Page 1

FormNo.3395-784RevD

MultiPro

ModelNo.41240—SerialNo.315000001andUp

®

WMTurfSprayer

Registeratwww.T oro.com.

OriginalInstructions(EN)

Note:

TheinstallationoftheMultiProWMrequirestheinstallation

ofoneormoreinterdependentkits.ContactyourAuthorized

ToroDealerformoreinformation.

*3395-784*D

Page 2

TheMultiProWMisadedicatedturfspray

modicationforWorkmanvehiclesandisintended

tobeusedbyprofessional,hiredoperatorsin

commercialapplications.Itisprimarilydesigned

forsprayingonwell-maintainedlawnsinparks,golf

courses,sportselds,andoncommercialgrounds.

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Readthismanualcarefullytolearnhowtooperate

andmaintainyourproductproperly.Theinformation

inthismanualcanhelpyouandothersavoidinjury

andproductdamage.AlthoughT orodesignsand

producessafeproducts,youareresponsiblefor

operatingtheproductproperlyandsafely.Youmay

contactT orodirectlyatwww.T oro.comforproduct

safetyandoperationaltrainingmaterials,accessory

information,helpndingadealer,ortoregisteryour

product.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

illustratesthelocationofthemodelandserialnumbers

ontheproduct.

g022350

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safetyalertsymbol.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2019—TheToro®Company

8111L yndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

Training..............................................................4

BeforeOperating................................................4

ChemicalSafety.................................................5

WhileOperating..................................................6

Maintenance.......................................................8

SafetyandInstructionalDecals..........................9

Setup......................................................................13

1RemovingtheExistingBed............................15

2PreparingtoInstalltheTankSkid...................15

3InstallingtheConsoleMounting

Bracket..........................................................17

4InstallingtheHold-downBracketsforthe

TankSkid......................................................17

5InstallingtheTankSkid..................................18

6ConnectingtheSpeedSensor

Harness........................................................20

7CouplingtheSprayerPump...........................21

8InstallingtheControlConsoleandElectrical

Harness........................................................21

9InstallingtheSprayerFuseBlock...................22

10ConnectingtheSprayerHarnesstothe

Battery..........................................................24

11LoweringtheTankSkid................................25

12InstallingtheCenterBoomSection...............26

13InstallingtheLeftandRightBoom

Section..........................................................27

14InstallingtheBoomHoses............................29

15InstallingtheNozzles...................................31

16InstallingtheFresh-WaterTank....................31

17InstallingtheAnti-siphonFill

Receptacle....................................................32

18CheckingtheBoomHingeSprings...............33

19StoringtheJackStands(Optional)...............34

20LearningMoreaboutY ourProduct...............34

ProductOverview...................................................36

Controls...........................................................36

Specications..................................................39

Operation................................................................39

ThinkSafetyFirst..............................................39

UsingtheInfoCenter.........................................39

PreparingtoUsetheSprayer............................48

OperatingtheSprayer......................................48

FillingtheFreshWaterTank..............................49

FillingtheSprayT ank........................................49

OperatingtheBooms........................................50

Spraying...........................................................51

TurfCarePrecautionswhileOperatingin

StationaryModes..........................................51

SprayingTips....................................................51

UncloggingaNozzle.........................................52

SelectingaNozzle............................................52

CleaningtheSprayer........................................52

CalibratingtheSprayer.....................................53

Maintenance...........................................................58

RecommendedMaintenanceSchedule(s)...........58

DailyMaintenanceChecklist.............................59

NotationforAreasofConcern...........................59

Pre-MaintenanceProcedures..............................60

AccessingtheMachine.....................................60

Lubrication..........................................................61

GreasingtheSprayerSystem...........................61

GreasingtheBoomHinges...............................62

SpraySystemMaintenance.................................62

InspectingtheHoses........................................62

ChangingthePressureFilter............................63

InspectingtheSprayerPump............................63

AdjustingtheBoomstoLevel............................63

InspectingtheNylonPivotBushings.................65

Cleaning..............................................................65

CleaningtheFlowmeter....................................65

CleaningtheSprayerValves.............................66

Storage...................................................................75

RemovingtheSprayerandT ankSkid...............76

Troubleshooting......................................................78

Schematics.............................................................79

3

Page 4

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.T oreducethepotential

forinjury ,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

meansCaution,Warning,orDanger—“personalsafety

instruction.”Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Important:Readandunderstandtheinformation

inthesafetysectionoftheoperator’smanual

foryourWorkmanvehiclebeforeoperatingthe

machine.

SafeOperatingPractices

Important:Themachineisdesignedprimarily

asanoff-roadvehicleandisnotintendedfor

extensiveuseonpublicroads.

Whenusingthemachineonpublicroads,follow

alltrafcregulationsanduseanyadditional

accessoriesthatmayberequiredbylaw,suchas

lights,turnsignals,slowmovingvehicle(SMV)

sign,andothersasrequired.

TheWorkmanwasdesignedandtestedtooffer

safeservicewhenoperatedandmaintained

properly.Althoughhazardcontrolandaccident

preventionpartiallyaredependentuponthe

designandcongurationofthemachine,these

factorsarealsodependentupontheawareness,

concern,andpropertrainingofthepersonnel

involvedintheoperation,maintenanceand

storageofthemachine.Improperuseor

maintenanceofthemachinecanresultininjury

ordeath.

Thisisaspecializedutilityvehicledesignedfor

off–roaduseonly.Itsrideandhandlingwillhave

adifferentfeelthanwhatdriversexperiencewith

passengercarsortrucks.Sotaketimetobecome

familiarwithyourWorkman.

NotalloftheattachmentsthatadapttotheWorkman

arecoveredinthismanual.SeetheInstallation

Instructionsprovidedwithattachmentforadditional

safetyinstructions.

Toreducethepotentialforinjuryordeath,complywith

thefollowingsafetyinstructions:

Supervisor'sResponsibilities

•Makesurethatoperatorsarethoroughlytrained

andfamiliarwiththeOperator’sManual,the

Operator’sManualoftheWorkmanvehicle,

TrainingMaterial,EngineManual,andalllabels

ontheWorkmanvehicle.

•Besuretoestablishyourownspecialprocedures

andworkrulesforunusualoperatingconditions

(e.g.slopestoosteepforvehicleoperation).Use

thethirdhighlockoutswitchifhighspeedcould

resultinasafetyorvehicleabusesituation.

Training

•ReadtheOperator'sManualandothertraining

materialbeforeoperatingthemachine.

Note:Iftheoperator(s)ormechanic(s)cannot

readthemanuallanguage,itistheowner's

responsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverallowuntrainedpeopletooperateorservice

theequipment.

Note:Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeople,ordamagetoproperty.

BeforeOperating

•Operatethemachineonlyafterreadingand

understandingthecontentsofthismanual.

•Neverallowchildrentooperatethesprayer.

•Neverallowotheradultstooperatethesprayer

withoutrstreadingandunderstandingthe

Operator'sManual.Onlytrainedandauthorized

personsshouldoperatethissprayer.Makesure

thatalloperatorsarephysicallyandmentally

capableofoperatingthesprayer.

•Thissprayerisdesignedtocarryonlyyou,the

operatorandonepassengerintheseatprovided

bythemanufacturer.Nevercarryanyadditional

passengersonthesprayer.

•Neveroperatethesprayerwhenunderthe

inuenceofdrugsoralcohol.Evenprescription

drugsandcoldmedicinescancausedrowsiness.

•Donotdrivethesprayerwhenyouaretired.Be

suretotakeoccasionalbreaks.Itisveryimportant

thatyoustayalertatalltimes.

•Becomefamiliarwiththecontrolsandknowhow

tostoptheenginequickly.

•Keepallshields,safetydevices,anddecals

inplace.Ifashield,safetydevice,ordecalis

malfunctioning,illegible,ordamaged,repairor

replaceitbeforeoperatingthemachine.

4

Page 5

•Wearappropriateclothing;includingahardhat,

safetyglasses,longpants,safetyshoes,rubber

boots,gloves,andhearingprotection.Donot

wearloosettingclothingorjewelrywhichcould

getcaughtinmovingpartsandcausepersonal

injury.Donotoperatethemachinewhilewearing

sandals,tennisshoes,orsneakers.Donotwear

loosettingclothingorjewelrywhichcouldget

caughtinmovingpartsandcausepersonalinjury.

Note:Wearingsafetyglasses,safetyshoes,long

pants,andahelmetisadvisableandrequiredby

somelocalsafetyregulations.

•Keepeveryone,especiallychildrenandpets,away

fromtheareasofoperation.

•Beextremelycarefulwhenoperatingaround

people.Alwaysbeawareofwherebystanders

mightbeandkeepthemawayfromtheworkarea.

•Avoiddrivingwhenitisdark,especiallyin

unfamiliarareas.Ifyoumustdrivewhenitisdark,

besuretodrivecautiously,usetheheadlights,and

evenconsideraddingadditionallights.

•Beforeoperatingthevehicle,alwayscheckall

partsofthevehicleandanyattachments.If

somethingiswrong,stopusingthevehicle.

Makesurethattheproblemiscorrectedbeforethe

vehicleorattachmentisoperatedagain.

•Makesuretheoperatorandpassengerareais

cleanandfreefromchemicalresidueanddebris

buildup.

•Ensurethatalluidlineconnectorsaretightand

allhosesareingoodconditionbeforeapplying

pressuretothesystem.

Note:Donotusethesprayerifitisleakingor

damaged.

•Sincefuelishighlyammable,handleitcarefully.

–Useanapprovedfuelcontainer.

–Donotremovethecapfromthefueltankwhen

theengineishotorrunning.Allowtheengine

tocoolbeforefuelingthemachine.

–Donotsmokewhilehandlingfuel.

–Fillthefueltankofthemachineoutdoors.

–Fillthefueltankofthemachinetoabout25mm

(1inch)belowthetopofthetank(thebottom

ofthellerneck).Donotoverllthefueltank.

ChemicalSafety

WARNING

Chemicalsubstancesusedinthe

spreader-sprayersystemmaybehazardous

andtoxictoyou,bystanders,animals,plants,

soilsorotherproperty .

•Carefullyreadandfollowthechemical

warninglabelsandMaterialSafetyData

Sheets(MSDS)forallchemicalsusedand

protectyourselfaccordingtothechemical

manufacturer'srecommendations.Ensure

thataslittleskinaspossibleisexposed

whileusingchemicals.Useappropriate

PersonalProtectiveEquipment(PPE)

toguardagainstpersonalcontactwith

chemicals;personalprotectiveequipment

includes:

–safetyglasses,goggles,and/orface

shield

–respiratororltermask

–chemicalresistantgloves

–rubberbootsorothersubstantial

footwear

–hearingprotection

–cleanchangeofclothes,soap,and

disposabletowels,tobekepton-hand,

intheeventofachemicalspill.

•Keepinmindthattheremaybemorethan

onechemicalused,andinformationon

eachchemicalshouldbeassessed.

•Refusetooperateorworkonthesprayerif

thisinformationisnotavailable!

•Beforeworkingonasprayersystem,

makesurethatthesystemhasbeen

triplerinsedandneutralizedaccording

totherecommendationsofthechemical

manufacturer(s)andallofthevalveshave

beencycled3times.

•Verifythereisanadequatesupplyofclean

waterandsoapnearby ,andimmediately

washoffanychemicalsthatcontactyou.

–Wipeupanyspilledfuel.

•Obtainpropertrainingbeforeusingorhandling

chemicals.

•Usethecorrectchemicalforthejob.

•Followthechemicalmanufacturer'sinstructionsfor

thesafeapplicationofthechemical.Donotexceed

recommendedsystemapplicationpressure.

5

Page 6

•Donotll,calibrate,orcleantheunitwhenpeople,

especiallychildren,orpetsareinthearea.

•Handlechemicalsinawellventilatedarea.

•Havecleanwateravailableespeciallywhenlling

thespraytank.

•Donoteat,drink,orsmokewhileworkingwith

chemicals.

•Donotcleanspraynozzlesbyblowingthrough

themorplacinginmouth.

•Alwayswashyourhandsandotherexposedareas

assoonaspossibleafteryounishworkingwith

chemicals.

•Keepchemicalsintheiroriginalpackagesand

storedinasafelocation.

•Properlydisposeofunusedchemicalsand

chemicalcontainersasinstructedbythechemical

manufacturerandyourlocalcodes.

•Chemicalsandfumesaredangerous;neverenter

thetankorplaceyourheadoverorintheopening

ofatank.

•Followalllocal,state,federalregulationsfor

spreadingorsprayingchemicals.

WhileOperating

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorless,deadlypoisonthatcan

killyou.

Donotrunengineindoorsorinanenclosed

area.

•Operatorandpassengershouldremainseated

wheneverthemachineisinmotion.Operator

shouldkeepbothhandsonsteeringwheel,

wheneverpossibleandpassengershoulduse

handholdsprovided.Keeparmsandlegs

withinthevehiclebodyatalltimes.Never

carrypassengersintheboxoronattachments.

Rememberyourpassengermaynotbeexpecting

youtobrakeorturnandmaynotbeready.

•Alwayswatchoutforandavoidlowoverhangs

suchastreelimbs,doorjambs,andover-head

walkways.Makesurethereisenoughroomover

headtoeasilyclearthemachine,sprayerboom

sectionsandyourhead.

•Whenstartingtheengine:

–Sitonoperator’sseatandensureparking

brakeisengaged.

–IfyourmachineisequippedwithaPTOor

handthrottlelever,disengagePTOandreturn

handthrottlelevertoOffposition.

–MoveshiftlevertoNeutralanddepressclutch

pedal.

–Keepfootoffacceleratorpedal.

–TurnignitionkeytoStart.

•Usingthemachinedemandsattention.Failureto

operatevehiclesafelymayresultinanaccident,tip

overofvehicleandseriousinjuryordeath.Drive

carefully.T opreventtippingorlossofcontrol:

–Useextremecaution,reducespeedand

maintainasafedistancearoundsandtraps,

ditches,creeks,ramps,andanyunfamiliar

areasorotherhazards.

–Watchforholesorotherhiddenhazards.

–Usecautionwhenoperatingvehicleona

steepslope.Normallytravelstraightupand

downslopes.Reducespeedwhenmaking

sharpturnsorwhenturningonhillsides.Avoid

turningonhillsideswheneverpossible.

–Useextracautionwhenoperatingvehicleon

wetsurfaces,athigherspeedsorwithafull

load.Stoppingtimewillincreasewithafull

load.Shiftintoalowergearbeforestartingup

ordownahill.

–Avoidsuddenstopsandstarts.Donotgo

fromreversetoforwardorforwardtoreverse

withoutrstcomingtoacompletestop.

–Slowdownbeforeturning.Donotattempt

sharpturnsorabruptmaneuversorother

unsafedrivingactionsthatmaycausealoss

ofvehiclecontrol.

–Donotpassanothervehicletravelinginthe

samedirectionatintersections,blindspots,or

atotherdangerouslocations.

–Keepallbystandersaway .Beforebackingup,

looktotherearandassurenooneisbehind.

Backupslowly.

–Watchoutfortrafcwhenyouarenearor

crossingroads.Alwaysyieldtherightofwayto

pedestriansandothervehicles.Thissprayeris

notdesignedforuseonstreetsorhighways.

Alwayssignalyourturnsorstopearlyenough

sothatotherpeopleknowwhatyouplantodo.

Obeyalltrafcrulesandregulations.

–Neveroperatevehicleinornearanareawhere

thereisdustorfumesintheairwhichare

explosive.Theelectricalandexhaustsystems

ofthevehiclecanproducesparkscapableof

ignitingexplosivematerials.

–Whendrainingthetank,donotletanyone

standbehindvehicleanddonotdrainliquid

onanyone’sfeet.

–Ifeverunsureaboutsafeoperation,stopwork

andaskyoursupervisor.

6

Page 7

•DonotuseacabonaWorkmanvehicleequipped

withaspraysystem.Thecabisnotpressurized

andwillnotprovideadequateventilationwhen

usedwithasprayer.Thecabwillalsooverloadthe

vehiclewhenthespraysystemtankisfull.

•Donottouchengine,transaxle,muferormufer

manifoldwhileengineisrunningorsoonafterit

hasstoppedbecausetheseareasmaybehot

enoughtocauseburns.

•Ifthemachineevervibratesabnormally,stop

immediately,turnengineoff,waitforallmotionto

stopandinspectfordamage.Repairalldamage

beforeresumingoperation.

•Beforegettingofftheseat:

–Stopmovementofthemachine.

–Shutengineoffandwaitforallmovementto

stop.

–Setparkingbrake.

–Removethekeyfromthestarterswitch.

Important:Donotparkthemachineonan

incline.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

Braking

•Slowdownbeforeyouapproachanobstacle.

Thisgivesyouextratimetostoporturnaway.

Hittinganobstaclecandamagethevehicleandits

contents.Moreimportant,itcaninjureyouand

yourpassenger.

