Page 1

TOSHIBA 2181 TB

General Information

Also Covers

2180 TB

C80 Chassis

Recommended Safety Parts

Item Part No. Description

C440 24082342 PF, 5400pF, ±3%, 1500V

C463 24212152 CD, 1500pF, ±10%

C801 24082927 PF, 0.22µF, ±20%, AC275V

C802 24094656 CD, 2200pF, ±20%, AC400V

C803 24094656 CD, 2200pF, ±20%, AC400V

R327 24339479 MF, 4.7 ohm, 2W

R444 24338398 MF, 0.39 ohm, 1W

R448 24338338 MF, 0.33 ohm, 1W

R801 24009954 Metal-Glazed Resistor, 2.2M ohm, 1/2W

R844 24005007 Metal-Glazed Resistor, 8.2M ohm, 1W

R890 24019340 PTC Thermistor, 18 ohm

R920 24000940 FR, 2 ohm, 2W

L901 23200205 Coil, Degaussing, TSB-2333AR

T401 23224983 Transformer, Horiz. Drive, TLN1039

T461 23236510 Transformer, Flyback, TFB4123BE

T801 23211858 Line Filter, TRF3139

T803 23217240 Transformer, Converter, TPW3301AR

Q826 A8643108 Photo Coupler, TLP621(GR-LF)

F801 23144507 Fuse, 3.15A

F803 23144875 Fuse, 0.63A

P801 23372012 Power Cord (2181TB)

P801 23372014 Power Cord (2180TD)

S801 23145434 Switch, Power, 2C2P

V901A 23902022 Socket, CRT, 8P (2181TB)

V901A 23902891 Socket, CRT (2180TD)

V901 23312726 Picture Tube, A51EF583X69

A401 23426841 Back Cover

X-Ray Note

X-RAY RADIATION PRECAUTION

1. Excessive high voltage can produce potentially hazardous X-RAY RADIATION. To avoid

such hazards, the high voltage must not be

above the specified limit. The nominal value

of the high voltage of this receiver is 28.3 kV

at zero beam current (minimum brightness)

under a 220-240 V AC power source. The

high voltage must not, under any circumstances, exceed 31.0 kV. Each time a

receiver requires servicing, the high voltage

should be checked following the HIGH

VOLTAGE CHECK procedure in this manual.

It is recommended that the reading of the high

voltage be recorded as a part of the service

record. It is important to use an accurate and

reliable high voltage meter.

2. The only source of X-RAY RADIATION in this

TV receiver is the picture tube. For continued

X-RAY RADIATION protection, the replacement tube must be exactly the same type tube

as specified in the parts list.

3. Some part in this receiver have special

safety-related characteristics for X-RAY

RADIATION protection. For continued safety,

parts replacement should be undertaken only

after referring to the PRODUCT SAFETY

NOTICE.

PRODUCT SAFETY NOTICE

Many electrical and mechanical components in

this chassis have special safety-related

characteristics. These characteristics are often

passed unnoticed by a visual inspection and the

X-ray radiation protection afforded by them

cannot necessarily be obtained by using

replacements rated at higher voltages or

wattage, etc. Components which have these

special safety characteristics in this book are

identified by the international hazard symbols on

the schematic diagram and parts list. Before

replacing any of these components read the

parts list in this manual carefully. Substitute

replacement components which do not have the

same safety characteristics as specified in the

parts list may create X-ray radiation.

