Page 1

AutomatedRowSelectionKit

2024DirectionalDrill

ModelNo.132-4193

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

Safety

SafetyandInstructionalDecals

FormNo.3397-156RevA

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

125-6184

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3397-156*A

Page 2

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

Rotarysensor1

Innersensorbracket1

Outersensorbracket

Bolt(M4-10mm)

Bolt(M8-1.25x20mm)

Locknut(M8)

Camassembly

Flangenut15

Bolt(M10-1.5x30mm)

Bolt(M10-1.5x35mm)

Locknut(M10)

Nut(M10-1mm)

Nut(M4-0.07mm)

Flatwasher2

Bolt(M8-1.25x40mm)

Bolt(M8-1.25x30mm)

Bolt(M5-0.08x25mm)

Nut(M5-0.08mm)

Bolt(M8-1.25x20mm)

Wiringharness1

Cableties

Gasket

Adjustmentblock4

Brace4

Nut(3/8-16inch)

Bolt(3/8-16x11/4inch)

Bolt(3/8-16x1inch)

Spacer

Washer8

Bolt(M12-13/4x70mm)

Bracket1

Plateag

Bolt(M5-0.08x25mm)

Nut(M5)

Cabletie

Valvecap1

Monitorcap1

Decal1

Qty.

16

Use

1

2

2

4

1

3

1

1

1

2

2

2

2

2

2

1

8

4

4

8

8

1

4

4

2

Installtherotarysensor.

Movetheproximitysensorandreplace

theadjustmenthardware.

Installthewiringharness.

Removetherotarypumpsupplyand

drainorices.

Installthethrustmotoranti-rotation

supports.

Installtheproximityswitchbracket.

Installthecapsanddecal.

Parkthemachineonalevelsurface,turnofftheengine,andremovethekey .

2

Page 3

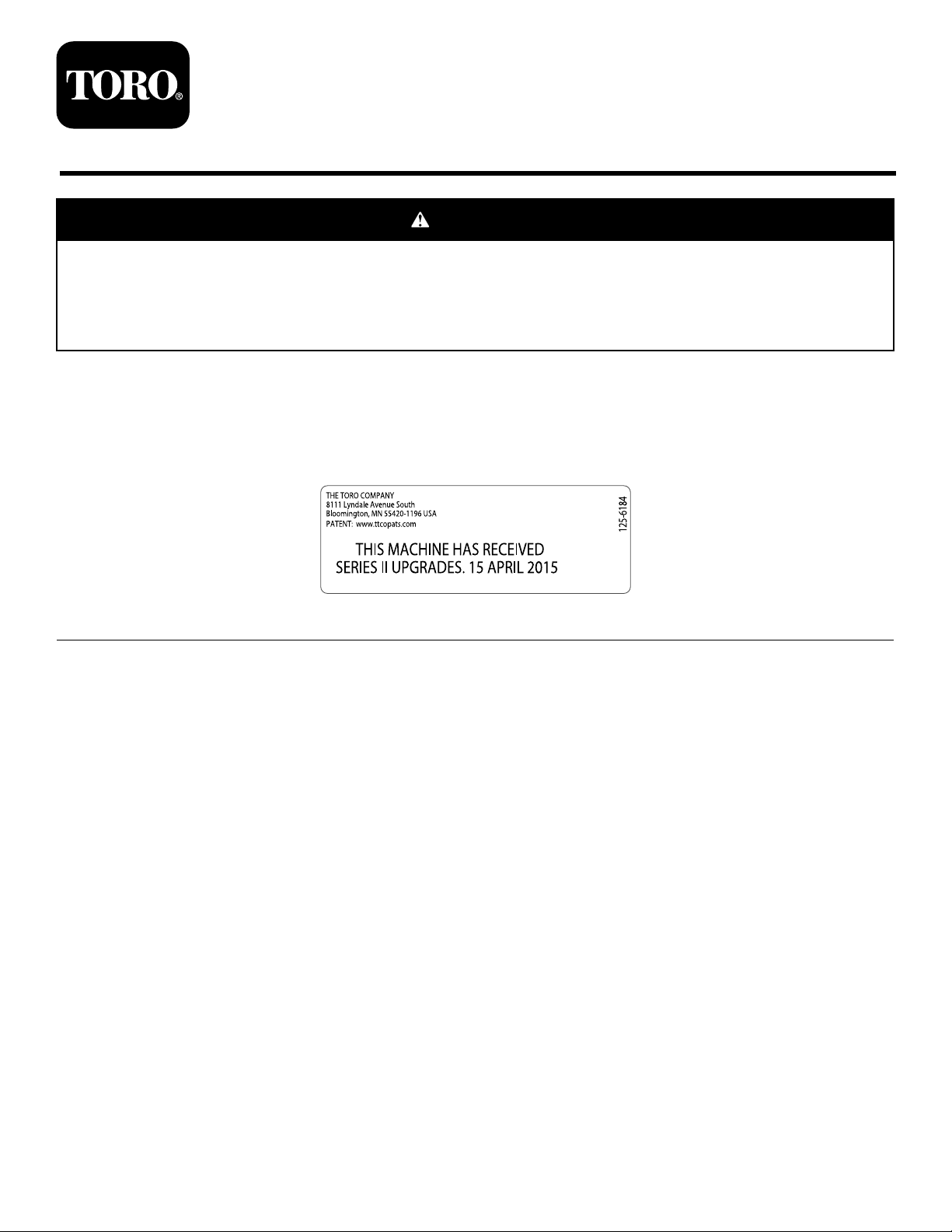

1

g0304 85

InstallingtheRotarySensor

Partsneededforthisprocedure:

