Industrial Crane Scale

Instruction Manual Model:

BA15S – BA150S

BA15SR – BA150SR

Table of Contents

…

…

…

…

…

…

.

.

…

.

…

…

…

…

…

…

…

…

…

…

.

…

…

…

…

…

…

…

…

…

…

…

…

…

…

.

…

…

.

…

.

…

Cautionary Notes and Precautions…………………………………………………………………………………….………

1.

Important Handling Cautions and Warnings……………………….………………………… ……………….…….

1.1.

Specifications……………………………………………………………………………...……………………………….……

2.

Scale’s Specifications……………………………………………………………… ………..…………………………

2.1.

Remote Control’s Specifications…………………………………………………………………….………… …… …

2.2.

Keys, Display Indicators and Abbreviations…………………………………………………………… ……………….……

3.

Parts Descriptions………………………………………………………………………………………………………………

4.

Unpacking Balance and Getting Started…………………………………………………..………… ……………….………

5.

Battery Operation………………………….…………………………………………………………………… ……….………

6.

7.

Remote Control…………………………………………………………………………… ………… ……………… …… ……

Basic Principles of Weighing.………………………………………………………………………………………….……….

8.

Functions, Descriptions and Definitions………………………………………………………………………………………

9.

Weighing…………………………………………………………………………………………….……………………………

10.

Taring……..…………………………………………...………………………………………….………………….……

10.1

Extending the Resolution………………………...………………………………………….…………………….……

10.2

Zeroing the Scale……..…………………….………………………………………………………..………….………

10.3

Auto Zero…………….……………...…………………………………………………………………………………..………

11.

Parts Counting………………………………………………………………………………………….………………………

12.

Using the Default Sample Setting.……………………………………………………………………...……………

12.1.

Using a Custom Sample Setting…………………………………………………………………...…………………

12.2.

Counting Based on a Known Individual Piece Weight…………..………….…………………………..…….……

12.3.

Units of Measure……………………………………………………………………………………....………………………

13.

Percent Weighing…………………………………..…………………………………………………………...………………

14.

Recipe Weighing…………………………………………………………………………………………….……………...…

15.

Calibration……..………………………………………………………………………………….……………………………

16.

Quick Calibration……….………………………………………………………………………………… ……………

16.1.

Stepped Calibration………………………………………………………………………………………………………

16.2.

Port 1 – RS232 Communication Port Configuration…………………………..………………………………….…………

17.

Data Transmission and Exchange Protocol…….………………………………………………………..….………

17.1

Baud Rate………………………………………………………………………………… ….…………..……….……

17.2

Bites………..……………………………………………………………………………………………..…….…………

17.3.

Parity…………...…………………………………………………………………………………………………………

17.4.

Receipt Printout………………………………………..……………………………… ……………………………..…………

18.

Enabling and Disabling Receipt Fields……………………………………………………………………….………

18.1.

Assigning Operator and Product ID Numbers……………………………………………………………….………

18.2.

Dynamic and Animal Weighing……………………….………………………………………… ……………………..………

19.

Storing Tare Values…………………………………………………………………….…………………………….…………

20.

Storing a Tare Value Manually……………………………………………………………..……………….……… …

20.1.

Storing a Tare Value Automatically……………………………………………………………………..….…………

20.2.

Recalling a Previously Stored Tare Value...……….……………………………………....……………….…………

20.3.

Min Max Weighing…………………………………...…….………………………………………………………….………

21.

Newton – Force Measurement……….…...……………………………………………………… ……………………..……

22.

Filtering……………..………………………..…………………………………………………………………………………

23.

Date and Time………………………………………………………………………….……………….…………….…………

24.

Enabling and Disabling Date and Time Stamping…………………………………………………………………...

24.1.

Setting the Current Time and Date……………………………………………………………………………… ……

24.2.

Enabling PIN Access to the Date Configuration Function……………………………………………..………..…

24.3.

Threshold Check Weighing and Opto-Isolator…………………………………………………………………………….…

25.

25.1.

26.

27.

29.

30.

31.

32.

33.

34.

35.

36.

Enabling Check Weighing and Setting Threshold Limits…………….………………………………………………

Totalizing…………………………………………………………………………………………………………………………

RF Channel Setup for Remote Control………………………………………………………………………………………

LCD Back Light……………………………………………………………………………..…………… ……..………………

Auto Off….……………………………………………………………………….………………………………… ……………

Changing to Grams (g) or Pounds (lb)……….……………………………………… ……….………………..……………

Menu Customization………………………………………………………………………………………………………….…

Restoring Default Setting…………………………………………………….…………………… ……………………………

Common Errors and Troubleshooting…………………………………………………………………………………………

Maintenance………………………………………………………………………………………….………………………….

