Page 1

FormNo.3383-389RevA

18inTurfSeeder

ModelNo.23511—SerialNo.314000001andUp

ModelNo.33511—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3383-389*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Figure1

1.Locationofthemodelandserialnumbers

ThissparkignitionsystemcomplieswithCanadianICES-002.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Introduction

Thismachineseedsturf.Itisintendedforsmall-to

medium-sizedlawnapplicationsinresidentialandcommercial

properties.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.

Figure1illustratesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Introduction..................................................................2

Safety...........................................................................3

SafeOperatingPractices...........................................3

SlopeIndicator.......................................................5

SafetyandInstructionalDecals.................................6

Setup............................................................................9

UnfoldingtheHandle..............................................9

CheckingtheEngine-OilLevel..................................9

ProductOverview..........................................................9

Controls...............................................................10

Specications........................................................12

Attachments/Accessories........................................12

Operation....................................................................13

CheckingtheEngine-OilLevel.................................13

CleaningDebrisfromtheMachine............................13

RecommendedFuel................................................13

StartingandStoppingtheEngine..............................14

OperatingtheMachine............................................15

OperatingTips......................................................15

Maintenance.................................................................16

RecommendedMaintenanceSchedule(s)......................16

PremaintenanceProcedures........................................16

DisconnectingtheSpark-PlugWire...........................16

EngineMaintenance..................................................17

ServicingtheAirCleaner.........................................17

ChangingtheEngineOil.........................................17

CleaningtheSedimentCup......................................18

ServicingtheSparkPlug..........................................18

BeltMaintenance......................................................19

CheckingtheBeltTension.......................................19

AdjustingtheBeltTension.......................................20

MaintainingtheCuttingBlades....................................20

InspectingtheCuttingBlades...................................20

ReplacingW ornCuttingBlades................................20

Storage........................................................................22

RemovingtheMachinefromStorage.........................22

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

means

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Caution

,

W ar ning

,or

Danger

—personalsafety

SafeOperatingPractices

Training

•ReadtheOperator’ sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglishitis

theowner’sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeople,ordamageto

property.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Useonlyaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludingsafetyglassesand

hearingprotection.Longhair,looseclothing,orjewelry

maygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toys,andwire,whichcan

becontactedbythemachine.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethegascaporaddfuelwiththeengine

running.

–Allowtheenginetocoolbeforerefueling.

–Donotsmoke.

–Neverrefuelordrainthemachineindoors.

•Checkthattheoperatorpresencecontrols,safetyswitches,

andshieldsareattachedandfunctioningproperly .Donot

operatethemachineunlessitisfunctioningproperly.

3

Page 4

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Starttheengineonlyfromtheoperator’sposition.

•Neveroperatewithouttheshields,covers,orotherguards

securelyinplace.Besureallinterlocksarefunctioning

properly.

•Watchforditches,holes,rocks,dips,andrisesthatchange

theoperatingangle,asroughterraincouldoverturnthe

machine.

•Alwaysavoidsuddenstartingorstoppingonaslope.

Iftireslosetraction,disengagethecuttingbladesand

proceedslowlyofftheslope.

•Followtherecommendationsforwheelweightsor

counterweightstoimprovestability.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Raisethecuttingblades,stopthemachine,andstopthe

enginebeforeleavingtheoperator’spositionforany

reason.

•Stoptheequipmentandinspectthecuttingbladesafter

strikinganobjectorifanabnormalvibrationoccurs.

Makenecessaryrepairsbeforeresumingoperation.

•Keephandsandfeetawayfromthecuttingbladearea.

•Nevercarrypassengers,andkeeppetsandbystanders

away.

•Bealert,slowdown,andusecautionwhenmakingturns.

Lookbehindandtothesidebeforechangingdirections.

•Slowdownandusecautionwhencrossingroadsand

sidewalks.

•Donotoperatethemachinewhileundertheinuence

ofalcoholordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Useextremecarewhenloadingorunloadingthemachine

intoatrailerortruck.

MaintenanceandStorage

•Waitforallmovementtostopbeforeadjusting,cleaning,

orrepairing.Raisethecuttingblades,stopthemachine,

stoptheengine,anddisconnectthespark-plugwire.

•Cleangrassanddebrisfromtheblades,drives,mufers,

andenginetohelppreventres.Cleanupoilorfuelspills.

•Lettheenginecoolbeforestoring,anddonotstorethe

machinenearaame.

•Shutoffthefuelwhilestoringortransportingthemachine

ontrailers.Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevel,hardground.Neverallow

untrainedpersonneltoserviceit.

•Usejackstandsorsafetylatchestosupportcomponents

whenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Removethespark-plugwirebeforemakinganyrepairs.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Alwaysbeawareofobstaclesthatmaybeinthearea

ofoperation.Planyourpathtoavoidcontactwithany

obstaclebyyouorthemachine.

SlopeOperation

•Donotoperateneardrop-offs,ditches,steepbanks,or

water.Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjuryordeath.

•Donotoperateonslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcauseslidingand

lossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Reducespeedanduseextremecautiononslopes.

•Donotoperateonaslopegreaterthan20degrees.

•Removeormarkobstaclessuchasrocks,treelimbs,etc.

fromtheoperatingarea.Tallgrasscanhideobstacles.

•Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonToro

genuineparts.Whenitcomestoreliability,Torodelivers

replacementpartsdesignedtotheexactengineering

specicationsofourequipment.Forpeaceofmind,insist

onTorogenuineparts.

