Page 1

400XT Series Tractor

Service

Manual

Page 2

ABOUT THIS MANUAL

This service manual was written expressly for Toro service technicians. The Toro Company

has made every effort to make the information in this manual complete and correct.

Basic shop safety knowledge and mechanical/electrical skills are assumed. The Table of

Contents lists the systems and the related topics covered in this manual.

For additional information on the electrical system, please refer to the Toro Electrical

Demystification Guide (492-4404). For service information on drive systems, please refer to

the Hydro-Gear (330-3000) service manual. For information information specific to the

engines used on this unit, refer to the appropriate engine manufacturer’s service and repair

instructions.

Tractor model years 2003 - 2004 are covered in this manual. The manual may also be

specified for use on later model products.

The hydrostatic transaxle is a sophisticated piece of machinery. Maintain strict cleanliness

control during all stages of service and repair. Cover or cap all hose ends and fittings

whenever they are exposed. Even a small amount of dirt or other contamination can

severely damage the system.

We are hopeful that you will find this manual a valuable addition to your service shop. If you

have questions or comments regarding this manual, please contact us at the following

address:

The Toro Company

Consumer Service Department

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

The Toro Company reserves the right to change product specifications or this manual

without notice.

Copyright© All Rights Reserved

©2003 The Toro Company

Page 3

SPECIFICATIONS

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

Think Safety First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

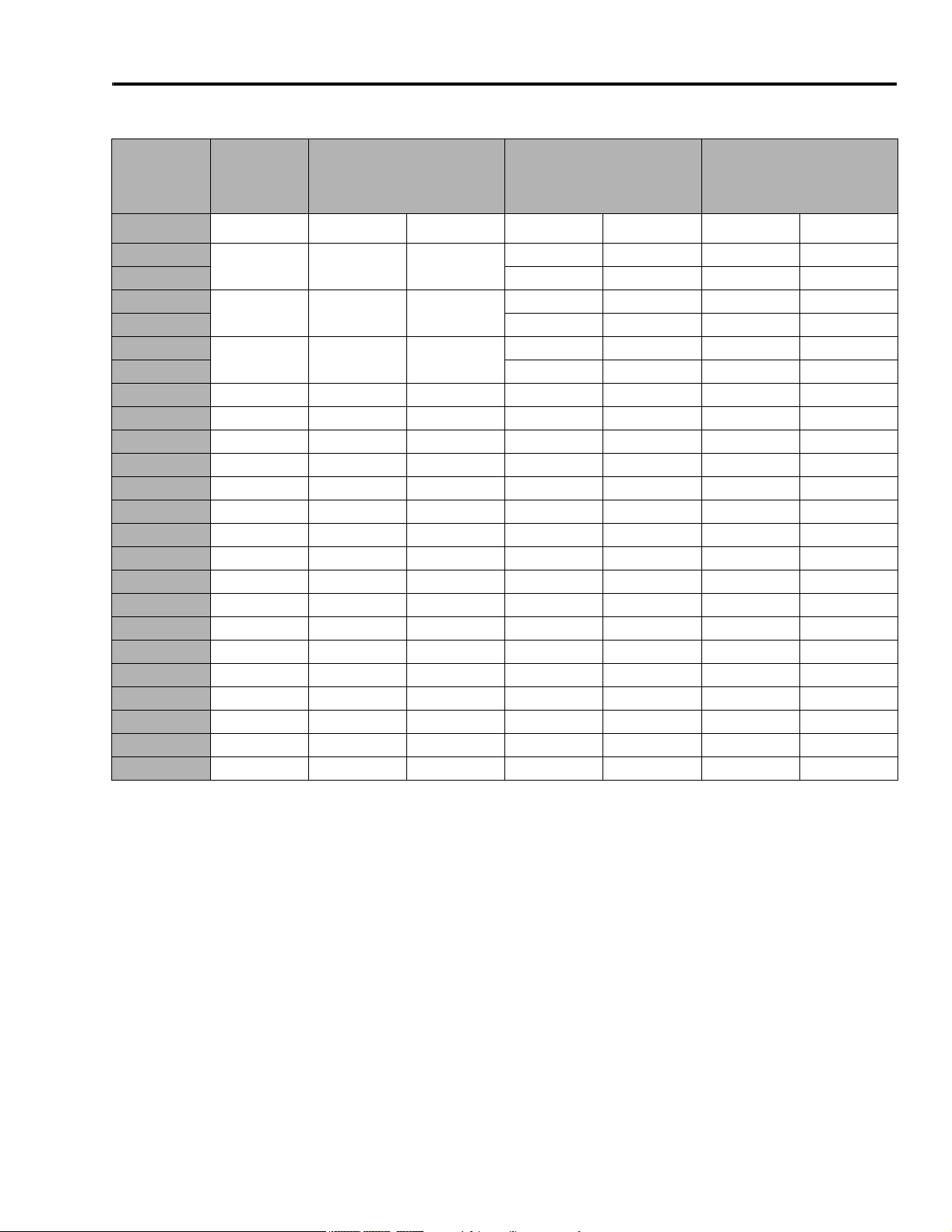

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

Hydrostatic Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 3

Identification: Hydro-Gear Model 330-3000 Transaxle . . . . . . . . . . . . . . . . . . . . .1 - 3

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 3

Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 4

Fastener Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 4

Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series) . . . . . . . .1 - 5

Standard Torque for Dry, Zinc, and Steel Fasteners (Metric Fasteners) . . . . . . . . .1 - 6

Other Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 7

SAE Grade 8 Steel Set Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 7

Thread Cutting Screws (Zinc Plated Steel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 7

Conversion Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 7

Wheel Bolts and Lug Nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 7

Thread Cutting Screws (Zinc Plated Steel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 7

Equivalents and Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 8

Decimal and Millimeter Equivalents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 8

U.S. to Metric Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 9

TABLE OF CONTENTS

CHASSIS

Model and Serial Number Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

Greasing and Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

Front Wheel Toe-in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

Front Wheel Toe-in Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 2

Front Wheel and Spindle Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . .2 - 3

Front Axle Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 4

Steering Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 5

Steering Backlash Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 5

Steering Gear Shaft Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 7

Steering Gear Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 9

Sector Gear Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 11

Sector Gear Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 11

Tilt Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 12

Tilt Steering Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 13

Tilt Steering Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 13

Steering Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 14

Hood Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 15

Seat and Fender Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 15

Gas Tank Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 16

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 3

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 5

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 12

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 17

400XT Series Tractor Service Manual iii

Page 4

TABLE OF CONTENTS

CHASSIS (cont’d)

Lift Bar Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 17

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 17

Lift Lever Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 18

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 18

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 18

Lift Arm/Lift Lever Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 19

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 19

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 20

Electric Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 21

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 21

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 21

HYDRO-GEAR TRANSAXLE

Hydro-Gear Hydrostatic Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Internal Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Fluid Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Transaxle Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Installation - Hydro-Gear Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

Neutral Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 7

Transaxle Purging Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 8

Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 9

Checking the Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 9

Brake Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 9

Foot Control Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 10

Traction Belt Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

ELECTRICAL SYSTEMS

Electrical Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

How it Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

iv 400XT Series Tractor Service Manual

Page 5

ELECTRICAL SYSTEMS (con’d)

Ignition Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 4

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 4

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 4

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 4

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 5

Electric (PTO) Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 5

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 5

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 5

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 5

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 5

Coil Resistance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 5

Measuring Clutch Current Draw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 6

Clutch Burnishing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 6

PTO Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 6

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 6

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 7

How it Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 7

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 7

Seat Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 7

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 7

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 8

How It works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 8

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 8

Hourmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 8

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 8

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 8

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 8

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 8

Magnet Assembly - Cruise Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 9

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 9

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 9

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 9

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 9

Switch, Cruise Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 9

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 9

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 9

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 9

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 10

Brake Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 10

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 10

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 10

How it Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 10

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 10

TABLE OF CONTENTS

400XT Series Tractor Service Manual v

Page 6

TABLE OF CONTENTS

ELECTRICAL SYSTEMS (con’d)

KeyChoice™ Reverse Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 11

Testing the Key Choice™ Reverse Operating System - Unactivated . . . . . . . . 4 - 11

Testing the KeyChoice™ Reverse Operating System - Activated . . . . . . . . . . 4 - 11

KeyChoice™ Reverse Operating System Switch . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 13

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 13

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 13

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 13

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 13

Reverse Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 14

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 14

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 14

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 14

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 14

Module Low Voltage/KeyChoice™ Reverse Operating System . . . . . . . . . . . . . . 4 - 14

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 14

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 15

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 15

Testing - Low Voltage Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 15

KeyChoice™ Reverse Operating System Module . . . . . . . . . . . . . . . . . . . . . . . . 4 - 15

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 15

vi 400XT Series Tractor Service Manual

Page 7

General Information

This symbol means WARNING or

PERSONAL SAFETY INSTRUCTION

- read the instruction because it has to

do with your safety. Failure to comply

with the instruction may result in

personal injury or even death.

This manual is intended as a service and repair

manual only. The safety instructions provided herein

are for troubleshooting, service, and repair of the

400XT Series tractors. The 400XT Series tractors

Think Safety First

SAFETY INFORMATION

tractors and attachment operator’s manuals contain

safety information and operating tips for safe operating

practices. Operator’s manuals are available through

your Toro parts source or:

The Toro Company

Publications Department

8111 Lyndale Avenue South

Bloomington, MN 55420

Avoid unexpected starting of engine...

Always turn off the engine and disconnect the spark

plug wire(s) before cleaning, adjusting, or repair.

Avoid lacerations and amputations...

Stay clear of all moving parts whenever the engine is

running. Treat all normally moving parts as if they were

moving whenever the engine is running or has the

potential to start.

Avoid burns...

Do not touch the engine, muffler, or other components

which may increase in temperature during operation,

while the unit is running or shortly after it has been

running.

Avoid fires and explosions...

Avoid spilling fuel and never smoke while working with

any type of fuel or lubricant. Wipe up any spilled fuel or

oil immediately. Never remove the fuel cap or add fuel

when the engine is running. Always use approved,

labeled containers for storing or transporting fuel and

lubricants.

Avoid injury from batteries...

Battery acid is poisonous and can cause burns. Avoid

contact with skin, eyes, and clothing. Battery gases

can explode. Keep cigarettes, sparks, and flames away

from the battery.

Avoid injury due to inferior parts...

Use only original equipment parts to ensure that

important safety criteria are met.

Avoid injury to bystanders...

Always clear the area of bystanders before starting or

testing powered equipment.

Avoid injury due to projectiles...

Always clear the area of sticks, rocks, or any other

debris that could be picked up and thrown by the

powered equipment.

Avoid modifications...

Never alter or modify any part unless it is a factory

approved procedure.

Avoid asphyxiation...

Never operate an engine in a confined area without

proper ventilation.

400XT Series Tractor Service Manual 1 - 1

Avoid unsafe operation...

Always test the safety interlock system after making

adjustments or repairs on the machine. Refer to the

Electrical section in this manual for more information.

Page 8

SPECIFICATIONS

General Specifications

Item Specification

16 H.P. Kohler OHV Command Single Cylinder

17 H.P. Kawasaki OHV Twin Cylinder

Engines

RPM Setting, All Models High RPM Setting (no load) – 3250 + or -100 RPM

Construction Frame: 2” X 2” X 1/4” Welded Angle Frame

Fuel Capacity 3.9 Gallons (14.7 liter)

Wheel Base 49.5” (125.7cm)

Overall Length 71.0’ (180.3cm)

Overall Width 35.5” (90.1cm) without the mower

Weight

Traction System Hydro-Gear Transaxle model 330-3000

Ground Speed Forward - Infinite 0 to 6.8 MPH 90 (10.9 km/hr)

Steering Four (4) position tilt wheel

Tires Front: 16 X 6.50 - 8 Super Turf Tread

Tire Pressure Front Tires 20 p.s.i (138 kpa)

Attachment Drive Electric Clutch, Maintenance Free, No Adjustments

19 H.P. Kawasaki OHV Twin Cylinder

For more information on servicing the engines, contact either Briggs & Stratton or

Kawasaki.

