Page 1

SERVICE MANUAL

PLAIN PAPER COPIER

Click the Page Only button to close the overview area of the window.

Click the Bookmarks and Page button to open the Contents and

2060/2860/70

AUTOMATIC DUPLEXING UNIT

MD-5002

display bookmarks created for the document. Click a bookmark’s name

to go to the Page marked by that bookmark.

Click the Thumbnails and Page button to open the overview area and

display thumbnail images of each document page. Click a thumbnail to

go to the page marked by that thumbnail.

Copyright TOSHIBA CORPORATION 1995

ALL RIGHTS RESERVED

Page 2

GENERAL PRECAUTIONS REGARDING THE INSTALLATION

AND SERVICE FOR THE COPIER 2060, 2860/70 AND THE

AUTOMATIC DUPLEXING UNIT MD-5002

1. Transportation/Installation

• When transporting/installing the copier, use two persons and be sure to use the positions as indicated below.

The copier is fairly heavy and weighs approximately 73 kg (161 lb), therefore pay full attention

when handling it. (2870: 84 kg)

4 portions

2. Installation

• Be sure to use a dedicated outlet with AC 115V/15A (220V, 240V/10A) or more for its power

source.

• The copier must be grounded for safety.

Never ground it to a gas pipe or a water pipe.

• Select a suitable place for installation.

Avoid excessive heat, high humidity, dust, vibration and direct sunlight.

• Also provide proper ventilation as the copier emits a slight amount of ozone.

• To insure adequate working space for the copying oper ation, keep a minim um clearance of 80 cm

(32”) on the left, 80 cm (32”) on the right and 10 cm (4”) in the rear.

3. Service of Machines

• Basically, be sure to turn the main switch off and unplug the power cord during service.

• Be sure not to touch high-temperature sections such as the exposure lamp, the fuser unit, the

damp heater and their periphery.

• Be sure not to touch high-voltage sections such as the chargers and the high-voltage tr ansformer .

• Be sure not to touch rotating/operating sections such as gears, belts, pulleys, etc.

• When servicing the machines with the main switch turned on, be sure not to touch live sections

such as the lamp terminal, etc.

• Use suitable measuring instruments and tools.

Page 3

4. Main Service Parts for Safety

• The breaker , door switch, fuse, thermostat, thermofuse, thermistor, etc. are particularly important

for safety. Be sure to handle/install them properly.

5. Notice Labels

• Be sure to check the rating plate and the cautionary labels such as “Unplug the power cord during

service”, “Hot area” etc. to see if there is any dirt on their surface or if they are properly stuck to the

copier during servicing.

6. Disposition of Consumable Parts/Packing Materials

• Regarding the recovery and disposal of the copier, supplies , consumable parts and packing materials, it is recommended to follow the relevant local regulations or rules.

7. When parts are disassembled, reassembly is basically the reverse of disassembly unless

otherwise noted in this manual or other related documents. Be careful not to reassemble

small parts such as screws, washers, pins, E-rings, toothed washers in the wrong places.

8. Basically, the machine should not be operated with any parts removed or disassembled.

9. Precautions Against Static Electricity

• The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband,

because the ICs on it may become damaged due to static electricity.

Page 4

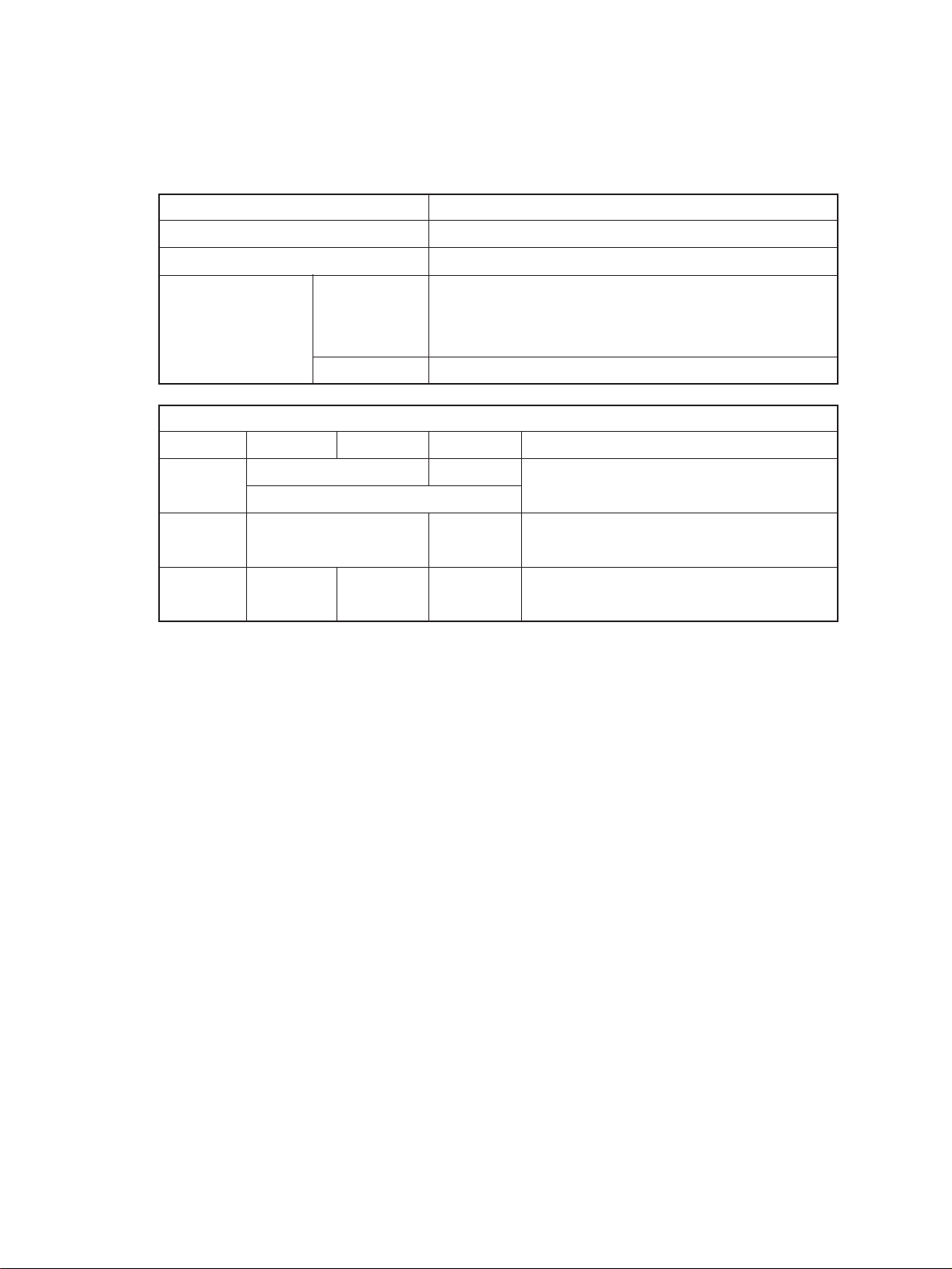

1. SPECIFICATIONS • ACCESSORIES • OPTIONS • SUPPLIES

1.1 Specifications

Copy process Indirect electrophotographic process (dry)

Type Desk top (console when the pedestal is used)

Exposure Type Slit exposure with fixed table

Acceptable originals Kind Sheets, books, and 3-dimensional objects.

When the document feeder is used:

Sheet originals only (60 g/m2~90 g/m2) (16 lb.~24 lb.)

Maximum size A3 (Ledger)

Copy paper

Cassette Duplexing Manual Note

Size A3~A5-R A3~A6-R Adjustable to

(Ledger~Statement-R) Unfixed, Arbitary sizes

Thickness 64~80 64~130 Unit: g/m

(Weight) (17~22) (17~34) (Unit: lb.)

2

Special _ _ OHP film

paper etc.

Dec. 1996 © TOSHIBA 1 - 1 2060, 2860/70 SPECIFICATIONS

Page 5

Copy speed

System copy speed

Cassette/manual LCF

Paper size 2060 2860 2060 2860

A4, B5, A5-R 20 28 20 28

LT, ST-R

A4-R, B5-R 20 26 — —

LT-R

B4, FOLIO 20 22 — —

LG, Computer

A3 19 19 — —

LD

Reduction/ 15 15 15 15

Enlargement

Manual feeding represents the value when the size is set.

CPM

(BLI format)

Mode CPM

Original→Copy Number of copies 2060 2860

1 → 1 1 set 19 24

3 set 20 27

5 set 20 28

1 → 2 1 set 10 10

3 set 15 18

5 set 17 21

2 → 2 1 set 8 8

3 set 14 16

5 set 16 19

2 → 1 1 set 16 16

3 set 19 23

5 set 19 25

*Ten originals (A4) are set in the ADF. This includes the first

copy time.

First copy Approx. 4.0 sec. (Actual-size A4 or Letter from upper cassette)

Warm-up time Approx. 80 sec.

Multiple copying 1~999, keyboard entry

Reproduction ratio

Actual ratio 100% or 101% (Setting mode)

Zoom ratios 50~200% (Multiple reduction and enlargement in 1% steps)

2060, 2860/70 SPECIFICATIONS 1 - 2 Dec. 1996 © TOSHIBA

Page 6

Paper supply Cassette or sheet-bypass feeding

Cassette: 600 sheets

Sheet-bypass feeding: 50 sheets

Toner supply Automatic density detection and replenishment

Toner cartridge replacement

Exposure Automatic control and manually selectable (9 steps)

Weight Copier: 73 kg (with 2 cassettes and the platen cover),

ADU: 10 kg

Power source 115 V ~ 60 Hz, 12A For the U.S.A. and Canada

220 V ~ 50/60 Hz, 8A

240 V ~ 50 Hz, 8A

Power consumption 1.5 kW (115 V), 1.7 kW (220 V/240 V)

Counter 6-digit total counter

Machine size

598mm

640mm

For Europe

123

540mm

Dec. 1996 © TOSHIBA 1 - 3 2060, 2860/70 SPECIFICATIONS

Page 7

1.2 Accessories

Copy receiving tray : 1 pc.

Operator’s manual : 1 pc.

Set-up report : 1 pc.

Drum : 1 pc.

Developer : 1 bottle

Toner : 1 pc.

*Accessories vary according to the destination.

1.3 Options

Automatic duplexing unit: ADU MD-5002

Automatic document feeder: ADF MR-3006 (RADF), MR-2008 (ADF)

Paper feed pedestal: PFP KD-1003 (1 cassette), KD-2009 (2 cassettes)

Paper feed unit MY-1006

Large capacity feeder: LCF MP-1501

Sorter MG-1003A (10 bins)

Key copy counter MU-8/MU-10 (6 digit)

*Options vary according to the destination.

1.4 Supplies

Drum OD-2060

Developer ZD-2060

Toner ZT-2060

MG-1004 (10 bins staple)

MG-2009 (20 bins)

MG-2010 (20 bins staple)

2060, 2860/70 SPECIFICATIONS 1 - 4 Dec. 1996 © TOSHIBA

Page 8

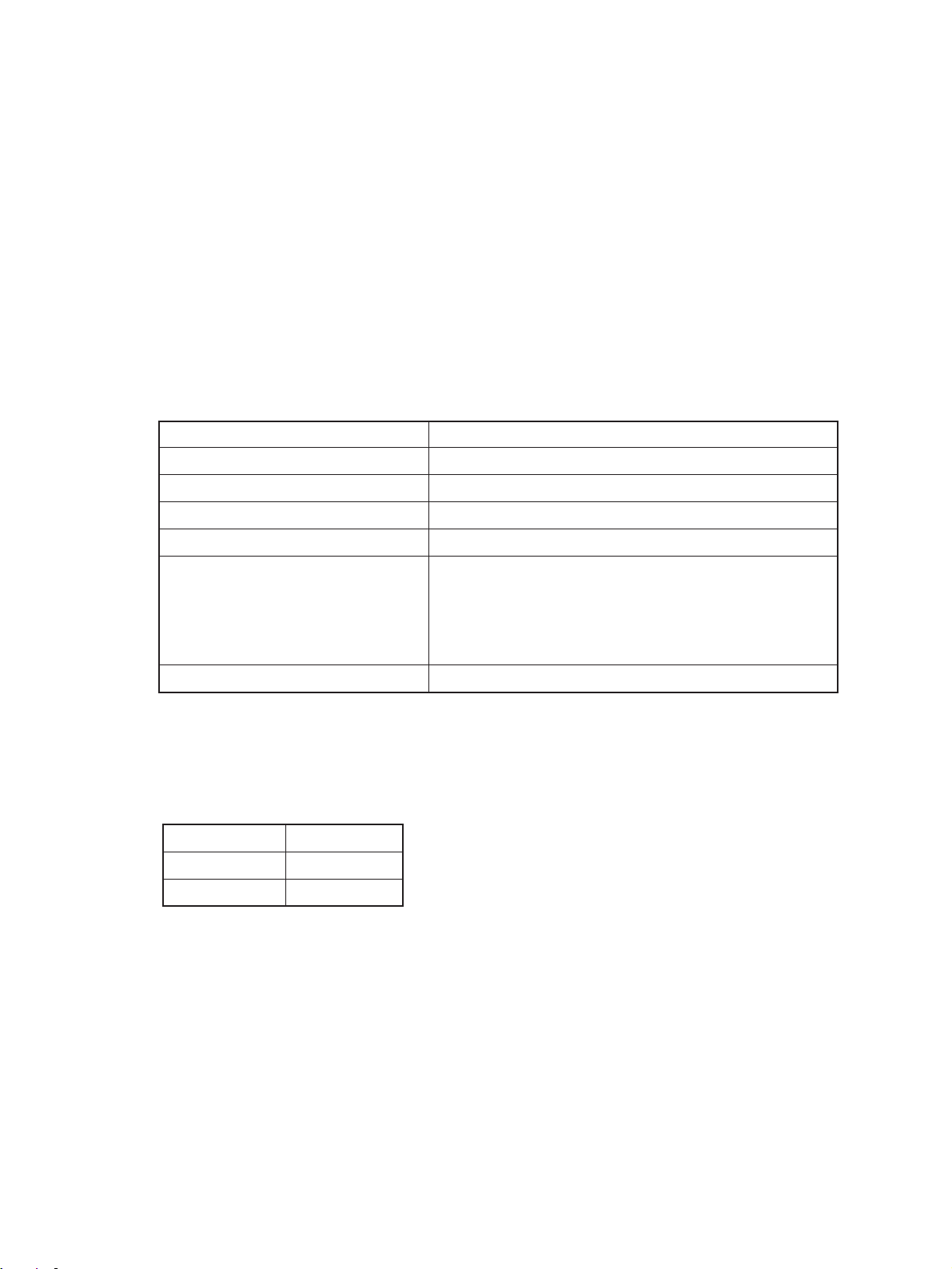

2. OUTLINE OF THE MACHINE

2.1 Sectional Views and Electrical Parts Location Diagram

2.1.1 Sectional view

[A] Front view

6

BT

7

8

2

AQ

5

FR

FR

1

FQ

FK

ES

ES

4

EP ER

FT

3

EQ

EO

ENEM

EL

EK

GK

GT

CT

AO

AS

AP AN

AR BK AL

BL

BN

BM

BR

BO

BP

BQ

FS

BS

CL

CK

ET

DS

CN

DR

CO

CM

DP

AM

AT

AK

DO

CS

DT

CR

FL

DN

9

CP

FM

DQ

DK

DL

CQ

FO

DMFN

FP

(This diagram includes an installed ADU. Refer to Chapter 13 concerning the ADU.)

