Toshiba 29VH14P Schematic

SERVICE MANUAL

FILE NO. 050-200127

29VH14P

PRINTED IN U. K

COLOUR TELEVISION

1. Precautions

1-1 Safety Precautions

1. Be sure that all of the built-in protective

devices are replaced. Restore any missing

protective shields.

2. When reinstalling the chassis and its

assemblies, be sure to restore all protective

devices, including: nonmetallic control knobs

and compartment covers.

3. Make sure that there are no cabinet openings

through which people—particularly

children—might insert fingers and contact

dangerous voltages. Such openings include

the spacing between the picture tube and the

cabinet mask, excessively wide cabinet

ventilation slots, and improperly fitted back

covers.

If the measured resistance is less than 1.0

megohm or greater than 5.2 megohms, an

abnormality exists that must be corrected

before the unit is returned to the customer.

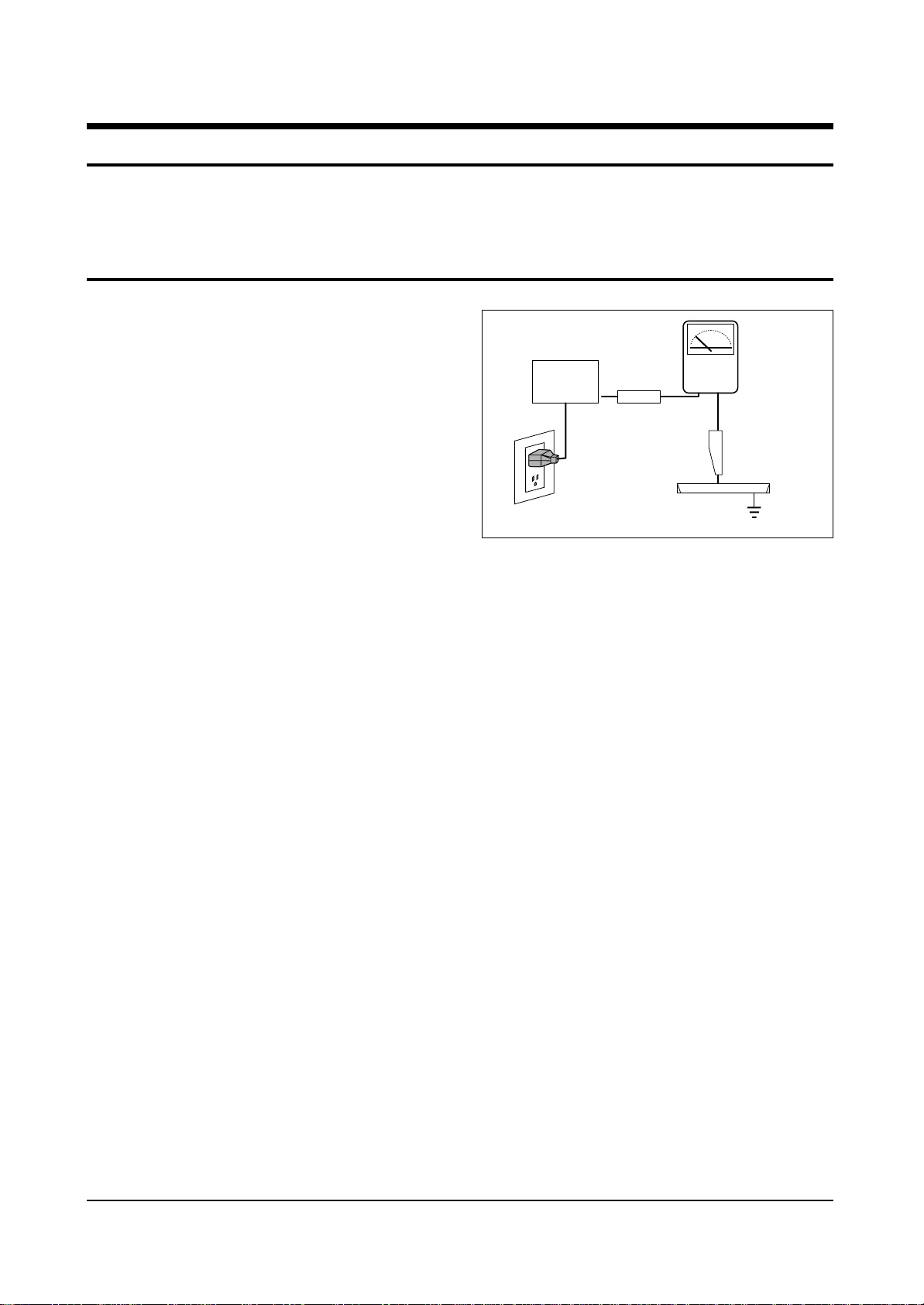

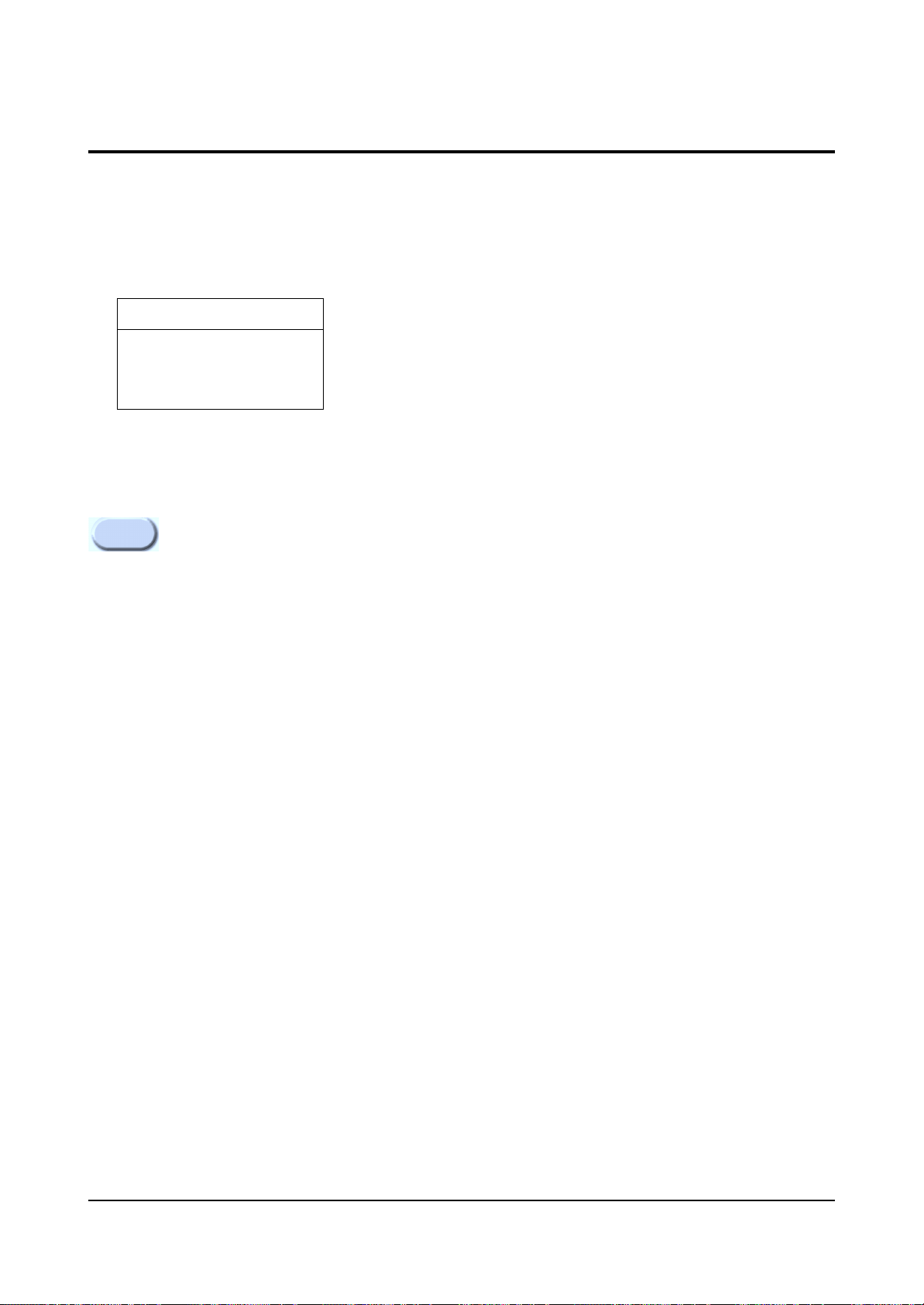

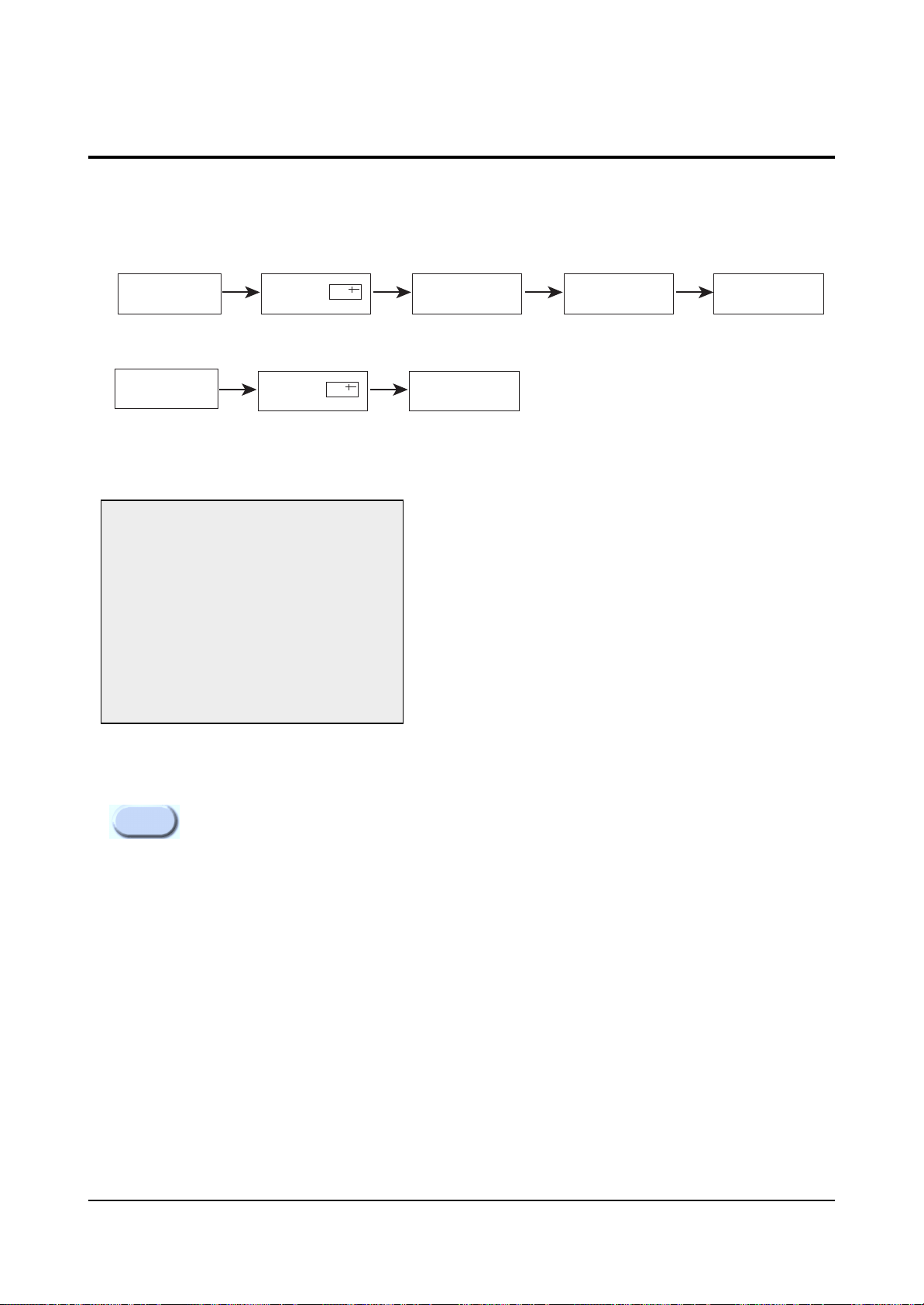

4. Leakage Current Hot Check (Figure 1-1):

Warning: Do not use an isolation

transformer during this test. Use a leakagecurrent tester or a metering system that

complies with American National Standards

Institute (ANIS C101.1, Leakage Current for

Appliances), and Underwriters Laboratories

(UL Publication UL1410, 59.7).

5. With the unit completely reassembled, plug

the AC line cord directly into the power

outlet. With the unit’s AC switch first in the

ON position and then OFF, measure the

current between a known earth ground (metal

water pipe, conduit, etc.) and all exposed

metal parts, including: antennas, handle

brackets, metal cabinets, screwheads and

control shafts. The current measured should

not exceed 0.5 milliamp. Reverse the powerplug prongs in the AC outlet and repeat the

test.

Fig. 1-1 AC Leakage Test

6. Antenna Cold Check:

With the unit’s AC plug disconnected from the

AC source, connect an electrical jumper across

the two AC prongs. Connect one lead of the

ohmmeter to an AC prong. Connect the other

lead to the coaxial connector.

7. X-ray Limits:

The picture tube is especially designed to

prohibit X-ray emissions. To ensure continued

X-ray protection, replace the picture tube only

with one that is the same type as the original.

Carefully reinstall the picture tube shields and

mounting hardware; these also provide X-ray

protection.

8. High Voltage Limits:

High voltage must be measured each time

servicing is done on the B+, horizontal

deflection or high voltage circuits.

Correct operation of the X-ray protection

circuits must be reconfirmed whenever they

are serviced.

(X-ray protection circuits also may be called

“horizontal disable” or “hold-down”.)

Heed the high voltage limits. These include

the X–ray Protection Specifications Label, and

the Product Safety and X-ray Warning Note on

the service data schematic.

Precautions

1-1

LEAKAGE

CURRENT

TESTER

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

3-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

EARTH

GROUND

(READING SHOULD

NOT BE ABOVE

0.5mA)

Follow these safety, servicing and ESD precautions to prevent damage and protect against potential

hazards such as electrical shock and X-rays.

1-1 Safety Precautions (Continued)

9. High voltage is maintained within specified

limits by close-tolerance, safety-related

components and adjustments. If the high

voltage exceeds the specified limits, check

each of the special components.

10. Design Alteration Warning:

Never alter or add to the mechanical or

electrical design of this unit. Example: Do not

add auxiliary audio or video connectors. Such

alterations might create a safety hazard. Also,

any design changes or additions will void the

manufacturer’s warranty.

11. Hot Chassis Warning:

Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord. If an isolation transformer is not

used, these units may be safely serviced only

if the AC power plug is inserted so that the

chassis is connected to the ground side of the

AC source.

To confirm that the AC power plug is inserted

correctly, do the following: Using an AC

voltmeter, measure the voltage between the

chassis and a known earth ground. If the

reading is greater than 1.0V, remove the AC

power plug, reverse its polarity and reinsert.

Re-measure the voltage between the chassis

and ground.

12. Some TV chassis are designed to operate with

85 volts AC between chassis and ground,

regardless of the AC plug polarity. These units

can be safely serviced only if an isolation

transformer inserted between the receiver and

the power source.

13. Some TV chassis have a secondary ground

system in addition to the main chassis ground.

This secondary ground system is not

isolated from the AC power line. The two

ground systems are electrically separated by

insulating material that must not be defeated

or altered.

14. Components, parts and wiring that appear to

have overheated or that are otherwise

damaged should be replaced with parts that

meet the original specifications. Always

determine the cause of damage or

overheating, and correct any potential

hazards.

15. Observe the original lead dress, especially

near the following areas: Antenna wiring,

