Page 1

FormNo.3429-698RevA

MMX-655H-SMortarMixer

ModelNo.60213—SerialNo.404320000andUp

ModelNo.60216—SerialNo.404320000andUp

ModelNo.60220—SerialNo.404320000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3429-698*A

Page 2

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

TireInformation—TheDOTtireinformationislocated

onthesideofeachtire.Thisinformationgivesload

andspeedratings.Replacementtiresshouldhavethe

sameorbetterratings;refertoSpecications(page

15)toensurethatthetiresonyourmachinemeetor

exceedtheweightrequirementsofyourmachine.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g248834

Figure1

Introduction

Thismachineisdesignedtomixmortar,plaster,

reproongmaterial,grout,andothersmall-grained

Portlandcementproducts.Avehicleequippedwith

anappropriatepintlehitchorballhitchcantowthe

machine.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.T oro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

SafetyandInstructionalDecals..........................7

Setup........................................................................9

1InstallingtheDumpHandle..............................9

2InstallingtheT owPole.....................................9

3InstallingtheSafetyChain..............................10

4AdjustingtheMixingPaddles.........................10

ProductOverview...................................................12

Controls...........................................................12

EngineControls............................................13

Specications..................................................15

Operation................................................................16

ThinkSafetyFirst..............................................16

TowingtheMachine..........................................16

AdjustingtheAxleWidth...................................19

PreparingtoUsetheMachine...........................20

OpeningtheCowl.............................................20

OpeningandClosingtheCowl..........................21

AddingFuel......................................................21

PerformingDailyMaintenance..........................23

StartingtheEngine...........................................23

ShuttingOfftheEngine.....................................24

MixingtheMaterial...........................................24

DumpingtheMaterial........................................25

CleaningtheDrum............................................26

Maintenance...........................................................27

RecommendedMaintenanceSchedule(s)...........27

Pre-MaintenanceProcedures..............................28

PreparingtheMachineforMaintenance............28

DisconnectingtheSpark-PlugWire..................28

RemovingtheDividerPlate..............................28

InstallingtheDividerPlate................................28

Lubrication..........................................................29

LubricatingtheBearingsandSeals...................29

EngineMaintenance...........................................30

ServicingtheAirCleaner..................................30

ServicingtheEngineOil....................................31

ServicingtheSparkPlug...................................32

CleaningtheSparkArrester..............................34

RemovingandInstallingtheEngine..................35

FuelSystemMaintenance...................................37

CleaningtheFuel-SedimentCup......................37

DrainingtheFuelT ank......................................37

DriveSystemMaintenance..................................38

TireAirPressure...............................................38

InspectingtheTires..........................................38

TorquingtheWheelLugNuts............................38

ServicingtheReductionCase...........................39

BeltMaintenance................................................41

InspectingtheBelts..........................................41

AdjustingtheBeltT ension.................................41

ReplacingtheBelts...........................................42

AligningthePulleys..........................................44

PaddleMaintenance............................................45

AdjustingthePaddles.......................................45

3

Page 4

Cleaning..............................................................47

CleaningtheMachine.......................................47

Storage...................................................................47

Troubleshooting......................................................49

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.T oreducethepotential

forinjury ,complywiththesesafetyinstructions

andalwayspayattentiontothesafety-alertsymbol

(Figure2),whichmeans:Caution,Warning,or

Danger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

Thisproductiscapableofamputatinghands.Always

followallsafetyinstructionstoavoidseriousinjuryor

death.

WARNING

Machiningorhandlingstone,masonry,

concrete,metal,andothermaterialscan

generatedust,mists,andfumescontaining

chemicals,suchassilica,knowntocause

seriousorfatalinjuryorillness,suchas

respiratorydisease,silicosis,cancer,birth

defects,orotherreproductiveharm.

•Controldust,mist,andfumesatthe

sourcewherepossible.Usewaterfordust

suppressionwheneverpossible.

•Usegoodworkpracticesandfollowthe

recommendationsofthemanufactureror

suppliers,OSHA,andotheroccupational

andtradeassociations.

•Alwaysfollowrespiratoryprecautions.

•Whenyoucannoteliminatethehazards

frominhalation,youandallbystanders

shouldweararespiratorapprovedby

OSHAforthematerialthatyouare

handling.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichislethalifinhaled.

Donotruntheengineindoorsorinan

enclosedarea.

Training

•Parkthemachineonalevelsurface,shutoffthe

engine,waitforallmovingpartstostop,andallow

themachinetocoolbeforeadjusting,cleaning,

storing,orrepairingthemachine.

4

Page 5

•Readandunderstandthecontentsofthis

Operator’sManualbeforeyoustarttheengine.

Ensurethateveryoneusingthisproductknows

howtouseitandunderstandsthewarnings.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingthem.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriestopeopleordamageto

property.

Towing

•Checkwithyourlocalcountyorstatetowingsafety

regulationsbeforetowingthemachine.

•Toreducethepossibilityofanaccidentwhile

transportingthemachineonpublicroads,ensure

thatthetowingvehicleismechanicallysoundand

ingoodoperatingcondition.

•Shutofftheenginebeforetransportingthe

machine.

•Whentowingwithaballhitch,ensurethatitisthe

propersizeforthehitchcoupleronthemachine.

•Whentowingwithapintlehitch,ensurethatthe

eyeofthetowpoleisthecorrectdimensionfor

thepintlehook.

•Inspectthehitchandcouplingforwear.Donot

towthemachinewithdamagedorwornhitches,

couplings,chains,orothercomponents.

•Checktheairpressureofthetiresonthetowing

vehicleandadjustthepressureasneeded.

•Checkthetiretreadandsidewallfordamageand

wearandreplacethetireifnecessary.

•Properlyattachthesafetychainstothetowing

vehiclebycrossingthechainsandremovingany

extraslack.

•Ensurethatthedirectionalandbrakelightsare

workingproperly(ifequipped).

•Ensurethatthedirectional,backup,andbrake

lightsofthetowvehicleareworkingproperly(if

equipped).

•Beforetowing,ensurethatyourmachineis

correctlyandsecurelyattachedtothetowing

vehicle.

•Ensurethatthesafetychainsareproperlysecured

tothevehicle,andleaveenoughslackforturning.

•Donotcarryanymaterialinthemachinewhen

towing.

•Avoidsuddenstopsandstarts.Thiscancause

skiddingorjackkning.Smooth,gradualstartsand

stopsimprovestowing.

•Avoidsharpturnstopreventrolling.T owonlywith

avehiclethathasahitchdesignedfortowing.Do

notattachtowedequipmentexceptatthehitch

point.

•Donottowthemachinefasterthan88km/h(55

mph).

•Usecautionwhenbackingup;useaspotter

outsidethevehicletoguideyou.

•Donotallowanyonetositorrideonthemachine.

•Disconnectthemachinefromthetowvehicle

beforeusingit.

•Placechocksunderneaththetirestopreventthem

fromrollingwhilethemachineisparked.

Preparation

Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Useonlyaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearpersonalprotectiveequipmentand

appropriateclothingincluding:

–Hardhat

–Respiratorordustmask

–Faceshield

–Safetyglasses

–Hearingprotection

–Safetyshoes

–Longpants

–Shirtwithlongsleevesthataretightatthe

wrists

–Tight-ttinggloveswithoutdrawstringsorloose

cuffs

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearloosejewelry .

•Ensurethatthemachineisonalevelsurface

beforeoperatingit.

•Chockthetiresofthemachinetoprevent

unintendedmovement.

•Beforeeveryuse,dothefollowing:

–Inspectthecoupler,ball,andhitch.

–Ensurethatalllightsarefunctioningproperly

(ifequipped).

–Ensurethatthetiresareproperlyinated.

–Ensurethatthelugnutsaretightandtorqued

properly.

–Ensurethatthemachineisproperlysecured.

5

Page 6

FuelSafety

•Useextremecareinhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Ifthemixingpaddlesstrikeanobjectorifthe

machinestartsmakinganunusualnoiseor

vibration,shutofftheengine,waitforallmoving

partstostop,andemptythedrum.Inspectfor

cloggingordamage.Clean,repair,and/orreplace

anydamagedparts.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainfuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

Operation

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotrunanengineinanenclosedorpoorly

ventilatedarea.

•Operatethemachineonlyingoodlighting

conditions.

•Beforestartingthemachine,ensurethatthereare

nopeopleorobstaclesnearorunderthemachine.

•Shutofftheenginebeforeleavingthemachinefor

anyreason.

Neverleavearunningmachineunattended.

Alwaysshutofftheengineandverifythatall

movingpartshavestopped.

•Chockthetiresofthemachineorkeepitattached

tothetowingvehiclewhenitisnotinuse.

•Keepyourhandsawayfromanymovingparts.

Keepyourfeetawayfromthetiresandthefront

post.

•Donotoperatethemachineundertheinuence

ofalcoholordrugs.

•Donotplaceyourhandsoranysolidobjectinto

thedrumwhenthemachineisinoperation.

•Donottouchpartsthatmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,

adjust,orservicethemachine.

•Nevermovethemachinewhiletheengineis

running.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Donotoperatethemachinewhenthereistherisk

oflightning.

MaintenanceandStorage

•Beforeperformingmaintenance,dothefollowing:

–Parkthemachineonalevelsurface.

–Shutofftheengineandwaitforallmovement

tostopbeforeadjusting,cleaning,orrepairing

themachine.

–Lettheenginecoolbeforeperforming

maintenanceorstoringthemachine.

–Disengageallpowerandoperationcontrols.

•Neverlubricate,service,repair,oradjustthe

machinewiththeenginerunning.

•Keepequipmentmaterialsclearfromthemufer

andenginetopreventres.Cleanupoilorfuel

spills.

•Neverallowuntrainedpersonneltoservicethe

machine.

•Keepyourhands,feet,andclothingawayfrom

movingparts.Ifpossible,donotmakeadjustments

withtheenginerunning.

•Keepallpartsingoodworkingconditionandall

fastenerstightened.Replaceallwornordamaged

decals.

•Removeanybuildupofgrease,oil,ordebrisfrom

themachine.

•Stopandinspectthemachineifanobjectenters

thedrumorcausesanotherobstruction.Makeall

necessaryrepairsbeforestartingthemachine.

•Donottamperwithsafetydevices.

•Chockthetireswhenstoringthemachine.

•Keepallfastenersandhoseclampssecurely

tightenedandallequipmentingoodcondition.

•UseonlygenuineTororeplacementparts.

•Keepthecowlclosedandlatchedduringoperation.

•Ensurethatalltheguardsandshieldsaresecurely

inplacebeforeoperatingthemachine.

6

Page 7

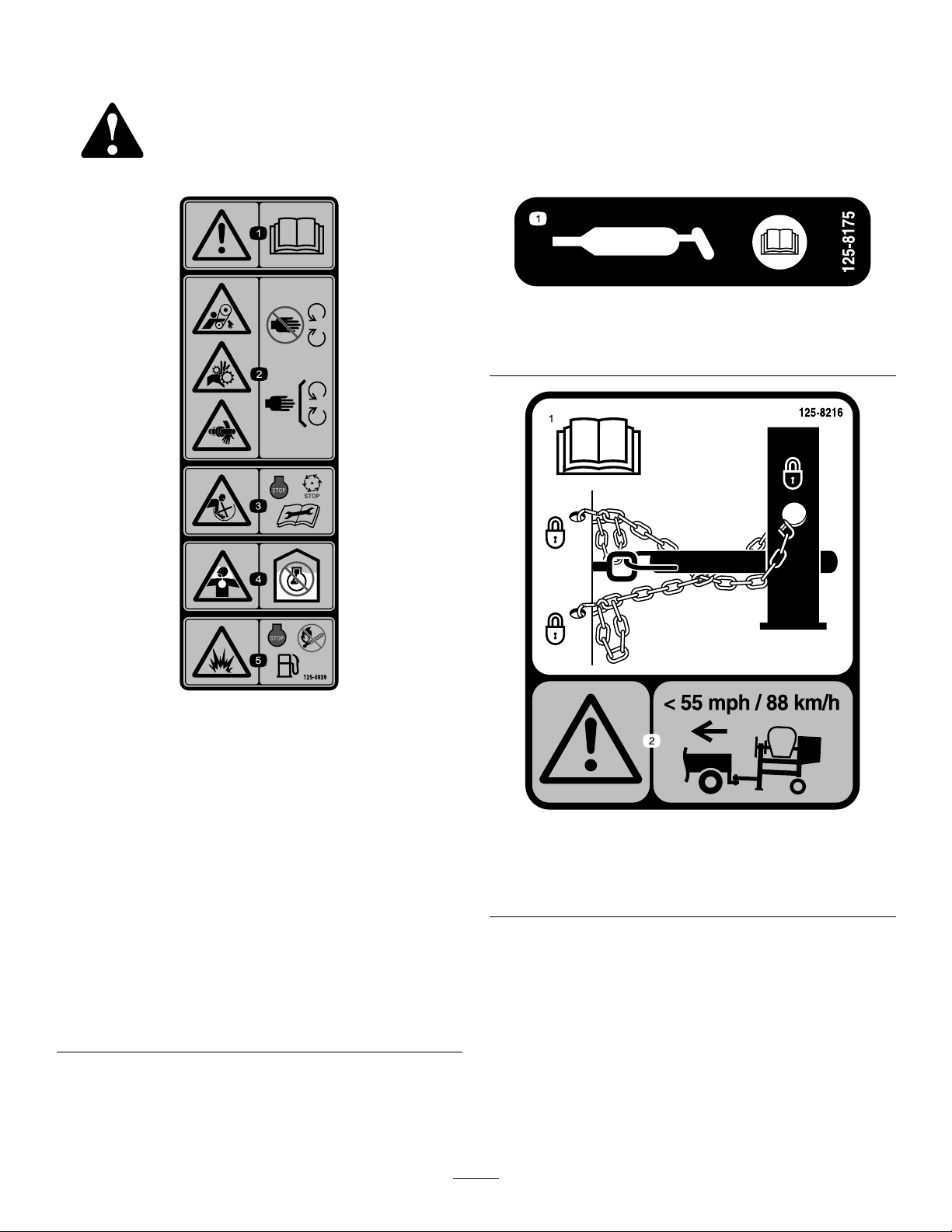

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal125-8175

125-8175

1.ReadtheOperator’sManualforinformationongreasing

themachine.

1.Warning—readthe

Operator’sManual.

2.Handandarm

entanglementatthe

beltdrive;crushinghazard

ofhand;entanglement

hazardofhandatthe

shaft—keepyourhands

awayfrommovingparts;

keepallguardsand

shieldsinplace.

3.Entanglementhazard

atpaddles—shutoff

theengineandwait

forallmovingpartsto

stopbeforeperforming

maintenance.

decal125-4939

125-4939

4.Toxicgasinhalation

hazard—Donotrunthe

engineinanenclosed

space.

5.Explosionhazard—shut

offtheengineandkeep

awayfromameswhen

refueling.

1.ReadtheOperator’s

Manualforinformationon

howtotowthemachine.