•GrossVehicleWeight(GVW)hasamajorimpact

onyourabilitytostopand/orturn.Heavyloadsand

attachmentsmakeavehiclehardertostoporturn.

Theheaviertheload,thelongerittakestostop.

•Turfandpavementareslickwhentheyarewet.

Itcantake2to4timesaslongtostoponwet

surfacesasondrysurfaces.Ifyoudrivethrough

standingwaterdeepenoughtogetthebrakes

wet,theywillnotworkwelluntiltheyaredry.After

drivingthroughwater,youshouldtestthebrakes

tomakesuretheyworkproperly.Iftheydonot,

driveslowlywhileputtinglightpressureonthe

brakepedal.Thiswilldrythebrakesout.

OperatingonHillsandRough

Terrain

Operatingthesprayeronahillmaycausetippingor

rollingofthesprayer,ortheenginemaystallandyou

couldloseheadwayonthehill.Thiscouldresultin

personalinjury.

•Donotacceleratequicklyorslamonthebrakes

whenbackingdownahill,especiallywithaload.

•Neverdriveacrossasteephill;alwaysdrive

straightupordownorgoaroundthehill.

•Iftheenginestallsoryoubegintoloseheadway

whileclimbingahill,graduallyapplythebrakes

andslowlybackstraightdownthehill.

•Turningwhiletravelingupordownhillscanbe

dangerous.Ifyouhavetoturnwhileonahill,doit

slowlyandcautiously.Nevermakesharporfast

turns.

•Heavyloadsaffectstability.Reducetheweightof

theloadandyourspeedwhenoperatingonhills.

•Avoidstoppingonhills,especiallywithaload.

Stoppingwhilegoingdownahillwilltakelonger

thanstoppingonlevelground.Ifthesprayermust

bestopped,avoidsuddenspeedchanges,which

mayinitiatetippingorrollingofthesprayer.Donot

slamonthebrakeswhenrollingbackward,asthis

maycausethesprayertooverturn.

•Usetheseatbeltwhenoperatingthemachineand

becertainthatitcanbereleasedquicklyinthe

eventofanemergency .

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontactthem.

•Donotremovetherolloverprotectionsystem

(ROPS).

•Reducespeedandloadwhenoperatingonrough

terrain,unevenground,andnearcurbs,holes,and

othersuddenchangesinterrain.Loadsmayshift,

causingthesprayertobecomeunstable.

WARNING

Suddenchangesinterrainmaycause

abruptsteeringwheelmovement,possibly

resultinginhandandarminjuries.

•Reduceyourspeedwhenoperatingonrough

terrainandnearcurbs.

•Gripthesteeringwheellooselyaroundthe

perimeter.Keepyourhandsclearofthesteering

wheelspokes.

Loading

TheweightofthecargocanchangetheWorkman

centerofgravityandhandling.T oavoidlossofcontrol

andpersonalinjury ,followtheseguidelines:

•Reducetheweightoftheloadwhenoperating

onhillsandroughterraintoavoidtippingor

overturningofthevehicle.

•Liquidloadscanshift.Thisshiftinghappens

mostoftenwhileturning,goingupordownhills,

suddenlychangingspeeds,orwhiledrivingover

roughsurfaces.Shiftingloadscancausethe

vehicletotipover.

7

Page 8

•Whenoperatingwithaheavyload,reduceyour

speedandallowforsufcientbrakingdistance.Do

notsuddenlyapplythebrakes.Useextracaution

onslopes.

•Beawarethatheavyloadsincreaseyourstopping

distanceandreduceyourabilitytoturnquickly

withouttippingover.

Maintenance

•Onlypermitqualiedandauthorizedpersonnelto

maintain,repair,adjust,orinspectthevehicle.

•Beforeservicingormakingadjustmentstothe

machine,stoptheengine,settheparkingbrake,

andremovethekeyfromtheignitiontoprevent

someonefromaccidentallystartingtheengine.

•Emptythetankbeforetiltingorremovingsprayer

fromvehicleandbeforestorage.

•Neverworkunderasprayerwithoutusingtank

supportproprod.

•Makesureallhydrauliclineconnectorsaretight,

andallhydraulichosesandlinesareingood

conditionbeforeapplyingpressuretothesystem.

•Keepbodyandhandsawayfrompinholeleaks

thatcanejecthydraulicuidunderhighpressure.

Usepaperorcardboard,nothands,tosearchfor

leaks.

•Donotoverspeedtheenginebychangingthe

governorsettings.Themaximumenginespeedis

3650rpm.T oassuresafetyandaccuracy,have

anAuthorizedToroDistributorcheckmaximum

enginespeedwithatachometer.

•Ifmajorrepairsareeverneededorassistanceis

required,contactanAuthorizedT oroDistributor.

•Tobesureofoptimumperformanceandsafety,

alwayspurchasegenuineT ororeplacement

partsandaccessories.Replacementpartsand

accessoriesmadebyothermanufacturerscould

bedangerous.Alteringthisvehicleinanymanner

mayaffectthevehicle’soperation,performance,

durabilityoritsusemayresultininjuryordeath.

SuchusecouldvoidtheproductwarrantyofThe

Toro®Company.

•Thisvehicleshouldnotbemodiedwithout

TheT oro®Company’sauthorization.Direct

anyinquiriestoTheT oro®Company,

CommercialDivision,VehicleEngineeringDept.,

300West82ndSt.,Bloomington,Minnesota

55420–1196.USA

•Refertoyourvehicle’sOperator’sManualforother

maintenance.

DANGER

Hydraulicuidescapingunderpressure

canhavesufcientforcetopenetrateskin

anddoseriousdamage.

Ifuidisinjectedintotheskinitmustbe

surgicallyremovedwithinafewhoursby

adoctorfamiliarwiththisformofinjuryor

gangrenemayresult.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinsystemmust

berelievedbystoppingengine,cyclingdump

valvefromraisetolowerand/orloweringthetank

andattachments.Ifthetankmustbeintheraised

position,secureitwiththesafetysupport.

•Tomakesureentiremachineisingoodcondition,

keepallnuts,boltsandscrewsproperlytightened.

•Toreducepotentialrehazard,keeptheengine

areafreeofexcessivegrease,grass,leavesand

accumulationofdirt.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,

clothing,andanypartsofthebodyawayfromthe

engineandanymovingparts.Keepeveryone

away.

8

Page 9

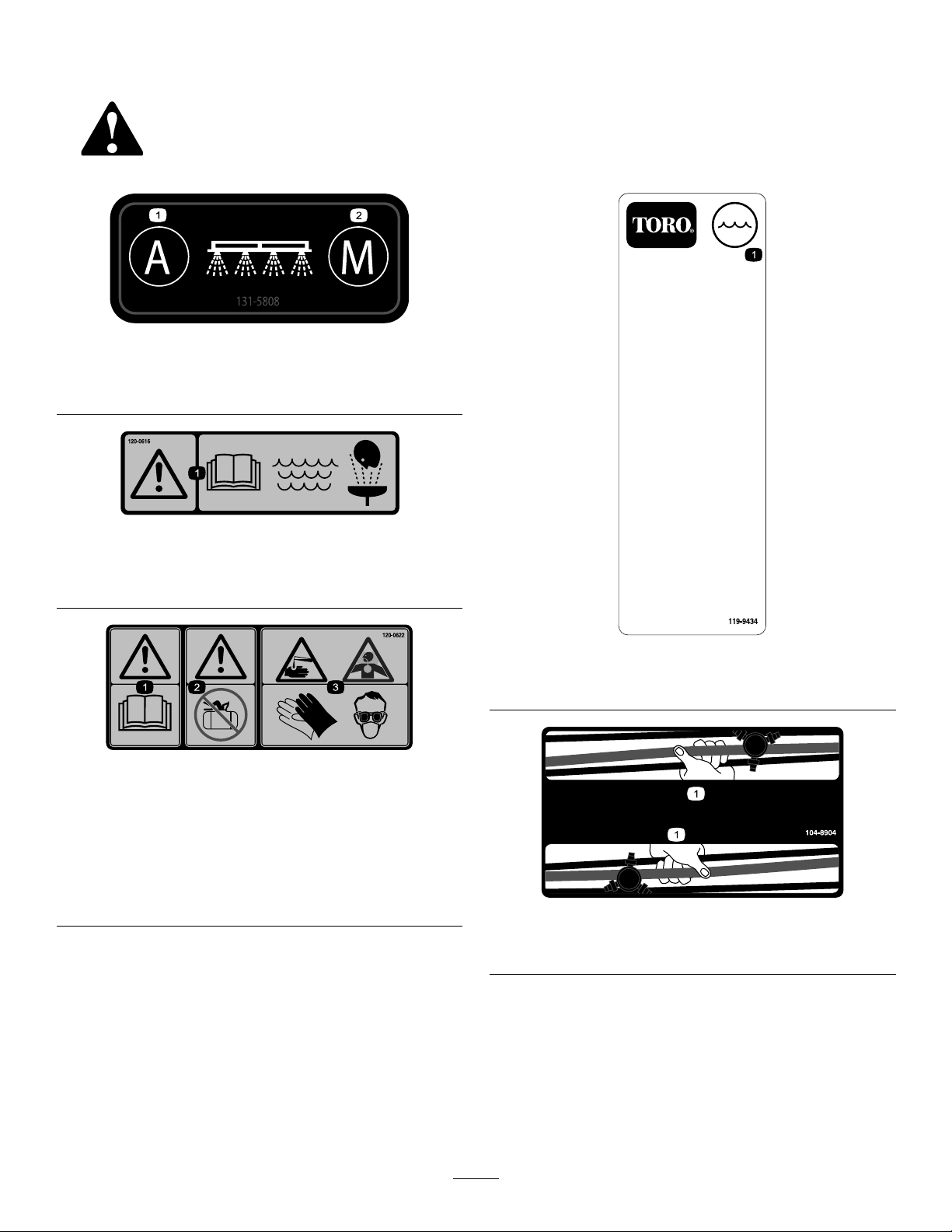

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedorlost.

131-5808

decal131-5808

1.Automatic—closed

loop-ratecontrol

2.Manual—openloop-rate

control

120–0616

1.Warning—readtheOperator’sManual;usefresh,clean

waterforrst-aidwashing.

120–0622

1.Warning—readthe

Operator’sManual.

2.Warning—donotenterthe

sprayertank.

3.Chemicalburnhazard;

toxicgasinhalation

hazard—wearhandand

skinprotection;weareye

andrespiratoryprotection.

decal120-0616

decal119-9434

119-9434

1.Tankcontents

decal120-0622

decal104-8904

104-8904

1.Grasptheboomhere.

9

Page 10

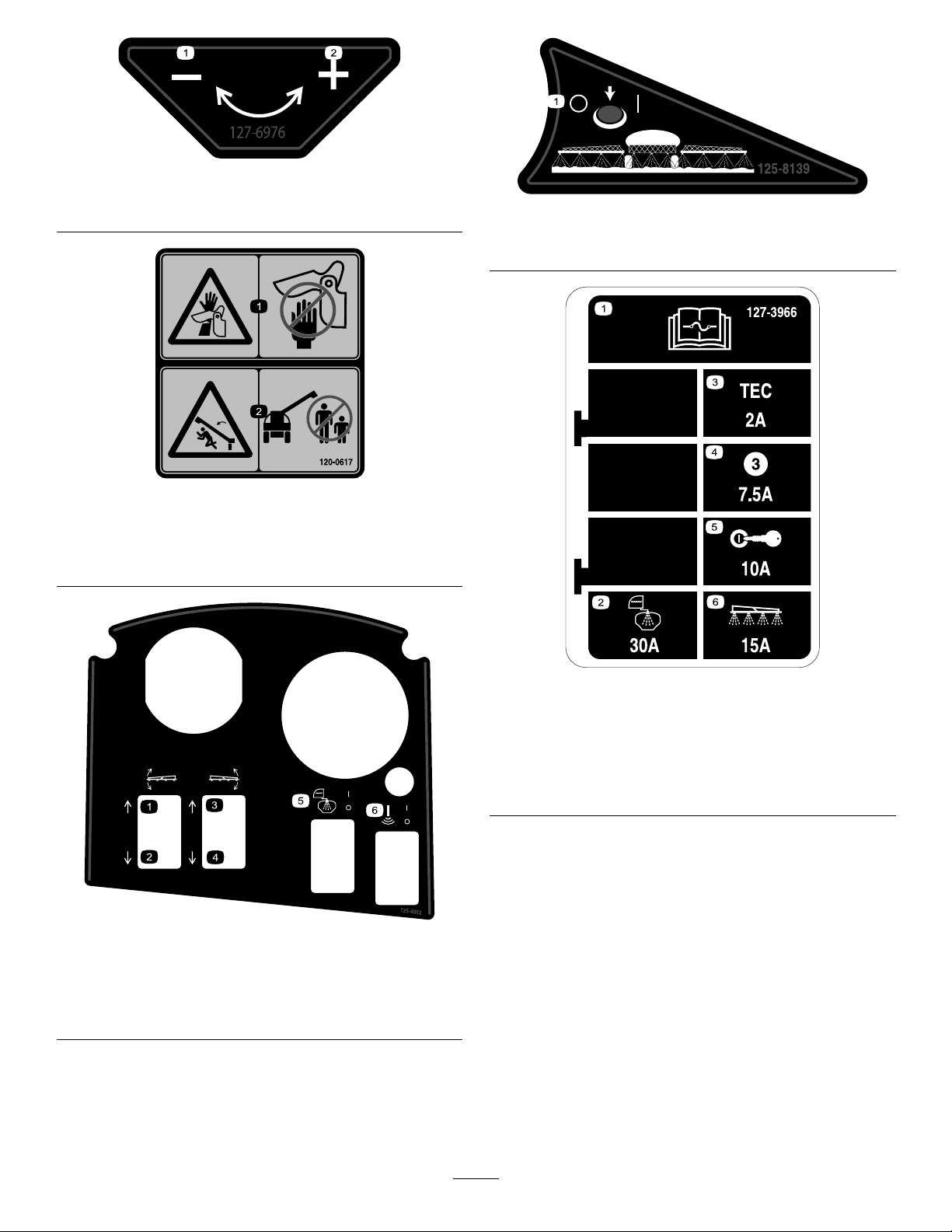

127-6976

1.Decrease2.Increase

120–0617

decal127-6976

decal125-8139

125–8139

1.Toggleboomsprayerson/off

decal120-0617

1.Severinghazardofhand,

pinchingpoint—keep

awayfromactuatedjoints.

2.Crushinghazard—keep

bystandersawayfromthe

machine.

decal125-4052

125–4052

1.Raiseleftboom

2.Lowerleftboom5.Toggletankrinseon/off

3.Raiserightboom

4.Lowerrightboom

6.Togglesonicboomon/off

127–3966

1.ReadtheOperator’s

Manualforinformationon

fuses.

2.30A—Tankrinse5.10A—Ignition

3.2A—TECcontrollerlogic6.15A—Sprayerboom

4.7.5A—TECcontroller

output

decal127-3966

10

Page 11

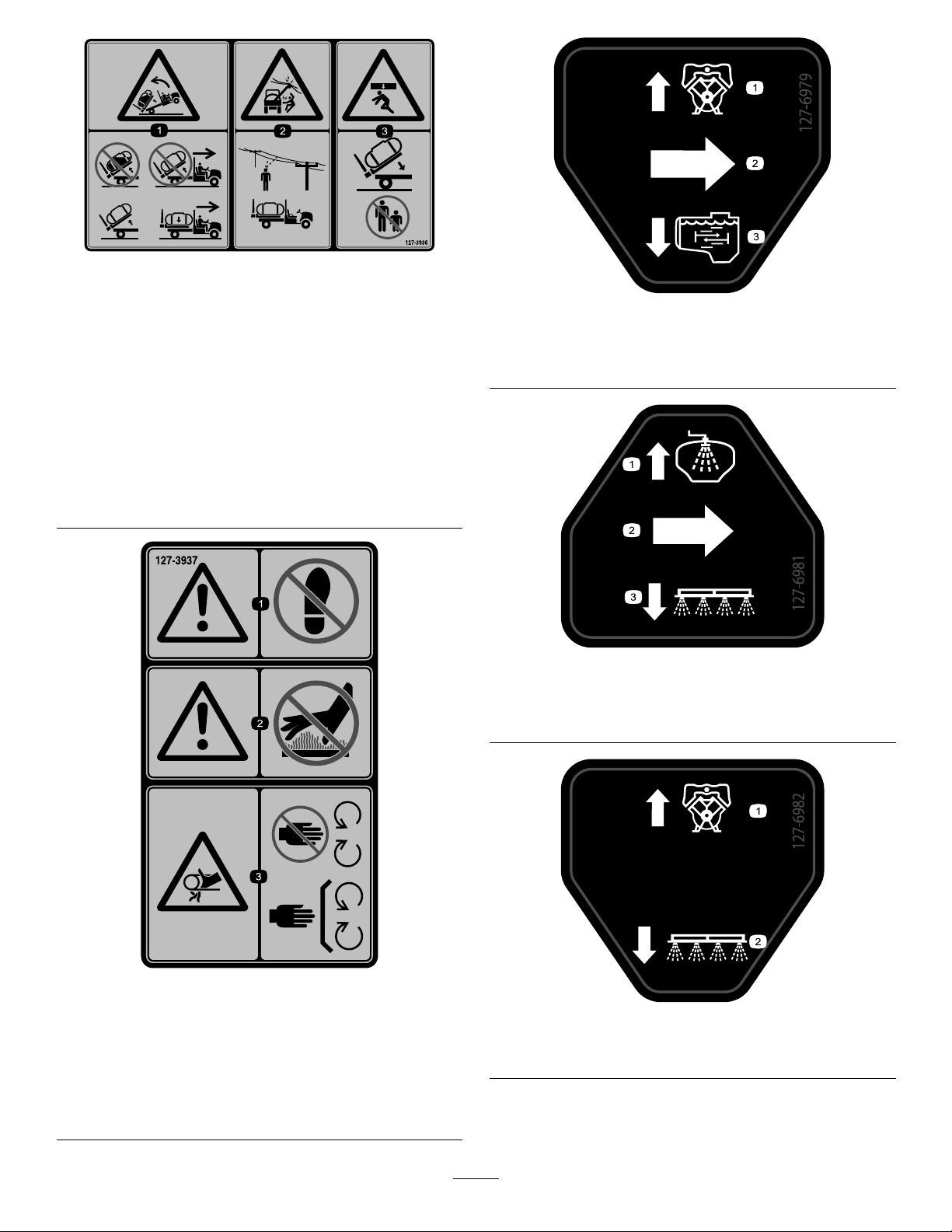

1.Backwardtipping

hazard—donotraise

afulltank;donotmove

themachinewitharaised

tank;onlyraiseand

emptytank;onlymovethe

machinewithalowered

tank.

