Toshiba 29SZ5DA, 29SZ5DE, 29SZ5SH, 29SZ5ST Schematic

SERVICE MANUAL

Color Television

29SZ5DA

FILE NO. 060-200325

S3ES Chassis

29SZ5DE

29SZ5SH

29SZ5ST

PRINTED IN MALAYSIA Dec. 2003 (YC/X)

CHAPTER 1 GENERAL ADJUSTMENTS

SAFETY INSTRUCTIONS ........................................................................................................................................ 3

SET-UP ADJUSTMENT ............................................................................................................................................ 4

SERVICE MODE ...................................................................................................................................................... 8

DESIGN MODE ...................................................................................................................................................... 11

ELECTRICAL ADJUSTMENTS .............................................................................................................................. 12

CIRCUIT CHECK.................................................................................................................................................... 14

GENERAL ADJUSTMENTS

CHAPTER 2 SPECIFIC INFORMATIONS

SETTING & ADJUSTING DATA .............................................................................................................................. 15

LOCATION OF CONTROLS ................................................................................................................................... 16

PROGRAMMING CHANNEL MEMORY................................................................................................................. 18

CHASSIS AND CABINET REPLACEMENT PARTS LIST ......................................................................................21

PC BOARDS TOP & BOTTOM VIEW...................................................................................................................... 32

TERMINAL VIEW OF TRANSISTORS ................................................................................................................... 41

CIRCUIT BLOCK DIAGRAM .................................................................................................................................. 43

TABLE OF CONTENTS

SPECIFICATIONS .............................................................................................................................................. END

APPENDIX:

CIRCUIT DIAGRAM

– 2 –

CHAPTER 1 GENERAL ADJUSTMENTS

SAFETY INSTRUCTIONS

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECAUTION”, “SAFETY PRECAU-

TION” AND “PRODUCT SAFETY NOTICE” INSTRUCTIONS BELOW.

X-RAY RADIATION PRECAUTION

1. Excessive high voltage can produce potentially hazardous X-RAY RADIATION. To avoid such hazards, the high

voltage must not be above the specified limit. The nominal

value of the high voltage of this receiver is (A) kV at zero

beam current (minimum brightness) under a (C) V AC power

source. The high voltage must not, under any circumstances, exceed (B) kV.

Refer to table-1 for high voltage (A), (B) & AC voltage (C).

(See SETTING & ADJUSTING DATA on page 15)

Each time a receiver requires servicing, the high voltage

should be checked following the HIGH VOLTAGE CHECK

procedure in this manual. It is recommended that the reading of the high voltage be recorded as a part of the service

record. It is important to use an accurate and reliable high

voltage meter.

SAFETY PRECAUTION

WARNING : Service should not be attempted by anyone unfamiliar with the necessary precautions on this receiver. The following

are the necessary precautions to be observed before servicing this chassis.

1. An isolation transformer should be connected in the power line between the receiver and the AC line before any service is

performed on the receiver.

2. Always discharge the picture tube anode to the CRT conductive coating before handling the picture tube. The picture tube

is highly evacuated and if broken, glass fragments will be violently expelled. Use shatter proof goggles and keep picture tube

away from the unprotected body while handling.

3. When replacing a chassis in the cabinet, always be certain that all the protective devices are put back in place, such as; nonmetallic control knobs, insulating covers, shields, isolation resistor-capacitor network etc.

2. The only source of X-RAY RADIATION in this TV receiver

is the picture tube. For continued X-RAY RADIATION protection, the replacement tube must be exactly the same

type tube as specified in the parts list.

3. Some part in this receiver have special safety-related characteristics for X-RAY RADIATION protection. For continued safety, parts replacement should be undertaken only

after referring to the PRODUCT SAFETY NOTICE below.

GENERAL ADJUSTMENTS

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These characteristics are

often passed unnoticed by a visual inspection and the protection afforded by them cannot necessarily be obtained by using

replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special safety characteristics are identified in this manual and its supplements; electrical components having such features are identified by

the international hazard symbols on the schematic diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use of substitute replacement

parts which do not have the same safety characteristics as specified in the parts list may create shock, fire, X-ray

radiation or other hazards.

– 3 –

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECAUTION”, “SAFETY PRECAU-

TION” AND “PRODUCT SAFETY NOTICE” ON PAGE 3 OF THIS MANUAL.

SET-UP ADJUSTMENT

■ The following adjustments should be made when a complete realignment is required or a new picture tube is installed.

Perform the adjustments in order as follows :

