Toshiba 32L2333D(G) Schematic

SERVICE MANUAL

LCD Color Television

32L2333D(G)

REVISED:01

32W2333D(G)

REVISION HISTORY

REV Date Reason for Change

1 Apr/19/2013 - Correction of the Signal name in INTERCONNECT

- Addition of the parts code of E310A, E310B and E310C in

INTERCONNECT

- Deletion of the unnecessary old parts in Parts List (Exploded

View)

- Addition of "PANEL IDENTIFICATION"

CONTENTS

1. IMPORTANT NOTICE

2. GREEN PRODUCT PROCUREMENT

3. LEAD-FREE SOLDER

4. SAFETY INSTRUCTION

5. HOTEL MODE

6. COPYING HOTEL MODE SETTING

7. FIRMWARE UPDATING

8. INTERCONNECT

9. EXPLODED VIEW

10. PANEL IDENTIFICATION

1

IMPORTANT NOTICE

WARNING:

You are requested that you shall not modify or alter the information or data provided

herein without prior written consent by Toshiba. Toshiba shall not be liable to

anybody for any damages, losses, expenses or costs, if any, incurred in connection

with or as a result of such modification or alteration.

THE INFORMATION OR DATA HEREIN SHALL BE PROVIDED "AS IS" WITHOUT ANY

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED WARRANTY OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Toshiba shall not be liable for any damages, losses, expenses or costs, if any,

incurred in connection with or as a result of use of any information or data provided

herein.

GREEN PRODUCT PROCUREMENT

The EC is actively promoting the WEEE & RoHS Directives that define standards for

recycling and reuse of Waste Electrical and Electronic Equipment and for the Restriction of

the use of certain Hazardous Substances. From July 1, 2006, the RoHS Directive will

prohibit any marketing of new products containing the restricted substances.

Increasing attention is given to issues related to the global environmental. Toshiba

Corporation recognizes environmental protection as a key management tasks, and is doing

its utmost to enhance and improve the quality and scope of its environmental activities. In

line with this, Toshiba proactively promotes Green Procurement, and seeks to purchase

and use products, parts and materials that have low environmental impacts.

Green procurement of parts is not only confined to manufacture. The same green parts

used in manufacture must also be used as replacement parts.

LEAD-FREE SOLDER

This product is manufactured using lead-free solder as a part of a movement within the

consumer products industry at large to be environmentally responsible. Lead-free solder

must be used in the servicing and repair of this product.

WARNING: This product is manufactured using lead free solder.

DO NOT USE LEAD BASED SOLDER TO REPAIR THIS PRODUCT!

The melting temperature of lead-free solder is higher than that of leaded solder by 30ºC to

40ºC (54ºF to 72ºF). Use of a soldering iron designed for lead-based solders to repair

product made with lead-free solder may result in damage to the component and or PCB

being soldered. Great care should be made to ensure high-quality soldering when servicing

this product especially when soldering large components, through-hole pins, and on PCBs

as the level of heat required to melt lead-free solder is high.

(1/4)

SAFETY INSTRUCTION

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "SAFETY PRECAUTION"

AND "PRODUCT SAFETY NOTICE" INSTRUCTIONS BELOW.

Safety Precaution

WARNING: SERVICING SHOULD NOT BE ATTEMPTED BY ANYONE UNFAMILIAR WITH

THE NECESSARY PRECAUTIONS ON THIS RECEIVER. THE FOLLOWING ARE THE

NECESSARY PRECAUTIONS TO BE OBSERVED BEFORE SERVICING THIS CHASSIS.

1. An isolation transformer should be connected in the power line between the receiver

and the AC line before any service is performed on the receiver.

2. Always disconnect the power plug before any disassembling of the product. It may

result in electrical shock.

3. When replacing a chassis in the cabinet, always be certain that all the protective

devices are put back in place, such as nonmetallic control knobs, insulating covers,

shields, isolation resistor-capacitor network, etc.

4. Always keep tools, components of the product, etc away from the children, These items

may cause injury to children.

5. Depending on the model, use an isolation transformer or wear suitable gloves when

servicing with the power on, and disconnect the power plug to avoid electrical shock

when replacing parts. In some cases, alternating current is also impressed in the

chassis, so electrical shock is possible if the chassis is contacted with the power on.

