Page 1

TOSHIBA 2857 DB

1

General Information

Chassis: C5SS

Matrix

Item See Model Book

Adjustments (Not Service mode) ..................................................................2152 DB 5

X-RAY RADIATION PRECAUTION

1. The E.H.T. must be checked every time the

receiver is serviced to ensure that the C.R.T.

does not emit X-ray radiation as result of

excessive E.H.T. voltage. The nominal E.H.T.

for this receiver is 31.5 kV at zero beam

current (minimum brightness) operating at

240V a.c. The maximum E.H.T. voltage

permissible in any operating circumstances

must not exceed 32.0 kV. When checking the

E.H.T., use the ‘High Voltage Check’ procedure, using an accurate E.H.T. voltmeter.

2. The only source of X-RAY radiation in this

receiver is the C.R.T. To prevent X-ray

radiation, the replacement C.R.T. must be

identical to the original fitted as specified in

the Parts List.

3. Some components used in this receiver have

safety related characteristics preventing the

C.R.T. from emitting X-ray radiation. For

continued safety, replacement component

should only be made after referring the

Product Safety Notice below.

SAFETY PRECAUTION

1. This receiver has a nominal working E.H.T.

voltage of 28.5 kV. Extreme caution should be

exercised when working on the receiver with

the back removed. Do not attempt to service

this receiver if you are not conversant with the

precautions and procedures for working on

high voltage equipment. When handling or

working on the C.R.T., always discharge the

anode to the receiver chassis before removing the anode cap The C.R.T., if broken, will

violently expel glass fragments. Use shatter

proof goggles and take extreme care while

handling. Do not hold the C.R.T. by the neck

as this is a very dangerous practice.

2. It is essential that to maintain the safety of the

customer all cable forms be replaced exactly

as supplied from factory.

3. A small part of the chassis used in this

receiver is, when operating, at approximately

half mains potential at all times. It is therefore

essential in the interest of safety that when

serving or connecting any test equipment the

receiver should be supplied via a suitable

isolating transformer of adequate rating.

4. Replace blown fuses within the receiver with

the fuse specified in the parts list.

5. When replacing wires or components to

terminals or tags, wind the leads around the

terminal before soldering. When replacing

safety components identified by the international hazard symbols on the circuit diagram

and parts list, it must be a Toshiba approved

type and must be mounted as the original.

6. Keep wires away from high temperature

components.

PRODUCT SAFETY NOTICE

Many electrical and mechanical components in

this chassis have special safety-related

characteristics. These characteristics are often

passed unnoticed by a visual inspection and the

X-ray radiation protection afforded by them

cannot necessarily be obtained by using

replacements rated at higher voltages or

wattage, etc. Components which have these

special safety characteristics in this manual and

its supplements are identified by the international hazard symbols on the schematic diagram

and parts list. Before replacing any of these

components read the parts list in this manual

carefully. Substitute replacement components

which do not have the same safety characteristics as specified in the parts list may create Xray radiation.

Recommended Safety Parts

Item Part No. Description

A401 23426393 Back Cover

C440 24082482 PF, 7000pF, ±3%, 1500V

C441 24082669 PF, 0.33µF, 250V

C442 24082672 PF, 0.43µF, 250V

C444 24082519 PF, 6200pF, ±3%, 1800V

C463 24212222 CD, 2200pF, ±10%

C801 24082374 PE, 0.22µF , AC250V

C805 24092281 CD, 4700pF, ±20%, AC250V

C806 24092281 CD, 4700pF, ±20%, AC250V

R801 24009954 Metal-Glazed Resistor, 2.2M ohm, 1/2W

R808 24019340 PTC Thermistor, 18 ohm, 290V

R810 24007489 Cement, 3 ohm, 20W

R811 24568271 Cement, 270 ohm, 7W

R824 24569689 Cement, 6.8 ohm, 10W

R841 24531120 FR, 12 ohm, 1/2W

R899 24005007 Metal-Glazed Resistor, 8.2M ohm, 1W

L462 ------------- DY, Supplied with V901

L901 23200276 Coil, Degaussing, TSB-2330BR

T401 23224336 Transformer, Horiz. Drive, TLN1083

T461 23236447 Transformer, Flyback, TFB4115AR

T801 23211891 Line Filter, TRF3164

T803 23217301 Transformer, Converter, TPW3336AR

Q404 A6872801 Transistor, 2SD2253(FA)