Dec. 1996 © TOSHIBA 2 - 1 2060, 2860/70 GENERAL

Page 9

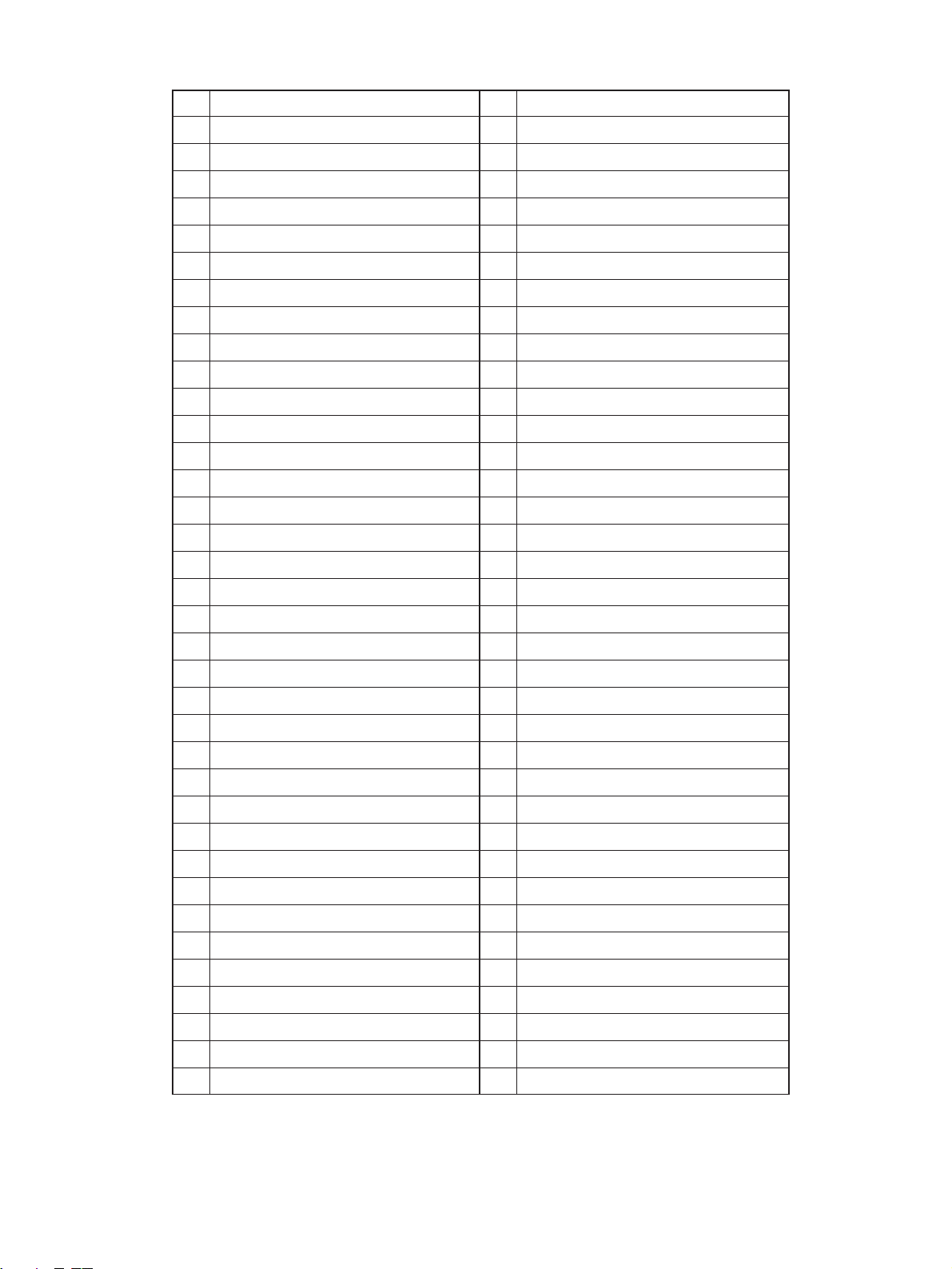

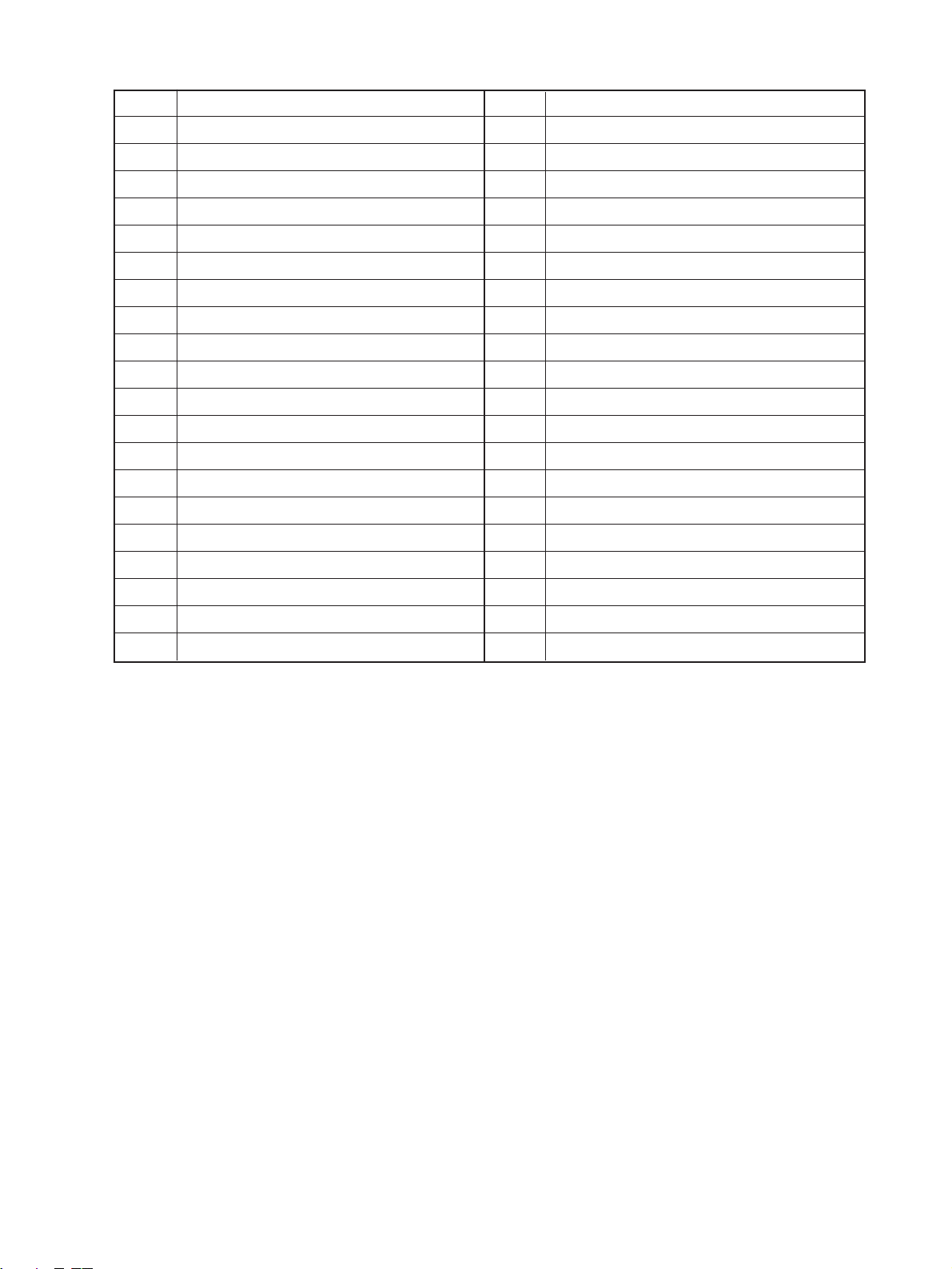

No. Name

No. Name

1 Carriage 1

2 Mirror 1

3 Reflector

4 Light distribution adjustment plates

5 Exposure lamp

6 Carriage 2

7 Mirror 2

8 Mirror 3

9 Mirror unit

AT Mirror 4

AK Mirror 5

AL Mirror 6

AM Slit glass

AN Auto exposure sensor

AO Lens

AP Original glass

AQ Ozone filter

AR Main charger

CQ Cassette

CR Manual feed separation pad

CS Manual feed roller

DT Manual pickup roller

DK Cassette separation roller

DL Cassette feed roller

DM Cassette pickup roller

DN Upper transport roller

DO Manual feed switch (S6)

DP Paper guide

DQ Lower transport roller

DR Aligning switch (S8)

DS Aligning roller (U)

ET Aligning roller (L)

EK Thermistor-1 (THMS1)

EL Thermostat (THERMO)

EM Heater lamp

EN Heat roller (upper side)

AS Discharge lamp

BT Receiving tray

BK LED eraser array

BL Main blade

BM Recovery blade

BN Toner recovery auger

BO Separation claw (for drum)

BP Transfer charger

BQ Separation charger

BR Drum

BS Bias guide

CT Transport belt

CK Magnetic roller

CL Leveller (doctor)

CM Auto-toner sensor

CN Mixer 1

CO Mixer 2

CP Sheet bypass guide

EO Pressure roller (lower side)

EP Separation claw (for heat roller)

EQ Felt roller

ER Heat roller cleaning blade

ES Fuser exit roller

FT Scraper

FK Fuser cover

FL Paper stop switch-1 (S7)

FM Paper stop switch-2 (S16)

FN Paper-empty switch-2 (S14)

FO Cassette tray

FP Cassette size switch-2 (S15)

FQ Exit/ADU selection gate

FR Exit roller

FS ADU

GT Exit fan (M7)

GK Bottom fan (M8)

2060, 2860/70 GENERAL 2 - 2 Dec. 1996 © TOSHIBA

Page 10

[B] Rear side view

HP HO IO IP

GQ

HLGRHKHTHRITIK

HS

GS

IT

IM

IT

IN

HN

HQ

HM

CT

EN

GP

FRES

IL

IN

Dec. 1996 © TOSHIBA 2 - 3 2060, 2860/70 GENERAL

Page 11

No. Name

GP Scanning motor (M2)

GQ Carriage drive wire

GR Drum gear

GS Aligning clutch (CLT2)

HT Drum driving gear

HK Drum belt

HL Belt for dev-unit, ALGN-roller & paper feeding drive

HM Belt for fuser drive

HN Main motor (M1)

HO Lens motor (M3)

HP Mirror motor (M4)

HQ Thermistor-2 (THMS2)

HR Dev-unit drive gear

HS Aligning roller

IT Paper feed belt

IK Manual feed clutch (CLT4)

IL Transport roller clutch (CLT1)

IM Transport roller drive belt

IN Cassette feed clutch (CLT3, 5)

IO Optical fan (M6,12)

IP Document motor (M11)