2.Electricalshockhazard,

overheadpower

lines—checkthearea

foroverheadpowerlines

beforeoperatingthe

machineinthearea.

decal127-3936

127–3936

3.Crushinghazard—keep

bystandersawaywhen

loweringthetank.

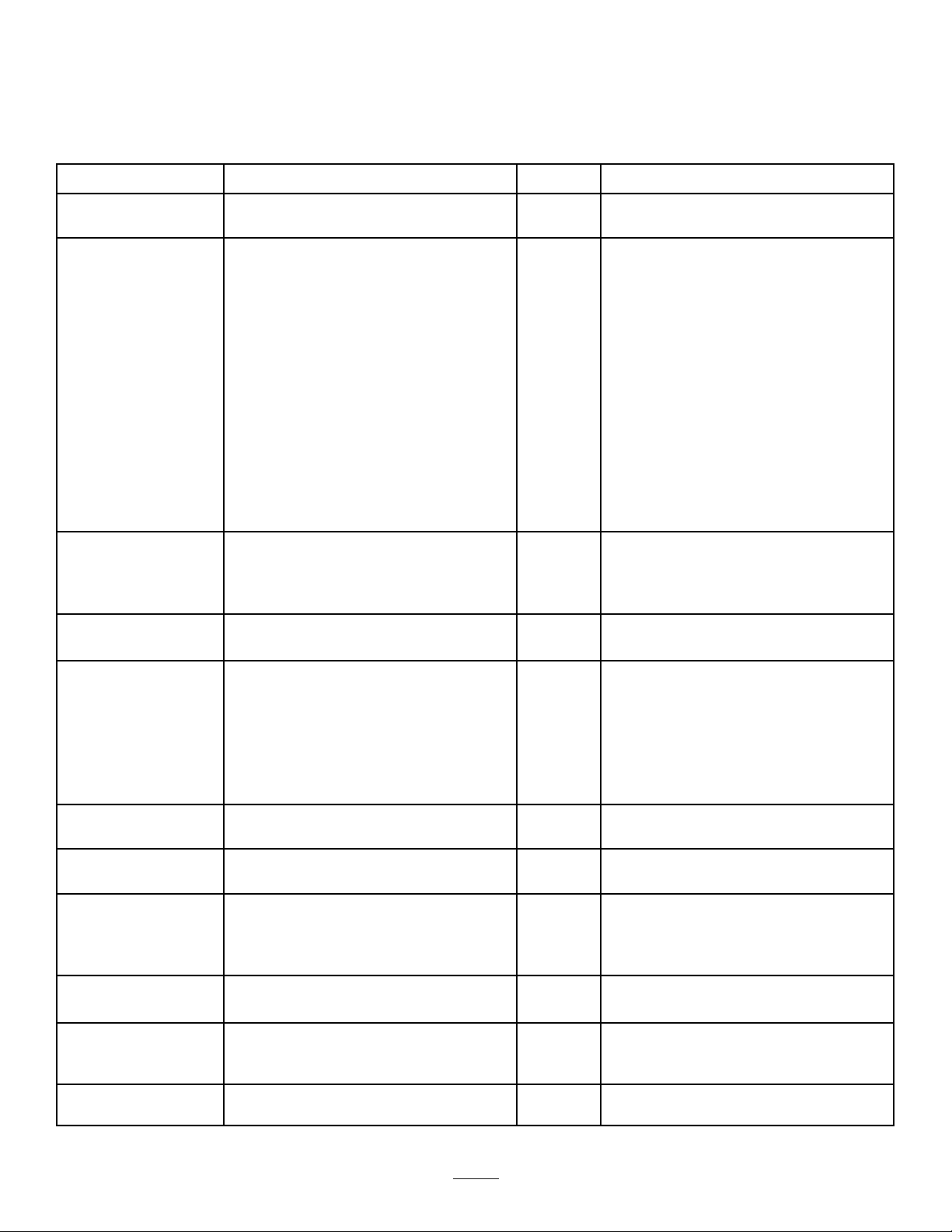

127-6979

1.Bypass-returnow3.Agitationow

2.Flow

decal127-6979

decal127-6981

127-6981

127–3937

1.Warning—donotstep.3.Entanglementhazard,

belt—keepawayfrom

movingparts;keepall

guardsandshieldsin

place.

2.Warning—keepawayfrom

hotsurfaces.

1.Bypass-returnow

3.Boomspray

2.Flow

decal127-3937

decal127-6982

127-6982

1.Bypass-returnow

2.Boomspray

11

Page 12

decal127-6984

127-6984

1.Flow

2.Tank-returnow

130-8294

1.Leftboom5.Centerboomsprayon9.Rightboomsprayoff

2.Leftboomsprayon6.Centerboomsprayoff10.Speed

3.Leftboomsprayoff

4.Centerboom

7.Rightboom11.Increasespeed

8.Rightboomsprayon12.Decreasespeed

decal130-8294

13.Agitation

14.Agitationon

15.Agitationoff

12

Page 13

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

Nopartsrequired

RearPTOKit,Heavy-DutyWorkman

Vehicle(HD-SeriesModelswitha

ManualTransmission)

MultiProWMTurfSprayerFinishing

Kit,ManualWorkmanUtilityVehicle

(HD-SeriesModelswithaManual

Transmission)

Hairpin1

Controlconsole

MultiProWMTurfSprayerFinishing

Kit,ManualWorkmanUtilityVehicle

(HD-SeriesModelswithaManual

Transmission)

MultiProWMTurfSprayerFinishing

Kit,AutomaticWorkmanUtilityVehicle

(HDX-AutoModel)

Consolemountingbracket

Flangelocknut(5/16inch)

Flange-headbolt(5/16inch)

Plasticbushing2

Hold-downbrackets2

Tankandskidassembly1

Clevispins

Taperedclevispin2

Hairpins2

Lynchpins4

Bolt(1/2x1-1/2inches)

Nuts(1/2inch)

Qty.

Use

–

1

1

1

1

1

1

3

3

2

2

2

Removetheexistingbed.

Preparetoinstallthecenterboom

section.

Installtheconsolemountingbracket.

Installtheattachmenthold-down

brackets.

Installthetankskid.

6

7

8

9

10

11

Nopartsrequired

Nopartsrequired

Knob1

J-clips3

Bolt(1/4x3/4inch)

Flangenut(1/4inch)

Fusedecal(127–3966)

Batteryterminalbolt1

Clampnut

Cover(batteryterminal—red)

Bolt(1/2x1-1/2inch

Locknut(1/2inch)

13

–

–

1

1

1

2

1

2

2

Connectthespeedsensorharness.

Couplethesprayerpump.

Installthecontrolconsoleontothe

machine.

Installthecontrolconsoleandthe

electricalharness.

Connectthesprayerharnesstothe

battery.

Lowerthetankskid.

Page 14

ProcedureDescription

12

13

14

16

17

Center-boomassembly

Bolt(3/8x1inch)

Flangedlocknut(3/8inch)

Boom-transportcradle2

Bolt(1/2x1-1/4inches)

Flangenut(1/2inch)

Leftboomsection

Rightboomsection1

Flanged-headbolts(3/8x1-1/4inch)

Backingplates8

Flangedlocknuts(3/8inch)

Clevispin

Hairpin2

Hoseclamps3

R-clamp2

Shoulderbolt

Washer2

Nut2

Supporttube(freshwatertank)

Jamnut(3/8inch)

Bolt(3/8x1inch)

Shoulderbolt

Locknut(3/8inch)

Fresh-watertank1

Fresh-watertankmount1

Flangedlocknut(5/16inch)

Washer(5/16inch)

Flanged-headbolt(5/16x2-1/4inch)

Flanged-headbolt(5/16x5/8inch)

Fillreceptacleassembly1

Flange-headbolt(5/16x3/4inch)

Qty.

10

10

Use

1

Installtheboomsection.

4

4

1

8

Installtheleftandrightboomsections.

8

2

2

1

1

1

2

2

2

2

2

4

1

Installtheboomhoses.

Installthefresh-watertank.

Installtheanti-siphonllreceptacle.

18

19

20

Nopartsrequired

Frontjackstand2

Rearjackstand2

Cotterpin

Clevispin(4-1/2inch)

Clevispin(3inch)

Knob2

Operator'sManual

Operatortrainingmaterial

PartsCatalog

Registrationcard1

Selectionguide

Pre-deliveryinspectionsheet1

–

4

2

2

1

1

1

1

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Checktheboomhingesprings.

Storethejackstands(optional).

Readthemanualsandviewthetraining

materialbeforeoperatingthemachine.

14

Page 15

pinstowardthecenterlineofthemachine(Figure

3).

1

RemovingtheExistingBed

NoPartsRequired

Procedure

CAUTION

Thefullbedweighsapproximately95kg(210

lb),sodonottrytoinstallorremoveitby

yourself.Getthehelpof2or3otherpeople

oruseanoverheadcrane.

1.Ensurethattheparkingbrakeissetandstart

theengineofthemachine.

2.Movethehydraulicliftleverforwardandlower

thebeduntiltheclevispinsforthecylinderrod

endliftcylindersarelooseinthemountingslots

ofthebedmountingplates.

3.Releasethehydraulicliftlever,setthehydraulic

liftlocklever,andshutofftheengine;refertothe

Operator’sManualofyourmachine.

6.Removethelynchpinsandclevispinssecuring

thepivotbracketsofthebedtotheframe

channelsofthemachine(Figure4).

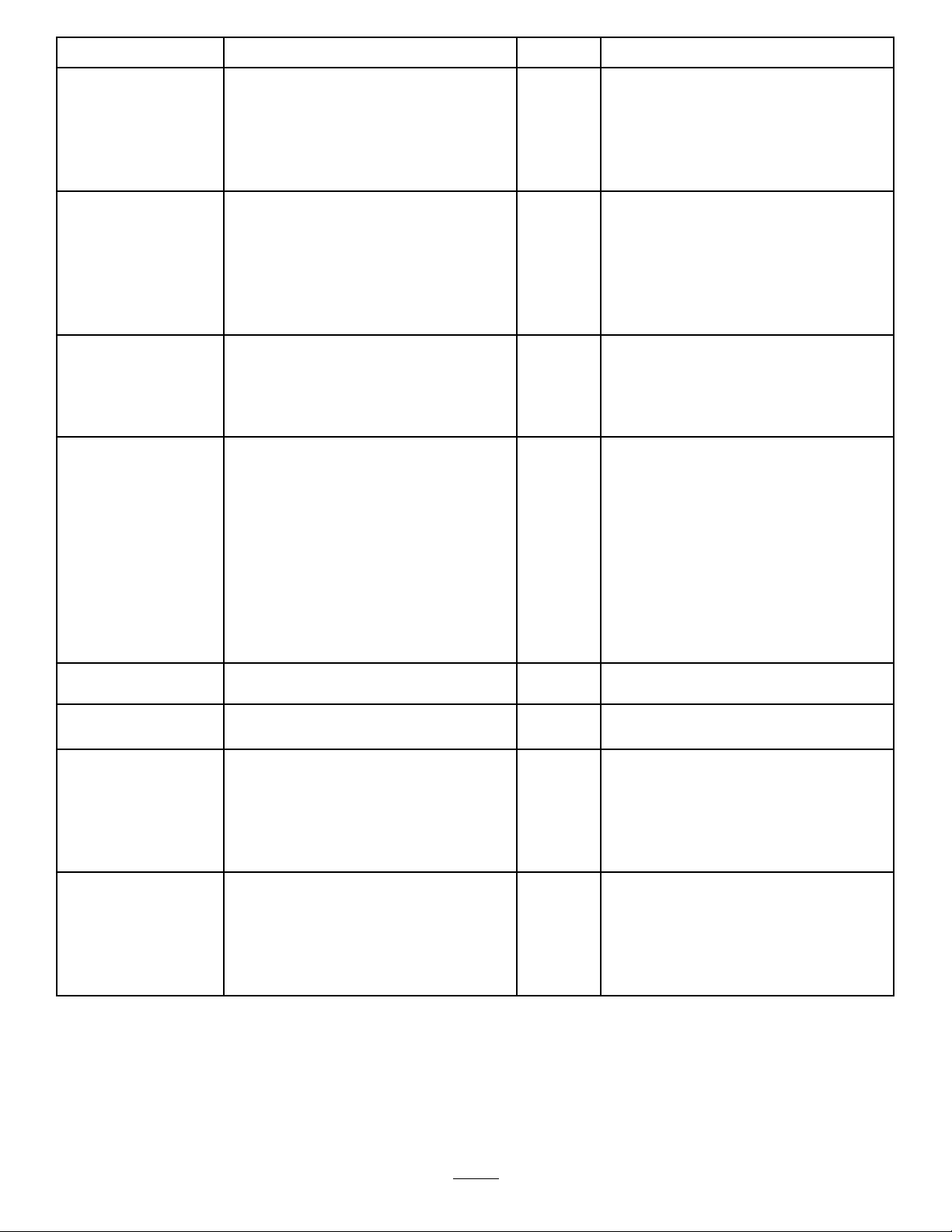

Figure4

1.Leftrearcornerofbed4.Clevispin

2.Vehicleframechannel

3.Pivotplate

5.Lynchpin

g002369

4.Removethelynchpinsfromtheouterendsof

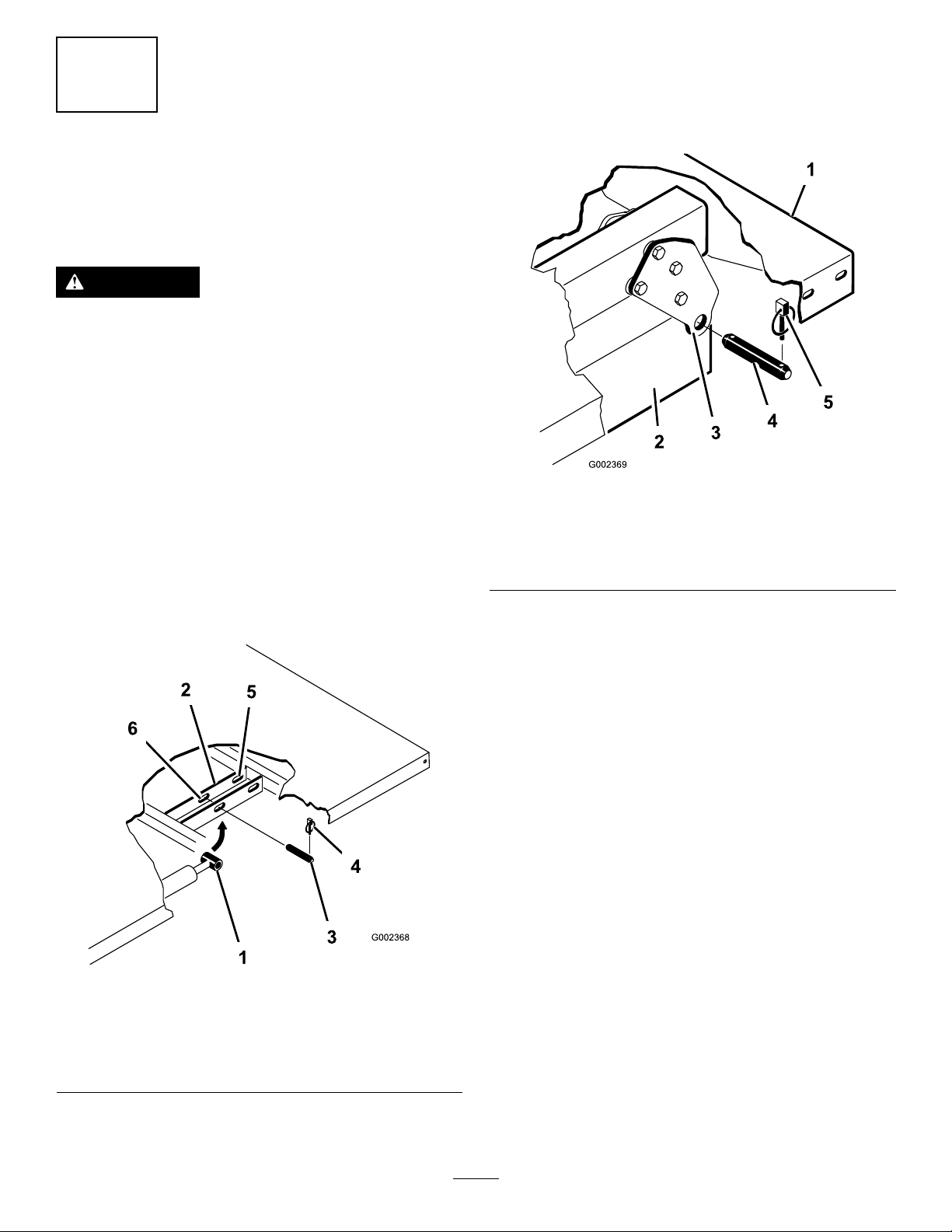

thecylinderrodclevispins(Figure3).