1. Color Purity

2. Convergence

3. White Balance

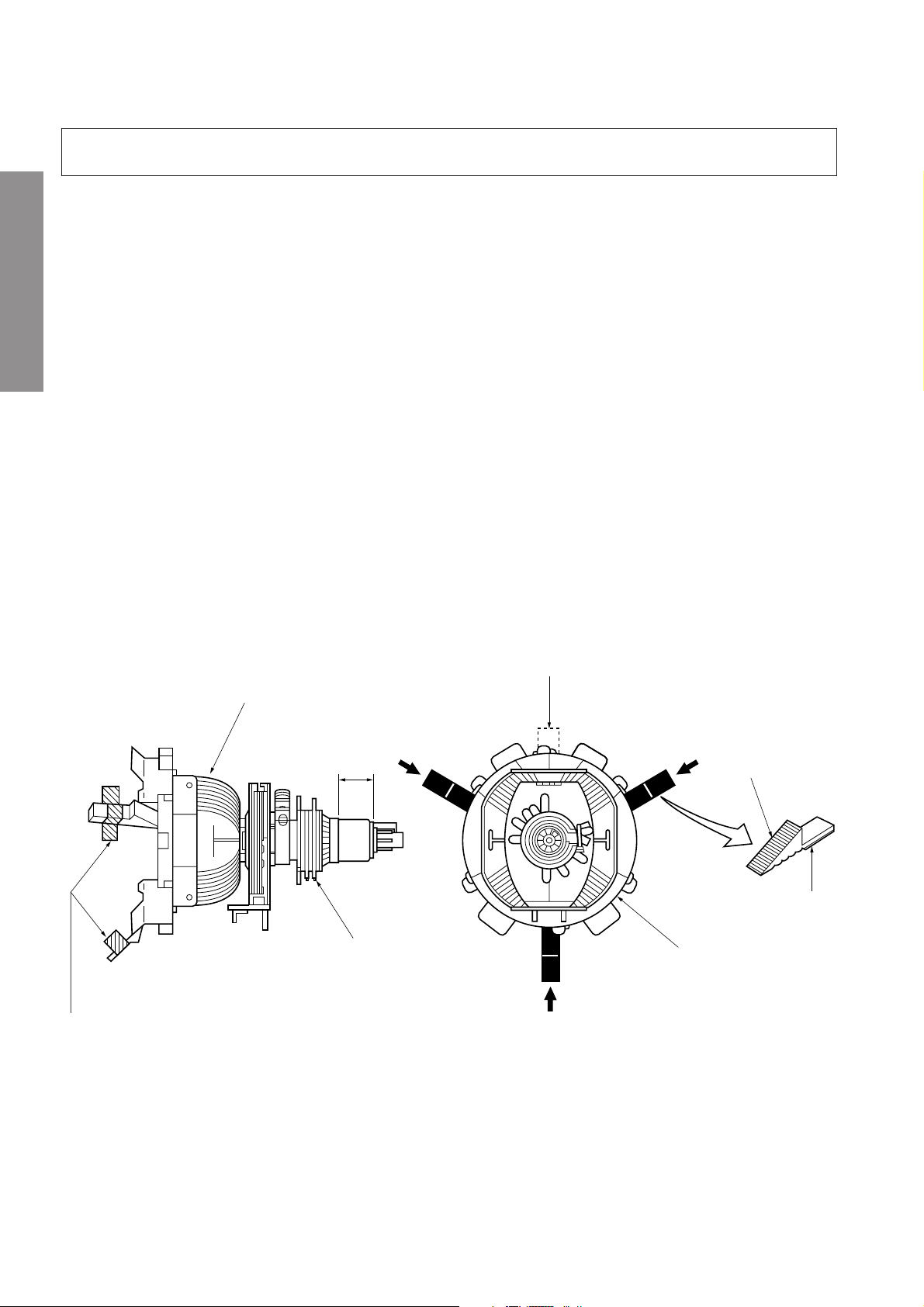

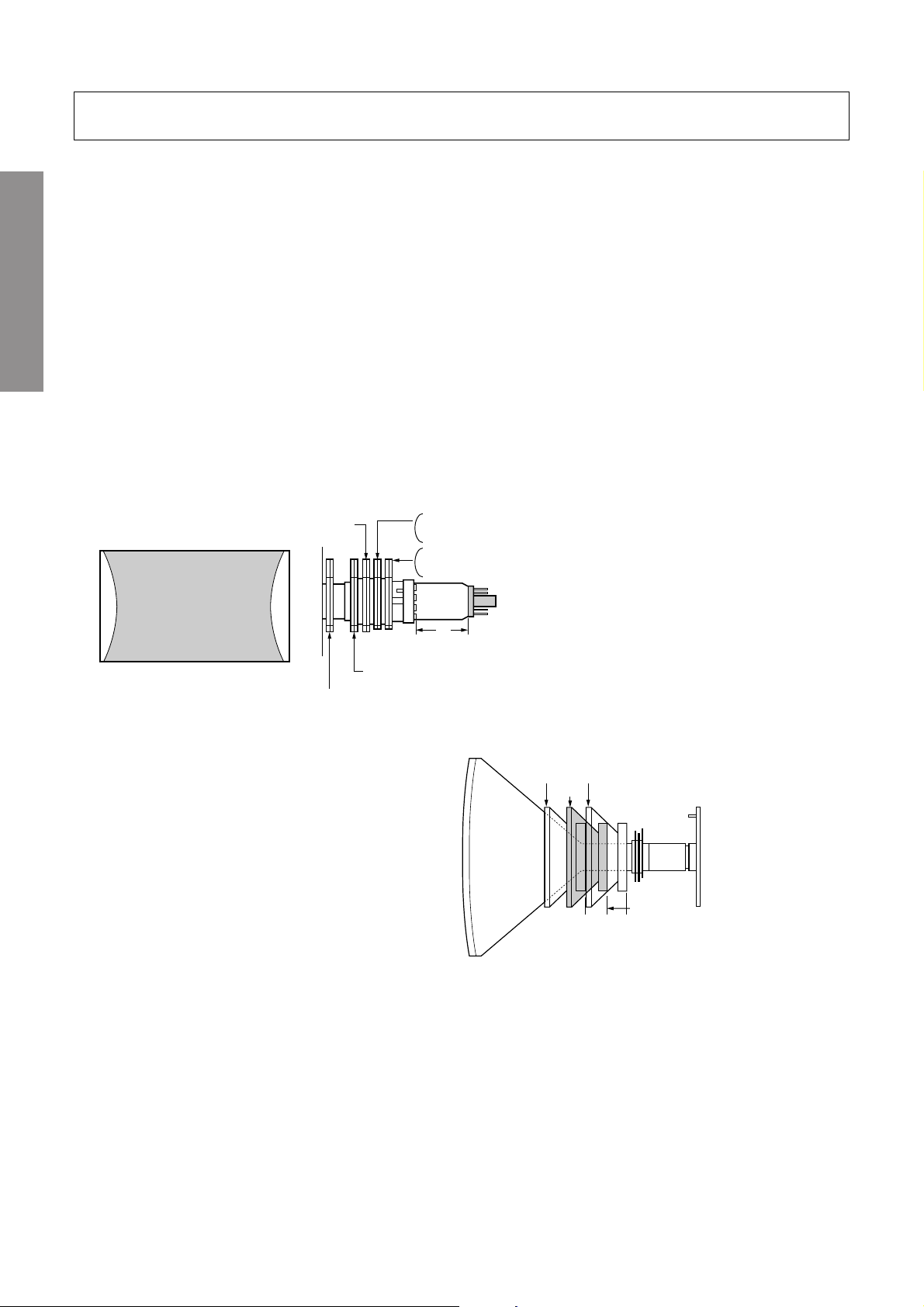

Note: 1.The PURITY/CONVERGENCE MAGNET assembly and rubber wedges need mechanical positioning.

Refer to figure 1.

GENERAL ADJUSTMENTS

*

COLOR PURITY ADJUSTMENT

NOTE : Before attempting any purity adjustments, the receiver

1. Demagnetize the picture tube and cabinet using a degauss-

2. Set the brightness and contrast to maximum.

3. Use a green raster from among the built-in test signals.

4. Loosen the clamp screw holding the yoke and slide the

2.Mounting position of the purity magnet assembly should fit to same position as old one because slightly difference

to the position depend on a kind of tube.

There are no adjustment of purity and convergence in some picture tube (Unified with purity magnet)

5. Remove the Rubber Wedges.

should be operated for at least fifteen minutes.

ing coil.

yoke backward or forward to provide vertical green belt

(zone) in the picture screen.

6. Rotate and spread the tabs of the purity magnet (See figure 2.) around the neck of the picture tube until the green

belt is in the center of the screen. At the same time, enter

the raster vertically.

7. Slowly move the yoke forward or backward until a uniform

green screen is obtained. Tighten the clamp screw of the

yoke temporarily.

8. Check the purity of the red and blue raster.

GLASS CLOTH

TAPES

DEFLECTION

YOKE

29.1mm(28", 29")

25mm(25")

19mm(19", 20", 21")

14mm(13", 14")

PURITY/

CONVERGENCE

MAGNET ASS'Y

Figure 1.

TEMPORARY

MOUNTING

RUBBER WEDGE

ADHESIVE

DEFLECTION

YOKE

– 4 –

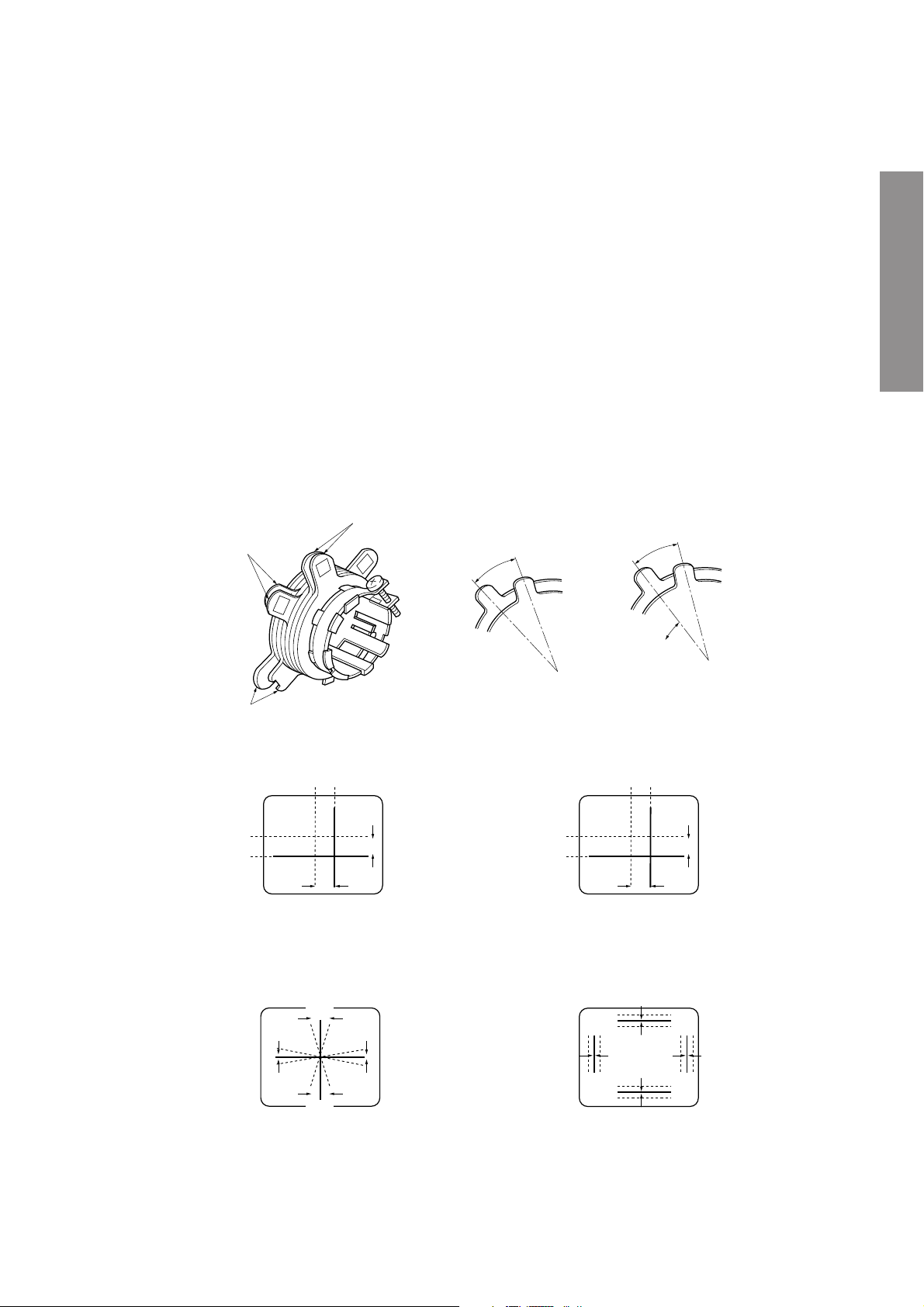

CONVERGENCE ADJUSTMENTS

NOTE: Before attempting any convergence adjustments, the

receiver should be operated for at least fifteen minutes.

