Page 1

SERVICE MANUAL

LCD Color Television

32E2533D

FILE NO. 050-2015019

32E2543D

(System Information)

Page 2

CONTENTS

1. IMPORTANT NOTICE

2. GREEN PRODUCT PROCUREMENT

3. LEAD-FREE SOLDER

4. SAFETY INSTRUCTION

5. FIRMWARE UPDATING

6. INTERCONNECT

7. FACTORY MODE

8

. SCHEMATIC DIAGRAM

1

Page 3

IMPORTANT NOTICE

WARNING:

You are requested that you shall not modify or alter the information or data provided

herein without prior written consent by Toshiba. Toshiba shall not be liable to

anybody for any damages, losses, expenses or costs, if any, incurred in connection

with or as a result of such modification or alteration.

THE INFORMATION OR DATA HEREIN SHALL BE PROVIDED "AS IS" WITHOUT ANY

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED WARRANTY OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Toshiba shall not be liable for any damages, losses, expenses or costs, if any,

incurred in connection with or as a result of use of any information or data provided

herein.

Page 4

GREEN PRODUCT PROCUREMENT

The EC is actively promoting the WEEE & RoHS Directives that define standards for

recycling and reuse of Waste Electrical and Electronic Equipment and for the Restriction of

the use of certain Hazardous Substances. From July 1, 2006, the RoHS Directive will

prohibit any marketing of new products containing the restricted substances.

Increasing attention is given to issues related to the global environmental. Toshiba

Corporation recognizes environmental protection as a key management tasks, and is doing

its utmost to enhance and improve the quality and scope of its environmental activities. In

line with this, Toshiba proactively promotes Green Procurement, and seeks to purchase

and use products, parts and materials that have low environmental impacts.

Green procurement of parts is not only confined to manufacture. The same green parts

used in manufacture must also be used as replacement parts.

LEAD-FREE SOLDER

This product is manufactured using lead-free solder as a part of a movement within the

consumer products industry at large to be environmentally responsible. Lead-free solder

must be used in the servicing and repair of this product.

WARNING: This product is manufactured using lead free solder.

DO NOT USE LEAD BASED SOLDER TO REPAIR THIS PRODUCT!

The melting temperature of lead-free solder is higher than that of leaded solder by 30ºC to

40ºC (54ºF to 72ºF). Use of a soldering iron designed for lead-based solders to repair

product made with lead-free solder may result in damage to the component and or PCB

being soldered. Great care should be made to ensure high-quality soldering when servicing

this product especially when soldering large components, through-hole pins, and on PCBs

as the level of heat required to melt lead-free solder is high.

Page 5

(1/4)

SAFETY INSTRUCTION

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "SAFETY PRECAUTION"

AND "PRODUCT SAFETY NOTICE" INSTRUCTIONS BELOW.

Safety Precaution

WARNING: SERVICING SHOULD NOT BE ATTEMPTED BY ANYONE UNFAMILIAR WITH

THE NECESSARY PRECAUTIONS ON THIS RECEIVER. THE FOLLOWING ARE THE

NECESSARY PRECAUTIONS TO BE OBSERVED BEFORE SERVICING THIS CHASSIS.

1. An isolation transformer should be connected in the power line between the receiver

and the AC line before any service is performed on the receiver.

2. Always disconnect the power plug before any disassembling of the product. It may

result in electrical shock.

3. When replacing a chassis in the cabinet, always be certain that all the protective

devices are put back in place, such as nonmetallic control knobs, insulating covers,

shields, isolation resistor-capacitor network, etc.

4. Always keep tools, components of the product, etc away from the children, These items

may cause injury to children.

5. Depending on the model, use an isolation transformer or wear suitable gloves when

servicing with the power on, and disconnect the power plug to avoid electrical shock

when replacing parts. In some cases, alternating current is also impressed in the

chassis, so electrical shock is possible if the chassis is contacted with the power on.

6. Always use the replacement parts specified for the particular model when making

repairs. The parts used in products require special safety characteristics such as

inflammability, voltage resistance, etc. therefore, use only replacement parts that have

these same characteristics. Use only the specified parts when the

in the circuit diagram or parts list.

7. Parts mounting and routing dressing of wirings should be the same as that used

originally. For safety purposes, insulating materials such as isolation tube or tape are

sometimes used and printed circuit boards are sometimes mounted floating. Also make

sure that wirings is routed and clamped to avoid parts that generate heat and which use

high voltage. Always follow the manufactured wiring routes / dressings.

mark is indicated

Page 6

(2/4)

8. Always ensure that all internal wirings are in accordance before re-assembling the

external casing after a repairing completed. Do not allow internal wiring to be pinched

by cabinets, panels, etc. Any error in reassembly or wiring can result in electrical

leakage, flame, etc., and may be hazardous.

9. NEVER remodel the product in any way. Remodeling can result in improper operation,

malfunction, or electrical leakage and flame, which may be hazardous.

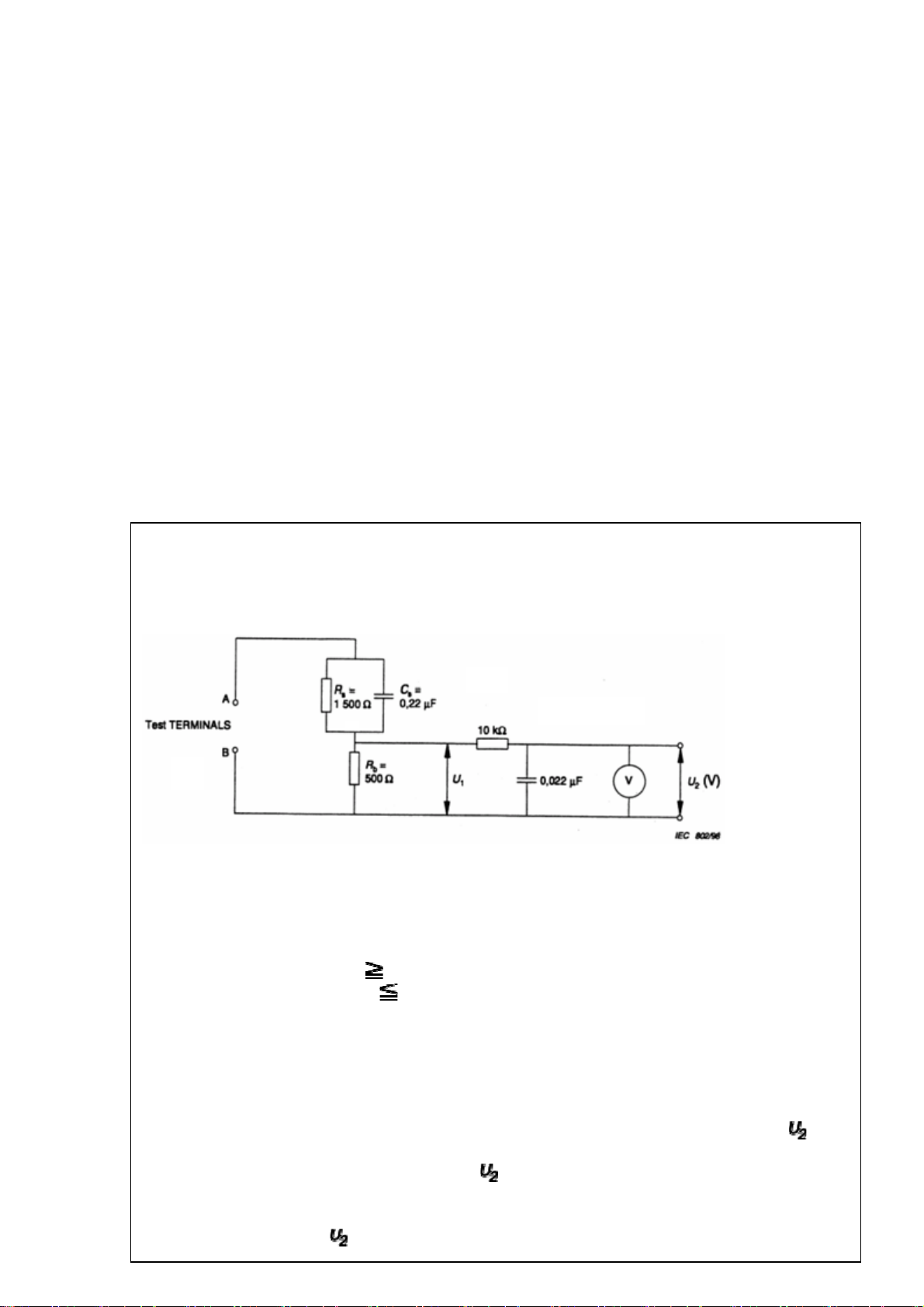

10. Touch current check. (After completing the work, measure touch current to prevent an

electric shock.)

Plug the AC cord directly into the AC outlet. Do NOT use an isolation transformer for

this check.

Connect a measuring network for touch currents between each exposed metallic part

on the set and a good earth ground such as a water pipe.

Annex D

(normative)

Measuring network for TOUCH CURRENTS

Resistance values in orms (Ω).

V: Voltmeter or oscilloscope

(r.m.s. or peak reading)

Input resistance :

1 MΩ

Input capacitance : 200 pF

Frequency range : 15 Hz to 1 MHz and d.c. respectively

Note: Appropriate measures should be taken to obtain the correct value in case of non

sinusoidal waveforms.

The measuring instrument is calibrated by comparing the frequency factor of with

the solid line in figure F.2 of IEC 60990 at various frequencies. A calibration curve is

constructed showing the deviation of

from the ideal curve as a function of

frequency.

TOUCH CURRENT =

/ 500 (peak value).

Page 7

(3/4)

The potential at any point (TOUCH CURRENT) expressed as voltage and does

not exceed the following value:

The part or contact of a TERMINAL is not HAZARDOUS LIVE if:

a) The open-circuit voltage should not exceed 35 V (peak) a.c. or 60 V d.c. or, if a) is

not met.

b)

The measurement of the TOUCH CURRENT shall be carried out in accordance

with IEC 60990, with the measuring network described in Annex D of this

standard.

The TOUCH CURRENT expressed as voltages and , does not exceed the

following values:

- for a.c. : = 35 V (peak) and = 0.35 V (peak);

- for d.c. : = 1.0 V

Note: The limit values of = 0.35 V (peak) for a.c. and = 1.0 V for d.c.

correspond to the values 0.7 mA (peak) a.c. and 2.0 mA d.c.

Page 8

(4/4)

Product Safety Notice

Many electrical and mechanical parts in this chassis have special safety-related characteristics.

These characteristics are often passed unnoticed by a visual inspection and the protection

afforded by them cannot necessarily be obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which have these special safety

characteristics are identified in this manual and its supplements; electrical components having

such features are identified by the international hazard symbols on the schematic diagram and

the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use

of substitute replacement parts which do not have the same safety characteristics as specified

in the parts list may create electrical shock, fire, or other hazards.