Limited Warranty…………………..……………………………………………………………….……………..……………

2

3

5

5

5

6

7

8

9

10

11

12

13

13

15

15

16

17

17

19

21

23

24

26

29

29

31

33

33

34

35

35

36

37

37

38

39

39

40

41

42

43

44

45

45

45

47

48

48

50

52

52

53

54

55

55

56

56

57

Torbal Crane Scales

Chapter 1: Cautionary Notes

Remember choose a proper location for you scale. Always handle the unit with care.

The correct location and proper environment make an important contribution to the accuracy of the weighing

results of TORBAL industrial scales.

The optimum location and installation for your scale:

• Stable, vibration-free mounting installation.

• Away from direct sunlight

• Not exposed to high temperature variations

• Away from direct drafts

• When mounting take extra caution and make sure that your mounting method

will support a load which is equal to twice the weight of the scale’s maximum

weighing capacity. Improper mounting of the crane scale can result in having the

unit fall from its mounted height and can cause serious injury or death.

- 2 -

CAUTION:

WARNING:

• The scale is designed for indoor use only.

• Do not operate the scale in hazardous areas or conditions.

• Do not use the scale in locations subject to high humidity.

• Do not connect cables in ways other than those mentioned in this manual.

• Be sure to set the scale on a firm, stable, horizontal surface.

• Never stand on or lean upon this product. Equipment may fall or collapse, causing breakage

and possible injury.

• Before moving the product, unplug it and unplug all cables connected to it.

• When storing, transporting or returning the scale for service, always use the original

packaging.

• Never attempt to repair, disassemble or modify the scale yourself. Tampering with the scale

may result in injury and cause more damage to the equipment.

• Be sure to use the specified power source.

• Do not allow foreign matter to fall into the scale.

• If water or other liquid spills into the scale, do not continue to use it. Unplug the power cord

immediately and contact technical support.

1.1. Important handling Cautions and Warnings

Follow all safety guidelines in order to avoid electrical shock, or damage to

connected peripheral devices.

• All necessary repairs or internal adjustments should be made by authorized personnel only.

• To avoid the risk of fire use an outlet of the proper type that provides the specified voltage. The

required voltage for the power supply is 115vAC @ 60Hz and requires a minimum of 1.2 amperes

of current.

• Do not use the scale when the cover is open.

• Do not use the scale in explosive atmospheres.

• Do not use the scale in very high humidity.

• If the scale does not operate properly, unplug the power supply and do not use it until checked by

authorized personnel.

Disposal of electronic equipment in waste containers is

forbidden by law.

• Please dispose of electronic equipment in appropriate recycling centers or by

returning to the original point of purchase.

- 3 -

Always handle your scale with care. Damage caused by improper handling is not covered

under the scale’s warranty. Improper installation can cause a safety hazard.

When mounting take extra caution and make

sure that your mounting method will support a

load which is equal to twice the weight of the

scale’s maximum weighing capacity. Improper

mounting of the crane scale can result in having

the unit fall from its mounted height and can

cause serious injury or death.

DO NOT let the scale fall or drop from its

tabletop surface!

Never drop or throw articles at the scale or any

other parts of the unit!

DO NOT spray water or any other liquids at the

scale to avoid liquid damage!

- 4 -

Chapter 2: Specifications

2.1 Scale Specifications

BA15S BA15SR BA30S BA30SR BA60S BA60SR BA150S BA150SR

Capacity

Readability (d)

Temporary (BP) Increased

Resolution

Stabilization time (typical)

Tare Range

Indicator Dimensions

Overall Height

Scale Weight

Internal Battery

Working Time w/Battery

Charging Time

External Power Supply

Operating Temperature

RS232 Female Opto-Isolator

RS232 Male Opto-Isolator

Class

Warranty

2.2 Remote Control Specifications

Operating Range

Frequency

Channels

Power

Battery Operating Time

(no backlight)

Battery Operating Time

(with backlight)

Power Consumption

(no backlight)

Power Consumption

(no backlight)