4

Page 5

SlopeIndicator

G011841

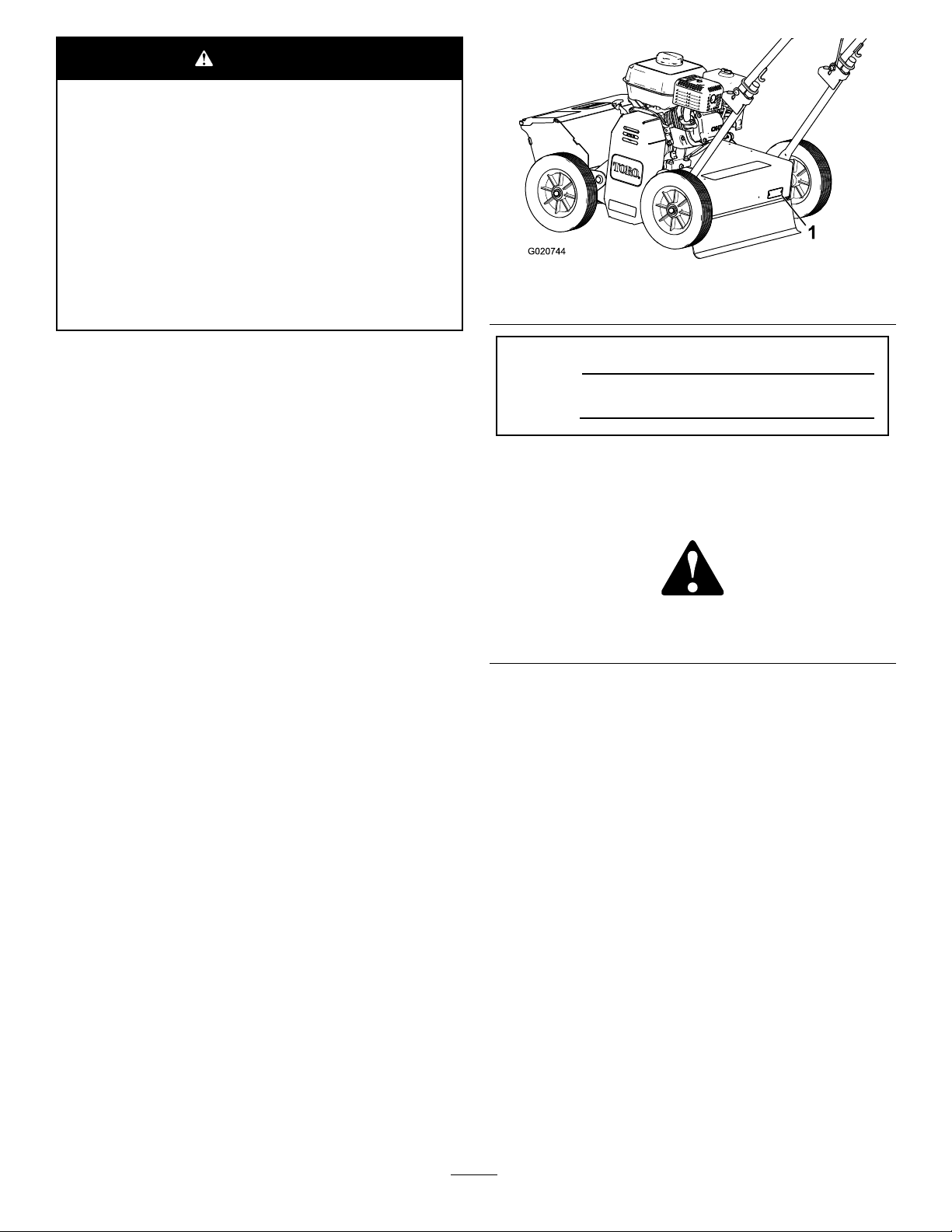

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis20degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan20degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

5

Page 6

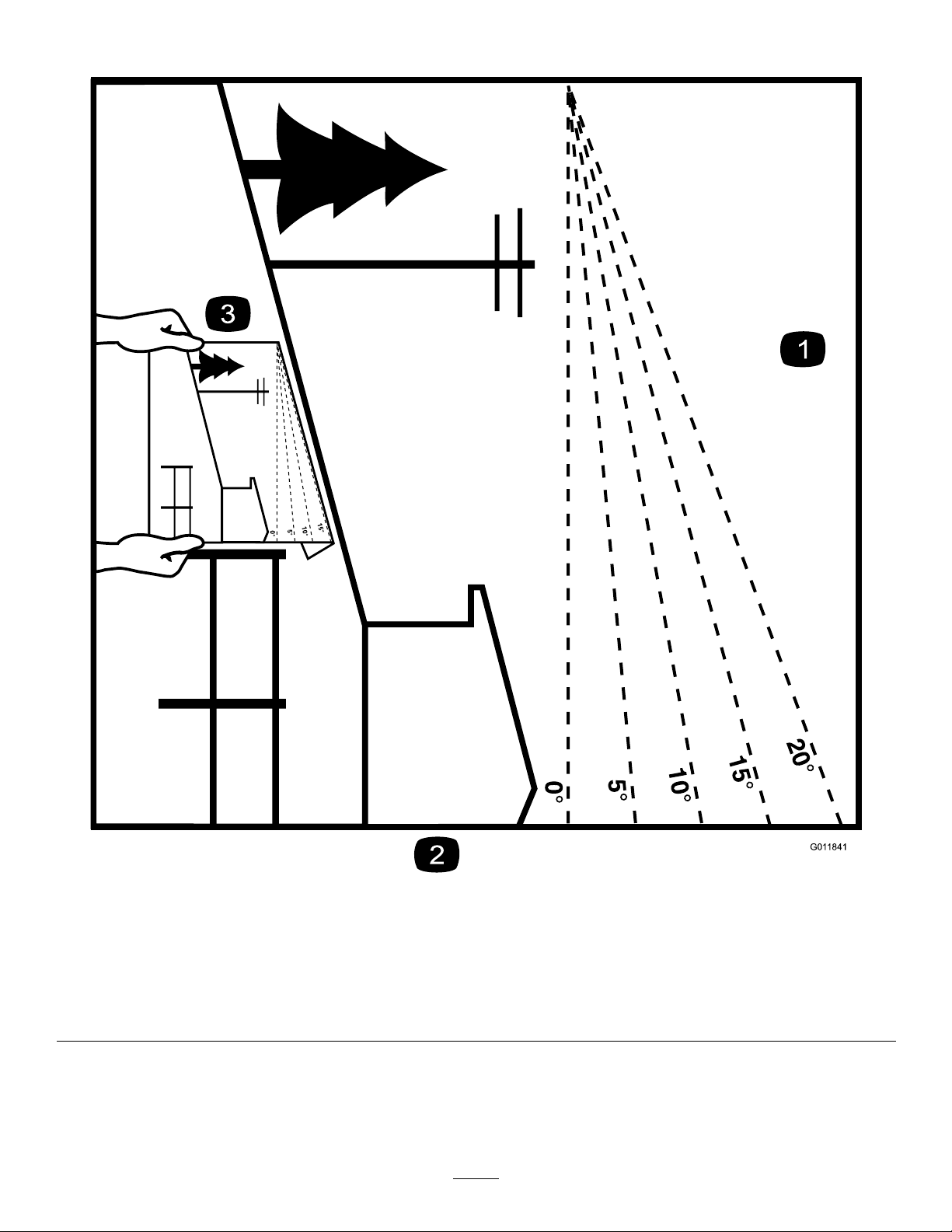

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

93–7321

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

125–3897

1.Warning-stayawayfrommovingparts;keepallguardsand

shieldsinplace.