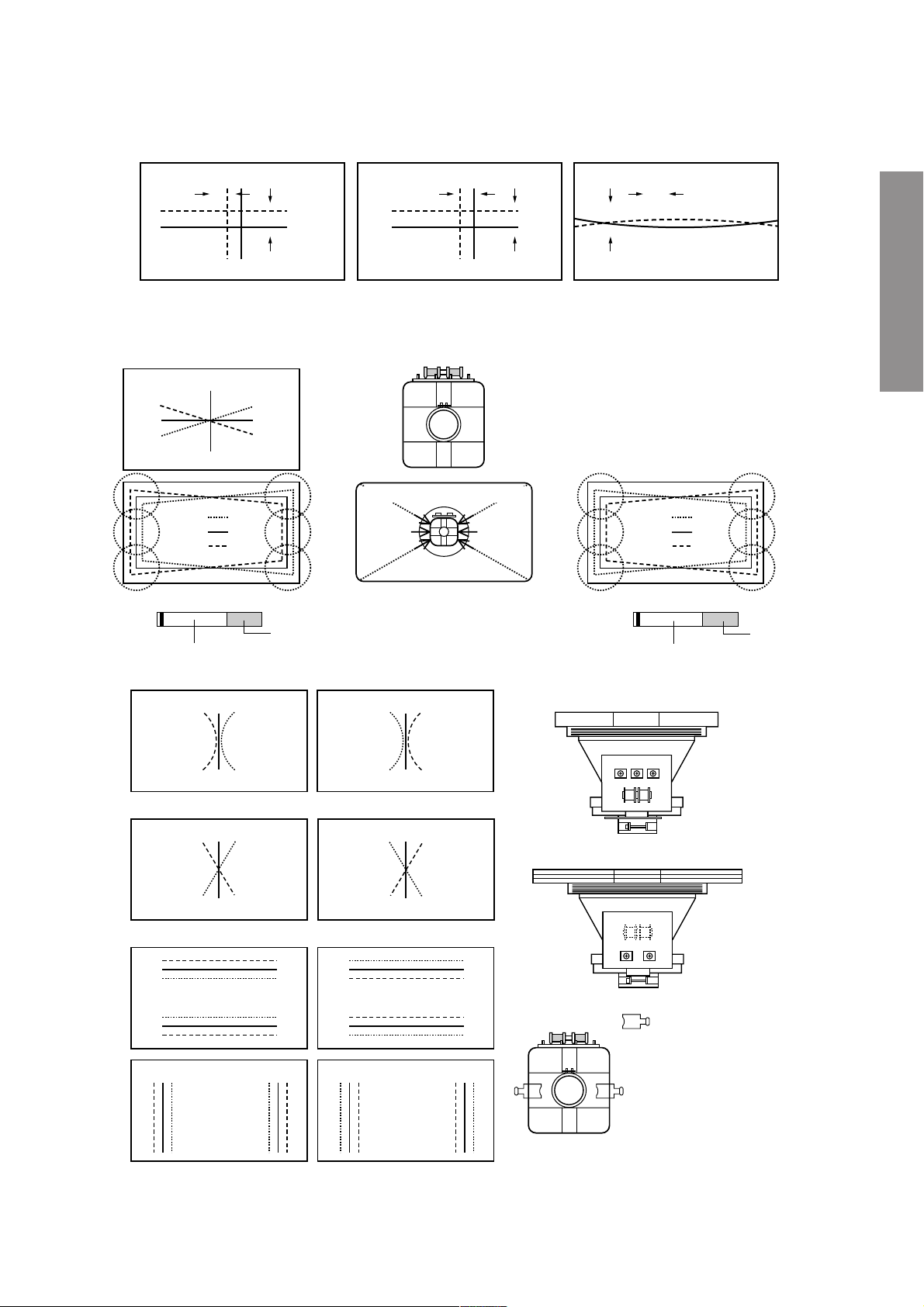

■ CENTER CONVERGENCE ADJUSTMENT

1. Use the cross-dot pattern from among the built-in test signals.

2. Set the brightness and contrast for well defined pattern.

3. Adjust two tabs of the 4-Pole Magnets to change the angle between them (See figure 2.) and superimpose red

and blue vertical lines in the center area of the picture

screen.

4. Turn the both tabs at the same time keeping the angle

constant to superimpose red and blue horizontal lines at

the center of the screen.

5. Adjust two tabs of 6-Pole Magnets to superimpose red/

blue line and green one. Adjusting the angle affects the

vertical lines and rotating both magnets affects the horizontal lines.

6. Repeat adjustments 3, 4, 5 keeping in mind red, green

and blue movement, because 4-Pole Magnets and 6-Pole

Magnets have mutual interaction and make dot movement

complex.

4-POLE

MAGNETS

6-POLE

MAGNETS

ADJUST THE ANGLE

(VERTICAL LINES)

■ CIRCUMFERENCE CONVERGENCE ADJUSTMENT

1. Loosen the clamping screw of deflection yoke slightly to

allow the yoke to tilt.

2. Temporarily put a wedge as shown in figure 1. (Do not

remove cover paper on adhesive part of the wedge.)

3. Tilt front of the deflection yoke up or down to obtain better

convergence in circumference. (See figure 3.) Push the

mounted wedge into the space between picture tube and

the yoke to fix the yoke temporarily.

4. Put other wedge into bottom space and remove the cover

paper to stick.

5. Tilt front of the yoke right or left to obtain better convergence in circumference. (See figure 3.)

6. Keep the yoke position and put another wedge in either

upper space. Remove cover paper and stick the wedge

on picture tube to fix the yoke.

7. Detach the temporarily mounted wedge and put it in another upper space. Stick it on picture tube to fix the yoke.

8. After fixing three wedges, recheck overall convergence.

Tighten the screw firmly to fix the yoke and check the yoke

is firm.

9. Stick three adhesive tapes on wedges as shown in figure

1.

FIXED

GENERAL ADJUSTMENTS

ROTATE TWO TABS

AT THE SAME TIME

(HORIZONTAL LINES)

PURITY

MAGNETS

CONVERGENCE MAGNET ASSEMBLY ADJUSTMENT OF MAGNETS

Figure 2.

BLU RED

BLU

RED

4-POLE MAGNETS MOVEMENT

BGR

R

G

B

RGB

RED/BLU

GRN

Center Convergence by Convergence Magnets

B

G

R

RED/BLU GRN

6-POLE MAGNETS MOVEMENT

B

G

R

BGR

RGB

R

G

B

INCLINE THE YOKE UP (OR DOWN)

Circumference Convergence by DEF Yoke

Figure 3. Dot Movement Pattern

INCLINE THE YOKE RIGHT (OR LEFT)

– 5 –

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECAUTION”, “SAFETY PRECAU-

TION” AND “PRODUCT SAFETY NOTICE” ON PAGE 3 OF SERVICE MANUAL.

■ The following adjustments should be made when a complete realignment is required or a new picture tube is installed.

Perform the adjustments in order as follows :

1. Color Purity

2. Convergence

3. White Balance

Note:The PURITY/CONVERGENCE MAGNET assembly and rubber wedges need mechanical positioning.

Refer to figure 1.

COLOR PURITY ADUSTMENT

(1)Let the screen face in the installing direction or toward the east (when it is to be moved), bring up the service mode

screen after demagnetizing (front, left, right, and top) with the degaussing coil, receive white signals by pressing the

GENERAL ADJUSTMENTS

[TV/VIDEO] button, and then the receiver should be operated for more than 40 minutes.

(2)Perform rough adjustment of the central convergence with the P/C magnet according to the adjustment item.

(3)Receive built-in green signals, loosen set screws on the deflection yoke, remove rubber wedges, and shift the deflection

yoke to toward front.

(4)Move alternately the two 2-pole magnets of the P/C magnets so that the green raster can come to the center of the

screen.

SET-UP ADJUSTMENT (FOR FLAT TUBE)

Figure 1.

2-pole purity magnet

(27": Magnet is fixed with deflection yoke.)

Green Belt

Sub-4-pole convergence magnet (32" : 34")

Sub-4-pole convergence magnet (to be installed on deflection yoke for 30", 32”)

Main 4-pole convergence magnet (30" : 32")

6-pole convergence magnet (34")

6-pole convergence magnet (30" : 32")

Main 4-pole convergence magnet (34")

P/C magnet installing position A

• 30"=26.5 mm

A

• 32"=30.5 mm or 32.5 mm

• 34"=37 mm

• 34"=39 mm

(5)Receive built-in red and blue signals, check that there is no inclination of the single color raster toward one side, and if

each color tilts to a great extent, make adjustment with the 2-pole magnet so that the 3 colors will come to the center

evenly.

