Page 1

FormNo.3360-879RevA

G005648

Multi-Pro5700-DTurfSprayer

ModelNo.41582—SerialNo.280000274andUp

Registeratwww.T oro.com.OriginalInstructions(EN)

Page 2

Warning

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Theenclosed

Engine Owner’ s Man ual

issupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

Introduction

Readthismanualcarefullytolearnhowtooperateand

maintainyourproductproperly.Theinformationinthis

manualcanhelpyouandothersavoidinjuryandproduct

damage.AlthoughTorodesignsandproducessafe

products,youareresponsibleforoperatingtheproduct

properlyandsafely.YoumaycontactTorodirectlyat

www.Toro.comforproductandaccessoryinformation,

helpndingadealer,ortoregisteryourproduct.

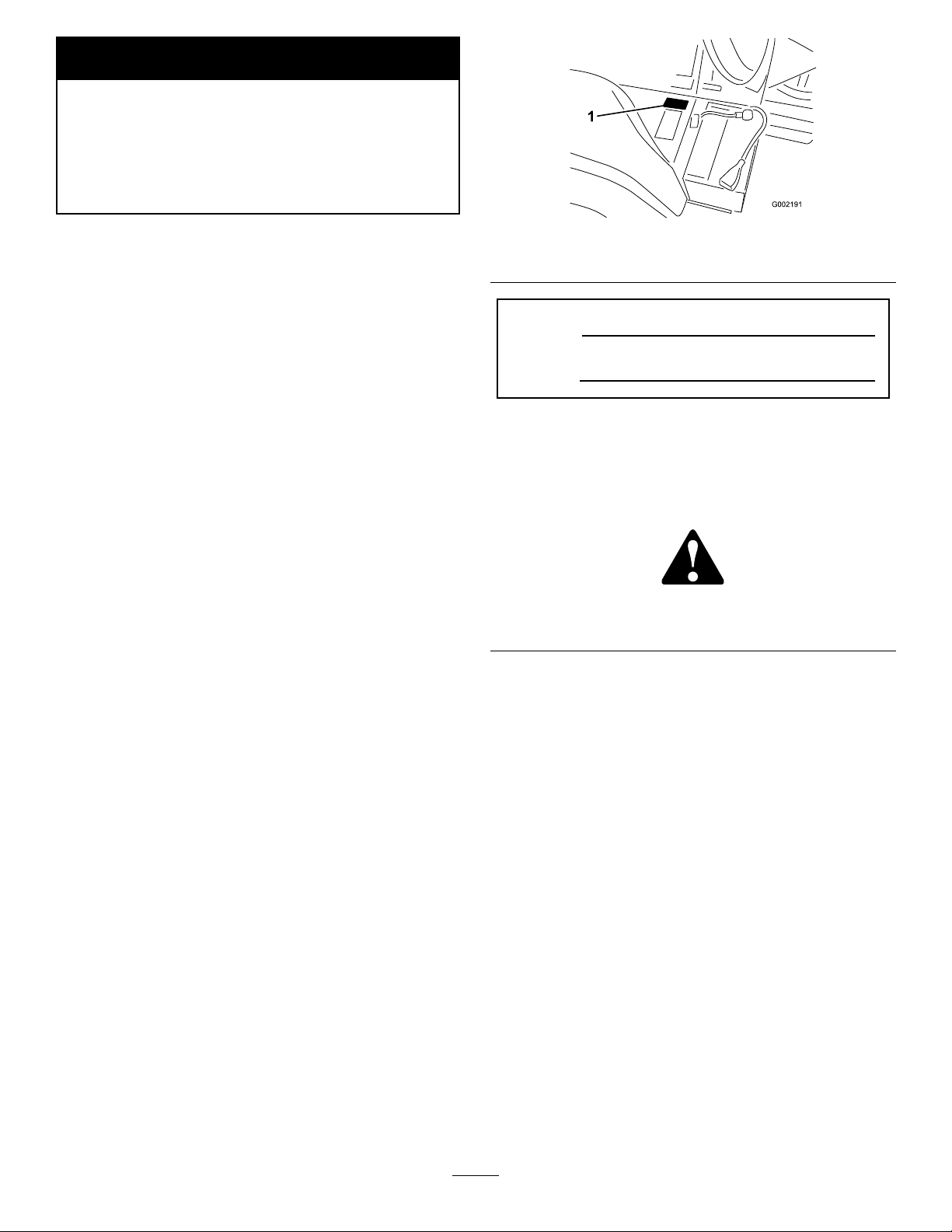

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Figure1

illustratesthelocationofthemodelandserialnumbers

ontheproduct.

©2008—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ChemicalSafety....................................................4

BeforeOperating.................................................5

WhileOperating...................................................5

Maintenance.........................................................7

SafetyandInstructionalDecals.............................8

Setup..........................................................................12

1CheckingtheBoomHingeSprings...................12

2Learningmoreaboutyourproduct...................13

ProductOverview......................................................14

Controls.............................................................15

Specications.....................................................19

Operation...................................................................19

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

ThinkSafetyFirst...............................................19

BeforeDrivingtheSprayerfortheFirst

Time..............................................................19

Pre-StartingChecks............................................22

DrivingtheSprayer.............................................22

NewSprayerBreak-In........................................23

OperatingtheSprayer.........................................23

FillingtheFreshWaterTank...............................24

FillingtheSprayTank.........................................24

OperatingtheBooms.........................................25

Spraying.............................................................25

TurfCarePrecautionsWhileOperatingin

StationaryModes............................................25

SprayingTips.....................................................26

UncloggingaNozzle..........................................26

SelectingaNozzle..............................................26

CleaningtheSprayer...........................................26

CalibratingtheBoomBypassValves....................27

Pump.................................................................28

TransportingtheSprayer....................................28

TowingtheSprayer.............................................28

Maintenance...............................................................30

RecommendedMaintenanceSchedule(s)................30

DailyMaintenanceChecklist...............................31

NotationforAreasofConcern...........................32

PremaintenanceProcedures....................................32

JackingtheSprayer.............................................32

Lubrication.............................................................33

GreasingtheSprayer...........................................33

GreasingtheBoomHinges.................................34

GreasingtheActuatorRodBearings...................34

EngineMaintenance...............................................36

ServicingtheAirCleaner....................................36

ServicingtheEngineOil.....................................36

FuelSystemMaintenance.......................................38

CheckingtheFuelLineandConnections.............38

BleedingtheFuelSystem....................................38

BleedingAirfromtheInjectors...........................39

DrainingtheFuelTank.......................................39

ServicingtheFuelFilters....................................40

ElectricalSystemMaintenance................................41

ReplacingtheFuses............................................41

ServicingtheBattery...........................................41

DriveSystemMaintenance.....................................43

ChecktheTirePressure......................................43

InspectingtheWheels/Tires...............................43

ChangingthePlanetaryGearboxFluid................43

AdjustingtheFrontWheelToe-In.......................44

CoolingSystemMaintenance..................................45

CheckingtheCoolantLevel................................45

ServicingtheCoolingSystem..............................45

BrakeMaintenance.................................................47

CheckingtheBrakes...........................................47

AdjustingtheBrakes...........................................47

BeltMaintenance....................................................48

ServicingtheDriveBelts.....................................48

HydraulicSystemMaintenance...............................48

CheckingtheHydraulicFluid..............................48

ServicingtheHydraulicOil.................................49

SpraySystemMaintenance......................................51

InspectingtheHoses..........................................51

PumpMaintenance.............................................51

AdjustingtheBoomActuator.............................51

EmergencyManualOperationoftheBoom

Actuators.......................................................52

InspectingtheNylonPivotBushings...................52

Cleaning.................................................................53

CleaningtheSuctionStrainer..............................53

Storage.......................................................................54

Troubleshooting.........................................................55

Schematics.................................................................58

3

Page 4

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol,whichmeans

CAUTION,WARNING,orDANGER-“personalsafety

instruction."Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Supervisors,operators,andservicepersonsshouldbe

familiarwiththefollowingstandardsandpublications:

(Thematerialmaybeobtainedfromtheaddressshown).

•FlammableandCombustibleLiquidsCode:

ANSI/NFPA30

•NationalFireProtectionAssociation:

ANSI/NFPA#505;PoweredIndustrialTrucks

NationalFirePreventionAssociation

BarrymarchParkQuincy,Massachusetts

02269U .S.A.

•SAEJ2258LightUtilityV ehicle

SAEInternational400Commonwealth

Drive,Warrendale,PA15096-0001,U.S.A.

•ANSI/UL558;InternalCombustion

EnginePoweredIndustrialTrucks

AmericanNationalStandardsInstitute,Inc.

1430BroadwayNewYork,NewYork10018U.S.A.

orUnderwritersLaboratories333PngstenRoad

Northbrook,Illinois60062U .S.A.

ChemicalSafety

Chemical substances used in the spray system

may be hazardous and to xic to y ou, bystander s,

animals, plants, soils or other pr oper ty .

•Carefullyreadandfollowthechemical

warninglabelsandMaterialSafetyData

Sheets(MSDS)forallchemicalsused

andprotectyourselfaccordingtothe

chemicalmanufacturer’srecommendations.

Forexample,useappropriatePersonal

ProtectiveEquipment(PPE)including

faceandeyeprotection,gloves,orother

equipmenttoguardagainstpersonalcontact

withthechemical.

•Keepinmindthattheremaybemorethan

onechemicalusedandinformationoneach

shouldbeassessed.

R efuse to operate or w or k on the spray er if

•

this inf or mation is not a v aila ble!

•Beforeworkingonaspraysystem

makesurethesystemhasbeentriple

rinsedandneutralizedaccordingto

therecommendationsofthechemical

manufacturer(s).

•Verifythereisanadequatesupplyofclean

waterandsoapnearby,andimmediately

washoffanychemicalsthatcontactyou.

SafeOperatingPractices

Thesprayerisanoff-highwayvehicleonlyand

isnotdesigned,equipped,ormanufacturedfor

useonpublicstreets,roads,orhighways.

Supervisor’sResponsibilities

•Makesurethatoperatorsarethoroughlytrainedand

familiarwiththeOperator’sManual,EngineManual,

andalllabelsonthesprayer.

•Establishyourownspecialproceduresandwork

rulesforunusualoperatingconditions(e.g.slopes

toosteepforsprayeroperation).

•Obtainpropertrainingbeforeusingorhandling

chemicals.

•Usethecorrectchemicalforthejob.

•Followthechemicalmanufacturer’ sinstructionsfor

thesafeapplicationofthechemical.

•Handlechemicalsinawellventilatedarea.

•Weargogglesandotherprotectiveequipmentas

instructedbythechemicalmanufacturer.Ensure

thataslittleskinaspossibleisexposedwhileusing

chemicals.

•Havecleanwateravailableespeciallywhenllingthe

spraytank.

•Donoteat,drink,orsmokewhileworkingwith

chemicals.

•Alwayswashyourhandsandotherexposedareasas

soonaspossibleafternishingthework.

4

Page 5

•Properlydisposeofunusedchemicalsand

chemicalcontainersasinstructedbythechemical

manufacturerandyourlocalcodes.

•Chemicalsandfumesinthetanksaredangerous;

neverenterthetankorplaceyourheadoverorin

theopening.

BeforeOperating

•Operatethemachineonlyafterreadingand

understandingthecontentsofthismanual.

•Neverallowchildrentooperatethesprayer.

•Neverallowotheradultstooperatethesprayer

withoutrstreadingandunderstandingtheOperator’ s

Manual.Onlytrainedandauthorizedpersonsshould

operatethissprayer.Makesurethatalloperators

arephysicallyandmentallycapableofoperatingthe

sprayer.

•Thissprayerisdesignedtocarryonlyyou,the

operatorandonepassengerintheseatprovided

bythemanufacturer.Nevercarryanypassengers

onthesprayer.

•Neveroperatethesprayerwhenundertheinuence

ofdrugsoralcohol.Evenprescriptiondrugsand

coldmedicinescancausedrowsiness.

•Donotdrivethesprayerwhenyouaretired.Besure

totakeoccasionalbreaks.Itisveryimportantthat

youstayalertatalltimes.

•Becomefamiliarwiththecontrolsandknowhowto

stoptheenginequickly.

•Keepallshields,safetydevices,anddecalsinplace.

Ifashield,safetydevice,ordecalismalfunctioning,

illegible,ordamaged,repairorreplaceitbefore

operatingthemachine.

•Alwayswearsubstantialshoes.Donotoperate

themachinewhilewearingsandals,tennisshoes,

orsneakers.Donotwearloosettingclothingor

jewelrywhichcouldgetcaughtinmovingpartsand

causepersonalinjury.

•Wearingsafetyglasses,safetyshoes,longpants,anda

helmetisadvisableandrequiredbysomelocalsafety

andinsuranceregulations.

•Avoiddrivingwhenitisdark,especiallyinunfamiliar

areas.Ifyoumustdrivewhenitisdark,besure

todrivecautiously,usetheheadlights,andeven

consideraddingadditionallights.

•Beextremelycarefulwhenoperatingaroundpeople.

Alwaysbeawareofwherebystandersmightbeand

keepthemawayfromtheworkarea.

•Beforeoperatingthesprayer,alwayscheckthe

designatedareasofthesprayerthatarestatedin

thePre-StartingChecksintheOperationsection.

Ifthemachinedoesnotfunctioncorrectlyoris

damagedinanyway,donotusethesprayer.Make

surethattheproblemiscorrectedbeforethesprayer

orattachmentisoperated.

•Ensurethatalluidlineconnectorsaretightandall

hosesareingoodconditionbeforeapplyingpressure

tothesystem.

•Sincegasolineishighlyammable,handleitcarefully.

–Useanapprovedgasolinecontainer.

–Donotremovethecapfromthefueltankwhen

theengineishotorrunning.

–Donotsmokewhilehandlinggasoline.

–Fillthefueltankoutdoors,andllittoabout

1inch(25mm)belowthetopofthetank(the

bottomofthellerneck).Donotoverllit.

–Wipeupanyspilledgasoline.

WhileOperating

Engineexhaustcontainscarbonmonoxide,

whichisanodorless,deadlypoisonthatcan

killyou.

Donotrunengineindoorsorinanenclosed

area.

•Theoperatorshouldremainseatedwheneverthe

sprayerisinmotion.Theoperatorshouldkeepboth

handsonthesteeringwheelwheneverpossible.

Keepyourarmsandlegswithinthesprayerbody

atalltimes.

•Alwayswatchoutforandavoidlowoverhangssuch

astreelimbs,doorjambs,andoverheadwalkways.

Makesurethereisenoughroomoverheadtoeasily

clearthesprayerandyourhead.

