Page 1

FormNo.3398-974RevA

TimeCutter

®

MX5050Riding

Mower

ModelNo.74770—SerialNo.316000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3398-974*A

Page 2

WARNING

G014523

1

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orotherreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratoryratedbytheengine

manufacturerinaccordancewithSAEJ1940.Ascongured

tomeetsafety,emission,andoperatingrequirements,the

actualenginehorsepoweronthisclassoflawnmowerwill

besignicantlylower.

Introduction

Figure1

Undertheseat

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthespace

below:

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

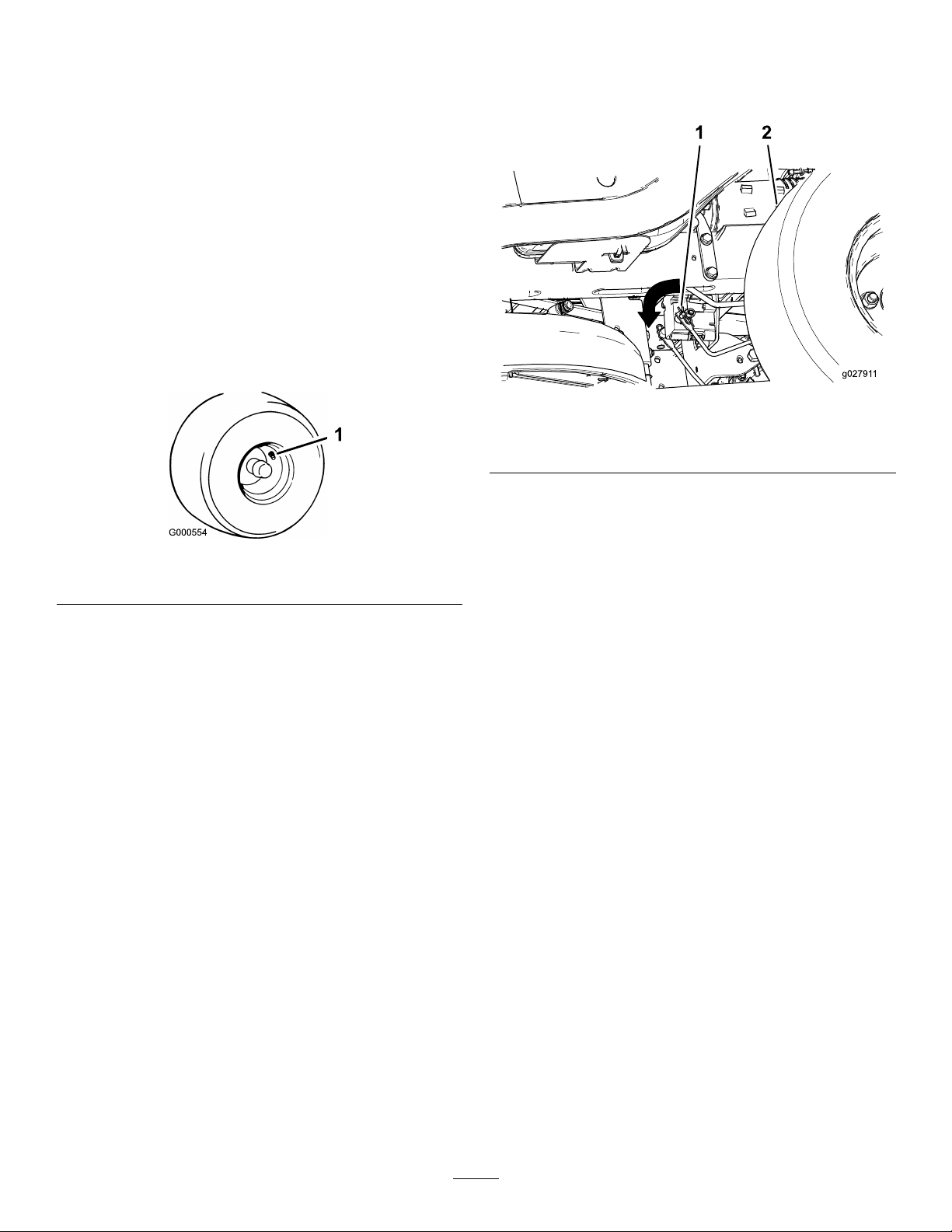

Figure2

1.Safety-alertsymbol.

Thismachineisaride-on,rotary-bladelawnmowerintended

tobeusedbyhomeownersinresidentialapplications.Itis

primarilydesignedforcuttinggrassonwell-maintainedlawns.

Itisnotdesignedforcuttingbrush,mowinggrassandother

growthalongsidehighways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................6

SlopeIndicator.......................................................7

SafetyandInstructionalDecals.................................8

ProductOverview.........................................................12

Controls...............................................................12

Operation....................................................................14

AddingFuel...........................................................14

CheckingtheEngine-OilLevel.................................15

BreakinginaNewMachine......................................15

ThinkSafetyFirst...................................................15

UnderstandingtheSafety-InterlockSystem................16

TestingtheSafety-InterlockSystem...........................16

StartingtheEngine.................................................17

OperatingtheBlades...............................................17

StoppingtheEngine...............................................17

DrivingtheMachine...............................................18

StoppingtheMachine.............................................20

AdjustingtheHeight-of-Cut....................................20

AdjustingtheAnti-ScalpRollers...............................20

PositioningtheSeat................................................20

AdjustingtheMotion-ControlLevers........................21

PushingtheMachinebyHand..................................21

UsingtheGrassDeector.......................................22

TransportingtheMachine........................................22

LoadingtheMachine..............................................22

OperatingTips......................................................24

Maintenance.................................................................25

RecommendedMaintenanceSchedule(s)......................25

PremaintenanceProcedures........................................26

RaisingtheSeat......................................................26

Lubrication...............................................................26

GreasingtheBearings.............................................26

EngineMaintenance..................................................27

ServicingtheAirCleaner.........................................27

ServicingtheEngineOil..........................................27

ServicingtheSparkPlug..........................................29

CleaningtheBlowerHousing...................................30

FuelSystemMaintenance...........................................31

ReplacingtheIn-LineFuelFilter...............................31

ElectricalSystemMaintenance....................................32

ChargingtheBattery...............................................32

ServicingtheFuses.................................................33

DriveSystemMaintenance.........................................34

CheckingtheTirePressure......................................34

ReleasingtheElectricBrake.....................................34

HydraulicSystemMaintenance....................................35

CheckingtheHydraulicFluidLevel...........................35

ChangingtheHydraulicSystemFluidand

Filters................................................................35

MowerMaintenance...................................................37

ServicingtheCuttingBlades.....................................37

LevelingtheMowerDeck........................................39

RemovingtheMower..............................................41

InstallingtheMower...............................................42

ReplacingtheGrassDeector..................................42

MowerBeltMaintenance............................................43

InspectingtheBelts................................................43

ReplacingtheMowerBelt........................................43

Cleaning...................................................................44

WashingtheUndersideoftheMower........................44

Storage........................................................................45

CleaningandStorage..............................................45

Troubleshooting...........................................................46

Schematics...................................................................48

3

Page 4

Safety

Toreducethepotentialforinjury,complywiththesesafety

instructionsandalwayspayattentiontothesafety-alert

symbol,whichmeansCaution,Warning,orDanger—personal

safetyinstruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

ThefollowinginstructionsareadaptedfromANSIstandard

B71.1-2012.AllthelanguagewithinthisANSIstandard

appliestothismachine;however,duetotheapplicationof

thestandardacrossmanydifferenttypesofproductssome

statementscanseemgeneralormisleading.Intheseinstances,

Torohasrenedthestatementtoconveythemeaningofthe

standardwhilebettermatchingtheproductthisOperator's

Manualpertains.Safetyinformationinadditiontothe

instructionsfoundintheANSIstandardbelowcanbefound

inToroRidingMowerSafetyattheendofthissection.

GeneralOperation

•Read,understand,andfollowallinstructionsinthe

Operator'sManualandonthemachinebeforestarting.

•Donotplaceyourhandsorfeetnearrotatingpartsor

underthemachine.Keepclearofthedischargeopening

atalltimes.

•Allowonlyresponsibleadultswhoarefamiliarwiththe

instructionstooperatethemachine.

•Cleartheareaofobjectssuchasrocks,toys,wire,etc.,

whichcouldbepickedupandthrownbytheblade.

•Besuretheareaisclearofotherpeoplebeforemowing.

Stopthemachineifanyoneentersthearea.

•Nevercarrypassengers.

•Donotmowinreverseunlessabsolutelynecessary.

Alwayslookdownandbehindbeforeandwhilebacking

up.

•Beawareofthemowerdischargedirectionanddonot

pointitatanyone.Avoiddischargingmaterialagainsta

wallorobstruction.Materialmayricochetbacktoward

your.Stoptheblade(s)whencrossinggravelsurfaces.

•Donotoperatethemachinewithoutdeector,discharge

coverorentiregrasscollectionsysteminplaceand

working.

•Bealert,slowdownandusecautionwhenmakingturns.

Lookbehindandtothesidebeforechangingdirections.

•Neverleavearunningmachineunattended.Alwaysturn

offblades,setparkingbrake,shutofftheengine,and

removethekeybeforedismountingthemachine.

•Turnoffthebladeswhennotmowing.Shutoffthe

engine,waitforallpartstocometoacompletestop,and

removethekeybeforecleaningthemachine,removing

thegrasscatcheroruncloggingthedischargechute.

•Operatethemachineonlyindaylightorgoodarticial

light.

•Donotoperatethemachinewhiletired,ill,orunderthe

inuenceofalcoholordrugs.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Useextracarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Wearappropriateclothingincludingeyeprotectionand

substantial,slip-resistantshoes.Tiebacklonghair.Do

notwearjewelry.

•Alwaysfollowtherecommendationsforanyapplication

ofcounterweights.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

SlopeOperation

Slopesareamajorfactorrelatedtolossofcontroland

tip-overaccidents,whichcanresultinsevereinjuryordeath.

Operationonallslopesrequiresextracaution.Ifyoucannot

backuptheslopeorifyoufeeluneasyonit,donotmowit.

•Donotmowslopesgreaterthan15degrees.

•Watchforditches,holes,rocks,dips,andrisesthatchange

theoperatingangle,asroughterraincouldoverturnthe

machine.

•Choosealowgroundspeedsothatyouwillnothaveto

stopwhileoperatingonaslope.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcauseslidingand

lossofcontrol.

•Alwayskeepthedrivewheelsengagedwhengoingdown

slopes.

•Reducespeedanduseextremecautiononslopes.

•Donotmakesuddenturnsorrapidspeedchanges.

•Removeormarkobstaclessuchasrocks,treelimbs,etc.

fromthemowingarea.Tallgrasscanhideobstacles.

•Avoidsuddenstartswhenmowinguphillbecausethe

mowermaytipbackward.

•Beawarethatlossoftractionmayoccurgoingdownhill.

Weighttransfertothefrontwheelsmaycausedrive

wheelstoslipandcauselossofbrakingandsteering.

•Alwaysavoidsuddenstartingorstoppingonaslope.If

thetireslosetraction,stopthemachine,disengagethe

bladesandproceedslowlydowntheslope.

•Useextremecarewithgrasscatchersorotherattachments.

Thesecanchangethestabilityofthemachineandcause

lossofcontrol.

4

Page 5

•Donottrytostabilizethemachinebyputtingyourfoot

ontheground.

•Donotmowneardrop-offs,ditches,steepbanks,or

water.Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathordrowning.

•Useawalkbehindmowerand/orahandtrimmernear

drop-offs,ditches,steepbanks,orwater.

Children

Tragicaccidentscanoccuriftheoperatorisnotalerttothe

presenceofchildren.Childrenareoftenattractedtothe

machineandthemowingactivity.Neverassumethatchildren

willremainwhereyoulastsawthem.

•Keepchildrenoutofthemowingareaandunderthe

watchfulcareofanotherresponsibleadult,notthe

operator.

•Bealertandturnthemachineoffifchildrenenterthe

area.

•Beforeandwhilebackingorchangingdirection,look

behind,down,andside-to-sideforsmallchildren.

•Nevercarrychildrenonthemachine,evenwiththe

bladesoff.Childrenmayfalloffandbeseriouslyinjured

orinterferewiththesafeoperationofthemachine.

•Childrenwhohavebeengivenridesinthepastmay

suddenlyappearinthemowingareaforanotherrideand

berunoverorbackedoverbythemower.

•Neverallowchildrentooperatethemachine.

Service

SafeHandlingofGasoline

Toavoidpersonalinjuryorpropertydamage,useextracare

whenhandlinggasolineandotherfuels.Theyareammable

andthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedcontainer.

•Neverremovethefuelcaporaddfuelwhentheengineis

running.Allowtheenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerinsidewhere

thereisanopename,suchasnearawaterheateror

furnace.

•Neverllcontainersinsideavehicleoronatruckor

trailerwithaplasticliner.Alwaysplacecontainersonthe

ground,awayfromyourvehiclebeforelling.

•Removefuel-poweredequipmentfromthetruckortrailer

andrefuelitontheground.Ifthisisnotpossible,then

refuelsuchequipmentwithaportablecontainerrather

thanfromagasoline-dispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilthefuelingis

complete.Donotuseanozzlelock-opendevice.

•Ifyouspillfuelonclothing,changeyourclothing

immediately.

•Neveroverllthefueltank.Replacethefuelcapand

tightenitsecurely.

•Useextracarewhenapproachingblindcorners,shrubs,

trees,theendofafence,orotherobjectsthatmay

obscurevision.

TowingSafety

•Donotattachtowedequipmentexceptatthehitchpoint.

•Followtheattachmentmanufacturer'srecommendation

forweightlimitsfortowedequipmentandtowingon

slopes.Towedweightmustnotexceedtheweightofthe

machine,operator,andballast.Usecounterweightsor

wheelweightsasdescribedintheattachment,orinthe

towingmachineOperator’sManual.

•Neverallowchildrenorothersinorontowedequipment.

•Onslopes,theweightofthetowedequipmentmaycause

lossoftraction,increasedriskofrollover,andlossof

control.Reducethetowedweightandslowdown.

•Thestoppingdistanceincreaseswiththeweightofthe

towedload.Travelslowlyandallowextradistancetostop.

•Makewideturnstokeeptheattachmentclearofthe

machine.

GeneralService

•Neveroperateamachineinsideaclosedarea.Engine

exhaustcontainscarbonmonoxide,whichisanodorless,

deadlypoisonthatcankillyou.

•Keepnutsandboltstight,especiallythebladeattachment

bolts.Keepequipmentingoodcondition.

•Neverinterferewiththeintendedfunctionofasafety

deviceortoreducetheprotectionprovidedbyasafety

device.Checktheirproperoperationregularly.

•Keepthemachinefreeofgrass,leaves,orotherdebris

buildup.Cleanupoilorfuelspillsandfuel-soakeddebris.

Allowthemachinetocoolbeforestoringit.

•Stopandinspecttheequipmentifyoustrikeanobject.

Repair,ifnecessary,beforestartingthemachine.

•Nevermakeanyadjustmentsorrepairswiththeengine

running.

•Grasscatchercomponentsaresubjecttowear,damage,

anddeterioration,whichcouldexposemovingpartsor

allowobjectstobethrown.Frequentlycheckcomponents

andreplacethemwiththemanufacturers'recommended

parts,whennecessary.

•Mowerbladesaresharpandcancut.Wraptheblade(s)or

wearthickly-paddedglovesanduseextracautionwhen

servicingthem.

5

Page 6

•Checkforproperbrakeoperationfrequently .Adjustand

servicethemasrequired.

•Maintainorreplacesafetyandinstructiondecalsas

necessary.

•UseonlygenuineTororeplacementpartstoensurethat

theoriginalstandardsaremaintained.

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

maynotbeincludedintheANSIstandards.

•Stoptheengine,movethemotion-controlleversto

NEUTRALandoutwardtothePARKposition,disengage

theblade-controlswitch,removekeybeforeand

disconnectsparkplugwire(s)performinganyservice,

repairs,maintenanceoradjustments.

•Keephands,feet,hair,andlooseclothingawayfrom

attachmentdischargearea,undersideofmowerandany

movingpartswhileengineisrunning.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowthemtocoolbefore

attemptingtomaintain,adjust,orservicethem.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparksand

amesawayfromthebattery.

•UseonlyToroapprovedattachments.Youmayvoid

thewarrantyifyouusethemachinewithunapproved

attachments.

•Ifloadingthemachineontoatrailerortruck,useasingle,

full-widthramponly.Therampangleshouldnotexceed

15degrees.