LCD Dimensions

Remote Control Dimensions

Operating Temperature

Model

15 kg / 30 lbs 30 kg / 60 lbs 60 kg / 150 lbs 150 kg / 300 lbs

5 g / 0.01 lbs 10 g / 0.02 lbs 20 g / 0.05 lbs 50 g / 0.1 lbs

0.5 g / 0.001 lbs 1 g / 0.002 lbs 2 g / 0.005 lbs 5 g / 0.01 lbs

< 3s

-15 kg -30 kg -60 kg -150 kg

195x165x100 mm (7.7x6.5x3.9 in)

500 mm (19.7 in)

3.3 kg (7.3 lb)

Lead Acid

> 8 hours

< 3 hours

12 VDC@160ma

-10C to +40C

Bidirectional

Bidirectional

III

One Year

Remote Control

656 ft (200m)

915 Mhz, 868 Mhz

16

4 x 1.5V AAA Batteries

60 hours

20 hours

20 mA

50 mA

47 x 33 mm (1.9 x 1.3 in)

80 x 185 x 35 mm (3.1 x 7.3 x 1.4 in)

-10C to +40C

- 5 -

Chapter 3: Keys, Display Indicators and Abbreviations

Key Primary Function

ÆTÅ

Æ0Å

MENU

B/G

HR

Display Indicator

AUT

NET

Power On and Power Off

Tare – used to tare the weighing pan

Zero – used to zero the scale (Legal for Trade models only)

Menu – used to access the main menu

Data Transfer – used to print data or transfer data to a PC via the RS232 communication port

Gross Weight – used to change display from Net Weight to Gross Weight

High Resolution – temporarily (5 sec) increases the display resolution

Description

Stability Indicator - The weighing result has stabilized and an accurate reading may be taken.

Zero - The scale is maintaining a “center of zero” condition. (Legal for Trade models only)

AZSM (Automatic Zero Setting Mechanism) is enabled. Always enabled in Legal for Trade models.

Net Weight – indicates that the container weight has been removed by tare

- 6 -

Chapter 4: Parts Description

Front View Front View w/Remote Control Side View

Rear View Remote Control RS232 Port and

- 7 -

Opto-Isolator Output

Chapter 5: Unpacking the Balance and Getting Started

1. Carefully remove the crane scale, ac adapter, as well as the remote control and antenna (optional) out

of the packaging.

2. After removing all of the components, place the crane scale on a table top surface.

3. Using scissors cut the plastic tie straps which secures the hook during shipping.

4. If an optional remote control is purchased, mount the remote antenna onto the

crane scale by firmly screwing it into the antenna port located on the left side.

5. After assembling the unit, plug in the AC adapter to the AC adapter socket

located on the right side the scale. Leave the adapter plugged in for

minimum of 3 hours in order to charge the scale’s internal battery.

6. Once the battery has been charged the scale maybe installed.

Before installing the scale make sure that the scale’s hook is

in place, and firmly secured with two locking retaining rings

located on both sides of the hook shaft.

7. When mounting take extra caution and make sure that your mounting method will support a load

which is equal to twice the weight of the scale’s maximum weighing capacity.

Improper mounting of the crane scale can result in having the unit fall from

its mounted height and can cause serious injury or death.

8. After installing the scale, the unit can be turned on by pressing the power ON key ( ).

C-1 0

9. To turn the scale OFF press the Power “OFF” button (

- 8 -

).

00

Chapter 6: Battery Operation

The BAS Crane Scale is equipped with six Ni-MH 1.2V or two 3.7V internal rechargeable batteries. The

battery pack is built in as an integrated part of the scale’s back cover. The battery has been designed to handle

up to 1,000 charging cycles, which should allow the battery to last anywhere from two to three years. The

battery pack should be replaced when after fully charged its operating time is reduced to 20% of its nominal

value (fewer than 4 hours). In order to replace the battery pack, please contact Torbal Technical Support.

Never attempt to replace the battery on your own. By doing so you may cause scale damage and void the

manufacture’s warranty.

Useful Tips for Operating the Scale with a Battery

• In order to increase the battery’s operating life, it is recommended to set the scale’s back light mode to

(“back light battery” – B_LBAT). Refer to Chapter 29 (LCD back light).

• The scale’s internal battery’s are always in the charging mode when the scale is plugged into a power

outlet. Do not allow the battery’s to completely discharge as this may damage the battery or reduce its

life.

• When operating the unit on batteries it is recommended to enable the scale’s “Auto-Off” function by

setting it to AUT BAT. This will turn the scale off automatically after 5 minutes of inactivity. Refer to

Chapter 30 (Auto Off).

