADJUSTMENT MAY.1997 © TOSHIBA CORP.2-19

Loading...

Loading...