6

Page 7

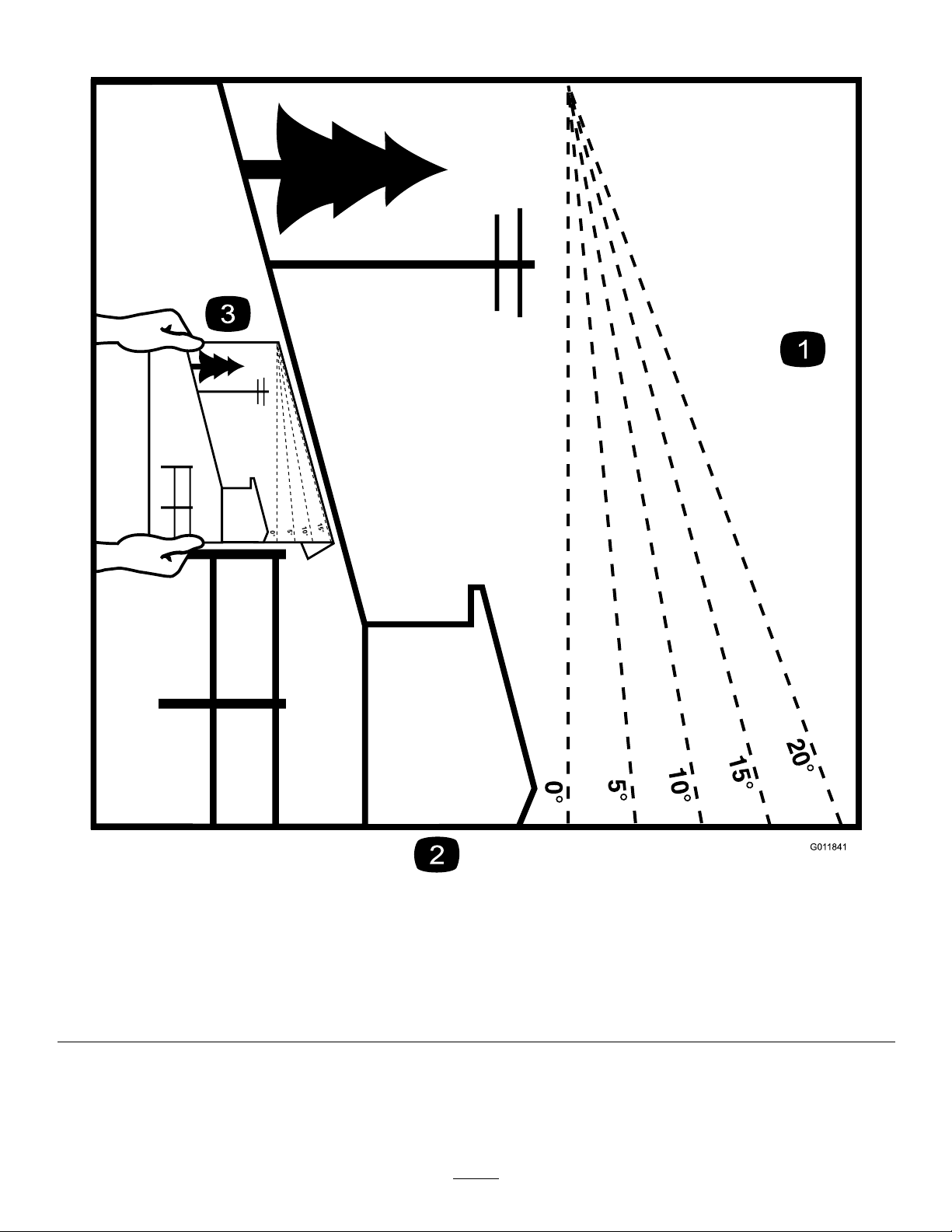

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

7

Page 8

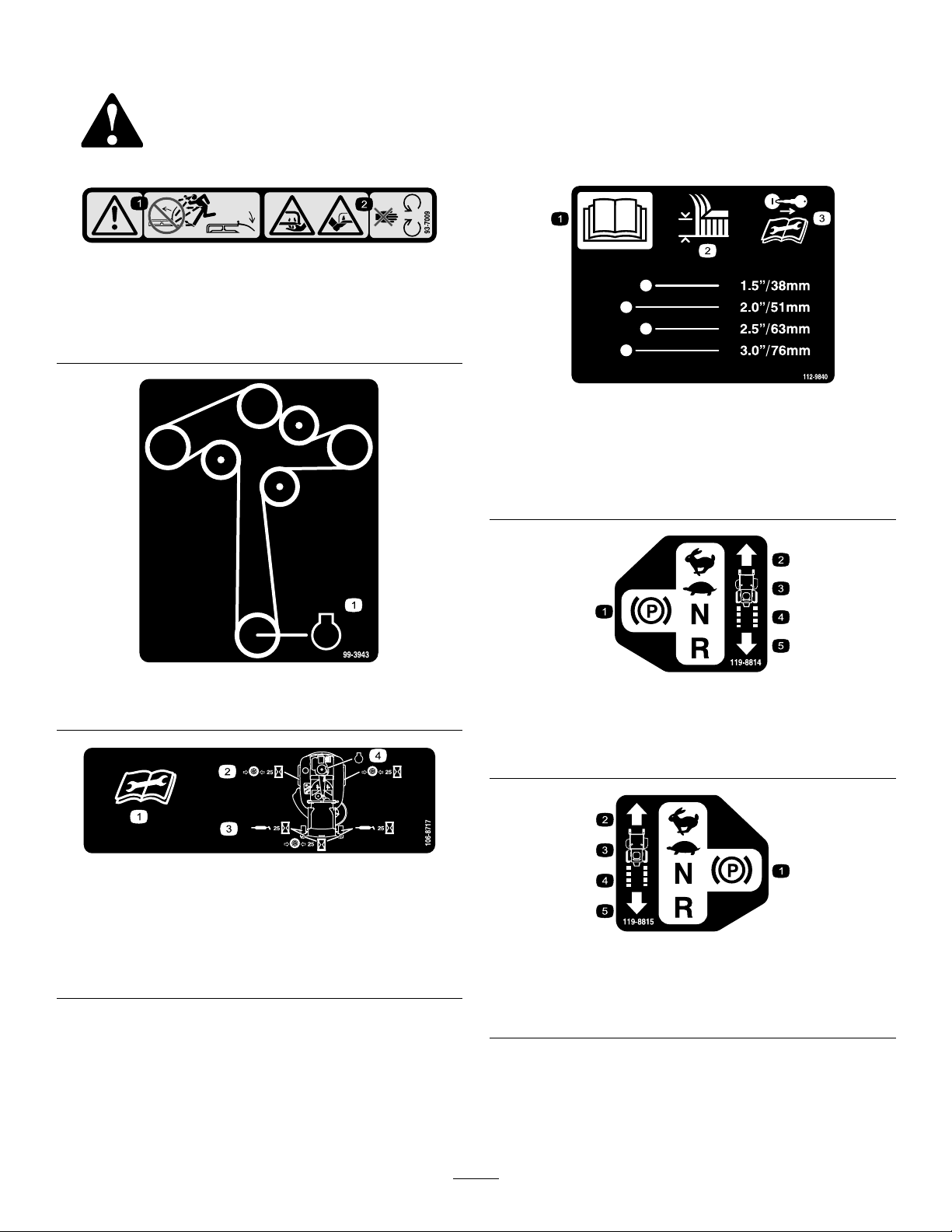

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-7009

1.Warning—donotoperatethemowerwiththedeectorup

orremoved;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

112-9840

1.ReadtheOperator's

Manual.

2.Heightofcut

99-3943

1.Engine

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

3.Removetheignitionkey

andreadtheinstructions

beforeservicingor

performingmaintenance.

119-8814

106-8717

1.Readtheinstructionsbeforeservicingorperforming

maintenance.

2.Checktirepressureevery25operatinghours.

3.Greaseevery25operatinghours.

4.Engine

119-8815

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

8

Page 9

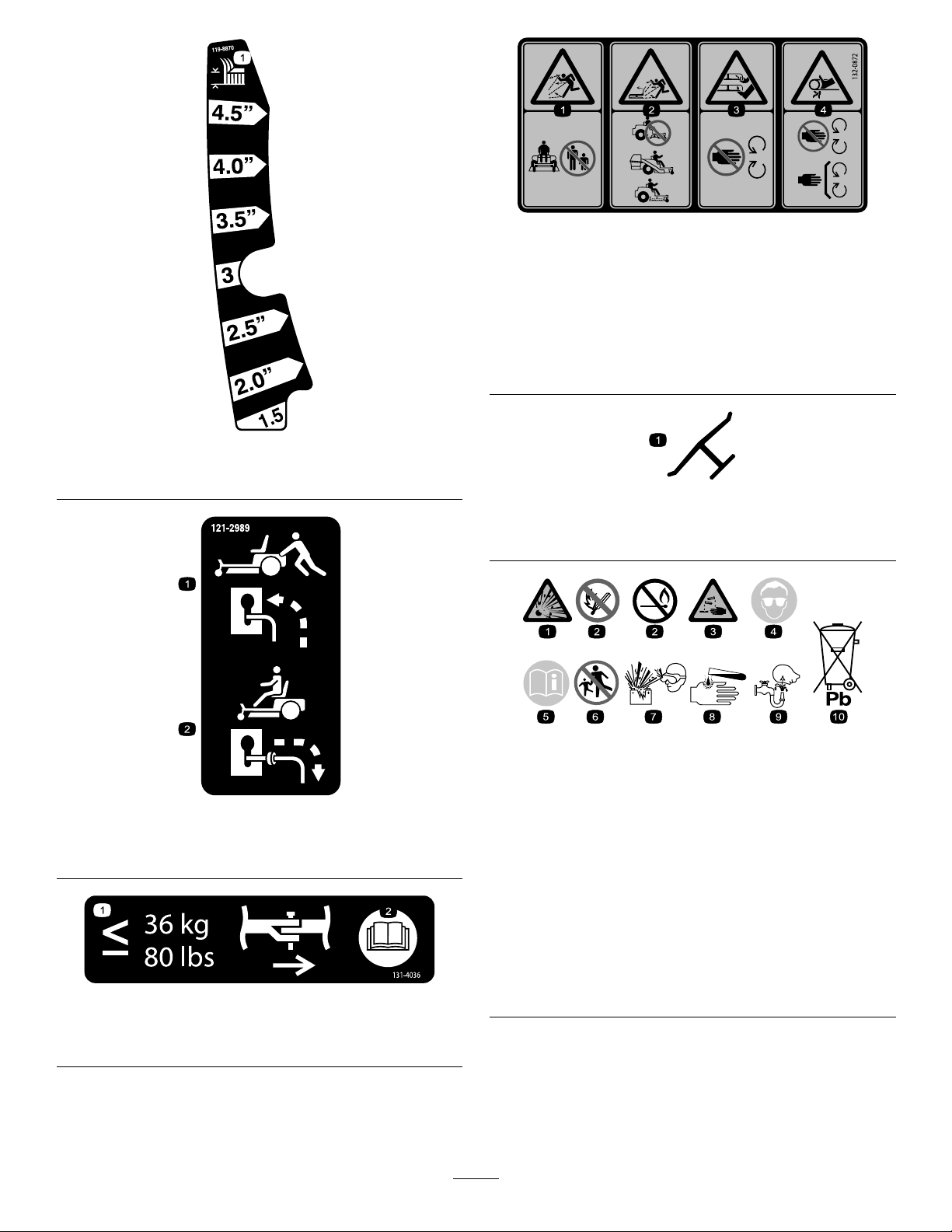

132-0872

1.Heightofcut

1.Thrownobject

hazard—keepbystanders

awayfromthemachine.

2.Thrownobjecthazard,

raisedbafe—donot

operatethemachinewith

anopendeck;usea

baggerorabafe.

3.Severinghazardofhand

orfoot—keepawayfrom

movingparts.

4.Entanglement

hazard—keepaway

frommovingparts;keep

allguardsandshieldsin

place.

119-8870

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

1.Bypassleverpositionfor

pushingthemachine

1.Maximumdrawbarpull36

kg(80lb)

121-2989

2.Bypassleverpositionfor

operatingthemachine

131-4036

2.ReadtheOperator's

Manual.

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

9

Page 10

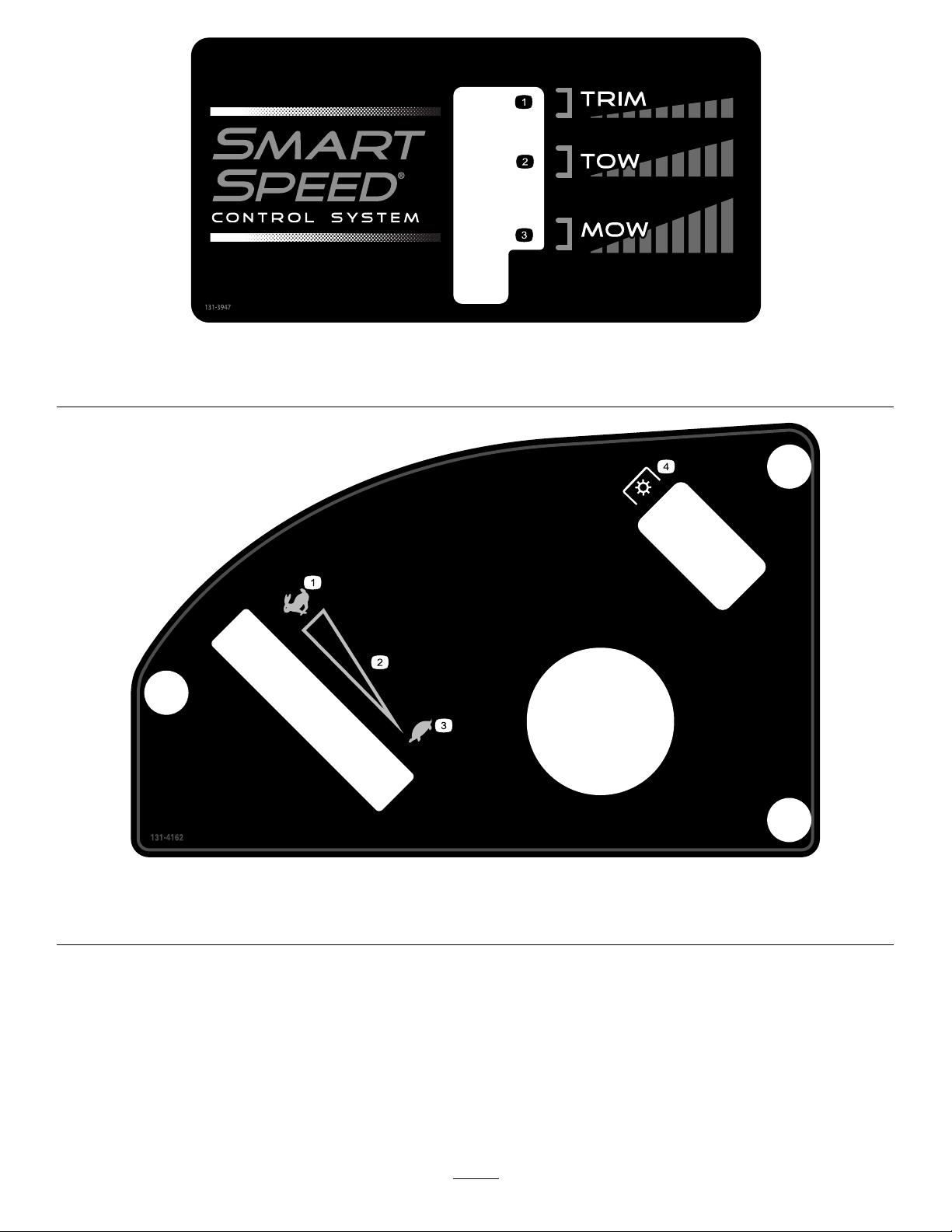

131-3947

1.Trim—slow

2.Tow—medium

3.Mow—fast

131-4162

1.Fast

2.Continuous-variablesetting4.Powertakeoff

3.Slow

10

Page 11

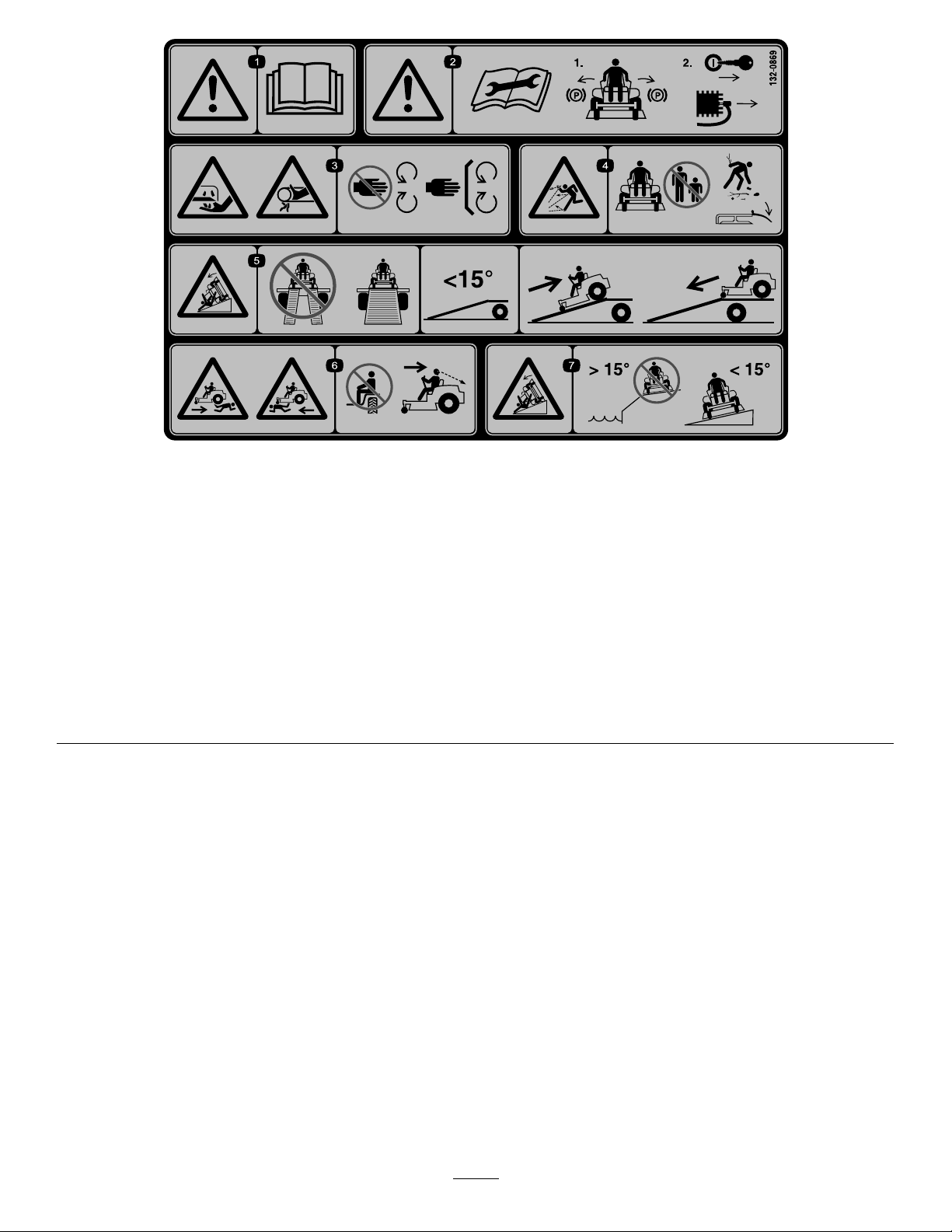

132-0869

1.Warning—readthe

Operator'sManual.