416XT net weight 530 lbs. (240.4kg)

417XT net weight 560 lbs. (254kg)

419XT net weight 580 lbs. (263kg)

Reverse - Infinite 0 to 3.2 MPH (0 - 4.8 km/hr)

Turning Radius: 16” (40.6cm) RH and LH

Rear: 23 X 10.50 - 12 Super Turf Tread

Rear Tires 20 p.s.i. (138 kpa)

416XT: 15 amp Regulated DC Charging System

Battery Voltage - 12 volt negative ground

Battery Type: BCI Group U1, 260 CCA

417XT: 13 amp Regulated DC Charging

Battery Voltage - 12 volt negative ground

Battery Type: BCI Group U1, 340 CCA

Electrical System

1 - 2 400XT Series Tractor Service Manual

417XT: 13 amp Regulated DC Charging

Battery Voltage – 12 volt negative ground

Battery Type: BCI Group U1, 340 CCA

25 amp, Charge Circuit

30 amp, Main Circuit

10 amp, Light Circuit

10 amp, Dash Circuit

Page 9

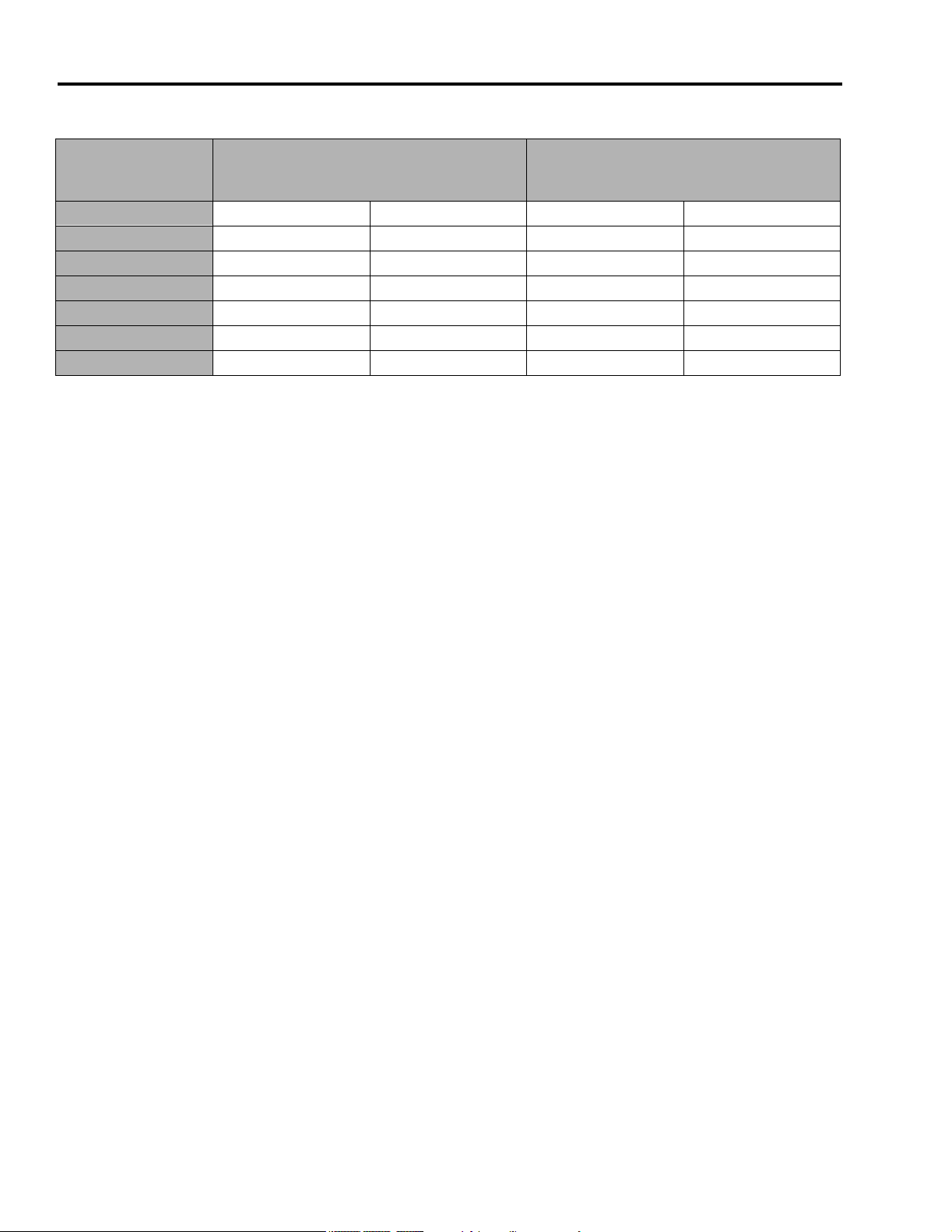

Hydrostatic Transaxle

Identification:

Hydro-Gear Model 330-3000 Transaxle

330-3000

SPECIFICATIONS

General Specifications

Lubrication

Oil Capacity

Oil Level

SAE 20W-50 API Classification SH/CD Oil

3.8 qts. (3.6l)

The transaxle is a sealed system and does not require periodic checking. If the

oil needs to be checked, IT CAN ONLY BE CHECKED COLD. There is a plug

located on the right rear side of the transaxle. Using a ¼ inch Allen wrench,

slowly remove the plug. Oil level should be to the bottom of the port.

400XT Series Tractor Service Manual 1 - 3

Page 10

SPECIFICATIONS

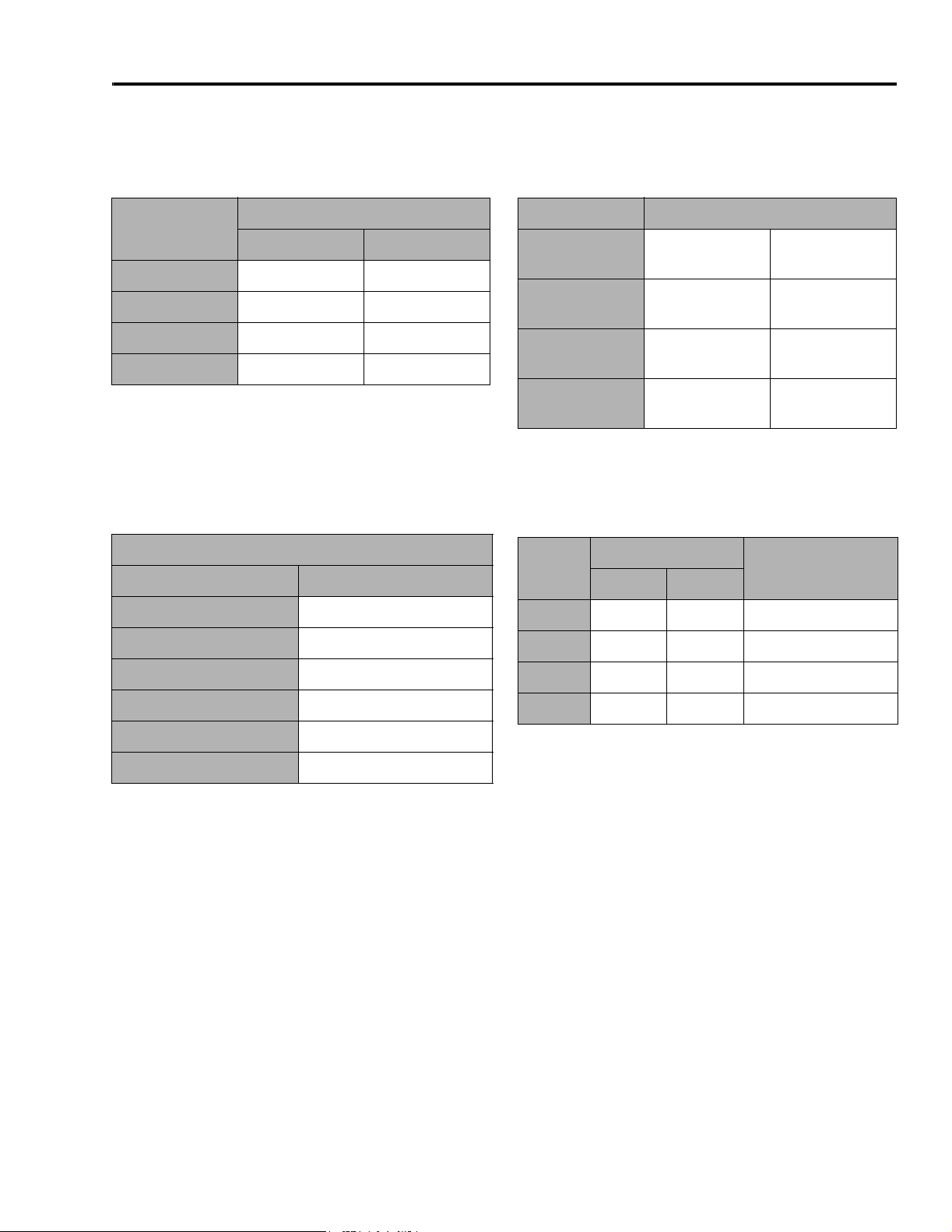

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as determined

by Toro, either the recommended torque or a torque

that is unique to the application is clearly identified and

specified in the service manual.

These torque specifications for the installation and

tightening of fasteners shall apply to all fasteners which

do not have a specific requirement identified in the

service manual. The following factors shall be

considered when applying torque: cleanliness of the

fastener, use of a thread sealant (Loctite), degree of

lubrication on the fastener, presence of a prevailing

torque feature, hardness of the surface underneath of

the fastener’s head, or similar condition which affects

the installation.

As noted in the following tables, torque values should

be reduced by 25% for lubricated fasteners to

achieve the similar stress as a dry fastener. Torque

values may also have to be reduced when the fastener

is threaded into aluminum or brass. The specific torque

value should be determined based on the aluminum or

brass material strength, fastener size, length of thread

engagement, etc.

