Toro 13AL60RG044, 13AL60RG048, 13AL60RG544, 13AP60RP544, 13AP60RP744 Service Manual

...

Consumer Products

LX Lawn

Tractor

Service Manual

TABLE OF CONTENTS

SAFETY INFORMATION

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Think Safety First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

Torque Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series) . . . . . . . . . . . . . .

Standard Torque for Dry, Zinc and Steel Fasteners (Metric Fasteners) . . . . . . . . . . . . . .

Other Torque Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equivalents and Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHASSIS

Front Pivot Axle Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Axle Assembly Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Wheel Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Shaft Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electric PTO Clutch Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Tank Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hood Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fender Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tower Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lower Transmission Drive Belt Replacement - Gear Drive Models

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upper Transmission Drive Belt Replacement - Gear Drive Models

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Drive Belt (Hydro) Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Variable Speed Pulley Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

1-1

2-1

2-2

2-3

2-4

2-5

2-6

3-1

3-7

3-14

3-17

3-19

3-20

3-21

3-24

3-27

3-28

3-29

3-30

3-31

3-32

3-33

3-39

3-45

3-53

3-62

3-64

3-67

3-69

3-71

3-74

3-77

3-79

iLX Lawn Tractor Service Manual

TABLE OF CONTENTS

CHASSIS cont.

Variable Speed Pulley Service

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purging the System - Hydrostatic Models . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Change - Hydrostatic Models . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Neutral Adjustment - Hydrostatic Models . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Wheel Toe-in Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Wheel Toe-in Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Autodrive Pedal Adjustment - Hydrostatic Models . . . . . . . . . . . . . . . . . . . . . . .

Brake Adjustment - Hydrostatic Models . . . . . . . . . . . . . . . . . . . . . . . . . . .

Throttle/Choke Cable Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE

Engine Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GEAR DRIVE SYSTEM

CVT Transmission Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Puck Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-81

3-82

3-82

3-83

3-84

3-85

3-86

3-87

3-91

3-93

3-96

4-1

4-7

5-1

5-4

5-9

5-11

5-14

HYDROSTATIC DRIVE SYSTEM

Hydro Transmission Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MOWER DECK

42” Mower Deck - Brake Idler Assembly Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42” Mower Deck - Idler Assembly Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42” Mower Belt Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46” Mower Deck - RH Idler Bracket Assembly

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46” Mower Deck - Brake Assembly

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46” Mower Deck - LH Idler Assembly

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1

6-7

7-1

7-3

7-6

7-8

7-11

7-13

7-14

7-16

7-19

7-20

7-21

7-23

ii LX Lawn Tractor Service Manual

TABLE OF CONTENTS

MOWER DECK cont.

46” Mower Deck - Lower Idler Bracket

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46” Mower Deck - Lower Mower Deck Belt Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46” Mower Deck - Upper Mower Deck Belt Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50” Mower Deck - Belt Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50” Mower Deck - Idler Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42” Mower Deck - Spindle Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42” Mower Deck - Spindle Service . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46” Mower Deck - Double Pulley Spindle Service . . . . . . . . . . . . . . . . . . . . . .

46” Mower Deck - Single Pulley Spindle Service . . . . . . . . . . . . . . . . . . . . . . .

50” Mower Deck - Spindle Service . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42” Mower Deck Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42” Mower Deck Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46” Mower Deck Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46” Mower Deck Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50” Mower Deck Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50” Mower Deck Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-25

7-26

7-27

7-30

7-34

7-35

7-36

7-38

7-39

7-41

7-43

7-45

7-47

7-51

7-56

7-60

7-64

7-67

7-69

7-72

7-74

7-76

ELECTRICAL

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1

iiiLX Lawn Tractor Service Manual

TABLE OF CONTENTS

THIS PAGE INTENTIONALLY LEFT BLANK.

iv LX Lawn Tractor Service Manual

SAFETY INFORMATION

General Information

This symbol means WARNING or

PERSONAL SAFETY INSTRUCTION

- read the instruction because it has to

do with your safety. Failure to comply

with the instruction may result in

personal injury or even death.

This manual is intended as a service and repair

manual only. The safety instructions provided herein

are for troubleshooting, service, and repair of the

LX Series Riding Lawn Tractor.

Think Safety First

Avoid unexpected starting of engine...

Always turn off the engine and disconnect the spark

plug wire(s) before cleaning, adjusting, or repair.

Avoid lacerations and amputations...

Stay clear of all moving parts whenever the engine is

running. Treat all normally moving parts as if they were

moving whenever the engine is running or has the

potential to start.

The riding mower and attachment operator's manual

contain safety information and operating tips for safe

operating practices. Operator's manuals are available

through your Toro parts source or:

The Toro Company

Publications Department

8111 Lyndale Avenue South

Bloomington, MN 55420

Avoid injury from batteries...

Battery acid is poisonous and can cause burns. Avoid

contact with skin, eyes, and clothing. Battery gases

can explode. Keep cigarettes, sparks, and flames away

from the battery.

Avoid injury due to inferior parts...

Use only original equipment parts to ensure that

important safety criteria are met.

1

Avoid burns...

Do not touch the engine, muffler, or other components

which may increase in temperature during operation,

while the unit is running or shortly after it has been

running.

Avoid fires and explosions...

Avoid spilling fuel and never smoke while working with

any type of fuel or lubricant. Wipe up any spilled fuel or

oil immediately. Never remove the fuel cap or add fuel

when the engine is running. Always use approved,

labeled containers for storing or transporting fuel and

lubricants.

Avoid asphyxiation...

Never operate an engine in a confined area without

proper ventilation.

Avoid injury to bystanders...

Always clear the area of bystanders before starting or

testing powered equipment.

Avoid injury due to projectiles...

Always clear the area of sticks, rocks, or any other

debris that could be picked up and thrown by the

powered equipment.

Avoid modifications...

Never alter or modify any part unless it is a factory

approved procedure.

Avoid unsafe operation...

Always test the safety interlock system after making

adjustments or repairs on the machine. Refer to the

Electrical section in this manual for more information.

1-iLX Lawn Tractor Service Manual

1

SAFETY INFORMATION

THIS PAGE INTENTIONALLY LEFT BLANK.

1-ii LX Lawn Tractor Service Manual

SPECIFICATIONS

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as

determined by Toro, either the recommended torque or

a torque that is unique to the application is clearly

identified and specified in the service manual.

These torque specifications for the installation and

tightening of fasteners shall apply to all fasteners which

do not have a specific requirement identified in the

service manual. The following factors shall be

considered when applying torque: cleanliness of the

fastener, use of a thread sealant (Loctite), degree of

lubrication on the fastener, presence of a prevailing

torque feature, hardness of the surface underneath of

the fastener’s head, or similar condition which affects

the installation.

As noted in the following tables, torque values should

be reduced by 25% for lubricated fasteners to

achieve the similar stress as a dry fastener. Torque

values may also have to be reduced when the fastener

is threaded into aluminum or brass. The specific

torque value should be determined based on the

aluminum or brass material strength, fastener size,

length of thread engagement, etc.

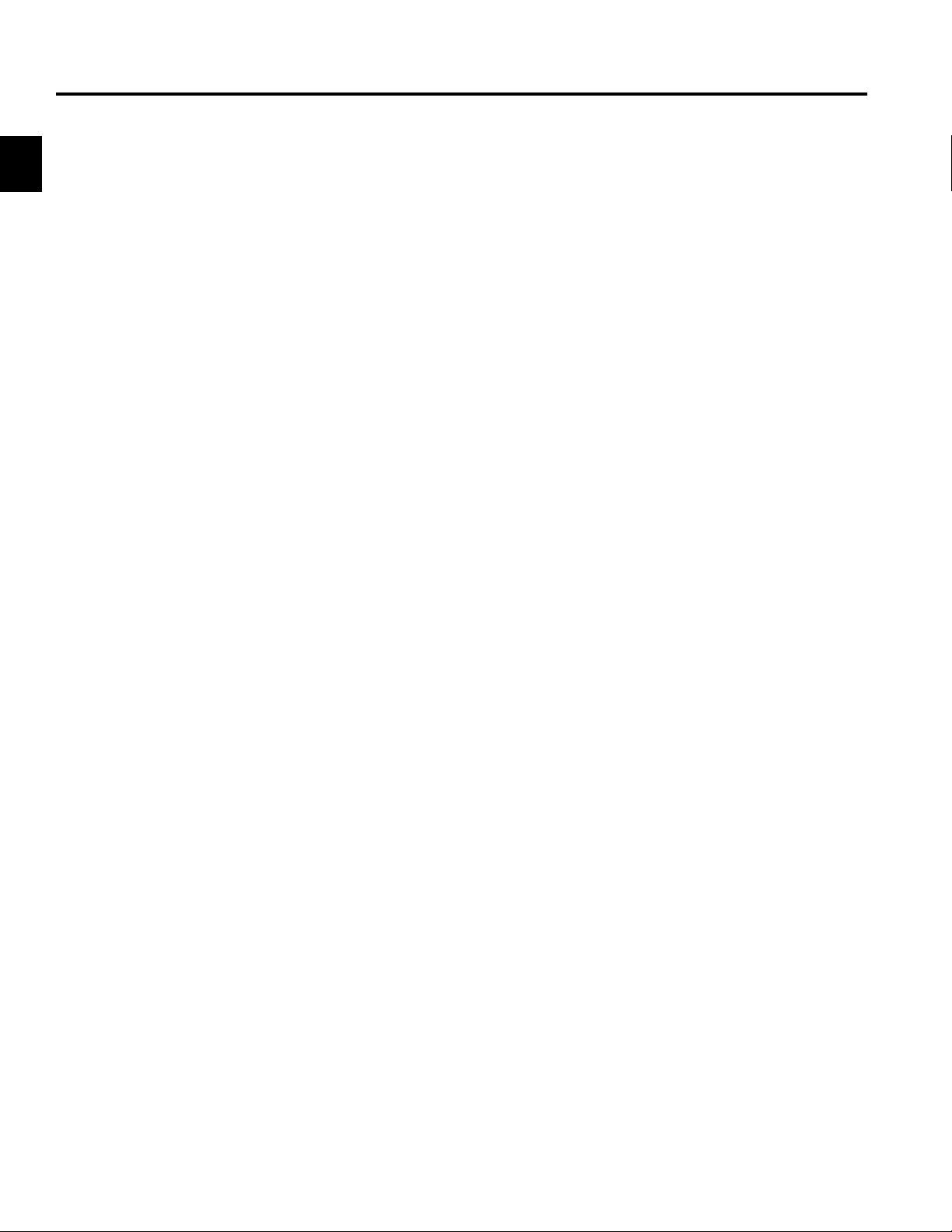

Fastener Identification

Inch Series Bolts and Screws

(A) Grade 1

(B) Grade 5

2

Figure 1

(C) Grade 8

The standard method of verifying torque shall be

performed by marking a line on the fastener (head or

nut) and mating part, then back off fastener 1/4 of a

turn. Measure the torque required to tighten the

fastener until the lines match up.