125–3917

1.SeederOn2.SeederOff

119-4655

6

Page 7

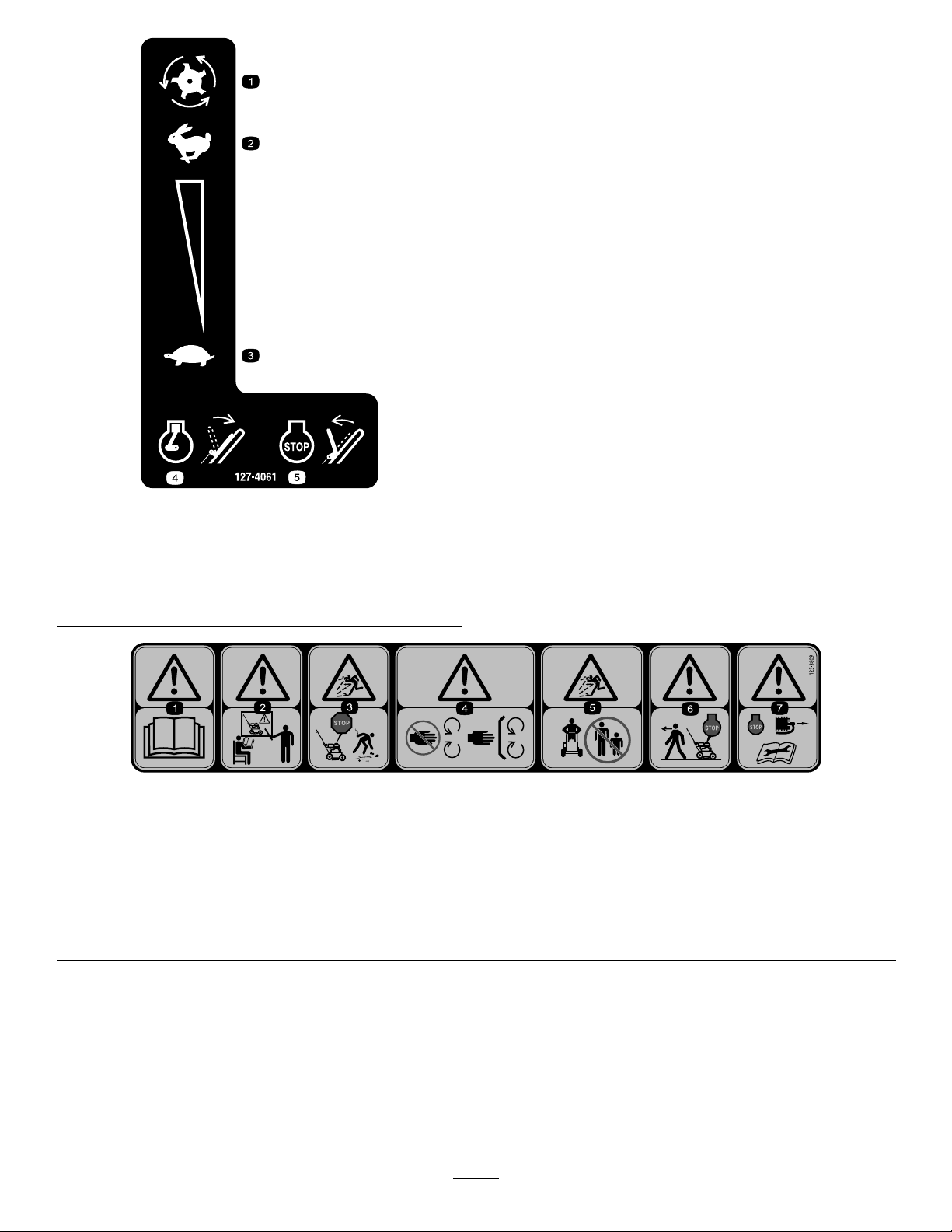

127–4061

1.Cuttingblades

2.Fast5.Releasethehandletostop

3.Slow

4.Holdthehandletostart

theengine.

theengine.

125–3809

1.Warning—readtheOperator’sManual.5.Thrownobjecthazard—keepbystandersawayfromthe

2.Warning—donotoperatethismachineunlessyouaretrained.

3.Thrownobjecthazard—stoptheengineandremoveany

debrisfromyourpath.

4.Warning—stayawayfrommovingparts;keepallguardsin

place.

machine.

6.Warning—stoptheenginebeforewalkingawayfromthe

machine.

7.Warning—stoptheengineanddisconnectthesparkplugwire

beforeperformingmaintenanceonthemachine.

7

Page 8

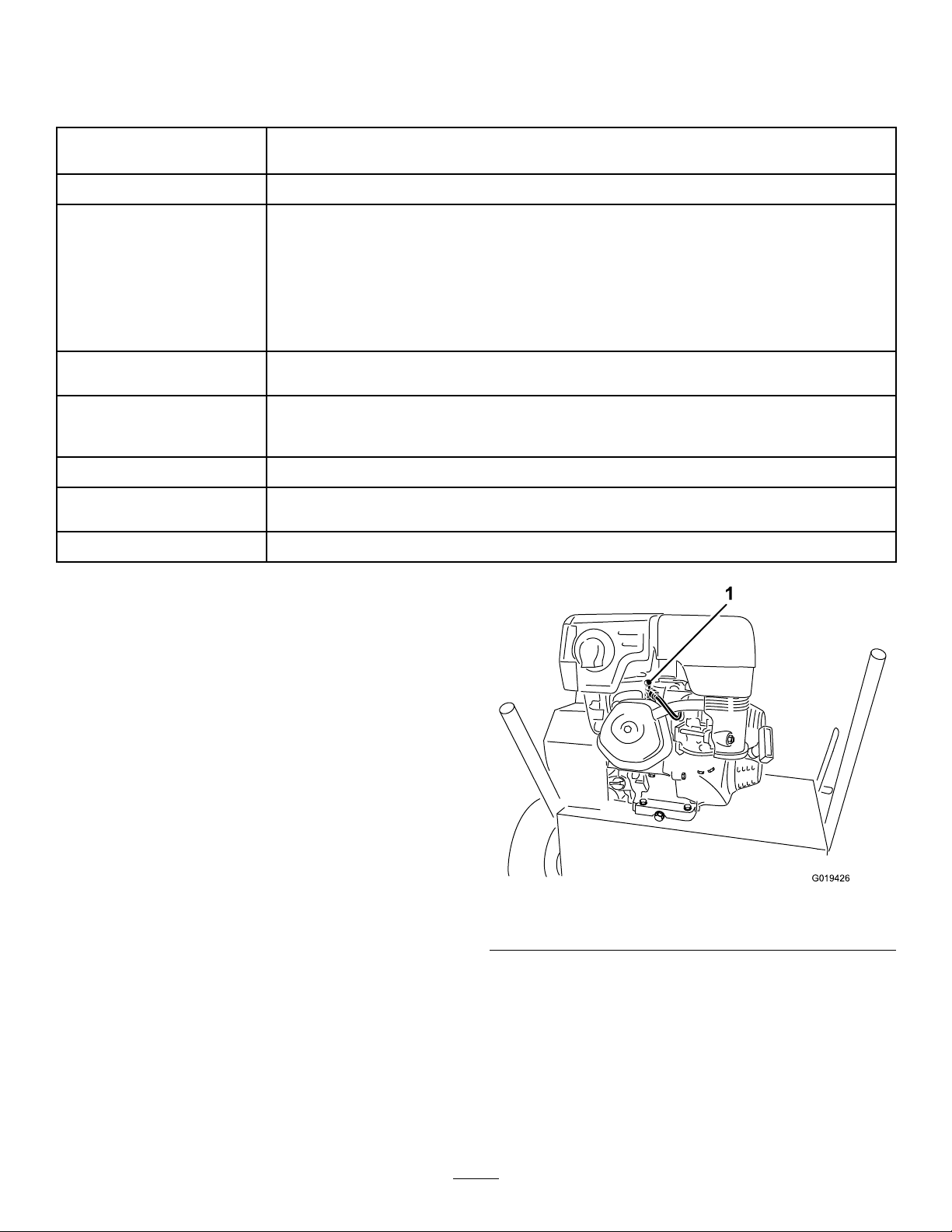

117–4979

1.Entanglementhazard,belt—keepawayfrommovingparts;

keepallguardsandshieldsinplace.