2060, 2860/70 GENERAL 2 - 4 Dec. 1996 © TOSHIBA

Page 12

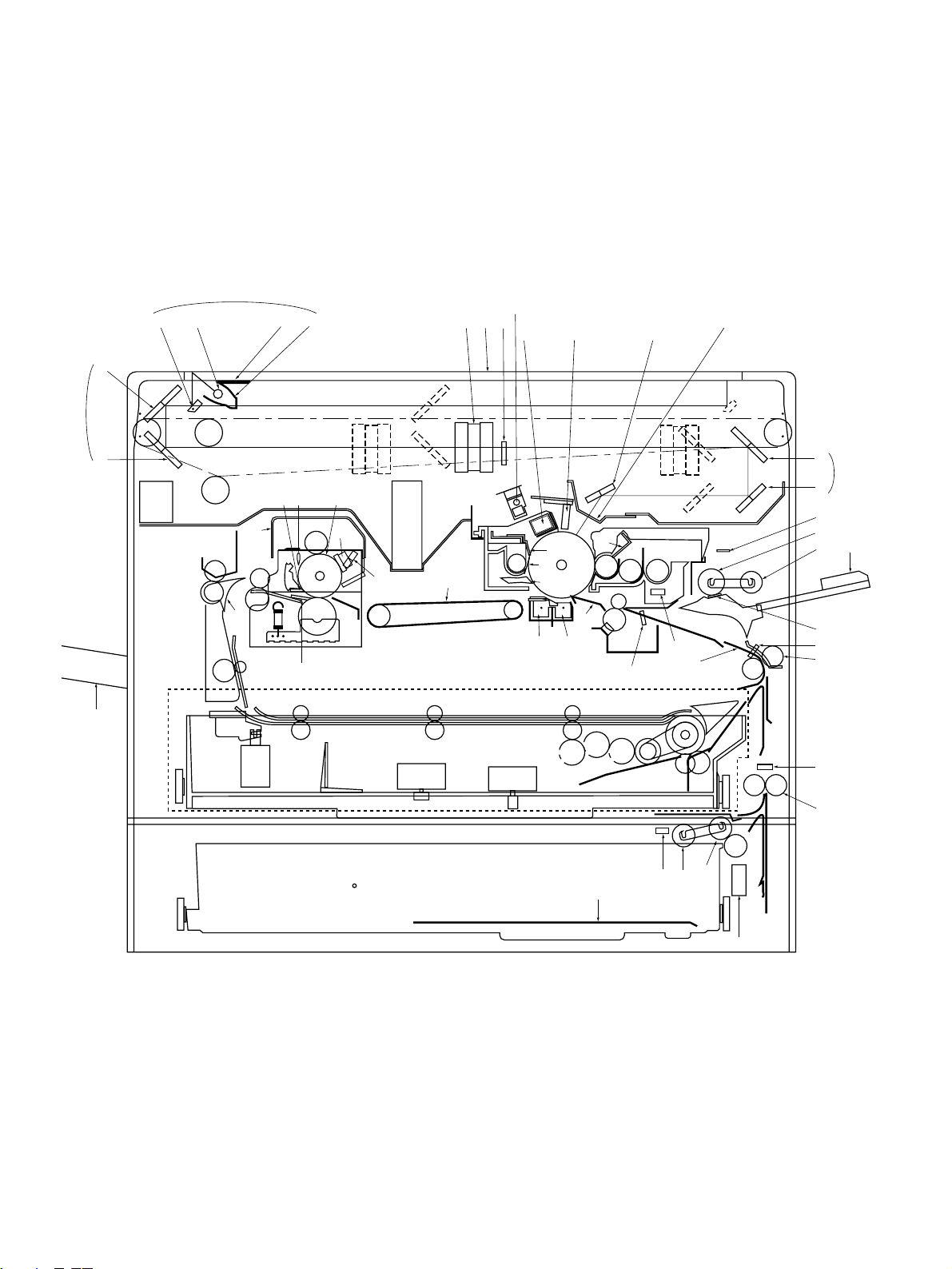

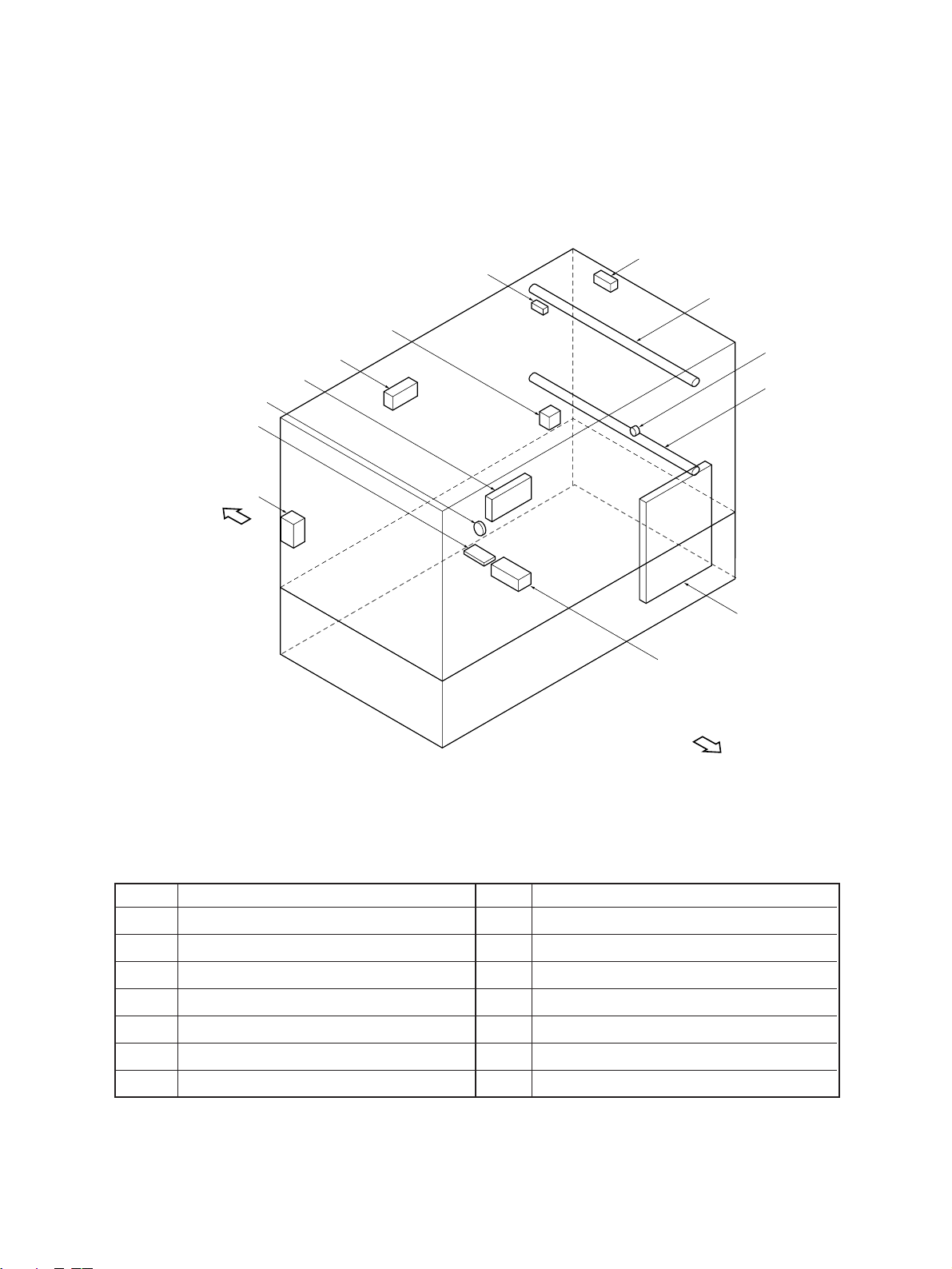

2.1.2 Electrical parts layout

[A] DC electrical parts (except motors)

[Front side]

1

BT

6

3

2

7

BO

8

AK

AL

BP

BN

AQ

AT

AS

AP

BK

CM

AR

CS

CP

CO

CT

DT

CK

CN

4

BQ

BL

BM

AN

AO

CQ

9

CR

AM

BS

5

CL

[Rear side]

Dec. 1996 © TOSHIBA 2 - 5 2060, 2860/70 GENERAL

Page 13

No. Name

No. Name

1 Control panel key PC board (PWA-KEY)

2 Display PC board (PWA-DSP)

3 Liquid crystal module (LCD)

4 Total counter (T-CTR)

5 Logic PC board (PWA-LGC)

6 Auto paper sensor-2 (APS-R)

7 Auto paper sensor-3 (APS-C)

8 Auto paper sensor-4 (APS-F)

9 Toner-full switch (T-FUL-SW) (S13)

*AT Size switch 1 (SIZE1-SW) (S5)

AK Discharge lamp PC board (PWA-ERS)

AL LED eraser array PC board (K-DCH)

AM High-voltage power supply (PS-HVT)

AN Home switch (HOME-SW) (S10)

AO Platen switch (PTN-SW) (S27)

AP Manual feed switch (M-FED-SW) (S6)

AQ Aligning switch (PSTPO-SW) (S8)

AR Paper stop switch 1 (PSTP1-SW) (S7)

*BK Paper-empty switch-1 (EMP1-SW) (S3)

BL Exit switch (EXIT-SW) (S9)

BM Heat-roller thermistor 1 (THMS1-HTR)

BN Toner sensor (TNR-ATC)

BO Lens switch (LNS-SW) (S11)

BP Mirror switch (MRR-SW) (S12)

BQ Automatic exposure PC board (PWA-AES)

BS Aligning-roller clutch (RGT0-CLT) (CLT2)

CT Transport-roller clutch (RGT1-CLT) (CLT1)

CK Manual-feed roller clutch (MFED-CLT) (CLT4)

*CL Feed-roller clutch 1 (FED1-CLT) (CLT3)

CM Size switch 2 (SIZE2-SW) (S15)

CN Feed-roller clutch 2 (FED2-CLT) (CLT5)

CO Paper-empty switch 2 (EMP2-SW) (S14)

CP Paper stop switch 2 (PSTP2-SW) (S16)

CQ Heat-roller thermistor-2 (THMS2-HTR)

CR Drum thermistor (DRM-THMS)

*CS Tray-up switch (T-UP1-SW) (S28)

AS Side door switch (U-COV-SW) (S4)

BT Auto paper sensor-1 (APS-3B)

*: Option

DT Tray-up switch (T-UP2-SW) (S29)

2060, 2860/70 GENERAL 2 - 6 Dec. 1996 © TOSHIBA

Page 14

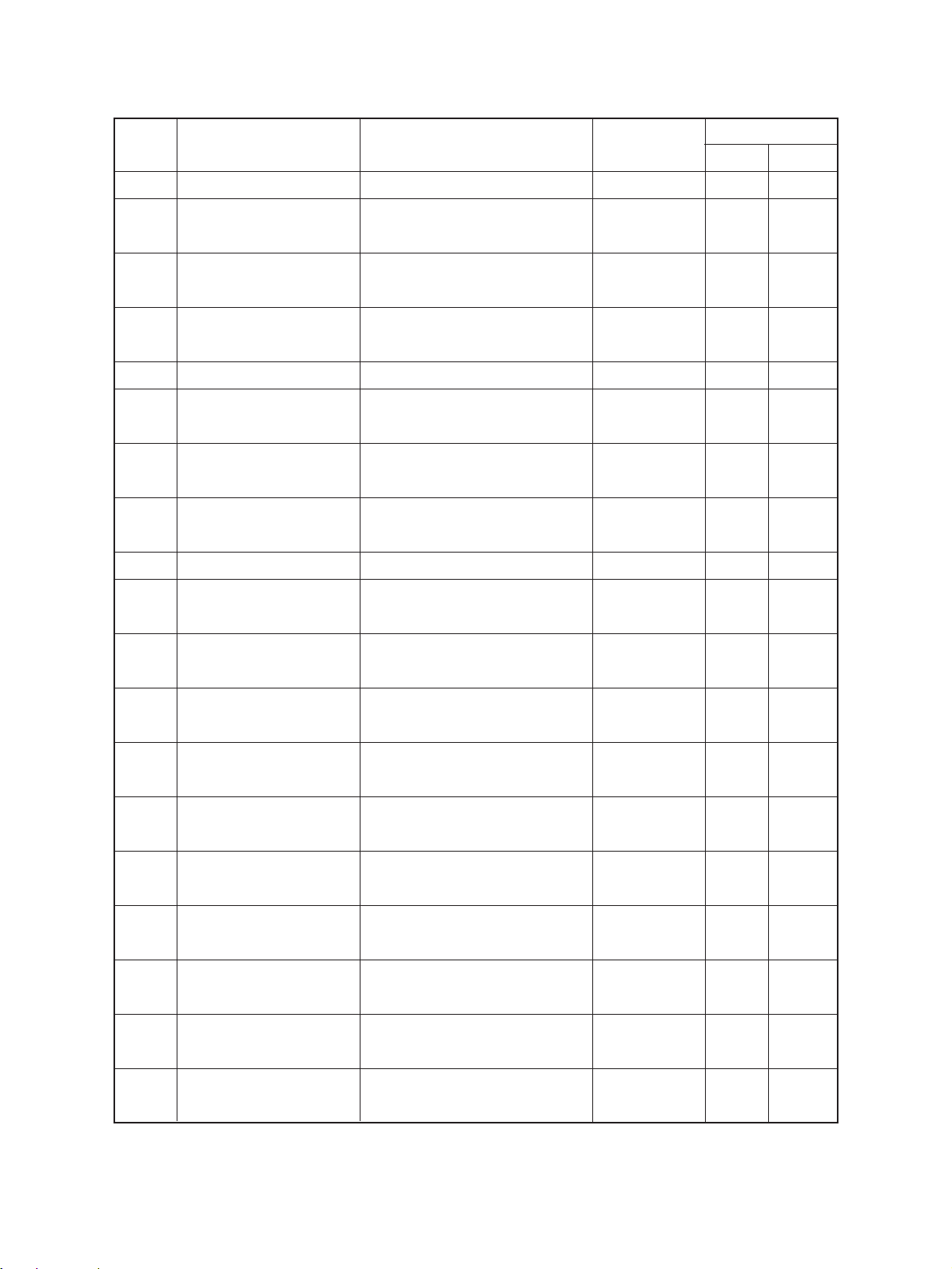

[B] DC electrical parts (motors)

EK

DO

[Front side]

DS

DP

DL

ET

EL

No. Name

DK Main motor (MAIN-MOT) (M1)

DL Scanning motor (SCN-MOT) (M2)

DM Lens motor (LNS-MOT) (M3)

DN Mirror motor (MRR-MOT) (M4)

DO Toner motor (TNR-MOT) (M9)

DP Document motor (DCM-MOT) (M11)

DK

DM

DN

DQ

DR

[Rear side]

No. Name

*DQ Tray-up motor-1 (T-UP1-MOT) (M13)

DR Tray-up motor-2 (T-UP2-MOT) (M14)

DS Optical fan-F (OPT-FAN-F) (M12)

ET Optical fan-R (OPT-FAN-R) (M6)

EK Exit fan (EXIT-FAN) (M7)

EL Bottom fan (BTM-FAN) (M8)

*: Option

Dec. 1996 © TOSHIBA 2 - 7 2060, 2860/70 GENERAL

Page 15

[C] AC electrical parts

[Front side]

FM

EN

FK

EP

FT

FN

EO

FO

FL

ES

EQ

EM

ER

[Rear side]

No. Name

EM SW power supply (PS-ACC)

EN Door switch (DOOR-SW) (S2)

EO Main switch (MAIN-SW) (S1)

EP Lamp regulator PC board (PWA-LRG)

EQ Heater lamp (HTR-LAMP)

ER Damp heater L (D-HTR-L) (Option)

No. Name

FT Thermostat (Option)

FK Damp heater U1 (D-HTR-U1) (Option)

FL Exposure lamp (EXPO-LAMP)

FM Thermofuse (FU-EXPO)

FN Fuse PC board (PWA-FUS) (Option)

FO Damp heater U2 (D-HTR-U2) (Option)

ES Thermostat (K-THERMO)

2060, 2860/70 GENERAL 2 - 8 Dec. 1996 © TOSHIBA

Page 16

2.2 Symbol and Function of Electrical Parts

(1) Motors

Symbol

M1 MAIN-MOT (Main motor) Drives the drum, developer, IC motor 10 31

M2 SCN-MOT (Scanning motor) Scans the optical system Pulse motor 5 23

M3 LNS-MOT (Lens motor) Drives the lens unit Pulse motor 11 23

M4 MRR-MOT (Mirror motor) Drives the mirror unit Pulse motor 11 23

M6 OPT-FAN-R (Optics fan-R) Cools the optical system IC motor: Z80 5 8

M7 EXIT-FAN (Exit-fan) Cools the drum and cleaner IC motor: Z80 4 14

M8 BTM-FAN (Bottom fan) Prevents the paper from floating IC motor: Z80 4 14

M9 TNR-MOT (Toner motor) Replenishes the toner Brush motor 23 30

M11 DCM-MOT (Document motor) Drives copy-area indicators Pulse motor 9 2

M12 OPT-FAN-F (Optical fan-F) Cools the optical system IC motor: Z80 4 14

M13 T-UP1-MOT (Tray-up motor-1) Drives the upper cassette tray to Brush motor 12 36

Code name Remarks

heat roller and transport belt

up through suction

lift up/down

Function

Parts list

Page Item

M14 T-UP2-MOT (Tray-up motor-2) Drives the lower cassette tray to Brush motor 12 36

lift up/down

(2) Electromagnetic spring clutches

Parts list

Symbol

CLT1 RGT1-CLT Transmits transport-roller drive. 13 40

(Transport-roller clutch)

CLT2 RGT0-CLT Transmits aligning-roller drive. 15 16

(Aligning-roller clutch)

CLT3 FED1-CLT Transmits feed-roller clutch 12 24

(Feed-roller clutch-1) drive. (Upper cassette)

CLT4 MFED-CLT Transmits manual-feed roller 14 17

(Manual-feed roller clutch) clutch drive.