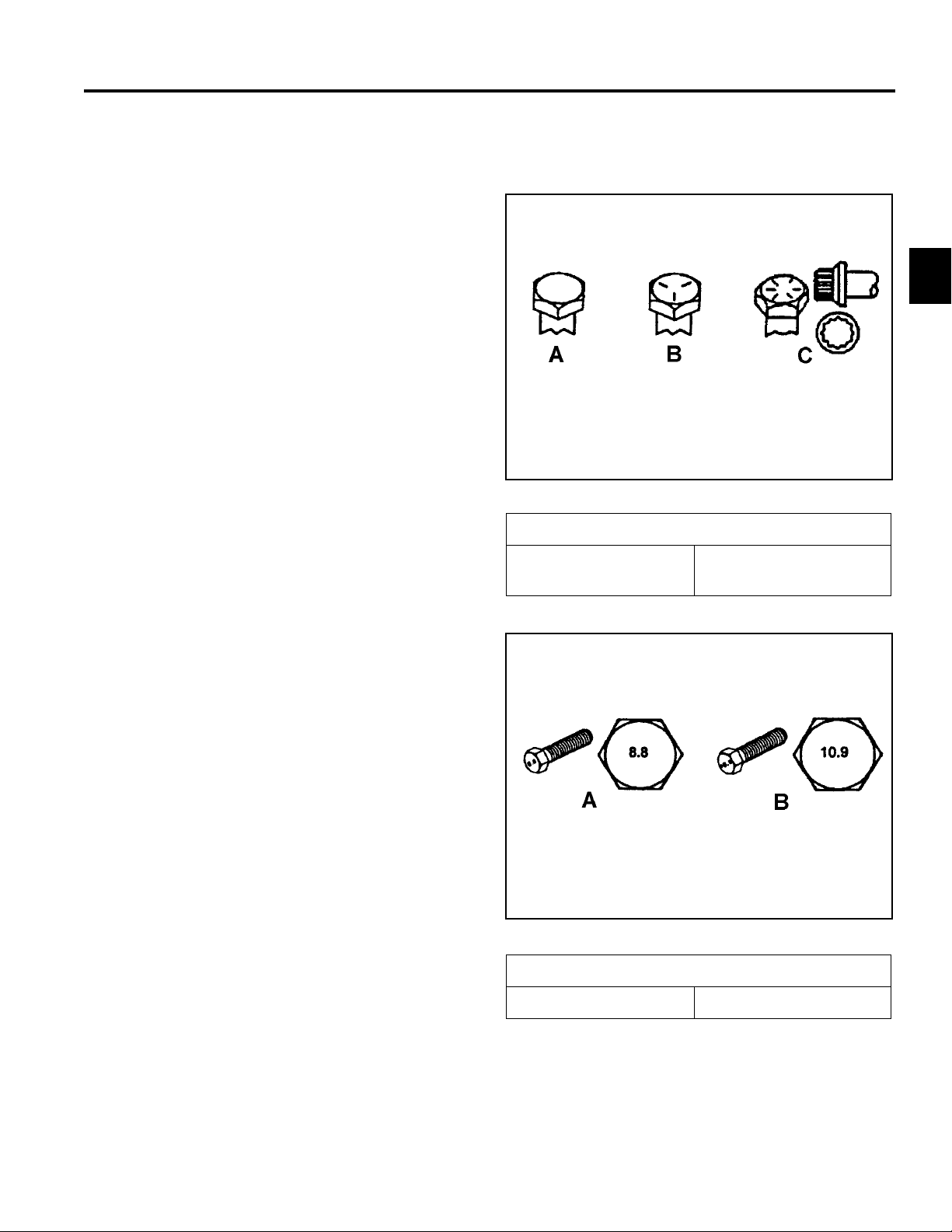

Figure 2

Metric Bolts and Screws

(A) Class 8.8 (B) Class 10.9

2-1LX Lawn Tractor Service Manual

SPECIFICATIONS

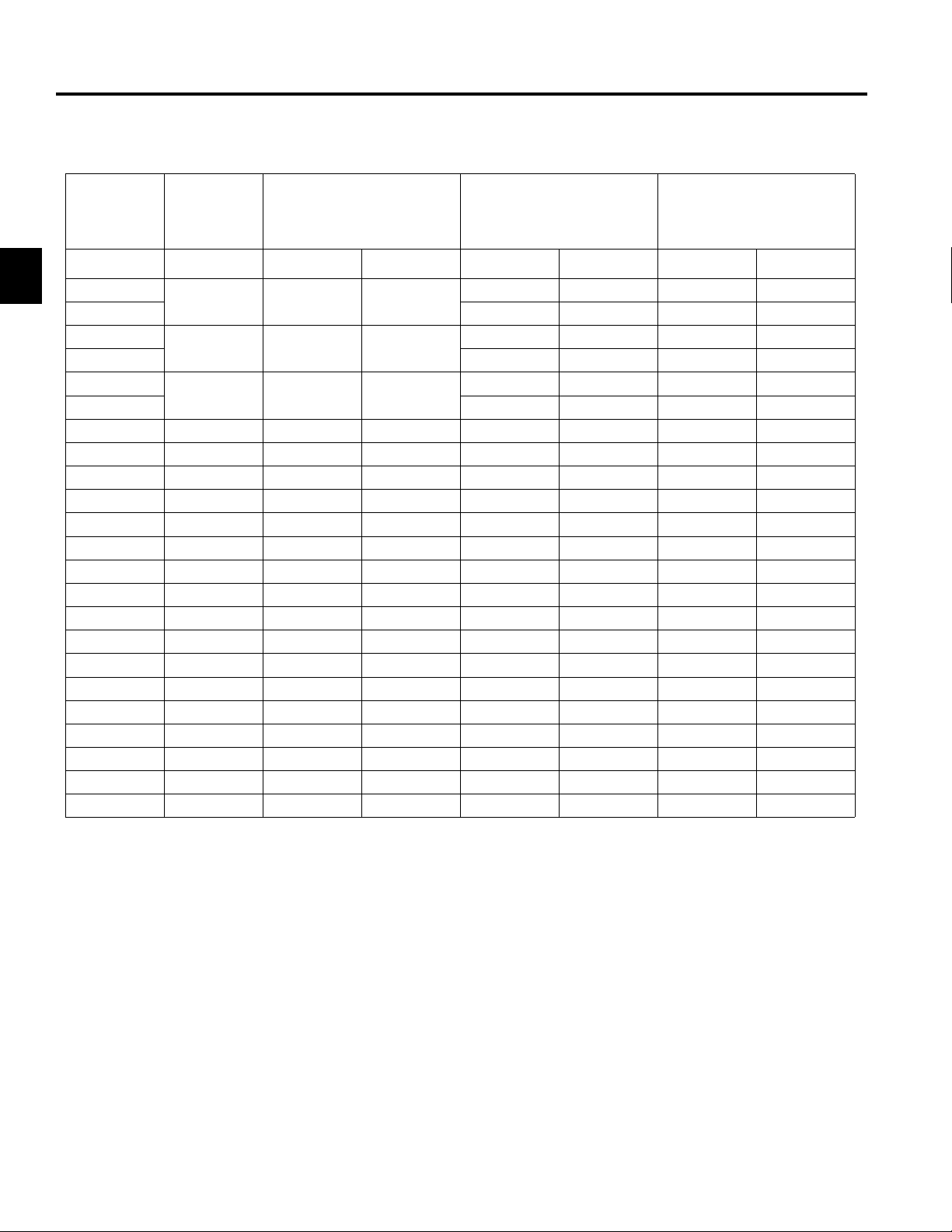

Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

2

Grade 1, 5, &

Thread Size

# 6 - 32 UNC

# 6 - 40 UNF 17 ± 2 190 ± 20 25 ± 2 280 ± 20

# 8 - 32 UNC

# 8 - 36 UNF 31 ± 3 350 ± 30 43 ± 4 31 ± 3

# 10 - 24 UNC

#10 - 32 UNF 48 ± 4 540 ± 45 68 ± 6 765 ± 70

1/4 - 20 UNC 48 ± 7 53 ± 7 599 ± 79 100 ± 10 1125 ± 100 140 ± 15 1580 ± 170

1/4 - 28 UNF 53 ± 7 65 ± 10 734 ± 113 115 ± 10 1300 ± 100 160 ± 15 1800 ± 170

5/16 - 18 UNC 115 ± 15 105 ± 17 1186 ± 169 200 ± 25 2250 ± 280 300 ± 30 3390 ± 340

5/16 - 24 UNF 138 ± 17 128 ± 17 1446 ± 192 225 ± 25 2540 ± 280 325 ± 30 3670 ± 340

3/8 - 16 UNC 16 ± 2 16 ± 2 22 ± 3 30 ± 3 41 ± 4 43 ± 4 58 ± 5

3/8 - 24 UNF 17 ± 2 18 ± 2 24 ± 3 35 ± 3 47 ± 4 50 ± 4 68 ± 5

7/16 - 14 UNC 27 ± 3 27 ± 3 37 ± 4 50 ± 5 68 ± 7 70 ± 7 68 ± 9

7/16 - 20 UNF 29 ± 3 29 ± 3 39 ± 4 55 ± 5 75 ± 7 77 ± 7 104 ± 9

1/2 - 13 UNC 30 ± 3 48 ± 7 65 ± 9 75 ± 8 102 ± 11 105 ± 10 142 ± 14

1/2 - 20 UNF 32 ± 3 53 ± 7 72 ± 9 85 ± 8 115 ± 11 120 ± 10 163 ± 14

5/8 - 11 UNC 65 ± 10 88 ± 12 119 ± 16 150 ± 15 203 ± 20 210 ± 20 285 ± 27

5/8 - 18 UNF 75 ± 10 95 ± 15 129 ± 20 170 ± 15 230 ± 20 240 ± 20 325 ± 27

3/4 - 10 UNC 93 ± 12 140 ± 20 190 ± 27 265 ± 25 359 ± 34 374 ± 35 508 ± 47

3/4 - 16 UNF 115 ± 15 165 ± 25 224 ± 34 300 ± 25 407 ± 34 420 ± 35 569 ± 47

7/8 - 9 UNC 140 ± 20 225 ± 25 305 ± 34 430 ± 45 583 ± 61 600 ± 60 813 ± 81

7/8 - 14 UNF 155 ± 25 260 ± 30 353 ± 41 475 ± 45 644 ± 61 660 ± 60 895 ± 81

8 with Thin

Height Nuts

In-lb In-lb N-cm In-lb N-cm In-lb N-cm

10 ± 2 13 ± 2 147 ± 23

13 ± 2 25 ± 5 282 ± 30

18 ± 2 30 ± 5 339 ± 56

ft-lb ft-lb N-m ft-lb N-m ft-lb N-m

SAE Grade 1 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995 Grade

2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995 Grade

2 or Stronger Nuts)

15 ± 2 170 ± 20 23 ± 2 260 ± 20

29 ± 3 330 ± 30 41 ± 4 460 ± 45

42 ± 4 475 ± 45 60 ± 6 674 ± 70

SAE Grade 8 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995 Grade

2 or Stronger Nuts)

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the

minimum proof load specified in SAE J429. The

tolerance is approximately

value. Thin height nuts include jam nuts.

± 10% of the nominal torque

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

2-2 LX Lawn Tractor Service Manual

SPECIFICATIONS

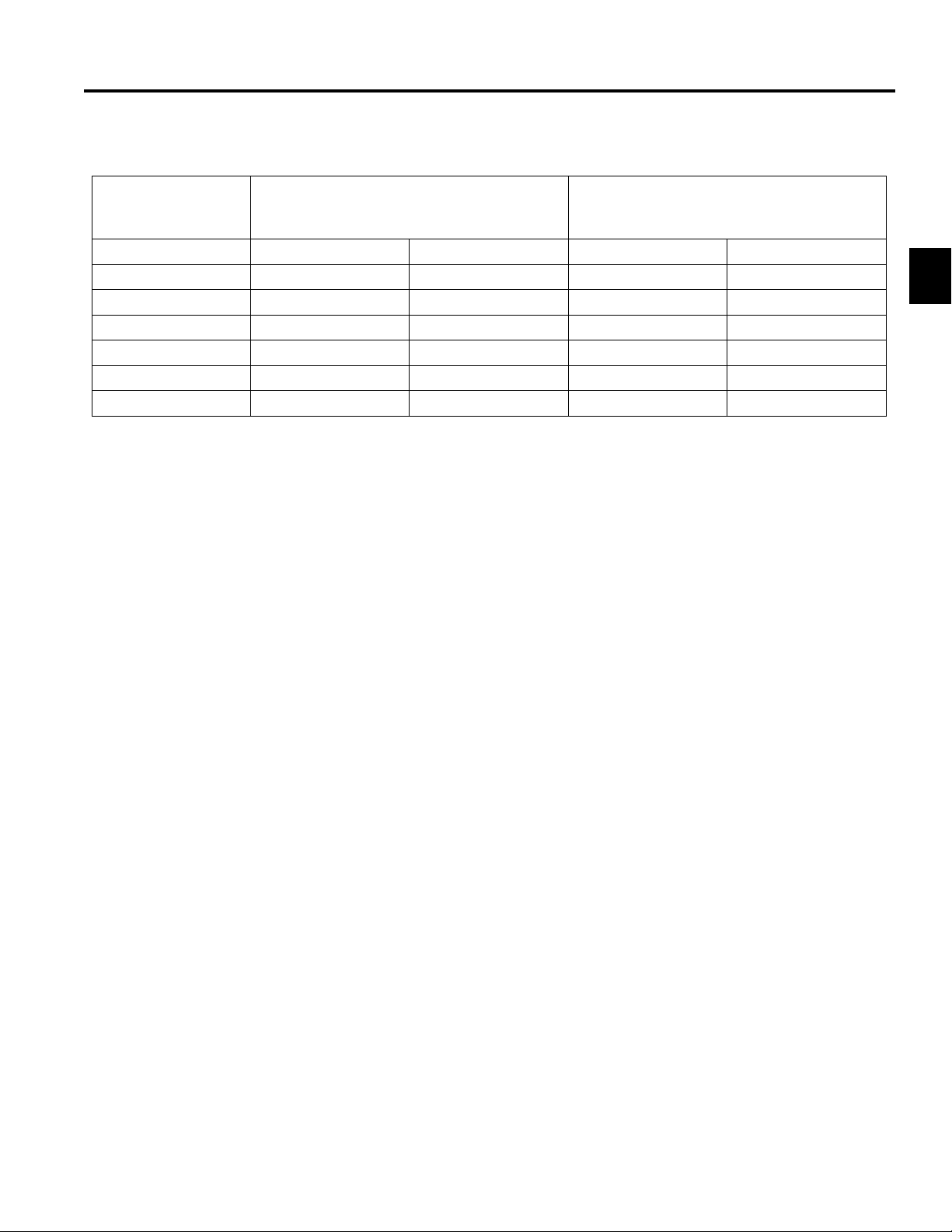

Standard Torque for Dry, Zinc, and Steel Fasteners (Metric Fasteners)

Class 8.8 Bolts, Screws, and Studs with

Thread Size

M5 X 0.8 57 ± 5 in-lb 640 ± 60 N-cm 78 ± 7 in-lb 885 ± 80 N-cm

M6 X 1.0 96 ± 9 in-lb 1018 ± 100 N-cm 133 ± 13 in-lb 1500 ± 150 N-cm

M8 X 1.25 19 ± 2 ft-lb 26 ± 3 N-m 27 ± 2 ft-lb 36 ± 3 N-m

M10 X 1.5 38 ± 4 ft-lb 52 ± 5 N-m 53 ± 5 ft-lb 72 ± 7 N-m

M12 X 1.75 66 ± 7 ft-lb 90 ± 10 N-m 92 ± 9 ft-lb 125 ± 12 N-m

M16 X 2.0 166 ± 15 ft-lb 225 ± 20 N-m 229 ± 22 ft-lb 310 ± 30 N-m

M20 X 2.5 325 ± 33 ft-lb 440 ± 45 N-m 450 ± 37 ft-lb 610 ± 50 N-m

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Regular Height Nuts

(Class 8 or Strong Nuts)

Note: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately

the nominal torque value. Thin height nuts include jam nuts.

