Page 1

PowerDeckLiftKit

ZMaster3000,5000,and6000SeriesMowers

ModelNo.132-5986

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Note:ThiskitisnotcompatiblewithmachinesthathavetheMyRide™suspensionsystem.

Safety

FormNo.3405-296RevA

InstallationInstructions

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotentialdanger.

Replaceanydecalthatisdamagedorlost.

119–6807

1.Warning—nostep

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

132-5992

1.Pressdownonthepedaltoliftthedeck.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3405-296*A

Page 2

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

Nopartsrequired

Deckfootpedal

Switchtemplate

Momentaryswitch1

Powerliftfootpedal

Screw(1/4x3/4inch)

Flatwasher(1/4inch)

Whiz-locknut(1/4inch)

ZMaster6000seriestemplate1

ZMaster3000/5000seriestemplate

Actuatorbracket1

Screw(7/16x4–1/2inches)

Springdiscwasher(7/16inch)

Whiz-locknut(7/16inch)

Screw(3/8x3–1/2inches);forZMaster

6000seriesunitsonly

Conediscwasher

Whiz-locknut(3/8inch)

Screw(3/8x3–1/4inches);forZMaster

3000and5000seriesunitsonly

Nylocnut1

Frontdeckliftbracket

Screw(1/2x6–1/2inches)

Springdiscwasher(1/2inch)

Locknut(1/2inch)

Actuator1

Clevispin

Cotterpin

Actuatorsideplate2

Flatwasher(1/2inch)

Spacer

Screw(1/2x2–1/2inches)

Wireharness1

Cabletie

Fuse,25A1

Fuse,30A1

Qty.

Use

–

1

1

1

2

2

2

1

1

1

1

1

1

1

1

1

2

2

3

2

2

2

2

1

8

Preparethemachine.

Installthedeckfootpedal.

Installthepowerliftfootpedaland

switch.

Installtheactuatorbracket.

Installtheactuator.

Installthedeckliftharness.

7

8

Nopartsrequired

Nopartsrequired

2

–

–

Completetheinstallation.

Makethenaldeckliftadjustment.

Page 3

1

2

PreparingtheMachine

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface,disengagethePTO ,

movethemotion-controlleverstotheNEUTRAL-LOCK

position,shutofftheengine,settheparkingbrake,and

removethekeyfromtheignitionswitch.

CAUTION

Ifyouleavethekeyintheignitionswitch,

someonecouldaccidentlystarttheengineand

seriouslyinjureyouorbystanders.

Removethekeyfromtheignitionswitch

beforeyouperformanymaintenance.

2.Disconnectthenegativecablefromthebatterypost;

refertotheOperator’ sManualforyourmachine.

InstallingtheDeckFootPedal

Partsneededforthisprocedure:

1

Deckfootpedal

Procedure

WARNING

InstallingthepowerliftfootpedalonZMaster3000,

5000,and6000seriesmowerswithoutreplacingthe

deckfootpedalcouldresultinseriousinjury.

Replacethedeckfootpedalonallunits.

Note:Usetheexistinghardware.

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

3.Disconnectthepositivecablefromthebatterypost;

refertotheOperator’ sManualforyourmachine.

4.Removethespark-plugwirefromtheterminalofthe

sparkplug.

Figure1

3

Page 4

4.Insertthebottomhalfoftheswitchthroughthe

undersideofthetoeboard,makingsurethecontacts

3

pointdownward(Figure2).Screwonthetophalfof

theswitchhand-tight.Donotovertighten.

InstallingthePowerLiftFoot

PedalandMomentarySwitch

Partsneededforthisprocedure:

1

Switchtemplate

1Momentaryswitch

1

Powerliftfootpedal

2

Screw(1/4x3/4inch)

2

Flatwasher(1/4inch)

2

Whiz-locknut(1/4inch)

Procedure

1.Raiseandlockthedeckinthe14cm(5–1/2inch)

transportposition.

2.Cutouttheswitchtemplate,alignthetemplateas

showninFigure2,centerpunchtheholes,anddrill

theholesasfollows:

•Fortheswitch-mountinghole,drillahole(5/8inch

diameter)throughthetoeboard.

5.Handtightenthenutonthebottomhalfoftheswitch

untilitrestsagainsttheundersideofthetoeboard.Do

notovertighten.