2.Warning—beforeservicing,

engagetheparkingbrake,

removethekeyandthe

sparkplugconnection.

3.Cuttinghazardofhand,

mowerblade;pinching

hazardofhand,belt—keep

handsandfeetawayfrom

movingparts;keepall

guardsandshieldsinplace.

4.Thrownobject

hazard—keepbystanders

awayfromthemachine;

removedebrisfromthe

areabeforemowing;keep

thedeectorshielddown.

5.Ramptipping

hazard—whenloading

ontoatrailer,donotuse

dualramps;onlyusea

singlerampwideenough

forthemachineandthat

hasaninclinelessthan

15degrees;backupthe

ramp(inreverse)anddrive

forwardofftheramp.

6.Bodilyharmhazard—no

riders;lookbehindyou

whenmowinginreverse.

7.Tippinghazardon

slopes—donotuseon

slopesnearopenwater;do

notuseonslopesgreater

than15degrees.

11

Page 12

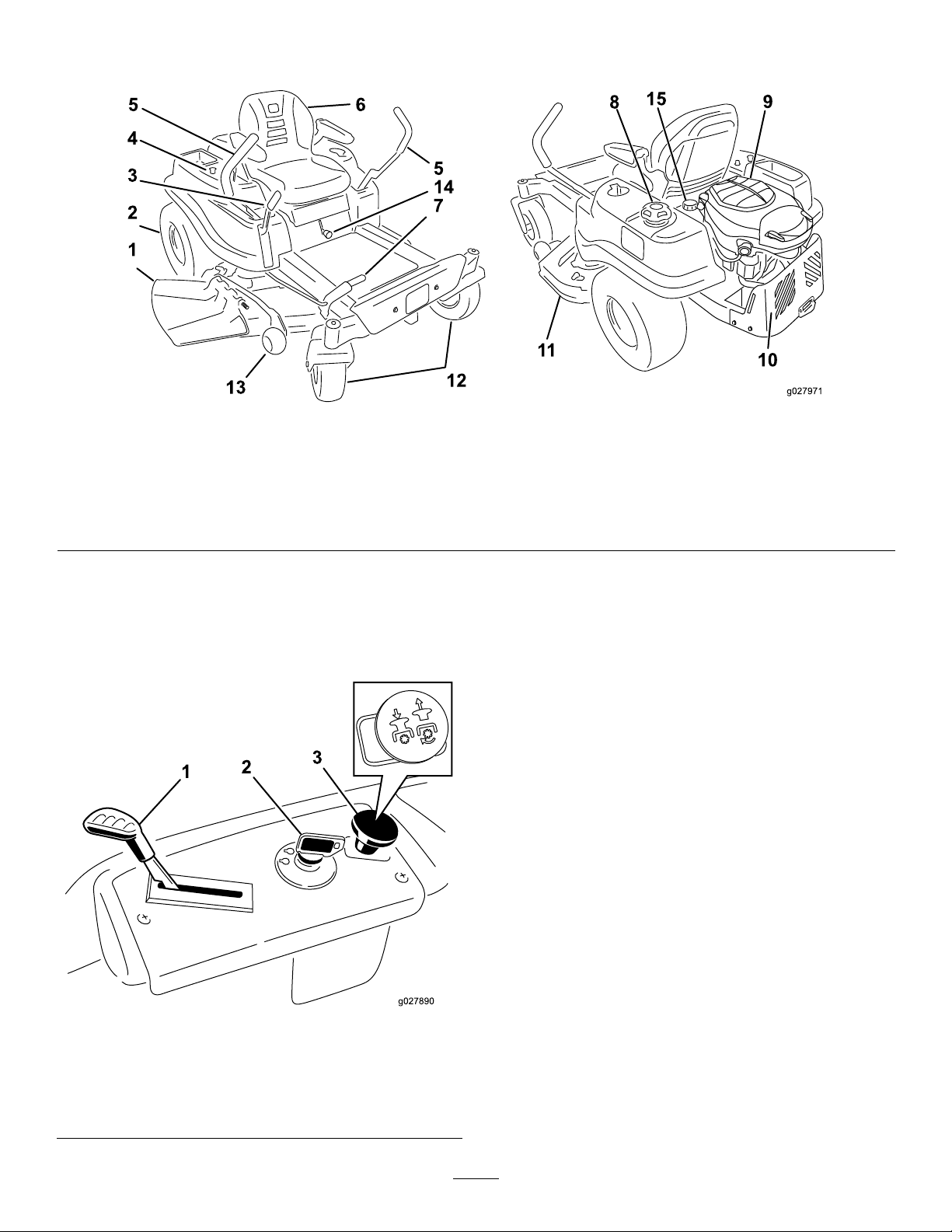

ProductOverview

Figure4

1.Deector

2.Reardrivewheel

3.Height-of-cutlever7.Foot-assistlever(certain

4.Controlpanel

5.Motion-controllevers9.Engine13.Anti-scalproller

6.Seat

modelsonly)

8.Fuel-tankcap12.Frontcasterwheel

Controls

BecomefamiliarwithallthecontrolsinFigure4andFigure5

beforeyoustarttheengineandoperatethemachine.

10.Engineguard

11.Mowerdeck15.Hydraulicreservoir

14.SmartSpeed™lever

IgnitionSwitch

Theignitionswitchhas3positions:OFF,RUN,andSTART.

ThekeyturnstoSTARTandmovesbacktoRUNupon

release.TurningthekeytotheOFFpositionstopstheengine;

however,alwaysremovethekeywhenleavingthemachine

topreventsomeonefromaccidentallystartingtheengine

(Figure5).

Throttle

Thethrottlecontrolstheenginespeedandhasacontinuous

variablesettingfromSlowtoFast(Figure5).

Blade-ControlSwitch(PowerTakeoff)

Figure5

ControlPanel

1.Throttle3.Blade-controlswitch

(powertakeoff)

2.Ignitionswitch

Theblade-controlswitch,representedbyapower-takeoff

(PTO)symbol,engagesanddisengagespowertothemower

blades(Figure5).

12

Page 13

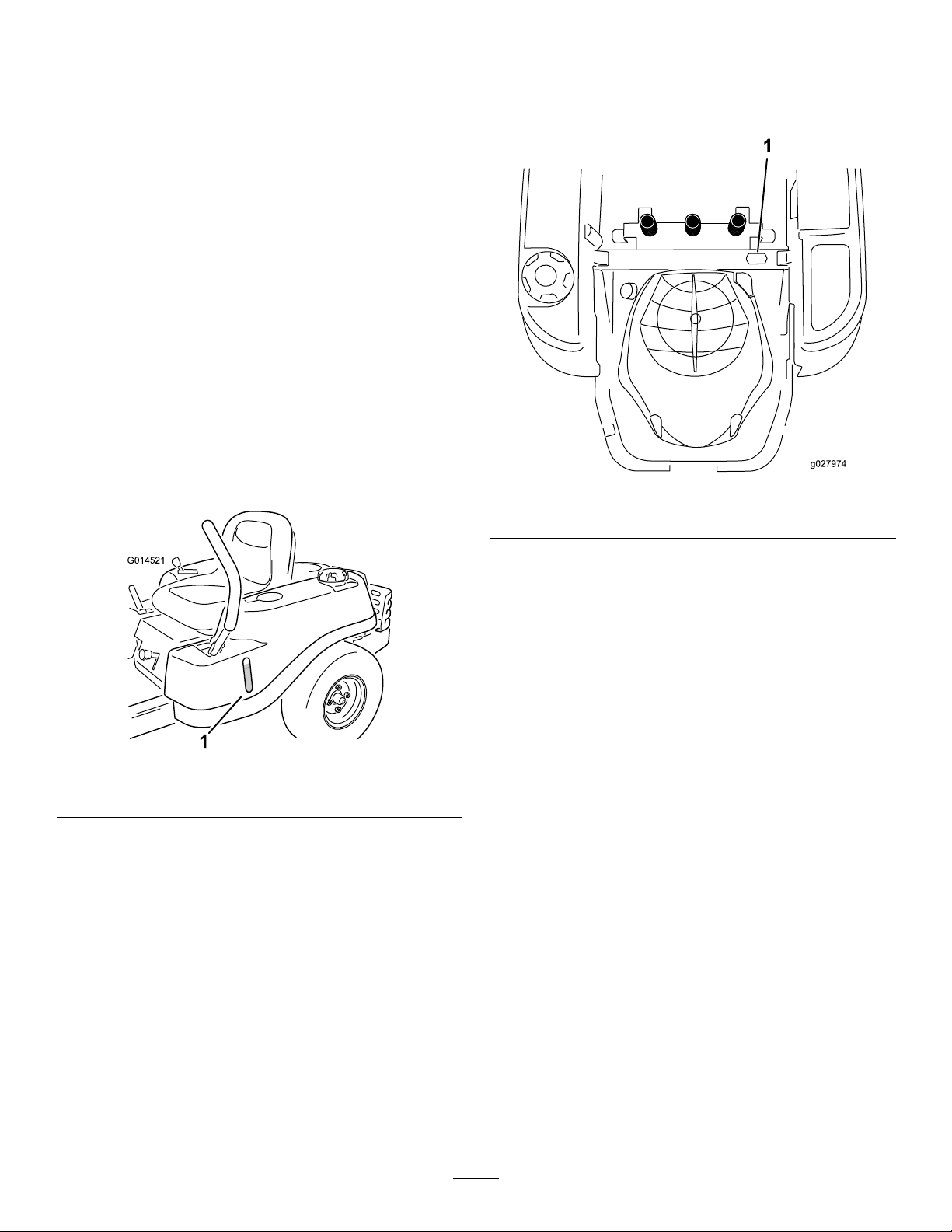

Motion-ControlLeversandPark

G014521

1

Position

Themotion-controlleversarespeed-sensitivecontrolsof

independentwheelmotors.Movingaleverforwardor

backwardturnsthewheelonthesamesideforwardorin

reverse;thewheelspeedisproportionaltotheamountyou

movethelever.Movethemotion-controlleversoutward

fromthecentertothePARKpositionwhenexitingthe

machine(Figure14).Alwayspositionthemotion-control

leversintothePARKpositionwhenyoustopthemachine

orleaveitunattended.

SmartSpeed™ControlSystemLever

TheSmartSpeed™Control-Systemlever,locatedbelowthe

operatingposition,givesyouachoicetodrivethemachineat

3speedranges—trim,tow ,andmow(Figure17).

Fuel-PresenceWindow

Youcanusethefuelwindow ,locatedontheleftsideofthe

machine,toverifythepresenceofgasolineinthetank(Figure

6).

HourMeter

Thehourmeterrecordsthenumberofhourswhenyou

areintheseatandtheignitionswitchisintheONposition

(Figure7).

Figure7

1.Hourmeterlocationbehindtheseat

Figure6

1.Fuel-presencewindow

Height-of-CutLever

Usetheheight-of-cutlevertolowerandraisethedeckfrom

theseatedposition.Movingtheleverup(towardyou)raises

thedeckfromthegroundandmovingtheleverdown(away

fromyou)lowersthedecktowardtheground.Adjustthe

height-of-cutonlywhilethemachineisnotmoving(Figure

18).

13

Page 14

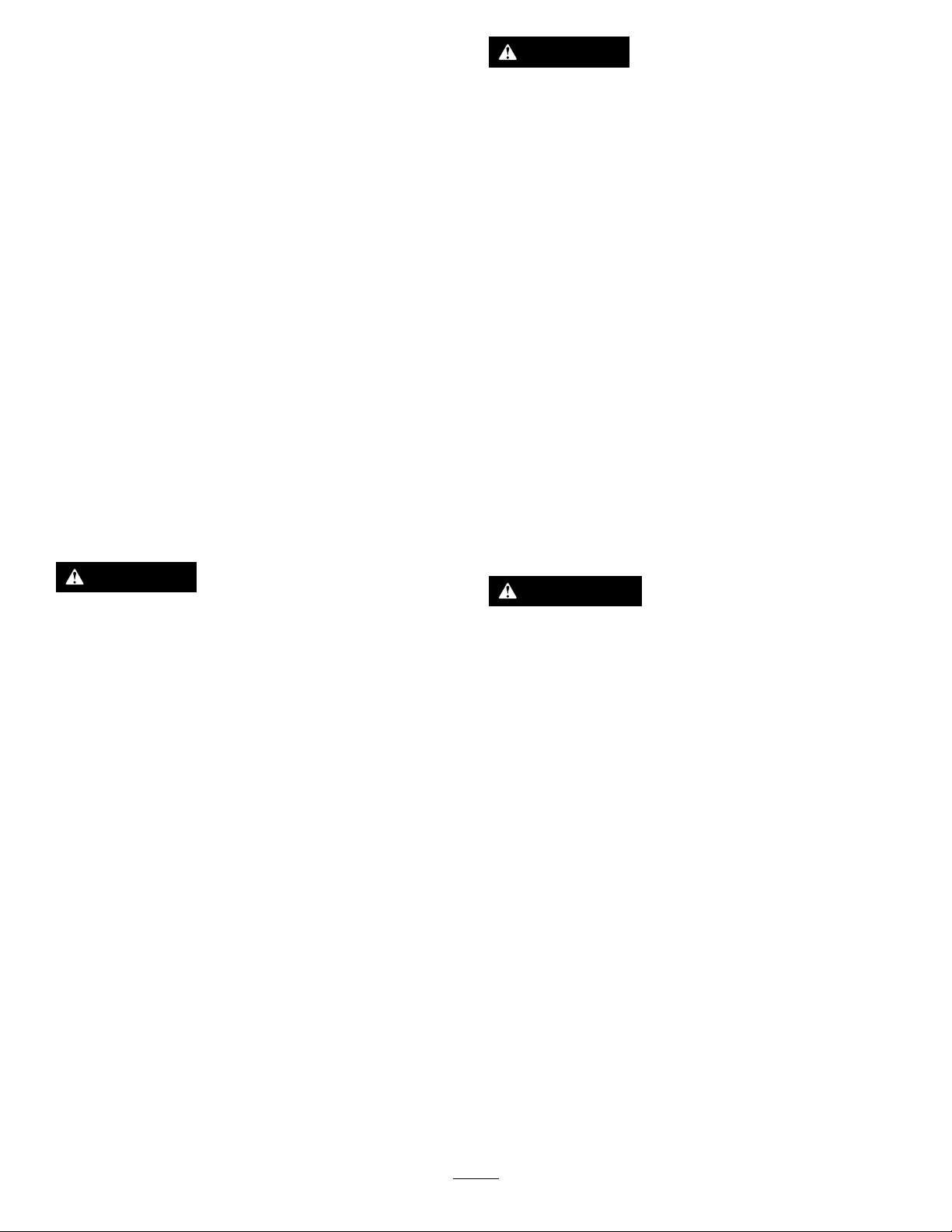

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleased,causingasparkthatcan

ignitethegasolinevapors.Areorexplosionfrom

gasolinecanburnyouandothersandcandamage

property.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbed,becauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

containerratherthanfromagasoline-dispenser

nozzle.