Class 10.9 Bolts, Screws, and Studs with

Regular Height Nuts (

Class 10 or Strong Nuts)

2

± 10% of

2-3LX Lawn Tractor Service Manual

SPECIFICATIONS

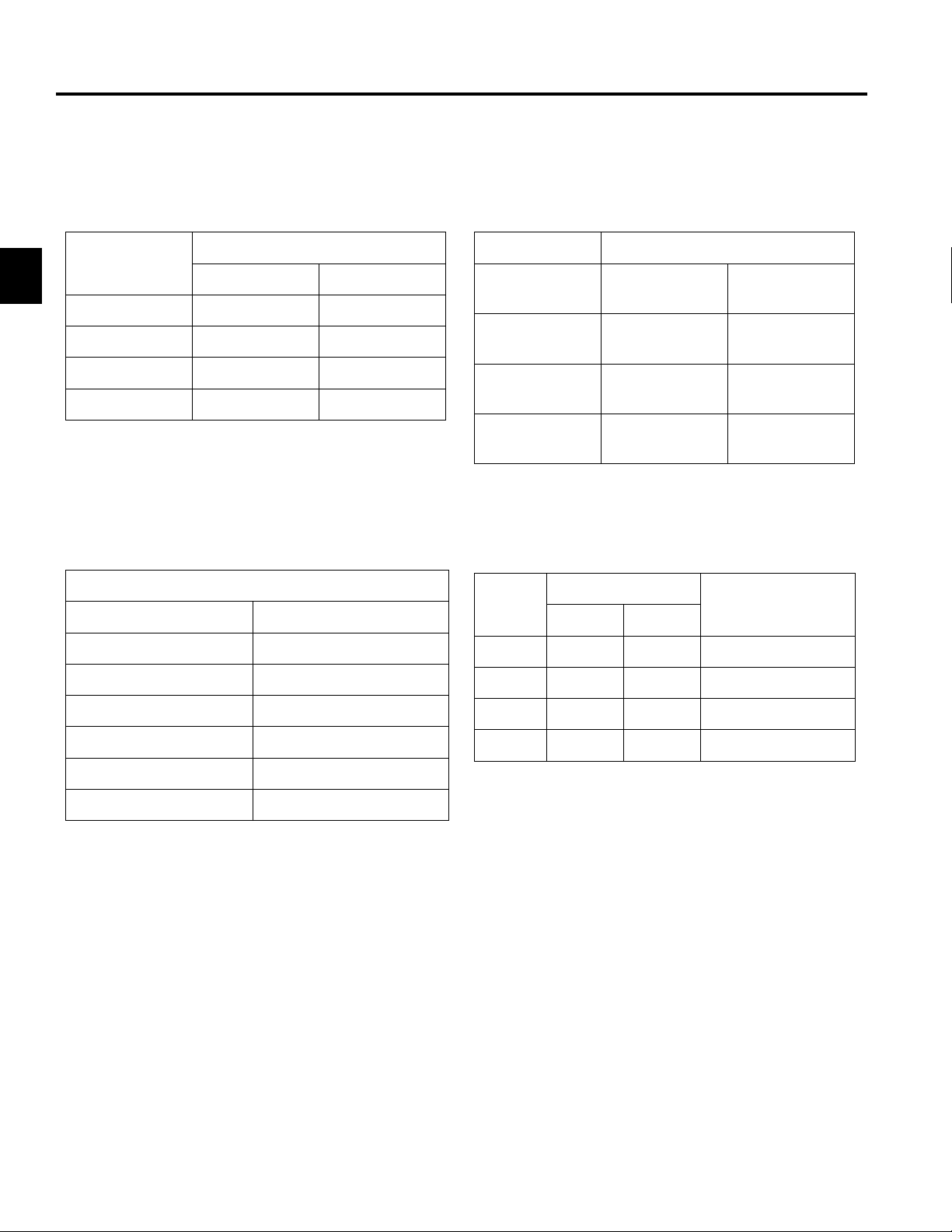

Other Torque Specifications

2

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 - 20 UNC 140 ± 20 in-lb 73 ± 12 in-lb

5/16 - 18 UNC 215 ± 35 in-lb 145 ± 20 in-lb

3/8 - 16 UNC 35 ± 10 ft-lb 18 ± 3 ft-lb

1/2 - 13 UNC 75 ± 15 ft-lb 50 ± 10 ft-lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23, or Type F

Thread Size Baseline Torque*

No. 6 - 32 UNC 20 ± 5 in-lb

Wheel Bolts and Lug Nuts

Thread Size Recommended Torque**

7/16 - 20 UNF

Grade 5

1/2 - 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non-lubricated fasteners.

Thread

Size

No. 6 18 20 20 ± 5 in-lb

Threads per Inch

Type A Type B

65 ± 10 ft-lb 88 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

Thread Cutting Screws

(Zinc Plated Steel)

Baseline Torque*

No. 8 - 32 UNC 30 ± 5 in-lb

No.10 - 24 UNC 38 ± 7 in-lb

1/4 - 20 UNC 85 ± 15 in-lb

5/16 - 18 UNC 110 ± 20 in-lb

3/8 - 16 UNC 200 ± 100 in-lb

Conversion Factors

in-lb X 11.2985 - N-cm

ft-lb X 1.3558 = N-m

No. 8 15 18 30 ± 5 in-lb

No. 10 12 16 38 ± 7 in-lb

No. 12 11 14 85 ± 15 in-lb

* Hole size, material strength, material thickness and

finish must be considered when determining specific

torque values. All torque values are based on nonlubricated fasteners.

N-cm X - 0.08851 = in-lb

N-cm X 0.73776 - ft-lb

2-4 LX Lawn Tractor Service Manual

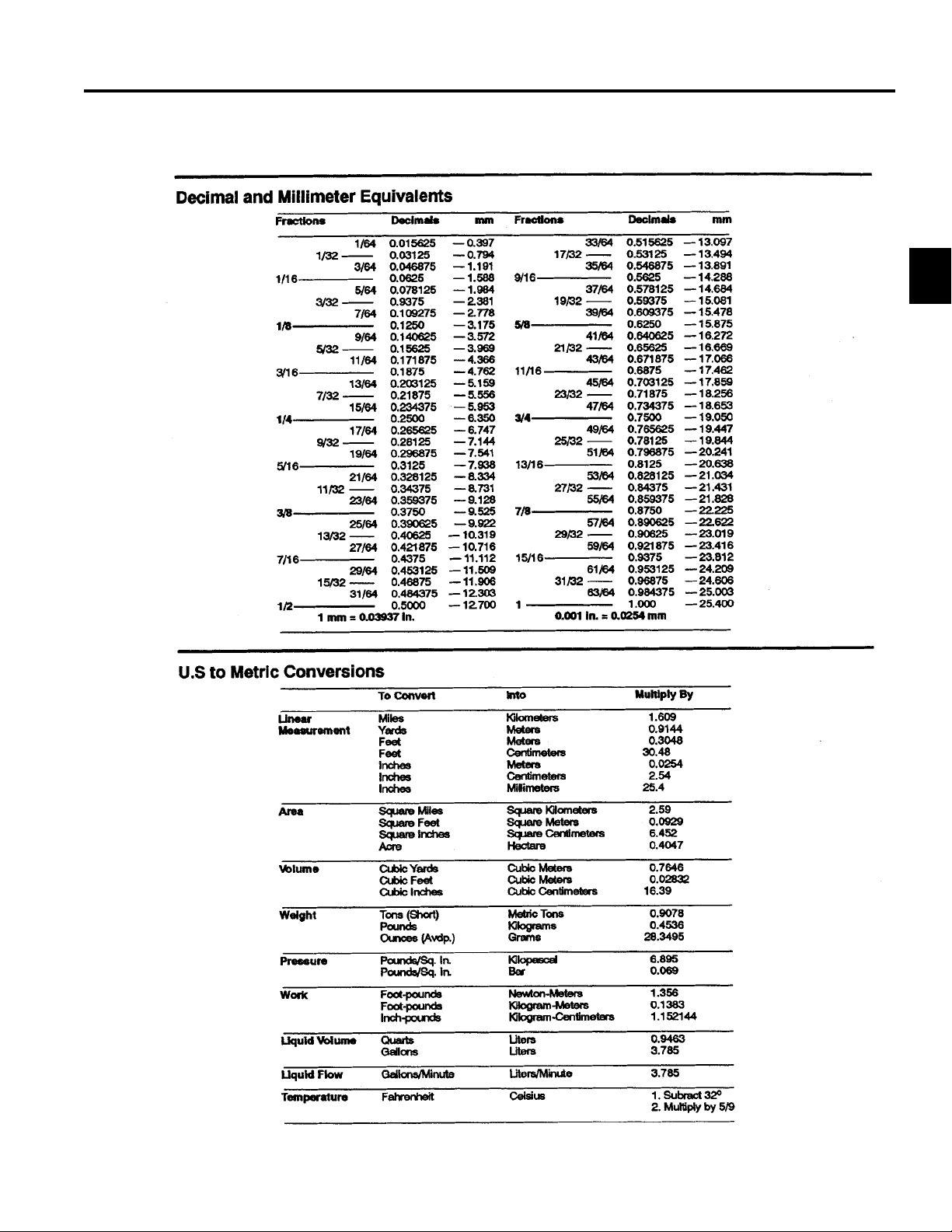

Equivalents and Conversions

SPECIFICATIONS

2

2-5LX Lawn Tractor Service Manual

2

SPECIFICATIONS

Product Specifi cations

Name LX420 LX425 LX460 LX465 LX500

Engine 18 HP

Single Cylinder

Kohler Courage

RPM Setting -

High

RPM Setting –

Low

Construction

Fuel Capacity

Wheel Base 46” (116.8cm) 46” (116.8cm) 46” (116.8cm) 46” (116.8cm) 46” (116.8cm)

Overall Length 68” (172.7cm) 68” (172.7cm) 68” (172.7cm) 68” (172.7cm) 68” (172.7cm)

Overall Width 42” (114.3cm) 42” (114.3cm) 48” (127.9cm) 49” (124.4cm) 54” (137.2cm)

Overall Height 43” (109.2cm) 43” (109.2cm) 43” (109.2cm) 43” (109.2cm) 43” (109.2cm)

Weight

(approximate)

Traction System CVT* Transaxle CVT* Transaxle CVT* Transaxle Hydro-Gear

Ground Speed –

Forward

Ground Speed –

Reverse

Front Tires

Rear Tires 20 x 8 20 x 8 20 x 8 20 x 8 20 x 10

Tire Pressure

(Front/Rear)

Turning Radius

Electrical

System

3450 + 75 3450 + 75 3450 + 75 3450 + 75 3300 + 75

1700 + 150 1700 + 150 1700 + 150 1700 + 150 1750 + 150

498 lbs.

(225.9kg)

0 – 5.5 mph 0 – 5.5 mph 0 – 5.5 mph 0 – 6.4 mph 0 – 5.5 mph

0 – 2.3 mph 0 – 2.3 mph 0 – 2.3 mph 0 – 2.5 mph 0 – 2.3 mph

20 HP

Single Cylinder

Kohler Courage

498 lbs.

(225.9kg)

Alternator: 15 Amp Regulated

20 HP

Single Cylinder

Kohler Courage

12 Gauge Steel Frame

3.0 Gallon (11.4 Liters)

501 lbs.

(227.25kg)

15 x 6

14psi / 10psi

18” (46cm)

Voltage: 12-volt Negative

Ground Battery: 190 CCA

Fuse: 20 Amp

20 HP

Single Cylinder

Kohler Courage

498 lbs.

(225.9kg)

LT-0510

22 HP

Twin Cylinder

Kohler Courage

525 lbs.