Figure3

1.Cylinderrodend

2.Bedmountingplate

3.Clevispin6.Frontslots(2/3bed)

4.Lynchpin

5.Rearslots(Fullbed)

7.Liftthebedoffthevehicle.

8.Stowtheliftcylindersinstorageclips.

g002368

5.Removetheclevispinssecuringthecylinderrod

endstothebedmountingplatesbypushingthe

15

Page 16

2

PreparingtoInstallthe

TankSkid

Partsneededforthisprocedure:

RearPTOKit,Heavy-DutyWorkmanVehicle

1

(HD-SeriesModelswithaManualTransmission)

MultiProWMTurfSprayerFinishingKit,Manual

1

WorkmanUtilityV ehicle(HD-SeriesModelswitha

ManualTransmission)

1Hairpin

1

Controlconsole

MultiProWMTurfSprayerFinishingKit,Manual

1

WorkmanUtilityV ehicle(HD-SeriesModelswitha

ManualTransmission)

MultiProWMTurfSprayerFinishingKit,Automatic

1

WorkmanUtilityVehicle(HDX-AutoModel)

InstallingtheRearPTOKitfor

HeavyDutyWorkmanVehicles

(HD-SeriesModelswithaManual

Transmission)

ForHD-andHDX-SeriesWorkmanmodelswith

amanualtransmission,fullyinstalltheRearPTO

KitforHeavy-DutyWorkmanVehicles;refertothe

InstallationInstructionsfortheRearPTOKitforHeavy

DutyWorkmanVehicles.

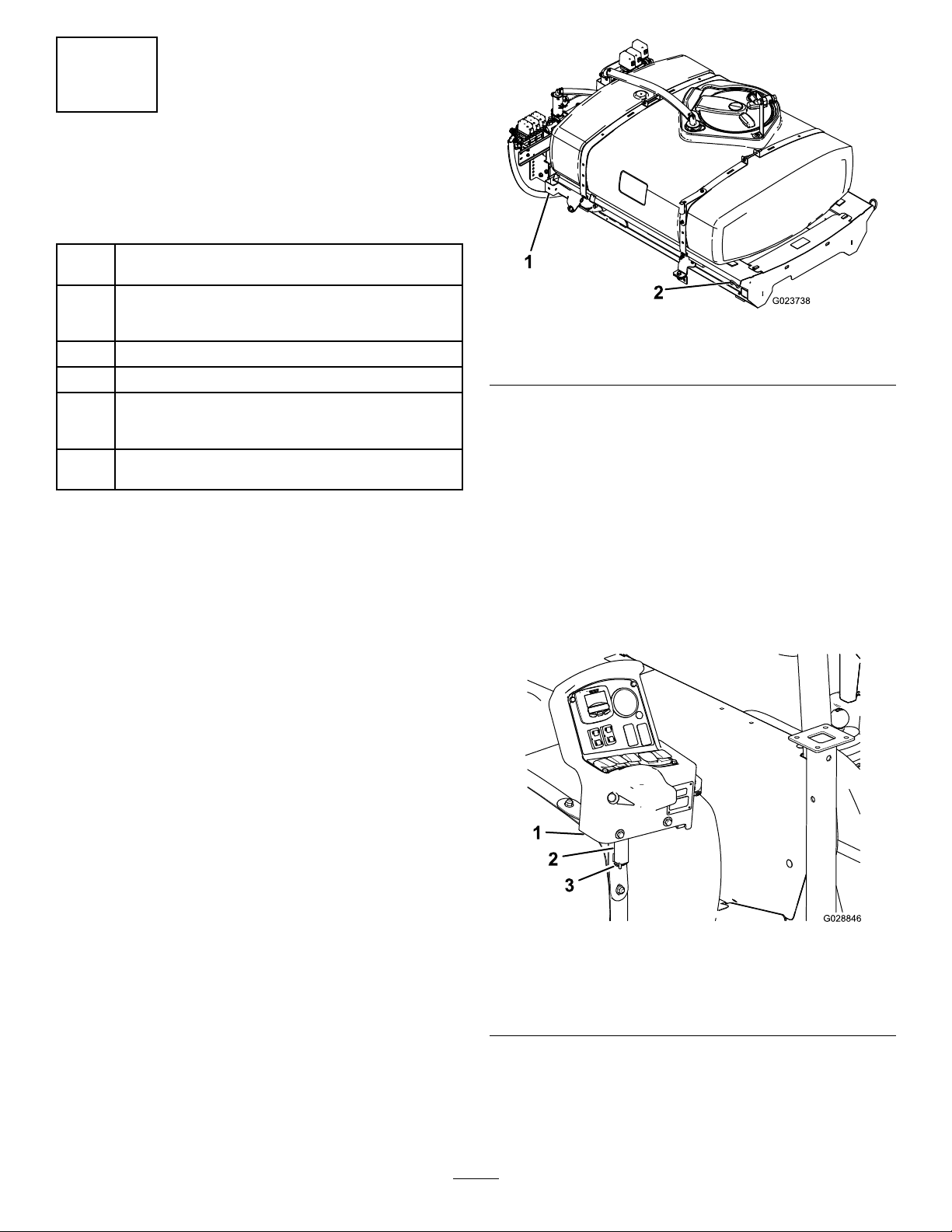

g023738

Figure5

1.Rearliftpoint2.Frontliftpoint

InstallingtheControlConsole

Note:Thissteptemporarilymountsthecontrol

consoletothetankwhileyouassemblethesprayer

tothemachine.Youwillcompletetheinstallationof

thecontrolconsolein9InstallingtheSprayerFuse

Block(page22).

1.Carefullyremovethecontrolconsolefromthe

shippingcontainer

2.Alignthepivotpinonthecontrolconsolewiththe

storagebracketatthefronttankstrap(Figure6).

High-FlowHydraulicsKit,

WorkmanHDX-AutoUtilityVehicle

(Non-TC—HDX-AutoModel)

FullyinstalltheHigh-FlowHydraulicsKitforWorkman

HDX-AutoUtilityVehicles;refertotheInstallation

InstructionsfortheHigh-FlowHydraulicsKit,

WorkmanHDX-AutoUtilityVehicle.

LiftingtheSprayerSkid

Usingliftingequipmentwitha408kg(900lb)lift

capacity,liftthetankskidfromtheshippingcrateat

the2frontand2rearliftpoints(Figure5).

Note:Ensurethatthetankskidisraisedhighenough

toinstallthejackstands.

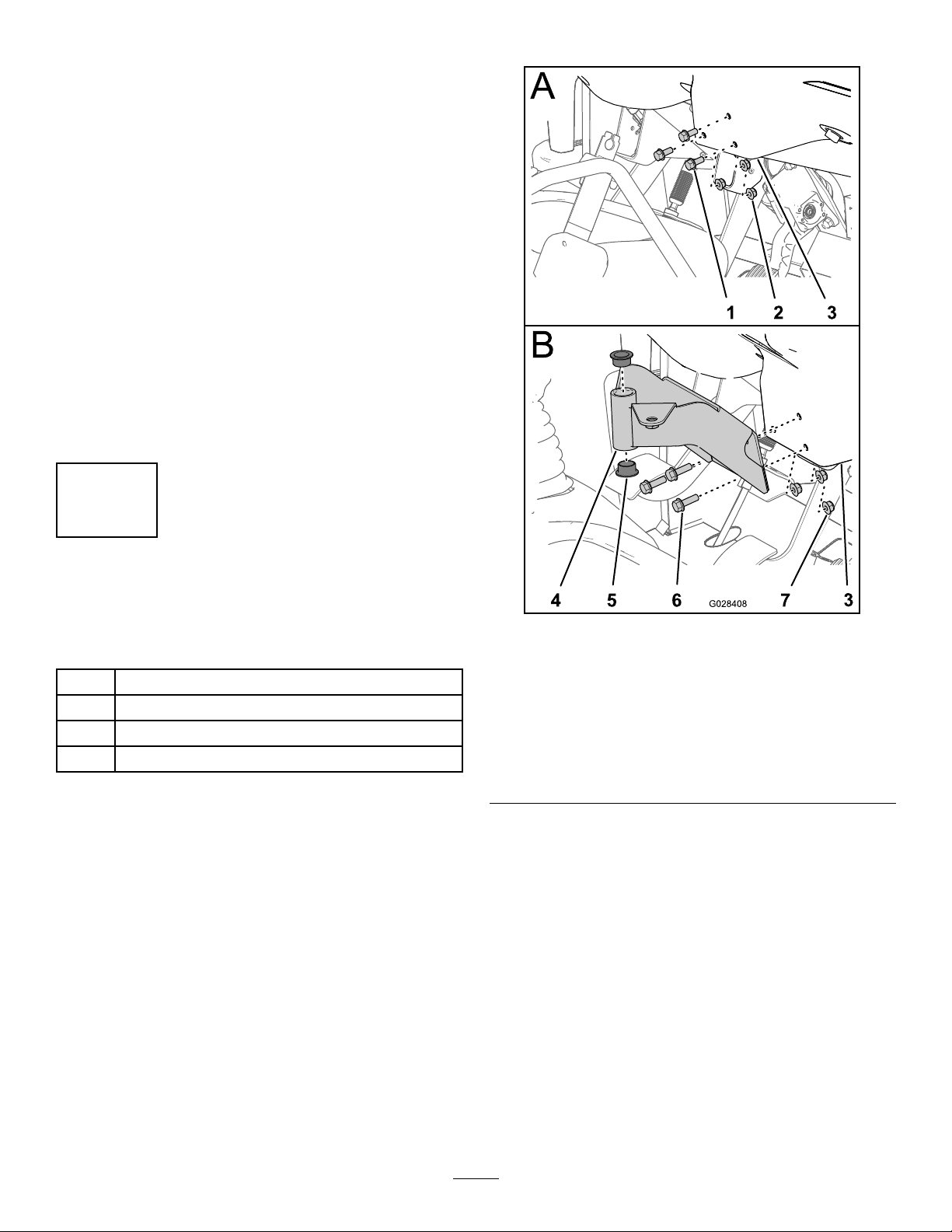

Figure6

1.Controlconsole

2.Storagebracket(fronttank

strap)

3.Assembletheconsoletothebracketandsecure

thepivotpintothebracketwiththehairpin

(Figure6).

16

3.Hairpin

g028846

Page 17

MultiProWorkmanTurfSprayer

FinishingKit(HD-SeriesModels

withaManualTransmission)

ForHD-andHDX-SeriesWorkmanmodelswith

amanualtransmission,completethestepsinthe

MultiProWMTurfSprayerFinishingKitforManual

WorkmanUtilityVehicles;refertotheInstallation

InstructionsfortheMultiProWMTurfSprayer

FinishingKit,ManualWorkmanUtilityVehicle.

MultiProWorkmanTurfSprayer

FinishingKit(HDX-AutoModel)

HDX-AutomaticSeriesWorkmanmodels,complete

thestepsintheMultiProWMTurfSprayerFinishing

KitforAutomaticWorkmanUtilityVehicles;referto

theInstallationInstructionsfortheMultiProWMTurf

SprayerFinishingKit,AutomaticWorkmanUtility

Vehicle.

Note:Discardtheboltsandnuts.

3

InstallingtheConsole

MountingBracket

Partsneededforthisprocedure:

1

Consolemountingbracket

3

Flangelocknut(5/16inch)

3

Flange-headbolt(5/16inch)

2Plasticbushing

Procedure

Note:OnsomeWorkmanvehicles,thecontrolmount

plateisattachedtothedashboardatthesamelocation

wherethebracketfortheoptionalhandthrottlekit

ismounted.Ifthehandthrottlekitisinstalled,you

willneedtoremovethebracketofthehandthrottle

assemblyfromthedashboard,alignthecontrolmount

platetothedash,andinstallthehandthrottlebracket

ontopofthecontrolmountplate.RefertotheHand

ThrottleKitInstallationInstructionsfordirectionson

removingandinstallingthehandthrottleassembly .

Figure7

1.Bolt

2.Nut

3.Cashpanel(lowercenter

area)

4.Mountingbracket(control

console)

2.Aligntheholesinthemountingbracketforthe

controlconsolewiththeholesinthedashand

supportbracket(Figure7).

3.Assemblethemountingbracketdashpaneland

supportbracketwiththe3anged-headbolts

(5/16x1inch)and3angedlocknuts(5/16inch)

4.Torquethenutsandboltsto(Figure7).

5.Insertthe2plasticbushingsintothemounting

bracket(Figure7).

5.Bushing(plastic)

6.Flanged-headbolts(5/16

x1inch)

7.Flangedlocknuts(5/16

inch)

g028408

1.Removethe3boltsand3nutsthatsecurethe

lower-centerportionofthedashpaneltothe

dashsupportbracket(Figure7).

Note:SomeolderWorkmanmachinesmayuse

4boltsandangenuts.

17

Page 18

4

InstallingtheHold-down

BracketsfortheTankSkid

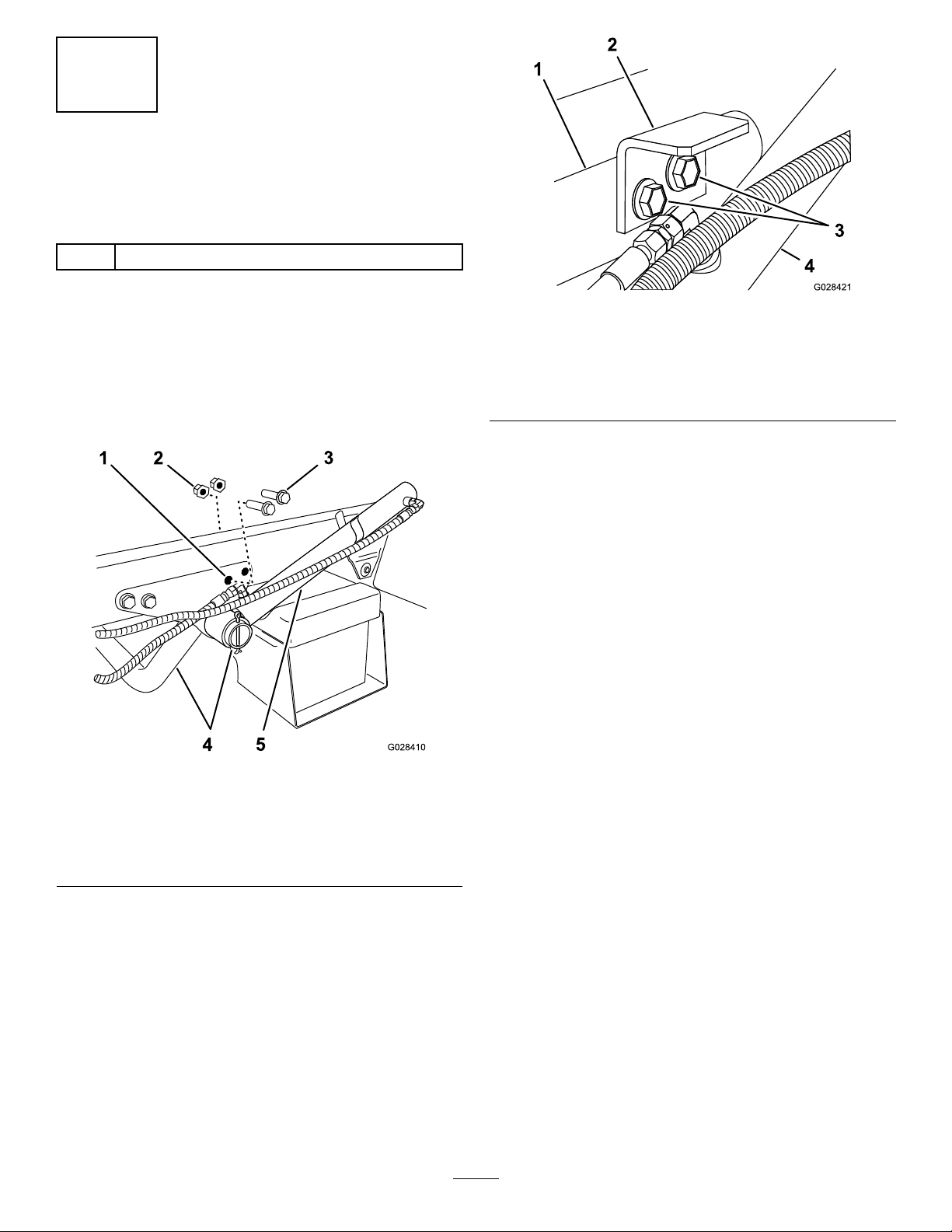

Partsneededforthisprocedure:

2Hold-downbrackets

Procedure

1.Removethe2rearanged-headboltsand2

angedlocknutsthatsecurethesupportbracket

fortheenginetubetotheframeofthemachine

(Figure8).

