Page 1

TOSHIBA 2555 DB

1

General Information

Also Covers

2855 DB

2852 DB

2552 DB

Safety Instructions

X-RAY RADIATION PRECAUTION

1. The E.H.T. must be checked every time the

receiver is serviced to ensure that the C.R.T.

does not emit X-ray radiation as result of

excessive E.H.T. voltage. The nominal E.H.T.

for this receiver is 26.5 kV at zero beam

current (minimum brightness) operating at

240V a.c. The maximum E.H.T. voltage

permissible in any operating circumstances

must not exceed 29.0 kV. When checking the

E.H.T., use the ‘High Voltage Check’ procedure in this manual using an accurate E.H.T.

voltmeter.

2. The only source of X-RAY radiation in this

receiver is the C.R.T. To prevent X-ray

radiation, the replacement C.R.T. must be

identical to the original fitted as specified in

the Parts List.

3. Some components used in this receiver have

safety related characteristics preventing the

C.R.T. from emitting X-ray radiation. For

continued safety, replacement component

should only be made after referring the

Product Safety Notice below.

SAFETY PRECAUTION

1. This receiver has a nominal working E.H.T.

voltage of 24.5 kV. Extreme caution should be

exercised when working on the receiver with

the back removed. Do not attempt to service

this receiver if you are not conversant with the

precautions and procedures for working on

high voltage equipment. When handling or

working on the C.R.T., always discharge the

anode to the receiver chassis before removing the anode cap. The C.R.T., if broken, will

violently expel glass fragments. Use shatter

proof goggles and take extreme care while

handling. Do not hold the C.R.T. by the neck

as this is a very dangerous practice.

2. It is essential that to maintain the safety of the

customer all cable forms be replaced exactly

as supplied from factory.

3. A small part of the chassis used in this

receiver is, when operating, at approximately

half mains potential at all times. It is therefore

essential in the interest of safety that when

serving or connecting any test equipment the

receiver should be supplied via a suitable

isolating transformer of adequate rating.

4. Replace blown fuses within the receiver with

the fuse specified in the parts list.

5. When replacing wires or components to

terminals or tags, wind the leads around the

terminal before soldering. When replacing

safety components identified by the international hazard symbols on the circuit diagram

and parts list, it must be a Toshiba approved

type and must be mounted as the original.

6. Keep wires away from high temperature

components.

PRODUCT SAFETY NOTICE

Many electrical and mechanical components in

this chassis have special safety-related

characteristics. These characteristics are often

passed unnoticed by a visual inspection and the

X-ray radiation protection afforded by them

cannot necessarily be obtained by using

replacements rated at higher voltages or

wattage, etc. Components which have these

special safety characteristics in this manual and

its supplements are identified by the interna-

Recommended Safety Parts

Item Part No. Description

C440 24082581 PF, 7000pF, ±3%, 1500V

C463 24212222 CD, 2200pF, ±10%

C801 24082318 PF, 0.1µF, ±20%, AC250V

C802 24094656 CD, 2200pF, ±20%, AC400V

C803 24094656 CD, 2200pF, ±20%, AC400V

C804 24082318 PF, 0.1pF, ±20%, AC250V

R327 24339479 MF, 4.7 ohm, 2W

R448 24338338 ME, 0.33 ohm, 1W

R801 24004914 Metal-Glazed Resistor, 5.6M ohm, 1/2W

R878 24531560 FR, 56 ohm, 1/2W

R884 24531120 FR, 12 ohm, 1/2W

3890 24019340 PTC Thermistor, 18 ohm, 290V

3920 24000907 FR, 3.9 ohm, 1W

RD01 24000211 FR, 15 ohm, 1/2W

RV25 24019261 FR, 47 ohm, ±2%, 1/4W

L462 ------------- DY, Supplied with V901

L901 23200275 Coil, Degaussing, TSB-2329BR (2555DB/2552DB)

L901 23200276 Coil, Degaussing, TSB-2330BR (2855DB/2852DB)