6.Installthepowerliftfootpedalusing2screws(1/4x

3/4inch),2atwashers(1/4inch),and2whiz-lock

nuts(1/4inch)asshowninFigure2.

•Forthepowerliftfootpedalmountingholes,drill2

holes(11/32inchdiameter)throughthetoeboard.

Figure2

1.Whiz-locknut(1/4inch)6.Washer(1/4inch)

2.Switch—bottomhalf7.Screw(1/4x3/4inch)

3.Deckfootpedal8.Switchtemplate

4.Switch—tophalf

5.Powerliftfootpedal

9.Toeboard

3.Unscrewthetophalfoftheswitchfromthebottom

halfandunscrewthenutfromthebottomhalfuntilit

stops.

4

Page 5

Note:Ifthehardwareisdifculttoremove,cutoff

thebolthead.

4

InstallingtheActuatorBracket

Partsneededforthisprocedure:

1ZMaster6000seriestemplate

1

ZMaster3000/5000seriestemplate

1Actuatorbracket

1

Screw(7/16x4–1/2inches)

1

Springdiscwasher(7/16inch)

1

Whiz-locknut(7/16inch)

Screw(3/8x3–1/2inches);forZMaster6000series

1

unitsonly

1

Conediscwasher

1

Whiz-locknut(3/8inch)

Screw(3/8x3–1/4inches);forZMaster3000and

1

5000seriesunitsonly

1Nylocnut

Procedure

1.Raiseandlockthedeckinthe14cm(5–1/2inch)

transportposition.

2.Inserttheheight-adjustmentpinintothe14cm(5–1/2

inch)holetoassurethedeckislockedinthefull-up

(transport)position.

3.Ontheleftsideoftheunit,measurethedistance

betweenthenutontheendofthespringandthe

bracket(Figure3).Notethismeasurement.

5.Removeandretainthefrontspringhardwareandthe

sidespring.

