SERVICE MANUAL

(*1), as indicated by the underlined serial number.

Стр. 1 из

1

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\toshiba_32lv17_sm\32LV17

-

...

LCD Color Television

32LV17

Ver. 1.01

This model is classified as a green product

This Service Manual describes replacement parts for the green product. When repairing this

green product, use the part(s) described in this manual and lead-free solder (*2).

For (*1) and (*2), refer to

SOLDER

© TOSHIBA CORPORATION

.

GREEN PRODUCT PROCUREMENT

and

LEAD-FREE

GREEN PRODUCT PROCUREMENT

Corporation recognizes environmental protection as a key management tasks, and is doing its

Стр. 1 из

1

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\toshiba_32lv17_sm\32LV17

-

...

The EC is actively promoting the WEEE & RoHS Directives that define standards for

recycling and reuse of Waste Electrical and Electronic Equipment and for the Restriction of

the use of certain Hazardous Substances. From July 1, 2006, the RoHS Directive will

prohibit any marketing of new products containing the restricted substances.

Increasing attention is given to issues related to the global environmental. Toshiba

utmost to enhance and improve the quality and scope of its environmental activities. In line

with this, Toshiba proactively promotes Green Procurement, and seeks to purchase and use

products, parts and materials that have low environmental impacts.

Green procurement of parts is not only confined to manufacture. The same green parts used

in manufacture must also be used as replacement parts.

LEAD-FREE SOLDER

free solder must

free solder may result in damage to the component and or PCB being

Стр. 1 из

1

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\toshiba_32lv17_sm\32LV17

-

...

This product is manufactured using lead-free solder as a part of a movement within the

consumer products industry at large to be environmentally responsible. Lead-

be used in the servicing and repair of this product.

WARNING: This product is manufactured using lead free solder.

DO NOT USE LEAD BASED SOLDER TO REPAIR THIS PRODUCT!

The melting temperature of lead-free solder is higher than that of leaded solder by 86ºF to

104ºF (30ºC to 40ºC). Use of a soldering iron designed for lead-based solders to repair

product made with lead-

soldered. Great care should be made to ensure high-quality soldering when servicing this

product especially when soldering large components, through-hole pins, and on PCBs as the

level of heat required to melt lead-free solder is high.

IMPORTANT NOTICE

Through WEB, ver. 6.5 has been released but with it, the linking function in this manual may

Стр. 1 из

2

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\toshiba_32lv17_sm\32LV17

-

...

A Known Malfunction

Autodesk® DWF™ Viewer version

(Free software provided through WEB)

Use Autodesk DWF Viewer ver. 6.0.

not work properly.

If ver. 6.5 has been installed, uninstall it and reinstall ver. 6.0.

To get ver. 6.0, click the icon, or contact to the nearest Toshiba Service Centre for further

assistance.

Freezing windows opened

(Cannot close the open windows)

This may happen occasionally.

In case of encountering this, follow the procedure below.

1. Press [Ctrl], [Alt] and [Delete] keys at the same time to engage windows security

windows.

2. Then, choose TASK manager and Application tab, and select TOSHIBA SERVICE

MANUAL-Microsoft Internet Explorer.

3. Click TASK-end.

Main Window back forwarded

The real cause has not been found yet but with this condition, nothing disturbs the service

manual operation.

Continue to use by operating the windows.

Стр. 2 из

2

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

Precaution when opening the diagrams

While opening the diagrams, the menu in the left frame changes its color to GRAY. This is

an indication that the viewer is processing.

With this condition, the menu indication color may stick to the GRAY color or Windows

may freeze if clicking other menu.

To avoid such things, do not operate any others while menu turns GRAY color.

If entering this, re-open the service manual or refresh the left frame.

IMPORTANT NOTICE

Стр. 1 из

4

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\toshiba_32lv17_sm\32LV17

-

...

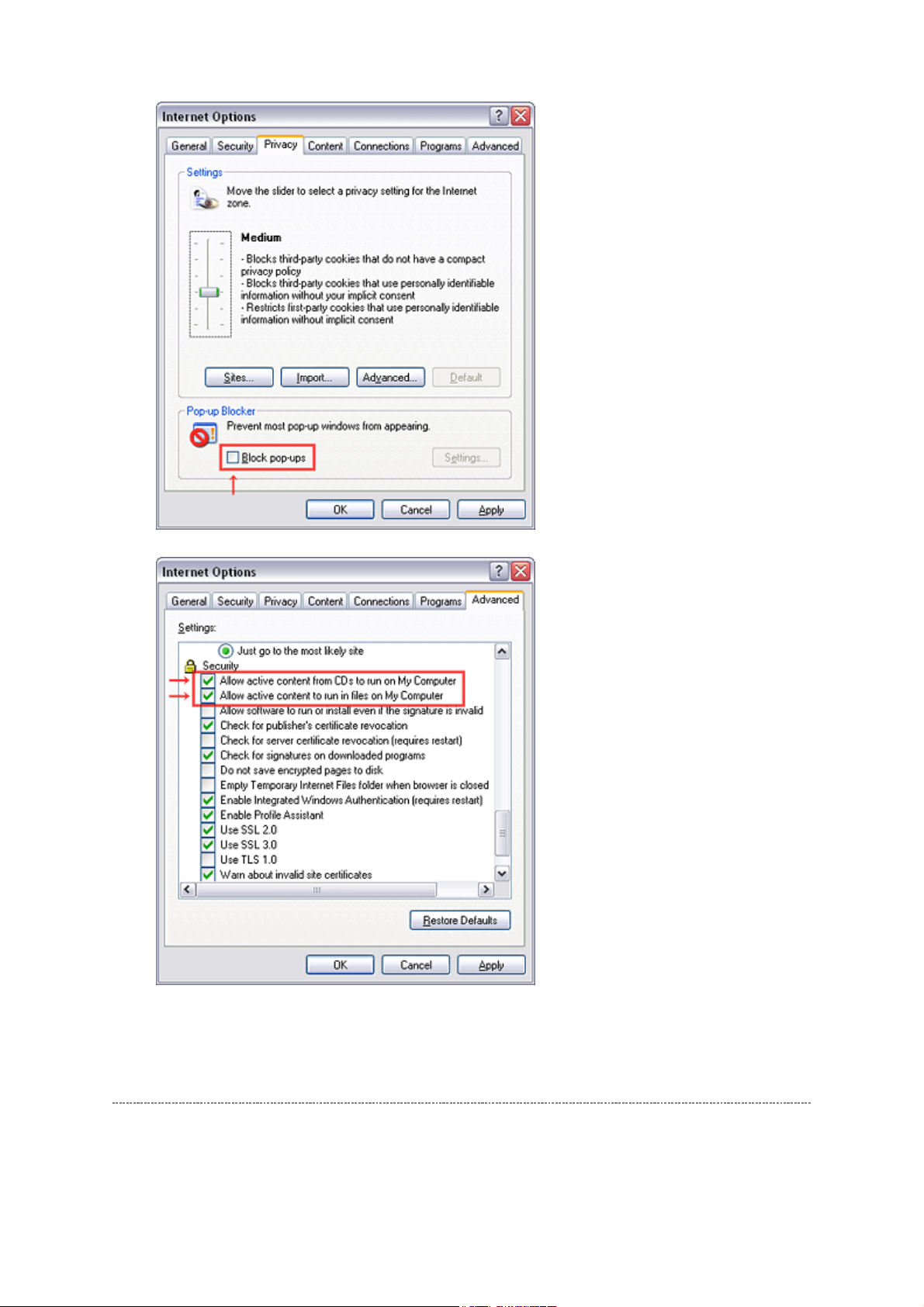

User Guide

Autodesk® DWF™ Viewer

this system. Please download and install.

When

function and this sample may not work. In that case, perform the Internet Explorer setting

using the following procedure to restore normal operation.

Windows XP SP2

1. Windows version check

[My Computer (right-click)] - [Properties]

is necessary to view drawings and to activate the functions of

is used, pop-up windows are limited by the enhanced security

2. Internet Explorer setting

[Tools] - [Internet Options]

Стр. 2 из

4

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

Operating Environment

PC : Pentium III or higher recommended

Monitor : 1024 x 768 or higher resolution recommended

Mouse : A mouse with wheel recommended

Стр. 3 из

4

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

OS : Microsoft Windows 2000/XP

Browser :

Drawing viewer : Autodesk DWF Viewer 6.0

* Use the software following respective license terms and conditions.

Microsoft Internet Explorer 6.0 or later

Note:

In case of using this service manual with network connection, allocate its folder to the client

PCs as

network drive

to avoid any possible malfunction.

Or in case of accessing it through WEB site, the small pop-up window appears at the left

bottom corner on the screen whenever searching the location links. This is not malfunction.

Functions Provided on Each Drawing Page

Parts Information Reference Function

When the character string of a part on the drawing is clicked, its information is popped up at

the location. You can get any parts information immediately on the screen without referring

to the maintenance parts list.

Parts Search Function

You can search any part within the displayed drawing or within the whole schematic

diagram/board view by specifying a location number. The pop-up window displayed by

clicking a part's character string allows to search the part within the applicable schematic

diagram, board view or spare parts list.

A circle appears when the part is found, showing the part's location within the drawing.

Signal Line/Connector Destination Display Function

When a name at the end of a signal line in a divided schematic diagram is clicked, the

destination of the signal is searched and the display changes to the destination. Connecter

destinations can also be searched in the same way.

When two or more search results are provided, their drawing names are displayed, allowing

you to choose a desired drawing to display.

Layer Display Changing Function

When a pattern on a board view is clicked, it is highlighted in green. This allows easy pattern

Стр. 4 из

4

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

When any of the color buttons on the toolbar is clicked, it can be selected to display desired

layer in its color or not to display each layer. This allows you to see the pattern layer only by

setting other layers to "non-display".

PC Board View Pattern Highlighting Function

tracing.

Specified Area Printing Function

The Autodesk DWF Viewer enables to print the displayed drawing region as it is on a

printer. It also allows to print a large-sized drawing in multiple pieces (tile printing).

IMPORTANT NOTICE

Стр. 1 из

1

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\toshiba_32lv17_sm\32LV17

-

...

WARNING:

You are requested that you shall not modify or alter the information or data

provided herein without prior written consent by Toshiba. Toshiba shall not

be liable to anybody for any damages, losses, expenses or costs, if any,

incurred in connection with or as a result of such modification or alteration.