1Rotarysensor

1Innersensorbracket

1

Outersensorbracket

2

Bolt(M4-10mm)

2

Bolt(M8-1.25x20mm)

4

Locknut(M8)

1

Camassembly

15Flangenut

3

Bolt(M10-1.5x30mm)

1

Bolt(M10-1.5x35mm)

1

Locknut(M10)

1

Nut(M10-1mm)

2

Nut(M4-0.07mm)

2Flatwasher

Figure2

1.Camassembly

3.Disconnectthehydraulicttingonthefrontsideofthe

camassembly(Figure3).

Procedure

1.Ensurethatthethrustframeisinthehorizontal

position.

2.Supportthecamtubewithanoverheadcraneoroor

jackbeforeproceedingtothenextstep(Figure1).

Figure1

1.Cam-tubeassembly

2.Rod-loaderassembly

Figure3

4.Measurethedistancebetweentheagandtheendof

theadjustmentboltsasshowninBoxAofFigure4.

3

Page 4

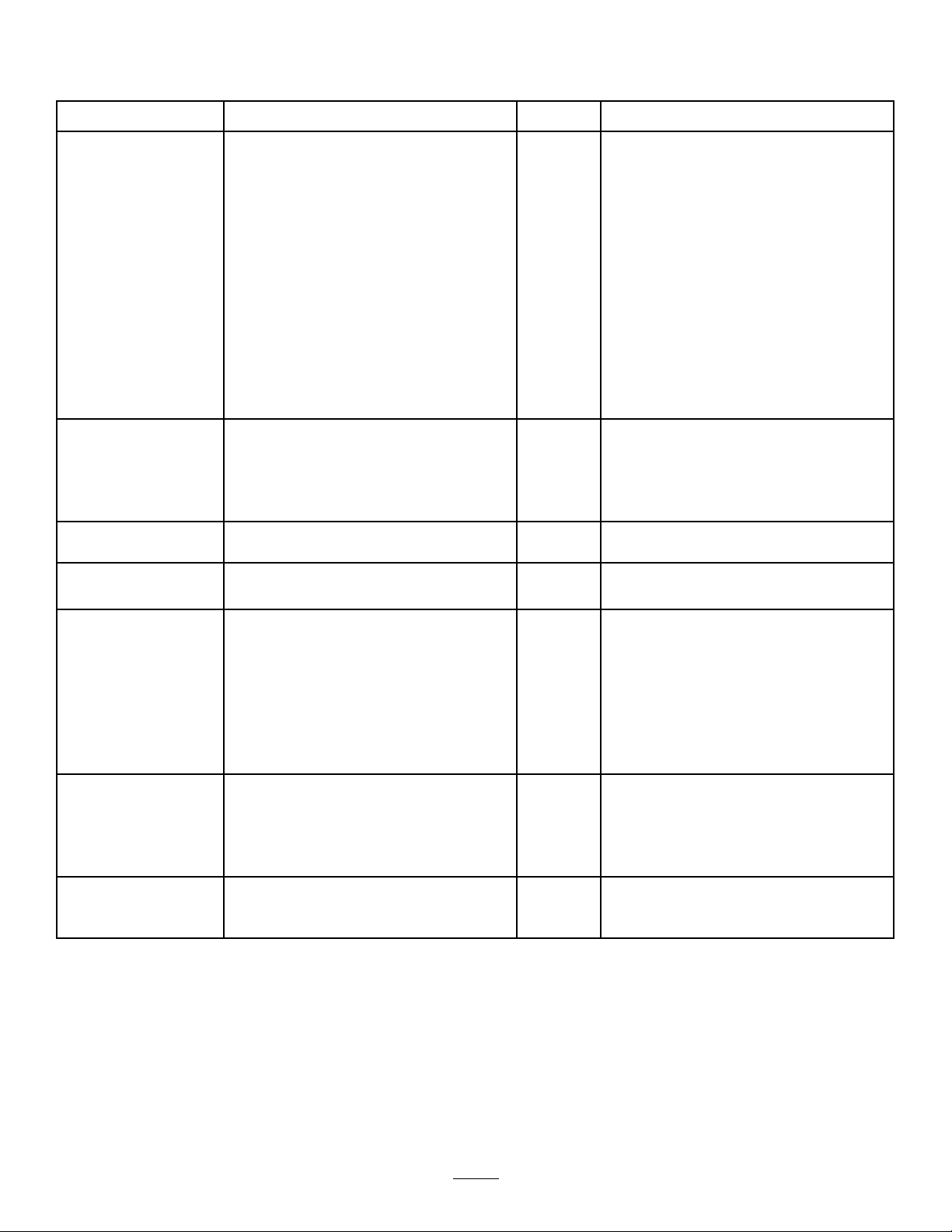

11.Assemblethenewcamassemblyusingthewearpads

andboltsfromthepreviouscamassemblyand14

angenutsand2locknuts(M8)includedinthiskit

(Figure5).