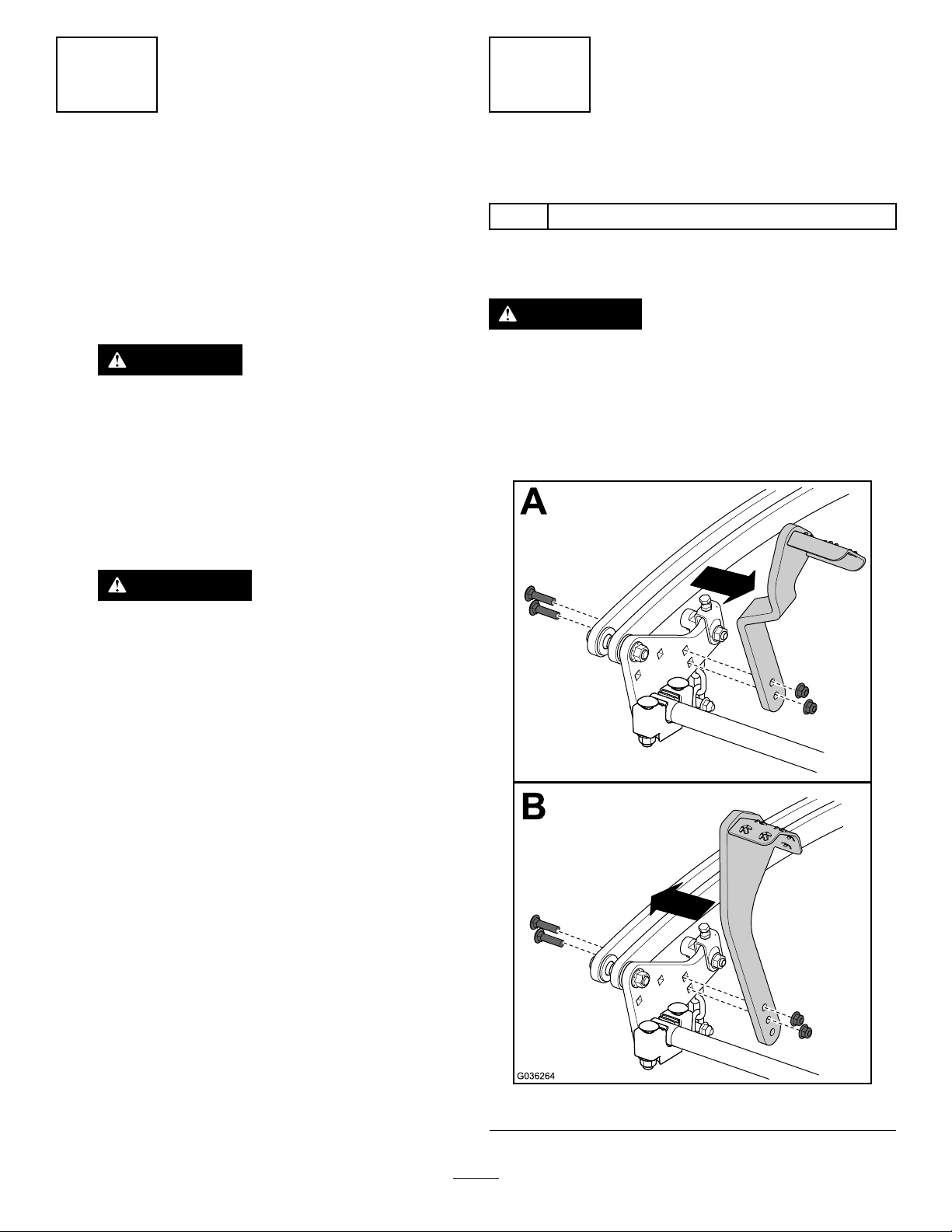

6.Cutouttheappropriatereardeckliftarmtemplate,

alignthetemplateasshowninFigure4,centerpunch

thehole,anddrilltheholeasfollows:

•ForZMaster6000seriesunits,drillahole(25/64

or13/32inchdiameter).

•ForZMaster3000and5000seriesunits,drillapilot

hole(5/16inchdiameter)andtap3/8-16UNC.

Note:Aat-bottomtapisnecessarytofullythread

thehole.