•Failuretooperatethesprayersafelymayresultinan

accident,tipoverofthesprayer,andseriousinjury

ordeath.Drivecarefully .Topreventtippingorloss

ofcontrol:

–Useextremecaution,reducespeed,andmaintain

asafedistancearoundsandtraps,ditches,creeks,

ramps,unfamiliarareas,oranyareasthathave

abruptchangesingroundconditionsorelevation.

–Watchforholesorotherhiddenhazards.

–Useextracautionwhenoperatingthesprayeron

wetsurfaces,inadverseweatherconditions,at

higherspeeds,orwithafullload.Stoppingtime

anddistancewillincreasewithafullload.

5

Page 6

–Avoidsuddenstopsandstarts.Donotgofrom

reversetoforwardorforwardtoreversewithout

rstcomingtoacompletestop.

–Slowdownbeforeturning.Donotattempt

sharpturnsorabruptmaneuversorotherunsafe

drivingactionsthatmaycausealossofsprayer

control.

–Beforebackingup,looktotherearandensure

thatnooneisbehindyou.Backupslowly.

–Watchoutfortrafcwhenyouarenearor

crossingroads.Alwaysyieldtherightofway

topedestriansandothervehicles.Thissprayer

isnotdesignedforuseonstreetsorhighways.

Alwayssignalyourturnsorstopearlyenough

sothatotherpeopleknowwhatyouplantodo.

Obeyalltrafcrulesandregulations.

–Theelectricalandexhaustsystemsofthesprayer

canproducesparkscapableofignitingexplosive

materials.Neveroperatethesprayerinornear

anareawherethereisdustorfumesintheair

whichareexplosive.

–Ifyouareeverunsureaboutsafeoperation,stop

workandaskyoursupervisor.

•Donottouchtheengineormuferwhiletheengine

isrunningorsoonafterithasstopped.Theseareas

maybehotenoughtocauseburns.

•Ifthemachineevervibratesabnormally,stop

immediately,waitforallmotiontostop,andinspect

thesprayerfordamage.Repairalldamagebefore

resumingoperation.

•Beforegettingoffoftheseat:

1.Stopthemovementofthemachine.

2.PlacetherangeselectorinNeutralandsetthe

parkingbrake.

3.TurntheignitionkeytoOff.

4.Removetheignitionkey.

Important:Donotparkthemachineonan

incline.

onwetsurfacesasondrysurfaces.Ifyoudrive

throughstandingwaterdeepenoughtogetthe

brakeswet,theywillnotworkwelluntiltheyare

dry.Afterdrivingthroughwater,youshouldtestthe

brakestomakesuretheyworkproperly .Iftheydo

not,driveslowlywhileputtinglightpressureonthe

brakepedal.Thiswilldrythebrakesout.

OperatingonHillsandRoughTerrain

Operatingthesprayeronahillmaycausetippingor

rollingofthesprayer,ortheenginemaystallandyou

couldloseheadwayonthehill.Thiscouldresultin

personalinjury.

•Donotacceleratequicklyorslamonthebrakes

whenbackingdownahill,especiallywithaload.

•Neverdriveacrossasteephill;alwaysdrivestraight

upordownorgoaroundthehill.

•Iftheenginestallsoryoubegintoloseheadway

whileclimbingahill,graduallyapplythebrakesand

slowlybackstraightdownthehill.

•Turningwhiletravelingupordownhillscanbe

dangerous.Ifyouhavetoturnwhileonahill,do

itslowlyandcautiously.Nevermakesharporfast

turns.

•Heavyloadsaffectstability.Reducetheweightofthe

loadandyourspeedwhenoperatingonhills.

•Avoidstoppingonhills,especiallywithaload.

Stoppingwhilegoingdownahillwilltakelonger

thanstoppingonlevelground.Ifthesprayermust

bestopped,avoidsuddenspeedchanges,whichmay

initiatetippingorrollingofthesprayer.Donotslam

onthebrakeswhenrollingbackward,asthismay

causethesprayertooverturn.

•TheToroCompanystronglyrecommendsinstalling

theoptionalROPSKitwhenoperatingonhilly

terrain.IfyouinstallaROPS,alwaysweartheseat

beltwhendrivingthesprayer.

Braking

•Slowdownbeforeyouapproachanobstacle.This

givesyouextratimetostoporturnaway.Hittingan

obstaclecandamagethesprayeranditscontents.

Moreimportant,itcaninjureyou.

•GrossVehicleWeight(GVW)hasamajorimpacton

yourabilitytostopand/orturn.Heavyloadsand

attachmentsmakeasprayerhardertostoporturn.

Theheaviertheload,thelongerittakestostop.

•Turfandpavementaremuchmoreslipperywhen

theyarewet.Itcantake2to4timesaslongtostop

•Reducespeedandloadwhenoperatingonrough

terrain,unevenground,andnearcurbs,holes,and

othersuddenchangesinterrain.Loadsmayshift,

causingthesprayertobecomeunstable.

Suddenchangesinterrainmaycauseabrupt

steeringwheelmovement,possiblyresultingin

handandarminjuries.

6

Page 7

•Reduceyourspeedwhenoperatingonroughterrain

andnearcurbs.

•Gripthesteeringwheellooselyaroundtheperimeter.

Keepyourhandsclearofthesteeringwheelspokes.

Loading

Theweightofthecargocanchangethesprayercenter

ofgravityandsprayerhandling.Toavoidlossofcontrol

andpersonalinjury,followtheseguidelines:

•Reducetheweightoftheloadwhenoperating

onhillsandroughterraintoavoidtippingor

overturningofthesprayer.

•Liquidloadscanshift.Thisshiftinghappensmost

oftenwhileturning,goingupordownhills,suddenly

changingspeeds,orwhiledrivingoverrough

surfaces.Shiftingloadscancausethesprayertotip

over.

•Whenoperatingwithaheavyload,reduceyour

speedandallowforsufcientbrakingdistance.Do

notsuddenlyapplythebrakes.Useextracautionon

slopes.

•Donotadjustthetractioncontrolspeed.To

ensuresafetyandaccuracy,haveanAuthorizedT oro

Distributorcheckthegroundspeed.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressureuid.Use

cardboardorpapertondleaks.Fluidescaping

underpressurecanpenetrateskinandcauseinjury

requiringsurgerywithinafewhoursbyaqualied

surgeonorgangrenemayresult.

•Ifmajorrepairsareeverneededorassistanceis

required,contactanAuthorizedToroDistributor.

•Tobesureofoptimumperformanceandsafety,

alwayspurchasegenuineT ororeplacementpartsand

accessories.Replacementpartsandaccessoriesmade

byothermanufacturerscouldbedangerous.Altering

thissprayerinanymannerthatmayaffectsprayer

operation,performance,durability,oritsuse,may

resultininjuryordeath.Suchusecouldvoidthe

productwarranty.

•Beawarethatheavyloadsincreaseyourstopping

distanceandreduceyourabilitytoturnquickly

withouttippingover.

Maintenance

•Onlypermitqualiedandauthorizedpersonnelto

maintain,repair,adjust,orinspectthesprayer.

•Beforeperforminganymaintenance,ensurethatthe

systemhasbeenthoroughlyrinsedandcleaned.

•Beforeservicingormakingadjustmentstothe

machine,stoptheengine,settheparkingbrake,

andremovethekeyfromtheignitiontoprevent

someonefromaccidentallystartingtheengine.

•Tomakesurethattheentiremachineisingood

condition,keepallnuts,bolts,andscrewsproperly

tightened.

•Toreducethepotentialforre,keeptheengine

areafreeofexcessivegrease,grass,leaves,and

accumulationofdirt.

•Neveruseanopenametocheckthelevelor

leakageoffuelorbatteryelectrolyte.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keepyourhands,feet,

clothing,andanypartsofyourbodyawayfromthe

engineandanymovingparts.Keepeveryoneaway.

•Donotuseopenpansoffuelorammablecleaning

uidswhencleaningparts.

7

Page 8

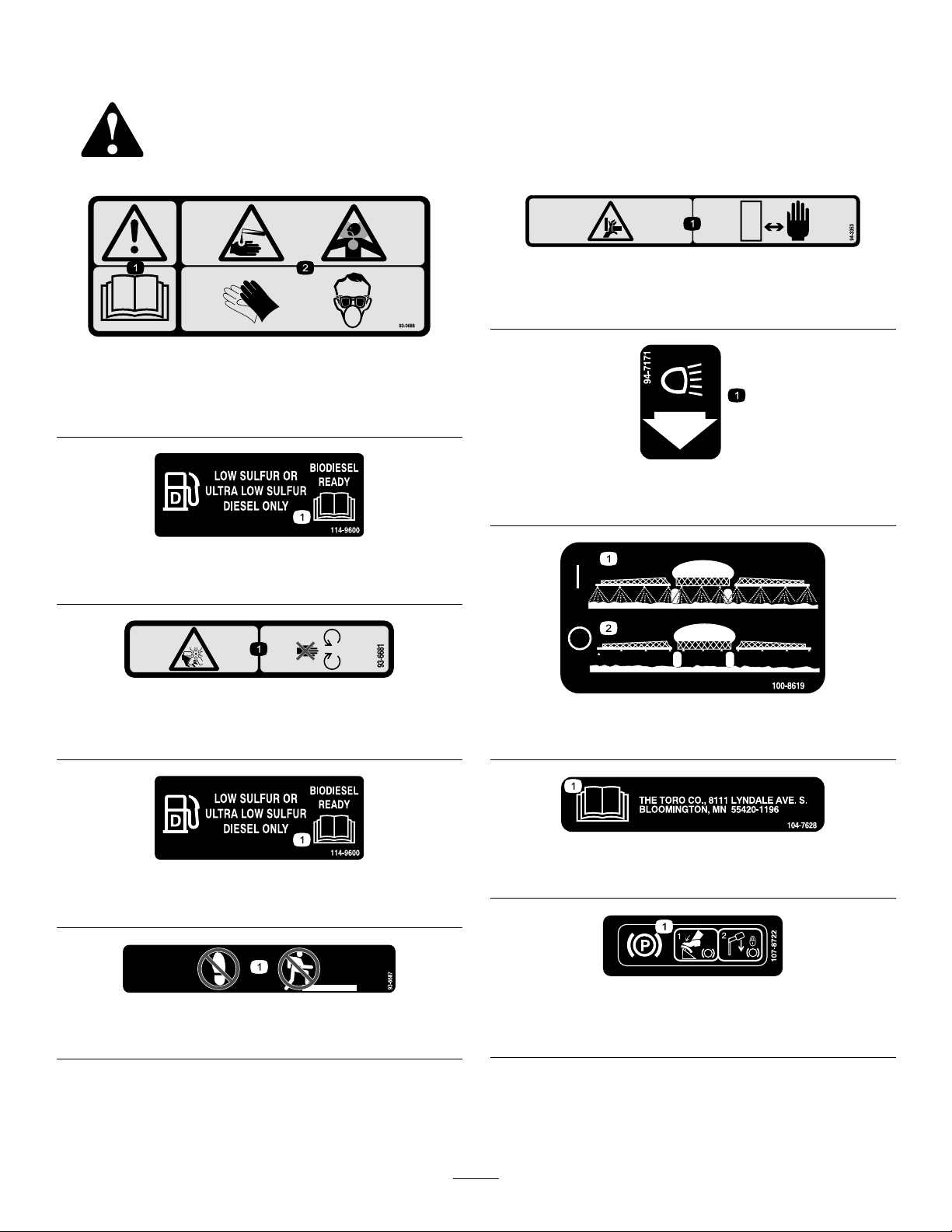

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

93-0688

1.Warning—readtheOperator’sManual.

2.Causticliquid/chemicalburnandtoxicgasinhalation

hazards—wearhand,skin,eye,andrespiratoryprotection.

94-3353

1.Crushinghazardofhand—keepyourhandsasafedistance

away.

94-7171

1.Lights

114-9600

1.ReadtheOperator’sManual.

93-6681

1.Cutting/dismemberment—hazard,fan-stayawayfrom

movingparts.

114-9600

1.ReadtheOperator’sManual.

93-6687

1.Donotstephere.

100-8619

1.Sprayon2.Sprayoff

104-7628

1.ReadtheOperator’sManual.

107-8722

1.Tosettheparkingbrake,pressthebrake,movetheparking

breaklevertothelockedposition.

8

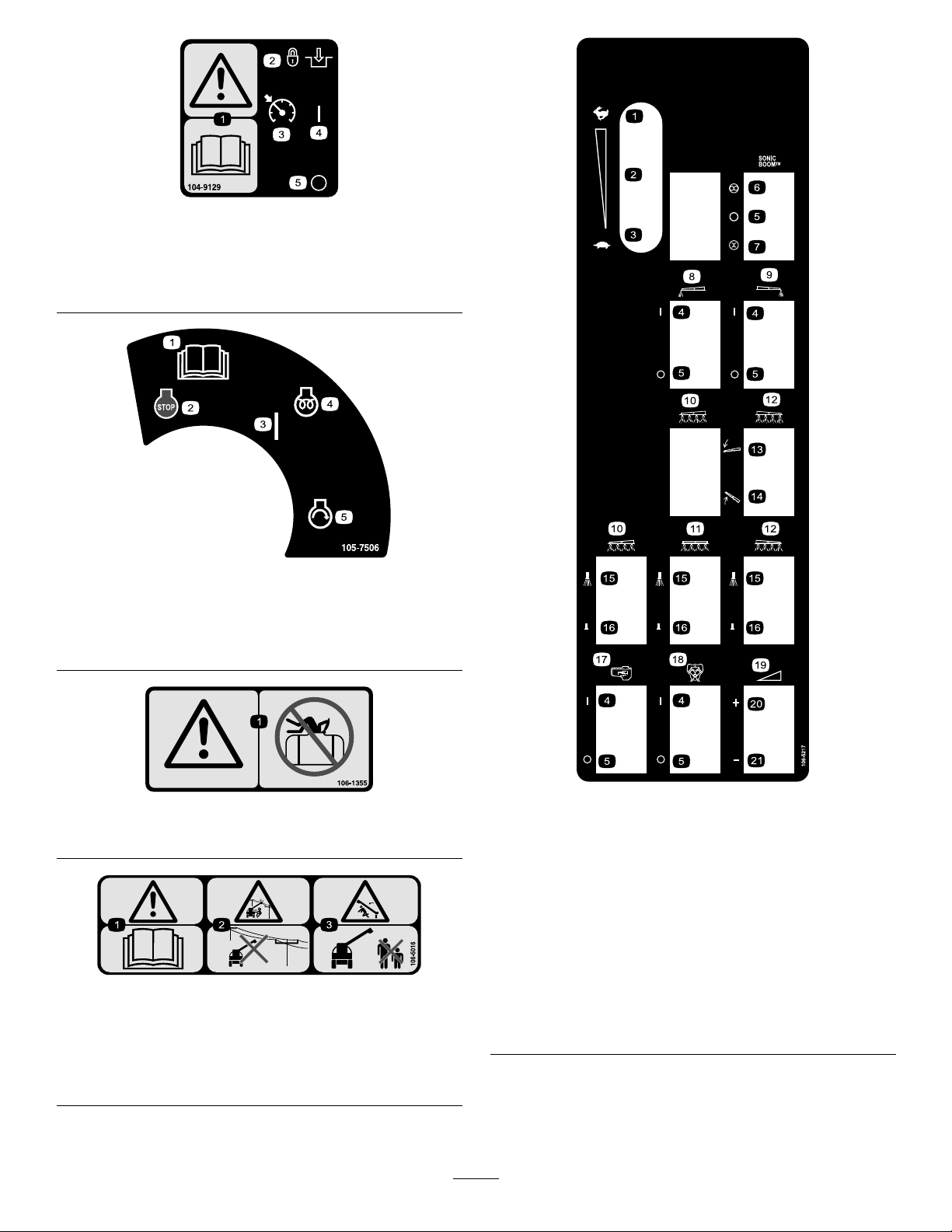

Page 9

1.Warning—readthe

Operator’sManual.

