Page 1

File No. SME08000800

R080621G1100-TTEC

Ver00_2008-11

Page 2

Trademarks

x Fiery is a registered trademark of Electronics for Imaging, Inc. in the U.S. Patent and Trademark Office and/or

certain other foreign jurisdictions.

x Company names and product names in this manual are the trademarks or registered trademarks of their

respective companies.

© 2008 TOSHIBA TEC CORPORATION All rights reserved

Under the copyright laws, this manual cannot be reproduced in any form without prior written

permission of TOSHIBA TEC CORPORATION. No patent liability is assumed, however, with respect

to the use of the information contained herein.

Page 3

Revision Record

File No. SME08000800

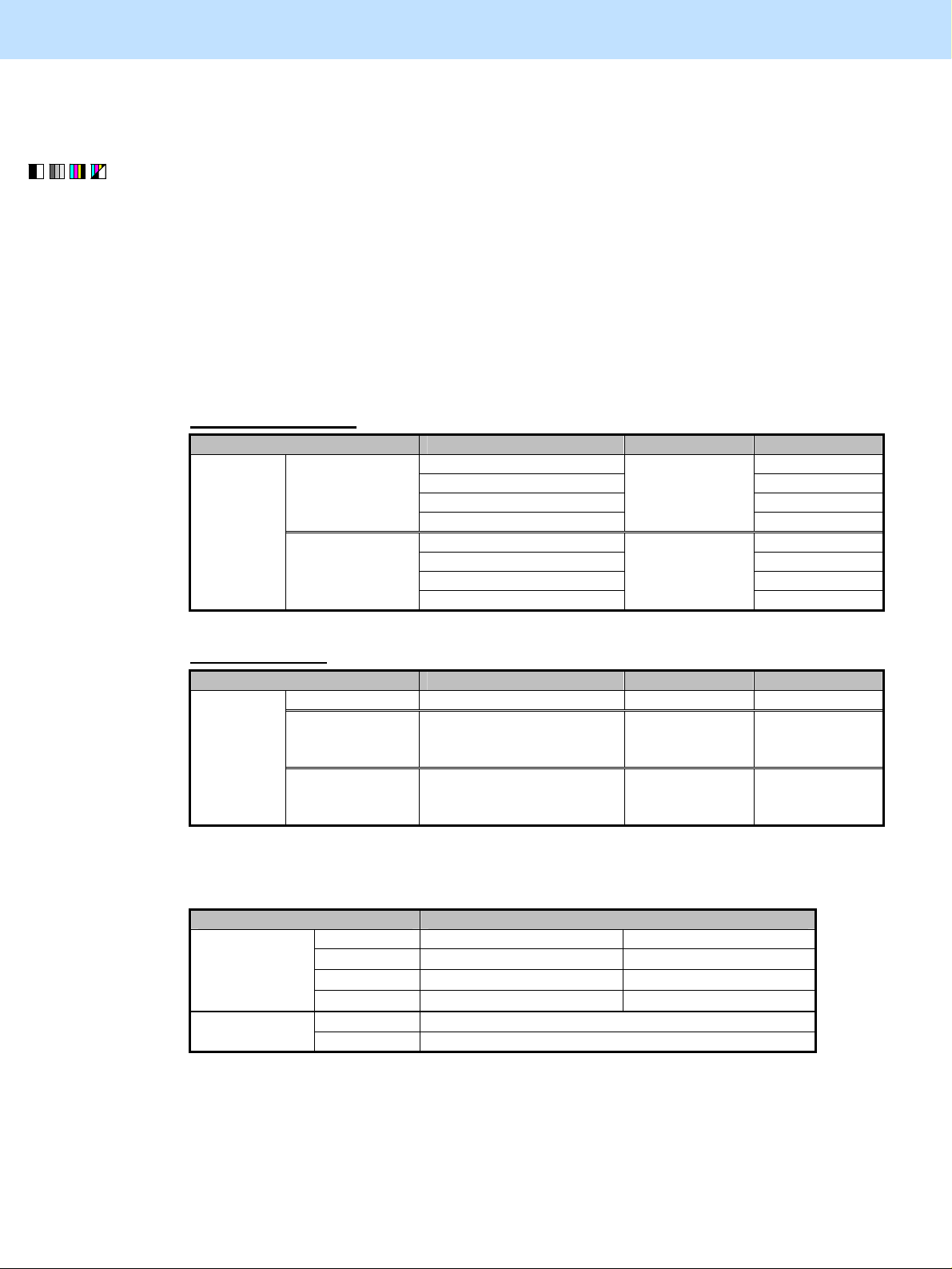

Date Rev.No Item Descriptions Remarks

Page 4

Page 5

Purpose of the Imaging Manual

The Imaging Manual is intended for customers using the Toshiba e-STUDIO5520C/6520C/6530C with a variety

of specific needs and inquiries for high image quality, such as:

x How to obtain a clearer copy image

x How to maintain the current image quality

x How to make the text look sharper on the copy

The Toshiba MFPs are factory-configured to provide image quality settings that satisfy the majority of customers.

However, these settings may not be necessarily optimal for the specific needs of all customers. Proper image

quality adjustments can satisfy such needs. Most of the adjustments described in this manual must be performed

by a service technician, but a few of them can also be performed by the customer.

It is strongly recommended that this manual be fully utilized by not only the service technician, but also the sales

representative, who also has opportunities of obtaining customer feedback on the image quality. This manual

helps the sales representative to study and comprehend what kind of customer requirements for image quality

can be satisfied, to make proposals to customers to improve image quality, and to communicate the customers’

specific requirements with ease to the service technician. In addition, this manual is expected to facilitate the

marketing of Toshiba MFPs to prospective customers that have a specific demand for image quality and the

expansion of sales.

The adjustments described in this manual are all based on the requests of actual customers. Meeting their

specific wishes will only add to their satisfaction.

Please remember to read "Caution after the adjustment," to which you must pay close attention, after finishing

the adjustment.

Precautions in Servicing

• For adjustments to be performed by the service technician, the precautions given in the Service Manual must be

stringently followed. The adjustments must be performed by a qualified service technician who has completed

the service training course.

• The default listed mentioned in this manual may be different from the actual ones, due to the timing of shipping

(firmware version). But note that the recommended values and acceptable value range stated in this manual

remain the same.

Page 6

Purpose of the Imaging Manual

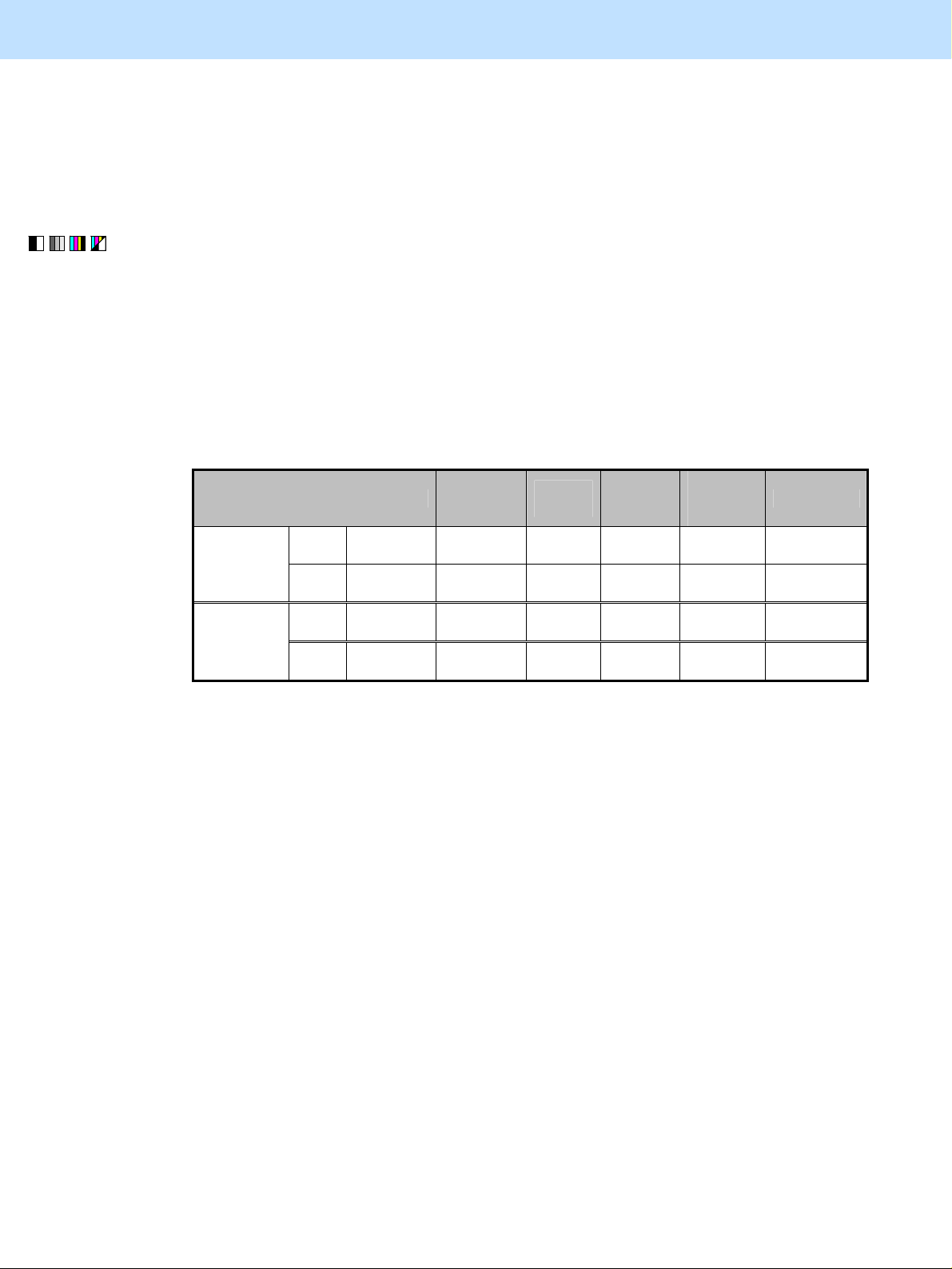

Icons

The following icons used in this manual denote the following:

: • Copy ——— An adjustment having an effect on copying in the Black mode (excluding

the Image smoothing mode)

• Printer ——– An adjustment having an effect on Black and White mode printing

* The adjustment will be effective, if "Black and White" is selected from

among the "Color" options on the Windows printer driver or if "Mono"

is selected from among the "Color Type" options on the Macintosh print

dialog.

• Scan ——— An adjustment having an effect on scanning in the Black mode

: • Copy ——–– An adjustment having an effect on copying in the Image smoothing mode

in the Black mode

• Scan ——— An adjustment having an effect on scanning in the Gray scale mode

: • Copy ——— An adjustment having an effect on copying in the Full color mode

• Printer ——– An adjustment having an effect on full-color printing

* The adjustment will be effective, if "Auto" or "Color" is selected from

among the "Color" options on the Windows printer driver or if "Auto" or

"Color" is selected from among the "Color Type" options on the

Macintosh print dialog.

• Scan ——— An adjustment having an effect on scanning in the Full color mode

: • Copy ——— An adjustment having an effect on copying in the Auto color mode

• Scan ——— An adjustment having an effect on scanning in the Auto color mode

PCL6

PS3

XPS

Mac

Scan to Box

Copy to Box

Print to Box

Fax to Box

: An adjustment having an effect on printing with the Windows PCL6 emulation printer

driver

: An adjustment having an effect on printing with the Windows PS3 emulation printer

driver

: An adjustment having an effect on printing with the Windows PSX emulation printer

driver

: An adjustment having effect on printing with the Macintosh printer driver

: An adjustment having an effect on an image stored in the e-Filing box by the scanning

functions (including Scan to Box, Scan to File and Scan to E-mail)

: An adjustment having an effect on an image stored in the e-Filing box by the copying

functions (Copy to Box)

: An adjustment having an effect on an image stored in the e-Filing box by the printing

functions (Print to Box)

: An adjustment having an effect on an image stored in the e-Filing box by the Fax and

Internet Fax functions (including Received Fax to Box and Received Internet Fax to Box)

Page 7

Table of Contents

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

1.1 To Obtain a Darker Image ............................................................................1-1

1.2 To Adjust the Density on a Solid Colored Image ..........................................1-5

1.3 To Achieve the Image Quality Most Suitable for the Paper Used

(To eliminate blur and graininess from an image) ...1-10

1.4 To Minimize Variations in the Image Quality under the Operating Conditions

(To optimally program image quality control) ..........1-15

1.5 To Correct Out-of-Registration Colors ........................................................1-21

2. Copier-specific Adjustments

2.1 To Copy Text Clearly (To eliminate faint, smudged or blurred text)..............2-1

2.1.1 To Adjust the Copy Image Quality in the Black Mode .................................... 2-2

2.1.2 To Adjust the Copy Image Quality in the Full Color Mode.............................. 2-6

2.1.3 To Adjust the Copy Image Quality in the Auto Color Mode ............................2-9

2.2 To Closely Match the Color Balance of the Original ...................................2-12

2.3 To Improve the Reproducibility of Gray.......................................................2-16

2.4 To Copy in Vivid Colors ..............................................................................2-18

2.5 To Make the Pale Area of the Original Look Darker and Sharper

(To improve the highlight reproducibility) ................2-22

2.6 To Eliminate the Background Color ............................................................2-25

2.6.1 To Adjust the Copy Image Quality in the Black Mode .................................. 2-26

2.6.2 To Adjust the Copy Image Quality in the Full Color Mode............................ 2-28

2.7 To Avoid Copying the Image Seen through

the Back of a Page Printed on Thin Paper ..............2-31

2.7.1 To Adjust the Copy Image Quality in the Black Mode .................................. 2-32

2.7.2 To Adjust the Copy Image Quality in the Full Color Mode............................ 2-35

2.8 To Eliminate Moiré ......................................................................................2-37

2.9 To Copy Sharply (To enhance sharpness) .................................................2-41

2.10 To Make Photo Edges Look Softer .............................................................2-44

2.11 To Make Solid Filled Bold Text (Logo) Highly Colored................................2-49

2.11.1 To Adjust the Copy Image Quality of a Black Logo ..................................2-50

2.11.2 To Adjust the Copy Image Quality of a Colored Logo...............................2-52

2.12 To Sharply Contrast the Hues of Highlighters on the Copy.........................2-54

2.13 To Obtain a Good Color Balance on Thick Paper.......................................2-57

2.14 To Obtain Smooth Gray-Scale Photo Images.............................................2-61

2.15 To Change the Threshold in Auto Color Mode

(To change the threshold between the Full Color mode and the Black mode

to meet the user’s needs) .........................................................................2-63