12.Installthenewcamassemblyusingthe3bolts(M10-1.5

x30mm),1bolt(M10-1.5x35mm),and1locknut

(M10)asshowninFigure6.

Figure6

Figure4

1.Measurehere3.Bolt

2.Nut4.Hydrauliccylinder

5.Disconnectthehydrauliccylinder(BoxBofFigure4).

6.Removethepillow-bearingassembly(BoxCofFigure

4).

Note:Discardthewasherbutkeeptheboltsandnuts.

7.Supporttherod-loaderassembly(Figure1).

8.Removethehardwaresecuringthecamassemblytothe

machine(BoxDofFigure4).

9.Removethecamassembly(Figure2).

10.Removethewearpadsandhardwareconnectedtothe

camassemblyasshowninFigure5.

1.Bolt(M10-1.5x35mm)

andlocknut(M10)

2.Bolts(M10-1.5x30mm)

13.Connectthehydraulicttingdisconnectedinstep3

(Figure3).

14.Installthehydrauliccylinderassemblyusingthebottom

boltfromthepreviouscamassemblyand1angenut

fromthiskitasshowninFigure7.

Figure5

Figure7

1.Flangenut

15.TorquetheM10boltsto47to57N-m(34to42ft-lb).

16.Discardthewasherthatwasremovedduringthe

removalofthecamassemblyinstep6;refertoBoxC

ofFigure4andFigure8.