1.Supportbracket(engine

tube)

2.Hold-downbracket(tank

skid)

g028421

Figure9

3.Flanged-headbolts

4.Liftcylinder

Note:Retainthefastenersforlateruse.

Figure8

1.Rearhole—support

bracket(enginetube)

2.Flangedlocknut

3.Flanged-headbolt

4.Torquetheboltsandnutsto91to113N-m(67

to83ft-lb).

5.Repeatsteps1to4attheoppositesideofthe

machine.

g028410

4.Enginesupporttube

5.Liftcylinder

2.Rotatetheliftcylindertoprovideclearanceto

installthehold-downbracketforthetankskid

(Figure8).

3.Assemblethehold-downbracketstosupport

bracketandframetheusingthe2anged-head

boltandangelocknutremovedinstep1(Figure

9).

18

Page 19

5

InstallingtheTankSkid

Partsneededforthisprocedure:

1Tankandskidassembly

2

Clevispins

2Taperedclevispin

2Hairpins

4Lynchpins

2

Bolt(1/2x1-1/2inches)

2

Nuts(1/2inch)

2.Positionthedrainvalveasfollows:

A.Attheleftsideofthetank,loosenthe2

anged-headboltsthatsecurethedrain

valvetothevalve-supportbracket(Figure

11).

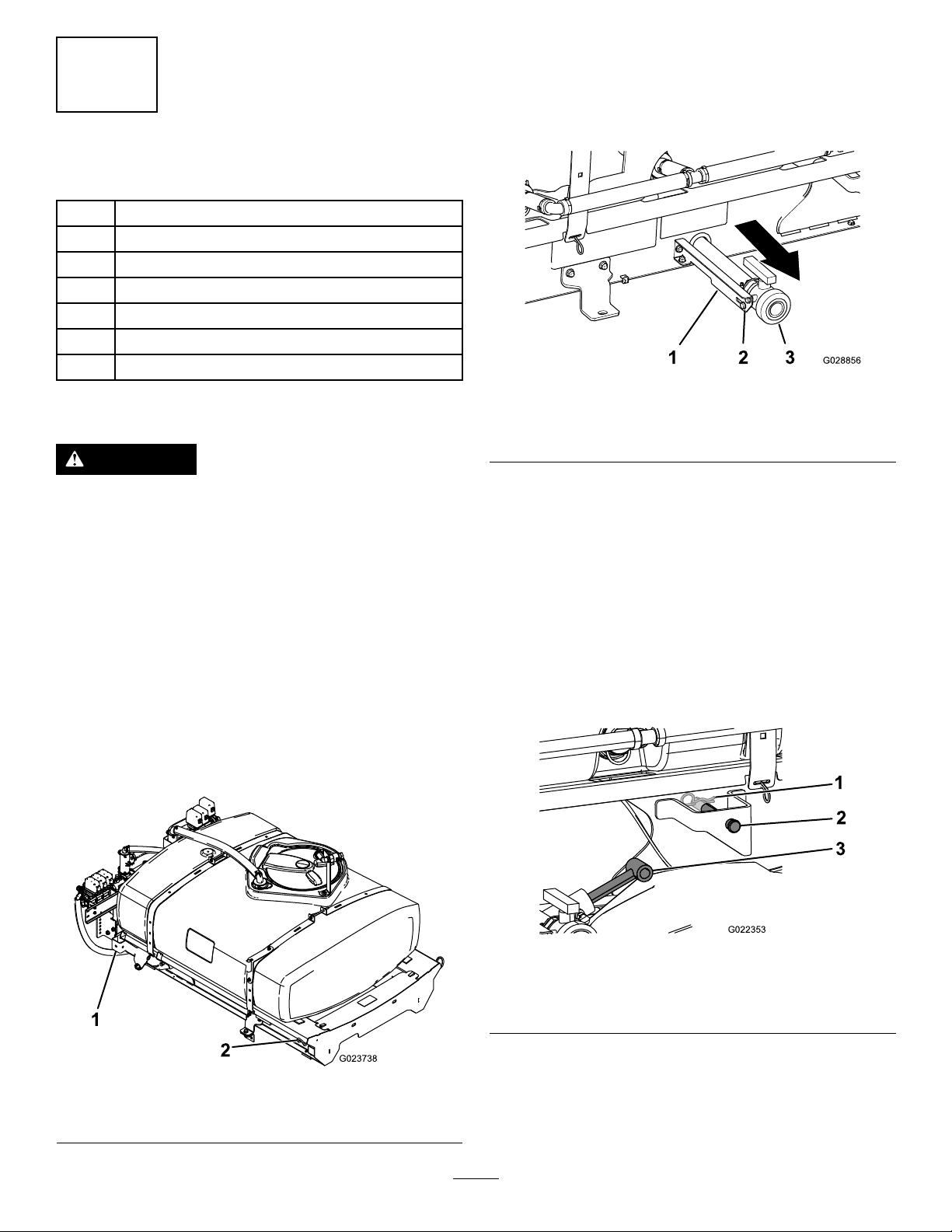

g028856

Figure11

Procedure

DANGER

Thesprayertankassemblyrepresentsa

storedenergyhazard.Ifnotproperlyretained

wheninstallingorremovingtheassembly,

itcanmoveorfallandinjureyouorother

bystanders.

Usestrapsandanoverheadlifttosupport

thesprayertankassemblyduringinstallation,

removal,oranymaintenancewhenthe

retainingfastenersarebeingremoved.

1.Usingalift,raisethetankskidassembly(Figure

10)andpositionitoverthevehicleframewith

thepumpandvalveassembliesfacingrearward.

Note:Haveanotherpersonhelpyouperform

thefollowingsteps.

1.Valve-supportbracket3.Drainvalve

2.Flanged-headbolt

B.Movethedrainvalvefullyoutwardinthe

slotsofthebracket(Figure11).

Note:Ensurethatthedrainhoseatthe

inboardsideofthesprayerskidisnot

kinked.

C.Tighten2angedheadbolts(Figure11).

3.Slowlylowerthetankskidontotheframeofthe

machine.

4.Extendtheliftcylinderstothebracketsonthe

tankskid,andalignthecylinderttingswiththe

holesinthetankskidbrackets(Figure12).

Figure10

1.Rearliftpoint2.Frontliftpoint

g022353

Figure12

1.Hairpin

2.Clevispin

g023738

5.Securethetankskidtotheliftcylinderswith

theclevispinsandhairpinsatbothsidesofthe

machine.

6.Lineuptheholesinthepivotlugsattherear

ofthetankskidassemblywiththeholesinthe

19

3.Liftcylinders

Page 20

bedpivottubeattheendofthevehicleframe

(Figure13).

Figure13

1.Taperedclevispin2.Lynchpin

7.Installataperedclevispinand2lynchpinsto

thepivotlugtosecurethetankassemblytothe

frame(Figure13).

8.Extendtheliftcylinderstoraisethetankand

supportitsweight.

Note:Disconnectthetankassemblyfromthe

liftingequipment.

9.Removethebedsupportfromthestorage

bracketsonbackoftheROPSpanel(Figure14).

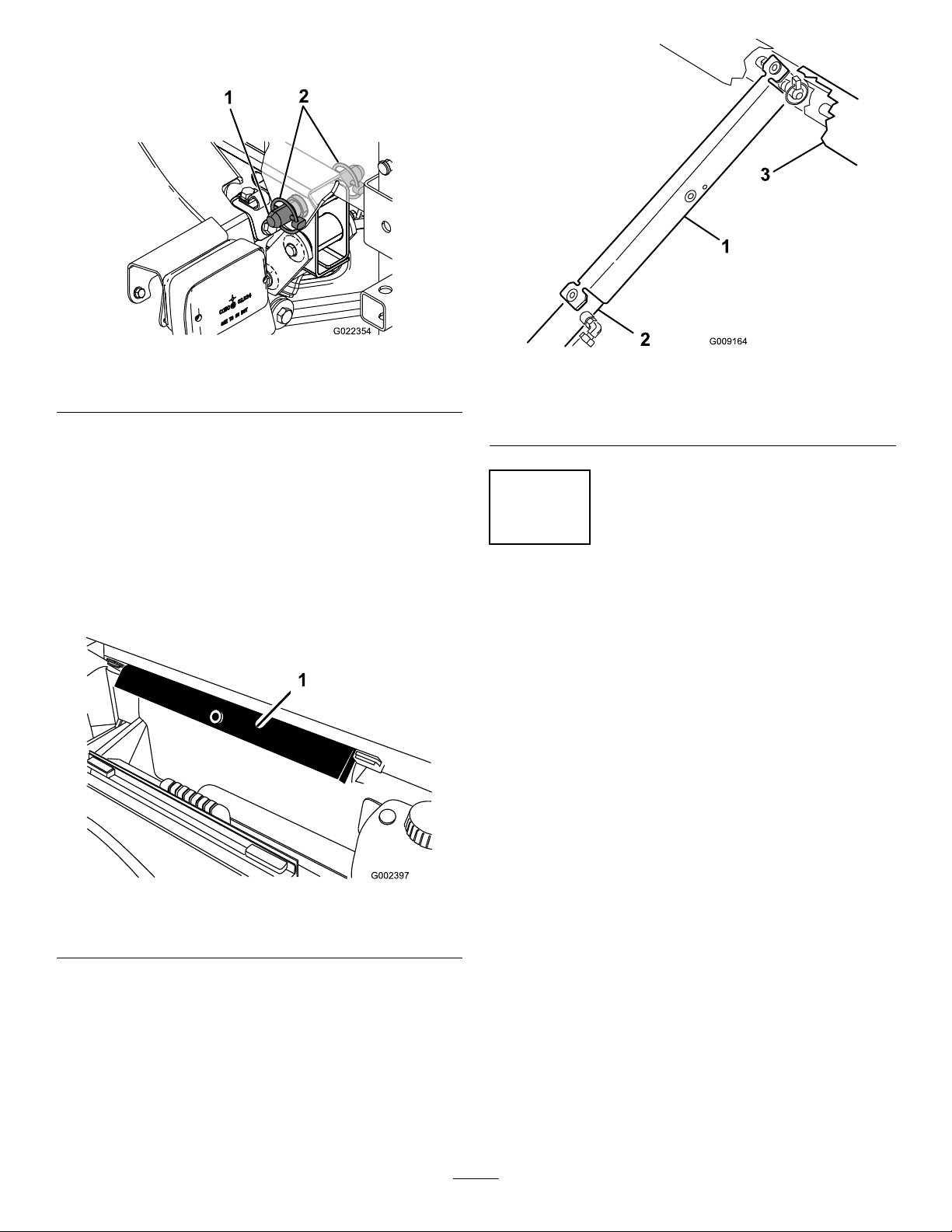

g022354

Figure15

1.Bedsupport

2.Liftcylinder

3.Skidframe

g009164

6

ConnectingtheSpeed

SensorHarness

NoPartsRequired

ConnectingtheSpeedSensor

Harness(HD-SeriesModelswitha

ManualTransmission)

Figure14

1.Bedsupport

10.Pushthebedsupportontothecylinderrod,

makingsurethatthesupportendtabsreston

theendofcylinderbarrelandonthecylinderrod

end(Figure15).

1.Atthewiringharnessforthesprayer,locatethe

3-socketconnectorforthespeedsensorcircuit

andthe3-pinconnectorforthevehiclecircuit.

2.Atthetransaxleofthemachine,connectthe

g002397

20

3-pinconnectorofthewiringharnessofthe

machineforspeedsensorintothe3-socket

connectorofthesprayerharnessforthespeed

sensor(Figure16).

Page 21

2.Connectthe3-pinconnectorofthewiring

harnessofthemachineforspeedsensorinto

the3-socketconnectorofthesprayerharness

forthespeedsensor(Figure17).

7

CouplingtheSprayerPump

NoPartsRequired

Figure16

1.Existingspeedsensorplugs

3.Connectthe3-pinconnectorforthevehicle

circuitofthewiringharnessofthesprayerinto

the3-pinsocketforthevehiclecircuitofthe

wiringharnessforthemachine.

ConnectingtheSpeedSensor

Harness(HDX-AutoModel)

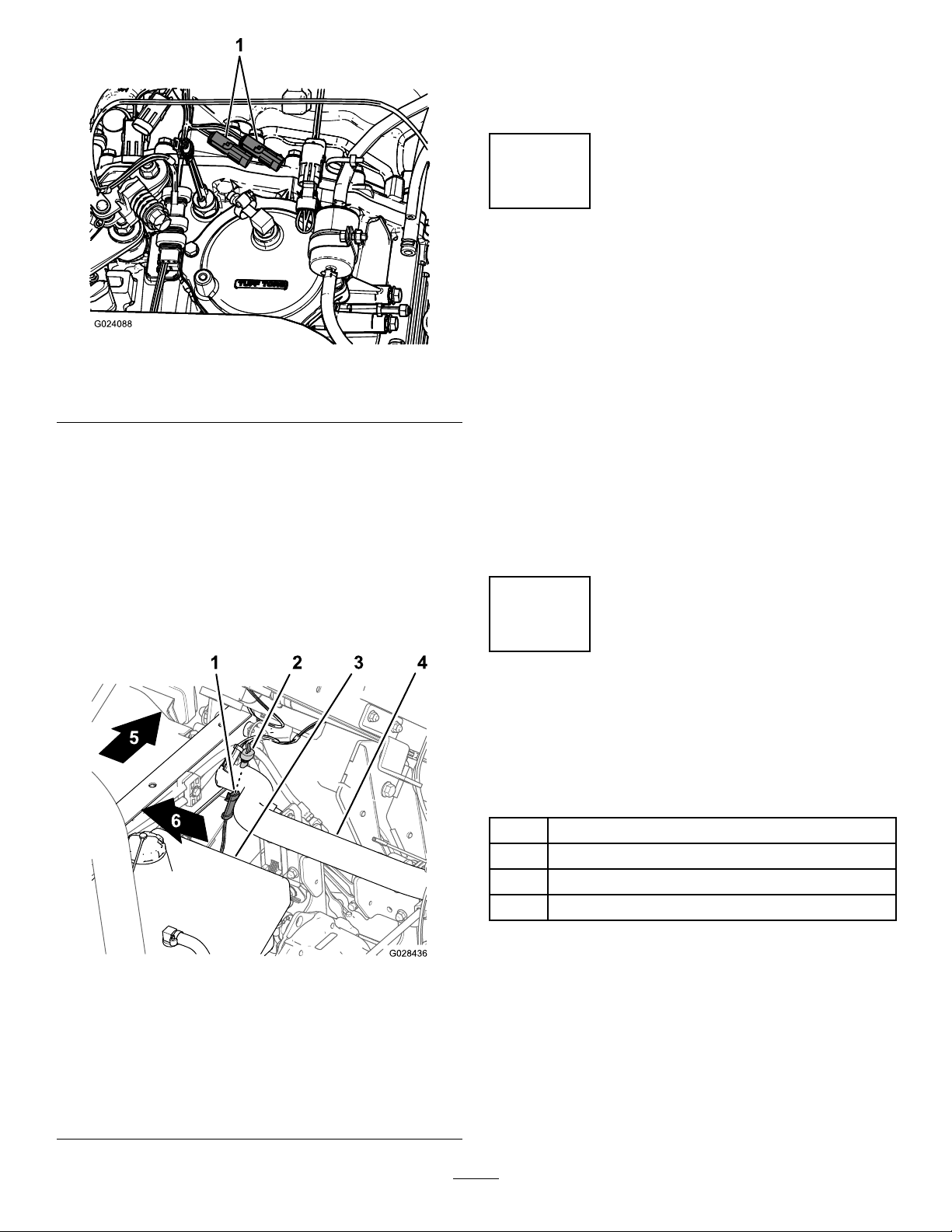

1.Atthewiringharnessforthesprayer,locatethe

3-socketconnectorforthespeedsensorcircuit

(Figure17).

g024088

Procedure

•ForHD-seriesmodelswithamanualtransmission,

couplethePTOshafttothetransaxlePTO;refer

totheInstallationInstructionsfortheMultiProWM

TurfSprayerFinishingKit,ManualWorkmanUtility

Vehicle.

