Toro 132-4165 Installation Instructions

CamSensorImprovementsKit

4045DirectionalDrill

ModelNo.132-4165

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

Safety

SafetyandInstructionalDecals

FormNo.3395-934RevA

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

125-6184

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Thrustwasher1

1

2

Washer1

Flangelocknut1

Rod-loadersensor1

Bracket1

Plate1

Flangenut2

Bolt(M6–1x16mm)

Hexnut(M10)

Flatwasher2

Bolt(M10–1x40mm)

Bolt(M4x10mm)

Nut(M4)

Sensorharnessadapter

Qty.

Use

Installtherod-loaderspacer.

2

1

1

2

2

1

Installtherod-loadersensor.

©2015—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3395-934*A

ProcedureDescription

3

4

5

1

InstallingtheRodLoader

Bracket1

Bolt(M12-13/4x60mm)

Locknut(M12)

Hexnut(M10)

Bolt(M4)

Sensorassembly

Nut(M4)

Cotterpins

Sensorharnessadapter

Sensor-connectorclip

Gasket

Monitorcap1

Decal1

Qty.

Use

2

2

1

2

1

2

2

1

1

1

Installtherodcamsensor.

Removingtherotarypumpsupplyand

drainorices.

Installthecapanddecal.

Spacer

Partsneededforthisprocedure:

1Thrustwasher

1Washer

1Flangelocknut

Procedure

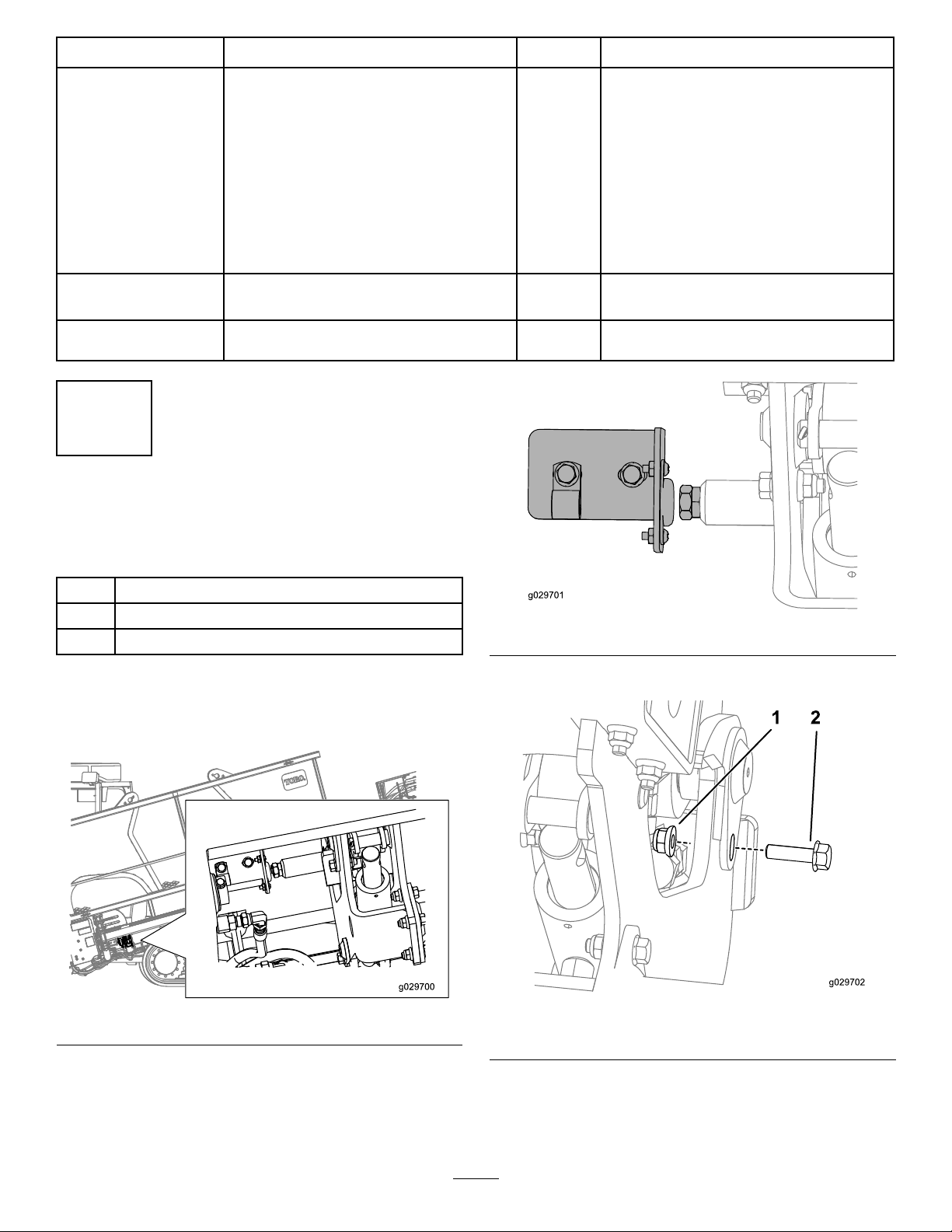

RefertolocationhighlightedinFigure1forthisprocedure.

Figure2

3.RemovetheretainingboltandnutasshowninFigure3.

Figure1

1.Supporttherodloaderassemblytoensurethatthe

pivotpinassemblyisabletomove.

2.Removethesensorassemblyandbracketandsetaside

thehardware(Figure2).

Figure3

1.Retainingnut(existing)2.Retainingbolt(existing)

4.Movetherod-loaderassemblytothesidetocreatea

gapforthewasher.

2

Important:Movetherodloaderassemblyasfar

aspossiblesothatthereisnotagapbetweenthe

rod-loaderpivotandtheloaderassembly(Figure

4).

2

5.Slidethepivotpinouttoallowtheinstallationforthe

washer(Figure4).

Figure4

1.Washer3.Pivotpin

2.Ensurethereisnogap

here.

6.Installthethickwasher.

Note:Ifthegapisnotlargeenoughforthethick

washer,installthethinwasher.

InstallingtheRodLoader Sensor

Partsneededforthisprocedure:

1Rod-loadersensor

1Bracket

1Plate

2Flangenut

2

Bolt(M6–1x16mm)

1

Hexnut(M10)

2Flatwasher

1

Bolt(M10–1x40mm)

2

Bolt(M4x10mm)

2

Nut(M4)