Q801 23905084 IC, STR-S6709

Q826 A8643106 Photo Coupler, TLP621(GR)

D801 23316795 Diode, D6SB60L,F05

F470 23144873 Fuse, 1.0A

F801 23144898 Fuse, 3.15A

P801 23372012 Power Cord

V901A 23902891 Socket, CRT, 10P

V901 23312645 Picture Tube, A66EAK252X21

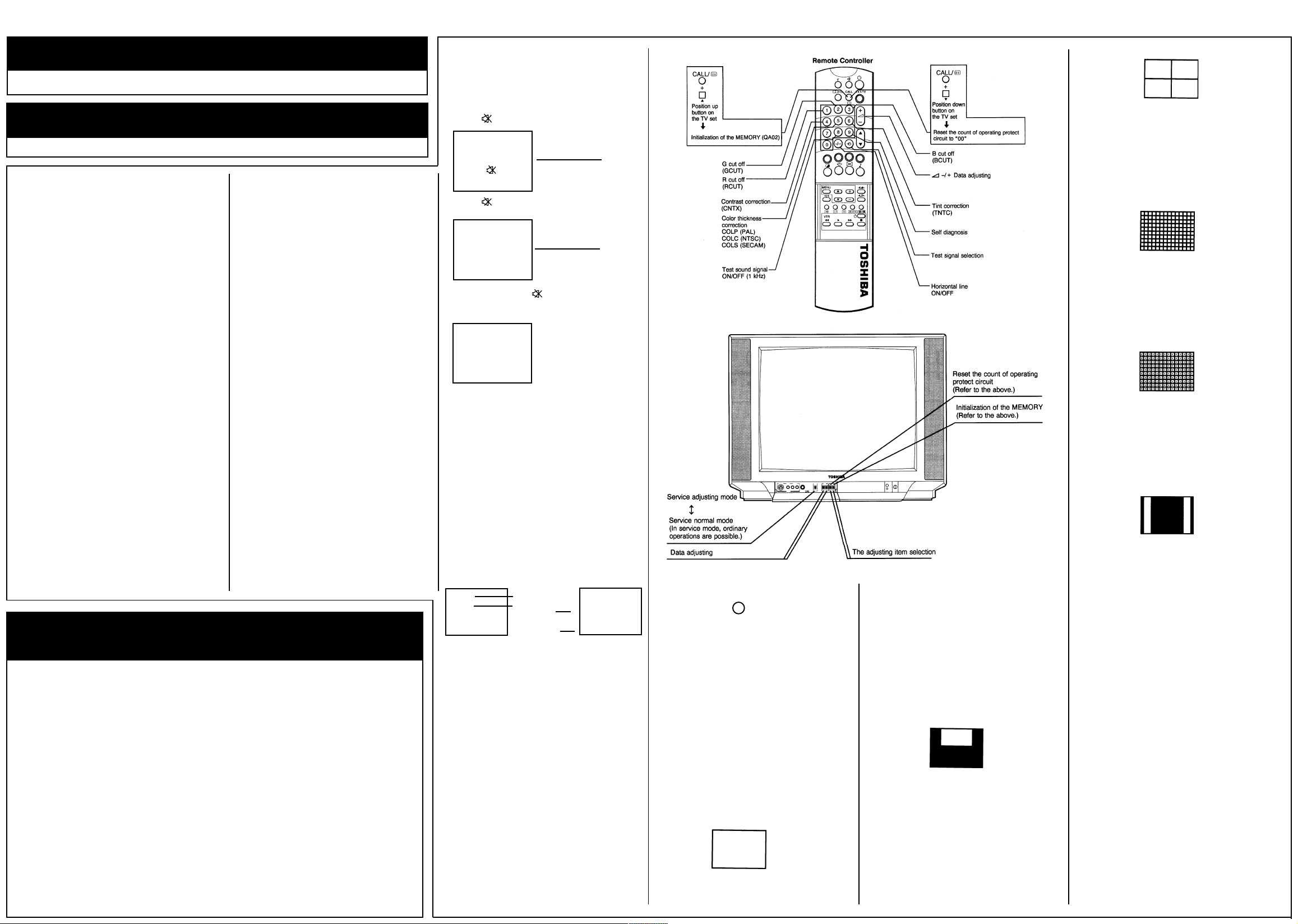

Service Mode General

Instructions

1. ENTERING TO SERVICE MODE

1) Press button once on Remote Control.

2) Press button again to keep pressing.

3) Keep pressing the button, press MENU

button on TV set.

RCUT S

32H

(Service mode dIsplay)

2. SELECTING THE ADJUSTING ITEMS

Every pressing of CHANNEL ▲ button changes

the adjustment items in the following order.

(▼ button for reverse order.)

3. ADJUSTING THE DATA

Pressing of VOLUME ▲ or ▼ button will change

the value of data in the range from 00 to FF. The

variable range depends on the adjusting item.

4. NORMAL OPERATION ON THE SERVICE

MODE

Press MENU button on TV.

Adjustment mode Service mode

RCUT Address S

➤

➤

32H Data

5. EXIT FROM SERVICE MODE

Press POWER button on the remote control to

turn off the TV once.

OTHER SERVICE FUNCTION

The following key entry during display of

adjustment menu provides special functions.

Press

Press

➤

➤

➤

➤

TEST SIGNAL SELECTION

Every pressing of button changes the test

patterns on screen as described below in

SERVICE MODE.

Signal off ➜ NTSC signals (14 patterns)

PAL signals (14 patterns)

About inside signal: The inside signal is output

at video input terminal from QA01, and is not

output with the pin inserted into terminal.

(Single color signal can be output.)

Signals

Red single colour

Green single colour

Blue single colour

Black single colour