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

i

Page 8

Table of Contents

2.16 To Adjust the Twin-Color Copy Image Quality ............................................2-66

2.16.1 To Adjust the Tint of Colors other than Black ........................................... 2-67

2.16.2 To Adjust the Reproducibility of Black in the Red and Black Mode ..........2-68

2.16.3 To Adjust the Boundary between Black and Colors other than Black.......2-69

2.17 To Adjust the Image Quality Scanned from the RADF................................2-70

2.18 To Program Frequently Used Copy Settings (To Use Custom Mode) .......2-73

2.18.1 To Adjust Custom Mode Settings in Black Mode...................................... 2-73

2.18.2 To Adjust Custom Mode Settings in Color Mode...................................... 2-78

2.19 To Copy While Erasing Shadow Outside of Image .....................................2-82

2.20 To Avoid Copying Blank Page of Original Scanned with RADF..................2-83

2.21 To Obtain Image in Even Density Level......................................................2-85

3. Printer-specific Adjustments

Restrictions on Use of Printer Functions................................................................3-1

3.1 To Maintain a Steady Color Balance.............................................................3-2

3.2 To Maintain a Steady Color Balance on Thick Paper or Special Paper ..............3-4

3.3 To Obtain the Desired Color Balance ...........................................................3-6

3.4 To Closely Match the Color Balance on the Monitor...................................3-14

3.5 To Maintain a Uniform Gray Hue

(To maintain Consistency in Gray among Text, Photos and Graphics) ..3-17

3.6 To Use Only the Black Toner to Reproduce Gray Areas

(To use only the black toner to reproduce black-and-white photos or

gradational images) ................................................................................3-20

3.7 To Easily Adjust the Overall Brightness ......................................................3-24

3.8 To Adjust the Overall Saturation .................................................................3-27

3.9 To Easily Adjust the Overall Contrast .........................................................3-31

3.10 To Obtain a Sharper Print Image ................................................................

3.11 To Obtain a Softer Image............................................................................

3-34

3-37

3.12 To Make Low-resolution Data Look Finer (To soften an image) .................3-40

3.13 To Eliminate Smudges from Highly Colored Text and Lines

(To prevent toner scattering around text and lines where a large amount of

toner is used) ..........................................................................................3-43

3.14 To Clearly Print Light-Colored Thin Lines or Text .......................................3-47

3.14.1 To Adjust the Print Image Quality in the Color Mode................................3-48

3.14.2 To Adjust the Print Image Quality in the Black and White Mode ..............3-56

3.15 To Make the Light-Colored Area Darker on the Printout.............................3-60

3.16 To Clearly Print Thin Lines/Double Lines....................................................3-66

3.17 To Decrease the Image Density and Save Toner

(To Print in the Toner Save Mode) ..........................3-71

3.18 To Adjust the Image Density in the Toner Save Mode................................3-74

3.19 To Print Illegible Gray or Colored Text in Black ..........................................3-77

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

ii

Page 9

Table of Contents

3.20 To Ignore Blank Pages for Printing .............................................................3-79

3.21 To Sharply Print Black Text ........................................................................3-82

3.22 To Prevent Dark Toner from Coming Off ....................................................3-92

3.23 To Register the Image Quality Adjusted Corresponding to a Preference

(To use the Custom Color Settings) ........................3-94

3.24 To Print a Full-Color Original in Two Colors................................................3-97

3.24.1 To Adjust Colors ....................................................................................... 3-98

3.24.2 To Adjust the Sharpness ........................................................................3-103

3.24.3 To Print a Full-Color Original in Two Colors ...........................................3-105

3.25 To Use ICC Profile ....................................................................................3-106

3.25.1 To Create ICC Profiles for Printing on the Paper to be Used .................3-107

3.25.2 To Print Precise Colors Using Existing RGB Source ICC Profiles..........3-112

3.25.3 To Perform Simulated Printing with CMYK Inks of

Each Ink Manufacturer .............

3.25.4 To Convert Colors with Specified Source ICC Profiles

(Not Using Embedded ICC Profiles) ....

3.25.5 To Perform Further Adjustment After Using ICC Profiles .......................3-125

3-116

3-120

4. e-Filing-specific Adjustments

4.1 To Clearly Store a B/W Image in the Auto Color Mode.................................4-1

4.2 To Store an Original while Reducing the File Size........................................4-3

4.3 To Store a Color Photo Image, while Minimizing Moiré ................................4-5

4.4 To Match the Color Balance on the Original

(To adjust the color balance in Print to Box)..............4-7

4.5 To Scan and Print, while Minimizing Moiré ...................................................4-9

4.6 To Finely Print the Image Stored in the e-Filing box

(To print images stored through Copy to Box or Print to Box) ............4-11

4.7 To Store an Image Suitable for Displaying on

the Monitor or Image Editing ...................................4-13

4.8 To Finely Print Color Images Scanned and Stored

(To print images stored through Scan to Box).........4-15

4.9 Appendix.....................................................................................................4-17

5. Scanning-specific Adjustments

5.1 To Clearly Scan Text (To reduce noise around text) ....................................5-1

5.2 To Scan an Original, while Eliminating the Background Color

(To eliminate the background density) ......................5-3

5.3 To Clearly Scan and Print an Original in Black and White

(To improve gradation and reduce graininess)..........5-5

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

iii

Page 10

Table of Contents

5.4 To Scan the Original, while Reducing the File Size ......................................5-7

5.4.1 To Reduce the File Size by Changing the Options

when Scanning the Original .........5-8

5.4.2 To Reduce the File Size in Slim PDF ...........................................................5-11

5.5 To Sharply Scan the Original (To increase the sharpness intensity) ..........5-13

5.6 To Scan an Original, while Enhancing Black ..............................................5-15

5.7 To Scan an Original with the Desired Gradation.........................................5-17

5.8 To Register the Original Mode Optimal for a Particular Type of Original

(To have "Custom" selected) ...5-19

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

iv

Page 11

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

1.1 To Obtain a Darker Image

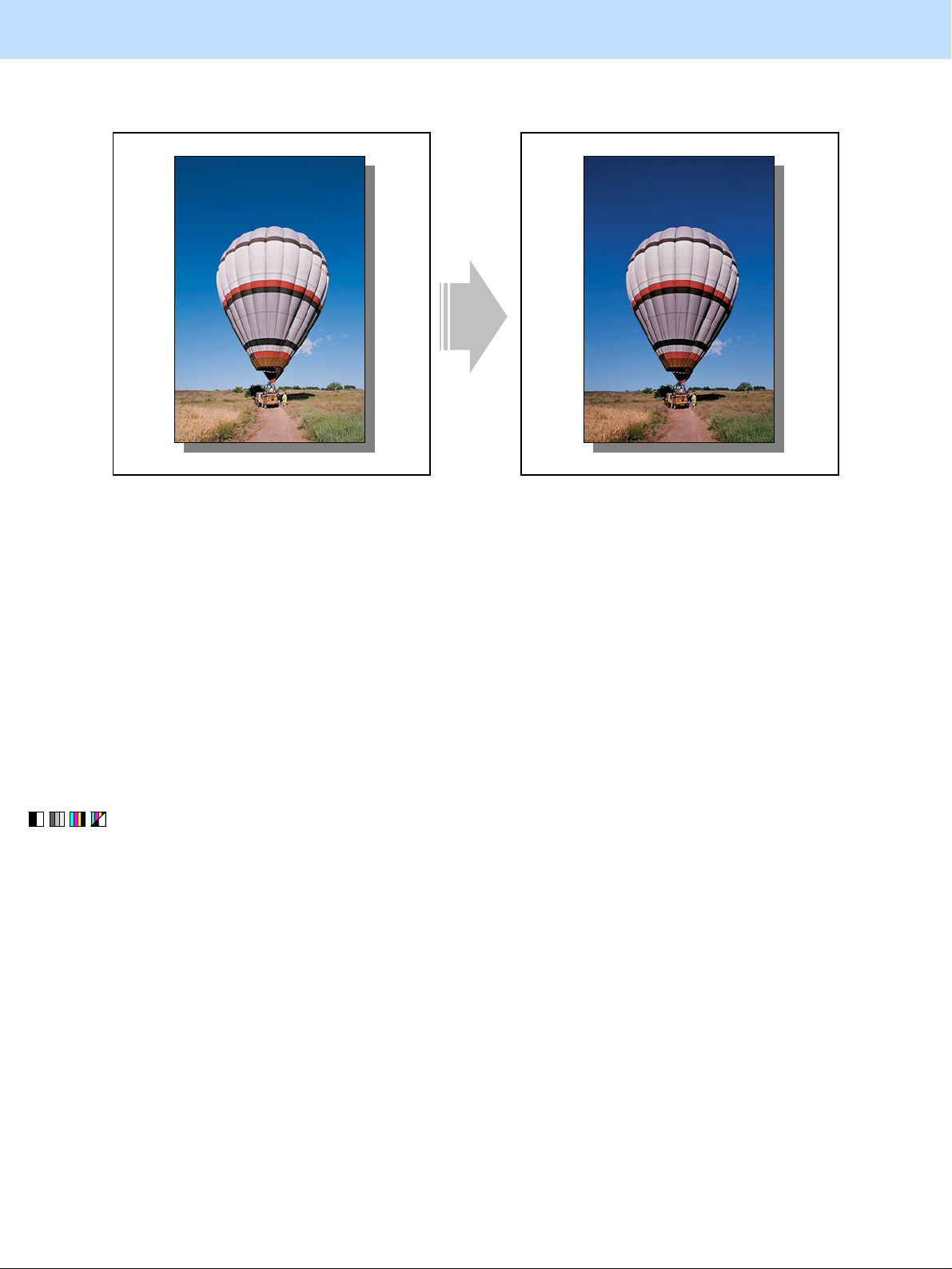

Before the adjustment After the adjustment

The output image looks light and blurred. The output image looks darker and sharper.

Explanation

When an original containing photo images or gradational images is printed, the output image sometimes looks

light and blurred. Perform image quality control or automatic calibration, and adjust the transfer roller bias

output, in order to obtain a darker and sharper image.

Procedures

* Perform the adjustment in accordance with the procedures below.

* Both the service technician and the user can use procedure (1).

* Only the service technician must use procedures (2) and (3).

(1) Perform automatic calibration to correct variations in image density.

* "ADMIN" is selected from among the "CALIBRATION DISPLAY LEVEL" options by default. In other

words, an administrator is authorized to operate automatic calibration. But "USER" can also be selected to

allow the user to operate it. Refer to the User Functions Guide for further information regarding how to

select the "CALIBRATION DISPLAY LEVEL" option.

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-1

Page 12

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

To adjust the copy image quality

Use steps (a) through (i) to perform automatic calibration.

(a) Press the [USER FUNCTIONS] button on the Control Panel to enter the "User Functions" menu.

(b) Press the [ADMIN] tab.

(c) Enter the 6 to 10 digit administrator password. Press the [ENTER] button.

(d) Press the [GENERAL] button.

(e) Press the [CALIBRATION] button.

(f) Press the [COPY] button.

(g) Press the [CALIBRATION] button to print out the test chart.

(h) Place the printed test chart on the original glass.

(i) Press the [START] button to perform calibration. When the calibration comes to an end, the message

"Scanning and calibrating" will disappear.

* As a result of the above steps, the copy image quality will be corrected in the Full Color mode and

Black and White mode simultaneously.

* To correct variations in image density by performing automatic calibration for each paper type, refer

to " (1) Perform automatic calibration for each paper type to correct variations in image density" in

"2.13 To Obtain a Good Color Balance on Thick Paper".

To adjust the print image quality

Use steps (a) through (j) to perform automatic calibration.

(a) Press the [USER FUNCTIONS] button on the Control Panel to enter the "User Functions" menu.

(b) Press the [ADMIN] tab.

(c) Enter the 6 to 10 digit administrator password. Press the [ENTER] button.

(d) Press the [GENERAL] button.

(e) Press the [CALIBRATION] button.

(f) Press the [PRINT] button.

(g) Press the [CALIBRATION] button to print out the test chart.

(h) Place the printed test chart on the original glass.

(i) Press the [START] button to perform calibration. When the calibration comes to an end, the message

"Scanning and calibrating" will disappear.