6. Always use the replacement parts specified for the particular model when making

repairs. The parts used in products require special safety characteristics such as

inflammability, voltage resistance, etc. therefore, use only replacement parts that have

these same characteristics. Use only the specified parts when the

in the circuit diagram or parts list.

7. Parts mounting and routing dressing of wirings should be the same as that used

originally. For safety purposes, insulating materials such as isolation tube or tape are

sometimes used and printed circuit boards are sometimes mounted floating. Also make

sure that wirings is routed and clamped to avoid parts that generate heat and which use

high voltage. Always follow the manufactured wiring routes / dressings.

mark is indicated

(2/4)

8. Always ensure that all internal wirings are in accordance before re-assembling the

external casing after a repairing completed. Do not allow internal wiring to be pinched

by cabinets, panels, etc. Any error in reassembly or wiring can result in electrical

leakage, flame, etc., and may be hazardous.

9. NEVER remodel the product in any way. Remodeling can result in improper operation,

malfunction, or electrical leakage and flame, which may be hazardous.

10. Touch current check. (After completing the work, measure touch current to prevent an

electric shock.)

Plug the AC cord directly into the AC outlet. Do NOT use an isolation transformer for

this check.

Connect a measuring network for touch currents between each exposed metallic part

on the set and a good earth ground such as a water pipe.