4

Page 5

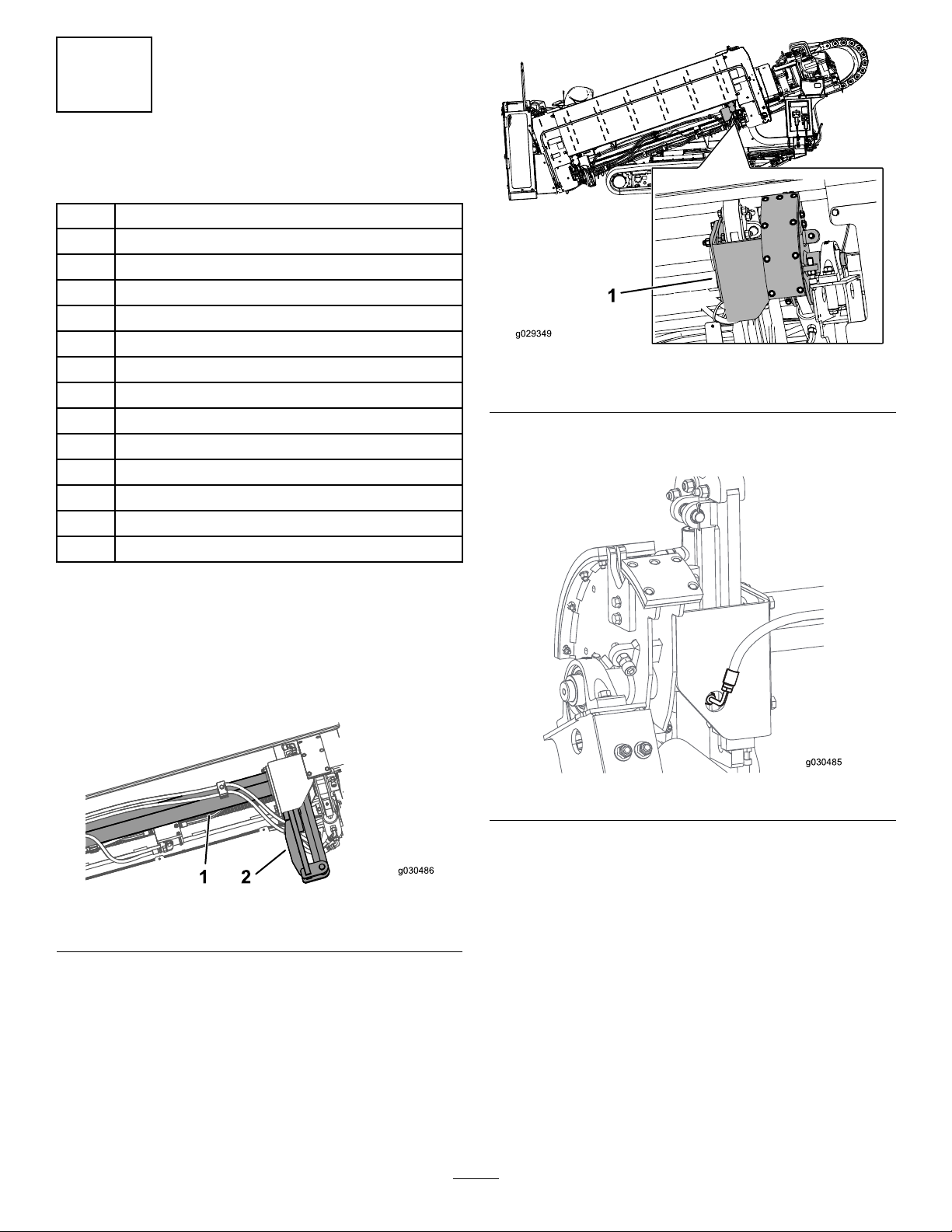

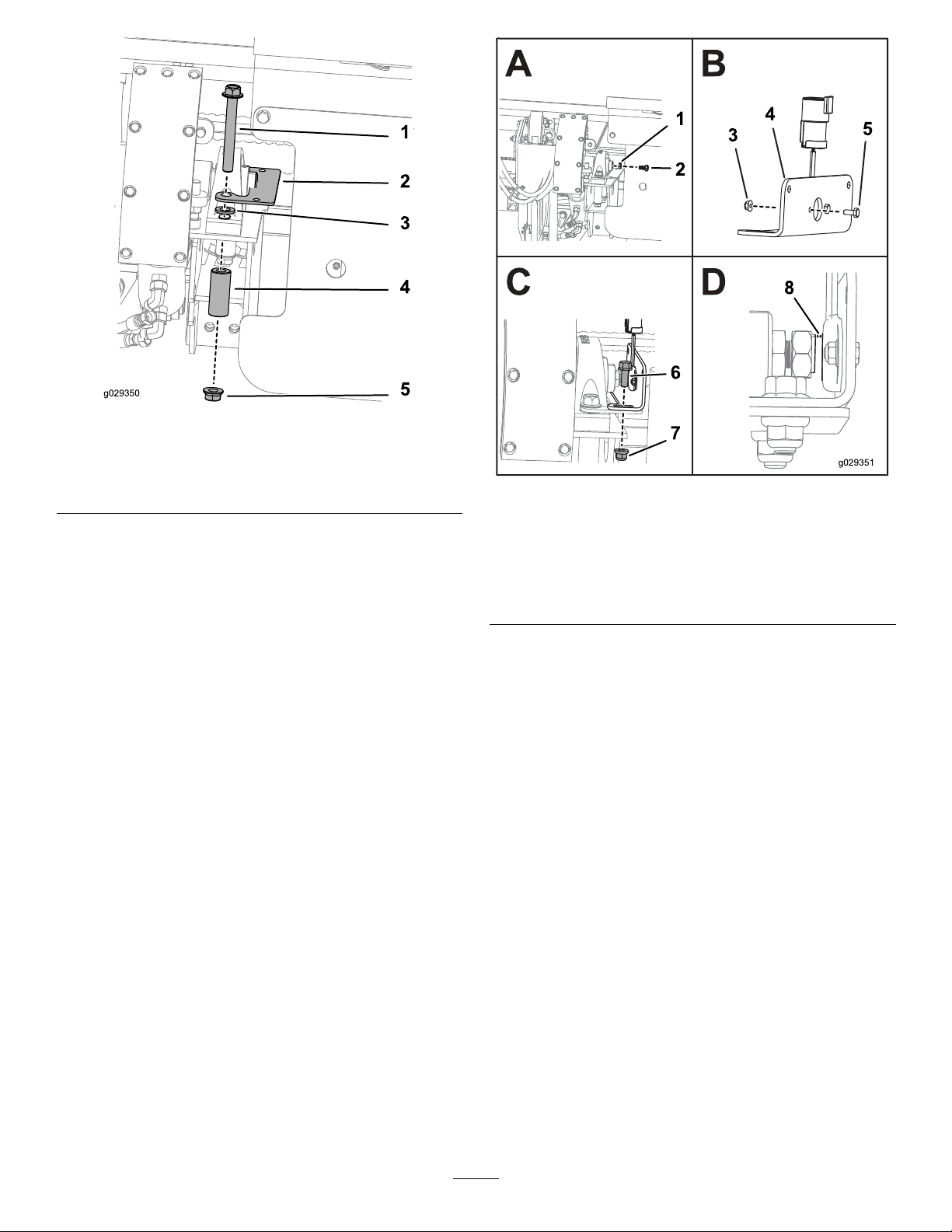

1.Bolt(existing)4.Spacer(existing)

1

2

3

4

g0293 51

A B

C D

5

6

7

8

2.Innersensorbracket

3.Flatwasher(new)

17.Usingathread-lockingcompoundonthebolt,install

theinnersensorbracketusingthehardwarepreviously

removedwithanewatwasherasshowninFigure8.

18.Torquetheboltto103to127N-m(78to102ft-lb).

19.Tightenthebearingsetscrew.

20.Installthenut(M10-1mm)andmagneticboltfromthe

rotarysensortotheendofthecamassemblyshaftas

showninBoxAofFigure9.

Figure8

5.Nut(existing)

Figure9

1.Nut(M10-1mm)5.Bolt(M4-10mm)

2.Magneticboltfromthe

rotarysensor

3.Nut(M4-0.07mm)

4.Outerbracket8.Gapof0.12to0.24inch

21.Securetherotarysensorontotheouterbracketusing2

bolts(M4-10mm)and2nuts(M4-0.07mm)asshown

inBoxBofFigure9.

Note:Usethread-lockingcompoundontheboltsif

thelocknutsarenotnylonlocknuts.

22.Torquetheboltsto2.2to2.7N-m(19to23in-lb).

23.Securetheouterbracketandrotary-sensorassembly

ontotheinnerbracketusing2bolts(M8-1.25x20mm)

and2locknutsasshowninBoxCofFigure9.