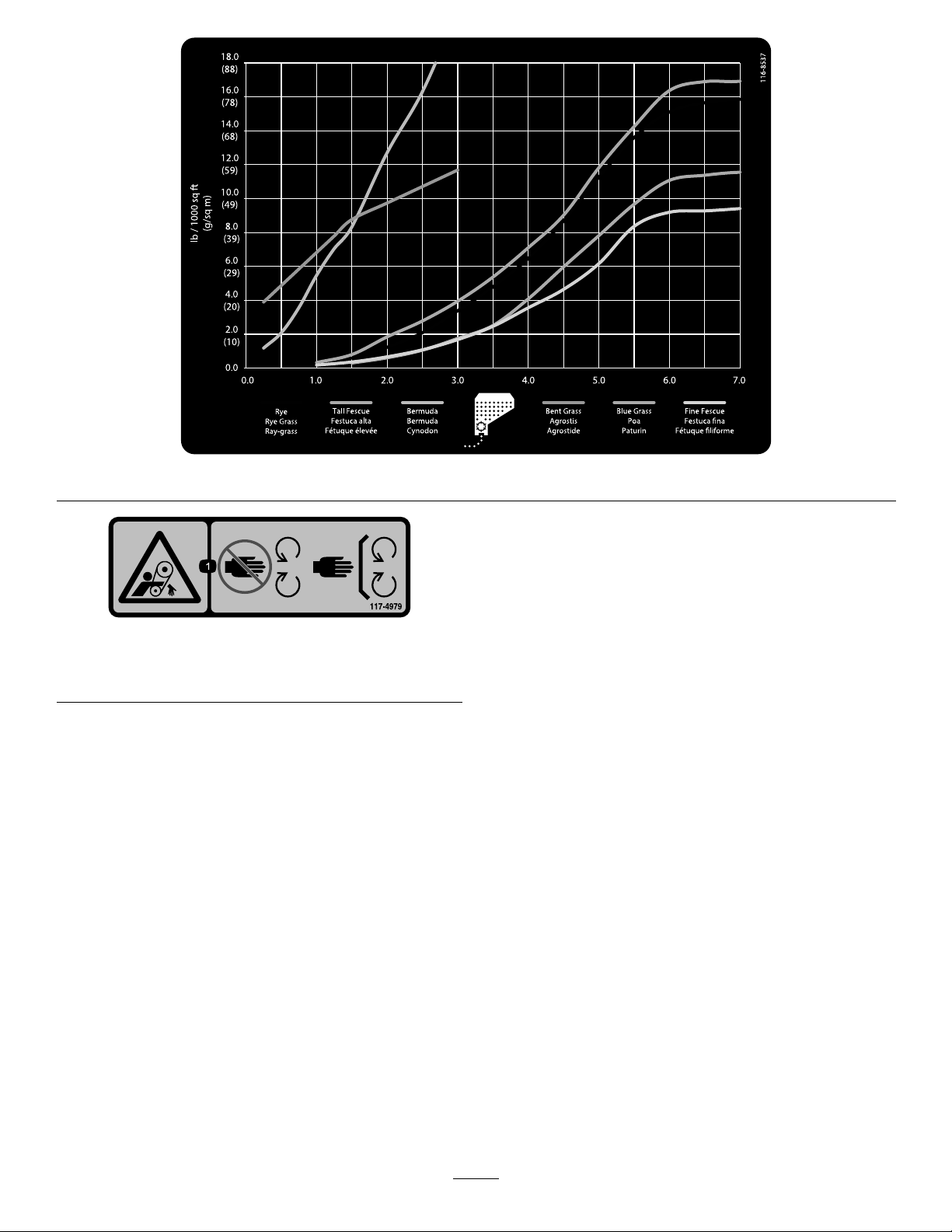

116–8537

8

Page 9

Setup

g023004

1

1

2

3

4

5

6

7

8

g023003

UnfoldingtheHandle

1.Raisethehandletotheoperatingposition(Figure4).

ProductOverview

Figure5

1.Operatorpresencebail

2.Handlebar

3.Throttlecontrollever7.Depthcontrollever

4.Seedgatecontrollever

5.Fueltank

6.Seedingrategauge

8.Recoil-starterrope

Figure4

2.Slidetheovallockingringsdowneachsideoftheupper

handleoverthelowerhandle(

handlesectionstogether.

Figure4),lockingthe

CheckingtheEngine-OilLevel

Themachinecomesfromthefactorywithoilintheengine

crankcase;however,youmayneedtoaddoil.Referto

ChangingtheEngineOil(page17).Addonlyenoughoilto

raisetheleveltotheFullmarkonthedipstick.

9

Page 10

Controls

G023178

Figure6

1.Recoil-starterhandle

2.Sedimentcup

3.Fuel-shutoffvalve

4.Chokelever

5.Throttlelever

Recoil-Starter

Pulltherecoil-starterhandletostartengine(Figure6).

Fuel-ShutoffValve

Closethefuel-shutoffvalvewhentransportingorstoringthe

machine(Figure6).

ChokeLever

Beforestartingacoldengine,movethechokeleverforward.

Aftertheenginestarts,regulatethechoketokeeptheengine

runningsmoothly.Assoonaspossible,movethechokelever

allthewayrearward.

Note:Awarmenginerequireslittleornochoking.

Figure7

1.Throttlelever

Operator-PresenceBail

Theoperator-presencebailallowsthemachinetostartand

run.

•Tostartthemachine,holddowntheoperator-presence

bail(Figure8).Continuetoholddownthe

operator-presencebailtoallowthemachinetorun.

ThrottleLever

Movethecontrolforwardtoincreasetheenginespeedand

rearwardtodecreasespeed;refertoFigure7.

10

Page 11

Depth-ControlLever

1

2

3

4

g019441

Thedepth-controlleverallowsyoutosetthedepthofthe

cuttingbladesin10cuttingpositionsalongwith1position

fortransportation.Toadjustthedepth,removethehairpin

cotter,pullthelockingpinout,andmovetheleverforwardor

rearwardtothedesireddepthsetting(Figure9).

Important:Donotpulltheleversidetosideasthis

willbendit.

Figure8

1.Operator-presencebail

•Tostopthecuttingblades,releasetheoperator-presence

bail.

Figure9

1.Depth-controllever3.Hairpincotter

2.Transport-positionhole4.Lockingpin

Seeding-RateGauge

Usetheseeding-rategaugetosettheseedowrate.Itis

calibratedwiththemachinespeedtogiveyouanevenseeding

rateatanyspeed.Tochangetheseedingrate,loosenthe

knobonthegaugeandmovethegaugepointertothedesired

position,thentightentheknobtoholditinplace.

11

Page 12

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Figure10

Refertotheseedinggraphlocatedonthemachineto

determinethecorrectgaugesettingforthetypeofgrassyou

areplantingandthethicknessinwhichyouwanttoplantit.

Seed-Gate-ControlLever

Pushtheseed-gate-controllever(Figure11)forwardtostart

theseedow ,andpullitrearwardtostoptheseedow .

Note:Themachineisdesignedsothattheseedowslows

and/orstopswhenyoustopthemachineorslowforaturn.

Toreduceseedloss,raisethefrontwheelsasthemachineis

turned.Thereisnoneedtoturntheseedowonandoff

foreachturn.