CLT5 FED2-CLT Transmits feed-roller clutch 12 24

(Feed-roller clutch-2) drive. (Lower cassette)

Code name Function Remarks

Page Item

(3) Counters

Parts list

Symbol Code name

T T-CTR (Total counter) Total counter 6-digit 3 23

K K-CTR (Key-copy counter) Individual counter 6-digit (option) 101 5

Dec. 1996 © TOSHIBA 2 - 9 2060, 2860/70 GENERAL

Function

Remarks

Page Item

Page 17

(4) Switches

Parts list

Symbol

S1 MAIN-SW (Main switch) Power supply Tumbler type 6 3

S2 DOOR-SW (Door switch) For safety, cancels abnormal Push switch 6 4

S3 EMP1-SW Detects lack of paper in the upper Photointerruptor 12 32

S4 U-COV-SW For safety, detects open/closed Push switch 2 27

Code name

condition

(Paper-empty switch-1) cassette

Function

Remarks

Page Item

(Side door switch)

S5 SIZE1-SW (Size switch-1) Detects upper cassette size Push switch 13 50

S6 M-FED-SW Detects manual feeding Photointerruptor 14 3

(Manual-feed switch)

S7 PSTP1-SW Detects paper in front of the Photointerruptor 13 8

(Paper stop switch-1) upper transport roller

S8 PSTP0-SW Detects paper in front of the Photointerruptor 15 20

(Aligning switch) aligning roller

S9 EXIT-SW (Exit switch) Detects exiting paper Photointerruptor 28 8

S10 HOME-SW (Home switch) Detects home position of the Photointerruptor 11 8

S11 LNS-SW (Lens switch) Detects home position of the lens Photointerruptor 11 8

S12 MRR-SW (Mirror switch) Detects home position of the mirror Photointerruptor 11 8

S13 T-FUL-SW Detects when the used toner bag Push switch 10 25

(Toner-full switch) is full

S14 EMP2-SW Detects lack of paper in the lower Photointerruptor 12 32

condition of paper jam release cover

optical system

unit

unit

(Paper-empty switch-2) cassette

S15 SIZE2-SW Detects lower cassette size Push switch 13 50

(Size switch-2)

S16 PSTP2-SW Detects paper in front of the lower Photointerruptor 2 26

(Paper stop switch-2) transport roller

S27 PTN-SW Detects open/closed condition of Photointerruptor 5 38

(Platen switch) the platen cover

S28 T-UP1-SW Detects the position of the upper Photointerruptor 12 32

(Tray-up-1 switch) cassette tray

S29 T-UP2-SW Detects the position of the lower Photointerruptor 12 32

(Tray-up-2 switch) cassette tray

2060, 2860/70 GENERAL 2 - 10 Dec. 1996 © TOSHIBA

Page 18

(5) Heaters and lamps

Parts list

Symbol

EXP EXPO-LAMP Exposes the original Halogen lamp 18 13

HTR HTR-LAMP (Heater lamp) Fixing Halogen lamp 25 6

ERS ERS-LAMP Discharges the drum Fuse type 4 12

DCH DCH-LED To interrupt the charge LED 4 10

DHU1

Code name

(Exposure lamp) 300W

(Discharge lamp)

(LED eraser array)

D-HTR-U1 (Damp heater U1) Keeps optical system warm (option)

Function

Remarks

900W

(100V series)

1100W

(200V series)

Cement resistor 102 4

Page Item

DHU2

DHL D-HTR-L (Damp heater L)

D-HTR-U2 (Damp heater U2) Keeps optical system warm (option)

Keeps the drum and transfer/separation

charger case warm (option)

Cement resistor 102 4

Cement resistor 7 30

(6) PC boards

Symbol

LGC PWA-LGC (Logic PC board) Controls the entire copier 8 15

DSP PWA-DSP Controls condition displays 3 20

(Display PC board)

KEY PWA-KEY Controls operation keys 3 21

(Key PC board)

LRG PWA-LRG Controls exposure lamp 5 20

(Lamp regulator PC board)

DCH K-DCH Turns on and drives LED during 4 10

(LED eraser array PC board) reduction

ERS PWA-ERS Discharge lamp 4 12

Code name

Function

Remarks

Parts list

Page Item

(Discharge lamp PC board)

AES PWA-AES Reads dark/light of the original 17 37

(Automatic exposure PC board)

FUS PWA-FUS (Fuse PC board) Fuse for the damp heater circuit 7 31

Dec. 1996 © TOSHIBA 2 - 11 2060, 2860/70 GENERAL

Page 19

(7) Transformers

Parts list

Symbol

HVT PS-HVT (Charging transformer) Generates high voltage electricity

ACC PS-ACC Power supply for whole copier 8 7

(Power supply for all) power

Code name

for charging (negative voltage)

(Transfer/separation Generates high voltage electricity

transformer) for transfer/separation and

developing bias voltage

(Transfer bias Generates bias voltage to raise

transformer) transfer efficiency

Function

Remarks

Mono unit type 7 27

Page Item

(8) Others

Parts list

Symbol

ATS SNR-ATC Reads toner density with a magnetic 23 33

Code name

Function

Remarks

Page Item

(Auto-toner sensor) sensor

THMS1 THMS1-HTR Detects temperature of the heat roller 26 19

(Heat-roller thermistor-1)

THMS2 THMS2-HTR Detects the temperature of the heat roller 26 27

(Heat-roller thermistor-2) end

THERMO K-THERMO Prevents abnormal heating of heat roller 26 8

(Thermostat)

FU FU-EXPO (Thermofuse) Prevents abnormal heating of the 18 12

exposure lamp

2060, 2860/70 GENERAL 2 - 12 Dec. 1996 © TOSHIBA

Page 20

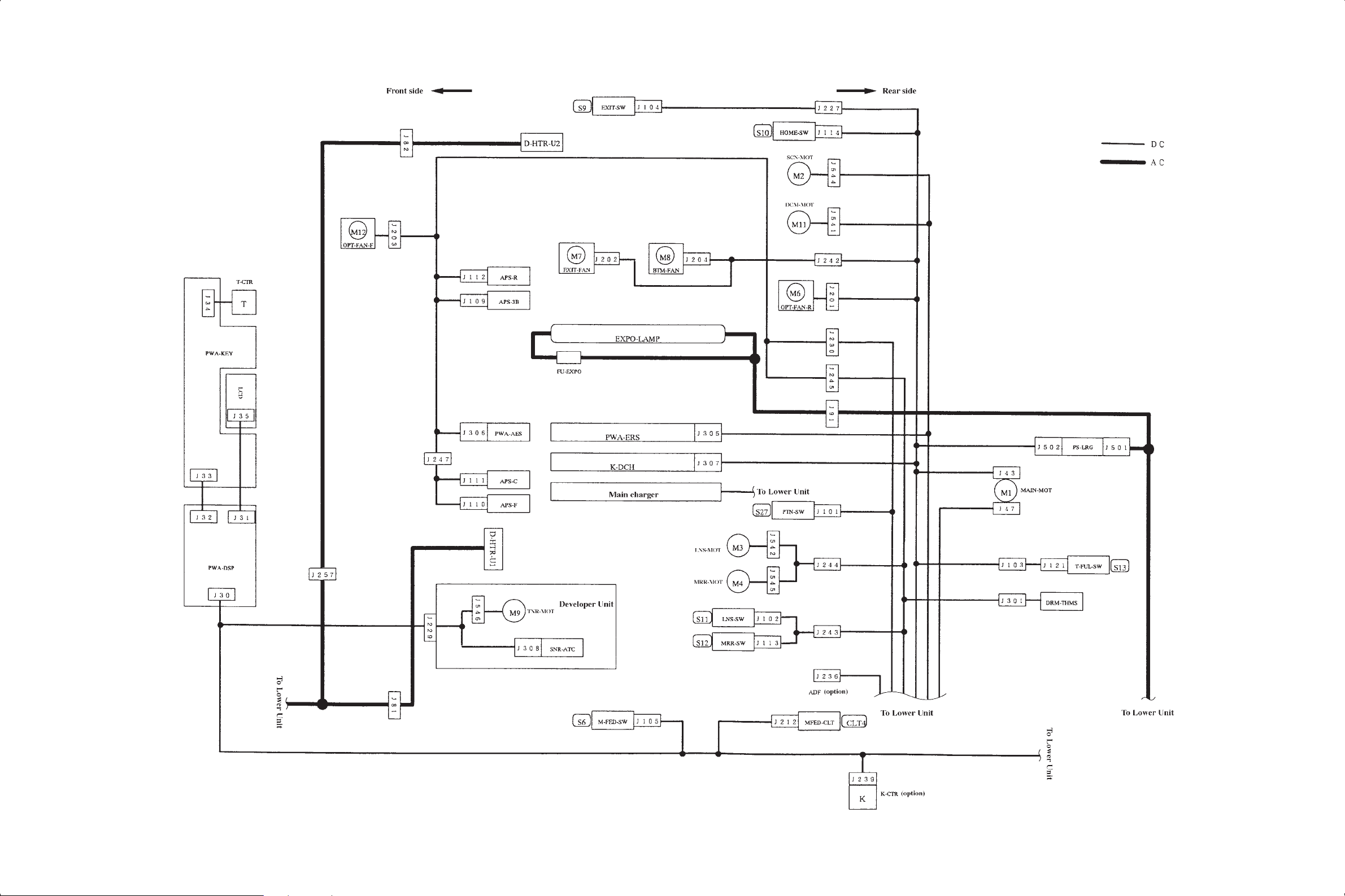

2.3 Wire Harness Location Diagram

[A] Location diagram for upper unit

Dec. 1996 © TOSHIBA 2 - 13 2060, 2860/70 GENERAL

Page 21

[B] Location diagram for lower unit

2060, 2860/70 GENERAL 2 - 14 Dec. 1996 © TOSHIBA

Page 22

Return

3560/70 S/M

Skip

2.4 Removal of Co vers and PC Boards

2.4.1 Removal of covers

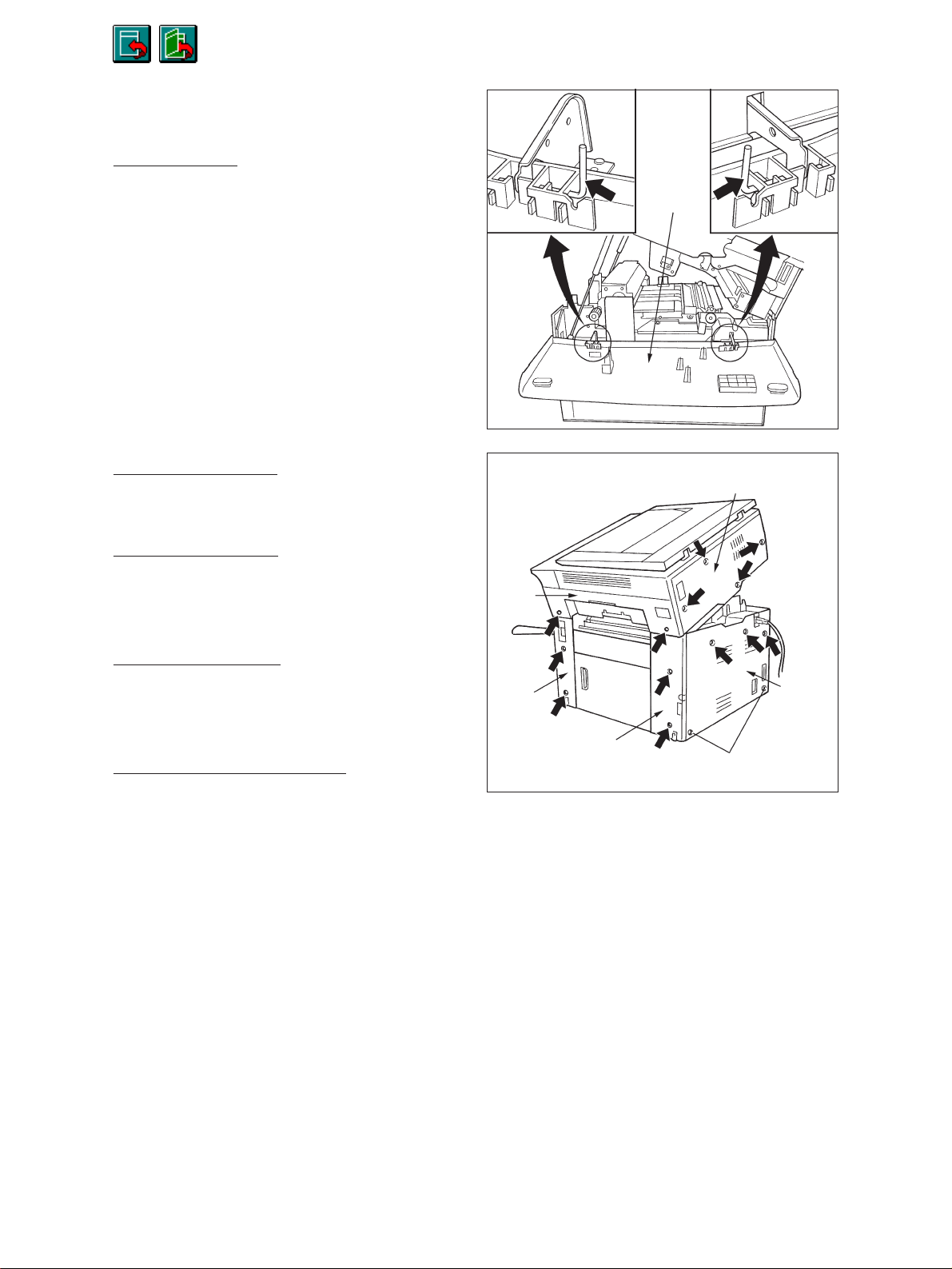

[A] Front cover

(1) Open the front cover.

(2) Remove the pins on the hinges at both ends

(1 each).

[B] Upper rear cover

(1) Remove the 4 screws.

[C] Lower rear cover

(1) Remove the upper 3 screws.

(2) Loosen the lower 2 screws.

Front cover

Upper rear cover

Upper

feed

cover

[D] Upper feed cover

(1) Open the front cover and the bypass tray and

then remove the 2 screws.

[E] Feed cover (left and right)

(1) Remove the paper feed cover.

(2) When removing the left feed cover, open the

front cover.

(3) Remove the screws (2 on each side).