125-8216

2.Warning—limittowing

speedtolessthan88km/h

(55mph).

decal125-8216

7

Page 8

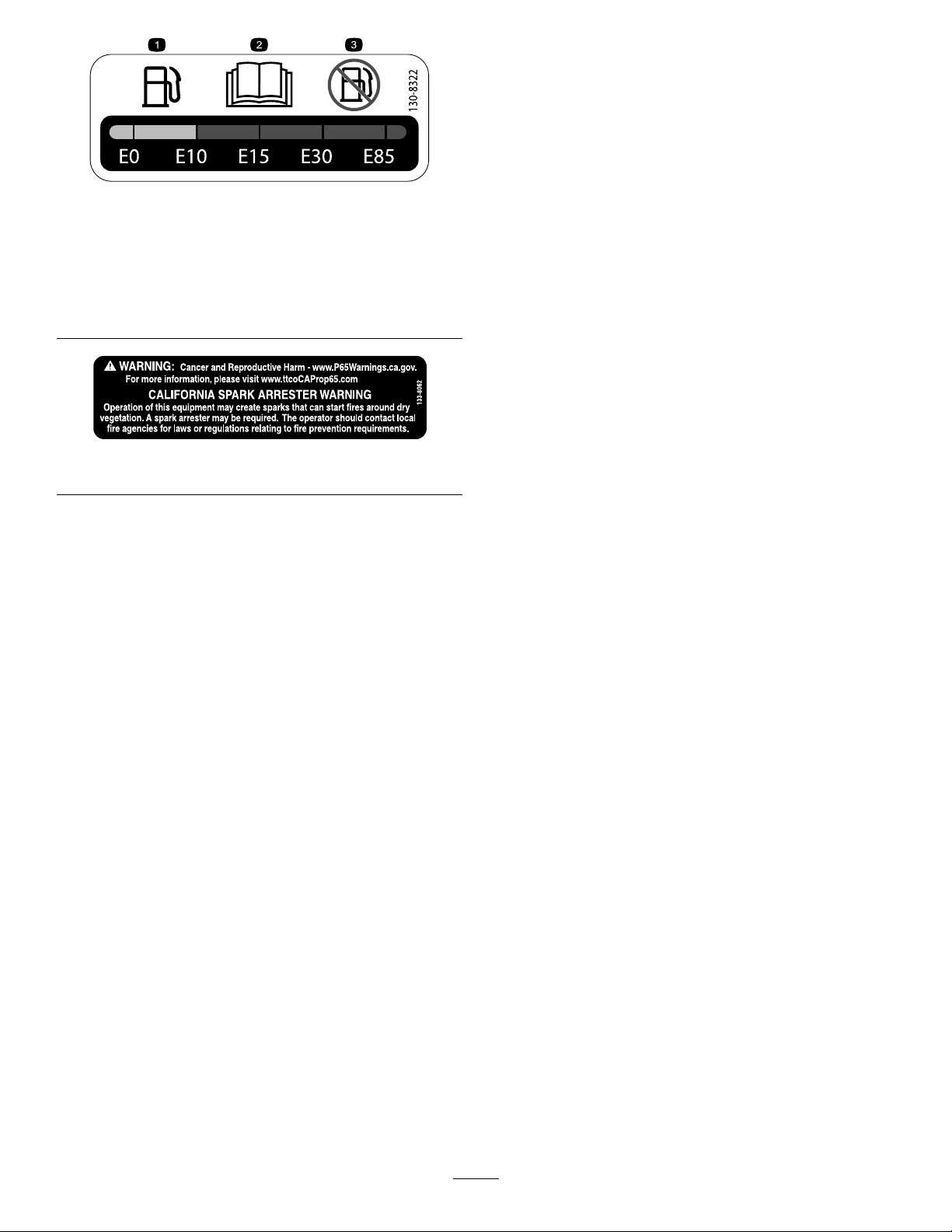

decal130-8322

130-8322

1.Usefuelwithanalcohol

contentbyvolumeunder

10%only.

2.ReadtheOperator's

Manualformore

informationonfuel.

3.Donotusefuelwithan

alcoholcontentgreater

than10%byvolume.

decal133-8062

133-8062

8

Page 9

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Dumphandle1

1

2

3

4

Carriagebolt

Nut2

Towpolekit(soldseparately)

Safetychain(includedwiththetowpole

kit)

Connectinglink(includedwiththetow

polekit)

Nopartsrequired

1

InstallingtheDumpHandle

Partsneededforthisprocedure:

1Dumphandle

2

Carriagebolt

2Nut

Qty.

Use

2

1

1

2

–

Installthedumphandle.

Installthetowpole(side-dumpmodels

only).

Installthesafetychain.

Adjustingthemixingpaddles.

Procedure

1.Cutthecabletiestoremovethedumphandle

fromtheundersideofthegrate.

2.Installthedumphandletothesideofthedrum

using2carriagebolts(installedontheinsideof

thedrum)andnutsasshowninFigure3.

g028569

Figure3

9

Page 10

2

InstallingtheTowPole

Partsneededforthisprocedure:

1

Towpolekit(soldseparately)

4.Threadthenutontotheboltandtightenthem

untiltheyaretightagainsttheframetting

(Figure4).

Note:Iftheself-lockingnyloninsertinthe

locknutwearswithuse,replacethenutwitha

newGrade5orGrade8locknut.

3

TowPoleSpecications

Purchasethetowpolekit(includingfasteners)that

meetsyourneedsfromyourAuthorizedService

Dealer.Themachinehasthefollowingtowpole

options:

HitchTypeLength

50mm(2inch)ball—stamped78.7cm(31inches)or127cm

50mm(2inch)ball—forged78.7cm(31inches)or127cm

Pintle

(50inches)

(50inches)

78.7cm(31inches)or127cm

(50inches)

InstallingtheTowPole

1.Removetheboltandnutfromthetowpole

(Figure4).

InstallingtheSafetyChain

Partsneededforthisprocedure:

1

Safetychain(includedwiththetowpolekit)

2

Connectinglink(includedwiththetowpolekit)

Procedure

Safetychainandconnectinglinkareincludedinthe

towpolekit(soldseparately);referto2Installingthe

TowPole(page9).

Formahookontheendofabendablepieceofrodor

stiffwire(notincluded)andinstallthesafetychainand

connectinglinksasshowninFigure5.

Figure4

1.Towpole4.Bolthole

2.Frontpost

3.Bolt6.Nut

2.Slidethetowpoleforwardandaligntheholein

thepolewiththeholeintheframetting(Figure

4).

3.Inserttheboltthroughtheholesinthettingand

thepole(Figure4).

5.Frametting

g019804

g035100

Figure5

Note:Ensurethatapproximatelyequallengthsof

safetychainextendfromeithersideofthefrontpost.

10

Page 11

4

AdjustingtheMixing

Paddles

NoPartsRequired

Procedure

Ifthemixingpaddlesandwipersneedadjustment,

adjustthepaddlesandwipers;refertoAdjustingthe

Paddles(page45).

11

Page 12

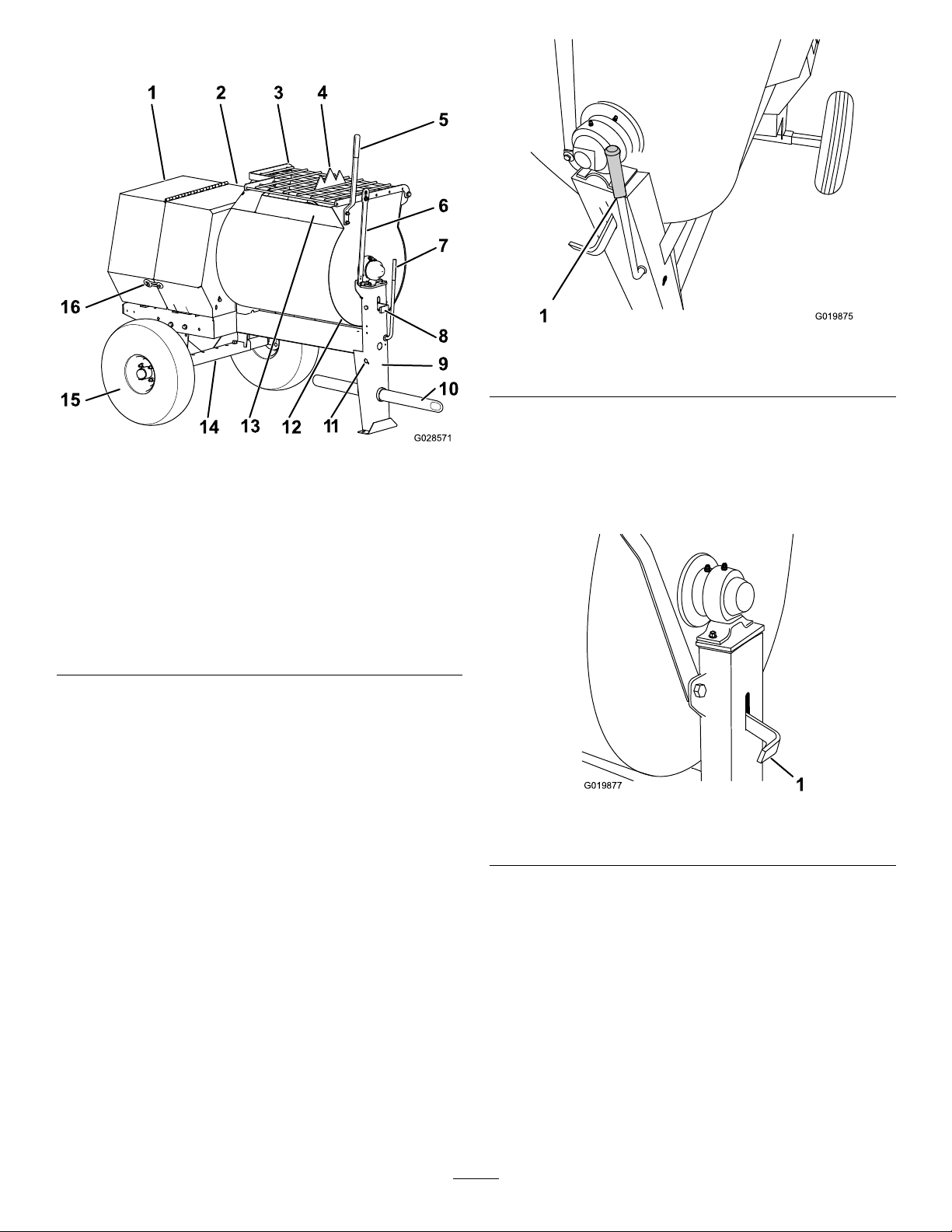

ProductOverview

g019875

Figure7

1.Clutchlever

Figure6

Rightside

1.Rearcowl

2.Frontcowl8.Drumlatch14.Axle

3.Grate

4.Bagsplitter10.Towpole

5.Dumphandle

6.Grateliftarm

7.Clutchlever13.Chute

9.Frontpost15.Wheel

assembly

16.Cowllatch

11.Safety-chain

keyhole

12.Drum

Controls

Becomefamiliarwithallthecontrolsbeforeyou

operatethemachine.

ClutchLever

Usetheclutchlevertoengageanddisengagethe

paddles.

g028571

DrumLatch

Usethedrumlatchtosecurethedrumtothemix

position(upright)formixingoperationsandwhen

transportingthemachine.

g019877

Figure8

1.Drumlatch

12

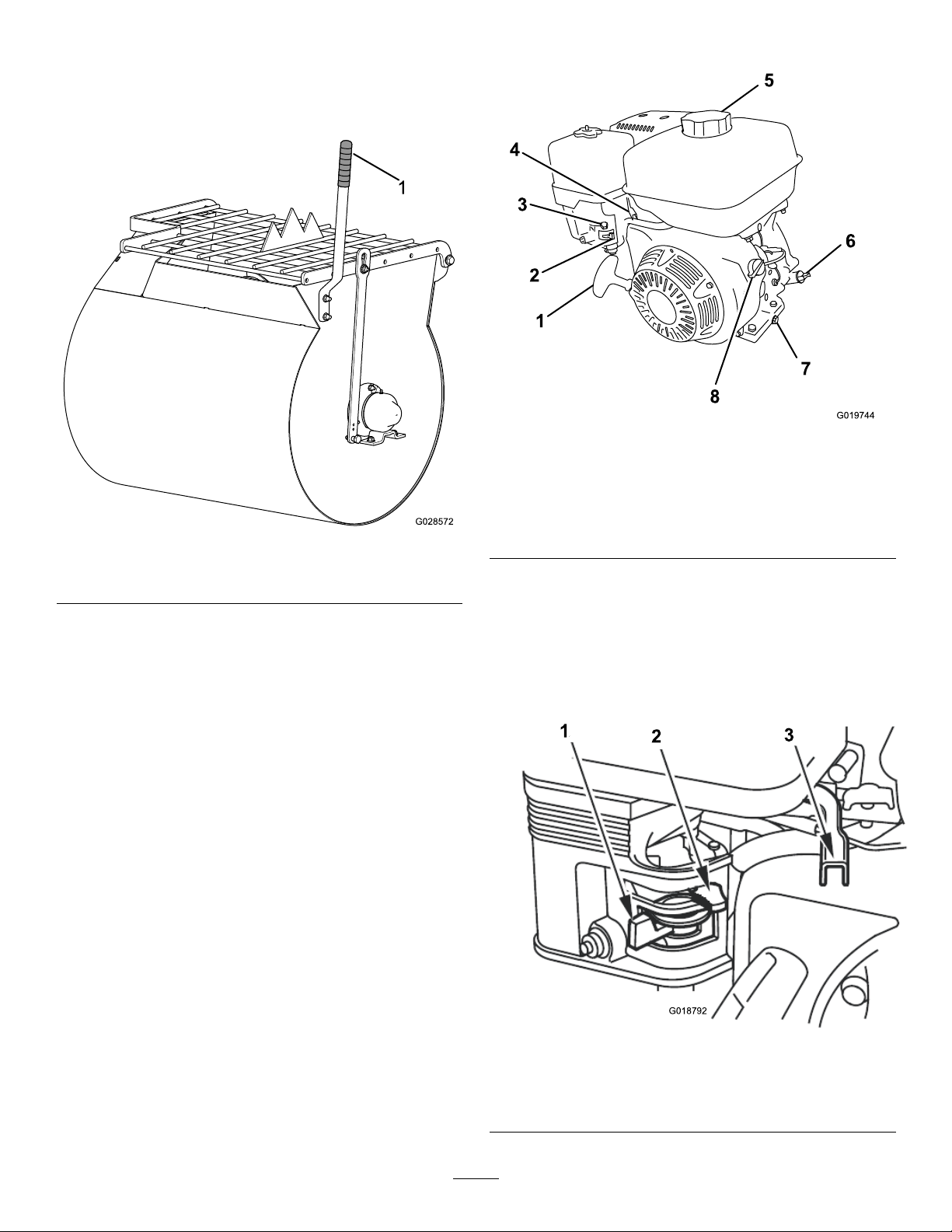

Page 13

DumpHandle

Usethedumphandletorotatethedrumtothedump

positionandtorotatethedrumtothemixposition

(upright).

Figure9

EngineControls

g019744

Figure10

1.Recoil-starthandle5.Fuelcap

2.Fuelvalve

3.Chokelever

g028572

4.Throttlelever

6.Oildipstick

7.Oil-drainplug

8.On/Offswitch

1.Dumphandle

FuelValve

Thefuelvalve(Figure11)islocatedunderneaththe

chokelever.Movetheleverforthefuelvalvetothe

ONpositionbeforeattemptingtostarttheengine.

Whenyouhavenishedmixing,shutofftheengine

andmovethefuel-valvelevertotheOFFposition.

Figure11

1.Fuelvalve3.Throttlelever

2.Chokelever

13

g018792

Page 14

ChokeLever

Usethechokelever(Figure11)tostartacoldengine.

Beforepullingtherecoil-starthandle,movethechoke

levertotheCLOSEDposition.Oncetheengineis

running,movethechokelevertotheOPENposition.

Donotusethechokeiftheengineisalreadywarmed

uporiftheairtemperatureishigh.

ThrottleLever

Thethrottlelever(Figure11)controlsthespeed(rpm)

oftheengine.Itislocatednexttothechokelever.It

setstheenginespeedandthereforecanincreaseand

decreasetherotationspeedofthemixingpaddles.

Forbestperformance,setthiscontroltotheFAST

positionwhenmixingmaterial.