THE INFORMATION OR DATA HEREIN SHALL BE PROVIDED "AS IS"

WITHOUT ANY WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED

WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE.

Toshiba shall not be liable for any damages, losses, expenses or costs, if

any, incurred in connection with or as a result of use of any information or

data provided herein.

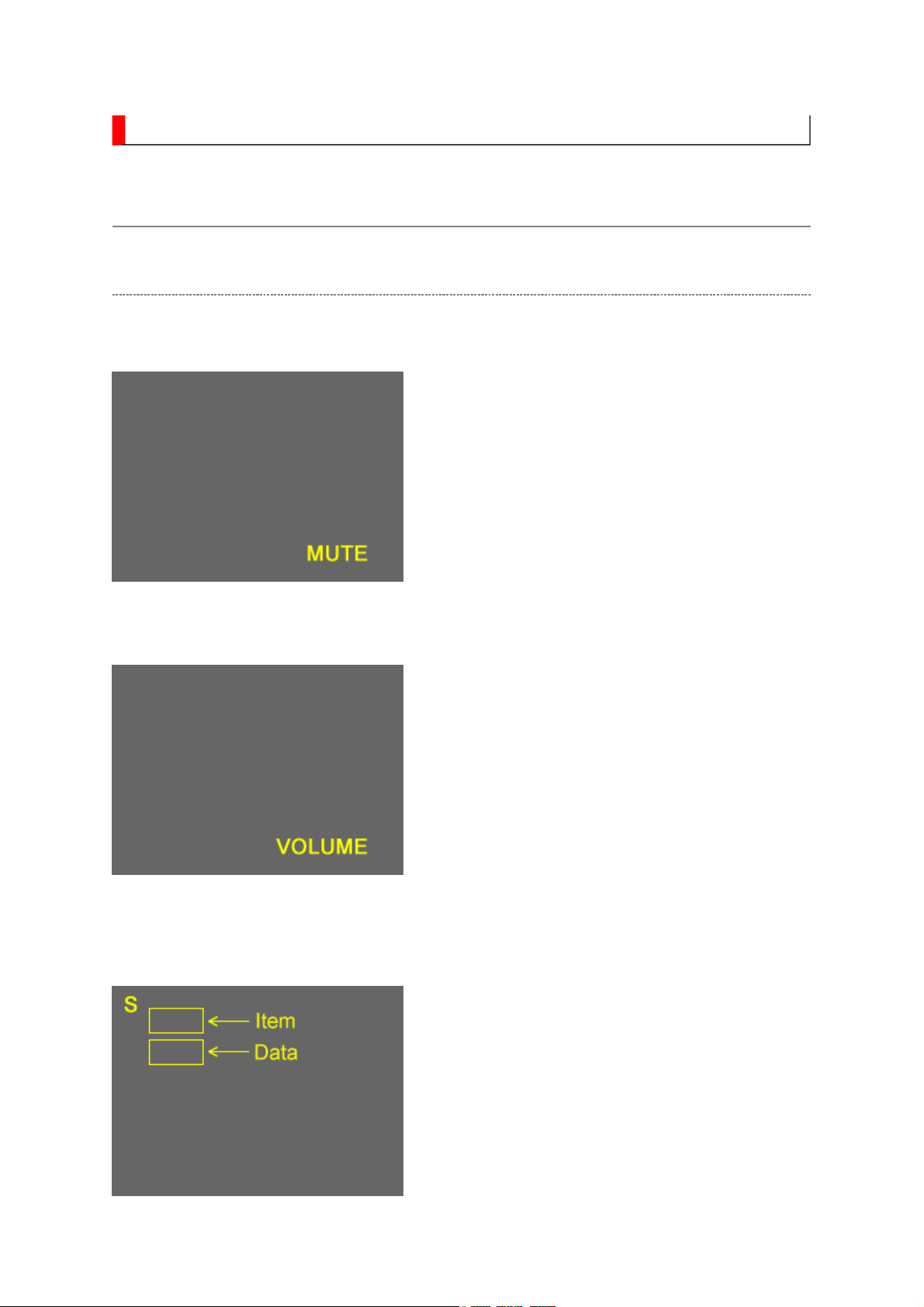

ADJUSTMENT

While holding the MUTE button, press MENU

Стр. 1 из 8ADJUSTMENT [LCD] USA

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\toshiba_32lv17_sm\32LV17

-

...

Service Mode

Entering to Service Mode

1. Set VOLUME to minimum and press MUTE

button twice on Control.

↓

↓

Service Mode display

2. Press MUTE button again and hold button

down.

3.

button on TV set.

Стр. 2 из 8ADJUSTMENT [LCD] USA

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

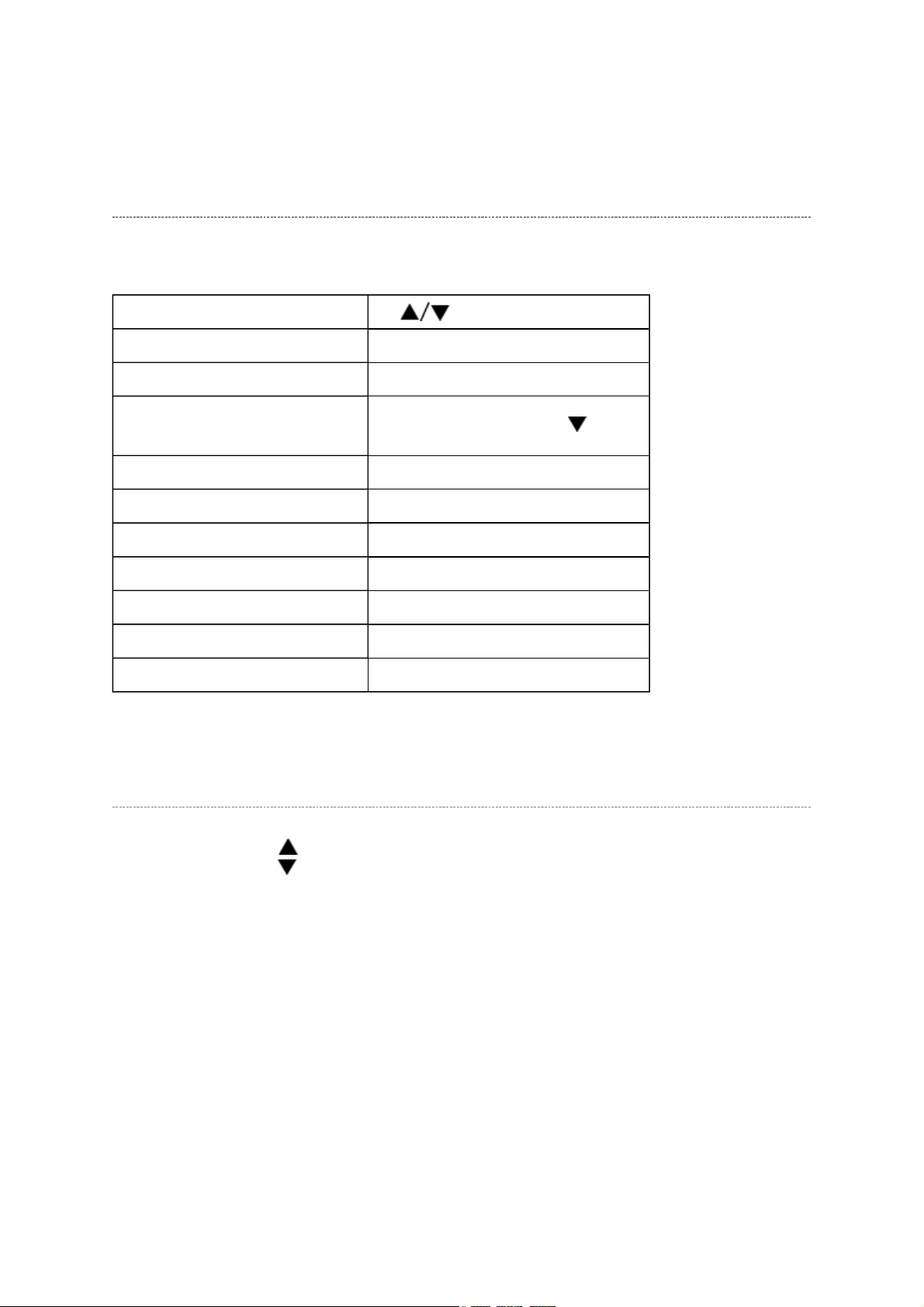

Key Function in the Service Mode

The following key entry during display of adjustment menu provides special functions.

Selection of the adjustment items CH (on TV or remote control)

Change of the data value Volume +/- (on TV or remote control)

Adjustment menu mode ON/OFF MENU button (on remote control)

Reset the count of operating

protect circuit to "00"

"RCUT" selection 1 button

"GCUT" selection 2 button

"BCUT" selection 3 button

"CNTX" selection 4 button

"COLC" selection 5 button

"UVTT" selection 6 button

Self diagnostic display ON/OFF 9 button

CALL + CH button on TV ( )

Selecting the Adjusting Item

Every pressing of CH button in the service mode changes the adjustment items in the

order of table below. ( button for reverse order)

SETTING & ADJUSTING DATA

[ SERVICE MODE ]

ADJUSTING ITEMS AND DATA IN THE SERVICE MODE:

Note:

(1) The image system data may be different for each image format chosen. The factory

preset data value is indicated in the table.

(a) HOST-MICRO EEPROM data

Prior to changing any board containing an EEPROM IC, the exisiting data in each image

Стр. 3 из 8ADJUSTMENT [LCD] USA

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

DRAMA0543 for LV series

(b) TV-MICRO EEPROM data

DRAMA0542 for LV series

(2)

format should be copied down as a precautionary measure.

