Page 1

FORM NO. 92-3889

Model No. 41185-90001 & UP

& PARTS MANUAL

ROPS

OPERATOR'S, SET-UP,

for the MULTI-PRO® 1100 Vehicle

To assure maximum safety, optimum

performance, and to gain knowledge of the

product, it is essential that you or any other

operator of this Vehicle read and understand

the contents of this manual before the engine

is ever started. Pay particular attention to the

SAFETY INSTRUCTIONS highlighted by the

triangular safety alert symbol.

The safety alert symbol means CAUTION,

WARNING or DANGER - personal safety

instruction. Failure to comply with the

instruction may result in personal injury.

SAFETY INSTRUCTIONS

Keep this Operator’s Manual in the plastic tube behind the operator seat.

It is very important that all persons operating this equipment have easy access to these instructions at

all times!

Carefully read and follow the “Set-Up” Instructions that are provided with this equipment and the Safety

Instructions in the Multi-Pro

RECOGNIZE SAFETY INFORMATION

TM

1100 Operator’s Manual.

This safety-alert symbol is used to call

attention to a dangerous situation, which

could result in serious injury or death to

the operator or a bystander.

Safety, mechanical and some general

information in this manual are emphasized.

DANGER, WARNING and CAUTION identify

safety messages. Whenever the triangular safety

symbol appears, it is followed by a safety

message that must be read and understood. For

more details concerning safety, read the Safety

Instructions on this page and page 2.

IMPORTANT identifies special mechanical

information and NOTE identifies general

information worthy of special attention.

These instructions are provided as a guide for the

safe operation and maintenance of this

equipment. However, the operator’s personal

safety, as well as those persons in the work area,

will depend on the careful actions and good

judgement of the operator. To reduce the

potential for injury or death, comply with the

following safety instructions.

BEFORE OPERATING:

1. Operate this machine equipped with this

ROPS only after reading and understanding the

contents of this manual and the Multi-Pro™

Operators Manual. A replacement manual is

available by sending complete model and serial

number to: Hahn Inc., 1625 N. Garvin,

Evansville, IN 47711.

1100

2. Keep all safety devices and decals in place. If

a safety device or decal is malfunctioning, illegible

or damaged, replace it before operating the

machine.

3. It is mandatory to wear the seat belt at all times

when operating the machine equipped with the

ROPS system. (Always adjust and secure Seat

Belt before operating the machine.)

WHILE OPERATING:

1. Since this attachment adds extra weight to the

vehicle, drive safely and cautiously to prevent loss

of control and possible upset.

2. Gross vehicle weight has a major impact on

your ability to stop and/or turn. Heavier loads and

heavier attachments make a vehicle harder to stop

or turn. The heavier the load, the longer it takes to

stop.

3. The ROPS is equipped with a roll bar, shoulder

restraints and seat belt. The ROPS system used

on the vehicle will reduce the risk of serious or fatal

injury in the unlikely event of a tip over, although

the system cannot protect the operator from all

possible injuries.

4. Replace a damaged ROPS, do not repair or

revise. Any alteration of ROPS must be approved

by the manufacturer.

©The TORO Company - 1999

All Rights Reserved

1

Page 2

SAFETY INSTRUCTIONS

SEAT BELT OPERATION:

1. Pull the seat belt across lap and latch. Extend

belt completely from retractor and adjust out

slack.

WARNING

Non-locking retractor effective only

when belt is fully extended.

• An improperly latched seat belt

could result in the operator being

thrown from the vehicle.

• Being thrown from vehicle can

result in serious injury or death.

• Read and understand these

instructions and charts, and all seat

belt safety information presented here.

TORQUE SPECIFICATION CHART

BOLT SIZE

3/8"

7/16"

1/2"

3. To be sure of optimum performance and

safety, always purchase genuine TORO

replacement parts and accessories. Replacement

parts and accessories made by other

manufacturers could be dangerous. Altering this

equipment in any manner may affect the

machine’s operation, performance, durability or

its use may result in injury or death. Such use

could void the product warranty of The TORO

Company.

TORQUE VALUE

30 FT. LB.

50 FT. LB.

75 FT LB.

MAINTENANCE:

1. Before servicing or making any adjustments

to the Sprayer:

A. Stop the Vehicle and set the parking brake.

B. Shut off the vehicle’s engine and remove

key from ignition.

C. Disengage all power and wait until all

moving parts have stopped.

2. Keep all nuts, bolts and other fasteners

tightened to torque. Replace any shields

removed during servicing or adjustments.