T401 23224336 Transformer, Horiz. Drive, TLN1083

T461 23236454 Transformer, Flyback, TFB41 17AR

T801 23211670 Line, Filter, TRF3164G

T803 23217214 Transformer, Converter, TPW3283AR

Q404 A6872801 Transistor, 2SD2253(FA)

Q826 A8643108 Photo Coupler, TLP621(GR-LF

Q827 A6907751 IC, S1854

F801 23144507 Fuse, 3.15A

F803 23144874 Fuse, 0.8A

P801 23372012 Power Cord

V901A 23902891 Socket, CRT, lop

V901 23312462 Picture Tube, A59EAK71X01 (2555DB/2552DB)

V901 23312463 Picture Tube, A66EAK71X01 (2855DB/2852DB)

tional hazard symbols on the schematic diagram

and parts list. Before replacing any of these

components read the parts list in this manual

carefully. Substitute replacement components

which do not have the same safety characteristics as specified in the parts list may create Xray radiation

Service Adjustments

GENERAL INFORMATION

All adjustments are thoroughly checked and

corrected when the receiver leaves the factory.

Therefore the receiver should operate normally

and produce proper colour and B/W pictures

upon installation. However, several minor

adjustments may be required depending on the

particular location in which the receiver is

operated.

This receiver is shipped completely in cardboard

carton. Carefully draw out the receiver from the

carton and remove all packing materials. Plug

the power cord into a convenient 240 volts 50

Hz AC two pin power outlet. Turn the receiver

ON. Check and adjust all the customer controls

such as BRIGHTNESS, CONTRAST and

COLOUR Controls to obtain natural colour or B/

W picture.

AUTOMATIC DEGAUSSING

A degaussing coil is mounted around the picture

tube so that external degaussing after moving

the receiver is normally unnecessary, providing

the receiver is properly degaussed upon

installation. The degaussing coil operates for

about 1 second after the power to the receiver is

switched ON. If the set is moved or faced in a

different direction, the power switch must be

switched off at least 30 minutes in order that the

automatic degaussing circuit operates properly.

Should the chassis or parts of the cabinet

become magnetized to cause poor colour purity,

use an external degaussing coil. Slowly move

the degaussing coil around the faceplate of the

picture tube, the sides and front of the receiver

and slowly withdraw the coil to a distance of

about 2 m before disconnecting it from AC

source. If colour shading still persists, perform

the COLOUR PURITY ADJUSTMENT and

CONVERGENCE ADJUSTMENTS procedures.

HIGH VOLTAGE CHECK

CAUTION: There is no HIGH VOLTAGE

ADJUSTMENT on this chassis.

1. Connect an accurate high voltage meter to

the second anode of the picture tube.

2. Turn on the receiver. Set the BRIGHTNESS

and CONTRAST Controls to minimum (zero

beam current).

3. High voltage will be measured below 29.0 kV.

HORIZONTAL CENTRE ADJUSTMENT

1. Receive the UK PHILIPS pattern.

2. Set the contrast and colour to centre, and the

brightness to centre.

3. Adjust H. CENTER USER Control (R452) so

the pattern centre can be located at the

screen centre.

FOCUS ADJUSTMENT

Adjust FOCUS Control on FLYBACK TRANS.

(T461) for well defined scanning lines in the

centre area on the screen.

SIF FM DET (LG04) ADJUSTMENT (NICAM

BOARD)

1. Connect SIF generator through 0.01 pF

capacitor to pin D1 of PD01 on NICAM Board.

2. Connect the oscilloscope to pin 9 of ICD03.

3. Set up the SIF generator as described.

Sound carrier frequency: 6.0 MHz

Modulation frequency :1000 Hz Frequency

deviation : ± 15 kHz

Signal level :100 dBp (50 ohm load)

4. Adjust LG04 for the maximum response of

1000 Hz det-out on scope.

PAL MATRIX ADJUSTMENT

1. Tune in the colour programme of the Philips

pattern.

2. Set the COLOUR Control to obtain the proper

colour.