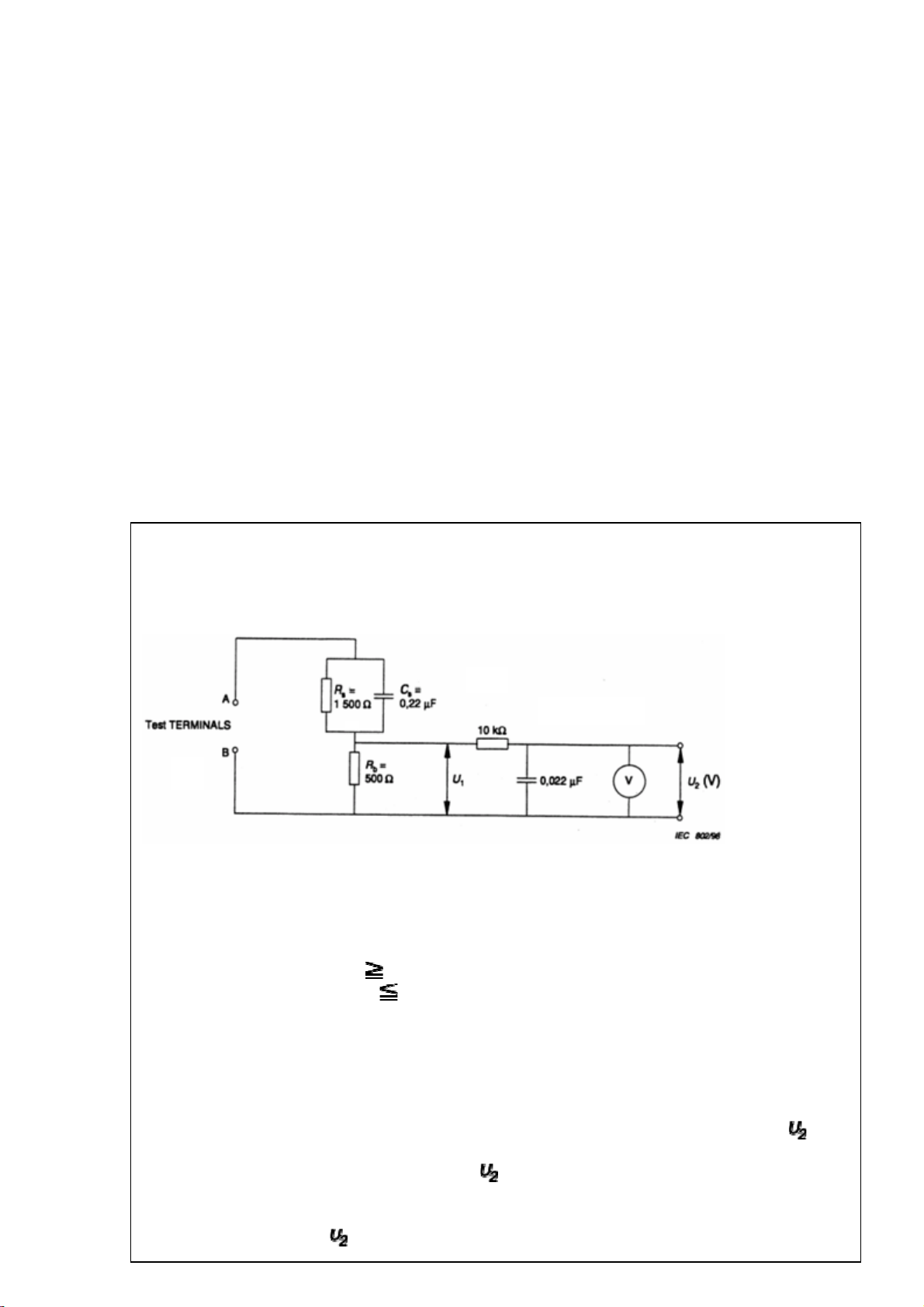

Annex D

(normative)

Measuring network for TOUCH CURRENTS

Resistance values in orms (Ω).

V: Voltmeter or oscilloscope

(r.m.s. or peak reading)

Input resistance :

1 MΩ

Input capacitance : 200 pF

Frequency range : 15 Hz to 1 MHz and d.c. respectively

Note: Appropriate measures should be taken to obtain the correct value in case of non

sinusoidal waveforms.

The measuring instrument is calibrated by comparing the frequency factor of with

the solid line in figure F.2 of IEC 60990 at various frequencies. A calibration curve is

constructed showing the deviation of

from the ideal curve as a function of

frequency.

TOUCH CURRENT =

/ 500 (peak value).

(3/4)

The potential at any point (TOUCH CURRENT) expressed as voltage and does

not exceed the following value:

The part or contact of a TERMINAL is not HAZARDOUS LIVE if:

a) The open-circuit voltage should not exceed 35 V (peak) a.c. or 60 V d.c. or, if a) is

not met.

b)

The measurement of the TOUCH CURRENT shall be carried out in accordance

with IEC 60990, with the measuring network described in Annex D of this

standard.

The TOUCH CURRENT expressed as voltages and , does not exceed the

following values:

- for a.c. : = 35 V (peak) and = 0.35 V (peak);

- for d.c. : = 1.0 V

Note: The limit values of = 0.35 V (peak) for a.c. and = 1.0 V for d.c.

correspond to the values 0.7 mA (peak) a.c. and 2.0 mA d.c.

(4/4)

Product Safety Notice

Many electrical and mechanical parts in this chassis have special safety-related characteristics.

These characteristics are often passed unnoticed by a visual inspection and the protection

afforded by them cannot necessarily be obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which have these special safety

characteristics are identified in this manual and its supplements; electrical components having

such features are identified by the international hazard symbols on the schematic diagram and

the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use

of substitute replacement parts which do not have the same safety characteristics as specified

in the parts list may create electrical shock, fire, or other hazards.

