Page 1

FILE NO. 010-200106

SERVICE MANUAL

COLOUR TELEVISION

F1DS Chassis

29AX9UM

Sep., 2001

Page 2

CHAPTER 1 GENERAL ADJUSTMENTS

SAFETY INSTRUCTIONS ........................................................................................................................................ 3

SET-UP ADJUSTMENT ............................................................................................................................................ 4

SERVICE MODE ...................................................................................................................................................... 8

DESIGN MODE ...................................................................................................................................................... 11

ELECTRICAL ADJUSTMENTS .............................................................................................................................. 12

CIRCUIT CHECK .................................................................................................................................................... 17

GENERAL ADJUSTMENTS

CHAPTER 2 SPECIFIC INFORMATIONS

SETTING & ADJUSTING DATA ..............................................................................................................................18

LOCATION OF CONTROLS ................................................................................................................................... 19

PROGRAMMING CHANNEL MEMORY................................................................................................................. 21

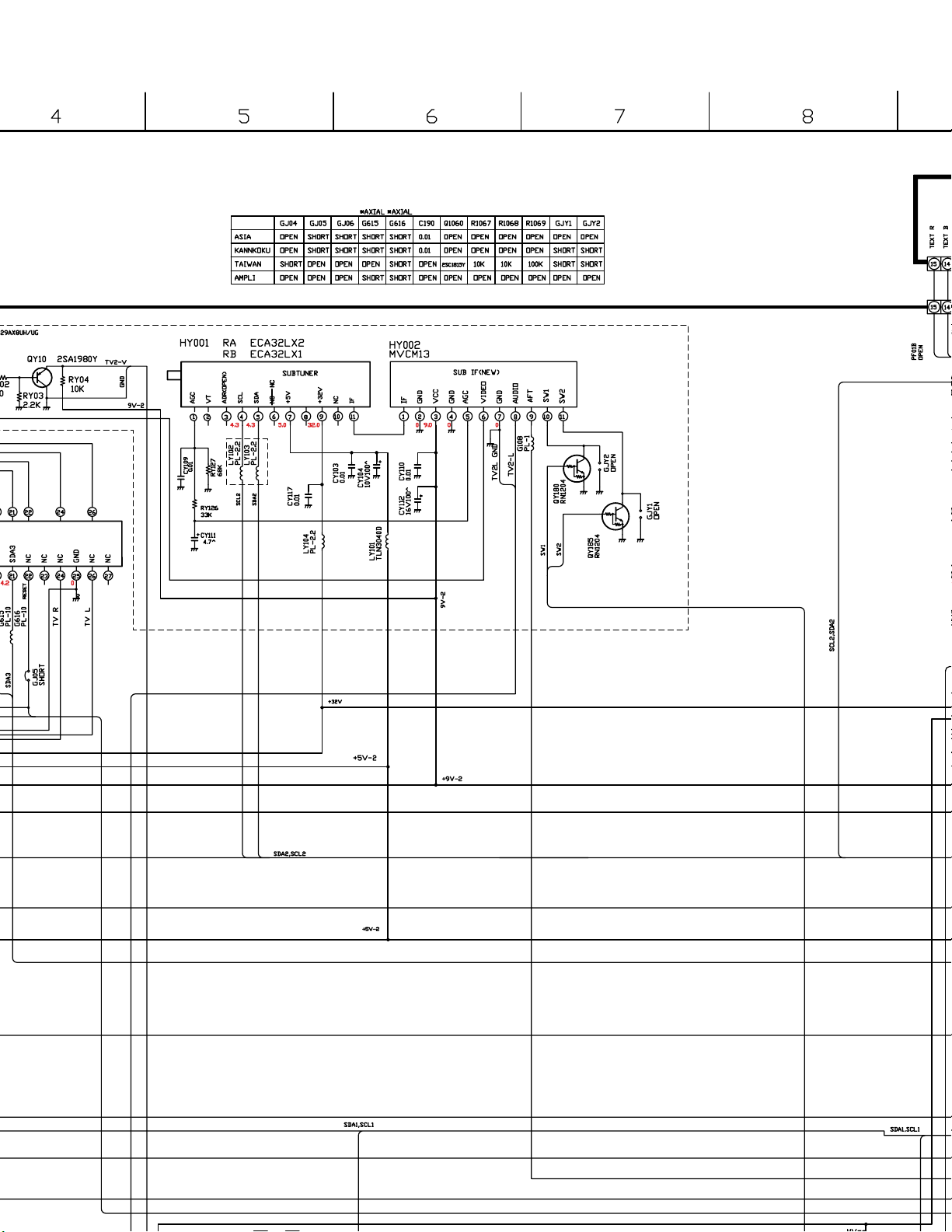

CIRCUIT BLOCK DIAGRAM .................................................................................................................................. 23

CHASSIS AND REPLACEMENT PARTS LIST ...................................................................................................... 24

PC BOARDS BOTTOM VIEW................................................................................................................................. 39

TERMINAL VIEW OF TRANSISTORS ................................................................................................................... 50

TABLE OF CONTENTS

SPECIFIC INFORMATIONS

SPECIFICATIONS .................................................................................................................................................. 51

APPENDIX:

CIRCUIT DIAGRAM

– 2 –

Page 3

CHAPTER 1 GENERAL ADJUSTMENTS

SAFETY INSTRUCTIONS

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECAUTION”, “SAFETY PRECAU-

TION” AND “PRODUCT SAFETY NOTICE” INSTRUCTIONS BELOW.

X-RAY RADIATION PRECAUTION

1. Excessive high voltage can produce potentially hazardous X-RAY RADIATION. To avoid such hazards, the high

voltage must not be above the specified limit. The nominal

value of the high voltage of this receiver is (A) kV at zero

beam current (minimum brightness) under a (C) V AC power

source. The high voltage must not, under any circumstances, exceed (B) kV.

Refer to table-1 for high voltage (A), (B) & AC voltage (C).

(See SETTING & ADJUSTING DATA on page 18)

Each time a receiver requires servicing, the high voltage

should be checked following the HIGH VOLTAGE CHECK

procedure in this manual. It is recommended that the reading of the high voltage be recorded as a part of the service

record. It is important to use an accurate and reliable high

voltage meter.

SAFETY PRECAUTION

WARNING : Service should not be attempted by anyone unfamiliar with the necessary precautions on this receiver. The following

are the necessary precautions to be observed before servicing this chassis.

1. An isolation transformer should be connected in the power line between the receiver and the AC line before any service is

performed on the receiver.

2. Always discharge the picture tube anode to the CRT conductive coating before handling the picture tube. The picture tube

is highly evacuated and if broken, glass fragments will be violently expelled. Use shatter proof goggles and keep picture tube

away from the unprotected body while handling.

3. When replacing a chassis in the cabinet, always be certain that all the protective devices are put back in place, such as; nonmetallic control knobs, insulating covers, shields, isolation resistor-capacitor network etc.

2. The only source of X-RAY RADIATION in this TV receiver

is the picture tube. For continued X-RAY RADIATION protection, the replacement tube must be exactly the same

type tube as specified in the parts list.

3. Some part in this receiver have special safety-related characteristics for X-RAY RADIATION protection. For continued safety, parts replacement should be undertaken only

after referring to the PRODUCT SAFETY NOTICE below.

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These characteristics are

often passed unnoticed by a visual inspection and the protection afforded by them cannot necessarily be obtained by using

replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special safety characteristics are identified in this manual and its supplements; electrical components having such features are identified by

the international hazard symbols on the schematic diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use of substitute replacement

parts which do not have the same safety characteristics as specified in the parts list may create shock, fire, X-ray

radiation or other hazards.

– 3 –

Page 4

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECAUTION”, “SAFETY PRECAU-

TION” AND “PRODUCT SAFETY NOTICE” ON PAGE 3 OF THIS MANUAL.

■ The following adjustments should be made when a complete realignment is required or a new picture tube is installed.

Perform the adjustments in order as follows :

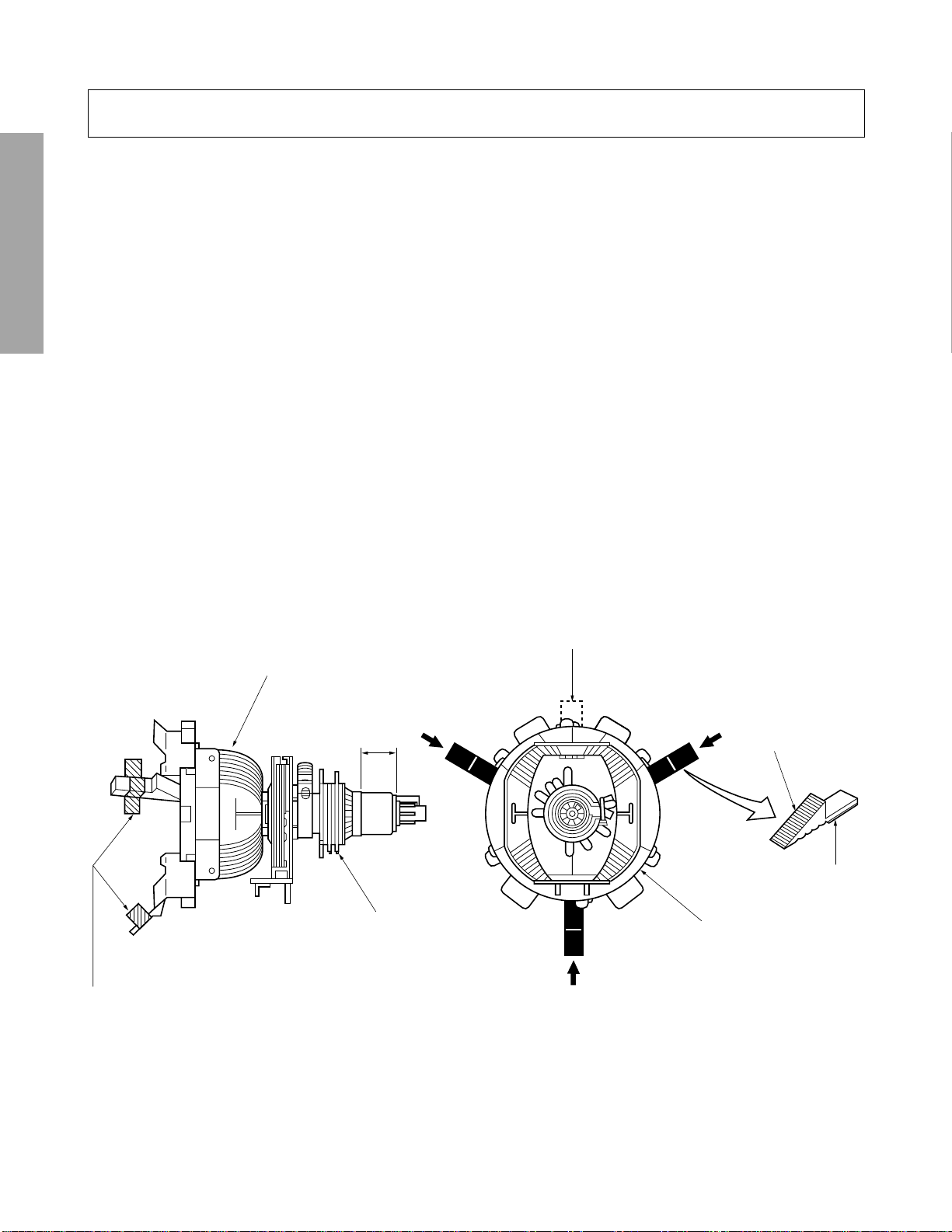

1. Color Purity

2. Convergence

3. White Balance

Note: 1.The PURITY/CONVERGENCE MAGNET assembly and rubber wedges need mechanical positioning.

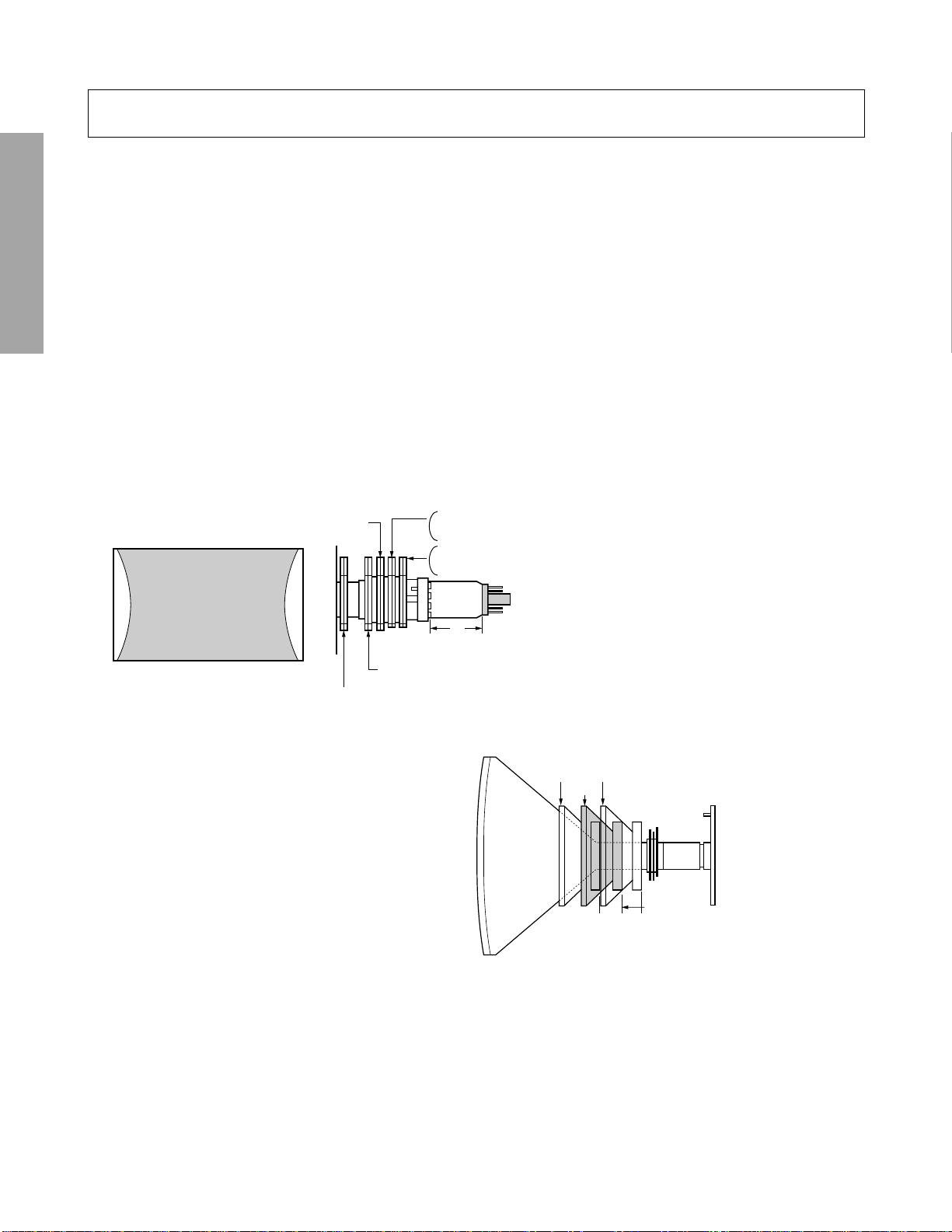

Refer to figure 1.

GENERAL ADJUSTMENTS

*

COLOR PURITY ADJUSTMENT

NOTE : Before attempting any purity adjustments, the receiver

1. Demagnetize the picture tube and cabinet using a degauss-

2. Set the brightness and contrast to maximum.

3. Use a green raster from among the built-in test signals.

4. Loosen the clamp screw holding the yoke and slide the

2.Mounting position of the purity magnet assembly should fit to same position as old one because slightly difference

to the position depend on a kind of tube.

There are no adjustment of purity and convergence in some picture tube (Unified with purity magnet)

should be operated for at least fifteen minutes.

ing coil.

yoke backward or forward to provide vertical green belt

(zone) in the picture screen.

SPECIFIC INFORMATIONS

SET-UP ADJUSTMENT

5. Remove the Rubber Wedges.

6. Rotate and spread the tabs of the purity magnet (See figure 2.) around the neck of the picture tube until the green

belt is in the center of the screen. At the same time, enter

the raster vertically.

7. Slowly move the yoke forward or backward until a uniform

green screen is obtained. Tighten the clamp screw of the

yoke temporarily.

8. Check the purity of the red and blue raster.

GLASS CLOTH

TAPES

DEFLECTION

YOKE

29.1mm(28", 29")

25mm(25")

19mm(19", 20", 21")

14mm(13", 14")

PURITY/

CONVERGENCE

MAGNET ASS'Y

Figure 1.