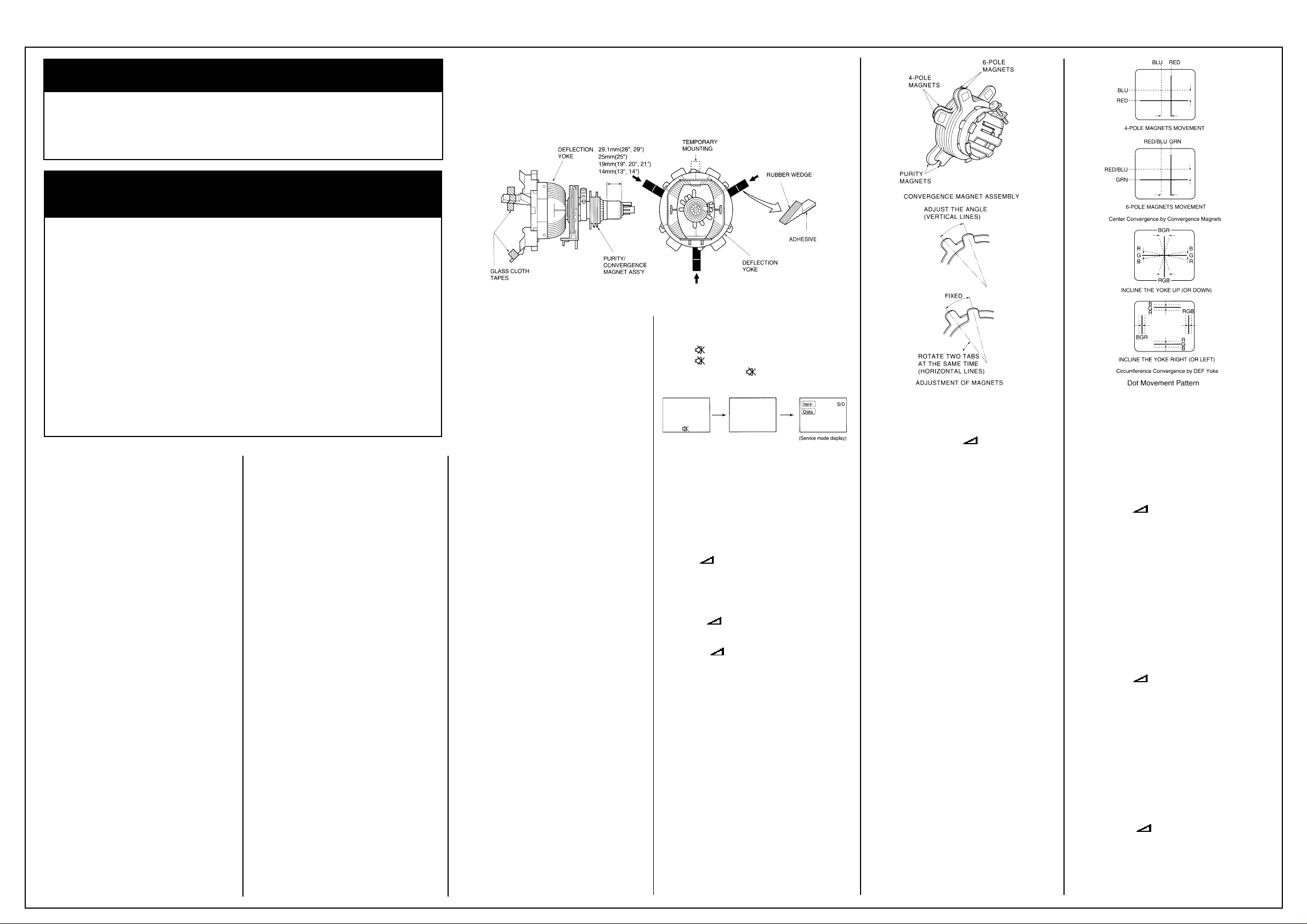

SET-UP ADJUSTMENT

The following adjustments should be made

when a complete realignment is required or a

new picture tube is installed.

Perform the adjustments in order as follows:

1. Color Purity

2. Convergence

3. White Balance

Note: The PURITY/CONVERGENCE MAGNET

assembly and rubber wedges need mechanical

positioning. Refer to figure 1.

* There are no adjustment of purity and

convergence in some picture tube (Unified

with purity magnet)

COLOR PURITY ADJUSTMENT

NOTE: Before attempting any purity adjust-

ments, the receiver should be operated for at

least fifteen minutes.

1. Demagnetize the picture tube and cabinet

using a degaussing coil.

2. Set the brightness and contrast to maximum.

3. Use a green raster from among the built-in

test signals.

4. Loosen the clamp screw holding the yoke and

slide the yoke backward or forward to provide

vertical green belt (zone) in the picture

screen.

5. Remove the Rubber Wedges.

6. Rotate and spread the tabs of the purity

magnet (See figure 2.) around the neck of the

picture tube until the green belt is in the

center of the screen. At the same time, enter

the raster vertically.