sharp edges, and especially the AC and high

voltage power supplies. Always inspect for

pinched, out-of-place, or frayed wiring. Do

not change the spacing between components

and the printed circuit board. Check the AC

power cord for damage. Make sure that leads

and components do not touch thermally hot

parts.

16. Picture Tube Implosion Warning:

The picture tube in this receiver employs

“integral implosion” protection. To ensure

continued implosion protection, make sure

that the replacement picture tube is the same

as the original.

17. Do not remove, install or handle the picture

tube without first putting on shatterproof

goggles equipped with side shields. Never

handle the picture tube by its neck. Some

“in-line” picture tubes are equipped with a

permanently attached deflection yoke; do not

try to remove such “permanently attached”

yokes from the picture tube.

18. Product Safety Notice:

Some electrical and mechanical parts have

special safety-related characteristics which

might not be obvious from visual inspection.

These safety features and the protection they

give might be lost if the replacement

component differs from the original—even if

the replacement is rated for higher voltage,

wattage, etc.

Components that are critical for safety are

indicated in the circuit diagram by shading,

( ) or ( ).

Use replacement components that have the

same ratings, especially for flame resistance

and dielectric strength specifications.

A replacement part that does not have the

same safety characteristics as the original

might create shock, fire or other hazards.

Precautions

1-2

!

1-2 Servicing Precautions

1. Servicing precautions are printed on the

cabinet. Follow them.

2. Always unplug the unit’s AC power cord from

the AC power source before attempting to:

(a) Remove or reinstall any component or

assembly, (b) Disconnect an electrical plug or

connector, (c) Connect a test component in

parallel with an electrolytic capacitor.

3. Some components are raised above the printed

circuit board for safety. An insulation tube or

tape is sometimes used. The internal wiring is

sometimes clamped to prevent contact with

thermally hot components. Reinstall all such

elements to their original position.

4. After servicing, always check that the screws,

components and wiring have been correctly

reinstalled. Make sure that the portion around

the serviced part has not been damaged.

5. Check the insulation between the blades of the

AC plug and accessible conductive parts

(examples: metal panels, input terminals and

earphone jacks).

6. Insulation Checking Procedure: Disconnect the

power cord from the AC source and turn the

power switch ON. Connect an insulation

resistance meter (500V) to the blades of the AC

plug.

The insulation resistance between each blade

of the AC plug and accessible conductive parts

(see above) should be greater than 1 megohm.

7. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of

its assemblies) unless all solid-state heat sinks

are correctly installed.

8. Always connect a test instrument’s ground

lead to the instrument chassis ground before

connecting the positive lead; always remove

the instrument’s ground lead last.

Precautions

1-3

Warning1: First read the “Safety Precautions” section of this manual. If some unforeseen circumstance creates a conflict between

the servicing and safety precautions, always follow the safety precautions.

Warning2: An electrolytic capacitor installed with the wrong polarity might explode.

1. Some semiconductor (“solid state”) devices

are easily damaged by static electricity. Such

components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect

transistors. The following techniques will

reduce the occurrence of component damage

caused by static electricity.

2. Immediately before handling any semicon

ductor components or assemblies, drain the

electrostatic charge from your body by

touching a known earth ground. Alternatively,

wear a discharging wrist-strap device. (Be

sure to remove it prior to applying power—

this is an electric shock precaution.)

3. After removing an ESD-equipped assembly,

place it on a conductive surface such as

aluminum foil to prevent accumulation of

electrostatic charge.

4. Do not use freon-propelled chemicals. These

can generate electrical charges that damage

ESDs.

5. Use only a grounded-tip soldering iron when

soldering or unsoldering ESDs.

6. Use only an anti-static solder removal device.

Many solder removal devices are not rated as

“anti-static”; these can accumulate sufficient

electrical charge to damage ESDs.

7. Do not remove a replacement ESD from its

protective package until you are ready to

install it. Most replacement ESDs are

packaged with leads that are electrically

shorted together by conductive foam,

aluminum foil or other conductive materials.

8. Immediately before removing the protective

material from the leads of a replacement ESD,

touch the protective material to the chassis or

circuit assembly into which the device will be

installed.

9. Minimize body motions when handling

unpackaged replacement ESDs. Motions such

as brushing clothes together, or lifting a foot

from a carpeted floor can generate enough

static electricity to damage an ESD.