TEMPORARY

MOUNTING

RUBBER WEDGE

ADHESIVE

DEFLECTION

YOKE

– 4 –

Page 5

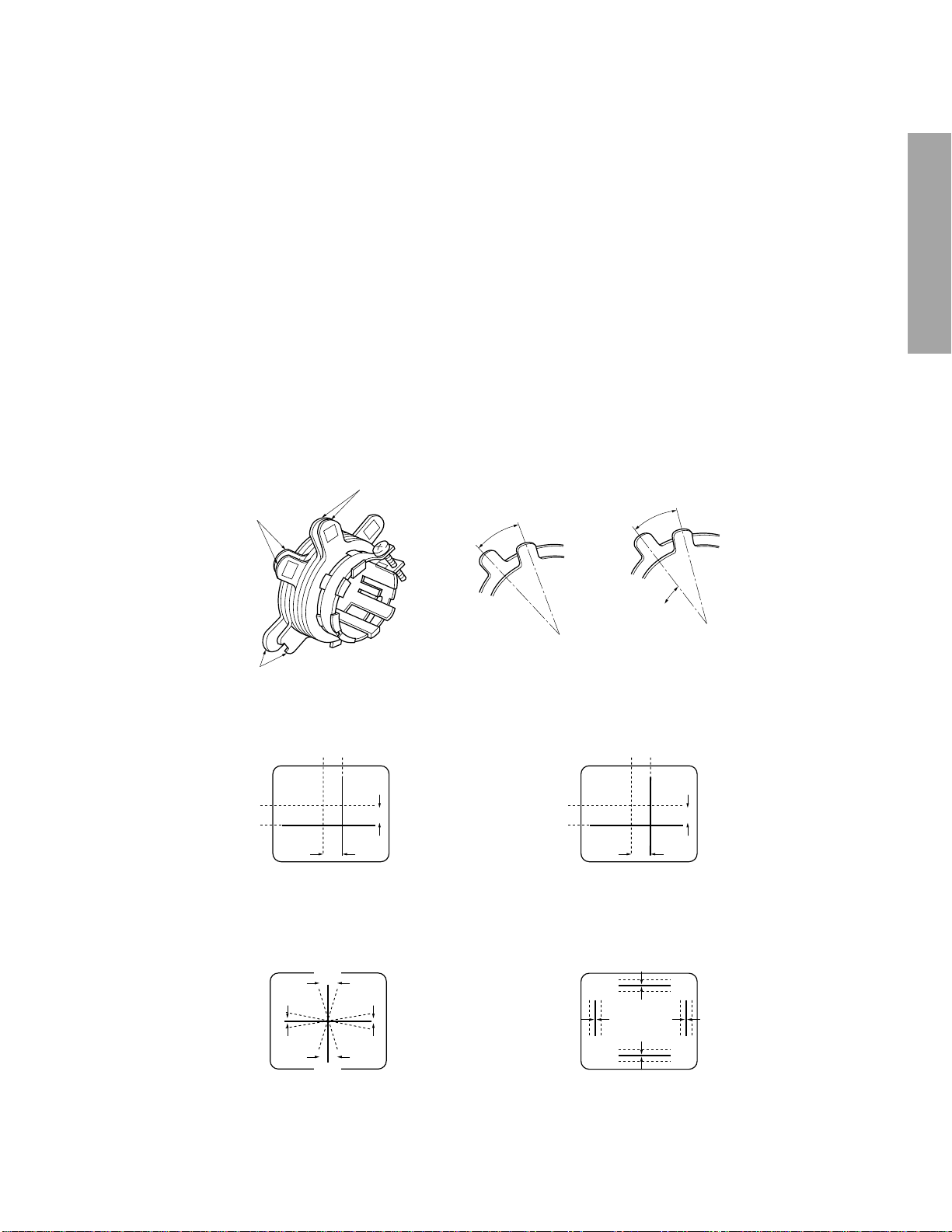

CONVERGENCE ADJUSTMENTS

NOTE: Before attempting any convergence adjustments, the

receiver should be operated for at least fifteen minutes.

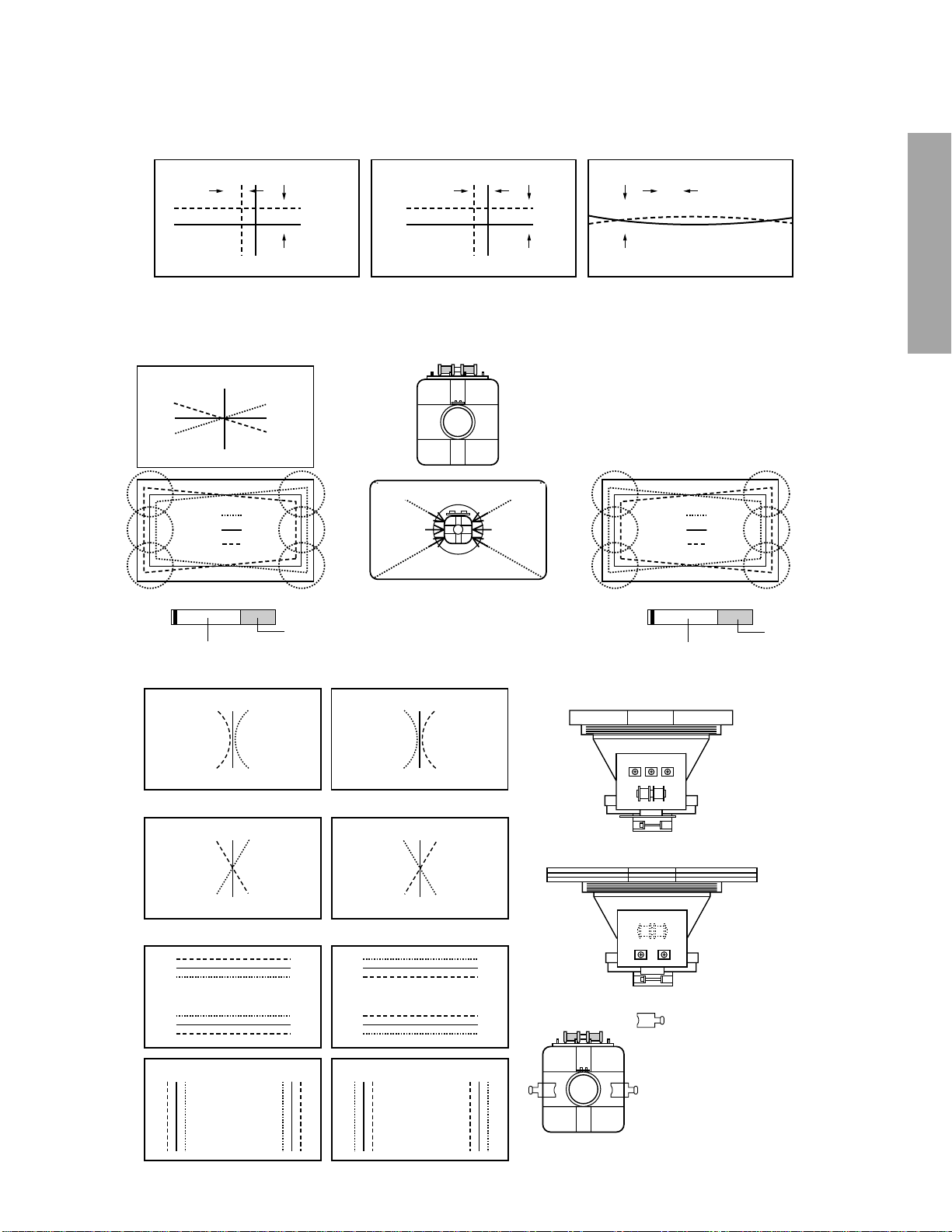

■ CENTER CONVERGENCE ADJUSTMENT

1. Use the cross-dot pattern from among the built-in test signals.

2. Set the brightness and contrast for well defined pattern.

3. Adjust two tabs of the 4-Pole Magnets to change the angle between them (See figure 2.) and superimpose red

and blue vertical lines in the center area of the picture

screen.

4. Turn the both tabs at the same time keeping the angle

constant to superimpose red and blue horizontal lines at

the center of the screen.

5. Adjust two tabs of 6-Pole Magnets to superimpose red/

blue line and green one. Adjusting the angle affects the

vertical lines and rotating both magnets affects the horizontal lines.

6. Repeat adjustments 3, 4, 5 keeping in mind red, green

and blue movement, because 4-Pole Magnets and 6-Pole

Magnets have mutual interaction and make dot movement

complex.

6-POLE

4-POLE

MAGNETS

MAGNETS

ADJUST THE ANGLE

(VERTICAL LINES)

■ CIRCUMFERENCE CONVERGENCE ADJUSTMENT

1. Loosen the clamping screw of deflection yoke slightly to

allow the yoke to tilt.

2. Temporarily put a wedge as shown in figure 1. (Do not

remove cover paper on adhesive part of the wedge.)

3. Tilt front of the deflection yoke up or down to obtain better

convergence in circumference. (See figure 3.) Push the

mounted wedge into the space between picture tube and

the yoke to fix the yoke temporarily.

4. Put other wedge into bottom space and remove the cover

paper to stick.

5. Tilt front of the yoke right or left to obtain better convergence in circumference. (See figure 3.)

6. Keep the yoke position and put another wedge in either

upper space. Remove cover paper and stick the wedge

on picture tube to fix the yoke.

7. Detach the temporarily mounted wedge and put it in another upper space. Stick it on picture tube to fix the yoke.

8. After fixing three wedges, recheck overall convergence.

Tighten the screw firmly to fix the yoke and check the yoke

is firm.

9. Stick three adhesive tapes on wedges as shown in figure

1.

FIXED

GENERAL ADJUSTMENTS

ROTATE TWO TABS

AT THE SAME TIME

(HORIZONTAL LINES)

PURITY

MAGNETS

CONVERGENCE MAGNET ASSEMBLY ADJUSTMENT OF MAGNETS

Figure 2.

BLU RED

BLU

RED

4-POLE MAGNETS MOVEMENT

BGR

R

G

B

RGB

RED/BLU

GRN

Center Convergence by Convergence Magnets

B

G

R

RED/BLU GRN

6-POLE MAGNETS MOVEMENT

B

G

R

BGR

RGB

R

G

B

SPECIFIC INFORMATIONS

INCLINE THE YOKE UP (OR DOWN)

Circumference Convergence by DEF Yoke

Figure 3. Dot Movement Pattern

INCLINE THE YOKE RIGHT (OR LEFT)

– 5 –

Page 6

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECAUTION”, “SAFETY PRECAU-

TION” AND “PRODUCT SAFETY NOTICE” ON PAGE 3 OF SERVICE MANUAL.

■ The following adjustments should be made when a complete realignment is required or a new picture tube is installed.

Perform the adjustments in order as follows :

1. Color Purity

2. Convergence

3. White Balance

Note: The PURITY/CONVERGENCE MAGNET assembly and rubber wedges need mechanical positioning.

Refer to figure 1.

COLOR PURITY ADUSTMENT

GENERAL ADJUSTMENTS

(1)Let the screen face in the installing direction or toward the east (when it is to be moved), bring up the service mode

screen after demagnetizing (front, left, right, and top) with the degaussing coil, receive white signals by pressing the

[TV/VIDEO] button, and then the receiver should be operated for more than 40 minutes.

(2)Perform rough adjustment of the central convergence with the P/C magnet according to the adjustment item.

(3)Receive built-in green signals, loosen set screws on the deflection yoke, remove rubber wedges, and shift the deflection

yoke to toward front.

(4)Move alternately the two 2-pole magnets of the P/C magnets so that the green raster can come to the center of the

screen.

SET-UP ADJUSTMENT (FOR FLAT TUBE)

Figure 1.

(27": Magnet is fixed with deflection yoke.)

SPECIFIC INFORMATIONS

Green Belt

(5)Receive built-in red and blue signals, check that there is no inclination of the single color raster toward one side, and if

each color tilts to a great extent, make adjustment with the 2-pole magnet so that the 3 colors will come to the center

evenly.

(6)Receive the green raster, shift the deflection yoke from a

foremost position (hitting against the picture tube) to a

backward position horizontally, stop the deflection yoke

at a position where it begins to become a green raster,

and perform accurate marking on the picture tube.

(7)Shift the deflection yoke further backward, and perform

accurate marking at a position where the green raster

begins to being luck.

(8)Fix the deflection yoke at a position 60% forward within

the range marked in items (6) and (7) above.

CONVERGENCE ADJUSTMENTS

* Adjust the convergence magnet to get vest convergence in the the order to (1) ~ (5).

■ CENTER CONVERGENCE:

(1)Receive the white crosshatch or dot pattern from the service signal generator.

(2)Use the 2 pieces of main 4-pole magnets of P/C magnets, change the open angle, and align the red and blue vertical

lines on the screen center.

(3)Freeze the open angle of the main 4-pole magnets, turn them simultaneously, and align the horizontal lines.

(4)Take the same steps for items (2) and (3) above and align red/blue with green on the screen center using two 6-pole

magnets.

2-pole purity magnet

Main 4-pole convergence magnet (30" : 32")

6-pole convergence magnet (34")

6-pole convergence magnet (30" : 32")

Main 4-pole convergence magnet (34")

P/C magnet installing position A

• 30"=26.5 mm

A

Sub-4-pole convergence magnet (32" : 34")

Sub-4-pole convergence magnet (to be installed on deflection yoke for 30", 32”)

Picture tube

• 32"=30.5 mm or 32.5 mm

• 34"=37 mm

• 34"=39 mm

Shift deflection yoke

(7) Perform marking of each point

(6)

(8)

on the tape of picture tube

CRT-D board

P/C Mag

100 60 0%

Fix the deflection yoke at a position 60% forward from a

point between (6) and (7)

– 6 –

Page 7

(5)Adjust the sub-4-pole magnets only in case there is any deviation of Xv bow-shaped convergence. (To be usually set at

the initial position)

Align both sides with the sub-4-pole magnets and minimize the deviation of blue and red with the main 4-pole magnets.

blue

blue

red

red

Main 4-pole magnet

red/blue

red/blue

green

6-pole magnet

■ CIRCUMFERENCE CONVERGENCE:

Perform correction in the following manner.

*

blue

green

red

A

B

C

(Parts code:23 948 274) TC-S

blue

green

red

S

N

Blue color or blue mark

D

E

F

*Insert the correction piece between the

picture tube and the deflection yoke.

Bonded surface

(Insertion position of correction

piece)

D

E

F

A

B

C

Adjust VR 1 and minimize the deviation of YH. *Only 27", 30" and 32".

Red

green

blue

blue

green

Red

Xv bow-shaped deviation of convergence

blue

green

red

Sub-4-pole magnet

• Adjust coils and minimize deviation

(The 27” unit has coils underneath it)

A

B

C

■ 30", 27", 32"

blue

green

red

(Parts code:23 948 464)

N

S

Transparent

D

E

F

Bonded surface

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

Red

green

blue

blue

green

Red

Adjust VR 2 (YHC) and minimize the deviation of YH.

Red

blue

green

green

blue

Red

blue

Red

green

green

Red

blue

Adjust VR 3 (YV) and minimize the deviation of YV.

Red

green

blue

blue

green

Red

GH

Red

blue

green

green

blue

red

green

blue

red

green

green

Red

– 7 –

blue

Red

Red

blue

blue

green

VR3

VR2 VR1

■ 34"

YV YHC

27" (Part No. 23 947 371)

32", 30" (Part No. 23 947 121)

34" (Part No. 23 993 080)

GH

Perform correction by inserting the

correction piece into the clearance of terminal board coils of

the deflection yoke.

Note:

Perform insertion by turning the

metal side to the terminal board

side of the deflection yoke.