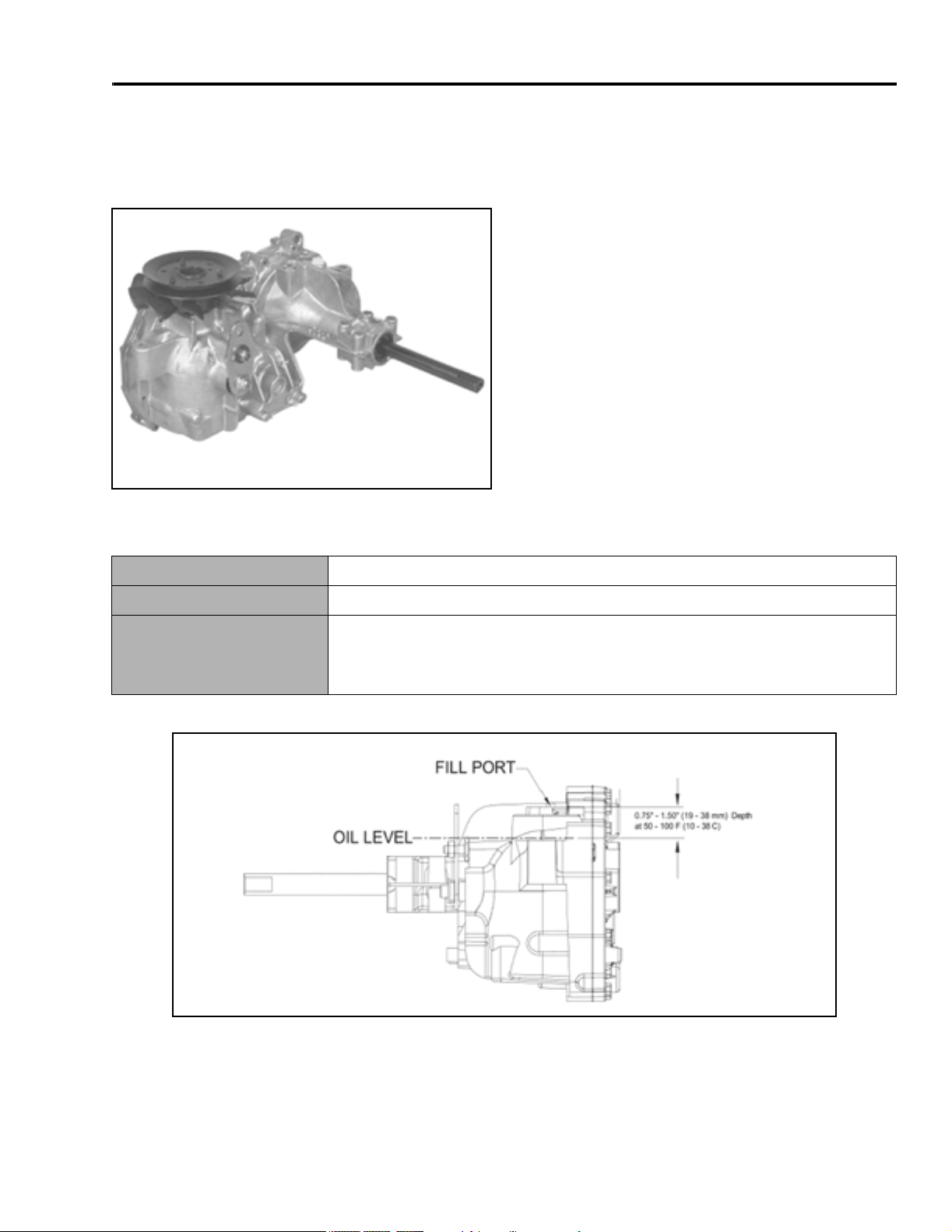

Fastener Identification

Inch Series Bolts and Screws

(A) Grade 1

(B) Grade 5

Figure 1

(C) Grade 8

The standard method of verifying torque shall be

performed by marking a line on the fastener (head or

nut) and mating part, then back off fastener 1/4 of a

turn. Measure the torque required to tighten the

fastener until the lines match up.

Figure 2

Metric Bolts and Screws

(A) Class 8.8 (B) Class 10.9

1 - 4 400XT Series Tractor Service Manual

Page 11

SPECIFICATIONS

Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

Grade 1, 5, &

Thread Size

# 6 - 32 UNC

# 6 - 40 UNF 17 ± 2 190 ± 20 25 ± 2 280 ± 20

# 8 - 32 UNC

# 8 - 36 UNF 31 ± 3 350 ± 30 43 ± 4 31 ± 3

# 10 - 24 UNC

#10 - 32 UNF 48 ± 4 540 ± 45 68 ± 6 765 ± 70

1/4 - 20 UNC 48 ± 7 53 ± 7 599 ± 79 100 ± 10 1125 ± 100 140 ± 15 1580 ± 170

1/4 - 28 UNF 53 ± 7 65 ± 10 734 ± 113 115 ± 10 1300 ± 100 160 ± 15 1800 ± 170

5/16 - 18 UNC 115 ± 15 105 ± 17 1186 ± 169 200 ± 25 2250 ± 280 300 ± 30 3390 ± 340

5/16 - 24 UNF 138 ± 17 128 ± 17 1446 ± 192 225 ± 25 2540 ± 280 325 ± 30 3670 ± 340

3/8 - 16 UNC 16 ± 2 16 ± 2 22 ± 3 30 ± 3 41 ± 4 43 ± 4 58 ± 5

3/8 - 24 UNF 17 ± 2 18 ± 2 24 ± 3 35 ± 3 47 ± 4 50 ± 4 68 ± 5

7/16 - 14 UNC 27 ± 3 27 ± 3 37 ± 4 50 ± 5 68 ± 7 70 ± 7 68 ± 9

7/16 - 20 UNF 29 ± 3 29 ± 3 39 ± 4 55 ± 5 75 ± 7 77 ± 7 104 ± 9

1/2 - 13 UNC 30 ± 3 48 ± 7 65 ± 9 75 ± 8 102 ± 11 105 ± 10 142 ± 14

1/2 - 20 UNF 32 ± 3 53 ± 7 72 ± 9 85 ± 8 115 ± 11 120 ± 10 163 ± 14

5/8 - 11 UNC 65 ± 10 88 ± 12 119 ± 16 150 ± 15 203 ± 20 210 ± 20 285 ± 27

5/8 - 18 UNF 75 ± 10 95 ± 15 129 ± 20 170 ± 15 230 ± 20 240 ± 20 325 ± 27

3/4 - 10 UNC 93 ± 12 140 ± 20 190 ± 27 265 ± 25 359 ± 34 374 ± 35 508 ± 47

3/4 - 16 UNF 115 ± 15 165 ± 25 224 ± 34 300 ± 25 407 ± 34 420 ± 35 569 ± 47

7/8 - 9 UNC 140 ± 20 225 ± 25 305 ± 34 430 ± 45 583 ± 61 600 ± 60 813 ± 81

7/8 - 14 UNF 155 ± 25 260 ± 30 353 ± 41 475 ± 45 644 ± 61 660 ± 60 895 ± 81

8 with Thin

Height Nuts

In-lb In-lb N-cm In-lb N-cm In-lb N-cm

10 ± 2 13 ± 2 147 ± 23

13 ± 2 25 ± 5 282 ± 30

18 ± 2 30 ± 5 339 ± 56

ft-lb ft-lb N-m ft-lb N-m ft-lb N-m

SAE Grade 1 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

15 ± 2 170 ± 20 23 ± 2 260 ± 20

29 ± 3 330 ± 30 41 ± 4 460 ± 45

42 ± 4 475 ± 45 60 ± 6 674 ± 70

SAE Grade 8 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the

minimum proof load specified in SAE J429. The

tolerance is approximately

value. Thin height nuts include jam nuts.

± 10% of the nominal torque

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

400XT Series Tractor Service Manual 1 - 5

Page 12

SPECIFICATIONS

Standard Torque for Dry, Zinc, and Steel Fasteners (Metric Fasteners)

Class 8.8 Bolts, Screws, and Studs with

Thread Size

M5 X 0.8 57 ± 5 in-lb 640 ± 60 N-cm 78 ± 7 in-lb 885 ± 80 N-cm

M6 X 1.0 96 ± 9 in-lb 1018 ± 100 N-cm 133 ± 13 in-lb 1500 ± 150 N-cm

M8 X 1.25 19 ± 2 ft-lb 26 ± 3 N-m 27 ± 2 ft-lb 36 ± 3 N-m

M10 X 1.5 38 ± 4 ft-lb 52 ± 5 N-m 53 ± 5 ft-lb 72 ± 7 N-m

M12 X 1.75 66 ± 7 ft-lb 90 ± 10 N-m 92 ± 9 ft-lb 125 ± 12 N-m

M16 X 2.0 166 ± 15 ft-lb 225 ± 20 N-m 229 ± 22 ft-lb 310 ± 30 N-m

M20 X 2.5 325 ± 33 ft-lb 440 ± 45 N-m 450 ± 37 ft-lb 610 ± 50 N-m

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Regular Height Nuts

(Class 8 or Strong Nuts)

Note: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately

nominal torque value. Thin height nuts include jam nuts.

Class 10.9 Bolts, Screws, and Studs with

Regular Height Nuts (

Class 10 or Strong Nuts)

± 10% of the

1 - 6 400XT Series Tractor Service Manual

Page 13

Other Torque Specifications

SPECIFICATIONS

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 - 20 UNC 140 ± 20 in-lb 73 ± 12 in-lb

5/16 - 18 UNC 215 ± 35 in-lb 145 ± 20 in-lb

3/8 - 16 UNC 35 ± 10 ft-lb 18 ± 3 ft-lb

1/2 - 13 UNC 75 ± 15 ft-lb 50 ± 10 ft-lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23, or Type F

Thread Size Baseline Torque*

No. 6 - 32 UNC 20 ± 5 in-lb

Wheel Bolts and Lug Nuts

Thread Size Recommended Torque**

7/16 - 20 UNF

Grade 5

1/2 - 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non-lubricated fasteners.

Thread

Size

No. 6 18 20 20 ± 5 in-lb

Threads per Inch

Type A Type B

65 ± 10 ft-lb 88 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

Thread Cutting Screws

(Zinc Plated Steel)

Baseline Torque*

No. 8 - 32 UNC 30 ± 5 in-lb

No.10 - 24 UNC 38 ± 7 in-lb

1/4 - 20 UNC 85 ± 15 in-lb

5/16 - 18 UNC 110 ± 20 in-lb

3/8 - 16 UNC 200 ± 100 in-lb

Conversion Factors

in-lb X 11.2985 - N-cm

ft-lb X 1.3558 = N-m

No. 8 15 18 30 ± 5 in-lb

No. 10 12 16 38 ± 7 in-lb

No. 12 11 14 85 ± 15 in-lb

* Hole size, material strength, material thickness and

finish must be considered when determining specific

torque values. All torque values are based on nonlubricated fasteners.