3. If the PAL MATRIX adjustment is incorrect,

the Venetian Blind would appear in the colour

bars area. This case needs the adjustment.

4. At the first, adjust DL PHASE ADJ. Coil (L551)

to minimize the Venetian Blind.

5. Next adjust 1H-DL ADJ. VR (R551) to

minimize the Blind.

6. If the Venetian Blind still remains, adjust 1 HDL PHASE ADJ. Coil (L551) to minimize the

Blind again.

7. Repeat the item 5 and 6 procedures, adjust

the R551 and L551 until the Blind does not

appear.

CRT GREY SCALE ADJUSTMENT

1. Tune in an active channel.

2. Set the SERVICE SW. (S202) in the “H. LINE”

position.

3. Turn the SCREEN Control (on T461) fully

counterclockwise.

4. By rotating the RED, GREEN and BLUE CUT

OFF Controls (R557, R558, R559) to the mid

position.

5. Set the GREEN and BLUE DRIVE Controls

(R252, R253) to the center.

6. Rotate the SCREEN Control gradually

clockwise until the first line appears slightly on

the screen. Set the SCREEN Control to this

position.

7. Adjust the CUT OFF Controls to obtain the

slightly lighted horizontal lines in the same

levels of three colours (RED, GREEN and

BLUE). The lines may look like white if the

CUT OFF Controls are adjusted properly.

8. Set the SERVICE SW. (S202) in the “RECEIVE” position.

9. Set the CONTRAST and COLOUR Controls

to minimum, and BRIGHTNESS Control to the

maximum.

10.Adjust the BLUE and GREEN DRIVE

Controls (R252/R253) to obtain proper whitebalanced picture in high light areas.

11.Set the BRIGHTNESS and CONTRAST

Controls to obtain dark grey raster. Then

check the white balance in low brightness. If

the white balance is not proper, retouch the

CUT OFF Controls and DRIVE Controls to

obtain a good white balance in both low and

high light areas.

SUB-BRIGHTNESS ADJUSTMENT

1. Tune in a colour programme.

2. Set the CONTRAST Control to the minimum

and the BRIGHTNESS Control to the centre.

3. Set the COLOUR Control to the centre.

4. Set the SUB-BRIGHT. Control (R255) to the

centre and leave the receiver for five minutes

in this state.

5. Watching the picture well, adjust the SUBBRIGHT. Control in the position where the

picture does not show evidence of blooming in

high bright area and not appear too dark in

low bright portion.

6. Check the proper picture variation by rotating

the CONTRAST and BRIGHTNESS Controls

to both extremes.

7. If the picture does not appear dark with the

CONTRAST and BRIGHTNESS Controls

turned to the minimum, or not appear bright

with the controls turned to the maximum,

adjust the SUB-BRIGHT. Control again for the

acceptable picture.

