Page 1

SERVICE MANUAL

Стр. 1 из

1

03.05.2015

file://C:\Program Files\zeus\js\!!fcover.html

LCD Color Television

19AV501P

Ver. 2.00

This model is classified as a green product (*1), as indicated by the underlined serial number. This

Service Manual describes replacement parts for the green product. When repairing this green

product, use the part(s) described in this manual and lead-free solder (*2).

For (*1) and (*2), refer to

© TOSHIBA CORPORATION

GREEN PRODUCT PROCUREMENT

and

LEAD-FREE SOLDER

.

Page 2

FUNCTION AND OPERATION

Стр. 1 из

2

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.989\19A

...

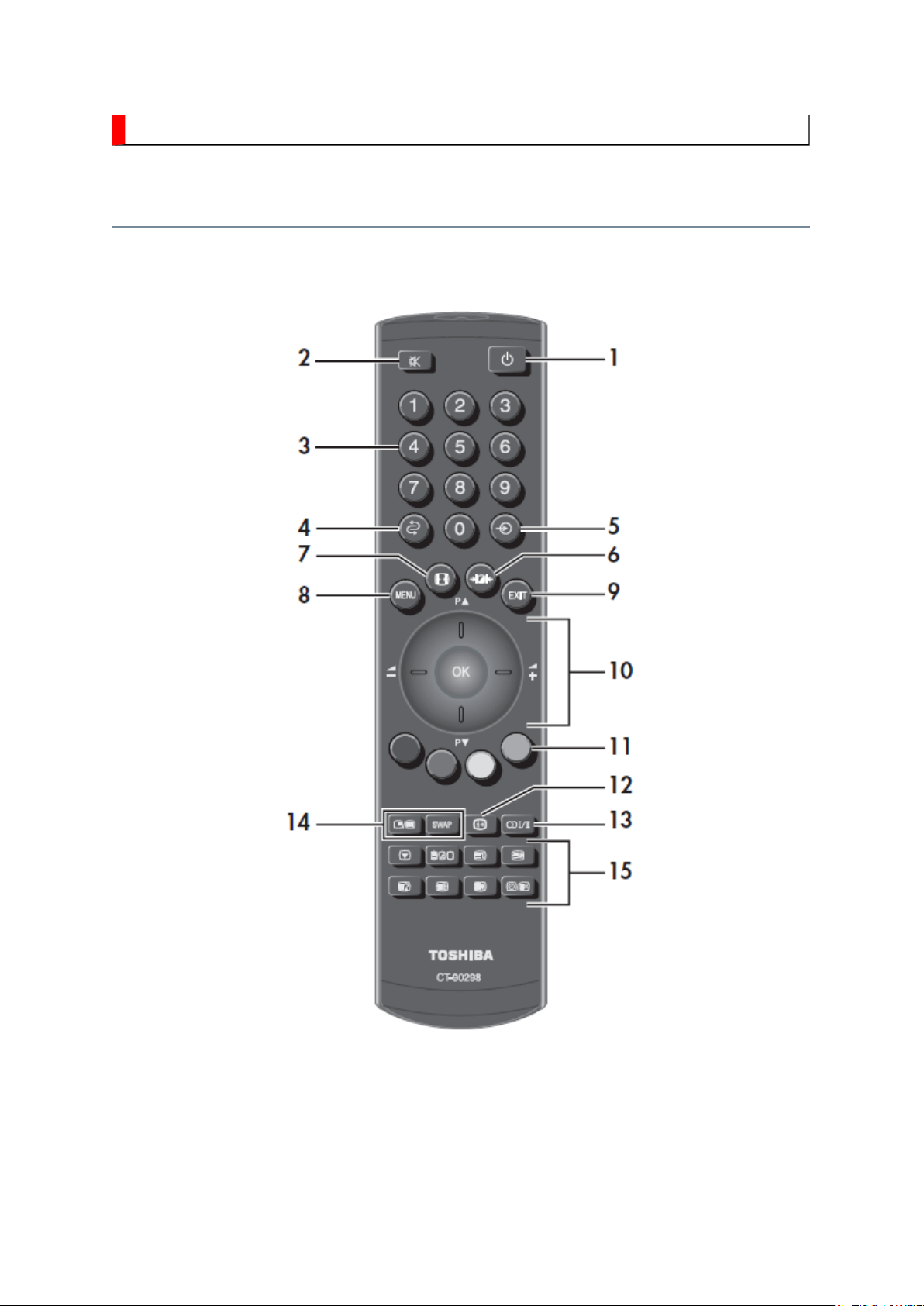

The Remote Control

Simple at-a-glance reference of your remote control.

Page 3

Стр. 2 из

2

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.989\19A

...

Page 4

FUNCTION AND OPERATION

Стр. 1 из

2

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.896\19A

...