N-cm X - 0.08851 = in-lb

N-cm X 0.73776 - ft-lb

400XT Series Tractor Service Manual 1 - 7

Page 14

SPECIFICATIONS

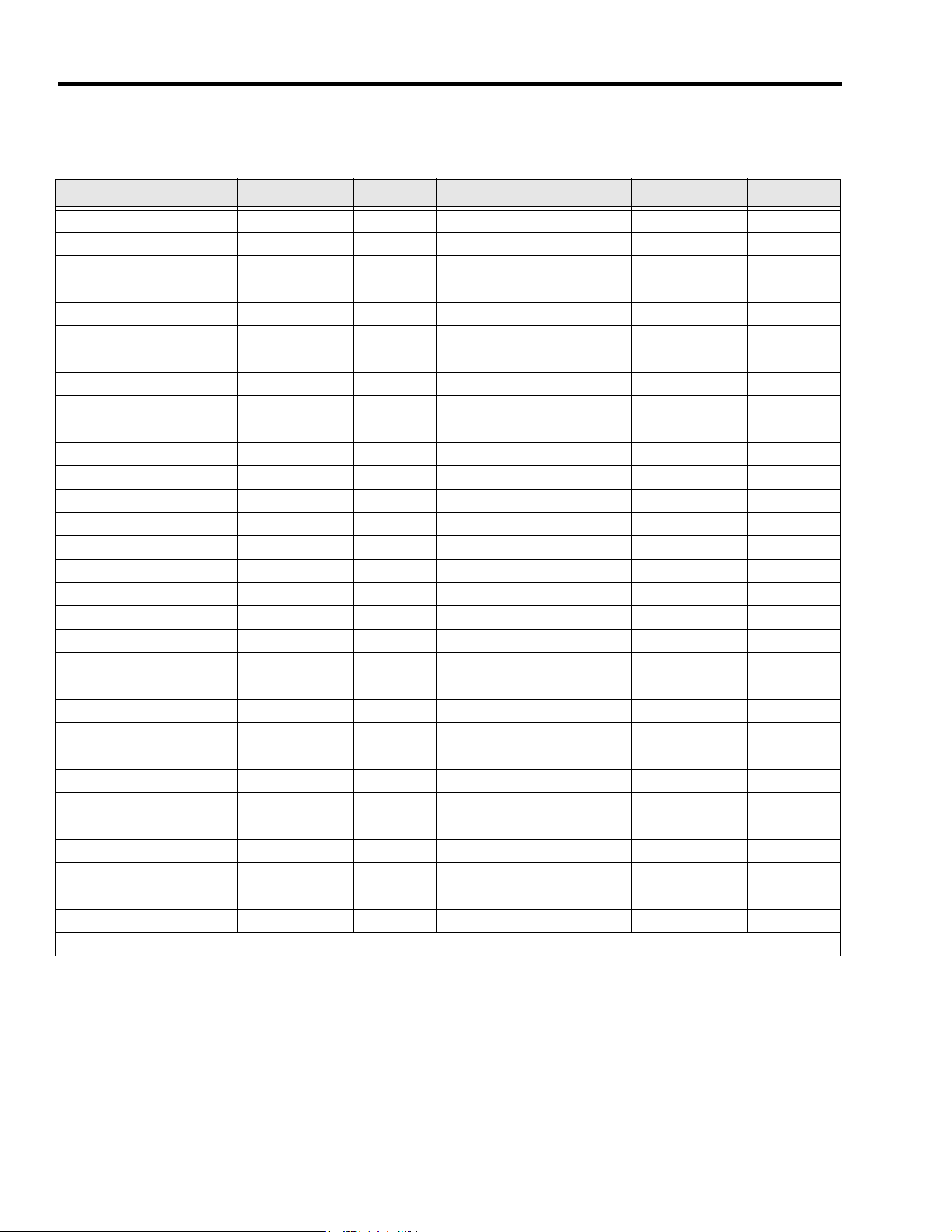

Equivalents and Conversions

Decimal and Millimeter Equivalents

Fractions Decimals mm Fractions Decimals mm

1/64 0.015625 0.397 33/64 0.515625 13.097

1/32 0.03125 0.794 16/32 0.53125 13.484

3/64 0.046875 1.191 35/64 0.546875 13.891

1/16 0.0625 1.588 9/16 0.5625 14.288

5/64 0.078125 1.984 37/64 0.578125 14.684

3/32 0.9375 2.381 19/32 0.59375 15.081

1/8 0.1250 3.175 5/8 0.6250 15.875

9/64 0.140625 3.572 41/64 0.640625 16.272

5/32 0.15625 3.969 21/32 0.65625 16.669

11/64 0.171875 4.366 43/64 0.671875 17.066

3/16 0.1875 4.762 11/16 0.6875 17.462

13/64 0.203125 5.159 45/64 0.703125 17.859

7/32 0.21875 5.556 23/32 0.71875 18.256

15/64 0.234375 5.953 47/64 0.734375 18.653

1/4 0.2500 6.350 3/4 0.7500 19.050

17/64 0.265625 6.747 49/64 0.765625 19.447

9/32 0.28125 7.144 25/32 0.78125 19.844

19/64 0.296875 7.541 51/64 0.796875 20.241

5/16 0.3125 7.541 13/16 0.8125 20.638

21/64 0.328125 8.334 53/64 0.828125 21.034

11/32 0.34375 8.731 27/32 0.84375 21.431

23/64 0.359375 9.128 55/64 0.859375 21.828

3/8 0.3750 9.525 7/8 0.8750 22.225

25/64 0.390625 9.922 57/64 0.890625 22.622

13/32 0.40625 10.319 29/32 0.90625 23.019

27/64 0.421875 10.716 59/64 0.921875 23.416

7/16 0.4375 11.112 15/16 0.9375 23.812

29/64 0.453125 11.509 61/64 0.953125 24.209

15/32 0.46875 11.906 31/32 0.96875 24.606

31/64 0.484375 12.303 63/64 0.984375 25.003

1/2 0.5000 12.700 1 1.000 25.400

1 mm = 0.03937 in. 0.001 in. = 0.0254 mm

1 - 8 400XT Series Tractor Service Manual

Page 15

SPECIFICATIONS

U.S. to Metric Conversions

To Convert Into Multiply By

Linear

Measurement

Area

Volume

Weight

Pressure

Work

Liquid Volume

Liquid Flow

Miles

Yards

Feet

Feet

Inches

Inches

Inches

Square Miles

Square Feet

Square Inches

Acre

Cubic Yards

Cubic Feet

Cubic Inches

Tons (Short)

Pounds

Ounces

Pounds/Sq. In. Kilopascal 6.895

Foot-pounds

Foot-pounds

Inch-pounds

Quarts

Gallons

Gallons/Minute Liters/Minute 3.785

Kilometers

Meters

Meters

Centimeters

Meters

Centimeters

Millimeters

Square Kilometers

Square Meters

Square Centimeters

Hectare

Cubic Meters

Cubic Meters

Cubic Centimeters

Metric Tons

Kilograms

Grams

Newton-Meters

Kilogram-Meters

Kilogram-Centimeters

Liters

Liters

1.609

0.9144

0.3048

30.48

0.0254

2.54

25.4

2.59

0.0929

6.452

0.4047

0.7646

0.02832

16.39

0.9078

0.4536

28.3495

1.356

0.1383

1.152144

0.9463

3.785

Temperature

Fahrenheit Celsius 1. Subtract 32°

2. Multiply by 5/9

400XT Series Tractor Service Manual 1 - 9

Page 16

THIS PAGE INTENTIONALLY LEFT BLANK

1 - 10 400XT Series Tractor Service Manual

Page 17

CHASSIS

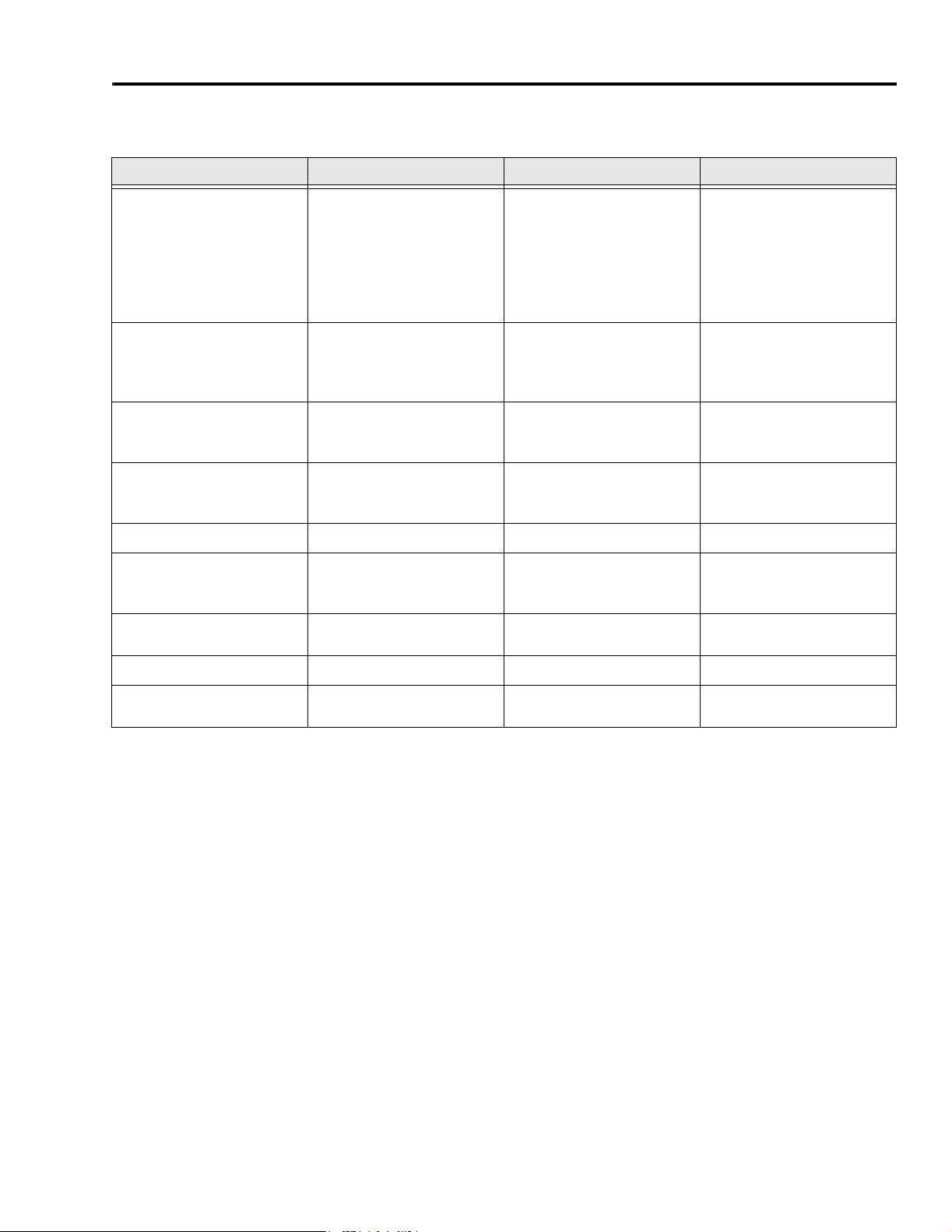

Model and Serial Number Location

The model and serial number plate location is under

the seat (Figure 3).