(j) The message "Is a result made to reflect?" will appear. Press the [YES] button.

* To correct variations in image density by performing automatic calibration for each paper type, refer

to "3.2 To Maintain a Steady Color Balance on Thick Paper or Special Paper".

After performing automatic calibration, print and check the image quality.

If further image quality adjustments are still necessary, use the next procedure.

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-2

Page 13

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

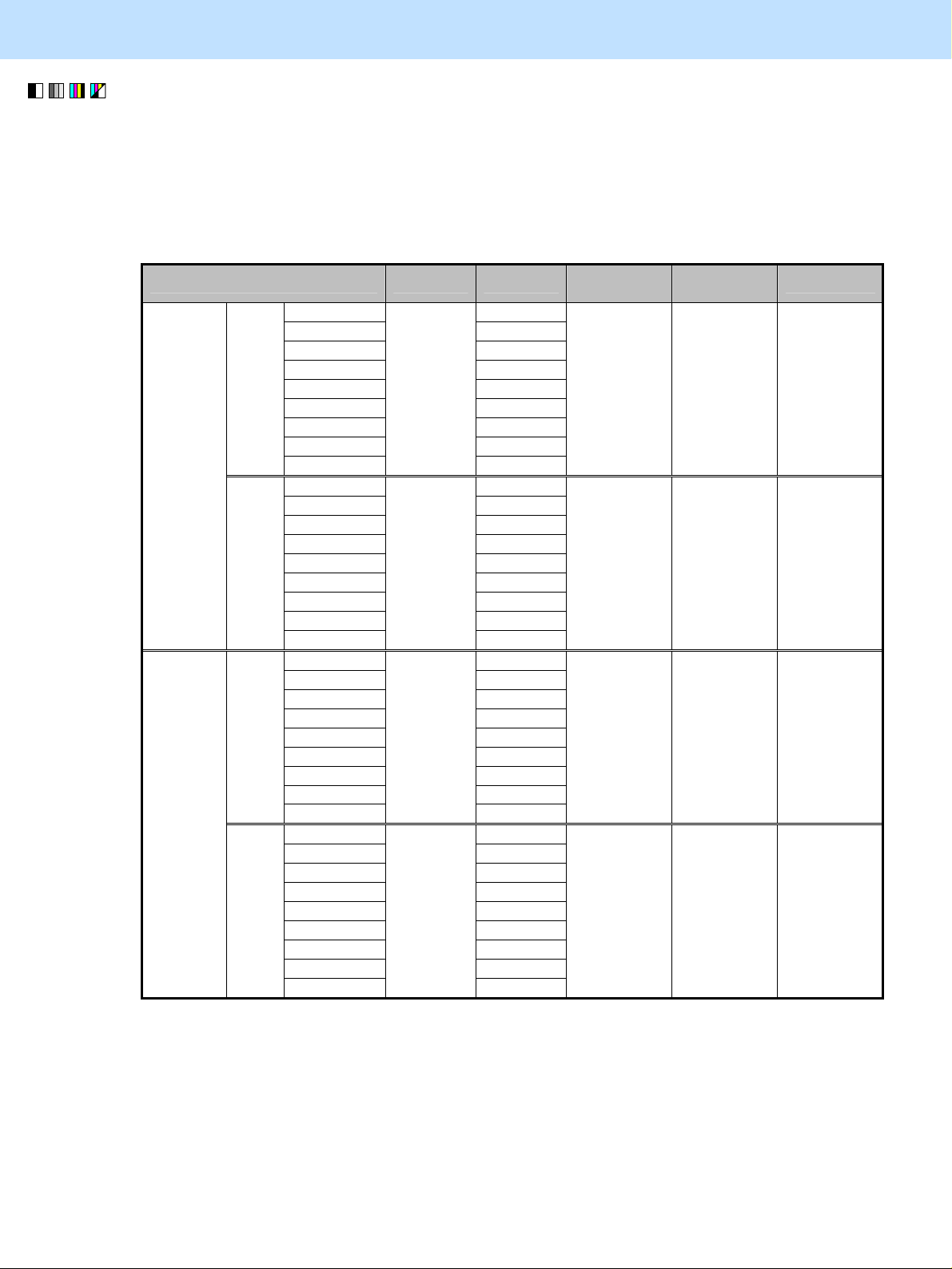

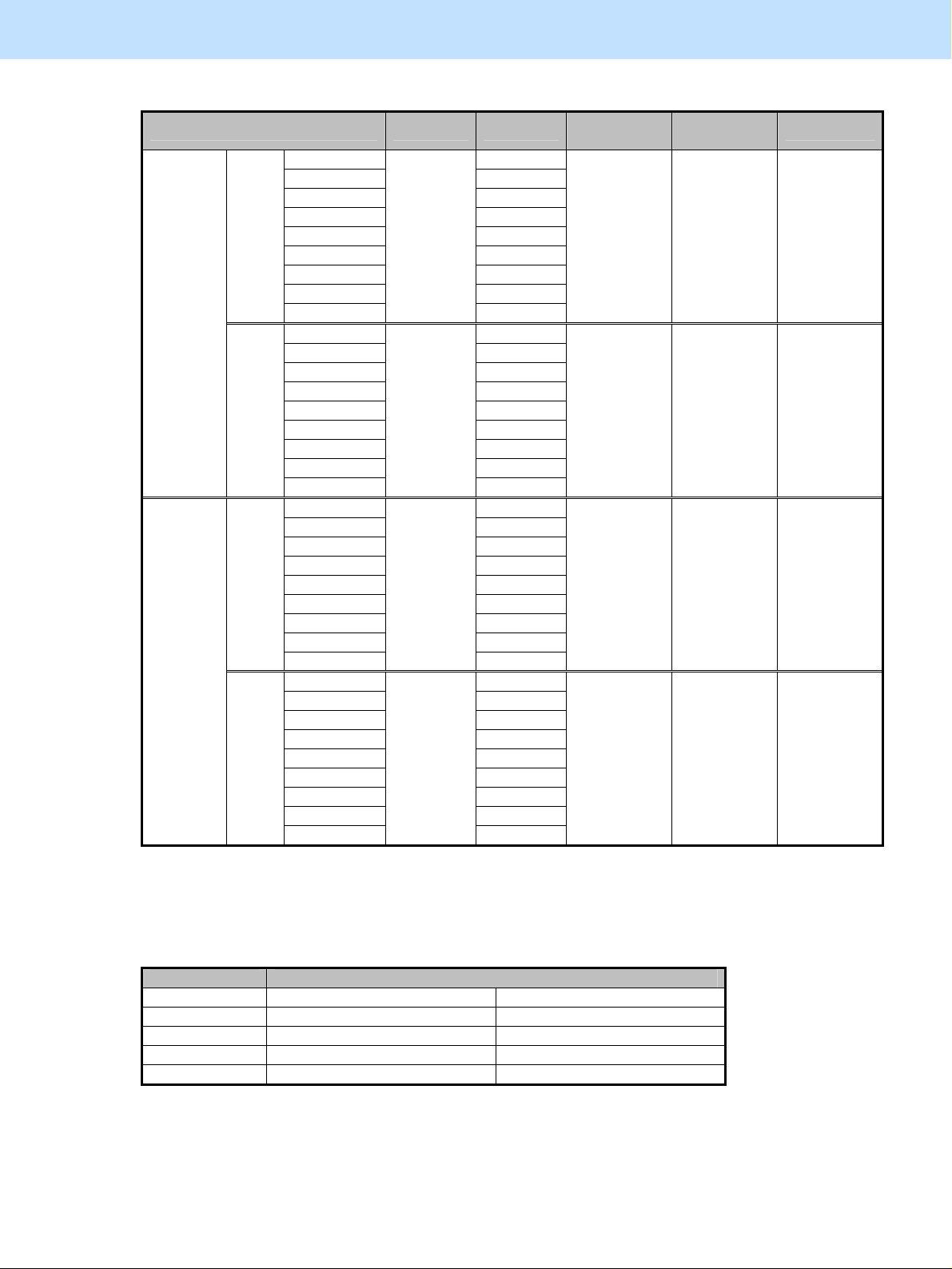

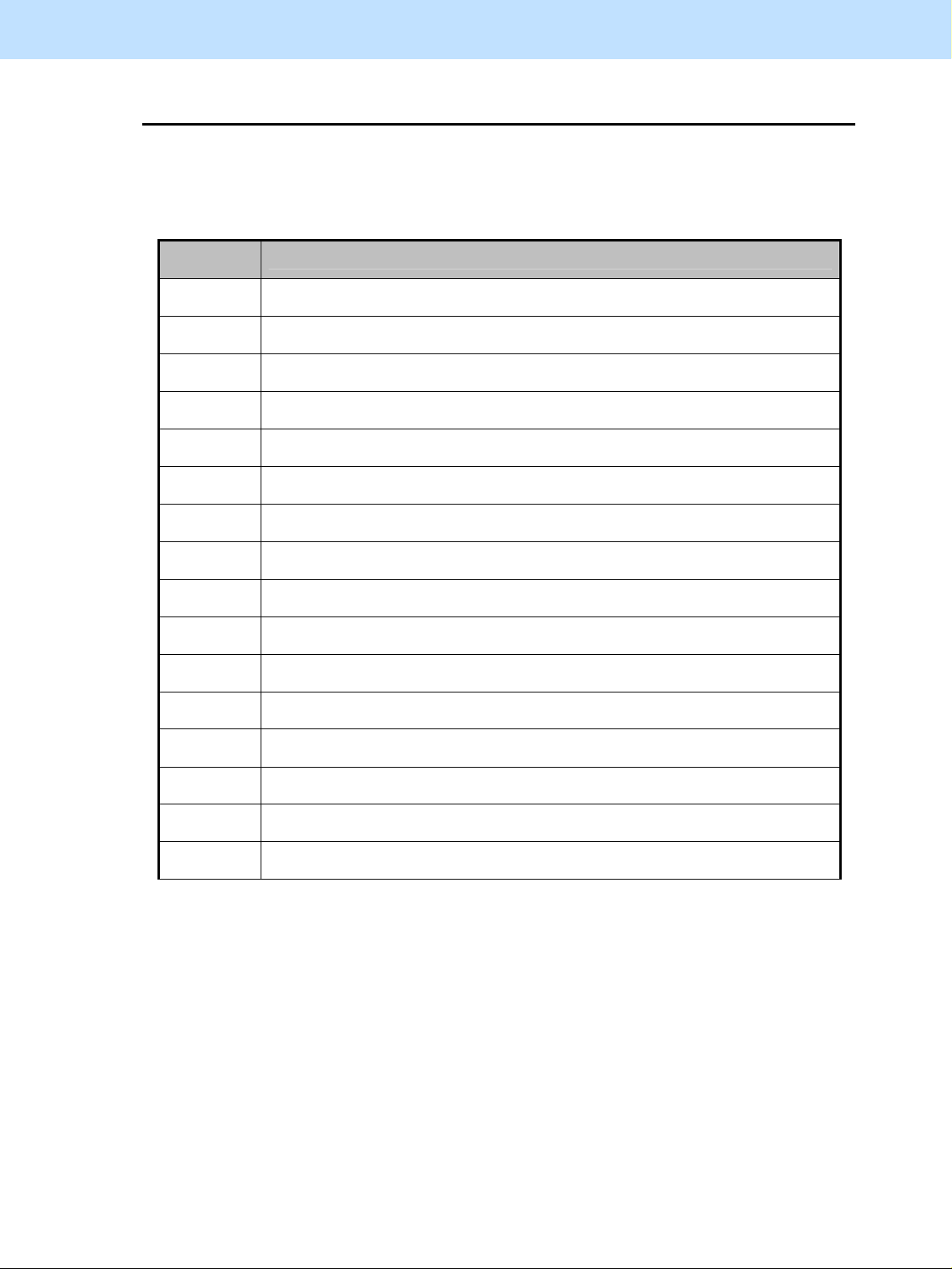

(2) Enter adjustment mode [05]. Change the values for codes [2934 to 2937] to adjust the transfer (2nd

transfer) roller bias output.

(Adjust the offset voltage of transfer roller bias so as to increase the density of the image.)

• The code to use varies depending on the paper type. Adjust the value for [05] code corresponding to the

paper type for which you would like to improve the image quality. Set the value within a range of "2" to

"8" to obtain the highest density of the image.

Full color

Black

Paper type [05] code Subcode

Plain paper 0

Thick 1 1

Thick 2 2

Thick 3 3

Front

OHP 4

05-2934

Special 1 5

Special 2 6

Recycled paper

Thick 4

7

8

Plain paper 0

Thick 1 1

Thick 2 2

Thick 3 3

Back

OHP 4

05-2935

Special 1 5

Special 2 6

Recycled paper

Thick 4

7

8

Plain paper 0

Thick 1 1

Thick 2 2

Thick 3 3

Front

OHP 4

05-2936

Special 1 5

Special 2 6

Recycled paper

Thick 4

7

8

Plain paper 0

Thick 1 1

Thick 2 2

Thick 3 3

Back

OHP 4

05-2937

Special 1 5

Special 2 6

Recycled paper

Thick 4

7

8

Recommended

value

2 to 8 0 to 10 5

2 to 8 0 to 10 5

2 to 8 0 to 10 5

2 to 8 0 to 10 5

Acceptable

value range

Default

* "Front" refers to the printed side in the simplex mode or the side that is delivered facing upwards in the duplex mode.

"Back" refers to the printed side that is delivered facing downwards in the duplex mode.