•Ifyoumustuseagasoline-dispensernozzle,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillswith

soapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns.

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasolinestabilizer/conditioner

tothegasoline.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.T ominimizethechance

14

Page 15

ofvarnishdepositsinthefuelsystem,usefuelstabilizer

g027243

A

B

E

D

C

atalltimes.

FillingtheFuelTank

Note:Ensurethattheengineisshutoffandthe

motion-controlleversareinthePARKEDposition.

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthesafety

section.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

DANGER

Note:Youcanusethefuelwindowtoverifythepresenceof

gasolinebeforellingthetank(Figure8).

Important:Donotoverllthefueltank.Fillthefuel

tanktothebottomofthellerneck.Theemptyspace

inthetankallowsthefueltoexpand.Overllingmay

resultinfuelleakage,damagetotheengine,ordamage

totheemissionssystem.

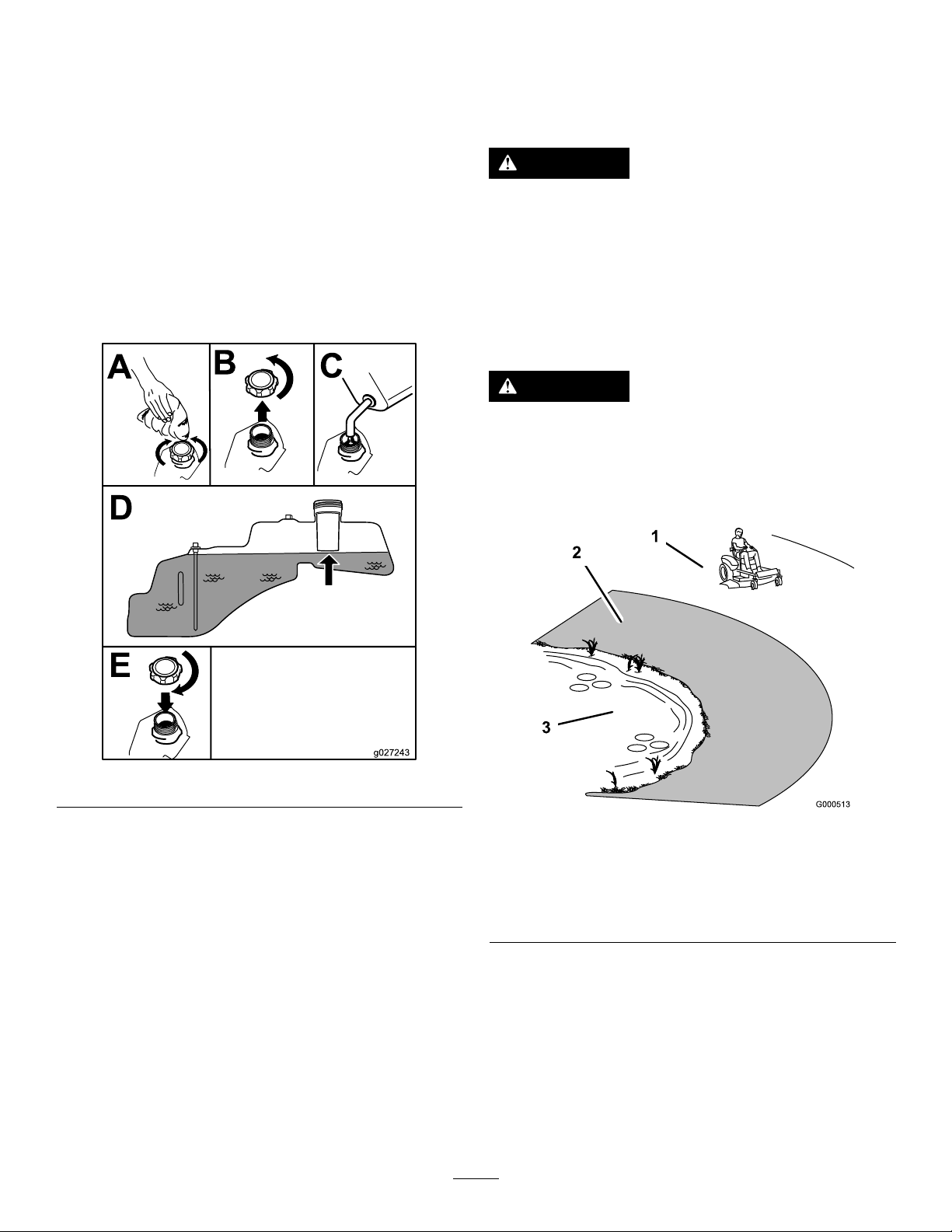

Operatingthemachineonwetgrassorsteepslopes

cancauseslidingandlossofcontrol.

•Donotoperateonslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Donotoperatethemachinenearwater.

DANGER

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,or

drowning.

Donotoperatethemachineneardrop-offs.

Figure8

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page27).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

1.Safezone—usethe

machinehere

2.Useawalk-behindmower

and/orhandtrimmernear

drop-offsandwater.

15

Figure9

3.Water

Page 16

CAUTION

G009027

1

2

TestingtheSafety-Interlock

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator’searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Useprotectiveequipmentforyoureyes,ears,hands,feet,

andhead.

Figure10

1.Wearsafetyglasses.

2.Wearhearingprotection.

Understandingthe Safety-InterlockSystem

WARNING

Ifthesafety-interlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly,

causingpersonalinjury.

System

Testthesafety-interlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Whilesittingontheseat,withthecontrolleversinthe

PARKposition,andmovetheblade-controlswitchto

theONposition.Trystartingtheengine;theengine

shouldnotcrank.

2.Whilesittingontheseat,movetheblade-controlswitch

totheOFFposition.Moveeithermotioncontrol

levertothecenter,unlockedposition.Trystartingthe

engine;theengineshouldnotcrank.Repeatwiththe

othermotion-controllever.

3.Whilesittingontheseat,movethebladecontrolswitch

totheOFFposition,andlockthemotion-controllevers

inthePARKposition.Starttheengine.Whilethe

engineisrunning,engagetheblade-controlswitch,and

riseslightlyfromtheseat;theengineshouldstop.

4.Whilesittingontheseat,movetheblade-controlswitch

totheOFFposition,andlockthemotion-controllevers

inthePARKposition.Starttheengine.Whilethe

engineisrunning,movethemotion-controlleversto

thecenter,unlockedposition,engagetheblade-control

switch,andriseslightlyfromtheseat;theengine

shouldstop.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Thesafety-interlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Thebladesaredisengaged.

•Themotion-controlleversareinthePARKposition.

Thesafety-interlocksystemalsoisdesignedtostoptheengine

wheneverthecontrolleversareoutofthePARKpositionand

yourisefromtheseat.

16

Page 17

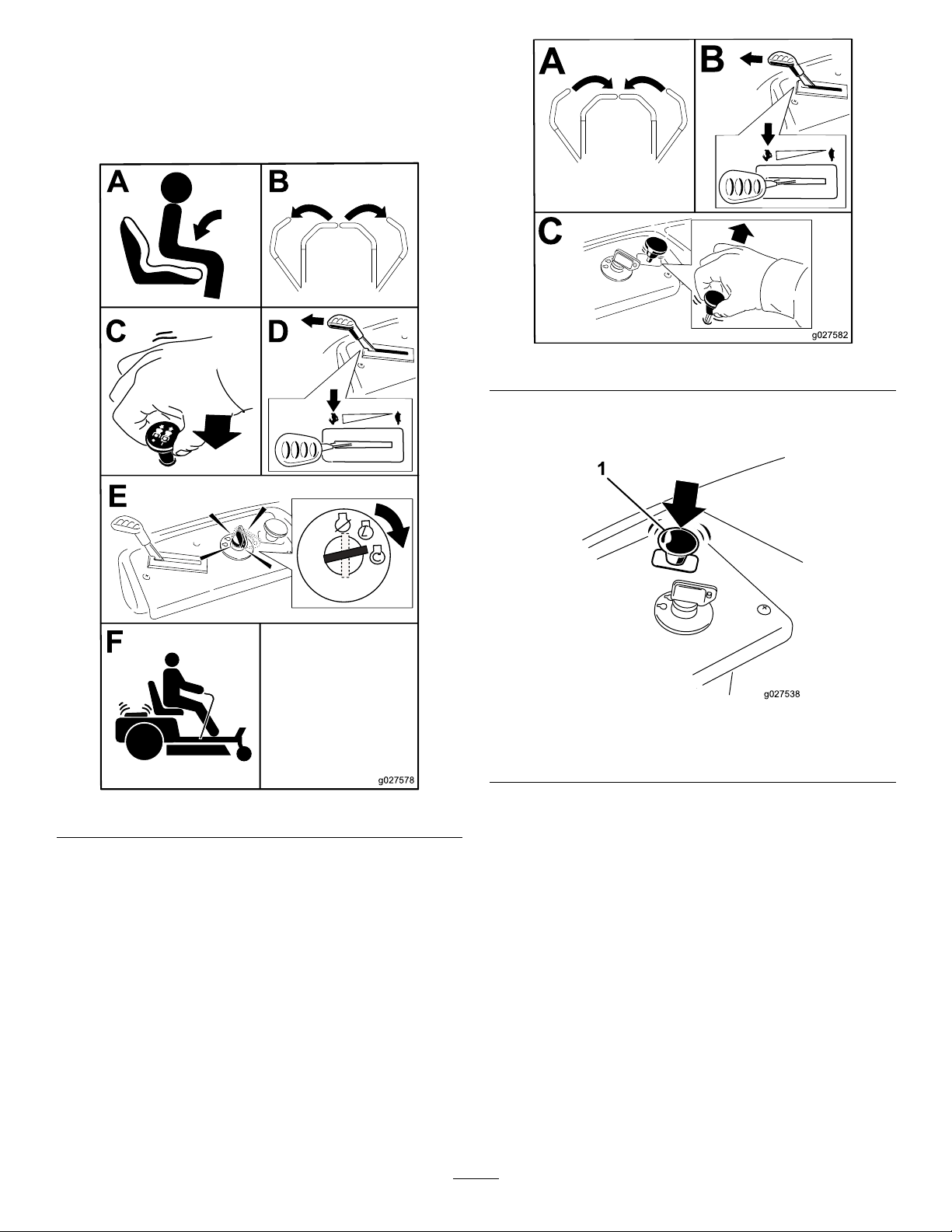

StartingtheEngine

g027578

B

C

D

E

A

F

g027582

B

C

A

1

g027538

Important:Donotengagethestarterformorethan

10secondsatatime.Iftheenginefailstostart,wait

60secondsbetweenattempts.Failuretofollowthese

instructionscandamagethestartermotor.

Figure12

DisengagingtheBlades

Figure11

OperatingtheBlades

Theblade-controlswitchengagesanddisengagespower

tothemowerblades.Thisswitchcontrolspowertoany

attachmentsthatdrawpowerfromtheengine,includingthe

mowerdeckandcuttingblades.

EngagingtheBlades

Important:Donotengagethebladeswhenthemachine

isparkedintallgrass.Beltorclutchdamagecanoccur.

Note:Alwaysengagethebladeswiththethrottleinthe

FASTposition.

Figure13

1.Blade-controlswitch—Off

StoppingtheEngine

1.Disengagethebladesbymovingtheblade-control

switchtotheOFFposition(Figure13).

2.MovethethrottlelevertotheFASTposition.

3.TurntheignitionkeytotheOFFpositionandremove

thekey.

17

Page 18

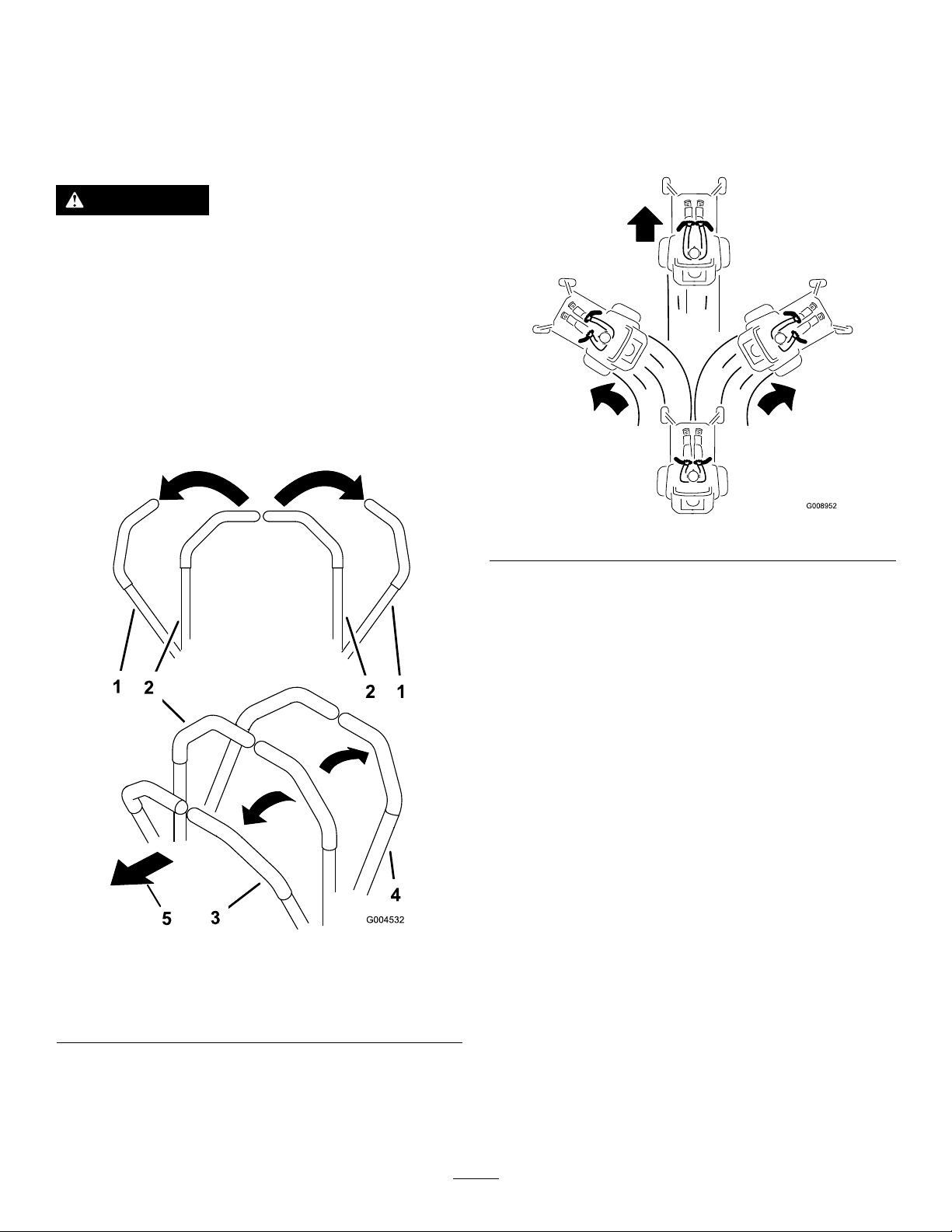

DrivingtheMachine

G008952

DrivingForward

Thedrivewheelsturnindependently,poweredbyhydraulic

motorsoneachaxle.Youcanturn1sideinreversewhileyou

turntheotherforward,causingthemachinetospinrather

thanturn.Thisgreatlyimprovesthemachinemaneuverability

butmayrequiresometimeforyoutoadapttohowitmoves.

WARNING

Themachinecanspinveryrapidly.Y oumaylose

controlofthemachineandcausepersonalinjuryor

damagetothemachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Setthethrottlecontrolin

theFASTpositionforperformance.Formostapplications,

operatethemachineinthefull-throttleposition.

Note:Alwaysusecautionwhenbackingupandturning.

1.Movetheleverstothecenter,unlockedposition.

2.Togoforward,slowlypushthemotion-controllevers

forward(Figure14).

Figure15

Figure14

1.Park(brake)position

2.Center,unlockposition5.Frontofthemachine

3.Forward

4.Backward

Togostraight,applyequalpressuretoboth

motion-controllevers(Figure15).

Toturn,releasepressureonthemotion-controllever

towardthedirectionyouwanttoturn(Figure15).

Thefartheryoumovethemotion-controlleversin

eitherdirection,thefasterthemachinemovesinthat

direction.

Tostop,pullthemotion-controlleverstoneutral.

18

Page 19

DrivingBackward

G008953

Tochangespeeds,dothefollowing:

Note:Alwaysusecautionwhenbackingupandturning.

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,lookbehindyouanddown,asyou

slowlypullthemotion-controlleversrearward(Figure

16).

Figure16

1.Movethemotion-controlleverstoneutralandoutward

tothePARKposition.

2.Disengagetheblade-controlswitch.

3.Adjustthelevertothedesiredposition.

Thefollowingareonlyrecommendationsforuse.

Adjustmentsvarybygrasstype,moisturecontent,andthe

heightofthegrass.

Suggested

uses:

ParkingX

Heavy,wet

grass

TrainingX

BaggingX

MulchingX

Normal

mowing

TransportX

TrimTowMow

X

X

Trim

Togostraight,applyequalpressuretoboth

motion-controllevers(Figure16).