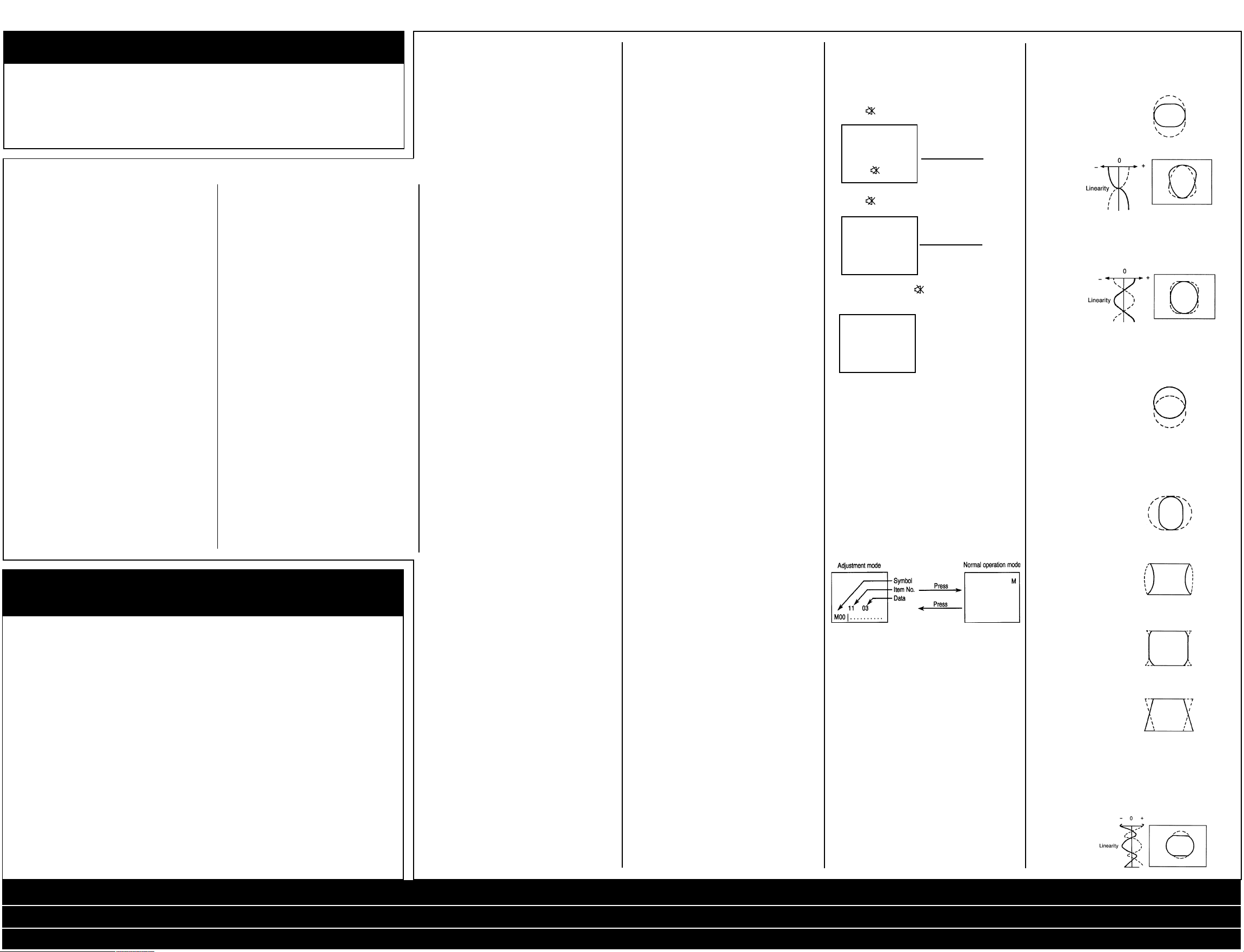

Service Mode General

Instructions

1. ENTERING TO SERVICE MODE

1) Press button once on Remote Control.

➤

2) Press button again to keep pressing.

➤

3) Keep pressing the button, press MENU

button on TV set.

RCUT S

32H

(Service mode dIsplay)

2. SELECTING THE ADJUSTING ITEMS

Every pressing of CHANNEL ▲ button changes

the adjustment items in the following order.

(▼ button for reverse order.)

3. ADJUSTING THE DAT A

Pressing of VOLUME ▲ or ▼ button will change

the value of data in the range from 00 to FF. The

variable range depends on the adjusting item.

4. NORMAL OPERATION ON THE SERVICE

MODE

Press MENU button on TV.

5. EXIT FROM SERVICE MODE

Press POWER button on the remote control to

turn off the TV once.

See next page for Adjustment Procedure and

Rom Data List.

SUB DATA ADDITIONAL DESCRIPTION

Symbol Description

HIT V amplitude adjustment.

LIN V linearity correction 1.

Linearity balance

between top and bottom

screen.

VSC V linearity correction 2.

Linearity balance

between top/bottom and

center.

VPC V picture position

adjustment

VCP Setting of amount of V

amplitude correction

against variation of

screen brightness.

WID H amplitude adjustment.

DPC H pin-cushion distortion

correction.

CNR H pin-cushion distortion

correction at four

corners.

KEY Pedestal distortion

correction.