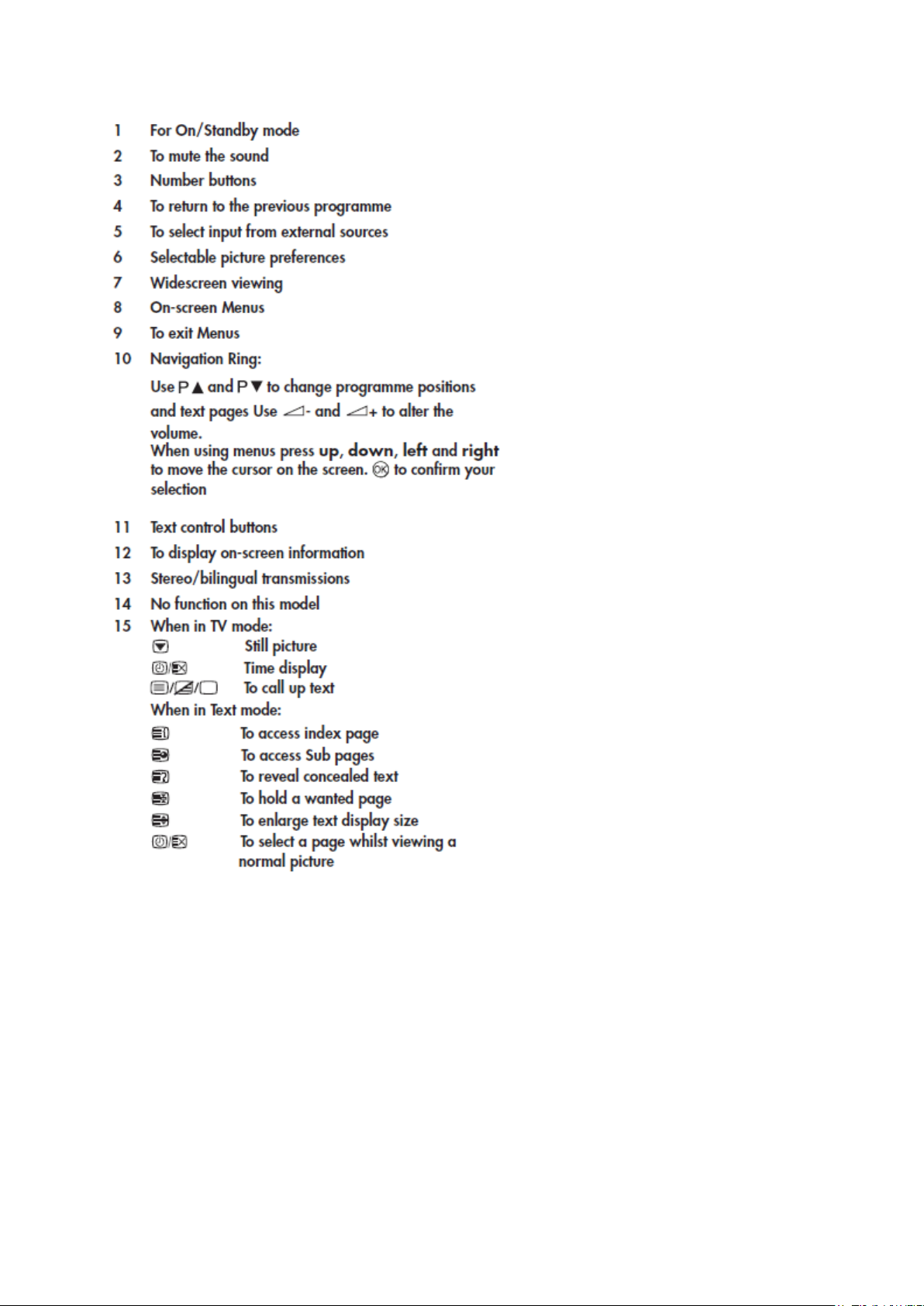

Using the Controls

Whilst all the necessary adjustments and controls for the television are made using the

remote control, the buttons on the television may be used for some functions.

Switching On

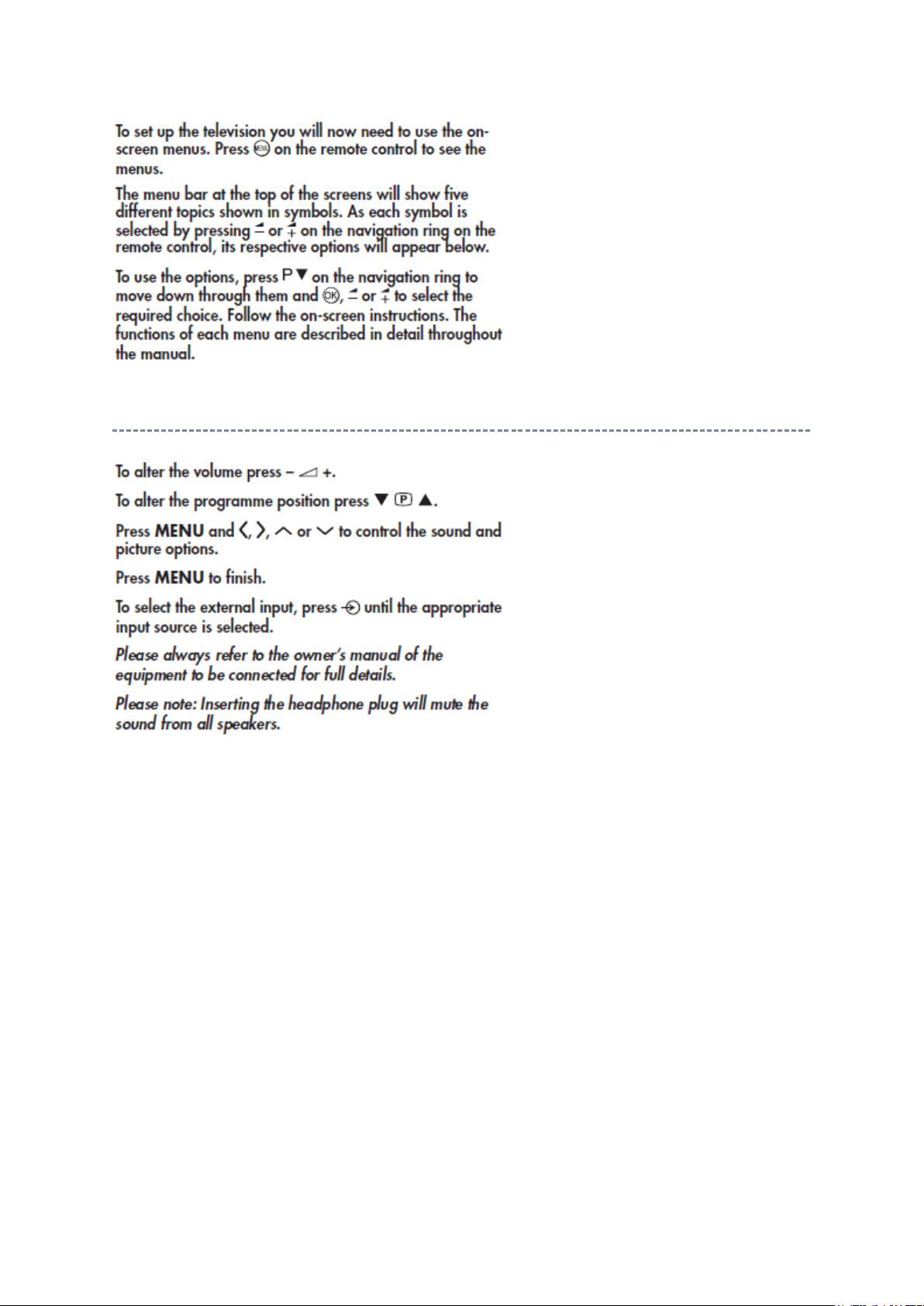

Using the Remote Control

Page 5

Using the Controls

Стр. 2 из

2

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.896\19A

...