Page 8

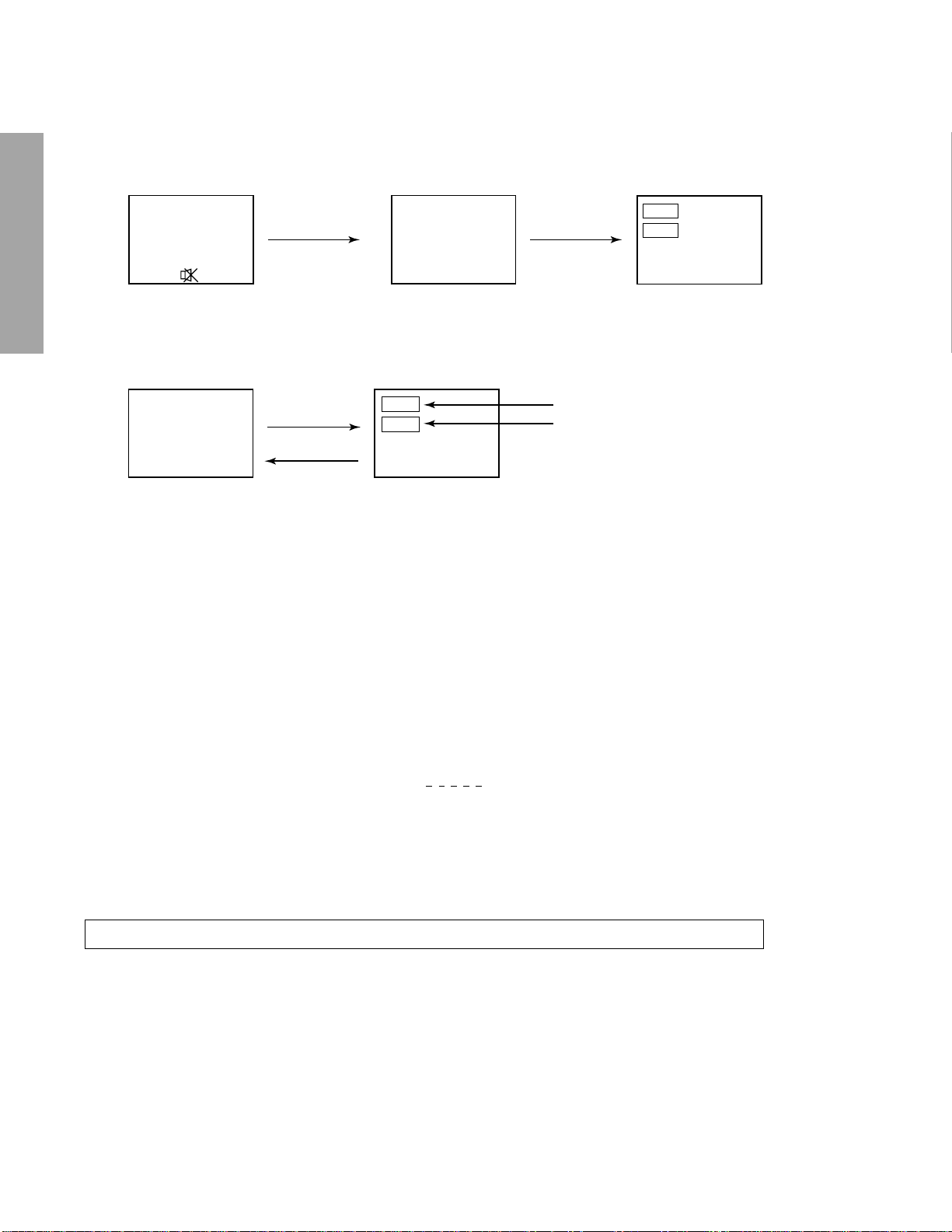

1. ENTERING TO SERVICE MODE

1) Press o button once on

Remote Control.

SERVICE MODE

2) Press o button again to

keep pressing.

3) While pressing the o button,

press MENU button on TV set.

(or SOUND MUTE)

GENERAL ADJUSTMENTS

2. DISPLAYING THE ADJUSTMENT MENU

1) Press MENU button on TV.

Service mode

3. KEY FUNCTION IN THE SERVICE MODE

The following key entry during display of adjustment menu provides special functions.

SPECIFIC INFORMATIONS

A single horizontal line ON/OFF: - / - - button (on Remote) or a button (on TV)

Test signal selection : a button (on Remote)

Selection of the adjustment items : Channel s/t (on TV or Remote)

Change of the data value : Volume ; +/– (on TV or Remote)

Adjustment menu mode ON/OFF : MENU button (on TV)

Initialization of the memory (QA02) : CALL + Channel button on TV (s)

Reset the count of operating protect

circuit to “00”: CALL + Channel button on TV (t)

“RCUT” selection : 1 button

“GCUT” selection : 2 button

“BCUT” selection : 3 button

“CNTX” (or “SCNT”) selection : 4 button

“COLC” selection : 5 button

“TNTC” selection : 6 button

Test audio signal ON/OFF (1kHz) : 8 button

Self diagnostic display ON/OFF : 9 button

Item

Data

(Service mode display)

Adjustment mode

S

Press

Press

Item

Data

S

Color thickness correction

note: Displayed differently as shown below, de-

pending on the setting of the receiving color

system.

COLP (PAL)

COLC (NTSC)

COLS (SECAM)

CAUTION : Never try to perform initialization unless you have changed the memory IC.

– 8 –

Page 9

4. SELECTING THE ADJUSTING ITEMS

1) Every pressing of CHANNEL s button in the service mode changes the adjustment items in the order of table-2.

(t button for reverse order)

Refer to table-2 for preset data of adjustment mode.

(See SETTING & ADJUSTING DATA on page 18)

5. ADJUSTING THE DATA

1) Pressing of VOLUME ; +/– button will change the value of data in the range from 00H to FFH. The variable range

depends on the adjusting item.

6. EXIT FROM SERVICE MODE

1) Pressing POWER button to turn off the TV once.

■ INITIALIZATION OF MEMORY DATA OF QA02

After replacing QA02, the following initialization is required.

1. Enter the service mode, then select any register item.

2. Press and hold the CALL button on the Remote, then press the CHANNEL s button on the TV. The initialization of QA02 has

been complated.

3. Check the picture carefully. If necessary, adjust any adjustment item above.

Perform “Auto search Memory” on the owner’s manual.

CAUTION: Never attempt to initialize the data unless QA02 has been replaced.

7. TEST SIGNAL SELECTION

1) Every pressing of a button on the Remote Control changes the built-in test patterns on screen as described below

in SERVICE MODE.

GENERAL ADJUSTMENTS

Signal off

PAL signals (5 patterns)

The signals marked with are not usable to display in the Test signal for some model.

*

NTSC signals (5 patterns)

• Red raster

• Green raster

• Blue raster

• All White

• Black cross-hatch

Signals Picture

SPECIFIC INFORMATIONS

– 9 –

Page 10

8. SELF DIAGNOSTIC FUNCTION

1) Press “9” button on Remote Control during display of adjustment menu in the service mode.

The diagnosis will begin to check if interface among IC’s are executed properly.

2) During diagnosis, the following displays are shown.

<SELF CHECK>

23******

POWER

BUS LINE

BUS CONT

BLOCK

GENERAL ADJUSTMENTS

: 00

: OK

: OK

: UV V1 V2

QV01

Indicated color of mode now selected : Green and Red

Indicated color of other modes : White

Green : Normal

Red : The microcomputer operates to provide judgement

of no video signal. The red color is still indicated

though the signal is input, failure may exist in input

signal line including QV01.

QV01 : In case of indication green ---Normal

In case of indication red with input signal---Failure may exist in output line including QV01.

Part number of microcomputer (QA01)

Operation number of protecting circuit ----“00” is nor-

mal.

When indication is other than “00”, overcurrent apts to

flow, and circuit parts may possibly be damaged.

BUS LINE CHECK ----“OK” is normal.

“SDA1-GND” ------------- SDA-GND short circuit.

“SCL1-GND” -------------- SCL-GND short circuit.

“SCL1-SDA1” ------------- SCL-SDA short circuit.

BUS CONT ----“OK” is normal.

When indication shows “Q uuu NG”, the device with

SPECIFIC INFORMATIONS

the number may possibly be damaged.

BLOCK

UV : TV reception mode

V1 : VIDEO 1 input mode (a1)

V2 : VIDEO 2 input mode (a2)

The items marked with are not usable to display in the SELF DIAGNOSTIC FUNCTION for some model.

*

NOTE: Component which controls character display on

screen is QT01 (TELETEXT IC.). If this display

function fails to operate due to damage in QT01,

self diagnosis procedure is as follows.

(1) In case that power indicator is blinking with

interval of 0.5 seconds; it means protecting

circuit (Current limiter) is operating, and circuit components may possibly be damaged.

Check related components.

(2) In case that power indicator is blinking with

interval of 1 second; Protecting circuit does

not operate, but a part of Bus line does not

operate normally. Check Bus line.

– 10 –

Page 11

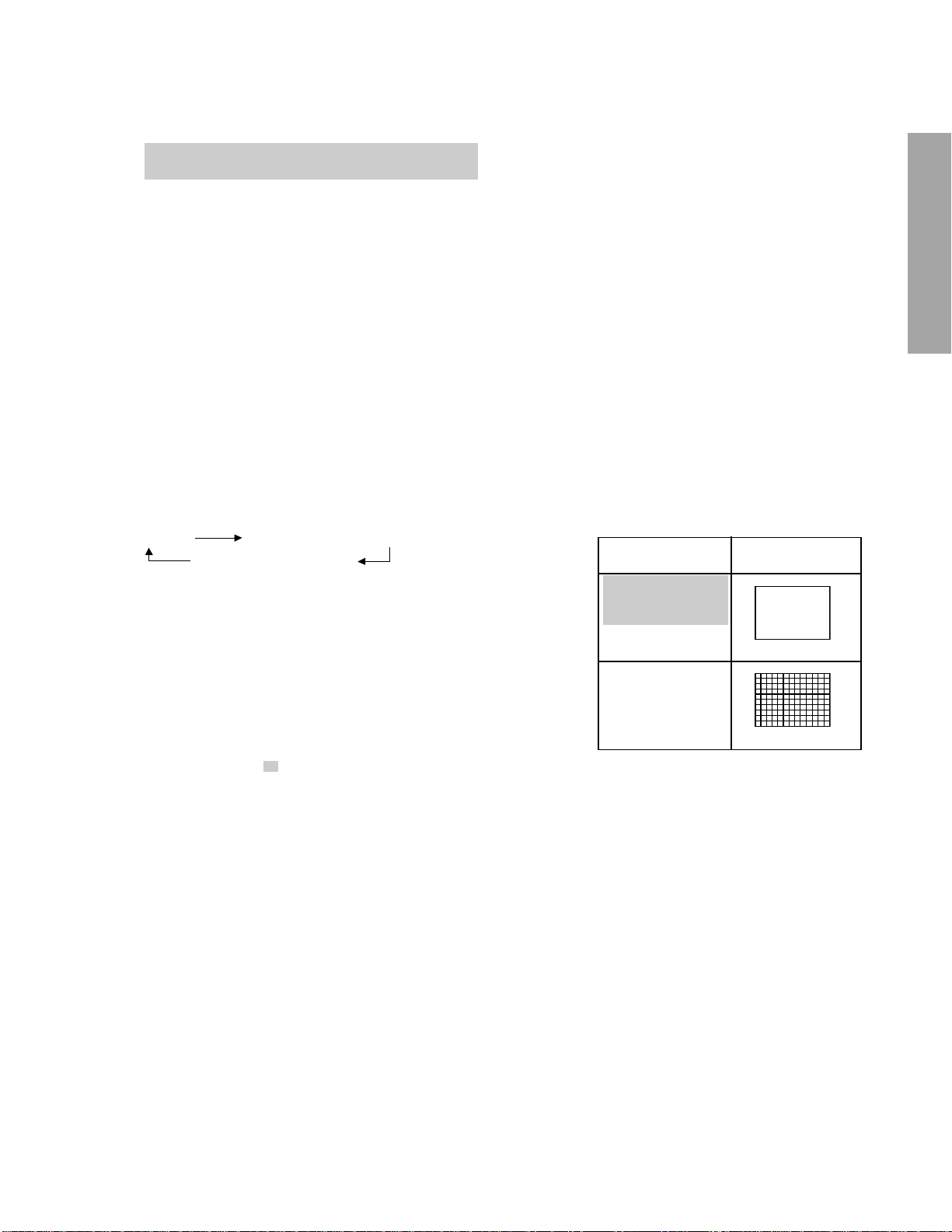

1. ENTERING TO DESIGN MODE

1) Select the Service mode.

DESIGN MODE

2) While pressing o(or CALL) button on

Remote and press MENU button on TV.

3) Press MENU button on TV.

S D

(Design mode) (Adjustment mode)

When QA02 is initialized, items “OPT0”, “OPT1”, “OPT2” and “OPT3” of DESIGN MODE are set to the data of the representative

model of this chassis family.

Therefore, because ON-SCREEN specification remains in the state of the representative of model. This model is required to

reset the data of items “OPT0”, “OPT1”, “OPT2” and “OPT3”.

2. SELECTING THE ADJUSTING ITEMS

Every pressing of CHANNEL t button in the design mode changes the adjustment items in the order of table-3.

(s button for reverse order)

Refer to table-3 for data of design mode.

(See SETTING & ADJUSTING DATA on page 18)

3. ADJUSTING THE DATA

Pressing of VOLUME s or t button will change the value of data.

Press

Press

ITEM

DATA

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

– 11 –

Page 12

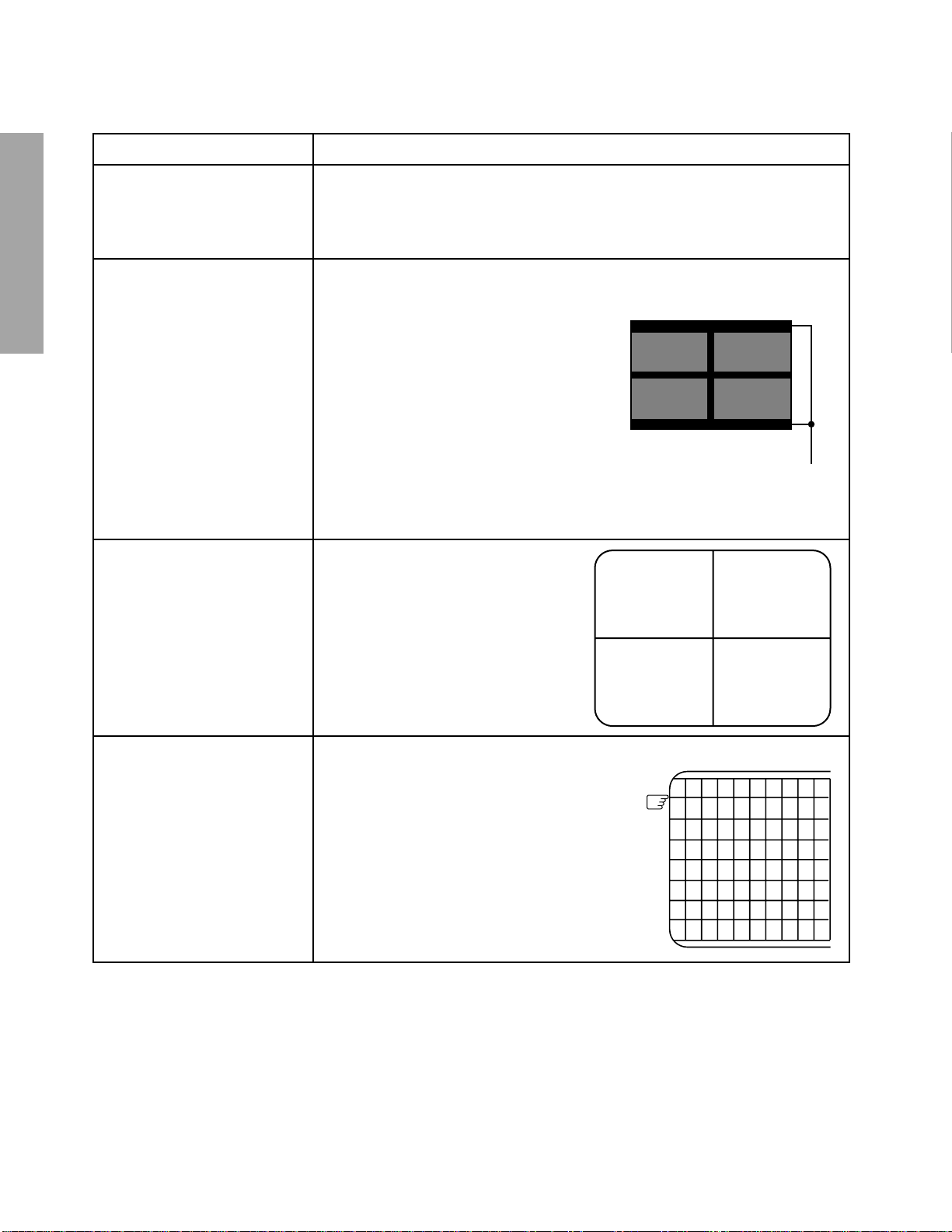

ELECTRICAL ADJUSTMENTS

ITEM ADJUSTMENT PROCEDURE

FOCUS VR ADJ

SUB-BRIGHTNESS

(BRTC)

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

Note: Constrict the picture height

until the vertical retrace line

appears adjusting the item

HIT (HEIGHT).

HORIZONTAL POSITION

ADJUSTMENT (HPOS)

VERTICAL POSITION

ADJUSTMENT (VPOS)

1. Enter the service mode, then select any register item.

2. Press the TV/VIDEO button on the Remote until the black cross-bar pattern appears on the screen.

3. Adjust the FOCUS control (on T461) for well defined scanning lines on the picture

screen.

1. Set CONTRAST to minimum, and

BRIGHTNESS to center by adjusting user

controls.

2. Set the TV in service mode to get Black

cross-bar of inside pattern.

3. Select BRTC (brightness correction), and

adjust the ; – /+ button to reduce the

value so that white portion of inside pattern slightly light.

4. Adjust ; – /+ button to increase the data

value of BRTC, and set it just before the

difference between the belt of vertical retrace and the border of black portion of

inside pattern is visible.

After that, return vertical height and contrast.

1. Set the TV in service mode, and get

black cross-bar signal with VIDEO

button on remote hand unit.