Width

Length(operating)130cm(51inches)

Length(withhandlestored)96.5cm(38inches)

Height(operating)94cm(37inches)

Height(withhandlestored)63.5cm(25inches)

Weight

70cm(27.5inches)

77kg(170lbs)

Attachments/Accessories

Approvedattachmentsandaccessoriesareavailableforuse

withthemachinetoenhanceandexpanditscapabilities.

ContactanAuthorizedServiceDealerorDistributororgo

towww .Toro.comforalistofallapprovedattachmentsand

accessories.

1.Seed-gate-controllever

Figure11

12

Page 13

Operation

1

2

3

4

g019686

5

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

1.Stopthemachineonalevelsurface.

Note:Toensureamoreaccuratemeasurement,adjust

thedepthcontrolleveruntiltheengineisalsolevel.

2.Disengagethecuttingblades,stoptheengine,waitfor

allmovingpartstostop,andturnofftheengineswitch.

3.Cleanaroundthedipstick(Figure12)sothatdirt

cannotfallintothellerholeanddamagetheengine.

Figure13

1.Fillertube4.Lowerlimit

2.Dipstick

3.Upperlimit

5.Oil-drainbolt

Figure12

1.Dipstick

4.Unscrewthedipstickandwipetheendclean(Figure

12).

5.Insertthedipstickfullyontothellertube.Donot

screwin.(Figure12).

6.Removethedipstickagainandlookattheend.Ifthe

engineoillevelislow,slowlypouronlyenoughoilinto

thellertubetoraisetheleveltothemiddleofthe

dipstick(Figure13).

Important:Donotoverllthecrankcasewith

engineoilandruntheengine;enginedamage

mayresult.

CleaningDebrisfromthe Machine

ServiceInterval:Beforeeachuseordaily

1.Disengagethecuttingblades,stoptheengine,waitfor

allmovingpartstostop,andturnofftheengineswitch.

2.Brushdirtanddebrisawayfromtheaircleanerand

engineopenings.

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontainsmore

than10%ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85(contains

85%ethanol).Usingunapprovedgasolinemaycause

performanceproblemsand/orenginedamagewhichmay

notbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

13

Page 14

•Donotstorefueleitherinthefueltankorfuelcontainers

g013315

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithouttheentireexhaust

systeminplaceandinproperworkingcondition.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthetractionunittokeep

gasolinefreshduringstorageof90daysorless.Forlonger

storagedrainthefueltank.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionertothe

gas.

Note:Afuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.Tominimizevarnishdepositsin

thefuelsystem,usefuelstabilizeratalltimes.

FillingtheFuelTank

1.Disengagethecuttingblades,stoptheengine,waitfor

allmovingpartstostop,andturnofftheengineswitch.

2.Allowtheenginetocool.

3.Cleanaroundthefueltankcapandremoveit(Figure

14).

Note:Thecapistetheredtothefueltank.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleased,causingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbed,becauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailer,andrefuelthe

equipmentwithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

containerratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

Figure14

4.Addunleadedgasolinetothefueltankuntilthelevel

isjustinsidethemeshlterbasket.

Important:Thisspaceinthetankallowsgasoline

toexpand.Donotllthefueltankcompletelyfull.

5.Installthefueltankcapsecurely.

6.Wipeupanyspilledgasoline.

StartingandStoppingthe Engine

StartingtheEngine

1.Movethechokelevertotheleftifyouarestartinga

coldengine.

2.MovethethrottlelevermidwaybetweentheSlow

(turtle)andFast(rabbit)positions.

14

Page 15

Note:Awarmorhotenginemaynotrequirechoking.

3.Holddowntheoperatorpresencebailwithonehand.

4.Pulltherecoilhandlesharplytostarttheengine.

5.Aftertheenginestarts,graduallymovethechoketo

theright.

Note:Iftheenginestallsorhesitates,movethechoke

leftagainuntiltheenginewarmsup.

6.Movethethrottlelevertothedesiredsetting.

StoppingtheEngine

1.Releasetheoperator-presencebail.

OperatingtheMachine

1.Movethedepthcontrollevertothedesiredsetting.

2.Starttheengine.

3.Pushdownonthehandletoraisethefrontwheelsoff

theground.

4.Pullthecutting-blade-controllevertothehandle,and

slowlylowerthefrontwheelstotheground,allowing

thebladestograduallyworkintothegrassandsoil.

5.Whennished,releasethecutting-blade-controllever,

stoptheengine,andraisethecuttingbladestothe

transportsetting.

2.Closethefuelvalve.

3.Waitforallmovingpartstostop.

OperatingTips

•Asseedowvariesgreatlybetweendifferentseedtypes,

llthehopperwithaminimalamountofseed,andrun

atrialportionoftheyardtoensureyouhavethedesired

seedoutput.

•Foroptimalcoverage,reducetheseedowto1/2the

desiredamountandseedtheentireyardin1direction,

thencompleteasecondcoverageperpendiculartothe

rst.

PowerSeeding

•Setthecuttingblades3to6mm(1/8to1/4inch)into

theearth(belowthezeroposition).

•Mowtheyardshorterthannormalmowinglengthbefore

seeding.

•Seedalawnbeforeprimegrassgrowingseason.

•Givelawnextrawateringafterseeding.

PowerRaking/Renovating

Tobreaknewgroundortillanexistinglawn,setthecutting

blades6to12mm(1/4to1/2inch)intotheearth(below

thezeroposition).Allowthemachinetomoveatitsown

pacethroughthesoil,goingforwardandbackwardoverthe

areatobeleveled,ormakingmultiplepassesfromdifferent

directions.

15

Page 16

Maintenance

G019426

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours

Beforeeachuseordaily

Every50hours

Every100hours

Every200hours

Every300hours

Yearlyorbeforestorage

MaintenanceProcedure

•Changetheengineoil.

•Checktheengine-oillevel.

•Cleandebrisformthemachine.

•Inspecttheaircleanerelements.

•Checkthebelttension.Iftheengineisworkingbutthecuttingbladesseem

underpowered,checkthebelttension.

•Checkthecuttingbladesforwearordamage.

•Checkthebladesforwearordamage.

•Checkforloosefasteners.

•Cleantheairlterelements.Cleanthemmorefrequentlyindustyoperating

conditions.

•Changetheengineoil.

•Cleanthesedimentcup.

•Inspect,clean,andadjustthesparkplug;replaceitifnecessary.

•Replacethesparkplug.

•Replacethepaperaircleanerelement.Replaceitmorefrequentlyindustyoperating

conditions.

•T ouchupchippedpaint.

Premaintenance

Procedures

DisconnectingtheSpark-Plug Wire

Beforeperforminganymaintenanceontheengine,belts,or

cuttingblades,disconnectthespark-plugwirefromthespark

plug(Figure15).

Figure15

1.Spark-plugwire

16

Page 17

EngineMaintenance

G019427

g013375

0 20 40 60 80 100 F

-20 -10 0 10 20 30 40 C

o

o

30

5W - 30 / 10W - 30

10.Cleanthefoamelementinwarm,soapywaterorina

nonammablesolvent.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Inspecttheair

cleanerelements.

Every50hours—Cleantheairlterelements.Clean

themmorefrequentlyindustyoperatingconditions.

Every300hours/Yearly(whichevercomes

rst)—Replacethepaperaircleanerelement.Replace

itmorefrequentlyindustyoperatingconditions.