Precautions

1-4

1-3 Precautions for Electrostatically Sensitive Devices (ESDs)

Reference Information

2-1

2. Reference Information

2-1 Tables of Abbreviations and Acronyms

A

Ah

Å

dB

dBm

°C

°F

°K

F

G

GHz

g

H

Hz

h

ips

kWh

kg

kHz

kΩ

km

km/h

kV

kVA

kW

I

MHz

Ampere

Ampere-hour

Angstrom

Decibel

Decibel Referenced to One

Milliwatt

Degree Celsius

Degree Fahrenheit

degree Kelvin

Farad

Gauss

Gigahertz

Gram

Henry

Hertz

Hour

Inches Per Second

Kilowatt-hour

Kilogram

Kilohertz

Kilohm

Kilometer

Kilometer Per Hour

Kilovolt

Kilovolt-ampere

Kilowatt

Liter

Megahertz

MV

MW

MΩ

m

µA

µF

µH

µm

µs

µW

mA

mg

mH

mI

mm

ms

mV

nF

Ω

pF

Ib

rpm

rps

s

V

VA

W

Wh

Megavolt

Megawatt

Megohm

Meter

Microampere

Microfarad

Microhenry

Micrometer

Microsecond

Microwatt

Milliampere

Milligram

Millihenry

Milliliter

Millimeter

Millisecond

Millivolt

Nanofarad

Ohm

Picofarad

Pound

Revolutions Per Minute

Revolutions Per Second

Second (Time)

Volt

Volt-ampere

Watt

Watt-hour

Table 2-1 Abbreviations

Reference Information

2-2

Table 2-2 Table of Acronyms

ABL

AC

ACC

AF

AFC

AFT

AGC

AM

ANSI

APC

APC

A/V

AVC

BAL

BPF

B-Y

CATV

CB

CCD

CCTV

Ch

CRT

CW

DC

DVM

EIA

ESD

ESD

FBP

FBT

FF

FM

FS

GND

G-Y

H

HF

HI-FI

IC

IC

IF

Automatic Brightness Limiter

Alternating Current

Automatic Chroma Control

Audio Frequency

Automatic Frequency Control

Automatic Fine Tuning

Automatic Gain Control

Amplitude Modulation

American National Standards Institute

Automatic Phase Control

Automatic Picture Control

Audio-Video

Automatic Volume Control

Balance

Bandpass Filter

Blue-Y

Community Antenna Television (Cable TV)

Citizens Band

Charge Coupled Device

Closed Circuit Television

Channel

Cathode Ray Tube

Continuous Wave

Direct Current

Digital Volt Meter

Electronics Industries Association

Electrostatic Discharge

Electrostatically Sensitive Device

Feedback Pulse

Flyback Transformer

Flip-Flop

Frequency Modulation

Fail Safe

Ground

Green-Y

High

High-Frequency

High Fidelity

Inductance-Capacitance

Integrated Circuit

Intermediate Frequency

I/O

L

L

LED

LF

MOSFET

MTS

NAB

NEC

NTSC

OSD

PCB

PLL

PWM

QIF

R

RC

RF

R-Y

SAP

SAW

SIF

SMPS

S/N

SW

TP

TTL

TV

UHF

UL

UV

VCD

VCO

VCXO

VHF

VIF

VR

VTR

VTVM

TR

Input/output

Left

Low

Light Emitting Diode

Low Frequency

Metal-Oxide-Semiconductor-Field-Effect-Tr

Multi-channel Television Sound

National Association of Broadcasters

National Electric Code

National Television Systems Committee

On Screen Display

Printed Circuit Board

Phase-Locked Loop

Pulse Width Modulation

Quadrature Intermediate Frequency

Right

Resistor & Capacitor

Radio Frequency

Red-Y

Second Audio Program

Surface Acoustic Wave(Filter)

Sound Intermediate Frequency

Switching Mode Power Supply

Signal/Noise

Switch

Test Point

Transistor Transistor Logic

Television

Ultra High Frequency

Underwriters Laboratories

Ultraviolet

Variable-Capacitance Diode

Voltage Controlled Oscillator

Voltage Controlled Crystal Oscillator

Very High Frequency

Video Intermediate Frequency

Variable Resistor

Video Tape Recorder

Vacuum Tube Voltmeter

Transistor

Reference Information

2-3

2-2 IC Line Up

Table 2 - 3 IC Line - Up

NO

1

DESCRIPTION

Video Processor

Sipadoss-Module, Video Processor

Multistandard Sound Processor

MICOM, TTX(MTP)

EEPROM

Audio AMP

RGB Drive AMP Hybrid IC

100Hz Horizontal Pulse AMP

Vertical IC

Horizontal Drive IC

E/W Drive IC

SPS Controllor

Bridge Diode

Photo Coupler

Rectifier Diode

3.3V Regulator

6V Regulator

8V Controlled Regulator

3.3V Regulator

MICOM Reset IC

IIC Level Shifter

LOC. NO

IC201S

IC601

IC901

IC902

IC602

HIC201

HIC202

HIC203

HIC204

HIC401

IC301

Q402

Q401

D414

IC401

Q404

IC801S

D801S

PC801S

D805

D806

D807

D802

IC202

IC804

IC803

IC903

IC904

Q909

Q910

BOARD

MAIN

SPEC

VDP3140

DDP3310

VPC3230

SDA9401

MSP3411G

SDA555X

KSL51DC

TDA7297

DRGB001

DDRI001

LA7845

BUZ73A

2SC5446

FMP-3FU

LM393

IRF620

3S1265RD

GSIB660

PC123Y

FML-G12S

FMG-G2CS

KA78RM33

KA7806

KA78R08

KA78RM33

KIA7025AP

2N7000

REMARK

Refer to Table 2-3-1

Refer to Table 2-3-2

Refer to Table 2-3-3

VM Option

Option

HC401

HC801

VDPY

2-4

Table 2 - 3 IC Line - Up

NO

1

2

3

DESCRIPTION

Main Tuner with IF Block

Trans Switching

Trans FBT(ELDOR)

Video Output AMP R.G.B Drive

Push-Pull (VM)

TR-Power (TILT)

OP-AMP (TILT)

Video Switching IC with Adder Output

LOC. NO

TU01S

T801S

T444S

IC501

QF04

QF05

QG02

QG03

ICG01

ICS01

SPEC

TCPW3001PD16A

AA26-00046A

1372, 0079A

TDA6111Q

2SC2344

2SA1011

KSA940

KSD2073-H2

KA4558

TEA6425

REMARK

Refer to Table 2-3-4

Refer to Table 2-3-6

Refer to Table 2-3-7

Option

Option

BOARD

MAIN

CRT

V-S/W

Reference Information

SPEC

MSP3411G

MSP3410D

FUNCTION

Multistandard, A2 Stereo, Nicam, Vitual Dolby

Multistandard, A2 Stereo, Nicam

REMARK

SPEC

TDA7297

FUNCTION

15W x 2CH, 10W x 2CH

REMARK

SPEC

TCPW3001PD16A

FUNCTION

CW

REMARK

Main

Table 2-3-2 SOUND IC (IC601)

Table 2-3-3 SOUND AMP (IC602)

Table 2-3-4 1’st TUNER (TU01S)

SPEC

DDP3310

VPC3230

SDA9401

FUNCTION

Sipadoss Module

AA98-00134B(with SDA9401)

REMARK

Table 2-3-1 VIDEO IC (IC201S)

Specifications

3-1

3. Specifications

Specifications are subject to change.

Television

System

Antena Input

CW

Power

Consumption

Requirements

Frequency

Output

Sound

Effect

Jacks

Front

(AV2)

Back

PAL/SECAM-B/G,D/K,L,I

130W (Applied When 29” Flat)

220V Only

50Hz

15W x 2CH

Vitual Dolby

Turbo Sound

Pseudo Stereo

RCA Input

S-VHS

Head-Phone

2Scart Input/Output

AV2 Monitor Audio Output

75ohms, Coaxial Cable

Option

Option

AV1 : Scart I/O, RGB Input,

RF Out

AV2 : Scart I/O, Monitor Out

Option

3-2

MEMO

Alignment and Adjustments

4-1

4. Alignment and Adjustments

4-1 General Alignment Instructions

1. Usually, a color TV-VCR needs only slight

touch-up adjustment upon installation. Check

the basic characteristics such as height,

horizontal and vertical sync and focus.

2. Observe the picture for good black and white

details. There should be objectionable color

shading; if color shading is present,

demagnetize, perform purity and convergence

adjustments described below.

3. Use the specified test equipment or its

equivalent.

4. Correct impedance matching is essential.

5. Avoid overload. Excessive signal from a

sweep generator might overload the front-end

of the TV. When inserting signal markers, do

not allow the marker generator to distort test

results.

6. Connect the TV only to an AC power source

with voltage and frequency as specified on the

backcover nameplate.

7. Do not attempt to connect or disconnect any

wires while the TV is turned on. Make sure

that the power cord is disconnected before

replacing any parts.

8. To protect against shock hazard, use an

isolation transformer.

4-2 Automatic Degaussing

A degaussing coil is mounted around the

picture tube, so that external degaussing after

moving the TV should be unnecessary. But

the receiver must be properly degaussed upon

installation.

The degaussing coil operates for about 1

second after the power is switched ON. If the

set is moved or turned in a different direction,

the power should be OFF for at least 10

minutes.

If the chassis or parts of the cabinet become

magnetized, poor color purity will result. If

this happens, use an external degaussing coil.

Slowly move the degaussing coil around the

faceplate of the picture tube and the sides and

front of the receiver. Slowly withdraw the coil

to a distance of about 6 feet before turning

power OFF.

If color shading persists, perform the

following Color purity and Convergence

adjustments.

4-3 High voltage Check

CAUTION : There is no high voltage adjustment

on this chassis. The B+ power supply should be

+135 volts (with full color- bar input and normal

picture level).

1. Connect a digital voltmeter to the second

anode of the picture tube.

2. Turn on the TV. Set the Brightness and

Contrast controls to minimum (zero beam

current).

3. Adjust the Brightness and contrast controls to

both extremes. Ensure that the high voltage

does not exceed 32 KV under any conditions.

Alignment and Adjustments

4-2

4-4 SCREEN Adjustment

1. Input Toshiba Pattern

2. Enter “Service Mode”.(Refer to “Service Mode”)

3. Select “G2-Adjust”.

4. Set the values as below.

5. Turn the SCREEN VR until “MRCR G B” and “MRWDG” are green and those value are about 100.

(The incorrect SCREEN Voltage may result that “MRCR G B” and “MRWDG” should be red)

When you do not have Toshiba Pattern, follow this method.

1. Set the TV on the condition that AV mode no signal(black)

2. Enter the “Menu” and set the mode to blue screen off.

3. Enter the “Service Mode”.

4. Select “ G2-Adjust”.

5. Set the values as below.

IBRM = 215

WDRV = 47

CDL = 210

COLR G B = 45

6. Turn the SCREEN VR until the value of “ MRCR G B” is about 120. Do not mind that

the “OSD” Color is red.