2. Select either HPOS (Horizontal picture phase) or VPOS (Vertical picture

phase) with CHANNEL s, t buttons,

and adjust horizontal or vertical picture position in the center of screen

with VOLUME ; – /+ buttons.

Belt of vertical retrace

VERTICAL AMPLITUDE

ADJUSTMENT (HIT)

1. Set the TV in service mode, and get

black cross-hatch signal with VIDEO

button on remote hand unit.

2. Select HIT (Vertical amplitude) with

CHANNEL s, t buttons, and adjust

vertical amplitude with VOLUME

; – /+ buttons so that vertical amplitude lacks a little.

3. Adjust vertical amplitude with VOLUME ; – /+ buttons so that the first

bar on cross-hatch signal touches

edge of screen.

– 12 –

The first

Page 13

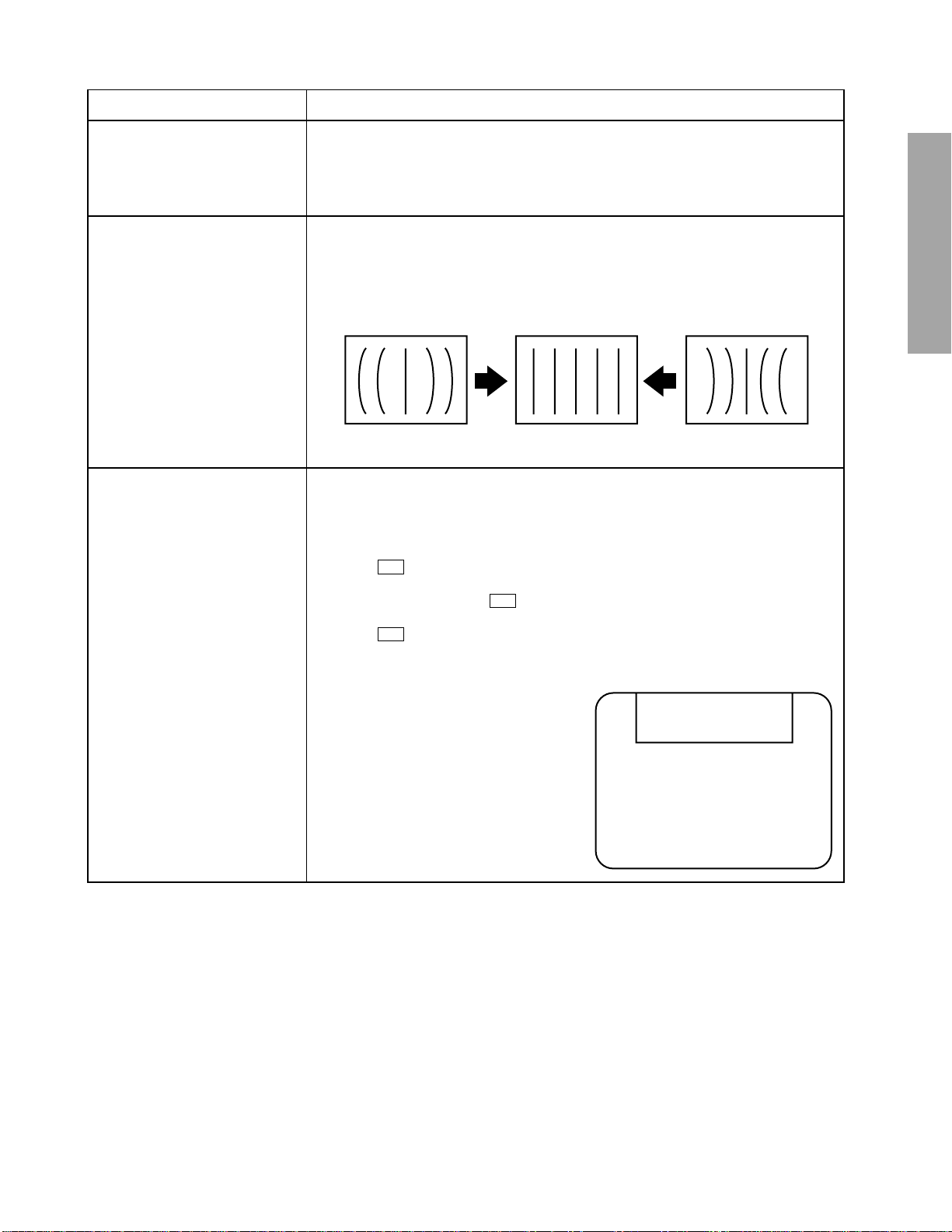

ITEM ADJUSTMENT PROCEDURE

WIDTH

(WID)

E-W PARABOLA

(PARA)

WHITE BALANCE

ADJUSTMENT

CUTOFF ADJUSTMENT

•

(RCUT)

(GCUT)

(BCUT)

DRIVE ADJUSTMENT

•

(GDRV)

(BDRV)

1. Call up the adjustment mode display, then select the item WID.

2. Press the ; – /+ button to get the picture so the left and rightedges of raster

begins to lack.

3. Press the ; – /+ button to advance the data by 7 steps.

Note : Check the horizontal picture position is correct.

1. Call up the adjustment mode display, then select the item PARA.

2. Press the a button on Remote until the cross-hatch pattern appears on the screen.

3. Press the ; – /+ button to make vertical lines straight as shown below.

1. Set Contrast to 40, and brightness to +20 by picture control.

2. Receive the Black and White pattern.

3. Select RCUT, GCUT and BCUT with CHANNEL s, t buttons, to set individual

values to Initial reference data, and to set GDRV and BDRV to Initial reference

data with VOLUME ; – /+ buttons (See page 18).

4. Press -/- - button on the remote control and rotate Screen VR to get one slight

horizontal line on screen.

Note: Every pressing of -/- - button provides Horizontal line picture and Normal

picture alternately.

5. Press -/- - button to release horizontal line picture, and select the two other colors

which did not light in the above step with CHANNEL s, t buttons. Then tap VOLUME ; – /+ buttons so that three colors slightly light in the same level.

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

X To correct white balance in light area,

select GDRV and BDRV with CHANNEL

s, t buttons to adjust.

X To correct white balance in dark area,

perform fine adjustment of RCUT, GCUT

and BCUT.

Light area check

(to show white)

Dark area check

(to show black)

– 13 –

Page 14

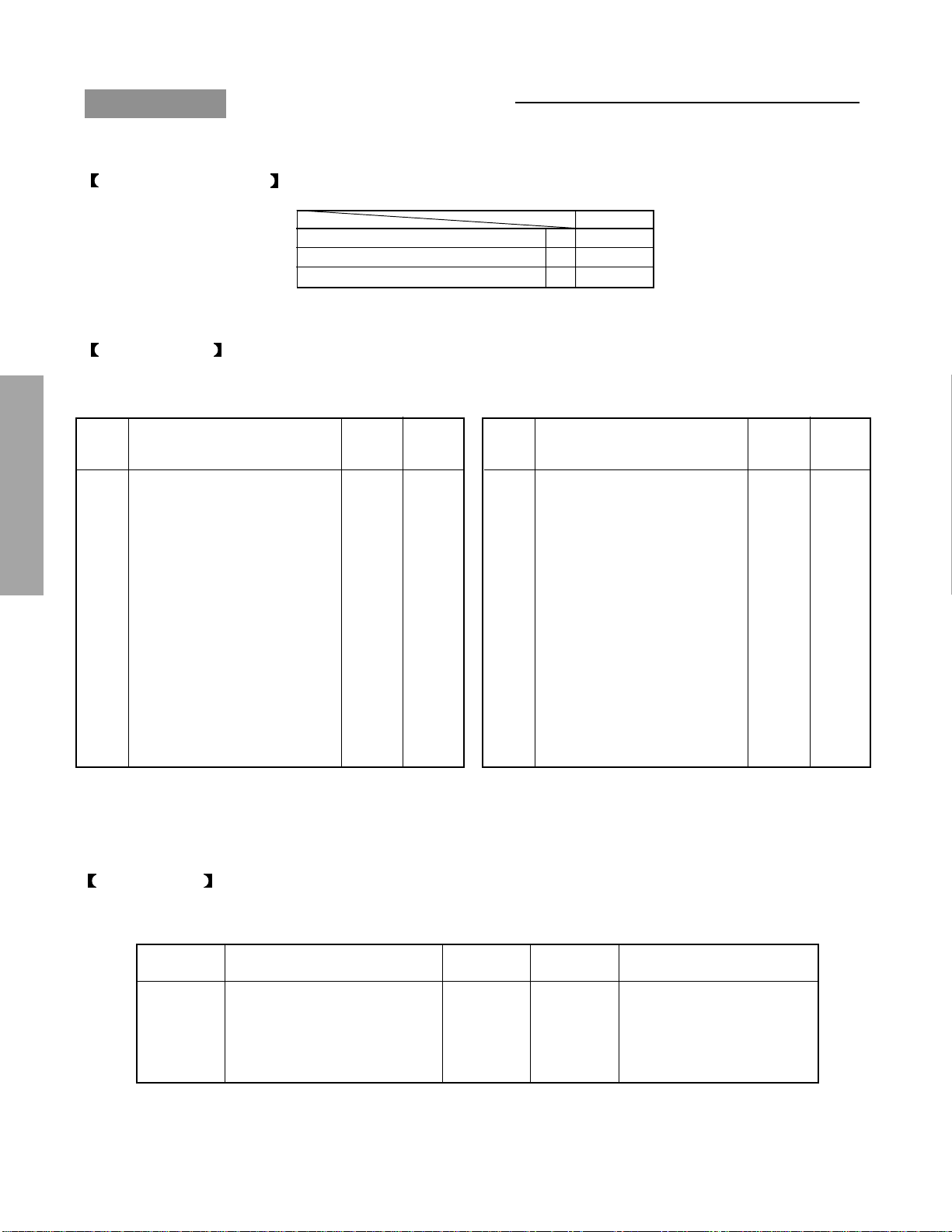

F1DS Series (Reference factory adjustment)

Items

SCNT

BRTC

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

COLC

COLS

R CUT

G CUT

B CUT

Screen

VR

R CUT

G CUT

B CUT

GDRV

BDRV

Settings

Sub-contract

Sub-bright

center

Sub color

NTSC

Sub-color

SECAM

R cutoff

G cutoff

B cutoff

White balance

R cutoff

G cutoff

B cutoff

G drive

B drive

Input signals

Contrast: MAX

Bright: CNT

Color: CNT

Taint: CNT

Contrast: MAX

Bright: CNT

Color: MIN

Contrast: MAX

Bright: CNT

Color: CNT

Taint: CNT

Y mute: ON

Contrast: MAX

Bright: CNT

Color: CNT

Taint: CNT

Y mute: ON

Set to

R CUT: 40H

G CUT: 40H

B CUT: 40H

Enter horizontal straight-line

mode

Contrast: MAX

Bright: CNT

Color: MIN

Set to

GDRV: 40H

BDRV: 40H

Measuring

methods

Sub-bright

signal

(J2CH)

Sub-bright

signal

(J2CH)

Sub-bright

signal

(J 2CH)

SECAM

Color bar

(E 2ch)

Raster signal without

color burst

Adjusting

methods

TP46R

Screen

adjustment

TP46B

TP46B

Screen

adjustment

C·P·T

Measuring

instruments

Synchro

Screen

adjustment

Synchro

Synchro

Screen

judgment

W/B

checker

Adjusting methods

1 If SCNT is selected, Y signal

is transmitted from the

monitor output.

2 Adjust the amplitude from

pedestal level to white level.

1 Adjust the number of col-

lapsed black lines of the subbright signal.

2 Adjust after adjusting W/B,

SCNT.

1 If COLC is selected, B-Y

signals are transmitted from

the monitor output.

2 Adjust the amplitude of the

color bar output.

3 Adjust after adjusting SCNT,

TNTC.

1 If COLS is selected, B-Y

signals are transmitted from

the monitor output.

2 Adjust the amplitude of the

color bar.

3 Adjust after adjusting SCNT.

1 Carry out the setting as the

condition mentioned on the

left.

2 Gradually increase the screen

VR and stop it at a position

where any line of R, G, or B

begins to emit light slightly.

3 This position right here will be

set for screen VR adjustment.

4 Gradually increase remaining

two screen VRs – except the

line that emitted slight light as

mentioned in item 2 above –

and stop at positions where

respective lines begin to emit

light slightly. (Make adjust-

ment until the screen be-

comes virtually white.)

1 Carry out RCUT, GCUT, BCUT,

and Screen VR after checking

above-mentioned items

2 Carry out the setting of GDRV

and BDRV like the condition

mentioned on the left

3 Use a checker that can change

modulation factor to adjust

brightness

Adjusting

2.4V(P-P)

±0.2V(P-P)

4 lines±

1.5 lines

1.40V(P-P)

±0.2V(P-P)

* P-P

value of

upper

half

1.90V(P-P)

±0.2(P-P)

* P-P

value of

upper

half

HIGH

(103cd/m2)

11500k +

0.0075uv

DARK

(17cd/m2)

10500k +

0.0105uv

* The range

of adjustment is to

remain the

same as

what has

been set

until now.

– 14 –

Page 15

Adjusting partsAdjusting parts

Horizontal ampli-

tude adjustment

Adjustment on the

corrected number

of pin distortion

Adjustment on the

corrected number

of trapezoidal distortion

H. CENT

HEIGHT

VERT.POSITION

V901

Input/output points

Visual adjustment by

patterns (Bus control)

Visual adjustment by

patterns (Bus control)

Visual adjustment by

patterns (Bus control)

C.CRT adjusting magnetic field

Adjusting signals

WG Phillips pattern

Do not use the Phillips

pattern of FRANCE

SECAM.

WG Phillips pattern

Do not use the Phillips

pattern of FRANCE

SECAM.

WG Phillips pattern

Do not use the Phillips

pattern of FRANCE

SECAM.

Adjusting conditions and procedures

1 Conditions: These are to be Cont max, Bright cent, Color

cent, and DFS modes after adjusting V.HEIGHT, VERT

POSITION, and H.CENT.

2 Adjusting procedures

a. Turn the geomagnetism correction circuit OFF (cursor

= 00).

b. Adjust the horizontal amplitude by Sub Address WID.

Make sure that the left and right white flags are hidden

to the utmost possible limit.

c. Turn the left and right vertical bars into straight lines by

Sub Address PARA.

d. Correct the trapezoid distortion by Sub Address TRAP.

e. Adjust Sub Address WID again.

1 Conditions: Cont max, Bright cent, Color cent, and DFS

modes

2 Adjusting procedures

a Turn the geomagnetism correction circuit OFF (cursor

= 00).

b Adjust Sub Address HPOS and adjust the screen cen-

ter.

(Minimize D-C in the CRT adjusting magnetic field)

1. Conditions: Cont max, Bright cent, Color cent, and DFS

modes

2. Adjusting procedures

a. Turn the geomagnetism correction circuit OFF (cursor

= 00).

b. Adjust the V. Position to the center by Sub Address

VPOS so that the up-and-down positions of the Phillips

Pattern’s circle will come to the center.

c. Adjust HEIGHT by Sub Address HIT so that the up-

and-down flags of Phillips Pattern can be hidden to the

utmost possible limit.

d. Adjustment is to be made facing south or north. If it is

impossible to do so, offset the adjustment by geomagnetism.

Magnetic field UC/UM(BV=35µT)

UH/UE (BV=0µΤ)(BH=40µΤ)

UA (BV=–50µΤ)(BH=25µΤ)

UR (BV=45µΤ)(BH=20µΤ)

UG (BV=30µΤ)(BH=35µΤ)

UK (BV=35µΤ)(BH=30µΤ)

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

– 15 –

Page 16

THE PIP SCREEN SUB-BRIGHT ADJUSTMENTS

[DATA ADJUSTMENTS]

1 Adjustment of minor screen sub-bright

Condition) After the completion of main screen adjustments

(1) Let both the main and PIP screens receive signal.

(2) Select the adjustment item [MWBRC] and adjust the number of collapsed black lines.

Standard) ± 1.5 lines

<Reference data>

2 PIP screen color difference DC offset adjustments (White balance adjustment)

Condition) After adjusting PIP screen sub-bright

Adjustments) (1) Let both the main and PIP screens receive all black signals.

(2) Observe UM01#31 (R-Y out).

GENERAL ADJUSTMENTS

Standard) 0±10mV

(3) Select the adjustment item [MWBR] and adjust the amount of DC offset.

(4) Observe UM01#30 (R-Y out).

(5) Select the adjustment item [MWBB] and adjust the amount of DC offset.

SPECIFIC INFORMATIONS

– 16 –

Page 17

CIRCUIT CHECK

HIGH VOLTAGE CHECK

CAUTION: There is no HIGH VOLTAGE ADJUSTMENT on this chassis. Checking should be done following the steps

below.

1. Connect an accurate high voltage meter to the second anode of the picture tube.

2. Turn on the receiver. Set the BRIGHTNESS and CONTRAST controls to minimum (zero beam current).

3. High voltage must be measured below (B) kV.

Refer to table-1 for high voltage (B).