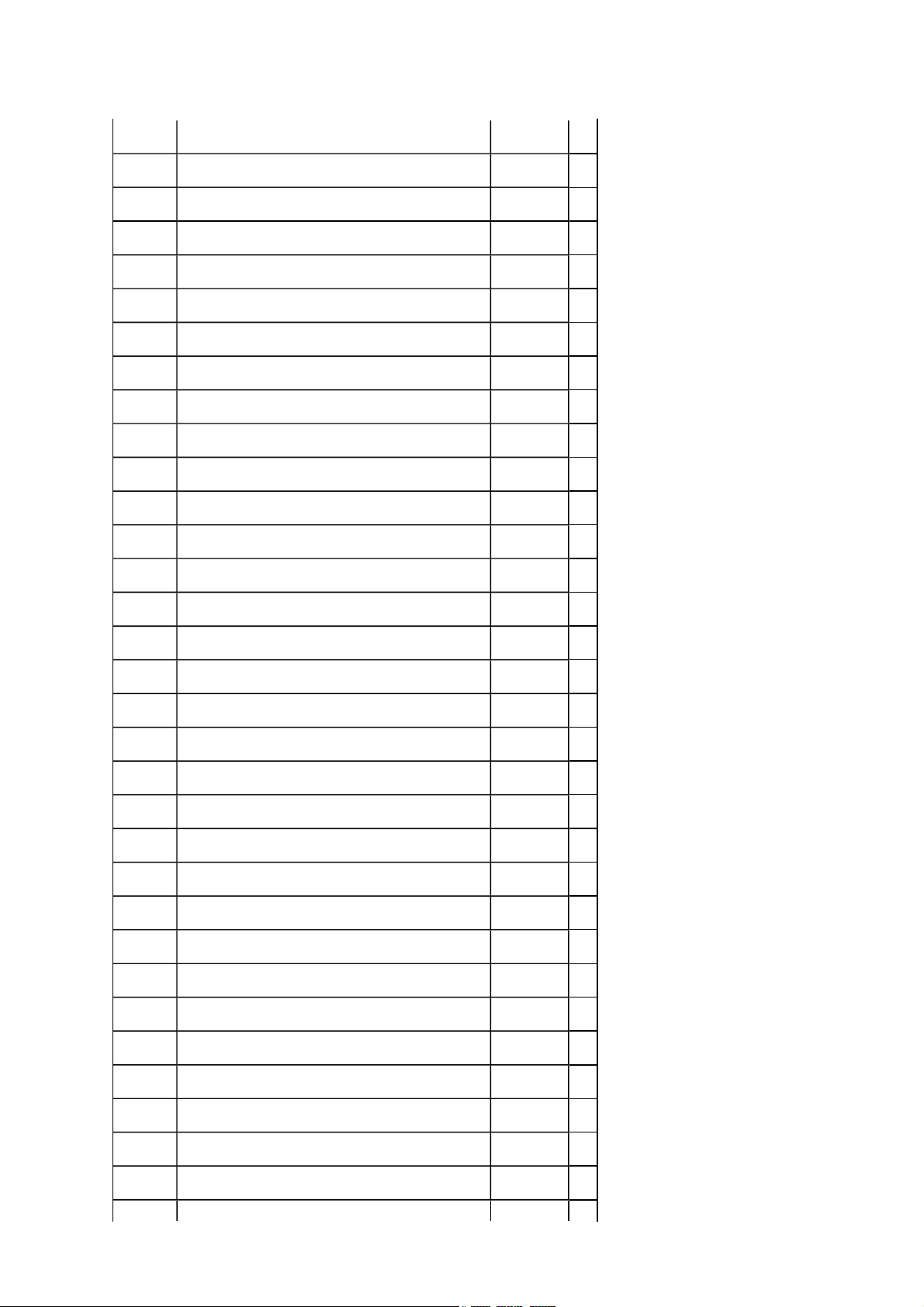

Item Name of adjustment Data

LV series

R-CUT R CUTOFF 00H (a)

G-CUT G CUTOFF 00H (a)

B-CUT B CUTOFF 00H (a)

R-DRV R DRIVE 64H (a)

G-DRV G DRIVE 64H (a)

B-DRV B DRIVE 64H (a)

*BRTC BRIGHTNESS CENTER 78H (a)

*COLC COLOR CENTER C0H (a)

*UVTT BASE BAND TINT 80H (a)

*CNTX CONTRAST MAX FFH (a)

SHRC SHARPNESS CENTER 60H (a)

VBIS VBI Setting 64H (a)

CC Closed Caption 64H (a)

ID1 VBID 64H (a)

GG Gemstar 00H (a)

BYBK B-Y OFF SET 00H (a)

RYBK R-Y OFF SET 00H (a)

Стр. 4 из 8ADJUSTMENT [LCD] USA

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

OPT1 TV SET OPTION 1 00H (b)

OPT2 TV SET OPTION 2 25H (b)

OPT3 TV SET OPTION 3 00H (b)

OPT4 TV SET OPTION 4 25H (b)

OPT5 TV SET OPTION 5 00H (b)

SET-ID MODEL ID *1 (b)

MAGC AGC of MTS decoder 00H (b)

VO1 Volume1 Data 5FH (b)

V25 Volume25 Data ADH (b)

V50 Volume50 Data DFH (b)

V75 Volume75 Data F9H (b)

V100 Volume100 Data FFH (b)

VOLBS Correction Volume at DTV 00H (b)

VOLST Correction Volume at Stereo/SAP of ATV 00H (b)

EVOL Reduce Volume For Bassboost (Nonuse) 00H (b)

VOLX Volume Limiter For Hotel 64H (b)

BASX Bass Max Data 1AH (b)

TREX Treble Max Data 1AH (b)

TONN Tone Min Data 08H (b)

BASC Bass center Data FEH (b)

TREC Treble center Data 00H (b)

EBAS Add Bass on FOCUS 04H (b)

ETRE Add Treble on FOCUS FEH (b)

WON2 Bass Reducer 10H (b)

ALS ALS point 00H (b)

ALOF Reduce in ALL (wow, TruSurround) off 01H (b)

VSTB Reduce Volume For Stable Sound 00H (b)

VS3D Reduce Volume For SRS3D 01H (b)

VFCS Reduce Volume For FOCUS 03H (b)

VTBH Reduce Volume For TruBass High FFH (b)

VTBL Reduce Volume For TruBass Low FFH (b)

button will change the value of data in the range from 00H to

ID data according to panel

VVDD Reduce Volume For Dolby F3H (b)

Стр. 5 из 8ADJUSTMENT [LCD] USA

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

WFCS FOCUS Level 01H (b)

WWSP SRS 3D Level 02H (b)

WTBH TruBass High Level 03H (b)

WTBL TruBass Low Level 02H (b)

VOLM Volume coefficient at 1/2 Mute 32H (b)

Factory preset data will be loaded after setting Model ID data.

Note:

(*1) SET-ID data is subject to the models.

Refer to Setting Panel Option Data and SET-ID Data for detail.

Adjusting the Data

Pressing of VOLUME or

FFH. The variable range depends on the adjusting item.

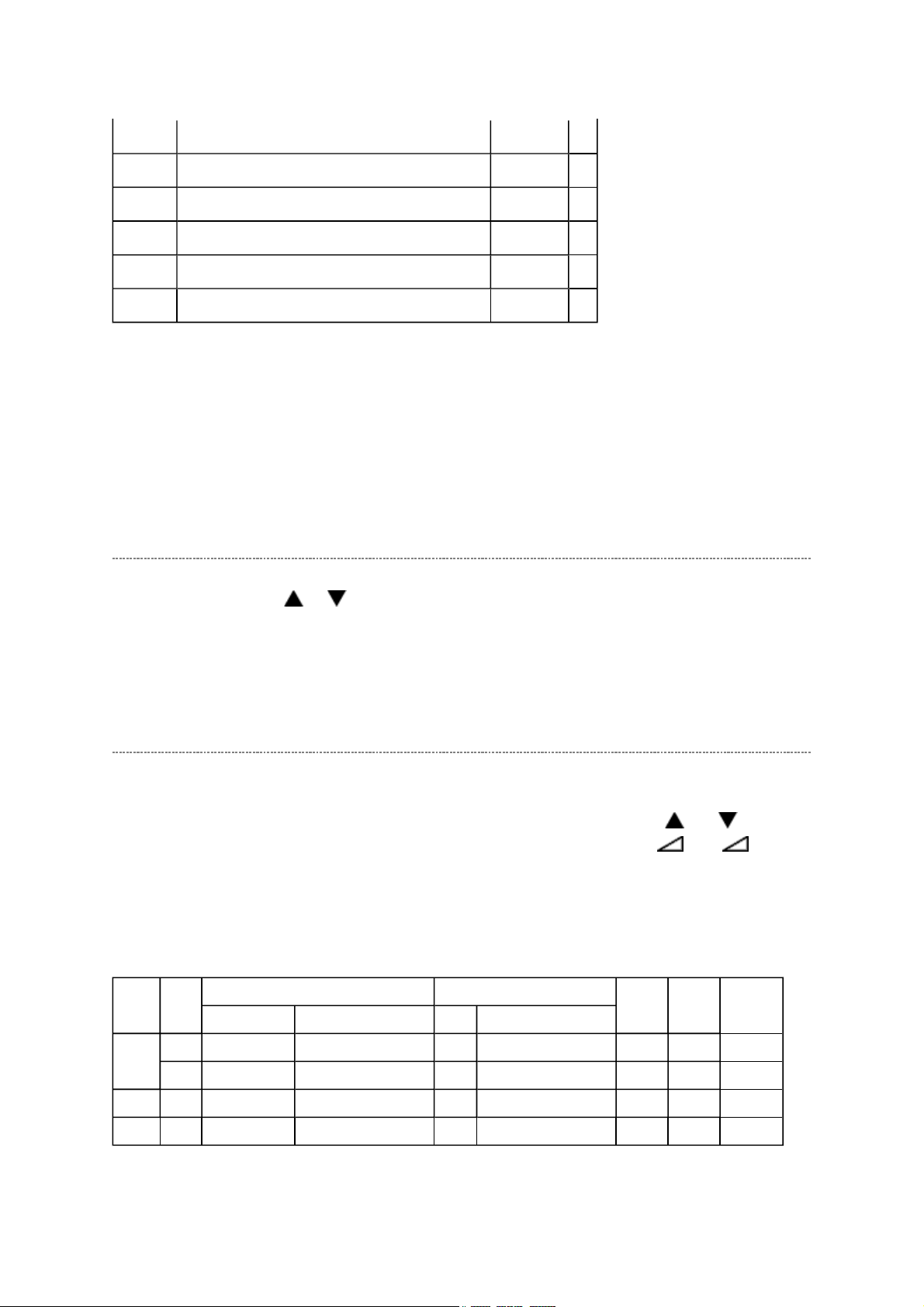

Setting Panel Option Data and SET-ID Data

1. Panel option data is subject to OP4 and OP5.

Enter to service mode and select menu of OP4 or OP5 by pressing P or P during

Display of adjustment menu. After selecting OPT4 or OPT5, press + or - to set

OPT4 or OPT5 value as table below.