White single colour

Picture

Using method

Purity and White uniformity of CRT

Red single colour.

➜

➜

➜

Stopping G and B output of Q501

Green single colour.

Stopping R and B output of Q501

Blue single colour.

Stopping R and G output of Q501

Black single colour.

Making black signal of approx. 1Vp-p in QA01

White single colour.

Making white signal of approx. 1Vp-p in QA01

Signals

W/B adjustment

Picture

Using method

White balance adjustment

White .

White balance adjustment/check in light area

Black part.

White balance adjustment/check in dark area.

Making. approx. 1Vp-p signal in QA01.

Signals

Black cross-bar

White cross-bar

Picture

Using method

Picture position (horizontal, vertical and slant) in

CRT adjustment.

Making approx. 1 Vp-p signal in QA01.

Signals

Black cross-hatch

White cross-hatch

Picture

Using method

Convergence and vertical amplitude adjustment

Making approx. 1 Vp-p signal in QA01.

Signals

Black cross-dot

White cross-dot

Picture

Using method

Convergence adjustment

Making approx. 1Vp-p signal in QA01.

Signals

H signal (Left, right, white)

H signal (Left, right, black)

Picture

Using method

For checking (of purity drift) of white uniformity

of CRT H signal (Left, right, white).

Check in light area.

H signal (Left, right, black).

Check in dark area.

The adjustment will be the best, if the time when

unevenness of color in light area occurs, is a

little longer than that in dark area.

Making approx. 1Vp-p signal in QA01.

Page 2

TOSHIBA 2857 DB

2

Service Mode Cont’d

ITEM:

Initialisation of QA02 (Memory)

ADJUSTMENT PROCEDURE:

After replacing QA02, the following initialisation

is required.