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-3

Page 14

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

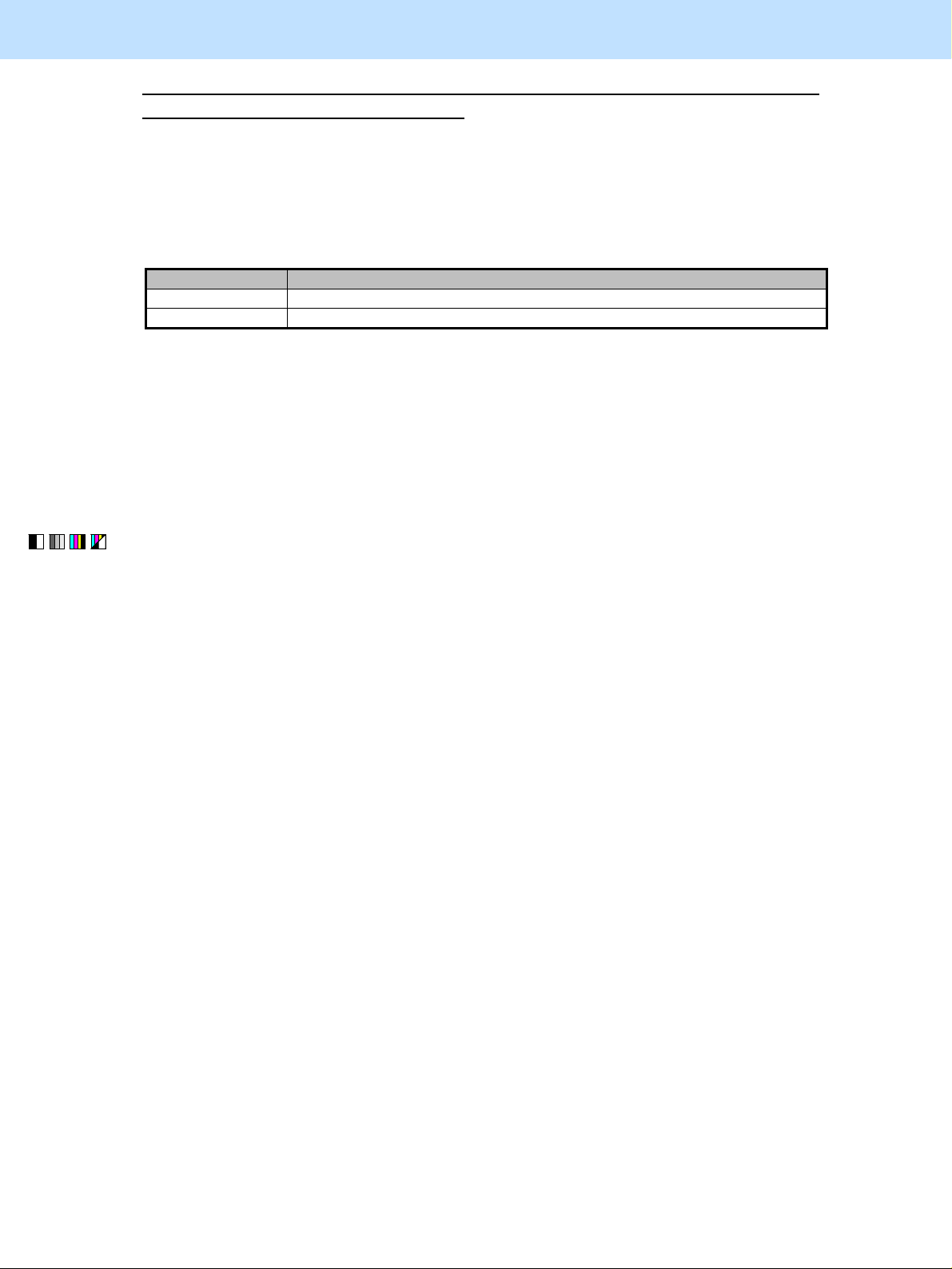

* The table below shows you the acceptable paper weight for the paper type.

Paper type Acceptable paper weight

Plain paper 64 to 105 g/m² 16 to 20 lb. Bond

Thick 1 106 to 163 g/m² Max. 60 lb. Cover

Thick 2 164 to 209 g/m² Max. 110 lb. Index

Thick 3 210 to 256 g/m² Max. 140 lb. Index

Thick 4 257 to 300 g/m² Max. 110 lb. Cover

• After adjusting the transfer roller bias output, perform automatic calibration in the same manner as in

procedure (1).

<Hint> The transfer voltage increases as the set value is increased. It is usually recommended that the

set value be increased, when you print on thick paper or paper with asperities on its surface. On

the other hand, the set value should be decreased, when you print on thin paper.

After adjusting the density, print and check the image quality.

If further image quality adjustments are still necessary, use the next procedure.

(3) Check the life of the consumables (particularly the drum and fuser unit) and replace them, if necessary.

• When replacing any consumable, use steps (a) to (c).

(a) Enter the PM support mode. Reset the counter corresponding to the replaced consumable to "0."

* For further information regarding the PM support mode, refer to the Service Manual.

(b) Enter adjustment mode [05], select code [396], and then press the [START] button.

• Image quality control will be performed and the image quality control value will be initialized.

(c) Perform automatic calibration in the same manner as in procedure (1).

* After replacing any consumable, remember to reset the counter corresponding to it to "0." Otherwise, it

may cause a loss in MFP performance, including degradation in the image quality and a reduction in the

life of the consumables.

* While replacing any consumable, also check the slit glass in the laser optical unit, and thoroughly clean it,

if it is soiled.

Caution after the adjustment

Nothing in particular.

Remarks

• Enter the value mentioned in the procedures or one within the recommended value range for the adjustment.

Otherwise, it may cause a loss in MFP performance, including degradation in the image quality and a reduction

in the life of the consumables.

• If printing on another type of paper causes a problem with the image quality after the adjustment, return the set

values (for codes 05-2934 to 2937) to the default (set value: 5) and then perform the adjustment again.

• When replacing any consumable, refer to the relevant information in the Service Manual and Service

Handbook.

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-4

Page 15

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

1.2 To Adjust the Density on a Solid Colored Image

If the density is decreased If the density is increased

The solid colored area becomes lighter. The solid colored area becomes darker.

Explanation

In thick paper printing, the density of a solid colored image can be made darker to enhance it or lighter in order

to match with the type or color of the original.

<Notes> • The function described in this chapter cannot be used for plain paper 1 and 2 in the full color

mode.

The type of plain paper 1 and 2 is as follows.

Paper type not available Acceptable paper weight

Full color

Do not use the following code corresponding to plain paper 1 and 2 for the adjustment.

Paper type Color to adjust [08] code Subcode

Full color /

Black

• When performing the adjustment in accordance with the procedure, note that the density of a

gradation area (halftone), such as a photograph, is adjusted as well as that of a solid colored

image.

Plain paper 1 64 to 80g/m² Max. 20 lb. Bond

Plain paper 2 81 to 105g/m² Max. 28 lb. Bond

Y (yellow) 0

Plain paper 1, 2

M (magenta) 1

C (cyan) 2

K (black)

08-2513

3

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-5

Page 16

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

Procedures

* The service technician must perform the adjustment in accordance with the procedures below.

(1) Enter setting mode [08]. Change the value to adjust the density of a solid area during the copying/printing

operation.

• Use steps (a) to (b) to perform the adjustment.

(a) Enter setting mode [08]. Change the values for codes [2514/2515/2546] to adjust the developer bias

output value.

* The value to use varies depending on the paper type and color to adjust. Check the code to use in

accordance with the following "Code" list, and refer to the "Value" list to select a proper value.

In the Full color mode

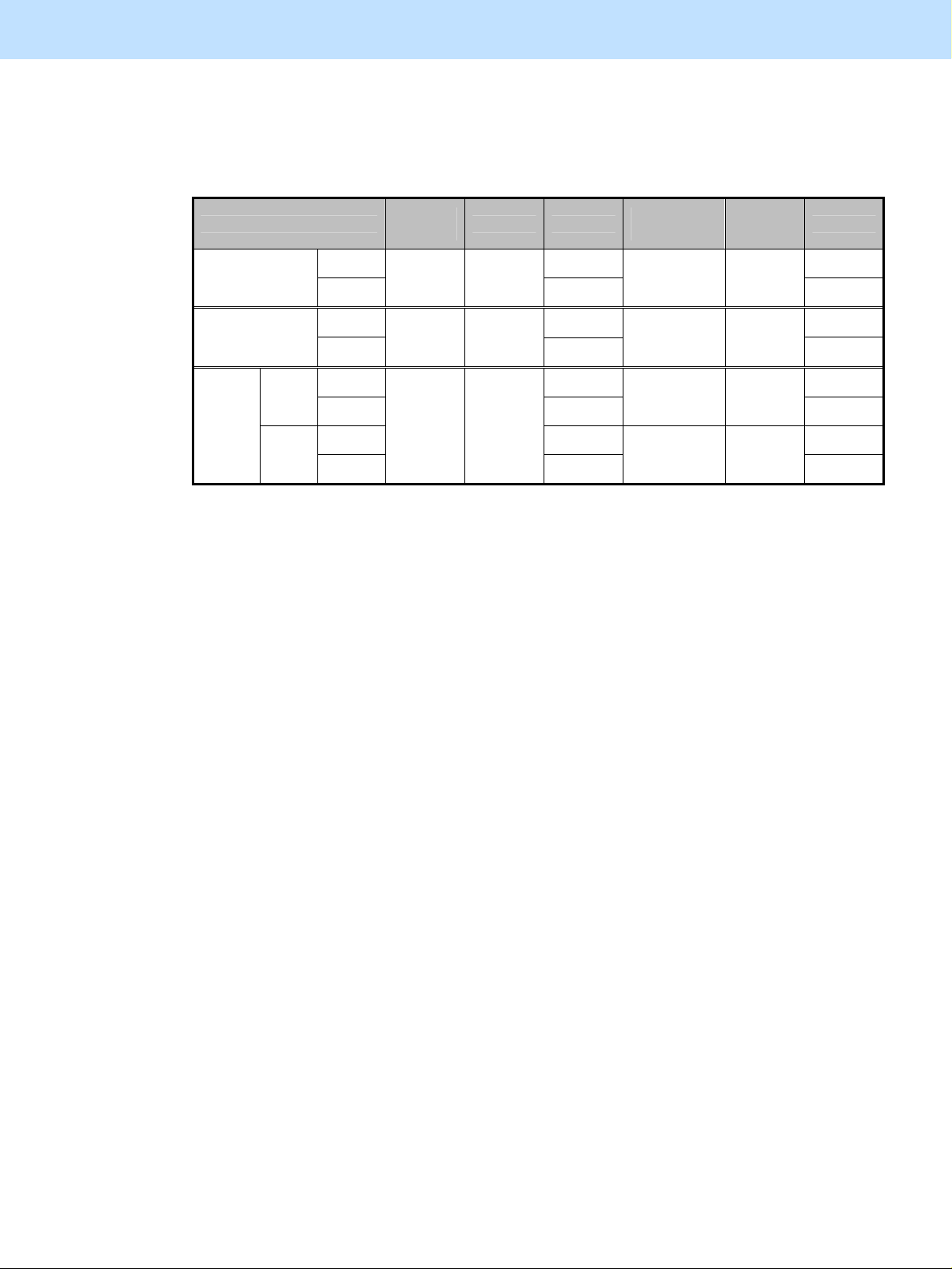

Paper type Color to adjust [08] code Subcode

Thick 1, 2

Full color

Thick 3, 4

Special 1, 2

Y (yellow) 0

M (magenta) 1

C (cyan) 2

08-2514

K (black)

Y (yellow) 0

M (magenta) 1

C (cyan) 2

08-2546

K (black)

3

3

In the Black mode

Paper type Color to adjust [08] code Subcode

Plain paper 1, 2 K (single color) 08-2515 * ---

K (single color: When thick

Black

Thick 1 to 4

paper is used in the Black

mode)

08-2514 3

K (single color: When

Special 1, 2

special paper is used in the

08-2546 3

Black mode)

* 08-2515 is available for e-STUDIO6530C only.

* The table below shows you the acceptable paper weight for the paper type.

Paper type Acceptable paper weight

Thick 1 106 to 163 g/m² Max. 60 lb. Cover

Full color /

Black

Thick 2 164 to 209 g/m² Max. 110 lb. Index

Thick 3 210 to 256 g/m² Max. 140 lb. Index

Thick 4 257 to 300 g/m² Max. 110 lb. Cover

Special 1 Water-resistant paper (CoLaCa) Full color /

Black

Special 2 Glossy paper (Eco-crystal)

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-6

Page 17

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

Code setting values

Value

Correction value for developer bias

output

0 Value automatically set −80 Light

1 Value automatically set −60

2 Value automatically set −40

3 Value automatically set −20

4 Value automatically set −10

5 Value automatically set

6 Value automatically set +10 Default

7 Value automatically set +20

8 Value automatically set +40

9 Value automatically set +60

10 Value automatically set +80 Dark

* Decreasing the value will make the solid colored area become lighter (decrease the amount of toner

on the solid colored area). On the other hand, increasing the value will make the solid colored area

become darker (increase the amount of toner on the area).

(b) Enter adjustment mode [05], select code [396], and then press the [START] button.

After the image quality control is finished, perform printing to check the image quality of the solid

colored area.

* The changed setting values for 08-2514/2515/2546 will be effective for the image printed

immediately after the change. When these values are changed, performing image quality control

with 05-396 is recommended.