2. Whenever using new signal board to the set, setting the SET-

option data.

Set Size

LV67 26 SAMSUNG - 63h - 00h 00h A0h

32 SHARP SAMSUNG 25h 65h 00h 00h A1h

LV37 32 SHARP SAMSUNG 25h 65h 00h 00h A1h

LV17 32 SHARP SAMSUNG 25h 65h 00h 00h A1h

Panel Maker OPT4

TOP Running change TOP Running change

OPT3 OPT5 SET-ID

Exit from Service Mode

Стр. 6 из 8ADJUSTMENT [LCD] USA

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

Pressing POWER button to turn off the TV once.

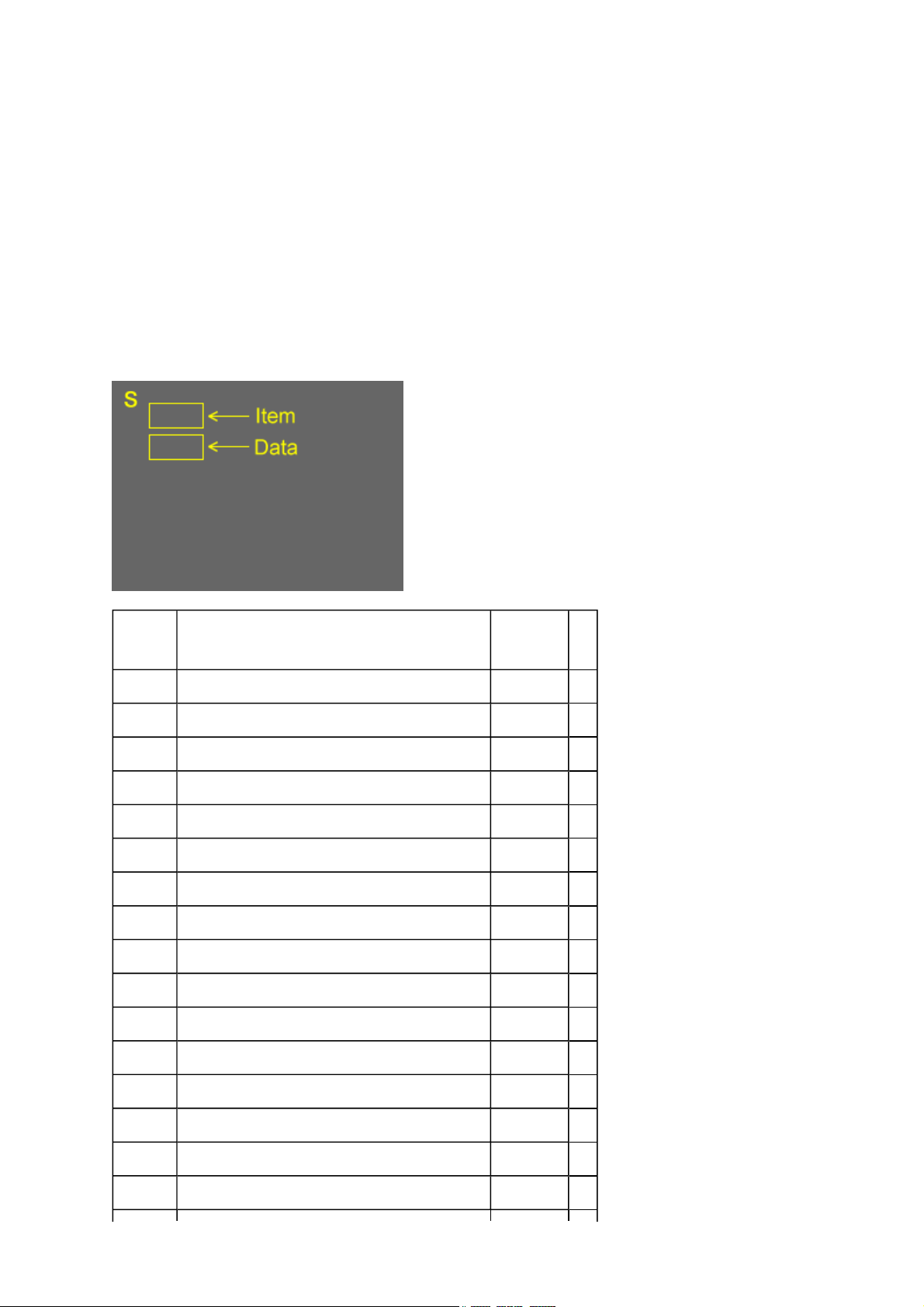

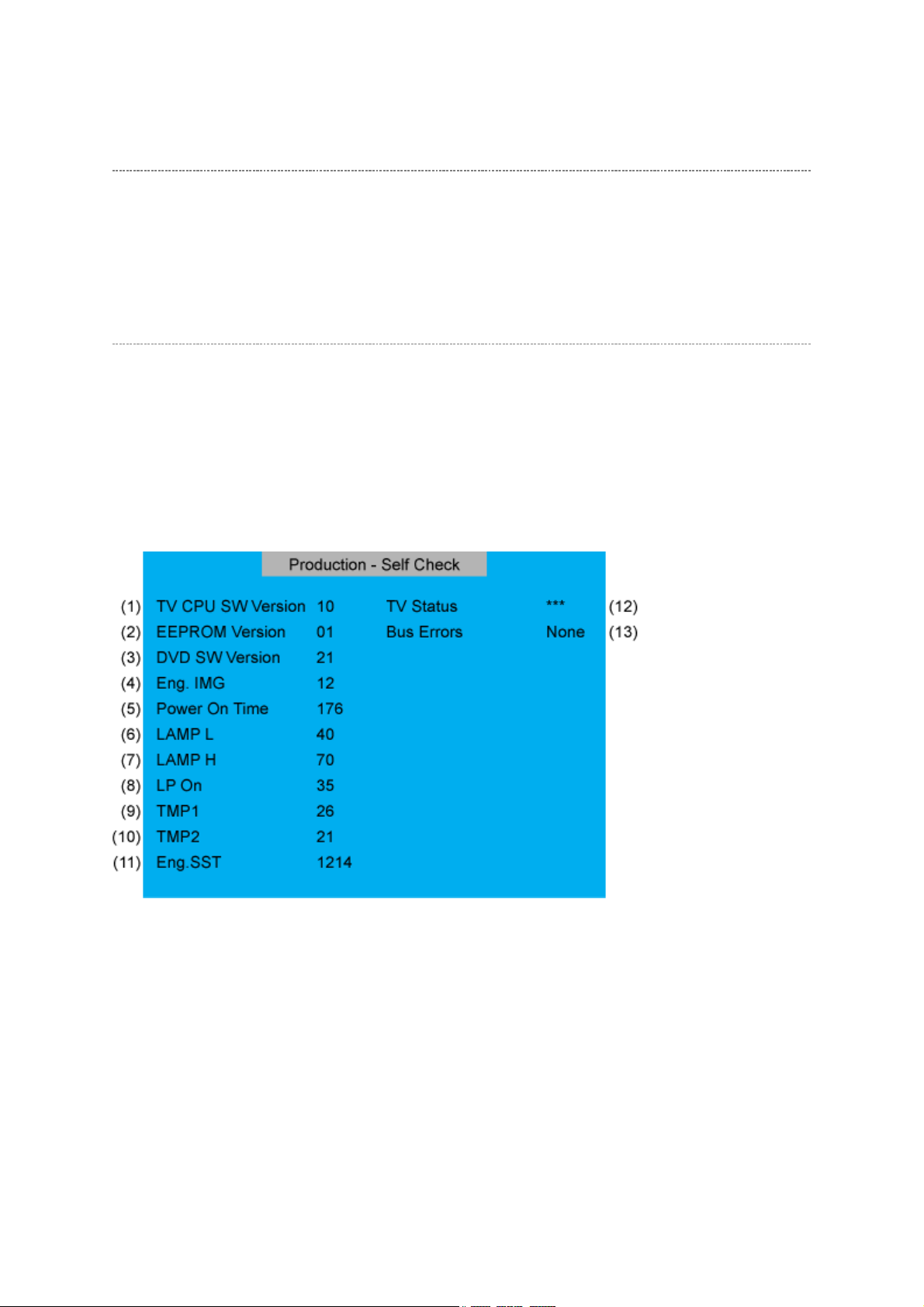

Self Diagnostic Function

1. Press "Recall" button on Remote Control during display of adjustment menu in the

service mode. This will bring up the "S" in the right corner of screen. Now press "9"

button on remote.

The diagnosis will begin to check if interface among IC's is executed properly.

2. During diagnosis, the following displays are shown.

(1) Version information of TV-MICRO : Display 1 byte data.

(2) Version information of TV-MICRO EEPROP : Display 1 byte data.

(3) Version information of DVD MPU : LV series

(4) Revision of image file : LCD Model not used.

(5) Total brightness hour of TV. : Display 4 bytes data.

(6) Operation hour of TV in LOW mode : Display 4 bytes data.

(7) Operation hour of TV in HIGH BRIGHT mode : LCD Model not used.

(8) Number of times of TV ON/OFF. : LCD Model not used.

Стр. 7 из 8ADJUSTMENT [LCD] USA

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

(9) Temperature display of thermo-Sensor. (DMD) : LCD Model not used.

(10) Temperature display of thermo-Sensor. (LAMP) : LCD Model not used.

(11) DMD Engine System status : LCD Model not used.

(12) TV-MICRO System status : Not used

(13) IIC-BUS status

Bus line normal is "None" displayed.

When it is abnormal, the block name is displayed as follows.