(6)Receive the green raster, shift the deflection yoke from a

foremost position (hitting against the picture tube) to a

Shift deflection yoke

(7) Perform marking of each point

(6)

(8)

on the tape of picture tube

backward position horizontally, stop the deflection yoke

at a position where it begins to become a green raster,

and perform accurate marking on the picture tube.

(7)Shift the deflection yoke further backward, and perform

Picture tube

CRT-D board

accurate marking at a position where the green raster

begins to being luck.

(8)Fix the deflection yoke at a position 60% forward within

the range marked in items (6) and (7) above.

CONVERGENCE ADJUSTMENTS

100 60 0%

Fix the deflection yoke at a position 60% forward from a

point between (6) and (7)

P/C Mag

* Adjust the convergence magnet to get vest convergence in the the order to (1) ~ (5).

■ CENTER CONVERGENCE:

(1)Receive the white crosshatch or dot pattern from the service signal generator.

(2)Use the 2 pieces of main 4-pole magnets of P/C magnets, change the open angle, and align the red and blue vertical

lines on the screen center.

(3)Freeze the open angle of the main 4-pole magnets, turn them simultaneously, and align the horizontal lines.

(4)Take the same steps for items (2) and (3) above and align red/blue with green on the screen center using two 6-pole

magnets.

– 6 –

(5)Adjust the sub-4-pole magnets only in case there is any deviation of Xv bow-shaped convergence. (To be usually set at

the initial position)

Align both sides with the sub-4-pole magnets and minimize the deviation of blue and red with the main 4-pole magnets.

blue

blue

red

red

Main 4-pole magnet

red/blue

red/blue

green

6-pole magnet

■ CIRCUMFERENCE CONVERGENCE:

Perform correction in the following manner.

*

blue

green

red

A

B

C

(Parts code:23 948 274) TC-S

blue

green

red

S

N

Blue color or blue mark

D

E

F

*Insert the correction piece between the

picture tube and the deflection yoke.

Bonded surface

(Insertion position of correction

piece)

D

E

F

A

B

C

Adjust VR 1 and minimize the deviation of YH. *Only 27", 30" and 32".

Red

green

blue

blue

green

Red

Xv bow-shaped deviation of convergence

blue

green

red

Sub-4-pole magnet

• Adjust coils and minimize deviation

(The 27” unit has coils underneath it)

A

B

C

■ 30", 27", 32"

blue

green

red

(Parts code:23 948 464)

N

S

Transparent

GENERAL ADJUSTMENTS

D

E

F

Bonded surface

Red

green

blue

blue

green

Red

Adjust VR 2 (YHC) and minimize the deviation of YH.

Red

blue

green

green

blue

Red

blue

Red

green

green

Red

blue

Adjust VR 3 (YV) and minimize the deviation of YV.

Red

green

blue

blue

green

Red

GH

Red

blue

green

green

blue

red

green

blue

red

blue

green

Red

Red

green

blue

green

Red

blue

VR3

VR2 VR1

■ 34"

YV YHC

27" (Part No. 23 947 371)

32", 30" (Part No. 23 947 121)

34" (Part No. 23 993 080)

GH

Perform correction by inserting the

correction piece into the clearance of terminal board coils of

the deflection yoke.

Note:

Perform insertion by turning the

metal side to the terminal board

side of the deflection yoke.

– 7 –

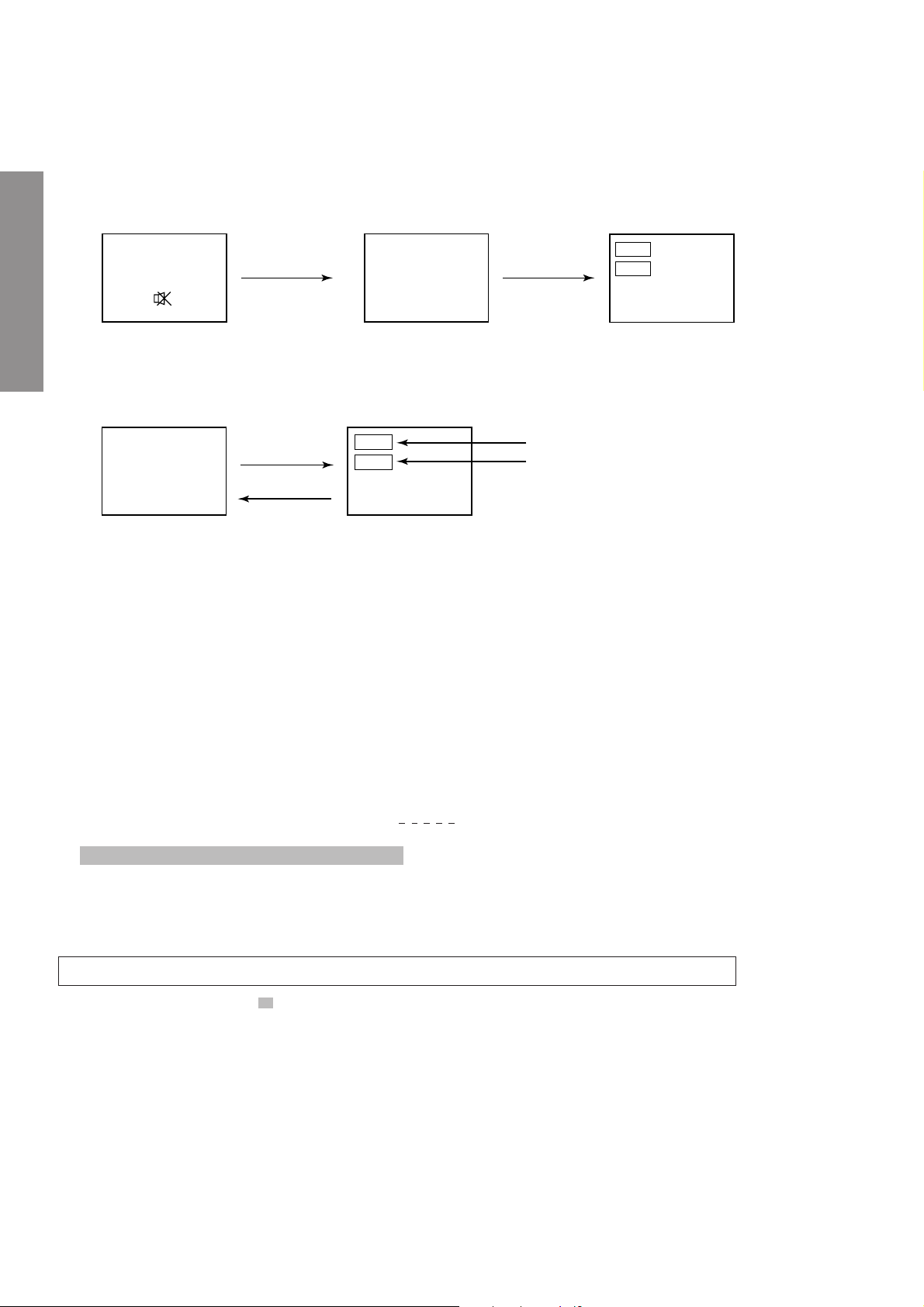

1. ENTERING TO SERVICE MODE

1) Press o button once on

Remote Control.

SERVICE MODE

2) Press o button again to

keep pressing.

3) While pressing the o button,

press MENU button on TV set.

GENERAL ADJUSTMENTS

2. DISPLAYING THE ADJUSTMENT MENU

1) Press MENU button on TV.

Service mode

S

3. KEY FUNCTION IN THE SERVICE MODE

The following key entry during display of adjustment menu provides special functions.

A single horizontal line ON/OFF: - / - - button (on Remote) or a button (on TV)

Test signal selection : a button (on Remote)

Selection of the adjustment items : Channel s/t (on TV or Remote)

Change of the data value : Volume ; +/– (on TV or Remote)

Adjustment menu mode ON/OFF : MENU button (on TV)

Initialization of the memory (QA02) : CALL + Channel button on TV (s)

Reset the count of operating protect

circuit to “00”: CALL + Channel button on TV (t)

“RCUT” selection : 1 button

“GCUT” selection : 2 button

“BCUT” selection : 3 button

“CNTX” (or “SCNT”) selection : 4 button

“COLC” selection : 5 button

“TNTC” selection : 6 button

Test audio signal ON/OFF (1kHz) : 8 button

Self diagnostic display ON/OFF : 9 button

Press

Press

Adjustment mode

Item

Data

(Service mode display)

Item

Data

Color thickness correction

note: Displayed differently as shown below, de-

pending on the setting of the receiving color

system.

COLP (PAL)

COLC (NTSC)

COLS (SECAM)

S

CAUTION : Never try to perform initialization unless you have changed the memory IC.

