Page 1

TOSHIBA 2550 TB

General Information

C4E-R Chassis

Recommended Safety Parts

Item Part No. Description

C440 24082583 PF, 7200pF, ±3%, 1500V

C441 24214221 CD, 220pF, ±10%, 500V

C443 24214221 CD, 220pF, ±10%, 500V

C444 24082517 PF, 5100pF, ±3%, 1800V

C463 24212222 CD, 2200pF, ±10%

C801 24082363 PF, 0.22µF, ±20%, AC250V

C802 24094656 CD, 2200pF, ±20%, AC400V

C803 24094656 CD, 2200pF, ±20%, AC400V

C807 24092281 CD, 4700pF, ±20%, AC250V

C808 24092281 CD, 4700pF, ±20%, AC250V

L462 ———— DY, Supplied with V901

L901 23200275 Coil, Degaussing, TSB-2329BR

T461 23236454 Transformer, Flyback, TFB4117AR

Q404 A6872801 Transistor, 2SD2253(FA)

F801 23144898 Fuse, 3.15A

F803 23144874 Fuse, 0.8A

P801 23372012 Power Cord

S801 23145434 Switch, Power, 2C2P

V901A 23902891 Socket, CRT, 10P

ZP30 23144450 Protector, PRF2000, 125V, 2A

ZP40 23144451 Protector, PRF5000, 125V, 5A

ZP80 23144450 Protector, PRF2000, 125V, 2A

ZP90 23144452 Protector, PRF1000, 125V, 1A

V901 23312643 Picture Tube, A59TMZ40X06

X-Ray Note

X-RAY RADIATION PRECAUTION

1. The E.H.T. must be checked every time the

receiver is serviced to ensure that the C.R.T.

does not emit X-ray radiation as result of

excessive E.H.T. voltage. The nominal E.H.T.

for this receiver is 26.3 kV at zero beam

current (minimum brightness) operating at

240V a.c. The maximum E.H.T. voltage

permissible in any operating circumstances

must not exceed 27.5 kV. When checking the

E.H.T., use the ‘High Voltage Check’ procedure in this manual using an accurate E.H.T.

voltmeter.

2.The only source of X-RAY radiation in this

receiver is the C.R.T. To prevent X-ray

radiation, the replacement C.R.T. must be

identical to the original fitted as specified in

the Parts List.

3.Some components used in this receiver have

safety related characteristics preventing the

C.R.T. from emitting X-ray radiation. For

continued safety, replacement component

should only be made after referring the

Product Safety Notice.

GENERAL INFORMATION

All adjustments are thoroughly checked and

corrected when the receiver leaves the factory.

Therefore the receiver should operate normally

and produce proper colour and B/W pictures

upon installation. However, several minor

adjustments may be required depending on the

particular location in which the receiver is

operated. This receiver is shipped completely in

cardboard carton. Carefully draw out the

receiver from the carton and remove all packing

materials. Plug the power cord into a convenient

240 volts 50 Hz AC two pin power outlet. Turn

the receiver ON. Check and adjust all the

customer controls such as BRIGHTNESS,

CONTRAST and COLOUR Controls to obtain

natural colour or B/W picture.

AUTOMATIC DEGAUSSING

A degaussing coil is mounted around the picture

tube so that external degaussing after moving

the receiver is normally A degaussing coil is

mounted around the picture tube so that external

degaussing after moving the receiver is normally

unnecessary, providing the receiver is properly

degaussed upon installation. The degaussing

coil operates for about 1 second after the power

to the receiver is switched ON. If the set is

moved or faced in a different direction, the

power switch must be switched off at least 30

minutes in order that the automatic degaussing

circuit operates properly. Should the chassis or

parts of the cabinet become magnetized to

cause poor colour purity, use an external

degaussing coil. Slowly move the degaussing

coil around the faceplate of the picture tube, the

sides and front of the receiver and slowly

withdraw the coil to a distance of about 2 m

before disconnecting it from AC source. If colour

shading still persists, perform the COLOUR

PURITY ADJUSTMENT and CONVERGENCE

ADJUSTMENTS procedures.

HIGH VOLTAGE CHECK

CAUTION: There is no HIGH VOLTAGE

ADJUSTMENT on this chassis.

1.Connect an accurate high voltage meter to the

second anode of the picture tube.

2.Turn on the receiver. Set the BRIGHTNESS

and CONTRAST Controls to minimum (zero

beam current).

3. High voltage will be measured below 27.5 kV.

4. Rotate the BRIGHTNESS Control to both

extremes to be sure the high voltage does not

exceed the limit of 27.5 kV under any

conditions.