1. Call up the adjustment mode display following

the steps 1 and 2.

2. Press the CALL button on the Remote Control

and CHANNEL ▲ buttons on the TV set

simultaneously. The initialisation of QA02 has

been completed.

3. Check the picture carefully. If necessary,

adjust any adjustment item.

Perform “AUTOMATIC SEARCH MEMORY”

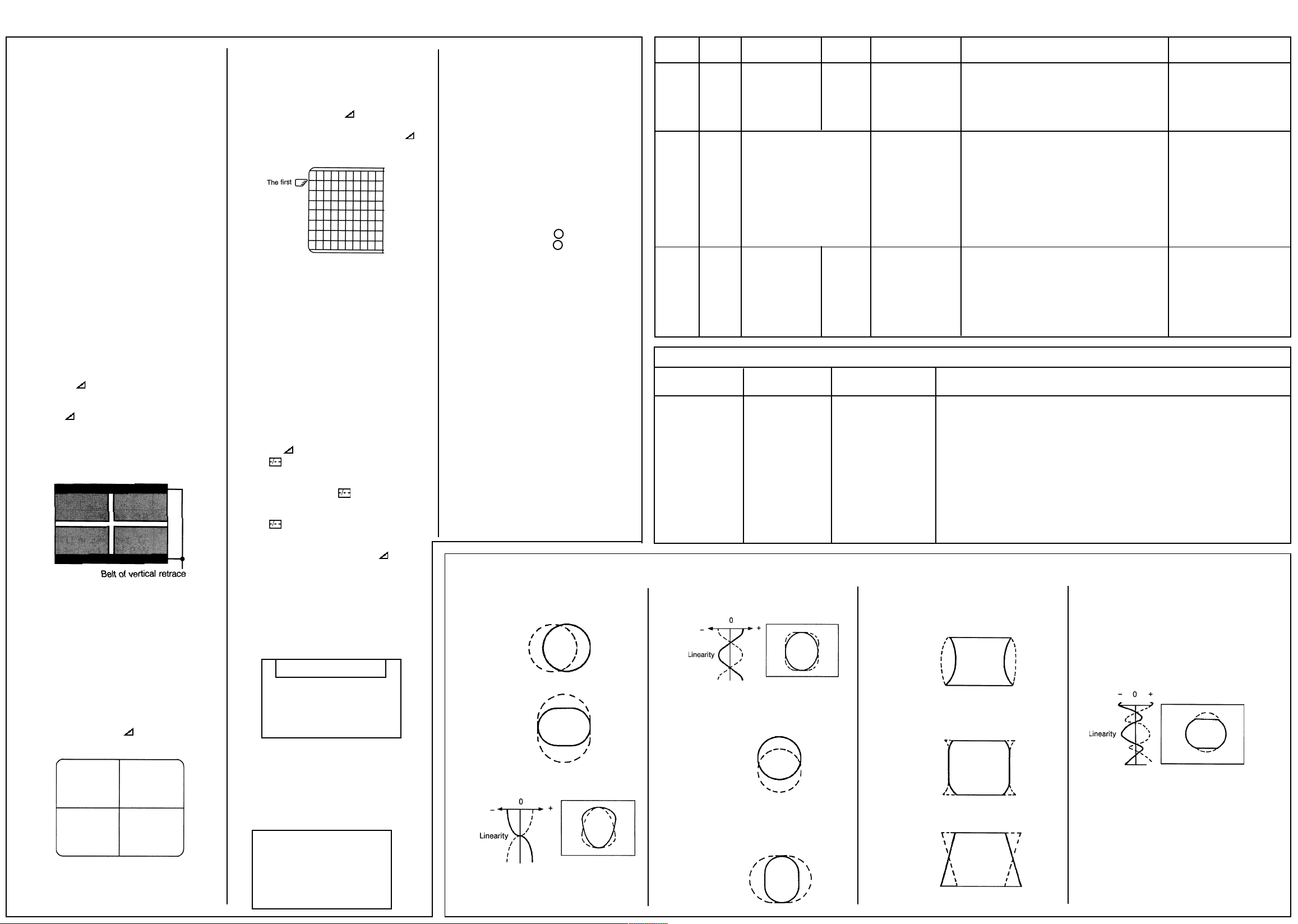

ITEM: SUB-BRIGHTNESS (Address: BRTC)

Note: Constrict the picture height until the

vertical retrace line appears adjusting the

address HIT (HEIGHT).