Toturn,releasethepressureonthemotion-control

levertowardthedirectionyouwanttoturn.

Tostop,pushthemotion-controlleverstoneutral.

UsingtheSmartSpeed

TM

Control

System

TheSmartSpeed

operatingposition(Figure17),givestheoperatorachoice

todrivethemachineat3groundspeedranges—trim,tow ,

andmow .

TM

Control-Systemlever,locatedbelowthe

Thisisthelowestspeed.Thesuggestedusesforthisspeed

areasfollows:

•Parking

•Heavy,wetgrassmowingconditions

•Training

Tow

Thisisthemediumspeed.Thesuggestedusesforthisspeed

areasfollows:

•Bagging

•Mulching

Mow

Thisisthefastestspeed.Thesuggestedusesforthisspeed

areasfollows:

•Normalmowing

•Transportingthemachine

1.Smart-speedlever

Figure17

19

Page 20

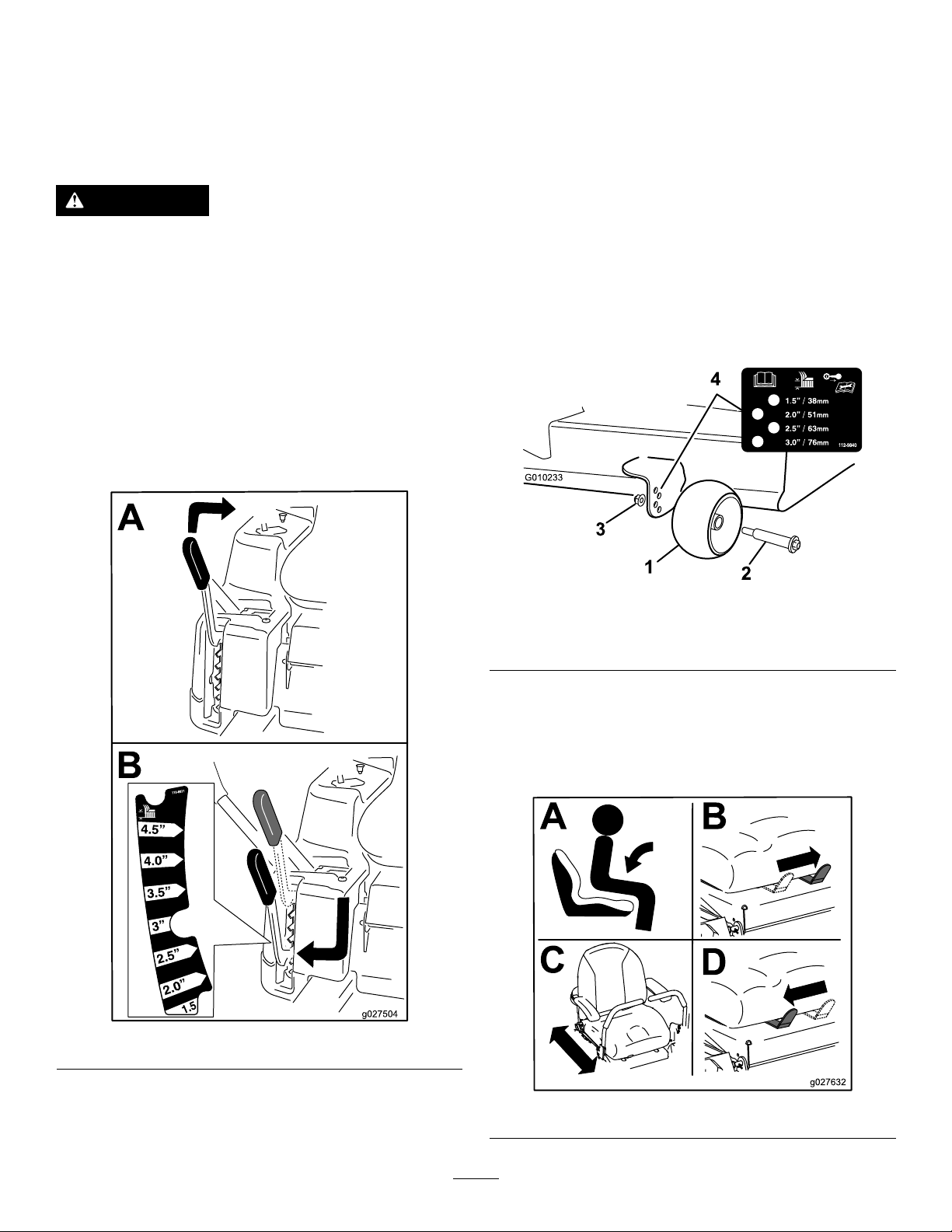

StoppingtheMachine

G010233

1

2

3

4

AdjustingtheAnti-Scalp

Tostopthemachine,movethemotion-controlleversto

NEUTRALandoutwardtothePARKposition,disengagethe

blade-controlswitch,ensurethatthethrottleisintheFAST

position,andturntheignitionkeytoOFF.Removethekey

fromtheignitionswitch.

WARNING

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemowerwhileitis

unattended.

Alwaysremovetheignitionkeyandmovethe

motion-controlleversoutwardtothePARKposition

whenleavingthemachineunattended,evenifjust

forafewminutes.

AdjustingtheHeight-of-Cut

Note:Thetransportpositionisthehighestheight-of-cut

positionat115mm(4-1/2inches)asshowninFigure18.

Rollers

Wheneveryouchangetheheightofcut,adjusttheheight

oftheanti-scalprollers.

Note:Adjusttheanti-scalprollerssothattherollersdonot

touchthegroundinnormal,atmowingareas.

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

andsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Adjusttheanti-scalprollersasshowninFigure19to

matchtheclosestheight-of-cutposition.

Figure19

1.Anti-scalproller3.FlangeNut

2.Bolt4.Holespacing

PositioningtheSeat

Theseatcanmoveforwardandbackward.Positiontheseat

whereyouhavethebestcontrolofthemachineandaremost

comfortable.

Figure18

Figure20

20

Page 21

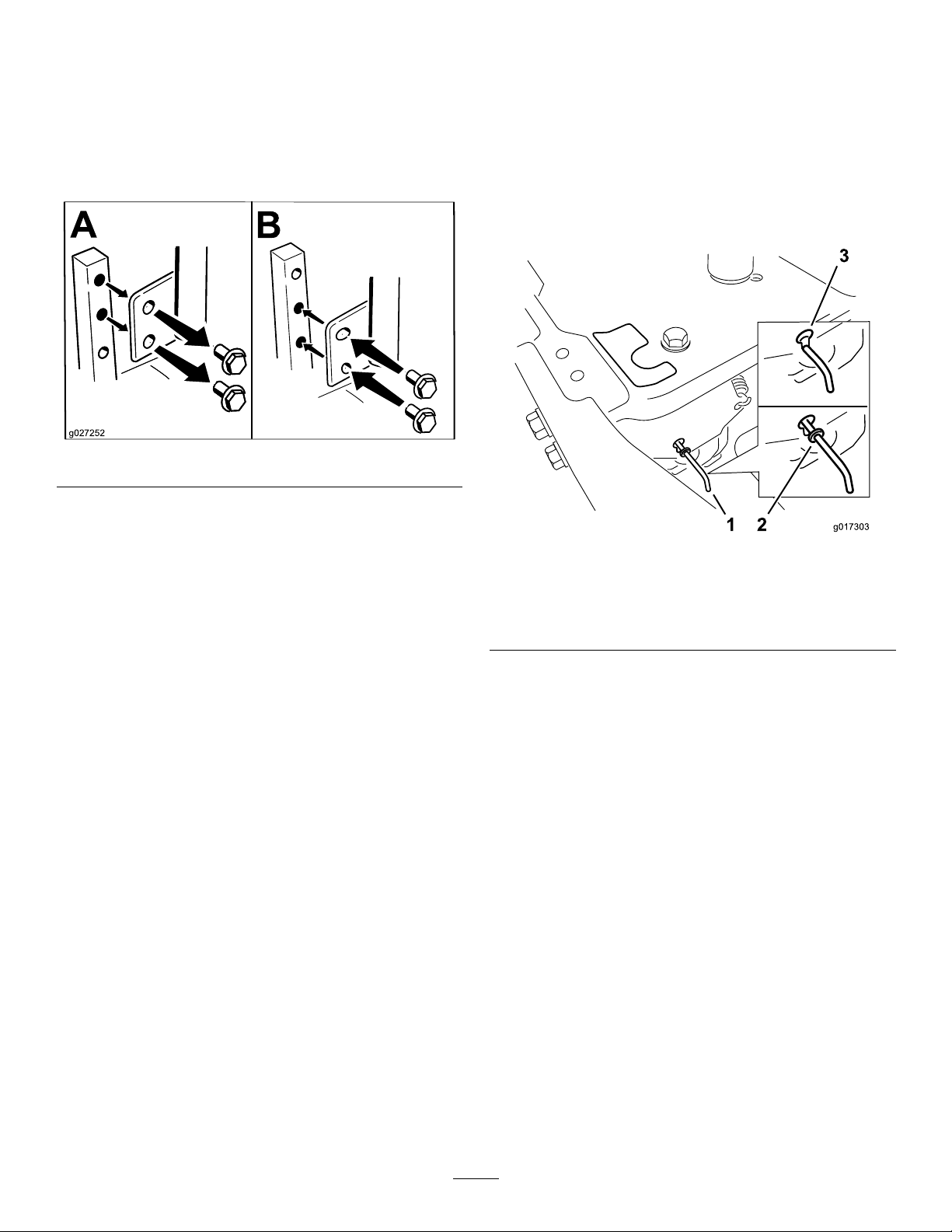

AdjustingtheMotion-Control

g027252

B

A

g017303

1 2

3

4.Movethebypassleversforwardthroughthekeyhole

anddowntolocktheminplace(Figure22).

Levers

Note:Dothisforeachlever.

AdjustingtheHeight

Youcanadjustthemotion-controllevershigherorlowerfor

maximumcomfort(Figure21).

Figure21

AdjustingtheTilt

Youcanadjustthemotion-controlleversforwardorrearward

foryourcomfort.

1.Loosentheupperboltholdingthecontrollevertothe

control-armshaft.

5.Movethemotion-controlleversinwardtothe

NEUTRALpositionandturntheignitionkeytothe

RUNposition.

Note:Donotstartthemachine.

Note:Youcannowpushthemachinebyhand.

Figure22

1.Bypass-leverlocations

2.Leverpositionfor

operatingthemachine

3.Leverpositionforpushing

themachine

2.Loosenthelowerboltjustenoughtopivotthecontrol

leverforwardorrearward(Figure21).

3.Tightenbothboltstosecurethecontrolleverinthe

newposition.

4.Repeattheadjustmentfortheothercontrollever.

PushingtheMachinebyHand

Important:Alwayspushthemachinebyhand.Donot

towthemachine,becausedamagemayoccur.

Thismachinehasanelectric-brakemechanism,andtopush

themachine,turntheignitionkeytotheRUNposition.The

batteryneedstobechargedandfunctioningtodisengage

theelectricbrake.

PushingtheMachine

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

6.Whennished,turnthekeytotheSTOPpositionto

avoiddrainingthebatterycharge.

Note:Ifthemachinefailstomove,theelectricbrakemay

stillbeengaged.Ifnecessary,releasetheelectricbrake

manually;refertoReleasingtheElectricBrake(page34).

OperatingtheMachine

Movethebypassleversrearwardthroughthekeyholeand

downtolocktheminplaceasshowninFigure22.

Note:Dothisforeachlever.

3.Locatethebypassleversontheframeonbothsidesof

theengine.

21

Page 22

UsingtheGrassDeector

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutthegrassdeector,dischargecover,or

completegrass-catcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

Figure23

•Neverremovethegrassdeectorfromthemower

becausethegrassdeectorroutesmaterialdown

towardtheturf.Ifthegrassdeectorisever

damaged,replaceitimmediately .

•Neverputyourhandsorfeetunderthemower.

•Nevertrytocleardischargeareaormower

bladesunlessyoumovetheblade-controlswitch

toOFFandrotatetheignitionkeytoOFF.Also

removethekeyandpullthewireoffthespark

plug(s).

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,pets,orbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerousandcan

leadtoaccidents,causingpersonalinjury.

Donotdrivethemachineonapublicstreetor

roadway.

1.Ifyouareusingatrailer,connectittothetowing

vehicleandconnectthesafetychains.

LoadingtheMachine

Useextremecautionwhenloadingorunloadingthemachine

ontoatraileroratruck.Useafull-widthrampthatiswider

thanthemachineforthisprocedure.Backthemachineupthe

rampsanddriveitforwarddowntheramps(Figure24).

Figure24

1.Backthemachineup

ramps.

Important:Donotusenarrowindividualrampsfor

eachsideofthemachine.

Ensuretherampislongenoughsothattheanglewiththe

grounddoesnotexceed15degrees(Figure25).Onat

ground,thisrequiresaramptobeatleast4timesaslongas

theheightofthetrailerortruckbedtotheground.Asteeper

anglemaycausemowercomponentstogetcaughtasthe

machinemovesfromtheramptothetrailerortruck.Steeper

anglesmayalsocausethemachinetotiporlosecontrol.If

youareloadingthemachineonornearaslope,positionthe

trailerortrucksothatitisonthedownsideoftheslopeand

therampextendsuptheslope.Thiswillminimizetheramp

angle.

2.Drivethemachineforward

downramps.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Shutofftheengine,removethekey,setthebrake,and

closethefuelvalve.

5.Tiedownthemachinenearthefrontcasterwheelsand

therearbumper(Figure23).

22

Page 23

WARNING

g027996

5

1

2

6

Loadingamachineontoatrailerortruckincreases

thepossibilityofatip-overandcouldcauseserious

injuryordeath.

•Useextremecautionwhenoperatingamachine

onaramp.

•Useonlyafull-widthramp;donotuseindividual

rampsforeachsideofthemachine.

•Donotexceeda15-degreeanglebetweenthe

rampandthegroundorbetweentherampand

thetrailerortruck.

•Ensurethelengthoframpisatleast4timesas

longastheheightofthetrailerortruckbedto

theground.Thiswillensurethatrampangle

doesnotexceed15degreesonatground.

•Backthemachineuprampsanddriveitforward

downramps.

•Avoidsuddenaccelerationordecelerationwhile

drivingthemachineonarampasthiscould

causealossofcontroloratip-over.

Figure25

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

4.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

23

Page 24

OperatingTips

FastThrottleSetting

Forbestmowingandmaximumaircirculation,operatethe

engineattheFASTposition.Airisrequiredtothoroughlycut

grassclippings,sodonotsettheheight-of-cutsolowasto

surroundthemowerinuncutgrass.Alwaystrytohave1side

ofthemowerfreefromuncutgrass,whichallowsairtobe

drawnintothemower.

UsingtheSmartSpeed™Control

System

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raisethe

cuttingheighthigherthanusualandcutthegrassatthis

setting.Thencutthegrassagainusingthelower,normal

setting.

WhenStopping

Ifyoumuststopthemachine'sforwardmotionwhilemowing,

aclumpofgrassclippingsmaydropontoyourlawn.Toavoid

this,moveontoapreviouslycutareawiththebladesengaged.

TheSmartSpeed™ControlSystemlever,locatedbelowthe

operatingposition,givesyouachoicetodrivethemachineat

3speedranges—high,tow ,andlow.Youcanbenetfromthe

lowerspeedsettingwhenmaneuveringthemachineintight

spacesoroperatingarounddelicatelandscapes.Youcanalso

usethelowsettingtooperatethemachineatahighthrottle

settingandbladespeedwhilestillbeingabletoreduceground

speedtoincreasethequalityofcut.

CuttingaLawnfortheFirstTime

Cutthegrassslightlylongerthannormaltoensurethat

thecuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebesttouse.Whencuttinggrasslongerthan15

cm(6inches)tall,youmaywanttocutthelawntwiceto

ensureanacceptablequalityofcut.

CutaThirdoftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

KeeptheUndersideoftheMowerClean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,the

cuttingqualityeventuallybecomesunsatisfactory.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseason,because

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthecutterbladesdailyforsharpnessandfor

anywearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replaceit

immediatelywithagenuineT ororeplacementblade.

MowingDirection

Alternatethemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippings,whichenhances

decompositionandfertilization.

MowatCorrectIntervals

Normally,mowevery4days.However,grassgrowsat

differentratesatdifferenttimes.Tomaintainthesamecutting

height,whichisagoodpractice,mowmoreofteninearly

spring.Asthegrassgrowthrateslowsinmidsummer,mow

lessfrequently .Ifyoucannotmowforanextendedperiod,

rstmowatahighcuttingheight;thenmowagain2days

lateratalowerheightsetting.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthemower

youpreviouslyused,raisethecuttingheighttoensurethat

uneventurfisnotcuttooshort.

24

Page 25

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst50hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every50hours

Every100hours

Every200hours

Every400hours

MaintenanceProcedure

•Changetheuidandltersforthehydraulicsystemandbleedthesystem.

•Checkthesafety-interlocksystem.

•Checktheaircleanerfordirty,looseordamagedparts.

•Checktheengine-oillevel.