♦ After completing G2-Adjust, follow this procedure.

! Enter the “Video Adjust 1”.

@ Choose any item in menu. (ex. Select “Red Cutoff”)

# Change the value of item you select, and recover the value.

For example, when the value of “Red Cutoff” is 127, change the value to 128 and restore

the value to 127.

If you do not follow this procedure, the picture may be abnormal.

For example, when the TV set is on, the picture becames brighter gradually.

Note 1.

29 Inch

IBRM = 215

WDRV = 44 -> 47

CDL = 235 -> 210

COLR G B = 122 -> 45

Alignment and Adjustments

4-3

4-5 E2PROM (IC902) Replacement

1. When IC902 is replaced, all adjustment data revert to the initial values.

So, all adjustment values when servicing should be readjusted.

2. After IC902 is replaced, connect the AC power supply cord.

3. Turn the power switch ON.

4. In stand-by, warm up the TV for at least 10 seconds.

5. Power on the TV.

4-6 White Balance Adjustment

■ Equipment : Color-Analyzer (CA-100)

■ Input Signal : Pattern signal (Toshiba pattern)

1. Select STANDARD from the menu.

2. Input an 100% White pattern.

3. Enter the “Service Mode”. (Refer to “4-8 Service Mode”)

4. Warm up the TV set at least for 30 minutes.

5. Input a Toshiba pattern signal.

6. Enter the “Video Adjust1”.

- Adjust “Sub Contrast” so that Y (luminance) becomes 34 ft ± 3.

- Use “Red Drive” and “ Blue Drive” to adjust High-Light (x : 290, y : 300)

- Adjust “Sub Bright” so that Y (luminance) becomes 1.3ft ± 0.3.

- Use “Red Cutoff” and “Blue Cutoff” to adjust Low-Light (x : 290, y : 300).