(See SETTING & ADJUSTING DATA on page 18)

4. Vary the BRIGHTNESS control to both extremes to be sure the high voltage does not exceed the limit under any conditions.

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

– 17 –

Page 18

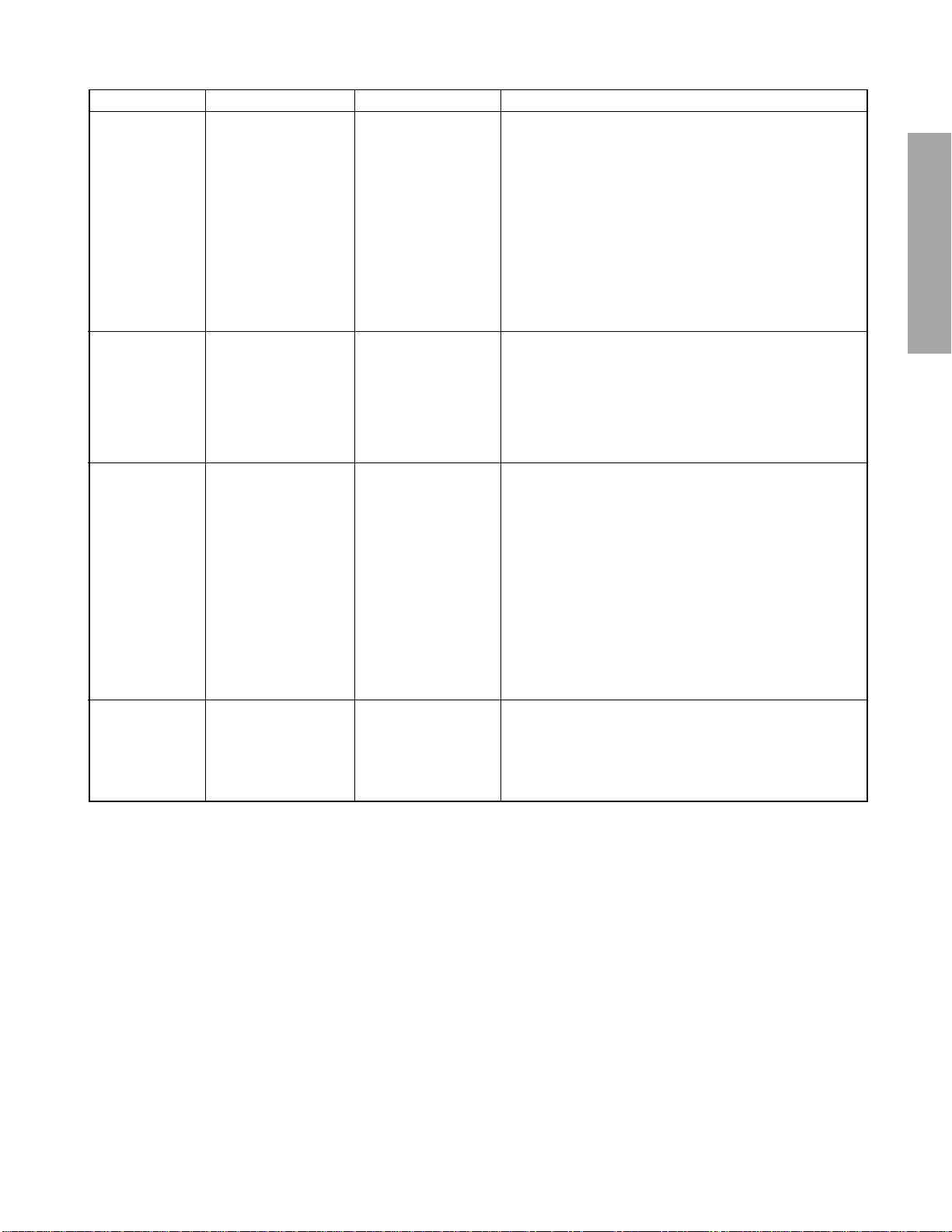

CHAPTER 2 SPECIFIC INFORMATIONS

SETTING & ADJUSTING DATA

SAFETY INSTRUCTIONS

HIGH VOLTAGE AT ZERO BEAM: (A) 32.8 kV

MAX HIGH VOLTAGE:

AC VOLTAGE

Table-1

29"

(B) 33.0 kV

(C) 110~240 V

GENERAL ADJUSTMENTS

SERVICE MODE

ADJUSTING ITEMS AND DATAS IN THE SERVICE MODE:

Item Name of adjustment

RCUT

GCUT

BCUT

GDRV

BDRV

SPECIFIC INFORMATIONS

CNTX

BRTC

COLC

TNTC

COLP

COLS

SCNT

VOLS

FVOL

NVOL

NICL

NICH

IDL

R CUTOFF (B/W)

G CUTOFF (B/W)

B CUTOFF (B/W)

G DRIVE

B DRIVE

SUB CONTRAST MAX (4:3 MODE)

SUB BRIGHT CEN

SUB COLOR CEN NTSC

SUB TINT CEN

SUB COLOR CEN PAL

SUB COLOR CEN SECAM

SUB CONTRAST

VOL SCART

FM VOL PRE SCALE

NICAM VOL PRE SCALE

NICAM THRESHOLD LEVEL

NICAM THRESHOLD LEVEL

IGR THRESHOLD LEVEL

Preset

40H

40H

40H

35H

35H

7FH

80H

45H

20H

01H

45H

0CH

75H

15H

3CH

03H

0AH

90H

Data

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

Item Name of adjustment

IDH

EVOL

HPOS

VPOS

HIT

VLIN

VSC

VPS

VCP

WID

PARA

CNR

TRAP

HCP

VFC

SRY

SBY

IGR THRESHOLD LEVEL

EXT PRE. VOLUME

50Hz H-POSITION

V-POSITION HEIGHT

HEIGHT

V-LINEARITY

V-S CORRECTION

V-SHIFT

V-COMPENSATION

PICTURE WIDTH

E-W PARABOLA

E-W CORNER

TRAPEZIUM

H-COMPENSATION

V-F CORRECTION

SECAM R-Y

SECAM-B-Y

Preset

A0H

00H

2CH

AEH

61H

13H

15H

06H

05H

1EH

1CH

09H

1AH

01H

0FH

07H

04H

Data

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

07H

04H

DESIGN MODE

ADJUSTING ITEMS AND DATAS IN THE DESIGN MODE:

Item Name of adjustment Preset Data Data Remarks

OPT0

OPT1

OPT2

OPT3

OPT4

OPTION 0

OPTION 1

OPTION 2

OPTION 3

OPTION 4

Table-2

00H

C2H

04H

DFH

63H

Table-3

– 18 –

00H

C2H

04H

DFH

63H

Page 19

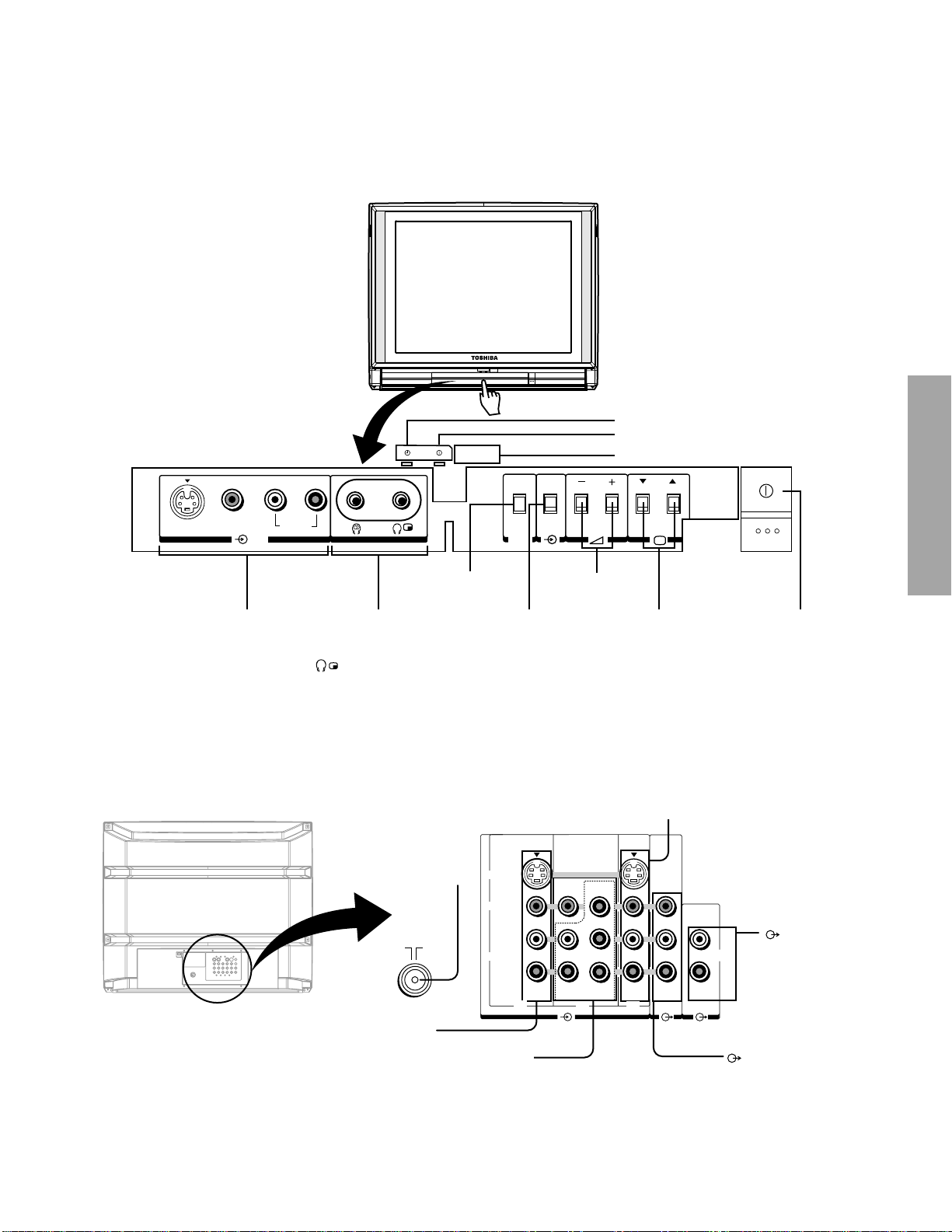

Behind the door

L/MONO R

LOCATION OF CONTROLS

Front

Y

ON-TIMER indicator (green)

I POWER indicator (red)

Remote sensor

GENERAL ADJUSTMENTS

S-VIDEO

a (3) Video 3 input

terminals

AUDIOVIDEO

(3)

Headphones jacks

(ø3.5 mm)

L Main sound

P-in-P

Back

] Aerial input

a (1) Video 1 input terminals

MENU

a (TV/VIDEO)

S-VIDEO

VIDEO

AUDIO

L/MONO

MENU

– ; +

Volume down/up

R

(1)

Y

PB/

CB

PR/

CR

COMPONENT

VIDEO INPUT

(2)

CH

t c s

I POWER switch

Channel select

a (3) Video 3 input terminals

L

AUDIO

R

(3)

(

)(

FIXED

)

MONITOR

SPECIFIC INFORMATIONS

FIXED AUDIO

output terminals

a (2) Video 2 input/COMPONENT VIDEO INPUT terminals

– 19 –

MONITOR output

terminals

Page 20

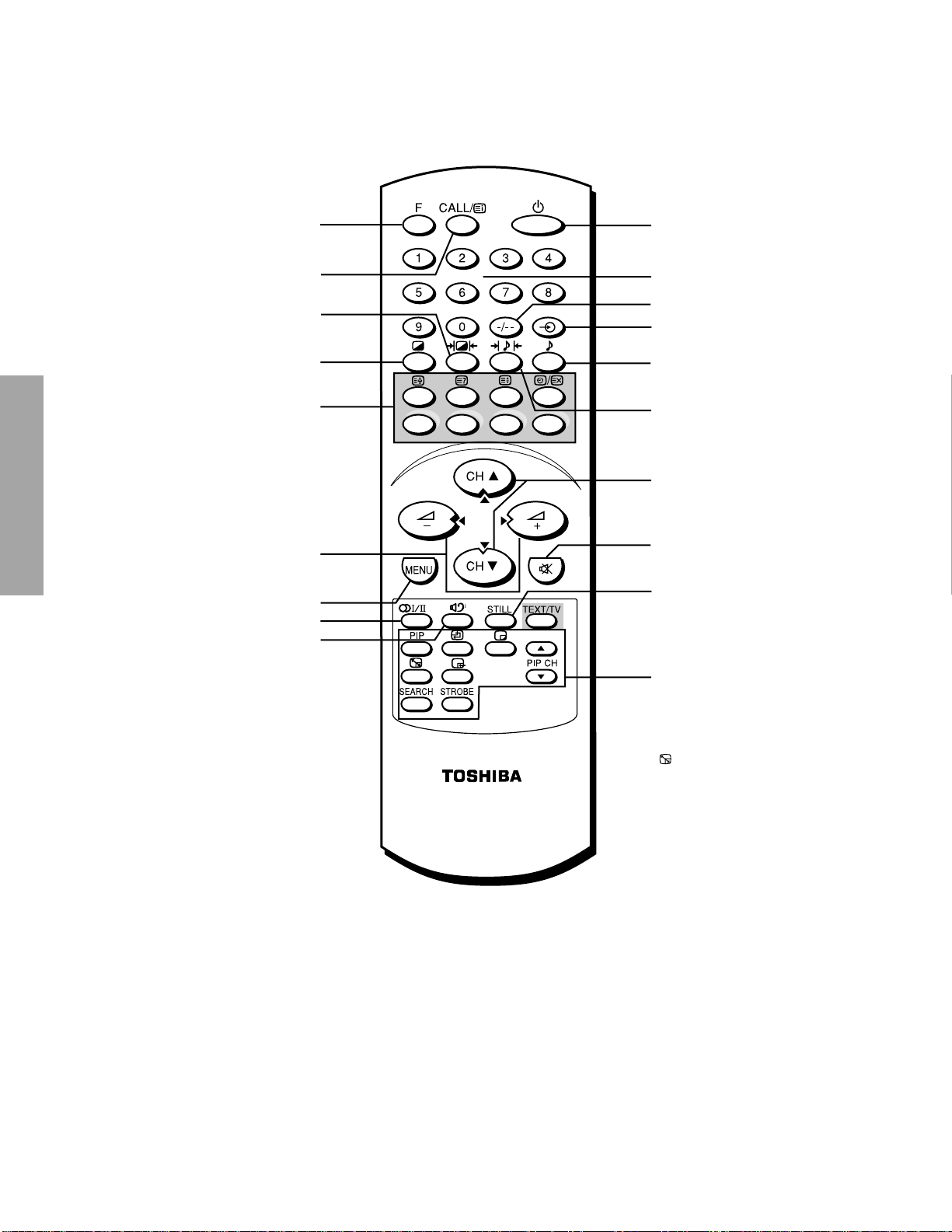

F (Quick operation)

f (Power on/standby)

Selectable picture

GENERAL ADJUSTMENTS

The color TV/color projection TV of model

CT-90089 used general remote control

of TOSHIBA color TV/color projection

TV. The 8 buttons in remote control are

not function button. If you prees any of

the buttons, the TV has no response.

This is not the malfunction of TV or

remote control.

SPECIFIC INFORMATIONS

Stereo/bilingual selection

CALL

Picture menu

Volume – +

Menu T S

MENU

Super woofer

Number buttons (0—9)

1 or 2 digit selection

Input source selection

Sound menu

Selectable sound

Channel position st

Menu st

Sound mute

STILL

P-in-P functions

PIP (P-in-P on/off)

rLocation

nContrast control

STILL (picture still)

Swap

a TV/VIDEO input select

CH t/s Channel select

– 20 –

Page 21

PROGRAMMING CHANNEL MEMORY

• First, use the ASM (Automatic Search Memory) function to preset all the active channels in your area automatically.

Then, arrange the preset channels with the MANUAL SEARCH (SEARCH or >>>), MFT (Manual Fine Tuning) and

SKIP functions so that you can tune into only desired channels.

• This section shows how to tune in channels using mainly the Remote Controller. You can also perform the system

select, ASM, MANUAL SEARCH (SEARCH or >>>), MFT and SKIP operations using the buttons on the TV set.

To preset channels (ASM)

ASM (Automatic Search Memory)

Select the first position number you want the ASM to

1

start presetting from with the CH buttons or the

direct select buttons.

Press the MENU button repeatedly to call up the SET

2

UP menu on the screen.

Confirm that “COLOR” is set to “AUTO ” and “SOUND”

3

is set to proper system.

If not, press the MENU

move the cursor (S) to “COLOR” or “SOUND” then press

the MENU –/+ (or; –/+) buttons to select the proper

systems.

Press the MENU

4

cursor (S) to “ASM”.

t/s

t/s

(or CH

(or CH

t/s

) buttons to move the

t/s

) buttons to

MFT (Manual Fine Tuning)

The adjustments below are not necessary under normal conditions. However, in areas of inferior broadcast conditions

where adjustment is necessary for a better picutre, adjust the

tuning with the MFT (Manual Fine Tuning).