Repeat procedures (a) to (b) as required in order to change the setting value so that the solid colored area

becomes your desired density.

Since the density of a gradation area (halftone), such as a photograph, is adjusted as well as that of a solid

colored image, follow the procedure below.

(2) Perform automatic calibration for each type of paper whose density has been adjusted by means of the

Density of the solid colored

area

↑

↑

↑

↑

↑

↓

↓

↓

following flowchart.

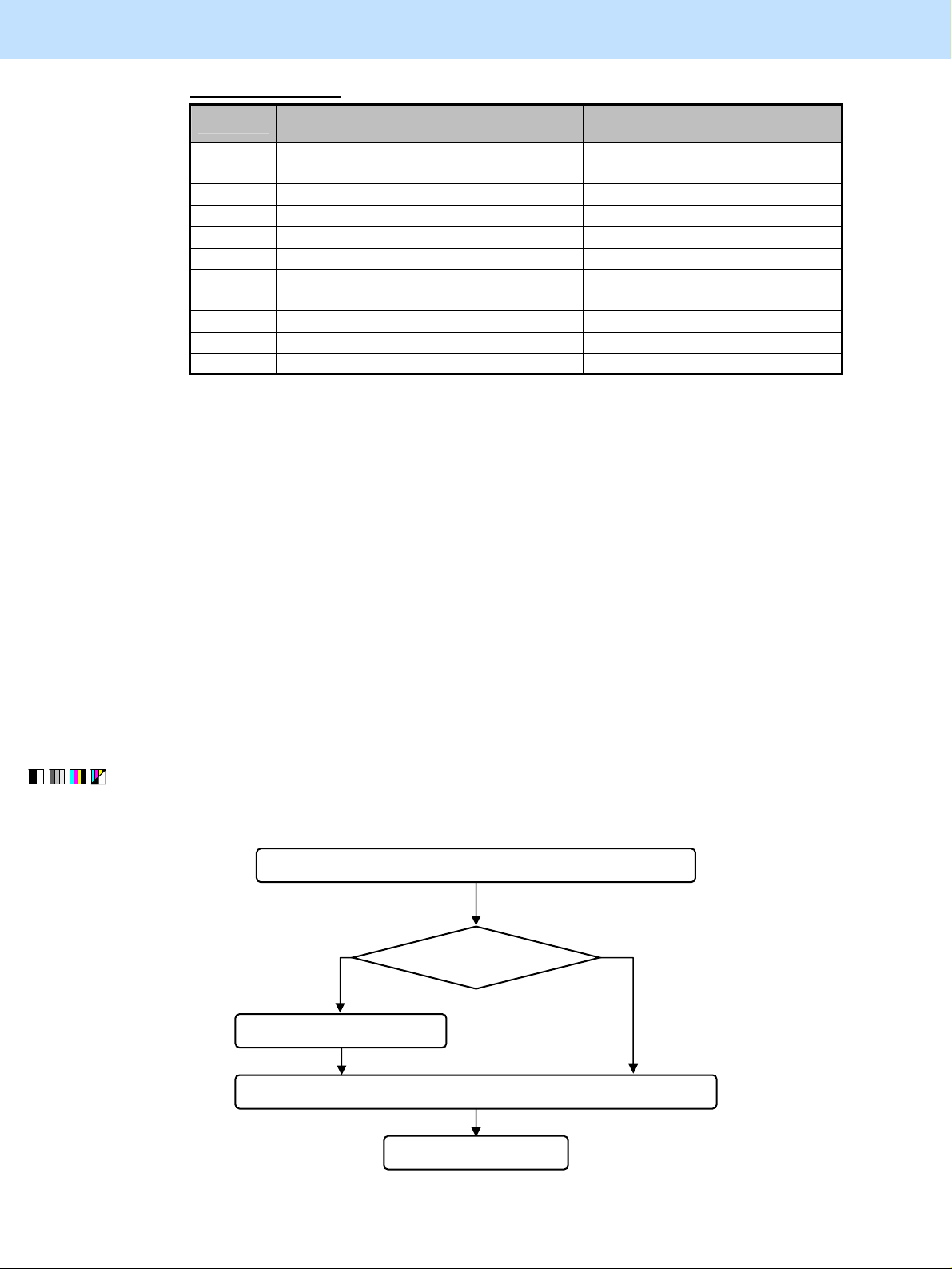

* This flowchart is common for the Full color and Black modes.

Start (Offsetting correction of contrast potential has been set.)

0: No automatic

calibration for each

Value for 08-9059

1: Automatic calibration

for each paper type

paper type

Set "1" for code 08-9059.

Perform automatic calibration

Finish

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-7

Page 18

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

<Hint> Automatic calibration

In paper types whose density has been adjusted, automatic calibration is performed for

all MFP modes in the following table. However, automatic calibration for each paper

type can be performed separately by changing the value of 08-9059 from "0" (default) to

"1". Automatic calibration only for paper types whose density has been adjusted can also

be performed; however, it is recommended to perform it for other paper types as well.

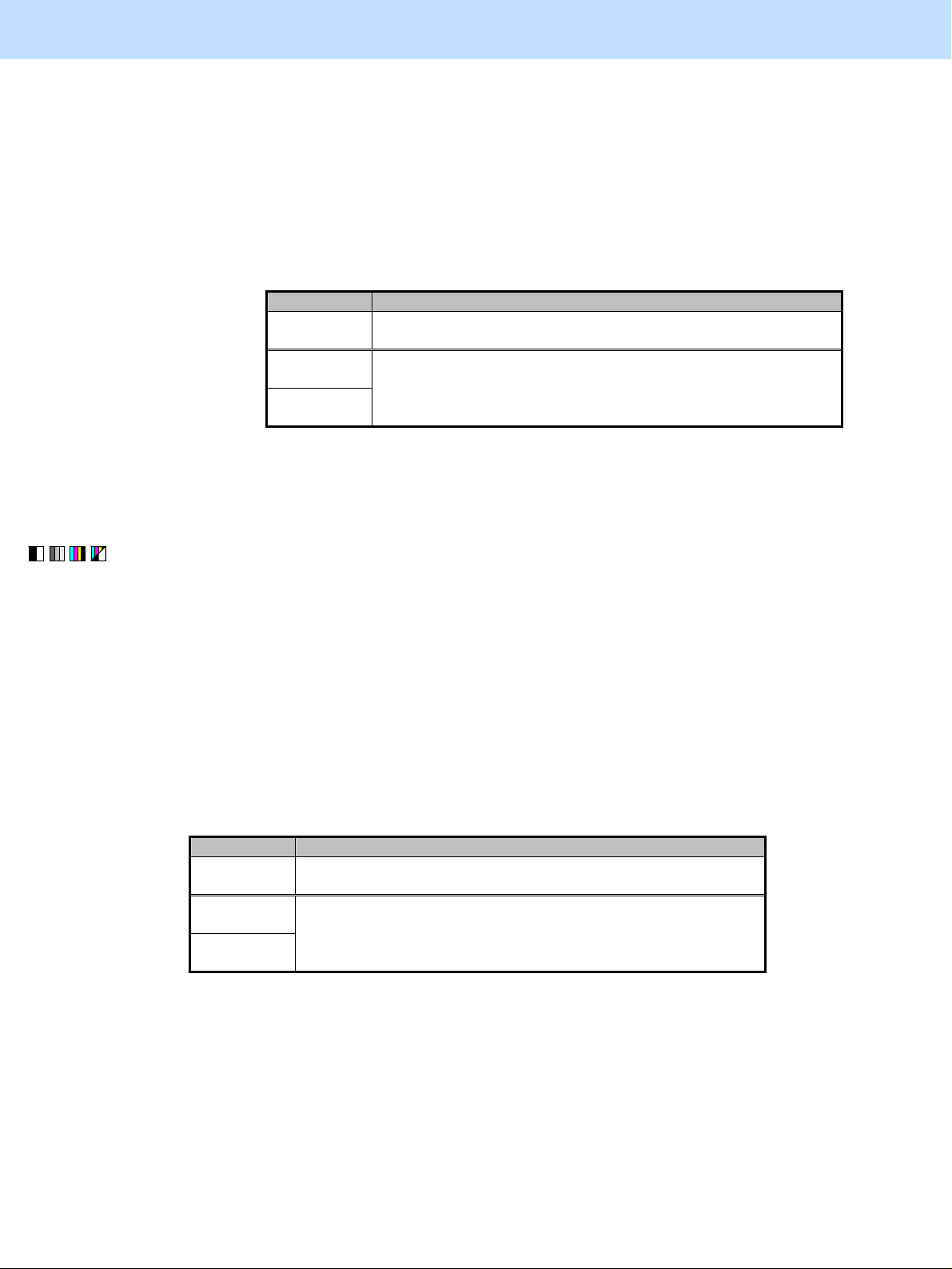

MFP mode How to perform automatic calibration

Copy

Print

(600dpi)

Print

(1200dpi)

After automatic calibration, perform printing and check the image quality.

Perform step (1) referring to "2.13 To Obtain a Good Color Balance on

Thick Paper". Perform step (2) and later if required.

Perform step (2) referring to "3.2 To Maintain a Steady Color Balance on

Thick Paper or Special Paper".

If further image quality adjustments are necessary, perform the next step.

(3) Check the life of the consumables (particularly the drum and transfer belt unit) and replace them, if

necessary.

• When replacing any consumable, use steps (a) to (b).

(a) Enter the PM support mode. Reset the counter corresponding to the replaced consumable to "0."

* For further information regarding the PM support mode, refer to the Service Manual.

Be sure to reset the counter. Otherwise, it may cause a loss in performance, including degradation

in the image quality and a reduction in the life of the consumables.

(b) Perform automatic calibration.

* Be sure to perform automatic calibration not only with the paper types adjusted in step (1) and (2),

but also all paper types. Refer to the following table for adjustment.

MFP mode How to perform automatic calibration

Copy

Perform step (1) referring to "To Obtain a Good Color Balance on

Thick Paper". Perform step (2) if required.

Print

(600dpi)

Print

Perform step (2) referring to "To Maintain a Steady Color Balance on

Thick Paper or Special Paper".

(1200dpi)

* After replacing any consumable, remember to reset the counter corresponding to it to "0." Otherwise, it

may cause a loss in MFP performance, including degradation in the image quality and a reduction in the

life of the consumables.

* While replacing any consumable, also check the slit glass in the laser optical unit, and thoroughly clean it,

if it is soiled.

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-8

Page 19

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

Caution after the adjustment

• The adjustment may possibly cause an increase in the amount of toner consumed, scattering of the toner,

diminished photo images or gradations (less accurate reproducibility of halftones), extremely dark images

(decreased resolving power), extremely light images (faint thin lines), and shorten the life of the consumables.

Therefore, carefully perform the adjustment, while checking the copy or print image.

• No effect of the adjustment may appear, depending on the operating environment of the MFP. Therefore,

carefully perform the adjustment, while checking the copy or print image.

Remarks

• The effect of the adjustment may vary, depending on the usage pattern of the consumables, such as the

developer material and drum, and the operating environment of the MFP.

• When replacing any consumable, refer to the relevant information in the Service Manual and Service Handbook.

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-9

Page 20

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

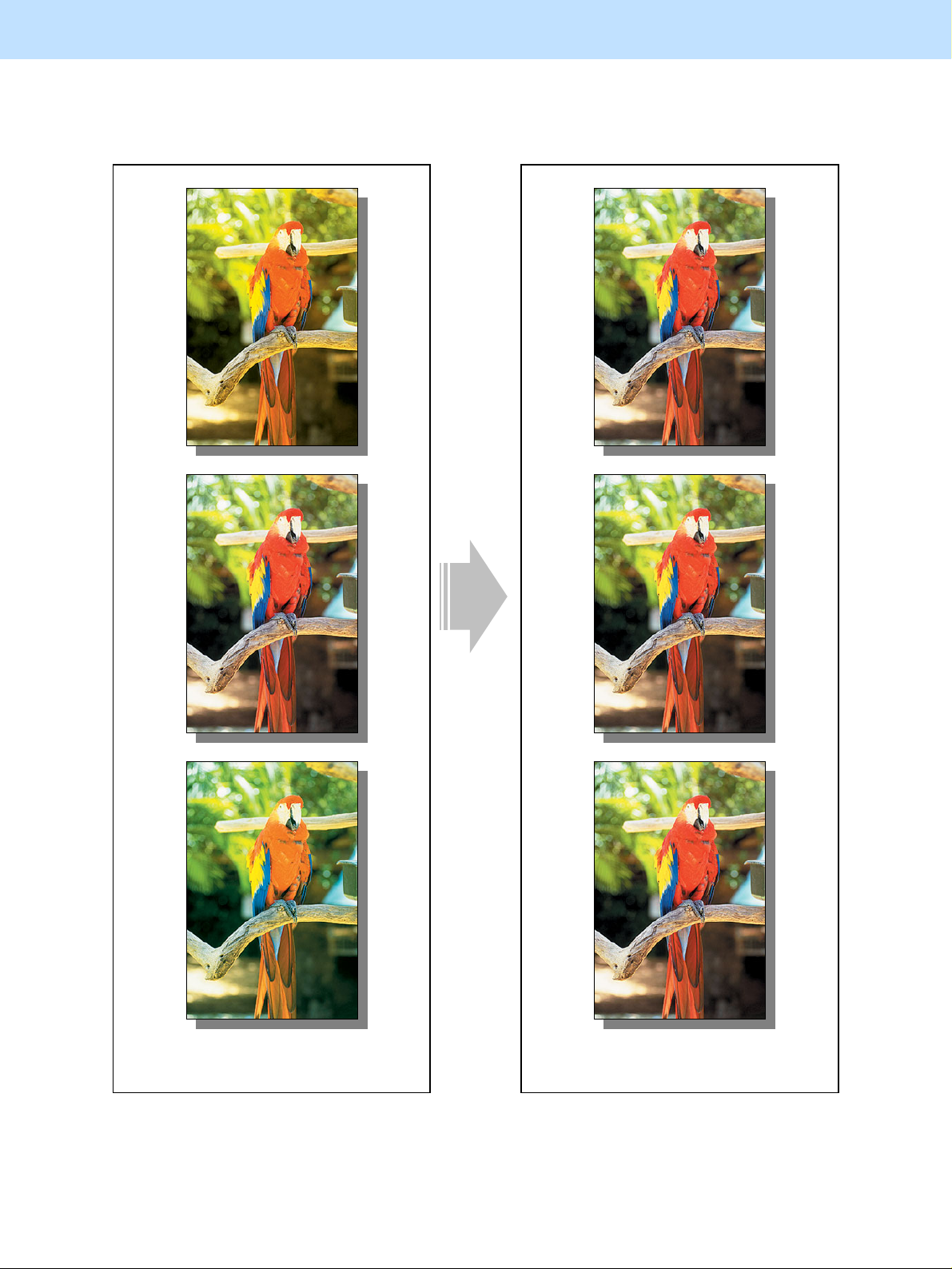

1.3 To Achieve the Image Quality Most Suitable for the Paper Used

(To eliminate blur and graininess from an image)

Before the adjustment After the adjustment

The image looks grained, depending on the

type of paper.