•Checkthecuttingblades.

•Inspectthegrassdeectorfordamage.

•Cleanthemower-deckhousing.

•Greasealllubricationpoints.

•Checktirepressure.

•Checkthehydraulicuidlevelintheexpansiontank.

•Checkthebeltsforwearorcracks.

•Servicetheair-cleanerpaperelement(moreoftenunderextremelydusty,dirty

conditions).

•Replacetheair-cleanerpaperelement(moreoftenunderextremelydusty,dirty

conditions).

•Changetheengineoilandtheengine-oillter.

•Cleantheblowerhousing(moreoftenunderextremelydusty,dirtyconditions).

•Replacethein-linefuellter.

•Checkthesparkplug(s)conditionandgap.

•Changetheuidandltersforthehydraulicsystemandbleedthesystem.

Every500hours

Beforestorage

•Replacethesparkplug(s).

•Chargethebatteryanddisconnectthebatterycables.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintanychippedsurfaces.

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

25

Page 26

Premaintenance

Lubrication

Procedures

GreasingtheBearings

RaisingtheSeat

Makesurethatthemotion-controlleversarelockedinthe

PARKposition.Lifttheseatforward.

Youcanaccessthefollowingcomponentsbyraisingtheseat:

•Serialplate

•Servicedecal

•Seat-adjustmentbolts

•Fuellter

•Batteryandbatterycables

ServiceInterval:Every25hours—Greasealllubrication

points.

GreaseType:No.2lithiumgrease

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettings(Figure26andFigure27)with

arag.

Note:Makesuretoscrapeanypaintoffthefrontof

thetting(s).

Figure26

1.Frontcastertire

Figure27

Locatedontheseat-panunderside

1.Readtheinstructions

beforeservicingor

performingmaintenance.

2.Checkthetirepressure

every25operatinghours.

4.Connectagreaseguntoeachtting(Figure26and

Figure27).

5.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

3.Greaseevery25operating

hours.

4.Engine

26

Page 27

EngineMaintenance

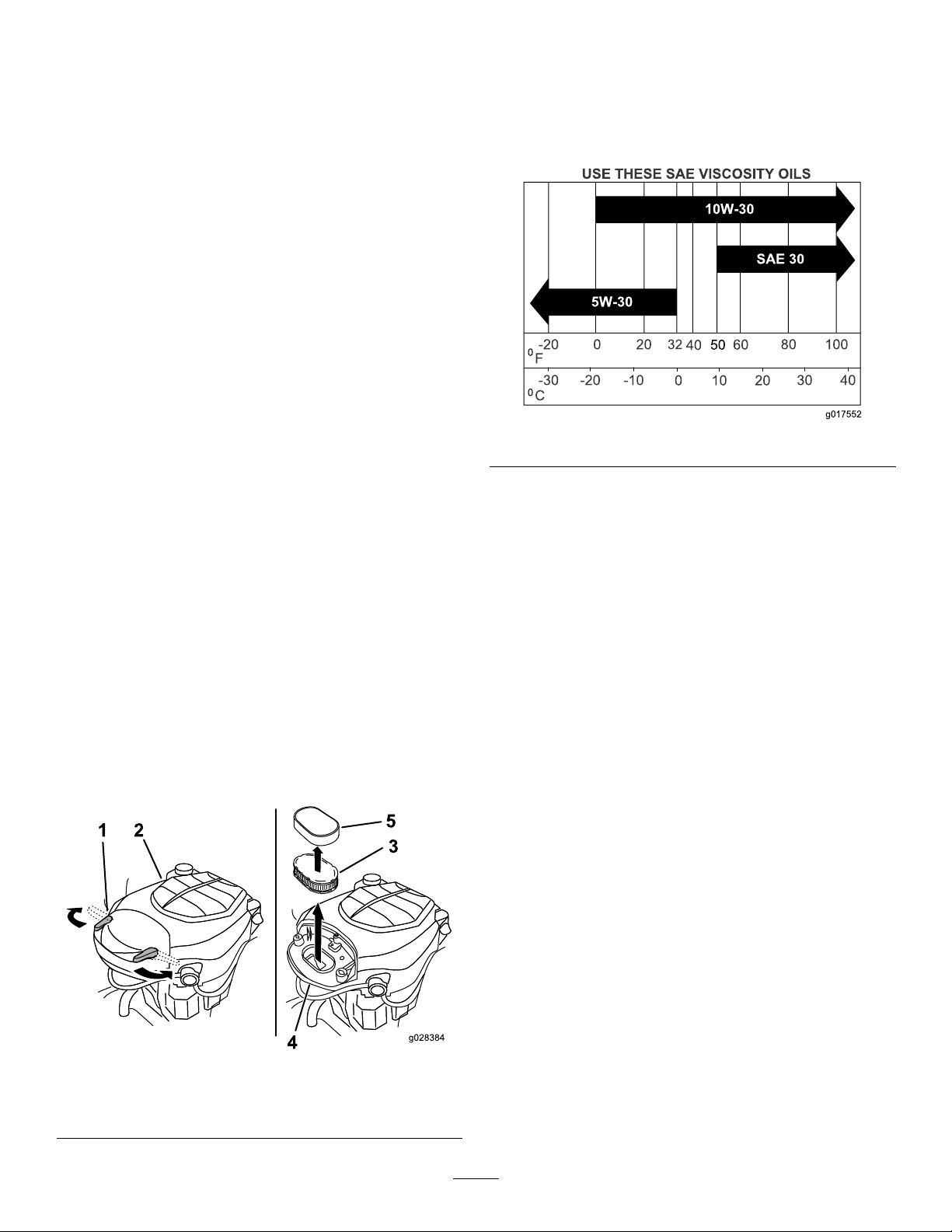

g017552

0

0

50

SAE 30

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Checktheair

cleanerfordirty,looseordamagedparts.

Every50hours—Servicetheair-cleanerpaperelement

(moreoftenunderextremelydusty,dirtyconditions).

Every100hours—Replacetheair-cleanerpaper

element(moreoftenunderextremelydusty,dirty

conditions).

Thisengineisequippedwithareplaceable,high-densitypaper

air-cleanerelement.Checktheaircleanerdailyorbefore

startingtheengine.Checkforabuildupofdirtanddebris

aroundtheair-cleanersystem.Keepthisareaclean.Also,

checkforlooseordamagedcomponents.Replaceallbentor

damagedair-cleanercomponents.

Note:Operatingtheenginewithlooseordamaged

air-cleanercomponentscouldallowunlteredairintothe

engine,causingprematurewearandfailure.

1.Rotatethelatchesoutward.

2.Removethecovertoaccesstheair-cleanerelement

(Figure28).

3.Removetheelement,andgentlytaptheelementto

dislodgedirt.

Note:Donotwashthepaperelementoruse

pressurizedair,asthiswilldamagetheelement.

Note:Replaceadirty,bent,ordamagedelement.

Handlethenewelementcarefully;donotuseifthe

sealingsurfacesarebentordamaged.

4.Cleantheair-cleanerbaseasrequiredandcheckthe

condition.

5.Installthepaperelementontotheair-cleanerbase.

6.Installthecoverandsecureitwiththelatches(Figure

28).

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSJorhigher)

CrankcaseCapacity:1.9L(64oz)whenthelterischanged

Viscosity:Seethetablebelow.

Figure29

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily—Checkthe

engine-oillevel.

1.Parkthemachineonalevelsurface,disengagethe

blade-controlswitch,shutofftheengine,andremove

thekey.

2.Makesuretheengineisstopped,level,andcoolsothe

oilhastimetodrainintothesump.

3.Checktheengine-oillevel(Figure30).

Figure28

1.Air-cleanerlatch3.Paperelement

2.Engine4.Air-cleanerbase

27

Page 28

B

A

C

D

E

g027515

F

G

H

ChangingtheEngineOilandthe

Engine-OilFilter

ServiceInterval:Every100hours—Changetheengineoil

andtheengine-oillter.

Note:Thedrainplugisattachedtothedrainhose.

Note:Disposetheusedoilatarecyclingcenter.

FillwithoilasspeciedinthetabletitledUseTheseSAE

ViscosityOils(Figure29).

1.Parkthemachinesothatthedrainsideisslightlylower

thantheoppositesidetoensurethattheoildrains

completely.

2.Disengagetheblade-controlswitchandmovethe

motion-controlleversoutwardtothePARKposition.

3.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

Figure30

Figure31

28

Page 29

4.Torquetheplugto14N∙m(125in-lb).

B

A

C D

E

F

3/4

g027477

B

A

C

D

E

g027517

5.Slowlypourapproximately80%ofthespeciedoil

intothellertube(Figure33).

Figure32

Figure33

ServicingtheSparkPlug

ServiceInterval:Every200hours—Checkthesparkplug(s)

conditionandgap.

Every500hours—Replacethesparkplug(s).

ThesparkplugisRFIcompliant.Equivalentalternatebrand

plugscanalsobeused.

Type:ChampionXC12YC

AirGap:0.76mm(0.03inch)

RemovingtheSparkPlug

1.Disengagetheblade-controlswitch,movethe

motion-controlleversoutwardtothePARKposition,

shutofftheengine,andremovethekey .

2.Beforeremovingthesparkplug(s),cleanthearea

aroundthebaseoftheplugtokeepdirtanddebrisout

oftheengine.

3.Removethesparkplug(Figure34).

29

Page 30

B

A

g027478

Figure34

B

A

g027479

CleaningtheBlowerHousing

Toensurepropercooling,makesurethatthegrassscreen,

coolingns,andotherexternalsurfacesoftheengineare

keptcleanatalltimes.

Annually,orevery100hoursofoperation(moreoftenunder

extremelydusty,dirtyconditions),removetheblowerhousing

andanyothercoolingshrouds.Cleanthecoolingnsand

externalsurfacesasnecessary.Makesurethatthecooling

shroudsareinstalled.Torquetheblowerhousingscrewsto

7.5N·m(5.5ft-lb).

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablackcoating,

wornelectrodes,anoilylm,orcracks.

Note:Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingontheinsulator

usuallymeanstheaircleanerisdirty.

Setthegapto0.76mm(0.030inch).

Figure35

InstallingtheSparkPlug

Important:Operatingtheenginewithablocked

grassscreen,dirtyorpluggedcoolingns,and/or

coolingshroudsremoved,causesenginedamagedue

tooverheating.

Tightenthesparkplugto25to29N∙m(18to22ft-lb).

Figure36

30

Page 31

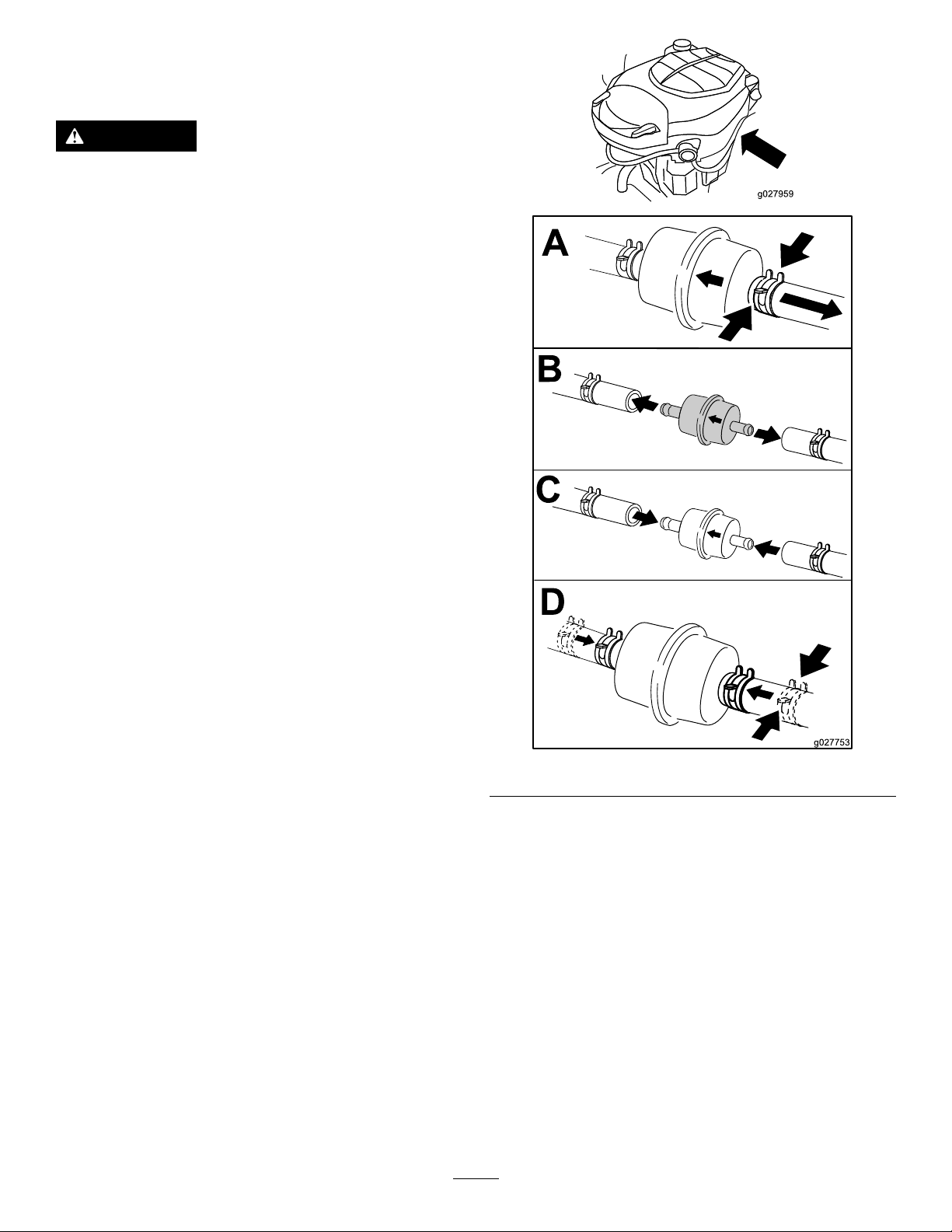

FuelSystem

B

A

C

D

g027753

Maintenance

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Performanyfuel-relatedmaintenancewhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasolineandstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

ReplacingtheIn-LineFuel Filter

ServiceInterval:Every100hours—Replacethein-linefuel

lter.

Neverinstalladirtylterifitisremovedfromthefuelline.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Replacethein-linelter(Figure37).

Figure37

31

Page 32

ElectricalSystem

g017701

2

3

4

5

6

7

1

Maintenance

WARNING

Incorrectbattery-cableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

WARNING

explode,resultinginpersonalinjury.

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

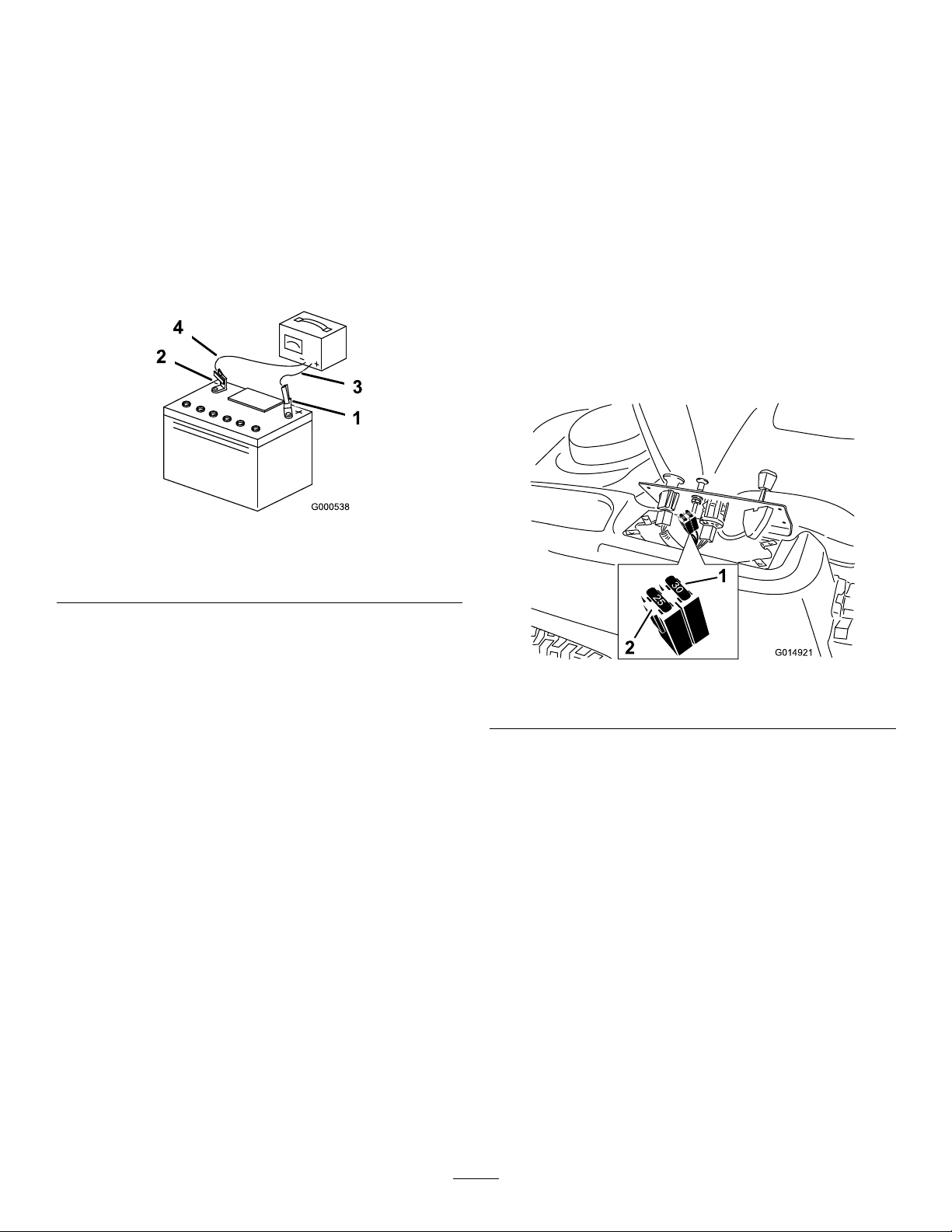

ChargingtheBattery

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

5.Slidetherubbercoverupthepositive(red)cable.

