Page 1

DeluxeSeatKit

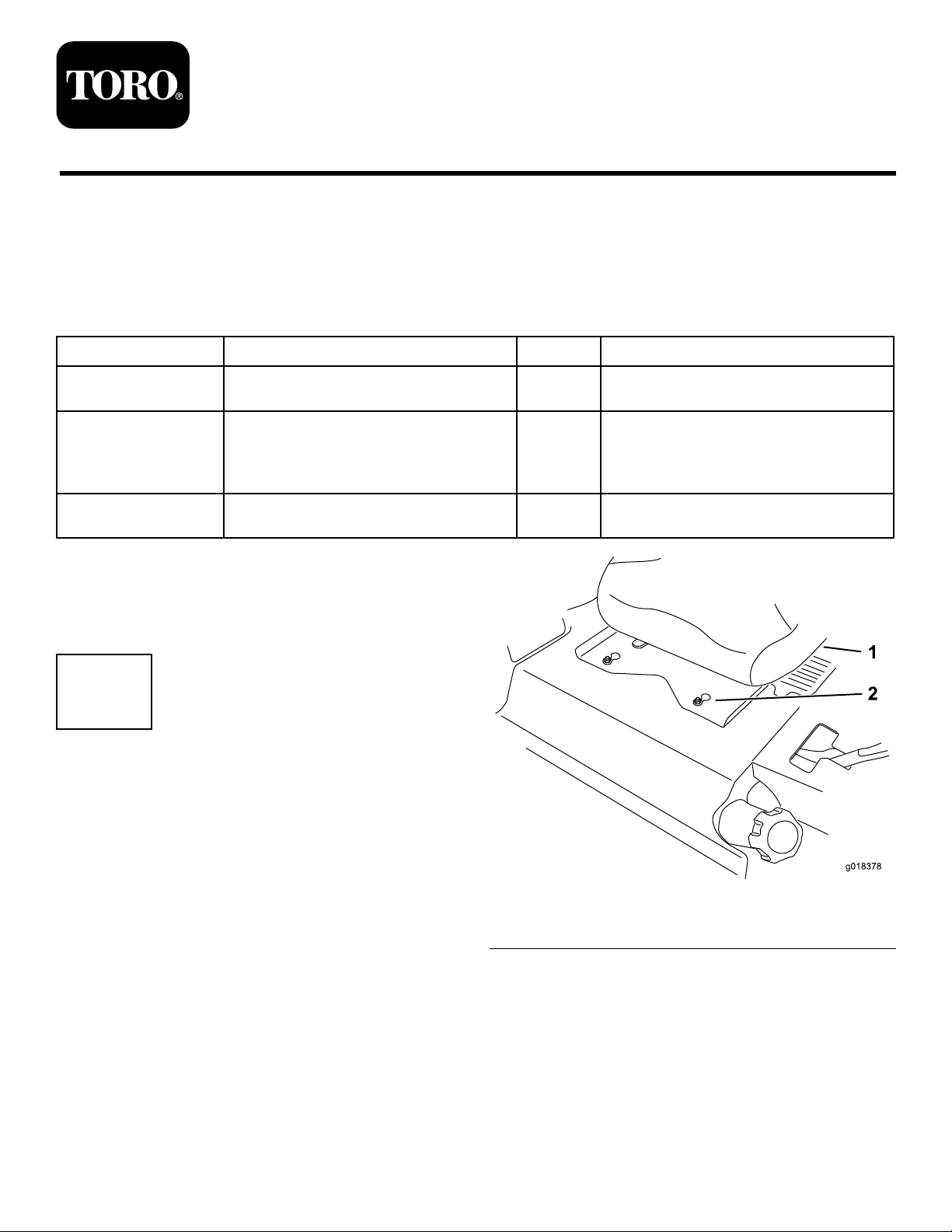

g018378

1

2

2000SeriesZMaster

ModelNo.132-5972

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3397-186RevA

®

RidingMower

InstallationInstructions

ProcedureDescription

1

2

3

Note:Forperformanceandsafety,2000Seriesmachines

with48inchmowerdecksrequireaweightkit(No.121-7576)

afterthedeluxeseatkitisinstalled.Obtainthecorrectweight

kitfromanAuthorizedServiceDealer.