HCP Setting of amount of H

amplitude correction

against variation of

screen brightness.

VMC V linearity correction.

Linearity balance at 1/4,

3/4 areas from top.

Service Mode / Safety Parts / Safety Instructions / Service Adjustments / Adjustment Procedure / Block Diagram

Signal Processing (2555 & 2855) ... Cont’d / Signal Processing (2552 & 2852) ... Cont’d

Power Audio Deflection (2555 & 2855) ... Cont’d / Power Audio Deflection (2552 & 2852) ... Cont’d

Page 2

TOSHIBA 2555 DB

Adjustment Procedure

Adjustment parts or Input point/ Adjustment signal Adjustment conditions and procedures

Bus control item Output point

Horizontal amplitude Visual check of picture WG Philips pattern 1. Conditions: After V. HEIGHT, VERT POSITION

adjustment (WID) (Bus control) and H. CENT have been adjusted, set

Pin distortion Do not use the Philips the controllers as follows:

compensation amount pattern of Contrast: MAX

adjustment (DPC) FRANCESECAM. Brightness: Center

Keystone distortion Color: Center

compensation amount 2. Adjustment procedure

adjustment (KEY) a. Adjust the horizontal amplitude by the sub

address WID. Adjust so that the left and right

white flags of Philips pattern disappear at the

very limits.

b. Make the left and right vertical bars straight

by the sub address DPC.

c. Compensate the key distortion by the sub

address KEY.

d. Again, adjust the sub address WID.