- 9 -

Chapter 7: Remote Control (Optional)

The wireless remote control allows controlling the scale and receiving the weighing result on the remote’s

LCD display in real time.

Key Primary Function

MENU

↑,↓,→,←

ENTER

→T←

→0←

PRINT

ON/OFF

BACKLIGHT

1. After unpacking the remote control install four AAA batteries. To do

2. To change the remote’s RF Channel, RS232, or LCD settings, press

B/G

HR

so unlock the remote’s access cover by moving the securities switch to

the right (1). After moving the security switch, open the battery cover

by lifting it on its left side (2). When installing the batteries be sure to

use correct polarity (+/-) (3).

To begin using the remote control press the On/Off key. By default the

remote control is set to receive and send data to the unit using RF

Channel 1. The BAS Crane Scale is set to the same RF channel

therefore; the remote control will communicate with the unit

automatically as soon as it turned on.

the MENU key and configure the remote with the appropriate settings.

Allows accessing the remote control main menu.

Allows navigating remote’s main menu.

Tares the scale or accepts selected options in the main

menu.

Zeros the scale.

Indicates the gross weight

Initializes the scale to print or perform data transfer

through RS232

Disables and enables the remote control

Indicates weighing result with higher resolution

Enables remote LCD backlight

- 10 -

Chapter 8: Basic Principles of Weighing

1. The scale should be properly zeroed before weighing. Proper zeroing is indicated by the Zero

→0←

Indicator (

(

→0←

) key to Zero an empty pan.

2. Weighing allows taring over the entire weight range. This is accomplished by pressing the Tare

key, (

→T←

capacity is not overloaded.

3. An accurate weighing result should not be taken until the stability indicator, ( ) , indicates that

the result is stable, and the hanging load is stable from swiveling.

4. For best results place the unknown weight in the center of the pan.

5. Always protect the scale from dirt, dust, and corrosive liquids. When Cleaning use of a clean cloth

with soap and water, and then dry with a clean wiper.

6. Use the “Active” function to customize the scale’s main menu and disable functions that are not used.

This makes use the main menu fast and easy.

7. Always secure the weighing load on the hook with extra caution to make sure it will not fall off.

) on the display. If the display signals an out of zero condition (----), press the

). Care should be exercised when tare is in use to be sure that the scale’s maximum

Never overload the scale in excess of 20% of the scale’s rated maximum

capacity.

- 11 -

Chapter 9: Functions, Descriptions and Definitions

• Parts Counting is used to count parts based on their established average piece weight.

• Percent weighing is used to establish the relative weight of an unknown, compared to that of a stored

reference weight and expressed as a percent.

• Recipe Making is used for weighing and summing individual ingredients such as powers or liquids

during recipe making or mixing compounds.

• Check weighing is used to check whether a weight of an object falls within specified threshold limits.

• Animal and dynamic weighing is used to weigh animals or objects which are in motion while on the

pan.

• Tare Storing is used to store the values of various containers used for weighing.

• Filtering is used to minimize or eliminate the effects of vibrations in the weighing surface.

• Min / Max Indication is used in conjunction with Check Weighing to control external indication or

sorting equipment.

• Totalizing is used for summation of sequential weighing results of items or articles.