7. Adjust CA-100 so that the final adjustment value can be fixed.

8. Use the Channel Up/Down (▲/▼) buttons to move the cursor on the adjustment modes.

9. Use the Volume +/- buttons to change the adjustment value.

Alignment and Adjustments

4-4

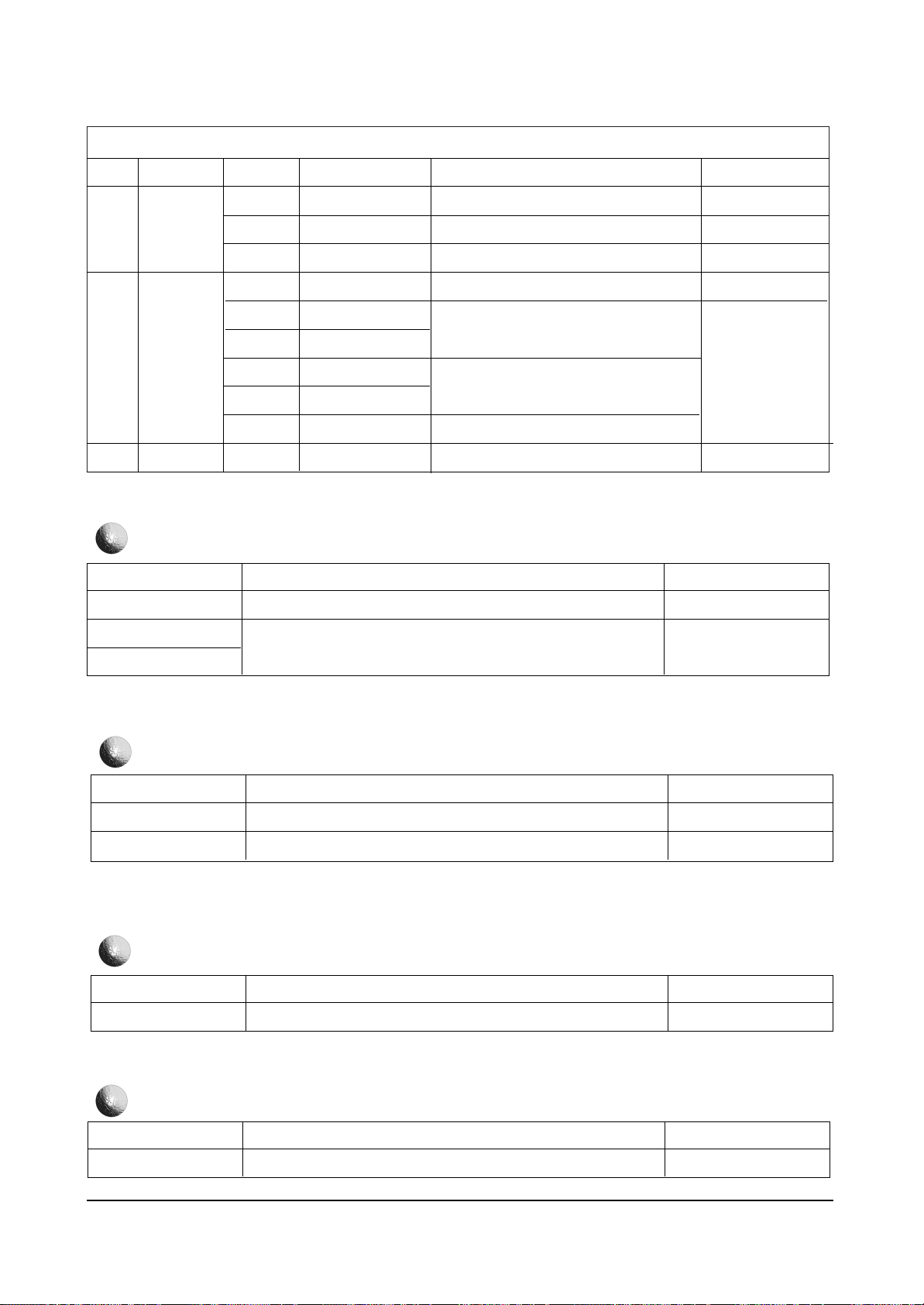

Note 2. 29V1 CHANGE

ASSY-MAIN

LOC NO CODE NO SPEC LOC NO CODE NO SPEC

AZ261102

R226

AZ664147

J221

AZ664147

J908

NONE NONE NONE R954

NONE NONE NONE R910

NONE NONE NONE R955

AZ261102

R910

AZ261301

R911

AZ261301

R912

AZ161102

C923

C926 DELETE DELETE C926

AZ664147

J204

NONE NONE NONE J913

AZ361008

L210

AZ362003

J406

L222 NONE NONE L222

C410 DELELTE DELETE C410

AZ664147

J239

J817 NONE NONE J817

L413 NONE NONE L413

AZ664147

J709

J701 NONE NONE J701

L412 NONE NONE L412

NONE NONE NONE CN701A

J226 DELETE DELETE J226

AZ261222

J231

AZ268057

R301

AZ268058

R302

AZ268059

R304

TOP DELETE DELETE R307

AZ268048

R314

R315 DELETE DELETE R315

AZ166050

C303

R926 NONE NONE R926

Q907 NONE NONE Q907

R902 NONE NONE R902

R952 NONE NONE R952

J902 NONE NONE J902

AZ261103

R919

AZ166023

TOP

AZ263076

TOP

J630 NONE NONE J630

AZ462001

D405

AZ162031

C415

AZ166022

C416

AZ166034

C411

AZ162006

C212

AZ664147

R241

R242 DELETE DELETE R242

AZ664147

L208

C246 DELETE DELETE C246

C247 DELETE DELETE C247

C248 DELETE DELETE C248

AZ664147

J829

AZ664147

J830

F802A DELETE DELETE F802A

F802B DELETE DELETE F802B

FD802S DELETE DELETE FD802S

FD802S DELETE DELETE FD802S

AZ363064

LX801S

LX802S DELETE DELETE LX802S

AZ166013

CX801S

AZ166013

CX802S

BEFORE AFTER

1KOHM,5%,1/8W R226

WIRE-NO SHEATH CU C203

WIRE-NO SHEATH CU R944

1KOHM,5%,1/8W R956

300 OHM,5%,1/8W R911

300 OHM,5%,1/8W R912

C-C,AXIAL;50V 1NF L910

AZ261471

AZ164009

AZ261392

AZ261473

AZ261223

AZ261101

AZ261471

AZ261331

AZ261103

AZ363067

AZ664147

470 OHM,5%,1/8W

C-AL;50V 10uF

3.9 KOHM,5%,1/8W

47 KOHM,5%,1/8W

22 KOHM,5%,1/8W

100 OHM,5%,1/8W

470 OHM,5%,1/8W

330 OHM,5%,1/8W

10 KOHM,5%,1/8W

8.2uH AL02

C-C,AXIAL;150 PF

JUMPER J204 DELETE DELETE

AZ664147

JUMPER

AL02 3.3uH L210

F/BEAD ,6MM J406

AZ664147

JUMPER

AZ664147

JUMPER

AZ361010

4.7uH AL02

AZ162005

C-FILM,PEF;220nF,5%,250V,TP

JUMPER J239 DELETE DELETE

AZ664147

JUMPER

AZ664147

JUMPER

JUMPER DELETE DELETE DELETE

AZ664147

JUMPER

AZ362003

F/BEAD ,6MM

AZ263070

R403

D403

2W 10 ohm

AZ462005

DIODE 1N4004

AZ760241

ASSY-LEAD CONNECTOR;3P

AZ664147

WIRE-NO SHEATH CU

2.2KOHM,5%,1/8W J231 DELETE DELETE

1.6KOHM,5%,1/2W R301

7.5Kohm,1%,1/2W R302

0.68ohm,5%,2W,AG R304

22Kohm,1%,1/2W R314

O.O15nF,5%,50V C303

10KOHM,5%,1/8W R919

C-C;400V 103 C830

2W 27 R826

1N4148 D405

POLY 50V 222 C415

POLY 100V 103 C416

POLY 50V 332 C411

POLY 50V 223 C212

JUMPER R241

JUMPER L208

AZ264003

4.7Kohm,1%,1/2W

AZ264007

22Kohm,1%,1/2W

AZ263061

1.2ohm,5%,2W,AG

AZ263061

1.2ohm,5%,2W,AG

AZ268048

22Kohm,1%,1/2W

AZ268041

51Kohm,1%,1/2W

AZ166032

O.O05nF,5%,500V

AZ664147

JUMPER

AZ561003

KSC815,NPN,400mW,TO-92,TP

AZ261102

1KOHM,5%,1/8W,AA,

AZ261103

10KOHM,5%,1/8W

AZ664147

JUMPER

AZ261471

470 OHM,5%,1/8W

AZ166023

C-C;400V 103 Model adapted ELDOR FBT

AZ263076

2W 27 Model adapted ELDOR FBT

AZ664147

JUMPER Delete, If VIDEO S/W MODULE

AZ664147

JUMPER

AZ162031

POLY 50V 272

AZ162012

POLY 50V 472

AZ162031

POLY 50V 222

AZ166022

POLY 100V 103

AZ261680

68ohm,5%,1/8W

AZ261750

75ohm,5%,1/8W

AZ363060

INDUCTOR-AXIAL;2.2uH,5%

AZ161271

C-C,-AXIAL;270PF,10%,50V

AZ161999

C-C,-AXIAL;18PF,10%,50V

AZ161271

C-C,-AXIAL;270PF,10%,50V

JUMPER J829 DELETE DELETE

JUMPER J830 DELETE DELETE

AZ664014

FUSE-HOLDER;-,-,30MOHM

AZ664014

FUSE-HOLDER;-,-,30MOHM

AZ760242

FUSE;800mA

AZ760243

FUSE;1A

28-20MH 1.5A,+-2.0,1.5K LX801S

220nF,20%,250V,TP,-,22.5mm CX801S

220nF,20%,250V,TP,-,22.5mm CX802S

AZ363064

28-20MH 1.5A,+-2.0,1.5K

AZ363064

28-20MH 1.5A,+-2.0,1.5K

AZ166013

220nF,20%,250V,TP,-,22.5mm

AZ166013

220nF,20%,250V,TP,-,22.5mm

CAUSE

A Improvement of TTX Error

Against 2H-Noise

A Improvement of OSD JITTER

(Added H-Sync Buffer)

Linearity

AV- CROSSTALK

50Hz : 800mA

100Hz : 1 A

Against Conduction

MODEL

All Model

100Hz Model

100Hz Model V-SIZE DRIFT

All Model

100Hz Model

100Hz Model

All Model

Alignment and Adjustments

4-5

ASSY-SIPADOS(9401)

y

)

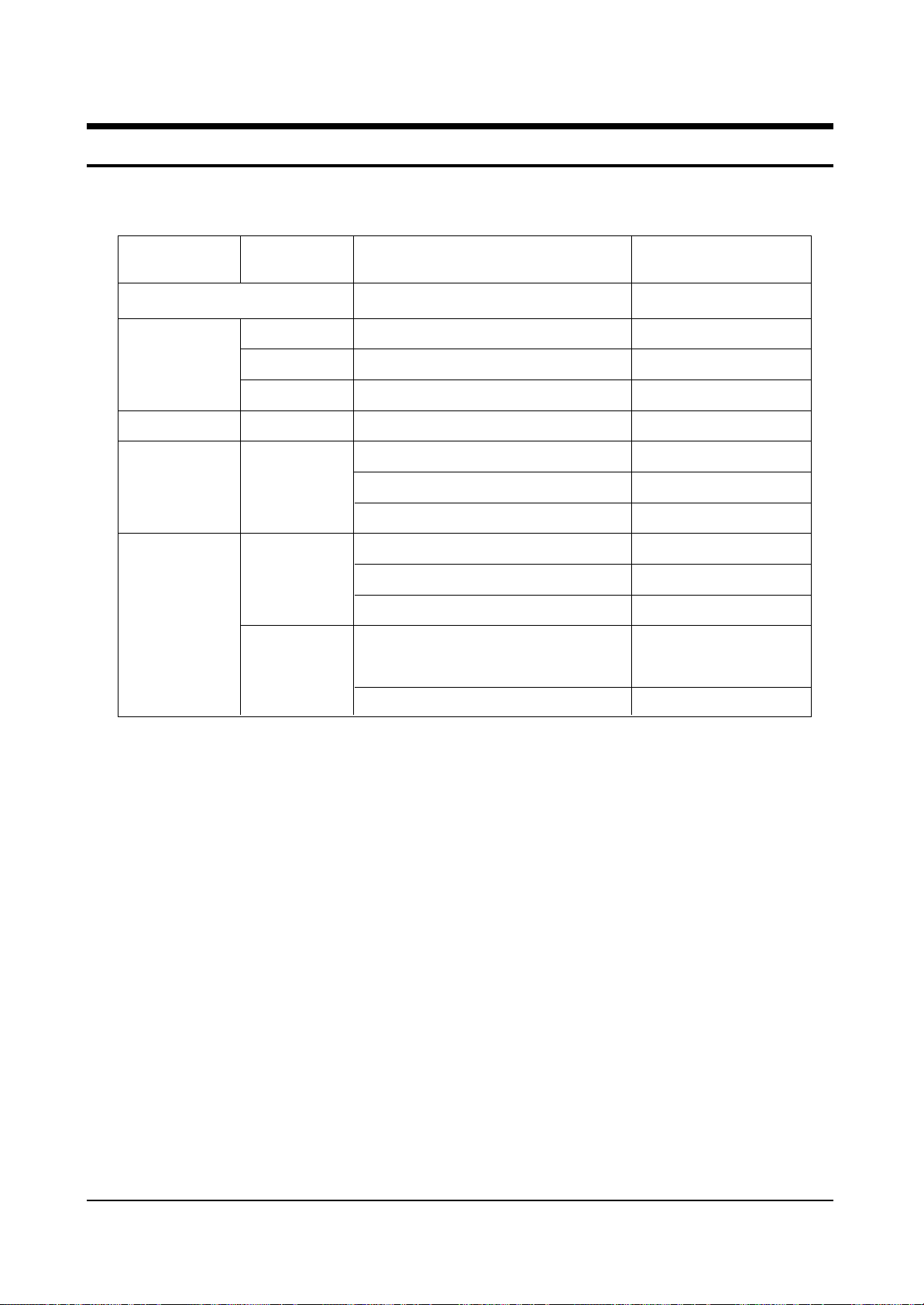

Note 3. PCB CORRECTION CONTENTS

LOC NO CODE NO SPEC LOC NO CODE NO SPEC

AZ760240

IC201S

AZ760222

IC3

AZ166044

C29

AZ166041

C30

AZ166044

C31

AZ268055

R8

AZ268053

R7

AZ363074

L1

BEFORE AFTER

Assy-sipados,SDA9401,F5 IC201S

DDP3310B-E4,PLCC,68P,-,5V,- IC3

0.27nF,5%,50V,NP0,TP,1608 C29 DELETE DELETE

0.018nF,5%,50V,NP0,TP,1608 C30

0.27nF,5%,50V,NP0,TP,1608 C31 DELETE DELETE

75ohm,5%,1/16W,DA,TP,1608 R8 DELETE DELETE

68ohm,5%,1/16W,DA,TP,1608 R7

2.2uH,10%,6x4mm L1 DELETE DELETE

AZ760244

AZ760245

AZ268050

AZ268050

Assy-sipados,SDA9401,F6

DDP3310B-F6,PLCC,68P,5V, A Improvement of TTX

0ohm,5%,1/16W,DA,TP,1608

0ohm,5%,1/16W,DA,TP,1608

A Improvement of AV CROSSTALK

CAUSE MODEL

LOC PCB correction contents Remark

C242 DELETE

C410 DELETE

J220 DELETE

Delete unnecessary materials

and locations

J221 DELETE

J231

delete only material(LOC exist)

J913 JUMPER added

C203 16V 10uF added

R944 1/8W 3.9K

R956 1/8W 470 added

A Improvement of TTX ERROR

R954 1/8W 47K added

R955 1/8W 100 added

C926 C-AXIAL;150P

L222 JUMPER added H-OUT LINE

J701 JUMPER added 2H-Noise

CN701A 3P WIRE OPTION(AA39-00306A) 2H-Noise (TO CN702A)

CN702 Polarit

changed.(Pattern changed

Against 2H-Noise

J817 JUMPER added Against 2H-Noise

J204 JUMPER added GND JUMPER

CN302 DELETE Delete if R307 add.

R307 2W 1.2ohm(AG) added Process changed(E -> V)

L910 8.2uH AL02

ASSY-SIPADOSS MODULE

Alignment and Adjustments

4-6

4-7 Factory Adjustment

1. To enter the “Service Mode”, Press the remote-control keys in this sequence :

- If you do not have Factory remote-control

- If you have Factory remote-control

2. After the Service Mode is entered, the initial screen is as shown in the figure below.

3. Use the Channel Up/Down buttons to move the cursor in the adjustment parameters.

- When CRT, CRT PCB, FBT, E

2

PROM (sometimes MICOM) is replaced, the adjustment values

should be controlled.

- After the Service adjustment is completed, Do not select “Reset” in the service mode menu.

(After above procedure is done, power is on initially and the “Plug and Play” will be operated.)

4-7-1 Service Mode

*

These hexa digits are check sum value which

depends on the MICOM.

If check sum value is changed, the value of

E

2

PROM Data newly initialed.

Note 2.