2

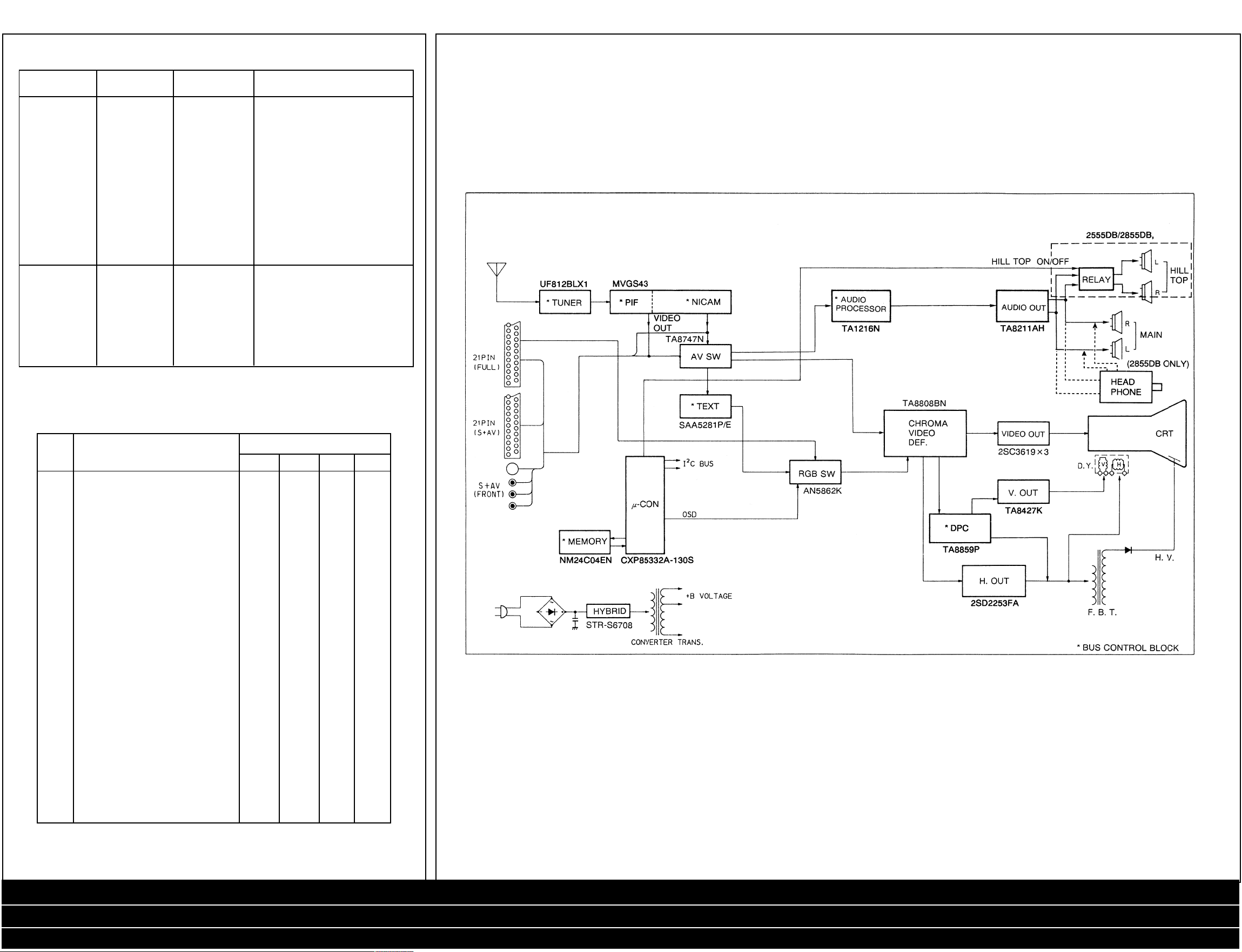

Block Diagram

HEIGHT (HIT) Visual check of picture Brightness: Center

VERT. POSITION (Bus control) Do not use the Philips Color: Center

ROM DATA LIST FOR IIC BUS CONTROL (Reference Value)

Symbol Comment Data

M00 MODE 0 51 51 51 51

M01 MODE 1 33 33 33 33

M01 MODE 1 USE ALPS TUNER 01 01 01 01

M02 MODE 2 03 03 02 02

M03 MODE 3 17 17 49 49

HIT HEIGHT *30 *30 *30 *30

LIN V. LINEARITY 32 32 32 32

VSC V. S-CORRECTION 32 32 32 32

VPS V. POSITION *07 *07 *07 *07

VCP V. COMPENSATION 30 30 30 30

WID H.WIDTH *22 *26 *22 *26

DPC DPC *26 *24 *26 *24

CNR DPC CORNER P44V32 32 P44V32 32

KEY KEYSTONE *09 *09 *09 *09

HCP H. COMPENSATION 10 10 10 10

VMC V. M-CORRECTION 52 41 52 41

SHI 16:9 SUB HEIGHT 00 00 00 00

SLI 16:9 SUB V. LINEARITY 32 32 32 32

SVS 16:9 SUB V.S-CORRECTION 17 17 17 17

SDP 16:9 SUB DPC P18V21 P17V21 P18V21 P17V21

SCN 16:9 SUB CORNER 30 30 30 30

WCT WOOFER FC SET 12 08 12 12

BAC BASS CENTER 40 34 50 50

TRC TREBLE CENTER 48 52 44 44

BAX BASS MAX 79 79 79 79

WON BAZOOKA AUTO 05 30 06 06

WOF BAZOOKA OFF 20 47 25 25

BAE BASS UP 01 03 01 01

TRE TREBLE UP 12 17 10 10

VOE VOL UP 02 02 00 00

WFL WOOFER LEVEL 100 100 100 100

EMX NICAM OFF LEVEL (PHIL) 252 252 252 252

EMN NICAM ON LEVEL (PHIL) 100 100 100 100

FMA FM INPUT ATT (PHIL) 00 00 00 00

STS STEREO SEPARATION — — — —

WG Philips pattern 1. Conditions:Contrast: Max

pattern of 2. Adjustment procedure

FRANCESECAM. a. By the bus address VPS, adjust V. position so

that the circle of Philips pattern comes to the

vertical center.

b. Adjust HIT so that the upper and lower flags of

Philips pattern disappear at the very limits.

2555DB 2855DB 2552DB 2852DB

* Mark items should be adjusted.