(238kg)

CVT* Transaxle

42”, Two Blade,

Mower Deck

CVT = Constant Velocity Transaxle

2-6 LX Lawn Tractor Service Manual

13 Gauge Steel

42”, Two Blade,

13 Gauge Steel

46”, Three Blade,

12 Gauge Steel

46”, Three Blade,

12 Gauge Steel

50”, Three Blade,

12 Gauge Steel

CHASSIS

Front Pivot Axle Replacement

Removal

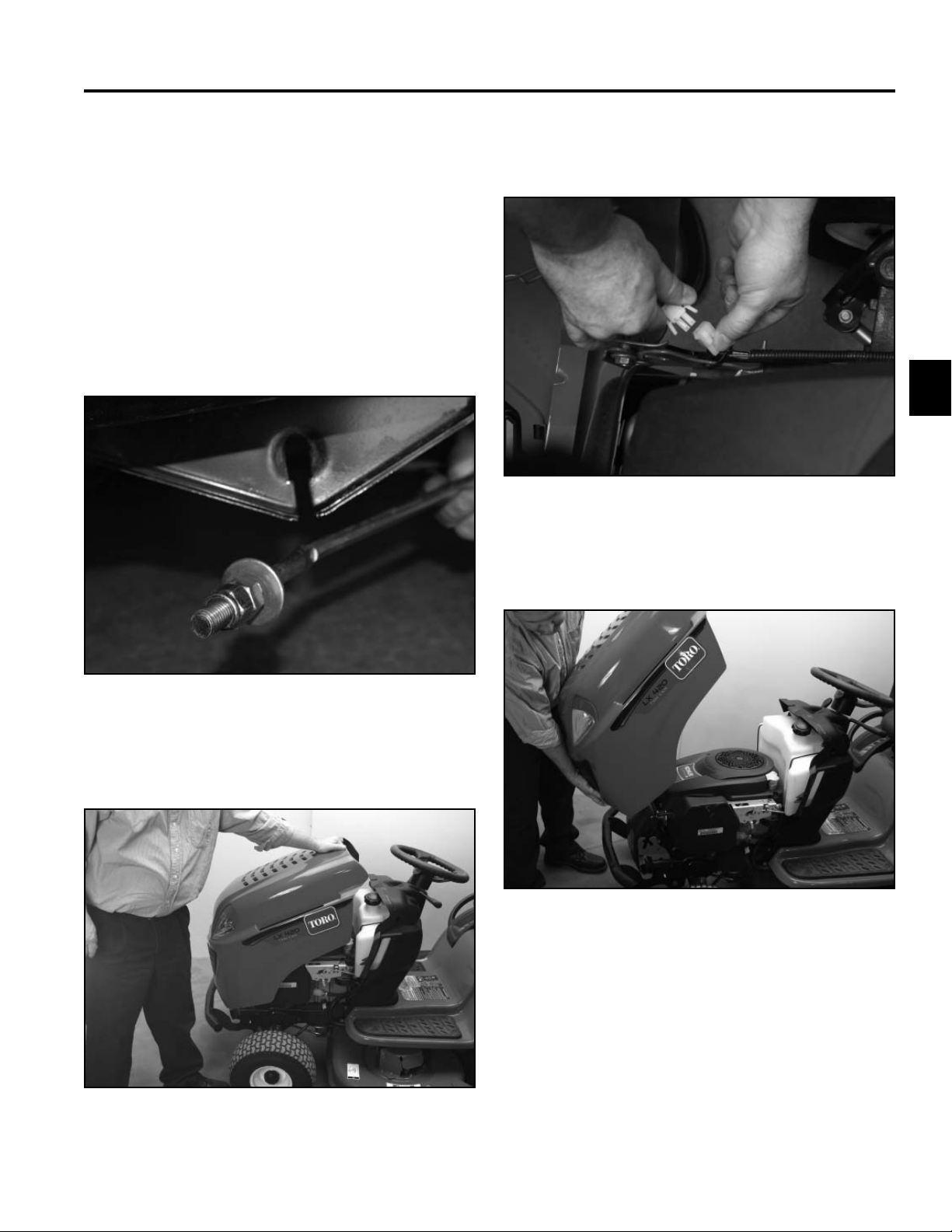

1. Disconnect the negative and then the positive

battery cable.

2. Remove the mower deck: 42” deck on page 7-64;

46” deck on page 7-69; 50” deck on page 7-74.

3. Remove the deck rod from the deck hanger bracket

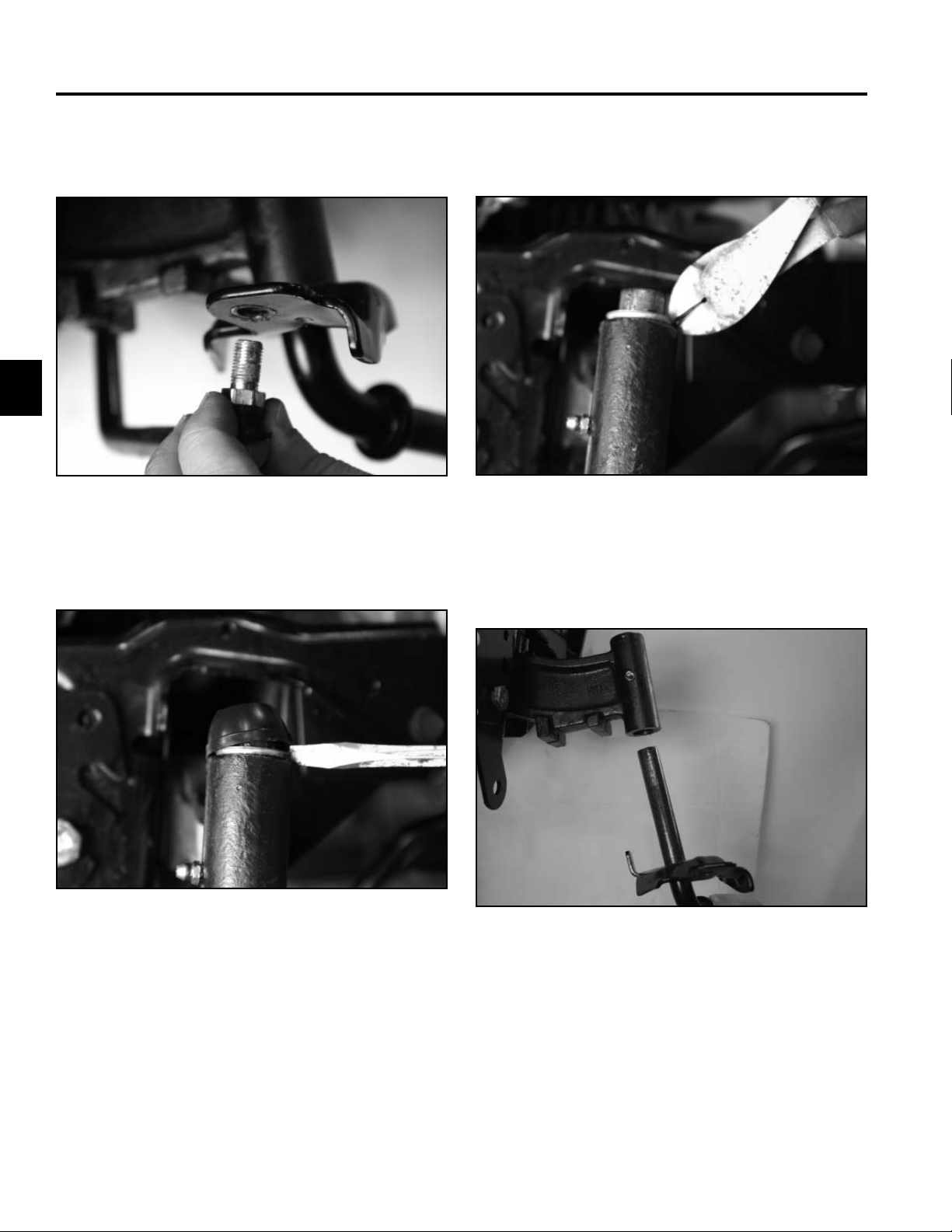

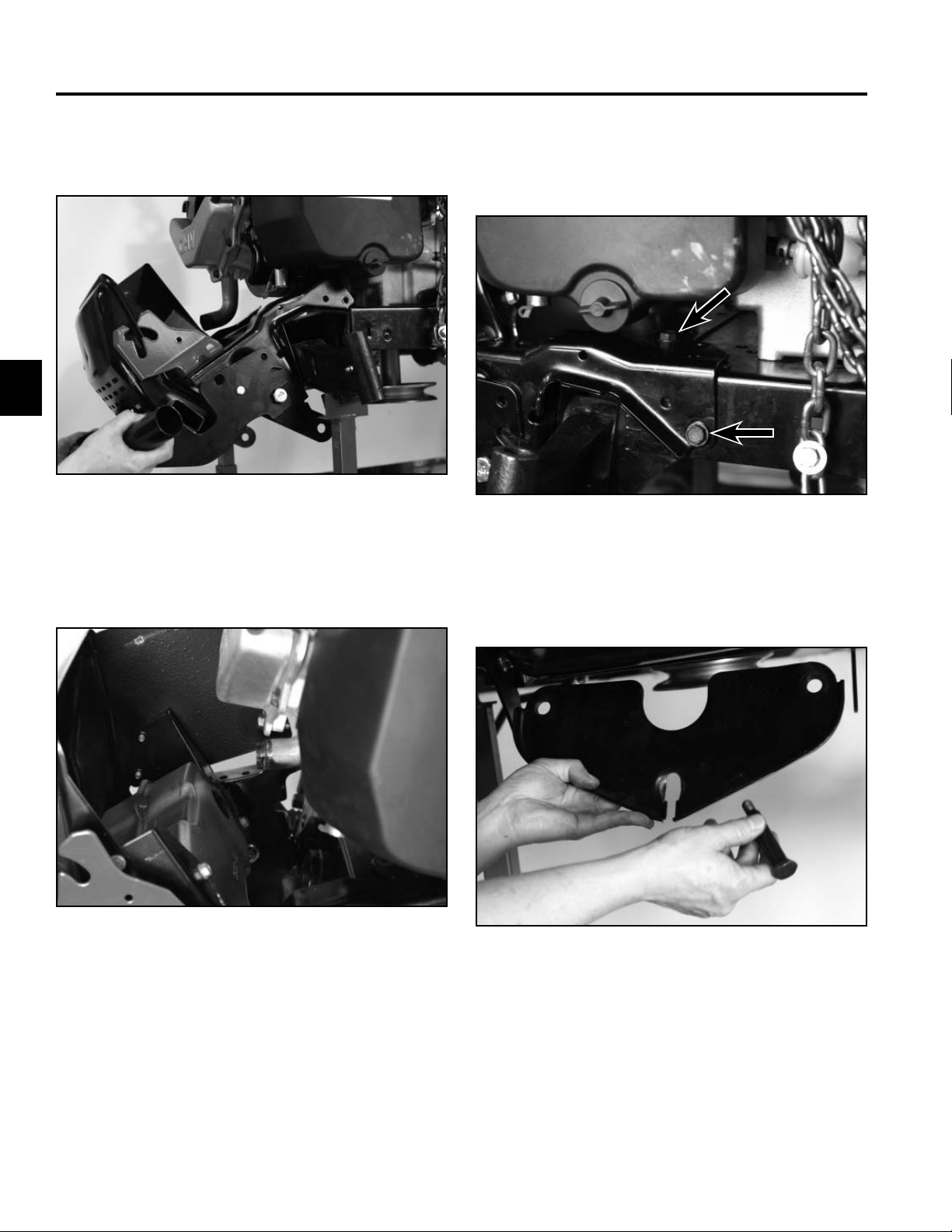

(Fig. 001).

5. Unplug the headlights from the wire harness (Fig.

003).