Nopartsrequired

Seat

Spacer

Flangenut(5/16inch)

Cabletie

Nopartsrequired

1

RemovingtheSeat

Qty.

Use

–

1

4

4

4

–

Removetheseat.

Installtheseat.

Testthesafety-interlocksystem.

NoPartsRequired

Procedure

1.Toexposethefrontnuts,movetheseattothefurthest

rearposition.

2.Loosenthefrontnuts(Figure1).

3.Toexposetherearnuts,movetheseattothefurthest

forwardposition.

4.Loosentherearnuts.

5.Slidetheseatandseatplateforwardtoallowthefront

nutstogothroughthekeyholes(Figure1).

6.Removetheseatandbasefromthemachine.

7.Unplugtheharnessconnectorfromtheseatswitch

locatedundertheseat.

©2015—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

Figure1

1.Existingseat2.Frontnutswithkeyhole

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3397-186*A

Page 2

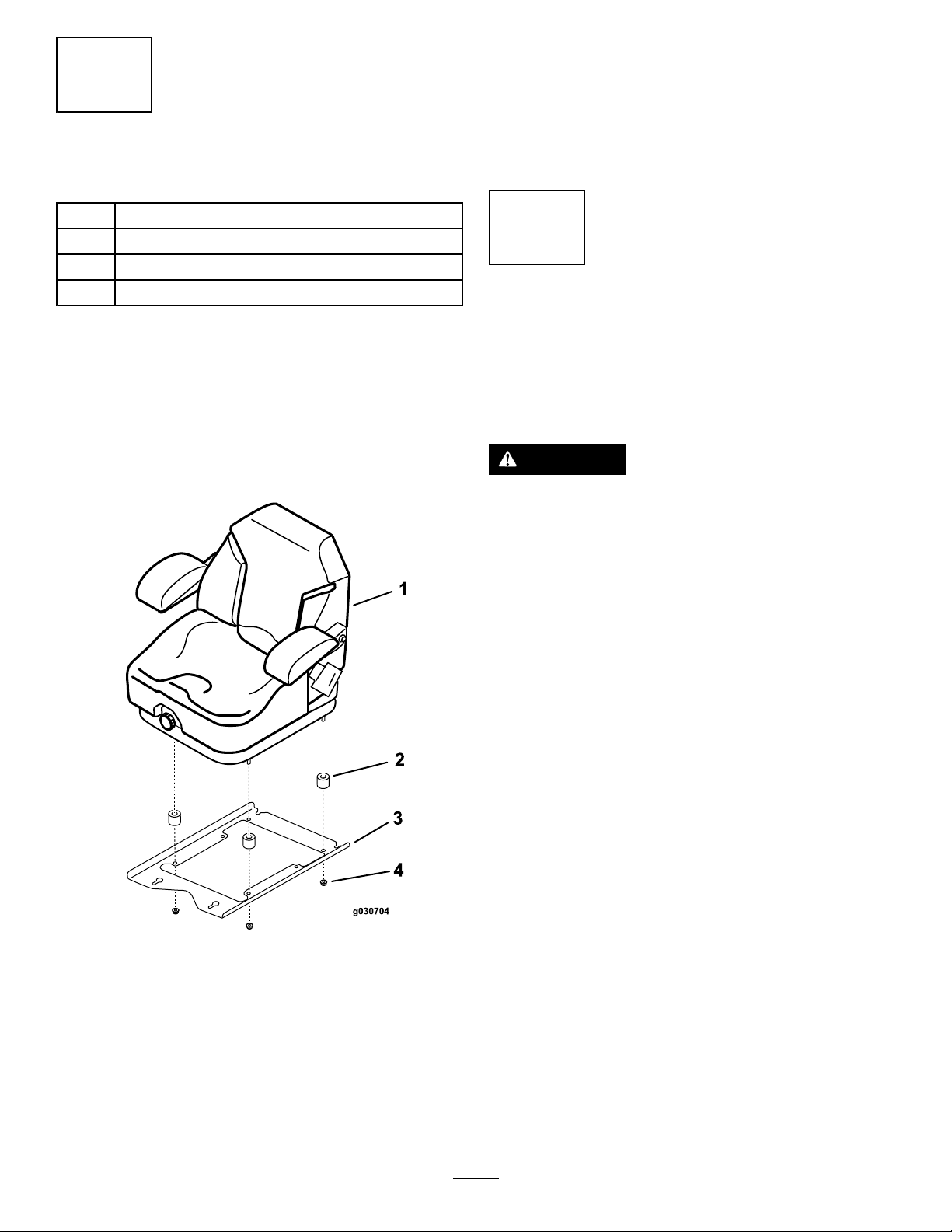

4

g030704

8.Installtheseattothemachineframebyaligningthe

frontnutswiththekeyholeintheseatplate.

