Page 1

Installation

LooseParts

FormNo.3406-164RevB

LoaderArmWearStripKit

TX1000CompactToolCarrier

ModelNo.133-0241

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Lefttemplate

1

2

3

Righttemplate1

Guide

Hex-socketbolt2

Leftwearpad

Rightwearpad1

Bolt(1/4x3/8inch)

Bolt(1/4x5/8inch)

Washer2

Locknut2

Thread-lockingcompound1

Nopartsrequired

Qty.

10

Use

1

2

1

6

–

Preparethemachine.

Installthekit.

Completetheinstallation.

©2016—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3406-164*B

Page 2

1

PreparingtheMachine

Partsneededforthisprocedure:

1

Lefttemplate

1Righttemplate

PreparingtheLoaderArms

1.Parkthemachineonalevelsurface,lowertheloader

arms,settheparkingbrake,shutofftheengine,and

removethekeyfromtheignitionswitch.

2.Removeanyattachmentsonthemachine.

3.Removeandretainthespacers,hoseplates,andbolts

thatsecurethehydraulichosestotheloaderarms

(Figure1).

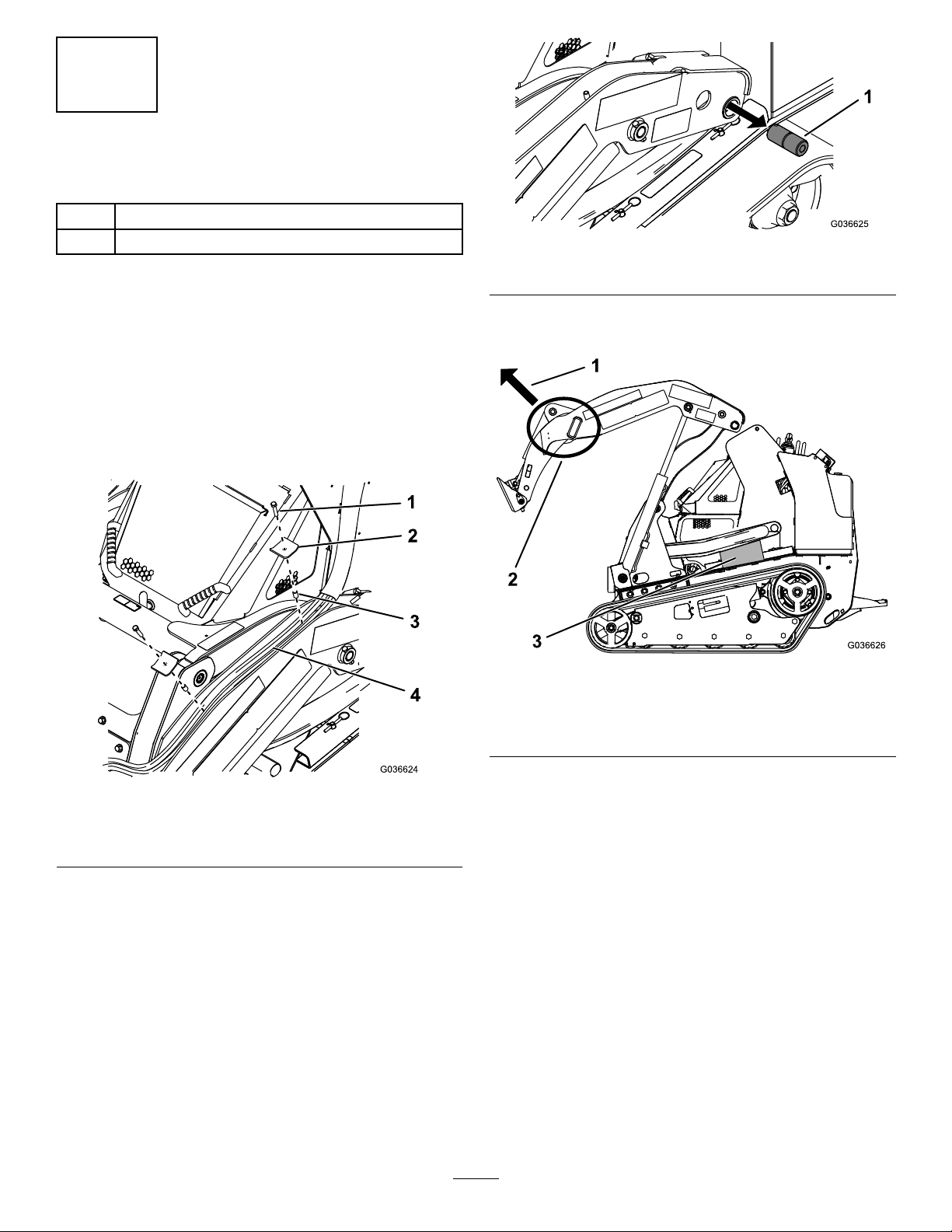

Figure2

1.Pin

6.AttachahoisttothelocationshowninFigure3and

carefullylifttheloaderarmassemblyupandforward.

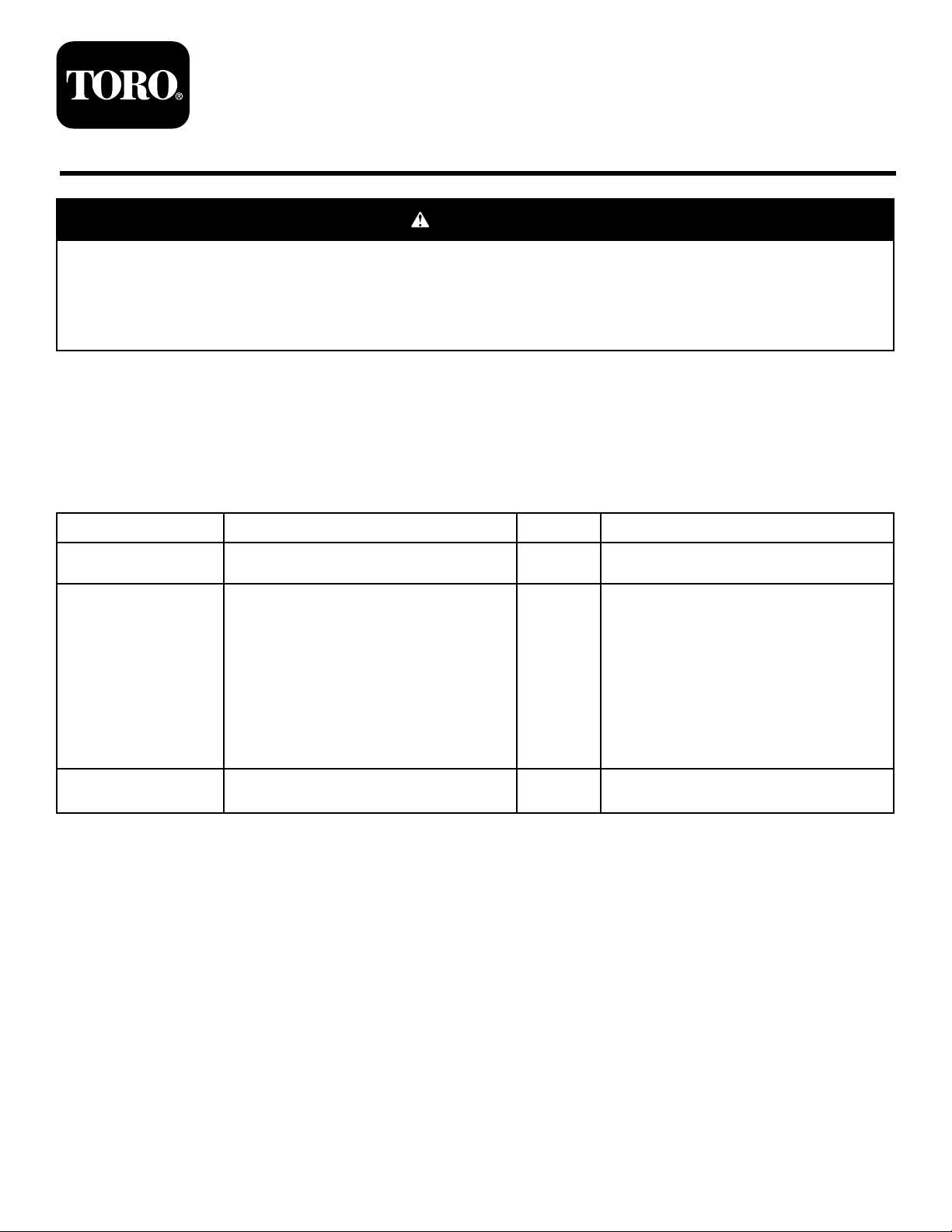

Figure1

1.Bolt

2.Hoseplate4.Hoses

4.Movethehosesofftheloaderarms.