Explanation

The image sometimes looks slightly blurred or grained on the copy or printout, depending on the type of paper

used. Adjust the transfer roller bias output and the fuser temperature, in order to achieve the image quality most

suitable for the paper used.

Procedures

* All the steps in the adjustment must be performed by the service technician. The procedure to be followed

differs depending on the purpose as follows:

• To adjust halftone image: Go to step (1)

• To adjust images on the high-density area (only when recycled paper is used): Go to step

(1) Enter adjustment mode [05]. Change the values for codes [2934 to 3937] to adjust the transfer (2nd

transfer) roller bias output.

(Adjust the offset voltage of transfer roller bias so as to optimize the halftones.)

A clear image quality, most suitable for a type

of paper used, is obtained.

• The code to use varies depending on the paper type. Adjust the value for [05] code corresponding to the

paper type for which you would like to improve the image quality. Set the value within a range of "2" to

"8" to optimize the halftones.

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-10

Page 21

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

Paper type [05] code Subcode

Recommended

value

Plain paper 0

Thick 1 1

Thick 2 2

Thick 3 3

Front

OHP 4

05-2934

2 to 8 0 to 10 5

Special 1 5

Special 2 6

Full color

Recycled paper

Thick 4

Plain paper 0

7

8

Thick 1 1

Thick 2 2

Thick 3 3

Back

OHP 4

05-2935

2 to 8 0 to 10 5

Special 1 5

Special 2 6

Recycled paper

Thick 4

7

8

Plain paper 0

Thick 1 1

Thick 2 2

Thick 3 3

Front

OHP 4

05-2936

2 to 8 0 to 10 5

Special 1 5

Special 2 6

Black

Recycled paper

Thick 4

Plain paper 0

7

8

Thick 1 1

Thick 2 2

Thick 3 3

Back

OHP 4

05-2937

2 to 8 0 to 10 5

Special 1 5

Special 2 6

Recycled paper

Thick 4

7

8

* "Front" refers to the printed side in the simplex mode or the side that is delivered facing downwards in the duplex

mode.

"Back" refers to the printed side that is delivered facing upwards in the duplex mode.

* The table below shows you the acceptable paper weight for the paper type.

Paper type Acceptable paper weight

Plain paper 64 to 105 g/m² 16 to 20 lb. Bond

Thick 1 106 to 163 g/m² Max. 60 lb. Cover

Thick 2 164 to 209 g/m² Max. 110 lb. Index

Thick 3 210 to 256 g/m² Max. 140 lb. Index

Thick 4 257 to 300 g/m² Max. 110 lb. Cover

• After adjusting the transfer roller bias output, perform automatic calibration.

* For further information regarding the procedures, refer to procedure (1) in 1.1 To Obtain a Darker Image.

Acceptable

value range

Default

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-11

Page 22

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

<Hint> The transfer voltage increases as the set value is increased. It is usually desirable that the set

value be decreased to obtain a clearly highlighted area.

After performing the adjustment, print and check the image quality.

If further image quality adjustment is necessary, go to step (3).

(2) If the image on the high-density area looks grained on plain paper other than the TOSHIBA-recommended

one is used, select "recycled paper" as a paper type.

* To select the paper type, refer to the Operator’s Manual for Copying Guide.

• If fine adjustment of image quality in the recycled paper mode is required in accordance with the paper

type, follow the steps from (a) to (b) below.

(a) Enter the adjustment mode [05]. Change the value of the codes [2934] to [2937] to adjust (2nd)

transfer bias output. (In this step the transfer roller bias offset voltage is adjusted to print the high-

density area or the halftone area of the image most clearly.)

Full color

Black

Paper type [05] code

Front

Back

Front

Back

Recycled

paper

Recycled

paper

Recycled

paper

Recycled

paper

05-2934 7 2 to 8 0 to 10 5

05-2935 7 2 to 8 0 to 10 5

05-2936 7 2 to 8 0 to 10 5

05-2937 7 2 to 8 0 to 10 5

Subco

de

Recom

mended

value

Accepta

ble value

range

Default

* "Front" refers to the printed side in the simplex mode or the side that is delivered facing

downwards in the duplex mode.

"Back" refers to the printed side that is delivered facing upwards in the duplex mode.

• After adjusting the transfer roller bias output, perform automatic calibration.

* Refer to step (1) in "1.1 To Obtain a Darker Image".

<Hint> The larger the setting value is, the more the transfer voltage increases. It is usually

recommended that the set value be increased when you print on thick paper or paper with

asperities on its surface. On the other hand, the set value should be decreased when you print on

thin paper.

After setting the value, print and check the image quality.

If further image quality adjustment is necessary, go to step (b).

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-12

Page 23

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

(b) Enter the setting mode [08]. Change the value of the codes [5293/5294/5296] to adjust fusing

temperature in the recycled paper mode. (In this step fusing temperature is adjusted to print the

high-density area of the image most clearly.)

Accepta

ble value

range

Default

8

Adjustment

Center heater

Black

Color

Paper

type

Recycled

paper

[08] code Subcode

0 10

08-5293

1

Recommen

ded value

7 to 10 0 to 16

Side heater

Pressure

roller

Center

Side

Black

Color

Black

Color

Black

Recycled

paper

Recycled

paper

08-5294

08-5296

Color

0 10

7 to 10 0 to 16

1

0 3

1 to 6 0 to 16

1

2 3

3

1 to 6 0 to 16

• After adjusting the fusing temperature, perform automatic calibration.

* Refer to step (1) in "1.1 To Obtain a Darker Image".

<Hint> The smaller the setting value, the lower the fusing temperature becomes. It is usually

recommended that the set value be decreased in order to suppress roughness on the high-density

area of the image. Adjust the value within the range of the recommended values while checking

the image carefully because if it is too small, insufficient fusing may occur.

Since temperatures on the long side of the paper cannot be kept in a proper balance, the same

value must be set for the [08] codes [5293] and [5294] unless otherwise required so.

After setting the value, print and check the image quality.

If further image quality adjustment is necessary, go to step (3).

8

1

1

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-13

Page 24

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

(3) Check the life of the consumables (particularly the drum and transfer belt unit) and replace them, if

necessary.

• When replacing any consumable, use steps (a) to (b).

(a) Enter the PM support mode. Reset the counter corresponding to the replaced consumable part to "0."

* For further information regarding the PM support mode, refer to the Service Manual.

(b) Perform automatic calibration.

* For further information regarding the procedures, refer to procedure (1) in 1.1 To Obtain a Darker

Image.

* After replacing any consumable, remember to reset the counter by making it correspond to "0." Otherwise,

it may cause a loss in MFP performance, including degradation in the image quality and a reduction in the

life of the consumables.

* While replacing any consumable, also check the slit glass in the laser optical unit, and thoroughly clean it,

if it is soiled.

Caution after the adjustment

After the fusing temperature was adjusted in step (2) above, printing interruption may occur due to improper

fusing temperature. Therefore adjust the value carefully. If you want to change the conditions for printing

interruption, change the value of the [08] code [5409] (abnormality process starting temperature setting /

recycled paper). For the setting values, refer to the Service Manual.

Remarks

• Enter the value mentioned in the procedures or one within the recommended value range for the adjustment.

Otherwise, it may cause a loss in MFP performance, including degradation in the image quality and a reduction

in the life of the consumables.

• The desired image quality may not be obtained, depending on the type of paper used. In this case, use the

recommended paper and then print or adjust the image quality.

• If an image problem occurs when you use the other paper type, temporarily set the values of the [08] codes

[2934] to [2937] (bias offset) and [5293] to [5296] (fusing temperature during printing) back to the default ones.

Then perform the adjustment again.

• When replacing any consumable, refer to the relevant information in the Service Manual and Service Handbook.

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-14

Page 25

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

1.4

To Minimize Variations in the Image Quality under the Operating Conditions

(To optimally program image quality control)

Before the adjustment After the adjustment

The image contrast varies, depending on the

date and time when copying or printing is

performed or the type of job.

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

The image quality is constantly maintained.

1-15

Page 26

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

Explanation

The image contrast may vary, depending on the date and time when copying or printing is performed or the type

of copy/print job. To constantly maintain image quality, shorten the waiting period until image quality control is

performed.

Procedures

* The service technician must perform the adjustment in accordance with the procedures below.

(1) Enter setting mode [08]. Change the value for code [570], [571], [572] or [2508] to specify the best interval

during which image quality control should be performed, according to use of the MFP.

The MFP is installed in a place where the temperature and humidity vary widely:

Make adjustment by either of the following procedures (A) or (B).

(a) Set "1" (value × 5%R.H.) for code 08-570 to increase the frequency of image quality control, in response

to a change in humidity.

* Image quality control will be performed, when the relative humidity changes in accordance with the

specified difference from the previous image quality control. If the difference in the relative humidity

exceeds the specified value, image quality control is performed first. Then a copy or print job will be

performed.

Value for 08-570 Difference in relative humidity

1 5%R.H.

2 10%R.H. (default)

(b) Set "5" or "3" for code 08-2508 to increase the frequency of image quality control, in response to a

change in humidity.

* Image quality control will be performed, when the drum temperature changes in accordance with the

difference from the previous image quality control. If the difference in the drum temperature exceeds

the specified value after a print job is performed, image quality control is performed.

Value for 08-2508 Difference in drum temperature

3 3°C

5 5°C

7 7°C (default)

• After setting the value for code 08-571 by procedure (a) or (b), forcibly perform image quality control, as

follows:

Enter adjustment mode [05], select code [396], and then press the [START] button.

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-16

Page 27

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

To Have Uniform Variations in the Image Quality after Return from the Auto Power Save Mode:

Change the value of the [08] code [571] to change the conditions for starting image quality control (shorten

the period of time the MFP is left unused) after the MFP was recovered from the auto power save mode, so

that the image quality control will be easily performed.

Value for

08-571

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

<Note> Do not disable the Auto shut off mode timer setting ("0" is set for 08-206) while the Auto

Period of time the MFP is left unused before starting image quality control

3 minutes or longer (image quality control is performed before the paused job is

resumed)

5 minutes or longer (image quality control is performed before the paused job is

resumed)

7 minutes or longer (image quality control is performed before the paused job is

resumed)

10 minutes or longer (image quality control is performed before the paused job is

resumed)

15 minutes or longer (image quality control is performed before the paused job is

resumed)

20 minutes or longer (image quality control is performed before the paused job is

resumed)

30 minutes or longer (image quality control is performed before the paused job is

resumed)

45 minutes or longer (image quality control is performed before the paused job is

resumed)

60 minutes or longer (image quality control is performed before the paused job is

resumed)

90 minutes or longer (image quality control is performed before the paused job is

resumed)

120 minutes or longer (image quality control is performed before the paused job is

resumed)

150 minutes or longer (default value - image quality control is performed before the

paused job is resumed)

180 minutes or longer (image quality control is performed before the paused job is

resumed)

240 minutes or longer (image quality control is performed before the paused job is

resumed)

300 minutes or longer (image quality control is performed before the paused job is

resumed)

360 minutes or longer (image quality control is performed before the paused job is

resumed)

power save timer setting is set to invalid ("0" is set for 08-205). If both settings are set to

invalid, this equipment does not enter the energy saving mode so it is always in the ready

status. Due to this, image quality control according to the period of time the MFP is left

unused is not performed regardless of the setting value of 08-571.

• After setting the value for code 08-571, forcibly perform image quality control, as follows:

Enter adjustment mode [05], select code [396], and then press the [START] button.

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-17

Page 28

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

A large number of sheets are printed (hundreds of copies or more per day) and the image

quality needs to be constantly maintained:

Set the value for code 08-572 within a range of "1" to "9" (Value × 100 sheets) to reduce the accumulated

number of printed sheets. It will determine the interval until the next image quality control is performed.