6.Bolt(M8-1.25x20mm)

7.Locknut

24.Torquetheboltsto23to29N-m(17to21ft-lb).

25.Adjustthebracketassemblytoachieveagapof0.12to

0.24inch(BoxDofFigure9).

26.PlacethecamassemblyintheHOMEpositionand

ensurethatthemarkontheboltisalignedwiththe

wireonthesensorasshowninFigure10.

5

Page 6

Figure10

1.Markonthebolt

27.Securethesensorwiretothebracketusingacabletie

asshowninFigure11.

2.Sensorwires

2

MovingtheProximity SensorandReplacingthe Rod-LoadingAdjustment Hardware

Partsneededforthisprocedure:

2

Bolt(M8-1.25x40mm)

2

Bolt(M8-1.25x30mm)

2

Bolt(M5-0.08x25mm)

2

Nut(M5-0.08mm)

2

Bolt(M8-1.25x20mm)

Procedure

1.Measurethedistancefromtheproximitysensortothe

extensiononthemachineasshowninFigure12.

Figure11

Figure12

1.Measurethedistancehere

2.Movethefrontcamproximitysensorandbracketfrom

thefrontofthemachinetotherearcamcylinderonthe

rearofthemachineasshowninBoxAofFigure13.

6

Page 7

Figure14

Figure13

1.Proximitysensorcurrent

location

2.Nut(M5)5.Bolt(M5)

3.Bracket

4.Proxsensor

6.Bolt(M8–11/4x20mm)

3.Securetheproximitysensorbracketwiththe2bolts

(M5-0.08x25mm)and2nuts(M5-0.08mm)asshown

inBoxBofFigure13.

4.Ensurethatthedistanceisthesamemeasurementfrom

step1(Figure12).

5.Torquetheboltsto791to971N-cm(70to86in-lb);

refertoBoxCofFigure13.

1.Measurehereonboth

sidesofthemachine

2.Bolt(M8–1.25x40mm)

3.Bolt(M8–1.25x30mm)

7.Replacethetopboltswiththelongbolt(M8-1.25x40

mm)(BoxBofFigure14).

8.Replacethebottomboltswiththeshortbolt(M8-1.25

x30mm)(BoxBofFigure14).

9.Adjusttheboltstomatchthemeasurementsfromstep

6.

10.Torquethebolts(M8)to23to29N-m(17to21ft-lb).

6.Measurethedistancebetweenthethreadedadjustment

blockandthetopofthebolt,asshowninBoxA

ofFigure14,onboththefrontandbackthreaded

adjustmentblocks.