Page 6

FUNCTION AND OPERATION

Стр. 1 из

6

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.807\19A

...

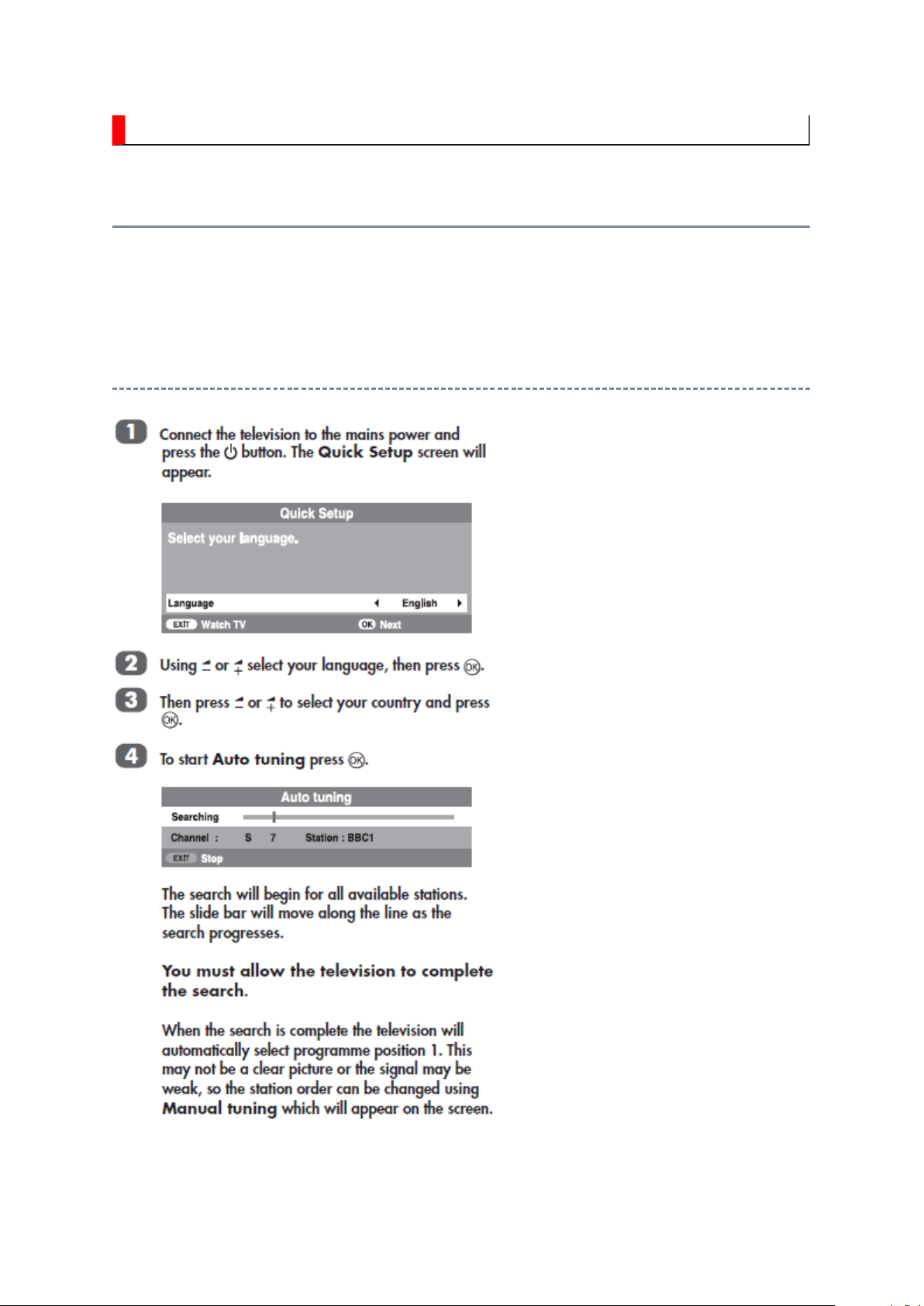

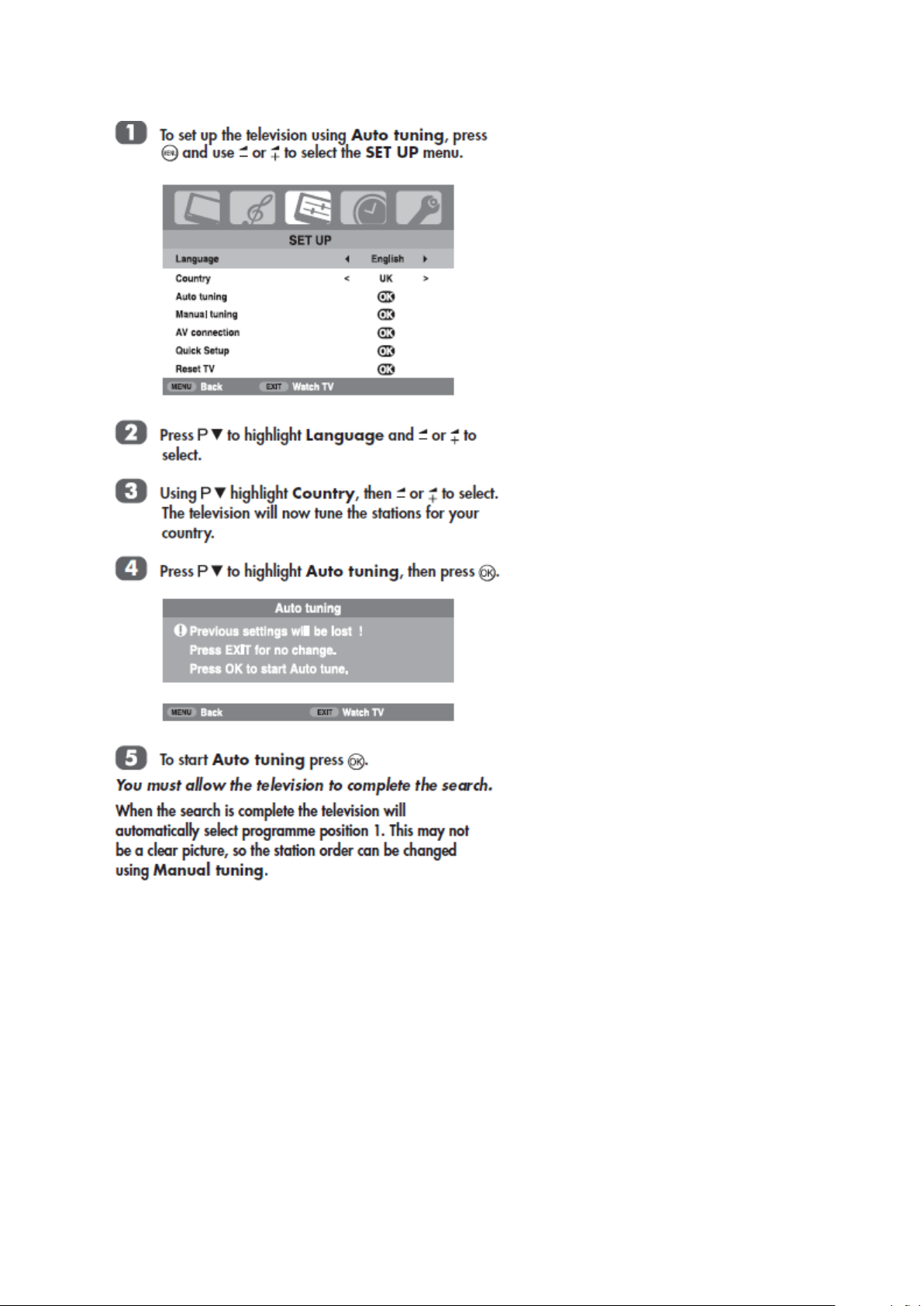

Tuning the Television

Before switching on the television put your decoder and media recorder to

are connected.

Quick Setup

Standby

if they

Page 7

Стр. 2 из

6

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.807\19A

...