•ForHDX-Automodel—connectthehydraulic

motorhosestothequick-disconnectttingsatthe

high-owhydraulicpanel;refertotheInstallation

InstructionsfortheMultiProWMTurfSprayer

FinishingKit,AutomaticWorkmanUtilityVehicle.

8

InstallingtheControl

ConsoleandElectrical

Harness

1.3-pinconnector(machine

wiringharness—speed

sensor)

2.3-socketconnector

(sprayerwiring

harness—speedsensor)

3.Hydrauliictank

Figure17

4.Rear-frametube

5.Backofthemachine

6.Rightsideofthemachine

Partsneededforthisprocedure:

1Knob

3J-clips

1

Bolt(1/4x3/4inch)

1

Flangenut(1/4inch)

g028436

InstallingtheControlConsoleto

theMachine

1.Removethehairpinsecuringthepivotpinofthe

controlconsoletothestoragebracketonthe

sprayertank.

2.Installthecontrolconsoleontothecontrol

mountingbracketandsecurethecontrolconsole

withthepreviouslyremovedhairpin(Figure18).

21

Page 22

HDX-AutoModel

g028443

Figure20

Figure18

1.Hairpin

2.Pivotpin(controlconsole)

3.Controlmountingbracket

4.Handknob

3.Installthehandknobandtightenittopreventthe

consolefromrotatingduringoperation(Figure

18).

InstallingtheControlConsole

ElectricalHarnesstotheMachine

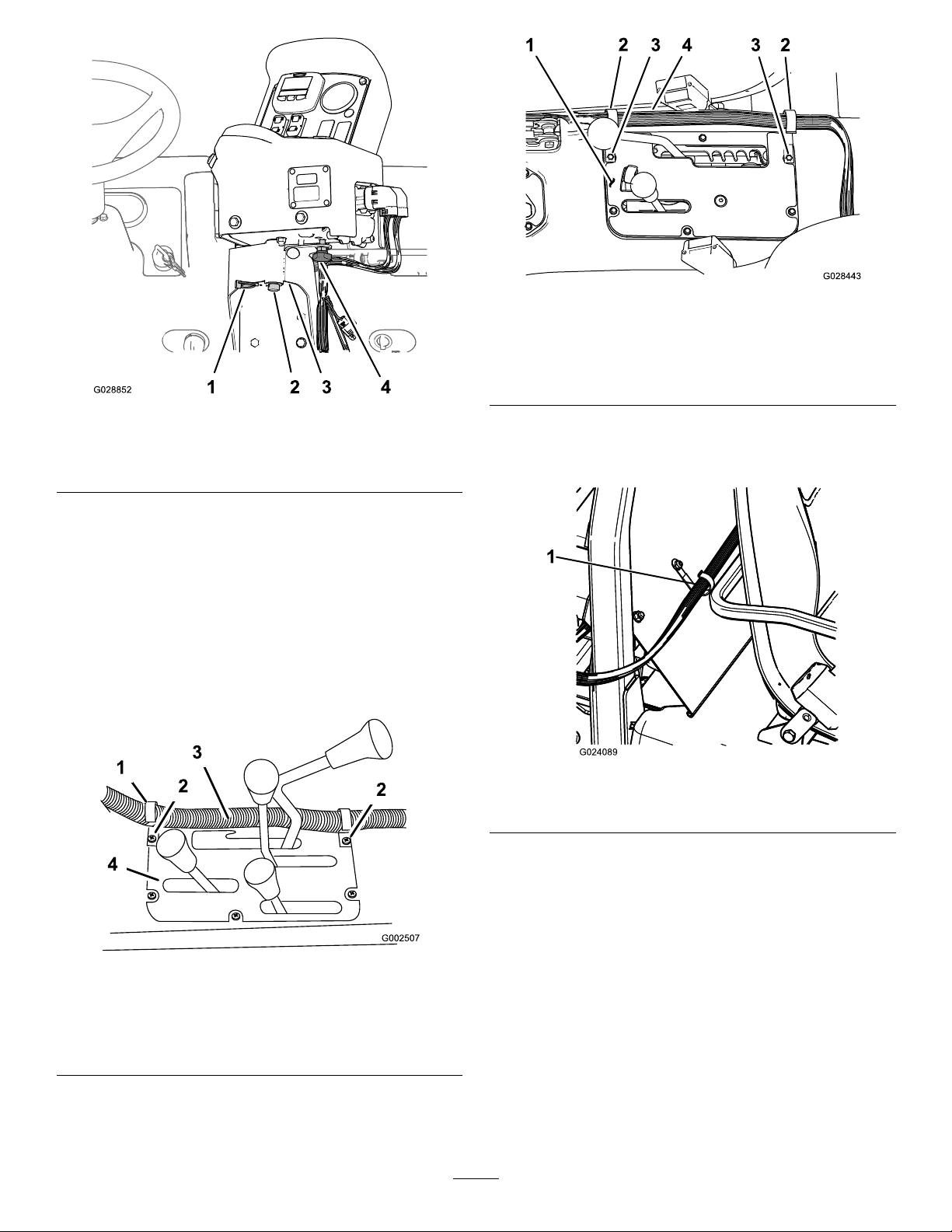

1.Install2J-clipsinthecenterconsoleatthe

pointslocatedinFigure19orFigure20using

theexistingscrews.

1.Centerconsole

2.J-clip

g028852

3.Existingscrews

4.Control-boxharness

2.InstallaJ-clipbehindthepassengerseatusing

abolt(1/4x1/2inch)andaangednut(1/4

inch)(Figure21).

g024089

Figure21

1.J-clip

HD-Seriesmodelswithanmanualtransmission

1.J-clip

2.Existingscrews

3.Securethecontrolconsoleharnesstothe

consoleandROPScoverusingtheJ-clips

(Figure21).

g002507

Figure19

3.Control-boxharness

4.Centerconsole

22

Page 23

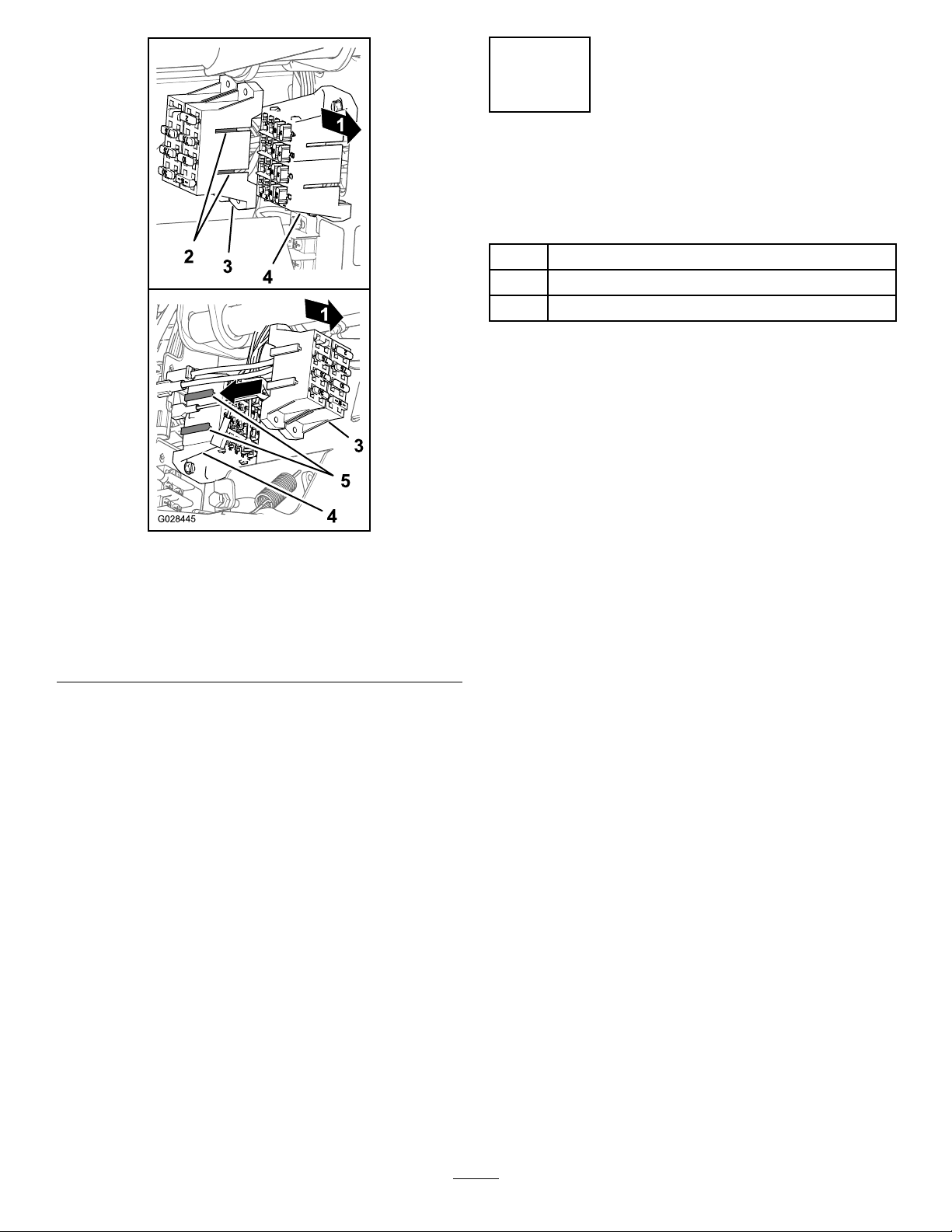

9

InstallingtheSprayerFuse

Block

Partsneededforthisprocedure:

1

Fusedecal(127–3966)

Procedure

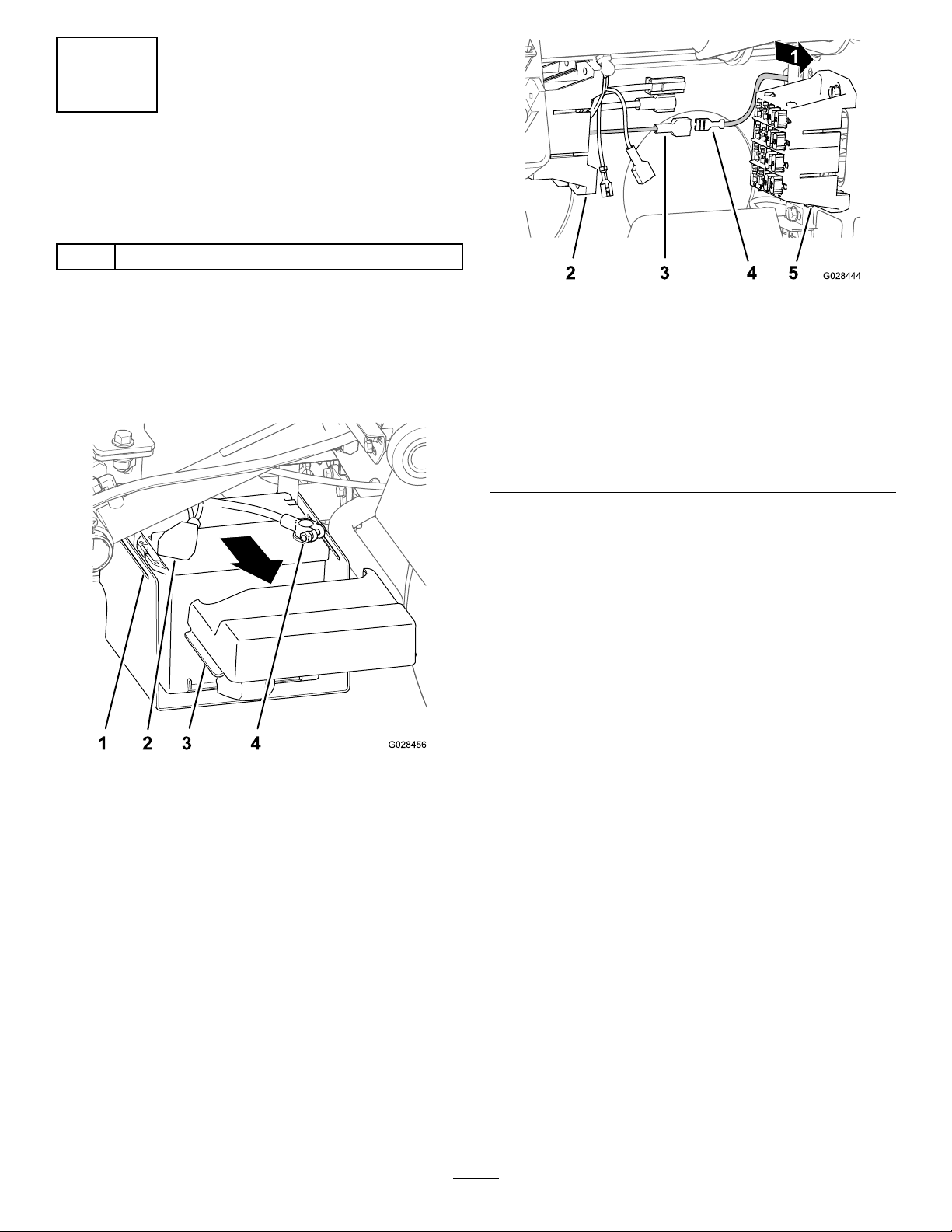

1.Squeezethesidesofthebatterycovertorelease

thetabsfromtheslotsinthebatterybase,and

removethebatterycoverfromthebatterybase

(Figure22).

Figure23

1.Backofthemachine

2.Fuseblock(sprayer

wiring)

3.Insulatedblade

terminal(yellow,

optional-power

wire—machinefuseblock)

5.Connecttheuninsulatedreceptacleterminalof

thefuseblockforthemachinetotheinsulated

bladeterminalofthefuseblockofthesprayer

(Figure23).

4.Uninsulatedreceptacle

terminal(yellowpower

wire—sprayerfuseblock)

5.Fuseblock(machine

wiring)

g028444

Figure22

1.Slot(batterybase)3.T ab(batterycover)

2.Cover(negativebattery

terminal)

2.Slidethecoverbackandremovethenegative

batteryterminalfromthebattery(Figure22).

3.Removethepositivebatteryterminalfromthe

battery(Figure22).

4.Locatetheuninsulatedreceptacleterminalatthe

endoftheopen,yellowpowerwireofthefuse

blockforthemachineandtheinsulatedblade

terminalattheendoftheyellow,optional-power

wireofthefuseblockofthesprayerwiring

(Figure23).

4.Terminal(positivebattery

cable)

6.AligntheT-ttingsontheofthefuseblockof

thesprayertotheT-slotsofthefuseblockfor

themachineandslidethesprayerfuseblock

intotheslotsuntilthefuseblockisfullyseated

(Figure24).

g028456

23

Page 24

Figure24

10

ConnectingtheSprayer

HarnesstotheBattery

Partsneededforthisprocedure:

1Batteryterminalbolt

2

Clampnut

1

Cover(batteryterminal—red)

Procedure

1.RemovetheexistingnutandT-boltandfromthe

positivebatteryterminal(AofFigure25).

Note:DiscardtheT-boltannut.

g028445

1.Backofthemachine4.T-slots(fuseblockforthe

2.T-ttings(fuseblockfor

thesprayer)

3.Fuseblockforthesprayer

7.Attachthefusedecalonasurfacenearbythe

fuseblockforthesprayer.

machine)

5.Fuseblockofthemachine

24

Page 25

Figure25

1.Terminal(positivebattery

cable)

2.Nut6.T erminalbolt

3.Positivebatterypost

4.T-bolt

2.Sliptheredbatteryterminalcoveroverthe

positivebatterycable(BofFigure25).

5.Cover(battery

terminal—red)

7.Clampnut

tightentheclampnutto1978to2542N-cm(175

to225in-lb).

7.Slidethecoverovertheforthepositivebattery

terminals.

8.Squeezethesidesofthebatterycoverand

inserttabsintotheslotsinthebatterybase.

11

LoweringtheTankSkid

Partsneededforthisprocedure:

2

Bolt(1/2x1-1/2inch

2

Locknut(1/2inch)

Procedure

1.Startthemachineandraisethetankskidslightly

withtheliftcylinders.