Page 9

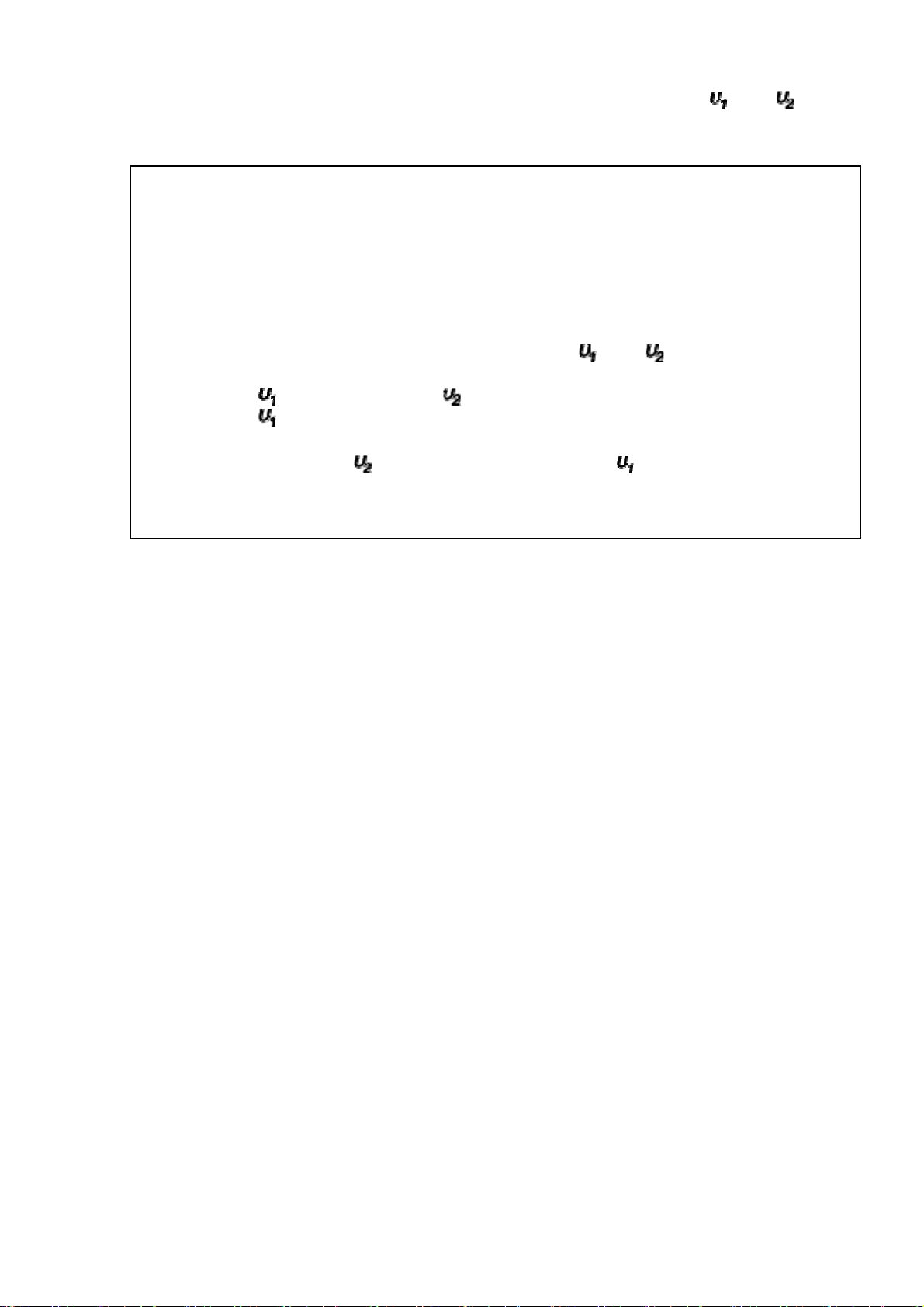

FIRMWARE UPDATING

xxx25xx.bin

TV

xxx25xx.bin for all panel type

TV TV TV

32"

MstarUpgrade.bi

TV

Choice one bin file by panel

TV

TV

TV

MstarUpgrade.bi

MstarUpgrade.bi

MstarUpgrade.bin

32"

40"

40"

50"

50"

How to upgrade F/W by a USB mass-storage device

Press right-exit-ok key into Engineering Information to confirm the Update xx25xx on the screen.

If update xx25xx display on the screen.

(1/3)

From UI upgrade

If update xx25xx not display on the screen.

From out side Input keypad upgrade.

Page 10

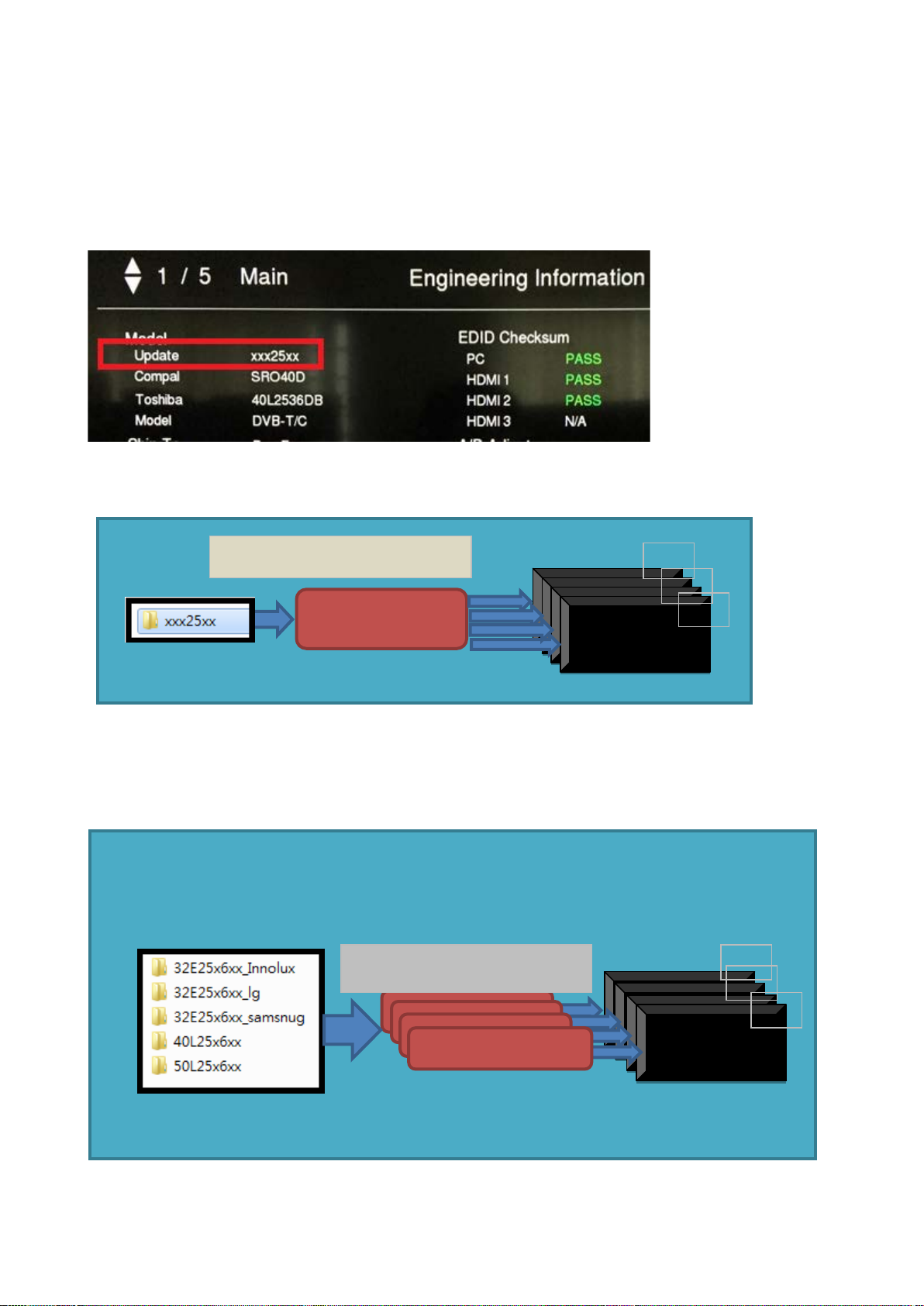

(2/3)

From UI upgrade

1. Copy xxx25xx.bin to the USB storage device.

USB storage device support FAT32 format only

2. Insert your USB storage device to the USB slot of the TV set.

3. Insert USB then TV will show “USB Devise was connected to TV. Do you want to

open Media Player?”

4. Change icon from “Yes” to “No”.

5. Press remote control “Menu” key and select “Installation” page.

6. Control remote down key to find “Software Update (USB)” icon and Press “OK” key.

7. Screen will show message “Do you want to upgrade software?”

8. Please Press "◄" Key and start t o upg r ade.

9. TV will show “SOFTWARE UPGRADE COMPLETE” mess ag e on sc r een.

10. TV is restarted when the update process finished.

11. After restarted, press "◄" and "EXIT" then "OK" key. Entry to Factory Mode.

12. Confirm Model ID / FW version /M-boot version and date.

Page 11

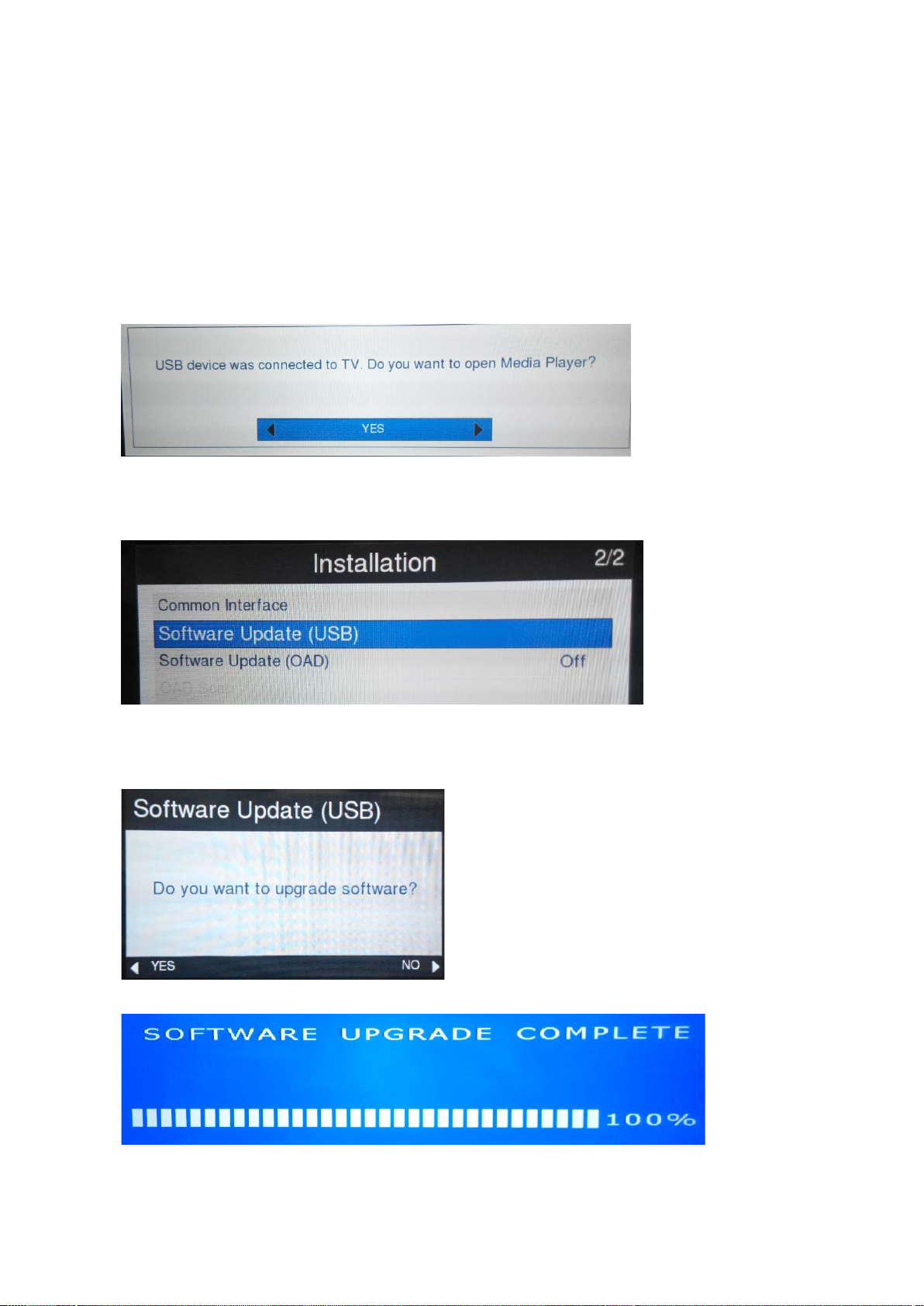

(3/3)

(To Check New FW version)

13. Press "MENU" key then using “◄” or “►” key until “Setup” page shows on the screen.

14. Press "▲ or ▼" key until you find "System Information" with focused blue bar.

15. To show the information, click "OK".

From out side Input keypad upgra de .

If don't care the model name mechanism whether exist .