HOTEL MODE

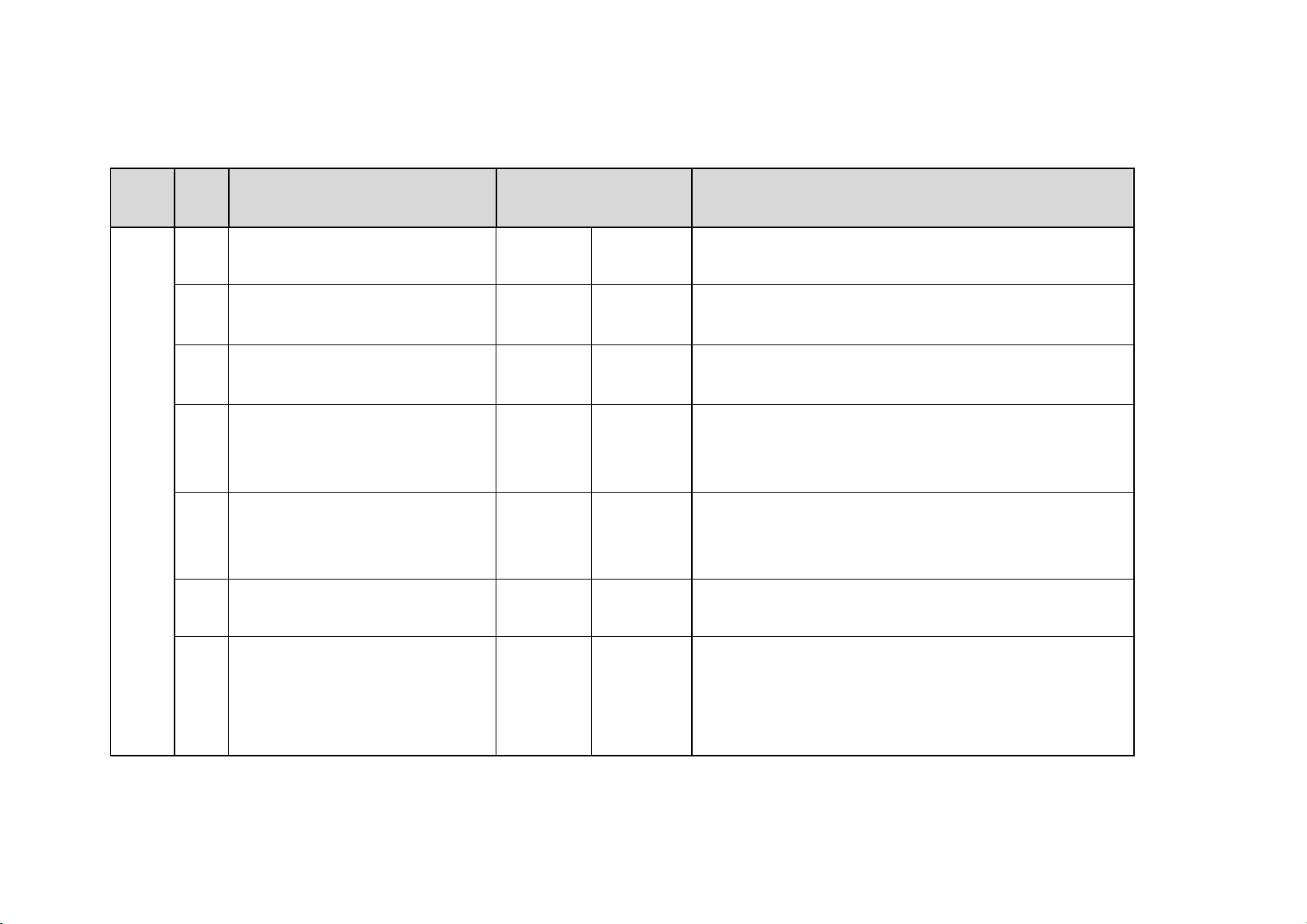

(1/5)

1

Function Setting *off(normal set)

Hotel Mode On/Off Off/On Off Hotel mode enable

1

Panel Lock Off/On Off Inhibit all buttons which are on TV body

2

Panel Lock W/O Input Selector Keys. Off/On Off Inhibit all buttons which are on TV body only disable input key

3

Disable Remote Control Off/On Off Inhibit the remote control.

4

Disable All Menu Off/On Off

5

Disable Setup Menu Off/On Off Inhibit set up menu

6

*On: hotel mode on

*On: not available Side key

*On: not available Side key only disable input key

*Setting is enable at the Service mode.

*On: not available remote control

*On: All of user menu will be disabled.

*Off: All of user menu will work normally.

*On: set up menu Inhibit

Information

Setup Menu W/O Lang. Off/On Off Inhibit display set up menu except for language

setting.

7

*There is only language setting at the Setup menu.

*On: only lang. display at setup menu.

Max Volume Setting 0~100[dec] 100 Max volume control

(2/5)

8

Digital Tuner Off/On On DTV source selection depends on Digital Tuner setting.

9

USB Port Off/On On MEDIA source selection depends on USB port setting.

10

TV to USB NO/YES NO It will clone the data of TV to USB disk. The data

11

USB to TV NO/YES NO It will clone the data of USB disk to TV. The data

12

Disable NIT Update Off/On Off *On: enable NIT update

13

Max vol setting Method:

Setting 100 volume, and turning and choice this value.