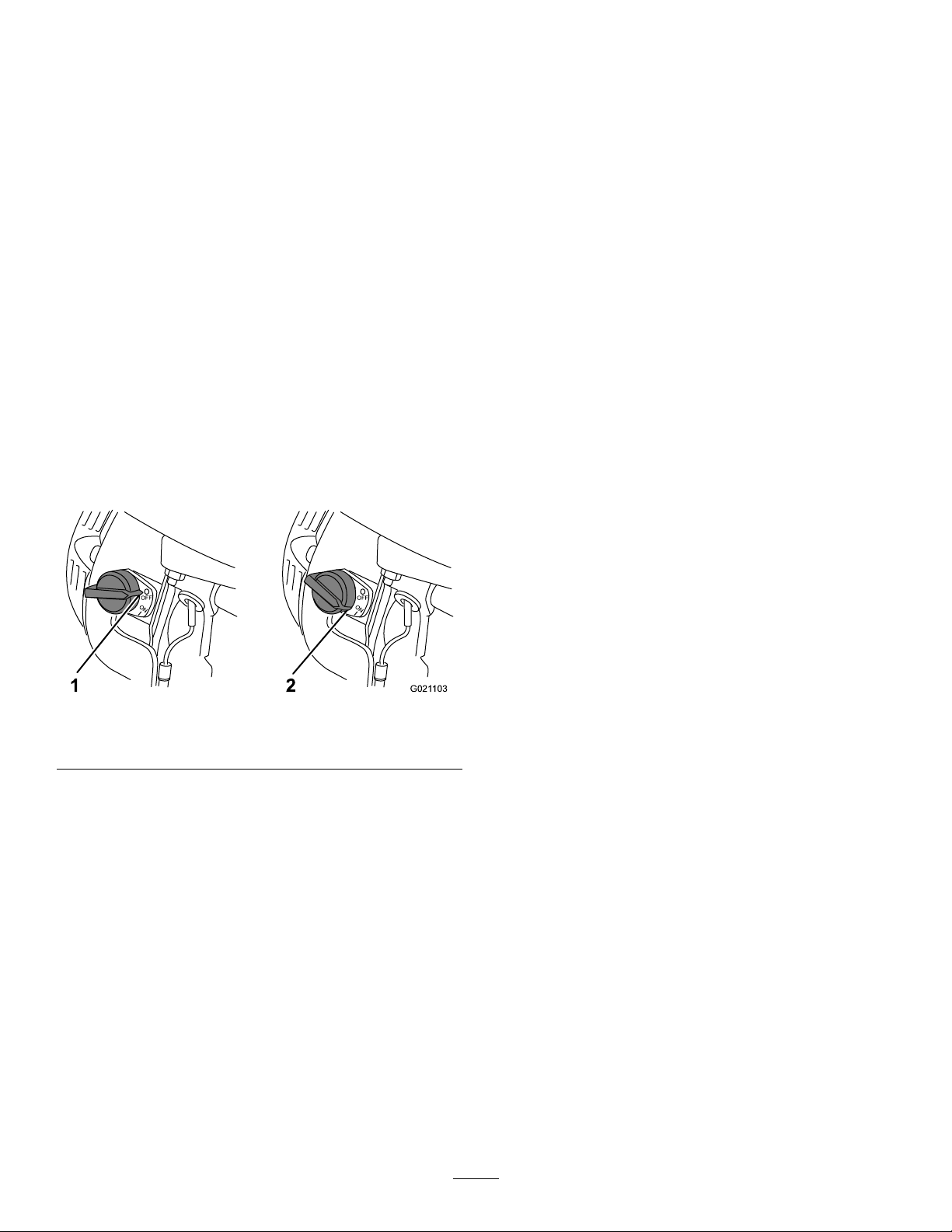

EngineOn/OffSwitch

TheOn/Offswitchislocatedonthefrontoftheengine.

•RotateittotheONpositiontostartandrunthe

engine.

•RotateittotheOFFpositiontoshutofftheengine.

Figure12

1.OFFposition2.ONposition

Recoil-StartHandle

Tostarttheengine,pulltherecoil-starthandle(Figure

10)quicklytoturntheengineover.Theengine

controlsdescribedabovemustallbesetcorrectlyfor

theenginetostart.

Oil-LevelSwitch

Theoil-levelswitchislocatedinsidetheengine,andit

doesnotallowtheenginetorunintheeventtheoil

levelisbelowthesafeoperatinglimit.

g021103

14

Page 15

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

MachineSpecications

Model

BatchCapacity0.17m

TotalVolume

60217,60217C60221,60221C

3

(6.0ft3)0.23m

3

0.19m

(6.7ft3)0.24m

3

(8.0ft3)0.23m

3

(8.6ft3)0.24m

DrumMaterialPolyethylenePolyethylenePolyethylene

Length

(withouttowpole)

Width86cm

Height142cm

Weight250kg

Axle

Engine

150cm

(59inches)

(34inches)

(56inches)

(552lb)

86to117cm(34to46inches)

extendable

®

Kohler

CH395Kohler

168cm

(66inches)

86cm

(34inches)

142cm

(56inches)

254kg

(560lb)

86to117cm(34to46inches)

extendable

®

CH395Honda

Drivebeltbeltbelt

60221HD

3

(8.0ft3)

3

(8.6ft3)

168cm

(66inches)

86cm

(34inches)

142cm

(56inches)

254kg

(560lb)

86to117cm(34to46inches)

extendable

®

GX240

15

Page 16

Operation

ThinkSafetyFirst

Carefullyreadallsafetyinstructionsandsymbolsin

thismanual,ontheproductdecals,andothermedia

suppliedwiththeproduct.Knowingthisinformation

couldhelpyouorbystandersavoidinjury.

Knowhowtoquicklyshutdownthemachineinan

emergency.

Useahard-hat,hearingprotection,ashirtwithlong

sleevesthataretightatthewrists,tight-ttinggloves

withoutdrawstringsorloosecuffs,eyeprotection,and

adustmaskorrespirator.Ameshvisoralonedoes

notprovidesufcienteyeprotection;supplementwith

protectiveglasses.

CAUTION

Thismachineproducessoundlevelsthatcan

causehearinglossthroughextendedperiods

ofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

TowingtheMachine

Beforetowingthemachine,readalltheinformation

andperformalltheapplicableprocedurestointhis

sectiontoensuresafeandpropertowing.

WARNING

Towingthemachineathighspeedincreases

theriskofahitchmalfunctionandtirefailure.

Higherspeedsalsoincreasethemomentum

ofthemachineandbrakingdistance.Ifthe

machinedetachesfromthetowvehicleathigh

speed,itcouldcausedamagetoproperty,or

injuryordeathtobystanders.

Donotexceed88km/h(55mph)whentowing

themachine.Forpoorroadconditionsor

inclementweather,reducespeedaccordingly .

WARNING

Towingthemachinewithmaterialinthedrum

increasestheriskofahitchmalfunctionand

tirefailure.Inaddition,materialcouldbounce

outofthedrumandhitothervehiclesand/or

people.Materialinthedrumincreasesthe

weight,whichaffectsmomentumandbraking

distance.

1.Wearhearingprotection.

Figure13

Donottowthemachinewithmaterialinthe

drum.

•ReviewandunderstandtheSafeOperating

g229846

Practices(page4).

•Testthebrakesofthetowvehiclebeforetowing.

•Avoidsuddenstartsandstopswhiletowingthe

machine.

TowVehicleRequirements

Beforeconnectingthemachinetoyourtowvehicle,

ensurethatyourvehicleispreparedasfollows:

•Ensurethatyourtowvehiclehastowing

capacityfortheweightofthemachine;referto

Specications(page15).

•UseaClass2orlargerreceiver.

•Ensurethatyourtowvehiclehastheappropriate

hitchtotowthemachine;optionsincludea50mm

(2inch)ballhitchorapintlehitch.

•Ifthemachineisequippedwithatrailer-lightkit,

ensurethattheelectricalconnectorofthetow

vehicleiscompatiblewiththeelectricalconnector

ofthemachine.Themachineusesastandard

4-pin,atplug.Ifyourtowvehiclehasadifferent

typeofplug,obtainanadapterfromanautomotive

partsstore.

16

Page 17

PreparingtheMachineforTowing

1.Shutofftheengineandfuelvalve.

2.Emptythedrum.

3.Positionthedruminthemixposition(upright)

andlockit.

4.Closetheenginecowlandsecurethecowl

latches(Figure14).

Figure14

5.Ifyouhaveadjustedtheaxletothenarrow

position(ifequippedonyourmodel),extendthe

axle;refertoAdjustingtheAxleWidth(page19).

g022324

6.Inspectthetires;refertoInspectingtheTires

(page38).

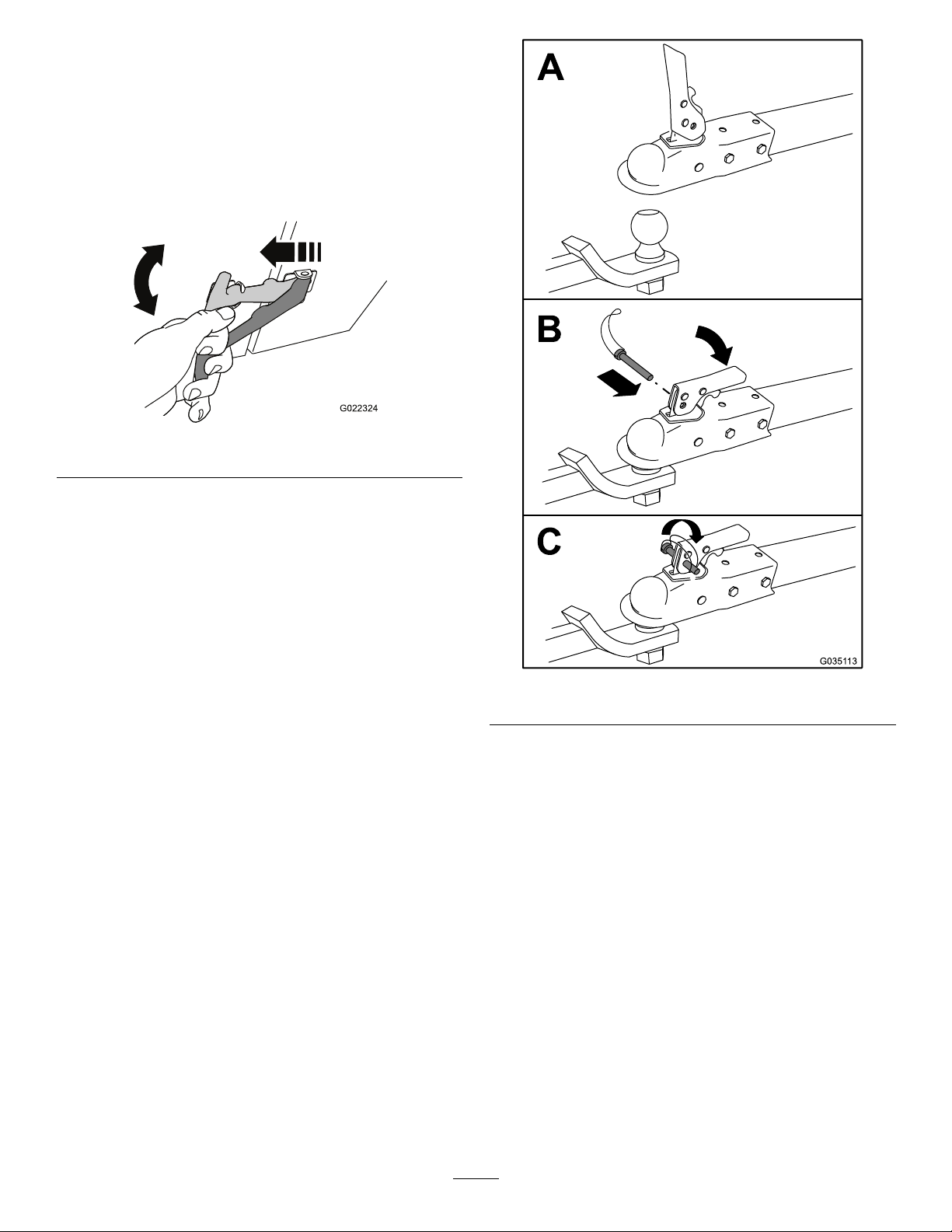

HitchingtheMachinetoaTow

Vehicle

Yourmachineisequippedwith1ofthefollowing

hitchtypes;hitchitasdescribedintheappropriate

procedure:

•Stamped-ballcoupler—HitchingaStamped-Ball

Coupler(page17)

•Forged-ballcoupler—HitchingaForged-Ball

Coupler(page17)

•Pintle-hitchcoupler—HitchingaPintle-Hitch

Coupler(page18)

HitchingaStamped-BallCoupler

1.Applychassisgreasetothesocketofthecoupler

andtheareaoftheclampthatcontactstheball.

2.Oilthepivotpointsandslidingsurfacesofthe

couplerwithSAE30motoroil.

g035113

Figure15

HitchingaForged-BallCoupler

1.Applyremovablethread-lockingcompoundto

thethreadsofthecouplerbolttopreventthe

couplerhandlefromcomingloose.

Important:Applythread-lockingcompound

asneededinthefuture.

2.Applychassisgreasetothesocketofthecoupler

andtheareaoftheclampthatcontactstheball.

3.HitchthemachineasshowninFigure16.

3.HitchthemachineasshowninFigure15.

17

Page 18

Figure16

Note:Useawrenchtokeeptheboltfrom

spinning.

HitchingaPintle-HitchCoupler

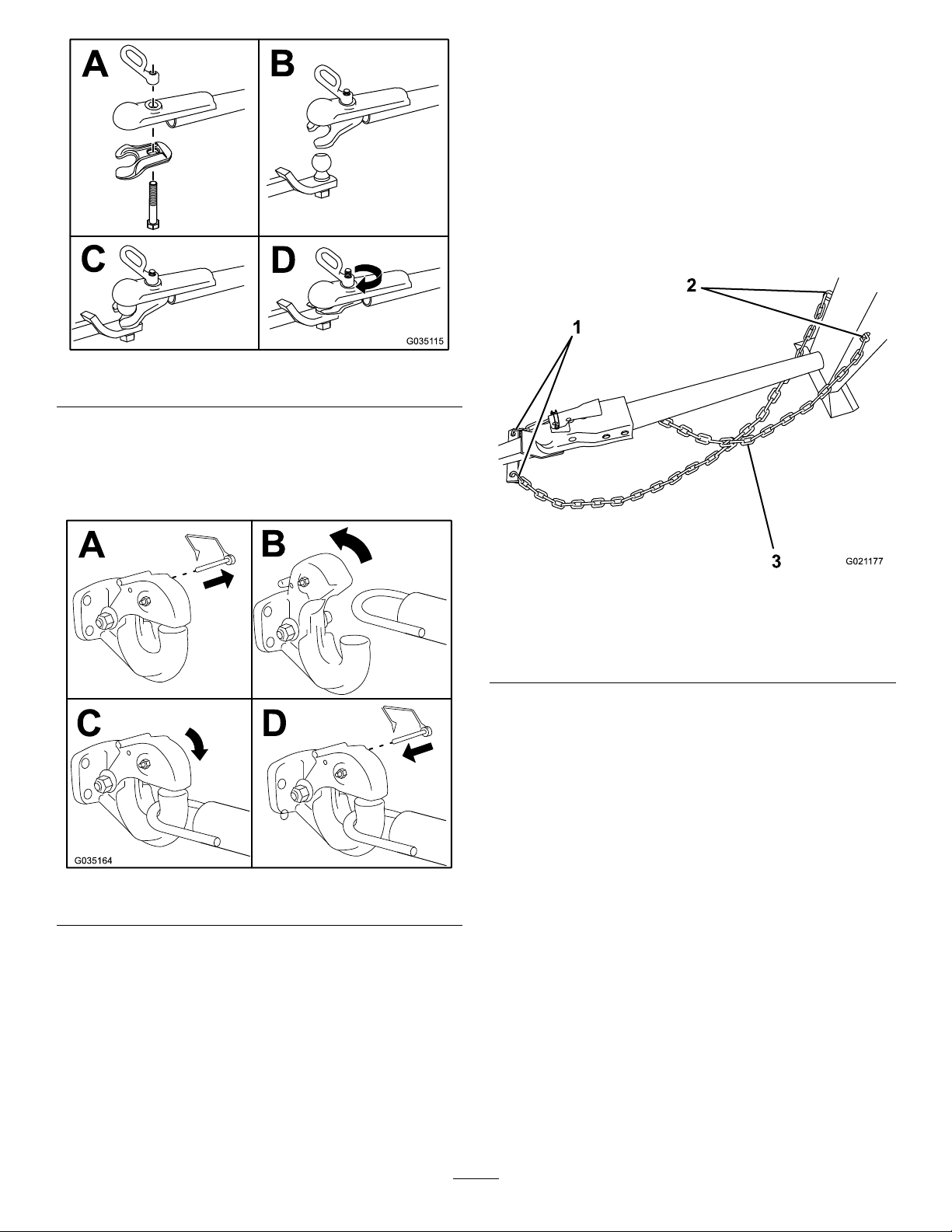

ConnectingtheSafetyChainsto

theTowVehicle

1.Pullthesafetychainthroughtheslotsinthe

keyholes,sothatthelengthsoneachsideare

equal.

2.Crossbothlengthsofchainunderthetowpole.

Note:Crossingthechainsdecreasesthe

chancesofthefrontofthemachinedropping

tothegroundifthehitchdoesnotholdthe

connection.

g035115

Figure17

g021177

Figure18

1.Connectinglinks3.Chaincrossedundertow

2.Keyholesinfrontpost

pole

3.Connecteachlengthofchaintothesafety

chainmountingpointonthetowvehiclewiththe

connectinglinks(Figure19).

Important:Ensurethatthechainhas

enoughslackforturningaroundcorners

whentowingthemachine.

Note:Stowtheexcesschaininsidethebottom

g035164

ofthefrontpostbypushingitintothekeyholes

andlatchingtheappropriatelinksintothe

keyholeslots.

18

Page 19

Thecorrespondingturn-signallightsofthe

machineshouldilluminate.