HORIZONTAL CENTRE ADJUSTMENT

1. Receive the WG PHILIPS pattern, and set the

contrast and colour to minimum, and the

brightness to centre.

2. Adjust HEIGHT Control (R351) so that white

blocks at top and bottom of the picture are

just masked.

FOCUS ADJUSTMENT

Adjust FOCUS Control on FLYBACK TRANS.

(T461) for well defined scanning lines in the

centre area on the screen.

1. Receive the WG PHILIPS pattern.

2. Set the contrast and colour to minimum, and

the brightness to centre.

3. Adjust H. CENTER SUB Control (R451) so

the pattern can be located for d-c to be + 4.0

mm.

FOCUS ADJUSTMENT

Adjust FOCUS Control on FLYBACK TRANS.

(T461) for well defined scanning lines in the

centre area on the screen.

DELAYED R-F AGC ADJUSTMENT

1. Tune the set in the strongest station in your

area.

2. Turn AGC DELAY Control (R151) on MAIN

Board to fully counterclockwise position.

3. Adjust AGC DELAY Control clockwise until

noise (snow) disappears on the screen.

CRT GREY SCALE ADJUSTMENT

1. Press VIDEO INPUT button on Remote

Control unit to turn TV to video input mode.

(Video input should have no signal.) Next

press PICTURE SELECT button to select

function and set CONTRAST to minimum,

BRIGHTNESS to maximum, COLOUR to

minimum.

2.Turn the SCREEN Control (on T461) fuly

counterclockwise.

3. Set the RED, GREEN and BLUE CUT OFF

Controls (R557, R558, R559)

counterclockwise to the centre position.

4. Set the GREEN and BLUE DRIVE Controls

(R252, R253) to the centre position.

5. Set the CUT OFF SW. (S202) in the H. line

position.

6. Set the SUB BRIGHTNESS Control to

minimum.

7. Rotate the SCREEN Control gradually

clockwise until the first horizontal line of a

colour (RED, GREEN or BLUE) appears

slightly on the screen. Set the SCREEN

Control to this position.

8. Adjust the CUT OFF Controls to obtain the

slightly lighted horizontal lines in the same

levels of three colours (RED, GREEN and

BLUE). The lines may look like white if the

CUT OFF Controls are adjusted properly.

9. Return the CUT OFF SW. (5202) in the

receiving position. Press VIDEO INPUT

button to turn TV to the TV mode.

10.Set the BRIGHTNESS Control to the

maximum and COLOUR Control to the centre.

11.Adjust the BLUE and GREEN DRIVE

Controls (R252/R253) to obtain proper whitebalanced picture in high light areas.

12.Set the BRIGHTNESS and CONTRAST

Controls to obtain dark grey raster. Then

check the white balance in low brightness. If

the white balance is not proper, retouch the

CUT OFF Controls and DRIVE Controls to

obtain a good white balance in both low and

high light areas.

SUB-BRIGHTNESS ADJUSTMENT

1. Tune in a colour programme of Philips

pattern.

2. Set the CONTRAST Control to the minimum

and the BRIGHTNESS Control to the centre.

3. Set the COLOUR Control to the minimum.

4. Set the SUB-BRIGHT. Control (R551) so that

the voltage across terminals Y-Z can be 0.2 +

0.05V with voltmeter and leave the receiver

for five minutes in this state.

5. Watching the picture well, adjust the SUBBRIGHT. Control in the position where the

picture does not show evidence of blooming in

high bright area and not appear too dark in

low bright portion.

6. Check the proper picture variation by rotating

the CONTRAST and BRIGHTNESS Controls

to both extremes.

7. If the picture does not appear dark with the

CONTRAST and BRIGHTNESS Controls

turned to the minimum, or not appear bright

with the controls turned to the maximum,

adjust the SUB-BRIGHT. Control again for the

acceptable picture.

1. In the TV set of initial lot of production,

SAA5290ZP/024 is used for QA01. But

replace with SAA5290ZP/032 for servicing.

2. When QA01 only is replaced, it is not

necessary to change the mode data.

3. When memory IC (QA02) is replaced, change

the mode data in the manner below.