*On: enable DTV

*Off: hide DTV

*On: enable MEDIA in inputs menu

*Off: hide MEDIA in inputs menu

*

Off (Enable 5V): Disable USB, but enable the 5V power.

includes user setting, the setting of hotel mode and

channel table.

includes user setting, the setting of hotel mode and

channel table.

*Off: disable NIT update

Detect SCART On / Off On

14

ON: Pin8 will go on normal operation and it is going to switch

between sources automatically.

Off: Pin8 is ignored and the automatic source switching would

be enabled.

(3/5)

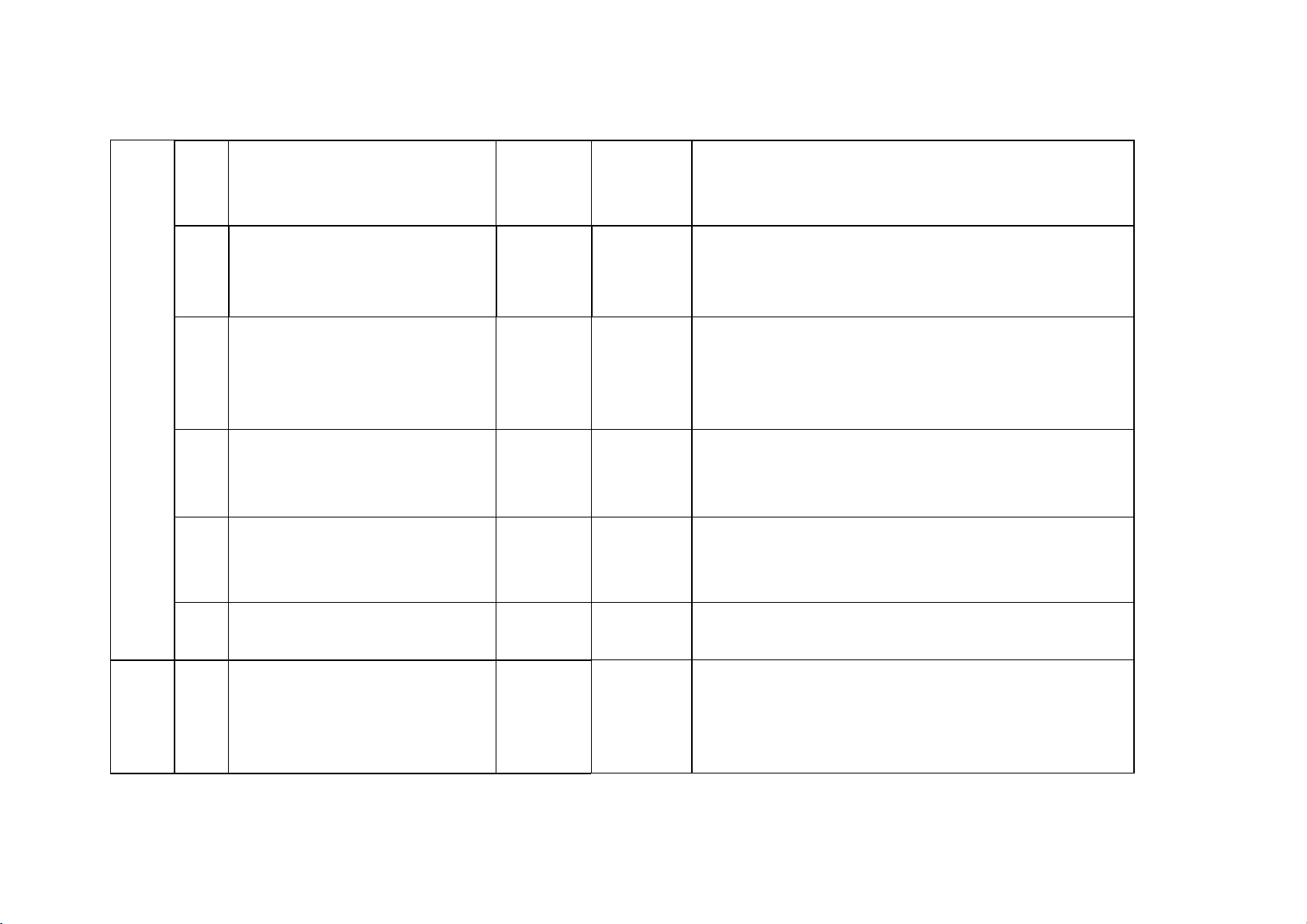

2

1 Fixed Pos/Video

2 Fixed Volume

3 Fixed Picture Mode

Off/ On(AC)/

On

ATV(0~99)/SCART/AV/

YPBPR/HDMI1/HDMI2/

PC/DTV

Off/On Off Remote control power button on or TV power switch(on side

0~100[dec] (normal:50)

Off/On Off Remote control power button on or TV power

0:Dynamic(Default)

1:Standard

2:Mild

Off Remote control power button on or TV power switch

(on side body) on, then display goes to fixed POS/Video

(= nealy equal #9)

*On: fixed pos/video set

*On (AC): TV tunes to preset “Pos/Video” (channel or input) only

when AC power is applied. When TV is powered on by power

button, tune to the last channel or input.

*TV, Component, AV,…, PC,HDMI,….Off

TV:1~255[dec] (normal:0)

DTV: depends on channel auto tuning

body) on , then forced volume setting

*101~ : not available

switch(on side body) on, then picture mode is selected

*On: Fixed selectable Pic.

4 Welcome Message

3:Movie