AdjustingtheAxleWidth

ModelswithAdjustableAxlesOnly

Ifyourmodelisequippedwithanadjustableaxle

(Figure22),youcanadjusttheaxletothenarrow

positiontomovethemachinethroughanarrow

accesspoint,suchasthegateofafenceorthe

doorwayofabuilding.

Figure19

1.Connectinglink3.Chainlink

2.Safetychainmounting

pointontowvehicle

4.Chain

ConnectingandCheckingthe

Lights

MachinesEquippedwithaLightKitOnly

1.Connecttheelectricalplugofthemachinewith

theelectricalplugofthetowvehicle(Figure22).

Figure20

g019927

WARNING

Themachineisnotstablewhentowedwith

theaxleinthenarrowposition.

Towthemachinewiththeaxleinthewide

position.

Important:Themachineislessstablewiththe

axleinthenarrowposition.Onlyadjustittothe

narrowpositionwhennecessarytomovepastan

obstruction,thenreturnittothewideposition

beforetowingoroperatingthemachine.

1.Parkthemachineonalevelsurfaceand

disconnectthemachinefromthetowvehicle.

2.Securethemachinefrommovement.

3.Emptythedrum,moveittotheuprightposition,

andlockthedrum.

4.Alignajackwithanadequateliftheight

g020828

andweightcapacityundertheaxle;referto

Specications(page15).

5.Liftthemachineuntilthetiresareofftheground.

Note:Themachineusesastandard4-pin,at

plug.Ifyourtowvehiclehasadifferenttype

ofplug,obtainanadapterfromanautomotive

partsstore.

2.EnsurethatthetowvehicleisintheNEUTRAL

position,engagetheparkingbrake,andstart

theengine.

3.Testthelightsasfollows:

A.Turnontheheadlightsofthetowvehicle.

Thetaillightsofthemachineshould

illuminate.

B.Pressthebrakepedalofthetowvehicle.

Thebrakelightsofthemachineshould

illuminate.

C.Operateeachturnsignalofthetowvehicle

inturn.

6.Useajackstandateachsupportpointonthe

rearframeextension(Figure21).

WARNING

Mechanicalorhydraulicjacksmayfailto

supportthemachineandcauseserious

injury.

Usejackstandswhensupportingthe

machine.

19

Page 20

PreparingtoUsethe

Machine

1.Parkthemachineonalevelsurfaceand

disconnectthemachinefromthetowvehicle.

2.Ensurethatallguardsandpaddlesareinplace

andingoodcondition.

3.Performalldailymaintenanceprocedures

prescribedinMaintenance(page27).

4.Chockthefrontandbackofthetirestoprevent

themachinefrommoving.

Figure21

1.Supportpoint(2)

7.Removetheboltsandnutsthatsecuretheinner

axletotheouteraxle(Figure22).

Figure22

1.Wideposition(towing)

2.Narrowposition5.Bolt—wideposition

3.Nut—wideposition6.Bolt—narrowposition

4.Nut—narrowposition

g020019

5.Movethedrumtotheuprightpositionandlockit.

OpeningtheCowl

g020020

8.Aligntheinneraxletothedesiredpositionas

follows:

•Slideeachsideoftheaxleinwardtothe

narrowposition(Figure22).

•Slideeachsideoftheaxleoutwardtothe

wide(tow)position(Figure22).

9.Securetheaxlewiththeboltsandnutsremoved

previously(Figure22)andtorquethemto87

N∙m(64ft-lb).

g035134

Figure23

20

Page 21

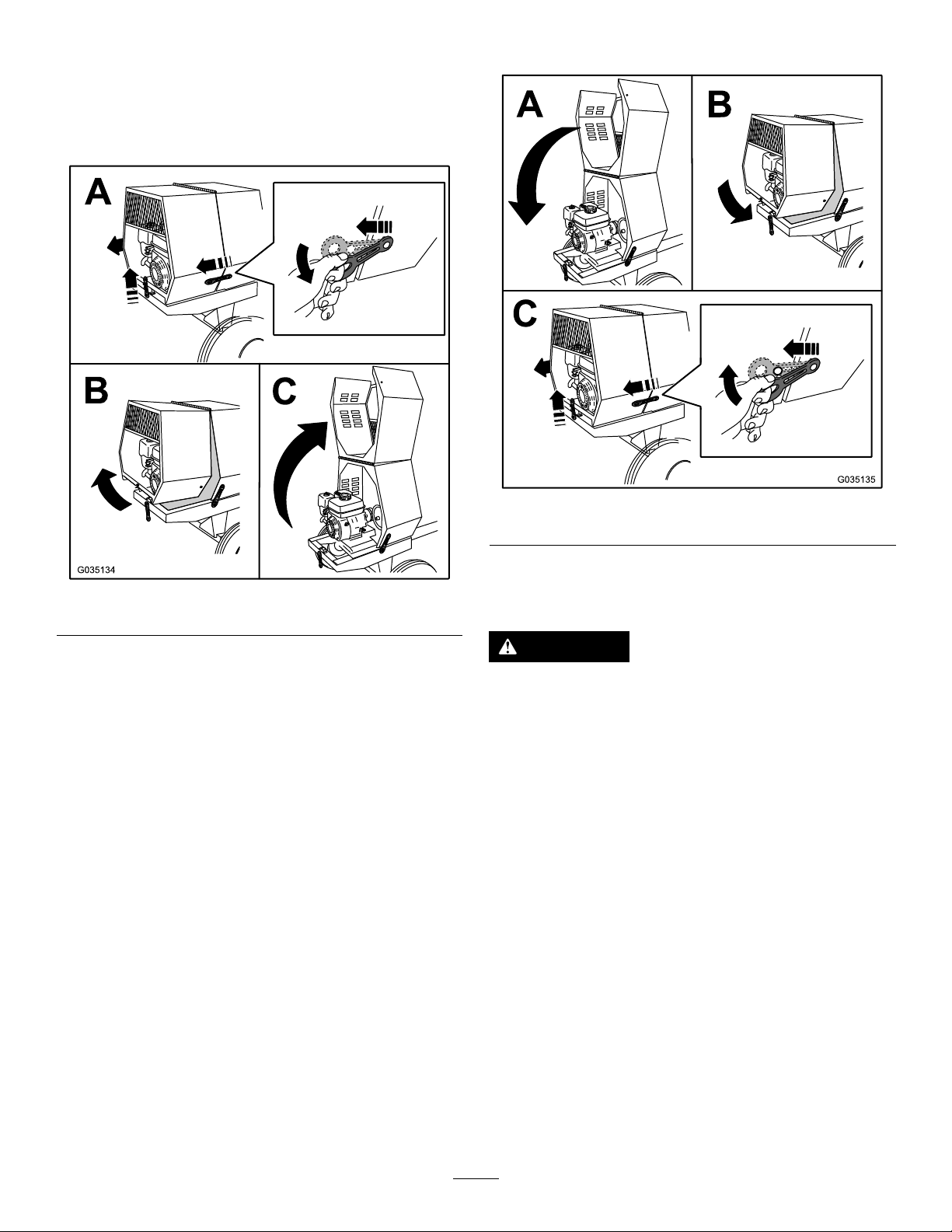

OpeningandClosingthe

Cowl

OpeningtheCowl

ClosingtheCowl

g035135

Figure25

Figure24

g035134

AddingFuel

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltanksoutdoors,inanopen

area,whentheengineiscold.Wipeupany

fuelthatspills.

•Neverllthefueltanksinsideanenclosed

trailer.

•Neversmokewhenhandlingfuelandstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

21

Page 22

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleased,causingaspark

thatcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbed,becauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removeequipmentfrom

thetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainerratherthanfroma

fuel-dispensernozzle.

•Ifyoumustuseafuel-dispensernozzle,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

•Donotstorefueleitherinthefueltankorinfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

Important:T oreducestartingproblems,addfuel

stabilizertothefuelallseason,mixingitwithfuel

lessthan30daysold;runthemachinedrybefore

storingitformorethan30days.

Donotusefueladditivesotherthanafuel

stabilizer/conditioner.Donotusefuelstabilizers

withanalcoholbasesuchasethanol,methanol,

orisopropanol.

FuelTankCapacity

Model

60213and60213C3.1L(0.82USgallons)

60216,60216C,60220,and

60220C

FuelTankCapacity

5.3L(1.40USgallons)

FillingtheFuelTank

1.Parkthemachineonalevelsurface,shutoffthe

engine,andallowtheenginetocool.

2.Cleanaroundthefuelcapandremoveit(Figure

26).

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleand

fueltankopening.

•Keepfuelawayfromyoureyesandskin.

FuelRecommendations

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

g019799

Figure26

1.Fuelcap

3.Addfueltothefueltankuntilthelevelisatthe

maximumfuellevel(Figure27).

Important:Thisspaceinthetankallows

fueltoexpand.Donotllthefueltank

completelyfull.

22

Page 23

Figure28

g019815

Figure27

1.Maximumfuellevel

4.Installthefuelcapsecurely(Figure26).

5.Wipeupanyspilledfuel.

PerformingDaily

Maintenance

Beforestartingthemachineeachday ,performthe

EachUse/DailyprocedureslistedinMaintenance

(page27).

StartingtheEngine

1.EnsurethattheclutchleverisintheOFF

position.

2.MovethefuelvalvetotheOPENposition,allthe

waytotheright(Figure28).

1.Chokelever

g020679

2.Fuelvalve

3.Throttlelever

3.MovethechokelevertotheONposition(Figure

28).

Note:Awarmorhotenginemaynotrequire

choking.

4.Movethethrottlelever1/3ofthewaytowardthe

MAXposition.

5.MovetheengineswitchtotheONposition

(Figure29).

g021103

Figure29

1.Engineswitch—OFF

position

2.Engineswitch—ON

position

6.Pullthestarterhandlelightlyuntilyoufeel

resistance,thenpullthehandlebriskly(Figure

30).Returnthestarterhandlegently.

23

Page 24

Figure30

7.Aftertheenginestarts,graduallymovethe

chokeleverbacktotheOFFposition.Ifthe

enginestallsorhesitates,movethechokeback

totheONpositionagainuntiltheenginewarms

up.ThenmoveittotheOFFposition.

MixingtheMaterial

DANGER

Eyeandskincontactwithconcretematerials

andbreathingthedustinvolvedishazardous

toyourhealth.

•Ensurethatthereisadequateair

ventilation.

•Wearadustmasktopreventinhalationof

dustwhileusingthemachine;refertoSafe

g019747

OperatingPractices(page4).

•Avoiddirectcontactofcementand

concretematerialswithskinandeyes.

DANGER

Thismachineiscapableofamputatinghands.

•Stayintheoperator’spositionwhilethe

machineisrunning.

ShuttingOfftheEngine

1.MovethethrottlelevertotheMINposition

(Figure11).

Note:Iftheenginehasbeenworkinghardor

ishot,letitidleforaminutebeforeshuttingoff

theengine.Thishelpstocooltheenginebefore

stopping.Inanemergency,shutofftheengine

immediately.

2.MovetheengineswitchtotheOFFposition.

3.MovethefuelvalvetotheCLOSEDposition,all

thewaytotheleft.

•Keepallbystandersasafedistanceaway

fromthemachine.

•Stopthemachineimmediatelyifany

peopleoranimalsentertheworkarea.

•Neverplaceanypartofyourbodyintoa

positionthatcausesanunsafeoperating

condition.

Important:Donotaddmorematerialthan

thebatchcapacityofthemachine;referto

Specications(page15).

Note:Followthemanufacturer’sinstructionsthatare

printedonthepackagingoftheproductyouareusing.

1.Ensurethatthereisnoold,loosematerialin

thedrumthatcancontaminatethebatchof

material;refertoCleaningtheDrum(page26)

andDumpingtheMaterial(page25),thenreturn

thedrumtotheuprightposition.

Note:Ensurethatthedrumisinthemix

position(upright)andthedrumlatchisengaged.

2.MovetheclutchlevertotheOFFposition(Figure

31).

3.Starttheengine.

Note:Allowtheenginetowarmupat2/3

throttlefor1to2minutes.

4.SetthethrottleleverontheenginetotheMAX

position.

5.MovetheclutchlevertotheONposition(Figure

31).

24

Page 25

7.Allowthepaddlestomixthematerialuntilthe

ingredientshaveauniformappearance.

Note:Ifneeded,addwaterorplaster,cement,

orotherbindingmaterialuntiltheconsistency

ofthebatchiscorrect.

DumpingtheMaterial

DANGER

Contactwiththemixingpaddlescouldcause

damageorinjury.

Neverputyourhandsinsidethedrumwhile

theengineisrunning.

Figure31

1.OFFposition2.ONposition

6.Addtheingredientsforthebatchasfollows:

A.Pourwaterintothedrumthroughthegrate.

B.Addtheplaster,cement,orotherbinding

material.

Note:Youcanopenbagsofcement,

plaster,andbindingmaterialsbylowering

thebagontothebagsplitter(Figure32).

g019873

Note:Whendumpingabatchofmaterial,leave

theengine/motorrunningandtheclutchintheON

positionsothattherotatingpaddleshelpdischarge

thematerial.

1.Alignawheelbarroworsimilarcontainerof

adequatecapacityinthepathofthedrum

opening.

2.Graspthedumphandlewithyourlefthand

(Figure33).

Figure32

C.Ifyouareusingsandand/orother

reinforcingmaterials,addthemintothe

drum.

g021179

1.Dumphandle—Mix

position

2.Drumlatch—Release

position

Figure33

3.Drumlatch—Locked

position

4.Dumphandle—Dump

position

g028574

3.Liftthehandleofthedrumlatch(Figure33).

25

Page 26

4.Withbothhandsonthedumphandle,rotateit

counterclockwisetodischargethecontentsof

thedrum(Figure33).

Note:Allowthemachinetocompletely

dischargethecontentsofthedrum.

5.Rotatethedumphandleclockwiseuntilthe

drumlatchlocksthedrumintheuprightposition

(Figure33).

6.Afterdumpingabatchofmaterial,clean

thedrumtopreventdriedmaterialfrom

contaminatingthenextbatchofmaterial;referto

CleaningtheDrum(page26).

CleaningtheDrum

Important:Donotstrikeonthedrumwitha

shovel,hammer,oranyotherdevicetoloosenany

accumulateddriedmaterials.

1.MovetheclutchlevertotheOFFpositiontostop

thepaddles.

2.Shutofftheengine/motor.

3.Ensurethatthedrumisinthemixposition

(upright).

4.Spraythemachinewithwatertoremoveany

accumulatedmaterial.

5.Starttheengine/motor.

6.MovetheclutchlevertotheONpositiontostart

thepaddles.

7.Dumpthedrum.

26

Page 27

Maintenance

WARNING

Failuretoproperlymaintainthemachinecouldresultinprematurefailureofmachinesystems

causingpossibleharmtoyouorbystanders.

Keepthemachinewellmaintainedandingoodworkingorderasindicatedintheseinstructions.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst20hours

Aftertherst25hours

Beforeeachuseordaily

Aftereachuse

Every40hours

Every50hours

Every100hours

Every300hours

MaintenanceProcedure

•Changethereduction-caseoil.

•Changetheengineoil.

•Inspectthebeltsandadjustasnecessary(belt-drivemodelsonly).

•Inspecttheair-cleanerelements.

•Checktheengine-oillevel.

•Inspectthetires.

•Checkthereduction-caseoil.

•Cleanthedrumbetweenmixingbatchesofmaterial.

•Lubricatethetrunnions.

•T orquethewheellugnutsto108to122N∙m(80to90ft-lb)aftertowing.

•Inspectthebeltsandadjustasnecessary(belt-drivemodelsonly).

•Checktheclutchoperation

•Cleantheair-cleanerelements.Cleanthemmorefrequentlyindustyoperating

conditions.

•Changetheengineoil.

•Checkthesparkplug.

•Cleanthesparkarrester(ifequipped).

•Cleanthefuel-sedimentcup.

•Changethereduction-caseoil.

•Replacethepaperair-cleanerelement.Replaceitmorefrequentlyindusty

operatingconditions.

•Replacethesparkplug.

Monthly

Yearlyorbeforestorage

Every2years

•Lubricatethepillow-blockbearings.

•Cleanthefuel-sedimentcup.

•Replacethebelts(belt-drivemodelsonly).

Important:RefertoyourEngineOperator'sManualforadditionalmaintenanceprocedures.

27

Page 28

Pre-Maintenance

Procedures

PreparingtheMachinefor

Maintenance

1.Shutofftheengineandallowittocool

completely.

2.Parkthemachineonalevelsurface.

3.Removethemachinefromthetowvehicle.