3

Fig 003 PICT-7064

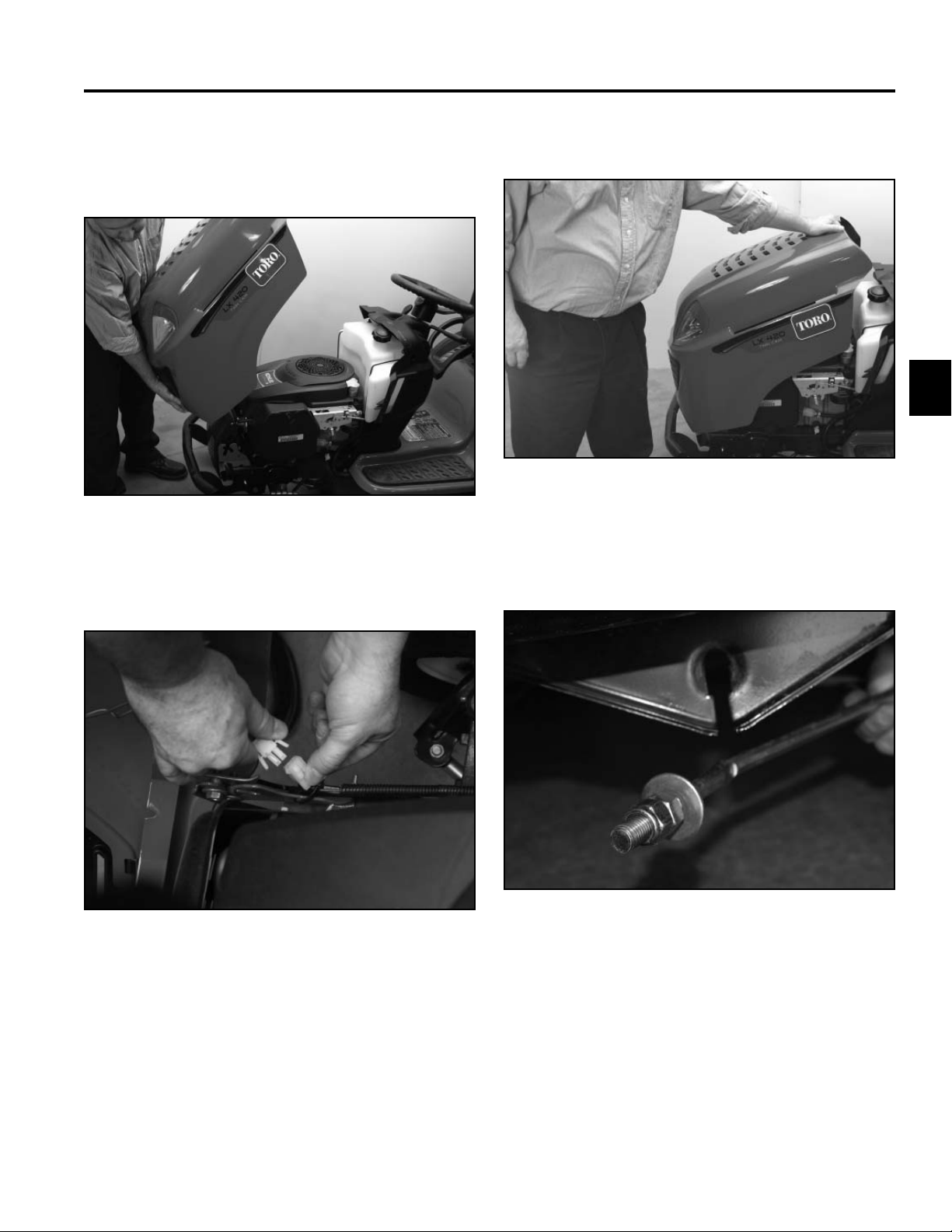

6. Remove the hood from the frame (Fig. 004).

Fig 001 PICT-7399a

4. Raise the hood (Fig. 002).

Fig 002 PICT-7063

Fig 004 PICT-7066

3-1LX Lawn Tractor Service Manual

3

CHASSIS

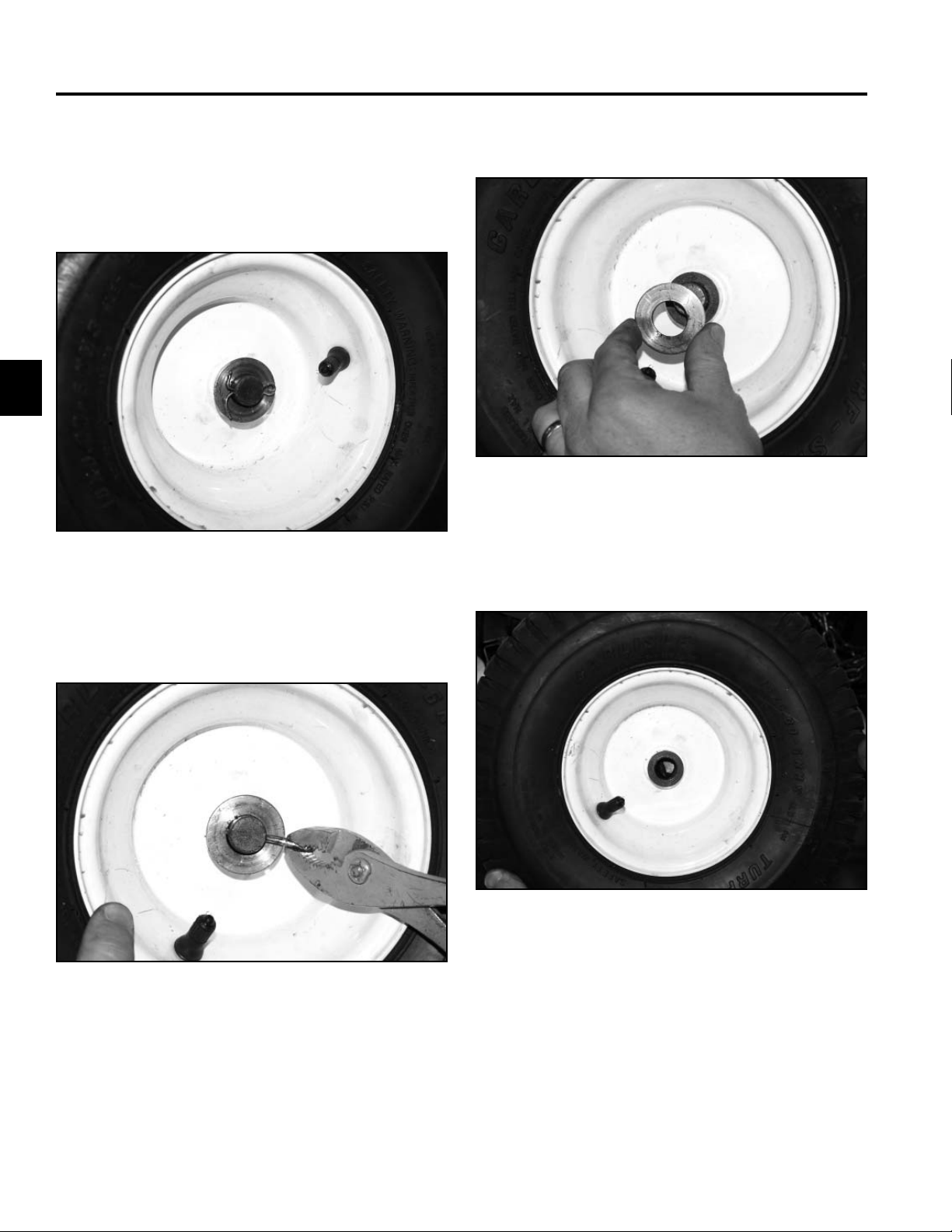

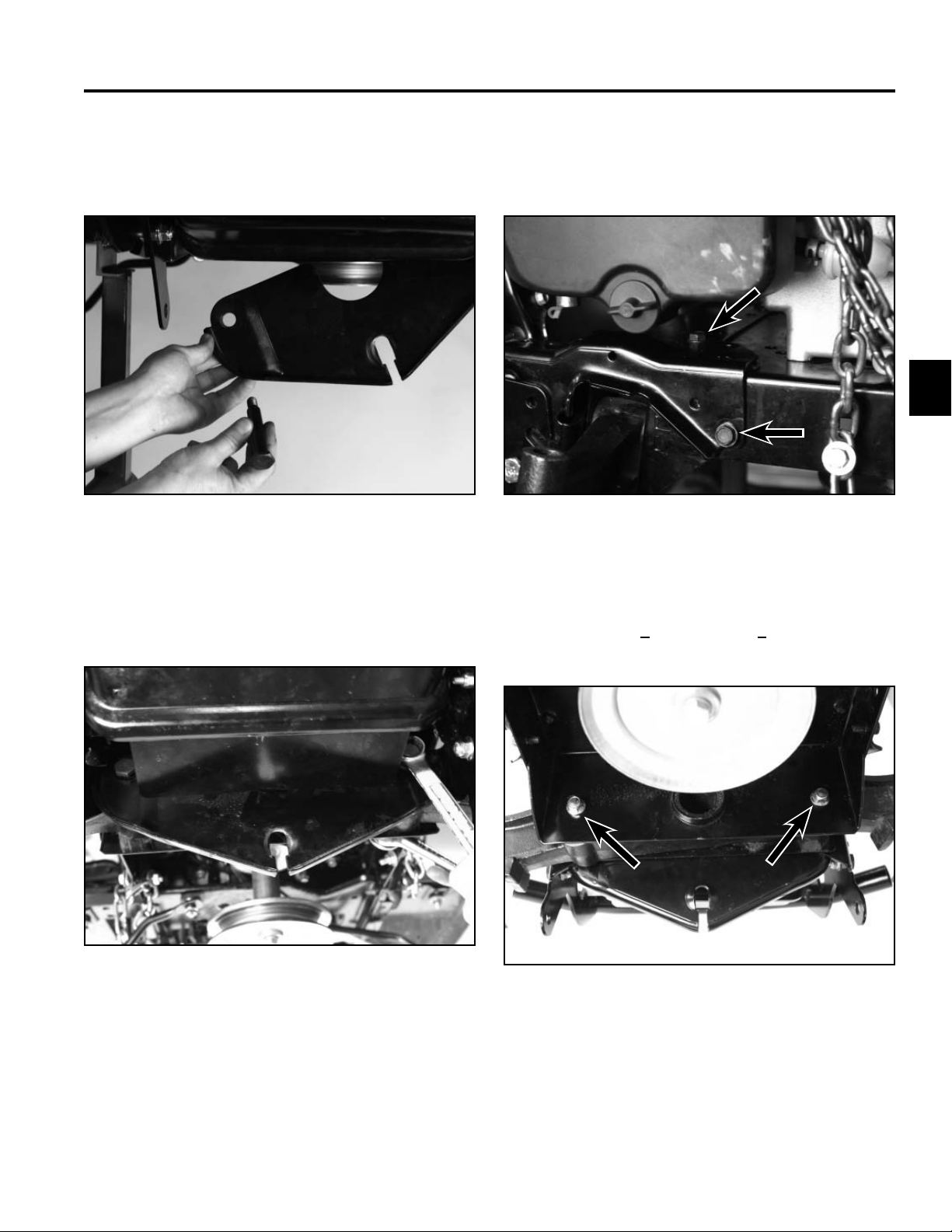

10. Remove the washer from the two axles (Fig. 007).7. Elevate and secure the front end of the machine so

the front axle can be accessed.

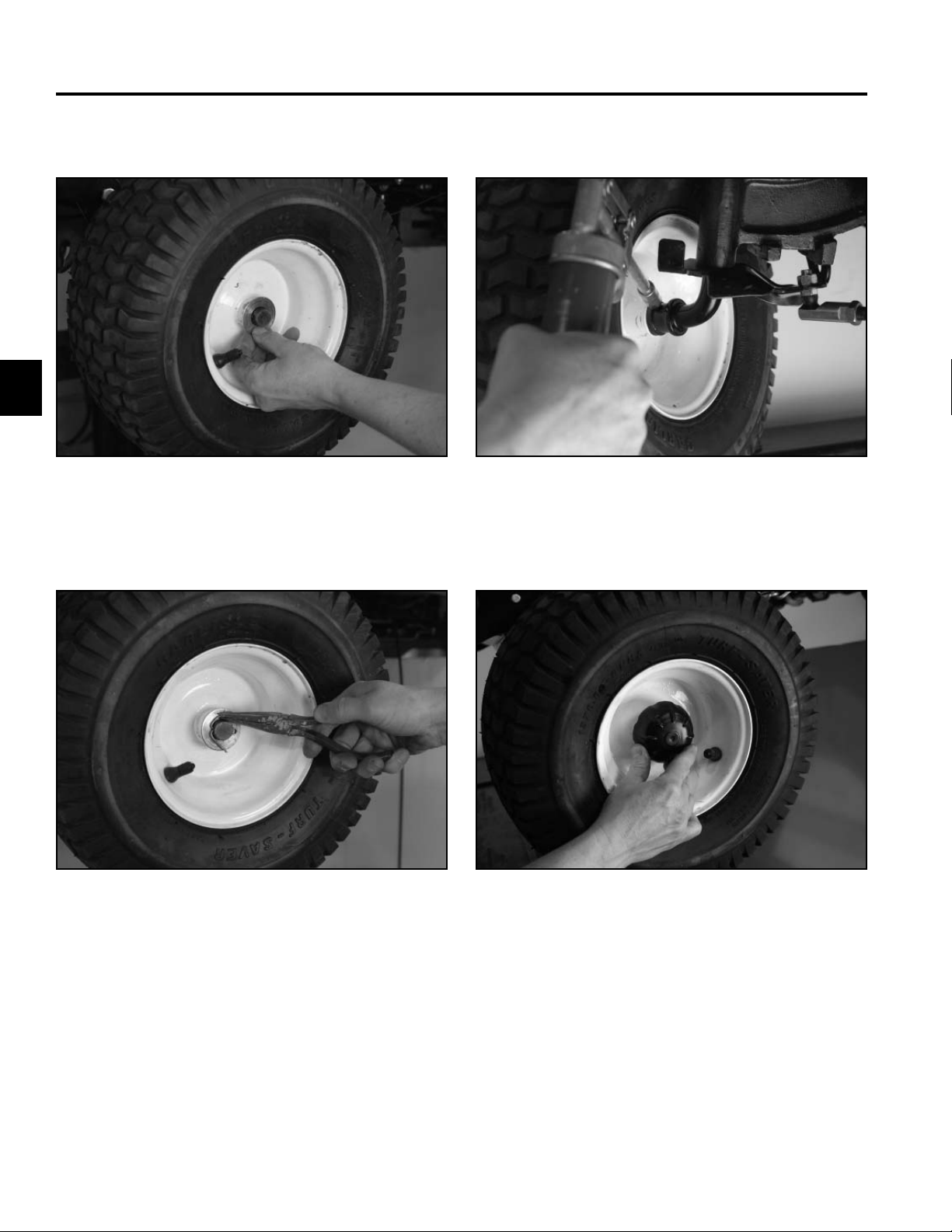

8. Remove the hub caps from the two front tires (Fig.

005).