7. Slowly move the yoke forward or backward

until a uniform green screen is obtained.

Tighten the clamp screw of the yoke temporarily.

8. Check the purity of the red and blue raster.

Figure 1

CONVERGENCE ADJUSTMENTS

NOTE: Before attempting any convergence

adjustments, the receiver should be operated for

at least fifteen minutes.

CENTER CONVERGENCE ADJUSTMENT

1. Use the cross-dot pattern from among the

built-in test signals.

2. Set the brightness and contrast for well

defined pattern.

3.Adjust two tabs of the 4-Pole Magnets to

change the angle between them (See figure

2.) and superimpose red and blue vertical

lines in the center area of the picture screen.

4. Turn the both tabs at the same time keeping

the angle constant to superimpose red and

blue horizontal lines at the center of the

screen.

5. Adjust two tabs of 6-Pole Magnets to

superimpose red! blue line and green one.

Adjusting the angle affects the vertical lines

and rotating both magnets affects the

horizontal lines.

6. Repeat adjustments 3, 4, 5 keeping in mind

red, green and blue movement, because 4Pole Magnets and 6-Pole Magnets have

mutual interaction and make dot movement

complex.

CIRCUMFERENCE CONVERGENCE ADJUSTMENT

1. Loosen the clamping screw of deflection yoke

slightly to allow the yoke to tilt.

2.Temporarily put a wedge as shown in figure 1.

(Do not remove cover paper on adhesive part

of the wedge.)

3. Tilt front of the deflection yoke up or down to

obtain better convergence in circumference.

(See figure 3.) Push the mounted wedge into

the space between picture tube and the yoke

to fix the yoke temporarily.

4. Put other wedge into bottom space and

remove the cover paper to stick.

5. Tilt front of the yoke right or left to obtain

better convergence in circumference. (See

figure 3.)

6. Keep the yoke position and put another

wedge in either upper space. Remove cover

paper and stick the wedge on picture tube to

fix the yoke.

7. Detach the temporarily mounted wedge and

put it in another upper space. Stick it on

picture tube to fix the yoke.

8. After fixing three wedges, recheck overall

convergence. Tighten the screw firmly to fix

the yoke and check the yoke is firm.

9. Stick three adhesive tapes on wedges as

shown in figure 1.

SERVICE AND DESIGN MODE

1. ENTERING SERVICE AND DESIGN MODE

1) Press button once on Remote Control.

2) Press button again to keep pressing.

3) While pressing the button, press Vol Down

button on TV set.

2. KEY FUNCTION IN THE SERVICE MODE

The following key entry during display of

adjustment menu provides special functions.

A single horizontal line ON/OFF:

- / - - button (on Remote)

Selection of the adjustment items:

CHANNEL ▲/▼ (on TV or Remote)

Change of the data value:

VOLUME +/- (on TV or Remote)

Initialization of the memory (QA02):

CALL + CHANNEL button on TV (▲)

12C BUS ON/OFF:

CALL+VOL + UP.

ASM start:

CALL+ VOL - DOWN.

Automatic VCO adjustment: 0 button.

“RCUT” selection: 1 button

“GCUT” selection: 2 button

“BCUT” selection: 3 button

“CNTX” (or “SCNT”) selection: 4 button

“COLC” selection: 5 button

— — — — Color thickness correction

“TNTC” selection: 6 button

note: Displayed differently as shown below, de“SECAM R-Y offset” selection: 7 button

pending on the setting of the receiving color

SECAM B-Y offset” selection: 8 button

system. COLP (PAL), COLC (NTSC), COLS

(SECAM)

CAUTION: Never try to perform initialization

unless you have changed the memory IC.

3. SELECTING THE ADJUSTING ITEMS

1) Every pressing of CHANNEL ▲ button in the

service mode changes the adjustment items

in the order of table-2. (▼ button for reverse

order)

Figure 2.

4. ADJUSTING THE DATA

1) Pressing of VOLUME +/- button wiil

change the value of data in the range from

OGH to FFH. The variable range depends on

the adjusting item.

5. EXIT FROM SERVICE MODE

1) Pressing POWER button to turn off the TV

once.

INITIALIZATION OF MEMORY DATA OF QA02

After replacing QA02, the following initialization

is required.