Figure4

1.ZMaster3000/5000series

reardeckliftarm

2.Template4.Bottomhole

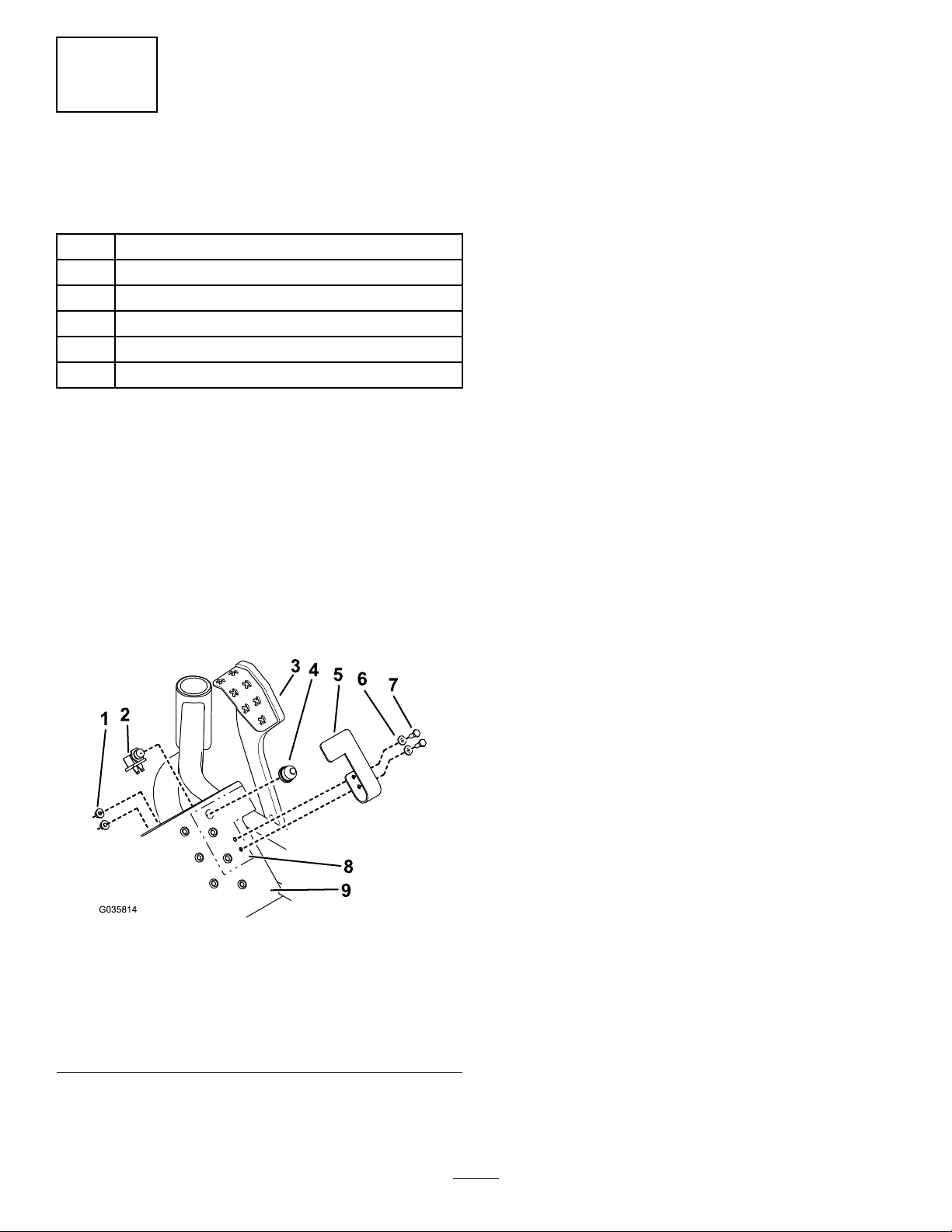

7.Installtheactuatorbrackettothereardeckliftarmby

performingthefollowing:

A.Alignthetopholeoftheactuatorbracketandrear

deckliftarm.

B.Attachtheactuatorbrackettothereardecklift

armwithascrew(7/16x4–1/2inches),spring

discwasher(7/16inch),andwhiz-locknut(7/16

inch)asshowninFigure5.Handtightenagainst

thebracket.

3.Zmaster6000seriesrear

deckliftarm

Figure3

1.Measuredistance

2.Bracket5.Fronthardware

3.Nut6.Rearhardware

4.Sidespring

4.Removeandretaintherearhardwareholdingthe

spring.

Figure5

1.Whiz-locknut(7/16inch)3.Springdiscwasher(7/16

2.Actuatorbracket

5

inch);conetowardsbolt

head

4.Screw(7/16x4–1/2

inches)

Page 6

C.Installhardwareintobottomholeoftheactuator

bracketbyperformingthefollowing:

•ForZMaster6000seriesunits,installascrew

(3/8x3–1/2inches),conediscwasher,

andwhiz-locknut(3/8inch)andtighten

hand-tight.

•ForZMaster3000and5000seriesunits,

installascrew(3/8x3–1/4inches)andcone

discwasher.

8.Torquethescrewsfromstep7accordingtothe

followingtable.

ScrewSizeTorqueSpecication

7/16inch61to75N∙m(45to55ft-lb)

3/8inch37to45N∙m(27to33ft-lb)

9.Installthesidespringbyplacingtherearhookonto

thescrew .Installthenylocnutandleavea9mm(0.35

inch)gapbetweenthenylocnutandwhiz-locknut

(7/16inch)asshowninFigure6.

5

InstallingtheActuator

Partsneededforthisprocedure:

1

Frontdeckliftbracket

2

Screw(1/2x6–1/2inches)

2

Springdiscwasher(1/2inch)

3

Locknut(1/2inch)

1Actuator

2

Clevispin

2

Cotterpin

2Actuatorsideplate

2

Flatwasher(1/2inch)

2

Spacer

1

Screw(1/2x2–1/2inches)

Procedure

Figure6

1.Nylocnut

2.Screw(7/16x4–1/2

inches)

10.Haveahelperpressdownonthedeckpedalandhold

thedecktothefull-up(transport)position.

11.Installthefrontboltofthesidespring,usethe

measurementrecordedinstep3tosetthegapbetween

thenutontheendofthespringandthebracket(see

Figure3),andtightenorloosenthespringboltuntil

theappropriategapisreached.

12.Yourhelpercannowreleasethedeckandallowitto

returntotheTRANSPORT-LOCKposition.

3.Whiz-locknut(7/16inch)

4.9mm(0.35inch)gap

1.Raisetheleftsideofthedeckandsupportitwithjack

stands.Makesurethatthereisnoweightontheleft

frontdeckliftlinkadjuster.