2

Page 3

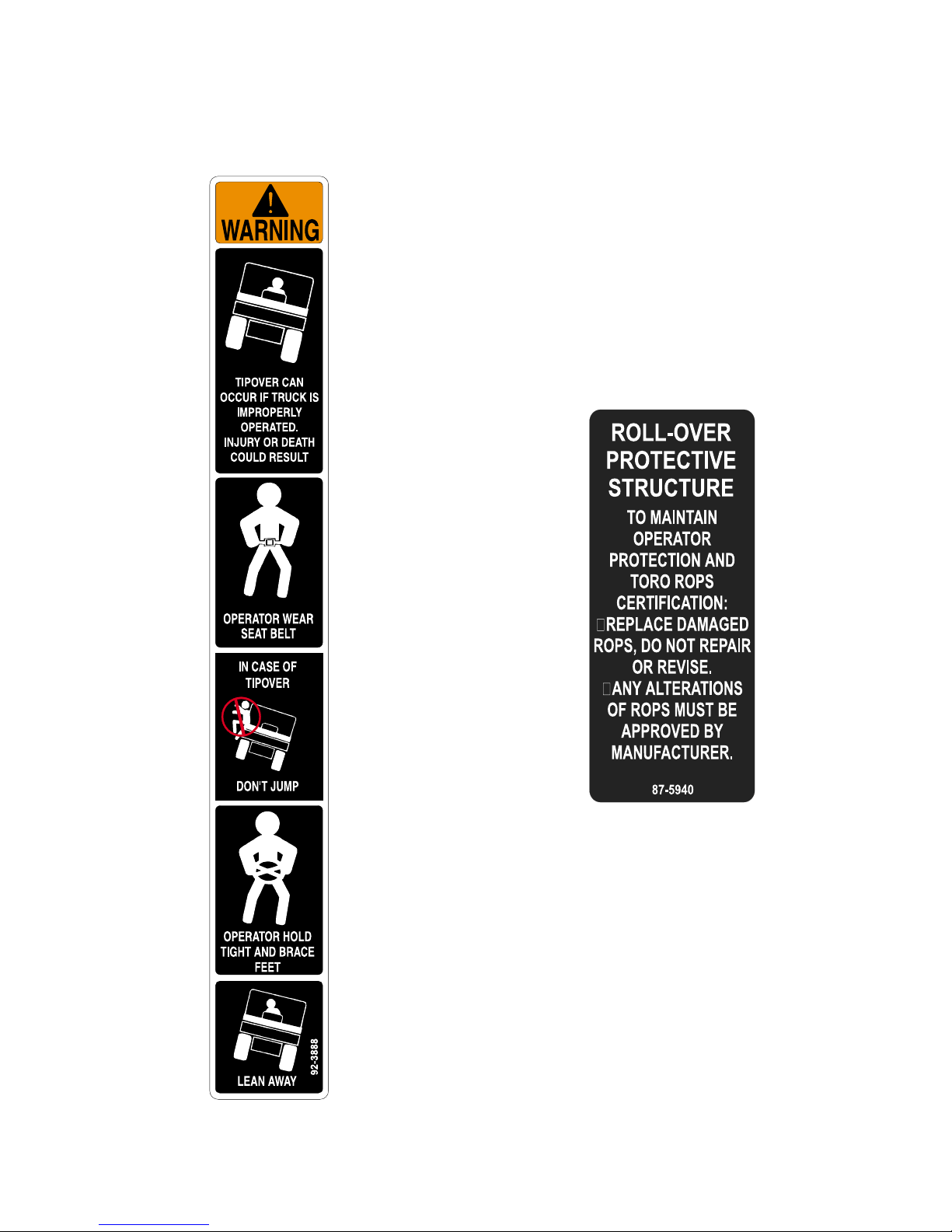

SAFETY AND INSTRUCTION DECALS

The following safety and instruction decals are installed on the Rops. If any become damaged or

illegible, replace them. Decals and part numbers are listed below and in the parts catalog. Order

replacements from your Authorized Toro Distributor.

Part No. 92-3888: Located on the

front of Rear ROPS Bar - R.H.S.

Part No. 87-5940: Located

below Decal No. 92-3888.

3

Page 4

SET-UP INSTRUCTIONS

IF INSTALLING OPERATOR ENCLOSURE AT

THIS TIME, DELETE STEPS 6-8, AND REFER

TO THE SET-UP INSTRUCTIONS PROVIDED

WITH THAT KIT FOR THESE ASSEMBLY

PROCEDURES.

IF MACHINE IS ALREADY EQUIPPED WITH A

HOSE REEL KIT, REMOVE AND DISCARD

EXISTING HOSE REEL MOUNT ANGLE

ASSEMBLIES.

AN ASSISTANT MAY BE NEEDED WHILE

INSTALLING THE ROPS PACKAGE ON THE

TORO MULTI-PRO™ 1100 AS OUTLINED IN THE

FOLLOWING STEPS.