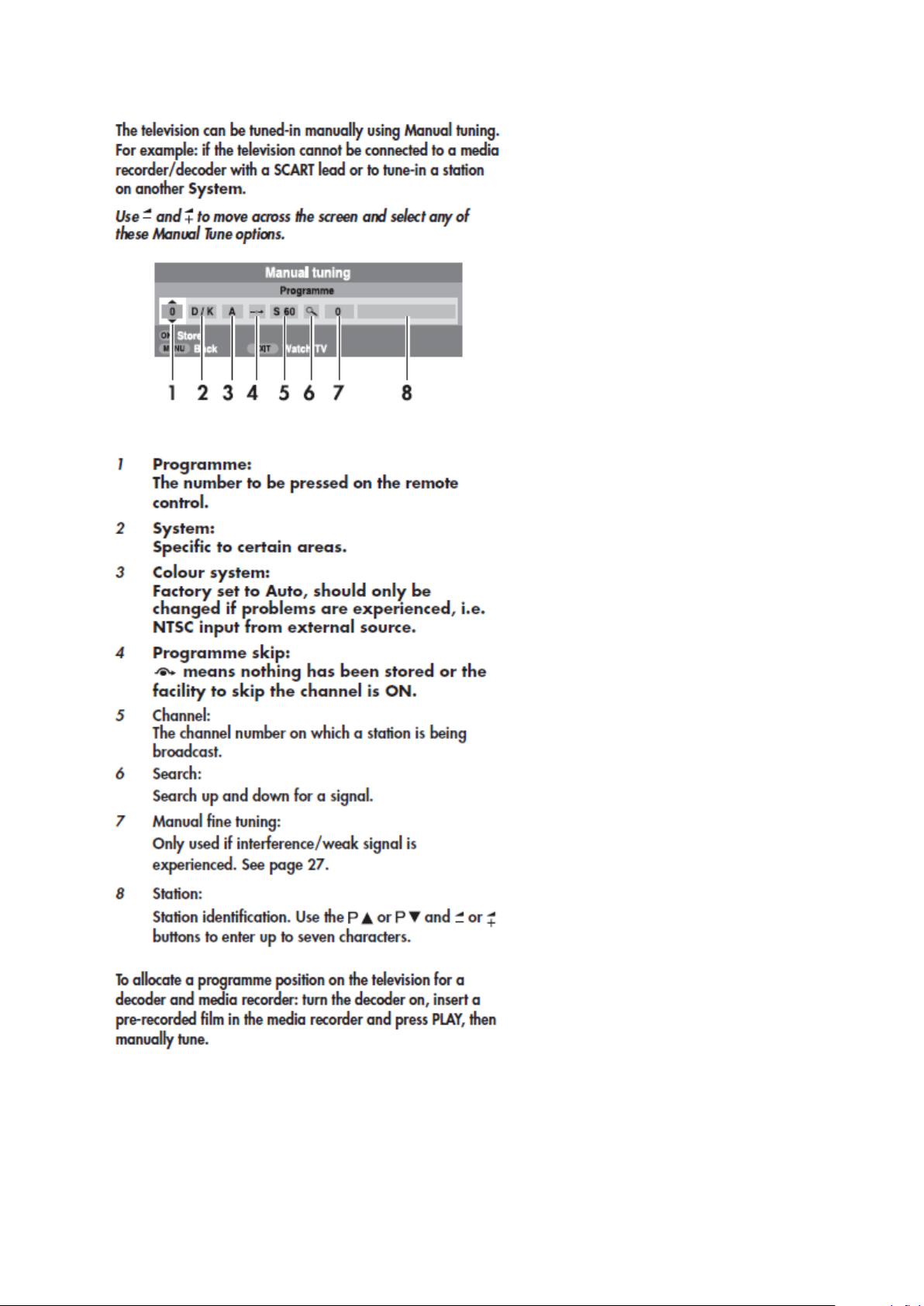

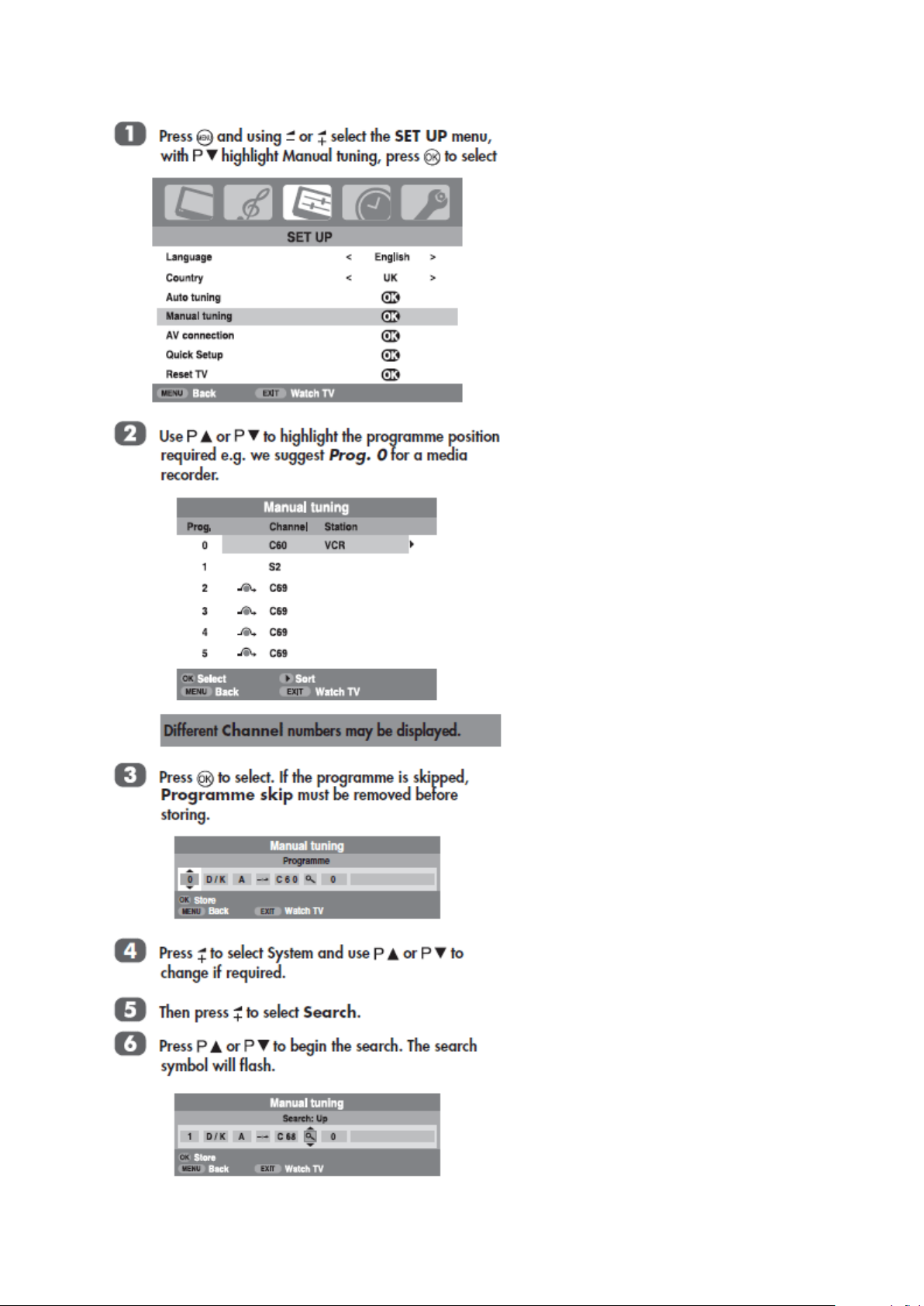

Manual Tune

Page 8

Стр. 3 из

6

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.807\19A

...

Page 9

Стр. 4 из

6

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.807\19A

...

Page 10

Стр. 5 из

6

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.807\19A

...

Using Auto Tuning

Page 11

Стр. 6 из

6

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.807\19A

...

Page 12

SAFETY INSTRUCTION

should enter the mouth, rinse the mouth thoroughly with water. If the fluid should contact the

When attaching the LCD module to the LCD cover, position it appropriately and fasten

Стр. 1 из 4Handling the LCD Module

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.549\19A

...

Handling the LCD Module

Safety Precaution

In the event that the screen is damaged or the liquid crystal (fluid) leaks, do not breathe in or

drink this fluid.

Also, never touch this fluid. Such actions could cause toxicity or skin irritation. If this fluid

skin or clothing, wipe off with alcohol, etc., and rinse thoroughly with water. If the fluid

should enter the eyes, immediately rinse the eyes thoroughly with running water.

Precautions for Handling the LCD Module

CAUTION: The metal edges of the LCD module are sharp, handle it with

care.

The LCD module can easily be damaged during disassembly or reassembly; therefore,

always observe the following precautions when handling the module.

1.

at the position where the display can be viewed most conveniently.

2. Carefully align the holes at all four corners of the LCD module with the corresponding