4:Memory

Off/On Off Remote control power button on or TV power

(4/5)

1:Default

2:8 Sec.

3:15 Sec.

Update Welcome Message YES/NO NO It will update the logo, when TV on the new logo show.

5

Teletext Off/On On Teletext functions are depend on Teletext setting

6

ATV/DTV P+/P- Off/On Off *On: enable ATV/DTV P+/P-

7

switch(on side body) on, then fixed "Welcome to our hotel"

Message is displayed.

'Until first operation' means that first event for TV

occur (ex. Ch up).

Using USB, user replaces the user original message with the

*

default welcome message.

As below is message, the file limitation items:

1. File format should be JPG file.

2. JPG Resolution <= 1360 x 768.

3. JPG file size < 64KB.

4. JPG file name is “Hotel_Logo.jpg”.

*On: enable Teletext functions and operation

*Off: disable Teletext functions and operation

*Off: disable ATV/DTV P+/P

TV Power Disabled/

8

Reset Menu YES/NO NO Set to default all setting in Hotel mode menu

9

On/ Standby

Disabled

*Disabled: TV returns to previous Standby/On state when AC

power is applied.

*On: Power TV on when AC power is applied.

*Standby: Put TV in Standby when AC power is applied.

How to enter Hotel Mode.

1) Press “MUTE” button on the remote, and display [mute].

2) Within 2 sec, press “MUTE” button on the remote again, and hold the button down for 3 sec.

3) Then, press “INPUT” button on the TV side. Then hotel mode menu will appear.

How to exit Hotel mode.

Turn the TV power off

(5/5)