Figure 3

MVC-742

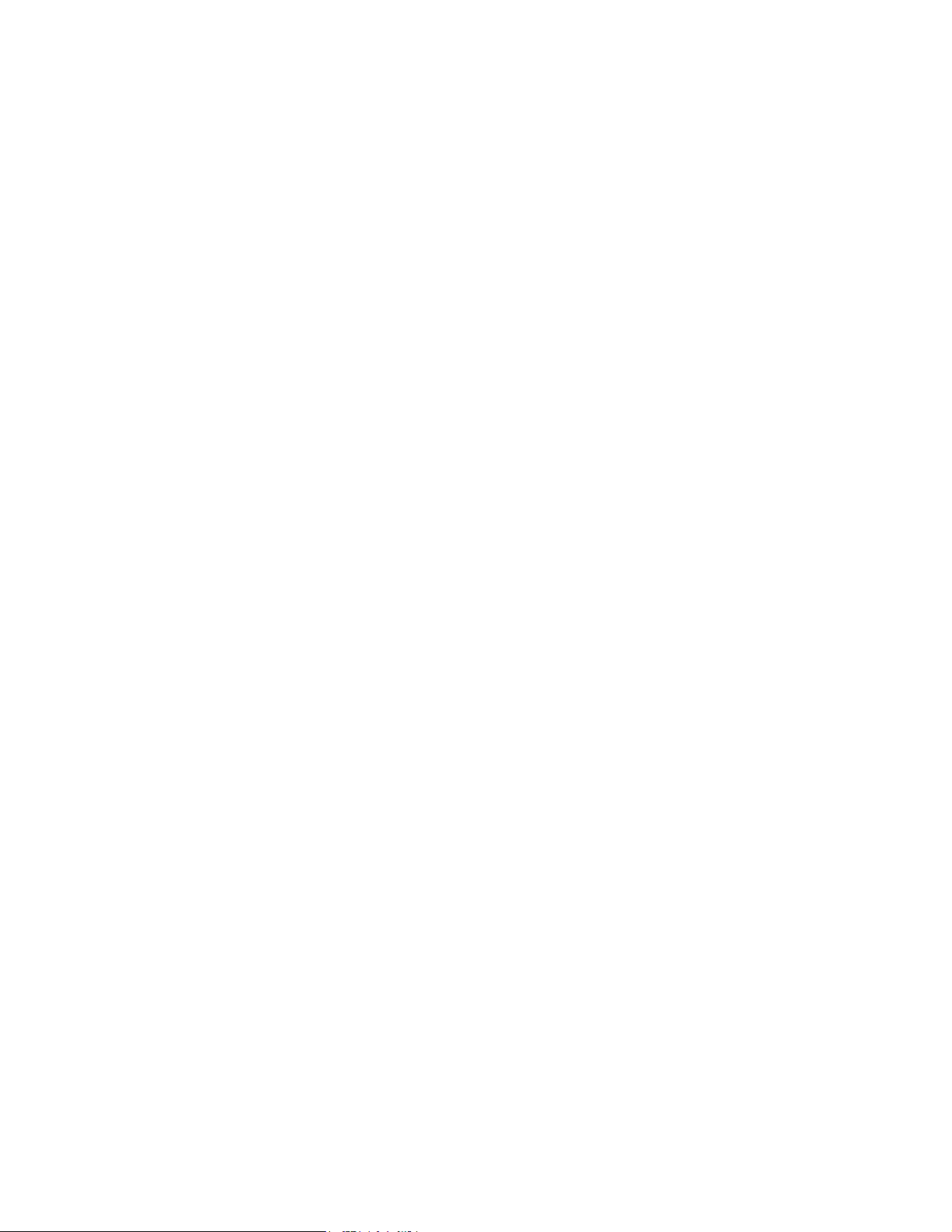

Greasing and Lubrication

3. One located on the front axle pivot area (1 total)

(Figure 4).

Figure 4

4. NOTE: On 2004 models, there is a grease zerk

located on the forward/reverse pedal.

MVC-746

Front Wheel Toe-in

The machine should be greased every 50 hours or

yearly, whichever occurs first. You should grease more

frequently when operating conditions are extremely

dusty or sandy.

Grease Type: General-purpose grease.

There are 5 grease fittings located in the front axle

area:

1. One located on the inside of each wheel hub (2

total).

2. One located on each end of the front axle for the

spindles (2 total).

If there is uneven tire wear, lawn scuffing, or hard

steering, toe-in may need to be adjusted. The front

toe-in measurement should be 1/8” to ¼” (3 to 6mm).

This should be checked every 100 hours or once a

year, whichever occurs first.

MEASUREMENT:

1. Disengage the PTO, set the parking brake, and

turn the ignition key to OFF to stop the engine.

Remove the key.

400XT Series Tractor Service Manual 2 - 1

Page 18

CHASSIS

2. Push the front of the tires out to remove normal

looseness in the linkage (Figure 5).

Figure 5

3. Measure the distance between both the front rims

at spindle level, in front and rear of the wheels.

You can also measure between the tread mold

marks if the tires are new (Figure 6).

MVC-747

4. The front measurement should be 1/8” to ¼”

(3mm to 6mm) less than the rear measurement

(Figure 7). If needed, follow the adjustment

procedure.

Figure 7

MVC-752

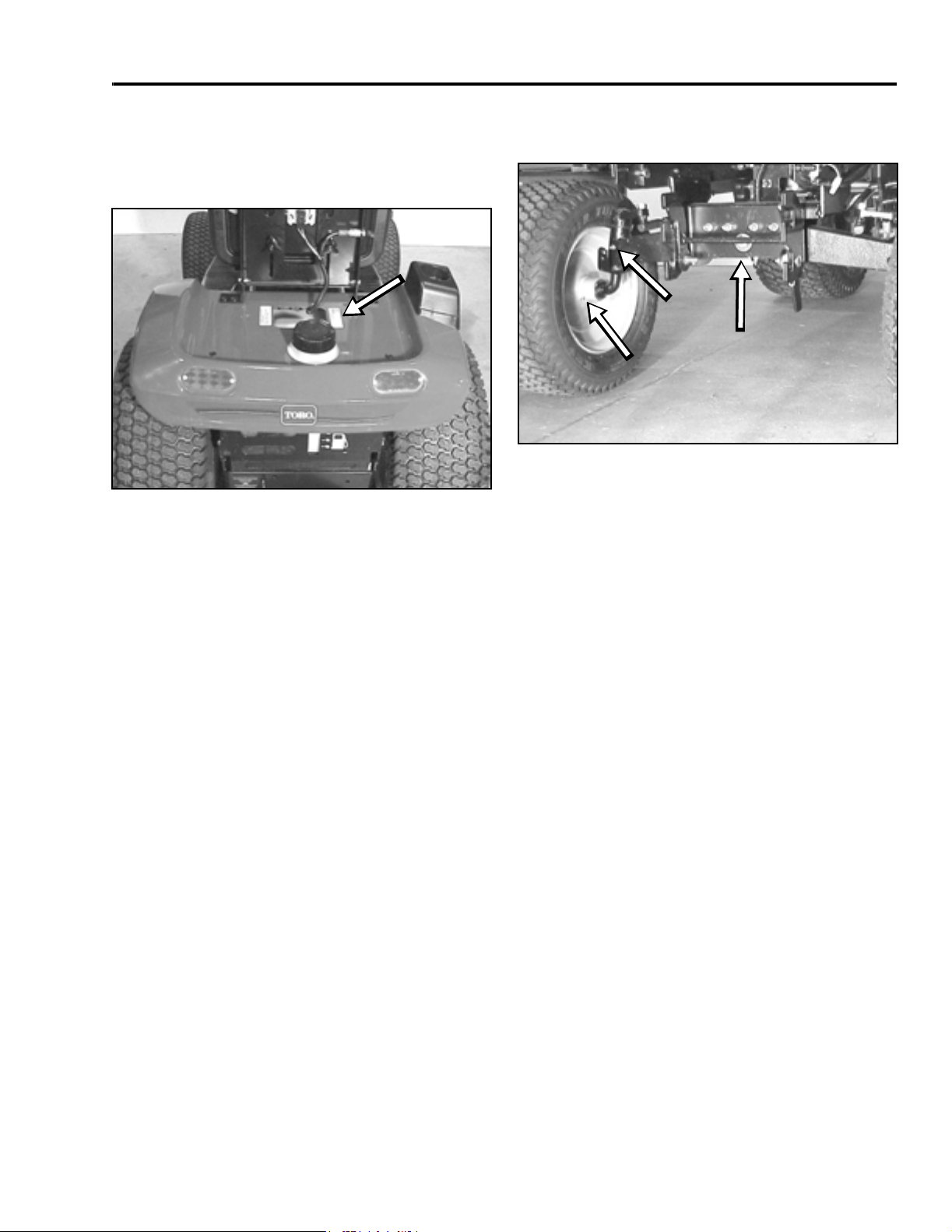

Front Wheel Toe-in Adjustment

Figure 6

1. Remove the tie rod from one steering arm.

2. Loosen the jam nut securing the ball joint to the

steering rod. Rotate the ball joint one turn:

clockwise to increase toe-in; counterclockwise to

decrease toe-in (Figure 8).

IMPORTANT: If more than one turn is required

to meet specifications, alternate between the

right and left steering rods to maintain

steering wheel alignment.

MVC-749

Figure 8

2 - 2 400XT Series Tractor Service Manual

MVC-095X

Page 19

CHASSIS

3. Hold the flats on the ball joint to align with the flats

on the tie rod and tighten the jam nut (Figure 9).

Figure 9

4. Install the ball joint to the steering arm and check

the toe-in as described in the measurement

section (Figure 10).

MVC-098X

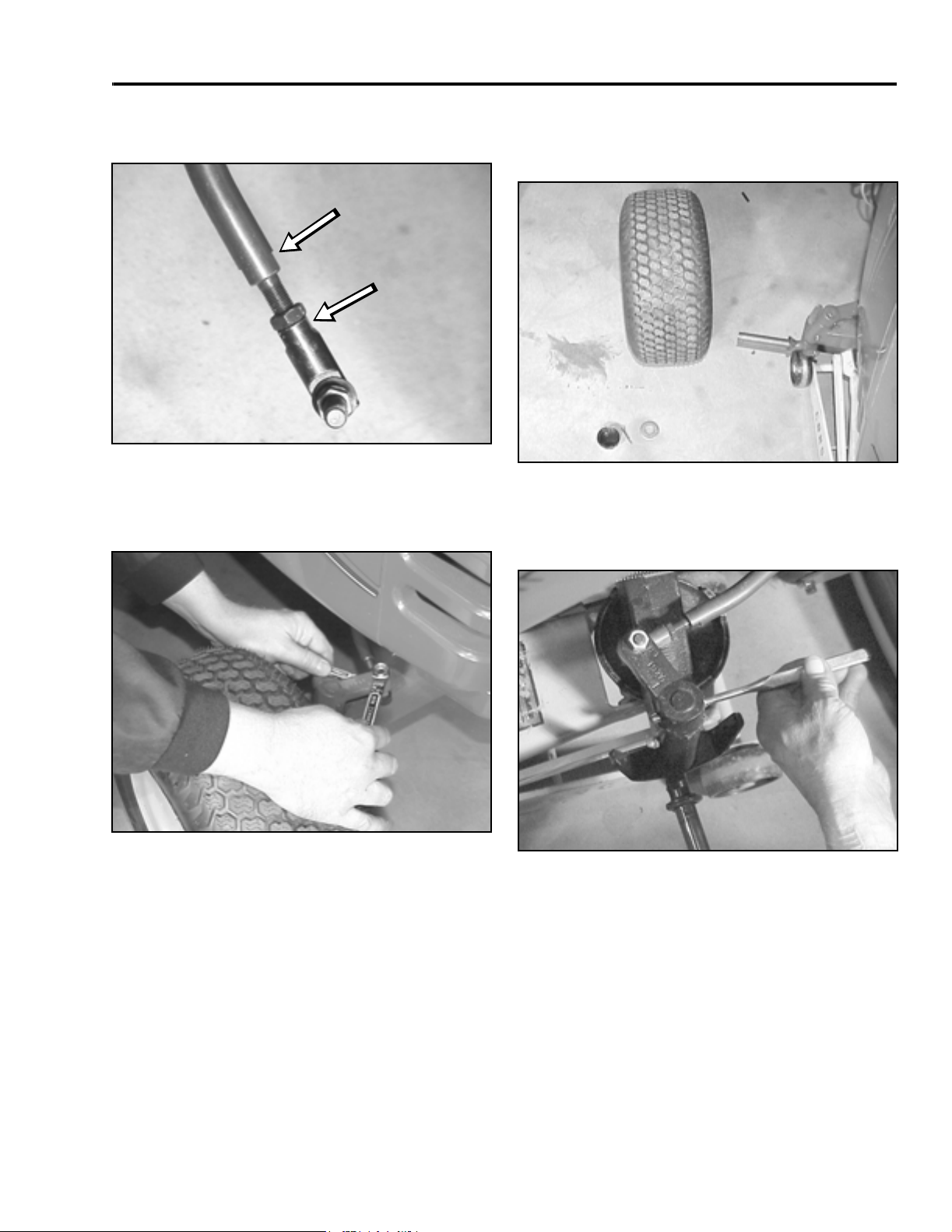

3. Remove the outer hub cap, cotter pin, washer,

and hub cap washer. Slide the wheel and tire off

the spindle (Figure 11).