holes in the LCD cover and fasten with screws. Do not strongly push on the module

because any impact can adversely affect the performance. Also use caution when

handling the polarized screen because it can easily be damaged.

Page 13

Стр. 2 из 4Handling the LCD Module

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.549\19A

...

3. If the panel surface becomes soiled, wipe with cotton or a soft cloth. If this does not

remove the soiling, breathe on the surface and then wipe again.

If the panel surface is extremely solied, use a CRT cleaner as a cleaner. Wipe off the

panel surface by drop the cleaner on the cloth. Do not drop the cleaner on the panel.

Pay attention not to scratch the panel surface.

4. Leaving water or other fluids on the panel screen for an extended period of time can

result in discoloration or stripes. Immediately remove any type of fluid from the screen.

5. Glass is used in the panel, so do not drop or strike with hard objects. Such actions can

damage the panel.

Page 14

6. CMOS-LSI circuitry is used in the LCD module, so avoid damage due to static

Стр. 3 из 4Handling the LCD Module

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.549\19A

...

electricity. When handling the module, use a wrist ground or anchor ground.

7. Do not expose the LCD module to direct sunlight or strong ultraviolet rays for an

extended period of time.

8. Do not store the LCD module below the temperature conditions described in the

specifications. Failure to do so could result in freezing of the liquid crystal due to cold

air or loss of resilience or other damage.