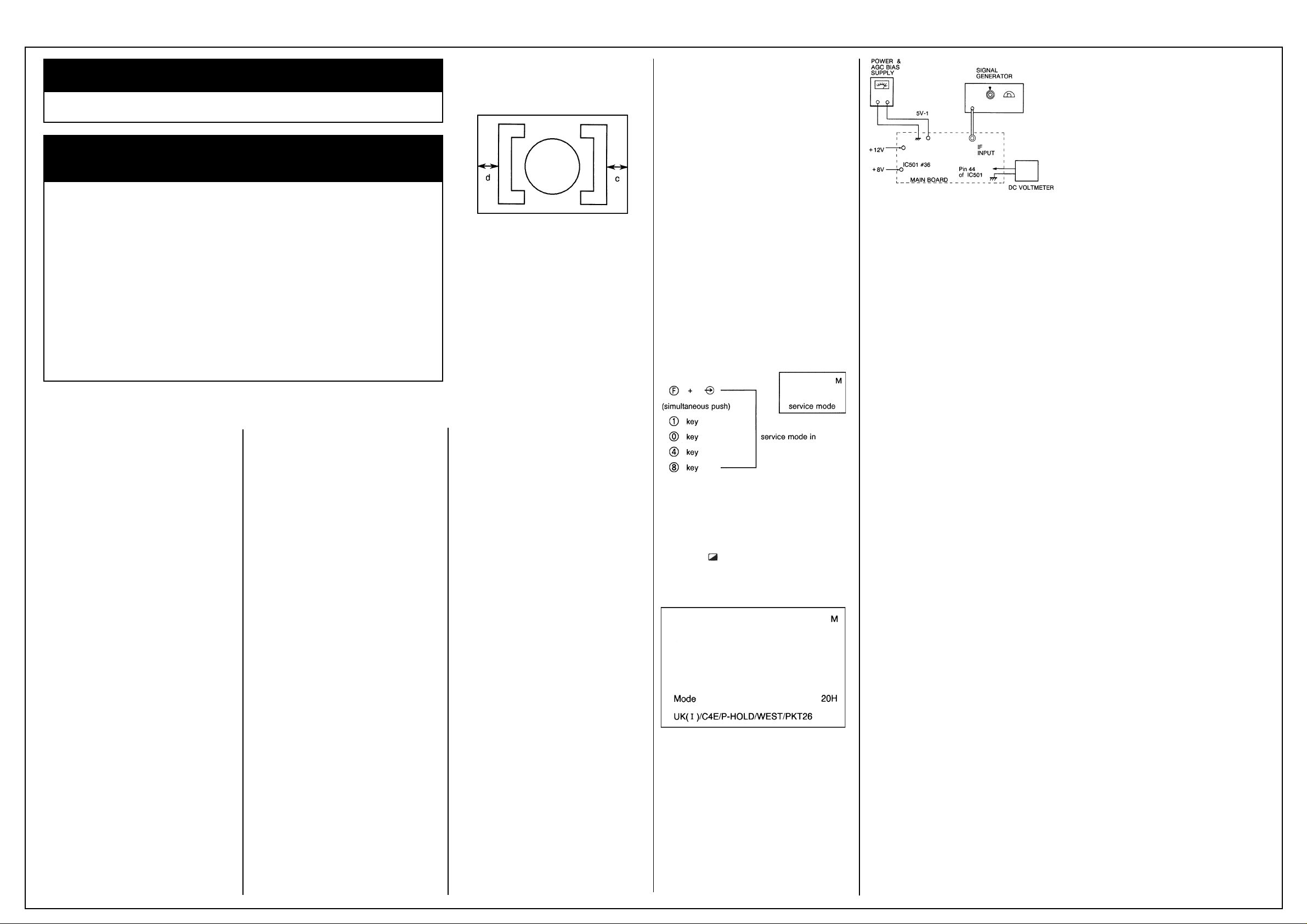

1. OUTLINE

In the service mode, MODE DATA adjustments

can be made easily with user remote control

unit. (CT-9689 only)

2. SERVICE MODE OPERATION

2-1. How to Enter the Service Mode

2-2. How to Exit from the Service Mode

Exit the service mode by turning the power on/

off with the remote control.

3. ADJUSTMENT IN THE SERVICE MODE

Service Mode Level Adjustments

1) Push F + key (simultaneous push) to

Mode Data to be adjusted.

2) Adjust with the level UP/DOWN (VOL UP/

DOWN key) key.

Example of screen display in level adjustment.

GENERAL: Refer to figure 4 for test equipment

connection.

PRELIMINARY STEPS: Supply +5 volts to the

5V-1 line.

SIGNAL GENERATOR: Connect to both leads of

R101 with signal level of 75 dBµ, and open the

solder-link at IF OUT of tuner on the Main

Board. (See figure 4.)

DVM Connect to pin #44 of IC501 on the Main

Board through the detector.