7

Page 8

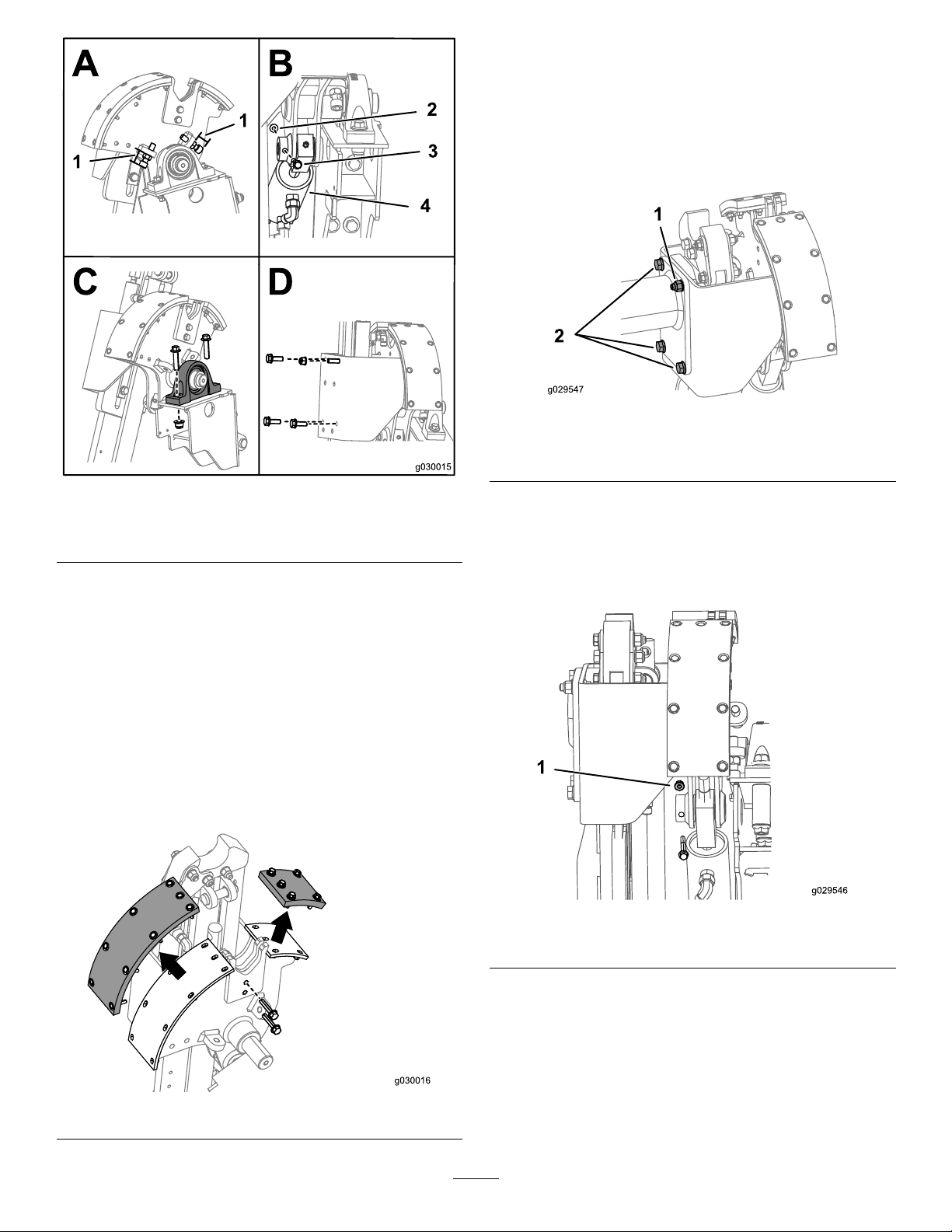

3

1

2

3

g0293 55

A

B

C

InstallingtheWiringHarness

Partsneededforthisprocedure:

1Wiringharness

16

Cableties

Procedure

1.Disconnectthebattery.

Note:Disconnectthenegativeterminalrstthenthe

positiveterminal.

2.Securethejunctionofthewiringharnesstothemain

wiringharnessasshowninFigure16.

Important:Routetheharnessalongthecurrent

machinewiringharnessandhydraulichoses.

Important:Usethecabletiestosecurethenew

wiringharnesstotheexistingwiringharnessand

frameofthemachine.

3.Routetheharnessleadmarkedstarteralongthewiring

harnessofthemachinestothestarterontheengine

andattachtheringterminaltothesamelocationasthe

currentwire(BoxBofFigure17).

Important:Ensurethattheharnessdoesnot

interferewithanyhotormovingparts.

Figure15

Topviewofthemachinewiththewiringharness

Figure17

Wiringharnesswithcableties

1.(colorandnumber)3.(colorandnumber)

2.(colorandnumber)

4.RoutethewiresmarkedasControllerApins8(red

wire),9(blackwire),and14(pinkwire)towardthe

stackofcontrollersasshowninBoxCofFigure17.

Note:Thecontrollerclosesttothemountingplate

shouldbeControllerA.Installthe3wiresintothe

properlocationsasindicatedonthetag.Thewire

sideoftheconnectorshasnumbersforreferenceto

locations.Thelocationshavearedsealpluginthehole

thatyouneedtoremovebeforeyoucaninstallthewire.

Inserttheterminaluntilthecontactclicksandlocks.

Pullslightlyonthewiretomakesurethatitisproperly

locked.Turntheconnectoroverandvisuallyinspectto

ensurethatterminalislockedalltheway.

5.Routetheremainingharnesstowardthethrustframe,

followingtheexistingharnessrouting(Figure15).

Figure16

Wiringharnesswithcableties

6.RoutethewiresmarkedasSetupValveandPipeLoader

(Front)forwardfromofthemachinefollowingthe

existingharnessrouting.

Note:Youshouldendupontheoutsideofthe

machineasshowninFigure18.

8

Page 9

Figure18

Wiringharnesswithcableties

7.RoutetheconnectorsmarkedSetupValveuptothe

9-sectionvalveblocktothetopsolenoidmarkedSetup

Valve(Figure18).

8.Disconnecttheconnectorfromthetopsolenoidvalve

andplugitintothematingconnectoronthenew

harness.

Figure20

15.Installthelatestversionofsoftwareintothemachine

andcompletethetestsdescribedinthatsoftware

update.

4

9.Plugtheotherconnectorintothevalveyoupreviously

disconnected.

10.Locatetheroundconnectorontheexistingharness

thatwaspreviouslyconnectedtotheproximitysensor

(Figure18).

11.Unscrewtheconnector,removethecabletiessecuring

thiswire,andattachtheexistingconnectortothe

connectoronthenewharness(Figure18).

12.Routetheremainderofthenewharnessalongthe

existingharnessunderthethrustframe(Figure15).

13.RoutethewireswiththeRotarySensorconnector

alongthethrustframewiththeexistingharnesstoward

therearofthemachineandcontinuetoroutethe

harnessalongthehydrauliclinesasshowninFigure19.

RemovingtheRotaryPump

SupplyandDrainOrices

Partsneededforthisprocedure:

1

Gasket

RemovingtheRotaryPumpSupplyand

DrainOrices

Important:Allowtheenginetocool.

1.Placeaoilpanunderthemachinetocatchoilfrom

therotarypump.

2.Removeandplugthecasedrainlinefromtherotary

pumpandcapoffthecasedrainttingtominimize

hydraulicuidloss.

Figure19

Wiringharnesswithcableties

14.Connecttheconnectorstotheproximitysensorand

therotarysensor(Figure19).

Note:Securethewiringharnesstothemachineas

showninFigure20.

9

Page 10

1.Removethesebolts

1

2

3

g029477

Figure21

2.Capoffthecase-drainline

10.Cleanthesealingsurfacesofthepumphousingand

controlhousing.

11.Installthecontrolhousingontothepumpusingthe

newgasket.