1. Enter the service mode, then select any

register item.

2. Press and hold the CALL button on the

Remote, then press the CHANNEL ▲ button

on the TV. The initialization of QA02 has been

completed.

3. Check the picture carefully. If necessary,

adjust any adjustment item above.

Perform “Auto search Memory”.

CAUTION: Never attempt to initialize the data

unless QA02 has been replaced.

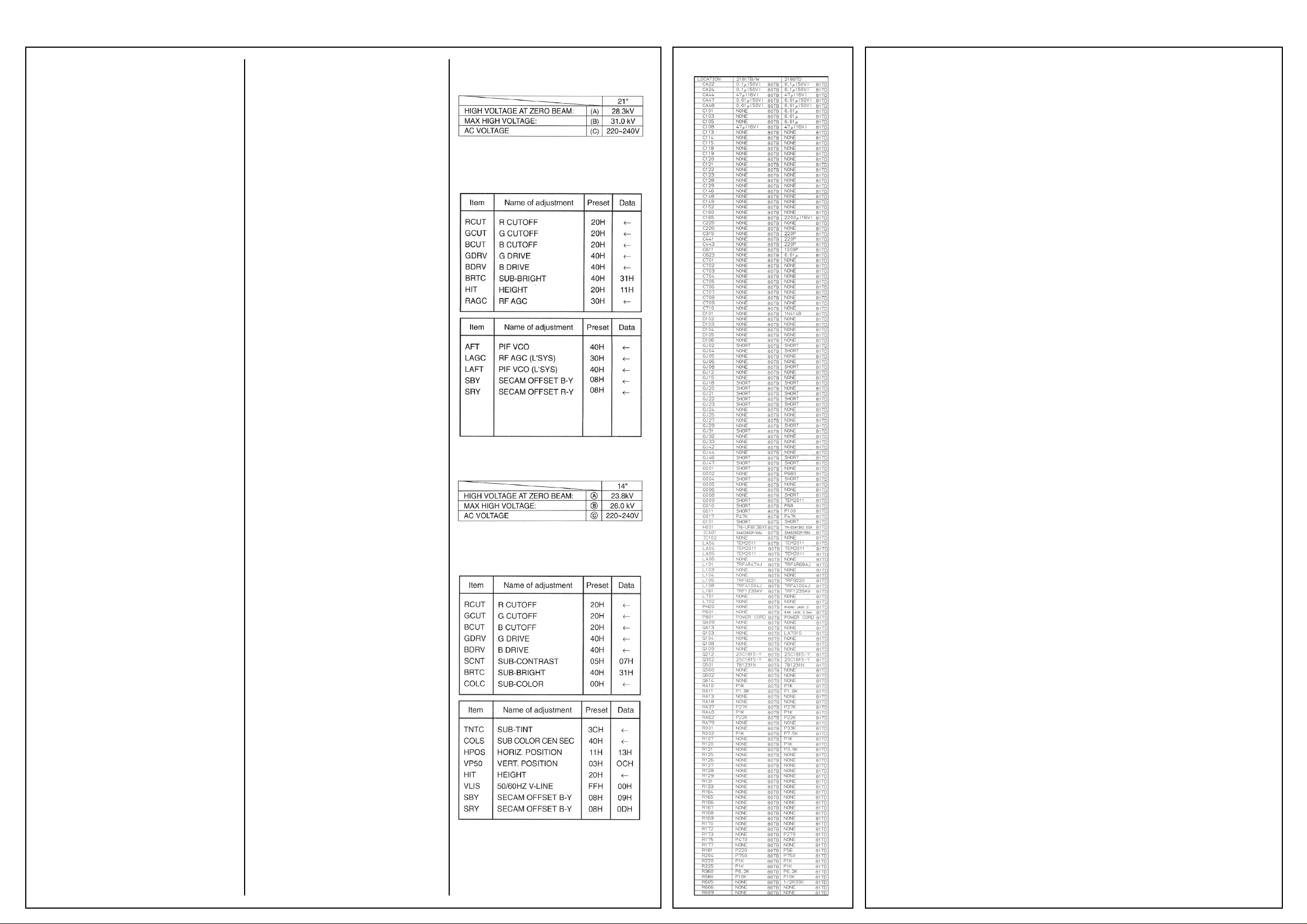

Electrical Adjustments

Model CBO Series (Reference factory

adjustments)

Item: [AFT].[LAFT].[RAGC]4[LAGC]

The entire set (including the micro) must be

powered for this alignment

For sets using the TB1231N Chroma Device the

following method must be used:

UK / German Sets

(1480TB1480RB.1480RD.2181TB.2180TD)

initial batches only:

1) Disconnect IF Pad, and set service and

design mode.