Left

feed

cover

Right feed cover

Lower

rear

cover

Loosen

Dec. 1996 © TOSHIBA 2 - 15 2060, 2860/70 GENERAL

Page 23

Return

3560/70 S/M

Skip

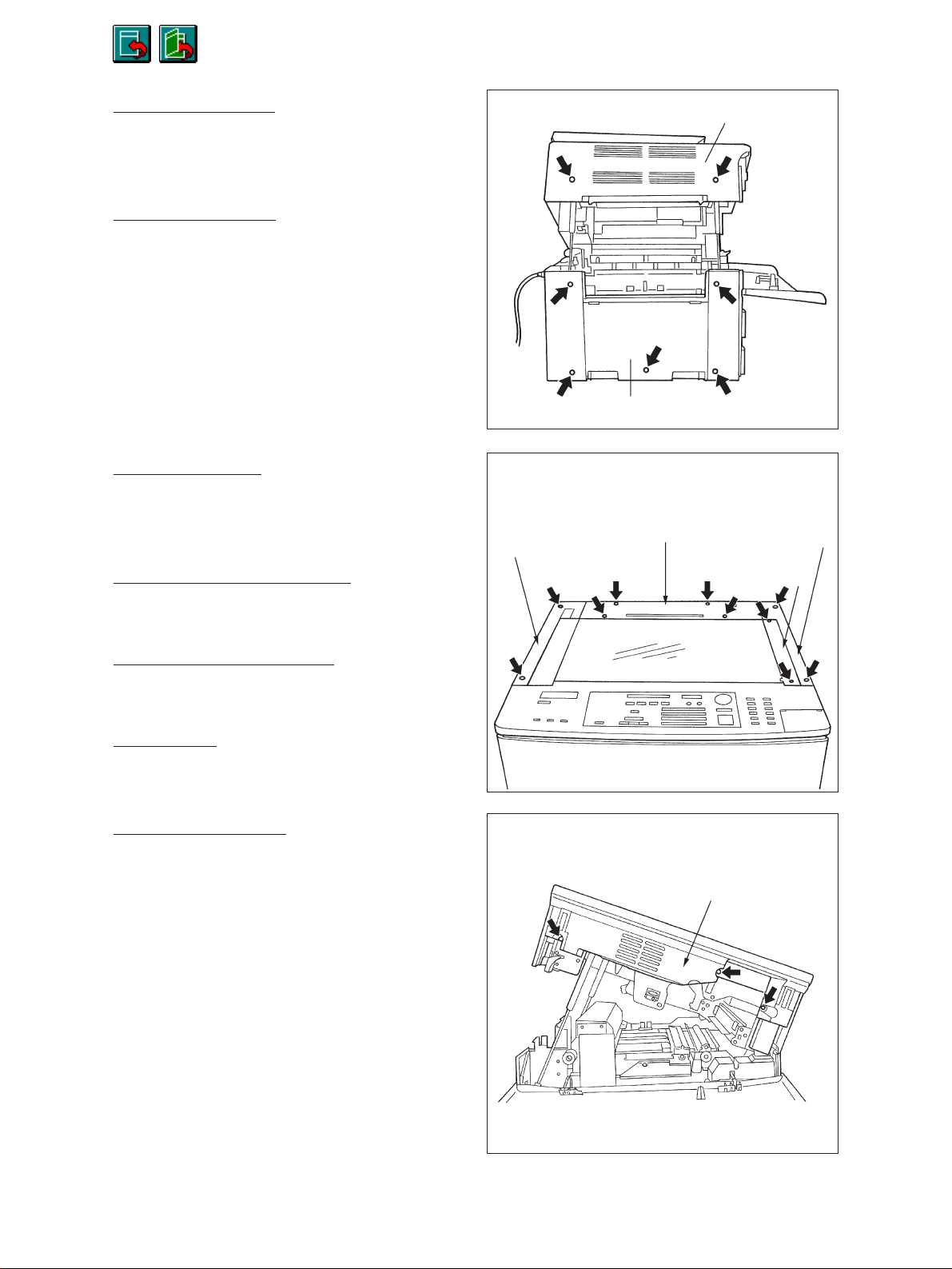

[F] Upper exit cover

(1) Remove the 2 screws.

(2) Open the front cover and remove the screw.

[G] Lower exit cover

(1) Lift the upper unit.

(2) Remove the 5 screws.

[H] Rear top cover

(1) Remove the original cover.

(2) Remove the 4 screws.

Left top cover

Upper exit cover

Lower exit cover

Rear top cover

Right top cover

[I] Right top cover (feed side)

(1) Remove the 2 screws.

[J] Left top cover (exit side)

(1) Remove the 2 screws.

[K] Glass fix

(1) Remove the 2 screws.

[L] Upper inner cover

(1) Remove the process unit.

(2) Remove the 3 screws.

Glass fix

Upper inner cover

2060, 2860/70 GENERAL 2 - 16 Dec. 1996 © TOSHIBA

Page 24

Return

3560/70 S/M

Skip

[M] Middle inner cover

(1) Remove the screw.

[N] Door switch cover

(1) Remove the 2 screws.

Middle inner cover

Door switch cover

[O] Lower inner cover

(1) Remove the toner box.

(2) Remove the middle inner cover.

Lower inner cover

(3) Remove the 1 screw.

Dec. 1996 © TOSHIBA 2 - 17 2060, 2860/70 GENERAL

Page 25

Return

3560/70 S/M

Skip

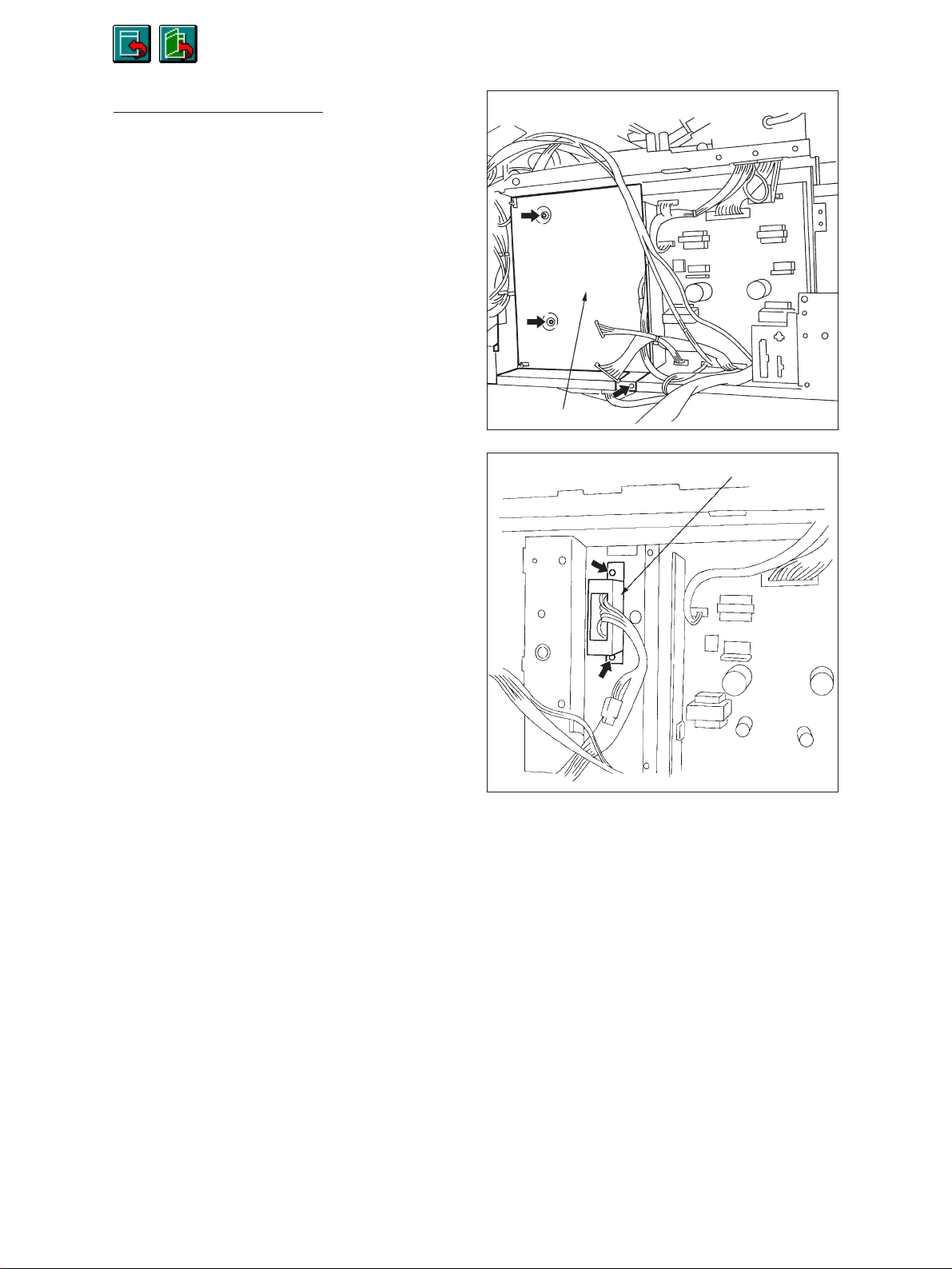

2.4.2 Removal of main PC boards

[A] Logic PC board (PWA-LGC)

(1) Remove the lower rear cover.

(2) Remove the 16 connectors (2860).

(15 connectors for 2060).

(3) Remove the lock supports (4 pcs.)

(4) Remove the logic PC board.

[B] Power supply PC board (PS-ACC)

(1) Remove the connector bracket (2 screws).

(2) Remove the 14 connectors.

(3) Remove the 4 screws.

(4) Remove the power supply PC board.

[C] Lamp regulator PC board (PWA-LRG)

(1) Remove the upper rear cover.

(2) Remove the 2 connectors.

Lock support

Lock support

PWA-LGC

PWA-LRG

Lock support

PS-ACC

Connector bracket

(3) Remove the lamp regulator PC board (4 lock

supports).

Connectors

2060, 2860/70 GENERAL 2 - 18 Dec. 1996 © TOSHIBA

Lock support

Page 26

Return

3560/70 S/M

Skip

[D] ADU drawer connector

(1) Remove the logic PC board.

(2) Remove the bracket for the logic PC board (3

screws).

Remove the connector J535 on the PS-ACC.

(3) Remove the bracket for the ADU drawer con-

nector (2 screws).

Bracket for PWA-LGC

ADU drawer connector bracket

Dec. 1996 © TOSHIBA 2 - 19 2060, 2860/70 GENERAL

Page 27

Return

Skip

3560/70 S/M

3. COPYING PROCESS

3.1 Copying Process

Original exposure

2

Halogen lamp

Paper exiting

300 W

7

Fixing

Heat roller

900 W (115V)

1030W (220/240V)

9

8

LED eraser array

63 LEDs

Charging

1

–635V ±5 V

Discharge lamp

1.8W x 9 lamps

Cleaning

Separation

AC 3.41 kV

1 kHz

Optical

section

_

_

+

+

+

_

_

+

+

Transfer

–DC 5.25 kV

5

6

Toner

Carrier

_

_

+

_

+

_

+

3

Black development

Magnetic roller

Bias –100 VDC

Sheet-bypass feeding

(50 sheets)

Cassette feeding (upper/

lower/PFP)(600 sheets)

LCF feeding

(1500 sheets)

4

Transfer bias

1 Charging :Negatively charges surface of

D

the photosensitive drum.

2 Exposure : Forms an electrical image on

D

the drum.

3 Development : toner adheres to surface of

D

photosensitive drum and forms

a visible image.

4 Transfer bias :Increases transfer efficiency.

D

5 Transfer :Transfers the visible image from

the drum onto the transfer

(copy) sheet.

–DC 990 V

6 Separation : Separates the transfer sheet,

along with the toner, from the

D

drum.

7 Fixing :Fixes the toner on the transfer

sheet by applying heat and

D

pressure.

8 Cleaning :Mechanically removes any re-

D

9

Discharge lamp

maining toner on the drum.

:Discharges any remaining

charge from the drum.

Dec. 1996 © TOSHIBA 3 - 1 2060, 2860/70 PROCESS

Page 28

Return

3560/70 S/M

Skip

3.2 Comparison with the 2050 of Copying Process Conditions

Process 2050 2060/2860

1. Drum OD-1710 (OPC ø60) OD-2060 (OPC ø60)

(1) Sensitivity Highly sensitized drum (1)

(2) Charger grid voltage DC –800V (2)–635 V DC

Scolotron system Scolotron system

Output adjustable by using the

ten keys

2. Main charger Variable output (fixed current) using

the digital keys

3. Exposure

(1) Light control Automatic exposure/manual (1)Automatic exposure and

slide volume setting manual 9-step setting

(2) Light source 300W halogen lamp stabilized with (2)

regulator (light intensity remains

constant even when voltage varies)

4. Development

(1) Magnetic roller One magnetic roller (with two shaft (1)

mixers)

(2) Auto-toner Magnetic bridge-circuit system (2)

(3) Toner replenishment Toner cartridge system (3)

(4) Toner-empty detection Intensity sensing system (4)

(5) Toner T-1710 (Black) (5)T-2060 (Black)

T-1710-R (Red)

T-1710-BL (Blue)

(6) Developing material D-1710 (Black) (6)D-2060 (Black)

D-1710-R (Red)

D-1710-BL (Blue)

(7) Developer bias –194V DC, volume adjustable (7)–100 V DC, adjustable using the

digital keys

5. Transfer bias –1.4KV DC –990 V DC

6. Transfer Adjustable output (fixed current) using

the digital keys

7. Separation Adjustable output (independently

adjustable using the digital keys)

2060, 2860/70 PROCESS 3 - 2 Dec. 1996 © TOSHIBA

Page 29

Return

Skip

3560/70 S/M

Process 2050 2060/2860

8. Discharge

(1) Discharging position Discharge by exposure after cleaning (1)

(2) Discharge lamp Discharge by tungsten lamp (2)

9. Cleaning

(1) System Blade system (1)

(2) Recovered toner Non-reusable (2)

10. Fixing

(1) System Long-life heat roller system (1)

• Fixing • Fixing roller: Teflon coated roller • Fixing roller:

Aluminum roller coated with

Teflon (ø40)

• Pressure • Pressure roller: PFA tube silicon • Pressure roller:

roller (ø28) Silicon rubber roller with

PFA tube. (ø35)

• Lamp rating Infrared heat Infrared heat

• 900W (100V series) • 900W (115V)

• 1100W (200V series) • 1030W (220/240V)

(2) Cleaning Cleaning with silicon impregnated (2)

roller

(3) Heater-temperature control ON/OFF control by thermistor (3)

11. Control Microcomputer

Dec. 1996 © TOSHIBA 3 - 3 2060, 2860/70 PROCESS

Page 30

Return

3560/70 S/M

Skip

4. COPIER OPERATION

4.1 Operation Outline

Copier operation Operation during warm up and standby

Automatic-feed copying using PRINT key

Copying operation Bypass-feed copying

Interrupt copying

4.2 Description of Operation

4.2.1 Operation up to standby state after power on

(1) Initial operation

• The main switch is turned ON.