2.Lockandengage

3.Cruisecontrol

1.ReadtheOperator’s

Manual.

2.Engine—stop5.Engine—start

3.On

104-9129

4.On

5.Off

105-7506

4.Engine—preheat

106-1355

1.Warning—donotenterthetank.

106-5016

1.Warning—readtheOperator’sManual.

2.Electricshockhazard,overheadpowerlines—stayaway

fromoverheadpowerlines.

3.Crushinghazard,boom—keepbystandersasafedistance

fromthemachine.

106-5217

1.Fast12.Rightboom

2.Continuousvariable

setting

3.Slow

4.On15.Sprayon

5.Off16.Sprayoff

6.Automatic17.Agitation

7.Manual18.Pump

8.Leftboomfoammarker19.Continuousvariable

9.Rightboomfoammarker

10.Leftboom

11.Centerboom

13.Lowertheboom.

14.Raisetheboom.

20.Increase

21.Decrease

9

setting,spraypressure

Page 10

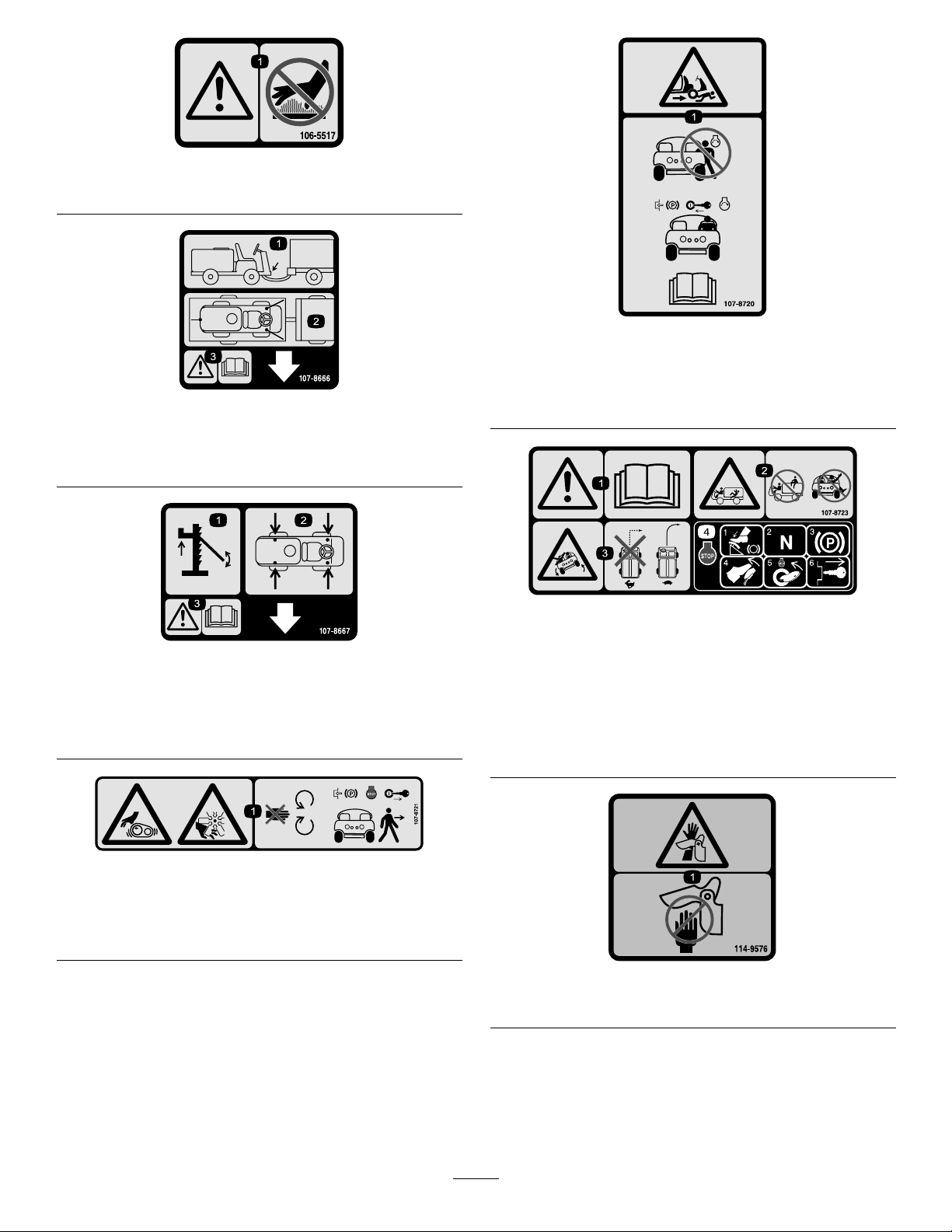

106-5517

1.Warning—donottouchthehotsurface.

107-8666

1.Towhitchlocation

2.Tiedownlocations

3.Warning—ReadtheOperator’sManual.

107-8667

1.Jacking

2.Jackpointlocations

3.Warning—ReadtheOperator’sManualformoreinformation

onjackingthevehicle

107-8720

1.Crushing/dismembermenthazard—donotstarttheengine

whileenteringorexitingthevehicle;engagetheparking

brake,insertthekey,andstarttheenginewhileseatedin

thedriversseat;readtheOperator’sManual.

107-8723

1.Warning—readtheOperator’sManual.

2.Falling,Crushinghazard—noridersontank;keeparms

andlegsinsideofthevehicleatalltimes.

3.Tippinghazard—donotturnsharplywhiletravelingfast;

driveslowlywhenturning.

4.Tostoptheengine,pressthebrake,putthegearselectorin

neutral,settheparkingbrake,releasethebrake,stopthe

engine,andremovethekey .

107-8721

1.Entanglementhazard,belt;cutting/dismembermenthazard,

fan—stayawayfrommovingparts;locktheparkingbrake,

stoptheengine,andremovethekeybeforeexitingthe

machine.

114-9576

1.Pinchpoint,hand—keephandawayfromhinge.

10

Page 11

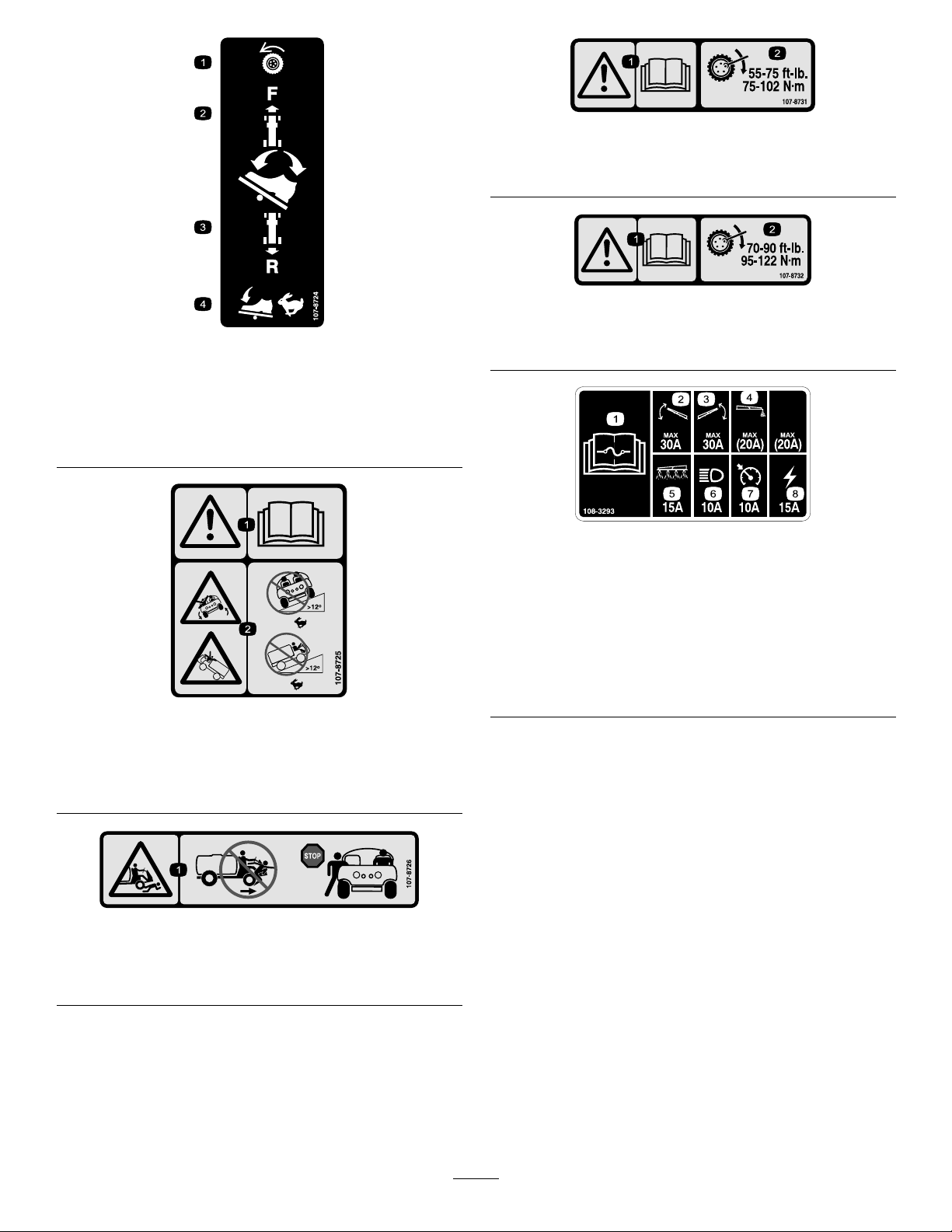

107-8724

1.Tractiondrive3.T odriveinreverse,press

2.Todriveforward,pressthe

topofthetractionpedal

forwardanddown.

thebottomofthepedal

rearwardanddown.

4.Vehiclespeedincreases

withmorepedalpressure.

107-8725

1.Warning—readtheOperator’sManual.

2.Tippinghazard—donotdrivefastacrossslopesgreater

than12degrees;donotdrivefastupslopesgreaterthan

12degrees.

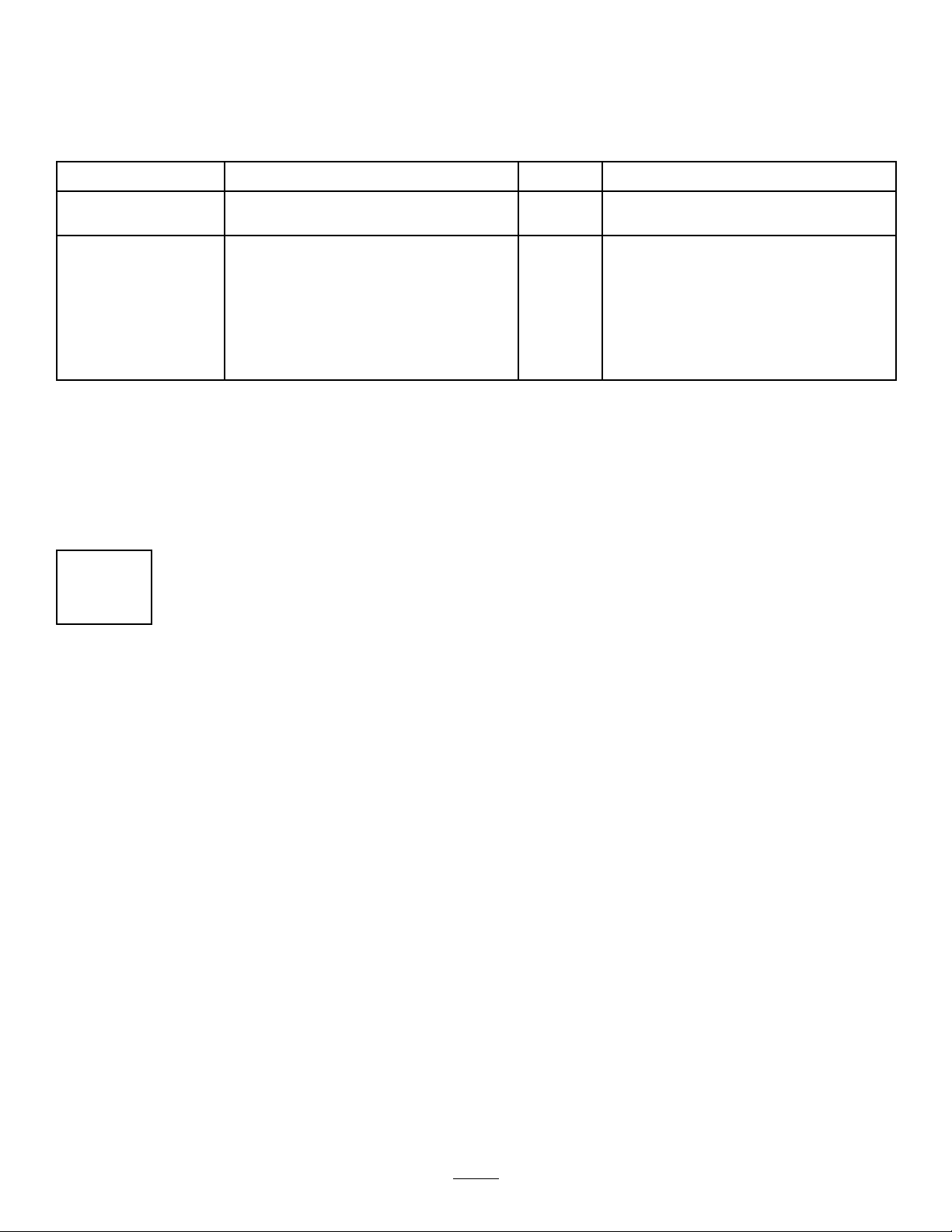

107-8731

1.Warning—readtheOperator’sManual.

2.Torquelugnutsto55-75ft-lb(75-102N-m).