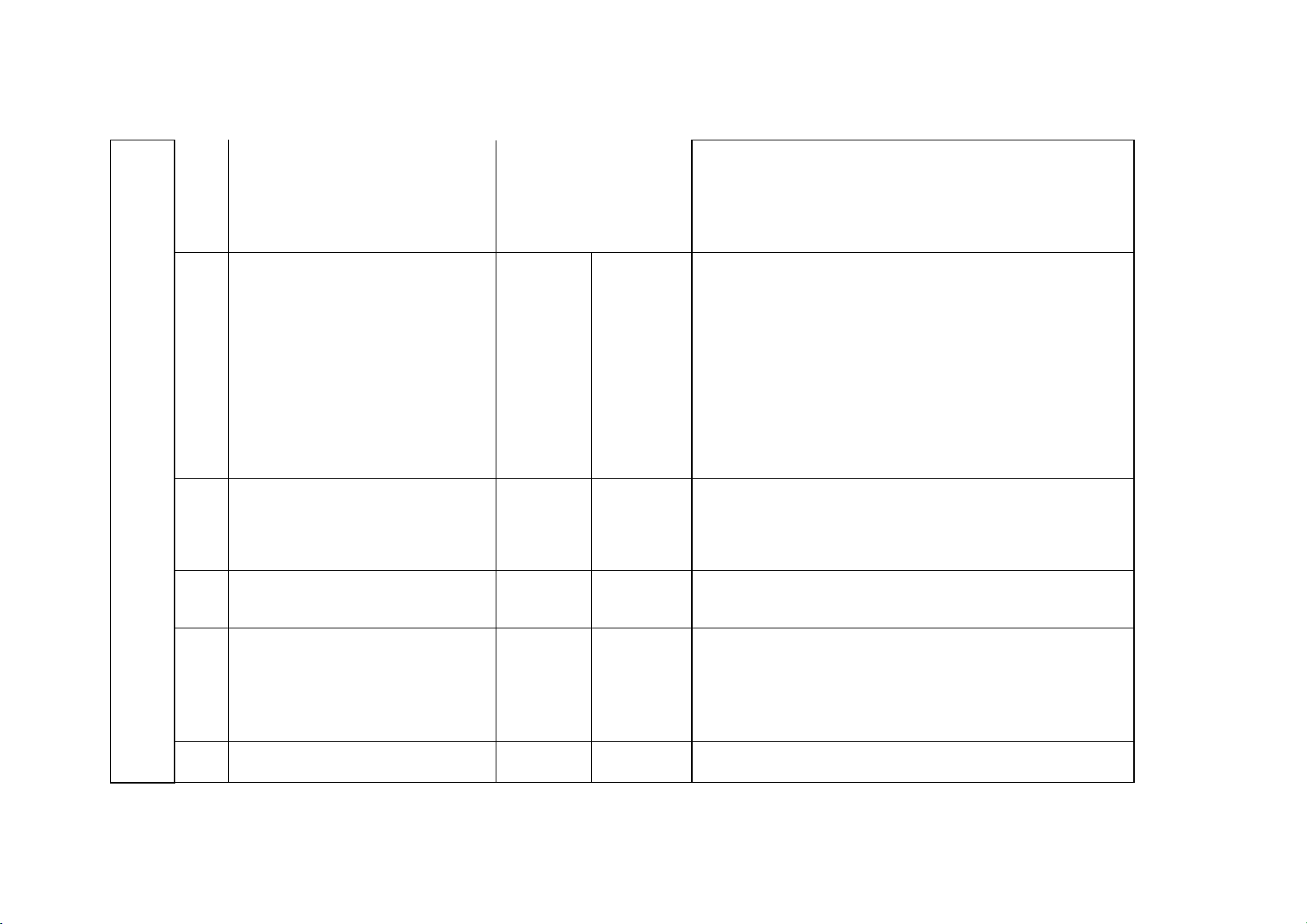

Copying Hotel Mode Setting

TV to USB:

TV to USB:

Copying a BIN file into USB flash.

Copying a BIN file into USB flash.

(1/4)

USB to TV:

USB to TV:

Copying a BIN file into TV.

Copying a BIN file into TV.

Copying Hotel Mode Setting

TV to USB Step :

1. Insert USB flash disk into TV USB port.

2. Please press “MUTE” key twice (MUTE icon disappear) ,

at the same time, press “SOURCE” by keypad for a while.

->“Hotel Menu” will come out.

3. Select the item “TV to USB” and press Left or Right

button to choose “YES”. Then press “OK” button.

->The hotel settings will copy into USB disk with file name

(2/4)

HOTEL_xxx23xxx.BIN

4. Once copy is finished. The OSD message “Please

wait...” will disappear then shown "OK! " message.

Copying Hotel Mode Setting

USB to TV Step (method 1) :

1. Insert USB disk with available file into TV USB port.

2. Please press “MUTE” key twice (MUTE icon disappear) , at

the same time, press “SOURCE” by keypad for a while.

->“Hotel Menu” will come out.

3. Selecting the item “USB to TV ” and press Left or Right

button to choose “YES”. Then press “OK” button.

(3/4)

->The hotel settings will copy from USB to TV with file name

HOTEL_xxx23xxx.BIN.

4. Once copy is finished. The OSD message “Please wait...”

will disappear then shown "Please remove USB memory, then

TV will be reset automatically" message.

Loading...

Loading...