• Copy quantity indicator “0” and “WAIT WARMING UP” are displayed.

• Initialization of the optical system

~ Carriages move to their home position and then stop.

~ Lens and mirror units move to their home position and then stop.

~ Indicators perform the initial operation and move to a position indicating the copy area.

• Initialization of the paper feed section

~ Each slot’s cassette trays move upward. If they were raised already, they are not moved.

(2) Pre-running

65 sec. have elapsed since the power was turned ON ~

Main motor rotates ~ Fuser unit drive section rotates: Pre-running

Pressure roller is warmed

After pre-running for 15 sec., the main motor stops

~ Fuser unit drive section stops

(3) When the heat roller temperature is sufficient for fixing, the heater lamp is turned off , and the copier

enters the standby mode.

4.2.2 Standby (ready)

• Bottom fan motor (M8) and exit fan motor (M7) are running at low speed.

• All keys on the control panel are operable.

When there is no key input for a set amount of time, the copy quantity “1” will be shown, the

reproduction ratio will indicate “actual size”, and the exposure will be set at automatic.

Dec. 1996 © TOSHIBA 4 - 1 2060, 2860/70 OPERATION

Page 31

Return

3560/70 S/M

Skip

4.2.3 Automatic feed copying using the PRINT key

(1) PRINT key is pressed

• Main, transfer, and separation chargers, transfer bias, discharge lamp and LED eraser array are

turned on.

• Optical fan motor (M6, M12), bottom fan motor (M8) and exit fan motor (M7) are running at high

speed.

• Main motor is turned on

~ Drum, developer unit, transport belt, heat roller, and exit roller are running.

(2) Cassette feeding

• Feed clutch (CLT3 or 5) is turned on

~ Pick-up roller, paper feed roller, and separation roller are running.

– Transpor t roller rotating

• Paper reaches the transport roller

~ Paper stop switch-2 (S14) is turned on. After a set amount of time , the feed clutch (CLT3 or 5) is

turned off.

* Paper reaches the aligning roller. Paper stop switch-1 (S7) is turned on.

~ Aligning operation

After a set amount of time, the feed roller stops rotating (CLT1).

(3) Carriage operation

• Exposure lamp is turned on.

Carriages -1 and -2 scan in a forward direction

~ Scanning motor (M15) is turned on. At this time , if the toner density of the de v eloper material is

lower than the set value, the copier enters the toner supply operation.

~ Toner motor (M9) is turned ON.

(4) A set time lag after the carriage operation;

aligning clutch (CLT2) is turned on:

~ paper is sent to the transfer unit.

The counter is increased by 1.

(5) Termination of carriage scanning.

• Scanning motor (M2) is turned off.

• Main charger and exposure lamp are turned off.

• Aligning clutch (CLT2) is turned off. (Timing of shutting off depends on paper size.)

(6) Exit operation

• Exit switch (S9) detects the passing of the paper trailing edge.

• Main motor (M1), transfer and separation chargers, transfer bias, discharge lamp, and LED

eraser array are turned off.

• Optical fan motor (M6, M12) stop, and bottom fan motor (M8) and exit fan motor (M7) are running

at low speed.

• Carriages and indicators move to the position indicating copy area.

• The copier enters the standby mode.

2060, 2860/70 OPERATION 4 - 2 Dec. 1996 © TOSHIBA

Page 32

Dec. 1996 © TOSHIBA 4 - 3 2060, 2860/70 OPERATION

Return

Skip

3560/70 S/M

MAIN-MOT

SCN

RGT

EXIT-SW

EXPO

HVT-M

Transfer

OFF

0.1

0.1

FWD

0.72

1.02 2.12 3.95 5.05

ON ON

0.44 2.13 3.37

ON ON

0.71

ON

1.37

BWDBWD

ON

2.03

2.35 4.10

2.10

High

OFF

CW

4.913.772.411.990.840.2

3.64 4.96

ON

BWDFWD

5.06

5.034.30

5.29

High

5.34

7.10 8.50 8.53

CCW

5.753.932.82

ON

OFF

6.85

Separation

Guide bias

OFF 0.1

1.47

2.46

4.10

High

4.40

ONON

Timing chart for two A4 actual-size cassette feeding

5.40

5.224.142.291.20

LOWLOW

Page 33

Return

3560/70 S/M

Skip

4.2.4 Bypass-feed copying

(1) A sheet of paper is inserted through the bypass guide

• Manual feed switch (S6) is turned on.

(2) PRINT key is pressed

• The main transfer and separation chargers, transfer bias, discharge lamp, and LED eraser array

are turned on.

• Optical fan motor (M6, M12), bottom fan motor (M8) and exit fan motor (M7) are running at high

speed.

• Main motor (M1) is turned on

~ Drum, developer unit, transport belt, heat roller, and exit roller are running.

(3) Sheet-bypass feeding

• Manual feed clutch (CLT4) is turned on

~ Manual feed roller is lowered.

~ Manual feed roller, paper feed roller, and separation roller are running.

– Aligning operation –

• Paper reaches aligning roller

~ Paper stop switch1 (S7) is turned on.

After a set time lag, the manual feed clutch (CLT4) is turned off and paper feeding is terminated.

(4) Same as operation (3) through (6) of “4.2.3 Automatic Feed Copying Using the PRINT key”.

4.2.5 Interrupt copying

(1) The INTERRUPT key is pressed.

• Interruption LED is turned on.

The copying operation is temporarily halted and carriages-1 and -2 return to their home position.

The copying mode is set to automatic exposure and 1-to-1 reproduction ratio. Register remains

unchanged.

(2) The preferred copying modes are specified.

(3) After interrupt copying is terminated when the INTERRUPT key is pressed again, the interrupt LED

goes off and the copier returns to the conditions before the interruption.

(4) PRINT key is pressed

The copying operation before the interruption is resumed.

2060, 2860/70 OPERATION 4 - 4 Dec. 1996 © TOSHIBA

Page 34

Return

3560/70 S/M

Skip

4.3 Fault Detection

If a fault occurs in the copier , a symbol corresponding to the type of fault will be displa yed in order to dr aw

the attention of the operator.

• Classification of faults

A) Faults which can be cleared without turning off the door switch (yellow flashing display on the

display panel).

(1) ADD PAPER

(2) BYPASS MISFEED

(3) INSERT KEY COPY COUNTER

(4) CASSETTE MISFEED

B) Faults which cannot be cleared without turning off the door switch (red flashing display on the

display panel).

(1) CLEAR PAPER

(2) ADD TONER (yellow flashing display)

(3) REPLACE TONER BAG

C) Faults which cannot be cleared unless the main switch (S1) is turned off.

(1) SERVICE CALL

A-1) ADD PAPER ( )

[In the case of the copier and PFP cassettes]

• When the cassette is not installed, the size switch (S5 or S15) detects the absence of the

cassette.

G

When the cassette is not installed.

When the cassette is installed but

there is no paper in the cassette.

6

4

7

4

8

~Size switches are all switched off.

Paper empty status.

ff

Signal sent to control circuit.

The ADD PAPER display will flash.

* The PRINT key will not function.

Dec. 1996 © TOSHIBA 4 - 5 2060, 2860/70 OPERATION

Page 35

Return

3560/70 S/M

Skip

[In the case of the LCF and the pedestal]

By combining the operation of the tray motor and the condition of the tray-up switch and the empty

switch, the CPU detects whether or not there is paper.

• When the power is turned on or when the LCF door is opened/closed (for the pedestal:

when the power is turned on or when the cassette is removed) ~

The PFC (Paper Feed Controller) causes the LCF to initialize.

ff

Detects whether or not there is paper

• Tray motor comes on ~ The tray rises.

f

At this time, both tray-up and LCF empty switches are off.

• A fixed time later, if the tray-up switch is not turned on:

The tray is

not normal

→

The “ADD PAPER” is displayed regardless of paper being present or not.

↕

Removing/reinstalling the LCF or turning off/on clears this condition. (For the pedestal, turn

off/on the power.)

f

• Within a fixed time, the tray-up switch turns on:

~ The tray motor stops.

At this time, if the empty switch is on ~ It is determined there is paper.

At this time, if the empty switch is off ~ It is determined there is no paper.

f

The “ADD PAPER” is displayed.

• During copying, sheets of paper are fed and when the paper supply becomes low →

The tray-up switch goes off → The PFC turns on the tray motor ~ The tray moves up.

The tray-up switch come on → The tray motor stops.

• During copying, when the empty switch goes off despite the tray-up switch being on

fff

It is determined there is no paper.

“ADD PAPER” is displayed.

Copying stops.

2060, 2860/70 OPERATION 4 - 6 Dec. 1996 © TOSHIBA

Page 36

Return

3560/70 S/M

Skip

A-2) BYPASS MISFEED ( )

• During sheet bypass copying

14443

The manual feed clutch (CLT4) has been tur ned on

f

The paper-stop switch-1 (S7) comes on

* If the paper-stop switch-1 (S7) does not come on within the specified time:

fff f

BYPASS MISFEED

The BYPASS MISFEED symbol is displayed

Copying cannot be started

Clearing method: Remove the paper from the sheet-bypass guide. The manual-f eed switch

(S6) goes off.

A-3) INSERT KEY COPY COUNTER ( )

• If the copy counter (optional) is installed in the copier and is then withdrawn:

The INSERT KEY COPY COUNTER display appears

f

Copying is not possible

• If the counter is withdrawn during copying, the machine will stop after the paper being copied

has exited.

B-1) CLEAR PAPER ( )

• Leading-edge jam detection by the exit switch (S9): (E01)

The aligning clutch (CLT2) is turned on

ff

1.875 sec.*

The exit switch (S9) comes on

* When the exit switch (S9) has not come

on after 1.875 seconds have elapsed.

The CLEAR PAPER symbol (E01) appears and copying will stop.

f

Aligning motor

Exit switch

Timer

On

On

0

1.875 sec

CLEAR PAPER (E01)

Dec. 1996 © TOSHIBA 4 - 7 2060, 2860/70 OPERATION

Page 37

Return

3560/70 S/M

Skip

•

• Immediately after power on

T railing-edge detection b y exit switch (S9): (E02)

Aligning clutch (CLT2) goes off.

↓ 1.92 sec*

The exit switch (S9) goes off (detects paper exit)

* When the exit switch (S9) does not go

off even after 1.92 seconds:

↓

The CLEAR P APER symbol appears (E02),

and copying stops.

↓

Exit switch (S9) is detecting paper (on)

↓

Aligning motor

Exit switch

Timer

Off

On

0

CLEAR PAPER (E02)

1.92 sec

CLEAR PAPER (E03)

• If the front cover is opened during copying

↓

CLEAR PAPER (E04)

• Leading edge jam detection by the paper stop switch in front of the aligning roller:

After the leading edge of the paper passes the transport rollers, if the paper stop switch-1 (S7)

is not turned on within a fixed time

↓

Paper misfeeding (E05)

• During paper feeding from the ADU:

After the feed clutch is turned on, if the paper stop switch (S16) does not come on within a

fixed time.

↓

Paper misfeeding (E11)

• During paper stacking in the ADU:

If the ADU jam switch (SA4) does not detect any paper at the fixed timing

↓

Paper misfeeding (E08)

2060, 2860/70 OPERATION 4 - 8 Dec. 1996 © TOSHIBA

Page 38

Return

3560/70 S/M

Skip

• During paper feeding from the copier and the pedestal:

After the feed clutch is turned on, if paper stop switches (S7/S16) do not come on within a fixed

time

↓

Paper misfeeding (E13 – E19)

E13 – E19: The error code is different according to the cassette used.

B-2) ADD T ONER ( )

Toner density has become low

↓

Toner empty detection: Auto-toner sensor

↓

Control circuit: f the ADD TONER symbol appears: copying is not possible

Clearing method: Replace the toner cartridge and close the front cover.

Toner supply operation: copying is possible

B-3) REPLACE TONER BAG ( )

The toner bag becomes full of toner

↓

The toner-recovery auger moves towards the rear of the copier: toner-full switch (S13) will be

turned on.

↓

REPLACE TONER BAG display

• When the toner-full switch (S13) comes on during copying

↓

Copying will stop after the last sheet has exited during copying

Clearing method: Replace with a new toner bag.

C-1) Service call

If the CLEAR/STOP key and the “8” key are pressed simultaneously when the SERVICE CALL symbol

symbol is flashing, one of the error codes will appear on the message display.

For the contents of the error codes, refer to the “SERVICE HANDBOOK”.

Dec. 1996 © TOSHIBA 4 - 9 2060, 2860/70 OPERATION

Page 39

Return

Skip

3560/70 S/M

4.4 Flow Charts

4.4.1 Power on to ready

Restart

Main switch on

DC power on

YES

Cover open?

NO

Heater lamp HTR ON

• SCN-MOT

• LNS-MOT

• MRR-MOT

• DCM-MOT

• STOP-MOT

• GUIDE-MOT

P-STP-SW

ON?

Start initialization

1444442444443

YES

NO

EXIT-SW ON?

NO

ADU-JAM-SW

YES

YES

ON?

NO

Paper jam

"E03"

A

2060, 2860/70 OPERATION 4 - 10 Dec. 1996 © TOSHIBA

Page 40

Return

Skip

3560/70 S/M

NO

A

T-FUL-SW

ON?

NO

Toner empty?

YES

Toner replen-

ishment

Initialization

over?

NO

YES

NO

Main motor

6 sec. ON

T-FULL SW

ON

(Toner-full removal

operation)

YES

Toner bag

replacement

NO

Have 20 sec.

passed since start

of initialization?

YES

Service call

“C21”or “C22” or “C23”

YES

• Lens and mirrors positioned for specified

reproduction ratio

• Carriage and indicator

indicate copy area

Is heat roller

pre-running sufficient

for fixing?

YES

Main motor ON

Pre-running operation

starts

NO

Have 15 sec.

passed

NO

Is the

thermistor

open?

YES

Service call

“C41”

NO

YES

Main motor OFF

Pre-running stops

READY

Dec. 1996 © TOSHIBA 4 - 11 2060, 2860/70 OPERATION

Page 41

Return

Skip

3560/70 S/M

4.4.2 Automatic feed copying

PRINT key

Transfer charger on

Separation charger on

Discharge lamp on

Process control

All LEDs of the LED eraser array on

Main charger on

LED eraser array off

All LEDs of the LED eraser array on

Main charger off

All LEDs of the LED eraser array off

NO

Is number

of remaining copies

zero?