Important:Thecontrollinkagepinonthecontrol

mustbeinsertedintotheswash-platelinkinthe

pump.

Note:Usepetroleumjellytohelpholdtheswash-plate

linkinplacewhilethecontrolisinstalled.

Important:DonotuseRTVsealant.RTVsealant

candamagethepump.

Note:Therewillberesistancewhenthefrontedge

ofthecontrolistiltedawayfromthepumphousingif

thecontrollinkagepinisinsertedintotheswash-plate

linkcorrectly.

Note:Ifthecontrollinkagepinisnotproperly

insertedintotheswash-platelink,thepumpwillnot

returntoneutralandtherotarymotorwillspinupon

enginestartup.

12.Installthe6retainingbolts;torquetheboltsto16N-m

(12lb-ft).

3.Cleantheexternalsurfaceoftherotarypump.

4.Unplugthewiringharnessfromthepumpcontrol.

5.Removethe6boltsasshowninFigure21.

6.Removethecontrolfromthepumphousing.

Note:Oilwilldrainfromthecasewhenthehousing

isremoved.

7.Useneedlenoseplierstopulltheretainingclip(T40)

fromthecontrol(Figure22).

Figure22

13.Connectthecasedrainlineandcheckthehydraulic

uidlevel;refertotheOperator’ sManualforthemachine.

14.Connectthewiringharnesstotherotarypumpcontrol.

15.Wipeupanyspilledoil.

16.Startthemachinetotesttherotarypump.

Important:Iftherotaryoutputspinswhenthe

machineisstartedbuttherotationcommandis

notgiven,thecontrollinkagepinisnotproperly

insertedintotheswash-platelink.Removeand

capthecasedrainlineandrepeattheabovesteps.

1.T50orice3.T60orice

2.T40,T30,andT20orices

8.Removethespring(T30)andsupplyorice(T20)from

thecontrol(Figure22).

9.Removethedrainorices(T50andT60)fromthe

controlhousing(Figure22).

10

Page 11

CheckingtheNeutralAdjustment

1.Installahydraulictestportanda1000psigaugeineach

ofthedisplacementcontrolports(M4andM5).

Figure23

5

InstallingtheThrustMotor Anti-RotationSupports

Partsneededforthisprocedure:

4Adjustmentblock

4Brace

8

Nut(3/8-16inch)

4

Bolt(3/8-16x11/4inch)

4

Bolt(3/8-16x1inch)

8

Spacer

8Washer

8

Bolt(M12-13/4x70mm)

1.M72port(adjustingscrew)3.M5port(displacement

controlport)

2.M90port(locknut)4.M4port(displacement

controlport)

2.Disconnecttheelectricalconnectorfromtherotary

pumpcontrol,startthemachine,andbringittohigh

idle.

3.Loosenthelocknut(M90)witha10mmand13mm

hexwrench.

4.Usinga3mmor4mminternalhexwrench,rotate

theadjustingscrew(M72)clockwiseuntilthepressure

increasesinoneofthepressuregauges.

Note:Notetheangularpositionofthewrench.

5.Rotatetheneutraladjustingscrewcounterclockwise

untilthepressureincreasesbyanequalamountonthe

othergauge.

Note:Notethepositionofthewrench.

6.Rotatetheadjustingscrew(M72)clockwisehalfthe

distancebetweenthelocationnotedinstep(4or5).

Note:Thegaugesshouldreadthesamepressure(case

pressure),indicatingthatthecontrolisinitsneutral

position.

Procedure

RefertolocationhighlightedinFigure24forthisprocedure.

Figure24

Important:Ensurethatthereisnoweldingorweld

spatteraroundthreadedholesoronthemotormount

surfaces.

Cleanoffthepaint,oil,and/orrustfromtheweldingarea.

1.Weldtheadjustmentblocktothecarriageassemblyas

showninFigure25,Figure26,Figure27,Figure28,

andFigure29.

7.Holdtheneutral-adjustingscrewstationaryandtighten

thelocknutto7N-m(62lb-in)forthe6mmscrewor

13N-m(120lb-in)forthe8mmscrew.

8.Oncetheneutralpositionisset,stoptheengine,

removethegauges,andremovethegaugeports.

9.Connecttheelectricalconnectortotherotarypump

control.

11

Page 12

Figure25

Sideview

Figure26

TopView–Rearmounts(motorsremoved)

Figure28

SideView–Frontmounts(motorsremoved)

1.Weldthefrontmotorblocks1/8inchovertheedge.

Figure29

SideView–RearMounts(Alignedwiththeedge;motors

removed)

2.Removeanddiscardtheexistingboltandwasherfrom

thethrustmotor(BoxAofFigure30).

1.Weldtheblocks3/4inchesawayfromtheedges.

Figure27

TopView–Frontmounts(motorsremoved)

1.Weldtheblocks3/4inchesawayfromtheedges.

12

Page 13

9.Torquethe8bolts(M12)to90to112N-m(67to83

ft-lb).

10.Painttheweldedarea.