107-8732

1.Warning—readtheOperator’sManual.

2.Torquelugnutsto75-90ft-lb(95-122N-m).

108-3293

1.ReadtheOperator’s

Manualforinformationon

fuses.

2.30amp.fusefortheboom

lift,left

3.30amp.fusefortheboom

lift,right

4.20amp.fuseforthefoam

marker

5.15amp.fuseforthespray

6.10amp.fuseforthe

7.10amp.fuseforthecruise

8.15amp.fuseforthe

system

headlights

control

ignition

107-8726

1.Crushing/dismembermenthazardofbystanders—donot

exitorenterthemachinewhileitismoving;stopthe

machinebeforeenteringorexiting.

11

Page 12

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Important:Tousethesprayer,

Distributorforinformationontheavailableboomkitsandaccessories.Afteryouinstallyournozzlesand

beforeusingthesprayerforthersttime(ifyou

bypassvalvessothatthepressureandapplicationrateremainsthesameforallboomswhenyouturnone

ormoreboomsoff.RefertoCalibratingtheBoomBypassV alvessectionintheOperationsection.

Nopartsrequired

Ignitionkey2

Operator’sManual

EngineOperator’sManual

PartsCatalog

OperatorTrainingMaterial

RegistrationCard

Pre-deliveryInspectionSheet

y ou must obtain and install nozzles

do not

useProControl™SpraySystem),adjusttheboom

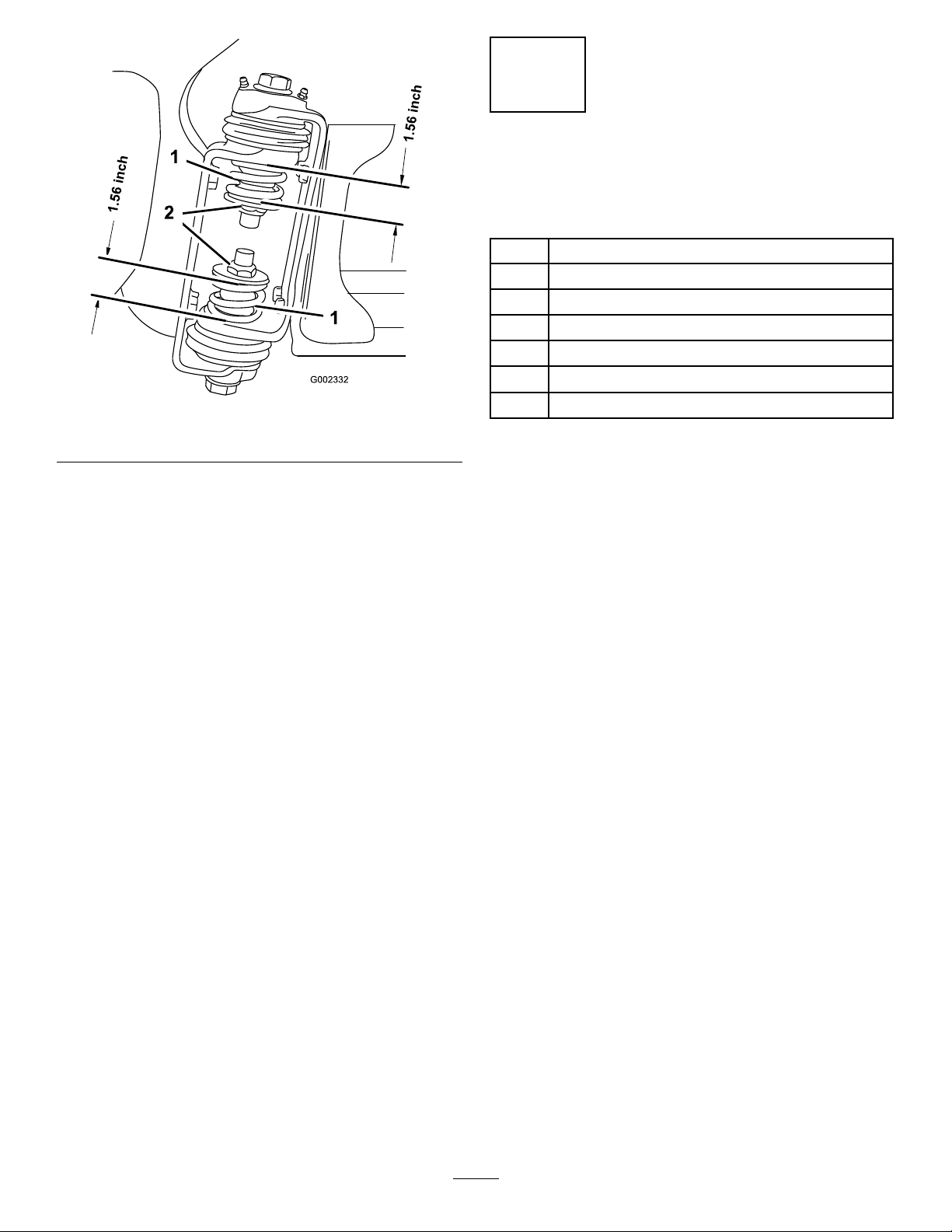

3.Attheboomhinge,measurethecompressionofthe

1

CheckingtheBoomHinge

Qty.

–

1

1

1

1

1

1

upperandlowerspringswhiletheboomsareintheir

extendedposition(Figure3).

A.Allspringsmustbecompresseduntilthemeasure

1.56inches.

Checktheboomhingesprings.

Readthemanualsandwatchthe

trainingmaterialsbeforeoperatingthe

machine.

.ContactyourAuthorizedT oro

Use

Springs

NoPartsRequired

Procedure

Important:Operatingthespraysystemwith

theboomhingespringsundertheincorrect

compressioncoulddamagetheboomassembly.

Measurethespringsandusethejamnutto

compressthespringsto1.56inchesifnecessary.

Thesprayisshippedwiththeboomextensionsswung

forwardtofacilitatepackagingofthemachine.The

springsarenotfullytightenedatthetimeofmanufacture

toallowtheboomstobeinthispositionfortransit.

Beforeoperatingthemachine,thespringsmustbe

adjustedtothecorrectcompression.

1.Ifnecessary,removethepackingcomponentsthat

securetherightandleftextensionboomsduring

shipping.

2.Supporttheboomswhiletheyareextendedtothe

sprayposition.

B.Usethejamnuttocompressanyspringthat

measuregreaterthan1.56inches.

12

Page 13

Figure3

1.Boomhingespring2.Jamnut

4.Repeattheprocedureforeachspringonbothboom

hinges.

5.Movetheboomsintothetransport“X”position.

SeeOperatingtheBoomsintheOperationsection

formoreinformation.

2

Learningmoreaboutyour

product.

Partsneededforthisprocedure:

2Ignitionkey

1

Operator’sManual

1

EngineOperator’sManual

1

PartsCatalog

1

OperatorTrainingMaterial

1

RegistrationCard

1

Pre-deliveryInspectionSheet

Procedure

1.Readthemanuals.

2.ViewtheOperatortrainingmaterial.

3.CompletetheregistrationcardandreturntoToro.

4.Storethedocumentationinasafeplace.