ADJUSTMENT PROCEDURE:

1. Set CONTRAST to “00,, and BRIGHTNESS to

“50” by adjusting user controls.

2. Set the TV in service mode to get white crossbar of inside pattern.

3. Select BRTC (brightness correction), and

adjust the - / + button to reduce the value

so that white portion of inside pattern slightly

light.

4. Adjust - / + button to increase the data

value of BRTC, and set it just before the

difference between the belt of vertical retrace

and the border of black portion of inside

pattern is visible. After that, return vertical

height and contrast.

ITEMS:

HORIZONTAL POSITION ADJUSTMENT

(HPOS)

VERTICAL POSITION ADJUSTMENT (VPOS)

ADJUSTMENT PROCEDURE:

1. Set the TV in service mode, and get black or

white cross-bar signal with VIDEO button on

remote hand unit.

2. Select either HPOS (Horizontal picture phase)

or VPOS (Vertical picture phase) with

CHANNEL ▲, ▼ buttons, and adjust horizontal or vertical picture position in the center of

screen with VOLUME - / + buttons.

ADJUSTMENT PROCEDURE:

1. Set the TV in service mode, and get black or

white cross-hatch signal with VIDEO button

on remote hand unit.

2. Select HIT (Vertical amplitude) with CHANNEL ▲, ▼ buttons, and adjust vertical

amplitude with VOLUME - / + buttons so

that vertical amplitude lacks a little.

3. Adjust vertical amplitude with VOLUME - /

+ buttons so that the first bar on cross-hatch

signal touches edge of screen.

WHITE BALANCE ADJUSTMENT

CUTOFF ADJUSTMENT

(RCUT)

(GCUT)

(BCUT)

DRIVE ADJUSTMENT

(GDRV)

(BDRV)

1. Set Contrast to 40, and brightness to +20 by

picture control.

2. Set the TV in service mode, and get the inside

W/B adjusting signal with VIDEO button.

3. Select RCUT, GCUT and BCUT with CHANNEL ▲, ▼ buttons, to set individual values to

32, and to set GDRV and BDRV to 20 with

VOLUME - / + buttons.

4. Press button on the remote control and

rotate Screen VR to get one slight horizontal

line on screen.

Note:Every pressing of button provides

Horizontal line picture and Normal picture

alternately.

5. Press button to release horizontal line

picture, and select the two other colors which

did not light in the above step with CHANNEL

▲,▼ buttons. Then tap VOLUME - / +

buttons so that three colors slightly light in the

same level.

To correct white balance in light area, select

GDRV and BDRV with CHANNEL ▲,▼ buttons

to adjust.

To correct white balance in dark area, perform

fine adjustment of RCUT, GCUT and BCUT.

Light area check (to show white)

Dark area check (to show black)

1) Part number of microcomputer (QA01)

2) Operation number of protecting circuit ----“00”

is normal. When indication is other than “00”,

overcurrent apts to flow, and circuit parts may

possibly be damaged.

3) BUS LINE CHECK ---- “OK” is normal.

“SDA1-GND” means that SDA line is shorted

to ground.

“SCL1-GND” means that SCL line is shorted

to ground.

“SCL1-SDA1” means that SDA line is shorted

to SCL line.

4) BUS CONT----“OK” is normal.

When indication shows “Q OOO NG”, the

device with the number may possibly be

damaged.

