Page 1

ElevatorPressureReliefandConsoleWireHarness

ProtectionKit

2024DirectionalDrill

ModelNo.132-4162

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3395-893RevA

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

Description

Guardplate

Bolts(M10)

U-nut2

Valve1

Straighttting

Valvebracket1

Bolt(M6)

Flangenut2

Largeteetting

Smallteetting

Longhydraulichose1

Shorthydraulichose

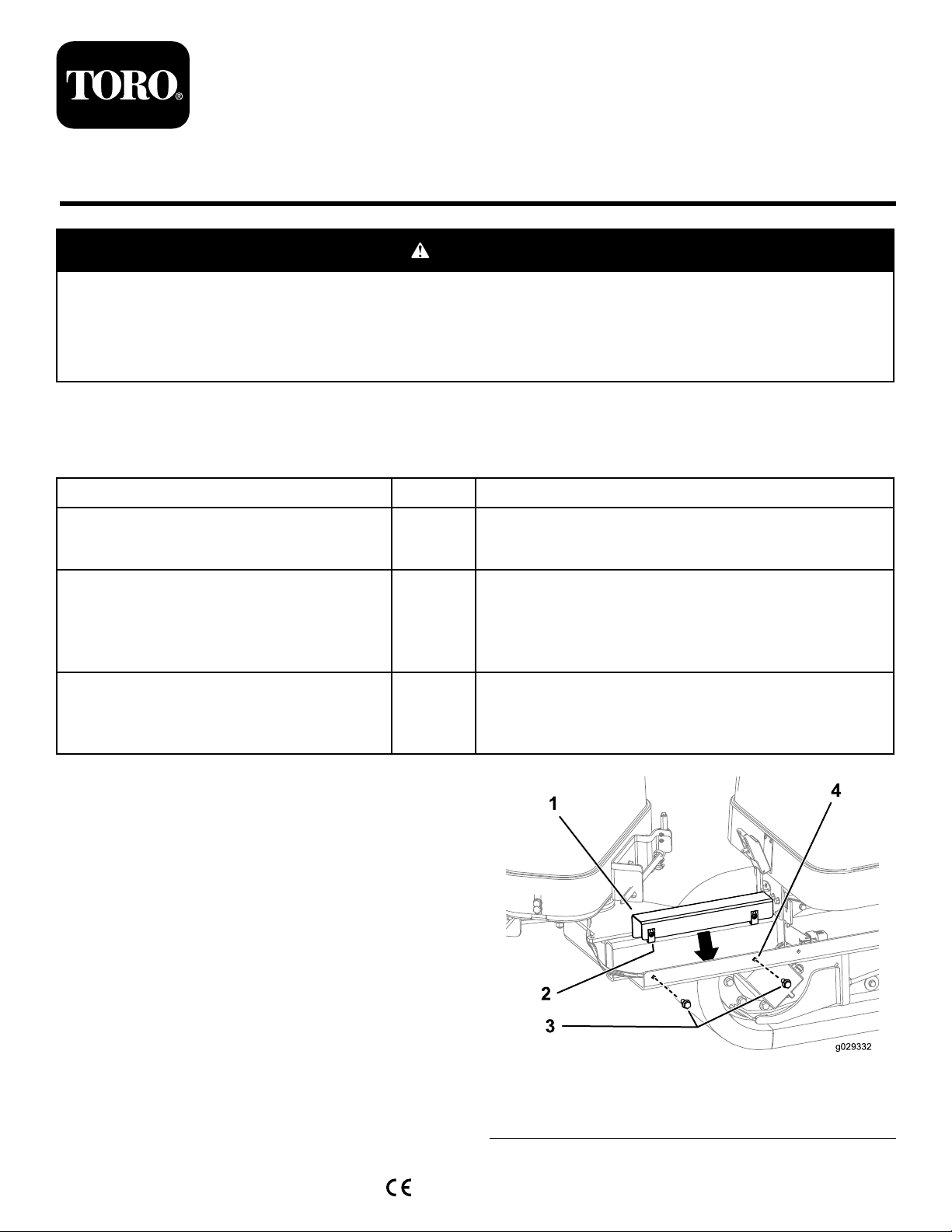

InstallingtheWiringHarness

Guard

1.Movethemachinetoalevelsurface,turnoffthe

machine,andremovethekey.

Note:Swingtheoperatorplatformfull-outforeasier

access;refertothemachineOperator’ sManual.

Qty.

Use

1

2

2

2

1

1

1

Installthewiringharnessguard.

Installthevalveandbracket.

Installthettingsandroutethehydraulichoses.

2.Usingtheguardplateasaguide,drillaholeintothe

frame;refertoFigure1.

Note:Becarefulnottodrillintothewiringharness

wires.

©2015—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

Figure1

1.Guardplate3.Bolt(M10)

2.U-nut4.Drilltheholehere.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3395-893*A

Page 2

3.InstalltheU-nutsontotheguardplateandsecurethe

assemblytothemachineusingthe2bolts(M10)as

showninFigure1.

4.Torquetheboltsto47to57N-m(34to42ft-lb).