WARNING

Raisingthemowerforserviceormaintenance

relyingsolelyonmechanicalorhydraulic

jackscouldbedangerous.Themechanicalor

hydraulicjacksmaynotbeenoughsupport

ormaymalfunctionallowingtheunittofall,

whichcouldcauseinjury.

Donotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstands

orequivalentsupport.

2.Raiseandlockthedeckinthe14cm(5–1/2inch)

transportposition.

3.Inserttheheight-adjustmentpinintothe14cm(5–1/2

inch)holetoassurethedeckislockedinthefull-up

(transport)position.

4.Removethehardwarefromtheleft,frontcross-shaft

support.

6

Page 7

5.Installthefrontdeckliftbracketusing2screws(1/2x

6–1/2inches),2springdiscwashers(1/2inch),and2

locknuts(1/2inch)asshowninFigure7.Torquethe

screwsto91to113N∙m(67to83ft-lb).

7.InstalltherearactuatorsideplatesasshowninFigure9.

Figure9

Figure7

1.Screw(1/2x6–1/2inches)4.Left,frontcross-shaft

2.Springdiscwasher(1/2

inch);conetowardsbolt

head

3.Frontdeckliftbracket

support

5.Locknut(1/2inch)

6.Installtheactuatoronthefront,deck-liftbracketusing

theclevispinandhairpincotter(Figure8).

Note:Makesurethatthemotorispointingdown.

1.Clevispin

2.Flatwasher(1/2inch)

3.Actuatorsideplates

4.Spacer8.Locknut(1/2inch)

5.Actuatorbracket

6.Hairpincotter

7.Screw(1/2x2–1/2inches)

8.Iftheactuatorholedoesnotalignwiththe

actuator-side-platehole,turntheendoftheactuator

clockwiseorcounterclockwiseuntilitalignsasshown

inFigure10.

Figure10

1.Actuatorend3.Turntoshorten

2.Turntolengthen

Figure8

1.Front,deck-liftbracket3.Clevispin

2.Actuator4.Hairpincotter

9.Installtheactuatorsideplatestotheactuatorbracket

asshowninFigure9.

Note:Usethetopcenterholeposition.

10.Carefullyremovethejackstand.

7

Page 8

6

12

3

4

5

7

5

8

9

10

6

5

G012951

InstallingtheDeckLiftHarness

Partsneededforthisprocedure:

1Wireharness

8

Cabletie

1Fuse,25A

1Fuse,30A

Procedure

2.Connecttheotherendtotheactuatorharness.Push

thedeckliftandactuatorharnessconnectioninside

thetoeboard(Figure12).

Harnessroutingoverview:

Figure11

1.Actuator6.Floorpan

2.Connectactuatorand

deckliftharness

3.Deckliftharness8.Controlpanelfront

4.Connectswitchtodecklift

harness

5.Cabletie10.Connectdeckliftharness

7.Rightmotioncontrolpanel

opening

9.Controlpanelrearopening

toaccessory

Figure12

1.Toeboard3.Actuatorharness

2.Deckliftharness

3.Removethe15Aaccessoryfusefromthefuseboxand

replaceitwiththe25Afuse.

4.Removethe25Amainfusefromthefuseboxand

replaceitwiththe30Afuse.

5.Removeandretainthehardwarefromthecontrol

panel,carefullyremovethecontrolpanel,andremove

thecapfromtheaccessoryplug.

6.Routethedeckliftharnessundertherightsideofthe

oorpanelalongthesideoftheframesothatitjoins

withthemainsystemwireharness.

Note:Usecabletiestosecurethewireharnesstothe

machineasshowninFigure11.

7.Insertthedeckliftharnessthroughthefrontopening

ofthecontrolpanel,routeitthroughtherearopening

ofthecontrolpanel,andconnectittotheaccessory

harnessplug.

8.Ifmultipleaccessoriesarebeingused,anadd-on

accessoryharnesskitisrequired(PartNo.109-9798).

9.Installthepreviouslyremovedcontrolpanelwiththe

correspondinghardware.

4.Actuator

1.Plugthedeckliftharnessintotheswitchandroute

theharnessaroundthecross-shaftusingcabletiesto

securetheharnessasnecessary.

8

Page 9

7

CompletingtheInstallation

NoPartsRequired

Procedure

1.Connectthepositivebatterycabletothepositivepost

ofthebattery;refertotheOperator’sManualforyour

machine.