- 12 -

Chapter 10: Weighing

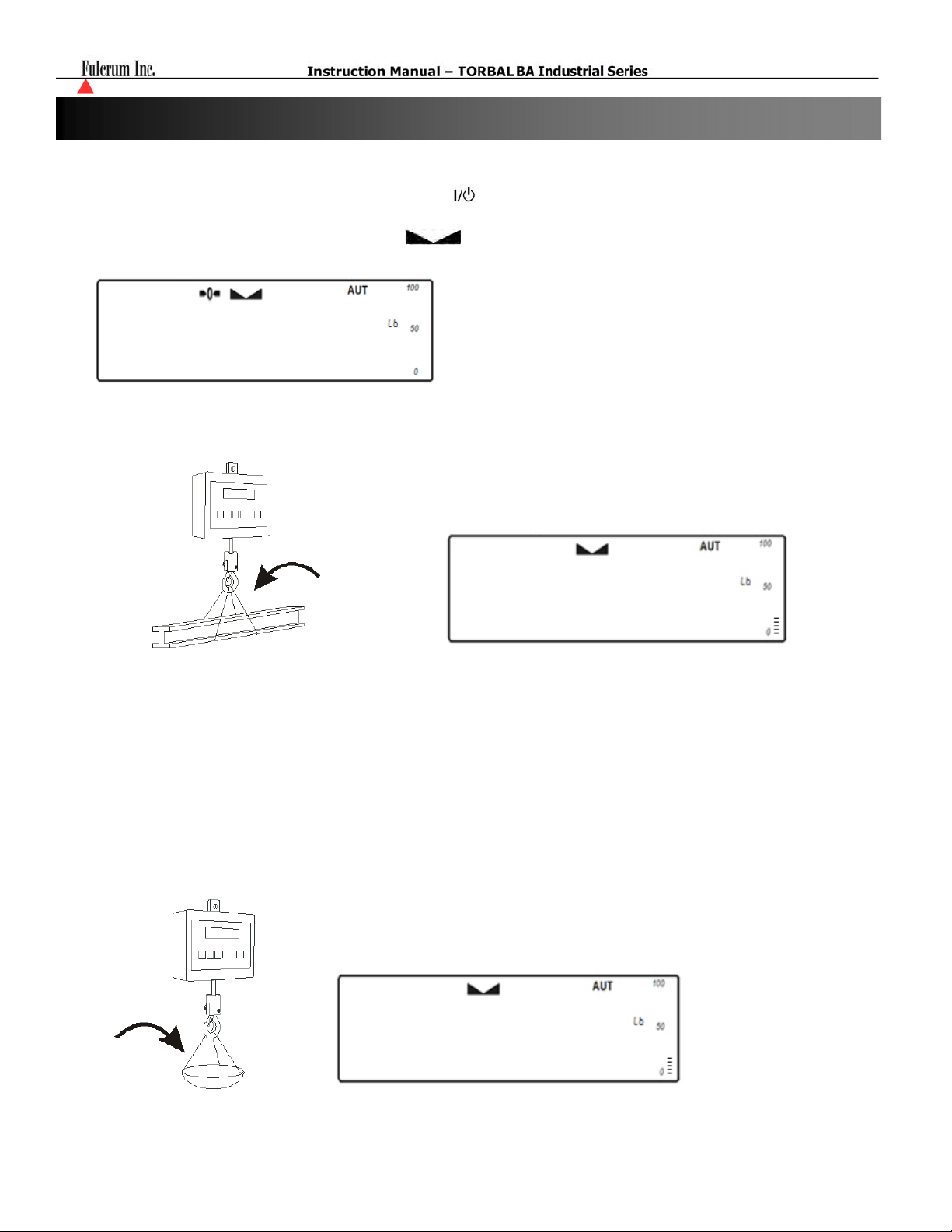

1. To begin weighing, press the power button ( ) to turn the scale ON. The scale will go through its

initialization procedure and automatically enter “Weighing Mode”. The scale is ready to begin

weighing as soon as the stabilization (

0

00

2. When weighing, always hang each load on the scale’s hook with caution and make sure it is safety

secured. The weighed result may be taken when the stabilization indicator appears on the display.

) and zero (Æ0Å) indicators appears on the display.

12

10.1 Taring

1. If a hanging pan is used for weighing, it may be tared. In taring the pan, the scale subtracts the weight

of the pan from the gross weight to obtain the net weight.

2. To tare the hanging pan, hang it on the hook. The pan’s weight will be shown on the display.

2

04

00

- 13 -

3. Once the stabilization indicator appears on the display, the pan is ready to be tared. To tare the pan,

press the “T” button. The display will show a dotted line which indicates the scale has begun the taring

process.

-------

4. When finished taring, the balance will return to weighing and the NET indicator will be lit. The

display will indicate 0.00g.

0.00

5. Place the unknown weight in the tared hanging pan. The NET weight will be displayed.

20.00

6. To obtain the gross weight (Tared pan + unknown weight) press the B/G key.

22

04

- 14 -

10.2 Extending the resolution

1. The resolution of the scale can be temporarily increased by pressing the HR key. This temporary

increase in resolution can be very useful in scales where d=e. The display resolution is increased for 5

seconds and then reverts automatically.

22

Note: These results are not legal for trade and cannot be sent to a printer or an external computer.

10.3 Zeroing the scale

If the display signals are out of zero condition “—“, the scale must be zeroed before weighing.

036

- -

1. To zero the scales press the Æ0Å key.

-------

- 15 -

0

00

(

)

Chapter 11: Auto-zero

All BA Scales are equipped with AZSM, the “Auto Zero Setting Mechanism.” AZSM automatically

maintains a center of zero and 5.0d.