- The .bin name should be ”MstarUpgrade.bin” on USB disc

1. Copy MstarUpgrade.bin to the USB storage device.

USB storage device support FAT32 format only

2. Insert your USB storage device to the USB slot of the TV set.

3. Press and hold Input of TV side key.

4. AC on, until LED green light flash then release input key.

5. TV will reboot after upgrade finish.

Page 12

32E2533D/2543D Wiring Diagram

CN8 P803

CN1 CN14 2 N/A 2

VLED2+

2

GREEN

2

3.3_ST 4 N/A 4

NC

3

GND

3

IRIN 5 N/A 5

VLED1-

4

5V

4

RED 6 N/A CN9 P802 6

VLED2-

CN1

7

3.3V_Normal 9

N/A 3 12V 3 12V2

1

GND

8

GND 10 N/A 4 GNDP 4 GND

17

N/A

11

ACD

11

ACD

CN7 29 B4P P801

1 L

2 N

IR/LED

Panel module

1 N/A 1 VLED1+

1 RED 1 GND 3 N/A 3

5 Green 7 N/A 1 12V 1 12V2 7 VLED36 SAR3 8

2 3.3V_ST 9 5V_ST 11 N/A 5 GNDP 5 GND

3 IRIN 12

4 N/A 13 N/A 7 GNDA 7 GND

5 N/A 14 N/A 8 NC 8 12V2

6 3.3V_Normal 15

Speaker(R)

Speaker(L)

1 R+SPK 30 B4N

2 R-SPK 31 B3P

3 L-SPK 32 B3N

4 L+SPK 33 BCLKP

N/A 2 12V 2 12V2

N/A

N/A

16 N/A 10 ACD 10 5V1

N/A

18

19 N/A 13 BLON 13 BLON

20 N/A 14 5V 14 5V1

21 LVDS_PWR 15 DIM 15 DIM

22 LVDS_PWR

23

LVDS_PWR

24 LVDS_PWR

25 GND

26 GND

27 GND

28 LVDS-SEL

34 BCLKN

35 B2P

36 B2N

37 B1P

38 B1N

39 B0P

40 B0N

12VA

6

GNDP

9

PWON

12

Main board

12VA

6

GND

9

PWON

12

Power board

VLED3+

Page 13

FACTORY MODE

Entering into factory Mode:

Press “◄” key, next press “EXIT” key, last press “ENTER” key in remote control to enter

into factory mode.

SRM32D_INX: COMPAL Model name and panel name

01.00.40 : F/W version.

Feb 18 2015 03:45:26:F/W release time.

PQ FW: Picture Quality FW version

AQ FW: Audio FW version.

Timer Clear:

Reset the timer which records hours of LCD panel burn in.

Page 14

5

D D

H1

C C

B B

H1

16

15

14

13

12

11

10

H85D45-HIT-TRI

H85D45-HIT-TRI

H5

H5

16

15

14

13

12

11

10

H85D40X50-HIT

H85D40X50-HIT

917

8

7

6

5

4

3

2

1

917

8

7

6

5

4

3

2

1

H2

H2

16

15

14

13

12

11

10

H85D45-HIT-TRI

H85D45-HIT-TRI

H6

H6

16

15

14

13

12

11

10

H85D45-HIT-TRI

H85D45-HIT-TRI

4

H3

H3

917

8

7

6

5

4

3

2

1

917

8

7

6

5

4

3

2

1

16

15

14

13

12

11

10

H85D45-HIT-TRI

H85D45-HIT-TRI

H7

H7

16

15

14

13

12

11

10

H85D4-HIT-TRI

H85D4-HIT-TRI

1

1

917

8

7

6

5

4

3

2

917

8

7

6

5

4

3

2

H4

H4

16

15

14

13

12

11

10

H85D45-HIT-TRI

H85D45-HIT-TRI

3

917

8

7

6

5

4

3

2

1

MSD8831Cover1

MSD8831Cover1

COVER1

COVER1

1 2

3

2

1

A A

Title

Title

Title

SCHEMATIC,M/B VTV-L50005

SCHEMATIC,M/B VTV-L50005

Size Document Num ber Rev

Size Document Num ber Rev

Size Document Num ber Rev

Date: Sheet of

Date: Sheet of

5

4

3

2

Date: Sheet of

SCHEMATIC,M/B VTV-L50005

B

B

B

401C7L

401C7L

401C7L

1C

1C

1C

1 19Monday, November 24, 2014

1 19Monday, November 24, 2014

1 19Monday, November 24, 2014

1

Page 15

5

4

3

2

1

5V Standby Power to 3.3V Standby /1.15V Core Power

+5V_Standby

C1

C1

10uF/0603/25V

10uF/0603/25V

D D

+3.3V_Standby

FB2

FB2

CLS/0603/60/3A

CLS/0603/60/3A

Vout=0.6 x (1+RU/RD)

LX1=0.6 x (1+560/124) =3.309

LX2=0.6 x (1+93.1/100) =1.1586

10uF/0603/25V

10uF/0603/25V

C11

C11

C12

C12

R6

R6

10uF/0603/25V

10uF/0603/25V

10uF/0603/25V

10uF/0603/25V

C2

C2

L2

L2

3.3uH/SCD0403/3.3A

3.3uH/SCD0403/3.3A

560K/0603/1%

560K/0603/1%

124K/0603/1%

124K/0603/1%

R1

100K/0402R1100K/0402

R12

R12

AX3771/1A/QFN12

AX3771/1A/QFN12

6

EN1

8

LX1

4

FB1

PADC13 15pF/0402/50VC13 15pF/0402/50V

13

U1

U1

VIN17NC15VIN2

GND19GND2

NC2

11

C4

C4

10uF/0603/25V

1

3

10uF/0603/25V

22uF/0805/6.3V

22uF/0805/6.3V

CLS/0603/60/3A

CLS/0603/60/3A

C83

C83

22uF/0805/6.3V

22uF/0805/6.3V

VCC1.10V

FB3

FB3

12

POWER_EN

EN2

2

LX2

3.3uH/SCD0403/3.3A

3.3uH/SCD0403/3.3A

10

93.1K/0603/1%

93.1K/0603/1%

FB2

R11

R11

100K/0603/1%

100K/0603/1%

POWER_EN

L3

L3

R7

R7

C1415pF/0402/50V C1415pF/0402/50V

C49

C49

+12V_Normal power to +5V_Normal power

+12V_NORMAL

R2

33K/0603/1%R233K/0603/1%

S

S

C5

R5

D

D

C6

R9

C15

C15

12K/0603/1%R512K/0603/1%

10uF/0603/25VC510uF/0603/25V

62K/0603R962K/0603

0.1uF/0402/16VC60.1uF/0402/16V

Vout=0.77V x {1+[(Rup*Rsw)/(Rup+Rsw)]/Rdw}

PG

Q30

Q30

YS-P2301/SOT-23

YS-P2301/SOT-23

R199

R199

1K/0402

1K/0402

G

G

2

7

6

8

0.1uF/0402/16V

0.1uF/0402/16V

U2

BD95835EFJU2BD95835EFJ

VIN

EN

RT

SS

10uF/0603/25VC910uF/0603/25V

FB1

FB1

CLS/0603/60/3A

CLS/0603/60/3A

C7

10uF/0603/25VC710uF/0603/25V

+5V_Normal

L1

L1

3.3uH/SCD0403/3.3A

3

SW

1

R3

BST

5

FB

GND

PW_PAD

4

9

82R/0603R382R/0603

R4

R4

Rsw

R8 56K/0603/1%R 8 56K/0603/1%

Rup

R10 9.1K/0603/1%R10 9.1K/0603/1%

Rdw

0.1uF/0402/16V

0.1uF/0402/16V

806K/0603/1%

806K/0603/1%

C10

C10

390pF/0402/50V/10%

390pF/0402/50V/10%

3.3uH/SCD0403/3.3A

C3

C3

C9

C18

C18

10uF/0603/25V

10uF/0603/25V

+5V_Normal power to +3.3V_Normal power

C C

+5V_Normal

FB6

FB6

CLS/0603/60/3A

CLS/0603/60/3A

U4

U4

AX1117AD33A/TO252

AX1117AD33A/TO252

VIN3VOUT

C25

C25

C24

C24

10uF/0603/25V

10uF/0603/25V

0.1uF/0402/16V

0.1uF/0402/16V

ADJ / GND

1

2

C26

C26

10uF/0603/25V

10uF/0603/25V

+5V_Normal power to +3.3V_TUNER

+5V_Normal

FB8

FB8

CLS/0603/60/3A

CLS/0603/60/3A

B B

U5

U5

AX1117AD33A/TO252

AX1117AD33A/TO252

VIN3VOUT

C28

C28

C29

C29

10uF/0603/25V

10uF/0603/25V

0.1uF/0402/16V

0.1uF/0402/16V

ADJ / GND

1

2

C30

C30

10uF/0603/6.3V

10uF/0603/6.3V

FB7

FB7

CLS/0603/60/3A

CLS/0603/60/3A

C27

C27

0.1uF/0402/16V

0.1uF/0402/16V

FB9

FB9

CLS/0603/60/3A

CLS/0603/60/3A

C31

C31

0.1uF/0402/16V

0.1uF/0402/16V

+3.3V_Normal

+3.3V_TUNER

+3.3V_Normal power to DDR_Power (DDR3-1.5V)

+3.3V_Normal

FB4

FB4

CLS/0603/60/3A

CLS/0603/60/3A

U3

U3

AX1117AEA/SOT223

AX1117AEA/SOT223

VIN3VOUT

ADJ/GND

1

VOUT

C20

C20

C19

C19

0.1uF/0402/16V

0.1uF/0402/16V

10uF/0603/6.3V

10uF/0603/6.3V

Vout=1.25V*(1+RB/RA)+80uA*RB

2

4

RA

RB

R13

R13

470R/0603/1%

470R/0603/1%

R14

R14

100R/0603/1%

100R/0603/1%

C21

C21

VCC1.5V

FB5

FB5

CLS/0603/60/3A

CLS/0603/60/3A

C22

C22

C23

C23

10uF/0603/6.3V

10uF/0603/6.3V

22uF/0805/6.3V

0.1uF/0402/16V

0.1uF/0402/16V

22uF/0805/6.3V

+5V_Normal power to MSB1312 Demod 1.2V

Vout =1.277V=1.25* (1+10.2/470)