6.Disconnectthepositive(red)cablefromthebattery

post(Figure38).

Note:Retainallfasteners.

7.Removethebatteryhold-downandliftthebattery

fromthebatterytray(Figure38).

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Raisetheseattoaccessthebattery.

4.Disconnectthenegative(black)groundcablefromthe

batterypost(Figure38).

Note:Retainallfasteners.

Figure38

1.Battery

2.Positive(+)batterypost

3.Bolt,washer,andnut7.Batteryhold-down

4.Terminalboot

5.Negative(–)batterypost

6.Wingnut,washer,andbolt

32

Page 33

ChargingtheBattery

30

25

30

25

G014921

2

1

ServicingtheFuses

ServiceInterval:Beforestorage—Chargethebatteryand

disconnectthebatterycables.

1.Removethebatteryfromthechassis;refertoRemoving

theBattery(page32).

2.Chargethebatteryforaminimumof1hourat6to

10A.

Note:Donotoverchargethebattery.

3.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure39).

Figure39

Theelectricalsystemisprotectedbyfuses.Itrequiresno

maintenance;however,ifafuseblows,checkthecomponent

orcircuitforamalfunctionorshort.

Fusetype:

•Main—F1-30A,blade-type

•ChargeCircuit—F2-25A,blade-type

1.Removethescrewssecuringthecontrolpaneltothe

machine.

Note:Retainallfasteners.

2.Liftthecontrolpaneluptoaccessthemainwire

harnessandfuseblock(Figure40).

3.Toreplaceafuse,pulloutthefusetoremoveit(Figure

40).

1.Positive(+)batterypost3.Red(+)chargerlead

2.Negative(–)batterypost4.Black(–)chargerlead

InstallingtheBattery

1.Positionthebatteryinthetray(Figure38).

2.Usingthefastenerspreviouslyremoved,installthe

positive(red)batterycabletothepositive(+)battery

terminal.

3.Usingthefastenerspreviouslyremoved,installthe

negativebatterycabletothenegative(-)battery

terminal.

4.Slidetheredterminalbootontothepositive(red)

batterypost.

5.Securethebatterywiththehold-down(Figure38).

6.Lowertheseat.

Figure40

1.Main—30A

2.Chargecircuit—25A

4.Returnthecontrolpaneltoitsoriginalposition.

Note:Usethescrewsremovedpreviouslytosecure

thepaneltothemachine.

33

Page 34

DriveSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseanunevencut.

Checkthepressureatthevalvestem(Figure41).Checkthe

tireswhentheyarecoldtogetthemostaccuratepressure

reading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrive-wheeltiresto90kPa(13psi).

ReleasingtheElectricBrake

Theelectricbrakereleasesbymanuallyrotatingthelinkarms

forward.Oncetheelectricbrakeisenergized,thebrakeresets.

Figure42

1.Brakelinkarmontheelectric-brake-controlmodule

2.Leftreartire

1.TurntheignitionkeytotheOFFpositionordisconnect

thebattery.

1.Valvestem

Figure41

2.Locatetheshaftontheelectricbrakewherethe

brake-linkarmsareconnected(Figure42).

3.Rotatetheshaftforwardtoreleasethebrake.

34

Page 35

HydraulicSystem

Maintenance

HydraulicSystemFluidSpecication

OilType:ToroHYPR-OIL®500or20W -50motoroil.

SystemCapacity:approximately4.5L(152oz)witha

lterchange.

CheckingtheHydraulicFluid Level

ServiceInterval:Every25hours

Checkthehydraulicuidlevelintheexpansionreservoirand

ifnecessaryaddthespecieduidtotheFullColdline.

RemovingtheHydraulicSystemFilters

1.Shutofftheengine,waitforallmovingpartstostop,

andallowenginetocool.Removethekeyandengage

theparkingbrake.

2.Raisetherearofthemachineandsupportitwithjack

stands(orequivalentsupport)justhighenoughto

allowdrivewheelstoturnfreely.

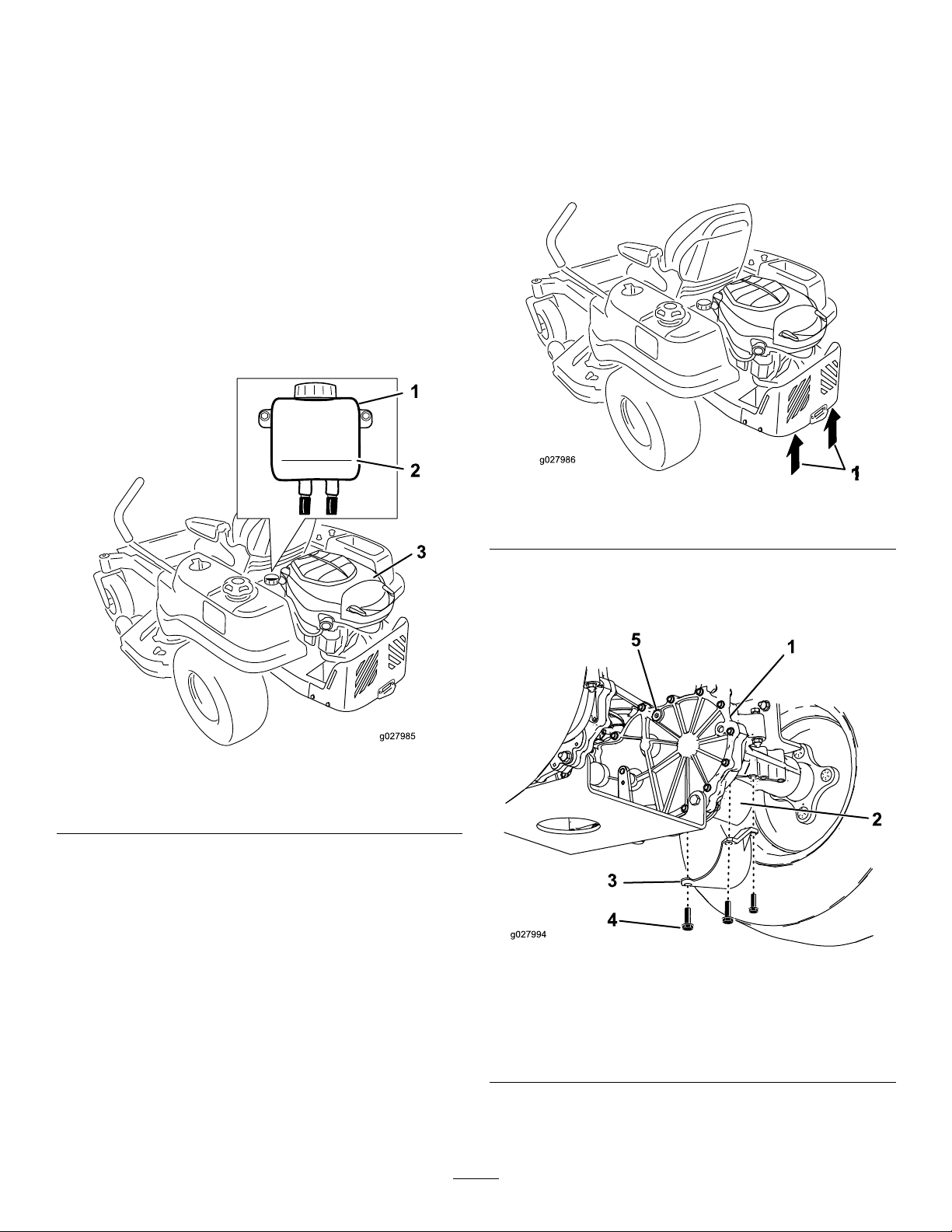

Figure44

Figure43

1.Expansionreservoir3.Engine

2.FullColdline

ChangingtheHydraulic SystemFluidandFilters

ServiceInterval:Aftertherst50hours

Every400hours

Important:Repeatthebleedingprocessuntilthe

uidremainsattheFullColdlineinthereservoirafter

purging.

can r esult in ir r epara ble dama ge to the transaxle dri v e

system.

F ailur e to pr oper l y perf or m this pr ocedur e

1.Jackingpoints

3.Locatethelterandlterguardsoneachtransaxle

drivesystem(Figure45).Removethe3screwssecuring

thelterguardandguard.

Figure45

Rightsideshown

1.Transaxledrive

2.Oillter

3.Filterguard

4.Screws

5.Ventplug

Note:Changethelteranduidatthesametime.Donot

reuseuid.Onceyouinstallthenewlterandadduid,

purgeanyairinthesystem.

4.Carefullycleanareaaroundthelters.

35

Page 36

Note:Ensurethatnodirtorcontaminationenters

B

A

C D

E

F

3/4

g027477

thehydraulicsystem.

5.Placeacontainerbelowtheltertocatchtheuidthat

drainswhenyouremovethelterandventplugs.

6.Locateandremovetheventplugoneachtransmission

7.Unscrewtheltertoremoveandallowtheuidto

drainfromdrivesystem.

8.Repeatthisprocedurefortheotherlter.

InstallingtheHydraulicSystemFilters

Note:Torquetheplugto20.3N∙m(180in-lb).

6.Continuetoaddoilthroughtheexpansionreservoir

untilitreachestheFullColdlineontheexpansion

reservoir.

7.ProceedtotheBleedingtheHydraulicSystem(page

36).

Important:Failuretobleedthehydraulicsystem

afterchangingthehydraulicltersandoilcan

resultinirreparabledamagetothetransaxledrive

system.

1.InstalltheltersasshowninFigure46.

2.Installthelterguardsovereachlteraspreviously

removed.

Figure46

BleedingtheHydraulicSystem

1.Sitontheseat.Starttheengine,movethethrottle

controltothe1/2-throttleposition,anddisengagethe

parkingbrake.

A.Movethebypassleversintothepushingthe

machineposition;refertothePushingthe

MachinebyHand(page21).

B.Withthebypassvalvesopenandtheengine

running,slowlymovethemotion-controlleversin

bothforwardandreverse(5or6times).

C.Movethebypassleversintotheoperatingthe

machineposition.

D.Withthebypassvalveclosedandtheengine

running,slowlymovethemotion-controlleversin

bothforwardandreversedirections(5to6times).

E.Stoptheengineandchecktheoillevelinthe

expansionreservoir.Addthespeciedoilasuntil

itreachestheFullColdlineontheexpansion

reservoir.

2.Repeatstep1untilalltheairiscompletelypurgedfrom

thesystem.

Note:Whenthetransaxleoperatesatnormalnoise

levelsandmovessmoothlyforwardandreverseat

normalspeeds,thenthetransaxleisconsideredpurged.

3.Checktheoillevelintheexpansionreservoiranal

time.AddthespeciedoilasuntilitreachestheFull

Coldlineontheexpansionreservoirifnecessary.

Note:Usethe3screwstosecurethelterguards.

3.Verifythattheventplugsareremovedbeforeadding

theuid.

4.Slowlypourthespecieduidthroughexpansion

reservoiruntiloilcomesoutof1vent-plughole.Install

thatventplug.

Note:Torquetheplugto20.3N∙m(180in-lb).

5.Continuetoaddoilthroughtheexpansionreservoir

untiloilcomesoutoftheremainingventplugholeon

thesecondtransmission.Installthatventplug.

36

Page 37

MowerMaintenance

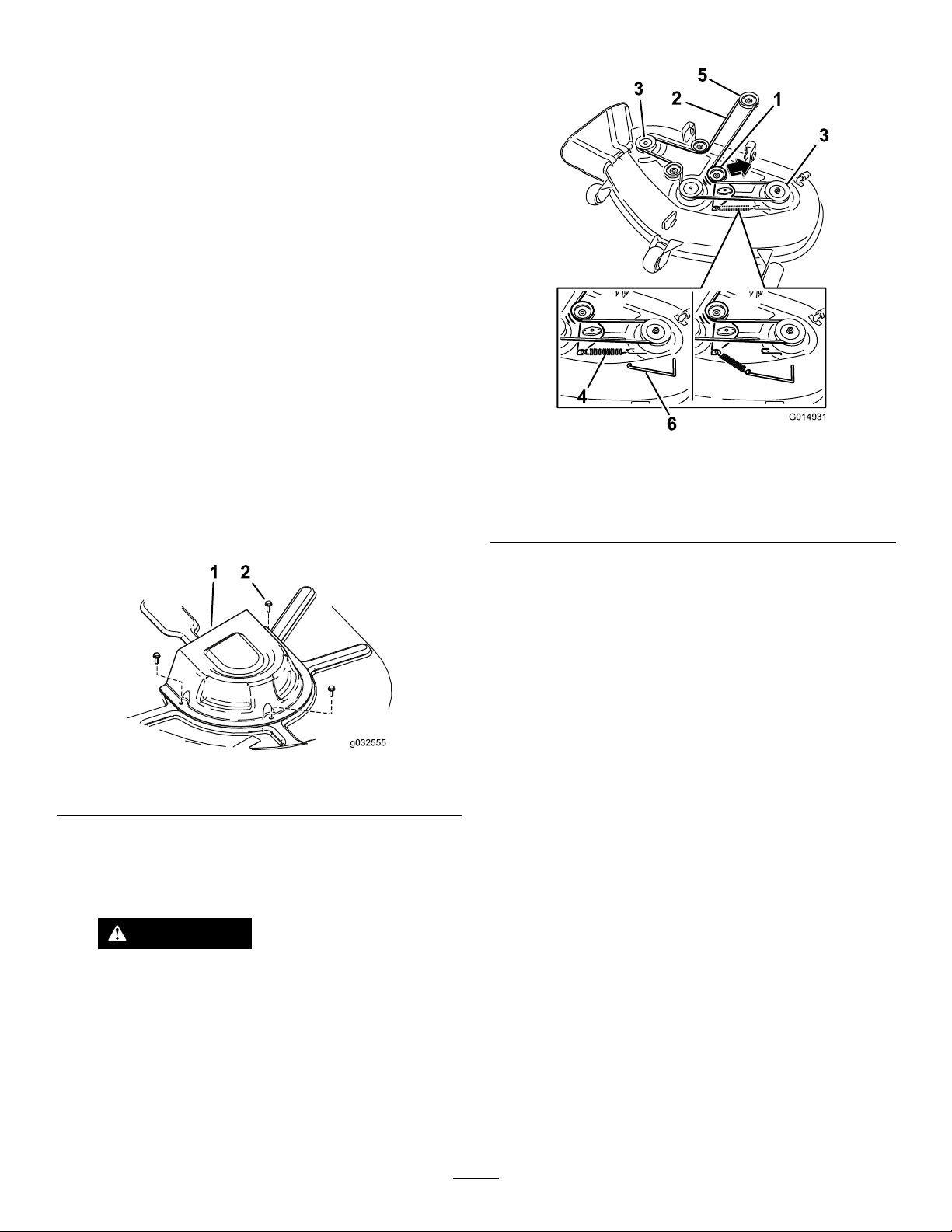

G014972

1

2

3

ServicingtheCuttingBlades

Maintainsharpbladesthroughoutthecuttingseason,because

sharpbladescutcleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingthegrassturnsitbrown

attheedges,whichslowsgrowthandincreasesthechance

ofdisease.

Checkthecuttingbladesdailyforsharpnessandforany

wearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineT ororeplacementblade.For

convenientsharpeningandreplacement,keepextrablades

onhand.