1. Enter the main Menu by pressing the MENU key

0

2. Select “AutotA” by pressing the T key.

AutotA

00

Autota

3. To enable Auto-zero press the T key when “Aut on” is displayed, to disable press the T key when

“AutoFF” is displayed or select “out” to exit.

Aut on

Autoff

- 16 -

(

)

Chapter 12: Parts Counting

Functions Options:

PCS Off

PCS On

PCS ..

PC Set

PC UM

PCS RS

12.1. Using a default sample size setting

1. Hang a container or a hanging pan on the hook while in the weighing and press the T key to tare.

( PCsoff)

(pcs on)

(PCS . .)

(PC SET)

(PC UMM)

(PCs rS)

Disables Parts Counting

Enables Parts Counting

Recalls the last Average Pieces Weigh used in for counting

Setting a custom sample size

Setting a custom known Individual Piece Weight

obtaining the average piece weight from secondary higher accuracy scale via RS232

PCS

-------

2. Place a sample in the pan. The sample size must equal to one of the pre-set options: 5,10,20,50,100,

200,500, and press the MENU key

PCS

25

3. Wait for PCS to appear on the display and press the T key

00

pCS

- 17 -

4. Select “PCS on” by pressing the T key.

pCS on

5. Available sample size options will alternate on the display. Press the T key to select a size value equal to

the number of the sample placed in the pan.

pCS 5

6. After the sample size has been selected, the scale will display the count of the sample. At any time you

can proceed with the count.

PCS

17

7. To turn parts counting off, select PCS from the main menu and press the T key when “PCSoFF” is

displayed.

- 18 -

12.2. Using a custom sample size

1. Hang a container or a hanging pan on the hook while in the weighing mode and press the T key to tare.

-------

2. Place a desired sample size in the pan and press the MENU key. (i.e. 12 as illustrated).

PCS

25

3. Wait for PCS to appear on the display and press the T key

00

pCS

4. Select “PCS on” by pressing the T key.

pCS on

5. Available sample size options will alternate on the display. Press the T key when “PC Set” is displayed.

pC set

- 19 -

6. A dashed line will be displayed indicating to manually enter the value for your sample size in the

container. To do so, use the following keys: the Æ0Å key to increment a digit, the T key to accept and go

to the next digit, and MENU to accept the entire setting.

To increment a digit To accept and go to next digit To accept entered value

.

7. Once your custom sample size value has been entered and the MENU key pressed, the scale will display

the count of the sample. At any time you can proceed with the count.

PCS

12

PCS

50

8. Once an accurate count has been taken, the contents may be removed from the scale. To turn parts

counting off, select PCS from the main menu and press the T key when PCSoFF is displayed.

- 20 -

12.3. Counting based on a known Individual Piece Weight (No Sample Size Required)

1. Hang a container or a hanging pan on the hook and press the T key to tare.

-------

2. Press the MENU key to enter the main menu.

3. Wait for “PCS” to appear on the display and press the T key

pCS

4. Select “PCS on” by pressing the T key.

pCS on

5. Available sample size options will alternate on the display. Press the T key when “PC uM” is displayed.

pC UMM

- 21 -

6. A dashed line will be displayed indicating to manually enter the exact individual piece weight of the

counted parts. To manually enter the individual piece weight, use the following keys: the C key to

increment a digit, the T key to accept and go to the next digit, the key to insert a decimal, and the

MENU key to accept the entire setting.

To increment a digit To accept and go to

next digit

To insert a decimal To accept entered

value

.

10.00

7. Once the individual piece weight is entered and the MENU key pressed, the scale will display “0pcs”. At

any time proceed with the count.

PCS

5

8. Once an accurate count has been taken, the contents may be removed from the scale. To exit parts

counting and return to basic weighing, select “PCS OFF” from the parts counting menu.

- 22 -

(

)

Chapter 13: Units of measure

The BA Scales can operate in nine different units of measure: Grams (g), Kilograms (kg), Carats (ct), Pounds

(lb), Newton, Grains, Ounces, Ounces Troy, Pennyweight. By factory default, the scale is set to weigh in

grams (lb). To select a different unit of measure, follow the steps below.

1. Enter the main menu by pressing the MENU key.

2. When command “UNITS” is displayed, press the T key.

Unit

Unit

3. The scale will display available units of measure sequentially.

Carat penny

4. When the desired unit is displayed, press the T key to make the selection.

5. Once the selection is made, the scale will automatically return to the weighing mode.

- 23 -

(

)

Chapter 14: Percent Weighing

Function Options:

PER Off

PER On

Percent weighing is used to express the weight of an object as a percentage of a stored sample weight.