Service Mode / Safety Parts / Safety Instructions / Service Adjustments / Adjustment Procedure / Block Diagram

Signal Processing (2555 & 2855) ... Cont’d / Signal Processing (2552 & 2852) ... Cont’d

Power Audio Deflection (2555 & 2855) ... Cont’d / Power Audio Deflection (2552 & 2852) ... Cont’d

Page 3

TOSHIBA 2555 DB

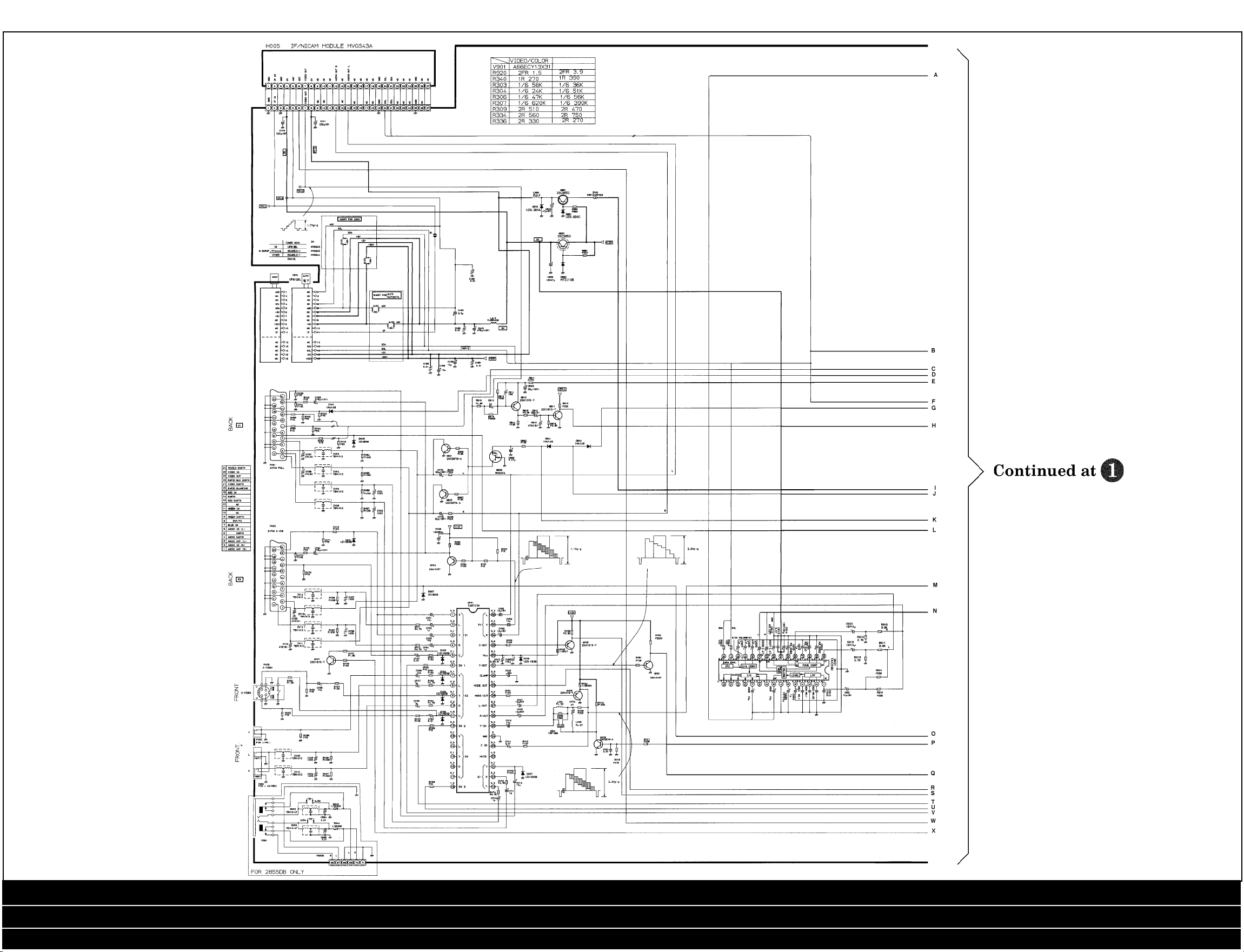

Signal Processing

(2555 & 2855)