PICTURE OFF PICTURE ON

PICTURE ON

DISPLAY

DISPLAY

()

()

MENU

FACTORY

MUTE

Service

Deflection

Video Adjust 1

Video Adjust 2

Video Adjust 3

Option(81h 0Ch)

Reset

G2-Adjust

Others

*

Alignment and Adjustments

4-7

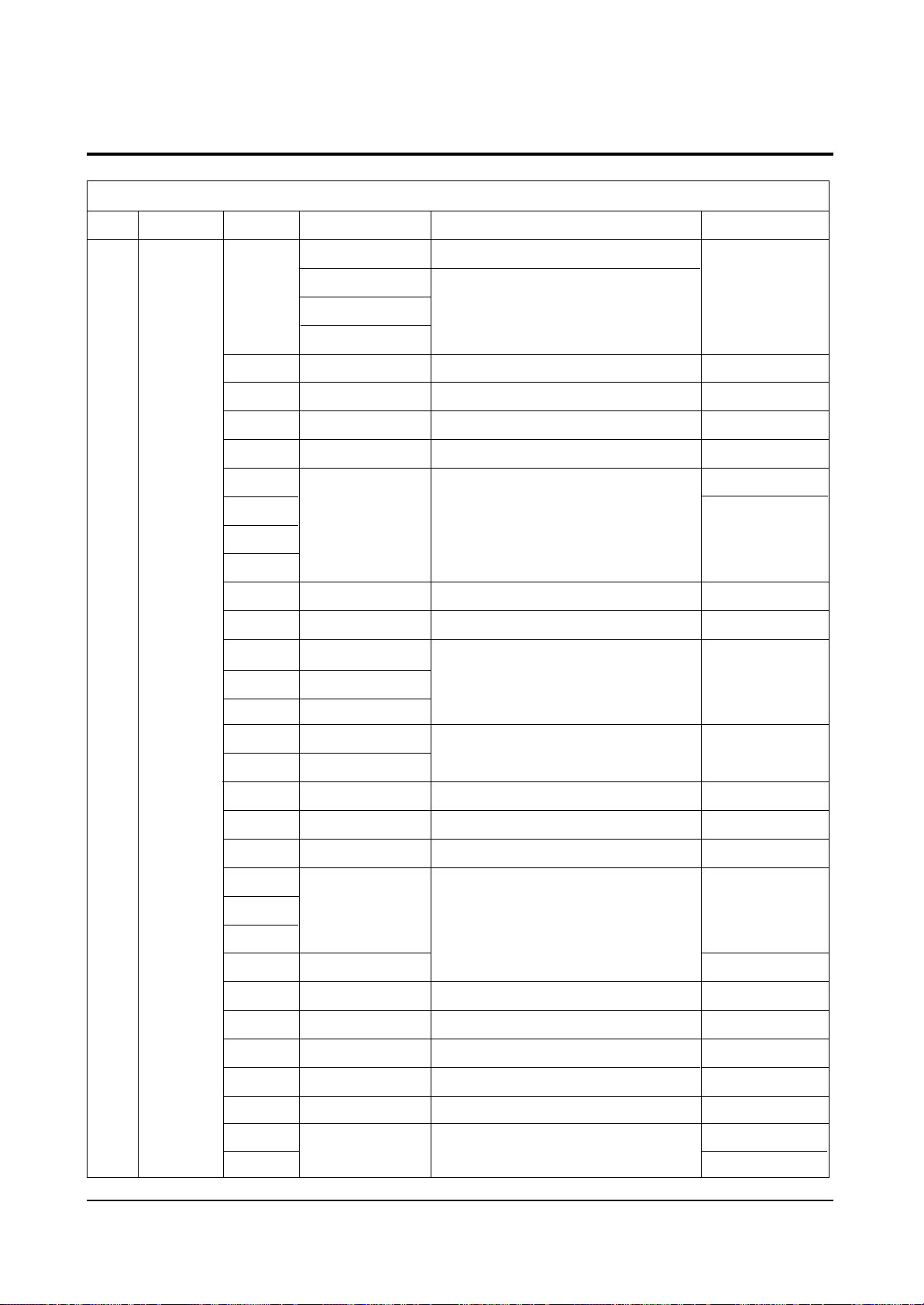

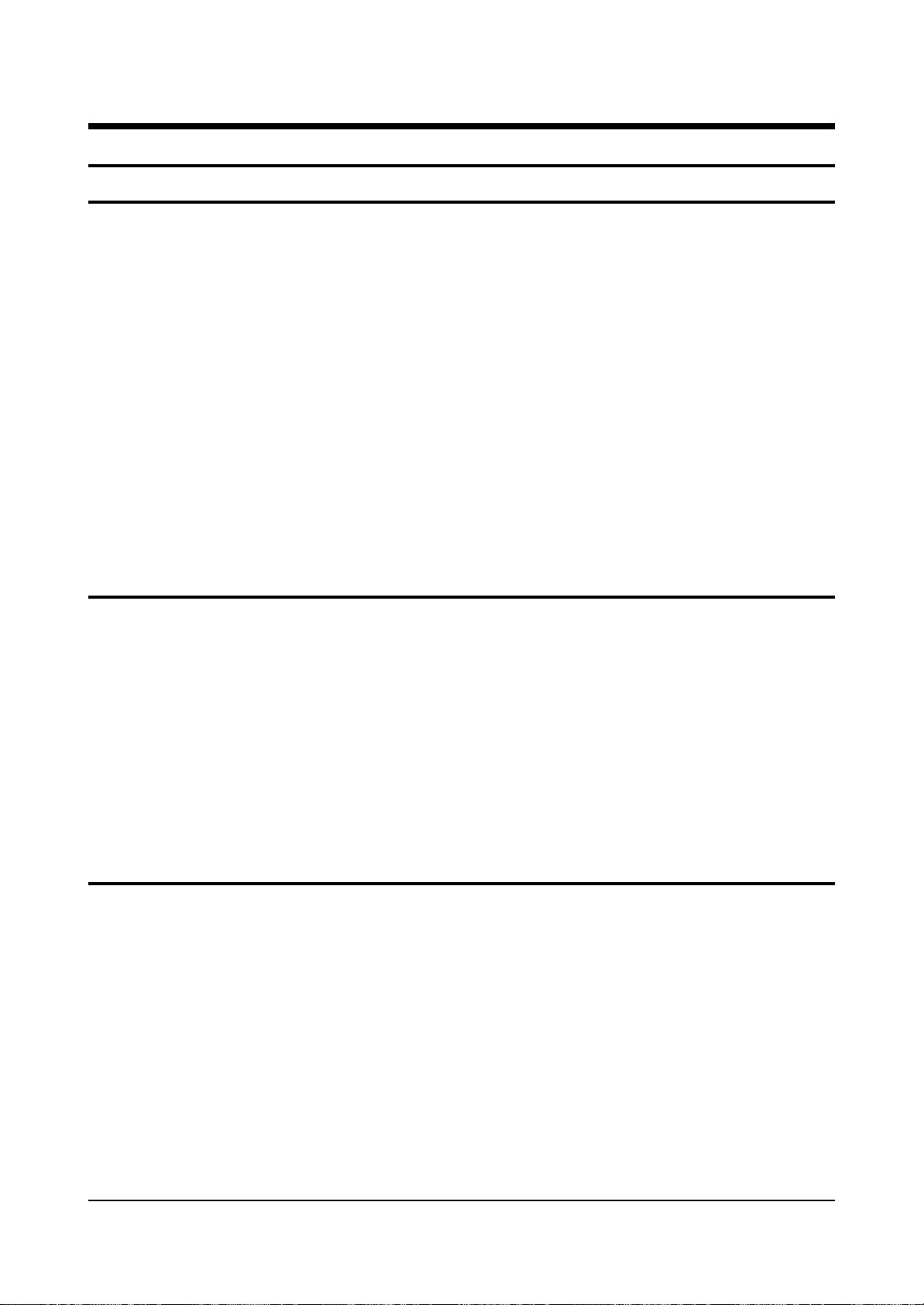

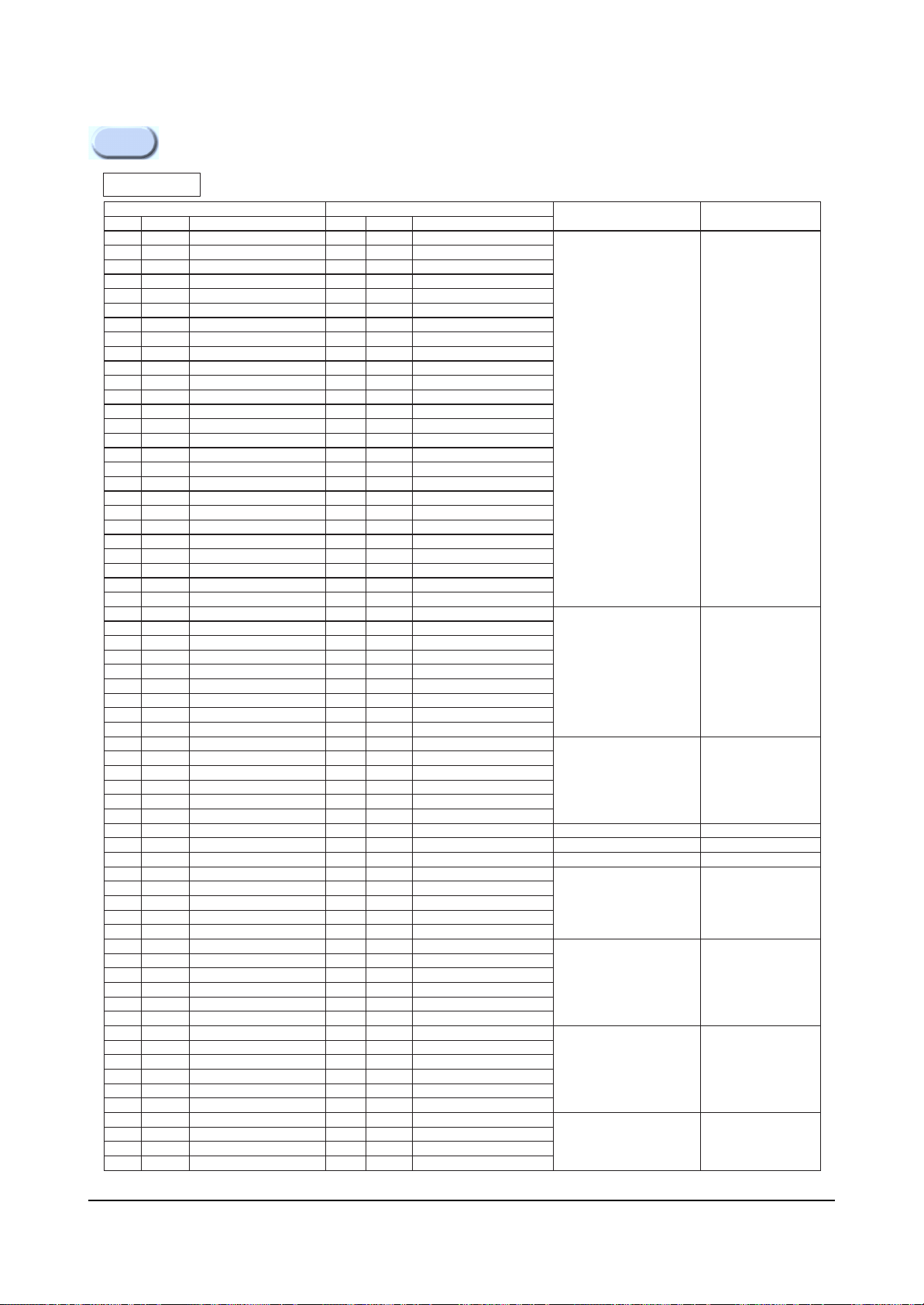

4-7-2 Memory Data

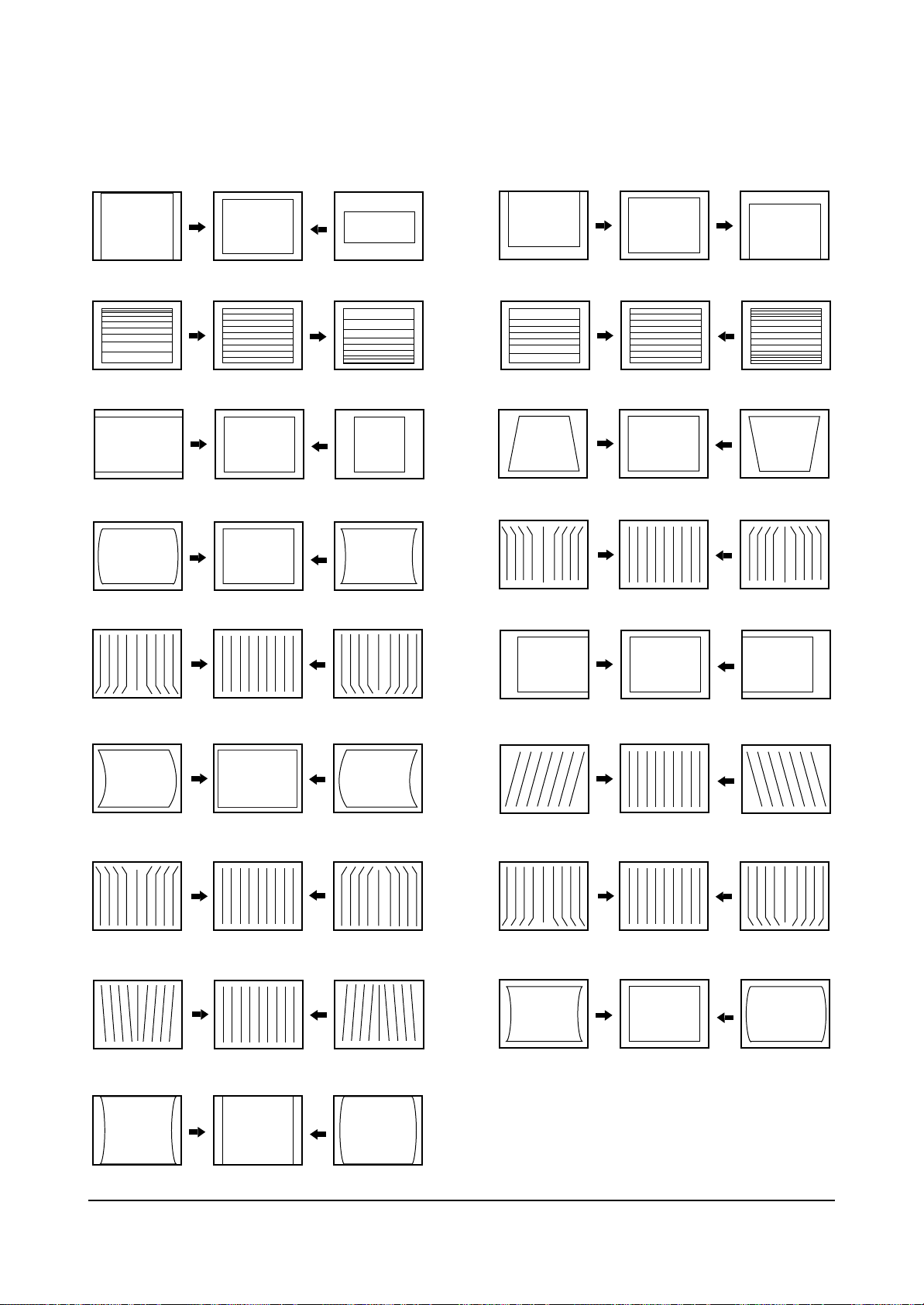

4-7-2(A) DEFLECTION (GEOMETRIC ADJUSTMENT VALUE)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

V Amp

V Shift

V Slope

V SC

H EW

H Trapizium

H Parabola

H Corner U

H Corner L

H Shift

BOW

Amgle

H Corner U6

H Corner L6

V Max

Zoom1 Amp

Zoom2 Amp

Zoom Trap

Zoom 4:3 Para

4:3~16:9 Para

Adjusts Vertical picture size. Adjusts 4:4 upper and lower picture size

in a lion head pattern at factory.

Adjusts Vertical picture position.

Adjusts Vertical Slope Correction.

Adjusts Vertical s-correction.

Horizontal east west width. Adjusts 5:5 left and right picture size in a

lion head pattern at factory.

Adjusts horizontal Trapezium.

Adjusts Horizontal Parabola.