Select the channel you want to fine-tune with the

1

CH buttons or direct select buttons.

Press the MENU button repeatedly to call up the SET

2

UP menu on the screen.

Press the MENU

3

cursor (S) to “MFT”.

t/s

(or CH

t/s

) buttons to move the

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

Press the MENU + (or; +) button to start the ASM.

5

All active channels will be preset automatically.

When presetting is complete, the initial position number

will reappear.

After presetting

Check the preset channels by pressing the

CH buttons.

• If the picture or sound of a certain channel is not

good, re-tune the channel using the ASM, MANUAL

SEARCH (SEARCH or >>>) or MFT function.

• If the colour of a certain channel is abnormal, the

automatic colour system selection (AUTO) may have

malfunctioned, or sound system selection is wrong.

In such a case, select another colour and/or sound

system.

– 21 –

Press the MENU –/+ (or; –/+) buttons until the best

4

possible picture and sound are obtained.

[–]DOWN or [+]UP is highlighted while tuning in.

Page 22

• Use the MANUAL SEARCH (SEARCH or >>>) function if desired channels cannot be preset with the ASM or if you

would like to preset channels to specific position numbers one by one.

• It is convenient to set the channel numbers to the same position numbers using MANUAL SEARCH (SEARCH or >>>)

and SKIP functions.

To preset channels (Manual search) and skip unnecessary position numbers

Manual search (SEARCH or >>>)

Select a desired position number with the CH or

1

direct select buttons.

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

Press the MENU button repeatedly to call up the SET

2

UP menu on the screen.

Press the MENU

3

cursor (S) to “SEARCH or >>>”.

Press the MENU –/+ (or; –/+)buttons to start search-

4

ing. The MENU – (or; –) button searches for lower-

numbered channels; the MENU + (or; +) button for

higher-numbered channels.

Repeat this process until you can get the desired channel.

When the desired channel is shown, press the MENU

5

t/s

buttons (or CH

to “

”.

t/s

(or CH

t/s

t/s

) to move the cursor (S)

) buttons to move the

To skip a position (CH) number

After presetting the channels, you may skip unnecessary position numbers so that only the channels you want to watch

are selected.

Select the position number to be skipped with the

1

CH

Press the MENU button repeatedly to call up the SET

2

UP menu on the screen.

Press the MENU

3

cursor (S) to “SKIP”.

Press the MENU –/+ (or; –/+) buttons to select “SKIP

4

ON”.

buttons or direct select buttons.

t/s

(or CH

t/s

) buttons to move the

Press the MENU + (or; +) button to store the chan-

6

nel at the current position.

When you desire to store another channel at another

7

position, move the cursor (S) to “POSITION” with the

MENU

t/s

(or CH

position number with the MENU –/+ (or; –/+)buttons.

Then, press the MENU

move the cursor (S) to “SEARCH or >>>” and repeat

the steps 4 to 7. Or, repeat the steps 1 to 7 after the

display disappears.

t/s

)buttons and select a desired

t/s

(or CH

t/s

) buttons to

Press the CALL button to turn off the SET UP menu

5

display.

Select the position number to be skipped with the direct select buttons. The * mark appears to the left of

the position number.

The position number will then be skipped when you

select channels with the CH buttons.

To restore a skipped position number

1 Select the position number you want to restore with the di-

rect select buttons.

2 Press the MENU button to call up the SET UP menu display

and press the MENU

cursor (S) to “SKIP”.

3 Press the MENU –/+ (or; –/+) buttons to select “SKIP

OFF”.

* Please refer to owner's manual.

– 22 –

t/s

(or CH

t/s

) buttons to move the

Page 23

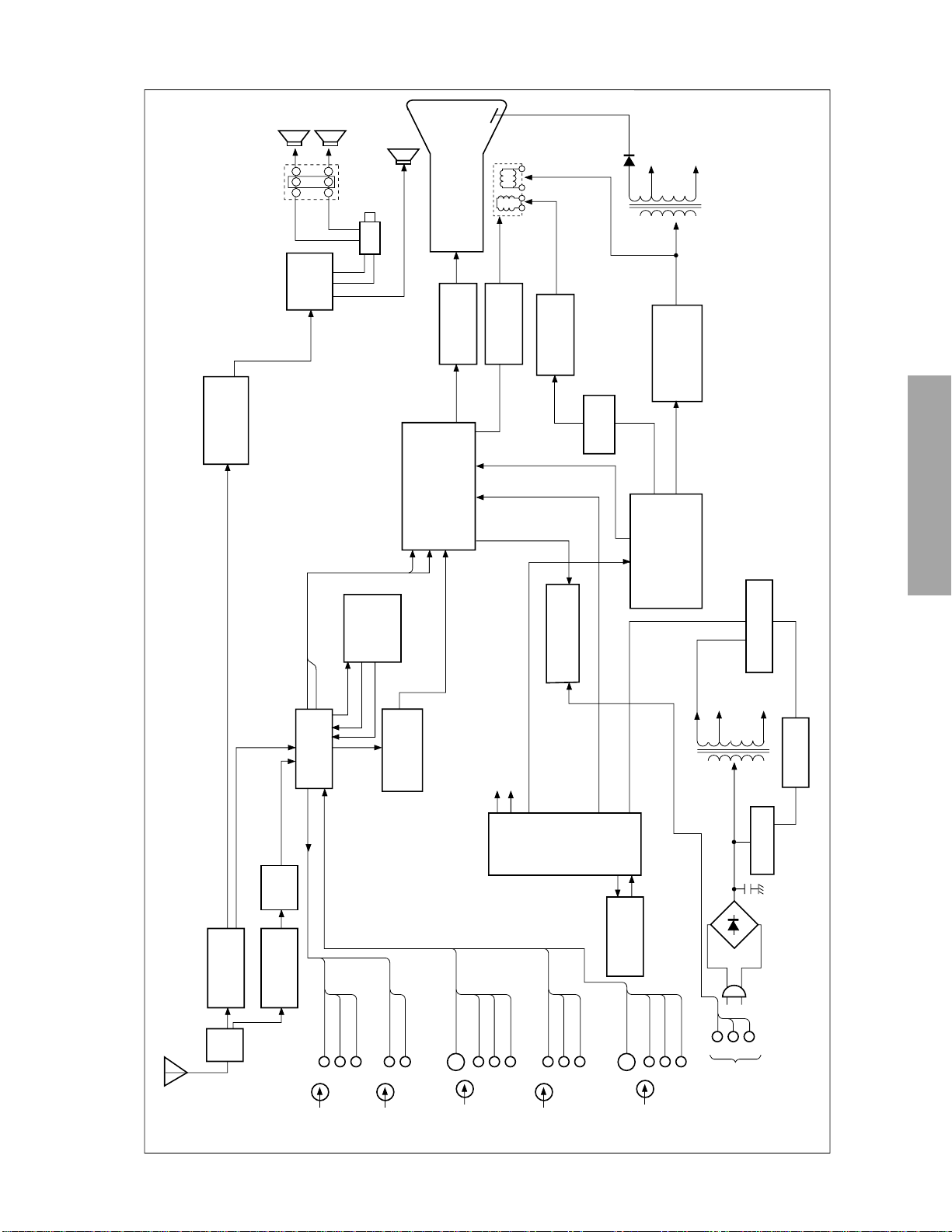

~

~

– +

TUNER

H001

TUNER

HY001

IF

HY002

QY10

QV01

QA01

QA02

Q801

Z801

Q404

Q302

Q301

Q501, Q510

Q901,Q903,Q905

MEMORY

µ-COM

I

2

C BUS

HYBRID

CONVERTER TRANS.

+B VOLTAGE

CHROMA

VIDEO

DEF.

VIDEO OUT

VSM

E/W

V. OUT

H. OUT

Q4420

PAL 100Hz

UP CONVERTER

F.B.T.

H.V.

D.Y.

V

H

CRT

AUDIO

OUT

HEAD PHONE

L/R/W

L

R

WOOFER

VIRTUAL

DOLBY

QD01

Q601,Q602

*

AV SW

*

QF01

TEXT

Q501

RGB

Y

C

OSD

RESET

MULTI-COLOR

DECODER

*

*

*

*

I

2

C BUS CONTROL

(FRONT/

REAR)

COLOR

DIFFERENCE

INPUT

(3)

(1)

R

V

S

L/MONO

R

V

S

L/MONO

(FRONT)

(2)

R

V

L/MONO

Cb

Y

Cr

MONITOR

OUT

R

V

L/MONO

AUDIO

OUT

L

R

QZ01

Y

C

V

Y

C

COMB

FILTER

ERROR AMP.

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

CIRCUIT BLOCK DIAGRAM

– 23 –

Page 24

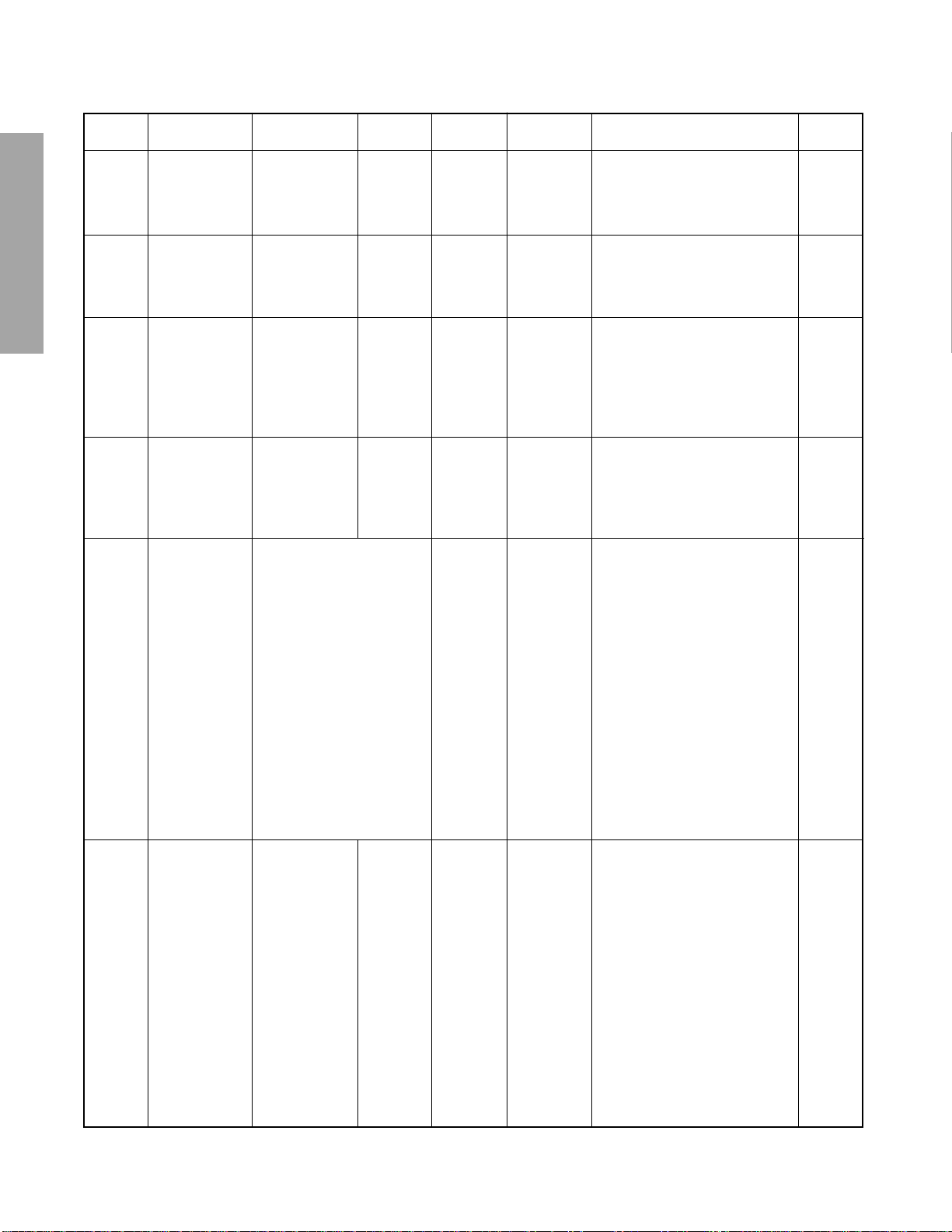

CHASSIS AND CABINET REPLACEMENT PARTS LIST

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECAUTION”, “SAFETY PRE-

CAUTION” AND “PRODUCT SAFETY NOTICE” ON PAGE 3 OF THIS MANUAL.

CAUTION: The international hazard symbols “ ” in the schematic diagram and the parts list designate components

which have special characteristics important for safety and should be replaced only with types identical to those in the

original circuit or specified in the parts list. The mounting position of replacements is to be identical with originals.

Before replacing any of these components, read carefully the PRODUCT SAFETY NOTICE. Do not degrade the

safety of the receiver through improper servicing.

NOTICE:

•

The part number must be used when ordering parts, in order to assist in processing, be sure to include the Model

number and Description.

•

The PC board assembly with * mark is no longer available after the end of the production.

Model : 29AX9UM

Capacitors ............. CD : Ceramic Disk PF : Plastic Film EL : Electrolytic

Resistors ............... CF : Carbon Film CC : Carbon Composition MF : Metal Film

OMF : Oxide Metal Film VR : Variable Resistor FR : Fusible Resistor

(All CD and PF capacitors are ±5%, 50V and all resistors, ±5%, 1/6W unless otherwise noted.)

LocationLocation

Location

LocationLocation

No.No.

No.

No.No.

Parts No.Parts No.

Parts No.

Parts No.Parts No.

CAPACITORS

C101 24668479 ELECTROLYTIC, 35V 4.7UF M 3A

C102 24665221 ELECTROLYTIC, 10V 220UF M 3A

SPECIFIC INFORMATIONS

C104 24665221 ELECTROLYTIC, 10V 220UF M 3A

C105 24212102 CERAMIC DISC, 50V B 1000PF K

C106 24797100 ELECTROLYTIC, 50V 10UF M

C107 24763221 ELECTROLYTIC, 16V 220UF M

C109 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

C115 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

C190 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

C202 24109103 CERAMIC CHIP, 50V B 10000PF K

C205 24797229 ELECTROLYTIC, 50V 2.2UF M

C206 24794220 ELECTROLYTIC, 16V 22UF M

C219 24105100 CERAMIC CHIP, 50V CH 10PF D

C220 24105100 CERAMIC CHIP, 50V CH 10PF D

C221 24105100 CERAMIC CHIP, 50V CH 10PF D

C303 24214471 CERAMIC DISC, 500V B 470PF K

C304 24693683 PLASTIC FILM, 100V 0.068UF J

C305 24617912 ELECTROLYTIC, 50V 2.2UF K 3A LI

C306 24667332 ELECTROLYTIC, 25V 3300UF M 3A

C307 24793101 ELECTROLYTIC, 10V 100UF M

C308 24669221 ELECTROLYTIC CE04Q 50V 220UF M 3A

C309 24073090 ELECTROLYTIC, 50V 100UF M 3A

C310 24669222 ELECTROLYTIC, 50V 2200UF M 3A

C312 24591103 PLASTIC FILM, 50V 0.01MF J

C313 24082058 PLASTIC FILM, 100V 270000PF J

C314 24212102 CERAMIC DISC, 50V B 1000PF K

C316 24567104 PLASTIC FILM, 50V 0.1UF J

C318 24666221 ELECTROLYTIC, 16V 220UF M 3A

C319 24212102 CERAMIC DISC, 50V B 1000PF K

C321 24591203 PLASTIC FILM, 50V 0.02UF J

C322 24617915 ELECTROLYTIC, 50V 1UF K 3A LI

C323 24567224 PLASTIC FILM, 50V 0.22UF J

C324 24567683 PLASTIC FILM, 50V 68000PF J

C325 24539684 PLASTIC FILM, 50V 0.68UF J

C326 24591182 PLASTIC FILM, 50V 1800PF J

C327 24073042 ELECTROLYTIC, 16V 1000UF M 3A

C328 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

C329 24212152 CERAMIC DISC, 50V B 1500PF K

DescriptionDescription

Description

DescriptionDescription

LocationLocation

Location

LocationLocation

C341 24567104 PLASTIC FILM, 50V 0.1UF J

C361 24539474 MT PLA CAP M 50V 474J MUL

C370 24794101 ELECTROLYTIC, 16V 100UF M

C371 24794100 ELECTROLYTIC, 16V 10UF M

C380 24797229 ELECTROLYTIC, 50V 2.2UF M

C406 24214471 CERAMIC DISC, 500V B 470PF K

C413 24214332 CERAMIC DISC, 500V B 3300PF K

C416 24109103 CERAMIC CHIP, 50V B 10000PF K

C416 24676330 ELECTROLYTIC, 100V 33UF M 3A

C417 24214391 CERAMIC DISC, 500V B 390PF K

C419 24212102 CERAMIC DISC, 50V B 1000PF K

C420 24666101 ELECTROLYTIC, 16V 100UF M 3A

C421 24567104 PLASTIC FILM, 50V 0.1UF J

C423 24829433 PLASTIC FILM, 400V 43000PF J

C432 24073059 ELECTROLYTIC, 25V 3300UF M 3A

C433 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

C440 24082942 PLASTIC FILM, 1500VH 3300PF H

C442 24829393 PLASTIC FILM, 400V 39000PF J

C443 24082637 PLASTIC FILM, 400V R1UF J

C444 24503076 PLASTIC FILM, 1800VH 5100PF H

C445 24828473 PLASTIC FILM, 200V 47000PF J

C446 24679330 ELECTROLYTIC, 250V 33UF M 3A

C448 24640908 ELECTROLYTIC, 160V 33UF M 3A LI

C451 24829273 PLASTIC FILM, 400V 27000PF J

C460 24073092 ELECTROLYTIC, 50V 330UF M 3A

C463 24591203 PLASTIC FILM, 50V 0.02UF J

C464 24640872 ELECTROLYTIC CE04R 100V 10UF M 3A

C467 24082425 PLASTIC FILM, 1250VH 8200PF H

C470 24794101 ELECTROLYTIC, 16V 100UF M

C472 24567474 PLASTIC FILM, 50V 0.47UF J

C473 24073081 ELECTROLYTIC, 50V 1.OUF M 3A

C475 24591681 PLASTIC FILM, 50V 680PF J

C476 24829273 PLASTIC FILM, 400V 27000PF J

C477 24591223 PLASTIC FILM, 50V 0.022MF J

C478 24591563 PLASTIC FILM, 50V 0.056MF J

C481 24567334 PLASTIC FILM, 50V 0.33UF J

C482 24212122 CERAMIC DISC, 50V B 1200PF K

C495 24092343 CERAMIC DISC, 2KV 680PF K

C496 24092343 CERAMIC DISC, 2KV 680PF K

No.No.