5.Removethenutandboltsecuringthepinsintheleft

andrightlowerlinksontheloaderarmassemblyand

removethepins(Figure2).

Note:Thelowerlinkscanmoveupwiththeloader

armassemblywhenraisedwithoutthepins.Placea

woodblockbetweentheframeandlowerlinkbefore

liftingthearmsorpreparetocapturethelowerlink

beforeitfalls(Figure3).Donotuseyourhandsto

supportorcatchthelowerlinkonceitisfreefromthe

assembly.

3.Spacer

Figure3

1.Lifttheloaderarm

assemblythisdirection.

2.Attachthehoisthere.

7.Oncethelowerlinksarefreefromtheassembly ,liftthe

loaderarmsuntiltheyarepasttheframe.

3.Woodblock

2

Page 3

DrillingtheHoles

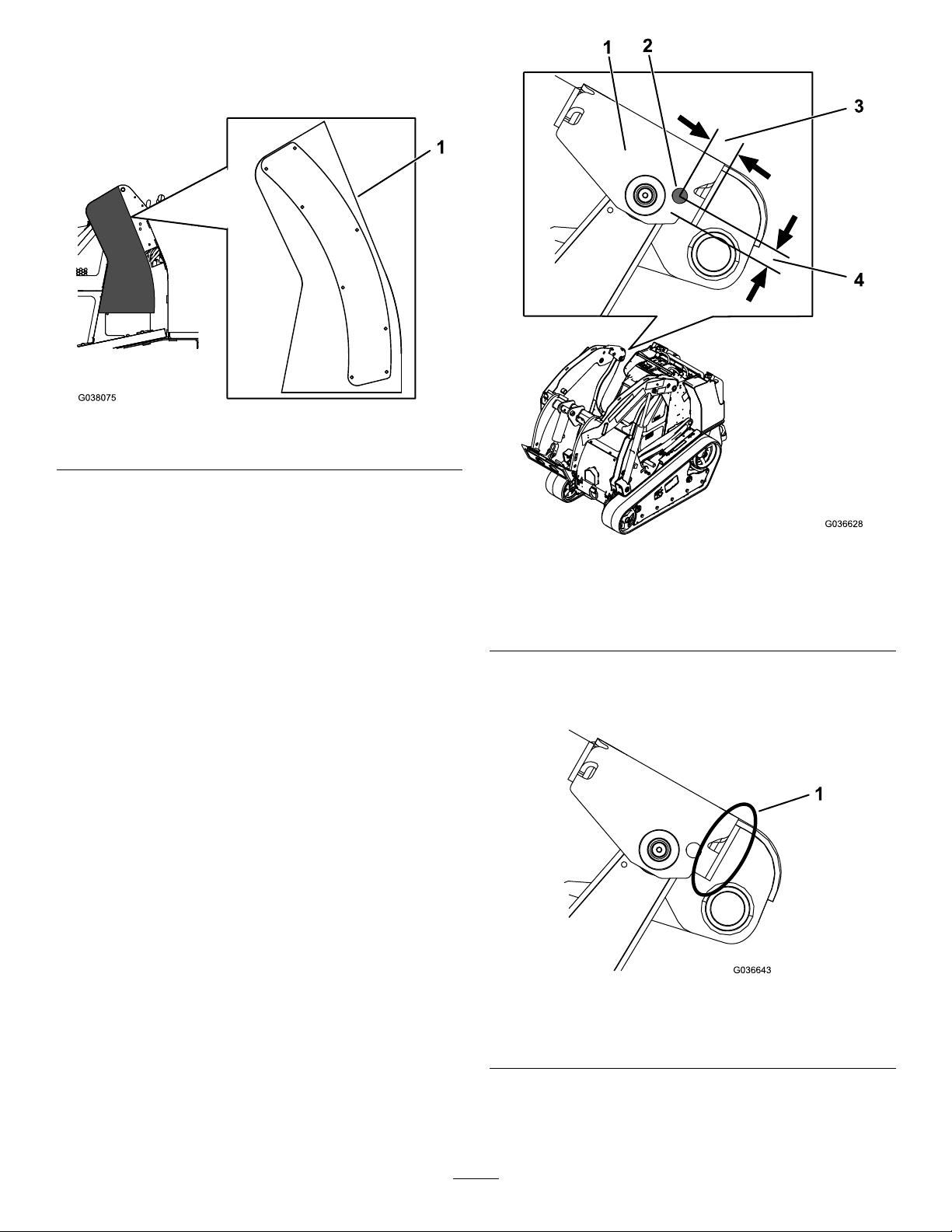

1.Tapethetemplatestocorrespondingsidesofthe

machine(Figure4).

Figure4

1.Lefttemplateandwearpad

2.Alignthewearpadstothetemplateandmarkthewear

padholesontothetemplate.

3.Drillholes(13/64-inchdiameter)atthelocations

thatyoumarked.Tapthreadsintheholes(1/4-inch

diameter,20threadsperinch).

Note:Theholesonthetemplateexistonlyasa

reference.

4.Drillahole(11/16-inchdiameter)intheconnectarm

plateoftheleftandrightloaderarmsatthelocation

showninFigure5.

Note:Youmayneedtodrillmultipletimestoachieve

thedesiredholesize.

Figure5

Insideofrightarmshown

1.Connect-armplate3.2.5cm(1inch)

2.Drillhere.

4.2.1cm(0.83inch)

5.Ifnecessary,grindtheedgeoftheconnect-armplateat

thelocationshowninFigure6toincreasetheclearance

betweenthemachineframeandloaderarm.

Figure6

Rightarmshown

1.Grindthisedge.

6.Cleanallmetalshavingsfromthemachineandpaint

exposedmetal.

3

Page 4

2

InstallingtheKit

Partsneededforthisprocedure:

2

Guide

2Hex-socketbolt

1

Leftwearpad

1Rightwearpad

6

Bolt(1/4x3/8inch)

10

Bolt(1/4x5/8inch)