Important:Donotoperatetheenginewithouttheair

lterassembly;extremeenginedamagewilloccur.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Removethenutthatsecuresthecover(

Figure16).

Note:Donotusegasolinetocleanthefoamelement

becauseitcouldcreateariskofreorexplosion.

11.Rinseanddrythefoamelementthoroughly.

12.Dipthefoamelementincleanengineoil,thensqueeze

outtheexcessoil.

Note:Excessoilinthefoamelementrestrictstheair

owthroughtheelementandmayreachthepaper

lterandclogit.

13.Wipedirtfromthebaseandthecoverwithamoistrag.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

14.Installtheaircleanerelementsandensurethattheyare

properlypositioned.

15.Securetheaircleanerelementswiththepreviously

removednut.

16.Securelyinstallthecoverwiththepreviouslyremoved

nut.

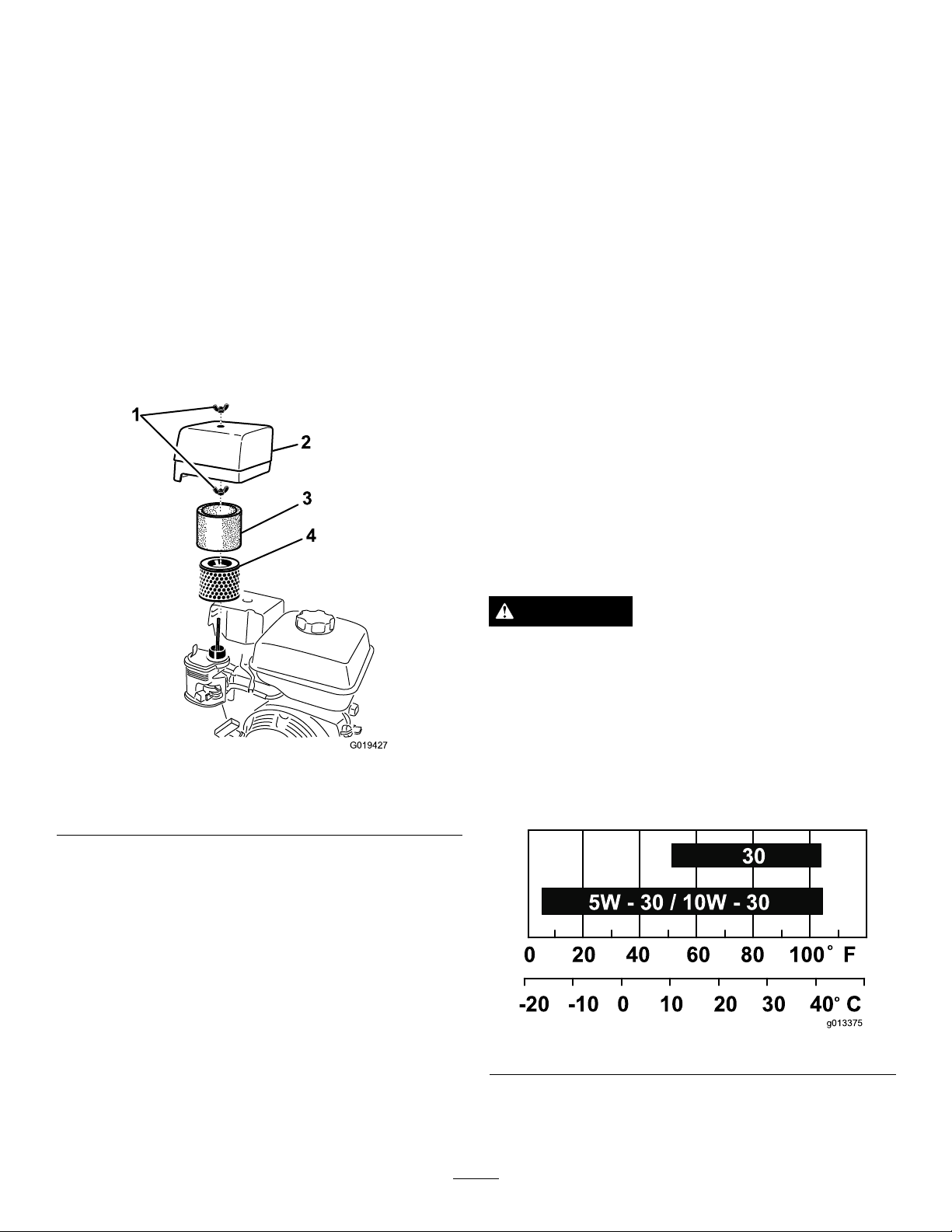

ChangingtheEngineOil

ServiceInterval:Aftertherst25hours

Every100hours

Figure16

1.Nut3.Paperelement

2.Cover

4.Removethecover.

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

5.Removethenutrestrainingairlterassembly.

6.Removethefoamandpaperelementsfromthebase

(

Figure16).

7.Removethefoamelementfromthepaperelement

(Figure16).

8.Inspectthefoamandpaperelements,andreplacethem

iftheyaredamagedorexcessivelydirty.

9.Ifthepaperelementisexcessivelydirty,replaceit.

Note:Nevertrytobrushdirtoffthepaperelement;

brushingforcesthedirtintothebers.

4.Foamelement

WARNING

Oilmaybehotaftertheenginehasbeenrun,and

contactwithhotoilcancauseseverepersonalinjury.

Avoidcontactingthehotengineoilwhenyoudrain

it.

OilType:Detergentoil(APIserviceSJorhigher)

CrankcaseCapacity:1.1l(37oz)

Viscosity:Seetablebelow

Figure17

1.Disengagethecuttingblades,stoptheengineby

releasingtheoperatorpresencebail,andwaitforall

movingpartstostop.

17

Page 18

2.Disconnectthewirefromthesparkplug.