13

Page 14

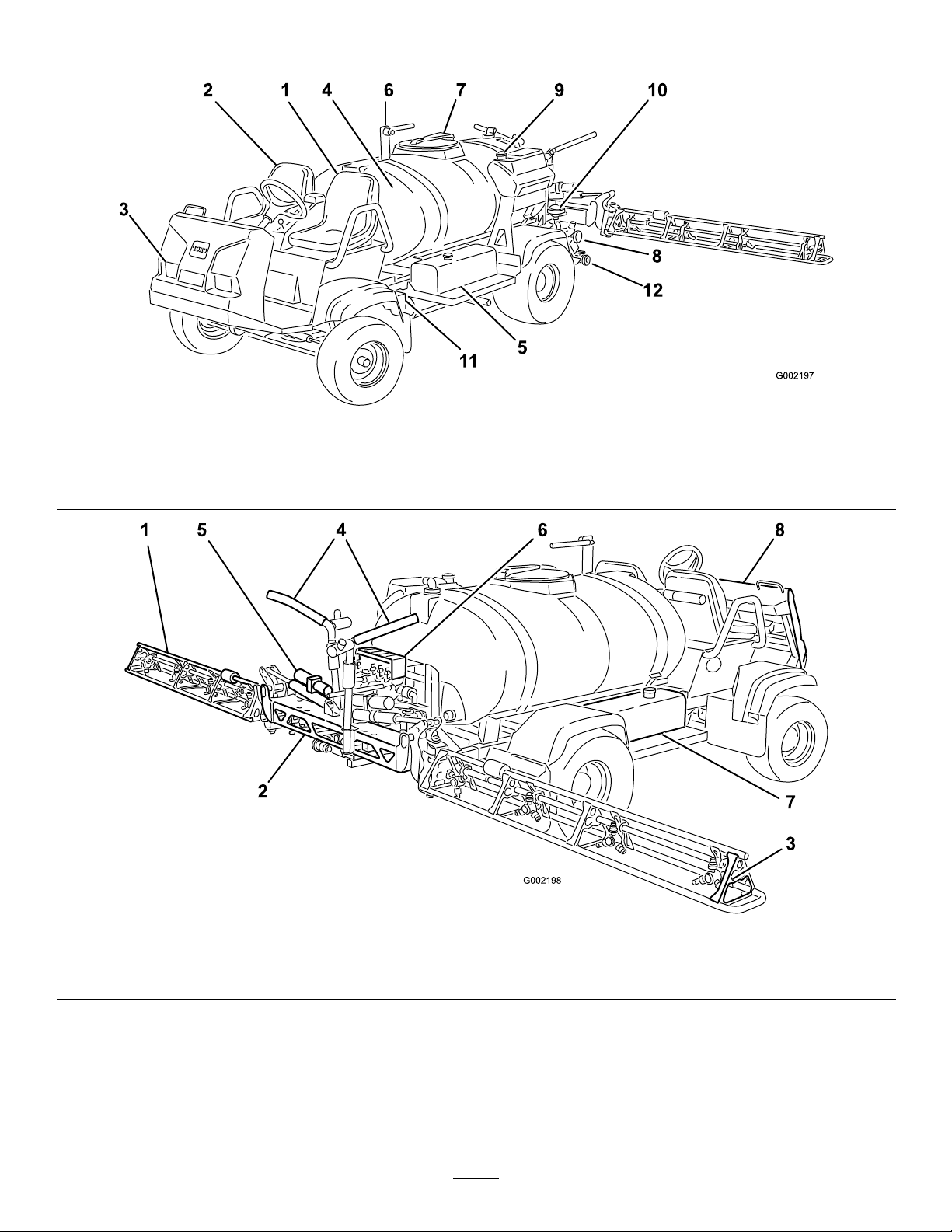

ProductOverview

G002197

21467910

8

11

5

3

12

Figure4

1.Operator’sposition4.Chemicaltank

2.Passenger’sposition5.Fueltank8.Pump11.Battery

3.Headlight

6.Anti-SiphonReceptacle

7.Tanklid10.Pumppressuredampener

9.Freshwatertank12.Tankdrain

1.Leftboom

2.Centerboom

3.Rightboom5.Boomcontrolcylinder7.Hydraulictank

4.Boomtransportcradle6.Valvecluster8.Dashcluster

Figure5

14

Page 15

Controls

G002199

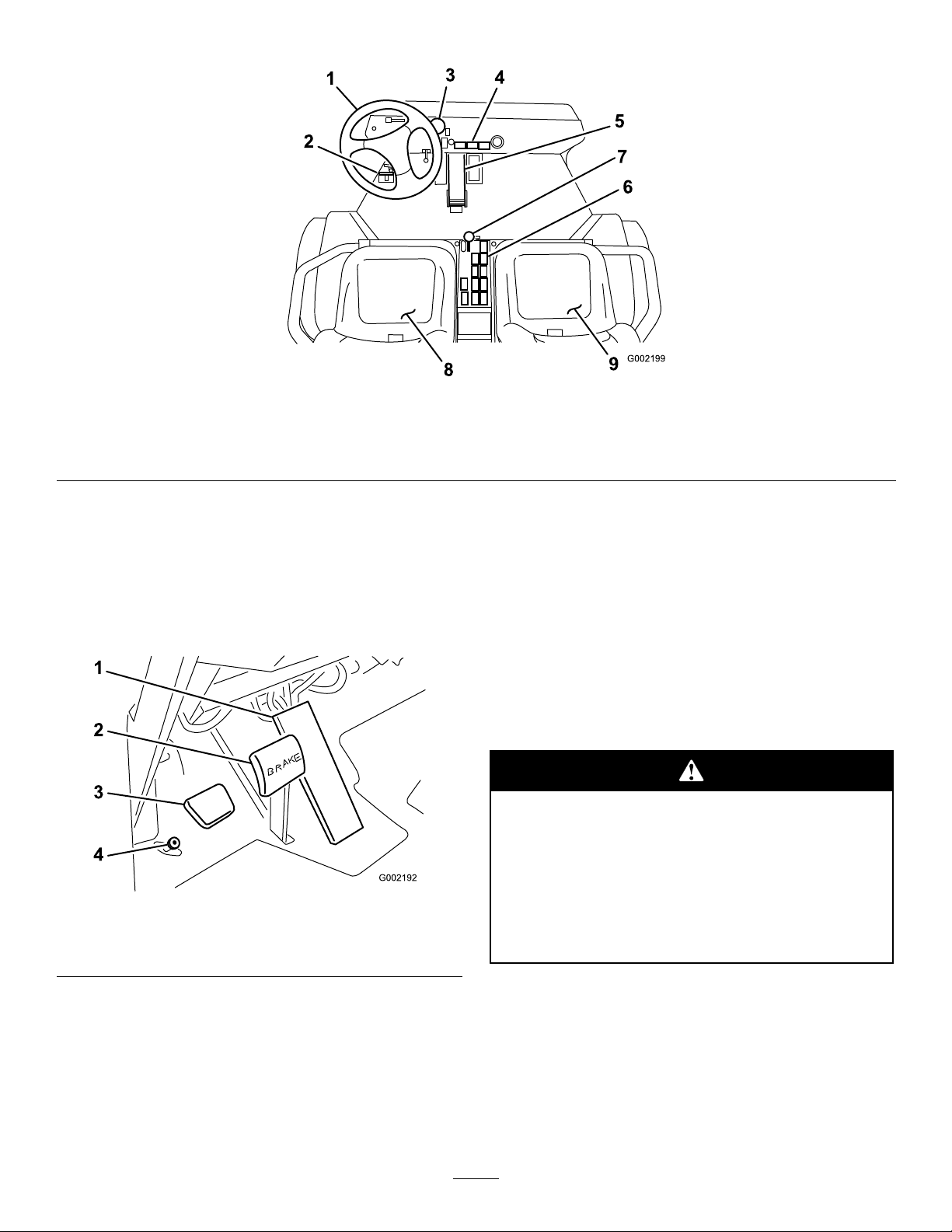

1

2

3

4

5

6

7

8

9

1.Steeringwheel

2.Masterboomfootswitch

3.Pressuregauge

Figure6

4.Dashcontrols7.Throttlelever

5.Tractionpedal

6.Sprayercontrols

8.Operator’sposition

9.Passengerposition

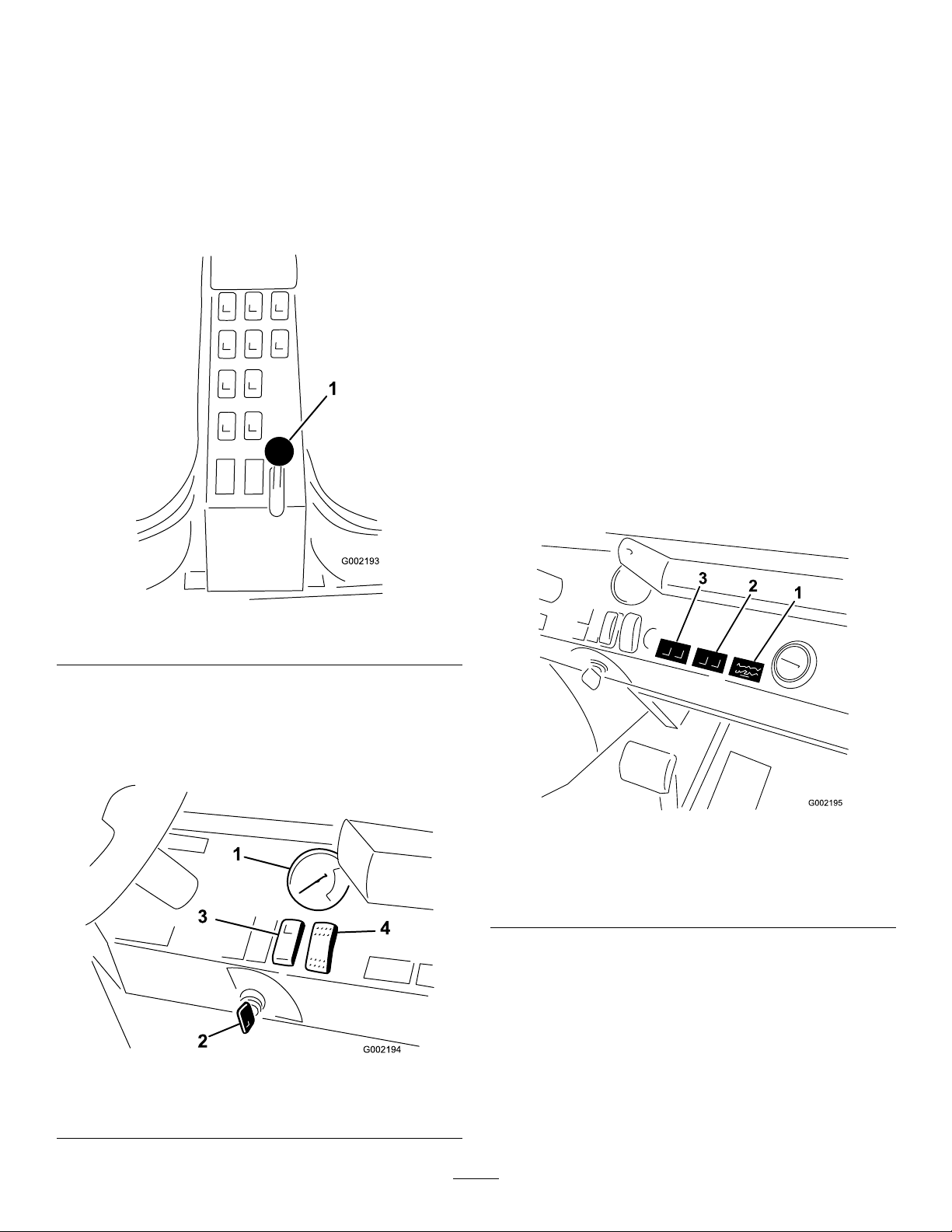

TractionPedal

Thetractionpedal(Figure7)controlsthemovementof

themachine,bothforwardandreverse.Usingtheheel

andtoeoftherightfoot,pressthetopofthepedalto

moveforwardorthebottomofthepedaltomovein

reverse.Releasethepedaltoslowandstop.

Figure7

1.Tractionpedal3.Parkingbrakepedal

2.Brakepedal4.Masterboomswitch

Fastpositionandpressthetractionpedalalltheway

forward.

Note:Toobtainmaximumpowerwithafulltankor

whentravelingupahill,setthethrottleleverintheFast

positionanddriveslowlysothattheengineremainsat

ahighrpm.

BrakePedal

Usethebrakepedaltostoporslowthesprayer

(Figure7).

Ifyouoperatethesprayerwithpoorlyadjusted

orwornbrakes,youcouldlosecontrolofthe

sprayer,resultinginseriousinjuryordeathto

youorbystanders.

Alwayscheckthebrakesbeforeoperatingthe

sprayerandkeepthemproperlyadjustedand

repaired.

Important:Ensurethatyouallowthesprayer

tocometoastopbeforeswitchingbetweenthe

ForwardandReverseposition.

Note:Thefartheryoupressthepedalineither

direction,thefasterthesprayerwilltravel.T oobtain

maximumforwardspeed,setthethrottlelevertothe

ParkingBrake

Theparkingbrakeisapedaltotheleftofthebrake

(Figure7).Engagetheparkingbrakewheneveryou

planonleavingtheseattopreventthesprayerfrom

accidentlymoving.Toengagetheparkingbrake,press

thebrakepedaland,whileholdingthebrake,pressthe

parkingbrakepedal.T odisengage,pressandreleasethe

15

Page 16

brakepedal.Ifthesprayerisparkedonasteepgrade,

applytheparkingbrakeandplacetheblocksonthe

downhillsideofthewheels.

ThrottleLever

PressureGauge

Thepressuregauge(Figure9).islocatedonthedash.

Thisgaugeshowsthepressureoftheuidinthesystem

inpsiandkPa.

Thethrottlelever,locatedonthecontrolpanelbetween

theseats(Figure8),controlsthespeedoftheengine.

Pushtheleverforwardtoincreasetheenginespeedand

pullitrearwardtodecreasetheenginespeed.

Figure8

1.Throttlelever

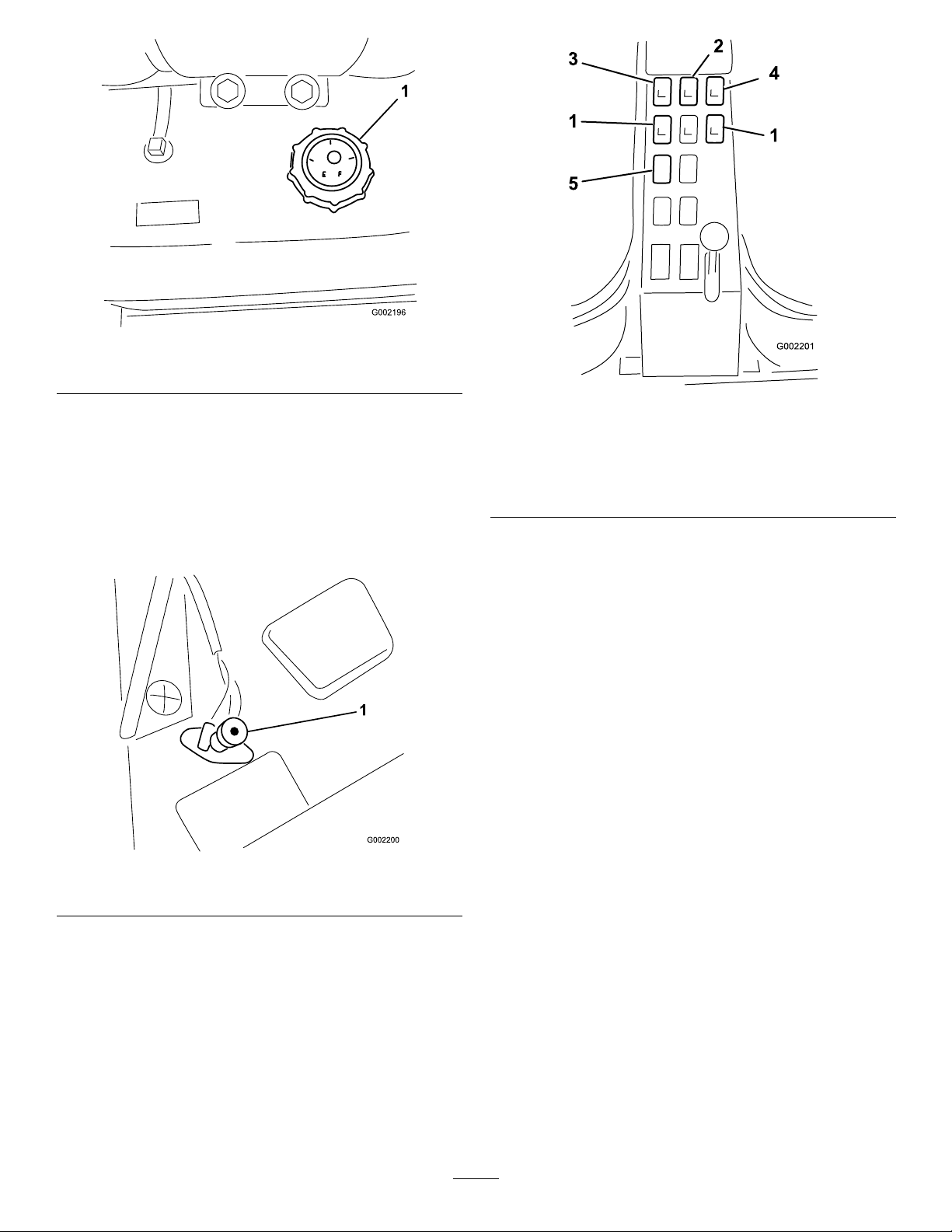

CruiseControlSwitch

Thecruisecontrolswitch(Figure9)lockstheposition

ofthetractionpedalatthetimetheswitchisengaged.

Thisensuresthesprayerstaysataconstantspeedwhile

drivingonlevelground.

HeadlightSwitch

Toggletheswitchtooperatetheheadlights(Figure9).

Pushitforwardtoturnthelightsonandrearwardto

turnthemoff.

HourMeter

Thehourmeter(Figure10)indicatesthetotalnumber

ofhourstheenginehasrun.Thehourmeterstartsto

functionwheneverthekeyisturnedtotheRunposition.

IgnitionSwitch

Theignitionswitch(Figure9)isusedtostartandstop

theengine,has3positions:Off,On/PreheatandStart.

Figure9

1.Pressuregauge3.Tractionpedallockswitch

2.Ignitionswitch4.Headlightswitch

Figure10

1.Hourmeter3.Watertemperatureand

glowpluglight

2.Oilpressureandbattery

light

FuelGauge

Thefuelgaugeislocatedontopofthefueltank

(Figure11),ontheleftsideofthemachineandshows

theamountoffuelinthetank.

16

Page 17

Figure11

1.Fuelgauge

MasterBoomSwitch

Themasterboomswitchislocatedontheoorboard

ofthemachinecabandtotheleftoftheoperator.It

allowsyoutostartorstopthesprayoperation.Press

theswitchwithyourfoottoenableordisablethespray

system(Figure12).

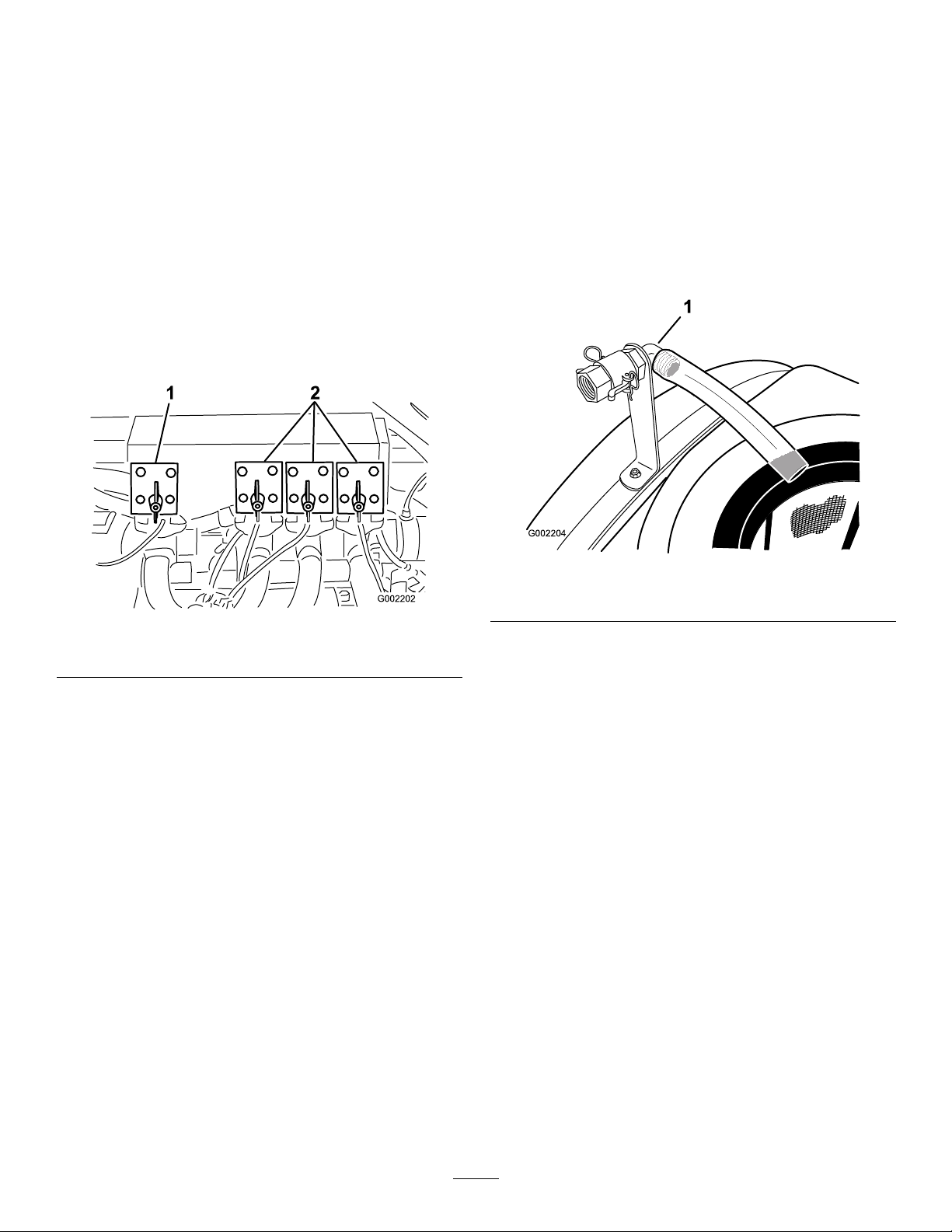

Figure13

1.Boomswitches,left,right

andcenter

2.Pumpswitch

3.Applicationrateswitch

4.Agitation

5.Boomliftswitch,leftand

right

PumpSwitch

Thepumpswitchislocatedonthecontrolpaneltothe

rightoftheseat(Figure13).Togglethisswitchforward

torunthepumporrearwardtostopthepump.When

theswitchisturnedon,alightontheswitchilluminates.