Fig 007 PICT-7402

Fig 005 PICT-7400

9. Remove and discard the cotter pins from the two

axles (Fig. 006).

Fig 006 PICT-7401

11. Remove the wheel and tire assembly from the two

axle assemblies (Fig. 008).

Fig 008 PICT-7403

3-2 LX Lawn Tractor Service Manual

CHASSIS

Note: There are inner and outer bushings included

with the rim assembly. When the wheel is

removed, the inner bushing may come off

with the wheel or stay on the axle.

Bushing stays in rim of tire (Fig. 009):

Fig 009 PICT-7410a

12. Remove the bushing from each of the axle assem-

blies if it stayed in place at tire assembly removal

(Fig. 011).

3

Fig 011 PICT-7415a

13. Remove the nut securing the ball joint to the axle

assemblies (Fig. 012).

Bushing stays on axle (Fig. 010):

Fig 010 PICT-7413

Fig 012 PICT-7421

3-3LX Lawn Tractor Service Manual

CHASSIS

3

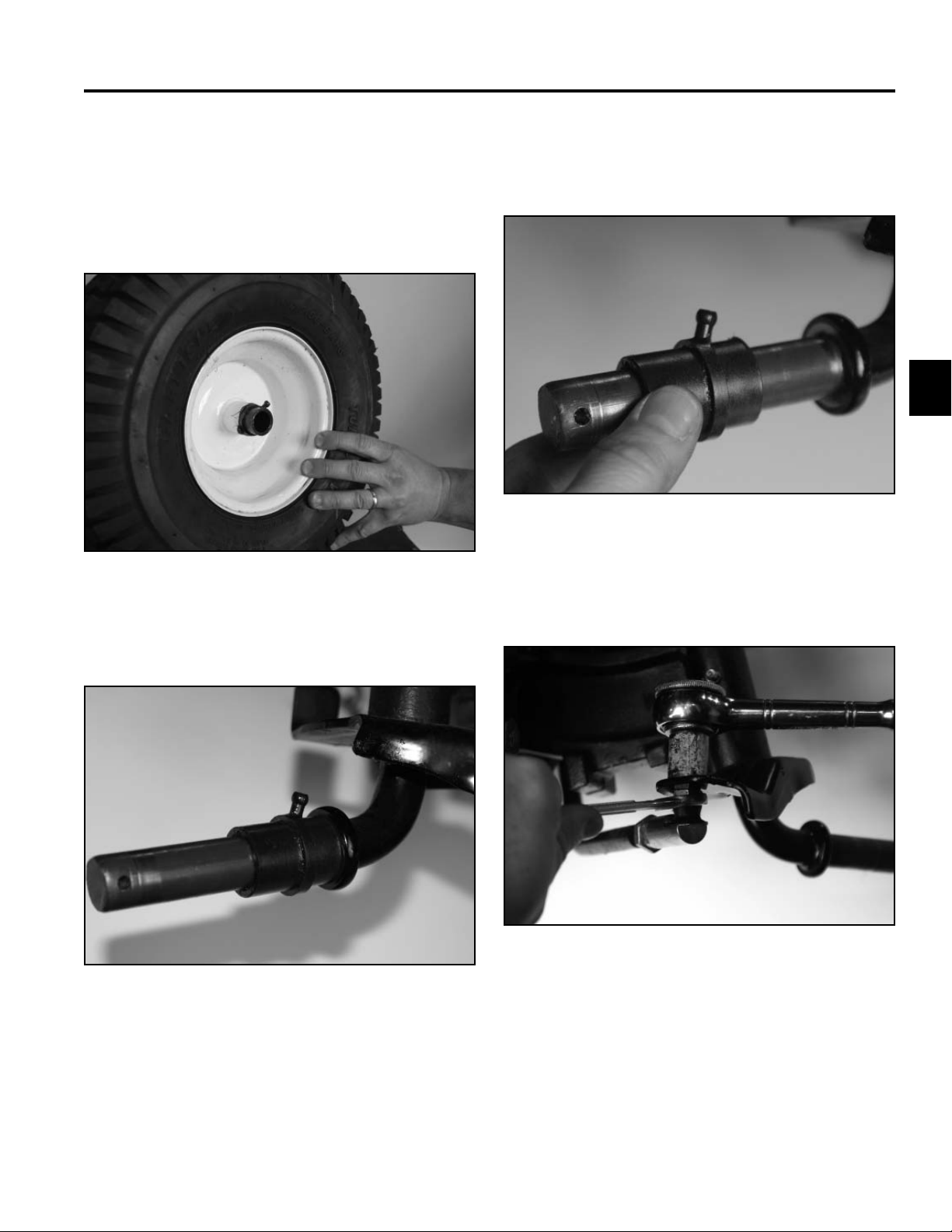

14. Remove the ball joint from the axle assembly (Fig.

013).

Fig 013 PICT-7423

15. Remove the cap from the axle assembly (Fig. 014). 17. Remove the axle assembly from the front pivot axle

16. Remove the push nut from the axle assembly (Fig.

015).

Fig 015 PICT-7425

(Fig. 016).

Fig 014 PICT-7424

Fig 016 PICT-7431a

18. Repeat steps 13-17 to remove the second axle.

3-4 LX Lawn Tractor Service Manual

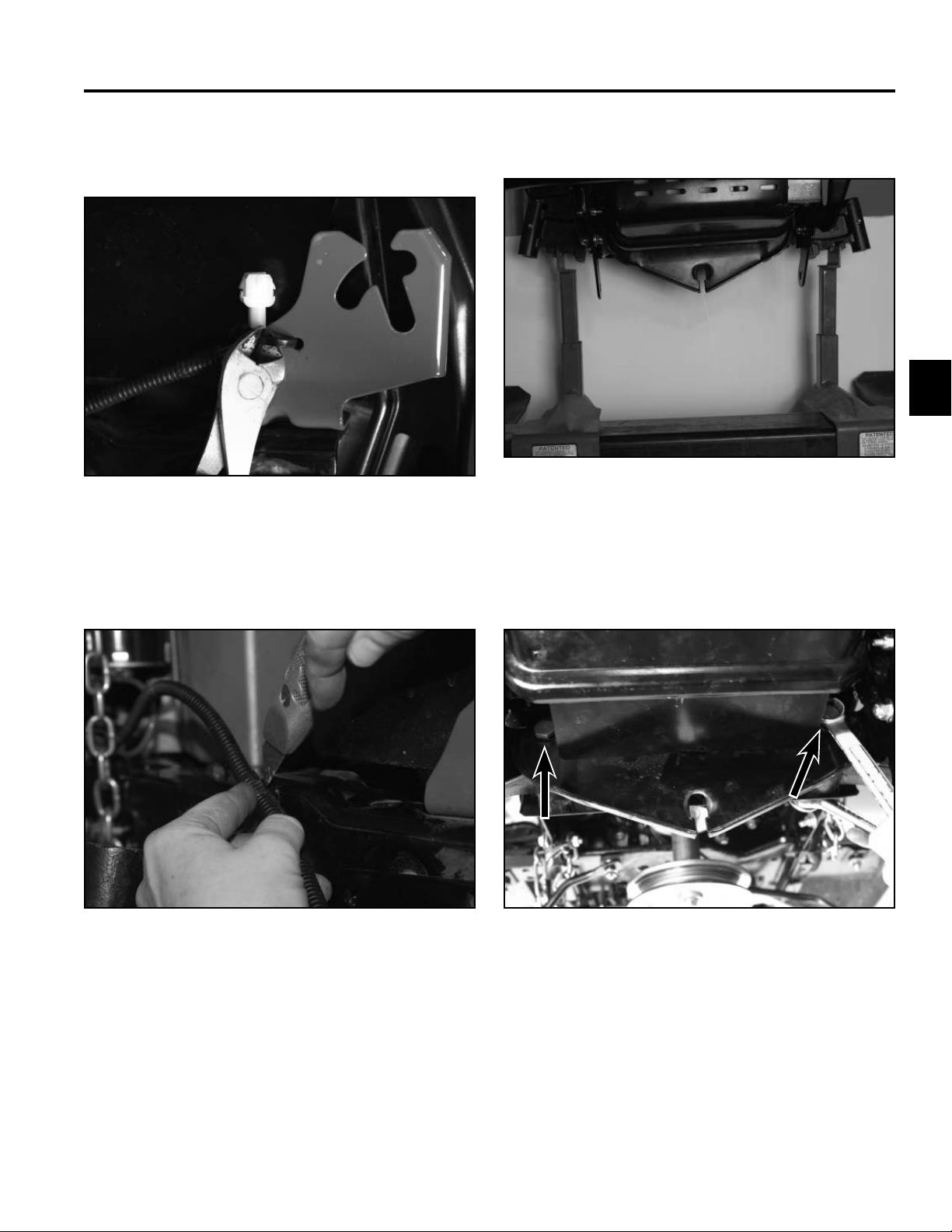

right hand hood pivot bracket (Fig. 017).

Fig 017 PICT-7434

CHASSIS

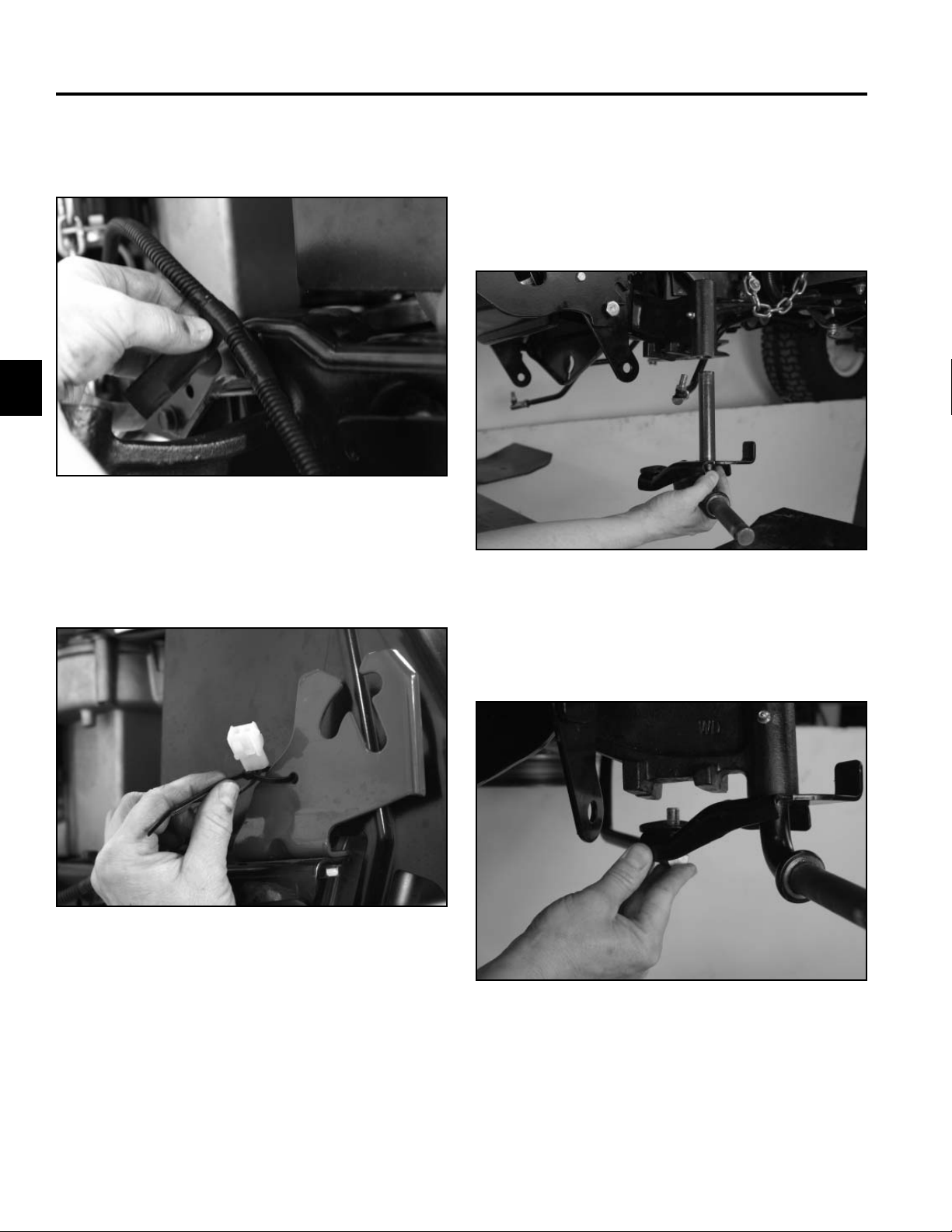

21. Support the front pivot axle (Fig. 019).19. Cut the cable tie securing the wire harness to the

3

Fig 019 PICT-7439a

20. Cut the electrical tape securing the wire harness to

the plastic harness guide (Fig. 018).