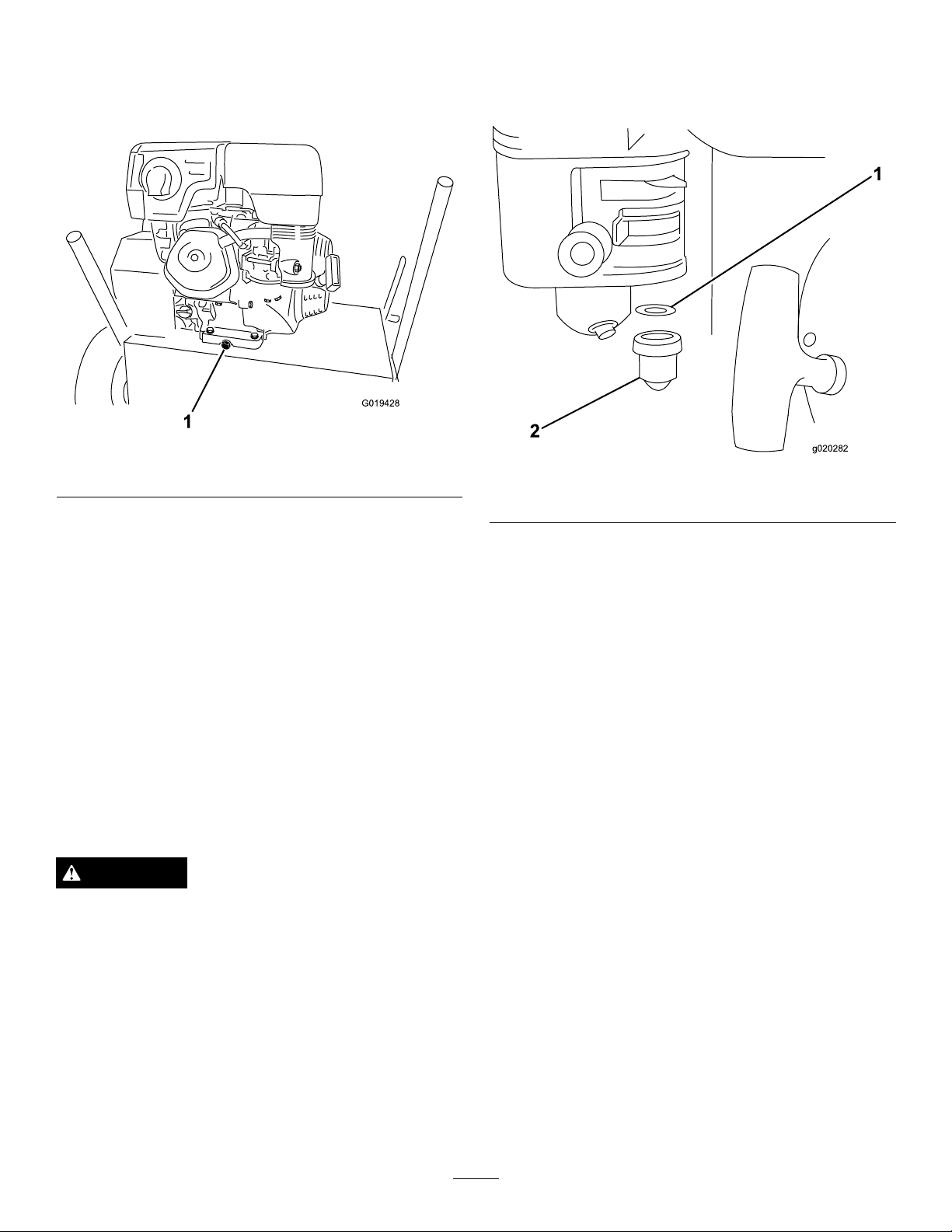

G019428

1

2

g020282

2.Disconnectthewirefromthesparkplug.

3.Raisethefrontwheelsafewinchesofftheground,and

placeapanunderthedrainplugtocatchtheoil.

4.Removethedrainplug(Figure18).

Figure18

1.Drainplug

5.Whentheoilhasdrainedcompletely,lowerthefront

wheelstotheground,replacethedrainplug,and

torqueto17n-m(13ft-lb).

Note:Disposeoftheusedoilatacertiedrecycling

center.

6.Removethedipstickandslowlypouroilintotheller

holeuntiltheoillevelreachesthemiddleofthedipstick

Figure13).

(

7.Replaceandsecurethedipstick.

3.MovethefuelshutoffvalvetotheOffposition.

4.RemovethesedimentcupandO-ring(Figure19).

Figure19

1.O-ring2.Sedimentcup

5.Washthesedimentcupinanonammablesolventand

dryitthoroughly .

6.PlacetheO-ringinthefuelvalveandinstallthe

sedimentcup,tighteningitsecurely.

7.MovethefuelshutofflevertotheOnposition.

Ifanyfuelleaks,repeatthisprocedureandreplacethe

O-ring.

8.Wipeupanyspilledoil.

9.Connectthewiretothesparkplug.

CleaningtheSedimentCup

ServiceInterval:Every100hours

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Stoptheengineandkeepheat,sparks,and

ameaway .

•Handlefuelonlyoutdoors.

•Wipeupspillsimmediately.

•Donotsmokewhilehandlingfuel.

1.Stoptheengineandwaitforallmovingpartstostop.

ServicingtheSparkPlug

ServiceInterval:Every100hours—Inspect,clean,and

adjustthesparkplug;replaceitif

necessary.

Every200hours—Replacethesparkplug.

UseanNGKBPR6ESsparkplugorequivalent.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,ordirty

sparkplug.Donotcleantheelectrodesbecause

gritenteringthecylindercandamagetheengine.

5.Setthegapontheplugto0.76mm(0.030inch)(

20

).

Figure

18

Page 19

BeltMaintenance

CheckingtheBeltTension

ServiceInterval:Beforeeachuseordaily—Checkthebelt

tension.Iftheengineisworkingbut

thecuttingbladesseemunderpowered,

checkthebelttension.

Figure20

1.Centerelectrodeinsulator

2.Sideelectrode

3.Airgap(nottoscale)

6.Carefullyinstallthesparkplugbyhand(toavoidcross

threading)untilitishandtight.

7.Tightenthesparkpluganadditional1/2turnifitis

new;otherwise,tightenitanadditional1/8to1/4turn.

Important:Aloosesparkplugcanbecomevery

hotandcandamagetheengine;overtighteninga

sparkplugmaydamagethethreadsinthecylinder

head.

8.Connectthewiretothesparkplug.

1.Stopthemachineonalevelsurface,stoptheengine

byreleasingtheoperatorpresencebail,disconnectthe

spark-plugwire,andraisethecuttingbladestothe

transportposition.

2.Removethe4boltssecuringthebeltcovertotheleft

sideofthemachineandremovethecover(Figure21).

Figure21

1.Belt3.Bolts

2.Cover

3.Checkthetensionofthebelt(Figure21).

Note:Thebeltshouldnotexmorethana12mm

(1/2inch)withmoderatengerpressureappliedtothe

spanjustabovethemachineframe.

4.Ifthebelttensionisloose,refertoAdjustingtheBelt

Tension(page20).

5.Installthebeltcoverbeforeoperatingthemachine.

19

Page 20

AdjustingtheBeltTension

1

g019740

1.Totightenthebelt,loosenthe4mountingnuts

securingtheenginetotheframe.

MaintainingtheCutting Blades

InspectingtheCuttingBlades

ServiceInterval:Beforeeachuseordaily—Checkthe

cuttingbladesforwearordamage.

Whenthecuttingbladesareworndownandarenolonger

functioningproperly;refertoReplacingWornCuttingBlades

(page20).

Important:Performthisprocedurewhenthefueltank

isemptyornearlyempty.Tiptheunitforwardtokeep

airlterup

ReplacingWornCutting Blades

ServiceInterval:Beforeeachuseordaily—Checktheblades

forwearordamage.

Figure22

1.Mountingnuts

2.Movetheenginetotightenthebelttotheproper

tension.

3.Securethe4mountingnutsandbolts.

Note:Torquetheboltsthatsecuretheenginetothe

frame271N-m(200in-lb).

Whenthecuttingbladesareworndownandnolonger

functioningproperly ,replacethem,asfollows:

Important:Performthisprocedurewhenthefueltank

isemptyornearlyempty .

1.Stopthemachineonalevelsurface,stoptheengine

byreleasingtheoperator-presencebail,disconnectthe

spark-plugwire,andraisethecuttingbladestothe

transportposition.

2.Removethe4boltsand4nutssecuringthebeltcover

totheleftsideofthemachine,andremovethecover.