1

Sensorharnessadapter

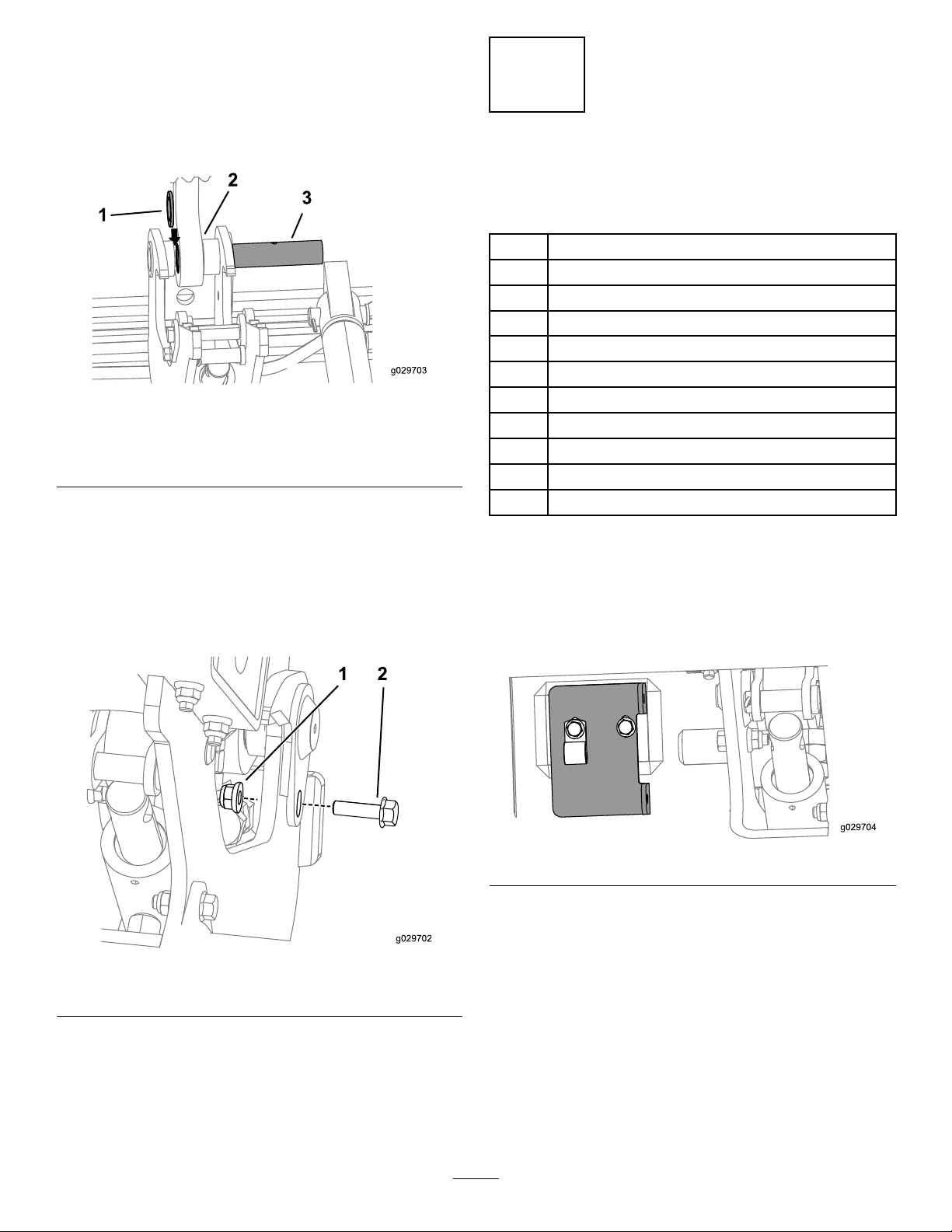

Procedure

7.Installthepivotpin.

8.Installtheretainingboltpreviouslyremovedandthe

locknutincludedinthiskitasshowninFigure5.

Figure5

1.Flangelocknut(new)2.Retainingbolt(existing)

1.Applythread-lockingcompoundtotheboltsremoved

inStep2in1InstallingtheRodLoaderSpacer(page

2)andlooselyinstallthebracketusingtheboltsand

R-clampasshowninFigure6.