5) BLOCK

UV : TV reception mode

V1: VIDEO 1 input mode ( 1)

V2 :VIDEO 2 input mode ( 2)

➜

➜

Indicated color of mode now selected: Green

and Red

Indicated color of other modes: White

Green: Normal

Red: The microcomputer operates to provide

judgement of no video signal. The red color is

still indicated though the signal is input, failure

may exist in input signal line including QV01.

QV01: In case of indication green --- Normal

In case of indication red with input signal ---Failure may exist in output line including QV01.

Sub Data Additional Description

Symbol Description

HPOS H screen position correction

HIT V amplitude adjustment.

Item Name Setting(User control) Input signal Measurement point Adjustment procedure Adjustment standard

[COLP] SUB Contrast: MAX Sub-bright IC501 1. Select slave address OCH 1.35V(p-p)

[RCUT] R cut-off RCUT 40 Hexa-decimal Screen 1. Set the controls as shown in

[GCUT] G cut-off GCUT 40 Hexa-decimal adjustment the left column.

[BCUT] B cut-off BCUT 40 Hexa-decimal 2. Gradually increase the screen

Screen VR Screen GDRV 40 Hexa-decimal VR (T461) until one of R, G or BDRV B line begins

[RCUT] R cut-off Contrast: MAX White, etc. Screen 1. This adjustment must be done HIGH LIGHT;

[GCUT] G cut-off Bright : CENTER adjustment after adjustment of the above- (103cd/m3)

[BCUT] B cut-off Color : CENTER mentioned cut-off and screen 7195K

[GDRV] C drive VR’s have been completed. -0.005uv [BDRV]

[BDRV] B drive 2. Adjust cut-off and drive DATA DARK;

Model name: C5SS (2857DB/3357DB)

Adjustment parts or Input point/ Adjustment signal Adjustment conditions and procedures

Bus control item Output point

Horizontal amplitude Visual check of picture WG Philips pattern 1. Conditions: After V. HEIGHT, VERT POSITION

adjustment (WID) (Bus control) and H. CENT have been adjusted, set

Pin distortion Do not use the Philips the controllers as follows:

compensation amount pattern of Contrast: MAX

adjustment (PARA) FRANCESECAM. Brightness: Center

Keystone distortion Color: Center

compensation amount 2. Adjustment procedure

adjustment (HOP) a. Adjust the horizontal amplitude by the sub address WID.

Symbol Description

VSC V linearity correction 2.

COLOUR Bright: CENTER signal #55 [COLP]. ± 0.2V(p-p)

PAL Color: CENTER (PAL) (TP501) 2. When [COLP] is selected, Y-signal is muted

Select horizontal line mode by to brighten slightly.

pressing

-I-

control in service mode. 4. Adjust RCUT, GCUT and BCUT, brighten other lines

(White alternately. (17cd/m3)

balance) 3. Use a checker to adjust 7695K ± 0uv

- button on the remote 3. Determine the position of the screen VR here.

Symbol Description

PARA H pin-cushion distortion

correction.

and only color signals are outputted.

3. Adjust amplitude of the upper half of the colour

bar output.

until they begin to light slightly.

(Adjust DATA so that the line becomes almost white.)

5. Press

-I-

horizontal line mode.

brightness by changing modulation factor.

Adjust so that the left and right white flags of

Philips pattern disappear at the very limits.

b. Make the left and right vertical bars straight by the sub address PARA.

c. Compensate the key distortion by the sub address HOP.

d. Again, adjust the sub address WID.

- button on the remote control to escape from the

Symbol Description

HCP Setting of amount of H amplitude

correction against variation of

screen brightness.

VFC V linearity correction.

Linearity balance at 1/4, 3/4

areas from top.

Linearity balance between top/

bottom and center.

CNR H pin-cushion distortion

VPOS VPS V picture position adjustment

correction at four corners.