To use percent weighing, follow these steps:

1. Hang a container or a hanging pan on the hook and press the T key to tare.

( Peroff)

(per on)

Disables Percent Weighing

Enables Percent Weighing

PerC

-------

2. Once the scale has been tared, place the sample reference weight on the pan.

15

3. The weight of the sample will be displayed as it is placed on the pan. Once the weight

of the sample stabilizes and the stability indicator appears on the display, press the

MENU key to enter the main menu.

4. When “PERCENT” is displayed, press the T key.

23

PerC

- 24 -

5. Commands “PER OFF” and “PER ON” will be displayed sequentially. To proceed with percent weighing

and set the reference sample weight, press the T key when command “PER ON” is displayed.

Per on

6. Once the reference sample weight is set, the scale will express the weight as a percentage.

%

100

7. Remove the sample and place an object in the pan. The scale will express the weight of that object as a

percentage of the stored sample.

%

50

8. To exit percent weighing and return to basic weighing, select “PER OFF” from the percent menu.

- 25 -

(

)

Chapter 15: Recipe Weighing

reCIpe

Function Options:

Rec Off

Rec On

Rec Con

( rECoff)

(reC on)

(reCCon)

Disables Recipe Weighing

Enables Recipe Weighing

allows to continue recipe making after obtaining a total

1. Hang a container or a hanging pan and press the T key to tare.

-------

2. Press the MENU key to enter the main menu.

3. Wait for “RECIPE” to appear on the display and press the T key

reCIpe

4. Select “Rec on” by pressing the T key.

REC on

- 26 -

5. The display will read 0 indicating that you may place the first ingredient into the pan. Once the Weight of

the ingredient stabilized press the T key to accept the ingredient weight.

0

22

6. Once the weight has been accepted place the second ingredient into the pan. Once the weight of the

second ingredient stabilizes press the T key to accept the ingredient weight.

0

37

7. Steps 1 and 2 can be repeated until all ingredients are in the pan. Before obtaining a Total make sure that

the last ingredient weight was accepted and the display reads 0.

0

44

8. To obtain the Total for the recipe press the MENU key, select the “Recipe” function, and then select “Rec

Off”

reCIpe

reCoff

- 27 -

9. The total of all ingredients will be displayed.

1

04

10. To continue Recipe making press the MENU select the “Recipe” function, and then select “Rec Con”

reCIpe

11. Press the T key to accept the current Total and repeat steps 5 through 7 to add more ingredients.

12. To clear and start a new recipe, remove all ingredients from the pan and press the zero key Æ0Å. Once

the result is cleared, repeat steps 1 through 9.

reCCon

- 28 -

(

)

Chapter 16: Calibration

Function Options:

CAL On

CAL Stp

Other

Calibration with an external Calibration Weight should be performed if the scale exhibits erroneous readings

or periodically to assure accuracy of all weighing results. The scale should be calibrated with a high accuracy

weight equal to its maximum capacity. Before starting calibration, have the appropriate calibration weight

available.

( CaL oN)

(CALSTP)

(other)

Starts Quick Calibration. Recommended when calibrating with a single calibration

weight.

Starts Stepped Calibration. Recommended when calibrating with multiple

calibration weights.

Calibration with calibration mass not equal to the scale’ capacity.

CaLIb

16.1 Quick Calibration (calibrating with a single calibration weight).

1. Press the MENU key, when the option “Calib” is displayed press the T key, and then select the option

“CAL On” by press the T key once again.

CaLIb

CAL oN

2. The scale will display a full a calibration mass equal to the scales capacity i.e.”30”, and an option to select

a different calibration mass”other“. To calibrate the scale with a mass value equal to the scales capacity

press the T key when the calibration mass value is displayed (proceed to step 4). To calibrate the scale

with a mass lower than the scale’s maximum capacity, press the T when “other” is displayed (proceed to

step 3).

30 other

3. If option “other” has been selected a dashed line will be displayed indicating to manually enter the exact

value of the calibration mass used to calibrate the scale. To manually enter the calibration value, use the

following keys: the C key to increment a digit, the T key to accept and go to the next digit, the key to

insert a decimal, and the MENU key to accept the entire setting.