Fig 018 PICT-7462a

22. Remove the nuts from the 2 bolts securing the pivot

axle and deck hanger bracket to the frame (Fig.

020).

Fig 020 PICT-7442

3-5LX Lawn Tractor Service Manual

CHASSIS

3

23. Remove the 4 bolts (2 on the right, 2 on the left)

securing the left and right pivot supports to the frame

(Fig. 021).

Fig 021 PICT-7436

24. Remove one of the bolts securing the deck hanger

plate and pivot axle to the frame (Fig. 022).

25. Remove the second bolt and deck hanger plate from

the pivot axle (Fig. 023).

Fig 023 PICT-7447

26. Remove the muffl er, heat shield and bracket assem-

bly (Fig. 024).

Fig 024 PICT-7449

Fig 022 PICT-7444

3-6 LX Lawn Tractor Service Manual

CHASSIS

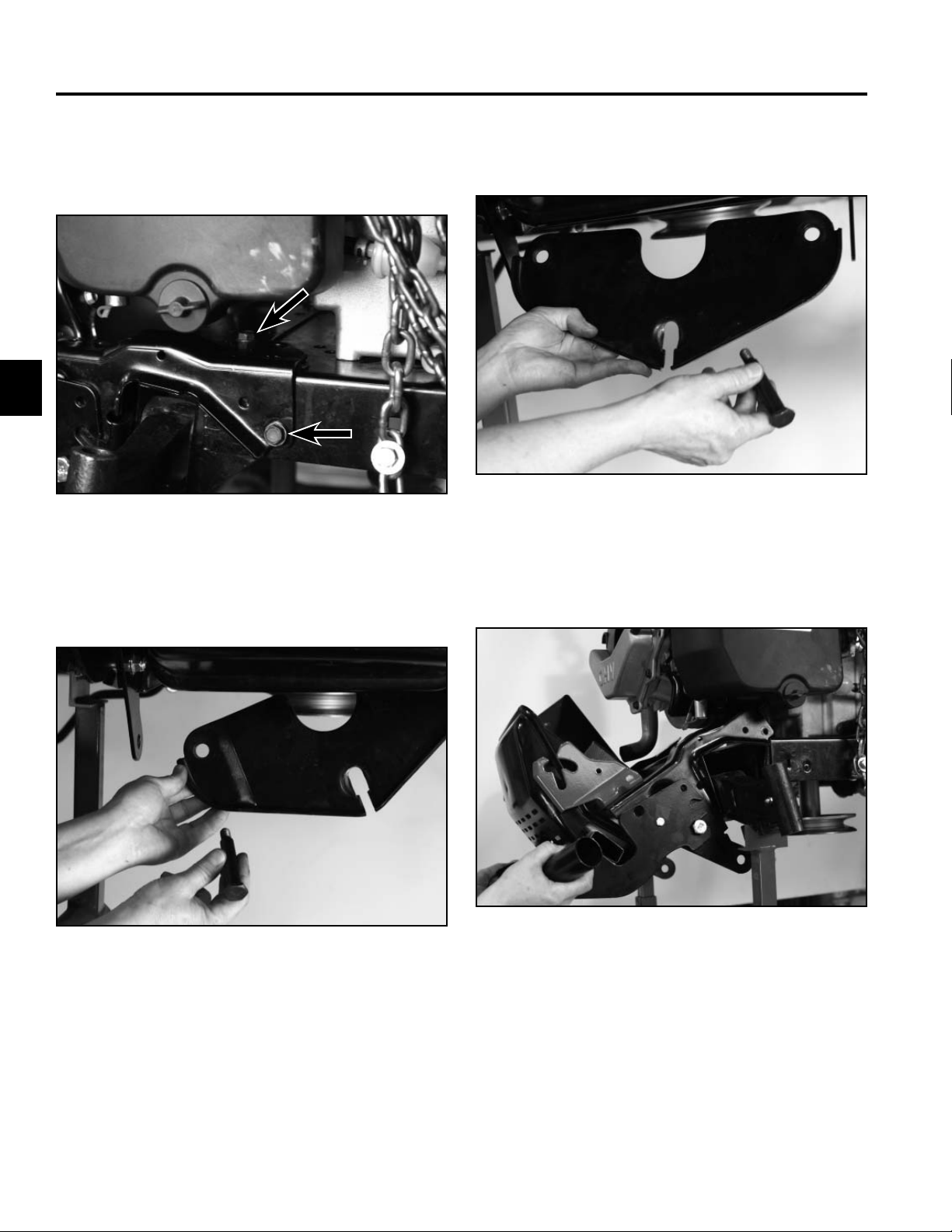

27. Remove the pivot bar bracket (Fig. 025).

Fig 025 PICT-7450

28. Remove the front pivot axle (Fig. 026).

Installation

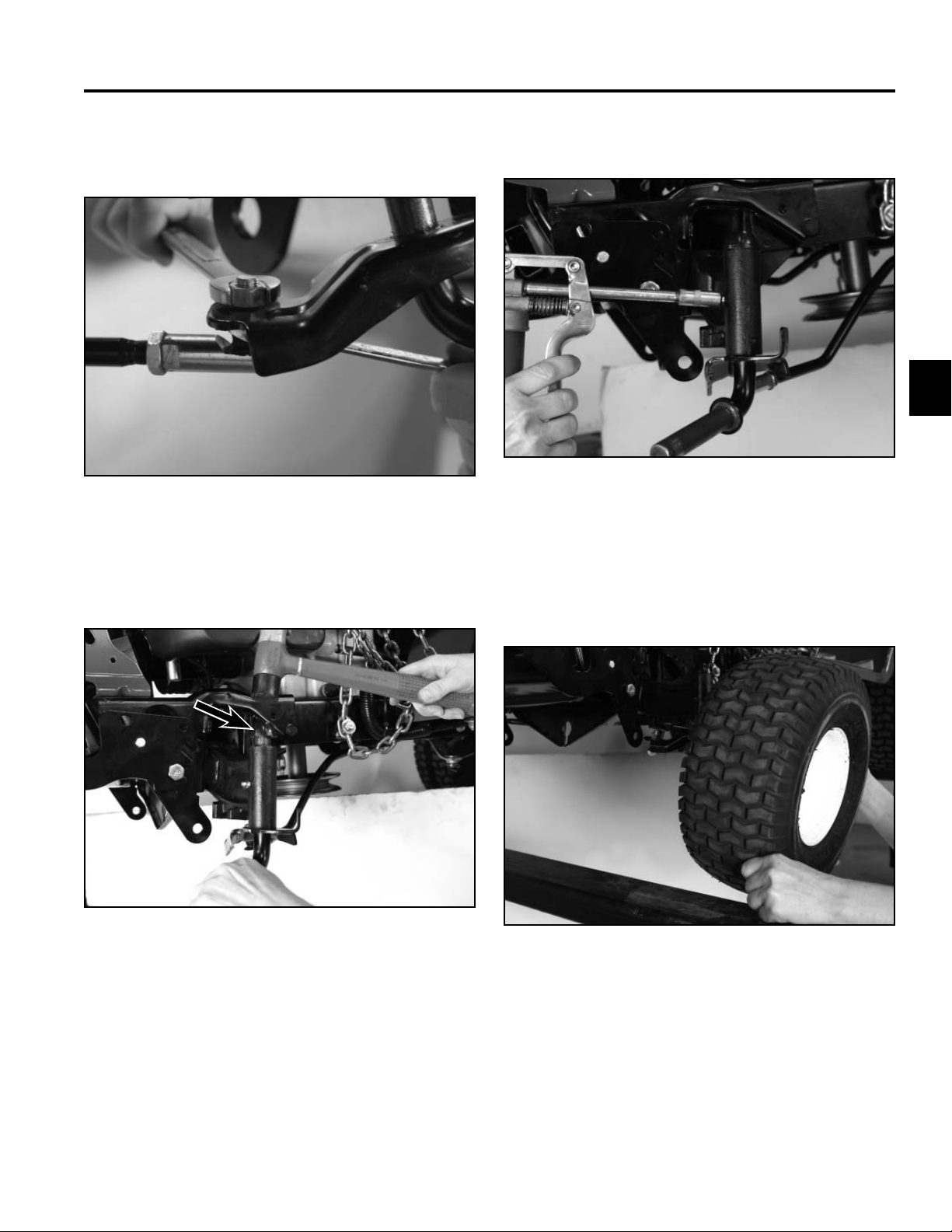

1. Position the front pivot axle to the front of the frame

(Fig. 027).

3

Fig 027 PICT-7451

Fig 026 PICT-7451

2. Position the pivot bar bracket to the front pivot axle

(Fig. 028).

Fig 028 PICT-7450

3-7LX Lawn Tractor Service Manual

CHASSIS

3

3. Position the muffl er, heat shield and bracket assem-

bly to the frame (Fig. 029).

Fig 029 PICT-7449

Note: The tailpipe needs to be aligned and inserted

into the muffl er upon assembly (Fig. 030).

4. Loosely install 4 bolts securing the left and right pivot

supports to the frame (2 bolts on the left side bracket

and 2 bolts on the right side bracket) (Fig. 031).

Fig 031 PICT-7436

5. Position the deck hanger plate to the pivot axle and

install a shoulder bolt (Fig. 032).

Fig 030 PICT-7457

Fig 032 PICT-7447

3-8 LX Lawn Tractor Service Manual

CHASSIS

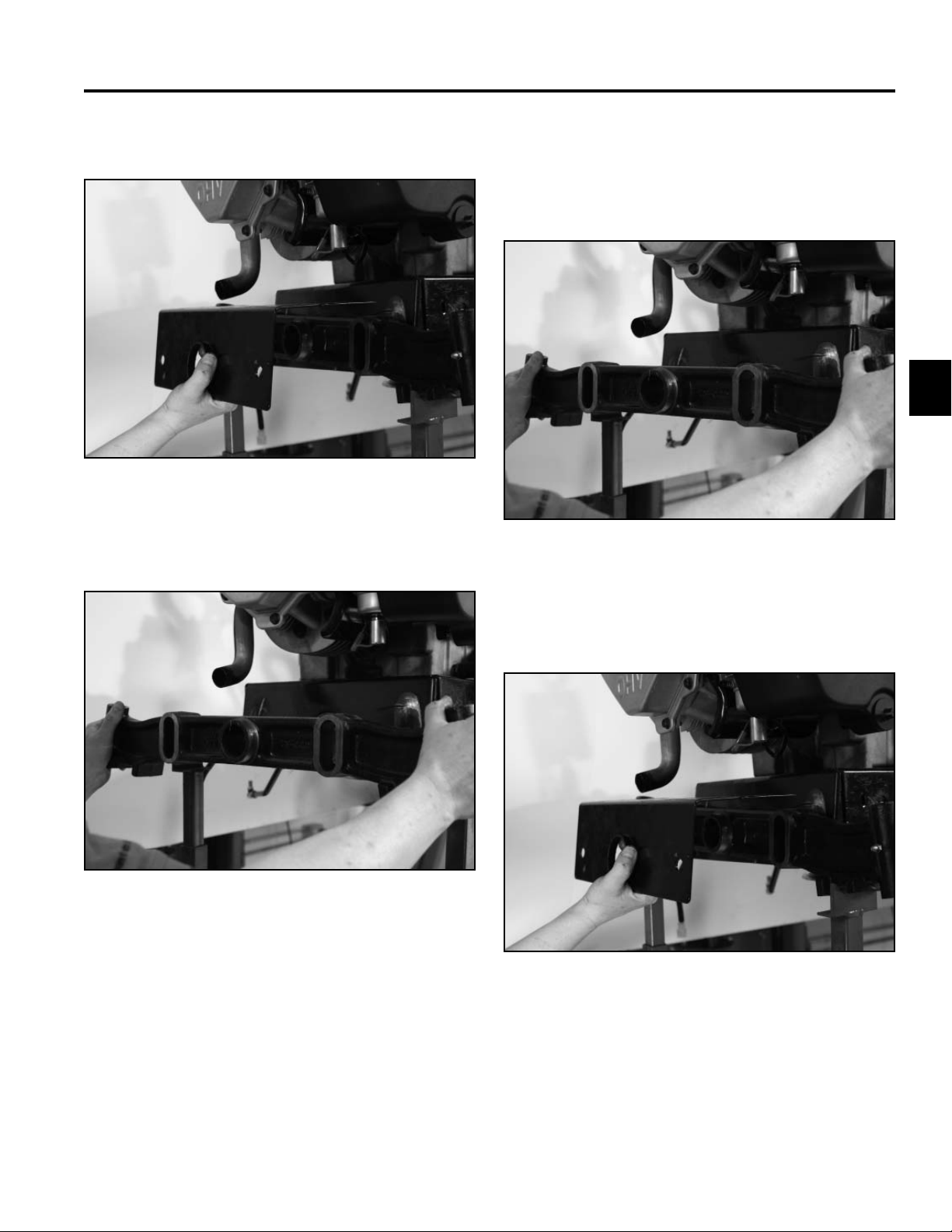

6. Align the second hole in the deck hanger bracket

with the pivot axle and install a second shoulder bolt

(Fig. 033).