2) Apply IF Carrier Signal at 38.9MHz/95dBuV

(39.5MHz/95dBuV for UK) to the cct side of

the IF pad.

3) Ensure Bus-Data is as follows:

[AFT] = 40H

4) Attach DVM to Q501 #4 and record the

voltage.

Figure 3.

5) Using a ceramic trimmer adjust L161 until

steep change of voltage between 0.2V and

4.8V (approximately).

6) Set the coil to get 2.5V (i.e. the centre of the

slope).

7) Disconnect the DVM

8) Select RAGC in the service mode and adjust

the RF-AGC of the tuner becomes 4V by

pushing VOL -/+ buttons on the remote.

9) Disconnect IF Signal Generator

10) Re-solder IF Pad. For sets using the TB1

238N Chroma Device the following method

must be used as it can be adjusted automatically: (Every model after initial batches above)

UK / German Sets:

1) Disconnect IF Pad, and set to service and

design mode.

2) Apply IF Carrier Signal at 38.9MHz/95dB uV

(39.5MHz/95dBuV for UK) to the cct

side of the IF Pad.

3) Push POS O button on Universal HHU then

wait for “AFT OK” to appear on screen.

4) Select RAGC in the service mode and adjust

the RF-AGC of the tuner becomes 4V by

pushing VOL -/+ buttons on the remote.

5) Disconnect IF Signal Generator

6) Re-solder IF Pad.

French Sets:

1) Ensure Position {n} is in the UHF Band in any

system

2) Disconnect IF Pad and and select position

{n}, and set service and design mode.

3) Appy IF Carrier Signal of 38.9MHz/95dbuV to

the cct side of the IF pad.

4) Push POS 0 button on Universal HHU then

wait for “AFT OK” to appear on screen.

5) Select RAGC in the service mode and adjust

the RF-AGC of the tuner becomes 4V by

pushing VOL -/+ buttons on the remote.

6) Select LAGC in the Service mode and input

the data value same as RAGC mode.

7) Disconnect IF Signal Generator and re-solder

IF Pad.

[There will be no French sets using the

Page 2

TOSHIBA 2181 TB

Electrical Adjustments

Cont’d

TB1231N VICID IC, all sets will eventually use

the TB1238N device. The automatic system

DOES NOT require a 34.47MHz signal for

SECAM L alignment, as the frequencies are

generated internally. (The Universal HHU

commands are Listed on the end of this

document including AFT/AGC)

Item [SCNT] NO ADJUSTMENT

Name: SUB-CONTRAST

SETTING:

Input Signal:

Measurement Place:

Adjustment Method:

Standard:

Item [BRTC]

Name: SUB-BRIGHT CENTRE

SETTING: Set user control setting to STANDARD 1

Input Signal: SUB-BRIGHT SIGNAL

Measurement Place: On Picture

Adjustment Method: Adjust the number of Black

Steps visible on the picture

Standard: 4th bar from black 1.5bars

Note: Adjust last

Item [COLP] NO ADJUSTMENT

Name: SUB-COLOUR CENTRE (PAL)

SETTING:

Input Signal:

Measurement Place:

Adiustment Method:

Standard:

Item [TNTC] NO ADJUSTMENT { [TnTC] on

REMOTE model }

Name: SUB-TINT CENTRE (M-NTSC Mode)

SETTING:

Input Signal:

Measurement Place:

Adjustment Method:

Standard:

Item [COLC] NO ADJUSTMENT

Name: SUB-COLOUR CENTRE (NTSC / PAL)

SETTING:

Input Signal:

Measurement Place:

Adjustment Method:

Standard:

Item [RCUT], [GCUT], [BCUT], [GDRV],

[BDRV], [SCREEN VR]

Name: CUT-OFF/DRIVE ADJUST

SETTING: [RCUT], [GCUT], [BCUT] data set to

20H [GDRV],[BDRV] data set to 40H

Set to Horizontal Line mode

Input Signal: White-Balance Signal (Reduced

Dual Window Patten)

Measurement Place: On Picture

Adjustment Method: Raise the screen VR

gradually and stop in the place where the line of

either R or G or B shines slightly. Set the VR

position at that point.