"SCL-GND" (Red indication) : SCL-GND short circuit

"SDA-GND" (Red indication) : SDA-GND short circuit

"SCL-SDA" (Red indication) : SCL-SDA short circuit

"NG : MTS"

"NG : APRO"

"NG : AVSW"

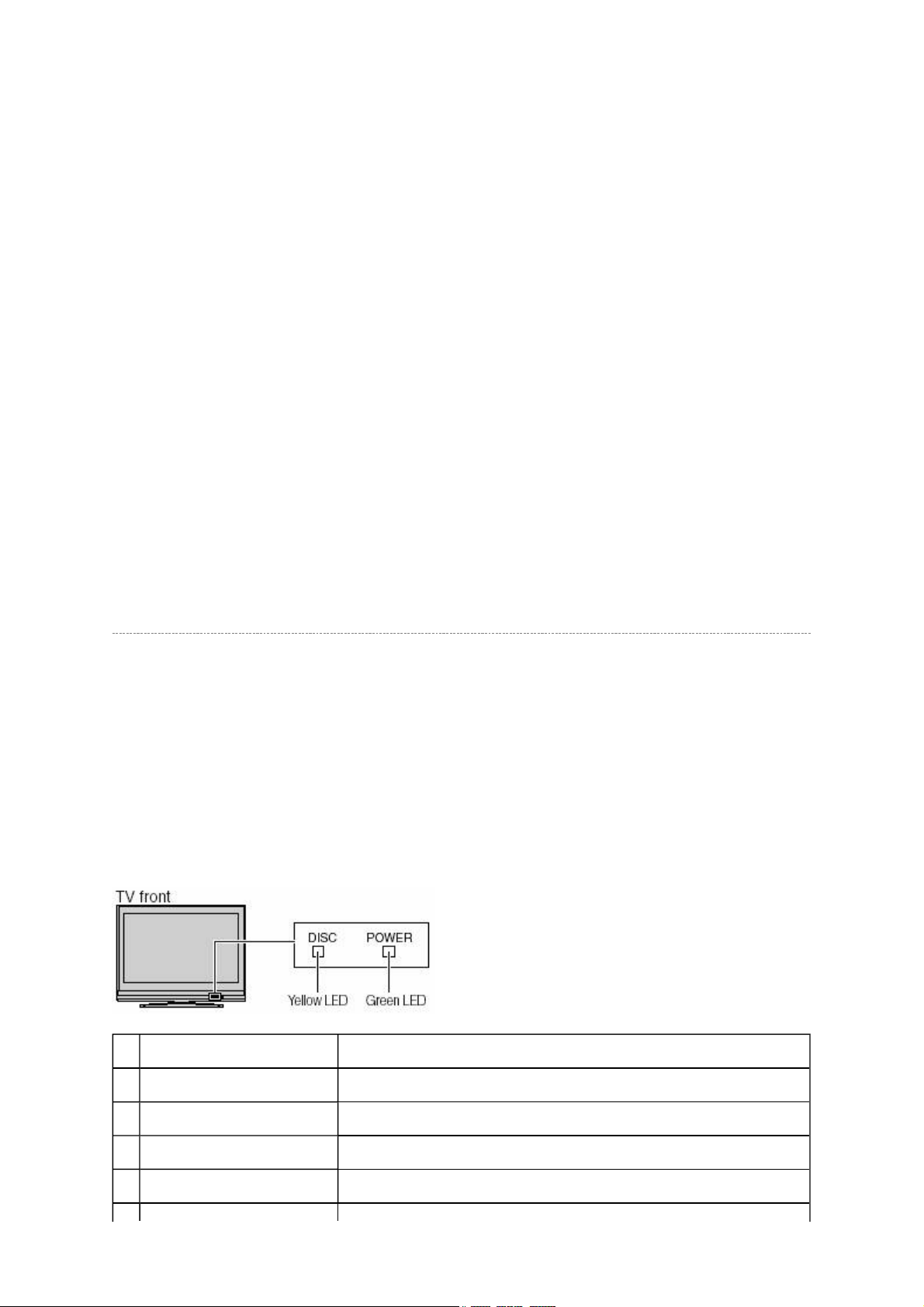

LED Indication

The yellow, blue and red/green LED lights on the TV (at the bottom center of the TV)

indicate the TV's status, as described below:

Note:

unplugged), when power is restored, the yellow LED will blink while the TV is booting until

the remote control is usable. This is normal and is not a sign of malfunction.

If the TV loses A/C power (e.g., a power outage occurs or the power cord is

LED Indication Condition

1 Green and Yellow are off. Power supply OFF. (AC)

2 Green and Yellow are off. Power supply OFF. (Stand by)

3 Green is on (solid). The TV is operating properly.

4 Yellow is on (solid). A disk is in the disk slot.

5 Green blinks Fan stop detection.

Стр. 8 из 8ADJUSTMENT [LCD] USA

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

6 Green blinks slowly. Abnormal operation of BUS line.

Turn the TV off and unplug the power cord, then plug the

power cord in again and turn the TV on.

7 Green blinks quickly. Power Protection Detection.

Turn the TV off and unplug the power cord, then plug the

power cord in again and turn the TV on.

8 Yellew blinks 3 times. The TV is rebooting.

Wait several seconds until the yellow LED stops blinking.

9 Green is on (solid).

Yellow is on (solid).

10 Green is on (solid).

Yellow is off.

11 Green is off.

Yellow is on (solid).

Upgrading in progress.

Upgrading succesful.

Upgrading failed.

FUNCTION AND OPERATION

Стр. 1 из

2

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\toshiba_32lv17_sm\32LV17

-

...

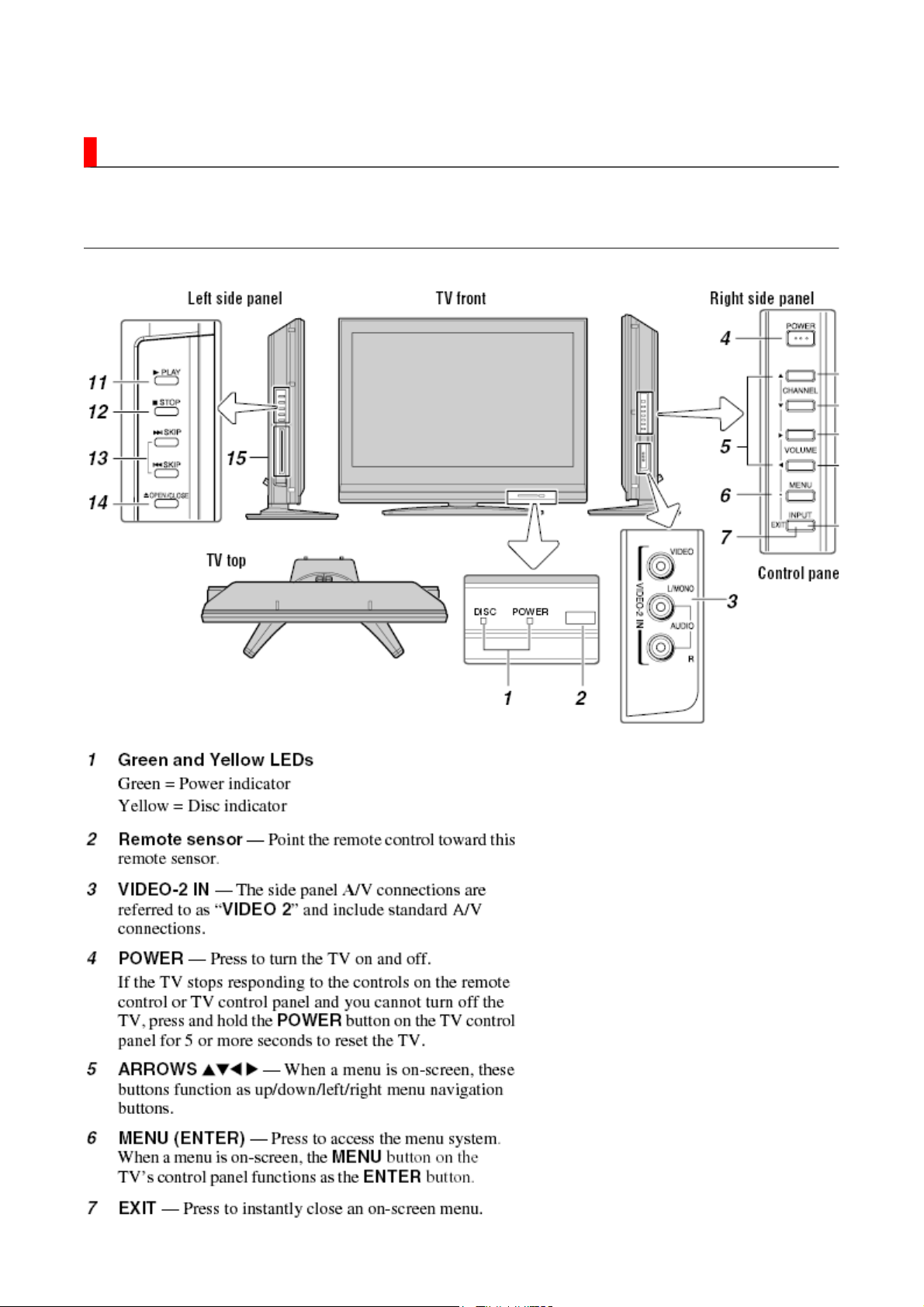

TV Front and Side Panel Control and Connection

Стр. 2 из

2

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

FUNCTION AND OPERATION

Стр. 1 из

3

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\toshiba_32lv17_sm\32LV17

-

...