Fig 033 PICT-7444

8. Tighten the 4 bolts securing the left and right pivot

supports to the frame (2 bolts on the left side bracket

and 2 bolts on the right side bracket) (Fig. 035).

3

Fig 035 PICT-7436

7. Loosely install a nut onto the 2 shoulder bolts securing the pivot axle and deck hanger bracket to the

frame (Fig. 034).

Fig 034 PICT-7442

9. Torque the 2 nuts installed on the shoulder bolts

securing the pivot axle and deck hanger bracket to

the frame to 30 + 3 ft-lbs. (40.67 + 4.06 Nm) (Fig.

036).

Fig 036 PICT-7460

3-9LX Lawn Tractor Service Manual

CHASSIS

3

10. Apply electrical tape to secure the wire harness to

the plastic harness guide (Fig. 037).

Fig 037 PICT-7464

11. Secure the wire harness to the right hand hood pivot

bracket with a cable tie (Fig. 038).

Note: The following steps, 12 thru 21, should be

done on both the right and left sides of the

axle.

12. Insert the axle assembly into the pivot axle (Fig.

039).

Fig 039 PICT-7468a

Fig 038 PICT-7466

13. Position the ball joint into the axle assembly (Fig.

040).

Fig 040 PICT-7469a

3-10 LX Lawn Tractor Service Manual

29 ft-lbs. (16.94 to 39.54 Nm) (Fig. 041).

Fig 041 PICT-7470a

CHASSIS

16. Apply grease to the axle assembly (Fig. 043).14. Install a nut onto the ball joint and torque to 12.5 to

3

Fig 043 PICT-7472

15. Install a cap/push nut onto the axle assembly (Fig.

042).

Fig 042 PICT-7471

17. Slide the wheel and tire assembly onto the axle

assembly (Fig. 044).

Note: The wheel bearing is installed in the rim.

Fig 044 PICT-7473

3-11LX Lawn Tractor Service Manual

3

CHASSIS

20. Apply grease to the wheel bearing (Fig. 047).18. Install a washer onto the axle assembly (Fig. 045).

Fig 045 PICT-7474a

19. Install a cotter pin into the axle assembly (Fig. 046). 21. Install the hub cap (Fig. 048).

Fig 046 PICT-7475a

Fig 047 PICT-7477a

Fig 048 PICT-7478

3-12 LX Lawn Tractor Service Manual

23. Position the hood on the chassis (Fig. 049).

Fig 049 PICT-7066

CHASSIS

25. Lower the hood (Fig. 051).22. Lower the machine.

3

Fig 051 PICT-7063

24. Plug the headlights into the wire harness (Fig. 050).

Fig 050 PICT-7064

26. Install the deck rod into the deck hanger bracket

(Fig. 052).

Fig 052 PICT-7399a

27. Install the mower deck: 42” deck on page 7-67; 46”

deck on page 7-72; 50” deck on page 7-76.

28. Connect the positive and then the negative battery

cable.

29. Check the toe-in measurement and adjust as needed. Refer to “Front Wheel Toe-In Measurement” on

page 3-85.

3-13LX Lawn Tractor Service Manual

CHASSIS

3

Axle Assembly Replacement

Removal

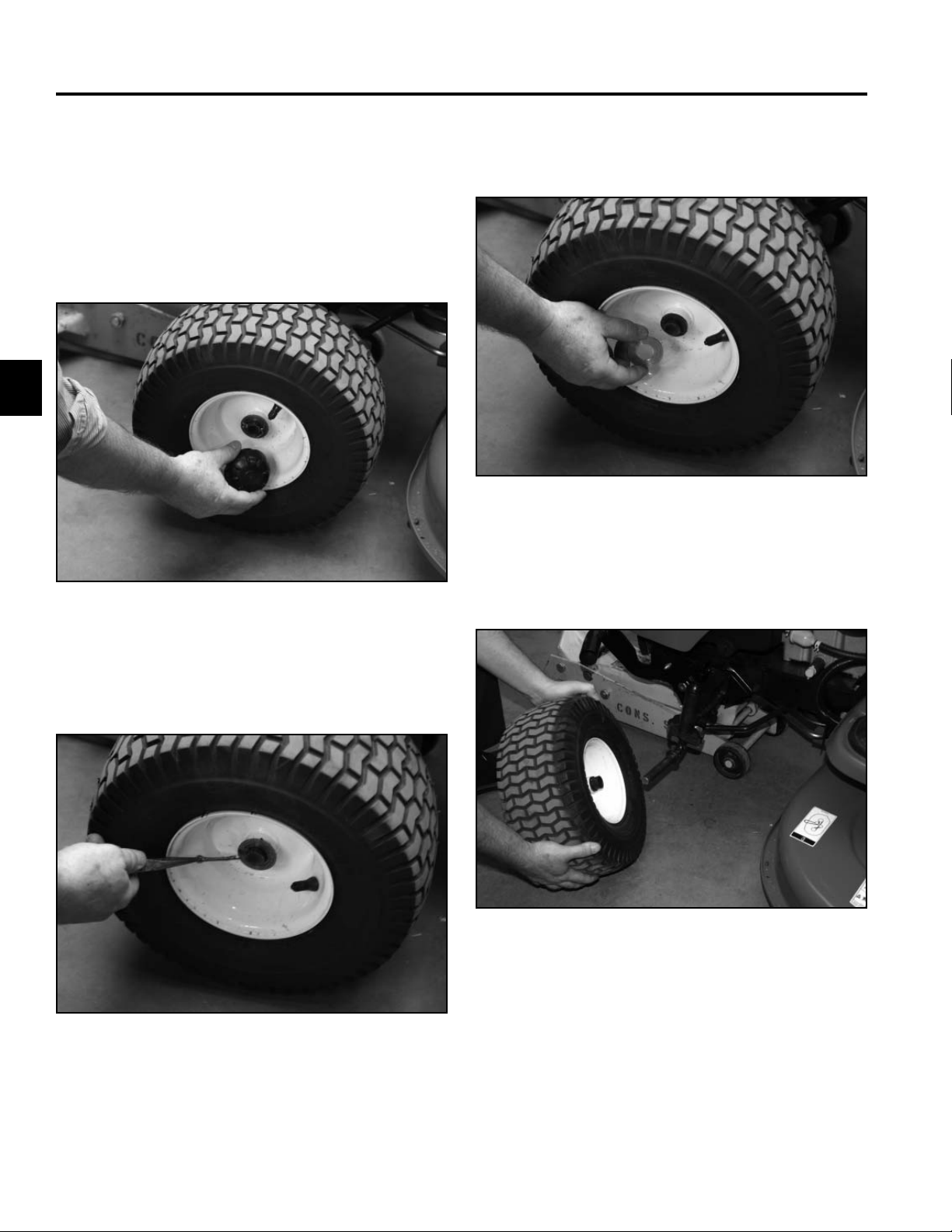

1. Raise the front of the machine.

2. Remove the hub cap (Fig. 053).

Fig 053 PICT-7067

4. Remove the washer from the axle assembly (Fig.

055).

Fig 055 PICT-7070

5. Remove the wheel and tire assembly from the axle

assembly (Fig. 056).

3. Remove the cotter pin from the axle assembly (Fig.

054).

Fig 054 PICT-7069

Fig 056 PICT-7072

3-14 LX Lawn Tractor Service Manual

CHASSIS

Note: There are inner and outer bushings included

with the rim assembly. When the wheel is

removed, the inner bushing may come off

with the wheel or stay on the axle assembly.

Bushing stays in rim of tire (Fig. 057):

Fig 057 PICT-7410a

6. Remove the bushing from each of the axle assem-

blies if it stayed in place at tire assembly removal

(Fig. 059).

3

Fig 059 PICT-7415a

7. Remove the nut securing the ball joint to the axle

assembly (Fig. 060).

Bushing stays on axle assembly (Fig. 058):

Fig 058 PICT-7413

Fig 060 PICT-7077a

3-15LX Lawn Tractor Service Manual

CHASSIS

3

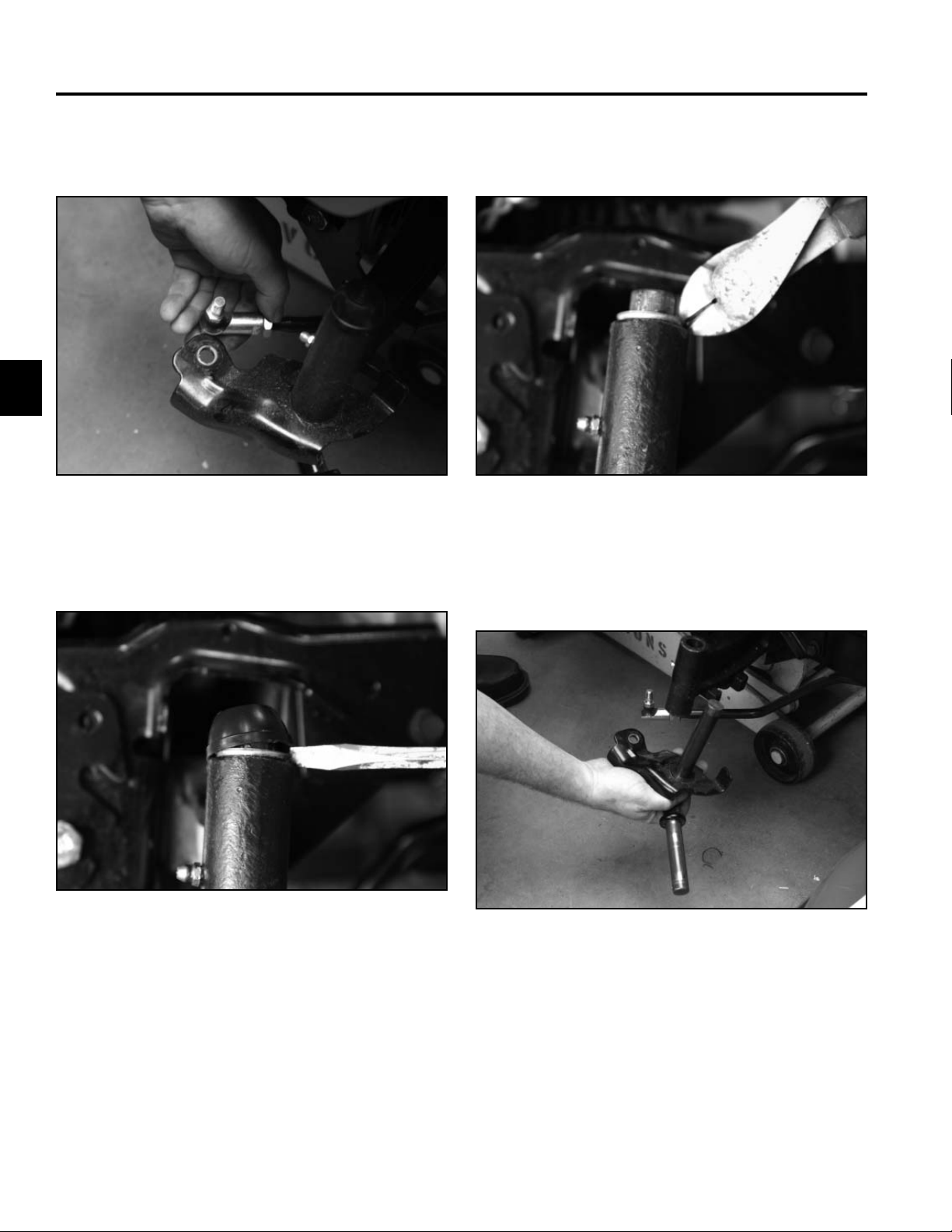

8. Remove the ball joint from the axle assembly (Fig.

061).

Fig 061 PICT-7078

9. Remove the cap from the axle assembly (Fig. 062).

10. Remove the push nut from the axle assembly (Fig.

063).

Fig 063 PICT-7425

11. Remove the axle assembly from the axle pivot (Fig.

064).

Fig 062 PICT-7424

Fig 064 PICT-7087

3-16 LX Lawn Tractor Service Manual

Loading...

Loading...