4.Securethemachinefrommovement.

5.Disconnectthespark-plugwire.

g020752

Figure35

3.Toremovethedividerplate,liftitupwardandtilt

itbacksothatitclearsvariouscomponents.

Disconnectingthe

Spark-PlugWire

Pullthespark-plugwireofftheterminalofthespark

plug(Figure34).

Figure34

1.Sparkplug

InstallingtheDividerPlate

Whennishedperformingmaintenance,installthe

dividerplateasfollows:

1.Guidethedividerplateintopositionagainstthe

frontcowl.

Note:Startwiththedividerplaterotatedslightly

counterclockwise,andthenrotateitclockwise

whileloweringitintoposition.

Ensurethatthedividerplateisnotbackward.

g019281

g020753

Figure36

RemovingtheDividerPlate

Ifyourmodelhasadividerplate,youmayneed

toremoveitbeforeperformingsomemaintenance

procedures:

1.Openthecowl.

2.Useawrenchtoremovethe4boltsthatsecure

thedividerplatetothefrontcowl.

Note:Retainthefastenersforinstallingthe

dividerplate.

2.Aligntheboltholesinthedividerplateandthe

frontcowl.

3.Installeachofthe4bolts,andhand-tighten

themtopreventcross-threading.

4.Tightentheboltswithawrenchuntiltheyare

secure.

28

Page 29

Lubrication

LubricatingtheBearings

andSeals

ServiceInterval:Aftereachuse—Lubricatethe

trunnions.

Monthly—Lubricatethepillow-blockbearings.

Note:Thepillow-blockbearingsareinsidethe

cowl—removethedividerplateifequipped)toaccess

them;refertoRemovingtheDividerPlate(page28).

GreaseType:No.2lithiumgrease.

1.CompletetheprocedureslistedinPreparingthe

MachineforMaintenance(page28).

2.Cleantheareaaroundeachgreasettingwitha

ragandlifttheplasticcapoffthegreasetting

(Figure37).

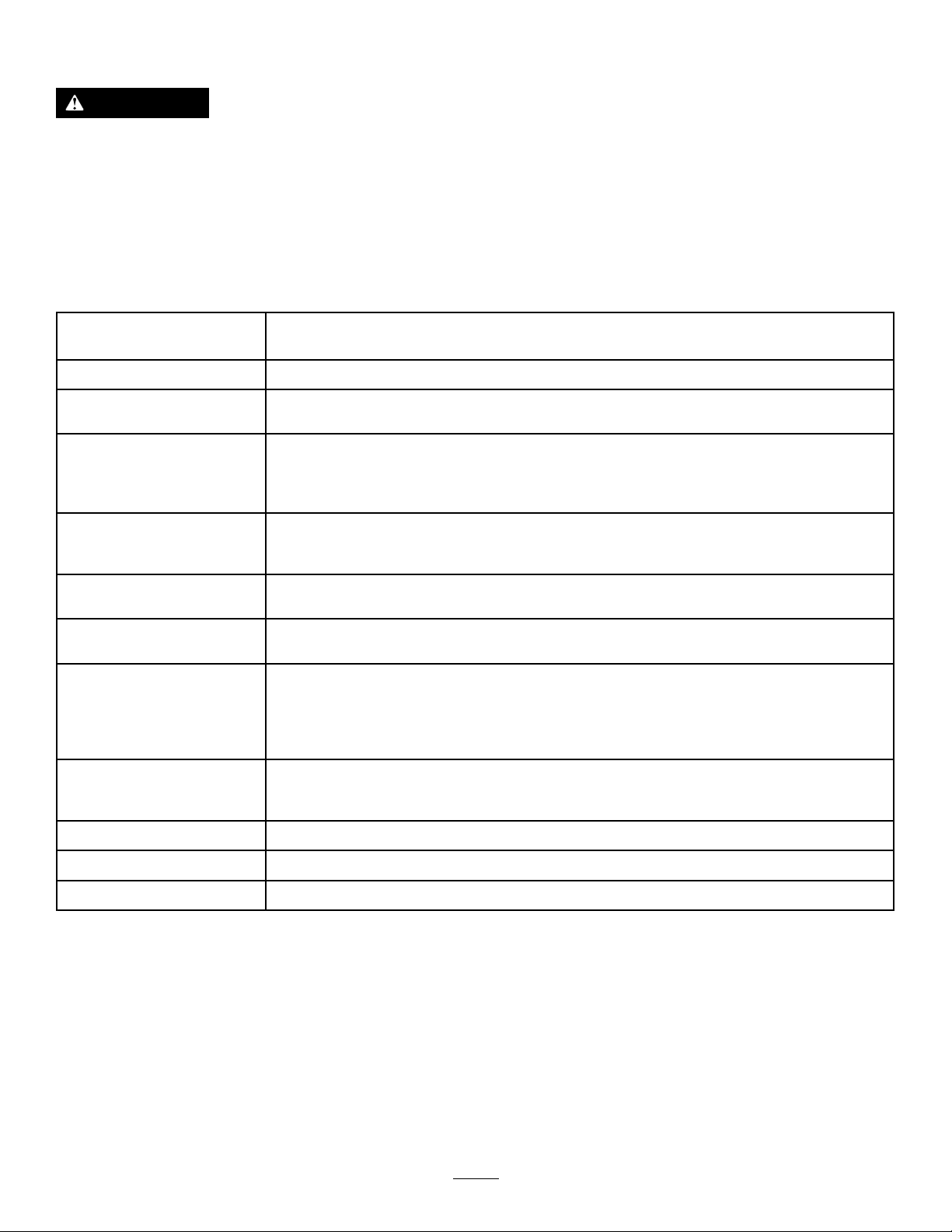

g020684

Figure37

1.Pillow-blockbearings3.Fronttrunnion

2.Reartrunnion

3.Pumpgreaseintoeachttingasfollows:

•Forthepillow-blockbearings,pump1shotof

greaseintoeachtting(Figure37).

•Forthetrunnions,pumpseveralshotsof

greaseintoeachttinguntilitstartstoooze

outofthebearinghousing(Figure37).

Important:Pumpgreaseinslowlyand

carefullytopreventdamagetothebearing

seals.

4.Wipeupanyexcessgrease.

g020685

29

Page 30

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Inspect

theair-cleanerelements.

Every50hours—Cleantheair-cleaner

elements.Cleanthemmorefrequentlyindusty

operatingconditions.

Every300hours/Y early(whichevercomes

rst)—Replacethepaperair-cleanerelement.

Replaceitmorefrequentlyindustyoperating

conditions.

Important:Donotoperatetheenginewithout

theair-lterassembly;extremeenginedamage

willoccur.

1.Shutofftheengineandwaitforallmovingparts

tostop.

2.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page28).

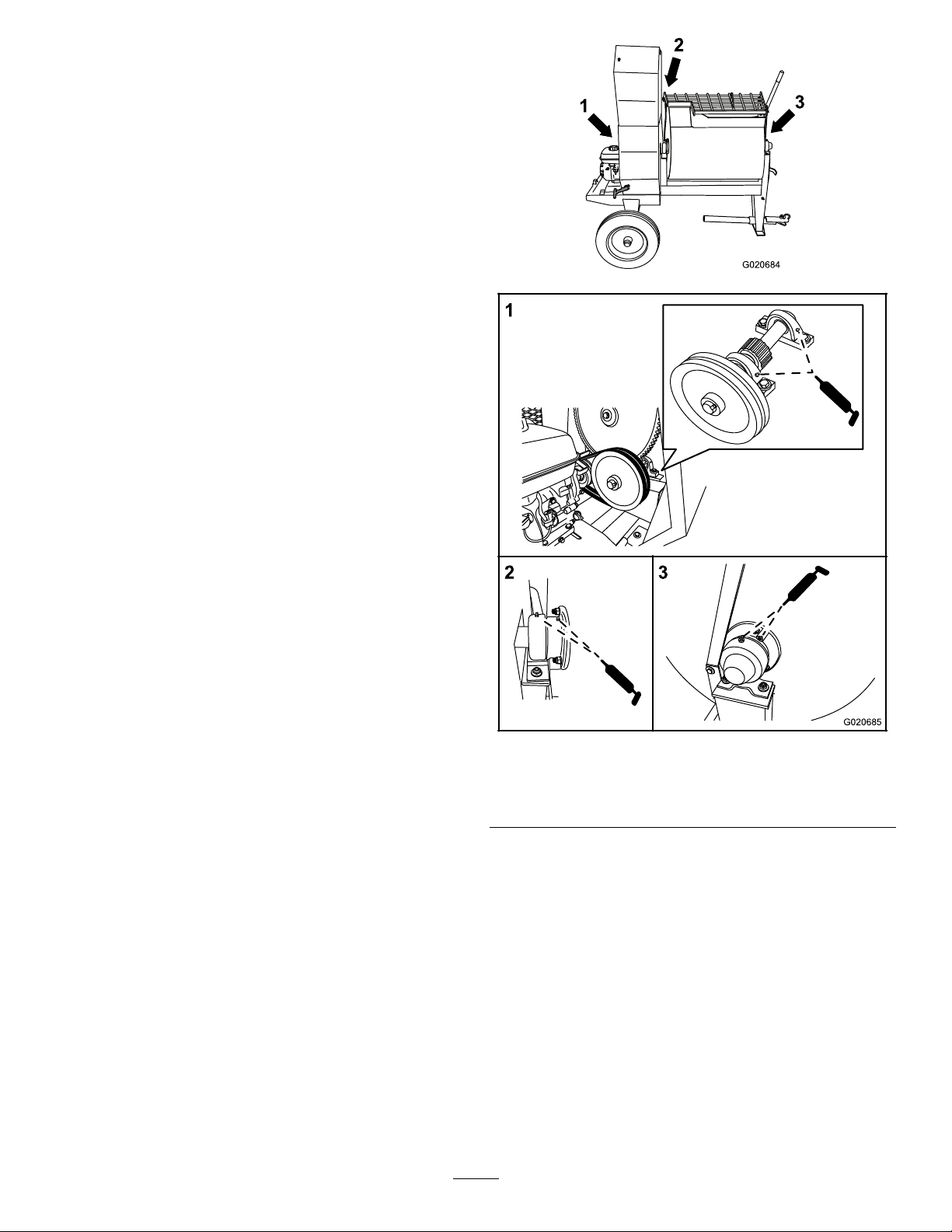

3.Removethenutthatsecuresthecover(Figure

38).

Figure38

1.Covernut

2.Cover

3.Wingnut6.Base

4.Removethecover.

4.Foamelement

5.Paperelement

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

5.Removethefoamandpaperelementsfromthe

base(Figure38).

6.Removethefoamelementfromthepaper

element(Figure38).

7.Inspectthefoamandpaperelementsand

replacethemiftheyaredamagedorexcessively

dirty.

Note:Nevertrytobrushdirtoffthepaper

element;brushingforcesthedirtintothebers.

8.Cleanthefoamelementinwarm,soapywater

orinanonammablesolvent.

g019728

Note:Donotusefueltocleanthefoamelement

becauseitcouldcreateariskofreorexplosion.

30

Page 31

9.Rinseanddrythefoamelementthoroughly .

10.Dipthefoamelementincleanengineoil,then

squeezeouttheexcessoil.

Note:Excessoilinthefoamelementrestricts

theairowthroughtheelementandmayreach

thepaperlterandclogit.

11.Wipedirtfromthebaseandthecoverwitha

moistrag.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

12.Installtheair-cleanerelementsandensurethat

theyareproperlypositioned.

13.Securelyinstallthecoverwiththenut.

ServicingtheEngineOil

Engine-OilSpecications

ToroPremiumEngineOilisavailablefromyour

AuthorizedT oroDealer.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Allowtheenginetocool.

3.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page28).

4.Cleanaroundthedipstick.

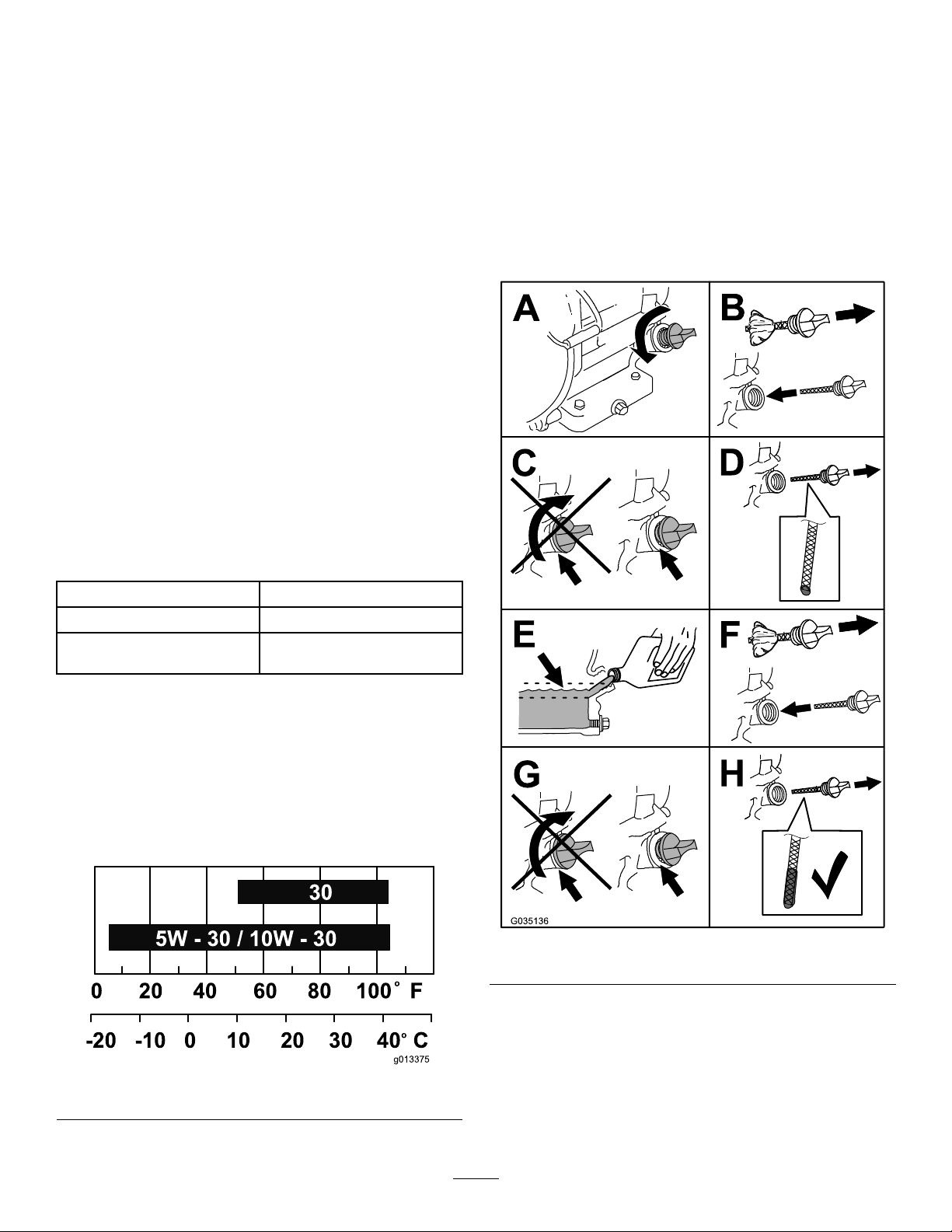

5.ChecktheoillevelasshowninFigure40.

Important:Use4-cycleengineoilthatmeetsor

exceedstherequirementsforAPIservicecategory

SJ,SL,SM,orhigher.

Model(s)CrankcaseCapacity

60213and60213C0.58L(19.6oz)

60216,60216C,60220,and

60220C

1.1L(1.2USqt)

Important:Iftheoillevelinthecrankcaseistoo

lowortoohighandyouruntheengine,youmay

damagetheengine.Thistypeofdamageisnot

coveredbythewarranty.