Demod :1.2V ~1.26V ~1.32V

+5V_Normal

FB10

FB10

CLS/0603/60/3A

CLS/0603/60/3A

C32

C32

A A

DVB-S require

5

U6

U6

AX1117AEA/SOT223

AX1117AEA/SOT223

VIN3VOUT

C33

C33

0.1uF/0402/16V

0.1uF/0402/16V

10uF/0603/25V

10uF/0603/25V

ADJ/GND

1

VOUT

2

4

RA

RB

R15

R15

470R/0603/1%

470R/0603/1%

R16

R16

10.2R/0603/1%

10.2R/0603/1%

C41

C41

C39

C39

0.1uF/0402/16V

0.1uF/0402/16V

10uF/0603/6.3V

10uF/0603/6.3V

CLS/0603/60/3A

CLS/0603/60/3A

C40

C40

22uF/0805/6.3V

22uF/0805/6.3V

DM_1.2V

FB12

FB12

Vout=1.25V*(1+RB/RA)+80uA*RB

4

+5V_Normal power to 8831-DVB-T2 Demod 1.2V

+5V_Normal

FB11

FB11

CLS/0603/60/3A

CLS/0603/60/3A

DVB-T2 require

3

U7

U7

AX1007E12A/SOT223

AX1007E12A/SOT223

VIN3VOUT

C35

C35

C34

C34

0.1uF/0402/16V

0.1uF/0402/16V

10uF/0603/25V

10uF/0603/25V

ADJ/GND

1

VOUT

2

4

C38

C38

C37

C37

C36

C36

10uF/0603/6.3V

10uF/0603/6.3V

0.1uF/0402/16V

0.1uF/0402/16V

FB13

FB13

CLS/0603/60/3A

CLS/0603/60/3A

22uF/0805/6.3V

22uF/0805/6.3V

MCP_VDDC

2

Title

Title

Title

SCHEMATIC,M/B VTV-L50005

SCHEMATIC,M/B VTV-L50005

SCHEMATIC,M/B VTV-L50005

Size Document Number Rev

Size Document Number Rev

Size Document Number R

C

C

C

401C7L

401C7L

401C7L

Date: Sheet of

Date: Sheet of

Date: Sheet of

2 19Monday, November 24, 2014

2 19Monday, November 24, 2014

2 19Monday, November 24, 2014

1

ev

1C

1C

1C

Page 16

5

U8C

U8C

C2

A_RX0N

C1

A_RX0P

D3

A_RX1N

D1

A_RX1P

D2

A_RX2N

E3

D D

HDMI-CEC

HDMI2-RX0N

HDMI2-RX0P

HDMI2-RX1N

HDMI2-RX1P

HDMI2-RX2N

HDMI2-RX2P

HDMI2-CLKN

HDMI2-CLKP

HDMI2-HPDIN

HDMI2-SCL

HDMI2-SDA

HDMI3-RX0N

HDMI3-RX0P

C C

B B

A A

HDMI3-RX1N

HDMI3-RX1P

HDMI3-RX2N

HDMI3-RX2P

HDMI3-CLKN

HDMI3-CLKP

HDMI3-HPDIN

HDMI3-SCL

HDMI3-SDA

SPDIF_OUT

MHL_CABLE_DET

MHL_VBUS_EN

A_RX2P

C3

A_RXCN

B1

A_RXCP

B2

HOTPLUGA

F1

DDCDA_CK

F2

DDCDA_DA

E2

PAD_ARC0

F3

CEC

W5

C_RX0N

Y5

C_RX0P

W6

C_RX1N

Y6

C_RX1P

AA6

C_RX2N

W7

C_RX2P

AA4

C_RXCN

Y4

C_RXCP

V4

HOTPLUGC

W4

DDCDC_CK

W3

DDCDC_DA

C6

D_RX0N

B5

D_RX0P

C5

D_RX1N

B4

D_RX1P

A4

D_RX2N

C4

D_RX2P

A6

D_RXCN

B6

D_RXCP

A2

HOTPLUGD

A3

DDCDD_CK

B3

DDCDD_DA

E10

SPDIF_IN

D10

SPDIF_OUT

F4

MHL_CABLE_DETECT/PM13

F5

MHL_VBUS_EN/PM14

PG

C74

C74

0.1uF/0402/16V

0.1uF/0402/16V

HDMI

HDMI

U15

U15

AX6902ERA/SOT23/2.93V

AX6902ERA/SOT23/2.93V

POR

POR

3

VCC

RESET

1

GND

SPDIF

SPDIF

EARPHONE_OUTL

EARPHONE_OUTR

Analog AudioI2S

Analog AudioI2S

MHL

MHL

2

LINE_IN_0L

LINE_IN_0R

LINE_IN_1L

LINE_IN_1R

LINE_IN_2L

LINE_IN_2R

LINE_IN_3L

LINE_IN_3R

LINE_OUT_0L

LINE_OUT_0R

LINE_OUT_2L

LINE_OUT_2R

I2S_IN_BCK

I2S_IN_WS

I2S_IN_SD

I2S_OUT_BCK

I2S_OUT_MCK

I2S_OUT_WS

I2S_OUT_SD

MSD8831RM2 FBGA-369

MSD8831RM2 FBGA-369

R303

R303

10K/0402

10K/0402

(High reset)

PG_BLK

5

VAG

VRM

IRIN

RESET

TESTPIN

XTALIN

XTALOUT

4

U5

HP_Audio-L

V5

HP_Audio-R

P3

LINE_IN_0L

R2

LINE_IN_0R

U2

LINE_IN_1L

T3

LINE_IN_1R

T2

T1

R1

R3

N3

AUVAG

P2

AUVRM

T4

T5

U3

LINEOUT2_L

U4

LINEOUT2_R

F12

E12

D12

F10

AUBCK_OUT

E11

AUMCK_OUT

F11

AUWS_OUT

D11

AUSD_OUT

B7

IRIN

E8

System-RST

R14

AA2

XTALI

Y2

XTALO

G

C71

C71

10uF/0603/6.3V

10uF/0603/6.3V

4

C42 2.2uF/0603/6.3VC42 2.2uF/0603/6.3V

C43 2.2uF/0603/6.3VC43 2.2uF/0603/6.3V

C44 2.2uF/0603/6.3VC44 2.2uF/0603/6.3V

C45 2.2uF/0603/6.3VC45 2.2uF/0603/6.3V

MCP_I2CS_SCL

MCP_RESET

MCP_I2CS_SDA

+3.3V_Standby +3.3V_Standby

R105 0R/04 02/NCR105 0R/04 02/NC

R106 0R/04 02/NCR106 0R/04 02/NC

R141 0R/04 02/NCR141 0R/04 02/NC

R304

R304

10K/0402

10K/0402

D

Q28

Q28

YS-2N7002/SOT23

YS-2N7002/SOT23

S

G

G

YS-P2301/SOT-23

YS-P2301/SOT-23

3

12/11 :MSD8831RM2 / MSD8832RKM2 for T2 Demod debug

E12: AUWS_IN // MCP_RESET

SC-Lin

SC-Rin

COMP_AUL

COMP_AUR

F12: AUSCK_IN //MCP_I2CS_SCL

D12: AUSD_IN //MCP_I2CS_SDA

Close to MST IC

with wide trace

AUVAG

C47

C46

C46

1uF/0402/6.3V

AUVRM

XTALI

C273

C273

18pF/0402/50V

18pF/0402/50V

S

S

Q25

Q25

D

D

+3.3V_Standby

R148

R148

0R/0402

0R/0402

C140

C140

0.1uF/0402/16V

0.1uF/0402/16V

1uF/0402/6.3V

Y1

Y1

24MHZ/HSX321G +-20PPM 12PF

24MHZ/HSX321G +-20PPM 12PF

H/W Reset

U9

U9

AX6902ERA/SOT23/2.93V

AX6902ERA/SOT23/2.93V

POR

POR

3

VCC

RESET

1

GND

(High reset)

3

C47

4.7uF/0603/6.3V

4.7uF/0603/6.3V

R305

R305

1M/0402

1M/0402

4 3

1

2

FB14

FB14

CLS/0603/60/3A

CLS/0603/60/3A

2

R18

R18

68R/0402

68R/0402

System-RST

C274

C274

18pF/0402/50V

18pF/0402/50V

2

R306

R306

820R/0402/1%

820R/0402/1%

2

1

HP_Audio-L

HP_Audio-R

SC-Lin

SC-Rin

COMP_AUL

COMP_AUR

LINEOUT2_L

LINEOUT2_R

AUBCK_OUT

AUMCK_OUT

AUWS_OUT

AUSD_OUT

SPDIF_OUT

MHL_CABLE_DET

MHL_VBUS_EN

IRIN

PG_MUTE

PG

XTALO

Size Document Num ber Rev

Size Document Num ber Rev

Size Document Num ber Rev

B

B

B

Date: Sheet of

Date: Sheet of

Date: Sheet of

HDMI-CEC

HDMI2-RX0N

HDMI2-RX0P

HDMI2-RX1N

HDMI2-RX1P

HDMI2-RX2N

HDMI2-RX2P

HDMI2-CLKN

HDMI2-CLKP

HDMI2-HPDIN

HDMI2-SCL

HDMI2-SDA

HDMI3-RX0N

HDMI3-RX0P

HDMI3-RX1N

HDMI3-RX1P

HDMI3-RX2N

HDMI3-RX2P

HDMI3-CLKN

HDMI3-CLKP

HDMI3-HPDIN

HDMI3-SCL

HDMI3-SDA

Title

Title

Title

SCHEMATIC,M/B VTV-L50005

SCHEMATIC,M/B VTV-L50005

SCHEMATIC,M/B VTV-L50005

401C7L

401C7L

401C7L

HP_Audio-L {11}

HP_Audio-R {11}

SC-Lin {8}

SC-Rin {8}

COMP_AUL {14}

COMP_AUR {14}

LINEOUT2_L {12}

LINEOUT2_R {12}

AUBCK_OUT {13}

AUMCK_OUT {13}

AUWS_OUT {13}

AUSD_OUT {13}

SPDIF_OUT {13}

MHL_CABLE_DET{10 }

MHL_VBUS_EN {10}

IRIN {5}

PG_MUTE

PG {5}

HDMI-CEC {10}

HDMI2-RX0N {10}

HDMI2-RX0P {10}

HDMI2-RX1N {10}

HDMI2-RX1P {10}

HDMI2-RX2N {10}

HDMI2-RX2P {10}

HDMI2-CLKN {1 0}

HDMI2-CLKP {10}

HDMI2-HPDIN {10}

HDMI2-SCL {10}

HDMI2-SDA {10}

HDMI3-RX0N {10}

HDMI3-RX0P {10}

HDMI3-RX1N {10}

HDMI3-RX1P {10}

HDMI3-RX2N {10}

HDMI3-RX2P {10}

HDMI3-CLKN {1 0}

HDMI3-CLKP {10}

HDMI3-HPDIN {10}

HDMI3-SCL {10}

HDMI3-SDA {10}

1

{5}

1C

1C

1C

3 19Monday, November 24, 2014

3 19Monday, November 24, 2014

3 19Monday, November 24, 2014

Page 17

5

H3

VGA_GINVGA_GIN+

VGA_BIN+ BIN0

VGA_HSYNC

VGA_VSYNC

RGB2-YPbPr_RIN+

D D

RGB2-YPbPr_GIN- GIN1N

RGB2-YPbPr_GIN+

RGB2-YPbPr_BIN+

SCART_RIN+

SCART_GIN- GIN2N

SCART_GIN+

SCART_BIN+ BIN2

SC-HSYNC

SC-VSYNC

R20 33R/0402R20 33R/0402

R22 68R/0402R22 68R/0402

R21 33R/0402R21 33R/0402

R23 33R/0402R23 33R/0402

R24 33R/0402R24 33R/0402

R25 68R/0402R25 68R/0402

R26 33R/0402R26 33R/0402

R27 33R/0402R27 33R/0402

R28 0R/0402R28 0R/0402

R29 33R/0402R29 33R/0402

R30 68R/0402R30 68R/0402

R31 33R/0402R31 33R/0402

R32 33R/0402R32 33R/0402

C50 47nF/0402/16VC50 47nF/0402/16V

C51 47nF/0402/16VC51 47nF/0402/16V

C52 47nF/0402/16VC52 47nF/0402/16V

C53 47nF/0402/16VC53 47nF/0402/16V

C54 47nF/0402/16VC54 47nF/0402/16V

C55 47nF/0402/16VC55 47nF/0402/16V

C56 47nF/0402/16VC56 47nF/0402/16V

C57 47nF/0402/16VC57 47nF/0402/16V

C58 1nF/0402/50VC58 1nF/0402/50V

C59 47nF/0402/16VC59 47nF/0402/16V

C60 47nF/0402/16VC60 47nF/0402/16V

C61 47nF/0402/16VC61 47nF/0402/16V

C62 47nF/0402/16VC62 47nF/0402/16V

RIN0VGA_RIN+

GIN0N

GIN0

RIN1

GIN1

BIN1

SOGIN1

RIN2

GIN2

G2

G1

G3

G4

G5

K3

J1

J2

H2

J3

L2

L3

K2

K1

H5

H4

Close to MST IC

with wide trace

U8B

PCM-D[7:0]{18}

C C

PCM-A[14:0]{18}

B B

A A

5

PCM-D[7:0]

PCM-A[14:0]