2.Removethecylinderlockfromtheliftcylinder

andstowthelockinthestoragebracketsatthe

backoftheROPSpanel(Figure14andFigure

15)

g028457

3.Useliftcylinderstoslowlylowerthetanktothe

frame.

Note:Haveanotherpersonobservethetank

skidasitlowers.Lookforhosesandwiringthat

mightbecomepinchedorbent.

4.Checkthealignmentofthetankskidtothe

frameofthemachine.

5.Removetheaccesspanelsatbothsidesofthe

skidframe.(Figure26).

3.Assemblethenewbatteryterminalboltand

1clampnutontotheterminalofthepositive

batterycable(CofFigure25).

4.Installtheterminalofthebatteryleadfromthe

sprayerwiringharnessontothebatteryterminal

boltandsecuretheterminalwith1clampnut

(DofFigure25).

Note:Alignthebatteryleadalongpositive

batterycable.Tightentheclampnutandboltto

1978to2542N-cm(175to225in-lb).

5.Connectthepositivebatteryterminaltothe

positivebatterypostandtightentheclampnut

to1978to2542N-cm(175to225in-lb).

6.Connectthenegativebatteryterminaltothe

negativebatterypost(EofFigure25)and

Figure26

1.Accesspaneldoor

2.Bolt(1/2x1-1/2inch

6.Checkthehosesorwiringthatyoucansee

throughtheopeningintheskidframeforsigns

ofpinchingorbending.

25

3.Locknut(1/2inch)

g022355

Page 26

Important:Ifanyhosesorwiringonthe

tankskidassemblyarepinchedorbent,

raisetheassemblyup,adjustitspositioning,

andtietheitemsback.

7.Alignthefrontmountingbracketswiththe

hold-downbracketsinstalledin4Installingthe

Hold-downBracketsfortheT ankSkid(page17).

8.Securetheholddownbracketofthetankskid

assemblytothebedbracketontheframeat

eachsideofthemachinewithabolt(1/2x1-1/2

inches)andalocknut(1/2inch)asshownin

Figure26.

9.Torquetheboltandlocknutto91to113N-m(67

to83ft-lb)

10.Repeatsteps7through9attheothersideofthe

tankskidandmachine.

g028458

Figure27

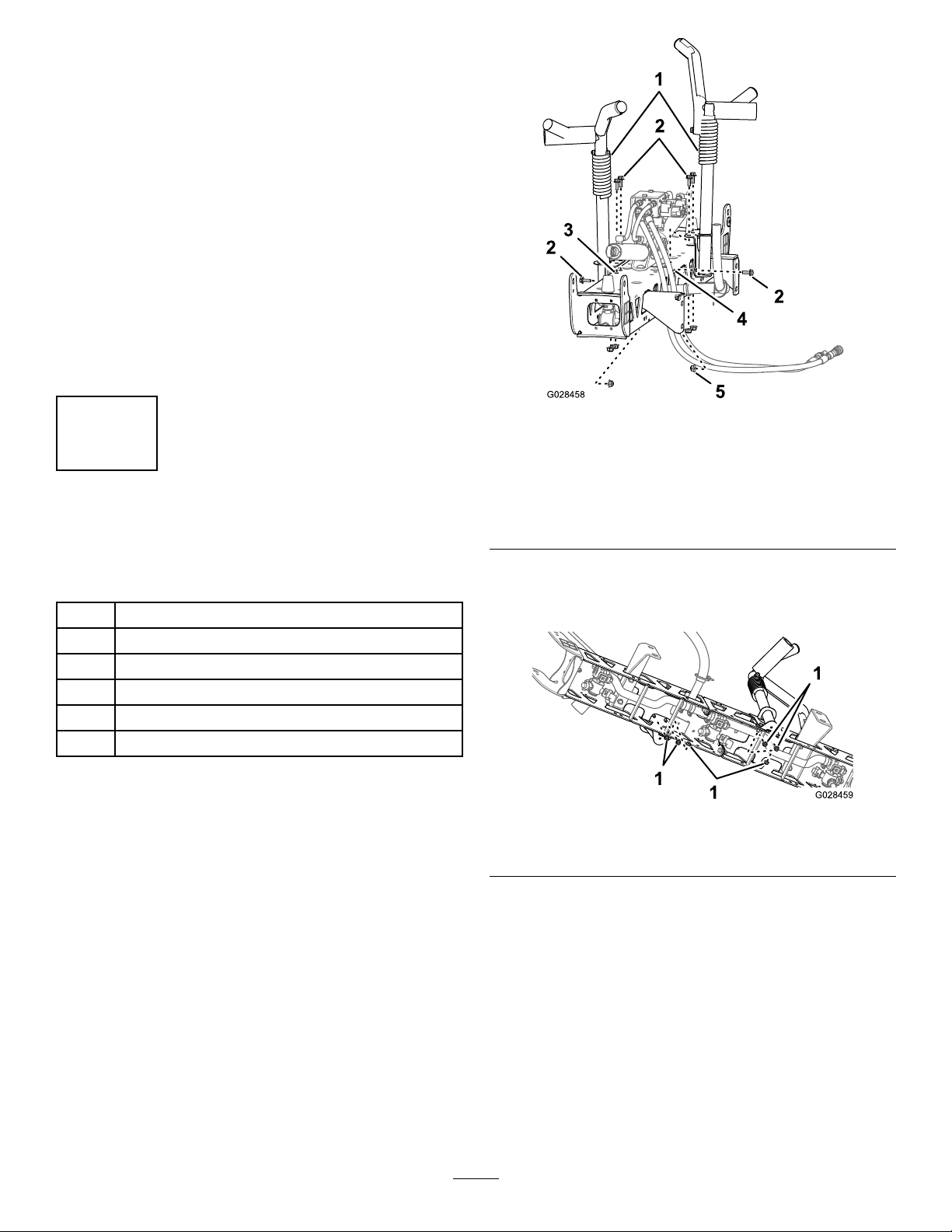

12

InstallingtheCenterBoom

Section

Partsneededforthisprocedure:

1

Center-boomassembly

10

Bolt(3/8x1inch)

10

Flangedlocknut(3/8inch)

2Boom-transportcradle

4

Bolt(1/2x1-1/4inches)

4

Flangenut(1/2inch)

AssemblingtheBoomTransport

Cradles

1.Attachliftingequipmenttothecenterboom

sectionandremoveitfromtheshipping

container.

2.Aligntheboomtransportcradlestothecenter

boomsection(Figure27).

1.Boom-transportcradle

2.Bolts(3/8x1inch)5.Flangedlocknut(3/8inch)

3.Verticalholes(boom

centersection)

3.Assemblethecradlestotheboomsection

(Figure27andFigure28)with6bolts(3/8x1

inch)and6angedlocknuts(3/8inch).

1.Locknuts(3/8inch)

4.Torquetheboltsandnutsto37to45N-m(27

to33ft-lb).

4.Horizontalhole(boom

centersection)

Figure28

g028459

InstallingtheCenterBoomSection

totheTankSkid

1.Startthemachine,removethebedsupportfrom

theliftcylinderandstowthesupport,lowerthe

tankskid,shutoffthemachine,andremovethe

keyfromtheSTARTERswitch.

2.Alignthebottomholeinthesectionmounting

bracketsofthecenterboomassemblywiththe

26

Page 27

thirdholefromthebottomintheboomsupports

onthesprayskidframe,asshowninFigure29.

Note:Ifnecessary,loosentheboomsupports

andadjustedthemtothecenterboomsection

forbetterholealignment.T orquetheboltsand

nutsto67to83N-m(91to113ft-lb).

Figure29

1.Locknut(1/2inch)4.Sectionmountingbracket

2.Hole3—fromthebottom

(boomsupport)

3.Sectionmountingbracket

(left)

3.Assemblethecenterboomassemblytothe

sprayskidframewith4bolts(1/2x1-1/4inches)

and4locknuts(1/2inch).

(right)

5.Bolt(1/2x1-1/4inches)

13

InstallingtheLeftandRight

BoomSection

Partsneededforthisprocedure:

1

Leftboomsection

1Rightboomsection

8

Flanged-headbolts(3/8x1-1/4inch)

8Backingplates

8

Flangedlocknuts(3/8inch)

2

Clevispin

2Hairpin

g028460

Procedure

Eachboomsectionweighsapproximately30lb.

1.Removethe4anged-headbolts(3/8x

1-1/4inch),4backingplates,and4anged

locknuts(3/8inch)fromthehingebracketofthe

center-boomsection.

2.Rotateeachpivotbracketattheendofthe

centerboomsectionsothatthebracketsalign

vertically(Figure30).

4.Torquetheboltsandnutsto67to83N-m(91

to113ft-lb).

ConnectingtheHosesandWiring

fortheBoomLiftValve

•ForHD-SeriesModelswithaManualTransmission,

refertotheinstallationinstructionsfortheMultiPro

WMTurfSprayerFinishingKit,ManualWorkman

UtilityVehicle.

•ForHDX-AutoModel,refertotheinstallation

instructionsfortheMultiProWMTurfSprayer

FinishingKit,AutomaticWorkmanUtilityVehicle.

Figure30

1.Center-boomsection

2.Boomextension6.Backingplates

3.Hingeplate

4.Flanged-headbolts(3/8x

1-1/4inch)

3.Lifttheouter-boomsectionandalignholesin

thetriangularmountingplateattheendofthe

outer-boomsectionwiththeholesinthepivot

bracket.

5.Triangularmountingplate

7.Flangedlocknuts(3/8

inch)

g028737

27

Page 28

Note:Ensurethattheturretsforthesprayer

nozzlesarefacingrearward.

4.Assemblehingeplatetothetriangularplate

using4anged-headbolts,4backingplates,

and4angedlocknuts,thatyouremovedinstep

1,asshowninFigure30.

5.Torquethenutsboltsandnutsto37to45N-m

(27to33ft-lb).

6.Aligntherodendoftheboomliftcylinderwith

theholesinthehornofthepivotbracket(Figure

30).

Figure31

1.Rodend(boomlift

cylinder))

2.Horn(pivotbracket)

3.Clevispin(5/8x4-3/4

inch)

4.Hairpin

7.Securetherodendtothepivotbracketwitha

clevispinandahairpin(Figure30).

8.Repeatstep1through5ontheothersideofthe

center-boomassemblywiththeopposingboom

section.

Note:Beforeyounishthisprocedure,ensure

thatallofturretsforthespraynozzlesarefacing

rearward.

g028738

28

Page 29

14

InstallingtheBoomHoses

Partsneededforthisprocedure:

3Hoseclamps

2R-clamp

2

Shoulderbolt

2Washer

2Nut

InstallingtheLeftandRightBoom

SectionHoses

1.Routetheboom-sectionhosesasshownin

Figure32andFigure33.

1.Nut

2.Washer

3.R-clamp6.Hoseclamp

4.Shoulderbolt7.Left-boomhose

5.T-tting8.Left-sectionvalve

g028468

Figure32

Hose—LeftBoomSegment

29

Page 30

Hose—RightBoomSegment

g028469

Figure33

1.Nut

2.Washer

3.R-clamp6.Hoseclamp

4.Shoulderbolt

5.T-tting

2.Securetheboomhosestothefrontsideofthe

centerboomsection(Figure32andFigure33)

with1R-clamp,1shoulderedbolt(5/16x1inch),

1locknut(5/16inch)and1washer(5/16inch).

3.Installtheboomsectionhoseoverthebarbed

T-ttingattheboomsectionandsecurethehose

withahoseclamp(Figure32andFigure33).

Note:Applyacoatofliquidsoaptothehose

barboftheteettingtoeaseinstallationofthe

hose.

4.Repeatsteps1through3onthehosetothe

boomsectionontheothersideofthesprayer.

7.Right-boomhose

8.Right-sectionvalve

InstallingtheCenterBoom-Section

Hose

1.Routethecenterboom-sectionhoseasshown

inFigure34.

Figure34

1.Up

2.T-tting5.Center-sectionvalve

3.Hoseclamp

4.Center-boomhose

6.Frontofthemachine

g028471

30

Page 31

2.Installtheboomsectionhoseoverthebarbed

T-ttingatthecenterboomsectionandsecure

thehosewithahoseclamp(Figure34).

Note:Applyacoatofliquidsoaptothehose

barboftheteettingtoeaseinstallationofthe

hose.

15

InstallingtheNozzles

NoPartsRequired

Procedure

Thenozzlesthatyouusetoapplyyourchemicals

varydependingontherateofapplicationthatyou

need;therefore,nozzlesarenotsuppliedwiththekit.

Toobtainthecorrectnozzlesforyourneeds,contact

yourAuthorizedT oroDistributorandbepreparedto

givethemthenfollowinginformation:

16

InstallingtheFresh-Water

Tank

Partsneededforthisprocedure:

1

Supporttube(freshwatertank)

1

Jamnut(3/8inch)

1

Bolt(3/8x1inch)

2

Shoulderbolt

2

Locknut(3/8inch)

1Fresh-watertank

1Fresh-watertankmount

2

Flangedlocknut(5/16inch)

2

Washer(5/16inch)

2

Flanged-headbolt(5/16x2-1/4inch)

4

Flanged-headbolt(5/16x5/8inch)

•Thetargetapplicationrateinlitersperhectare,US

gallonsperacre,orUSgallonsper1000sqft.

•Thetargetspeedofthevehicleinkilometersper

hourormilesperhour.

Toinstallanozzle,completethefollowing:

1.Threadorinsertthenozzleintothenozzle

receptaclefollowedbyagasket.

2.Slidethenozzlereceptacleoverthenozzle

ttingonaturret.

3.Turnthenozzleclockwisetolockthecamson

thereceptacleinplace.

4.Verifythefanportionofthenozzle.

SeetheInstallationInstructionsaccompanyingthe

nozzlesformoreinformation.

InstallingtheTankSupportTube

1.Alignthesupporttubeforthefreshwatertank

withthetanksupportchannel(Figure35).

Figure35

1.Supporttube(freshwater

tank)

2.Jamnut(3/8inch)6.Locknut(3/8inch)

3.Frontofthemachine7.Weldnut(tanksupport

4.Up

5.Bolt(3/8x1inch)

channel-freshwater

8.Shoulderbolt

g028872

2.Aligntheholesinthesupporttubewiththeholes

inthechannel(Figure35).

3.Securethetubetothechannel(Figure35)with

the2shoulderboltsand2locknuts(3/8inch).

31

Page 32

4.Threadthejamnut(3/8inch)intothebolt(3/8x

1inch);refertoFigure35.

5.Threadtheboltandjamnutintotheweldnut

atthebottomofthetanksupportchanneland

tightentheboltandjamnut(Figure35).

InstallingtheTank

Note:Thefresh-watertankcannotbeinstalledona

2postROPS.

1.Aligntheholesinthemountforthefresh-water

tankwiththeholesinthesupporttube(Figure

36).

g028474

Figure37

Figure36

1.Supporttube4.Washer(5/16inch)

2.Flangedlocknut(5/16

inch)

3.Mount(fresh-watertank)

5.Flanged-headbolt(5/16x

2-1/4inch)

2.Securethemounttothetube(Figure36)with2

anged-headbolts(5/16x2-1/4inch),2washers

(5/16inch),and2angedlocknuts(5/16inch).

3.Torquetheboltsandnutsto1978to2542N-cm

(175to225in-lb).

4.Applymedium-gradethread-lockingcompound

tothe4anged-headbolt(5/16x5/8inch).

1.Flanged-headbolt(5/16x

5/8inch)

2.Hole(fresh-watertank

mount)

3.Threadedinsert

(fresh-watertank)

6.Securethefresh-watertanktothemount(Figure

37)with4anged-headbolt(5/16x5/8inch).

7.Torquetheboltsandnutsto1978to2542N-cm

(175to225in-lb).

g028473

5.Alignthethreadedinsertsinthefreshwatertank

withtheholesinthefresh-watertankmount

(Figure37).

32

Page 33

17

18

InstallingtheAnti-siphon

FillReceptacle

Partsneededforthisprocedure:

1Fillreceptacleassembly

1

Flange-headbolt(5/16x3/4inch)

Procedure

Placethell-receptacleassemblyoverthethreaded

holeinthetankandsecureitwithaange-headbolt

(5/16x3/4inch)(Figure38).

CheckingtheBoomHinge

Springs

NoPartsRequired

Procedure

Important:Operatingthespraysystemwith

theboomhingespringsundertheincorrect

compressioncoulddamagetheboomassembly.

Measurethespringsandusethejamnutto

compressthespringsto4cm(1–1/2inches)if

necessary.

Thesprayerisshippedwiththeboomextensions

swungforwardtofacilitatepackagingofthemachine.

Thespringsarenotfullytightenedatthetimeof

manufacturetoallowtheboomstobeinthisposition

fortransit.Beforeoperatingthemachine,adjustthe

springstothecorrectcompression.

1.Ifnecessary,removethepackingcomponents

thatsecuretherightandleftextensionbooms

duringshipping.

Figure38

1.Fill-receptacleassembly2.Flangebolt

(5/16x3/4inch)

2.Supporttheboomswhiletheyareextendedto

g024091

thesprayposition.