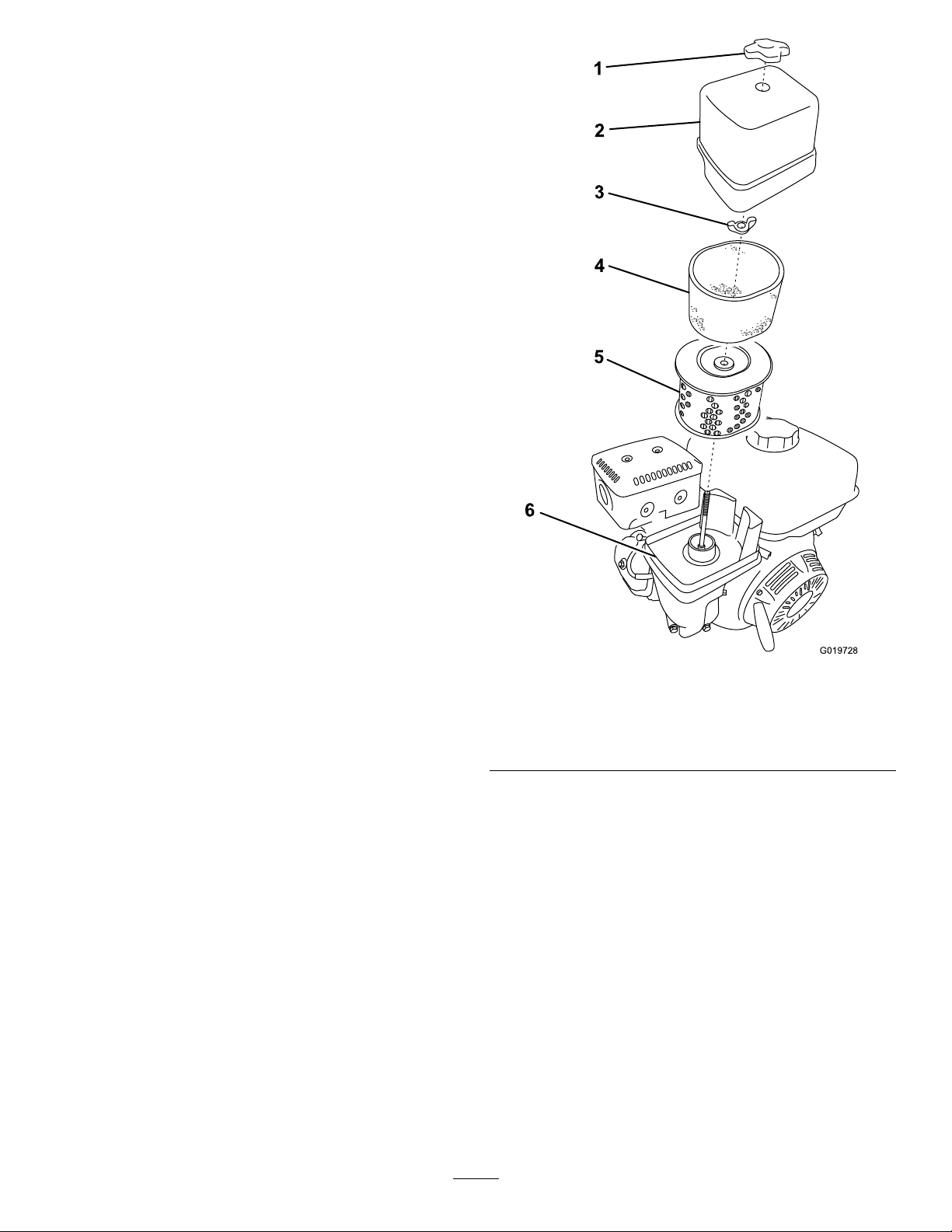

Note:UseSAE10W-30forgeneraluse.Youcan

usetheotherviscositiesshowninthechartwhen

theaveragetemperatureinyourareaiswithinthe

indicatedrange(Figure39).

g035136

Figure40

Figure39

ChangingtheEngineOil

g013375

ServiceInterval:Aftertherst25hours

Every100hours

31

Page 32

WARNING

Oilmaybehotaftertheenginehasbeenrun,

andcontactwithhotoilcancausesevere

personalinjury.

Avoidcontactingthehotengineoilwhenyou

drainit.

1.Shutofftheengineandwaitforallmovingparts

tostop.

2.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page28).

3.Placeadrainpanundertheoil-drainholeofthe

engine(Figure41).

Figure42

1.Oil-llhole3.Oil-levelupperlimit

2.Dipstick

7.Replaceandsecurethedipstick.

8.Wipeupanyspilledoil.

4.Oil-levellowerlimit

ServicingtheSparkPlug

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)—Checkthe

sparkplug.

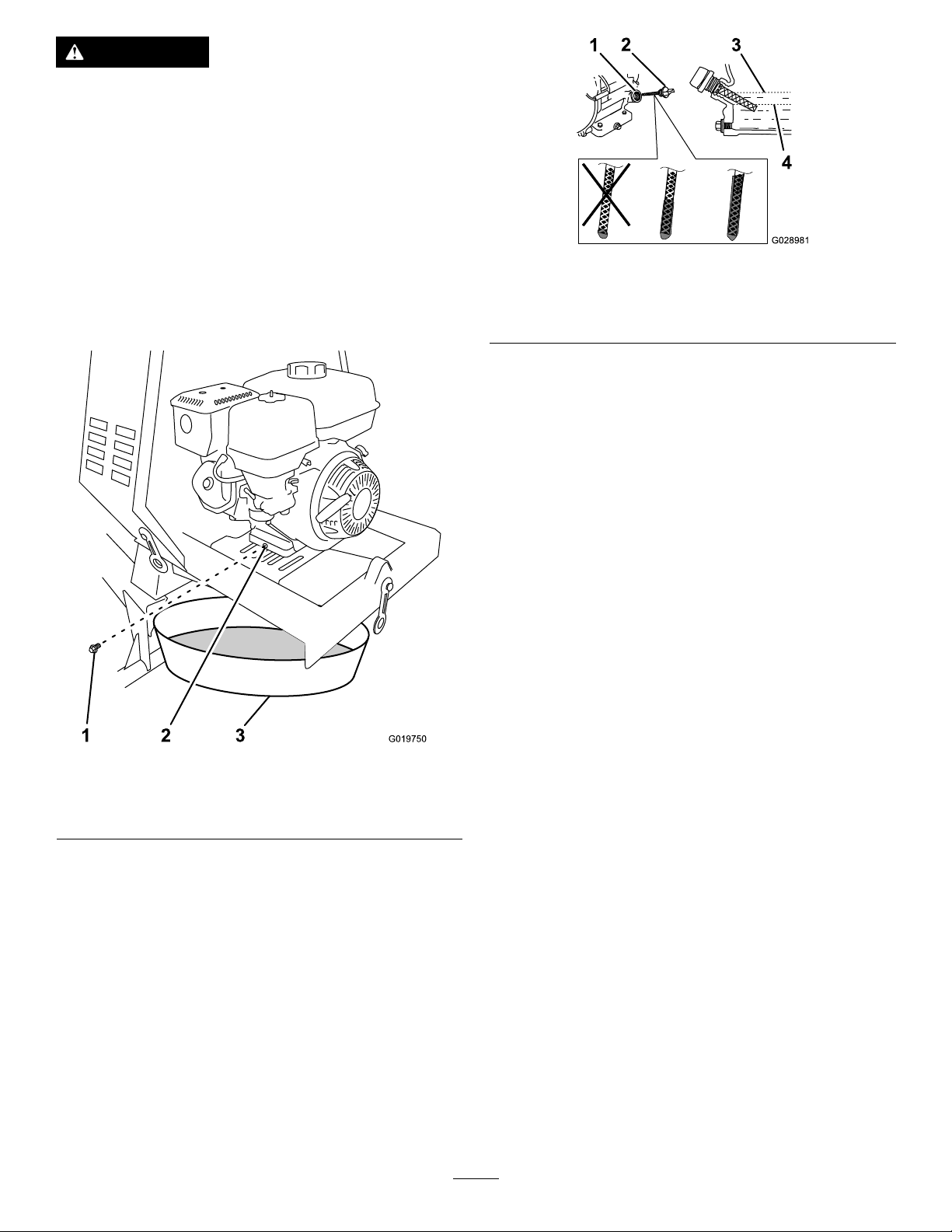

g028981

Figure41

1.Oil-drainplug3.Oil-drainpan

2.Oil-drainhole

4.Removethedrainplugandcatchtheoilinthe

oil-drainpan(Figure41).

5.Whentheoilhasdrainedcompletely,installthe

drainplugwithanewwasher(Figure41).

Note:Disposeoftheusedoilatacertied

recyclingcenter.

Every300hours/Y early(whichevercomes

rst)—Replacethesparkplug.

SparkPlugSpecications

Type:NGKBPR6ESorequivalent

Gap:0.7to0.8mm(0.028to0.031inch)

Note:Usea21mm(13/16inch)spark-plugwrench

forremovingandinstallingthesparkplug.

g019750

RemovingtheSparkPlug

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Ensurethatthemachinesurfacesarecool.

3.Pullthespark-plugwireofftheterminalofthe

sparkplug(Figure43).

6.Removethedipstick(Figure42)andslowly

pouroilintothellholeuntiltheoilreachesthe

upper-limitmark(bottomedgeoftheoil-llhole)

onthedipstick.

32

Page 33

Figure43

g206628

Figure45

g014506

1.Sparkplug

2.Wire

4.Cleanaroundthesparkplug.

5.Rotatethesparkplugcounterclockwiseusing

a21mm(13/16inch)spark-plugwrenchto

removetheplugandthesealingwasher(Figure

44).

Figure44

g019749

CheckingtheSparkPlug

Important:Donotcleanthesparkplug.Always

replacethesparkplugwhenithasablackcoating,

wornelectrodes,anoilylm,orcracks.

Note:Ifyouseelightbrownorgrayontheinsulator,

theengineisoperatingproperly.Ablackcoatingon

theinsulatorusuallymeansthattheaircleanerisdirty.

Setthegapto0.7to0.8mm(0.028to0.031inch).

33

Page 34

InstallingtheSparkPlug

CleaningtheSparkArrester

Important:Ensurethatthegapbetweentheside

andcenterelectrodesiscorrectbeforeinstalling

thesparkplug.

1.Threadthesparkplugclockwiseintothe

spark-plugholebyhand.

Note:Avoidcross-threadingthesparkplugwith

thethreadsofthespark-plughole.

2.Rotatethesparkplugclockwiseusinga21mm

(13/16inch)spark-plugwrenchuntiltheplug

andsealingwasherareseated(Figure44).

3.Tightenthesparkplugasfollows:

•Wheninstallinganin-servicesparkplug,

tightenthepluganadditional1/8to1/4turn.

•Wheninstallinganewsparkplug,tightenthe

pluganadditional1/2turn.

Important:Aloosesparkplugmaycause

thecylindertooverheat.Anover-tightspark

plugmaydamagethethreadsinthecylinder

head.

4.Pushthespark-plugwireontotheterminalofthe

sparkplug(Figure43).

ServiceInterval:Every100hours

Note:Asparkarresterisavailableasanoption.If

yourequireasparkarrester,contactyourAuthorized

ServiceDealer.GenuineT orosparkarrestersare

approvedbytheUSDAForestryService.

WARNING

Iftheenginehasbeenrunning,themufer

willbehot.Contactwithhotsurfacesmay

causepersonalinjury.

Keepyourhands,feet,face,clothingand

otherbodypartsawayfromthemuferand

otherhotsurfacesuntiltheyhavecooled.

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Allowtheenginetocool.

3.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page28).

4.Removethedividerplate(ifequipped);referto

RemovingtheDividerPlate(page28).

5.Removethe2nuts(8mm)andremovethe

muferfromthecylinder(Figure46).

Figure46

1.Deector(if

applicable)

2.Protector

3.Screw(6mm)7.Gasket

4.Mufer8.Bolt(8mm)12.Screw(4mm)

6.Removethe3screws(4mm)fromtheexhaust

deector,andremovethedeector(Figure46).

34

5.Exhaustpipe

6.Nut(8mm)10.Screws(5mm)

g019331

9.Sparkarrester

11.Exhaustport

Page 35

7.Removethescrews(5mmand6mm)from

themuferprotector,andremovethemufer

protector(Figure46).

7.Usingaspring-removaltool(T oroPartNo.

92-5771),removethespringfromtheanchor

bracketontheenginedeck(Figure48).

8.Removethescrews(4mm)fromthespark

arrester,andremovethesparkarresterfromthe

mufer(Figure46).

9.Useabrushtocarefullyremovecarbondeposits

fromthespark-arresterscreen(Figure47).

Note:Replacethesparkarresterifithas

breaksorholes.

Figure47

1.Screen

10.Installthesparkarrester,muferprotector,

exhaustdeector,andmuferinthereverse

orderofdisassembly.

2.Brush

Note:Leavetheotherendofthespring

attachedtotheframeofthemachine.

g020119

Figure48

1.Anchorbracket

g208746

2.Enginedeck

3.Spring-removaltool(T oro

PartNo.92-5771)

8.Removetheboltandnutthatsecuretherear

bracketfortheenginedeckhingetotheframe

ofthemachine(Figure49).

4.Spring-removaltool

(springremoved)

5.Spring(springremoved)

11.Installthedividerplate(ifequipped);referto

InstallingtheDividerPlate(page28).

RemovingandInstalling

theEngine

RemovingtheEngine

WARNING

Thespringisundertensionwheninstalled

andcancausepersonalinjury .

Becarefulwhenremovingthespring.

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Allowtheenginetocool.

3.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page28).

4.Removethedividerplate;refertoRemovingthe

DividerPlate(page28).

5.Removethebeltguide;refertoRemovingthe

Belts(page42).

6.Removethebelts;refertoRemovingtheBelts

(page42).

g020120

Figure49

1.Enginedeck4.Frame

2.Pivot5.Nut

3.Rearhingebracket6.Bolt

9.Liftuptherearedgeoftheenginedeckand

removethehingebracket(Figure49).

10.Slidetheenginedeckrearwardandoutfromthe

forwardhingebracket(Figure50).

35

Page 36

Note:Donotremovetheforwardhingebracket.

Figure50

InstallingtheEngine

1.Aligntheengineandenginedecktotherear

frameofthemachine.

Note:Thedrivepulleyontheenginemustalign

forward.

2.Alignthepivotontheenginedeckwiththe

forwardhingebracket(Figure50).

3.Slidetheenginedeckforwardandthepivotinto

theforwardhingebracket(Figure50).

4.Aligntherearhingebracketwiththepivotonthe

engine-deckhinge(Figure50).

5.Liftupontherearedgeoftheenginedeckand

slipthehingebracketontothepivot.

6.Securetherearbrackettotheframeofthe

g020121

machineusingtheboltandnut(Figure49)

removedinstep8ofRemovingtheEngine

(page35).

11.Removetheengineandenginedeckfromthe

machine(Figure50).

7.Usingaspring-removaltool(T oroPartNo.

92-5771),installthetensionspringtotheanchor

bracketontheenginedeck(Figure48).

8.Installthebeltsandbeltguide;refertoInstalling

theBelts(page43).

9.Adjustthebeltguide;refertoAdjustingtheBelt

Guide(page43).

10.Installthedividerplate;refertoInstallingthe

DividerPlate(page28).

36

Page 37

FuelSystem

9.Installthefuellterinthebottomofthe

carburetor(Figure51).

Maintenance

CleaningtheFuel-Sediment

Cup

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)—Cleanthe

fuel-sedimentcup.

Yearlyorbeforestorage—Cleanthe

fuel-sedimentcup.

Underneaththefuelvalveisasedimentcuptocatch

dirtinthefuel.

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Allowtheenginetocool.

3.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page28).

4.MovetheleverofthefuelvalvetotheOFF

position,allthewaytotheleft(Figure51).

10.AligntheO-ringintothegrooveinthesediment

cupandinstallthesedimentcuptothefuel-valve

housing.

11.MovetheleverofthefuelvalvetotheON

position(allthewaytotheright)andcheckfor

leaks.Ifitleaks,replacetheO-ring.

DrainingtheFuelTank

1.Removetheengine;refertoRemovingthe

Engine(page35).

2.Removethefuelcapbyrotatingit

counterclockwise(Figure52).

5.Unscrewthefuel-sedimentcup(Figure51).

6.RemoveandretainthefuellterandO-ring

(Figure51).

Note:DonotcleantheO-ringinsolvent.

Figure51

g035167

Figure52

3.Alignadrainpantothehingeoftheenginedeck.

4.Rotatetheengineonthehingesideofthe

enginedeckanddrainthefuelfromthetank

(Figure53).

g019333

Figure53

g035168

1.Fuelvalve—OFFposition3.Fuellter

2.O-ring

7.Cleanthefuellterandsedimentcupusinga

nonammablesolvent,anddryitcarefully.

8.WipetheO-ringwithaclean,drycloth.

4.Fuel-sedimentcup

5.Carefullylowertheengineandenginedeck.

6.Installthefuelcap.

7.Installtheengine;refertoInstallingtheEngine

(page36).