YES

Transport control

for main motor

Feed motor on

Feed motor off

Aligning motor on

Counter on

Scraper solenoid on

Counter off

Scraper solenoid off

Aligning motor off

NO

remaining copies

PLL check

OK?

YES

Is

number of

zero?

YES

NO

Service call

"C01"

YES

Optical section control

Carriage moves to

home position

Exposure lamp on

Carriage advances

Carriages stops

Exposure lamp off

Is number

of remaining copies

zero?

NO

Carriage retreats to home

position

Process control end

Exit switch

check 1

OK

NG

B

2060, 2860/70 OPERATION 4 - 12 Dec. 1996 © TOSHIBA

Copying area indicated

Optical section

control end

Paper jam

"E01"

Page 42

Return

Skip

3560/70 S/M

B

Paper jam

“E02”

NG

Exit switch

check 2

Transfer changer OFF

Separation charger OFF

Discharge lamp OFF

Drum rotation reversed

Standby

OK

Dec. 1996 © TOSHIBA 4 - 13 2060, 2860/70 OPERATION

Page 43

5. DISPLAY UNIT

The display unit consists of key switches for copier operation/selection of each mode, LEDs and an LCD

displaying the copier state or messages.

Particularly, when the operator’s attention is recommended, a graphic symbol lights or flashes and the

message indicating that condition is displayed.

5.1 Detailed Drawing of the Control Panel and the Display Panel

For the U.S.A. and Canada

For Europe

STAPLE 2 in 1

SORT

GROUP

SORTER DUPLEXADF

READY

PREV. HELP YES NO

SADF

ADF

CASSETTE

IMAGE MODE

LIGHT AUTO DARK

READY

PREV. INFO YES NO

100%LT

ENERGY SAVE INTERRUPT

123

456

789

C

0

100%A4

/

CLEAR/STOP

200%

100%

ZOOM

FUNCTION CLEAR

PRINT

100%

123

456

789

C

0

/

50%

FC

200%

ORIGINAL

LD

LG

LT

ST

OTHER

AMS APS

ORIGINAL

50%

FC

UNIV

AMS APS

Arrangement of the control panel

For the U.S.A. and Canada For Europe

COPY SIZE

A4

A3

B4

B5

M1

M2

USER SET

COPY

USER SET

JOB MEMORY

SET RECALL

M1

M2

MODE MEMORY

SET RECALL

LEFT RIGHT BOOK

EDGE ERASE DUAL PAGE

LEFT RIGHT BOOK

EDGE ERASE DUAL PAGE

IMAGE SHIFT

IMAGE SHIFT

CASSETTE

Details of the display panel

Dec. 1996 © TOSHIBA 5 - 1 2060, 2860/70 DISPLAY

Page 44

5.2 Items Shown on the Display Panel

5.2.1 Display during normal copying

No. Message Conditions of machine Notes

1 WAIT WARMING UP Being warmed up • The number and reproduction ratio

• Indicated after the main switch

is switched on up until the example, as “0”, “100%” when the

machine becomes capable of main switch comes on.

copying.

2 READY Capable of copying. •

• Indicated when the machine is “1”. When a digital key is pressed,

capable of copying and the the set number is indicated.

operator’s instructions for •

copying conditions are awaited. pressing the CLEAR/STOP key.

• Returns to the initial condition •Manual copying is possible.

if no key input is given for 45

seconds.

3 COPYING Now copying. •

• Indicated by pressing the quantity indicator returns to the

PRINT key. initially set number.

•

Copy quantity indicator becomes

“1” and copying is completed.

4 SAVING ENERGY Energy saving conditions. •

PRESS PRINT

5 PLACE NEXT ADU 1-sided copying standby •

ORIGINAL state. C below. not using ADF.

of the copies are indicated, for

Copy quantity indicator indicates as

The set number is cleared to “1” by

After completion of copying, the copy

Released by pressing the ENERGY

SAVER key or the PRINT key.

When using ADU 1-sided, and when

In case of lateral paper feeding, the symbol A lights up and for longitudinal feeding, the symbol B lights

up on the display panel.

C

BA

2060, 2860/70 DISPLAY 5 - 2 Dec. 1996 © TOSHIBA

Page 45

5.2.2 Display in the event of faulty conditions

No. Message Abnormal state & indication Solution

6 ADD PAPER Indication of lack of paper. • Supply paper to the selected

•

Indicates when there is no paper

in the cassette. (A below.) • Select another cassette.

• Indicates which cassette has no

paper. (E below.)

• Manual copying is possible.

7 ADD TONER: Indication of lack of toner. •

• B below is indicated when and the front cover is closed.

PRESS INFO the toner in the toner cartridge

runs out.

•

When this message is displayed,

it is not possible to copy.

8 INSERT Key copy counter withdrawn. • Released and returned to normal

• Indicated when the key copy conditions by inserting the key

KEY COPY COUNTER

9 DISPOSE OF Indication of need to replace the Open the front cover and replace

USED TONER • Indicated when the toner bag is

counter is withdrawn when the copy counter.

machine is READY or during

copying. C below.

• When it is removed after

pressing the PRINT key, the

machine stops after that copy is

completed, but the counter

counts it.

toner bag. the toner bag.

full. D below.

The copier stops.

cassette.

Released after the toner is supplied

D

B C

AE

Dec. 1996 © TOSHIBA 5 - 3 2060, 2860/70 DISPLAY

Page 46

No. Message Abnormal state & indication Solution

10 PAPER MISFEED Bypass paper jamming The machine is returned to normal

• Indicates when paper jams at conditions automatically by pulling

IN BYPASS the bypass guide. A below.

11

MISFEED IN COPIER

PRESS INFO the machine. B, C, D and H copier following the message.

12 MISFEED Original jammed Open the ADF feed cover and

IN DOC. FEEDER jammed in the optional

13

MISFEED IN SORTER:

PRESS INFO

14 MISFEED IN ADU: Indicates when paper is jammed

PRESS INFO copier following the message.

Paper jammed in the machine. • Press the HELP (INFO) key and

• Indicated when paper jams in remove the paper jammed in the

below.

• Indicated when an original is remove the jammed original.

document feeder. E and F

below.

Paper jammed in the sorter. Remove the paper jammed in the

• Indicates when paper is jammed sorter and open and close the front

in the sorter. G below. cover once.

in the ADU section. I below.

the paper out from the bypass guide.

Press the HELP (INFO) key and

remove the paper jammed in the

B

G

I

E

F

C

A

D

H

2060, 2860/70 DISPLAY 5 - 4 Dec. 1996 © TOSHIBA

Page 47

No. Message Abnormal state & indication Solution

15

CALL FOR SERVICE:

PRESS INFO abnormal. A below. machine back on.

16

TIME FOR PERIODIC

MAINTENANCE periodic maintenance and

Some or one of the mechanism, Turn off the machine, remove the

motors, switches or sensors are cause of the fault and turn the

Indication of PM cycle. Maintenance and inspection by a

• Indicated when it is time for qualified service technician.

inspection.

• Capable of copying.

A

Dec. 1996 © TOSHIBA 5 - 5 2060, 2860/70 DISPLAY

Page 48

5.3 Relationship between Copier Conditions and Operator’s Actions

Sheet

bypass

key

SHIFT

IMAGE

key

PAGE

COPY

DUAL-

key

EDGE

ERASE

key

SAVER

ENERGY

key

RUPT

INTER-

key

CASSETTE

SELECTION

SIZE

COPY

SIZE

ORIGINAL

key

EXPOSURE

RATIO

REPRO-

DUCTION

keys

Digital

STOP

CLEAR/

key

PRINT

key

key

key

selection

key

– _____________

– _____________

Operation

During copying ......... Interruption of the copying (Stop function .....The copy quantity indicator will not change.)

Condition

Warming up – _____________

Ready ______________

Reproduction-ratio

changing

Copying – _ ––_ ––__ ––––_

Add paper – _____________

Add toner – _____________

Key copy counter not

inserted (optional)

Bypass misfeed ––––––––––––––

Replace toner bag – – ____________

Clear paper ––––––––––––––

Service call ––––––––––––––

Interrupt mode _ ––______ – _ – __

Energy-saving mode _ ––––––––_ ––––

_: Machine operates or indicates in accordance with the operator’s action. – : Operation is ignored.

2060, 2860/70 DISPLAY 5 - 6 Dec. 1996 © TOSHIBA

(1) By pressing the ENERGY SAVER key or the PRINT key, the energy-saving mode will be cancelled.

(2) During copying, avoid changing exposure as far as possible.

(3) The function of the CLEAR/STOP key changes in the following manner according to the machine status.

When not copying ....When pressed once, the copy quantity indicator returns to “1”.

(4) During copying, avoid sheet bypass feeding because of possible paper jamming.

Note: The interrupt mode will be automatically cancelled when the machine is not used for 45 seconds.

Page 49

5.4 Description of Operation

5.4.1 Dot matrix LCD display circuit

(1) Structure

• Dot matrix LCD display circuit has a display capacity of 40 characters (20 characters x 2 lines).

• 1 character is a unit consisting of ON/OFF lights

made of 35-element (5 x 7) dots.

(2) Drive Operation

• LED control: The LCD’s internal control driver drives.

• What character is displayed in what position: IC19 (main CPU), IC9 (HC244), IC37 (7407), and

IC18 (gate array) of the logic circuit control.

• Message data and executable programs are stored in the main PROM.

• The character codes are stored in the PROM on the LCD.

The main CPU divides the display bloc k into 4 b locks . The main CPU outputs the RAM address data

for the starting position at which each block is displayed and then outputs display data for the number

of characters (10 characters) to be displayed to the LCD. When the message is changed, the main

CPU outputs the display data for the blocks 1~4.

12

34

(4a)

When changing the display data only for the reproduction ratio, the leading RAM address data in the

display position of the reproduction-ratio block (4a)

Display blocks

are first output and then the display data for the

number of reproduction-ratio characters (4 characters) are output to the LCD.

Dec. 1996 © TOSHIBA 5 - 7 2060, 2860/70 DISPLAY

Page 50

AD15

~

AD0

IO10

IO17

A7

B7

~

A0

~

~

B0

DB7

~

DB0

O17

O14

O15

OE

244

Gate array

LCD-E

LCD-RS

E

RS

Main CPU

5.4.2 LED display circuit

(1) LED display method

For example, the following shows how the LED LP12 (APS) lights up for displaying “automatic paper

sensing”.

+5VD

R9

DSPON0

“L”

R11

Q2

R

(APS)

LP12

“L” 14

D10

R7

IC4

When DSPON0 signal becomes “L” lev el, tr ansistor Q2 is turned ON. Further, when IC4 pin14 (D10)

becomes “L” level, current flows from +5VD to LP12 (APS) through the transistor. In this way LP12

(APS) lights up.

2060, 2860/70 DISPLAY 5 - 8 Dec. 1996 © TOSHIBA

Page 51

(2) The actual circuit is controlled as follows.

VDD

1000

R18

21

1000

R17

12

1000

R20

12

1000

R19

21

27

1

C4

2

CKME0.1/25

4

26

28

2

3

29

30

1

23

18

13

8

SGD

GND

4B3 4C8

R16

DSPDAT

4B3

DSPLTH

4B3

DSPRST

DSPCLK

4B3

1000

12

R15

1000

12

1

C6

2

CKM33P/50J

1

C7

2

CKM33P/50J

HC14

HC14

21

43

IC3

IC3

LAST

L/R

SIN

LATCH

BE0

STB

CK

VDD

VSSL

VSSD3

VSSD2

VSSD1

VSSD0

IC4

7932M

DSPON1

4B8

DSPON0

A-EXPO5

EXPO9-4

EXPO8-3

EXPO7-2

EXPO6-1

DSPOUT1

DSPCLK1

DSPLTH1

PHOTO

4B8

4C8

4C8

4C8

4C8

4C8

4B8

4C8

4C8

4C8

R2

100

12

LTL16KG

R3

100

P/3

12

LTL16KG

R4

100

P/2

21

LTL16KG

R5

100

P/1

12

6

D16

7

D15

9

D14

10

D13

11

D12

12

D11

14

D10

15

D9

16

D8

17

D7

19

D6

20

D5

21

D4

22

D3

24

D2

25

D1

5

SOUT

DSON1

4B3

DSON0

4B3

R6

100

21

R7

100

21

R12

100

21

R14

100

R13

100

21

R10

12

R11

LTL16KG

P/0

LTL16KG

P/USER

LTL16KG

APS

LTL16KG

USER/AJ

12

LTL16KG

EDGE

LTL16KG

DP

150

150

21

R8

R9

21

21

21

12

12

12

12

12

12

12

2200

21

2200

1

LTL16KG

LP7

LTL16KG

LP8

LTL16KG

LP9

LTL16KG

LP10

LTL16KG

LP11

LTL16KG

LP12

LTL16KG

LP13

LTL16KG

LP17

LTL16KG

LP18

1

3

Q2

2SA1428Y

2

LP1

LP2

LP3

LP4

LP5

LP6

LP16

LP15

LP14

3

Q1

2SA1428Y

2

21

O/3

12

O/2

12

O/1

12

O/0

12

O/USER

12

AMS

12

MSB

12

MSR

12

MSL

5VD

(14.2.1 Display Circuit (PWA-DSP) 1/4)

• The signals of DSPON0 and DSPON1 become “L” level by one turn every 8 msec.

DSPON0

8 msec 8 msec

Q2

OFFQ2ON

• Q1 (or Q2) is turned ON when DSPON0 (or

DSPON1) is “L” level.

DSPON1

Q1ONQ1

OFF

• LED ON/OFF signal from LGC is inputted

to the SIN (pin 26) terminal of IC4 through

DSPDAT

DSPDAT signal line. (Serial data)

• The LED ON/OFF signal is inputted to IC2

in serial is outputted to output terminals of

D1 – D16 in parallel.

D7

LP14

(example)

LP18

(example)

ON

ON ON

Condition of LED lighting

1 The transistor (Q1 or Q2) connected on the anode side of the LED is ON status.

2 Output connected on the cathode side of the LED is “L” level.

When the above conditions 1 and 2 are fulfilled, the LED lights.

Refer to the following names of the LED which are ON/OFF controlled by DSPON0/DSPON1 signals.