Adjusts the top horizontal corner of picture.

Adjusts so that the top of H corner can be linear.

Adjusts the bottom horizontal corner of picture.

Adjusts so that the bottom of H corner can be linear.

Adjusts Horizontal Position.

Adjusts Horizontal BOW.

Adjusts Horizontal Angle.

Adjusts so that the top horizontal corner of picture can be linear.

Adjusts so that the bottom horizontal corner of picture can be linear.

Adjusts Max value of vertical amplitude

Adjusts vertical amplitude in zoom1.

SIM-806HEW only.

Adjusts horizontal Trapezium in Zoom

Corrects the vertical linearity in Zoom mode of P-SIZE.

The data depends on CRT (see data above).

Corrects the vertical linearity in 16:9 mode of P-SIZE.

The data depends on CRT (see data above).

GEOM

GEOM

FIX

FIX

GEOM

GEOM

GEOM

FIX

FIX

GEOM

GEOM

GEOM

GEOM

GEOM

FIX

FIX

FIX

FIX

FIX

FIX

98

143

125

230

193

72

75

112

138

161

128

128

140

141

200

175

202

128

125

138

No. OSD Initial Value Function Remark

Alignment and Adjustments

4-8

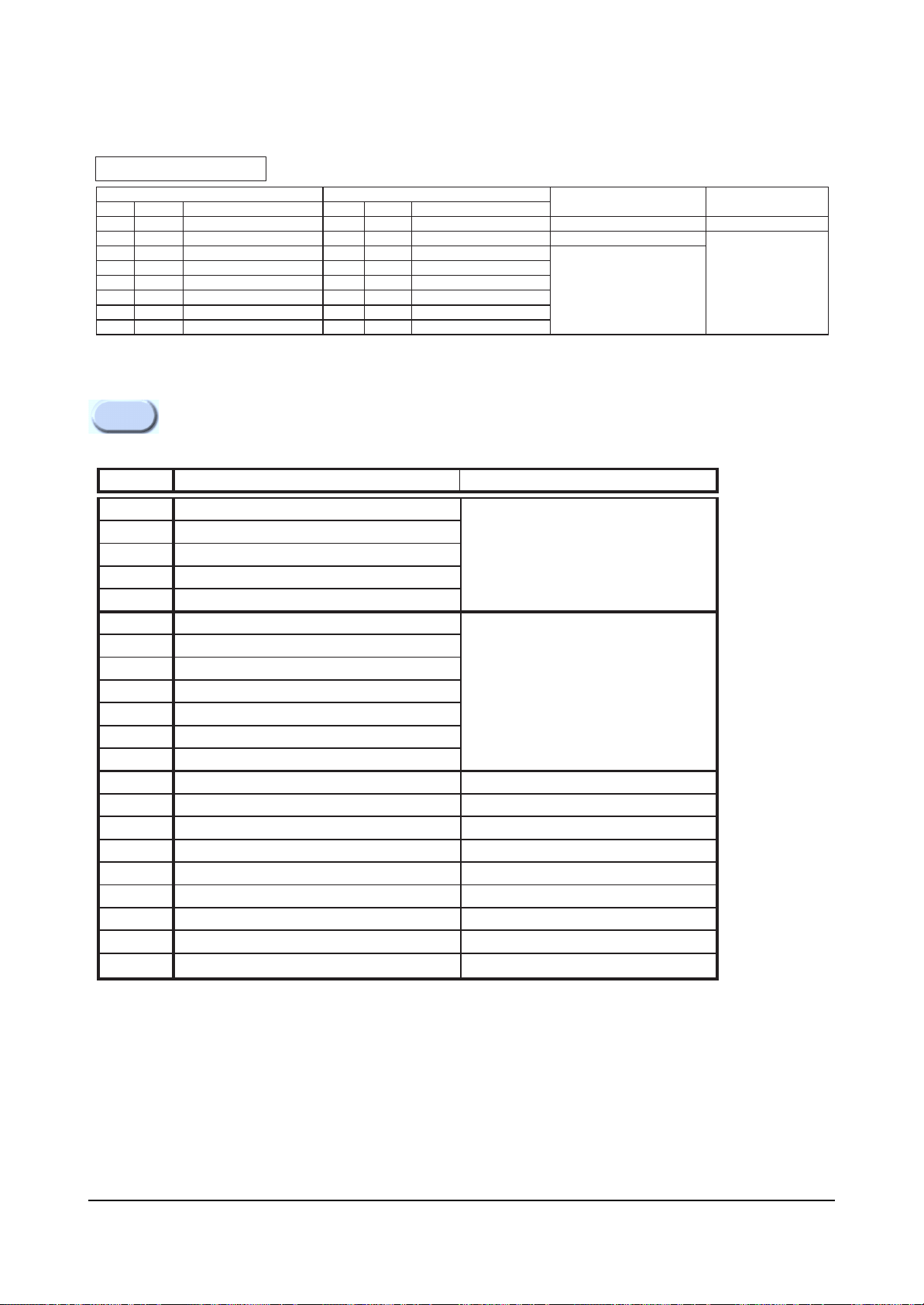

4-7-2(B) SCREEN CHANGE (I2C BUS GEOMETRIC ADJUSTMENT)