37

Page 38

DriveSystem

Maintenance

TireAirPressure

Thefollowingtableshowstheappropriateairpressure

forthetiresasinstalledatthefactory.

Important:Alwayschecktheinformationon

theactualtiresforthecorrectairpressure

requirement.

ModelMaximumAirPressure

60212,60213,and60216

60218,60219,and60220

InspectingtheTires

ServiceInterval:Beforeeachuseordaily

WARNING

Failuretomaintaincorrecttirepressure

mayresultintirefailureandlossofcontrol,

resultinginpropertydamageandserious

injuryordeath.

•Checkthetirepressurefrequentlyto

ensureproperination.Ifthetiresarenot

inatedtothecorrectpressure,theywill

wearprematurely .

414kPa(60psi)

241kPa(35psi)

g020836

Figure54

1.Exampleoftirewearcausedbyunderination

g010293

Figure55

1.Exampleoftirewearcausedbyoverination

2.Ensurethatthetiresareinatedtothecorrect

airpressure;refertoTireAirPressure(page38).

Important:Themostcommoncauseoftire

troubleisunder-ination.Maintainfullair

pressure.

•Inspectthetireconditionbeforetowing

andafteranyoperatingaccident.

TheDOTtireinformationislocatedonthesideof

eachtire.Thisinformationgivesloadandspeed

ratings.Replacementtiresshouldhavethesameor

betterratings

Note:Ensurethatanytiresinstalledonyourmachine

meetorexceedtheweightrequirementsofyour

machineaslistedinSpecications(page15).

1.Visuallyinspectthetiresfordamageandwear

(Figure54andFigure55).

TorquingtheWheelLug

Nuts

ServiceInterval:Aftereachuse

Torquethewheellugnutsinitiallyandaftertowing.

Torquethewheellugnuts108to122N∙m(80to90

ft-lb),inthesequenceshowninFigure56.

g021107

Figure56

38

Page 39

ServicingtheReduction

Case

Important:Iftheoillevelinthereductioncase

istoolowortoohighandyouruntheengine,

youmaydamagetheengineorthereduction

case.Thistypeofdamageisnotcoveredbythe

warranty.

Reduction-CaseOilSpecications

Oiltype:4-cycle,SAE10W-30motoroil

OilAPIservicecategory:SJ,SL,SM,orhigher

Reduction-casecapacity:1.2L(40oz)

CheckingtheReduction-CaseOil

ServiceInterval:Beforeeachuseordaily—Check

thereduction-caseoil.

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Allowtheenginetocool.

3.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page28).

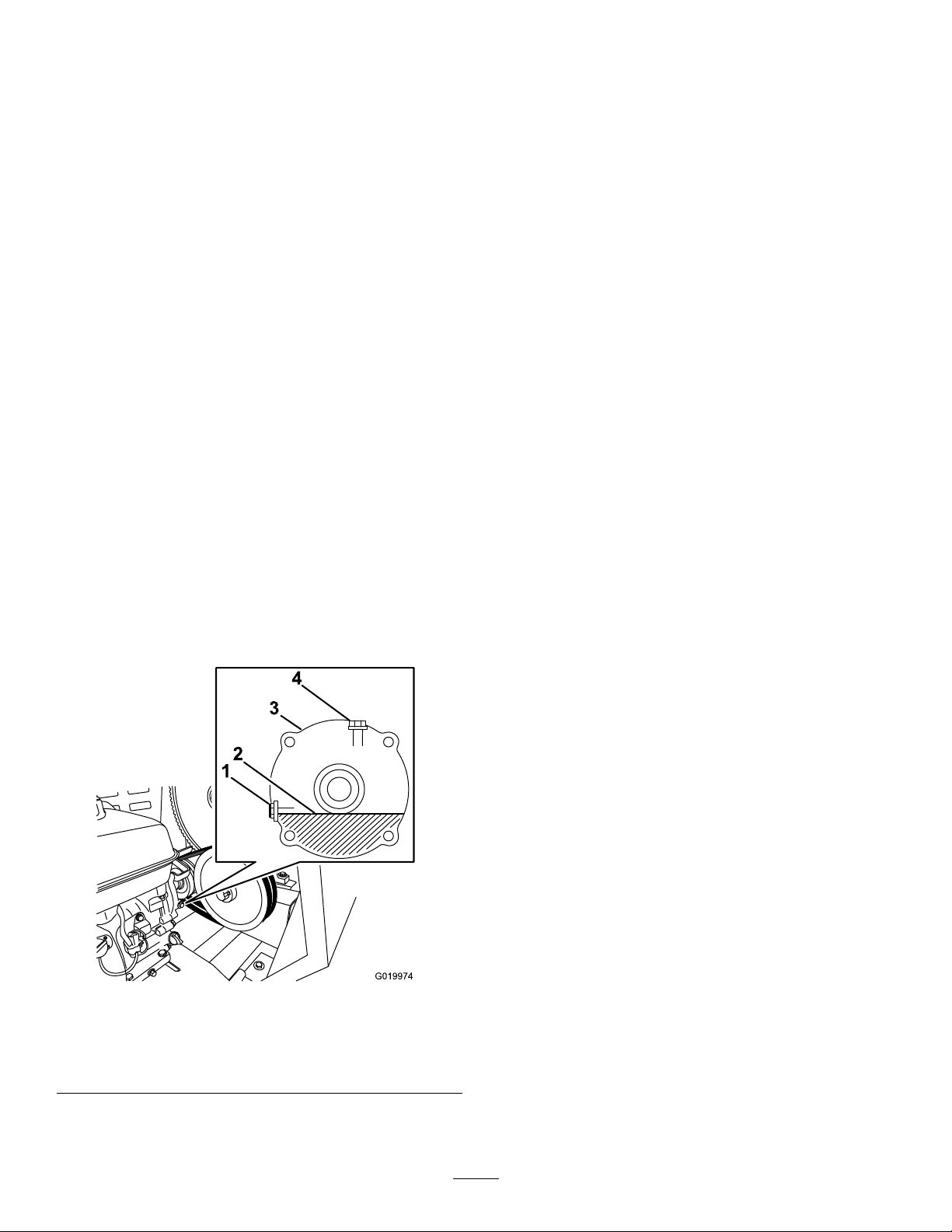

7.Removetheoil-level-checkboltandwasher

fromtheoil-levelport(Figure57).

•Iftheoillevelisbelowthethreadsinthe

oil-levelport,addoilasfollows:

A.Removethellerboltandwasherfrom

thellerportonthetopofthereduction

case(Figure57).

B.Slowlypourthespeciedoilintothell

portuntiltheoillevelislevelwiththe

threadsatthebottomoftheoil-level

port.

C.Installthellerboltandthewasherto

thellerportofthereductioncase,and

tightenthellerbolt(Figure57).

•Iftheoillevelistoohigh,allowtheoiltoow

outuntilitisushwiththethreadsatthe

bottomoftheoil-levelport.

8.Whentheoilislevelisushwiththethreads

atthebottomoftheoil-levelport,installthe

oil-level-checkboltandwashertotheport,and

tightenthebolt(Figure57).

9.Installthedividerplate;refertoDisconnecting

theSpark-PlugWire(page28).

4.Removethedividerplate;refertoRemovingthe

DividerPlate(page28).

5.Locatethereductioncasebetweentheengine

andtheenginepulley(Figure57).

Figure57

ChangingtheReduction-CaseOil

ServiceInterval:Aftertherst20hours—Change

thereduction-caseoil.

Every100hours/Every6months(whichever

comesrst)—Changethereduction-caseoil.

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Allowtheenginetocool.

3.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page28).

4.Removetheengine;refertoRemovingthe

Engine(page35).

5.Drainthefueltank;refertoDrainingtheFuel

Tank(page37).

6.Removethellerboltandwasherfromtheller

portonthetopofthereductioncase(Figure58).

g019974

1.Oil-level-checkboltand

washer

2.Oillevel(normal)

6.Alignaragbelowtheoil-levelportintheside

ofthereductioncase.

3.Reductioncase

4.Fillerboltandwasher

39

Page 40

Figure58

13.Installthellerboltandwashertothellerport

ofthereductioncaseandtightenthellerbolt

(Figure58).

14.Installtheengine;refertoInstallingtheEngine

(page36).

g020127

1.Oil-level-check

bolt

2.Washer4.Pulley6.Fillerbolt

3.Oil-levelport

5.Fillerport

7.Removetheoil-level-checkboltandwasher

fromtheoil-levelportinthesideofthereduction

case(Figure58).

8.Alignadrainpantothehingeoftheenginedeck

(Figure59).

Figure59

g020128

9.Rotatetheengineonthehingesideofthe

enginedeck,anddraintheoilfromthereduction

case(Figure59).

10.Carefullylowertheengineandenginedeck.

11.Slowlypourthespeciedoilintothellport

untiltheoillevelislevelwiththethreadsatthe

bottomoftheoil-levelport(Figure57).

12.Installtheoil-level-checkboltandwashertothe

oil-levelportofthereductioncase,andtighten

thebolt(Figure58).

40

Page 41

BeltMaintenance

InspectingtheBelts

ServiceInterval:Aftertherst25hours—Inspect

thebeltsandadjustasnecessary

(belt-drivemodelsonly).

Every40hours—Inspectthebeltsandadjustas

necessary(belt-drivemodelsonly).

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Allowthemachinetocool.

3.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page28).

4.Removethedividerplate;refertoRemovingthe

DividerPlate(page28).

5.MovetheclutchlevertotheOFFposition.

6.Examinethebeltsforwearordamage.Ifthe

beltsarewornordamaged,replacethem;refer

toReplacingtheBelts(page42).

7.Examinethepulleysforwear,damage,and

misalignment;refertoAligningthePulleys(page

44).

8.Installthedividerplate;refertoInstallingthe

DividerPlate(page28).

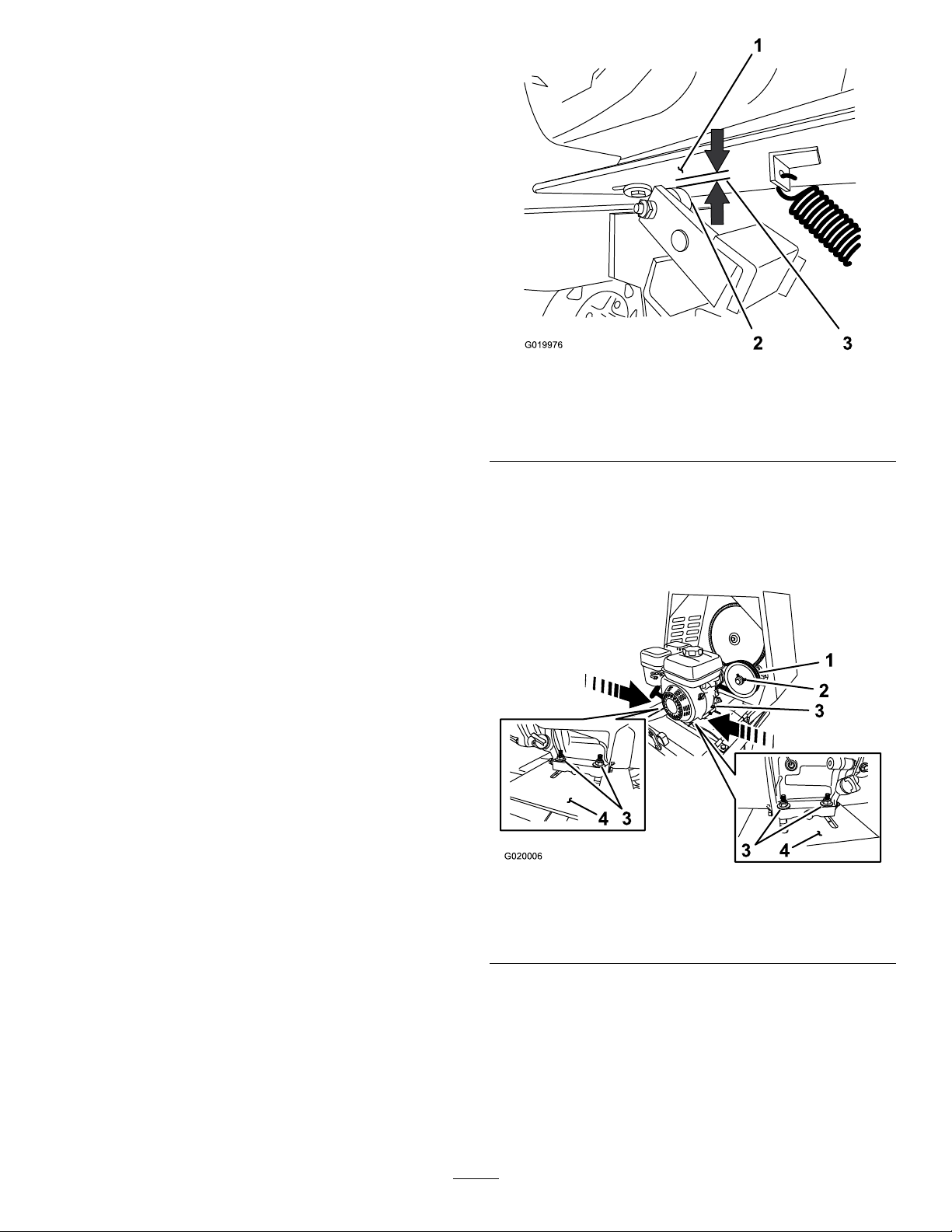

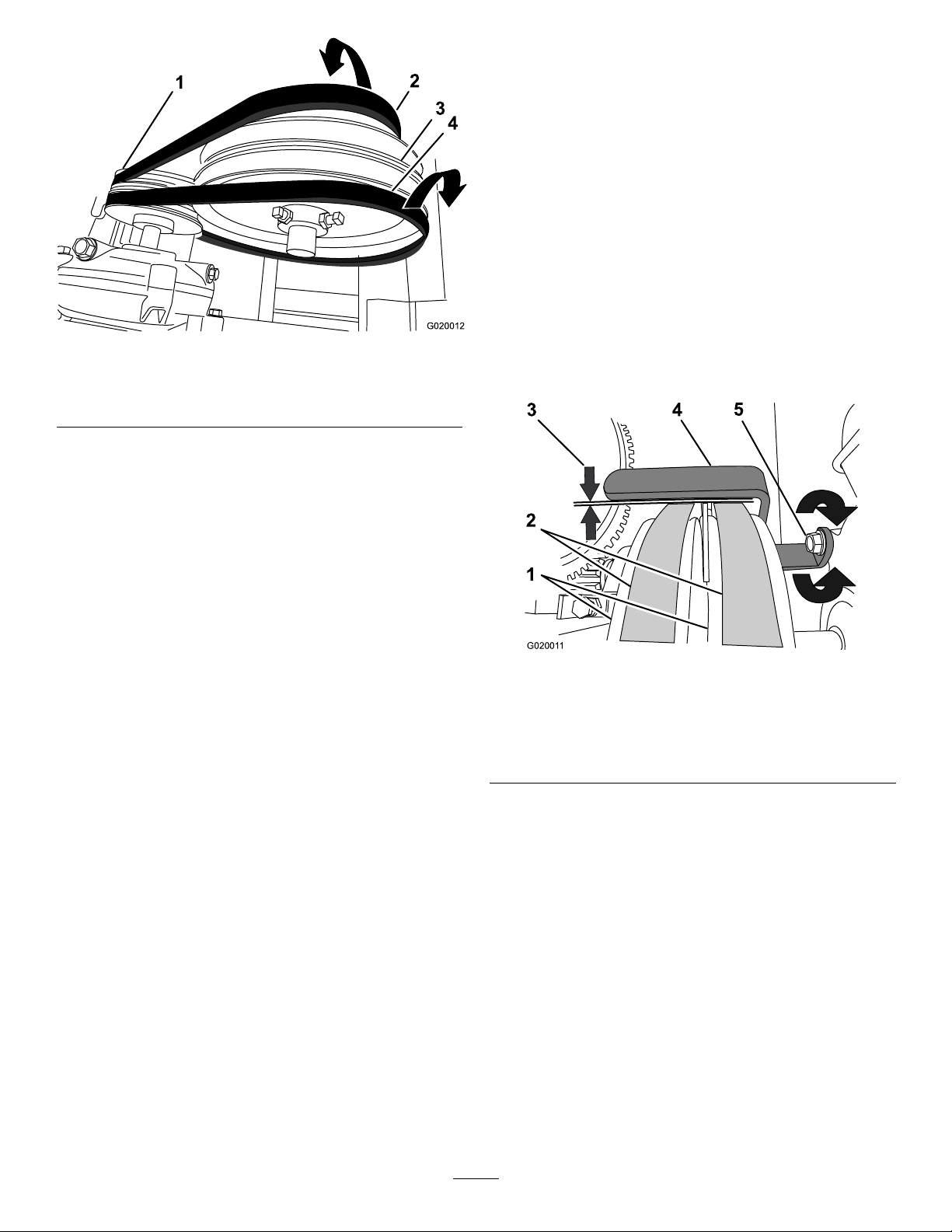

Figure60

1.Enginedeck

2.Clutchroller

6.Ifthemeasuredairgapisnotwithinthespecied

range,adjustthegapasfollows:

A.MovetheclutchlevertotheOFFposition.