2.Iftheactuatordoesnotraisethedeckhighenoughto

getoutoftheTRANSPORT-LOCKposition,movethe

rearclevispinbackaholeasshowninFigure13.

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

2.Connectthenegativecablefromthebatterypost;refer

totheOperator’sManualforyourmachine.

3.Connectthespark-plugwiretotheterminalofthe

sparkplug.

8

Figure13

1.Moveforwardifdeckhits

framestops

2.Initialposition

3.Iftheactuatorraisesthedecktoofarandthedeckhits

theframe(Figure14)priortotheactuatorbeingfully

retracted,anoticeableloudbangingsoundoccursas

theclutchslipserratically.Ifthishappens,movethe

rearclevispinforwardahole;refertoFigure13.

3.Movebackwardif

unabletogetin/outof

TRANSPORT-LOCK

MakingtheFinalDeckLift Adjustment

NoPartsRequired

Procedure

1.Afterthedeckliftkitiscompletelyinstalled,turnonthe

keyandactivatethepowerliftfootpedal.Theactuator

retractsandliftsthedecktothehighestposition.

Note:Theactuatorhasaratchetingslipclutchyou

cannoticeablyhearwhentheactuatorisbeingfully

retracted.Ifthedeckliftisadjustedproperly ,thedeck

liftsoutoftheTRANSPORT-LOCKpositionandthere

isarapidclickingsoundwhentheactuatorisfully

retracted.

Figure14

1.Deckstop3.Actuatorbracket

2.Framestop

4.Ifthedeckdoesnotfallunderitsownweight,lengthen

thedistancebetweenthedeckbracketandsidespring

nutby1/8inch(3mm);refertoFigure3.Testthe

actuatoragain.Repeatthisstepuntilthedeckfalls

underitsownweight.

9

Page 10

Operation

Thepowerdeckliftkitisdesignedtoworkinconjunction

withtheoriginaldeck-lift,height-of-cut,andtransport-lock

mechanismsalreadyonthemower.Whenthepowerdeck

liftkitisproperlyinstalled,anelectricactuatorprovides

apoweredliftingfeaturethatreducestheneedtopush

onthemanualfootleverwhenraisingthedecktothe

TRANSPORT-LOCKposition.However,themanualfootlever

maystillbeusedformanualoverrideofthepoweredsystem,

intheeventitisconvenientornecessarytodoso.

RaisingtheDeckUsingthe PoweredDeckLift

Pressthepowerliftfootpedaltoraisethedecktothe

TRANSPORT-LOCKposition.Theelectricactuatorhasaslip

clutchthatratchetswhenthedeckisfullyraised,andthere

isarapidclickingsoundwhentheclutchisslipping.This

ratchetingsoundisnormalastheactuatorisdesignedto

ratchettoalimiteddegree.

Note:Holdingthepowerliftfootpedalagainsttheswitch

formorethan2seconds,afteritisfullyraised,causesthe

actuatortooverheatandreducesthelifeoftheactuator.It

isrecommendedtolimittheactuatorratchetingtonolonger

than2secondsatatime,witharestingperiodofatleast30

seconds,orexcessiveheatingandactuatordamagemayoccur.

PutthedeckinTRANSPORT-LOCK,orusethemanualfoot

lever,toholdthedeckinplaceforlongerperiodsoftime.

LoweringtheDeckUsingthe PoweredDeckLift

1.Stopthemachineandmovethemotioncontrollevers

outwardtotheNEUTRAL-LOCKposition.

2.DisengagethePTO.

3.WiththedeckintheTRANSPORT-LOCKposition,insert

theheight-adjustmentpinintothedesiredheight-of-cut

setting.

4.Releasepressurefromthetransportlockbypushing

eitherthepowerliftfootpedal,orthemanualdeckfoot

lever,andsimultaneouslypullingonthetransport-lock

rod.

5.Slowlyreleasethepowerliftfootpedalorthemanual

deckliftfootpedal.Whenreleased,thedeckisfree

tofallunderitsownweight,whichback-drivesthe

actuator,untilthedeckstopsontheheight-adjustment

pin.

Note:Ifthedeckdoesnotfallunderitsownweight

orifthedeckhitstheframewhenthedeckisinthe

full-upposition;referto8MakingtheFinalDeckLift

Adjustment(page9).

10

Page 11

Notes:

11

Page 12

Loading...

Loading...