NAND_ALE

NAND_CEZ

NAND_CEZ1

NAND_CLE

NAND_DQS

NAND_RBZ

NAND_REZ

NAND_WEZ

NAND_WPZ

NAND_AD0

NAND_AD1

NAND_AD2

NAND_AD3

NAND_AD4

NAND_AD5

NAND_AD6

NAND_AD7

PCM-D0

PCM-D1

PCM-D2

PCM-D3

PCM-D4

PCM-D5

PCM-D6

PCM-D7

PCM-A0

PCM-A1

PCM-A2

PCM-A3

PCM-A4

PCM-A5

PCM-A6

PCM-A7

PCM-A8

PCM-A9

PCM-A10

PCM-A11

PCM-A12

PCM-A13

PCM-A14

PCM-CD

PCM-CE

PCM-IORD

PCM-IOWR

PCM-IRQA

PCM-OE

PCM-REG

PCM-RST

PCM-WAIT

PCM-WE

U8B

T19

PCM_D0

T21

PCM_D1

T20

PCM_D2

Y18

PCM_D3

AA18

PCM_D4

W19

PCM_D5

Y17

PCM_D6

AA19

PCM_D7

V19

PCM_A0

U20

PCM_A1

W20

PCM_A2

Y16

PCM_A3

P19

PCM_A4

R20

PCM_A5

T18

PCM_A6

U19

PCM_A7

Y19

PCM_A8

W21

PCM_A9

W17

PCM_A10

Y20

PCM_A11

U18

PCM_A12

V21

PCM_A13

U17

PCM_A14

T17

PCM_CD_N

W18

PCM_CE_N

AA20

PCM_IORD_N

Y21

PCM_IOWR_N

V18

PCM_IRQA_N

AA16

PCM_OE_N

V20

PCM_REG_N

R21

PCM_RESET

P20

PCM_WAIT_N

R19

PCM_WE_N

T10

NAND_ALE

V8

NAND_CEZ

U8

NAND_CEZ1

U9

NAND_CLE

U11

NAND_DQS

U7

NAND_RBZ

V7

NAND_REZ

T11

NAND_WEZ

T7

NAND_WPZ

Y8

NAND_AD0

W9

NAND_AD1

AA9

NAND_AD2

W10

NAND_AD3

Y10

NAND_AD4

W11

NAND_AD5

W12

NAND_AD6

Y12

NAND_AD7

MSD8831RM2 FBGA-369

MSD8831RM2 FBGA-369

PCM NAND

PCM NAND

4

U8E

U8E

RIN0P

GIN0M

GIN0P

BIN0P

HSYNC0

VSYNC0

RIN1P

RGB

RGB

GIN1M

GIN1P

BIN1P

SOGIN1

RIN2P

GIN2M

GIN2P

BIN2P

HSYNC2

VSYNC2

MSD8831RM2 FBGA-369

MSD8831RM2 FBGA-369

TS0_D0

TS0_D1

TS0_D2

TS0_D3

TS0_D4

TS0_D5

TS0_D6

TS0_D7

TS0_CLK

TS0_VLD

TS0_SYNC

TS1_D0

TS1_D1

TSVIF

TSVIF

TS1_D2

TS1_D3

TS1_D4

TS1_D5

TS1_D6

TS1_D7

TS1_CLK

TS1_VLD

TS1_SYNC

VIFP

VIFM

IFAGC

TGPIO0

TGPIO1

TGPIO2/SCKM1

TGPIO3/SDAM1

4

RN

RP

TN

TP

PHYUSB

PHYUSB

DM_P0

DP_P0

DM_P1

DP_P1

CVBS1P

CVBS0P

VCOM

CVBS_OUT1

CVBS

CVBS

W14

TS0-D0

U16

TS0-D1

T16

TS0-D2

Y13

TS0-D3

AA15

TS0-D4

Y15

TS0-D5

Y14

TS0-D6

V15

TS0-D7

W15

TS0-CLK

W16

TS0-VLD

V16

TS0-SYNC

AA13

TS1-D0

W13

TS1-D1

U13

TS1-D2

V13

TS1-D3

T12

TS1-D4

T15

TS1-D5

U15

TS1-D6

U14

TS1-D7

T13

TS1-CLK

U12

TS1-VLD

T14

TS1-SYNC

V1

W1

Y1

AA3

V2

R49 0R/0402R49 0R/0402

Y3

W2

I2C:

Turner/Demod

3

B9

C9

B8

C8

A12

B12

AA7

Y7

M1

N1

N2

M2

C66

C66

0.1uF/0402/16V/NC

0.1uF/0402/16V/NC

MDI_RN

MDI_RP

MDI_TN

MDI_TP

USB1_DM

USB1_DP

C63 47nF/0402/16VC63 47nF/0402/16V

CVBS0

C64 47nF/0402/16VC64 47nF/0402/16V

VCOM0 CVBS-

C65 47nF/0402/16VC65 47nF/0402/16V

TS0-D[7:0] {18}

TS0-D[7:0]

TS0-CLK {18}

TS0-VLD {18}

TS0-SYNC {18}

TS1-D[7:0] {18}

TS1-D[7:0]

TS1-CLK {18}

TS1-VLD {18}

TS1-SYNC {18}

VIF_1

VIF_2

IFAGC

USB_EN

DVBS_RESETn

I2CM_SCL

I2CM_SDA

R33 33R/0402R33 33R/0402

R34 33R/0402R34 33R/0402

R35 68R/0402R35 68R/0402

SC_CVBS_OUT

YPbPr_AVIN CVBS-

SC_CVBS-IN C VBS-

CVBS-

RGB2-YPbPr_RIN+

RGB2-YPbPr_GIN+

RGB2-YPbPr_BIN+

VGA_RIN+

VGA_GIN+

VGA_BIN+

SCART_RIN+

SCART_GIN+

SCART_BIN+

3

SC_CVBS-INCVBS1

YPbPr_AVIN

SC_CVBS_OUT {8}

R36 75R /0402/1%R36 75R /0402/1%

R37 75R /0402/1%R37 75R /0402/1%

R38 0R/04 02R38 0R/04 02

R39 75R /0402/1%R39 75R /0402/1%

R40 75R /0402/1%R40 75R /0402/1%

R41 75R /0402/1%R41 75R /0402/1%

R42 75R /0402/1%R42 75R /0402/1%

R43 75R /0402/1%R43 75R /0402/1%

R44 75R /0402/1%R44 75R /0402/1%

R45 75R /0402/1%R45 75R /0402/1%

R46 75R /0402/1%R46 75R /0402/1%

R47 75R /0402/1%R47 75R /0402/1%

RGB2-YPbPr_GIN-

VGA_GIN-

SCART_GIN-

Close to MST IC

with wide trace

2

VGA_RIN+

VGA_GIN+

VGA_BIN+

VGA_HSYNC

VGA_VSYNC

RGB2-YPbPr_RIN+

RGB2-YPbPr_GIN+

RGB2-YPbPr_BIN+

SCART_RIN+

SCART_GIN+

SCART_BIN+

SC-HSYNC

SC-VSYNC

MDI_TP

MDI_TN

MDI_RP

MDI_RN

USB1_DM

USB1_DP

SC_CVBS-IN

YPbPr_AVIN

CVBSSC_CVBS_OUT

TS0-CLK

TS0-VLD

TS0-SYNC

TS1-CLK

TS1-VLD

TS1-SYNC

PCM-CD

PCM-CE

PCM-IORD

PCM-IOWR

PCM-IRQA

PCM-OE

PCM-REG

PCM-RST

PCM-WAIT

PCM-WE

NAND_ALE

NAND_CEZ

NAND_CEZ1

NAND_CLE

NAND_DQS

NAND_RBZ

NAND_REZ

NAND_WEZ

NAND_WPZ

NAND_AD0

NAND_AD1

NAND_AD2

NAND_AD3

NAND_AD4

NAND_AD5

NAND_AD6

NAND_AD7

VIF_1

VIF_2

IFAGC

DVBS_RESETn

I2CM_SDA

I2CM_SCL

USB_EN

Title

Title

Title

SCHEMATIC,M/B VTV-L50005

SCHEMATIC,M/B VTV-L50005

Size Document Num ber Rev

Size Document Num ber Rev

Size Document Num ber Rev

Date: Sheet of

Date: Sheet of

2

Date: Sheet of

SCHEMATIC,M/B VTV-L50005

B

B

B

401C7L

401C7L

401C7L

1

VGA_RIN+ <12>

VGA_GIN+ <12>

VGA_BIN+ <12>

VGA_HSYNC <12>

VGA_VSYNC <12>

RGB2-YPbPr_RIN+ <133>

RGB2-YPbPr_GIN+ <133>

RGB2-YPbPr_BIN+ <133>

SCART_RIN+ <10>

SCART_GIN+ <10>

SCART_BIN+ <10>

SC-HSYNC <10>

SC-VSYNC <10>

MDI_TP 6

MDI_TN 6

MDI_RP 6

MDI_RN 6

USB1_DM {17}

USB1_DP {17}

SC_CVBS-IN < 10>

YPbPr_AVIN

CVBSSC_CVBS_OUT <10>

TS0-CLK {18}

TS0-VLD {18}

TS0-SYNC {18}

TS1-CLK {18}

TS1-VLD {18}

TS1-SYNC {18}

PCM-CD {18}

PCM-CE {18}

PCM-IORD {18}

PCM-IOWR {18}

PCM-IRQA {18}

PCM-OE {18}

PCM-REG {18}

PCM-RST {18}

PCM-WAIT {18}

PCM-WE {18}

NAND_ALE {20}

NAND_CEZ {20}

NAND_CEZ1 {20}

NAND_CLE {20 }

NAND_DQS {20 }

NAND_RBZ {20}

NAND_REZ {20}

NAND_WEZ {20}

NAND_WPZ {20}

NAND_AD0 {20 }

NAND_AD1 {20 }

NAND_AD2 {20 }

NAND_AD3 {20 }

NAND_AD4 {20 }

NAND_AD5 {20 }

NAND_AD6 {20 }

NAND_AD7 {20 }

VIF_1 <6>

VIF_2 <6>

IFAGC <6>

DVBS_RESETn<6>

I2CM_SDA <6>

I2CM_SCL <6>

USB_EN <6>

4 19Monday, November 24, 2014

4 19Monday, November 24, 2014

4 19Monday, November 24, 2014

1

1C

1C

1C

Page 18

5

4

3

2

1

LVA0N

U8D

U8D

PCM_PWR_CTL

LED_G

BRI_ADJ-PWM2

PWM_PM

D D

LED_R

SPI_SCK

SPI_SDI

SPI_SDO

SPI_CSN_1

C C

B B

R50 0R/0402R50 0R/0402

R51 0R/0402R51 0R/0402

R53 0R/0402R53 0R/0402

R54 10K/0402R54 10K/0402

R308 0R/0402R308 0R/0402

R307 0R/0402/NCR307 0R/0402/NC

R56 33R/0402R56 33R/0402

R52 33R/0402R52 33R/0402

R58 33R/0402R58 33R/0402

R59 33R/0402R59 33R/0402

UART-RX

UART-TX

SCL_EEPROM

SDA_EEPROM

PWM0

PWM1

PWMPM

SAR0

SAR1

SAR2

SAR3

SAR5

SPI-SCK

SPI-SDI

SPI-SDO

SPI-CS1N

R273 100 R/0402R273 1 00R/0402

K17

PWM0

K18

PWM1

J18

PWM2

D9

PWM_PM

E4

SAR0

E5

SAR1

F7

SAR2

F6

SAR3

F8

SAR5

A10

PM_SPI_CK

B10

PM_SPI_DI

C11

PM_SPI_DO

B11

GPIO_PM6(SPI-CZ1N)

C21

UART_RX2

C20

UART_TX2

E7

DDCA_CK/UART0_RX

D7

DDCA_DA/UART0_T X

B21

DDCR_CK

B20

DDCR_DA

L17

SPI1_CK

L18

SPI1_DI

M18

SPI2_CK

M16

SPI2_DI

M17

VSYNC_LIKE

E9

GPIO19(UART2_TX1)

F9

GPIO20(UART2_RX1)

PWM SAR

PWM SAR

LVDS Block

SPI GPIO

SPI GPIO

LVDS

LVDS

GPIO_PM1(PM_UART)

GPIO_PM5 (PM_UART)

GPIO_PM0

GPIO_PM2

GPIO_PM3

GPIO_PM4

GPIO_PM7

GPIO_PM

GPIO_PM

LVA0N

LVA0P

LVA1N

LVA1P

LVA2N

LVA2P

LVACKN

LVACKP

LVA3N

LVA3P

LVA4N

LVA4P

LVB0N

LVB0P

LVB1N

LVB1P

LVB2N

LVB2P

LVBCKN

LVBCKP

LVB3N

LVB3P

LVB4N

LVB4P

LDE

LCK

LVSYNC

LHSYNC

TCON0

TCON1

TCON2

TCON3

TCON4

TCON5

TCON6

TCON7

PM_LED

K21

J19

K19

K20

L19

L20

M21

M20

N21

M19

N19

N20

E19

E20

F21

F20

G21

F19

G19

G20

H19

H20

J21

J20

D20

D19

D21

C19

R18

P17

N18

N17

P16

N16

R17

R16

D6

E6

A7

C10

C7

C12

A9

G6

LVA0N

LVA0P

LVA1NBRI_ADJ-PWM2-C

LVA1P

LVA2N

LVA2P

LVACLKN

LVACLKP

LVA3N

LVA3P

LVA4N

LVA4P

LVB0N

LVB0P

LVB1N

LVB1P

LVB2N

LVB2P

LVBCLKN

LVBCLKP

LVB3N

LVB3P

LVB4N

LVB4P

R63 4.7K/0402R63 4.7K/0402

R65 0R/0402R65 0R/0402

R66 0R/0402/NCR66 0R/0402/NC

R67 0R/0402/NCR67 0R/0402/NC

R68 0R/0402R68 0R/0402

R69 100R/0402R69 100 R/0402

Panel_ON-P1

VBLCTRL-P2

FLASH_WPN

Keypad_PWR

R71 0R/0402/NCR71 0R/0402/NC

POWER_SW

PM7

PM_LED

USB0_OCD

PRE-AMP_SD

MUTE_DAMP

AMP_RESET

MHL_OCD

HP_DET

WP_EEPROM

IC Configuration Selection

+3.3V_Standby

R55 4.7K/0402R55 4.7K/0402

R57 4.7K/0402R57 4.7K/0402

R60 4.7K/0402R60 4.7K/0402

+3.3V_Standby

R61 4.7K/0402R61 4.7K/0402R252 100 R/0402R252 1 00R/0402

PCM_PWR_CTL

1 0 0 1

PWM_PM

SPI-SDI

PM_LED:

High:Nand Start

Low:SPI Start

PM_LED

PM7

R70

R70

10K/0402

10K/0402

+3.3V_Normal

LVA0P

LVA1N

LVA1P

LVA2N

LVA2P

LVACLKN

LVACLKP

LVA3N

LVA3P

LVA4N

LVA4P

LVB0N

LVB0P

LVB1N

LVB1P

LVB2N

LVB2P

LVBCLKN

LVBCLKP

LVB3N

LVB3P

LVB4N

LVB4P

PCM_PWR_CTL

BRI_ADJ-PWM2

SAR0

SAR3

Keypad_PWR

UART-RX

UART-TX

USB0_OCD

MHL_OCD

PRE-AMP_SD

MUTE_DAMP

HP_DET

AMP_RESET

LED_G

LED_R

Panel_ON-P1

VBLCTRL-P2

POWER_SW

LVA0N {15,22}

LVA0P {15,22}

LVA1N {15,22}

LVA1P {15,22}

LVA2N {15,22}

LVA2P {15,22}

LVACLKN {15,22}

LVACLKP {15,22}

LVA3N {15,22}

LVA3P {15,22}

LVA4N {15,22}

LVA4P {15,22}

LVB0N {15,22}

LVB0P {15,22}

LVB1N {15,22}

LVB1P {15,22}

LVB2N {15,22}

LVB2P {15,22}

LVBCLKN {15,22}

LVBCLKP {15,22}

LVB3N {15,22}

LVB3P {15,22}

LVB4N {15,22}

LVB4P {15,22}

PCM_PWR_CTL

BRI_ADJ-PWM2

SAR0

SAR3

Keypad_PWR

UART-RX

UART-TX

USB0_OCD

MHL_OCD

PRE-AMP_SD

MUTE_DAMP

HP_DET <8>

AMP_RESET

LED_G

LED_R

Panel_ON-P1 {15}

VBLCTRL-P2 {15}

POWER_SW {2}

MSD8831RM2 FBGA-369

MSD8831RM2 FBGA-369

9/29: Add EEPROM

NC

NC

NC

GND4SDA

U18

U18

24C08/SOP8

24C08/SOP8

+3.3V_Standby

8

VCC

7

WP

6

SCL

5

R149

R149

4.7K/0402

4.7K/0402

WP_EEPROM

SCL_EEPROM

SDA_EEPROM

R163

R163

4.7K/0402/NC

4.7K/0402/NC

R151

R151

4.7K/0402

4.7K/0402

2

R153

R153

4.7K/0402

4.7K/0402

Title

Title

Title

SCHEMATIC,M/B VTV-L50005

SCHEMATIC,M/B VTV-L50005

Size Document Num ber Rev

Size Document Num ber Rev

Size Document Num ber R

Date: Sheet of

Date: Sheet of

Date: Sheet of

SCHEMATIC,M/B VTV-L50005

B

B

B

401C7L

401C7L

401C7L

5 19Monday, November 24, 2014

5 19Monday, November 24, 2014

5 19Monday, November 24, 2014

1

ev

1C

1C

1C

Boot Loader SPI Flash

+3.3V_Standby

R72

R72

4.7K/0402

+3.3V_Standby

A A

10K/0402

10K/0402

R75

R75

SPI_CSN_1

SPI_SDO

FLASH_WPN

R78

R78

10K/0402/NC

10K/0402/NC

5

4.7K/0402

1

2

3

+3.3V_Standby

U10

U10

CE#

VDD

SO

HOLD#

WP#

SCK

VSS4SI

W25Q16DVSSIG

W25Q16DVSSIG

C67

C67

0.1uF/0402/16V

0.1uF/0402/16V

8

7

6

SPI_SCK

5

SPI_SDI

R73

R73

10K/0402

10K/0402

Detect NAND Flash Power

+5V_Standby

R74

R74

200K/0402/1%

200K/0402/1%

RB

R76

R76

1K/0402/1%

1K/0402/1%

RC

R77

R77

51K/0402/1%

51K/0402/1%

4

RD

SAR5

EEPROM

C280

C280

0.1uF/0402/16V

0.1uF/0402/16V

1

2

3

3

Page 19

5

4

3

2

1

Vcore Power -Normal 1.15V

VCC1.10V

CLS/0603/60/3A

CLS/0603/60/3A

D D

VDDC

R79

R79

C68

C68

2.2uF/0603/6.3V

2.2uF/0603/6.3V

C70

C70

C69

C69

0.1uF/0402/16V

0.1uF/0402/16V

DDR3 POWER

VCC1.5V

VCC1.5V_N

C C

Standby Power 3.3V

+3.3V_Standby

R80

R80

0R/0603

0R/0603

R81

R81

0R/0603

0R/0603

AVDD_DRAM

C78

C78

10uF/0603/25V

10uF/0603/25V

AVDD_DM AVDD_NODIE AVDD_DMPLL

C86

C86

10uF/0603/25V

10uF/0603/25V

AVDDL_MOD

C96

C96

C138

C72

C72

C73

C73

0.1uF/0402/16V

0.1uF/0402/16V

0.1uF/0402/16V

0.1uF/0402/16V

C80

C80

C79

C79

0.1uF/0402/16V

0.1uF/0402/16V

2.2uF/0603/6.3V

2.2uF/0603/6.3V

C87

C87

C88

C88

0.1uF/0402/16V

0.1uF/0402/16V

0.1uF/0402/16V

0.1uF/0402/16V

AVDD_AU

C92

C92

C93

C93

0.1uF/0402/16V

0.1uF/0402/16V

0.1uF/0402/16V

0.1uF/0402/16V

C138

0.1uF/0402/16V

0.1uF/0402/16V

22uF/0805/6.3V

22uF/0805/6.3V

22uF/0805/6.3V

22uF/0805/6.3V

in Locate:J12,K12

P

AVDD_DRAM

C81

C81

C82

C82

0.1uF/0402/16V

0.1uF/0402/16V

0.1uF/0402/16V

0.1uF/0402/16V

C90

0.1uF/0402/16V

0.1uF/0402/16V

AVDD_AU

C90

Pin Locate:K5

C132

C132

0.1uF/0402/16V/NC

0.1uF/0402/16V/NC

C91

C91

0.1uF/0402/16V

0.1uF/0402/16V

C89

C89

Normal Power 3.3V

+3.3V_Normal

B B

R82

R82

0R/0603

0R/0603

VDDP

AVDD_MOD AVDD_PLL

C95

C95

C97

C94

C94

10uF/0603/25V

10uF/0603/25V

C97

0.1uF/0402/16V

0.1uF/0402/16V

0.1uF/0402/16V

0.1uF/0402/16V

MCP_VDD3

C100

C98

C98

0.1uF/0402/16V

0.1uF/0402/16V

C100

C99

C99

0.1uF/0402/16V

0.1uF/0402/16V

0.1uF/0402/16V

0.1uF/0402/16V

AVDDL_MOD

Pin Locate: A14,B14,C14,G9

C75

C75

C76

C76

0.1uF/0402/16V/NC

0.1uF/0402/16V/NC

C85

C85

C84

C84

0.1uF/0402/16V/NC

0.1uF/0402/16V/NC

0.1uF/0402/16V/NC

0.1uF/0402/16V/NC

0.1uF/0402/16V

0.1uF/0402/16V

AVDD_DM

Pin Locate:K4,L4

C133

C133

C134

C134

0.1uF/0402/16V/NC

0.1uF/0402/16V/NC

0.1uF/0402/16V/NC

0.1uF/0402/16V/NC

Pin Locate:N9 Pin Locate:P9 and R8

AVDD_PLL

MCP_VDD3

C135

C190

C190

C135

0.1uF/0402/16V/NC

0.1uF/0402/16V/NC

U8F

U8F

0.1uF/0402/16V/NC

0.1uF/0402/16V/NC

DVDD_NODIE

0.1uF/0402/16V/NC

0.1uF/0402/16V/NC

VDDC

AVDDL_MOD

AVDD_NODIE

AVDD_AU

AVDD_DMPLL

AVDD_DM

C77

C77

1uF/0402/6.3V

1uF/0402/6.3V

A14

VDDC

B14

VDDC

C13

VDDC

C14

VDDC

E14

VDDC

F13

VDDC

G9

VDDC

G10

VDDC

G11

VDDC

G12

VDDC

H9

VDDC

J9

VDDC

B13

DVDD_DDR

H10

DVDD_DDR

A13

DVDD_RX_0

H11

DVDD_RX_0

K9

AVDDL_MOD

H7

DVDD_NODIE

J6

AVDD_NODIE

K5

AVDD_AU33

L5

AVDD3P3_DMPLL

K4

AVDD_DVI_USB_MPLL

L4

AVDD_DVI_USB_MPLL

A15

GND

A18

GND

B15

GND

B18

GND

C15

GND

C18

GND

D15

GND

D18

GND

E15

GND

E18

GND

F15

GND

F18

GND

G7

GND

G8

GND

G15

GND

G18

GND

H6

GND

H8

GND

H18

GND

J4

GND

J8

GND

J16

GND

J17

GND

K8

GND

K15

GND

K16

GND

L6

GND

L7

GND

L8

GND

L9

GND

L10

GND

L11

GND

L12

GND

L13

GND

L14

GND

L15

GND

L16

GND

AVDD_DDR_DATA0

AVDD_DDR_DATA0

AVDD_DDR_DATA0

AVDD_DDR_DATA0

MSD8831RM2 FBGA-369

MSD8831RM2 FBGA-369

AVDD_DDR_CMD0

AVDD_DDR_CMD0

AVDD5V_MHL_C

AVDD5V_MHL_D

MCP DVB-T2

MCP DVB-T2

AVDD_DRAM

AVDD_DRAM

VDDP

VDDP

AVDD_PLL

AVDD_MOD

AVDD_MOD

VSENSE_VDD

GND_EFUSE

MCP_VDDC

MCP_VDDC

MCP_VDD33

MCP_AVDD

MCP_TESTPIN

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

B16

J10

A16

J11

J12

K12

A17

B17

M8

N8

N9

M10

N10

V3

D4

R15

R13

R6

R7

P9

R8

R12

M4

M6

M9

M11

M12

M13

M14

M15

N4

N6

N11

N12

N13

N14

N15

P5

P10

P11

P12

P13

P14

P15

R5

R9

R10

R11

T6

T8

T9

U6

U10

V6

V10

V12

W8

Y9

Y11

AA10

AA12

AVDD5V_MHL_C

AVDD_DRAM

VDDP

AVDD_PLL

AVDD_MOD

AVDD5V_MHL_C

MCP_VDDC

MCP_VDDC=Demod 1.2V

MCP_VDD3

MCP_VDDC=Demod 1.2V

MCP_VDDC

C101

C101

10uF/0603/25V

10uF/0603/25V

A A

5

C189

C189

C102

C102

2.2uF/0603/6.3V

2.2uF/0603/6.3V

0.1uF/0402/16V

0.1uF/0402/16V

Pin Locate:R6

MCP_VDDC

C191

C191

4

0.1uF/0402/16V/NC

0.1uF/0402/16V/NC

Title

Title

Title

SCHEMATIC,M/B VTV-L50005

SCHEMATIC,M/B VTV-L50005

SCHEMATIC,M/B VTV-L50005

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

C

C

C

401C7L

401C7L

401C7L

Date: Sheet of

Date: Sheet of

3

2

Date: Sheet of

6 19Monday, November 24, 2014

6 19Monday, November 24, 2014

6 19Monday, November 24, 2014

1

1C

1C

1C

Page 20

5

D D

AVDD_DRAM

R83

R83

2K/0402

2K/0402

C C

R84

R84

1K/0402/1%

1K/0402/1%

4

DDR3_RESETB

DDR3_CKE

3

DDR3_CKE

DDR3_RESETB

R85

R85

240R/0402/1%

240R/0402/1%

A20

A19

B19

U8A

U8A

A_DDR3_CKE

A_DDR3_RESETB

ZQ

MSD8831RM2 FBGA-369

MSD8831RM2 FBGA-369

2

MIU0

MIU0

1

B B

Title

Title

A A

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

Custom

Custom

Custom

Date: Sheet of

Date: Sheet of

Date: Sheet of

5

4

Title

SCHEMATIC,M/B VTV-L50005

SCHEMATIC,M/B VTV-L50005

SCHEMATIC,M/B VTV-L50005

1C

1C

401C7L

401C7L

401C7L

7 19Monday, November 24, 2014

7 19Monday, November 24, 2014

7 19Monday, November 24, 2014

3

2

1

1C

Page 21

5

4

3

2

1

Close to MST IC

Full SCART

CN1

CN1

SHILED

SHILED

VIN

VIN

VOUT

D D

VOUT

GNDVI

GNDVI

GNDVO

GNDVO

RGBSW

RGBSW

RIN

RIN

GNDSW

GNDSW

GNDR

GNDR

N.C.