3.Attheboomhinge,measurethecompressionof

theupperandlowerspringswhilethebooms

areintheirextendedposition(Figure39).

A.Compressallthespringsuntiltheymeasure

4cm(1–1/2inches).

B.Usethejamnuttocompressanyspringthat

measuresgreaterthan4cm(1–1/2inches).

33

Page 34

Figure39

1.Boomhingespring2.Jamnut

4.Repeattheprocedureforeachspringonboth

boomhinges.

5.Movetheboomsintothetransport“X”position.

Note:SeeUsingtheBoomTransportCradle

(page50)formoreinformation.

19

StoringtheJackStands

(Optional)

Partsneededforthisprocedure:

g023740

g002332

1.Frontjackstand2.Knob

2.Securethefrontjackstandswith2clevispins(3

inch)and2cotterpinsthroughthemiddlehole

onthestands.

3.Inserttherearjackstandsfromthebottom,up

intotheframe,nearthereartie-downpoints

(Figure41).

Figure40

2Frontjackstand

2Rearjackstand

4

Cotterpin

2

Clevispin(4-1/2inch)

2

Clevispin(3inch)

2Knob

Procedure

1.Insertthefrontjackstandsupsidedownintothe

framenearthefronttie-downpoints(Figure40).

g023739

Figure41

1.Rearjackstand

4.Securetherearjackstandswith4clevispins

(4-1/2inch)and4cotterpinsthroughthelast

holeonthestands.

34

Page 35

20

LearningMoreaboutYour

Product

Partsneededforthisprocedure:

1

Operator'sManual

1

Operatortrainingmaterial

1

PartsCatalog

1Registrationcard

1

Selectionguide

1Pre-deliveryinspectionsheet

Procedure

1.Readthemanuals.

2.Viewtheoperatortrainingmaterial.

3.Usethenozzleselectionguidetochoosethe

correctnozzlesforyourspecicapplication.

4.Storethedocumentationinasafeplace.

35

Page 36

ProductOverview

Figure42

1.Master-boomswitch

2.Boom-sectionswitches(sprayerOn/Off)7.Sonic-boomswitch(optional)

3.Boomliftswitches

4.InfoCenter

5.Pressuregauge

Controls

6.Rinseswitch(optional)

8.Application-rateswitch

9.Agitationswitch

andmore(Figure42).Formoreinformation,referto

UsingtheInfoCenter(page39).

InfoCenterLCDDisplay

TheInfoCenterLCDdisplayshowsinformationabout

yourmachineandbatterypacksuchasthecurrent

batterycharge,thespeed,diagnosticsinformation,

36

g028854

Page 37

Master-BoomSwitch

TheMASTER-BOOMswitchallowsyoutostartorstop

theallsprayoperation.Presstheswitchtorunorstop

thespraysystem(Figure42).

Boom-SectionSwitches

TheBOOM-SECTIONswitchesarelocatedalongthe

bottomofthecontrolpanel(Figure42).T oggle

eachswitchupwardtoturnthesprayersforthe

correspondingboomsectiononanddownwardtoturn

thesprayersoff.WhentheswitchissettotheOn

position,thelightontheswitchilluminates.These

switcheswillonlyaffectthespraysystemwhenthe

MASTER-BOOMswitchisintheOnposition.

Application-RateSwitch

g028486

Figure43

TheAPPLICA TION-RATEswitchislocatedontheleft

sideofthecontrolpanel(Figure42).Pressand

holdtheswitchupwardtoincreasethespraysystem

applicationrate,orpressandholditdownwardto

decreaseapplicationrate.

Boom-LiftSwitches

TheelectricBOOM-LIFTswitchesraiseandlowertheir

respectivebooms(Figure42).Thereisaleftandright

liftswitch.Pressandholdtheswitchupwardtoraise

therespectiveboom,orpressandholdtheswitch

downwardtolowertherespectiveboom.

Sprayer-ModeSwitch(HDX-Auto

Model)

UsetheSPRA YER-MODEswitchtoselectbetween

controllingthesprayerapplicationratemanuallyor

throughautomaticcomputerassistthatcontrolled

throughtheInfoCenter.

1.InfoCenterconsole

2.Sprayer-modeswitch

3.Automaticmode

(sprayer-modeswitch

position)

4.Manualmode

(sprayer-modeswitch

position)

Regulating(RateControl)Valve

Theregulatingvalvelocatedbehindthetank(Figure

44),Theregulatingvalvecontrolstheamountofuid

thatisroutedtotheboomsortheratereturntothe

tank.

Figure44

1.Regulating(ratecontrol)

valve

2.Agitationvalve5.Boomsectionvalve

3.Master-boomvalve

37

4.Flowmeter

g028483

Page 38

Flowmeter

Theowmetermeasurestheowrateoftheuidto

theboomsectionvalves(Figure44).

Boom-SectionValves

Usetheboom-sectionvalvestoturnthesprayer

pressureonorofftothesprayernozzlesintheleft,

center,andrightboomsections(Figure44).

BoomSection-BypassValves

Theboomsection-bypassvalves(Figure45)redirect

theuidowfromaboomtothetankwhenyouturn

offtheboomsection.Y oucanadjustthesevalvesto

ensurethattheboompressureremainsconstantno

matterwhichcombinationofboomsyouareoperating;

refertoCalibratingtheBoomBypass(page55).

g028484

Figure46

Figure45

1.Leftboomsection-bypass

valve

2.Centerboom

section-bypassvalve

3.Rightboom

section-bypassvalve

Agitation-ThrottleValve

Thisvalveislocatedontherearleftsideofthetank

(Figure46).Turntheknobonthevalvetothe6

o'clockpositiontoturnonthetankagitationandtothe

8o'clockpositiontoturnoffthetankagitation.

1.Agitation-controlvalve

Note:HD-seriesmodelswithamanual

transmission—foragitationtoworkthePTOand

clutchmustbeengagedandtheenginemustbe

runningaboveanidle.Ifyoustopthesprayerand

needagitationcirculatingthecontentofthetank,

placetherangeshiftleverintheNeutralposition,let

outtheclutch,settheparkingbrake,andsetthehand

throttle(ifequipped).

g028485

SprayerPump

Thesprayerpumpislocatedattherearofthemachine

(Figure47).

g028857

Figure47

1.Sprayerpump

38

Page 39

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Spraysystembaseweight

(vehicleweightnotincluded)

Tankcapacity

Overallvehiclelengthwiththe

standardspraysystem

Overallvehicleheightwith

standardspraysystemtothe

topofthetank

Overallvehicleheightwith

standardspraysystemand

theboomsstoredintheX

pattern

Overallvehiclewidthwiththe

standardspraysystemand

theboomsstoredintheX

pattern

757L(200USgallons)

OptionalEquipment

TheT oro®Companyhasoptionalequipmentand

accessoriesthatyoucanpurchaseseparatelyand

installonyourWorkman.ContactyourAuthorized

ServiceDealerforacompletelistofoptional

equipmentthatiscurrentlyavailableforyoursprayer.

424kg(935lb)

422cm(166inches)

147cm(58inches)

234cm(92inches)

175cm(69inches)

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Note:Ifyouneedtotransportthevehicleonatrailer

withthesprayerinstalled,makesuretheboomsare

tieddownandsecure.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsand

decalsinthesafetysection.Knowingthisinformation

couldhelpyouorbystandersavoidinjury.

UsingtheInfoCenter

TheInfoCenterLCDdisplayshowsinformationabout

yourmachine,suchastheoperatingstatus,various

diagnostics,andotherinformationaboutthemachine

(Figure48).Thereisasplashscreenandmain

informationscreenontheInfoCenter.Y oucanswitch

betweenthesplashscreenandmaininformation

screen,atanytime,bypressinganyoftheInfoCenter

buttonsandthenselectingtheappropriatedirectional

arrow.

Figure48

1.Indicatorlight3.Middlebutton

2.Rightbutton

4.Leftbutton

•Leftbutton,Menuaccess/Backbutton—press

thisbuttontoaccesstheInfoCentermenus.You

canalsouseittobackoutofanymenuyouare

currentlyusing.

•Middlebutton—usethisbuttontoscrolldown

menus.

•Rightbutton—usethisbuttontoopenamenu

wherearightarrowindicatedadditionalcontent.

Note:Thepurposeofeachbuttonmaychange

dependingonwhatfunctionisactiveatthetime.The

39

g020650

Page 40

LCDdisplayshowsaniconaboveeachbuttonthat

indicatesitscurrentfunction.

StartingtheInfoCenter

1.InsertthekeyintotheST ARTERswitchandrotate

ittotheOnposition.

Note:TheInfoCenterwillilluminateanddisplay

theinitializationscreen(Figure49).

g029189

Figure51

Figure49

2.Afterapproximately15seconds,thehome

screenwillappear,pressthecenterselection

buttontodisplaytheinformationcontext(Figure

50).

Figure50

•Pressthecenterselectionbuttonagainto

navigatetotheMainMenu.

•Rightselectionbutton:Totalareasprayed

(AofFigure51)

•Rightselectionbutton:Applicationrate(B

ofFigure51)

•Leftselectionbutton:Sub-areasprayed(C

ofFigure51)

•Leftselectionbutton:Tankvolume(Dof

Figure51)

g028527

Note:RotatingtheST ARTERswitchtothestart

positionandstartingtheenginewillcausethevalues

indicatedintheInfoCenterdisplaytoreectthe

runningmachine.

AccessingtheSettingsMenu

1.StarttheInfoCenter;refertoStartingthe

InfoCenter(page40).

Note:TheHomescreenwilldisplay.

2.Pressthecenterselectionbuttontoaccessthe

Informationcontext.

Note:Theinformationcontexticonwilldisplay

3.Pressthecenterselectionbuttontoaccessthe

MainMenu(Figure52).

g028528

40

Page 41

Figure52

AdditionaloptionsfortheHDX-Automodelisnotshown.

1.Rightselectionbutton(selectcontext)

4.Presstherightselectionbuttontodisplaytothe

Settingssub-menus.

Note:TheMainMenuwilldisplaywiththe

Settingsoptionselected

Note:Pressingthecenterselectionbutton(the

buttonbelowthedownarrowiconinthedisplay)

willmovetheselectedoptiondown.

g028416

Figure53

1.Listoptions(icon)3.Rightselectionbutton(list

context)

2.Scrolldown(icon)4.Centerselectionbutton

(scrollcontext)

g028519

Note:Pressingtheleftselectionbuttonwill

saveyourselection,exittheSettingsmenu,and

returntotheMainMenu.

3.Tochangethelanguageusedinthedisplay,

pressingthecenterselectionbutton(thebutton

belowthedownarrowinthedisplay)tomove

theselectedoptiontoLanguage(Figure53).

ChangingtheUnitsofMeasure

(EnglishandMetric)

1.AccesstheSettingsmenu;refertoAccessing

theSettingsMenu(page40).

2.Tochangetheunitofmeasure,presstheright

selectionbuttontochangethelistedunitsof

measure(Figure53).

•English:mph,gallons,andacre

•Turf:mph,gallons,and1000ft

•SI(metric):kph,liter,hectare

Note:ThedisplaywillswitchbetweenEnglish

andmetricunits

4.Presstherightselectionbutton(thebuttonbelow

thelisticoninthedisplay)willtohighlightthe

listedlanguageusedinthedisplay(Figure53).

Note:Availablelanguagesinclude:English,

Spanish,French,German,Portuguese,Danish,

Netherlands,Finnish,Italian,Norwegian,and

Swedish.

5.Presstheleftselectionbuttontosaveyour

selection(s),exittheSettingsmenu,andreturn

2

totheMainMenu(Figure52).

6.Presstheleftselectionbuttontoreturntothe

Homescreen(Figure53).

AdjustingtheBacklightingand

ContractLevelsoftheDisplay

1.AccesstheSettingsmenu;refertoAccessing

theSettingsMenu(page40).

2.Toadjustthebacklightlevelofthedisplay,press

thecenterselectionbutton(thebuttonbelow

thedownarrowiconinthedisplay)tomovethe

selectedoptiondowntotheBacklightsetting

(Figure54).

41

Page 42

selection,exittheBacklightmenu,andreturnto

theSettingsmenu(Figure54).

6.Toadjustthecontrastlevelofthedisplay,press

thecenterselectionbutton(thebuttonbelow

thedownarrowiconinthedisplay)tomovethe

selectedoptiondowntotheContrastsetting

(Figure54).

7.Presstherightselectionbuttontodisplaythe

valueadjustmentcontext(Figure54).

Note:Thedisplaywillshowa(―)iconoverthe

centerselectionbuttonanda(+)iconoverthe

rightselectionbutton.

8.Presstheleftselectionbutton(thebutton

belowthelisticoninthedisplay)tosaveyour

selection,exittheContrastmenu,andreturnto

theSettingsmenu(Figure54).

9.PresstheleftselectionbuttontoexittheSettings

menuandreturntotheMainMenu(Figure52

andFigure54).

10.Presstheleftselectionbuttontoreturntothe

Homescreen(Figure54).

Figure54

1.Selectarrow(icon)5.Increasethevalue(icon)

2.Scrolldown(icon)6.Decreasethevalue(icon)

3.Rightselectionbutton

(selectcontext)

4.Centerselectionbutton

(scrollcontext)

7.Rightselectionbutton

(raisevaluecontext)

8.Centerselectionbutton

(lowervaluecontext)

3.Presstherightselectionbuttontodisplaythe

valueadjustmentcontext(Figure54).

Note:Thedisplaywillshowa(―)iconoverthe

centerselectionbuttonanda(+)iconoverthe

rightselectionbutton.

InfoCenterIcons

IconDescriptions

Informationicon

Next

g028415

Previous

Scrolldown

Enter

Changethenextvalueinthe

list

Increase

Decrease

Activescreen

4.Usethecenterselectionbuttonandright

selectionbuttontochangethebrightnesslevel

ofthedisplay(Figure54).

Note:Asyouchangethebrightnessvalue,the

displaywillchangetheselectedbrightnesslevel.

5.Presstheleftselectionbutton(thebutton

belowthelisticoninthedisplay)tosaveyour

Inactivescreen

Gotothehomescreen

Activehomescreen

42

Page 43

IconDescriptions(cont'd.)

IconDescriptions(cont'd.)

Savevalue

Exitmenu

Hourmeter

CorrectPINcodeentered

CheckPINentry/Calibration

verication

MasterboomOn/Boom

sprayerOff

MasterboomOn/Boom

sprayerOn

Fullspraytank

Spraytankathalf

Tanklevellow

Emptyspraytank

Selectthenextareafor

accumulation

Applicationrate1

Applicationrate2

Boostrate

UsingtheMenus

AccessthecalibrationsettingsintheInfoCentermenu

systembypressingthemenuaccessbuttonwhileat

themainscreen.Thiswillbringyoutothemainmenu.

Refertothefollowingtablesforasummaryofthe

optionsavailablefromthemenus:

Calibration

MenuItemDescription

TestSpeedThismenusetsthetestspeedforcalibration.

Flow

Calibration

Speed

Calibration

Thismenucalibratestheowmeter.

Thismenucalibratesthespeedsensor.

TURFunits(1,000square

or

feet)

Areasprayed

SelectingtheSprayer

Programming

HDX-AutoModel

SwitchingbetweenManualModeand

AutomaticMode

Volumesprayed

Adjusttankvolume

Homescreen

Clearactivearea

g028518

Clearallareas

1.Automaticmode(switch

position)

Adjustdigit

Figure55

2.Manualmode(switch

position)

•Atthecontrolconsole,presstheSPRAYER-MODE

switchtothelefttocontroltheapplicationrate

43

Page 44

ofthesprayerthroughtheInfoCenterinthe

Automaticmode.

Note:Aniconfortheapplicationratewillappear

inthedisplayoftheInfoCenter.

•PresstheSPRAYER-MODEswitchtotherightto

controltheapplicationrateofthesprayerbyhand

intheManualmode.

Note:WhenswitchingfromtheAutomaticmode

totheManualmode,theiconfortheapplication

ratewilldisappearinthedisplay.

Note:Anicon

willappear.

Note:Theapplicationrateboostisanadditional

percentabovetheactiveprogram(1or2)

applicationrate.Pressandholdthebuttonsto

applytheboostapplicationrate;releasethe

buttonstostoptheboostrate.

ProgrammingtheApplicationRate

andApplicationRateBoost

HDX-AutoModel

SwitchingbetweenSprayerProgramming

Settings

ProgrammingtheApplicationRate1and2

1.FromtheHomescreen,pressthecenter

selectionbuttontonavigatetotheMainMenu.

2.Ifneeded,pressthecenterselectionbuttonto

highlighttheapplicationrateforsprayerprogram

1(Figure57).

Note:Theiconforsprayerapplicationrate1

lookslikethenumeral1inacircletotherightof

abull's-eyetarget.

Figure56

1.Leftandcenter

buttons—selecting

applicationrate1