Diagram

3

Service Mode / Safety Parts / Safety Instructions / Service Adjustments / Adjustment Procedure / Block Diagram

Signal Processing (2555 & 2855) ... Cont’d / Signal Processing (2552 & 2852) ... Cont’d

Power Audio Deflection (2555 & 2855) ... Cont’d / Power Audio Deflection (2552 & 2852) ... Cont’d

Page 4

TOSHIBA 2555 DB

Signal Processing

(2555 & 2855)

Diagram Cont’d

4

Service Mode / Safety Parts / Safety Instructions / Service Adjustments / Adjustment Procedure / Block Diagram

Signal Processing (2555 & 2855) ... Cont’d / Signal Processing (2552 & 2852) ... Cont’d

Power Audio Deflection (2555 & 2855) ... Cont’d / Power Audio Deflection (2552 & 2852) ... Cont’d

Page 5

TOSHIBA 2555 DB

Signal Processing

(2552 & 2852)

Diagram

5

Service Mode / Safety Parts / Safety Instructions / Service Adjustments / Adjustment Procedure / Block Diagram

Signal Processing (2555 & 2855) ... Cont’d / Signal Processing (2552 & 2852) ... Cont’d

Power Audio Deflection (2555 & 2855) ... Cont’d / Power Audio Deflection (2552 & 2852) ... Cont’d

Page 6

TOSHIBA 2555 DB

Signal Processing

(2552 & 2852)

Diagram Cont’d

6

Service Mode / Safety Parts / Safety Instructions / Service Adjustments / Adjustment Procedure / Block Diagram

Signal Processing (2555 & 2855) ... Cont’d / Signal Processing (2552 & 2852) ... Cont’d

Power Audio Deflection (2555 & 2855) ... Cont’d / Power Audio Deflection (2552 & 2852) ... Cont’d

Page 7

TOSHIBA 2555 DB

Power, Audio &

Deflection

Diagram

(2555 & 2855)

7

Service Mode / Safety Parts / Safety Instructions / Service Adjustments / Adjustment Procedure / Block Diagram

Signal Processing (2555 & 2855) ... Cont’d / Signal Processing (2552 & 2852) ... Cont’d

Power Audio Deflection (2555 & 2855) ... Cont’d / Power Audio Deflection (2552 & 2852) ... Cont’d

Page 8

TOSHIBA 2555 DB

Power, Audio &

Deflection Diagram

(2555 & 2855) Cont’d

8

Service Mode / Safety Parts / Safety Instructions / Service Adjustments / Adjustment Procedure / Block Diagram

Signal Processing (2555 & 2855) ... Cont’d / Signal Processing (2552 & 2852) ... Cont’d

Power Audio Deflection (2555 & 2855) ... Cont’d / Power Audio Deflection (2552 & 2852) ... Cont’d

Page 9

TOSHIBA 2555 DB

Power, Audio &

Deflection

Diagram

(2552 & 2852)

9

Service Mode / Safety Parts / Safety Instructions / Service Adjustments / Adjustment Procedure / Block Diagram

Signal Processing (2555 & 2855) ... Cont’d / Signal Processing (2552 & 2852) ... Cont’d

Power Audio Deflection (2555 & 2855) ... Cont’d / Power Audio Deflection (2552 & 2852) ... Cont’d

Page 10

TOSHIBA 2555 DB

Power, Audio &

Deflection Diagram

(2552 & 2852) Cont’d

10

Service Mode / Safety Parts / Safety Instructions / Service Adjustments / Adjustment Procedure / Block Diagram

Signal Processing (2555 & 2855) ... Cont’d / Signal Processing (2552 & 2852) ... Cont’d

Power Audio Deflection (2555 & 2855) ... Cont’d / Power Audio Deflection (2552 & 2852) ... Cont’d

Loading...

Loading...