Refer to illustrated parts list for the details of parts

used in assembling the ROPS.

NOTE: "RIGHT", "LEFT", "FRONT" AND "REAR"

ARE REFERENCED WHILE SEATED IN THE

OPERATORS POSITION.

1544

FIG. 1

1. Rear ROPS Bar 2. Vehicle Frame

2. Loosely mount the left hand ROPS bar to the

rear ROPS bar by screwing (2) 3/8" x 1" hex hd.

cap screws with lockwashers, into the insert

anchors located in the top of rear ROPS bar.

1543

1. Open shipping carton, remove the shipping

clamps and rear ROPS bar. Mount the ROPS

bar to the vehicle frame by inserting (8) 1/2" x 11/4" hex. hd. cap screws through the ROPS bar

and the vehicle frame. Start nuts on bolts by

hand. Use a torque wrench and torque nuts to

75 ft. lb. See FIG. 1.

4

1545

FIG. 2

1. R.H.-ROPS Bar 3. ROPS Cross Bar

2. L.H.-ROPS Bar 4. Rear ROPS Bar

3. Loosely mount the lower end of the hand

ROPS bar to the front vehicle frame using (2)

1/2" x 1-1/4" hex hd. cap screws, flatwashers, and

lock nuts. Start nuts on bolts by hand. See

FIG. 3.

Page 5

SET-UP INSTRUCTIONS

1546

FIG. 3

1. L.H.-ROPS Bar 2. Left Front Vehicle Frame

4. Loosely mount the right hand ROPS bar to

the rear ROPS bar by screwing (2) 3/8" x 1" hex

hd. cap screws with lockwashers, into the insert

anchors located in the top of the rear ROPS bar.

5. Loosely mount the lower end of the right

ROPS bar to the right front vehicle frame using

(2) 1/2" x 1-1/4" hex hd. cap screws, flatwashers,

and lock nuts. Start nuts on bolts by hand. See

FIG. 3.

6. Loosely mount the ROPS cross bar to the

right and left hand ROPS bars by screwing (4)

3/8" x 1" hex. hd. cap screw with flatwashers and

lockwashers, into the insert anchors located in

the ROPS bars. See FIG. 2.

7. Align the ROPS bars and using a torque

wrench, tighten the mounting bolts to their proper

torque specifications as outlined in the TORQUE

SPECIFICATION CHART.

1547

FIG. 4

1. Seat Belt Assembly 2. Rear ROPS Bar

1548

FIG. 5

1. Hose Reel Mounting Plate 2. Rear ROPS Bar

TORQUE SPECIFICATION CHART

BOLT SIZE

3/8"

TORQUE VALUE

30 FT. LB.

8. Mount the seat belt assembly to the rear ROPS

bar at a 45° angle using (2) 7/16" x 1-1/4" hex. hd.

cap screws, lockwashers, and hex nuts as shown

in FIG. 4. Using a torque wrench, torque nuts to

50 ft. lb.

NOTE: THE FOLLOWING STEP APPLIES ONLY

IF A HOSE REEL KIT IS TO BE INSTALLED ON

THE MULTI-PRO™ VEHICLE.

9. Mount the hose reel mounting plates to the

rear ROPS bar by screwing (4) 3/8" x 1" hex. hd.

cap screws with lockwashers attached, into the

insert anchors in the ROPS bar and tighten to 30

ft. lb. See FIG. 5.

7/16"

1/2"

50 FT. LB.

75 FT LB.

NOTE: TO ENSURE THE STRUCTURAL

RIGIDITY OF ROPS SYSTEM, MAINTAIN THE

TORQUE VALUES ON THE ATTACHING

HARDWARE AS OUTLINED ABOVE.

5

Page 6

1549

Ref.

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

Part No.

92-3793

92-3983

92-3964

323-6

3253-11

21-4191

324-5

325-5

3256-6

3256-4

32153-5

3217-8

3253-6

92-3801

92-3795

92-3799

ROPS

Description

Rear ROPS Bar

Insert Anchor 1/4" (with setting tool) f/w 92-3793

Hose Reel Mounting Plate

HHCS 3/8-16 UNC x 1"

Lockwasher 3/8

Seat Belt Assembly

HHCS 7/16-14 x 1-1/4"

HHCS 1/2-13 UNC x 1-14"

Flatwasher 1/2

Flatwasher 3/8

Lock Nut 1/2 UNC

Hex Nut 7/16 UNC

Lockwasher 7/16

ROPS Cross Bar

Right Hand ROPS Bar

Left Hand ROPS Bar

Qty.

1

23

2

12

8

1

2

12

4

4

12

2

2

1

1

1

6

Page 7

®

7

Page 8

®

8

Loading...

Loading...