2

InstallingtheSeat

Partsneededforthisprocedure:

1

Seat

4

Spacer

4

Flangenut(5/16inch)

4

Cabletie

Procedure

1.Removethepackingcoversguardingtheseatstuds.

2.Installaspacerontoeachseatstud(Figure2).

3.Securetheseatframetotheseatwith4angenuts

(5/16inch)(Figure2).

4.Torquethenutsto30.5N-m(22.5ft-lb).

9.Slidetheseatandseatplaterearwardtolockthefront

nutsintothekeyholeandtherearnutsintotheslots

(Figure1).

10.Torquethenutsto47.5N-m(35ft-lb).

3

TestingtheSafety-Interlock System

NoPartsRequired

Procedure

CAUTION

Ifthesafety-interlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly,

causingpersonalinjury.

Figure2

1.Seat3.Seatframe

2.Spacer

5.Plugtheharnessconnectorintotheseatswitchlocated

undertheseattowardthefront.

6.Carefullylowertheseatdownandensurethatyoudo

notpinchthewireharness.

7.Installthecableties.

4.Nut

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Thesafety-interlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Theparkingbrakeisengaged.

•Theblade-controlswitch(PTO)isdisengaged.

•Themotion-controlleversareintheNEUTRALLOCK

position.

Thesafety-interlocksystemisalsodesignedtostoptheengine

whenthetractioncontrolsaremovedfromtheLOCKED

positionwiththeparkingbrakeengagedorifyourisefrom

theseatwhenthePTOisengaged.

Thehourmeterhassymbolstonotifyyouwhenthe

interlockcomponentisinthecorrectposition.Whenthe

componentisinthecorrectposition,atrianglelightsupin

thecorrespondingsquare.

Testthesafety-interlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.1.Sitontheseat,engagetheparkingbrake,andmove

theblade-controlswitch(PTO)totheONposition.

Starttheengine:Theengineshouldnotcrank.

2

Page 3

2.Sitontheseat,engagetheparkingbrakeandmovethe

g019754

g019768

1

blade-controlswitch(PTO)totheOFFposition,and

moveeithermotion-controllever(outoftheNEUTRAL

LOCKposition).

Starttheengine:Theengineshouldnotcrank.Repeat

fortheothermotion-controllever.

3.Sitontheseat,engagetheparkingbrake,movethe

blade-controlswitch(PTO)totheOFFposition,and

movethemotion-controlleverstotheNEUTRALLOCK

position.

Starttheengine,releasetheparkingbrake,engagethe

PTO,andriseupslightlyfromtheseat:Theengine

shouldstop.

4.Sitontheseat,engagetheparkingbrake,movethe

blade-controlswitch(PTO)totheOFFposition,and

movethemotion-controlleverstotheNEUTRALLOCK

position.

Starttheengine,centereithermotion-controllever,and

move(forwardorreverse):Theengineshouldstop.

Repeatfortheothermotion-controllever.

5.Sitontheseat,disengagetheparkingbrake,movethe

blade-controlswitch(PTO)totheOFFposition,and

movethemotion-controlleverstotheNEUTRALLOCK

position.

Operation

PositioningtheSeat

Theseatcanmoveforwardandbackward.Positiontheseat

whereyouhavethebestcontrolofthemachineandaremost

comfortable.

Toadjust,movetheleversidewaystounlocktheseat(Figure

3).

Figure3

ChangingtheSeatSuspension

Starttheengine:Theengineshouldnotcrank.

Theseatisadjustabletoprovideasmoothandcomfortable

ride.Positiontheseatwhereyouaremostcomfortable.

Toadjusttheseat,turntheknobinfronteitherdirectionto

providethebestcomfort(Figure4).

Figure4

1.Seat-suspensionknob

3

Page 4

Loading...

Loading...