The key function marked with are not usable to control in the Test signal for some model.

*

– 8 –

4. SELECTING THE ADJUSTING ITEMS

1) Every pressing of CHANNEL s button in the service mode changes the adjustment items in the order of table-2.

(t button for reverse order)

Refer to table-2 for preset data of adjustment mode.

(See SETTING & ADJUSTING DATA on page 15)

5. ADJUSTING THE DATA

1) Pressing of VOLUME ; +/– button will change the value of data in the range from 00H to FFH. The variable

range depends on the adjusting item.

6. EXIT FROM SERVICE MODE

1) Pressing POWER button to turn off the TV once.

■ INITIALIZATION OF MEMORY DATA OF QA02

After replacing QA02, the following initialization is required.

1. Enter the service mode, then select any register item.

2. Press and hold the CALL button on the Remote, then press the CHANNEL s button on the TV. The initialization of QA02 has

been complated.

3. Check the picture carefully. If necessary, adjust any adjustment item above.

Perform “Auto search Memory” on the owner’s manual.

CAUTION: Never attempt to initialize the data unless QA02 has been replaced.

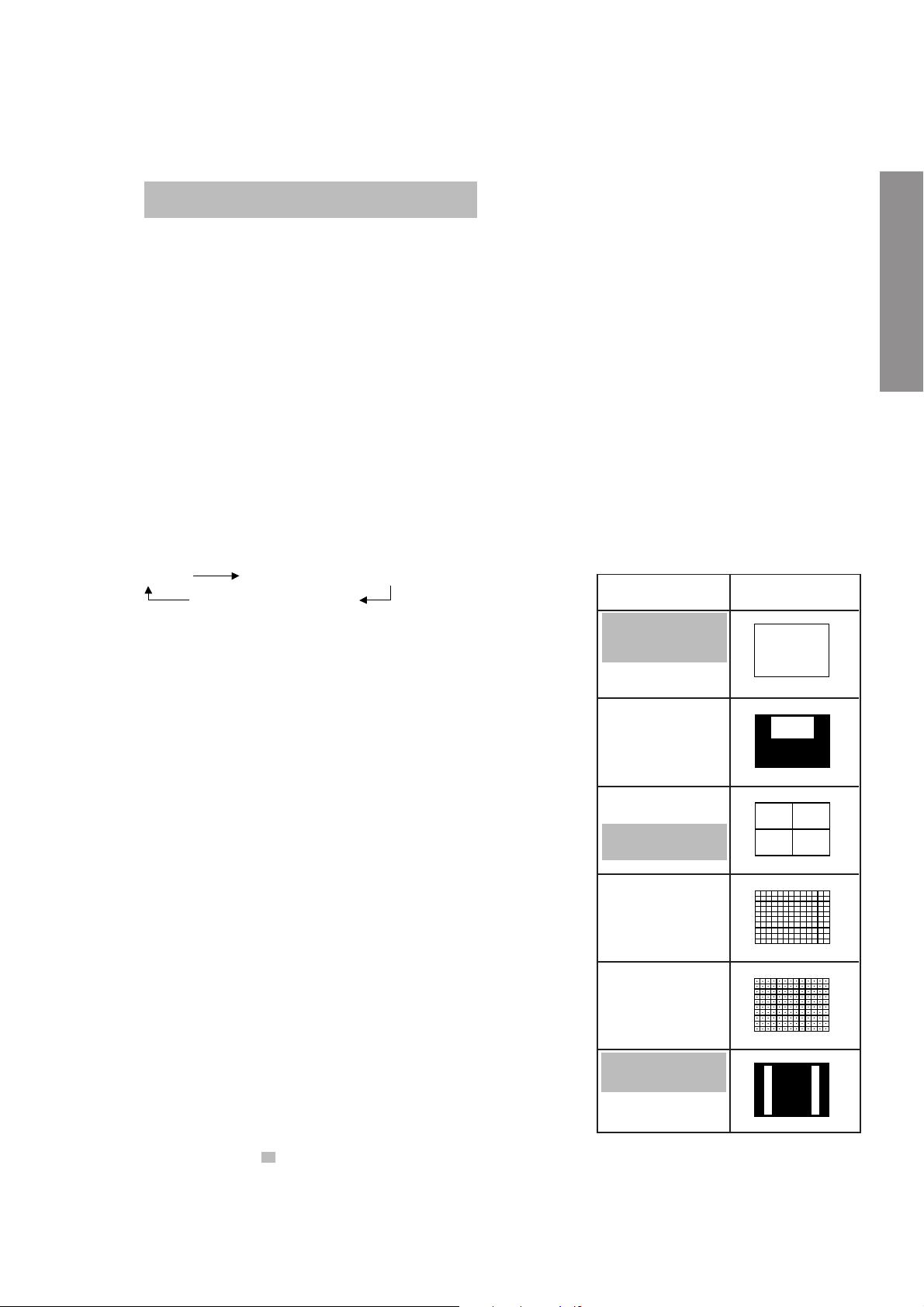

7. TEST SIGNAL SELECTION

1) Every pressing of a button on the Remote Control changes the built-in test patterns on screen as described below

in SERVICE MODE.

GENERAL ADJUSTMENTS

Signal off

NTSC signals (14 patterns)

PAL signals (14 patterns)

Signals Picture

• Red raster

• Green raster

• Blue raster

• All Black

• All White

• Black & White

• Black cross-bar

• White cross-bar

• Black cross-bar

on green raster

• Black cross-hatch

• White cross-hatch

• Black cross-dot

• White cross-dot

• H signal (white)

• H signal (black)

The signals marked with are not usable to display in the Test signal for some model.

*

– 9 –

8. SELF DIAGNOSTIC FUNCTION

1) Press “9” button on Remote Control during display of adjustment menu in the service mode.

The diagnosis will begin to check if interface among IC’s are executed properly.

2) During diagnosis, the following displays are shown.

Indicated color of mode now selected : Green and Red

<SELF CHECK>

23******

POWER : 00

BUS LINE : OK

BUS CONT : OK

BLOCK : UV V1 V2

V3 QV01

Indicated color of other modes : White

Green : Normal

Red : The microprocessor operates to provide judgement

of no video signal. The red color is still indicated

though the signal is input, failure may exist in input

signal line including QV01.

QV01 : In case of indication green ---Normal

In case of indication red with input signal----

GENERAL ADJUSTMENTS

Failure may exist in output line including QV01.

Part number of microprocessor (QA51)

Operation number of protecting circuit ----“00” is nor-

mal.

When indication is other than “00”, overcurrent apts to

flow, and circuit parts may possibly be damaged.

BUS LINE CHECK ----“OK” is normal.

“SDA1-GND” ------------- SDA-GND short circuit.

“SCL1-GND” -------------- SCL-GND short circuit.

“SCL1-SDA1” ------------- SCL-SDA short circuit.

BUS CONT ----“OK” is normal.

When indication shows “Q uuu NG”, the device with

the number may possibly be damaged.

BLOCK

NOTE: Component which controls character display on

screen is QA51 (TELETEXT IC.). If this display

function fails to operate due to damage in QA51,

self diagnosis procedure is as follows.

(1) In case that power indicator is blinking with

interval of 0.5 seconds; it means protecting

circuit (Current limiter) is operating, and circuit components may possibly be damaged.

Check related components.

(2) In case that power indicator is blinking with

interval of 1 second; Protecting circuit does

not operate, but a part of Bus line does not

operate normally. Check Bus line.

UV : TV reception mode

V1 : VIDEO 1 input mode (a1)

V2 : VIDEO 2 input mode (a2)

V3 : VIDEO 3 input mode (a3)

The items marked with are not usable to display in the SELF DIAGNOSTIC FUNCTION for some model.

*

– 10 –

1. ENTERING TO DESIGN MODE

1) Select the Service mode.

DESIGN MODE

2) While pressing

Remote and press MENU button on TV.

o(or CALL) button on

3) Press MENU button on TV.

S D

(Design mode) (Adjustment mode)

When QA02 is initialized, items “OPT0” and “OPT1” of DESIGN MODE are set to the data of the representative model of this

chassis family.

Therefore, because ON-SCREEN specification remains in the state of the representative of model. This model is required to

reset the data of items “OPT0” and “OPT1”.

2. SELECTING THE ADJUSTING ITEMS

Every pressing of CHANNEL t button in the design mode changes the adjustment items in the order of table-3.

(s button for reverse order)

Refer to table-3 for data of design mode.

(See SETTING & ADJUSTING DATA on page 15)

3. ADJUSTING THE DATA

Pressing of VOLUME s or t button will change the value of data.