* After a copy or print job is completed, if the accumulated number of printed sheets exceeds the specified

value, image quality control will be performed.

Value for 08-572

1 to 9 100 to 900 sheets

10 1,000 sheets (default)

• After setting the value for code 08-572, forcibly perform image quality control, as follows:

Enter adjustment mode [05], select code [396], and then press the [START] button.

After performing the adjustment, print and check the image quality.

If further image quality adjustments are still necessary, use the next procedure.

(2) The image density or color during continuous printing on the plain paper can be stabilized by changing the

fusing related settings by means of the following procedures.

Procedures

Follow the procedure below.

(a) Change each value of the [08] codes [411-0] "Temperature of the fuser unit at ready status (Heat

roller) – normal temperature" and [407-0] "fusing temperature at ready status (side / fuser belt –

normal temperature)" from the default value (10: 170°C) to "9" in order to lower the temperature by

5°C. The same value must be set for the [08] codes [411-0] and [407-0] unless otherwise required.

(b) Change the value of the [08] code [5241-1] "fusing temperature correction at ready status (pressure

roller – normal temperature)" from the default value (2: 0°C) to "0" in order to lower the temperature

by 10°C. Change each value of the [08] codes [2124-0] "fusing temperature at ready status (center /

pressure roller – normal temperature)" and [5236-0] "fusing temperature at ready status (side /

pressure roller – normal temperature)" from the default value (4: 140°C) to "2" in order to lower the

temperature by 10°C. The same value must be set for the [08] codes [2124-0] and [5236-0] unless

otherwise required.

<Notes>

• Confirm if the firmware version is the latest one before the setting. If not, update it to the latest one.

• After these settings, the machine may go into the "wait" status since the fusing temperature can not follow

depending on the usage conditions, such as low temperature, thick paper, just recovering after warming up, etc.

• After these settings, the fusing performance may degrade depending on the usage conditions, such as low

temperature, thick paper, just recovering after warming up, etc. In such a case, return the setting to default.

• These settings extend the First Print Out Time by the period of time required for pre-running of the first

printing.

• These settings always perform the pre-running for the first printing of each job by the time required for pre-

running of the first print. This results in reducing the life of consumables.

Accumulated number of printed sheets before image quality control is performed

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-18

Page 29

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

(3) Use the thick paper mode when you print on plain paper.

• If the thick paper mode is used, printing decelerates but image quality becomes more stable because

differences in color or temperatures during continuous printing will be reduced.

• Set the thick paper mode following steps (a) to (i) below.

(a) Press the [USER FUNCTIONS] button on the Control Panel to enter the "User Functions" menu.

(b) Press the [USER] tab.

(c) Press [DRAWER] in the USER menu.

(d) Select a drawer that you want to set for thick paper mode and paper size.

(e) Press [PAPER TYPE].

(f) Press [THICK 1].

(g) Enter the adjustment mode [05]. Then select the subcode "1" for the code [2934] and change the

setting value to "3".

• Change the level of transfer roller bias offset in the color mode, the front side of paper.

* Check how the copy image changes carefully. The setting value may be changed to "4" or "2" if

required.

(h) Place paper to be used on the drawer that you selected in step (d) above.

(i) Perform automatic calibration.

* Refer to step (1) in "1.1 To Obtain a Darker Image".

After setting the value, print and check the image quality.

If further image quality adjustment is necessary, go to the next step.

(4) Check the life of the consumables (particularly the drum and transfer belt unit) and replace them, if

necessary.

• When replacing any consumable, use steps (a) to (b).

(a) Enter the PM support mode. Reset the counter corresponding to the replaced consumable to "0."

* For further information regarding the PM support mode, refer to the Service Handbook.

(b) Perform automatic calibration.

* For further information regarding the procedures, refer to procedure (1) in 1.1 To Obtain a Darker

Image.

* After replacing any consumable, remember to reset the counter corresponding to it to "0." Otherwise, it

may cause a loss in MFP performance, including degradation in the image quality and a reduction in the

life of the consumables.

* While replacing any consumable, also check the slit glass in the laser optical unit, and thoroughly clean it,

if it is soiled.

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-19

Page 30

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

Caution after the adjustment

• The adjustment may possibly slow down the copying or printing speed, extend the warm-up time when the

MFP is returned from the auto power save mode, and shorten the life of the consumables, because of an

increase in the number of times image quality control is performed. Therefore, carefully perform the

adjustment, while checking the copy or print image.

• Note the following when you print in thick paper mode in step (3):

• Printing speed decelerates to 17.5 sheets per minute (A4/LT) after the adjustment.

• The thick paper mode cannot be set for the LCF (Large Capacity Feeder, optional). Therefore the

maximum number of sheets acceptable for continuous printing should be the one for the drawer.

However in the copying mode, you can set the thick paper mode to more than one drawer and copy

more paper continuously with the automatic drawer change function.

• The density level of the halftone image may differ from that of the plain paper mode after the

adjustment.

• The PM counter value increases by 2 counts for 1 sheet of thick paper.

Remarks

• Enter the value mentioned in the procedures or one within the recommended value range for the adjustment.

Otherwise, it may cause a loss in MFP performance, including slowdown in the copying or printing speed.

• When replacing any consumable, refer to the relevant information in the Service Manual and Service Handbook.

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-20

Page 31

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

1.5 To Correct Out-of-Registration Colors

Before the adjustment After the adjustment

Paper feeding direction Paper feeding direction

The text and background are misaligned or out

of registration.

Text is aligned with the background and a clear

copy/print image is obtained.

Explanation

Colors of text or a thin line are sometimes printed out of alignment. Perform color registration control, in order

to print or copy without out-of-registration colors.

Procedures

* The service technician must perform the adjustment in accordance with the procedure below.

(1) Make sure that no out-of-registration colors are visible on an original.

(2) Check the direction in which colors are misaligned.

* This adjustment is intended to correct misaligned colors due to differences between the paper feeding

speed and rotating speed of the transfer belt. Therefore, it will be effective, only if colors are misaligned in

the paper feeding direction (or the secondary scanning direction). This adjustment cannot improve

misaligned colors in the direction perpendicular to paper feeding (or primary scanning) or in the secondary

scanning direction periodically (partially at regular intervals). Refer to "Troubleshooting for the Image 1)

Color deviation" in the Service Manual.

(3) Enter adjustment mode [05] and print out the test print pattern to correct out-of-registration colors.

(a) Enter adjustment mode [05], select code [4719], and then press the [START] button.

• Registration control will be forcibly performed.

(b) Enter code [104] corresponding to a desired test print pattern. Press the [FAX] button.

• Paper is fed from the drawer to print out a test print pattern.

Code Test print pattern Paper size No. of copies

104

Test print pattern for identifying

out-of-registration colors

A3/LD 2

* Jot down the "paper feeding direction" on the printed test print pattern beforehand. This facilitates

identifying out-of-registration colors in the subsequent adjustment. Use only the second page of

the test print pattern.

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-21

Page 32

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

(4) Check the second page of the printed test print pattern to identify a pattern for the out-of-registration colors.

* There are 2 patterns for the out-of-registration colors. Check which pattern the out-of-registration colors to

adjust on the body are included.

Pattern A for out-of-registration colors

Patch eliminated at

the leading edge

Page number

Page 2

Paper feeding direction

Black belt at the leading edge in the paper feeding direction

Patch eliminated

trailing edge

Pattern B for out-of-registration colors

Paper feeding speed

slower than transfer belt

rotating speed

Patch eliminated at

the trailing edge

Patch eliminated at

the leading edge

Paper feeding speed

faster than transfer belt

Page 2

Paper feeding direction

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-22

rotating speed

Page 33

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

(5) Finely adjust the rotating speed of the registration motor, in accordance with a pattern for the out-of-

registration colors.

• Use steps (a) to (b) to perform the adjustment.

(a) Enter adjustment mode [05]. Select code [483]. Finely adjust the rotating speed of the registration

motor.

• Adjust the values in accordance with a pattern for the out-of-registration colors as shown in the

table below.

Pattern for

out-of-

registration

[05] code Subcode Recommended value

colors

Pattern A

Pattern B

05-483 0

(Set a value smaller than 128)

(Set a value larger than 128)

123 to 127

129 to 132

(b) After performing registration control, print out the test print pattern to check whether the misaligned

colors have been improved.

* For further information regarding the adjustment procedures, refer to procedures (3) and (4).

* Repeatedly use procedures (3) to (5) as necessary, to select a proper value.

<Hint> When subcode "0" is adjusted for code 05-483, the correlation between the paper feeding speed

Acceptable

value range

0 to 255 128

Default

and rotating speed of the transfer belt will be corrected in every paper mode. However, when

colors are misaligned on an image printed in the thick paper mode after the adjustment for

subcode "0", adjust subcode "3" (during deceleration in the thick paper mode).

* For subcode "3," use the steps and recommended values for subcode "0."

* Paper for printing a test print pattern will only be fed from the drawer. Load the desired

number of sheets of thick paper in the drawer, in order to print the test print pattern on thick

paper.

* Adjust subcode "0" and then subcode "3," in order to adjust only misaligned colors in the thick

paper mode.

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-23

Page 34

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

Caution after the adjustment

Nothing in particular.

Remarks

• Enter a value within the recommended value range mentioned in the procedures. Otherwise, it may cause a

loss in MFP performance, including degradation in the image quality.

•Out-of-registration colors cannot always be perfectly corrected; this depends on the type of text or lines to print.

• Also, refer to the relevant information in the Service Manual for further information regarding color

registration control procedures.