Figure 11

4. Remove the tie rod from the front spindle arm.

With a drift punch and hammer, drive the roll pin

out of the front spindle arm (Figure 12).

MVC-100X

Figure 10

MVC-099X

Figure 12

MVC-732X

Front Wheel and Spindle Removal

and Installation

Removal

1. Disengage the PTO. Set the parking brake, and

turn the ignition key to OFF to stop the engine.

Remove the key.

2. Raise the front axle by putting a jack under the

side you are removing the wheel or spindle from.

400XT Series Tractor Service Manual 2 - 3

Page 20

CHASSIS

5. The spindle can now be removed out the bottom

of the front axle assembly (Figure 13).

Figure 13

6. Installation – reverse the order of removal.

MVC-102X

Front Axle Removal and Installation

2. Using a drift punch and hammer, drive the roll pin

out of the front spindle arms and remove the arms

from the spindles (Figure 15). Remove the wheels

with steering spindles, from the axle.

Figure 15

3. On the front of the axle, in the center, remove the

E-ring and washers (Figure 16).

MVC-757

1. Jack-up the front of the tractor. Put jack stands

under the frame, just behind the front axle

assembly (Figure 14).

Figure 14

MVC-756

Figure 16

MVC-758

2 - 4 400XT Series Tractor Service Manual

Page 21

CHASSIS

4. On the back side of the axle assembly, remove the

bolt securing the axle pin (Figure 17).

Figure 17

5. Remove the axle pin; use a drift punch and

hammer to tap the axle pin out; if needed. Lower

the axle assembly out of the tractor frame (Figure

18).

mvc-761

Steering Gear

Description

The steering gear assembly is made up of a vertically

mounted steering shaft and a horizontal sector gear.

The sector gear is adjustable so that excessive

backlash play in steering gears can be removed

(Figure 19).

Figure 18

6. Installation - reverse the order of removal.

MVC-763

Figure 19

6-8

Steering Backlash Adjustment

Use the following procedure if there is excessive

steering backlash.

1. Remove battery and battery tray from the tractor.

400XT Series Tractor Service Manual 2 - 5

Page 22

CHASSIS

2. Disconnect the right and left tie rod assemblies

(Figure 20).

Figure 20

MVC-099X

3. Loosen the locking nut on the eccentric. Position

the steering wheel spokes so they extend outward

left to right.

4. Tighten the nut until the eccentric turns with a

small amount of friction (Figure 21).

5. Using a punch, turn the eccentric clockwise until

zero clearance is obtained between the end of the

steering shaft gear and the steering sector (Figure

22).

Figure 22

MVC-113X

6. Tighten the nut to 25 – 35 ft lb (34 – 48 Nm). DO

NOT OVERTIGHTEN.

7. Apply some multipurpose grease to the steering

gear teeth.

Figure 21

MVC-110X

8. Connect the tie rod ends to the steering arms.

9. Turn the wheels left and right. Recheck for zero

clearance (Figure 23).

Figure 23

MVC-115X

10. Reinstall the battery tray and battery.

11. Check wheel alignment and toe-in.

2 - 6 400XT Series Tractor Service Manual

Page 23

CHASSIS

Steering Gear Shaft Disassembly

1. Disconnect the battery cables. Remove the right

side plate and battery from the tractor.

2. Remove the center steering wheel cover.

Remove the nut, lock washer, and pull the

steering wheel off the steering shaft (Figure 24).

4. Rotate the steering shaft until the top bolt of the

universal joint faces the rear of the tractor.

Remove the bolt (Figure 26).

Figure 26

5. Pull the top shaft from the universal joint and

remove it from the top of the tractor (Figure 27).

MVC-729X

Figure 24

3. Remove the boot clip from the inside of the dash

and remove the rubber boot from the steering

shaft console (Figure 25).

Figure 25

MVC-765

MVC-766

Figure 27

6-12

400XT Series Tractor Service Manual 2 - 7

Page 24

CHASSIS

6. Rotate the steering gear shaft until the bottom bolt

of the universal joint faces the front of the tractor.

Remove the bolt (Figure 28).

Figure 28

6-14

7. Tilt steering to the rear position and remove the

universal joint from the steering shaft gear.

Remove the universal joint from the top of the

tractor (Figure 29).

8. Expand the snap ring found on the steering gear

shaft and slide if halfway down the shaft. Loosen

the setscrew on the locking collar of the steering

gear shaft and move it until it meets the snap ring

(Figure 30).

Figure 30

6-16

9. Lift the steering shaft upwards, out of the lower

bushing and through the opening in the mounting

bracket. Tilt the shaft towards the front of the

tractor and remove it (Figure 31).

Figure 29

6-15

Figure 31

6-17

2 - 8 400XT Series Tractor Service Manual

Page 25

CHASSIS

10. Remove the shims from the top of the lower

bushing and set aside for installation process

(Figure 32). Important: Check the bushing,

shaft, and gears for wear and replace with new

parts if necessary. Refer to “Steering

Specifications” on page 2 - 14.

Figure 32

11. Installation - reverse the order of removal.

Steering Gear Assembly

6-16

Figure 33 6-19

(1) Shims

(2) Lower Bushing

(3) Steering Gear Shaft

1. Place two 0.05” (1.27mm) shims,1, between the

top of the bushing, 2, and the steering gear shaft,

3.

Note: Lubricate the bushing with general

purpose grease during assembly.

2. Align the front wheels so that they face straight

ahead.

3. Install snap ring, 4; locking collar, 5; and upper

bushing, 6, onto the steering gear shaft.

4. Insert the steering gear shaft through the opening

in the mounting bracket and onto the lower

bushing.

Note: The shims must be in place.

(4) Snap Ring

(5) Locking Collar

(6) Mid Bushing

400XT Series Tractor Service Manual 2 - 9

Page 26

CHASSIS

5. Move the locking collar upward on the shaft until it

touches the column support mid bushing. Tighten

the collar set screw, then move the snap ring

upward on the shaft until it meets the bottom of

the locking collar (Figure 33).

5

3

3

4

1

2

Figure 34

(1) Universal Joint

(2) Lower Steering Gear

Shaft

(3) Retaining Bolts

(4) Upper Steering

Shaft

(5) Steering Bushing

6-22

8. Install the rubber boot over the steering shaft and

console with a boot clip (Figure 35).

Figure 35

9. Place the steering wheel on the steering shaft and

install the lock washer and nut. Reinstall the

steering wheel cover.

Important: Ensure that all hardware is securely

fastened that the steering wheel is centered when

the wheels are straight ahead, and that the

steering operates properly.

MVC-766

6. Tilt steering to the rear position and place the

universal joint,1, onto the top end of the lower

steering gear shaft, 2. Install the retaining bolt, 3,

of the universal joint through the joint and steering

gear shaft.

7. Place upper steering shaft, 5, onto the upper end

of the universal joint,1. Install the retaining bolt 3,

through the upper end of the universal joint and

upper steering.

Note: Ensure that electrical wiring can not come

into contact with upper steering shaft of universal

joint in any position.

Note: Ensure that electrical wiring can not come

into contact with upper steering shaft of universal

joint in any position.

2 - 10 400XT Series Tractor Service Manual

Page 27

CHASSIS

Sector Gear Disassembly

1. Remove the battery and battery bracket from the

tractor. Disconnect both steering tie rods from the

sector gear. Using the access hole in the

mounting bracket, remove the lock nut and

carriage bolt holding the sector in place (Figure

36).

Figure 36

6-25

Sector Gear Assembly

Figure 38 6-28

(1) Washer Bearing

(2) Sector Gear

(3) Bushing

1. Install the bearing washer, 1, on the mounting

bracket (Figure 38).

(4) Locking Plate

(5) Carriage Bolt

(6) Locknut

2. Remove the locking plate from the top of the

sector gear (Figure 37).

Figure 37

3. Remove the cam bushing, 3, and the sector gear,

2, from the mounting bracket (Figure 38).

Important: Inspect the sector gear teeth and cam

bushing for wear and replace if necessary.

6-26

2. Place the sector gear, 2, on top of the bearing

washer with the teeth facing the rear of the tractor

(Figure 38).

3. Ensure the steering wheel is centered, then center

the steering shaft with the sector gear (Figure 39).

Figure 39

6-8

400XT Series Tractor Service Manual 2 - 11

Page 28

CHASSIS

4. Insert the cam bushing, 3, into the bore of the

sector gear (Figure 38).

5. Place the locking plate, 4, on the cam bushing

(Figure 38).

6. From the bottom, insert the carriage bolt, 5,

through the bearing washer, cam bushing, and the

locking plate. Secure the bolt with the locknut, 6

(Figure 38).

7. Adjust the steering gear, refer to “Steering

Backlash Adjustment” on page 2 - 5.

8. Fasten both steering arms onto the sector gear.

Check wheel alignment and toe-in.

NOTE: On 2004 models and on new replacement

steering sector gears, make sure the angle of the

teeth are facing down.

Tilt Steering

Figure 40 6-34

Description

The tilt steering assembly is made up of the following

components (Figure 40):

1. Universal joint.

2. Steering column (bushing mounted).

3. Detent bracket (left side).

4. Support bracket (right side).

5. Spring-loaded control handle.

(1) Retaining Bolt

(2) Universal Joint

(3) Retaining Bolt

(4) Upper Steering

Shaft

(5) Spring Extension

(6) Bolts

(7) Detent Bracket

(8) Support Bracket

(9) Retaining Bolt

(10) Spacer-Yoke

(11) Column

(12) Tilt Lever

(13) Steering Bushing

Figure 41 6-35

2 - 12 400XT Series Tractor Service Manual

Page 29

CHASSIS

Tilt Steering Disassembly

1. Remove the steering wheel cover, nut, lock

washer, and steering wheel from top of the

steering shaft (Figure 42).

Figure 42

2. Remove the boot clip, from the inside of the dash

and remove the rubber boot from the steering

console (Figure 43).

Mvc-765

6. Remove the spring, 5, from the left pivot spacer

and tilt control handle (Figure 41).

7. Remove the four bolts, 6, and nuts from the left

and right support brackets, 8, and 9, and remove

the brackets (Figure 41).

8. Remove the two side pivot bolts, 9, and spacers,

10, from the steering column. Lift the column, 11,

out of the tractor (Figure 41).

9. Slide the tilt control handle, 12, off the steering

column bracket (Figure 41).

10. Remove the bushing, 13, from the top of the

steering column (Figure 41).

Important: Inspect all bushings and pivot areas

for wear and replace as necessary. Refer to

“Steering Specifications” on page 2 - 14.

Tilt Steering Assembly

1. Place bushing, 13, on top of the steering column

(Figure 41).

Figure 43

3. Remove the bottom retaining bolt, 1, from the

universal joint, 2 (Figure 41).

4. Remove the top retaining bolt, 3, from the

universal joint and disconnect the top steering

shaft, 4, from the tractor (Figure 41).

5. Tilt steering to the rear position and detach the

universal joint from the steering gear shaft. Take

the universal out of the tractor from the top side.

MVC-766

2. Insert the tilt control handle, 12, into the steering

column bracket (Figure 41).