9. Do not disassemble the LCD module. Such actions could result in improper operation.

Page 15

Стр. 4 из 4Handling the LCD Module

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.549\19A

...

10. When transporting the LCD module, do not use packing containing epoxy resin

(amine) or silicon resin (alcohol or oxim). The gas generated by these materials can

cause loss of polarity.

Page 16

Page 17

SAFETY INSTRUCTION

Always keep tools, components of the product, etc away from the children, These items

Стр. 1 из

4

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.934\19A

...

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "SAFETY

PRECAUTION" AND "PRODUCT SAFETY NOTICE" INSTRUCTIONS BELOW.

Safety Precaution

WARNING: SERVICING SHOULD NOT BE ATTEMPTED BY ANYONE

UNFAMILIAR WITH THE NECESSARY PRECAUTIONS ON THIS RECEIVER.

THE FOLLOWING ARE THE NECESSARY PRECAUTIONS TO BE OBSERVED

BEFORE SERVICING THIS CHASSIS.

1. An isolation transformer should be connected in the power line between the receiver

and the AC line before any service is performed on the receiver.

2. Always disconnect the power plug before any disassembling of the product. It may

result in electrical shock.

3. When replacing a chassis in the cabinet, always be certain that all the protective

devices are put back in place, such as nonmetallic control knobs, insulating covers,

shields, isolation resistor-capacitor network, etc.

4.

may cause injury to children.

5. Depending on the model, use an isolation transformer or wear suitable gloves when

servicing with the power on, and disconnect the power plug to avoid electrical shock

when replacing parts. In some cases, alternating current is also impressed in the

chassis, so electrical shock is possible if the chassis is contacted with the power on.

6. Always use the replacement parts specified for the particular model when making

repairs. The parts used in products require special safety characteristics such as

Page 18

inflammability, voltage resistance, etc. therefore, use only replacement parts that have

NEVER remodel the product in any way. Remodeling can result in improper operation,

Стр. 2 из

4

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.934\19A

...

these same characteristics. Use only the specified parts when the mark is indicated

in the circuit diagram or parts list.

7. Parts mounting and routing dressing of wirings should be the same as that used

originally. For safety purposes, insulating materials such as isolation tube or tape are

sometimes used and printed circuit boards are sometimes mounted floating. Also make

sure that wirings is routed and clamped to avoid parts that generate heat and which use

high voltage. Always follow the manufactured wiring routes / dressings.

8. Always ensure that all internal wirings are in accordance before re-assembling the

external casing after a repairing completed. Do not allow internal wiring to be pinched

by cabinets, panels, etc. Any error in reassembly or wiring can result in electrical

leakage, flame, etc., and may be hazardous.

9.

malfunction, or electrical leakage and flame, which may be hazardous.

10. Touch current check. (After completing the work, measure touch current to prevent an

electric shock.)

Plug the AC cord directly into the AC outlet. Do NOT use an isolation transformer

for this check.

Connect a measuring network for touch currents between each exposed metallic part

on the set and a good earth ground such as a water pipe.

Annex D

(normative)

Measuring network for TOUCH CURRENTS

Page 19

Resistance values in orms (Ω).

V: Voltmeter or oscilloscope

Стр. 3 из

4

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.934\19A

...

(r.m.s. or peak reading)

Input resistance : 1 MΩ

Input capacitance : 200 pF

Frequency range : 15 Hz to 1 MHz and d.c. respectively

Appropriate measures should be taken to obtain the correct value in case of non

Note:

sinusoidal waveforms.

The measuring instrument is calibrated by comparing the frequency factor of with the

solid line in figure F.2 of IEC 60990 at various frequencies. A calibration curve is

constructed showing the deviation of from the ideal curve as a function of frequency.

TOUCH CURRENT = /500 (peak value).

The potential at any point (TOUCH CURRENT) expressed as voltage and

does not exceed the following value:

The part or contact of a TERMINAL is not HAZARDOUS LIVE if:

a) The open-circuit voltage should not exceed 35 V (peak) a.c. or 60 V d.c. or, if a) is not

met.

b) The measurement of the TOUCH CURRENT shall be carried out in accordance with

IEC 60990, with the measuring network described in

The TOUCH CURRENT expressed as voltages and , does not exceed the

following values:

- for a.c. : = 35 V (peak) and = 0.35 V (peak);

- for d.c. : = 1.0 V

The limit values of = 0.35 V (peak) for a.c. and = 1.0 V for d.c. correspond to

Note:

the values 0.7 mA (peak) a.c. and 2.0 mA d.c.

Annex D

of this standard.

Page 20

Product Safety Notice

Стр. 4 из

4

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.934\19A

...

Many electrical and mechanical parts in this chassis have special safety-related

characteristics. These characteristics are often passed unnoticed by a visual inspection and

the protection afforded by them cannot necessarily be obtained by using replacement

components rated for higher voltage, wattage, etc. Replacement parts which have these

special safety characteristics are identified in this manual and its supplements; electrical

components having such features are identified by the international hazard symbols on the

schematic diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The

use of substitute replacement parts which do not have the same safety characteristics as

specified in the parts list may create electrical shock, fire, or other hazards.

Page 21

!"# $%&'(#)*+,$%# -%*.-*%$

"/-'(#0&1&-2 345 !"678 !97:;