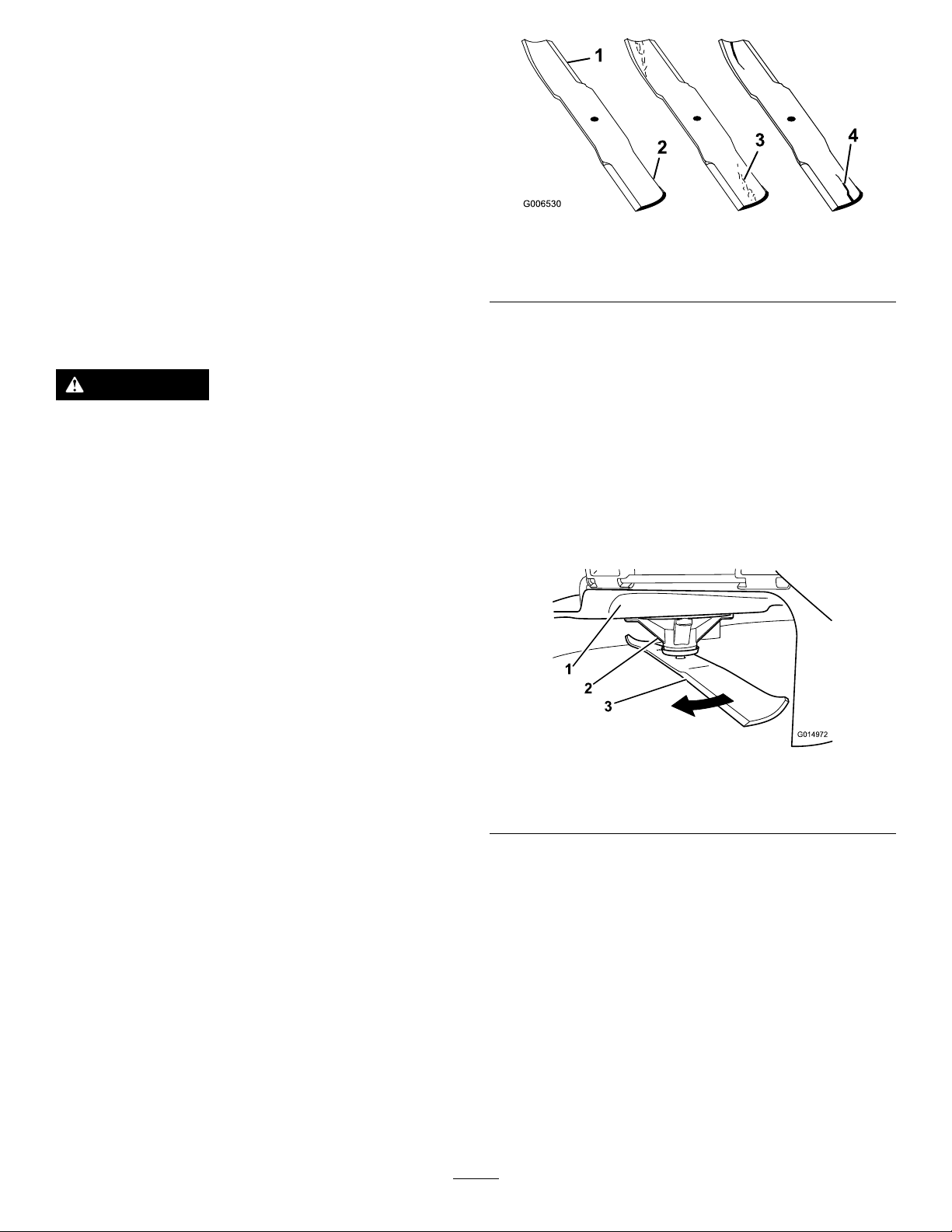

Figure47

1.Cuttingedge3.Wear/slotforming

2.Curvedarea

4.Damage

CheckingforBentBlades

WARNING

Awornordamagedbladecanbreakandapiece

ofthebladecouldbethrownatyouorbystanders,

resultinginseriouspersonalinjuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagethe

blade-controlswitch,movethemotion-controlleversoutward

tothePARKposition,shutofftheengine,andremovethekey .

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily—Checkthe

cuttingblades.

1.Inspectthecuttingedges(Figure47).

Note:Iftheedgesarenotsharporhavenicks,remove

andsharpentheblades;refertoSharpeningtheBlades

(page39).

Note:Parkthemachineonalevelsurfaceforthefollowing

procedure.

1.Raisethemowerdecktothehighestheight-of-cut

position.

2.Whilewearingthicklypaddedgloves,orotheradequate

handprotection,slowlyrotatethebladetobemeasured

intoapositionthatallowsyoutoeffectivelymeasure

thedistancebetweenthecuttingedgeandthelevel

surfacethatthemachineison(Figure48).

Figure48

1.Deck3.Blade

2.Spindlehousing

2.Inspecttheblades,especiallythecurvedarea(Figure

47).

Note:Ifyounoticeanydamage,wear,oraslot

forminginthisarea(items3and4inFigure47),

immediatelyinstallanewblade.

37

Page 38

3.Measurefromthetipofthebladetotheatsurface

G014973

1

2

3

G014974

1

2

3

G014973

1

2

3

(Figure49).

Figure49

1.Blade(inpositionformeasuring)

2.Levelsurface

3.Measureddistancebetweenbladeandthesurface(A)

4.Rotatethesameblade180degreessothattheopposing

cuttingedgeisnowinthesameposition(Figure50).

Figure51

1.Oppositebladeedge(inpositionformeasuring)

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

A.IfthedifferencebetweenAandBisgreaterthan

3mm(1/8inch),replacethebladewithanew

blade;refertoRemovingtheBlades(page39)and

InstallingtheBlades(page39).

Note:Ifyoureplaceabentbladewithanew

bladeandthedimensionobtainedcontinuesto

exceed3mm(1/8inch),thebladespindlecould

bebent.ContactanAuthorizedToroDealerfor

service.

Figure50

1.Blade(sidepreviouslymeasured)

2.Measurement(positionusedpreviously)

3.Opposingsideofbladebeingmovedintomeasurement

position

5.Measurefromthetipofthebladetotheatsurface

(Figure51).

Note:Thevarianceshouldbenomorethan3mm

(1/8inch).

B.Ifthevarianceiswithinconstraints,movetothe

nextblade.

6.Repeatsteps1through5foreachblade.

38

Page 39

RemovingtheBlades

Replaceabladeifithitsasolidobject,ifthebladeisoutof

balance,orifthebladeisbent.Forbestperformanceand

continuedsafetyconformanceofthemachine,usegenuine

Tororeplacementblades.Replacementbladesmadebyother

manufacturersmayresultinnon-conformancewithsafety

standards.

Figure54

1.Blade2.Balancer

1.Holdthebladeendusingaragorthicklypaddedglove.

2.Removethebladebolt,curvedwasher,andbladefrom

thespindleshaft(Figure52).

Figure52

1.Sailareaoftheblade3.Curvedwasher

2.Blade4.Bladebolt

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure53).

3.Repeatthisprocedureuntilthebladeisbalanced.

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure52).

Important:Thecurvedpartoftheblademust

pointupwardtowardtheinsideofthemowerto

ensurepropercutting.

2.Installthecurvedwasher(cuppedsidetowardthe

blade)andthebladebolt(Figure52).

3.Torquethebladeboltto47to88N∙m(35to65ft-lb).

LevelingtheMowerDeck

Ensurethatthemowerdeckislevelanytimeyouinstallthe

mowerdeckorwhenyouseeanunevencutonyourlawn.

Checkthemowerdeckforbentbladespriortoleveling;

removeandreplaceanybentblades;refertoCheckingfor

BentBlades(page37)beforecontinuing.

Levelthemowerdeckside-to-sidebeforeadjustingthe

front-to-rearslope.

Note:Maintaintheoriginalangle.

Note:Thebladeretainsitsbalanceifyouremovethe

sameamountofmaterialfrombothcuttingedges.

Figure53

1.Sharpenattheoriginalangle.

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure54).

Note:Ifthebladestaysinahorizontalposition,the

bladeisbalancedandreadytouse.

Note:Ifthebladeisnotbalanced,lesomemetaloff

onlytheendofthesailarea(Figure53).

Requirements:

•Themachinemustbeonalevelsurface.

•All4tiresmustbeproperlyinated;refertoChecking

theTirePressure(page34).

LevelingfromSidetoSide

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Settheheight-of-cutlevertomiddleposition.

4.Carefullyrotatetheblade(s)sothattheyareallside

toside(Figure55).

39

Page 40

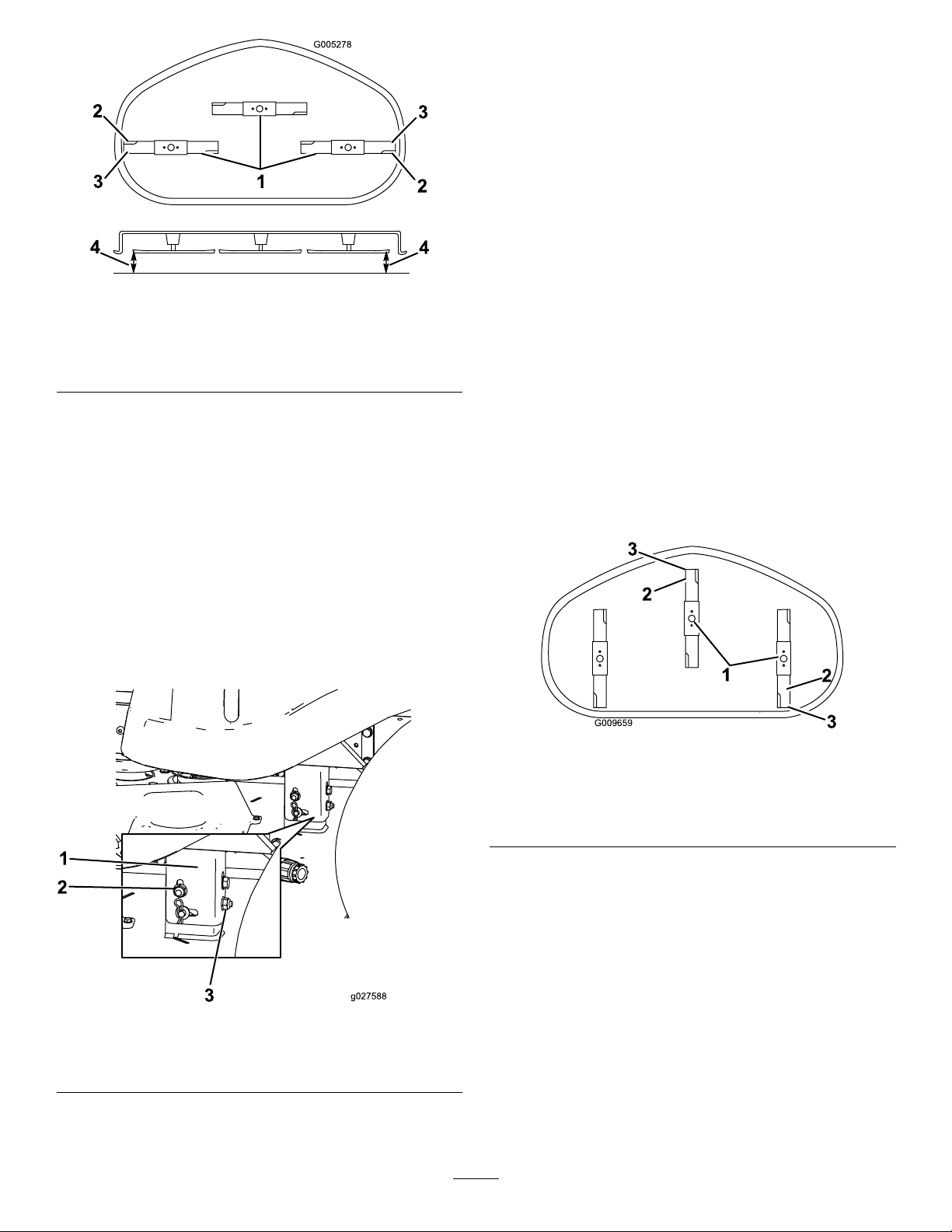

G005278

1

2

2

3

3

4

4

10.Continuelevelingthedeckbycheckingthefront-to-rear

G009659

1

2

3

2

3

bladeslope;refertoAdjustingtheFront-to-RearBlade

Slope(page40).

AdjustingtheFront-to-RearBlade

Slope

Checkthefront-to-rearbladelevelanytimeyouinstallthe

mower.Ifthefrontofthemowerismorethan7.9mm

(5/16inch)lowerthantherearofthemower,adjusttheblade

level.

Figure55

1.Bladessidetoside

2.Sailareaoftheblade4.measurefromthetipofthe

3.Outsidecuttingedges

bladetotheatsurface

here.

5.Measurebetweentheoutsidecuttingedgesandtheat

surface(Figure55).

Note:Ifbothmeasurementsarenotwithin5mm

(3/16inch),anadjustmentisrequired;continuewith

thisprocedure.

6.Movetotheleftsideofthemachine.

7.Loosenthesidelockingnut.

8.Raiseorlowertheleftsideofthemowerdeckby

rotatingtherearlockingnut.(Figure56).

Note:Rotatetherearlockingnutclockwiseto

raisethemowerdeck;rotatetherearlockingnut

counter-clockwisetolowerthemowerdeck.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Settheheight-of-cutlevertomiddleposition.

Note:Checkandadjusttheside-to-sidebladelevel

ifyouhavenotcheckedthesetting;refertoLeveling

fromSidetoSide(page39).

4.Carefullyrotatethebladessothattheyarefacingfront

torear(Figure57).

Figure57

1.Bladesfronttorear3.Measurefromthetipofthe

2.Outsidecuttingedges

bladetotheatsurface

here.

5.Measurefromthetipofthefrontbladetotheat

surface,andthetipoftherearbladetotheatsurface

(Figure57).

Note:Ifthefrontbladetipisnot1.6to7.9mm(1/16

to5/16inch)lowerthantherearbladetip,adjustthe

frontlocknut.

Figure56

1.Hangerbracket3.Rearlockingnut

2.Sidelockingnut

6.Toadjustthefront-to-rearbladeslope,rotatethe

adjustmentnutinthefrontofthemower(Figure58).

Note:Toraisethefrontofthemower,tightenthe

adjustmentnut.Tolowerthefrontofthemower,

loosentheadjustmentnut.

9.Checktheside-to-sideadjustmentsagain.Repeatthis

procedureuntilthemeasurementsarecorrect.

40

Page 41

G014634

1

2

3

Figure58

G014635

1

2

3

2

2

3

G005077

1

2

2

3

1.Adjustingrod3.Locknut

2.Adjustingblock

7.Afteradjustment,checkthefront-to-rearslopeagain,

continueadjustingthenutuntilthefrontbladetipis

1.6to7.9mm(1/16to5/16inch)lowerthantherear

bladetip(Figure57).

8.Whenthefront-to-rearbladeslopeiscorrect,checkthe

side-to-sidelevelofthemoweragain,refertoLeveling

fromSidetoSide(page39).

RemovingtheMower

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Lowertheheight-of-cutlevertothelowestposition.

4.Removethehairpincotterfromthefrontsupportrod

andremovetherodfromthedeckbracket(Figure59).

Figure59

1.Frontsupportrod3.Deckbracket

2.Lockingnut

5.Carefullylowerthefrontofthemowerdecktothe

ground.

6.Liftthemowerdeckandhangerbracketsclearof

therearliftrodandlowerthemowercarefullytothe

ground(Figure60).

Figure60

1.Mowerdeck

2.Hangerbracket

7.Slidethemowerdeckrearwardtoremovethemower

beltfromtheenginepulley.

8.Slidethemowerdeckoutfromunderneaththe

3.Rearliftrod

machine.

41

Page 42

Note:Retainallpartsforfutureinstallation.

G005192

1

2

3

4

5

6

7

InstallingtheMower

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Slidethemowerunderthemachine.

4.Lowertheheight-of-cutlevertothelowestposition.

5.Lifttherearofthemowerdeckandguidethehanger

bracketsovertherearliftrod(Figure60).

6.Attachthefrontsupportrodtothemowerdeckwith

theclevispinandhairpincotter(Figure59).

7.Installthemowerbeltontotheenginepulley;referto

ReplacingtheMowerBelt(page43).

Figure61

1.Mowerdeck

2.Grassdeector6.Nut(3/8inch)

3.Grass-deectorbracket7.Shortstandoff

4.Rod

5.Spring

ReplacingtheGrassDeector

ServiceInterval:Beforeeachuseordaily—Inspectthegrass

deectorfordamage.

WARNING

Anuncovereddischargeopeningcouldallowthe

lawnmowertothrowobjectsatyouorbystanders,

resultinginseriousinjury.Also,contactwiththe

bladecouldoccur.

Neveroperatethemachinewithoutthegrass

deector,thedischargecover,orthegrass-collection

systeminplace.

Inspectthegrassdeectorfordamagebeforeeachuse.

Replaceanydamagedpartsbeforeuse.

1.Removethenut(3/8inch)fromtherodunderthe

mower(Figure61).

2.Slidetherodoutoftheshortstandoff,spring,and

grassdeector(Figure61).

3.Removethedamagedorworngrassdeector.

4.Replacethegrassdeector(Figure61).

5.Slidetherod(straightend)throughtherear

grass-deectorbracket.

6.Placethespringontherod,withtheendwiresdown

andbetweenthegrass-deectorbrackets.

7.Sliderodthroughthesecondgrass-deectorbracket

(Figure61).

8.Inserttherodatthefrontofthegrassdeectorinto

theshortstandoffonthedeck.

9.Securetherearendoftherodintothemowerwitha

nut(3/8inch)asshowninFigure61.

Important:Thegrassdeectormustbe