Important:Onlyengagethepumpswitchwhen

theengineisatlowidletoavoiddamagingthe

pumpdrive.

ApplicationRateSwitch

Figure12

1.Masterboomswitch

BoomSwitches

Theboomswitchesarelocatedonthecontrolpanelto

therightoftheseat(Figure13).Toggleeachswitch

forwardtoturnthecorrespondingboomsectiononand

rearwardtoturnthemoff.Whentheswitchisturned

on,alightontheswitchilluminates.Theseswitches

willonlyaffectthespraysystemwhenthemasterboom

switchison.

Theapplicationrateswitchislocatedonthecontrol

paneltotherightoftheseat(Figure13).Pressandhold

theswitchforwardtoincreasethespraysystempressure,

orpressandholditrearwardtodecreasepressure.

BoomLift

Theboomliftswitchesarelocatedonthecontrolpanel

totherightoftheseatandusedtoraisetheleftandright

boomrespectively(Figure13).

SonicBoom(Optional)

TheSonicBoomswitchisarockerswitchusedto

operatetheSonicBoom.T oggleswitchforwardfor

automatic,rearwardformanualandcenterforOff.The

sprayercomeswithplasticplugsintheselocations.

17

Page 18

FoamMarkerSwitchLocations

G002204

1

(Optional)

Ifyouinstallthefoammarkerkit,youwilladdswitches

tothecontrolpanelforcontrollingtheiroperation.The

sprayercomeswithplasticplugsintheselocations.

AgitationSwitch

Theagitationswitchislocatedonthecontrolpanelto

therightoftheseat(Figure13).Togglethisswitch

forwardtoturnontheagitationinthetankorrearward

tostoptheagitation.Whentheswitchisturnedon,a

lightontheswitchilluminates.Foragitationtowork,

thepumpmustbeonandtheenginemustberunning

aboveanidle.Theagitationvalveislocatedbehindthe

tank(Figure14)

Anti-siphonFillReceptacle

Tothefrontofthetankcoverisahosereceptaclewitha

threadedtting,a90degreebarbedtting,andashort

hosewhichyoucandirecttowardthetankopening.This

receptacleallowsyoutoconnectawaterhosetoitand

llthetankwithwaterwithoutcontaminatingthehose

withthechemicalsinthetank.

Important:Donotlengthenthehosetoallow

contactwiththetankuids.Thedistancefromthe

endofthehosetotheuppermostwaterlevelshould

bewithinlocalregulatorylimits.

Figure14

1.Agitationvalve2.Boomvalves

BoomValves

Thesevalvesturnthethreeboomsonoroff(Figure14).

Ifyoueverneedtomanuallyturnoffaboom,rotate

theknobonthevalveclockwisetoturnthevalveoffor

counterclockwisetoturniton.

Note:Turningtheboomvalvemanuallycaninterfere

withthefunctionofthefuses.Thefusesshouldbe

checkedaftermanuallyrotatingthevalve.

BoomBypassValves

Theboombypassvalvesredirecttheuidowfora

boomtothetankwhenyouturnofftheboomsection.

Theyarelocatedatthebottomofeachboomvalve

section.Youcanadjustthesevalvestoensurethatthe

boompressureremainsconstantnomatterhowmany

boomsareon.RefertoCalibratingtheBoomBypass

ValvesintheOperationsection.

Figure15

1.Anti-siphonllreceptacle

TankCover

Thetankcoverislocatedinthecenterofthetopofthe

tank.Toopenit,turnofftheengine,thenturnthefront

halfofthecovertotheleftandswingitopen.Youcan

removethestrainerinsideforcleaning.T osealthetank,

closethecoverandrotatethefronthalftowardtheright.

Note:IfyouusetheProControl,youmustshutall

thebypassvalves.

18

Page 19

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Baseweight

Weightwithstandardspray

system,empty,without

operator

Weightwithstandardspray

system,full,withoutoperator

Maximumgrossvehicleweight

(GVW)(onlevelground)

Tankcapacity

Overallwidthwithstandard

spraysystemboomsstoredin

theXposition

2,700lb(1225kg)

2,700lb(1225kg)

5,645lb(2,560kg)

6,525lb(2,960kg)

300USgallons(1135.6L)

743/4inches(189cm)

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsand

decalsinthesafetysection.Knowingthisinformation

couldhelpyouorbystandersavoidinjury.

BeforeDrivingtheSprayerfor

theFirstTime

ChecktheEngineOil

Overalllengthwithstandard

spraysystem

Overalllengthwithstandard

spraysystemtothetopofthe

boomsstoredintheXposition

Overallheightwithstandard

spraysystem

Overallheightwithstandard

spraysystemtothetopofthe

boomsstoredintheXposition

Groundclearance7.25inches(18.4cm)

Wheelbase

154inches(391cm)

174inches(442cm)

57.5inches(146cm)

91inches(231cm)

78inches(198cm)

OptionalEquipment

TheToroCompanyhasoptionalequipmentand

accessoriesthatyoucanpurchaseseparatelyandinstall

onyoursprayer.ContactyourAuthorizedService

Dealerforacompletelistofoptionalequipmentthatis

currentlyavailableforyoursprayer.

Note:Thebesttimetochecktheengineoiliswhen

theengineiscool,beforeithasbeenstartedforthe

day.Ifithasalreadybeenrun,allowtheoiltodrain

backdowntothesumpforatleast10minutesbefore

checking.Iftheoillevelisatorbelowthe’add’mark

onthedipstick,addoiltobringtheoilleveltothe’full’

mark.Donotoverll.Iftheoillevelisbetweenthe

’full’and’add’marks,nooiladditionisrequired.

Theengineisshippedwithoilinthecrankcase;

however,thelevelofoilmustbecheckedbeforeyou

rststarttheengineandafteryouhaverunit.

1.Positionthemachineonalevelsurface.

2.Removethedipstick,locatedunderthepassenger

seat,andwipeitwithacleanrag(Figure16).Insert

thedipstickintothetubeandmakesureitisseated

fully.Removethedipstickandchecktheoillevel.

Figure16

1.Dipstick

3.Iftheoillevelislow,removethellercapfrom

thevalvecover(Figure17)andpouroilintothe

openinguntiltheoillevelisuptotheFullmarkon

19

Page 20

thedipstick;refertoServicingEngineOil,inthe

EngineMaintenancesection,fortheproperoiltype

andviscosity.Addtheoilslowlyandcheckthelevel

oftenduringthisprocess.Donotoverll.

Figure17

1.Oilllercap

AddFuel

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuel

thatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1inch

(25mm)belowthebottomofthellerneck.

Thisemptyspaceinthetankallowsfuelto

expand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

4.Installthellercap.

5.Installthedipstickrmlyinplace.

ChecktheTirePressure

Checkthetirepressureevery8hoursordailytoensure

properlevels.Fillthetiresto18psi(124kPa).Also,

checkthetiresforwearordamage.

•Storefuelinanapprovedcontainerandkeep

itoutofthereachofchildren.Neverbuy

morethana30-daysupplyoffuel.

20

Page 21

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblendsd.

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfromafuel

dispensernozzle.

•Contactyourdistributorifyouwishformore

informationonbiodiesel.

FillingtheFuelT ank

Thefueltankcapacityisapproximately10.6USgallons

(40l).

Note:Thefueltankcapcontainsagaugewhichshows

thefuellevel;checkitfrequently .

1.Positionthesprayeronalevelsurface.

2.Settheparkingbrake,stopthepump,stopthe

engine,removetheignitionkey,andallowthe

enginetocool.

3.Cleantheareaaroundthefueltankcap(Figure18).

•Ifafueldispensernozzlemustbeused,keep

thenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntil

fuelingiscomplete.

Recommendedfuel

TheenginerunsonNo.2-Dor1-Dautomotivetype

dieselfuelwithaminimumcetaneratingof40.

Note:Yourenginemayrequireahighercetane-rated

fuelifyouoperatethemachineathighaltitudesorin

lowatmospherictemperatures.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB20(20%biodiesel,80%petrodiesel).The

petrodieselportionshouldbeloworultralowsulfur.

Observethefollowingprecautions:

•Thebiodieselportionofthefuelmustmeet

specicationASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuelas

theymaybedegradedovertime.

Figure18

1.Fueltankcap

4.Removethefueltankcap.

21

Page 22

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.

Note:Thesetiresaredifferentthancartires;they

requirelesspressuretominimizeturfcompaction

anddamage.

•Checkalluidlevelsandaddtheappropriate

amountofspecieduids,ifanyarefoundtobe

low .

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1inch

(25mm)belowthebottomofthellerneck.

Thisemptyspaceinthetankallowsthefuel

toexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

5.Fillthetanktoaboutoneinchbelowthetopofthe

tank,(bottomofthellerneck).

Note:Thisspaceinthetankallowsfueltoexpand.

Donotoverll.

6.Installthefueltankcapsecurely .

7.Wipeupanyfuelthatmayhavespilled.

•Checkthebrakepedaloperation.

•Checktoseethatthelightsareworking.

•Withtheengineoff,checkforoilleaks,looseparts,

andanyothernoticeablemalfunctions.

Ifanyoftheaboveitemsarenotcorrect,notifyyour

mechanicorcheckwithyoursupervisorbeforetaking

thesprayeroutfortheday.Yoursupervisormaywant

youtocheckotheritemsonadailybasis,soaskwhat

yourresponsibilitiesare.

DrivingtheSprayer

StartingtheEngine

1.Sitontheoperator’sseatandkeepyourfootoffthe

tractionpedal.

2.Ensurethattheparkingbrakeisengaged,the

tractionpedalisintheNeutralposition,thethrottle

isintheSlowposition.

3.TurntheignitionswitchtotheOn/Preheatposition.

AdjustingtheBoomstoLevel

1.Attheoperator’sposition,turntheignitionkeyto

Ontoenergizethesystem.

2.Movetheboomsintopositionsothattheyarelevel

withtheground.

3.Removethekeyandexittheoperator’sposition.

4.Atthehinge,adjustthepositionofthebumpersso

theboomcannotmovepastlevelwiththeground.

Takecaretomakesurethebumperislevel.

5.Tightentheboltandnuttolockthebumpersinto

theadjustedposition.Torquethefastenersto

135-165ft-lbs(183-223N-m).

Note:Thebumpermayexperiencesomecompression

overtime.Iftheboomsdropbelowlevel,usethis

proceduretoreadjustthebumperpositionneeded.

Pre-StartingChecks

Checkthefollowingitemseachtimeyoubeginusing

thesprayerfortheday:

Note:Anautomatictimerwillcontrolthepreheat

forapproximately6seconds.

4.Afterpreheating,turnthekeytotheStartposition.

5.Cranktheenginefornolongerthan15seconds.

6.Releasethekeywhentheenginestarts.

7.Iftheenginerequiresadditionalpreheating,turn

thekeytotheOffposition,thentotheOn/Preheat

position.

Note:Repeatstepsthroughasrequired.

8.Runtheengineatidlespeedorpartialthrottleuntil

theenginewarmsup.

Driving

1.Pressthetractionpedalforwardtodriveforwardor

rearwardtodriveinreverse.

Important:Ensurethatyouallowthesprayer

tocometoastopbeforeswitchingbetweenthe

ForwardandReversepositions.

2.Toslowlystopthesprayer,releasethetractionpedal.

•Checkthetirepressure.

3.Tostopquickly,pressthebrakepedal.

22

Page 23

Note:Stoppingdistancemayvarydependingon

thesprayerloadandspeed.

SettingtheCruiseControl

•Avoidhardbrakingsituationsfortherstseveral

hoursofnewsprayerbreak-inoperation.New

brakeliningsmaynotbeatoptimumperformance

untilseveralhoursofusehascausedthebrakesto

becomeburnished(broken-in).

•Avoidracingtheengine.

Ifyoupresstheswitchtoturnoffthecruise

controlanddonothaveyourfootonthetraction

pedal,thetractionunitmaysuddenlystopand

causeyoutolosecontrol,possiblyinjuringyou

orbystanders.

Ensurethatyouhaveyoufootonthetraction

pedalwhenyoudisengagethecruisecontrol

usingtheswitch.

1.Driveforwardandattainthedesiredspeed;refer

toDrivingtheSprayer.

2.Pressthetopofthecruisecontrolswitch.

Note:Thelightontheswitchilluminates.

3.Takeyourfootoffthetractionpedal.

Note:Thesprayerwillmaintainthespeedyouset.

4.Toreleasethecruisecontrol,eitherplaceyourfoot

onthetractionpedalandpressthebottomofthe

cruisecontrolswitchorremoveyourfootfromthe

tractionpedalandpressthebrakepedal.

Note:Thelightontheswitchturnsoffandthe

tractioncontrolreturnstothetractionpedal.

StoppingtheEngine

1.Pressthebraketostopthesprayer.

•Varythesprayerspeedduringoperation.Avoidfast

startsandquickstops.

•RefertotheMaintenancesectionforanyspecial

lowhourchecks.

AdjustingtheBoomstoLevel

Thefollowingprocedurecanbeusedtoadjustthe

hardstopsonthecenterboomtokeeptheleftandright

boomsatlevel.

1.Attheoperator’sposition,turntheignitionkeyto

Ontoenergizethesystem.

2.Movetheboomsintopositionsothattheyarelevel

withtheground.

3.Removethekeyandexittheoperator’sposition.

4.Atthehinge,adjustthepositionofthebumpersso

theboomcannotmovepastlevelwiththeground.

Takecaretomakesurethebumperislevel.

5.Tightentheboltandnuttolockthebumpersinto

theadjustedposition.Torquethefastenersto

135-165ft-lbs(183-223N-m).

Note:Thebumpermayexperiencesomecompression

overtime.Iftheboomsdropbelowlevel,usethis

proceduretoreadjustthebumperpositionneeded.

2.MoveallthecontrolstotheNeutralposition.

3.Settheparkingbrake.

4.ShiftthethrottlelevertotheIdleposition.

5.TurntheignitionkeytotheOffposition.

6.Removethekeyfromtheswitchtoprevent

someonefromaccidentallystartingtheengine.