Press

Press

ITEM

DATA

GENERAL ADJUSTMENTS

– 11 –

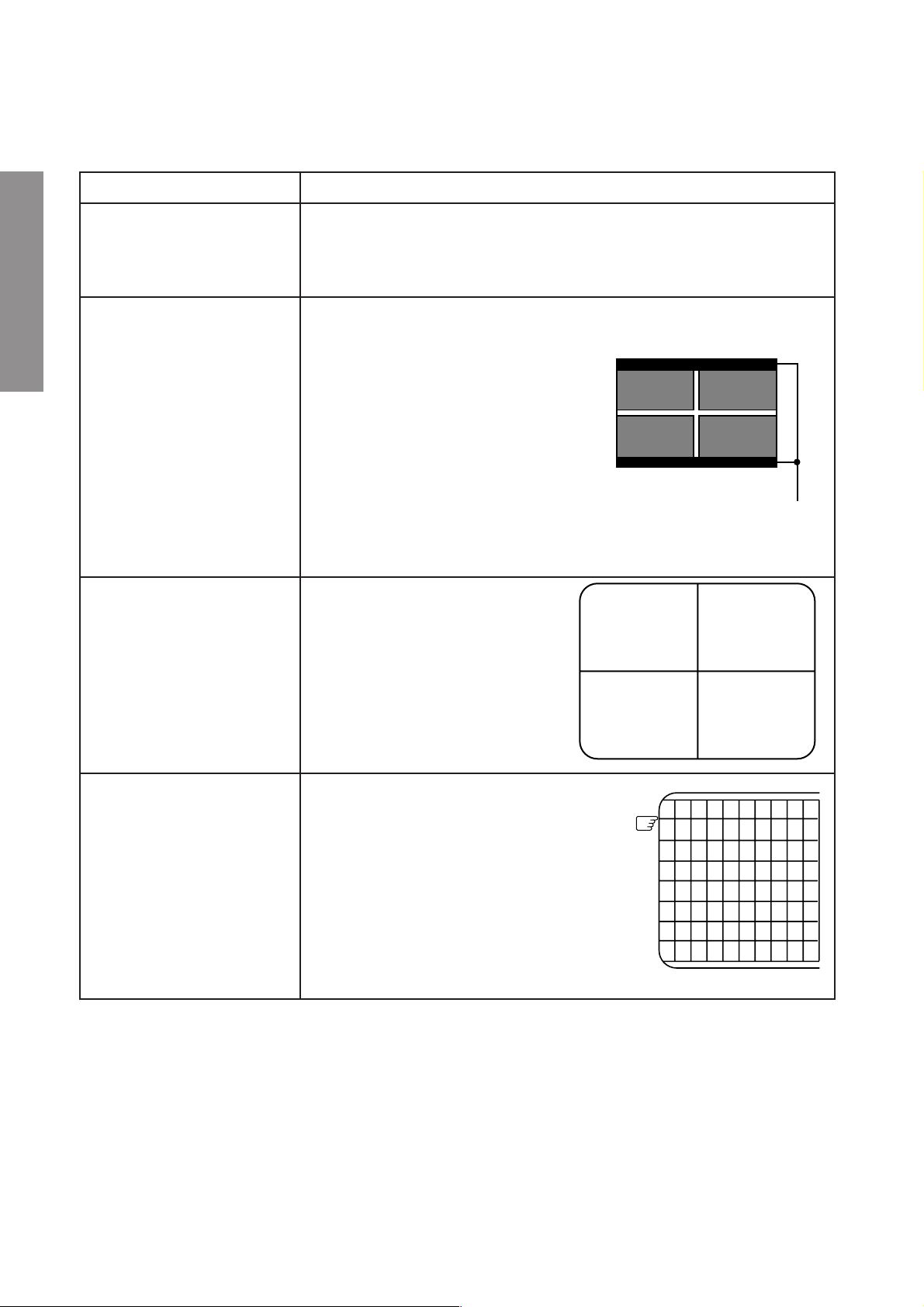

ELECTRICAL ADJUSTMENTS

ITEM ADJUSTMENT PROCEDURE

FOCUS VR ADJ

SUB-BRIGHTNESS

(BRTC)

GENERAL ADJUSTMENTS

Note: Constrict the picture height

until the vertical retrace line

appears adjusting the item

HIT (HEIGHT).

HORIZONTAL POSITION

ADJUSTMENT (HPOS)

VERTICAL POSITION

ADJUSTMENT (VPOS)

1. Enter the service mode, then select any register item.

2. Press the TV/VIDEO button on the Remote until the black cross-bar pattern appears on the screen.

3. Adjust the FOCUS control (on T461) for well defined scanning lines on the picture

screen.

1. Set CONTRAST to minimum, and

BRIGHTNESS to center by adjusting user

controls.

2. Set the TV in service mode to get white

cross-bar of inside pattern.

3. Select BRTC (brightness correction), and

adjust the ; – /+ button to reduce the

value so that white portion of inside pattern slightly light.

4. Adjust ; – /+ button to increase the data

value of BRTC, and set it just before the

difference between the belt of vertical retrace and the border of black portion of

inside pattern is visible.

After that, return vertical height and contrast.

1. Set the TV in service mode, and get

black or white cross-bar signal with

VIDEO button on remote hand unit.

2. Select either HPOS (Horizontal pic-

ture phase) or VPOS (Vertical picture

phase) with CHANNEL s, t buttons,

and adjust horizontal or vertical picture position in the center of screen

with VOLUME ; – /+ buttons.

Belt of vertical retrace

VERTICAL AMPLITUDE

ADJUSTMENT (HIT)

1. Set the TV in service mode, and get

black or white cross-hatch signal with

VIDEO button on remote hand unit.

2. Select HIT (Vertical amplitude) with

CHANNEL s, t buttons, and adjust

vertical amplitude with VOLUME

; – /+ buttons so that vertical am-

plitude lacks a little.

3. Adjust vertical amplitude with VOL-

UME ; – /+ buttons so that the first

bar on cross-hatch signal touches

edge of screen.

The first

– 12 –

ITEM ADJUSTMENT PROCEDURE

WHITE BALANCE

ADJUSTMENT

CUTOFF ADJUSTMENT

•

(RCUT)

(GCUT)

(BCUT)

DRIVE ADJUSTMENT

•

(GDRV)

(BDRV)

1. Set Contrast to 40, and brightness to +20 by picture control.

2. Set the TV in service mode, and get the inside W/B adjusting signal with VIDEO

button.

3. Select RCUT, GCUT and BCUT with CHANNEL s, t buttons, to set individual

values to Initial reference data, and to set GDRV and BDRV to Initial reference

data with VOLUME ; – /+ buttons (See page 19).

4. Press -/- - button on the remote control and rotate Screen VR to get one slight

horizontal line on screen.

Note: Every pressing of -/- - button provides Horizontal line picture and Normal

picture alternately.

5. Press -/- - button to release horizontal line picture, and select the two other colors

which did not light in the above step with CHANNEL s, t buttons. Then tap VOL-

UME ; – /+ buttons so that three colors slightly light in the same level.

X To correct white balance in light area,

select GDRV and BDRV with CHANNEL

s, t buttons to adjust.

X To correct white balance in dark area,

perform fine adjustment of RCUT, GCUT

and BCUT.

Light area check

(to show white)

Dark area check

(to show black)

GENERAL ADJUSTMENTS

NOTE: It is released built-in test pattern by changing the adjustment item for some model.

In this case, select the adjustment item with channel st button first and then select the built-in test pattern

with -/- - button.

– 13 –

CIRCUIT CHECK

HIGH VOLTAGE CHECK

CAUTION: There is no HIGH VOLTAGE ADJUSTMENT on this chassis. Checking should be done following the steps

below.

1. Connect an accurate high voltage meter to the second anode of the picture tube.

2. Turn on the receiver. Set the BRIGHTNESS and CONTRAST controls to minimum (zero beam current).

3. High voltage must be measured below (B) kV.

Refer to table-1 for high voltage (B).

(See SETTING & ADJUSTING DATA on page 15)

4. Vary the BRIGHTNESS control to both extremes to be sure the high voltage does not exceed the limit under any conditions.