Figure6

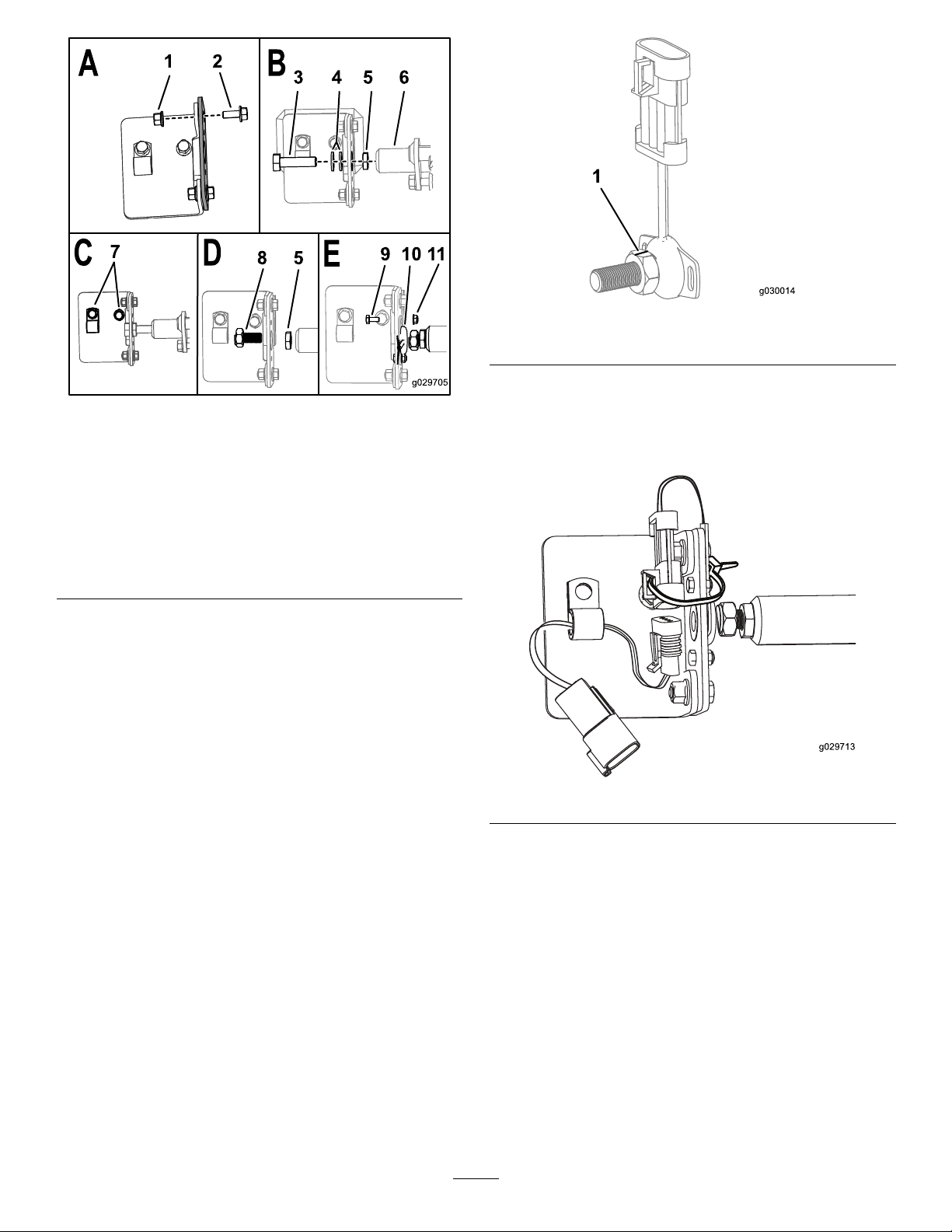

2.Looselyinstalltheplateonthebracketusing2bolts

(M6–1x16mm)and2angenutsasshowninBox

AofFigure7.

9.Torquetheboltto23to29N-m(17to21ft-lb).

3

Figure7

g0297 13

Figure8

1.Notch

11.Ensurethatthegapbetweenthemagneticsensorbolt

andthesensoris0.12to0.24inch.

1.Flangenut7.Applythread-locking

2.Bolts(M6–1x16mm)8.Sensor-magnetbolt

3.Bolt(M10–10x40mm)9.Bolt(M4x10mm)

4.Flatwashers

5.Hexnut

6.Pivotpin

compoundwhen

tighteningthesebolts.

10.Sensor

11.Nut(M4)

3.Installthebolt(M10-1x40mm),2atwashers,and

thehexnut(M10)ontothebracketplateandpivotpin

asshownBoxBofFigure7.

Note:Usethewasherstocenterthebracketandplate.

4.Tightenallofthehardwarethatissecuringthebrackets

tothemachine(BoxCofFigure7).

5.Torquetheboltsto972to1198N-cm(86to106in-lb).

6.Torquethebolts(M6)to972to1198N-cm(86to106

in-lb).

7.Removethebolt(M10–1x40mm),2atwashers,and

thehexnutfromthebracketplateandpivotpin(Box

BofFigure7).

8.Installthesensormagnetboltandhexnutintothe

pivotassemblyasshowninBoxDofFigure7.

9.Installthesensorontothebracketusing2bolts(M4

x10mm)and2nuts(M4–0.7inch)asshowninBox

EofFigure7.

12.Securethesensortothebracketwithacabletieas

showninFigure9.

Figure9

13.Torquethebolts(M4)to2.2to2.7N-m(19to23ft-lb).

14.Attachthesensor-harnessadaptertotheR-clampon

thebracketandattachtheadaptertothesensoras

showninFigure9.

15.Usethesensorharnessadaptertoconnectthesensor

tothewiringharnessofthemachine.

Note:Usethread-lockingcompoundontheboltsif

thelocknutsarenotnylonlocknuts.

10.PlacethecamassemblyintheHOMEpositionand

ensurethatthenotchinthemagneticsensorboltis

linedupwiththewiresonthesensorasshownin

Figure8.

4

Loading...

Loading...