3.Removethecuttingbladesdrivebeltfromthemachine.

4.Tiltthemachineforwardontoitsnose,restingona

blockofwood.

Note:Itwilltake2peopletotipthemachineforward

safely.

5.Lowerthecuttingbladestothelowestposition.

6.Spinthecuttingbladeassemblymanually.

Note:Thebladeassemblyshouldspinfreely.Ifit

makesagrindingnoiseandishalting,thebearingsare

worn;replacethemwhenyoureplacetheblades.

7.Removethe4boltsandlocknutssecuringthecutting

20

bladeassembly(Figure23),andremoveitfromthe

machine.

Page 21

Figure23

1.Bolt

2.Bearing

3.Washer7.Nut

4.Blade

8.Loosenandremovethenutandwasherfromtheshaft

(Figure23).

9.Slidethespacerofftheshaft(

Figure23).

10.Carefullyslidethebladesoffoftheshaft(Figure23)

andreplacethemasnecessary.

11.Reversethisproceduretoinstalltheassembly.

5.Spacer

6.Shaft

21

Page 22

Storage

5.Checktheengineoillevel;refertoCheckingthe

Engine-OilLevel(page13).

1.Raisethecuttingblades,stopthemachine,stopthe

engine,anddisconnectthesparkplugwire.

2.Removedirtandgrimefromtheentiremachine.

Important:Youcanwashthemachinewithmild

detergentandwater.Donotpressurewashthe

machine.Avoidexcessiveuseofwater,especially

neartheengine.

3.Servicetheaircleaner;referto

Cleaner(page17).

4.Changetheengineoil;refertoChangingtheEngine

Oil(page17).

5.Forstorageover30days,preparethetractionunitas

follows:

A.Addapetroleumbasedstabilizer/conditionerto

fuelinthetank.Followmixinginstructionsfrom

stabilizermanufacturer(1ozpergallon).Donot

useanalcoholbasedstabilizer(ethanolor

methanol).

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshgasolineandused

atalltimes.

ServicingtheAir

6.Fillthefueltankwithfreshgasoline;refertoFilling

theFuelTank(page14).

7.Connectthewiretothesparkplug.

B.Runtheengineuntilitstopsfromrunningout

offuel.

C.Choketheengine.

D.Startandruntheengineuntilitwillnotstartagain.

E.Disposeoffuelproperly.Recyclethefuel

accordingtolocalcodes.

Important:Donotstorestabilizer/conditioned

gasolineover90days.

6.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamaged.

7.Paintallscratchedorbaremetalsurfaceswithpaint

fromanAuthorizedServiceDealer.

8.Storethemachineinaclean,drygarageorstoragearea.

9.Coverthemachinetoprotectitandkeepitclean.

RemovingtheMachinefrom Storage

1.Checkandtightenallfasteners.

2.Inspectthesparkplugandreplaceitifitisdirty,worn,

orcracked;refertotheengineowner’smanual.

3.Installthesparkpluguntilitishand-tight,thenan

additional1/2turnifitisnew,otherwise,tightenitan

additional1/8to1/4turn.

4.Performanyneededmaintenanceprocedures;referto

Maintenance(page16).

22

Page 23

Notes:

23

Page 24

Alimitedwarranty(seewarrantyperiodsbelow)

TheToroWarranty

SWS

TurfRenovation

and

TreeCare

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroWarrantyCompany ,pursuantto

anagreementbetweenthem,jointlywarrantyourToroProductslisted

belowtobefreefromdefectsinmaterialsorworkmanship.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

TurfRenovation

Walk-BehindAerator1year

•Engine2years

Stand-OnAerator

•Battery90daysPartsandLabor

•Engine2years

Dethatcher1year

•Engine2years

TurfSeeder

•Engine2years

TreeCare

LogSplitter

•Battery90daysPartsandLabor

•Engine2years

StumpGrinder

•Engine2years

BrushChipper

•Battery90daysPartsandLabor

•Engine3years

Walk-BehindRotaryBroom1year

•Engine2years

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

1year

1yearPartsOnly

1year

1year

1yearPartsOnly

1year

1year

1yearPartsOnly

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure

1.ContactanyAuthorizedServicingOutlettoarrangeserviceattheir

dealership.T olocateoneconvenienttoyou,accessourwebsiteat

www.T oro.com.Select“WheretoBuy”andselect“Contractor”under

producttype.Y oumayalsocallourtollfreenumberbelow.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothem.

3.IfforanyreasonyouaredissatisedwiththeServiceOutlet’s

analysisorwiththeassistanceprovided,contactusat:

SWSCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:888-384-9940

**

ToroAuthorizedRentalCustomerswhohavepurchasedproductsdirectlyfromToroandhave

signedtheToroRentalCustomerAgreementhavetheabilitytoperformtheirownwarrantywork.

PleasevisitToro’ sRentalPortalforelectronicwarrantyclamlingproceduresorcallthetollfree

numberabove.

**

:

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

Partsscheduledforreplacementasrequiredmaintenance(“Maintenance

Parts”),arewarrantedfortheperiodoftimeuptothescheduled

replacementtimeforthatpart.Failuretoperformrequiredmaintenance

andadjustmentscanbegroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thisexpresswarranty

doesnotcoverthefollowing:

•Productfailureswhichresultfrominstallationanduseofadd-on,

modied,orunapprovedaccessories

•Failuretoperformrequiredmaintenanceand/oradjustments

•Repairsnecessaryduetofailuretofollowrecommendedfuel

procedure(consultOperator'sManualformoredetails)

–Removingcontaminantsfromthefuelsystemisnotcovered

–Useofoldfuel(morethanonemonthold)orfuelwhichcontains

morethan10%ethanolormorethat15%MTBE

–Failuretodrainthefuelsystempriortoanyperiodofnon-use

overonemonth

•Productfailureswhichresultfromoperatingtheproductinanabusive,

negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,include,belts,

cutters,blades,teeth,sparkplugs,tires,lters,etc.

•Failurescausedbyoutsideinuenceinclude,weather,storage,

contamination,lubricants,additives,orchemicals,etc.

•Normal“wearandtear”itemsincudespaintedsurfacesandscratched

decals,etc.

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedServicingOutletorSelf-ServiceasanAuthorized

RentalCustomerisyoursoleremedyunderthewarranty.

NeitherTheToroCompanynorT oroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwith

theuseoftheToroProductscoveredbythiswarranty ,including

anycostorexpenseofprovidingsubstituteequipmentorservice

duringreasonableperiodsofmalfunctionornon-usepending

completionofrepairsunderthiswarranty.Allimpliedwarranties

ofmerchantabilityandtnessforusearelimitedtotheduration

ofthisexpresswarranty.Somestatesdonotallowexclusionsof

incidentalorconsequentialdamages,orlimitationsonhowlong

animpliedwarrantylasts,sotheaboveexclusionsandlimitations

maynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

RefertotheCaliforniaEmissionControlWarrantyStatementsuppliedwith

yourProductorcontainedintheenginemanufacturer’sdocumentationfor

details.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtainguarantee

policiesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguarantee

information,contacttheT oroimporter .Ifallotherremediesfail,youmaycontactusatToroWarrantyCompany .

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

374-0289RevC

Loading...

Loading...