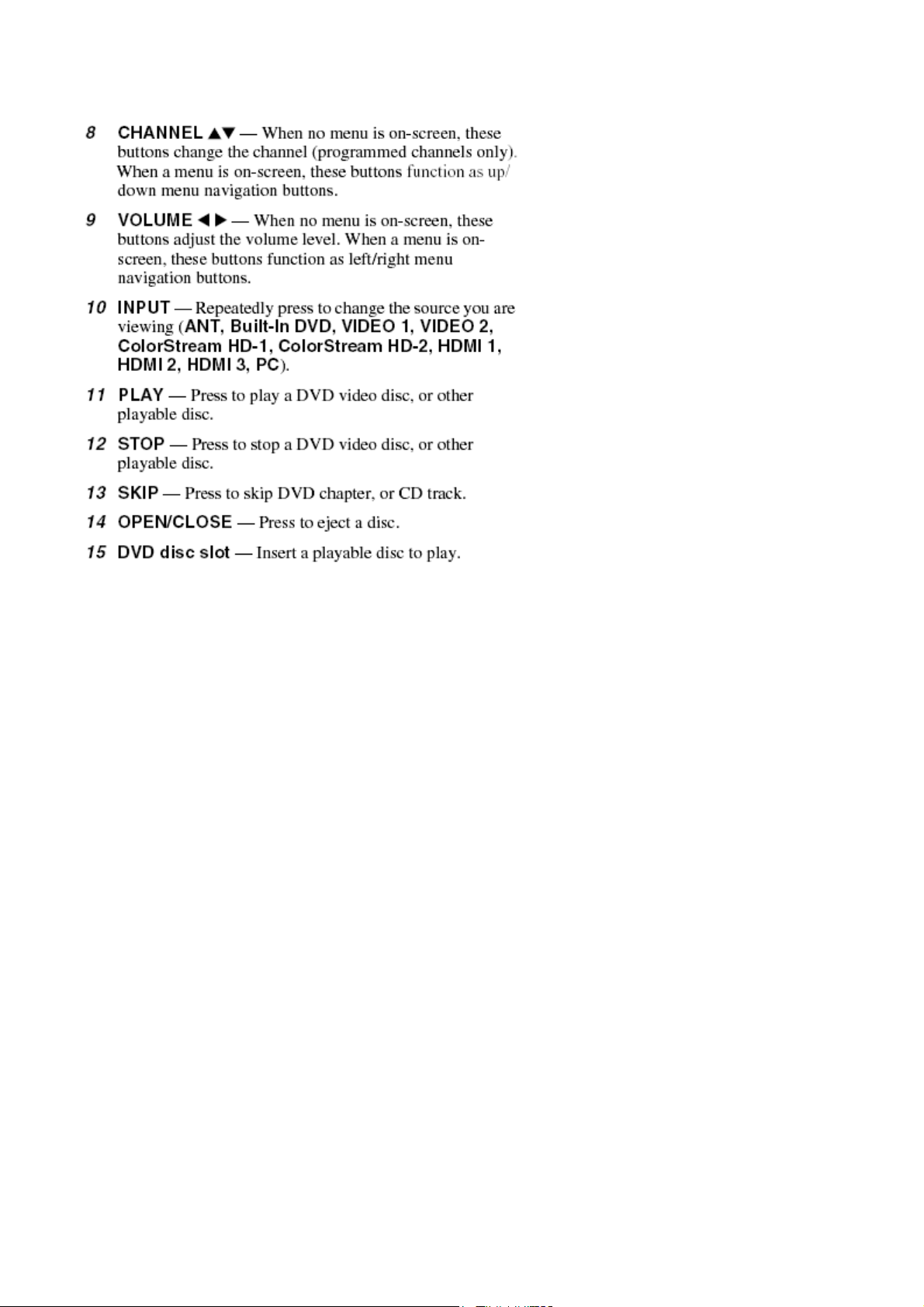

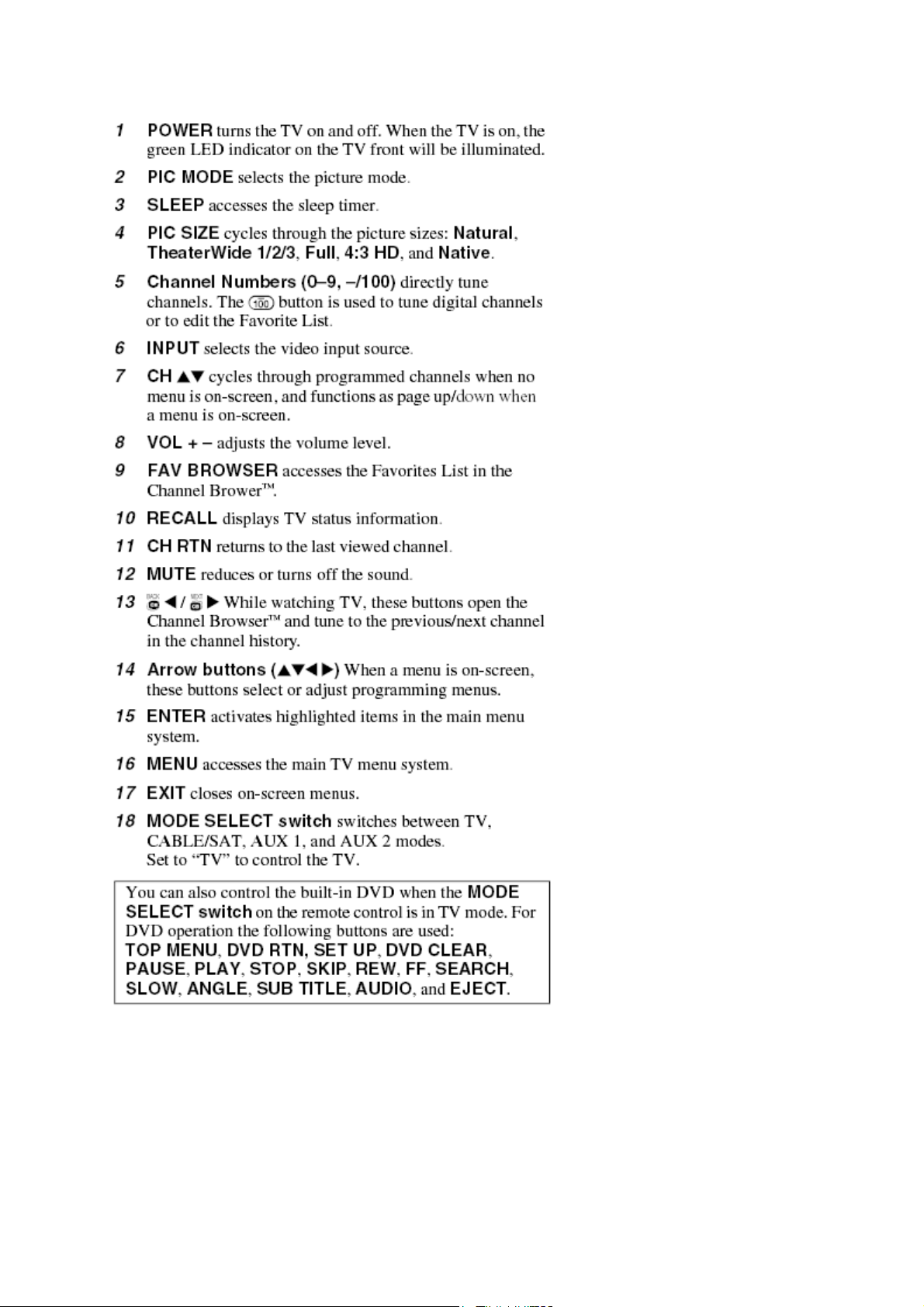

Learning about the Remote Control

Стр. 2 из

3

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

Стр. 3 из

3

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

FUNCTION AND OPERATION

Стр. 1 из

4

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\toshiba_32lv17_sm\32LV17

-

...