NewSprayerBreak-In

Toprovideproperperformanceandlongsprayerlife,

followtheseguidelinesfortherst100operatinghours:

•Checktheuidandengineoillevelsregularly

andbealertforindicationsofoverheatinginany

componentofthesprayer.

•Afterstartingacoldengine,letitwarmupforabout

15secondsbeforeaccelerating.

OperatingtheSprayer

TooperatetheMulti-ProSprayerrstllthespraytank,

thenapplythesolutiontotheworkarea,andnally

cleanthetank.Itisimportantthatyoucompleteall

threeofthesestepsinsuccessiontoavoiddamagingthe

sprayer.Forexample,donotmixandaddchemicalsin

thespraytankatnightandthensprayinthemorning.

Thiswouldleadtoseparationofthechemicalsand

possibledamagetothesprayercomponents.

23

Page 24

Chemicalsarehazardousandcancause

personalinjury.

•Readthedirectionsonthechemicallabels

beforehandlingthechemicalsandfollow

allmanufacturerrecommendationsand

precautions.

•Keepchemicalsawayfromyourskin.

Shouldcontactoccur,washtheaffectedarea

thoroughlywithsoapandcleanwater.

•Weargogglesandanyotherprotective

equipmentrecommendedbythechemical

manufacturer.

Toopenthefreshwatertankspigot,turntheleveron

thespigot.

TheMulti-ProSprayerhasbeenspecicallydesignedto

havehighdurabilityinordertogiveitthelongsprayer

lifeyouneed.Differentmaterialshavebeenchosenfor

specicreasonsatdifferentlocationsonyoursprayerto

meetthisgoal.Unfortunatelythereisnosinglematerial

whichisperfectforallforeseeableapplications.

Somechemicalsaremoreaggressivethanothers

andeachchemicalinteractsdifferentlywithvarious

materials.Someconsistencies(e.g.wettablepowders,

charcoal)aremoreabrasiveandleadtohigherwear

rates.Ifachemicalisavailableinaformulationthat

wouldprovideincreasedlifetothesprayer,usethis

alternativeformulation.

Asalways,remembertocleanyoursprayerthoroughly

afterallapplications.Thiswilldothemosttoensure

yoursprayerhasalongandtroublefreelife.

FillingtheFreshWaterTank

Alwaysllthefreshwatertankwithcleanwaterbefore

handlingormixinganychemicals.

Thefreshwatertankislocatedattherear,leftside

ofthechemicaltank(Figure19).Itsuppliesasource

offreshwaterforyoutowashchemicalsoffofyour

skin,eyes,orothersurfacesinthecaseofaccidental

exposure.

Figure19

1.Freshwatertank

2.Fillercap

3.Spigot

FillingtheSprayTank

Important:Ensurethatthechemicalsyouwill

beusingarecompatibleforusewithViton(see

themanufacturer’slabel;itshouldindicateifit

isnotcompatible).Usingachemicalthatisnot

compatiblewithVitonwilldegradetheO-ringsin

thesprayer,causingleaks.

Important:Thetankmarkingsareforreference

onlyandcannotbeconsideredaccuratefor

calibration.

1.Stopthesprayeronalevelsurface,movetherange

selectortotheNeutralposition,stoptheengine,

andsettheparkingbrake.

2.Determinetheamountofwaterneededtomixthe

amountofchemicalyouneedasprescribedbythe

chemicalmanufacturer.

3.Openthetankcoveronthespraytank.

Thetankcoverislocatedinthecenterofthetop

ofthetank.T oopenit,turnthefronthalfofthe

covercounterclockwiseandswingitopen.You

canremovethestrainerinsideforcleaning.Toseal

thetank,closethecoverandrotatethefronthalf

clockwise.

4.Add3/4oftherequiredwatertothespraytank

usingtheanti-siphonllreceptacle.

Important:Alwaysusefreshcleanwaterin

thespraytank.Donotpourconcentrateinto

anemptytank.

24

Page 25

5.Starttheengine,setthepumpswitchtotheOn

position,andmovethethrottlelevertoahigheridle.

6.SettheagitationswitchtotheOnposition.

Important:Priortointroducingwettable

powdersintoanyToroSpraySystemmixthe

powdersinasuitablecontainerwithsufcient

freshwatertocreateafreeowingslurry.Best

resultsmaybeobtainedbyusingwarmwater.

Failuretodosomayresultinchemicaldeposits

onthebottomofthetank,degradedagitation,

cloggingofltersandimproperagitationrates.

7.Addtheproperamountofchemicalconcentrateto

thetank,asdirectedbythechemicalmanufacturer.

8.Addtheremainingwatertothetank.

OperatingtheBooms

Theboomliftswitchesonthesprayercontrolpanel

allowsyoutomovetheboomsbetweentransport

positionandspraypositionwithoutleavingthe

Operator’sseat.Itisrecommendedtochangeboom

positionswhilethemachineisstationary.

Tochangetheboomposition:

1.Stopthesprayeronlevelground.

2.Usetheboomliftswitchestolowerbooms.W ait

untiltheboomsreachthefull,extendedspray

position.

3.Whentheboomsneedtoberetracted,stopthe

sprayeronlevelground.

4.Usetheboomliftswitchestoraisethebooms.Raise

theboomsuntiltheyhavemovedcompletelyinto

boomtransportcradleformingthe“X”transport

positionandtheboomcylindersarefullyretracted.

theboom(s)backintothetransportposition.Make

suretheboomcylindersarefullyretractedtoprevent

actuatorroddamageduringstorage.

Spraying

Important:Inordertoensurethatyoursolution

remainswellmixed,usetheagitationfeature

wheneveryouhavesolutioninthetank.For

agitationtowork,thepumpmustbeonandthe

enginemustberunningaboveanidle.

Note:Thisprocedureassumesthatthepumpison

fromtheFillingtheSprayTankprocedure.

1.SetthemasterboomswitchtotheOffposition.

2.Adjustthethrottletothedesiredpositiontospray

at.

3.Drivetothelocationwhereyouwillbespraying.

4.Lowertheboomsintoposition.

5.Settheindividualboomswitches,asneeded,tothe

Onpositions.

6.Usetheapplicationrateswitchtoachievethe

desiredpressureasindicatedintheNozzleSelection

Guideprovidedwiththesprayer.

7.Driveatthedesiredspeedandthensetthemaster

boomswitchtotheOnpositiontobeginspraying.

Note:Whenthetankisnearlyempty ,theagitation

maycausefoaminginthetank.Inthiscase,turn

theagitationswitchoff.Alternatively,youcanuse

ananti-foamingagentinthetank.

8.Whennishedspraying,setthemasterboomswitch

totheOffpositiontoturnoffallbooms,thenset

thepumpswitchtotheOffposition.

TheBoomTransportCradle

Thesprayerisequippedwithaboomtransportcradle

thathasauniquesafetyfeature.Intheeventof

accidentalboomcontactwithalowoverheadobject

whileinthetransportposition,theboom(s)canbe

pushedoutofthetransportcradles.Ifthisoccurs,the

boomswillcometorestinanearhorizontalposition

totherearofthevehicle.Whiletheboomswillnot

bedamagedduetothismovement,theyshouldbe

immediatelyputbackintothetransportcradle.

Important:Theboomscanbedamagedby

transportingtheminanypositionotherthanthe

“X”transportpositionusingtheboomtransport

cradle.

Toputtheboomsbackintothetransportcradle,

lowertheboom(s)tothesprayposition,andthenraise

Note:Returntheboomstothetransportposition

anddrivethesprayertothecleaningarea.

Important:Alwaysraisetheboomsuntilthey

havemovedcompletelyintoboomtransport

cradleformingthe“X”transportpositionand

theboomcylindersarefullyretractedwhenever

youmovethesprayerfromonesprayingareato

anotherormovetoastorageorcleaningarea.

TurfCarePrecautionsWhile

OperatinginStationaryModes

Important:Undersomeconditions,heatfrom

theengine,radiator,andmufercanpotentially

damagegrasswhenoperatingthesprayerina

stationarymode.Stationarymodesincludetank

25

Page 26

agitation,handsprayingwithaspraygun,orusing

awalkingboom.

1.Stopthesprayeronalevelsurface,stoptheengine,

andsettheparkingbrake.

Usethefollowingprecautions:

•Avoidstationarysprayingwhenconditionsarevery

hotand/ordry,asturfcanbemorestressedduring

theseperiods.

•Avoidparkingontheturfwhilestationaryspraying.

Parkonacartpathwheneverpossible.

•Minimizetheamountoftimethemachineisleft

runningoveranyparticularareaofturf.Bothtime

andtemperatureaffecthowmuchthegrassmaybe

damaged.

•Settheenginespeedaslowaspossibleto

achievethedesiredpressureandow .Thiswill

minimizetheheatgeneratedandtheairvelocity

fromthecoolingfan.

•Allowheattoescapeupwardfromtheengine

compartmentbyraisingtheseatassembliesduring

stationaryoperationratherthanbeingforcedout

underthevehicle.

SprayingTips

•Donotoverlapareasthatyouhavepreviously

sprayed.

•Watchforpluggednozzles.Replaceallwornor

damagednozzles.

2.SetthemasterboomswitchtotheOffpositionand

setthepumpswitchtotheOffposition.

3.Rotatetheturretofthenozzlesineitherdirection

tothecorrectnozzle.

CleaningtheSprayer

Important:Youmustalwaysemptyandcleanthe

sprayerimmediatelyaftereachuse.Failuretodo

somaycausethechemicalstodryorthickeninthe

lines,cloggingthepumpandothercomponents.

Cleanthespraysystemaftereachsprayingsession.To

properlycleanthespraysystem:

•Usethreeseparaterinses.

•Useaminimumof50gallonsforeachrinse.

•Usethecleanersandneutralizersasrecommended

bythechemicalmanufacturers.

•Usepurecleanwater(nocleanersorneutralizers)

forthelastrinse.

1.Stopthesprayer,settheparkingbrake,andturnoff

theengine.

2.Locatethetankdrainvalveontherearofthe

machine(Figure20).Thevalveistotherearof

pump,attachedtothesupportbracket.

•Usethemasterboomswitchtostopthesprayow

beforestoppingthesprayer.Oncestopped,use

theneutralenginespeedcontroltoholdtheengine

speeduptokeeptheagitationrunning.

•Youwillobtainbetterresultsifthesprayeris

movingwhenyouturntheboomson.

UncloggingaNozzle

Ifanozzlebecomescloggedwhileyouarespraying,

youcancleanitusingahandspraybottleofwaterora

toothbrush.

1.Stopthesprayeronalevelsurface,stoptheengine,

andsettheparkingbrake.

2.SetthemasterboomswitchtotheOffpositionand

thensetthepumpswitchtotheOffposition.

3.Removethecloggednozzleandcleanitusinga

spraybottleofwateroratoothbrush.

SelectingaNozzle

Theturretbodiescanacceptupto3differentnozzles.

Toselectthedesirednozzle:

Figure20

1.Tankdrainhandle

Openthevalvetodrainanyunusedmaterial

fromthetankanddisposeofitaccordingtolocal

codesandthematerialmanufacturer’ sinstructions

(Figure21).Afterdraining,removethelynchpinon

thebracketsecuringthedrainvalvetothemachine

andletthevalverestontheground.Thisallows

anyresidualmaterialinthelinetodrain.

26

Page 27

2

3

1

G005593

13.Repeatsteps4through12atleast2moretimesto

ensurethatthespraysystemisfullycleaned.

Important:Y oumustalwayscompletethis

procedureatleast3timestoensurethatthe

spraysystemisfullyclean,preventingdamage

tothesystem.

14.Cleanthestrainer;refertoCleaningtheSuction

StrainerinCleaningsection.

Important:Ifyouusedwettablepowder

chemicals,cleanthestraineraftereachtank.

15.Usingagardenhose,rinseofftheoutsideofthe

sprayerwithcleanwater.

16.Removethenozzlesandcleanthembyhand.

Replacedamagedorwornnozzles.

CalibratingtheBoomBypass

Valves

Figure21

1.Valveopen3.Valveclosed

2.Lynchpin

3.Whenthetankhasdrainedcompletely ,install

thevalvetoframewiththelynchpinremoved

previouslyandclosethedrainvalve(Figure21).

4.Fillthetankwithatleast50USgallons(190L)of

cleanfreshwaterandclosethecover.

Note:Youcanuseacleaning/neutralizingagentin

thewaterasneeded.Onthenalrinse,useonly

clean,clearwater.

5.Lowertheboomsintothesprayposition.

6.Starttheengineandmovethethrottlelevertoa

higheridle.

7.EnsurethattheagitationswitchisintheOn

position.

8.SetthepumpswitchtotheOnpositionandusethe

applicationrateswitchtoincreasethepressureto

ahighsetting.

9.Setthemasterboomswitchandboomcontrol

switchestotheOnpositionstobeginspraying.

10.Allowallofthewaterinthetanktosprayout

thoughthenozzles.

11.Checkthenozzlestoensurethattheyareall

sprayingcorrectly.

12.SetthemasterboomswitchtotheOffposition,

setthepumpswitchtotheOffposition,andstop

theengine.

Important:IfyouhavetheProControl™Spray

Systeminstalled,theboombypassvalvesmustbe

closed.Usethefollowingadjustmentonlywhen

not

youare

usingtheProControlSpraySystem.

Beforeusingthesprayerforthersttimeorifthe

nozzlesarechanged,adjusttheboombypassvalvesso

thatthepressureandapplicationrateremainsthesame

forallboomswhenyouturnoneormoreboomsoff.

Note:Theboombypassvalvesmustbecalibrated

eachtimethenozzlesarechanged.

Selectanopenatareatoperformthisprocedure.

1.Fillthespraytankwithcleanwater.

2.Puttheextensionboomsdown,ifinstalled.

3.Settheparkingbrakeandstarttheengine.

4.MovethethrottlelevertotheSprayposition.

5.SetthepumpswitchtotheOnpositiontostart

thepump.

6.Setallthreeboomswitchesandthemasterboom

switchtotheOnposition.

7.Usetheapplicationrateswitchtoadjustthepressure

asreadonthepressuregaugeuntilitisintherange

forthenozzlesyouinstalledonthebooms(typically

40psi).

8.Recordthereadingonthepressuregauge.

9.Turnoffoneoftheboomsusingtheappropriate

boomswitch.

10.Adjusttheboombypassvalve(Figure22)underthe

boomcontrolvalvefortheboomyouturnedoff

27

Page 28

untilthepressurereadingonthegaugeisthesame

asitwasinstep7.

Figure22

1.Boombypassvalves

11.Turntheboomonandofftoverifythepressure

doesnotchange.

12.Repeatsteps9through11fortheotherbooms.

13.Drivethesprayeratthedesiredspeedwhilespraying

andturneachboomoffindividually.Thepressure

onthegaugeshouldnotchange.