<'=$(

>'?#@A 345 ??? BBBBBB BB @A-C#0&1&-

D#0&1&-2 D#0&1&-2 E#0&1&-2 F0&1&-2 4C$=#-C$#G'=$(#H$%2&/=#&2#*G0'-$0#I&-C&=#-C$#2'+$#G'=$(#H$=0/%J# @ K%&1&='(

L

MMMMM@NOOOOOOP -C$#('2-#0&1&-#I&((#,$#&=.%$+$=-$0#,Q#@R F S$%2&/=#%$H&2$0

D S$%2&/=#%$H&2$0

$R1R @D-C#0&1&- @A-C#0&1&- A S$%2&/=#%$H&2$0

7=#.'2$#/T#:UKJ V&%2- : @ W S$%2&/=#%$H&2$0

H$2&/=#*G# F=0 : F E S$%2&/=#%$H&2$0

D%0 : D X S$%2&/=#%$H&2$0

YK><:; A-C : A Z S$%2&/=#%$H&2$0

U : @M@[DMM O S$%2&/=#%$H&2$0

YC&=' DM@[WMM 4C$=#-C$#G'=$(#&2#.C'=1$0#-/#'=/-C$%#G'=$(#H$=0/%J#-C$#'(GC',$-#G'=$(#

:2&'#L\:*2P WM@[XMM H$=0/%#&=0&.'-&/=#I&((#,$#.C'=1$0#-/#'../%0&=1(Q#I&-C#-',$(#,$(/IR

!U XM@[OMM

K-C$% OM@[OOO $R1R @D-C#0&1&- @A-C#0&1&-

K%&1&='(#:UK : @

3]3$'% Z FMMZ YC'=1$0#-/#;<; ; @

O FMMO

: FM@M

^ FM@@

Y FM@F

45]4$$_ M@ 45M@

MF 45MF

MD 45MD

MA 45MA

WD 45WD

Europe Model SET ID

19AV500PG 701

19AV500PR 702

19AV500PB 703

19AV501PG 704

19AV501PR 705

26AV500PB 706

26AV500PG 707

26AV500PR 708

19AV505DB 709

19AV505DG 710

19AV506DB 711

19AV506DG 712

26AV505DB 713

26AV505DG 714

Page 22

SPECIFICATION

Стр. 1 из

2

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.261\19A

...

Page 23

Стр. 2 из

2

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.261\19A

...

Page 24

Page 25

PARTS LIST

Electric Parts

E100

75011 551

H-CON SET, STV19TA MB CN6

-

SPK, 39C00I51L01

Electric Parts

E101

75011 552

H-CON SET, STV19TA MB CN1

-

KEY, 39C00I51L02

Electric Parts

E102

75011 554

PC BOARD ASSY, IR/B, 19AV500U, 39C00I51L04

Electric Parts

E103

75011 555

PC BOARD ASSY, KEY/B, 19AV500U, 39C00I51L05

Electric Parts

E104

75011 558

H-CON SET, STV19T POW

-

IF 12P, 39C00I51L08

Electric Parts

E109

75012 363

PC BOAD ASSY, POWER, 39C00S51L17

Electric Parts

E110

75012 364

PC BOARD ASSY, MAIN ,19AV500P, 39C00S51L04

Electric Parts

E114

75012 368

H-CON SET, LVDS, 39C00L51L06

Electric Parts

E115

75012 369

POWER CORD, 39C00S51L16

Miscellaneous

E105

75011 562

SPEAKER ASSY, 3W 6OHM 60X35.5X26, 39C00I51L16

Miscellaneous

E111

75011 549

LCD PANEL, LTM190 M2

-

L31 REV. 4.0D, 39C00I51LP1

Miscellaneous

E119

75012 373

SHEET FOR CLEAN CLOTH, 39C00S51L11

Miscellaneous

E120

75012 376

WARRANTY CARD, 39C00S51L12

Accessory

E117

75012 371

OWNERS MANUAL, 19AV500PG, 39C00S51L14

Accessory

E117

75012 375

OWNERS MANUAL, 19AV500PR, 39C00S51L13

Accessory

E118

75012 372

INSTRUCTION, 19AV500P, 39C00S51L01

Accessory

E121

75012 374

REMOCON HAND UNIT, 39C00S51L05

Cabinet

E108

75011 568

STAND ASSY, 19AV501U, 39C00I51L13

Cabinet

E112

75012 592

BACK COVER ASSY, 19AV501P,(CHINA), 39C00S51L07

Cabinet

E113

75012 593

BEZEL ASSY, 19AV501P, (EUROPE), 39C00S51L02

Packing

E021

75012 463

HANDLE, CARTON BOX 19V, 39C00J51L24

Packing

E106

75011 564

EPS FOAM, LEFT, 19AV500U, 39C00J51L01

Packing

E107

75011 565

EPS FOAM, RIGHR, 19AV500U, 39C00J51L02

Packing

E116

75012 594

CARTON BOX, 19AV501P, 39C00T51L01

Стр. 1 из

1

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.335\19A

...

Block :

All Block

Location :

Parts No. :

Block Location Parts No. Description

Search

Search

Page :

1 /

24

Jump

S MM L

Page 26

PARTS LIST

Electric Parts

E100

7501 1 551

H-CON SET, STV19TA MB CN6

-

SPK, 39C00I51L01

Electric Parts

E101

7501 1 552

H-CON SET, STV19TA MB CN1

-

KEY, 39C00I51L02

Electric Parts

E102

7501 1 554

PC BOARD ASSY, IR/B, 19AV500U, 39C00I51L04

Electric Parts

E103

7501 1 555

PC BOARD ASSY, KEY/B, 19AV500U, 39C00I51L05

Electric Parts

E104

7501 1 558

H-CON SET, STV19T POW

-

IF 12P, 39C00I51L08

Electric Parts

E109

7501 2 363

PC BOAD ASSY, POWER, 39C00S51L17

Electric Parts

E110

7501 2 364

PC BOARD ASSY, MAIN ,19AV500P, 39C00S51L04

Electric Parts

E114

7501 2 368

H-CON SET, LVDS, 39C00L51L06

Electric Parts

E115

7501 2 369

POWER CORD, 39C00S51L16

Стр. 1 из

1

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.335\19A

...

Block :

Electric Parts

Location :

Parts No. :

Block Location Parts No. Description

Search

Search

Page :

1 /

9

S MM L

Jump

Page 27

PARTS LIST

Miscellaneous

E105

7501 1 562

SPEAKER ASSY, 3W 6OHM 60X35.5X26, 39C00I51L16

Miscellaneous

E111

7501 1 549

LCD PANEL, LTM190 M2

-

L31 REV. 4.0D, 39C00I51LP1

Miscellaneous

E119

7501 2 373

SHEET FOR CLEAN CLOTH, 39C00S51L11

Miscellaneous

E120

7501 2 376

WARRANTY CARD, 39C00S51L12

Стр. 1 из

1

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.808\19A

...