Figure 4. Picture IF Alignment

STEP

Detector Coil

SIGNAL GENERATOR

39.5 MHz CARRIER WAVE (Level 75 dBµ)

ADJUST

T103

REMARKS

1. Supply external DC power (+ 5V) to 5V-1 line.

2. Supply + 8V to pin 36 of 1C501.

3. Supply external DC power to + 12V line.

4. Apply test signal to IF input.

5. Adjust T103 so that DC voltage at pin 44 of

IC501 becomes 3.2V ± 0.5V. After completing

the above steps, disconnect the equipment

and re-solder the liniks on the Main Board,

and adjust the AGC Delay Control (R151)

following DELAYED RF AGC ADJUSTMENTS.

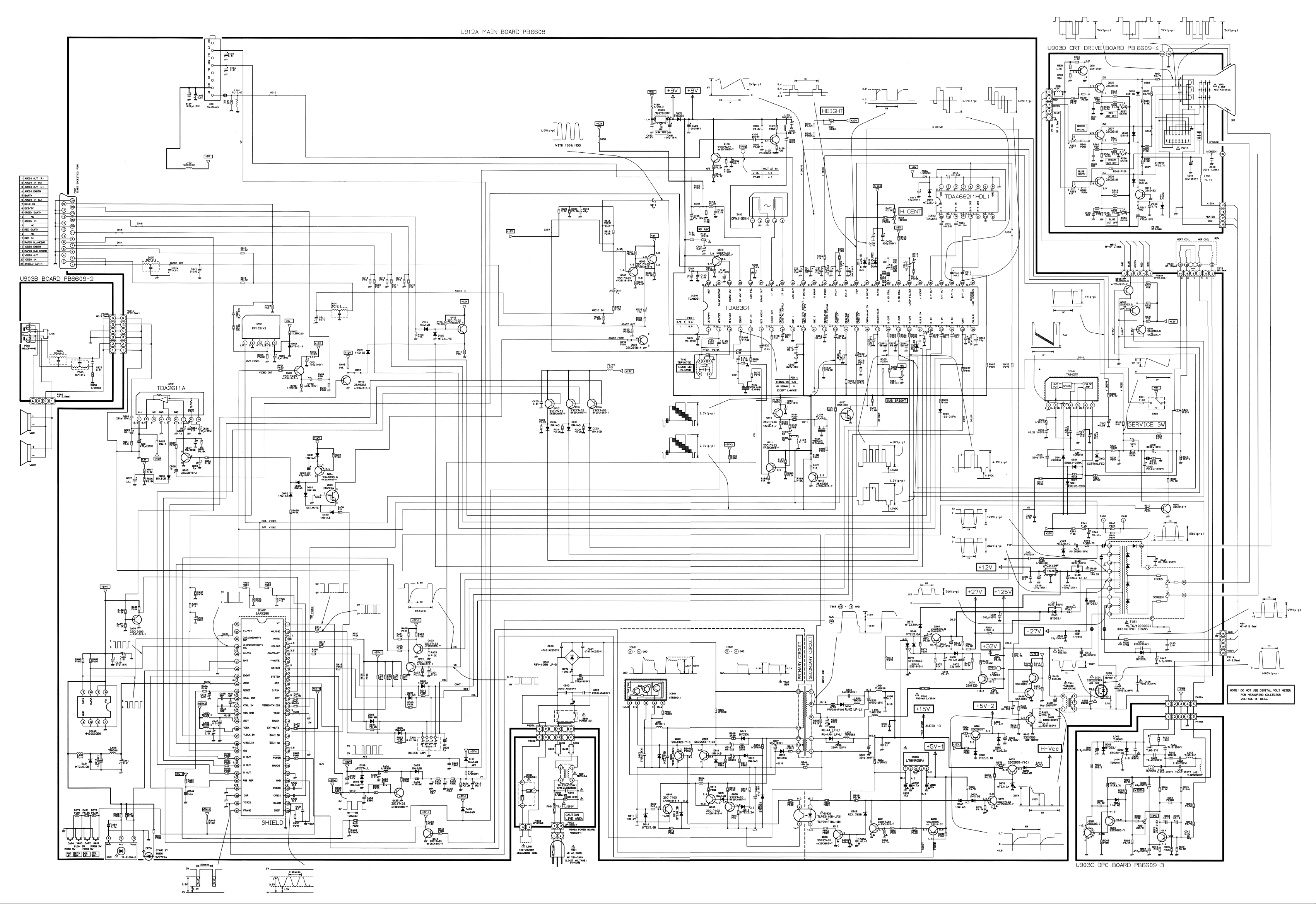

Page 2

Page 3

Page 4

Loading...

Loading...