No.

No.No.

Parts No.Parts No.

Parts No.

Parts No.Parts No.

DescriptionDescription

Description

DescriptionDescription

– 24 –

Page 25

LocationLocation

Location

LocationLocation

Parts No.Parts No.

Parts No.

Parts No.Parts No.

No.No.

No.

No.No.

C497 24214471 CERAMIC DISC, 500V B 470PF K

C499 24591272 PLASTIC FILM, 50V 2700PF J

C510 24100104 CERAMIC CHIP, 25V F 100000PF Z

C513 24109103 CERAMIC CHIP, 50V B 10000PF K

C514 24794101 ELECTROLYTIC, 16V 100UF M

C515 24085958 ELEC. NONPOLAR CE04J 50V 1.0UF M NP

C516 24100104 CERAMIC CHIP, 25V F 100000PF Z

C517 24100104 CERAMIC CHIP, 25V F 100000PF Z

C518 24100104 CERAMIC CHIP, 25V F 100000PF Z

C520 24591334 PLASTIC FILM, 50V 0.33MF J

C520 24591334 PLASTIC FILM, 50V 0.33MF J

C530 24797010 ELECTROLYTIC, 50V 1UF M

C530 24797100 ELECTROLYTIC, 50V 10UF M

C531 24100104 CERAMIC CHIP, 25V F 100000PF Z

C531 24212222 CERAMIC DISK CK45 B 50V 2200PF K

C532 24100104 CERAMIC CHIP, 25V F 100000PF Z

C532 24436561 CERAMIC DISC, 50V SL 560PF J

C533 24100104 CERAMIC CHIP, 25V F 100000PF Z

C533 24212332 CERAMIC DISC, 50V B 3300PF K

C534 24100104 CERAMIC CHIP, 25V F 100000PF Z

C535 24100104 CERAMIC CHIP, 25V F 100000PF Z

C536 24100104 CERAMIC CHIP, 25V F 100000PF Z

C537 24100104 CERAMIC CHIP, 25V F 100000PF Z

C538 24797010 ELECTROLYTIC, 50V 1UF M

C540 24100104 CERAMIC CHIP, 25V F 100000PF Z

C541 24100104 CERAMIC CHIP, 25V F 100000PF Z

C542 24100104 CERAMIC CHIP, 25V F 100000PF Z

C547 24109103 CERAMIC CHIP, 50V B 10000PF K

C548 24794101 ELECTROLYTIC, 16V 100UF M

C563 24797010 ELECTROLYTIC, 50V 1UF M

C564 24797479 ELECTROLYTIC, 50V 4.7UF M

C601 24591681 PLASTIC FILM, 50V 680PF J

C602 24591681 PLASTIC FILM, 50V 680PF J

C603 24797479 ELECTROLYTIC, 50V 4.7UF M

C604 24797479 ELECTROLYTIC, 50V 4.7UF M

C605 24795101 ELECTROLYTIC, 25V 100UF M

C606 24795101 ELECTROLYTIC, 25V 100UF M

C607 24591104 PLASTIC FILM, 50V 0.1UF J

C608 24591104 PLASTIC FILM, 50V 0.1UF J

C609 24073094 ELECTROLYTIC, 50V 1000UF M 3A

C610 24073094 ELECTROLYTIC, 50V 1000UF M 3A

C611 24795221 ELECTROLYTIC, 25V 220UF M

C613 24763471 ELECTROLYTIC, 16V 470UF M

C614 24797010 ELECTROLYTIC, 50V 1UF M

C615 24073094 ELECTROLYTIC, 50V 1000UF M 3A

C616 24591104 PLASTIC FILM, 50V 0.1UF J

C619 24795101 ELECTROLYTIC, 25V 100UF M

C621 24591103 PLASTIC FILM, 50V 0.01MF J

C623 24797330 ELECTROLYTIC, 50V 33UF M

C626 24797471 ELECTROLYTIC, 50V 470UF M

C627 24797010 ELECTROLYTIC, 50V 1UF M

C628 24794470 ELECTORLYTIC, 16V 47UF M

C630 24795101 ELECTROLYTIC, 25V 100UF M

C631 24797100 ELECTROLYTIC, 50V 10UF M

C632 24795221 ELECTROLYTIC, 25V 220UF M

C635 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

C640 24797229 ELECTROLYTIC, 50V 2.2UF M

C641 24797229 ELECTROLYTIC, 50V 2.2UF M

C680 24797471 ELECTROLYTIC, 50V 470UF M

C681 24206010 ELECTROLYTIC, 50V 1.0UF M 7L 3A

C704 24591822 PLASTIC FILM, 50V 8200PF J

C705 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

C707 24794470 ELECTORLYTIC, 16V 47UF M

C712 24666470 ELECTORLYTIC, 16V 47UF M 3A

C713 24790100 ELECTROLYTIC CE04G 160V 10UF M

DescriptionDescription

Description

DescriptionDescription

LocationLocation

Location

LocationLocation

* C801 24503057 PLASTIC FILM, AC275V 0.22UF M

* C802 24503057 PLASTIC FILM, AC275V 0.22UF M

* C811 24092553 CERAMIC DISC, AC250V B 470PF K

* C813 24092563 CERAMIC DISC, AC250V B 220PF K

* C814 24092563 CERAMIC DISC, AC250V B 220PF K

* C815 24092555 CERAMIC DISC, AC250V E 1000PF M

Parts No.Parts No.

Parts No.

Parts No.Parts No.

No.No.

No.

No.No.

C714 24436101 CERAMIC DISC CC45 SL 50V100PF J

C715 24214472 CERAMIC DISK CK45 B 500V 4700PF K

C716 24436101 CERAMIC DISC CC45 SL 50V100PF J

C717 24214472 CERAMIC DISK CK45 B 500V 4700PF K

C718 24766470 ELECTROLYTIC, 50V 47UF M

C719 24435560 CERAMIC DISC, 500V SL 56PF J

C720 24790100 ELECTROLYTIC CE04G 160V 10UF M

C721 24797470 ELECTROLYTIC, 50V 47UF M

C726 24212102 CERAMIC DISC, 50V B 1000PF K

C805 24092281 CERAMIC DISC, AC250V E 4700PF

C806 24092281 CERAMIC DISC, AC250V E 4700PF

C807 24567474 PLASTIC FILM, 50V 0.47UF J

C808 24796101 ELECTROLYTIC, 35V 100UF M

C809 24567474 PLASTIC FILM, 50V 0.47UF J

C810 24086069 ELECTROLYTIC, 450V 680UF M 3D

C816 24794470 ELECTORLYTIC, 16V 47UF M

C817 24092339 CERAMIC DISC, 2KV 330PF K

C818 24095931 PLASTIC FILM CF92T 1250VH 2200PF J

C819 24676220 ELECTROLYTIC, 100V 22UF M 3A

C821 24214471 CERAMIC DISC, 500V B 470PF K

C823 24214471 CERAMIC DISC, 500V B 470PF K

C825 24539104 PLASTIC FILM, 50V 0.1UF J

C828 24797470 ELECTROLYTIC, 50V 47UF M

C829 24212271 CERAMIC DISC, 50V B 270PF K

C832 24665470 ELECTROLYTIC, 10V 47UF M 3A

C833 24669229 ELECTROLYTIC, 50V 2.2UF M 3A

C834 24669100 ELECTROLYTIC, 50V 10UF M 3A

C835 24666470 ELECTORLYTIC, 16V 47UF M 3A

C838 24617040 ELECTROLYTIC, 25V 1000UF M 3D

C839 24793222 ELECTROLYTIC, 10V 2200UF M

C840 24762102 ELECTROLYTIC, 10V 1000UF M

C841 24669100 ELECTROLYTIC, 50V 10UF M 3A

C842 24669100 ELECTROLYTIC, 50V 10UF M 3A

C843 24567104 PLASTIC FILM, 50V 0.1UF J

C844 24539104 PLASTIC FILM, 50V 0.1UF J

C845 24539104 PLASTIC FILM, 50V 0.1UF J

C847 24214331 CERAMIC DISK CK45 B 500V 330PF K

C848 24796102 ELECTROLYTIC, 35V 1000UF M

C850 24214471 CERAMIC DISC, 500V B 470PF K

C851 24668222 ELECTROLYTIC, 35V 2200UF M 3A

C855 24214222 CERAMIC DISC, 500V B 2200PF K

C856 24212102 CERAMIC DISC, 50V B 1000PF K

C860 24666100 ELECTROLYTIC, 10V 10UF M 3A

C861 24591104 PLASTIC FILM, 50V 0.1UF J

C862 24669010 ELECTROLYTIC, 50V 1.0UF M 3A

C863 24669222 ELECTROLYTIC, 50V 2200UF M 3A

C865 24669222 ELECTROLYTIC, 50V 2200UF M 3A

C866 24214331 CERAMIC DISK CK45 B 500V 330PF K

C867 24214331 CERAMIC DISK CK45 B 500V 330PF K

C868 24092281 CERAMIC DISC, AC250V E 4700PF

C869 24086937 ELECTROLYTIC, 450V 120UF M 22D

C870 24092281 CERAMIC DISC, AC250V E 4700PF

C871 24667101 ELECTROLYTIC, 25V 100UF M 3A

C872 24082934 PLASTIC FILM CF92 T 1500VH 1500PF H

C873 24591272 PLASTIC FILM, 50V 2700PF J

C874 24503056 PLASTIC FILM, AC275V 0.1UF M

C875 24092551 CERAMIC DISC, AC250V B 220PF K

C876 24092551 CERAMIC DISC, AC250V B 220PF K

C877 24591471 PLASTIC FILM, 50V 470PF J

DescriptionDescription

Description

DescriptionDescription

SPECIFIC INFORMATIONS

– 25 –

Page 26

LocationLocation

Location

LocationLocation

SPECIFIC INFORMATIONS

Parts No.Parts No.

Parts No.

Parts No.Parts No.

No.No.

No.

No.No.

C878 24092339 CERAMIC DISC, 2KV 330PF K

C882 24591122 PLASTIC FILM, 50V 1200PF J

C884 24086916 ELECTROLYTIC CE692R 160V 330UF M 3D

C887 24214471 CERAMIC DISC, 500V B 470PF K

C891 24667332 ELECTROLYTIC, 25V 3300UF M 3A

C892 24667332 ELECTROLYTIC, 25V 3300UF M 3A

C893 24092337 CERAMIC DISC, 2KV 220PF K

C895 24676470 ELECTROLYTIC, 100V 47UF M 3A

C896 24214471 CERAMIC DISC, 500V B 470PF K

C898 24667332 ELECTROLYTIC, 25V 3300UF M 3A

C899 24214471 CERAMIC DISC, 500V B 470PF K

C902 24092353 CERAMIC DISC, 2KV 4700PF K

C904 24436561 CERAMIC DISC, 50V SL 560PF J

C905 24436471 CERAMIC DISC, 50V SL 470PF J

C907 24436681 CERAMIC DISC, 50V SL 680PF J

C909 24679330 ELECTROLYTIC, 250V 33UF M 3A

C911 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

C913 24666102 ELECTROLYTIC, 16V 1000UF M 3A

C914 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

C918 24567104 PLASTIC FILM, 50V 0.1UF J

C919 24567104 PLASTIC FILM, 50V 0.1UF J

C920 24567104 PLASTIC FILM, 50V 0.1UF J

C921 24567104 PLASTIC FILM, 50V 0.1UF J

C923 24794470 ELECTORLYTIC, 16V 47UF M

C924 24794470 ELECTORLYTIC, 16V 47UF M

C931 24214101 CERAMIC DISC, 500V B 100PF K

C940 24436220 CERAMIC DISC, 50V SL 22PF J

C941 24436220 CERAMIC DISC, 50V SL 22PF J

C942 24436470 CERAMIC DISC, 50V SL 47PF J

C3110 24085958 ELEC. NONPOLAR CE04J 50V 1.0UF M NP

C4030 24109103 CERAMIC CHIP, 50V B 10000PF K

C4300 24109103 CERAMIC CHIP, 50V B 10000PF K

C4311 24794221 ELECTROIYTIC, 16V 220UF M

C4401 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

C4402 24797010 ELECTROLYTIC, 50V 1UF M

C4403 24763331 ELECTROLYTIC, 16V 330UF M

C4404 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

C4405 24092730 CERAMIC CHIP, 16V B 0.1UF K

C4422 24085988 ELECTROLYTIC, NONPOLAR, 50V 1.0UF

C4461 24591224 PLASTIC FILM, 50V 0.22MF J

C4464 24797010 ELECTROLYTIC, 50V 1UF M

C5020 24100104 CERAMIC CHIP, 25V F 100000PF Z

C5030 24794101 ELECTROLYTIC, 16V 100UF M

CA14 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

CA30 24474101 CERAMIC CK141B 50V 100PF K

CA33 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

CA37 24474101 CERAMIC CK141B 50V 100PF K

CA38 24474101 CERAMIC CK141B 50V 100PF K

CA40 24474101 CERAMIC CK141B 50V 100PF K

CA41 24474101 CERAMIC CK141B 50V 100PF K

CA42 24794100 ELECTROLYTIC, 16V 10UF M

CA43 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

CA44 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

CA68 24794100 ELECTROLYTIC, 16V 10UF M

CA69 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

CA80 24794100 ELECTROLYTIC, 16V 10UF M

CA95 24797220 ELECTROLYTIC, 50V 22UF M

CB01 24744470 ELECTROLYTIC, 16V 47UF M

CB90 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

CD01 24797100 ELECTROLYTIC, 50V 10UF M

CD02 24539104 PLASTIC FILM, 50V 0.1UF J

CD03 24590472 PLASTIC FILM, 50V 4700PF J

CD04 24797479 ELECTROLYTIC, 50V 4.7UF M

CD05 24797479 ELECTROLYTIC, 50V 4.7UF M

DescriptionDescription

Description

DescriptionDescription

M 7L

LocationLocation

Location

LocationLocation

Parts No.Parts No.

Parts No.

Parts No.Parts No.

No.No.

No.

No.No.