Pump

pressureinthedampeneris1/3ofthespraying

pressure.Ifusingaspraypressuregreaterthan45psi

(3.1bar)adjustthedampeneraccordingly.

TransportingtheSprayer

Formovingthesprayerlongdistances,useatrailer.

Securethesprayertothetrailer.Figure24and

Figure25illustratethetie-downpoints.

Figure24

1.Tiedownpoints

Thepumpislocatednearthebackofthetankonthe

leftside(Figure23).

Figure23

1.Pump3.Pressuredampener

2.Greasetting

Figure25

1.Reartie-downpoint

TowingtheSprayer

Incaseofanemergency,thesprayercanbetowedfora

shortdistanceafteryouopenthetowvalve.However,

wedonotrecommendthisasastandardprocedure.

Towingatexcessivespeedscouldcausealoss

ofsteeringcontrol,resultinginpersonalinjury.

AdjustingtheAirPressurein

Dampener

Theairpressureinthedampeneronthepumpissetat

15psi(1bar)bythemanufacturer.Therecommended

Nevertowthesprayerfasterthan3mph(4.8

kph).

28

Page 29

Towingthesprayerisatwopersonjob.Ifthemachine

mustbemovedaconsiderabledistance,transportiton

atruckortrailer;refertoTransportingtheSprayer.

1.Rotatethetowvalve(Figure26)90degreesineither

directiontoopenit.

Figure28

1.Reartowingpoints

3.Releasetheparkingbrake.

4.Towthesprayeratlessthan3mph(4.8kph).

5.Whennished,closethetowvalveandtorqueitto

nomorethan5to8ft-lb(7to11N-m).

Figure26

1.Towvalve

Important:Ifyoudonotopenthetowvalve

beforetowingthesprayeryouwilldamagethe

transmission.

2.Afxatowlinetotheframe.Refertothefrontand

reartowingpointsinFigure27andFigure28.

Figure27

1.Fronttowingpoints

29

Page 30

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Aftertherst8hours

Aftertherst50hours

Aftertherst200hours

Beforeeachuseordaily

Every50hours

Every100hours

MaintenanceProcedure

•Replacethehydraulicoillter.

•T orquethewheellugnuts.

•Changetherearplanetarygearboxuid.

•Checkthefan/alternatorbelt

•Changetheengineoil(includingsyntheticoil)andoillter.

•Checkthefuellinesandconnections.

•Packthefrontwheelbearings.

•Checktheairlter,cap,andvalveforwearordamage.

•Checktheengineoil.

•Checkthetirepressure.

•Checkthecoolantlevel.

•Checkthebrakes.

•Checkthehydraulicoillevel.

•Cleanthesuctionstrainer.(Moreoftenwhenusingwettablepowders)

•Lubricatethepump.

•Lubricateallgreasettings.

•Checkthebatterycableconnections.

•Lubricatetheboomhinges.

•Servicetheaircleaner .(moreoftenindusty,dirtyconditions).

•T orquethewheellugnuts.

•Inspecttheconditionandwearofthetires.

•Checkthecoolingsystemhosesforwearanddamage.

•Checkthefan/alternatorbelt

Every150hours

Every200hours

Every400hours

•Replacetheengineoillter.

•Changetheengineoil,includingsyntheticoil(moreoftenwhenoperatingunder

heavyloadorinhightemperature).

•Checkfrontwheeltoe-in.

•Cleantheradiatorns.

•Inspectallhosesandconnectionsfordamageandproperattachment.

•Greasetheactuatorrodbearings.

•Completeallyearlymaintenanceprocedurespeciedintheengineoperator’s

manual.

•Checkthefuellinesandconnections.

•Drainandcleanthefueltank.

•Replacethefuelltercanister.

•Replacethein-tankfuellter.

•Packthefrontwheelbearings.

•Changetheplanetarygearboxuid.

•Checkthecoolant(asdirectedbythemanufacturer)andchangeifnecessary.

•Replacethehydraulicoillter.

•Changethehydraulicoil.

•InspecttheO-ringsinthevalveassembliesandreplacethemifnecessary.

•Inspectthepumpdiaphragmandreplaceifnecessary.(seeanAuthorizedT oro

ServiceDistributor)

•Inspectthepressuredampenerbladderandreplaceifnecessary.(seeanAuthorized

ToroServiceDistributor)

30

Page 31

MaintenanceService

Interval

MaintenanceProcedure

•Inspectthepumpcheckvalvesandreplaceifnecessary.(seeanAuthorizedT oro

ServiceDistributor)

•Checkboomactuatorhydraulicoilforairbubbles.

•Inspectthenylonpivotbushings.

•FlushthesprayerwithcleanwaterusingtheCleaningtheSprayerprocedure.During

Yearly

therinseprocedure,increasepumpspeedtoopenreliefvalve;purgingvalvesand

hosesofresidualuids.

Important:Refertoyourengine

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Checkthebrakeandparkingbrake

operation.

Checktheneutrallockoutswitchoperation.

Checkthefuellevel.

Checktheengineoillevel.

Checkthehydraulicoillevel.

Checkthecoolantlevel.

Inspecttheairlter.

Inspecttheradiatorandoilcoolerfor

debris.

Checkanyunusualenginenoises.

Checkanyunusualoperatingnoises.

Checkthetirepressure.

Checkforuidleaks.

Checkallhydraulicanduidhosesfor

damage,kinks,orwear.

Checktheinstrumentoperation.

Checktheacceleratoroperation.

Cleanthesuctionstrainer.

Lubricateallgreasettings.

Touchupanddamagedpaint.

1

Operator’ s Man ual

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

foradditionalmaintenanceprocedures.

Sat.Sun.

1

Immediatelyaftereverywashing,regardlessoftheintervallisted

31

Page 32

NotationforAreasofConcern

G002215

1

G002216

1

Inspectionperformedby:

ItemDate

1

2

3

4

5

6

7

8

9

10

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Information

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

Premaintenance

Procedures

JackingtheSprayer

Whenevertheengineisrunforroutinemaintenance

and/orenginediagnostics,therearwheelsofthesprayer

shouldbe1inch(25mm)offofthegroundwiththe

rearaxlesupportedonjackstands.

Asprayeronajackmaybeunstableandslipoff

ofthejack,injuringanyonebeneathit.

•Donotstarttheenginewhilethesprayeris

onajack.

•Alwaysremovethekeyfromtheignition

beforegettingoffofthesprayer.

Figure29

1.Frontjackingpoints

Thejackingpointattherearofthesprayerisonthe

rearsidewheretheboomsupportsareFigure30and

Figure31.

•Blockthetireswhenthesprayerisonajack.

Thejackingpointatthefrontofthesprayerisunderthe

frontaxle,directlyundertheleafsprings(Figure29)

Figure30

1.Rearjackingpoints

32

Page 33

Lubrication

GreasingtheSprayer

ServiceInterval:Every50hours—Lubricatethepump.

Every50hours/Yearly(whichever

comesrst)

GreaseType:No.2general-purposelithiumbase

grease.T oroPremiumAllPurposeGreaseisavailable

fromyouToroDistributor.

1.Rearjackingpoint(2)

Figure31

1.Wipethegreasettingcleansothatforeignmatter

cannotbeforcedintothebearingorbushing.

2.Pumpgreaseintothebearingorbushing.

3.Wipeoffexcessgrease.

Thegreasettingspositionsareillustratedbythe

following:Figure32throughFigure34.

33

Figure32

Pump(Donotovergrease,greasewillnotpurge)

1.Greasepoint

Page 34

Figure33

Threeinsideeachfrontwheel

2.Pumpgreaseintothebearingorbushingateach

ttingFigure35.

1.Greasepoint

Figure34

Oneoneachsideofthecenteringarm,betweenthetank

andtheenginecompartment

1.Greasepoint

Figure35

Rightboom

1.Greasetting

3.Wipeoffexcessgrease.

4.Repeattheprocedureforeachboompivot.

GreasingtheActuatorRod

Bearings

ServiceInterval:Every400hours/Yearly(whichever

comesrst)

GreaseType:No.2general-purposelithiumbase

grease.

1.Extendtheboomstothesprayposition.

2.Removethecottezrpinfromthepivotpin

(Figure36).

GreasingtheBoomHinges

ServiceInterval:Every100hours

Important:Iftheboomhingeiswashedwith

water,allwateranddebrismustbeclearedfromthe

hingeassemblyandfreshgreasemustbeapplied.

GreaseType:No.2general-purposelithiumbase

grease.

1.Wipethegreasettingscleansothatforeignmatter

cannotbeforcedintothebearingorbushing.

34

Page 35

G002016

1

4

2

3

5

Figure36

1.Actuator

2.Actuatorrod5.Pin

3.Boompivotpinhousing

7.Withthepininplace,releasetheboomandsecure

thepinwiththecotterremovedpreviously.

8.Repeattheprocedureforeachactuatorrodbearing.

4.Cotter

3.Liftupontheboomandremovethepin(Figure36).

Slowlylowertheboomtothehardstop.

4.Inspectthepinforanydamage,replaceifnecessary.

5.Manipulatetheactuatorrodbearingendandapply

greaseintothebearing(Figure37).Wipeoffexcess

grease.

Figure37

Rightboom

1.Greasebearing

6.Liftupontheboomtoalignthepivotwiththe

actuatorrod.Whileholdingtheboom,insertthe

pinthroughbothboompivotandactuatorrod

(Figure36).

35

Page 36

EngineMaintenance

8.Removetherubbervalvecoverfromtheaircleaner

cover.

ServicingtheAirCleaner

Checktheaircleanerbodyfordamagethatcouldcause

anairleak.Ensurethatthedustcapistightlysealed

ontotheaircleaner.Replaceadamagedaircleanerbody.

Squeezethevalve(Figure38)beforeeachusetoclearit

ofdustanddebris.Servicetheaircleanerlterevery

100hours.

Figure38

1.Aircleanerstrap(2)

2.Dustcap4.Valve

3.Filter

9.Cleanthevalveandreplaceitontheaircleanercover.

InstallingaNewFilterElement

ServiceInterval:Every100hours

1.Ifyouareinstallinganewlter,inspectitfor

shippingdamage.Checkthesealingendofthelter.

Important:Donotinstalladamagedlter.

2.Gentlyslidetheoldlteroutoftheaircleanerbody

toreducetheamountofdustdislodged.

Note:Avoidknockingthelteragainsttheair

cleanerbody .

3.Insertthelterintotheaircleanerbody.Ensurethat

thelterissealedproperlybyapplyingpressureto

theouterrimofthelterwheninstalling.Donot

pressontheexiblecenterofthelter.

4.Installthecoverwiththevalvepointingdownand

securethestraps(Figure38).

5.Squeezetheelementtodistributetheoil.

Note:Servicetheaircleanermorefrequentlyif

operatingconditionsareextremelydustyorsandy .

CleaningtheFilterandHousing

ServiceInterval:Beforeeachuseordaily

Important:Donotremovetheaircleanerinan

attempttocleanit.Thisincreasesthechanceof

dirtanddebrisenteringtheengine.

1.Settheparkingbrake,stopthepump,stopthe

engine,andremovetheignitionkey.

2.Raisethepassengerseat.

3.Loosentheaircleanerstrapthatsecurestheair

cleanercovertotheaircleanerbody(Figure38)and

separatethecoverfromthebody .

4.Uselowpressurecompressedair(40psi,cleanand

dry),toremovedirtanddebrisfromtheinsideofthe

aircleanercoverandaroundtheairlter.

Important:Avoidhighpressurecompressedair

whichcanforcedirtthroughthelterandinto

theengine.

5.Inspectthelterandreplaceitifitisdamaged.

6.Installthecoverwiththevalvepointingdownata

5–7o’clockpositionwhenviewedfromtheend.

7.Securethestraps(Figure38).

ServicingtheEngineOil

Changetheengineoilandtheoillteraftertherst

50operatinghoursandevery150operatinghours

thereafter.

CrankcaseCapacityis4.9qt(4.7l)withthelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4or

higher.

•Preferredoil:SAE15W40(above0degreesF)

•Alternateoil:SAE10W30or5W30(alltemperatures)

ToroPremiumEngineOilisavailablefromyour

distributorineither15W40or10W30viscosity .Seethe

PartsCatalogforpartnumbers.

ChecktheEngineOil

ServiceInterval:Beforeeachuseordaily

Every400hours/Y early(whichever

comesrst)

Note:Thebesttimetochecktheengineoiliswhenthe

engineiscool,beforeithasbeenstartedfortheday.Ifit

hasalreadybeenrun,allowtheoiltodrainbackdown

tothesumpforatleast10minutesbeforechecking.If

36

Page 37

theoillevelisatorbelowthe’add’markonthedipstick,

addoiltobringtheoilleveltothe’full’mark.Donot

overll.Iftheoillevelisbetweenthe’full’and’add’

marks,nooiladditionisrequired.

Theengineisshippedwithoilinthecrankcase;however,

thelevelofoilmustbecheckedbeforeyourststartthe

engineandafteryouhaverunit.

1.Positionthemachineonalevelsurface.

2.Removethedipstick,locatedunderthepassenger

seat,andwipeitwithacleanrag(Figure39).Insert

thedipstickintothetubeandmakesureitisseated

fully.Removethedipstickandchecktheoillevel.

4.Installthellercap.

5.Installthedipstickrmlyinplace.

ChangingtheEngineOilandFilter

ServiceInterval:Aftertherst50hours

Every150hours

Every150hours

1.Starttheengineandletitrununtilwarm;thiswarms

theoilsoitdrainsbetter.

2.Settheparkingbrake,stopthepump,stopthe

engine,andremovetheignitionkey.

3.Raisetheseats.

Componentsundertheseatwillbehotifthe

sprayerhasbeenrunning.Ifyoutouchhot

componentsyoumaybeburned.

Figure39

1.Dipstick

3.Iftheoillevelislow ,removethellercapfrom

thevalvecover(Figure40)andpouroilintothe

openinguntiltheoillevelisuptotheFullmarkon

thedipstick;refertoServicingtheEngineOilfor

theproperoiltypeandviscosity.Addtheoilslowly

andchecktheleveloftenduringthisprocess.Do

notoverll.

Allowthesprayertocoolbeforeperforming

maintenanceortouchingcomponentsunder

thehood.

4.Placeapanbelowtheoildrain.

5.Removethedrainplug(Figure41).

Figure41

1.Oildrainplug

6.Placeaseparatepanundertheoillter.

7.Removetheoldoillter(Figure42).

1.Oilllercap

Figure40

37

Page 38

Figure42

1.Oillter

8.Wipethelteradaptergasketsurface.

9.Applyathincoatofnewoiltotherubbergasket

onthereplacementlter.

10.Installthereplacementoilltertothelteradapter.

Turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional1/2turn(Figure42).

Note:Donotovertightenthelter.

FuelSystem

Maintenance

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.