2Washer

2Locknut

1Thread-lockingcompound

Procedure

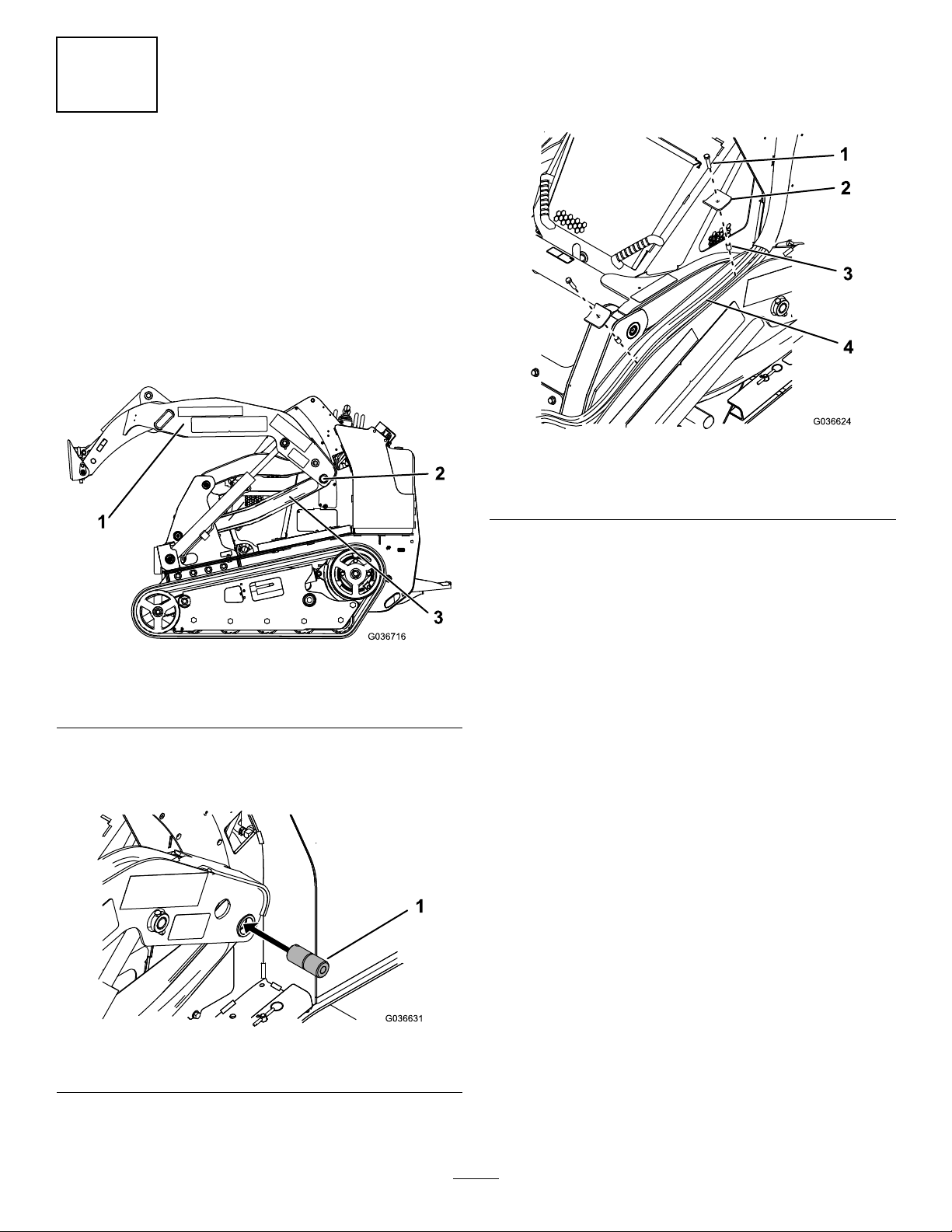

1.Installahex-socketbolt,guide,washer,andlocknutin

eachholethatyoudrilledintheloaderarms(Figure7).

1.Bolt(1/4x3/8inch)

2.Bolt(1/4x5/8inch)

Figure8

Wearpadwith6holes

3.Wearpad

Figure7

1.Hex-socketbolt3.Washer

2.Guide

4.Locknut

2.Addthreadlockingcompoundtotheboltsinthekit

andusethemtoinstalltheleftandrightwearpadsto

themachine(Figure8orFigure9).

Note:Ifthewearpadshave6holes,useonly4bolts

(1/4x3/8inch)and8bolts(1/4x5/8inch).Ifthe

wearpadshave12holes,useall6bolts(1/4x3/8

inch)and10bolts(1/4x5/8inch);youwillnotuseall

theholesinthewearpad.

1.Bolt(1/4x3/8inch)

2.Bolt(1/4x5/8inch)

Figure9

3.Wearpad

4

Page 5

3

CompletingtheInstallation

NoPartsRequired

Procedure

1.Lowertheloaderarmssothattheholesalignwiththe

holesinthelowerlinkswhenyouliftupthelowerlinks

(Figure10).Donotresttheloaderarmsagainstthe

frame.

Note:Youmayneedtolowerandlifttheloaderarms

multipletimestobeabletolineuptheholes.

4.Completelylowertheloaderarms.

5.Installthehosesandhardwarethatyouremovedin

PreparingtheLoaderArms(page2)asshowninFigure

12.

Figure12

Figure10

1.Loaderarm3.Lowerlink

2.Theholesarealigned.

2.Liftupthelowerlinksuntiltheholesalignwiththe

holesintheloaderarmassemblyandinstallthepins

(Figure8).

1.Bolt

2.Hoseplate4.Hoses

3.Spacer

Figure11

1.Pin

3.InstalltheboltandnutthatyouremovedinPreparing

theLoaderArms(page2)tosecurethepin.

5

Page 6

Notes:

Page 7

Notes:

Page 8

Loading...

Loading...