ITEM:

VERTICAL AMPLITUDE ADJUSTMENT (HIT)

SELF DIAGNOSTIC FUNCTION

1) Press “9” button on Remote Control during

display of adjustment menu. The diagnosis

will begin to check if interface among IC’s are

executed properly.

2) During diagnosis, the following displays are

shown.

(SELF CHECK)

(1) 2390XXXX

(2) POWER : 00

(3) BUS LINE : OK

(4) Bus CONT : OK

(5) BLOCK : UV V1 V2

QV01

LIN V linearity correction 1.

Linearity balance between top

and bottom screen.

VCP Setting of amount of V amplitude

correction against variation of

screen brightness.

WID H amplitude adjustment.

TRAP Pedestal distortion correction.

Page 3

TOSHIBA 2857 DB

3

Service Mode Cont’d

MULTI BUS E2PROM ADDRESS, ADJUSTING ADDRESS TABLE

Adjusting 0A02 Name Value of Initializing

method memory of QA02 Adjustments

address item (Hexa-decimal)

F 03H RCUT 40H R OUTOFF (B/W)

04H GCUT 40H G OUTOFF (B/W)

O5H BCUT 40H B OUTOFF (B,W)

06H GDRV 40H G DRIVE

➤

07H BDRV 40H B DRIVE

S 08H CNTX 7FH SUB CONTRAST MAX (4:3 MODE)