N.C.

GIN

GIN

N.C.

N.C.

GNDG

GNDG

FunSel

FunSel

BIN

BIN

AIL

AIL

GNDB

GNDB

GNDA

GNDA

AOL

AOL

AIR

AIR

AOR

AOR

SCART YS RC-2102 H17

SCART YS RC-2102 H17

Close to connector

with wide trace:12mils

21

CVBS-

20

SC_CVBS-IN

19

SCART_CVBSO

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

SC-VSYNC

SCART_RIN+

SCART_GIN+

SCART_BIN+

SCART-Lin

SCART-Lout

SCART-Rin

SCART-Rout

R89

R89

33K/0402

33K/0402

CVBS- {4,14,19}

C106

C106

4.7nF/0402/50V/10%

4.7nF/0402/50V/10%

R90

R90

33K/0402

33K/0402

C107

C107

4.7nF/0402/50V/10%

4.7nF/0402/50V/10%

R86

R86

10K/0402

10K/0402

C108

C108

47pF/0402/50V

47pF/0402/50V

2.7K/0402

2.7K/0402

R91

R91

R92

R92

75R/0402/1%

75R/0402/1%

D27

D27

CDZ55C5V6/1206/5%

CDZ55C5V6/1206/5%

R87 470R/0402R87 470R/0402

R88 470R/0402R88 470R/0402

D28

D28

CDZ55C5V6/1206/5%

CDZ55C5V6/1206/5%

SCART_FB_SUB

SC-VSYNC <7>

SC-HSYNC <7>

SCART_MODE

SCART_Lout

SCART_Rout

SCART MODE

2V~2.5V 4:3

0.9V~1.49V 16:9

0V~0.4V inactive

with wide trace

SC_CVBS-IN

C103

C103

10pF/0402/50V/NC

10pF/0402/50V/NC

C104

C104

10pF/0402/50V/NC

10pF/0402/50V/NC

C105

C105

10pF/0402/50V/NC

10pF/0402/50V/NC

SC_CVBS-IN <7>

SCART_RIN+ <7>

SCART_GIN+ <7>

SCART_BIN+ <7>

1nF/0402/50V

1nF/0402/50V

LINEOUT2_R

1nF/0402/50V

1nF/0402/50V

C118

C118

SCART-Rin

SCART-Lin

C127

C127

C109

C109

Close to connector

C C

SC_CVBS_OUT<7>

SOC side

SC_CVBS_OUT

R95

R95

CLS/0402/600/300mA

CLS/0402/600/300mA

C279

C253

C253

C279

SCART CVBS Output

100pF/0402/50V/5%/NC

100pF/0402/50V/5%/NC

AU_OUT_EN

High : Enable

Low : Disable

HP_EN

R118

R118

Q2

Q2

YS-MMBT3904/SOT23

YS-MMBT3904/SOT23

AU_OUT_EN

HP_EN

AU_OUT_EN

R109

R109

0R/0402

B B

PRE-AMP_SD<8>

R197 Short:

PRE-AMP SD , AU_OUT EN

Low (Ini) Low >> Mute AMP

High High >>Normal

A A

5

PRE-AMP_SD

ACD=PG

AC ON :3V~3.6V

AC OFF:<0.5V

PG_MUTE<15,133>

PG_MUTE

C ON :Low

A

AC OFF:High

R121

R121

1K/0402

1K/0402

0R/0402

R111

R111

0R/0402

0R/0402

C48

C48

4.7uF/0603/6.3V

4.7uF/0603/6.3V

+3.3V_Standby

10K/0402/NC

10K/0402/NC

C

B

E

100pF/0402/50V/5%/NC

100pF/0402/50V/5%/NC

<8>

4

SCART_CVBSO

SCART Side

R98

R98

75R/0402/1%

75R/0402/1%

LINEOUT2_L<7>

LINEOUT2_R<7>

Close to MSTAR IC

LINEOUT2_L

C110

C110

330pF/0402/50V/5%

330pF/0402/50V/5%

R104

R104

200K/0402/1%

200K/0402/1%

R115

R115

200K/0402/1%

200K/0402/1%

330pF/0402/50V/5%

330pF/0402/50V/5%

3

R93

R93

10K/0402

10K/0402

R94

R94

10K/0402

10K/0402

C117

C117

2.2uF/0603/6.3V

2.2uF/0603/6.3V

C121

C121

2.2uF/0603/6.3V

2.2uF/0603/6.3V

C125

C125

2.2uF/0603/6.3V

2.2uF/0603/6.3V

C129

C129

2.2uF/0603/6.3V

2.2uF/0603/6.3V

R96

R96

12K/0402

12K/0402

C111

C111

R97

R97

12K/0402

12K/0402

+3.3V_Normal

R102

R102

12K/0603/1%

12K/0603/1%

R107

R107

12K/0603/1%

12K/0603/1%

R110

R110

30.1K/0603/1%

30.1K/0603/1%

R112

R112

30.1K/0603/1%

30.1K/0603/1%

R113

R113

12K/0603/1%

12K/0603/1%

R116

R116

12K/0603/1%

12K/0603/1%

C112

C112

560pF/0402/50V

560pF/0402/50V

CLS/0603/60/3A

CLS/0603/60/3A

C119

C119

30pF/0402/50V

30pF/0402/50V

C128

C128

30pF/0402/50V

30pF/0402/50V

SC-Rin

SC-Lin

560pF/0402/50V

560pF/0402/50V

FB15

FB15

0.1uF/0402/16V

0.1uF/0402/16V

R100

R100

33K/0402/1%

33K/0402/1%

SC-Rin <7>

SC-Lin <7>

C113

C113

R103

R103

43K/0402/1%

43K/0402/1%

R108

R108

43K/0402/1%

43K/0402/1%

C122

C122

30pF/0402/50V

30pF/0402/50V

C124

C124

30pF/0402/50V

30pF/0402/50V

R114

R114

43K/0402/1%

43K/0402/1%

R117

R117

43K/0402/1%

43K/0402/1%

R119

R119

33K/0402/1%

33K/0402/1%

AU_OUT_EN

AU_OUT_EN

H

igh : Enable

Low : Disable

C114

C114

10uF/0603/25V

10uF/0603/25V

R99

R99

10K/0402/1%

10K/0402/1%

C115

C115

30pF/0402/50V

30pF/0402/50V

12

13

14

INL-

INL+

OUTL

INR+1INR-2OUTR3SGND4EN5PVSS6CN

C130

C130

30pF/0402/50V

30pF/0402/50V

2

Line Driver

R101

R101

4.7R/0603

4.7R/0603

C120

C120

1uF/0402/6.3V

1uF/0402/6.3V

11

9

8

10

CP

PVDD

PGND

NC/UVP

7

C126

C126

1uF/0402/6.3V

1uF/0402/6.3V

R120

R120

4.7R/0603

4.7R/0603

R122

R122

10K/0402/1%/NC

10K/0402/1%/NC

SCART_Lout

C116

C116

47pF/0402/50V

47pF/0402/50V

U11

U11

DRV632/TSSOP14

DRV632/TSSOP14

C123

C123

1uF/0402/6.3V

1uF/0402/6.3V

SCART_Rout

C131

C131

47pF/0402/50V

47pF/0402/50V

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

Date: Sheet of

Date: Sheet of

Date: Sheet of

OutputInput

Title

Title

Title

SCHEMATIC,M/B VTV-L50005

SCHEMATIC,M/B VTV-L50005

SCHEMATIC,M/B VTV-L50005

C

C

C

401C7L

401C7L

401C7L

1C

1C

8 19Monday, November 24, 2014

8 19Monday, November 24, 2014

8 19Monday, November 24, 2014

1

1C

Page 22

5

CN2

D D

VGAHSYNC VGA_BIN+

VGAVSYNC

C C

DDC_SCL_D

CN2

XH 30715FB1BB-H10.5

XH 30715FB1BB-H10.5

11

17

12

16

13

14

15

1

6

2

7

3

8

4

9

5

10

R139 0R/0402R139 0R/0402

R140 0R/0402R140 0R/0402

4

Close to MST IC

VGA_RIN+

VGA_GIN+

UART-RX

UART-TXDDC_SDA_D

UART-RX <8>

UART-TX <8>

3

VGA_RIN+ <7>

VGA_GIN+ <7>

VGA_BIN+ <7>

VGAHSYNC

VGAVSYNC

R125

R125

2.2K/0402

2.2K/0402

2

R123

R123

510R/0402

510R/0402

R124

R124

510R/0402

510R/0402

R126

R126

10K/0402

10K/0402

VGA_HSYNC

VGA_VSYNC

VGA_HSYNC <7>

VGA_VSYNC <7>

Close to MST IC

1

+5V_Standby

Debug port

R128

R128

R127

R127

B B

4.7K/0402

4.7K/0402

4.7K/0402

1

2

3

J3

J3

XINYA H2031_1x4_ P2.0/NC

XINYA H2031_1x4_ P2.0/NC

A A

5

4

4.7K/0402

R137 100R/0402R137 100R/0402

R138 100R/0402R138 100R/0402

4

UART-TX

UART-RX

3

Title

Title

Title

SCHEMATIC,M/B VTV-L50005

SCHEMATIC,M/B VTV-L50005

SCHEMATIC,M/B VTV-L50005

Size Document Number Rev

Size Document Number Rev

Size Document Number R

A

A

A

Date: Sheet of

Date: Sheet of

Date: Sheet of

401C7L

401C7L

401C7L

2

9 19Monday, November 24, 2014

9 19Monday, November 24, 2014

9 19Monday, November 24, 2014

1

ev

1C

1C

1C

Page 23

5

4

3

2

1

Rear Side HDMI

CN3

CN3

HDMI-19P-SMD-FREEPORT/V H10.5-L1.8

HDMI-19P-SMD-FREEPORT/V H10.5-L1.8

CEC/DDC GND

D D

Dat2 shield

Dat1 shield

Dat0 shield

C C

SHIELD

SHIELD

+5V

DDC SCL

DDC SDA

CEC

HPD

SHIELD

clk shield

DAT0+

DAT0-

DAT1+

DAT1-

DAT2+

DAT2-

clk+

ARC

20

21

18

HDMI3-5V

17

15

HDMI-3-SCL

16

HDMI-3-SDA

13

CEC

19

HDMI3_HPDIN

22

2

5

8

11

7

HDMI3-RX0P

9

HDMI3-RX0N

4

HDMI3-RX1P

6

HDMI3-RX1N

1

HDMI3-RX2P

3

HDMI3-RX2N

10

HDMI3-CLKP

12

clk-

HDMI3-CLKN

14

Right Side HDMI

CN4

CN4

HDMI XH 30619FK1CC3-H6.18

HDMI XH 30619FK1CC3-H6.18

CEC/DDC GND

Dat2 shield

B B

Dat1 shield

Dat0 shield

SHIELD

SHIELD

+5V

DDC SCL

DDC SDA

CEC

HPD

SHIELD

clk shield

SHIELD

DAT0+

DAT0-

DAT1+

DAT1-

DAT2+

DAT2-

clk+

20

21

18

HDMI2-5V

17

15

HDMI-2-SCL

16

HDMI-2-SDA

13

CEC

19

HDMI2_HPDIN

22

2

MHLCABLEDET

5

8

11

23

7

9

4

6

1

3

10

12

clk-

HDMI3-5V

HDMI2-5V

0.1uF/0402/16V

0.1uF/0402/16V

C136

C136

0.1uF/0402/16V

0.1uF/0402/16V

HDMI-3-SCL

HDMI-3-SDA

HDMI3-RX0P <7>

HDMI3-RX0N <7>

HDMI3-RX1P <7>

HDMI3-RX1N <7>

HDMI3-RX2P <7>

HDMI3-RX2N <7>

HDMI3-CLKP <7>

HDMI3-CLKN <7>

C278

C278

HDMI-2-SCL

HDMI-2-SDA

HDMI2-RX0P

HDMI2-RX0NHDMI2-RX0N

HDMI2-RX1P

HDMI2-RX1N

HDMI2-RX2P

HDMI2-RX2N

HDMI2-CLKP

HDMI2-CLKN

R131

R131

47K/0402

47K/0402

+5V_Standby

R326

R326

47K/0402

47K/0402

HDMI2-RX0P

HDMI2-RX0N

HDMI2-RX1P

HDMI2-RX1N

HDMI2-RX2P

HDMI2-RX2N

HDMI2-CLKP

HDMI2-CLKN

R132

R132

47K/0402

47K/0402

R134

R134

100R/0402

100R/0402

R135

R135

100R/0402

100R/0402

R323

R323

47K/0402

47K/0402

R324

R324

100R/0402

100R/0402

R325

R325

100R/0402

100R/0402

HDMI3-SCL <7>

HDMI3-SDA <7>

HDMI2-SCL

HDMI2-SDA

HDMI3_HPDIN

YS-MMBT3904/SOT23

YS-MMBT3904/SOT23

CEC HDMI-CEC

MHLCABLEDET MHL_CABLE_DET

47nF/0402/16V/NC

47nF/0402/16V/NC

+3.3V_Standby

Q3

Q3

C137

C137

HDMI3-5V

R129

R129

1K/0402

1K/0402

R133

R133

B

4.7K/0402

4.7K/0402

E C

R136

R136

200R/0402

200R/0402

R309

R309

0R/0402

0R/0402

HDMI-2-SCL

LBAT54C/SOT-23/NC

LBAT54C/SOT-23/NC

HDMI2-HPDINHDMI2_HPDIN

R142

R142

300K/0402/NC

300K/0402/NC

D

Q4

Q4

L2N7002/SOT23/NC

L2N7002/SOT23/NC

D8

D8

3

G

R130

R130

47K/0402

47K/0402

HDMI3-HPDIN

R317

R317

100R/0402/NC

100R/0402/NC

S

R327

R327

8.2K/0402/NC

8.2K/0402/NC

1

2

HDMI-CEC <7 >

HDMI2-HPDIN

R316

R316

10K/0402/NC

10K/0402/NC

B

+5V_Standby

HDMI3-HPDIN <7>

MHL_CABLE_DET

R143

R143

4.7K/0402/NC

4.7K/0402/NC

MHLI2CSW

Q21

Q21

LRC3904/SOT23/NC

LRC3904/SOT23/NC

E C

MHLI2CSW

MHL_VBUS_EN

MHL_CABLE_DET

R314

R314

4.7K/0402/NC

4.7K/0402/NC

R313

R313

2.2K/0402/NC

2.2K/0402/NC

R315

R315

1.5K/0402/NC

1.5K/0402/NC

+5V_Normal

FB30

FB30

CLS/0603/60/3A/NC

CLS/0603/60/3A/NC

R311

R311

0R/0402/NC

0R/0402/NC

R322

R322

1K/0402/NC

1K/0402/NC

1uF/0402/6.3V/NC

1uF/0402/6.3V/NC

C276

C276

C275

C275

0.1uF/0603/16V/NC

0.1uF/0603/16V/NC

1.5A/ active high

+5V_Standby +5V_Standby

R319

R319

4.7K/0402/NC

4.7K/0402/NC

B

Q20

Q20

LRC3906/SOT23/NC

LRC3906/SOT23/NC

C E

MHLI2CSW

HDMI-2-SDA

R318

R318

2.2K/0402/NC

2.2K/0402/NC

R320

R320

1.5K/0402/NC

1.5K/0402/NC

B

LRC3906/SOT23/NC

LRC3906/SOT23/NC

U17

U17

G5250N1T1U/SOT2 3-5L/NC

G5250N1T1U/SOT2 3-5L/NC

5

VIN

OC#

4

EN

VOUT

GND

2

Q22

Q22

C E

MHL_OCD

3

AVDD5V_MHL HDMI2-5V

1

R310

R310

0R/0603/NC

0R/0603/NC

R321

R321

0R/0402

0R/0402

R312

R312

0R/0603/NC

0R/0603/NC

C277

C277

22uF/0805/6.3V/NC

22uF/0805/6.3V/NC

HDMI2-5VAVDD5V_MHL_C

A A

Title

Title

Title

SCHEMATIC,M/B VTV-L50005

SCHEMATIC,M/B VTV-L50005

Size Document Num ber Rev

Size Document Num ber Rev

Size Document Num ber R

Date: Sheet of

Date: Sheet of

5

4

3

2

Date: Sheet of

SCHEMATIC,M/B VTV-L50005

B

B

B

401C7L

401C7L

401C7L

10 19Monday, November 24, 2014

10 19Monday, November 24, 2014

10 19Monday, November 24, 2014

1

ev

1C

1C

1C

Page 24

1

Audio Input/Coaxial output

HP_Audio-R

D D

<7>

Headphone Mute control

Low : Active and output

CN5

CN5

RCA-YI RCA-655-1 GBR/XWRs

RCA-YI RCA-655-1 GBR/XWRs

T6

T5

T4

S4

S5

S6

Or

Or

S1

S2

S3

G

G

B W

C C

B B

B W

T1

T2

C148

C148

B

B-SW

B-SW

R

R

R

R

T3

C149

C149

C150

C150

10pF/0402/50V/NC

10pF/0402/50V/NC

10pF/0402/50V/NC

10pF/0402/50V/NC

10pF/0402/50V/NC

10pF/0402/50V/NC

COMP-AUL2

330pF/0402/50V/5%

330pF/0402/50V/5%

COMP-AUR2

330pF/0402/50V/5%

330pF/0402/50V/5%

RGB2-YPbPr_RIN+

RGB2-YPbPr_BIN+

YPbPr_GIN+

C142

C142

C144

C144

R150

R150

10K/0402

10K/0402

12K/0402

12K/0402

R154

R154

10K/0402

10K/0402

12K/0402

12K/0402

R152

R152

R155

R155

COMP_AUL

C143

C143

560pF/0402/50V

560pF/0402/50V

COMP_AUR

C146

C146

560pF/0402/50V

560pF/0402/50V

R158

R158

0R/0402

0R/0402

COMP_AUL <7>

COMP_AUR <7>

RGB2-YPbPr_RIN+ <7>

RGB2-YPbPr_BIN+ <7>

RGB2-YPbPr_GIN+ <7>

YPbPr_AVIN <7>

High: Mute no output

HP_Audio-L

<7>

HP_Audio-R

10uH +-10% CL160808T 100K-N

10uH +-10% CL160808T 100K-N

HP_Audio-L

10uH +-10% CL160808T 100K-N

10uH +-10% CL160808T 100K-N

AU_HP_R

AU_HP_L

C151

C151

HP_EN

L4

L4

L5

L5

C152

C152

22nF/0402/25V

22nF/0402/25V

C139

C139

100uF/6D3/16V/ELNA

100uF/6D3/16V/ELNA

R146

R146

200R/0402

200R/0402

C141

C141

10uF/0603/6.3V

10uF/0603/6.3V

HP_EN

C145

C145

100uF/6D3/16V/ELNA

100uF/6D3/16V/ELNA

R156

R156

200R/0402

200R/0402

C147

C147

10uF/0603/6.3V

10uF/0603/6.3V

R159

R159

1K/0402

1K/0402

22nF/0402/25V

22nF/0402/25V

R160

R160

HP_IN

1K/0402

1K/0402

HP_EN

G

Q15

Q15

S

YS-2N7002/SOT23

YS-2N7002/SOT23

HP_EN

S

YQ PJ596-F07T3BY-A BLK H6.75

YQ PJ596-F07T3BY-A BLK H6.75

D

R147

R147

10K/0402

10K/0402

G

Q16

Q16

D

YS-2N7002/SOT23

YS-2N7002/SOT23

R157

R157

10K/0402

10K/0402

CN6

CN6

1

5

7

3

6

4

2

G

Q27

Q27

D

YS-2N7002/SOT23

YS-2N7002/SOT23

R256

R256

10K/0402

10K/0402

G

Q26

Q26

D

YS-2N7002/SOT23

YS-2N7002/SOT23

R262

R262

10K/0402

10K/0402

S

AU_HP_R

R261

R261

10K/0402

10K/0402

S

AU_HP_L

R263

R263

10K/0402

10K/0402

EarphoneYPBPR,CVBS/Video

FB32

+3.3V_Normal

R267

SPDIF_OUT<7>

A A

R267

100R/0402

100R/0402

10K/0402

10K/0402

R272

R272

FB32

CLS/0603/60/3A

CLS/0603/60/3A

C247

C247

22pF/0402/50V/5%

22pF/0402/50V/5%

C192

C192

10uF/0603/6.3V

10uF/0603/6.3V

C194

C194

0.1uF/0402/16V

0.1uF/0402/16V

CN10

CN10

SPDIF-ST JST1B16 BLK H13.9

SPDIF-ST JST1B16 BLK H13.9

3

VIN

2

VCC

1

GND

GND5GND

4

R162

R162

100K/0402

100K/0402

HP_IN

HP_IN HP_DET

+3.3V_Normal

G

R161

R161

10K/0402

10K/0402

HP_DET

D

Q7

Q7

YS-2N7002/SOT23

YS-2N7002/SOT23

S

HP_DET <8>

Headphone Mute control

Low : Active and output

High: Mute no output

Plug out : Low High

Plug in: High Low

Size Document Num ber Rev

Size Document Num ber Rev

Size Document Num ber Rev

Date: Sheet of

Date: Sheet of

1

Date: Sheet of

Title

Title

Title

SCHEMATIC,M/B VTV-L50005

SCHEMATIC,M/B VTV-L50005

SCHEMATIC,M/B VTV-L50005

B

B

B

401C7L

401C7L

401C7L

1C

1C

1C

11 19Monday, November 24, 2014

11 19Monday, November 24, 2014

11 19Monday, November 24, 2014

Page 25

5

L6

LVS505040-100M/10uH/2.8A

D D

C C

B B

SPK_OUTR+

SPK_OUTR-

LVS505040-100M/10uH/2.8A

0.68uF/0805/50V

0.68uF/0805/50V

0.68uF/0805/50V

0.68uF/0805/50V

DVDD

L6

C156

C156

680pF/0603/50V

680pF/0603/50V

C160

C160

C164

C164

LVS505040-100M/10uH/2.8A

LVS505040-100M/10uH/2.8A

R167

R167

5.6R/0603

5.6R/0603

R169

R169

5.6R/0603

5.6R/0603

C166

C166

680pF/0603/50V

680pF/0603/50V

L8

L8

R171

R171

100K/0402/1%

100K/0402/1%

10uF/0603/25V

10uF/0603/25V

2.2uF/0805/25V

2.2uF/0805/25V

AMP_VCC

C162

C162

C168

C168

C157

C157

2.2uF/0805/25V

2.2uF/0805/25V

4

C153

C153

10uF/0603/25V

10uF/0603/25V

C154

C154

C155

C155

18

17

10uF/0603/25V

10uF/0603/25V

REGG

BSP2P

19

OUT2P

20

VCCP2

21

GNDP2

22

BSP2N

23

OUT2N

24

ERROR

25

Pad

C170

C170

U12

U12

BD28620MUV

BD28620MUV

MCLK1SDATA

2

R172

R172

R173

R173

10pF/0402/50V

10pF/0402/50V

22R/0402/1%

22R/0402/1%

22R/0402/1%

22R/0402/1%

0.1uF/0603/50V

0.1uF/0603/50V

REGD16GNDA

15

BCLK3LRCLK4PLIMT5RSTX

C171

C171

R174

R174

22R/0402/1%

22R/0402/1%

10pF/0402/50V

10pF/0402/50V

14

VCCA

R175

R175

13

OUT1N

12

BSP1N

11

GNDP1

10

VCCP1

9

BSP1P

8

OUT1P

7

MUTEX

6

RST-AMP

PLIMT

22R/0402/1%

22R/0402/1%

AMP_VCC

C158

C158

2.2uF/0805/25V

2.2uF/0805/25V

C163

C163

10uF/0603/25V

10uF/0603/25V

C169

C169

2.2uF/0805/25V

2.2uF/0805/25V

3

AMP_VCC

L7

L7

LVS505040-100M/10uH/2.8A

LVS505040-100M/10uH/2.8A

C159

C159

680pF/0603/50V

680pF/0603/50V

R168

R168

5.6R/0603

5.6R/0603

R170

R170

5.6R/0603

5.6R/0603

C167

C167

680pF/0603/50V

680pF/0603/50V

L9

L9