Block :

Miscellaneous

Location :

Parts No. :

Block Location Parts No. Description

Search

Search

Page :

1 /

4

Jump

S MM L

Page 28

PARTS LIST

Accessory

E117

7501 2 371

OWNERS MANUAL, 19AV500PG, 39C00S51L14

Accessory

E117

7501 2 375

OWNERS MANUAL, 19AV500PR, 39C00S51L13

Accessory

E118

7501 2 372

INSTRUCTION, 19AV500P, 39C00S51L01

Accessory

E121

7501 2 374

REMOCON HAND UNIT, 39C00S51L05

Стр. 1 из

1

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.808\19A

...

Block :

Accessory

Location :

Parts No. :

Block Location Parts No. Description

Search

Search

Page :

1 /

4

S MM L

Jump

Page 29

PARTS LIST

Cabinet

E108

75011 568

STAND ASSY, 19AV501U, 39C00I51L13

Cabinet

E112

75012 592

BACK COVER ASSY, 19AV501P,(CHINA), 39C00S51L07

Cabinet

E113

75012 593

BEZEL ASSY, 19AV501P, (EUROPE), 39C00S51L02

Стр. 1 из

1

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.808\19A

...

Block :

Cabinet

Location :

Parts No. :

Block Location Parts No. Description

Search

Search

Page :

1 /

3

S MM L

Jump

Page 30

PARTS LIST

Packing

E021

7501 2 463

HANDLE, CARTON BOX 19V, 39C00J51L24

Packing

E106

7501 1 564

EPS FOAM, LEFT, 19AV500U, 39C00J51L01

Packing

E107

7501 1 565

EPS FOAM, RIGHR, 19AV500U, 39C00J51L02

Packing

E116

7501 2 594

CARTON BOX, 19AV501P, 39C00T51L01

Стр. 1 из

1

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.808\19A

...

Block :

Packing

Location :

Parts No. :

Block Location Parts No. Description

Search

Search

Page :

1 /

S MM L

4

Jump

Page 31

PARTS LIST

Стр. 1 из

2

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.791\19A

...

Precaution

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "X-RAY

RADIATION PRECAUTION" FOR DIRECT VIEW CTV ONLY, "SAFETY

PRECAUTION" AND "PRODUCT SAFETY NOTICE" OF THIS MANUAL.

CAUTION: The international hazard symbols " " in the schematic diagram

and the parts list designate components which have special characteristics

important for safety and should be replaced only with types identical to

those in the original circuit or specified in the parts list.

The mounting position of replacements is to be identical with originals.

Before replacing any of these components, read carefully the SAFETY

PRECAUTION and PRODUCT SAFETY NOTICE.

Do not degrade the safety of the receiver through improper servicing.

Note:

The part number must be used when ordering parts, in order to assist in processing, be

sure to include the Model number and Description.

The PC board assembly with mark is no longer available after the end of the

production.

Abbreviations

Capacitors CD : Ceramic Disk

Resistors CF : Carbon film

OMF : Oxide Metal Film

PF : Plastic Film

CC : Carbon Composition

VR : Variable Resistor

EL : Electrolytic

Page 32

MF : Metal Film

Стр. 2 из

2

03.05.2015

file://C:\Documents and Settings\Alexsandr\Local Settings\Temp\Rar$EXa0.791\19A

...

FR : Fusible Resistor

All CD and PF capacitors are ±5 %, 50 V and all resistor, ±5 %, 1/6 W unless otherwise

noted.

Page 33

Page 34

Page 35

KeypadMainBoard

PowerboardPanelmodule

Speaker

Keypad-7P

1

PWR_KEY

MENU

2

CH+

3

CH-

4

VOL+

5

6

VOL-

INPUT/EXIT

7

GND

8

IR board

IR boa rd -6 P

5V_STANDB Y

1

LED-G 15

2

3

LED-R 16

LED-C 17

4

IR_DATA 18

5

GND 19

6

L Speaker

1

LCH+ 25

LCH-

2

R Speaker

RCH-

1

RCH+

2

1

PWR_KEY 1

MENU 2

2

CH+ 3

3

CH- 4

4

VOL+ 5

5

6

VOL- 6

INPUT/EXIT 7

7

GND 8

8

LED-G 9

9

LED-R 10

10

11

LED-C 11

GND 12

12

13

IR_DATA 13

5V_STANDB Y 14

14

Speaker -4P

LCH+ 26

1

2

LCH- 27

RCH- 28

3

RCH+ 29

4

LVDS -2x15PKEY/IR -14P

RXE3+

Vcc:+5V

RXE3-

Vcc:+5V

RXECLK +

Vcc:+5V

RXECLK -

GND

RXE2+

GND

RXE2-

GND

RXE1+

GND

RXE1-

NC

RXE0+

NC

20

21

22

23

24

30

RXE0-

RXO0-

NC

RXO0+

RXO3+

RXO1-

RXO3-

RXO1+

RXOCLK+

RXO2-

RXOCLK-

RXO2+

Power supply - 12P 5

1 5V_IN 1 5V_IN 6

2 5V_IN 2 5V_IN 7

3 GND 3 GND_P 8

4 GND 4 GND_P 9

5 PO WER_EN 5 #POWER_EN 10

6 BK LT_ON_POwER 6 #IINVERT ER 11

7 BK LT_ADJ_PO wER 7 #B RIGHT 12

8 12V CCIN 8 12VCCIN 13

9 12V CCIN 9 12VCCIN 14

10 GND 10 GND_A 15

11 GND 11 GND_A 1 Hot-1 16

12 AC_LINE_DETE CTION 12 #ACD Upper 2 Cold-1 17

Power:JWT/A2008WV0-12P-6T

Back Light Unit

3 Hot-2 18

4 Cold-2 19

1 Hot-1 20

J901,J902,J903,J904 Low er 2 Cold-1 21

CCFL

1 HV 4 Cold-2 23

2 LV 24

AC In

1 Line 28

2 NC 29

3 Line 30

3 Hot-2 22

19” Sa msung panel LT M190M2-L31

UJU connector IS100-L30O-C23

1

2

3

4

25

26

27

RXO0-

RXO0+

RXO1-

RXO1+

RXO2-

RXO2+

GND

RXOCRXOC+

RXO3-

RXO3+

RXE0-

RXE0+

GND

RXE1-

RXE1+

GND

RXE2-

RXE2+

RXEC-

RXEC+

RXE3-

RXE3+

GND

NC

NC

NC

VDD:+5V

VDD:+5V

VDD:+5V

Loading...

Loading...