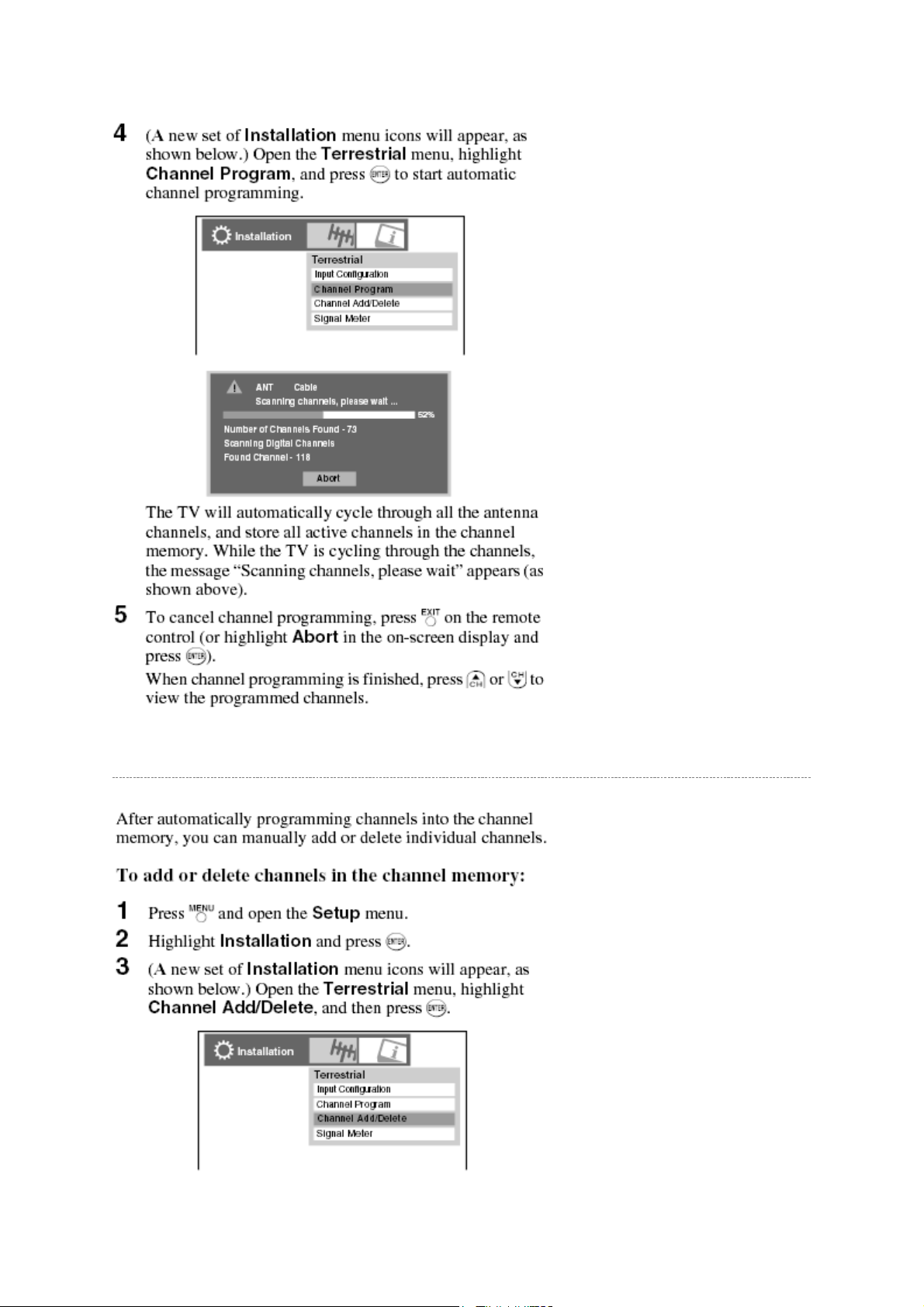

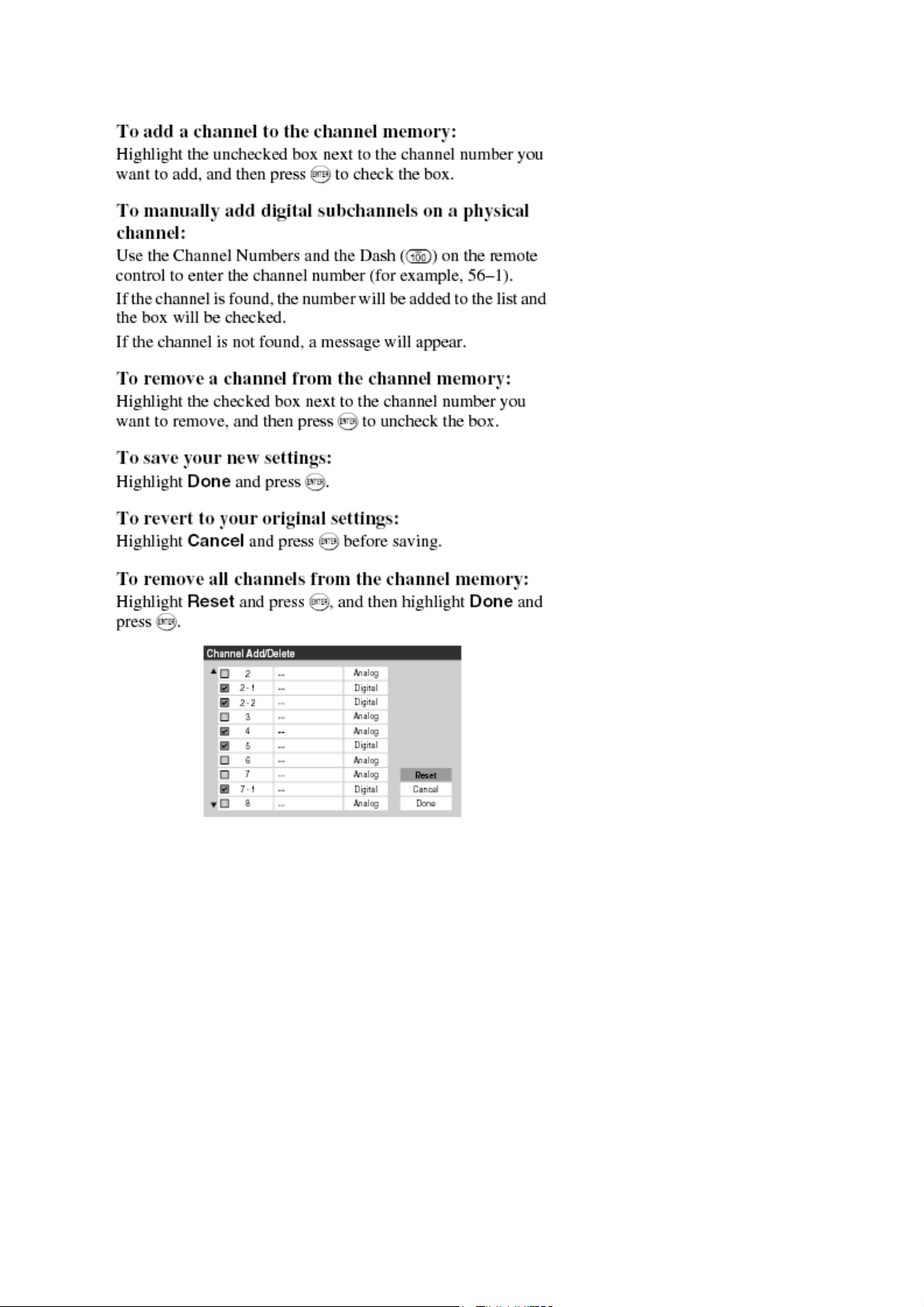

Programming Channel into the TV's Channel Memory

Programming Channel Automatically

Стр. 2 из

4

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

Стр. 3 из

4

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

Manually Adding and Deleting Channel in the Channel Memory

Стр. 4 из

4

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

SAFETY INSTRUCTION

should enter the mouth, rinse the mouth thoroughly with water. If the fluid should contact the

When attaching the LCD module to the LCD cover, position it appropriately and fasten

Стр. 1 из 4Handling the LCD Module

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\toshiba_32lv17_sm\32LV17

-

...

Handling the LCD Module

Safety Precaution

In the event that the screen is damaged or the liquid crystal (fluid) leaks, do not breathe in or

drink this fluid.

Also, never touch this fluid. Such actions could cause toxicity or skin irritation. If this fluid

skin or clothing, wipe off with alcohol, etc., and rinse thoroughly with water. If the fluid

should enter the eyes, immediately rinse the eyes thoroughly with running water.

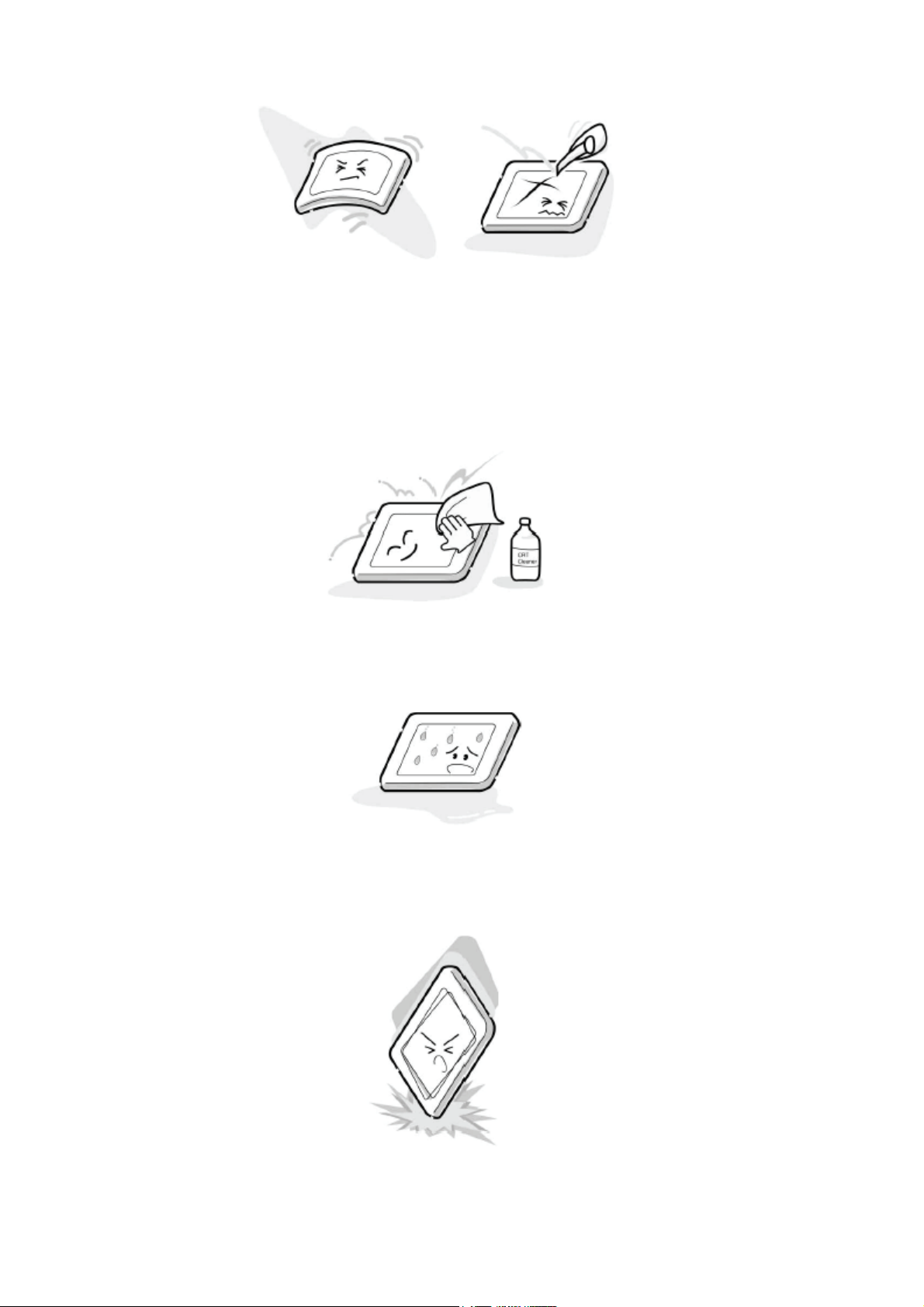

Precautions for Handling the LCD Module

CAUTION: The metal edges of the LCD module are sharp, handle it with

care.

The LCD module can easily be damaged during disassembly or reassembly; therefore,

always observe the following precautions when handling the module.

1.

at the position where the display can be viewed most conveniently.

2. Carefully align the holes at all four corners of the LCD module with the corresponding

holes in the LCD cover and fasten with screws. Do not strongly push on the module

because any impact can adversely affect the performance. Also use caution when

handling the polarized screen because it can easily be damaged.

Стр. 2 из 4Handling the LCD Module

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

3. If the panel surface becomes soiled, wipe with cotton or a soft cloth. If this does not

remove the soiling, breathe on the surface and then wipe again.

If the panel surface is extremely solied, use a CRT cleaner as a cleaner. Wipe off the

panel surface by drop the cleaner on the cloth. Do not drop the cleaner on the panel.

Pay attention not to scratch the panel surface.

4. Leaving water or other fluids on the panel screen for an extended period of time can

result in discoloration or stripes. Immediately remove any type of fluid from the screen.

5. Glass is used in the panel, so do not drop or strike with hard objects. Such actions can

damage the panel.

6. CMOS-LSI circuitry is used in the LCD module, so avoid damage due to static

Стр. 3 из 4Handling the LCD Module

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

electricity. When handling the module, use a wrist ground or anchor ground.

7. Do not expose the LCD module to direct sunlight or strong ultraviolet rays for an

extended period of time.

8. Do not store the LCD module below the temperature conditions described in the

specifications. Failure to do so could result in freezing of the liquid crystal due to cold

air or loss of resilience or other damage.

9. Do not disassemble the LCD module. Such actions could result in improper operation.

Стр. 4 из 4Handling the LCD Module

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

10. When transporting the LCD module, do not use packing containing epoxy resin

(amine) or silicon resin (alcohol or oxim). The gas generated by these materials can

cause loss of polarity.