B.Loosenthenutsandboltsthatsecurethe

enginetotheenginedeck(Figure61).

3.Clutchairgap:2.5to6.5

mm(3/32to1/4inch)

g019976

AdjustingtheBeltTension

Clutchairgap:2.5to6.5mm(3/32to1/4inch)

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Allowthemachinetocool.

3.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page28).

4.MovetheclutchlevertotheONposition.

5.Measuretheairgapbetweentheenginedeck

andtherollerontheclutch(Figure60).

Figure61

1.Idlerpulley3.Nutandbolt

2.Setscrew

C.Movetheenginepositionasfollows:

4.Enginedeck

•Increasetheairgap—movetheengine

awayfromtheidlerpulley(Figure61).

•Decreasetheairgap—movethe

enginetowardtheidlerpulley(Figure

61).

D.Alignastraightedgeacrosstheengine

pulleyandtheidlerpulley(Figure62).

g020006

41

Page 42

ReplacingtheBelts

ServiceInterval:Every2years(belt-drivemodels

only).

RemovingtheBelts

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Allowthemachinetocool.

3.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page28).

4.MovetheclutchlevertotheOFFposition.

5.Removethedividerplate;refertoRemovingthe

DividerPlate(page28).

Figure62

1.Enginepulley

2.Idlerpulley6.Jamnut

3.Reductioncase(engine)7.Setscrew

4.Beltguide

5.Idlershaft

8.Straightedge

E.Ifnecessary,pivottheengineontheengine

deckuntiltheenginepulleyandidlerpulley

arealignedtothestraightedge(Figure62).

F.Tightenthenutsandboltsthatsecurethe

enginetotheenginedecktoatorqueof18

N∙m(13ft-lb).

G.Checktheairgapbetweentheenginedeck

andtherollerontheclutch.Iftheairgapis

notwithinthespeciedrange,repeatstep6

untiltheairgapmeasurementiswithinthe

speciedrange.

H.Installthedividerplate;refertoInstalling

theDividerPlate(page28).

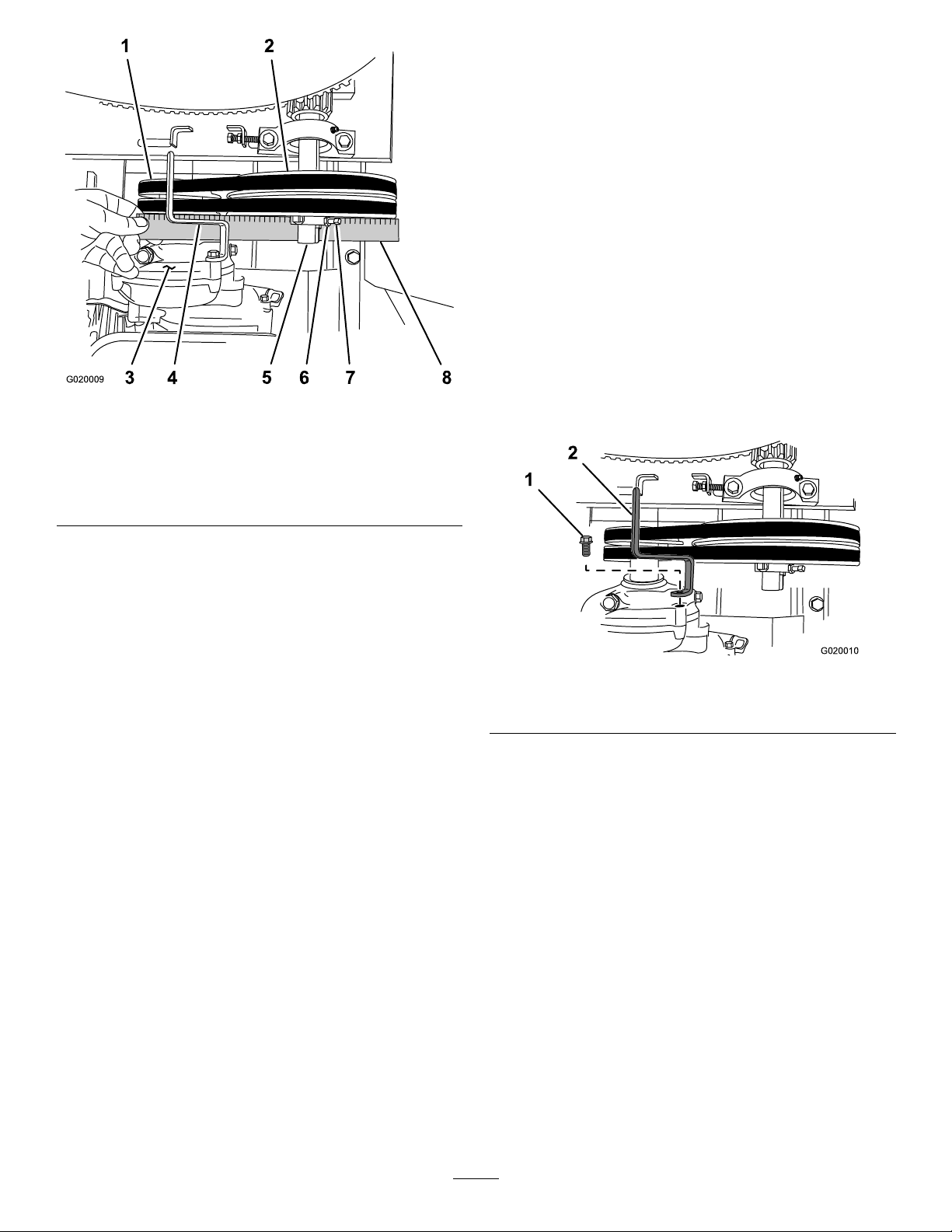

g020009

6.Removetheboltthatsecuresthebeltguideto

theengine,andremovethebeltguide(Figure

63).

g020010

Figure63

1.Bolt2.Beltguide

7.Sliptheforwardbeltforwardandofftheidler

pulley(Figure64).

Important:Ensurethatthepaddlesdonotrotate

whentheclutchleverisintheOFFposition.

42

Page 43

Figure64

1.Enginepulley3.Idlerpulley

2.Forwardbelt4.Rearbelt

8.Sliptherearbeltrearwardandofftheidlerpulley

(Figure64).

9.Slipthebeltsofftheenginepulley.

10.Removethebeltsfromthemachine.

AdjustingtheBeltGuide

Note:T oaccessthebeltguide,removethedivider

plate;refertoRemovingtheDividerPlate(page28).

Guideairgap:2.5to4.0mm(3/32to5/32inch)

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Allowthemachinetocool.

3.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page28).

4.EnsurethattheclutchleverisintheONposition.

5.Ensurethatthebelttensioniscorrect;referto

AdjustingtheBeltTension(page41).

g020012

6.Checkthattheairgapbetweenthebeltguide

andthebeltsis2.5to4.0mm(3/32to5/32

inch);refertoFigure65.

InstallingtheBelts

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Allowthemachinetocool.

3.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page28).

4.EnsurethattheclutchleverisintheOFF

position.

5.Aligntherearbelttothereargrooveinthe

enginepulley.

Note:Donotaligntherearbelttotheidler

pulley.

6.Aligntheforwardbelttotheforwardgrooveof

theidlerpulley.

7.Sliptherearbeltovertheidlerpulleyandalign

thebelttotherearpulleygroove.

8.Sliptheforwardbeltovertheenginepulleyand

alignthebelttotheforwardpulleygroove.

9.Checkthebelttension;refertostep4through6

inAdjustingtheBeltT ension(page41).

10.Looselysecurethebeltguidetotheengine

(Figure63)withtheboltthatwasremovedin

step6ofRemovingtheBelts(page42).

11.Adjustthebeltguide;refertoAdjustingtheBelt

Guide(page43).

12.Installthedividerplate;refertoInstallingthe

DividerPlate(page28).

g020011

Figure65

1.Enginepulleys4.Beltguide

2.Belts5.Bolt

3.Guideairgap:2.5to4.0

mm(3/32to5/32inch)

7.Iftheairgapisnotwithinthespeciedrange,

dothefollowing:

A.Loosentheboltthatsecuresthebeltguide

totheengine(Figure65).

Important:Ensurethatthebeltguideis

towardtheenginepulley.

B.Rotatethebeltguideupordownuntilthere

isanairgapof2.5to4.0mm(3/32to5/32

inch)betweentheguideandeachbelt

(Figure65).

Important:Thebeltguideshouldnot

contactthebeltswiththeclutchleverin

theONposition.

Note:Iftheairgapbetweenthebeltguide

andbothbeltscannotbeattained,then1of

thebeltsistoolong.

43

Page 44

C.Tightentheboltthatsecuresthebeltguide

totheengine(Figure65).

D.Checktheclutchoperation;referto

CheckingtheClutchOperation(page44).

8.Installthedividerplate;refertoInstallingthe

DividerPlate(page28).

CheckingtheClutchOperation

ServiceInterval:Every40hours

Important:Thepaddlesmustnotrotateinan

emptydrumwhentheclutchleverisintheOFF

position.

1.MovetheclutchlevertotheOFFposition.

2.Starttheengine.

3.Ifthepaddlesrotatewiththeclutchlevertothe

OFFpositiondothefollowing:

A.Shutofftheengine.

B.Checktheairgapbetweenthebeltguide

andthebelts.

Note:Iftheairgapislargerthan4.0mm

(5/32inch),decreasethegapbetweenthe

beltguideandthebelts;refertoAdjusting

theBeltGuide(page43).

4.Repeatsteps1through3untilallthefollowing

conditionsaremet:

•Theengineisrunat2/3throttle.

•TheclutchleverisintheOFFposition.

•Thepaddlesdonotrotateinanemptydrum

whiletheengineisrunning.

AligningthePulleys

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

Figure66

1.Enginepulley

2.Idlerpulley5.Locknut

3.Straightedge6.Setscrew

4.Idlershaft

Note:Bothpulleysmustbealignedushwith

thestraightedge.

6.Ifthepulleysarenotaligneddothefollowing:

A.MovetheclutchlevertotheOFFposition.

B.Loosenthelocknutsandsetscrewsthat

securetheidlerpulleytotheidlershaft

(Figure66).

C.Usingasoft-facemallet,taptheidlerpulley

forwardorbackwardalongtheidlershaft

untiltheenginepulleyandidlerpulleyare

alignedtothestraightedge(Figure66).

D.Tightenthesetscrewsandlocknutsthat

securetheidlerpulleytotheidlershaft

(Figure66).

7.Installthedividerplate;refertoInstallingthe

DividerPlate(page28).

g020015

2.Allowthemachinetocool.

3.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page28).

4.Removethedividerplate;refertoRemovingthe

DividerPlate(page28).

5.Placeastraightedgeacrossthefaceofthe

enginepulleyandidlerpulley(Figure66).

44

Page 45

PaddleMaintenance

AdjustingthePaddles

Important:CompletethePreparingtheMachine

forMaintenance(page28)beforeadjustingany

ofthepaddles.

Note:Overtime,youmayneedtoadjustthemixer

paddlestoaccountforwear.

AligningtheCircumferential-Drum

Wipers

1.Rotateapaddlefromtheleftrowofpaddles

aroundthedrumandlocateattheinteriorofthe

drumthesmallestdistancebetweenthedrum

andthewiperofthepaddle(Figure67).

Figure68

1.Wiper4.Paddleblade

2.Distancebetween

paddle-bladeedgeand

wiperedge—3to6mm

(1/8to1/4inch)

3.Wiperbar

5.Carriageboltandanged

locknut

g029188

2.Marktheinsideoftheinsideofthedrumatthe

locationthatyoudeterminedinstep1.

Figure67

3.Alignthewiperofapaddletothemark.

4.Loosenthecarriageboltsandangedlocknuts

thatsecurethepaddlebladeandwipertothe

paddle(Figure68).

5.Adjustthepositionofthewipersothatthewiper

lightlycontactsthedrumacrossthelengthof

thewiper(Figure69).

g029038

Figure69

1.Wiperlightlycontactingthedrumatthesmallestdistance

betweenthedrumandthewiperofthepaddle

g029066

6.Adjustthepositionofthepaddlebladesothat

theouteredgeis3to6mm(1/8to1/4inch)

fromtheouteredgeofthewiper.

7.T orquethecarriageboltsandnutsto19to25

N-m(14to18ft-lb).

8.Repeatsteps4through7fortheotherpaddle

forthatpaddlerow.

9.Repeattheprocedurefortheotherpaddlerows.

45

Page 46

AligningtheEnd-PaddleWipers

AligningtheAdjustable-End

1.Rotatethewiperandxedpaddlearoundthe

endplateofthedrumandlocatesmallest

distancebetweenthedrumandthewiperofthe

paddle.

2.Marktheinsideoftheendplateatthelocation

thatyoudeterminedinstep1.

Figure70

1.Carriageboltandanged

locknut

2.Closestpointofcontact

3.Drumendplate

3.Alignthewiperofapaddletothemark.

Paddles

1.Aligntheadjustable-endpaddletothemarkthat

youmadeinstep2ofAligningtheEnd-Paddle

Wipers(page46).

2.Loosenthecarriageboltsandangedlocknuts

thatsecuretheadjustableendpaddletothe

xedpaddle.(Figure71)

g029043

g029044

Figure71

1.Carriageboltandanged

locknut

2.Closestpointofcontact

3.Drumendplate

4.Loosenthecarriageboltsandangedlocknuts

thatsecurethepaddlebladeandwipertothe

xedpaddle.(Figure70)

5.Adjustthepositionofthewipersothatthewiper

lightlycontactstheendplateacrossthelength

ofthewiper.

6.Adjustthepositionofthepaddlebladesothat

theouteredgeofthebaris3to6mm(1/8to1/4

inch)fromtheouteredgeofthewiper.

7.T orquethecarriageboltsandnutsto19to25

N-m(14to18ft-lb).

8.Repeattheprocedureforthewiperattheend

plateontheotherendofthedrum.

3.Adjustthepositionoftheadjustable-endpaddle

sothatitisasclosetotheendplateaspossible,

acrossthelengthofthepaddle,withouttouching

endplatewhenthepaddlesarerotated.

4.T orquethecarriageboltsandnutsto37to45

N∙m(27to33ft-lb).

5.Repeattheprocedurefortheadjustableend

paddleattheendplateontheotherendofthe

drum.

46

Page 47

Cleaning

CleaningtheMachine

Regularcleaningandwashingwithmilddetergentand

waterincreasesthelifespanofthemachine.Clean

themachineaftereachusebeforethedirthardens.

Removedirtandgrimefromtheexternalpartsofthe

entiremachine,especiallytheengine.Cleandirtand

concretematerialsfromtheoutsideoftheengine.

Ensurethatthefuelcapandtheoil-llcap/dipstickare

securetoavoidgettingwaterintheengine.

Usecarewhenusingahigh-pressuresprayer

becauseitcandamagethesafetydecals,instruction

signs,andtheengine.

Important:Lubricatethebearingsandsealsafter

cleaning;refertoLubricatingtheBearingsand

Seals(page29).

Storage

Forstorageover30days,preparethemachineas

follows:

1.Removedirtandgrimefromtheexternalpartsof

theentiremachine,especiallytheengine.Clean

dirtanddebrisfromtheoutsideoftheengine

cylinder-headnsandblowerhousing.

Important:Youcanwashthemachinewith

milddetergentandwater.

2.Conditionthefuelsystemasfollows:

A.Addapetroleum-based

stabilizer/conditionertofuelinthe

tank.Followthemixinginstructionsfrom

thestabilizermanufacturer.Donotuse

analcohol-basedstabilizer(ethanolor

methanol).

Important:Donotstore

stabilizer/conditionedfuelover90

days.

Note:Fuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfueland

usedatalltimes.

B.Runtheenginefor5minutestodistribute

theconditionedfuelthroughthefuelsystem.

C.Shutofftheengine,allowittocool,and

drainthefueltankusingapump-type

siphon.Disposeoffuelproperly;recycleit