6

InstallingtheProximitySwitch Bracket

Partsneededforthisprocedure:

1Bracket

1

Plateag

4

Bolt(M5-0.08x25mm)

4

Nut(M5)

2

Cabletie

Figure30

1.Brace

2.Bolt(M12)

3.Washer

4.Spacer

5.Nut(3/8-16inch)

6.Bolt(3/8-16x11/4inch)rearmotorassemblies

7.Bolt(3/8-16x1inch)frontmotorassemblies

3.Liftthethrustmotorandinstallthebracesupports

(BoxBofFigure30).

Note:Themotorbraceshouldbecenteredonthe

thrust-motorange.

Note:Loosenthettingsonthethrust-motorttings,

ifnecessary.

4.Applythread-lockingcompoundtothe8bolts(M12)

andlooselyinstallthebolts,washers,andspacersinto

thethrustmotorassembly(BoxCofFigure30).

5.Installthenutsonthebolts,applythread-locking

compoundtothe4bolts(3/8-16x11/4inch),and

installtheassemblyintotherearmotorassembly(Box

DofFigure30).

6.Installthenutsonthebolts,applythread-locking

compoundtothe4bolts(3/8-16x1inch),andinstall

theassemblyintothefrontmotorassembly(BoxEof

Figure30).

Procedure

Cleanoffthepaint,oil,and/orrustfromtheweldingarea.

1.Placethebracket3inchesawayfromtherodbox

mountingplateand13/4inchesawayfromthebottom

ofthecarriageweldmenttothetopofthebracketand

weldthebrackettothethrustframe(Figure31and

Figure32).

Figure31

1.13/4-inchgap

2.3-inchgap

3.Bracket

7.Placethemotorbracecenteredagainstthethrust

motorangeandalternatelytightentheadjustment

bolts(3/8-16)to37toN-m(27to33ft-lb).

8.Tightenthejamnutsagainsttheadjustmentblocks.

13

Page 14

Figure32

2.Weldtheplateagtothecarriageassembly57/8

inchesawayfromthespindleendofthecarriage

assemblyasshowninFigure33.

Figure33

1.57/8-inchgap2.Plateag

Figure34

Currentrouting

Figure35

Existingrearsensor

1.Existingsensor

5.Tagthesensorandwiringharnesstonotewhichpart

oftheharnessgoestowhichsensor(Figure36).

6.Disconnectthewiringharnessfromthe2proximity

switches(Figure36).

3.Painttheweldedarea.

4.Disconnectthewiringharnessontheexistingrear

sensor(Figure34)androutethewiringharnessthrough

theholesonthebracketasshowninFigure35.

Figure36

1.Pipe-breakoutsensor2.Pipe-returnsensor

14

Page 15

7.Removethe2proximitysensorsfromthemounting

plateanddiscardthehardware(Figure36).

8.Looselysecurethe2proximitysensorstothebracket

with4bolts(M5)and4nuts(M5)asshowninFigure

37.

Figure37

Figure39

1.Rearwrench3.Frontwrench

2.Centerofthewrenches

B.Adjustthepipe-breakoutproximitysensoruntil

thelightilluminates(Figure40).

1.Bolt(M5)

2.Proximitysensor5.Pipe-returnproximity

3.Nut(M5)

4.Pipe-breakoutproximity

sensor

sensor

9.RoutethewiringharnessasshowninFigure38,

andconnecttheproperconnectionstotheproper

proximitysensors.

Note:Ensurethattheharnessdoesnotinterferewith

anyhotormovingparts.

Figure38

Figure40

1.Pipe-breakoutlight2.Pipe-returnlight

C.Tightentheboltsandnutsonthesensor.

D.Torquetheboltsto791to971N-cm(70to86

in-lb).

Pipe-ReturnSensor

10.Securetheexcessamountofthewiringharnesswitha

cabletie.

11.Use2(ormore)peopletoadjusttheproximityswitches:

Important:Ensurethatthegearboxiscompletely

forwardinthecarriageweldment.

Pipe-BreakoutSensor

A.Pullthedrillpipeandleadbarbackthroughthe

pipeguideandintothewrenchesuntilthepipe

jointisinthemiddleofthewrenches(Figure39).

A.Pullthedrillpipeandleadbarthroughthepipe

guideandthroughthewrenchesuntilthefrontof

thepipeislinedupwiththefrontoftherodbox

(Figure41).

15

Page 16

Figure41

1.Rearbracket2.Frontbracket

B.Adjustthepipe-returnproximitysensoruntilthe

lightilluminates(Figure40).

C.Tightentheboltsandnutsonthesensor.

D.Torquetheboltsto791to971N-cm(70to86

in-lb).

7

InstallingtheCapsandDecal

Partsneededforthisprocedure:

1Valvecap

1Monitorcap

1Decal

Procedure

InstallthedecalasshowninFigure42.

Figure43

1.Valvecap2.Manual-overridevalve

Gentlyliftthemonitorawayfromtheconsoleusingaat

headscrewdriverinthegapsasshowninBoxAofFigure44.

Figure42

1.Decal

Removethemanualoverridevalvescrewandinstallthevalve

capasshowninFigure43.

Figure44

1.Gapsbetweenthemonitorandconsolepanel

Insertthemonitorcapintotheportonthebackofthe

monitorandinstallthemonitorbackontotheconsole(Box

BofFigure44).

Connectthepositiveterminalofthebatterythenconnect

thenegativeterminal.

16

Loading...

Loading...