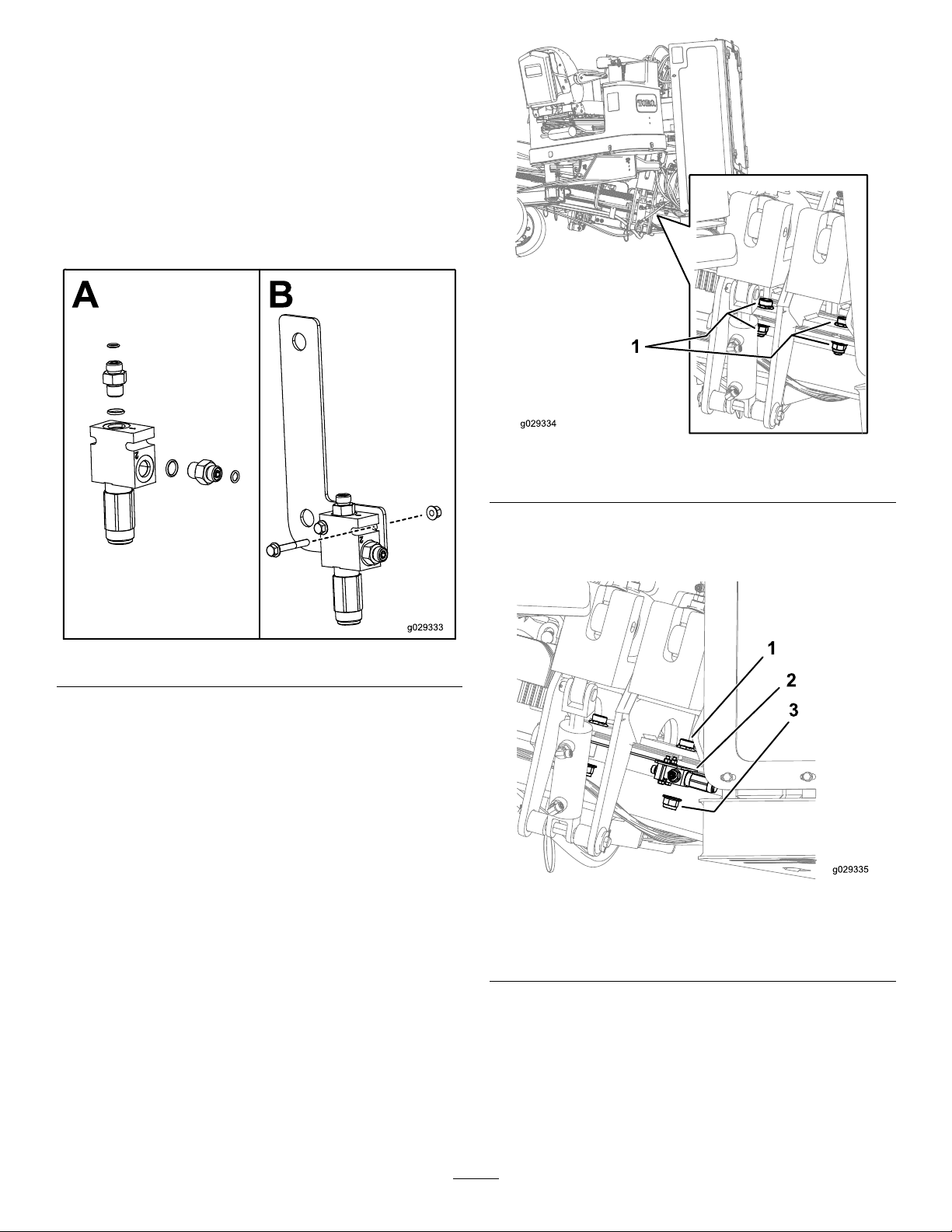

InstallingtheReliefValveand

Bracket

1.InstallthestraightttingsandO-ringstothevalveas

showninBoxAofFigure2.

Figure3

1.Existinghardware;removethesenuts

Figure2

2.Securethevalveassemblytothevalvebracketusing

2bolts(M6)and2angenutsasshowninBoxBof

Figure2.

3.Torquetheboltsto972to1198N-cm(86to106in-lb).

4.Removethe2nutsasshowninFigure3.

5.Securethevalveassemblyandbrackettothemachine

usingthe2nutspreviouslyremovedasshowninFigure

4.

Figure4

1.Bolt(existing)3.Nuts(existing)

2.Valveassemblyand

bracket

2

Page 3

InstallingtheFittingsand

RoutingtheHydraulicHoses

1.Removetheboltssecuringthesidepanelofthe

machineasshowninFigure5.

Figure5

Figure7

1.Large-teevalve

2.Disconnectthehydraulichoseconnectedtothe

90-degreettingonthelowervalve(Figure6).

Figure6

1.Small-teevalve

3.Installthesmall-teettingandO-ringstothe90-degree

ttingandconnectthehydraulichoseasshownin

Figure6.

4.Torquethettingto36to44N-m(27to33ft-lbs).

5.Disconnectthehydraulichoseconnectedtothetee

ttingonthetopofthe9sectionvalveblock(Figure7).

6.Installthelarge-teettingandO-ringstotheexisting

teevalveandconnectthehydraulichoseasshownin

Figure7.

7.Torquethettingto50to63N-m(37to47ft-lbs).

8.Installtheshorthosefromthesmall-teettingtothe

valveandbracketassemblypreviouslyinstalled,as

showninFigure8.

Figure8

1.Valveandbracket

assembly

2.Shorthose

9.Torquethettingonthevalveandbracketassemblyto

20to25N-m(15to19ft-lbs).

10.Torquethettingontheshorthoseto46to56N-m

(34to42ft-lbs).

3

Page 4

11.Installthelonghosefromthelarge-teettingtothe

valveandbracketassemblypreviouslyinstalled,as

showninFigure9.

Figure9

12.Torquetheupperttingto78to97N-m(58to72

ft-lbs).

13.Torquetheupperttingto20to25N-m(15to19

ft-lbs).

4

Loading...

Loading...