U03D

KEY

U02A LOW-B

U01A POWER

U03E

DVD-Key

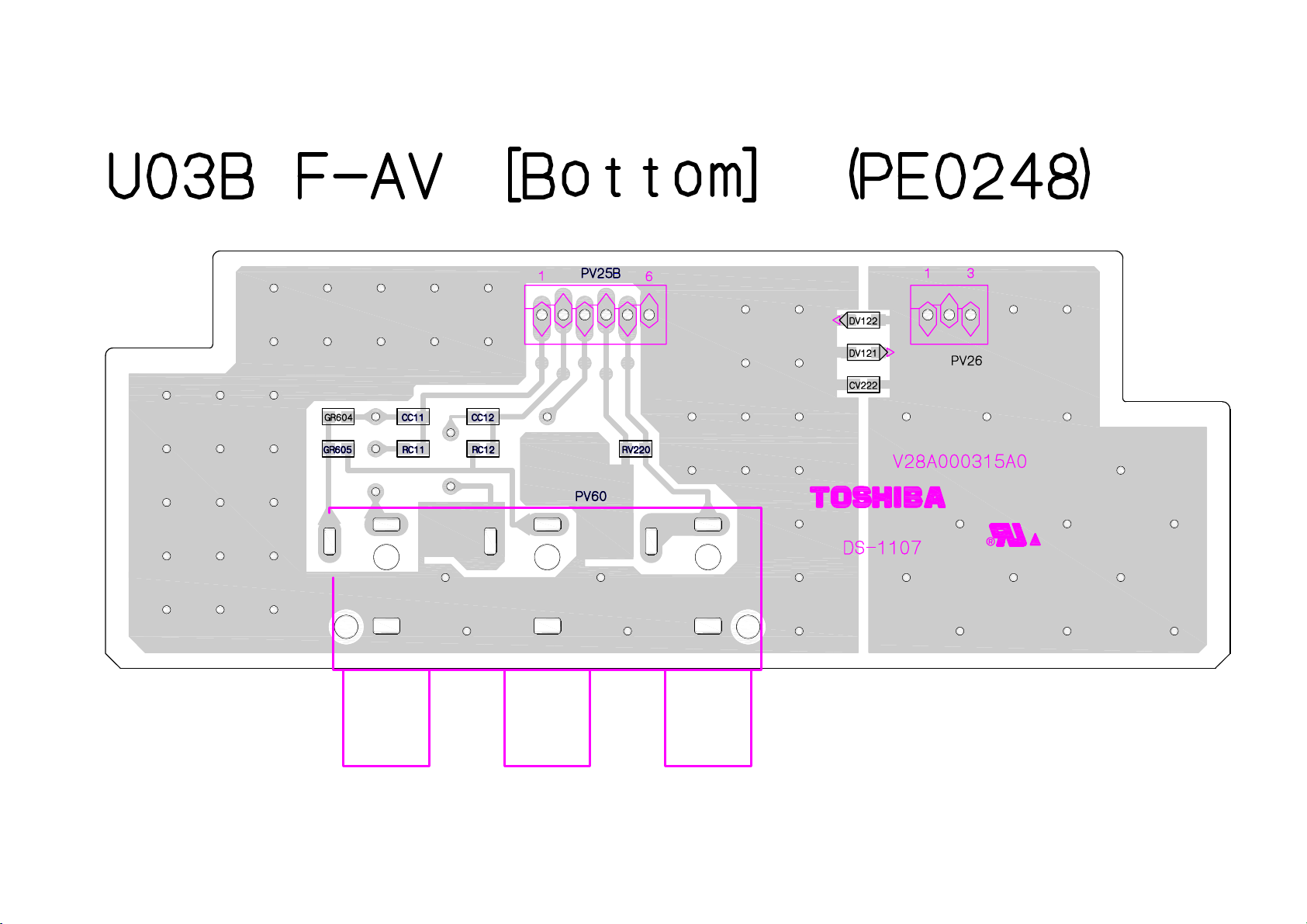

U03B

Front-AV

U03A TUNER-AV

U03C LED

U04A SEINE

DVD Unit

U03F

DVD-IF

SAFETY INSTRUCTION

Always keep tools, components of the product, etc away from the children, These items

Стр. 1 из 3SAFETY INSTRUCTION [LCD] USA

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\toshiba_32lv17_sm\32LV17

-

...

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "SAFETY

PRECAUTION" AND "PRODUCT SAFETY NOTICE" INSTRUCTIONS BELOW.

Safety Precaution

WARNING: SERVICING SHOULD NOT BE ATTEMPTED BY ANYONE

UNFAMILIAR WITH THE NECESSARY PRECAUTIONS ON THIS RECEIVER.

THE FOLLOWING ARE THE NECESSARY PRECAUTIONS TO BE OBSERVED

BEFORE SERVICING THIS CHASSIS.

1. An isolation transformer should be connected in the power line between the receiver

and the AC line before any service is performed on the receiver.

2. Always disconnect the power plug before any disassembling of the product. It may

result in electrical shock.

3. When replacing a chassis in the cabinet, always be certain that all the protective

devices are put back in place, such as nonmetallic control knobs, insulating covers,

shields, isolation resistor-capacitor network, etc.

4.

may cause injury to children.

5. Depending on the model, use an isolation transformer or wear suitable gloves when

servicing with the power on, and disconnect the power plug to avoid electrical shock

when replacing parts. In some cases, alternating current is also impressed in the

chassis, so electrical shock is possible if the chassis is contacted with the power on.

6. Always use the replacement parts specified for the particular model when making

repairs. The parts used in products require special safety characteristics such as

inflammability, voltage resistance, etc. therefore, use only replacement parts that have

NEVER remodel the product in any way. Remodeling can result in improper operation,

cabinet such as antennas, terminals, screw heads, metal overlays, control shafts and etc.

The leakage current checking. (After completing the work, measure the leakage current

Стр. 2 из 3SAFETY INSTRUCTION [LCD] USA

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

these same characteristics. Use only the specified parts when the mark is indicated

in the circuit diagram or parts list.

7. Parts mounting and routing dressing of wirings should be the same as that used

originally. For safety purposes, insulating materials such as isolation tube or tape are

sometimes used and printed circuit boards are sometimes mounted floating. Also make

sure that wirings is routed and clamped to avoid parts that generate heat and which use

high voltage. Always follow the manufactured wiring routes / dressings.

8. Always ensure that all internal wirings are in accordance before re-assembling the

external casing after a repairing completed. Do not allow internal wiring to be pinched

by cabinets, panels, etc. Any error in reassembly or wiring can result in electrical

leakage, flame, etc., and may be hazardous.

9.

malfunction, or electrical leakage and flame, which may be hazardous.

10. Always perform an AC leakage current checking on the exposed metallic parts of the

to be sure that the set is safe to operate without any dangerous of electrical shocks

before returning the set to the customer.

11.

to prevent an electrical shock.)

Plug the AC line cord directly into a 120V AC outlet. Do not use an isolation

transformer for this check.

Use an AC voltmeter having 5000 ohms per volt or more sensitivity in the following

manner.

Connect a 1500 ohm 10 watt resistor, paralleled by a 0.15 µF, AC type capacitor,

between a known good earth ground (water pipe, conduit, etc.) and the exposed

metallic parts, one at a time. Measure the AC voltage across the combination of 1500

ohm resistor and 0.15 µF capacitor. Reverse the AC plug at the AC outlet and repeat

AC voltage measurements for each exposed metallic part. Voltage measured must not

exceed 0.3 volts rms. This corresponds to 0.2 milliamp. AC. Any value exceeding this

limit constitutes a potential shock hazard and must be corrected immediately.

Стр. 3 из 3SAFETY INSTRUCTION [LCD] USA

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

Product Safety Notice

Many electrical and mechanical parts in this chassis have special safety-related

characteristics. These characteristics are often passed unnoticed by a visual inspection and

the protection afforded by them cannot necessarily be obtained by using replacement

components rated for higher voltage, wattage, etc. Replacement parts which have these

special safety characteristics are identified in this manual and its supplements; electrical

components having such features are identified by the international hazard symbols on the

schematic diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The

use of substitute replacement parts which do not have the same safety characteristics as

specified in the parts list may create electrical shock, fire, or other hazards.

SPECIFICATION

Стр. 1 из

3

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\toshiba_32lv17_sm\32LV17

-

...

Стр. 2 из

3

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

Стр. 3 из

3

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

SCHEMATIC DIAGRAM

Стр. 1 из

2

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\toshiba_32lv17_sm\32LV17

-

...

Precaution

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "X-RAY

RADIATION PRECAUTION" FOR DIRECT VIEW CTV ONLY, "SAFETY

PRECAUTION" AND "PRODUCT SAFETY NOTICE" OF THIS MANUAL.

CAUTION: The international hazard symbols " " in the schematic diagram

and the parts list designate components which have special characteristics

important for safety and

should be replaced only with types identical to those in the original circuit

or specified in the parts list.

The mounting position of replacements is to be identical with originals.

Before replacing any of these components, read carefully the SAFETY

PRECAUTION and PRODUCT SAFETY NOTICE.

Do not degrade the safety of the receiver through improper servicing.

Note:

1. RESISTOR

Resistance is shown in ohm [K=1,000, M=1,000,000]. All resistors are 1/6 W and 5 %

tolerance carbon resistor, unless otherwise noted as the following marks.

1/2R : Metal or Metal oxide of 1/2 watt

1/2S : Carbon composition of 1/2 watt

1RF : Fuse resistor of 1 watt

10 W : Cement of 10 watt

K : ±10 %

G : ±2 %

F : ±1 %

2. CAPACITOR

Unless otherwise noted in schematic, all capacitor values less than 1 are expressed in

µF, and the values more than 1 in pF.

All capacitors are ceramic 50 V, unless otherwise noted as the following marks.

Стр. 2 из

2

30.04.2015

file://D:\Documents and Settings\Admin\

Рабочий стол

\

toshiba_32lv17_sm\32LV17

-

...

= Electrolytic capacitor

= Mylar capacitor

3. The parts indicated with " " have special characteristics, and should be replaced with

identical parts only.

4. Voltages read with DIGITAL MULTI-METER from point indicated to chassis ground,

using a color bar signal with all controls at normal, line voltage at nominal AC volts.

5. Waveforms are taken receiving color bar signal with enough sensitivity.

6. Voltage reading shown are nominal values and may vary ±20 % except H.V.

Loading...

Loading...