F 09H BRTC 7FH SUB BRIGHT CEN

0AH COLC 50H SUB COLOR CEN NTSC

BH TNTC 40H SUB TINT CEN

0CH COLP 50H SUB COLOR CEN PAL

➤

0DH COLS 50H SUB COLOR CEN SECAM

S 0EH SCOL 8FH SUB COLOR

0FH SCNT 7FH SUB CONTRAST

25H VOLS 00H VOL SCART

26H FVOL 00H FM VOL PRE SCALE

27H NVOL 00H NICAM VOL PRE SCALE

28H NICL 00H NICAM THRESHOLD LEVEL

29H NICH 00H NICAM THRESHOLD LEVEL

2AH IDL 00H IGR THRESHOLD LEVEL

2BH IDH 00H IGR THRESHOLD LEVEL

20H EVOL 00H EXT PRE. VOLUME

2DH EMX FCH NICAM ON LEVEL

2EH EMN 64H NICAM OFF LEVEL

2FH FMA 00H FM ATTENUATOR LEVEL

➤

30H STS 00H STEREO SEPARATION

F 31H HPOS 15H 50Hz H-POSITION

32H VPOS 04H V-POSITION

33H HIT 3EH HEIGHT

37H VLIN 11H V-LINEARITY

38H VSC 0FH V-S CORRECTION

39H VPS 0EH V-SHIFT

➤

3AH VCP 06H V-COMPENSATION

F 3BH WID 0FH PICTURE WIDTH

F 30H PARA 2AH E-W PARABOLA

S 3DH CNR 0GH E-W CORNER

3EH TRAP 1FH TRAPEZIUM

3FH HCP 02H H-COMPENSATION

40H VFC 0EH V-F CORRECTION

C9H BELL 00H SECAM BELL FILTER

CAH SRY 08H SECAM R-Y

➤

CBH SBY 08H SECAM B-Y

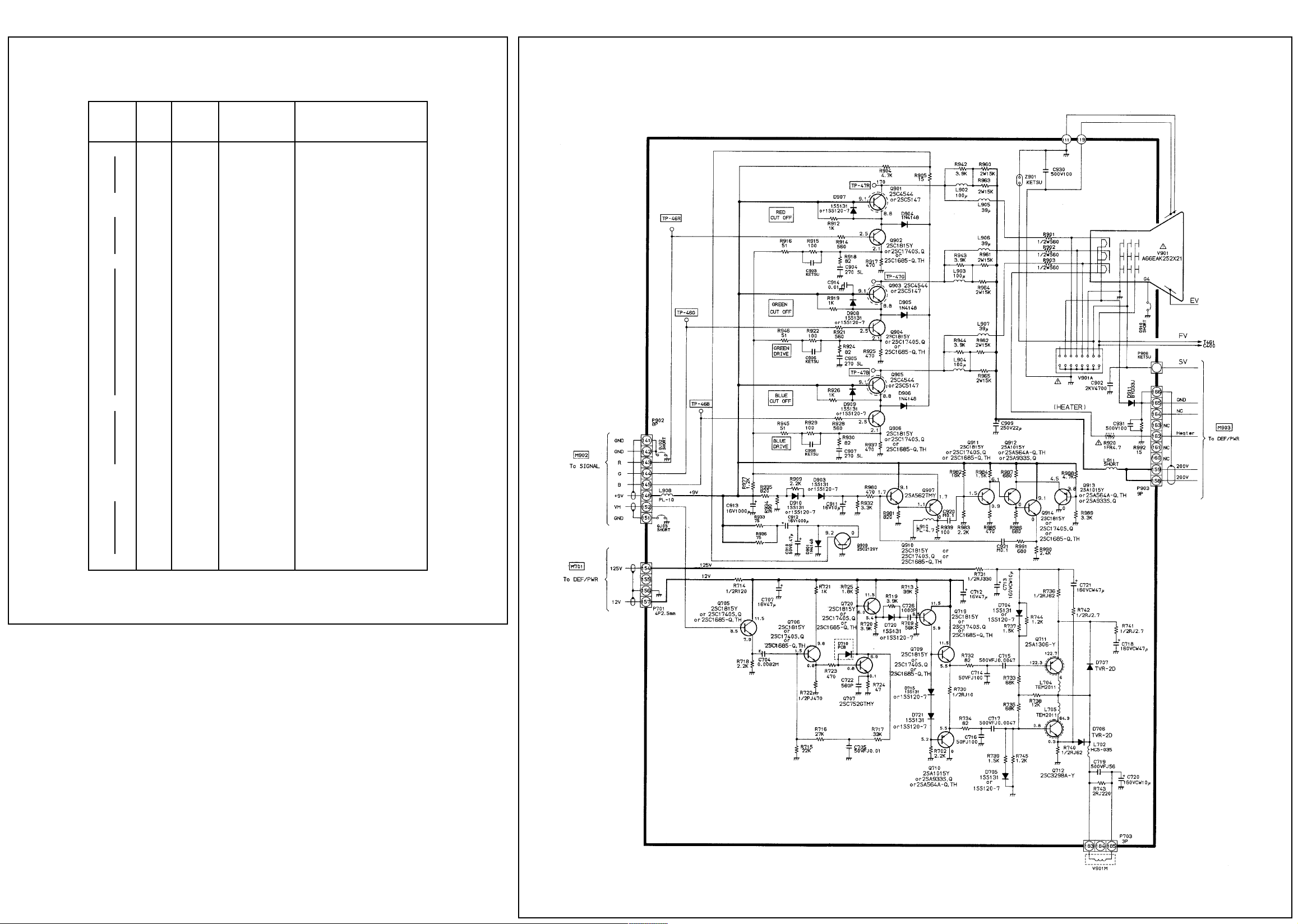

CRT PCB Diagram

S... semi-fixed data area which is fixed by model. (Do not adjust in field service.)

F... This item may require adjustments by models after initialization, when QA02 is replaced

Page 4

TOSHIBA 2857 DB

AV PCB Diagram

4

Page 5

TOSHIBA 2857 DB

5

Comb & Delay PCB Diagram

Page 6

TOSHIBA 2857 DB

6

Pro Logic Diagram

Page 7

TOSHIBA 2857 DB

7

Signal Processing Diagram

Page 8

TOSHIBA 2857 DB

8

Signal Processing Diagram Cont’d

Page 9

TOSHIBA 2857 DB

9

Power & Deflection Diagram

Page 10

TOSHIBA 2857 DB

10

Power & Deflection Diagram Cont’d

Text PCB Diagram

Loading...

Loading...