3. Secure the steering column to the mounting

bracket with pivot bolts, 9; spacers, 10; and

locknuts (Figure 41).

Note: The longer spacers should be positioned

on the left-hand side.

4. Install the left, 7, and right, 8, support brackets,

using four bolts, 6, and nuts. The notched bracket

goes on the left side. Adjust the brackets to obtain

minimal side play between the column and

brackets (Figure 41).

5. Attach the spring, 5, to the tilt handle and left pivot

spacers (Figure 41).

6. Tilt steering to its farthest rearward position and

place the universal joint, 2, on the steering gear

shaft. Pass the bottom bolt, 1, of the universal

joint through the universal and steering gear shaft

and secure (Figure 41).

400XT Series Tractor Service Manual 2 - 13

Page 30

CHASSIS

7. Insert the top steering shaft, 4, onto the upper end

of the universal joint check the front wheel

alignment, wheels should be straight ahead.

Install the retaining bolt, 3, through the upper end

of the universal joint and steering shaft (Figure

41).

Note: Ensure electrical wiring can not come into

contact with upper steering shaft or universal joint

in any position.

8. Install the rubber boot over the steering shaft and

secure the boot to console with the rubber clip

(Figure 44).

9. Align the steering wheel on the steering shaft.

Secure the steering wheel with lock washer and

nut. Install steering wheel cover (Figure 45).

Figure 45

MVC-765

Figure 44

MVC-766

Steering Specifications

Item Specification

Free Play – front axle pivot pin 0 – 0.015” (0 – 0.4mm)

End Play – front wheel on spindle 0 – 0.015” (0 – 0.4mm)

Toe-In 1/8” – ¼” (3 – 6mm)

Steering Wheel Free Play (Backlash) 0.5” – 1.0” (13 – 25mm)

Steering Shaft Bushings (standard dimensions)

Top (Fiber) ID 0.752 – 0.756” (19.1 – 19.2mm)

OD 1.310 – 1.320” (33.3 – 33.5mm)

Mid (Metal) ID 0.755 – 0.760” (19.2 – 19.3mm)

OD 0.988 – 1.00” (25.3 – 25.4mm)

Bottom (Metal) ID 0.753 – 0.758” (19.1 – 19.2mm)

OD 1.380 – 1.385” (35.0 – 35.2mm)

2 - 14 400XT Series Tractor Service Manual

Page 31

CHASSIS

Hood Removal

1. Disconnect the headlight wiring harness at the

plug and jack connection (Figure 46).

Figure 46

2. On 2003 model units, remove the rubber O-ring,

located on the left side hinge bracket, and raise

the hood. Slide the hood to the left and off the

hinge brackets. (Figure 47).

MVC-003

3. On 2004 and later model units, raise the hood in

the full up position, then bring the hood back

slightly and slide the hood toward the left side of

the tractor (Figure 48).

Figure 48

4. Reinstall the hood in reverse order.

MVC-015

Seat and Fender Removal

Figure 47

MVC-018

1. Unplug the seat switch, and the KeyChoice™

Reverse operating switch (Figure 49).

Figure 49

2. To make it easier to remove the fasteners for the

fender assembly, jack the tractor up in the rear

and remove both rear tires.

MVC-865F

400XT Series Tractor Service Manual 2 - 15

Page 32

CHASSIS

3. Remove the two rear carriage bolts, washers, and

nuts located in the rear of the fender assembly

(Figure 50).

Figure 50

4. Remove the four carriage bolts, washers, and

nuts, (two on the right and two on the left), located

between the footrest and fender (Figure 51).

MVC-122X

5. Remove the seat and fender together as one

piece (Figure 52).

Figure 52

6. Installation - follow the removal procedure in

reverse.

MVC-029

Gas Tank Removal

Figure 51

MVC-012

1. Follow the procedure for removing the rear fender

and seat.

2. Remove the two screws and spacers in the front

of the gas tank (Figure 53).

Figure 53

MVC-129X

2 - 16 400XT Series Tractor Service Manual

Page 33

CHASSIS

3. Lift the gas tank from the frame, close the gas

shut-off valve, and disconnect the gas line from

the shut-off valve (Figure 54).

Figure 54

4. Carefully remove the gas tank.

Installation

MVC-130X

2. Remove the right and left washers and e-rings

located on each end of the lift bar assembly

(Figure 56).

Figure 56

3. Slide the lift bar out of the flange bushings and the

rear lift plates (Figure 57).

MVC-800F

Reverse the order of removal.

Lift Bar Assembly

Removal

1. Remove the bolt, washer, and nut retaining the lift

chain to the lift bar (Figure 55).

Figure 57

MVC-803F

Figure 55

400XT Series Tractor Service Manual 2 - 17

MVC-798F

Page 34

CHASSIS

Lift Lever Assembly

Removal

1. Remove the center access plate. Remove the pin

clip and clevis pin retaining the two lift strap links

to the lift lever (Figure 58).

Figure 58

MVC-804F

3. Slide the right and left flange bearings inward from

the pivot linkage brackets, so you will have

enough clearance to remove the lift lever

assembly (Figure 60).

Figure 60

4. Remove the lift lever assembly from the pivot

linkage brackets (Figure 61).

MVC-807F

2. Remove the two retaining rings that are located on

each side of the lift lever assembly (Figure 59).

Figure 59

MVC-806F

Figure 61

Assembly

Reverse the order of removal.

MVC-809F

2 - 18 400XT Series Tractor Service Manual

Page 35

CHASSIS

Lift Arm/Lift Lever Assembly

Removal

1. Remove the right and left side panels. Remove

the center access plate. Disconnect the battery

cables and remove the battery from the tractor.

2. Remove the two bolts holding the battery support

and remove the support (Figure 62).

4. Pull the dash upwards, with the steering shaft, and

move carefully toward the front of the tractor to

give you enough clearance to get to the lift

assembly (Figure 64).

Figure 64

5. Remove the six bolts, three located on the right

and three on the left side, inside of the hood stand

(Figure 65).

MVC-820F

Figure 62

3. Remove the 4 screws and 2 nuts from the base of

the dash. Remove the bolt and nut located in the

center of the hood stand, just below the large

decal (Figure 63).

Figure 63

MVC-815F

MVC-817F

Figure 65

MVC-821F

400XT Series Tractor Service Manual 2 - 19

Page 36

CHASSIS

6. Remove spring for the brake assembly (Figure

66).

Figure 66

7. Lift the hood stand off the frame of the tractor

(Figure 67).

MVC-822F

8. Lift the lift assembly up and off the frame of the

tractor (Figure 68).

Figure 68

Installation

Reverse the order of removal.

MVC-826F

Figure 67

2 - 20 400XT Series Tractor Service Manual

MVC-827F

Page 37

Electric Lift

CHASSIS

Figure 69 Eleclift

(1) Actuator

(2) Spacer

(3) Clevis Pin

(4) Clip Pin

Removal

1. Remove the right and left hood stand panels to the

battery compartment.

2. Disconnect the negative and positive cables from

the battery.

3. Remove the two screws holding the battery

support and remove the support.

4. Unplug the actuator, 1, from the wiring harness.

5. Remove the clip pin, 4, and clevis pin, 6, that

holds the actuator, 1, to the actuator bracket

assembly, 7.

(5) Washer

(6) Clevis Pin

(7) Actuator Bracket Assembly

(8) Lift Arm Assembly

6. Remove the clip pin, 4, spacers, 2, washers, 5,

and clevis pin, 3, from the lift arm assembly, (8).

7. Remove the actuator, 1, from the tractor. The

actuator is serviced as an assembly; no repair

parts are available.

8. Remove the actuator

Installation

Reverse the order of removal.

400XT Series Tractor Service Manual 2 - 21

Page 38

THIS PAGE INTENTIONALLY LEFT BLANK

2 - 22 400XT Series Tractor Service Manual

Page 39

HYDRO-GEAR TRANSAXLE

Hydro-Gear Hydrostatic Transaxle

Internal Service

Internal service information is contained in the HydroGear Transaxle Service Manual, Form #492-0682.

Under warranty, internal service work should not be

performed unless authorized by your Distributor

Service Manager or the Toro Company.

Fluid Change

The Hydro-Gear transaxle is factory filled, sealed, and

does not require oil changes. However in the event of

oil contamination or degradation, oil replacement may

correct certain performance problems.

Transaxle Removal

1. Disconnect the negative battery cable from the

battery.

3. Disconnect the free wheeling valve I rod and the

vent hose clamp (Figure 118).

Figure 118

4. Remove the cotter pin located on the crown nut for

adjusting the brakes. Remove the crown nut,

brake bracket, brake arm spring and brake rod

(Figure 119).

MVC-060F

2. Raise the rear of the tractor and remove the right

and left rear tires. Support the rear frame, just in

front of the transaxle. Remove the center access

plate, fender, seat, and gas tank. Refer to the

“Chassis” section on page 2 - 15 and page 2 - 16.

Remove the center plate between the seat and

the hood stand (Figure 117).

Figure 117

MVC-061F

Figure 119

MVC-063F

400XT Series Tractor Service Manual 3 - 1

Page 40

HYDRO-GEAR TRANSAXLE

5. If the tractor is equipped with cruise control,

unplug the cruise control magnet wiring

connectors (Figure 120).

Figure 120

MVC-064F

6. Unbolt the cruise control magnet bracket from the

side of the frame (Figure 121).

7. Unhook the idler spring from the bottom of the

idler pulley (Figure 122).

Figure 122

MVC-066F

8. Remove the three bolts retaining the transmission

fan to the pulley (Figure 123).

MVC-067C

Figure 121

Figure 123

MVC-065F

3 - 2 400XT Series Tractor Service Manual

Page 41

HYDRO-GEAR TRANSAXLE

9. Remove the damper cylinder located next to the

transaxle input pulley. To remove the fastener on

the end of the cylinder, insert the blade of a

screwdriver between the back side of the fastener

and the shaft. Apply a little pressure toward the

back of the fastener and pull the damper cylinder

off the shaft (Figure 124).

Figure 124

MVC-070F

11. Use a floor jack under the transaxle to help lower

the transaxle from the frame of the tractor (Figure

126).

Figure 126

MVC-073

12. Remove the bolt, washer, and nut retaining the

torque strap to the transaxle, located on the left

front side (Figure 127).

10. Slip the belt off the transaxle input pulley (Figure

125).

Figure 125

MVC-171X

Figure 127

MVC-072F

400XT Series Tractor Service Manual 3 - 3

Page 42

HYDRO-GEAR TRANSAXLE

13. Remove the two nuts and washers that are

located on each side of the transaxle axle housing

holding the transaxle to the frame (Figure 128).

Figure 128

MVC-073F

14. Slowly lower the transaxle slightly and STOP. You

will need to disconnect the hydro rod from the

cruise control plate. Remove the cotter pin and

washer (Figure 129).

15. Continue to lower the transaxle out of the tractor

frame (Figure 130).

Figure 130

MVC-077F

Installation - Hydro-Gear Transaxle

1. Raise the transaxle up toward the frame allowing

enough room to install the hydro rod to the cruise

plate and secure with a cotter pin and washer

(Figure 129).

Figure 129

MVC-074F

2. Secure the transaxle to the frame brackets with

four carriage bolts, washers, and nuts (Figure

131).

Figure 131

MVC-078F

3 - 4 400XT Series Tractor Service Manual

Page 43

HYDRO-GEAR TRANSAXLE

3. Install the bolt, washer, and nut through the front

of the transaxle to the torque strap (Figure 132).