GENERAL ADJUSTMENTS

– 14 –

CHAPTER 2 SPECIFIC INFORMATIONS

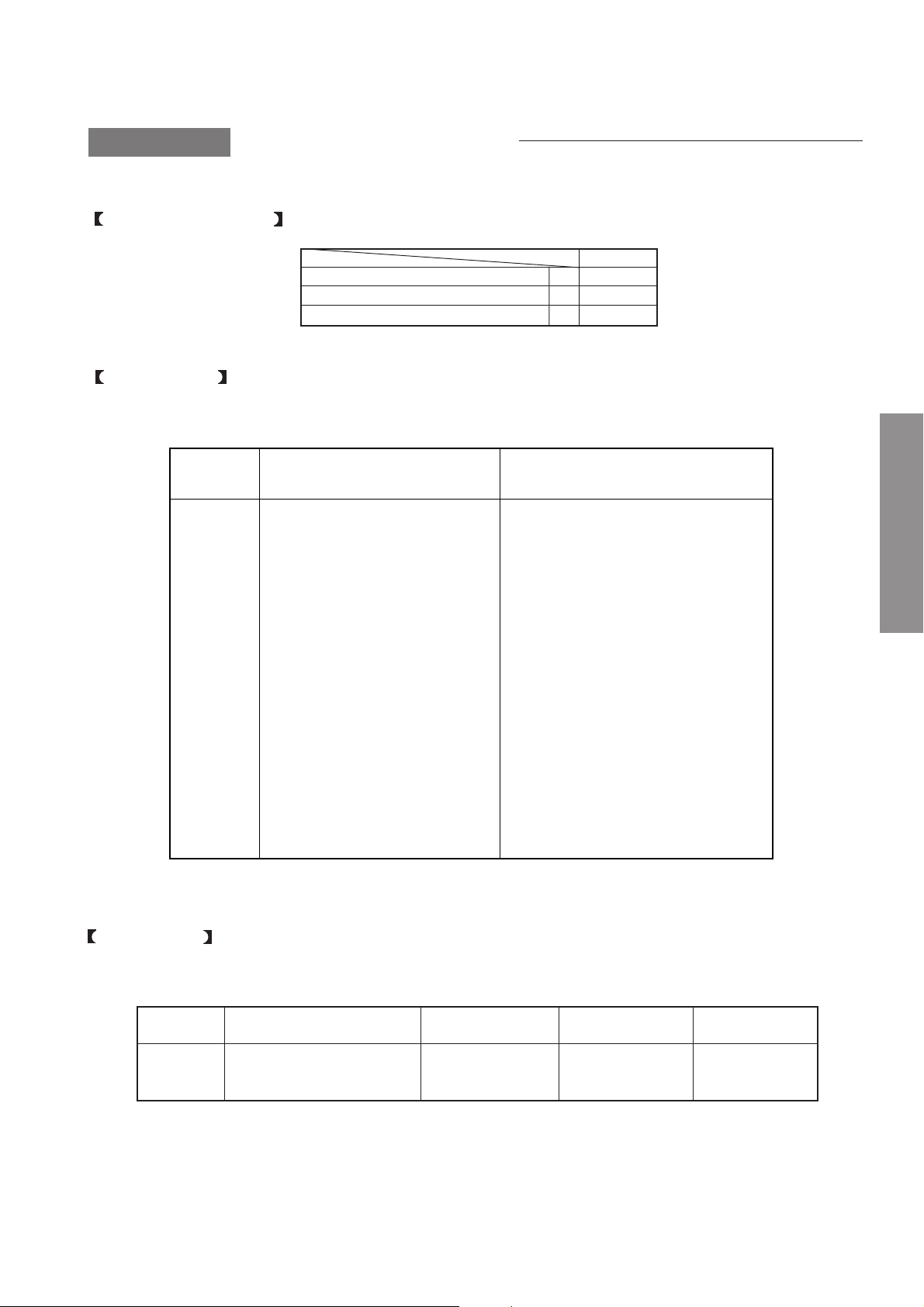

SETTING & ADJUSTING DATA

SAFETY INSTRUCTIONS

HIGH VOLTAGE AT ZERO BEAM: (A) 32.8 kV

MAX HIGH VOLTAGE:

AC VOLTAGE

Table-1

SERVICE MODE

ADJUSTING ITEMS AND DATAS IN THE SERVICE MODE:

Item Adjustment Reference data

29"

(B) 33.0 kV

(C) 110~240 V

RCUT

GCUT

BCUT

RDRV

GDRV

BDRV

BRTC

COLC

TNTC

COLP

COLS

SCNT

HPOS

VPOS

HIT

VLIN

WID

PARA

TRAP

BELL

SRY

SBY

DESIGN MODE

R CUTOFF H

G CUTOFF H

B CUTOFF H

R DRIVE H

G DRIVE H

B DRIVE H

SUB BRIGHT CEN

SUB COLOR CEN NTSC

SUB TINT CEN

SUB COLOR CEN PAL

SUB COLOR CEN SECAM

SUB CONTRAST

50Hz H-POSITION

V-POSITION

HEIGHT

V-LINEARITY

PICTURE WIDTH

E-W PARABOLA

TRAPEZIUM

SECAM BELL FILTER

SECAM R-Y

SECAM-B-Y

Table-2

04H

04H

04H

07H

07H

07H

80H

80H

40H

F6H

F6H

07H

12H

03H

20H

07H

2CH

2BH

0BH

01H

08H

08H

SPECIFIC INFORMATIONS

ADJUSTING ITEMS AND DATAS IN THE DESIGN MODE:

Item Name of adjustment Preset Data Data Remarks

OPT 1 OPTION 1 05H 22H

OPT 2 OPTION 2 10H 1DH

Table-3

– 15 –

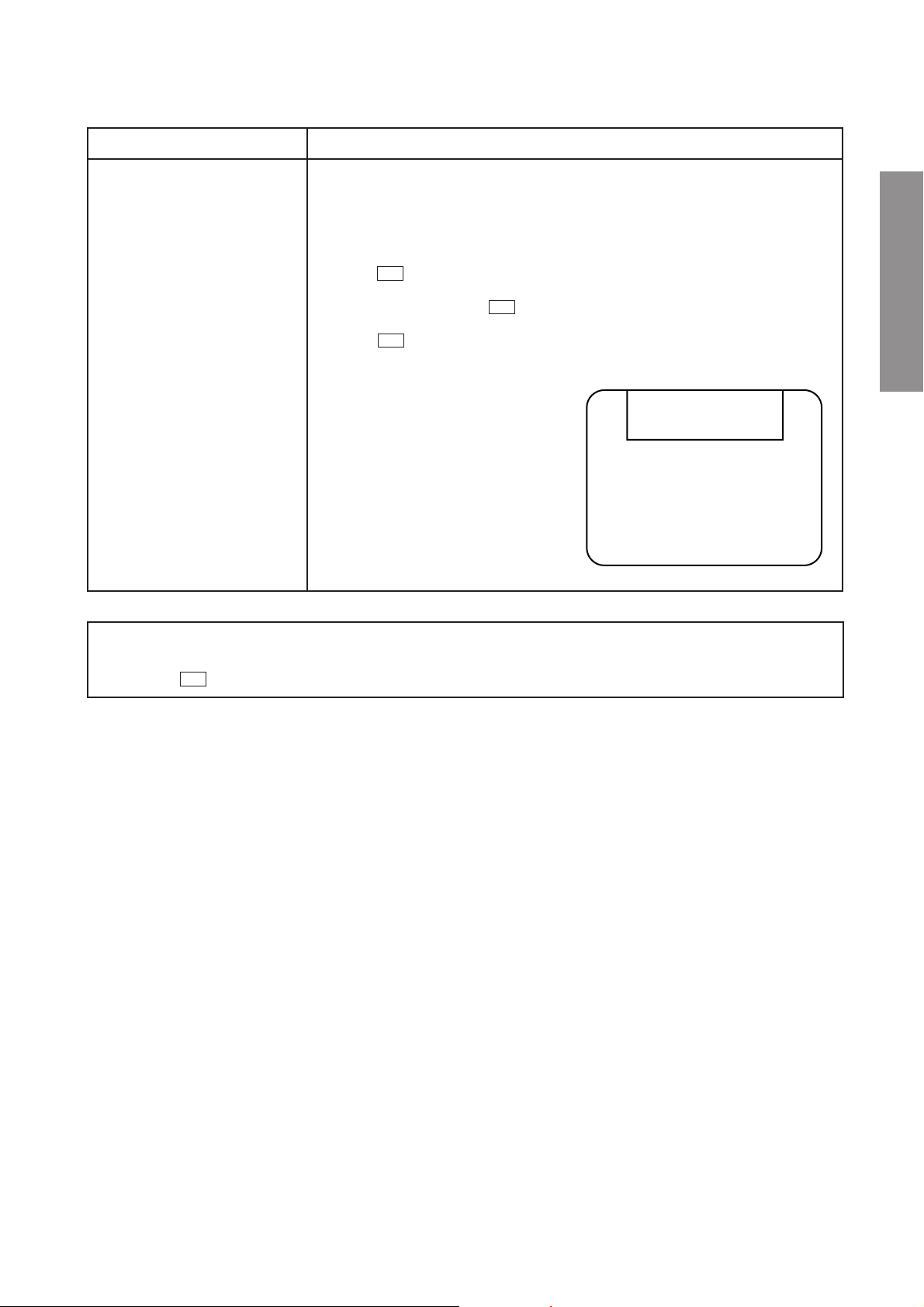

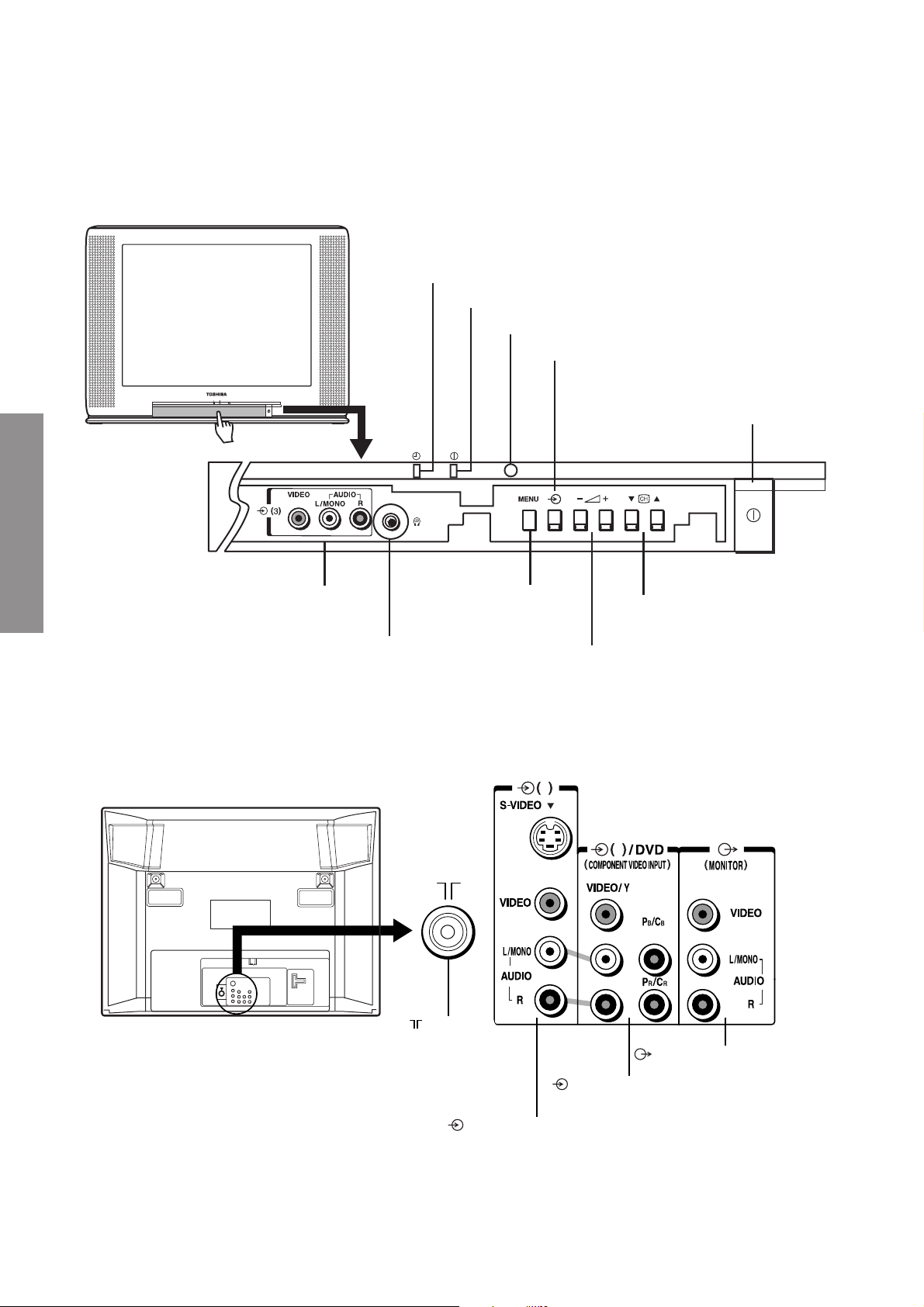

Front

Behind the door

LOCATION OF CONTROLS

Y

ON-timer indicator (green)

z Power indicator (red)

Remote sensor

a Input source selection

z Power switch

SPECIFIC INFORMATIONS

Back

a (3) Video 3 input

terminals

Headphones jack (ø3.5 mm)

For private listening, connect headphones.

The sound from the speakers will be cut off

automatically.

To adjust the volume, press the –; + buttons.

Aerial input

MENU

t c s

Channel select

Menu item select

–; +

Volume down/up

Menu item adjust

1

2

(1) Video 1 input terminals

– 16 –

MONITOR output terminals

(2) DVD/Video 2 input terminals

COMPONENT VIDEO INPUT terminals

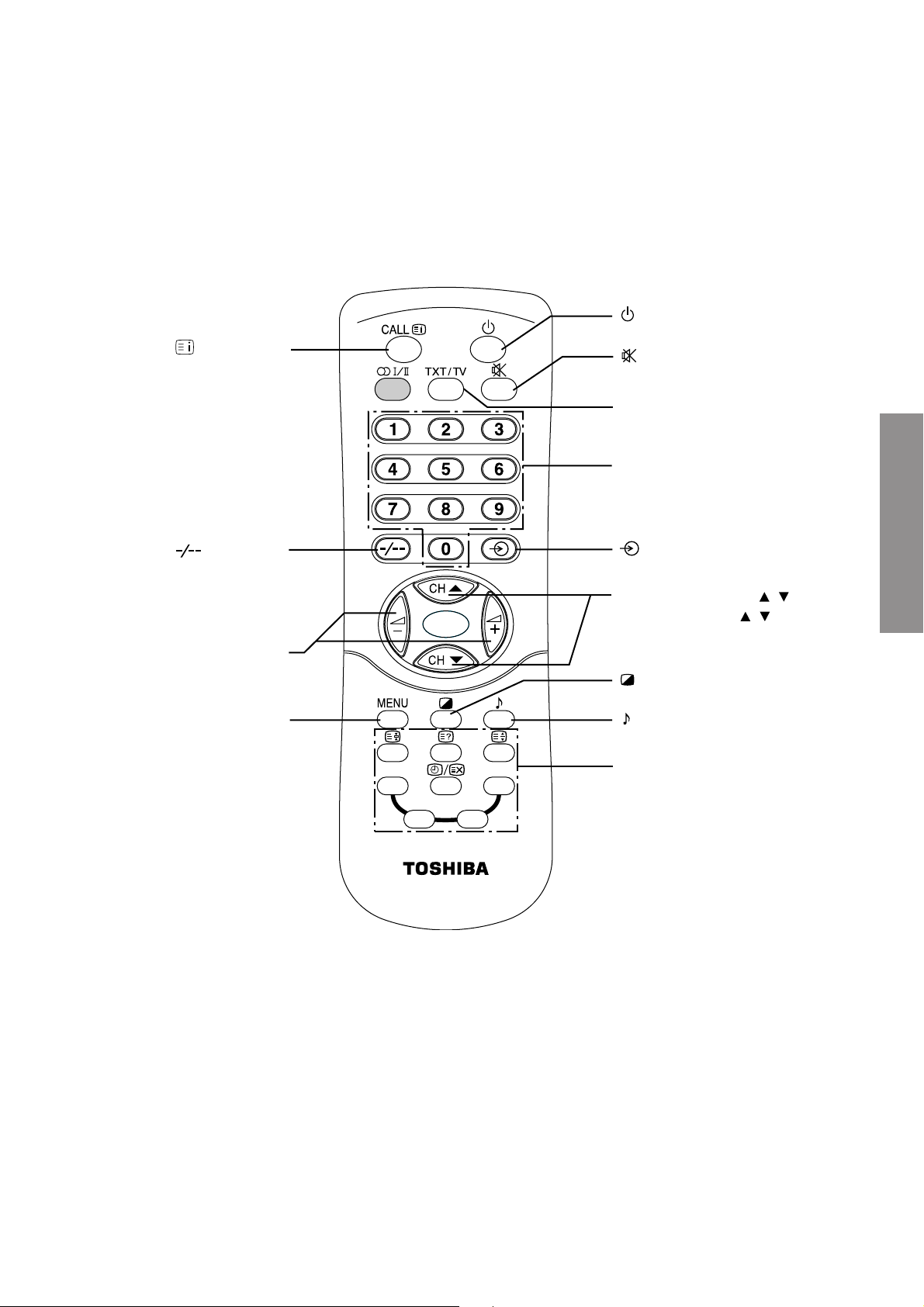

Remote control

CALL

index, initial

Digit select

Volume _/+

Menu item adjust _/+

MENU

Power on/standby

Sound mute

TXT/TV selection

Direct select (0_9)

Input source selection

CH (channel select) /

Menu item select /

Picture menu

Sound menu

SPECIFIC INFORMATIONS

Teletext function

– 17 –

Loading...

Loading...