CD06 24797479 ELECTROLYTIC, 50V 4.7UF M

CD07 24797479 ELECTROLYTIC, 50V 4.7UF M

CD08 24797100 ELECTROLYTIC, 50V 10UF M

CD09 24797220 ELECTROLYTIC, 50V 22UF M

CD10 24797100 ELECTROLYTIC, 50V 10UF M

CD11 24539104 PLASTIC FILM, 50V 0.1UF J

CD12 24539224 PLASTIC FILM, 50V 0.22 UF J

CD13 24794470 ELECTORLYTIC, 16V 47UF M

CD14 24590472 PLASTIC FILM, 50V 4700PF J

CD14 24590472 PLASTIC FILM, 50V 4700PF J

CD15 24539104 PLASTIC FILM, 50V 0.1UF J

CD16 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

CD17 24797100 ELECTROLYTIC, 50V 10UF M

CD18 24794221 ELECTROIYTIC, 16V 220UF M

CD21 24590102 PLASTIC FILM, 50V 1000PF J

CD22 24436151 CERAMIC DISC, 50V SL 150PF J

CD23 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

CD24 24590102 PLASTIC FILM, 50V 1000PF J

CD25 24436151 CERAMIC DISC, 50V SL 150PF J

CD41 24503041 PLASTIC FILM , 63V 0.1UF J

CD42 24590103 PLASTIC FILM, 50V 0.01MF J

CD43 24503041 PLASTIC FILM , 63V 0.1UF J

CD44 24503041 PLASTIC FILM , 63V 0.1UF J

CD45 24591184 PLASTIC FILM CQ921 M 50V 0.18MF J

CD46 24591184 PLASTIC FILM CQ921 M 50V 0.18MF J

CD47 24539334 PLASTIC FILM, 50V 0.33UF J

CD48 24539334 PLASTIC FILM, 50V 0.33UF J

CD49 24797010 ELECTROLYTIC, 50V 1UF M

CD60 24797100 ELECTROLYTIC, 50V 10UF M

CD61 24567333 PLASTIC FILM, 50V 33000PF J

CD61 24567333 PLASTIC FILM, 50V 33000PF J

CD62 24590103 PLASTIC FILM, 50V 0.01MF J

CD63 24539474 MT PLA CAP M 50V 474J MUL

CD64 24539334 PLASTIC FILM, 50V 0.33UF J

CD65 24436221 CERAMIC DISC, 50V SL 220PF J

CD70 24794221 ELECTROIYTIC, 16V 220UF M

CD71 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

CD73 24797100 ELECTROLYTIC, 50V 10UF M

CD74 24794221 ELECTROIYTIC, 16V 220UF M

CD75 24797100 ELECTROLYTIC, 50V 10UF M

CD76 24797100 ELECTROLYTIC, 50V 10UF M

CD77 24797100 ELECTROLYTIC, 50V 10UF M

CD79 24797220 ELECTROLYTIC, 50V 22UF M

CD80 24797220 ELECTROLYTIC, 50V 22UF M

CD81 24503041 PLASTIC FILM , 63V 0.1UF J

CD82 24503041 PLASTIC FILM , 63V 0.1UF J

CD83 24503041 PLASTIC FILM , 63V 0.1UF J

CD84 24503041 PLASTIC FILM , 63V 0.1UF J

CD85 24797100 ELECTROLYTIC, 50V 10UF M

CD86 24797100 ELECTROLYTIC, 50V 10UF M

CD87 24797100 ELECTROLYTIC, 50V 10UF M

CD88 24797100 ELECTROLYTIC, 50V 10UF M

CD103 24797220 ELECTROLYTIC, 50V 22UF M

CD104 24590102 PLASTIC FILM, 50V 1000PF J

CD105 24539104 PLASTIC FILM, 50V 0.1UF J

CD106 24539104 PLASTIC FILM, 50V 0.1UF J

CD107 24539563 PLASTIC FILM, 50V 0.056UF J

CD108 24797010 ELECTROLYTIC, 50V 1UF M

CD109 24797100 ELECTROLYTIC, 50V 10UF M

CD110 24590103 PLASTIC FILM, 50V 0.01MF J

CD110 24590103 PLASTIC FILM, 50V 0.01MF J

CD111 24797100 ELECTROLYTIC, 50V 10UF M

CD113 24797010 ELECTROLYTIC, 50V 1UF M

CD114 24797010 ELECTROLYTIC, 50V 1UF M

CD115 24797010 ELECTROLYTIC, 50V 1UF M

DescriptionDescription

Description

DescriptionDescription

– 26 –

Page 27

LocationLocation

Location

LocationLocation

Parts No.Parts No.

Parts No.

Parts No.Parts No.

No.No.

No.

No.No.

CD116 24590103 PLASTIC FILM, 50V 0.01MF J

CD117 24590103 PLASTIC FILM, 50V 0.01MF J

CD118 24567273 PLASTIC FILM, 50V 0.027UF J

CD119 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

CD120 24794221 ELECTROIYTIC, 16V 220UF M

CD121 24590822 PLASTIC FILM, 50V 8200PF J

CD123 24797100 ELECTROLYTIC, 50V 10UF M

CD123 24797100 ELECTROLYTIC, 50V 10UF M

CD124 24797010 ELECTROLYTIC, 50V 1UF M

CD125 24567273 PLASTIC FILM, 50V 0.027UF J

CD126 24590822 PLASTIC FILM, 50V 8200PF J

CD128 24797100 ELECTROLYTIC, 50V 10UF M

CF01 24762102 ELECTROLYTIC, 10V 1000UF M

CR12 24092730 CERAMIC CHIP, 16V B 0.1UF K

CR12 24100104 CERAMIC CHIP, 25V F 100000PF Z

CR13 24092730 CERAMIC CHIP, 16V B 0.1UF K

CR13 24100104 CERAMIC CHIP, 25V F 100000PF Z

CR14 24092730 CERAMIC CHIP, 16V B 0.1UF K

CR14 24100104 CERAMIC CHIP, 25V F 100000PF Z

CS01 24206229 ELECTROLYTIC, 50V 2.2UF M 7L 3A

CS02 24206229 ELECTROLYTIC, 50V 2.2UF M 7L 3A

CS03 24797229 ELECTROLYTIC, 50V 2.2UF M

CS05 24206229 ELECTROLYTIC, 50V 2.2UF M 7L 3A

CS06 24206229 ELECTROLYTIC, 50V 2.2UF M 7L 3A

CS07 24206229 ELECTROLYTIC, 50V 2.2UF M 7L 3A

CS08 24206229 ELECTROLYTIC, 50V 2.2UF M 7L 3A

CS09 24206229 ELECTROLYTIC, 50V 2.2UF M 7L 3A

CS14 24206100 ELECTROLYTIC, 50V 10UF M 7L 3A

CS15 24206100 ELECTROLYTIC, 50V 10UF M 7L 3A

CS16 24206229 ELECTROLYTIC, 50V 2.2UF M 7L 3A

CS19 24206478 ELECTROLYTIC, 50V 0.47UF M 7L 3A

CS20 24206100 ELECTROLYTIC, 50V 10UF M 7L 3A

CS21 24206100 ELECTROLYTIC, 50V 10UF M 7L 3A

CT01 24792221 ELECTROLYTIC CE04G 6.3V 220UF M

CT02 24109103 CERAMIC CHIP, 50V B 10000PF K

CT03 24109103 CERAMIC CHIP, 50V B 10000PF K

CT04 24793101 ELECTROLYTIC, 10V 100UF M

CT05 24100104 CERAMIC CHIP, 25V F 100000PF Z

CT06 24793470 ELECTROLYTIC CE04G 10V 47UF M

CT07 24092538 CERAMIC CHIP, 10V F 1UF Z

CT08 24105560 CERAMIC CHIP, 50V CH 56PF J

CT09 24105560 CERAMIC CHIP, 50V CH 56PF J

CT10 24793470 ELECTROLYTIC CE04G 10V 47UF M

CT11 24100104 CERAMIC CHIP, 25V F 100000PF Z

CT12 24793470 ELECTROLYTIC CE04G 10V 47UF M

CT13 24100104 CERAMIC CHIP, 25V F 100000PF Z

CT14 24100104 CERAMIC CHIP, 25V F 100000PF Z

CT15 24105101 CERAMIC CHIP, 50V CH 100PF J

CT16 24105100 CERAMIC CHIP, 50V CH 10PF D

CT17 24100104 CERAMIC CHIP, 25V F 100000PF Z

CT19 24794100 ELECTROLYTIC, 16V 10UF M

CT20 24109103 CERAMIC CHIP, 50V B 10000PF K

CT21 24794100 ELECTROLYTIC, 16V 10UF M

CT22 24100104 CERAMIC CHIP, 25V F 100000PF Z

CT23 24100104 CERAMIC CHIP, 25V F 100000PF Z

CV02 24073077 ELECTROLYTIC, 50V 0.1UF M 3A

CV03 24073077 ELECTROLYTIC, 50V 0.1UF M 3A

CV04 24073077 ELECTROLYTIC, 50V 0.1UF M 3A

CV05 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

CV06 24073077 ELECTROLYTIC, 50V 0.1UF M 3A

CV07 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

CV08 24763221 ELECTROLYTIC, 16V 220UF M

CV09 24073077 ELECTROLYTIC, 50V 0.1UF M 3A

CV12 24567104 PLASTIC FILM, 50V 0.1UF J

CV23 24794101 ELECTROLYTIC, 16V 100UF M

DescriptionDescription

Description

DescriptionDescription

LocationLocation

Location

LocationLocation

Parts No.Parts No.

Parts No.

Parts No.Parts No.

No.No.

No.

No.No.

CV24 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

CV25 24794220 ELECTROLYTIC, 16V 22UF M

CV26 24567473 PLASTIC FILM, 50V 47000PF J

CV35 24474102 CERAMIC, 50V B 1000PF K

CV37 24474102 CERAMIC, 50V B 1000PF K

CV48 24212102 CERAMIC DISC, 50V B 1000PF K

CV50 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

CV51 24666101 ELECTROLYTIC, 16V 100UF M 3A

CV52 24666100 ELECTROLYTIC, 10V 10UF M 3A

CV55 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

CV64 24797010 ELECTROLYTIC, 50V 1UF M

CV71 24794471 ELECTROLYTIC, 16V 470UF M

CV72 24794101 ELECTROLYTIC, 16V 100UF M

CV73 24212103 CERAMIC DISC, 50V B 10000PF K

CY103 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

CY104 24794101 ELECTROLYTIC, 16V 100UF M

CY109 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

CY110 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

CY111 24797479 ELECTROLYTIC, 50V 4.7UF M

CY112 24763101 ELECTROLYTIC, 16V 100UF M

CY117 24232103 CERAMIC DISK CK45 F 50V 10000PF Z

CY601 24794101 ELECTROLYTIC, 16V 100UF M

CY602 24797479 ELECTROLYTIC, 50V 4.7UF M

CY603 24797479 ELECTROLYTIC, 50V 4.7UF M

CY604 24794102 ELECTROLYTIC, 16V 1000UF M

CY605 24797479 ELECTROLYTIC, 50V 4.7UF M

CY606 24797479 ELECTROLYTIC, 50V 4.7UF M

CY608 24744101 ELECTROLYTIC, 16V 100UF

CY610 24206478 ELECTROLYTIC, 50V 0.47UF M 7L 3A

DescriptionDescription

Description

DescriptionDescription

RESISTORS

R101 24382153 OXIDE METAL FILM, 1W 15K OHM J

R205 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R206 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

R213 24871681 CHIP, METAL FILM, 1/8W 680 OHM J

R214 24871681 CHIP, METAL FILM, 1/8W 680 OHM J

R215 24871681 CHIP, METAL FILM, 1/8W 680 OHM J

R217 24366392 CARBON FILM, 1/6W 3.9K OHM J

R218 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R218 24366473 CARBON FILM, 1/6W 47K OHM J

R219 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R220 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R221 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R222 24011332 CHIP, METAL FILM, 1/20W 3.3K OHM J

R227 24366223 CARBON FILM, 1/6W 22K OHM J

R230 24366433 CARBON FILM, 1/6W 43K OHM J

R231 24366103 CARBON FILM, 1/6W 10K OHM J

R232 24366103 CARBON FILM, 1/6W 10K OHM J

R240 24366101 CARBON FILM, 1/6W 100 OHM J

R245 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

R299 24366103 CARBON FILM, 1/6W 10K OHM J

R303 24321109 OXIDE METAL FILM, 1/2W 1 OHM J

R305 24338688 OXIDE METAL FILM, 1W 0.68 OHM J

R307 24366621 CARBON FILM, 1/6W 620 OHM J

R309 24366363 CARBON FILM, 1/6W 36K OHM J

R310 24366102 CARBON FILM, 1/6W 1K OHM J

R315 24366684 CARBON FILM, 1/6W 680K OHM J

R316 24366474 CARBON FILM, 1/6W 470K OHM J

R317 24366472 CARBON FILM, 1/6W 4.7K OHM J

R318 24366471 CARBON FILM, 1/6W 470 OHM J

R319 24366471 CARBON FILM, 1/6W 470 OHM J

R320 24366101 CARBON FILM, 1/6W 100 OHM J

R321 24366153 CARBON FILM, 1/6W 15K OHM J

R322 24366102 CARBON FILM, 1/6W 1K OHM J

R323 24366103 CARBON FILM, 1/6W 10K OHM J

SPECIFIC INFORMATIONS

– 27 –

Page 28

LocationLocation

Location

LocationLocation

SPECIFIC INFORMATIONS

Parts No.Parts No.

Parts No.

Parts No.Parts No.

No.No.

No.

No.No.

R324 24366122 CARBON FILM, 1/6W 1.2K OHM J

R325 24366103 CARBON FILM, 1/6W 10K OHM J

R326 24366155 CARBON FILM, 1/6W 1.5M OHM J

R327 24339689 OXIDE METAL FILM, 2W 6.8 OHM J

R328 24366471 CARBON FILM, 1/6W 470 OHM J

R329 24366153 CARBON FILM, 1/6W 15K OHM J

R330 24366113 CARBON FILM, 1/6W 11K OHM J

R331 24366334 CARBON FILM, 1/6W 330K OHM J

R333 24366163 CARBON FILM, 1/6W 16K OHM J

R336 24383151 OXIDE METAL FILM, 2W 150 OHM J

R341 24366103 CARBON FILM, 1/6W 10K OHM J

R343 24366223 CARBON FILM, 1/6W 22K OHM J

R344 24383121 OXIDE METAL FILM, 1/2W 120 OHM J

R352 24366153 CARBON FILM, 1/6W 15K OHM J

R360 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

R360 24383181 OXIDE METAL FILM, 2W 180 OHM J

R361 24366433 CARBON FILM, 1/6W 43K OHM J

R362 24366103 CARBON FILM, 1/6W 10K OHM J

R363 24366103 CARBON FILM, 1/6W 10K OHM J

R364 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

R365 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

R366 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

R370 24322129 OXIDE METAL FILM, 1W 1.2 OHM J

R371 24366562 CARBON FILM, 1/6W 5.6K OHM J

R372 24366332 CARBON FILM, 1/6W 3.3K OHM J

R373 24366182 CARBON FILM, 1/6W 1.8K OHM J

R374 24366473 CARBON FILM, 1/6W 47K OHM J

R385 24366102 CARBON FILM, 1/6W 1K OHM J

R386 24366103 CARBON FILM, 1/6W 10K OHM J

R399 24366684 CARBON FILM, 1/6W 680K OHM J

R400 24946561 CARBON COMPOSITION, 1/2W 560 OHM K

R405 24553682 OXIDE METAL FILM, 1W 6.8K OHM J

R411 24366180 CARBON FILM, 1/6W 18 OHM J

R412 24323208 OXIDE METAL FILM, 2W 0.2 OHM J

R414 24366101 CARBON FILM, 1/6W 100 OHM J

R415 24366752 CARBON FILM, 1/6W 7.5K OHM J

R415 24554271 OXIDE METAL FILM, 2W 270 OHM J

R416 24366103 CARBON FILM, 1/6W 10K OHM J

R416 24381563 OXIDE METAL FILM, 1/2W 56K OHM J

R417 24510101 CERAMIC COVERED, 5W 100 OHM J

R424 24366751 CARBON FILM, 1/6W 750 OHM J

R425 24552182 OXIDE METAL FILM, 1/2W 1.8K OHM J

R426 24003898 METAL FILM, 1/4W 3.3K OHM J

R427 24366183 CARBON FILM, 1/6W 18K OHM J

R428 24366561 CARBON FILM, 1/6W 560 OHM J

R429 24321919 OXIDE METAL FILM, 1/2W 9.1 OHM J

R431 24366103 CARBON FILM, 1/6W 10K OHM J

R432 24366473 CARBON FILM, 1/6W 47K OHM J

R433 24366681 CARBON FILM, 1/6W 680 OHM J

R434 24366472 CARBON FILM, 1/6W 4.7K OHM J

R441 24383561 OXIDE METAL FILM, 2W 560 OHM J

R450 24321129 OXIDE METAL FILM, 1/2W 1.2 OHM J

R460 24552182 OXIDE METAL FILM, 1/2W 1.8K OHM J

R461 24381123 OXIDE METAL FILM, 1/2W 12K OHM J

R463 24323229 OXIDE METAL FILM, 2W 2.2 OHM J

R464 24366223 CARBON FILM, 1/6W 22K OHM J

R465 24366333 CARBON FILM, 1/6W 33K OHM J

R466 24366332 CARBON FILM, 1/6W 3.3K OHM J

R469 24531150 FUSIBLE, 1/2W 15 OHM J

R470 24338568 OXIDE METAL FILM, 1W 0.56 OHM J

R471 24531271 FUSIBLE, 1/2W 270 OHM J

R472 24366101 CARBON FILM, 1/6W 100 OHM J

R473 24366103 CARBON FILM, 1/6W 10K OHM J

R473 24366183 CARBON FILM, 1/6W 18K OHM J

R474 24366473 CARBON FILM, 1/6W 47K OHM J

DescriptionDescription