Dec. 1996 © TOSHIBA 5 - 9 2060, 2860/70 DISPLAY

Page 52

Transmission

LP SIGNAL DSP-ON-0 LP SIGNAL DSP-ON-1 LC7932

order

1 5 DF/SINGL ADF single feeding 6 DF/MULT1 ADF multiple feeding IC1-6

2 38 CST1 Cassette selection (LCF) 35 PEMP1 Paper empty (LCF) IC1-7

3 22 CST2

4 23 CST3

Cassette selection (Copier-U)

Cassette selection (Copier-L)

17 PEMP2 Paper empty (Copier-U) IC1-9

18 PEMP3 Paper empty (Copier-L) IC1-10

5 24 CST4 Cassette selection (PFP-U) 19 PEMP4 Paper empty (PFP-U) IC1-11

6 25 CST5 Cassette selection (PFP-M) 20 PEMP5 Paper empty (PFP-M) IC1-12

7 26 CST6 Cassette selection (PFP-L) 21 PEMP6 Paper empty (PFP-L) IC1-14

8 27 O/YOKO Horizontal original 28 O/TATE Vertical original IC1-15

9 12 DFJ ADFJAM (Feeding) 29 DEJ ADFJAM (Exiting) IC1-16

10 15 SRVC Call service 11 SJ Sorter JAM IC1-17

11 30 TEMP Toner empty 13 EJ Paper existing JAM IC1-19

12 16 TFULL Toner full 31 RJ

13 33 KCTR Key copy counter withdrawn 36 TJ

14 32

ADUSTUCK

ADU stacking 14 ADUJ ADUJAM IC1-22

Paper feeding JAM (Before aligning)

Paper feeding JAM (After aligning)

15 37 PJ PFPJAM IC1-24

16 34 MJ Bypass JAM IC1-25

17 53 MAG2/G

18 53 MAG2/B

19 53 MAG2/A

20 53 MAG2/F

21 53 MAG2/E

22 53 MAG2/D

23 53 MAG2/C

24 53 MAG3/G

25 53 MAG3/B

26 53 MAG3/A

27 53 MAG3/F

28 53 MAG3/E

29 53 MAG3/D

30 53 MAG3/C

Copy quantity display (tens)

Copy quantity display (tens)

Copy quantity display (tens)

Copy quantity display (tens)

Copy quantity display (tens)

Copy quantity display (tens)

Copy quantity display (tens)

Copy quantity display (units)

Copy quantity display (units)

Copy quantity display (units)

Copy quantity display (units)

Copy quantity display (units

) 1 STAPLE Staple mode IC2-20

Copy quantity display (units)

Copy quantity display (units)

53 MAG1/G Copy quantity display (hundreds) IC2-6

53 MAG1/B Copy quantity display (hundreds) IC2-7

53 MAG1/A Copy quantity display (hundreds) IC2-9

53 MAG1/F Copy quantity display (hundreds) IC2-10

53 MAG1/E Copy quantity display (hundreds) IC2-11

53 MAG1/D Copy quantity display (hundreds) IC2-12

53 MAG1/C Copy quantity display (hundreds) IC2-14

52 AC All clear IC2-15

50 PS Energy saving IC2-16

51 INT Interruption IC2-17

4 2IN1 2IN1 IC2-19

2 SORT Sort mode IC2-21

3 GROUP Group mode IC2-22

31 7 ADU1 Duplexing (1 → 2) 8 ADU2 Duplexing (2 → 2) IC2-24

32 9 ADU3 Duplexing (2 → 1) 10 ADU4 Duplexing (Book → 2) IC2-25

33 IC4-6

34 *7 P/3 Paper size *1 O/3 Original size IC4-7

35 *8 P/2 Paper size *2 O/2 Original size IC4-9

36 *9 P/1 Paper size *3 O/1 Original size IC4-10

37 *10 P/0 Paper size *4 O/0 Original size IC4-11

38 *11 P/USER

Paper size (User adjustment)

*5 O/USER Original size (User adjustment) IC4-12

39 *12 APS APS *6 AMS AMS IC4-14

40 *13 USER/AJ User adjustment *16 MSB Margin shift (Book) IC4-15

41 *17 EDGE Edge erasing *15 MSR Right margin shift IC4-16

42 *18 DP Dual-page copying *14 MSL Left margin shift IC4-17

43 39 PHOTO Photo mode IC4-19

44 40 AUTO Automatic exposure 45 EXPO5 Exposure display 5 IC4-20

45 49 EXPO9

Exposure display 9 (D MAX.)

44 EXPO4 Exposure display 4 IC4-21

46 48 EXPO8 Exposure display 8 43 EXPO3 Exposure display 3 IC4-22

47 47 EXPO7 Exposure display 7 42 EXPO2 Exposure display 2 IC4-24

48 46 EXPO6 Exposure display 6 41 EXPO1 Exposure display 1 (L MAX.) IC4-25

IC1-20

IC1-21

Mark *: LEDs on PWA-DSP

No mark: LEDs on PWA-KEY

2060, 2860/70 DISPLAY 5 - 10 Dec. 1996 © TOSHIBA

Page 53

Return

Skip

3560/70 S/M

6. DRIVE SYSTEM

6.1 Construction of Drive System

The drive system consists of a drum (cleaner unit), developer unit, transport belt, heat roller, exit roller,

transport roller, cassette feed roller and aligning roller.

The drive system is driven by the main motor.

6.2 Description of Operations

• Drum drive ......................... Main motor rotation is transmitted to the drum drive pulley via the timing

(Cleaner unit) belt, and drives the drum gear.

• Developer unit drive ........... Main motor rotation is transmitted to the developer unit drive gear via

the timing belt and the gear.

• Heat roller drive .................. Main motor rotation is transmitted to the heat roller gear via timing belt

and gears, and drives the heat roller.

• Transport belt ..................... Transport belt gear is driven by the heat roller gear via the idle gear.

• Exit roller ............................ Exit roller gear is driven by the heat roller gear via the idle gear.

• Aligning roller ..................... Main motor rotation is transmitted to the aligning roller clutch via the

timing belt and gears.

• Transport roller................... Main motor rotation is transmitted to the transport roller clutch via timing

belts and gears.

• Cassette feed roller............ Main motor rotation is transmitted to the cassette feed roller via timing

belts and gears.

Timing pulley of the

clamshell fulcrum

(TP24/TP30/G28)

Belt

(324 pitch)

Transport roller

(One-way clutch/TP15)

(One-way clutch/TP20)

(TP30/G28)

(G28)

Bypass feed roller

(Clutch/G28)

(G28)

(G28)

(G28)

Gear/Developer

unit drive gear

(G26)/(G23)

Belt

(324

pitch)

(TP24)(G24)

Arm fulcrum

gear (G26)

(G26)

Belt (324 pitch)

(G28)

Belt (258 pitch)

Lower transport roller

(Clutch/G28)(TP15)

Timing pulley/Drum

drive gear

(G20)

(TP40)

Aligning roller (Clutch/G28)

Aligning roller drive gear

(G32/G19)

Upper cassette feed roller

(Clutch/G28)

Lower cassette feed roller

(Clutch/G28)

(TP20))

Belt (248 pitch)

Belt

(324 pitch)

Drum

(G72)

Timing pulley

(G56/TP24)

Timing pulley

(G57/TP24/TP19)

Main motor

(G10)

Belt

(246 pitch)

Transport belt

Arm fulcrum gear

(G25)

(G20)

(G27/G19)

(G56)

(G35)

Heat roller

(G24/G18)

(G30)

(G20)

(G21)

ADU transport roller

(G20)

Exit roller

(G20)

(G22)

(G22)

Drive system (Rear side view)

Dec. 1996 © TOSHIBA 6 - 1 2060, 2860/70 DRIVE

Page 54

Return

3560/70 S/M

Skip

6.3 Disassembly and Replacement

[A] Clamshell fulcrum bracket and pulley

(1) Remove the upper rear cover and the upper

feed cover.

(2) Remove the clamshell fulcrum bracket (3

screws).

(3) Remove the 2 belts from the pulley.

(4) Remove the clamshell fulcrum pulley.

Clamshell fulcrum bracket

[B] Main motor

(1) Remove the main motor (2 connectors and 2

screws).

[C] Main drive unit

(1) Remove the drum tension bracket (1 screw).

Clamshell fulcrum pulley

Connectors

Connector

Belt

Main motor

Drum tension bracket

(2) Remove the shaft bracket (1 screw).

(3) Remove the main drive unit (connector and 5

screws).

Main drive unit

Shaft bracket

2060, 2860/70 DRIVE 6 - 2 Dec. 1996 © TOSHIBA

Page 55

Return

3560/70 S/M

Skip

[D] Main drive unit gears

(1) The developer-unit drive gear and the drum

drive gear are press-fitted to their shafts.

[E] Feed drive unit

(1) Remove the LCF connector bracket (2

Drum drive gear

Dev-unit drive gear

Fuser drive gear

screws).

(2) Remove the clamshell fulcrum bracket and the

feed roller bracket (3 screws) and then remove

the pulley and belt.

LCF connector bracket

Pulley

Belt

Dec. 1996 © TOSHIBA 6 - 3 2060, 2860/70 DRIVE

Page 56

Return

3560/70 S/M

Skip

(3) Remove the lower feed roller clutch (1 set-

screw).

(4) Remove the pulley and belt for the upper feed

roller (1 stop-ring).

Clutch

Set-screw

(5) Remove the feed drive unit (3 screws).

• This is easy to remove if the feed drive unit

is slanted.

Pulley

Stop-ring

Belt

Feed drive unit

2060, 2860/70 DRIVE 6 - 4 Dec. 1996 © TOSHIBA

Page 57

Return

Skip

3560/70 S/M

6.4 Main Motor

6.4.1 Main motor drive

FG pulse

Phase V

Hall

element B

Photointerruptor

Phase U

Hall element C

Reference frequency

(F-MOT-REF)

MAIN-CW/CCW

Control

MOT-BRK

signal

MAINMOT-ON

678

PLL-OK

Wave

shaping

Lock

protection

circuit

Phase

comparator

Speed

comparator

Difference

Difference

Voltage

detection

circuit

+

Rotation

control

Excitation

phase

switching

section

Rotor

position

detection

Phase W

Hall element A

Main motor (M1)

(1) The LGC transmits control signals for main motor rotation. (MAIN-CW/CCW: Direction of rotation,

MAINMOT-ON: Motor rotation command)

(2) The excited phase switching unit excites each phase on the main motor → Main motor runs.

(3) Hall elements A to C are used to detect the rotation position of the motor (or rotor).

(4) The excited phase switching unit switches the excitation for each phase.

(By repeating (2) through (4) above, the motor keeps running.)

(5) The FG pulse is generated by the FG pulse pattern and N/S magnets of rotor installed on the main

motor.

(6) The phases and velocities of the FG pulse and the reference frequency from the LGC are com-

pared, and the differences are added. Further to this are added the fluctuations in the supply volt-

age. (Signal generation)

(7) Changes the switching timing for the excited phase switching unit to match the signal amount ob-

tained in step (6).

i.e. control is done to equalize the FG pulse and reference frequency. → The main motor runs at a

constant speed. (Locked range state.)

(8) When the main motor enters the locked range state, the excited phase switching unit transmits the

PLL-OK signal to the LGC. (“L” level).

(9) When the MOT-BRK from LGC enters “L” level, the main motor rotation is braked, and when the

MAINMOT-ON signal enters “H” level, the main motor stops.

Dec. 1996 © TOSHIBA 6 - 5 2060, 2860/70 DRIVE

Page 58

Return

3560/70 S/M

Skip

6.4.2 Control signals

(1) MAIN-CW/CCW signal (LGC → MOT: Input)

Switches the rotation direction of the main motor. When this signal becomes “L” level, the main

motor rotates counterclockwise as viewed from the rear side, and drives the developer unit, drum,

heat roller, etc.

(2) PLL-OK signal (MOT → LGC: Output)

When the cycle of FG pulse deviation from the reference frequency is within fixed range, this state

is specified as lock range (normal rotation), and this PLL-OK signal becomes “L” lev el. Also , at this

time, the LED “LP1” light comes on.

(3) F-MOT-REF signal (LGC → MOT: Input)

This signal is a reference clock signal for the main motor to rotate at a fixed speed.

(4) MOT-BRK signal (LGC → MOT: Input)

When it becomes “L” level, the main motor rotation is broken down.

(5) MAINMOT-ON signal (LGC → MOT: Input)

This signal is main motor ON/OFF control signal, when it becomes “L” level, the motor rotates.

Signal level of motor circuit.

Signal “H” level “L” level

MAIN-CW/CCW CW CCW direction

PLL-OK Speed is out of the locked range. Locked range state.

F-MOT-REF Reference clock

MOT-BRK Brake OFF Brake ON

MAINMOT-ON Motor OFF Motor ON

* The signal names indicate a level in the connector J543, respectively.

2060, 2860/70 DRIVE 6 - 6 Dec. 1996 © TOSHIBA

Page 59

Return

3560/70 S/M

Skip

7. OPTICAL SYSTEM

7.1 Functions

In this copier, the surf ace of the original is directly exposed to light, and the reflected light is conducted to

the surface of the drum via the mirror, lens, and slit.

The whole original image is reflected on the drum surface through the light source being scanned from

the leading edge to the trailing edge.

This area where functions as above are performed is called the optical section, located at the upper side

of the copier.

Original width

indicator

Carriage 2

Carriage 1

Optical fan

Scanning motor

Original glass

Lens unit

Optical system (front view)

Mirror 6

Drum

Lens motor

Slit glass

Mirror motor

Mirror unit

Dec. 1996 © TOSHIBA 7 - 1 2060, 2860/70 OPTICAL

Page 60

Return

3560/70 S/M

Skip

7.2 Construction

The construction and purpose of the optical section are the followings:

(1) Original glass

The original is placed on this glass. Light from the exposure lamp exposes the surface of the original through this original glass.

(2) Carriage 1

Carriage 1 consists of the exposure lamp, reflector, mirror 1, thermofuse, and light distribution

adjustment plates, etc. Carriage 1 is scanned by the scanning motor. The relation between the

scanning speed and the drum rotation speed is specified as follows. In actual-size copying, both

speeds are the same. The reproduction ratio of the direction of paper transport (lengthwise reproduction ratio) is specified by this scanning speed being changed. In enlargement copying, the scanning speed is slower than the drum rotation speed, and in reduction copying it is faster.

Light distribution plates

Reflector

Mirror 1

a. Exposure lamp

The light source for exposing the original to light.

b. Reflector

The reflection plate for using the exposure lamp effectively.

The sub-reflector is slit for optical path width cutting.

Original

Thermofuse

Exposure lamp

Glass

Sub-reflector

Mirror 1

2060, 2860/70 OPTICAL 7 - 2 Dec. 1996 © TOSHIBA

Reflector

Exposure lamp

Page 61

Return

3560/70 S/M

Skip

c. Mirror 1

The mirror for conducting the reflected light from the original to mirror 2 (mentioned later).

d. Thermofuse

Prevents the exposure lamp from an increase in temperature due to excessive lighting.

e. Light distribution adjustment plates

It is positioned to shield the light irradiated from the reflector on the surface of original, and adjusts the

light intensity.

If the positions for the installation of this adjustment plate at the front or rear side are shifted, and the

light intensity is different at both sides, this may cause uneven light distribution.