Figure 132

MVC-072F

4. Install the drive belt around the transaxle input

pulley. Install the idler spring on the idler pulley

(Figure 133).

5. Connect the damper cylinder to the control linkage

(Figure 134).

Figure 134

MVC-080F

6. Install the three bolts to secure the transaxle

cooling fan to the transaxle pulley (Figure 135).

MVC-067

Figure 133

Figure 135

MVC-066F

400XT Series Tractor Service Manual 3 - 5

Page 44

HYDRO-GEAR TRANSAXLE

7. Install the cruise control bracket, with magnet, with

two bolts and nuts (Figure 136).

Figure 136

MVC-065

8. Reconnect the wire connector for the magnet

(Figure 137).

9. Install the brake arm with the brake spring, on the

brake stud. Install the castle nut, but do not install

the cotter pin until brake adjustment has been

performed (Figure 138). Refer to “Brake

Adjustment” on page 3 - 9.

Figure 138

MVC-063

10. Connect the free wheeling valve rod and vent

hose clamp (Figure 139).

Figure 137

MVC-064

Figure 139

MVC-060

3 - 6 400XT Series Tractor Service Manual

Page 45

HYDRO-GEAR TRANSAXLE

11. Reconnect the gas line to the gas tank and install

the gas tank with two screws and washers (Figure

140).

Figure 140

NOTE: When installing a new transaxle in the

machine or if any work was performed internally

on the transaxle, make sure the system is purged

prior to doing any neutral adjustment. Refer to

“Neutral Adjustment” on page 3 - 7.

MVC-081F

Neutral Adjustment

Before making a neutral adjustment, the transaxle

must be warmed up, usually 5 to 10 minutes. Steps to

perform neutral adjustment:

1. Jack-up and support the right rear end of the

tractor, allowing enough clearance to remove the

right rear tire. Make sure the left tire stays on the

ground (Figure 141). (Optional: remove the

fender and seat assembly. If they are removed,

you will need to temporarily bypass the seat

switch.)

12. Reconnect the negative battery cable.

13. Attach a jumper wire across the seat switch plug

terminals so the tractor will run without an

operator in the seat. Test to confirm proper

operation of the transaxle. If adjustment is

needed, refer to “Neutral Adjustment” on page 3 -

7.

14. Install fender and seat assembly and the center

access plate. Install the right tire.

15. Operate the tractor and make sure all safety

features are working. Check the forward and

reverse operation of the tractor. If you find there is

not enough speed in reverse or forward, follow the

adjustment procedures for the foot control; refer to

“Foot Control Adjustment” on page 3 - 10.

Figure 141

2. Locate the adjusting puck and loosen the Allen

head set screw (Figure 142).

Figure 142

MVC-161X

1703-07

3. Start the engine and run at 3/4 to full throttle.

400XT Series Tractor Service Manual 3 - 7

Page 46

HYDRO-GEAR TRANSAXLE

4. Rotate the adjusting puck in both directions and

watch the axle direction. You want to adjust the

puck so it is set in the mid-point between forward

and reverse axle rotation. Make sure the axle is

not moving (Figure 143).

Figure 143

5. Once you are in neutral, hold the puck with an

adjustable wrench so it won’t move when you retighten the Allen set screw (Figure 144).

1703-08

Transaxle Purging Procedures

Due to the effects air has on efficiency in hydrostatic

drive applications, it is critical that it be purged from the

system.

These purge procedures should be implemented any

time oil has been added to the system, when a new

transaxle is installed, or after a transaxle has been

repaired.

Air creates inefficiency because its compression and

expansion rate is higher than that of the oil normally

approved for use in hydrostatic drive systems.

The resulting symptoms in hydrostatic systems may

be:

1. Noisy operation.

2. Lack of power or drive after short term of

operation.

3. High operation temperature and excessive

expansion of “oil”; in the latter case, oil may

overflow.

Figure 144

6. Operate the foot control in forward and reverse

and allow the pedal to return to the neutral

position to test the adjustment.

NOTE: You may not be able to eliminate creep

entirely, due to the narrow neutral zone of this

transaxle. In this case, adjust for the smallest amount

of reverse creep possible. Correctly adjusted, a very

light tap on the foot control pedal should be all that is

needed to stop the reverse creep.

MVC-226X

Before starting, make sure the transaxle is at the

specified oil level; refer to page 1 - 3.

The following procedures should be performed with the

vehicle drive wheels off the ground, then repeated

under normal operating conditions.

1. With the bypass valve open and the engine

running, slowly move the directional control (foot

control) in both forward and reverse directions 5 to

6 times; as air is purged from the unit, the oil level

will drop.

2. With the bypass valve in the closed position and

the engine running, slowly move the directional

control valve (foot control) in both forward and

reverse directions 5 to 6 times. After stopping the

engine, check the oil level and add oil as required.

3. It may be necessary to repeat steps 1 and 2 until

all the air is completely purged from the system.

When the transaxle moves forward and reverse at

normal speed, purging is complete.

3 - 8 400XT Series Tractor Service Manual

Page 47

HYDRO-GEAR TRANSAXLE

CAUTION – DO NOT OVERFILL. If you overfill the

transaxle while the unit is “cold”, it may overflow as it

reaches normal operating temperatures. The oil level

should not be above the level described on page 1 - 3.

This will allow the space needed for the oil to expand

as it warms up.

Brake

Always set the parking brake when you stop the

machine or leave it unattended. If the parking brake

does not hold securely, an adjustment is required.

Checking the Brake

1. Park the machine on a level surface, disengage

the power take off (PTO), set the parking brake,

and turn the ignition key to “OFF” to stop the

engine. Remove the ignition key.

2. Rear wheels must lock and skid when you try to

push the tractor forward. Adjustment is required if

the wheels turn and do not lock; refer to “Brake

Adjustment” on page 3 - 9.

3. To adjust the brake, remove the cotter pin and

loosen the castle nut slightly (Figure 145).

Figure 145

4. Carefully insert a 0.020” (.508mm) feeler gauge

between the outer brake pad and rotor disc

(Figure 146).

MVC-163

3. Release the brake and move the free-wheeling

lever to the “PUSH” position. Wheels should

rotate freely.

4. If both conditions are met, no adjustment is

required.

Brake Adjustment

1. Check the brake before you adjust it; refer to

“Checking the Brake” on page 3 - 9.

2. Release the parking brake.

Figure 146

5. Tighten brake adjusting (crown) nut until slight

resistance is felt on the feeler gauge when sliding

it in and out. Install cotter pin.

6. Check the brake operation again.

IMPORTANT: With the parking brake released, the

rear wheels must rotate freely when you push the

tractor. If the 0.020” (.508mm) clearance cannot be

achieved, new brake pucks may need to be

installed.

MVC-164

400XT Series Tractor Service Manual 3 - 9

Page 48

HYDRO-GEAR TRANSAXLE

Foot Control Adjustment

If there is not enough ground speed in reverse and too

much in forward, check the adjustment of the foot

control.

1. Measure the distance between the footrest and

the back of the forward/reverse control pedal.

There should be 1¼” (31.75mm) to 1-3/8”

(34.925mm) gap (Figure 147).

Figure 147

2. If adjustment is needed, unbolt the hydro control

rod where it connects to the hydro forward/reverse

pedal. The location is under the tractor on the

inside of the frame (Figure 148).

MVC-776F

3. Loosen the jam nut and turn the rod end until you

achieve 1¼” (31.75mm) to 1-3/8” (34.925mm) gap

between the footrest and the back side of the

forward/reverse control pedal (Figure 149).

Figure 149

4. Another way of adjusting the forward/reverse

control rod is with the seat, fender, and gas tank

removed. Located on the hydro control rod are

two stop nuts and a turnbuckle. Loosen the stop

nuts and turn the turnbuckle to achieve 1¼”

(31.75mm) to 1 3/8” (34.92mm) gap between the

footrest and the back side of the forward/reverse

control pedal.

MVC-184X

Figure 150

Figure 148

3 - 10 400XT Series Tractor Service Manual

MVC-768F

MVC-770F

Page 49

HYDRO-GEAR TRANSAXLE

Traction Belt Replacement

1. If the mower deck is installed, remove the mower

deck. Remove the power take off (PTO) belt

between the pulley box and the electric clutch.

Note: Perform belt installation, routing, and

inspection procedures from beneath the tractor.

2. Disconnect the electric PTO clutch wire clutch

(Figure 151).

4. Unhook the idler spring at the idler pulley located

toward the rear of the tractor (Figure 153).

Remove the existing belt from the tractor.

Figure 153

5. Install drive belt around the transaxle pulley,

leaving the belt underneath the transaxle pulley

(Figure 154).

MVC-782F

Figure 151

3. Remove the RH bolt that holds the PTO stop

assembly. Loosen the LH bolt enough so you can

turn the PTO stop assembly enough to disengage

it from the slot in the electric PTO clutch housing

(Figure 152).

Figure 152

MVC-778

MVC-780F

Figure 154

MVC-783F

400XT Series Tractor Service Manual 3 - 11

Page 50

HYDRO-GEAR TRANSAXLE

6. Route the belt over the lift bar assembly (Figure

155).

Figure 155

MVC-785F

7. The belt then goes forward over the hydro pivot

shaft and steering sector (Figure 156).

8. Route the drive belt around the flat and v-idler

pulleys and then around the engine drive pulley

(Figure 157).

Figure 157

MVC-787F

9. Go back to the transaxle pulley and install the belt

around the pulley.

10. Check the routing of the belt around both the

engine and transaxle pulleys, the front flat and vidlers and the rear flat and v-idler pulleys (Figure

158).

Figure 156

MVC-786F

Figure 158

belt routing top

3 - 12 400XT Series Tractor Service Manual

Page 51

HYDRO-GEAR TRANSAXLE

11. Install the idler spring to the idler pulley, located

toward the rear of the tractor (Figure 159).

Figure 159

12. Turn the electric PTO clutch housing and align the

PTO stop bracket in the slot of the clutch housing.

Install the RH bolt and lock washer in the PTO

stop bracket and tighten. Tighten the LH bolt in

the PTO stop bracket (Figure 160).

MVC-782F

13. Reconnect the electric PTO clutch wire (Figure

161).

Figure 161

14. Test the tractor to make sure the tractor and the

safety system is operating properly.

MVC-797F

Figure 160

400XT Series Tractor Service Manual 3 - 13

MVC-796F

Page 52

THIS PAGE INTENTIONALLY LEFT BLANK

3 - 14 400XT Series Tractor Service Manual

Page 53

ELECTRICAL SYSTEMS

Electrical Systems

Two things happen when turning the ignition switch to

the “START” position. (1) Current flows from the

ignition switch through the PTO (Power Take Off)

switch, brake switch, seat switch, and activates the

interlock relay, which sends voltage to the coil of the

starter solenoid. The solenoid actuates and allows

voltage to the starter motor of the engine. (2) At the

same time, with the ignition in the “START” position,

current will flow to the kill relay, which activates and

takes the electronic ignition ground wire off of ground to

allow the engine to have spark.

Once you have the tractor running, you can now

engage the PTO (Power Take Off) switch which will

engage the electric clutch for the mower or

attachments only if you are in the seat, activating the

seat switch. Anytime you vacate the seat with the

electric clutch activated for the mower, the seat switch

will open and cut off voltage to the kill relay, which will

deactivate and ground the electronic ignition and stop

the engine. If you vacate the seat with the PTO switch

disengaged and the park brake engaged, the engine

will continue to run.

Relay