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

1-24

Page 35

2. Copier-specific Adjustments

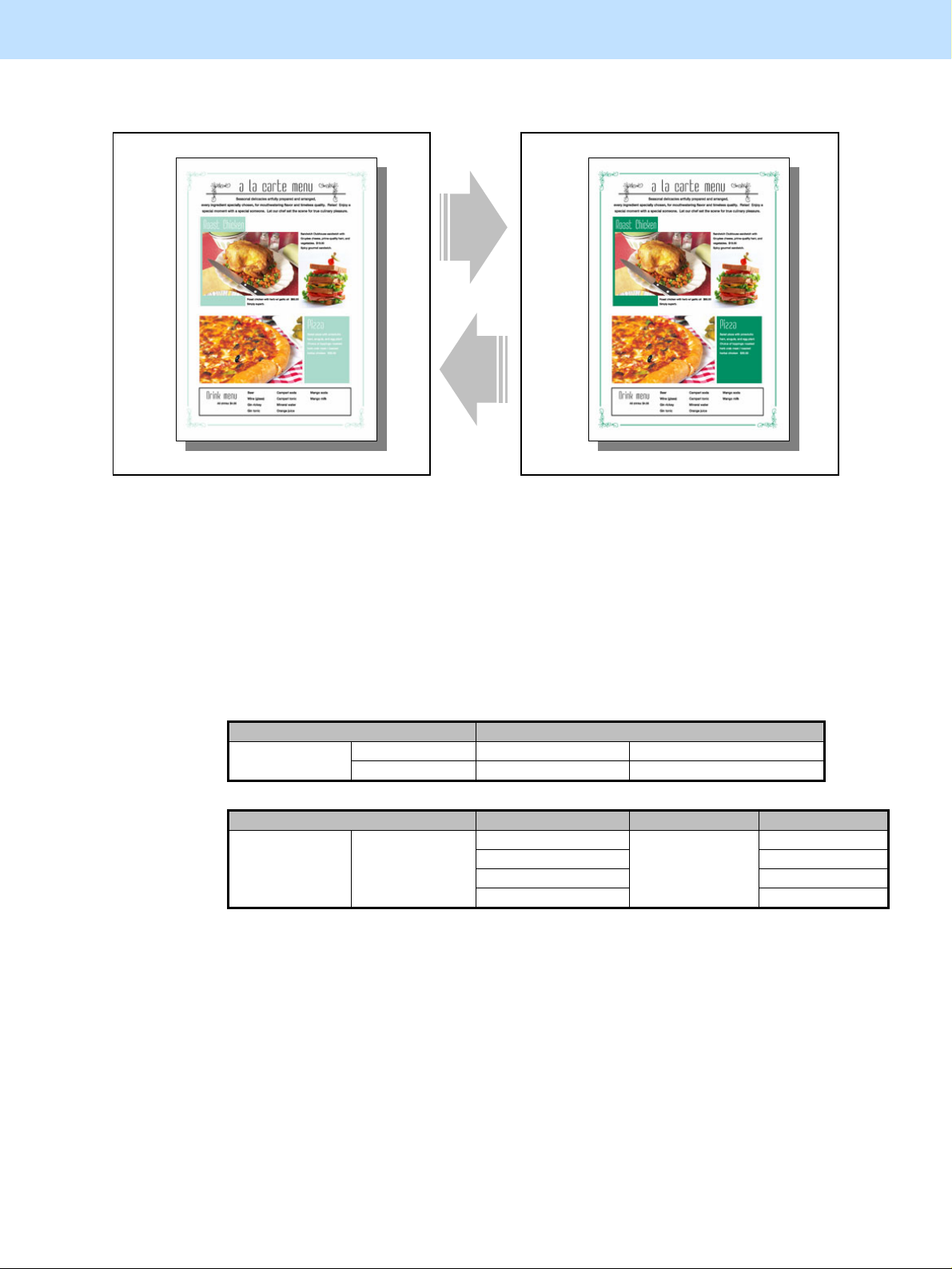

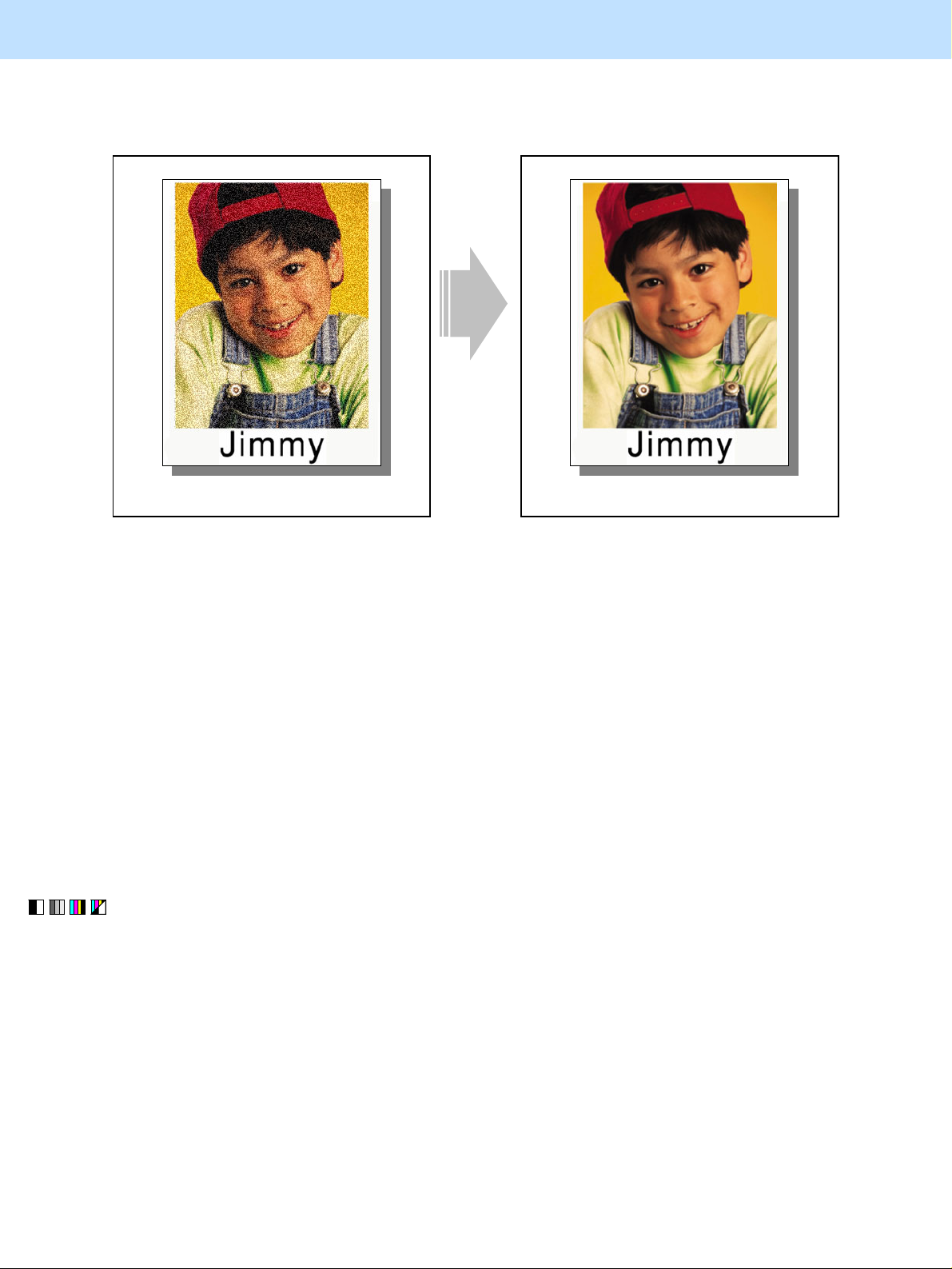

2.1 To Copy Text Clearly (To eliminate faint, smudged or blurred text)

Before the adjustment After the adjustment

When a light print image is copied, the text

looks blurred.

Explanation

Perform image processing, in order to obtain a sharp and dark copy image when copying an original containing

light text and graphic images, or a light copy image when copying an original containing a highly colored text

The graphic image and text look darker and

sharper.

and copy image.

Procedures

* The procedure to use varies, depending on whether to adjust the copy image quality in the Black mode, Full

color mode or Auto color mode. Refer to the procedure corresponding to the particular user’s request.

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

2-1

Page 36

2. Copier-specific Adjustments

2.1.1 To Adjust the Copy Image Quality in the Black Mode

* You can start with any of the procedures. But it is recommended to perform the procedures in order, as listed

below. You can use one procedure in conjunction with another. But if this changes the image quality more

than required or loses the effectiveness of the adjustment, restore the settings made in the previously used

procedure to the original ones. Then use other procedures.

* Both the service technician and the user can use procedures (1), (2) and (4).

* Only the service technician must use procedures (3), (5), (6) and (7).

(1) Press the [BASIC] button on the Control Panel. Press the [ ] button to increase the copy density.

After increasing the copy density, copy and check the copy image quality.

With the copy density set to the maximum, if further image quality adjustments are still necessary, use the

next procedure.

(2) Press the [IMAGE] button on the Control Panel. Press the [SHARPNESS] button.

Press the [SHARP] button to increase the sharpness intensity.

After increasing the sharpness intensity, copy and check the copy image quality.

With the sharpness intensity set to the maximum, if further image quality adjustments are still necessary, the

service technician must use the following procedures.

(3) Enter adjustment mode [05]. Increase the values for codes [604] to [606], [1757] and [7807] to [7809] to

make the copied text darker (sharpness level increases).

• The code to use varies depending on the original mode (Text/Photo, Text or Photo). Adjust the value for

[05] code corresponding to the original mode in which you would like to improve the image quality and set

values larger than "128" for codes 05-604/605.

Original mode [05] code

Text / Photo 05-604

Text 05-605

Photo 05-606

Image smoothing 05-7809

ACS / Black

Text/Photo

ACS / Black

Text

ACS / Black

Photo

05-1757

05-7807

05-7808

Recommended

value

Set a value larger than

128.

Acceptable

value range

0 to 255 128

Default

* Setting "0" provides the softest image, while setting "255" provides the sharpest image.

Changing the values for these codes will change the sharpness intensity, when the "Sharpness" indicator in

the "IMAGE" menu is set to the center. Remember that 1 step of the indicator will increase or decrease the

sharpness intensity by 25. If the sharpness intensity of the center value is changed, each step of the indicator

will be changed accordingly. (For instance, if the center value is increased by 25 (sharper), the value of each

step of the indicator will also be increased by 25 (sharper).)

After increasing the sharpness intensity, copy and check the copy image quality.

If further image quality adjustments are still necessary, use the next procedure.

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

2-2

Page 37

2. Copier-specific Adjustments

(4) Press the [BASIC] button on the Control Panel. Select "TEXT" from among the original mode options.

* To have "TEXT" selected from among the original mode options by default, refer to procedure (1) in 2.8

To Eliminate Moiré.

After selecting the Text mode, copy and check the copy image quality.

If further image quality adjustments are still necessary, use the next procedure.

(5) Enter adjustment mode [05]. Decrease the values for codes [648], [649], [925], [7102] and [7103] to make

the text darker (improving faint text or thin lines).

Original mode [05] code

Recommended

value

Acceptable

value range

Default

Text / Photo 05-648

Text 05-649

User custom 05-925

ACS / Black

Text/Photo

ACS / Black

Text

05-7102

05-7103

Set a value smaller

than 2.

0 to 4 2

* Set the value in increments of approximately 1, while checking the copy image until the optimum value is

obtained.

After increasing the copy density, copy and check the copy image quality.

If further image quality adjustments are still necessary, use the next procedure.

(6) Enter adjustment mode [05]. Change the values for codes [590] to [592] and [7956] to [7959] to adjust the

gamma balance in each of medium- and high-density areas.

Original mode [05] code Subcode

Recommended

value

Acceptable

value range

Default

Text / Photo 05-590

Text 05-591

Photo 05-592

Image smoothing 05-7956

ACS / Black

Text/Photo

ACS / Black

Text

ACS / Black

Photo

05-7957

05-7958

05-7959

1/2

Set a value larger

than 128.

0 to 255 128

* Set the value in increments of approximately 20, while checking the copy image until the optimum value is

obtained.

(Please be careful because the gradation (or density) of the medium-density area may exceed that of the

high-density area, depending on the set value.)

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

2-3

Page 38

2. Copier-specific Adjustments

* The subcode varies according to the area where the density is adjusted. Refer to the table below and set

the subcode for the area to be adjusted. The density of light text or a graphic image will vary, if the

medium- or high-density area is mainly adjusted. Setting "0" for the subcode allows you to adjust the low-

density area. But it will not affect the light text or graphic images. Therefore, never change the value for

the low-density area.

Subcode Area where the density is adjusted

1 Medium-density area

2 High-density area

After changing the value, make a copy and check the image quality.

If further image quality adjustments are necessary, reset all the values changed in steps (1) to (6) above to

the default ones and then follow the next step.

(7) Enter setting mode [08]. Change the value for subcode "3" of code [2548] to make the outline of the copied

text thicker and clearer, or thinner and finer.

* This adjustment can be made applicable to all colors by selecting the corresponding subcode. In this step,

however, change the setting value only for subcode "3" to adjust the image quality for the black mode.

Setting item [08] code Subcode Recommended value

Acceptable

range value

To make the outline of text

thicker and clearer:

Potential on printing

white text / Correction

setting (K)

08-2548 3

Set a value smaller than 5.

To make the outline of text

0 to 10 5

thinner and finer:

Set a value larger than 5.

* To check the amount changed with this setting, it is recommended to set the value at "2" or "3" first to

decrease it, and then to set the value at "7" or "8" first to increase it. Then check the copy image and

increase or decrease the value further so that the image will be adjusted finely.

• After changing the value, perform automatic calibration.

* Refer to step (1) in "1.1 To Obtain a Darker Image to perform automatic calibration".

If further adjustments are necessary after performing step (7), you can repeat steps (1) to (6). When

repeating these steps, however, adjust the value while checking the copy image carefully.

Default

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

2-4

Page 39

2. Copier-specific Adjustments

Caution after the adjustment

The adjustment may possibly cause an increase in the amount of toner used, moiré, blurred text (small, dark text

blurred), faint text (fine outlines of text shredded) diminished photo images or gradational images (less accurate

reproducibility of halftones), or in some consumption conditions of consumables, background fogging or a

decrease in the amount of developer material (carrier streaks). Therefore, carefully perform the adjustment while

checking the copy image.

Remarks

• Enter a value within the recommended value range mentioned in the procedures. Otherwise, it may cause a

loss in MFP performance, including degradation in the image quality and a reduction in the life of the

consumables.

• If you perform only step (7) above (changing the setting value of subcode "3" of code [08-2548]) as an image

quality adjustment for the black mode, it may cause an extra increase or decrease in the amount of K toner used

compared with that for the other colors, or it may create a difference in the reproducibility of halftones.

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

2-5

Page 40

2. Copier-specific Adjustments

2.1.2 To Adjust the Copy Image Quality in the Full Color Mode

* The setting value for the Full color mode shall be applied also when the original is judged as the full color

image in the Auto color mode.

* You can start with any of the procedures. But it is recommended to perform the procedures in order, as listed

below. You can use one procedure in conjunction with another. But if this changes the image quality more

than required or loses the effectiveness of the adjustment, restore the settings made in the previously used

procedure to the original ones. Then use other procedures.

* Both the service technician and the user can use procedures (1), (2) and (5).

* Only the service technician must use procedures (3), (4) and (6).

(1) Press the [BASIC] button on the Control Panel. Press the [ ] button to increase the copy density.

After increasing the copy density, copy and check the copy image quality.

With the copy density set to the maximum, if further image quality adjustments are still necessary, use the

next procedure.

(2) Press the [IMAGE] button on the Control Panel. Press the [SHARPNESS] button.

Press the [SHARP] button to increase the sharpness intensity.

After increasing the sharpness intensity, copy and check the copy image quality.

With the sharpness intensity set to the maximum, if further image quality adjustments are still necessary, the

service technician must use the following procedures.

(3) Enter adjustment mode [05]. Increase the values for codes [1737 to 1741] to strengthen the copy density of

text (or increase the sharpness intensity).

• The code to use varies depending on the original mode (Text/Photo, Text, Printed image, Photo or Map).

Adjust the value for [05] code corresponding to the original mode in which you would like to improve the

image quality and set values larger than "128" for codes 05-1737 to 1741.

Original mode [05] code Recommended value Acceptable value range Default

Text/Photo 05-1737

Text 05-1738

Printed image 05-1739

Set a value larger than 128. 0 to 255 128

Photo 05-1740

Map 05-1741

* Setting "0" provides the softest image, while setting "255" provides the sharpest image.

Changing the values for these codes will change the sharpness intensity, when the "Sharpness" indicator in

the "IMAGE" menu is set to the center. Remember that 1 step of the indicator will increase or decrease the

sharpness intensity by 25. If the sharpness intensity of the center value is changed, each step of the indicator

will be changed accordingly. (For instance, if the center value is increased by 25 (sharper), the value of each

step of the indicator will also be increased by 25 (sharper).)

e-STUDIO5520C/6520C/6530C © 2008 TOSHIBA TEC CORPORATION All rights reserved

2-6

Page 41

2. Copier-specific Adjustments

* The values adjusted for the sharpness intensity are shared in the Full color mode with the Printed image