1 V Amp

V Slope

3

5 H EW

7 H Parabola

9 H Corner L

2 V Shift

V SC

4

6

H Trapizium

8

H Corner U

10

H Shift

11 BOW

13 H Corner L

15 Zoom Trap

17 4:3~10:9 Para

12

Angle

14 H Corner L

16 Zoom 4:3 Para

Alignment and Adjustments

4-9

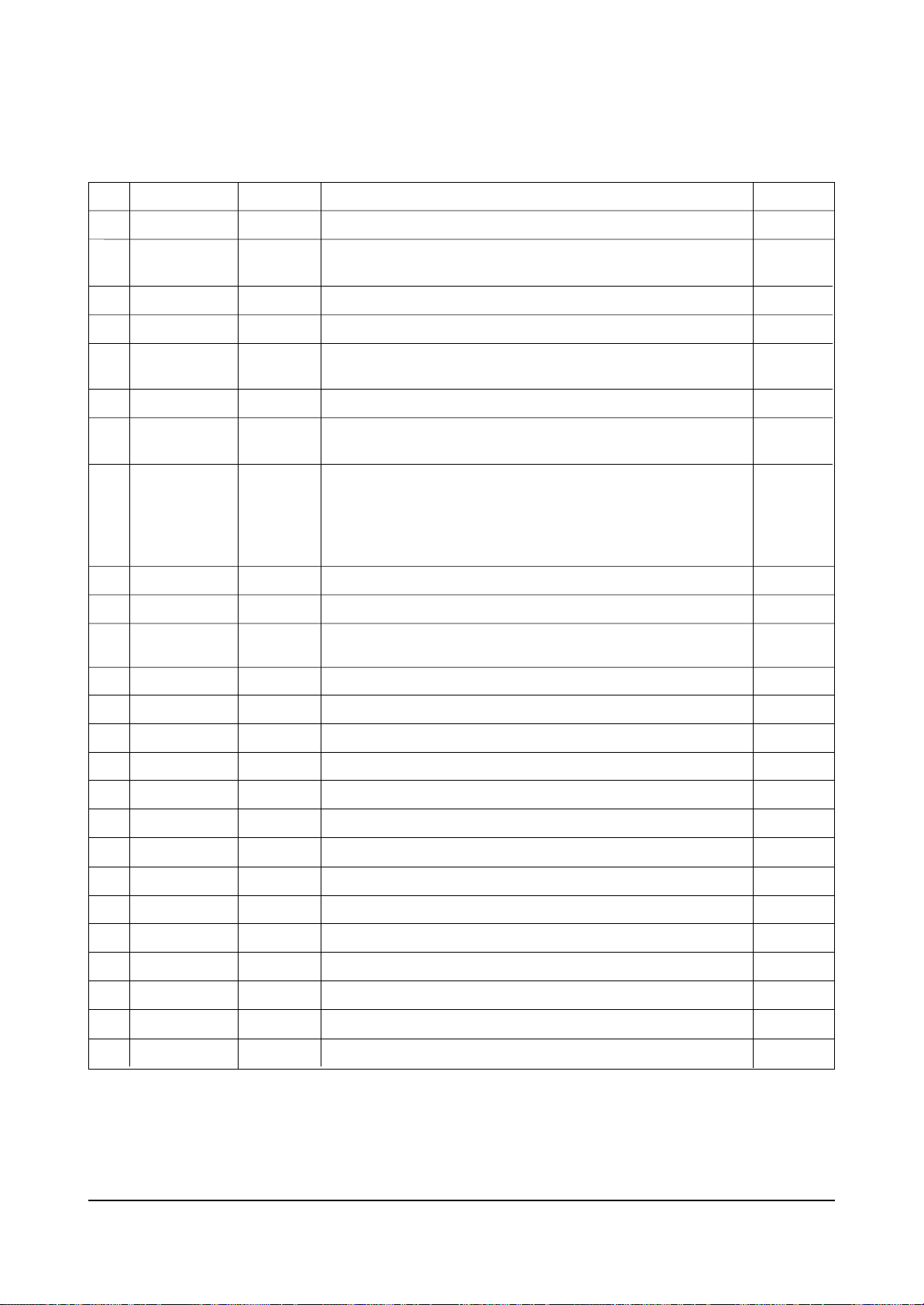

4-7-2(C) VIDEO ADJUST 1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Red Cufoff

Green Cutoff

Blue Cutoff

Red Drive

Green Drive

Blue Drive

Sub Bright

Sub Contrast

Sub Color

Sub Tint

Sub Threshold

BCL Gain

BCL Time

BCL Time2

BCL Bri Reduction

P.DK.YC Delay

P.I.YC Delay

P.L.YC Delay

S.BG.YC Delay

S.DK.YC Delay

S.L.YC Delay

P.BG.YC Delay

P.YC Delay

S.YC. Delay

N.YC. Delay

Adjusts the gain of red output from low light.

Adjusts the gain of green output from low light.

Fix this gain to 127.

Adjusts the gain of blue output from low light.

Adjusts the gain of red output from high light.

Adjusts the gain of green output from high light. After “G2-Adjustment”

and White Balance adjustments are complete, this data is fixed to 127."

Adjusts the gain of blue output from high light.

Adjust sub brightness level to set the low light luminance in Picture

Standard mode.

Adjust sub brightness level to set the low light luminance in Picture

Standard mode. Set the value of sub contrast to near 50. The user

control“contrast” depends on this value.

User contrast=[sub cont*2/100]If sub contrast data is 10, user contrast

changes into 1/5step.

Adjusts sub color level to set the gain for color in Picture Standard mode.

Adjusts the sub tint level of NTSC color system.

Beam Current Limit threshold current if SENSE input used 0...-2048 BCL

threshold current if RSW1 input used(max. ADC output ~2047)

Beam Current Limit loop Gain

BCL time constant; 0 = off

Teletext Contrast Level

BCL Brighness Reduction

PAL-D/K Y/C Delay

PAL-I Y/C Delay

PAL-L Y/C Delay

SECAM-B/G Y/C Delay

SECAM-D/K Y/C Delay

SECAM-L Y/C Delay

PAL-B/G Y/C Delay

External PAL Y/C Delay

SExternal SECAM Y/C Delay

External NTSC Y/C Delay

W/B

FIX

W/B

W/B

FIX

W/B

W/B

W/B

FIX

FIX

FIX

FIX

FIX

FIX

FIX

FIX

FIX

FIX

FIX

FIX

FIX

FIX

FIX

FIX

FIX

127

127

127

127

127

127

90

52

2

17

128

59

144

1

125

5

7

6

7

2

5

7

6

2

3

No. OSD Initial Value Function Remark

Alignment and Adjustments

4-10

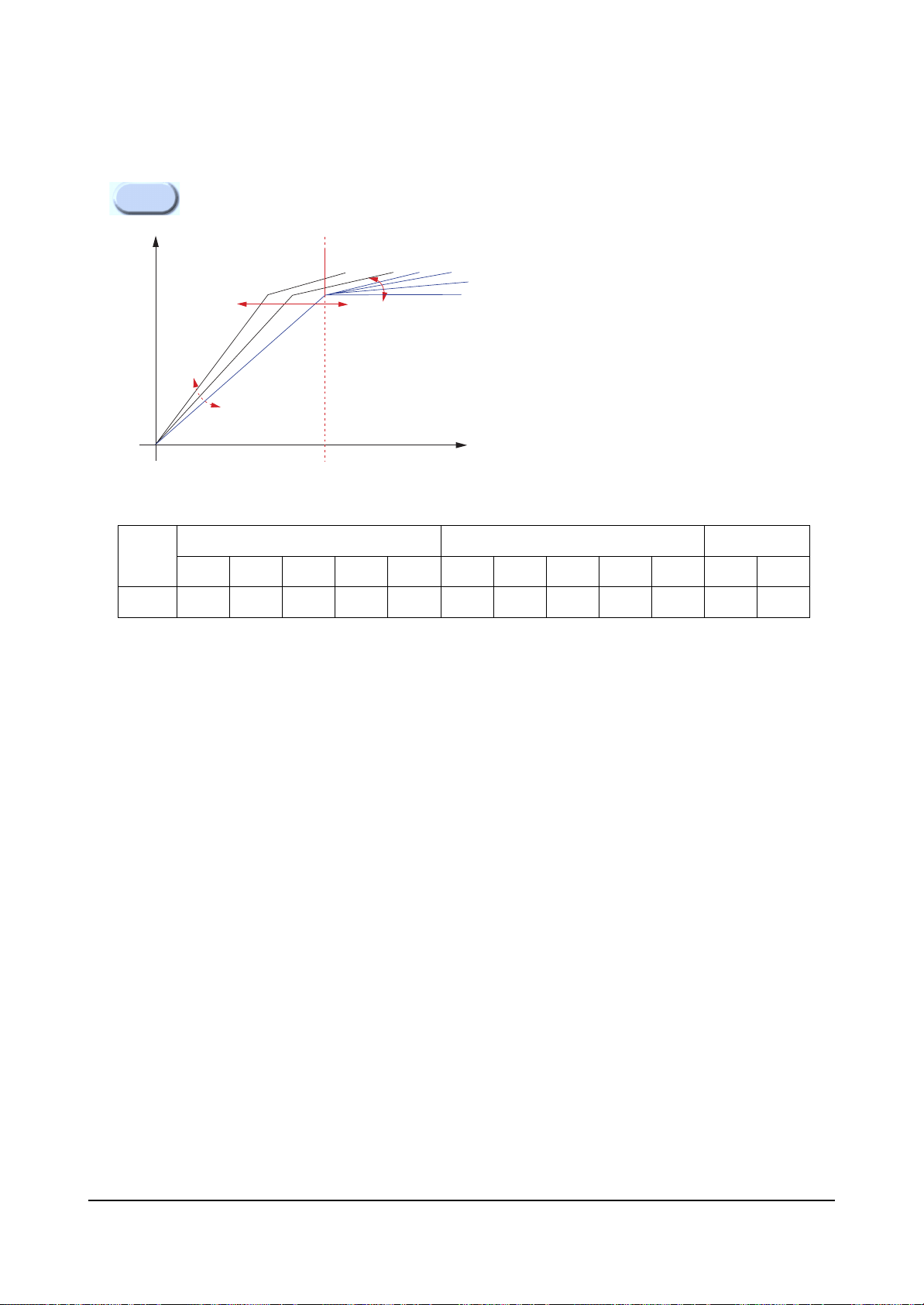

WDRGB

BCL THESHOLD

1.8mA

1.6mA

MIN

BCL GAIN

MAX

Table 1. YC Delay Adjustment Table

YC

Delay

Value

PAL

Def.

4

BG

3

DK

6

I

6

L

7

Def.

1

BG

1

DK

5

I

8

L

5

SECAM

Def.

4

Beam Control Limit Characteristic

Note 3.

M

3

NTSC

The “Def.” means that TV is in AV mode.

✐

beam

50

IRE

Loading...

Loading...