Raise the CUT-OFF data of the two colours that

did not appear first and stop when the line

becomes white.

Come out of Horizontal Line mode and usin

white balance gear adjust [GCUT], [BCUTJ in

Low-Lights (4 Ft-Lbts) and (GDRV], [BDRV] in

High-Lights (30 Ft-Lbts) until Standard achieved

in both conditions.

Item [SRY], [SBY], [SR], [SY] on REMOTE

model

Name: SECAM R-Y/B-Y BLACK LEVEL

SETTING

SETTING: COLOUR: MID

Input Signal: Two-tone White-Balance Signal

Measurement Place: On Picture

Adiustment Method:

1) Remember settings of the PAL White-Balance

Adjustment on the Low-Light.

2) Select Position 2 on the selector box and

confirm that the three colour boxes are visible

in the lower left hand corner of the screen.

3) Adjust [SRY] for a reading of within 2

indicators on the Green scale with respect to

the original results obtained from point (1)

above

4) Adjust [SBY] for a reading of within 2

indicators on the Blue scale with respect to

the original results obtained from point (1)

above

5) Re-select position 1 on the switch box to

confirm that the setting are within 2 on scale.

Standard:

Item [COLS] NO ADJUSTMENT

Name: SUB-COLOUR CENTRE (SECAM)

SETTING:

Input Signal:

Measurement Place:

Adjustment Method:

Standard:

Item [VPOS] NO ADJUSTMENT [VP50] on

REMOTE model

Name: VERTICAL PICTURE POSITION

SETTING:

Input Signal:

Measurement Place:

Adiustment Method:

Item [HIT]

Name: VERTICAL HEIGHT ADJUSTMENT

SETTING: CONTRAST= MAX BRIGHT =

CENTRE COLOUR = CENTRE

Input Signal: WG Philips Pattern (Do not use

French SECAM)

Measurement Place: On Picture

Adjustment Method: Adjust the [HIT] Bus-Data

until castellations just disappear from Top and

Bottom of picture

Item [HOPS]

Name: HORIZONTAL PICTURE POSITION

SETTING: CONTRAST = MAX BRIGHT =

CENTRE COLOUR = CENTRE

Input Signal: WG Philips Pattern (Do not use

French SECAM)

Measurement Place: On Picture

Adjustment Method: Adjust the [HOPS] BusData for the best Horizontal centring

HIGH VOLTAGE CHECK

CAUTION: There is no HIGH VOLTAGE

ADJUSTMENT on this chassis. Checking should

be done following the steps below.

1. Connect an accurate high voltage meter to

the second anode of the picture tube.

2. Turn on the receiver. Set the BRIGHTNESS

and CONTRAST controls to minimum (zero

beam current).

3. High voltage must be measured below (B) kV.

Refer to table-1 for high voltage (s).

(See SETTING & ADJUSTING DATA)

4. Vary the BRIGHTNESS control to both

extremes to be sure the high voltage does not

exceed the limit under any conditions.

SETTING & ADJUSTING DATA: 21”

(Safety Instructions)

(Service Mode)

ADJUSTING ITEMS AND DATA IN THE

SERVICE AND DESIGN MODE: 21”

SETTING & ADJUSTING DATA: 14”

(Safety Instructions)

(Service Mode)

ADJUSTING ITEMS AND DATA IN THE

SERVICE AND DESIGN MODE: 14”

Differences Table

This area is intentionally left blank

Standard:

1.03cd/m2 (30 Ft-Lbts) 8750k ± 0.0075uv

17cd/m2 (4 Ft-Lbts) 8750k ± 0.0020uv

(Automatic may be possible, [GDRV], [BDRV]

might be deleted on 14 on future models)

Page 3

Loading...

Loading...