To increment a digit To accept and go to

next digit

To insert a decimal To accept entered

- 29 -

value

4. The scale will perform a tare and the message “LOAD” will be displayed.

-CAL-

5. When the message “LOAD” is displayed, place the calibration weight on the scale’s hanging pan.

Calibration will begin automatically and “WAIT” will be displayed indicating that calibration is in

progress.

------

LOAD

wwAIT

6. When finished the scale will automatically return to the weighing mode, and the calibration weight can be

removed from the pan.

30

00

- 30 -

16.2 Stepped Calibration (calibrating with multiple calibration weights.)

1. Press the MENU key, when the option “Calib” is displayed press the T key, and then select the option

“CAL Stp” by press the T key once again.

CaLIb

2. The scale will display a full a calibration mass equal to the scales capacity i.e.”30”, and an option to select

a different calibration mass”other“. To calibrate the scale with a mass value equal to the scales capacity

press the T key when the calibration mass value is displayed (proceed to step 4). To calibrate the scale

with a mass lower than the scale’s maximum capacity, press the T when “other” is displayed (proceed to

step 3).

CAL STP

30 other

3. If option “other” has been selected a dashed line will be displayed indicating to manually enter the exact

value of the calibration mass used to calibrate the scale. To manually enter the calibration value, use the

following keys: the C key to increment a digit, the T key to accept and go to the next digit, the key to

insert a decimal, and the MENU key to accept the entire setting.

To increment a digit To accept and go to

next digit

4. The scale will display the message “Press Menu”. When you are ready to tare the scale press the MENU

key.

-CAL-

press

To insert a decimal To accept entered

mmenu

- 31 -

value

5. The scale will perform a tare and the message “LOAD” will be displayed indicating to place all

calibration weights on the pan. After placing all weights on the pan, press the MENU key to initiate the

calibrations process.

Caution: Do not press MENU until all calibration weights are on the scale’s pan

------

LOAD

-CAL-

press

6. Message “CCCCCC” will be displayed indicating that calibration is in progress. When finished the scale

will automatically return to the weighing mode and the calibration weights can be removed from the pan.

CCCCCC

mmenu

30.00

- 32 -

(

)

Chapter 17: Port 1-RS232 Communication Port Configuration

After a weighing transaction is completed, a result data receipt can be printed. To initiate printing,

press the data transfer key. Data may be sent to a printer or a PC via the Torbal Communication

Software.

Rs-1

17.1 Data Transmission and Exchange Protocol

Data Transmission (LONG):

Transmission Parameters: 8 bits, 1 stop bit, no parity, baud rate 4800bps,

Exchange data:

Transmit the weight (equivalent to the Print Key, , in weighing:

Computer→Scale: S I CR LF (53h 49h 0Dh 0Ah) – initiating signal,

Scale→Computer: scale sends 16 Bytes of data as follows:

Byte 1 - The charater ‘-‘ or space

Byte 2 - space

Bytes 3,4 - digit or space

Bytes 5-9 - digit, comma, or space

Byte 10 - digit

Byte 11 - space

Byte 12 - k, l, c, p or space (for kg,lb,ct,pc, or%)

Byte 13 - g, b, t, c or %

Byte 14 - space

Byte 15 - CR

Byte 16 - LF

‘Tare the weight’ (corresponds to the →T← key in weighing):

Computer→Scale: S T CR LF (53h 54h 0Dh 0Ah),

Scale→Computer: no response.

‘Zero the scale’ (corresponds to the key →0← in weighing):

Computer→Scale: S Z CR LF (53h 5Ah 0Dh 0Ah),

Scale→Computer: no reponse.

‘Turn On / Off the Scale (corresponds to the key I/ in weighing):

Computer→Scale: S S CR LF (53h 53h 0Dh 0Ah),

Scale→Computer: no response.

‘Display the MENU’ (corresponds to the key MENU in weighing):

Computer→Scale: S F CR LF (53h 46h 0Dh 0Ah),

Scale→Computer: no response.

Setting the threshold 1 (optional):

Computer→Scale: S L D1...DN CR LF (53h 4Ch D1...DN 0Dh 0Ah)

where: D1...DN – Threshold value, up to 8 characters,

Scale→Computer: no response,

- 33 -

Example:

To set 1000g in weight B1.5 (d=0.5g) type:

S L 1 0 0 0 . 0 CR LF (53h 4Ch 31h 30h 30h 30h 2Eh 30h 0Dh 0Ah).

To set 100kg in weight B150 (d=50g) type:

S L 1 0 0 . 0 0 CR LF (53h 4Ch 31h 30h 30h 2Eh 30h 30h 0Dh 0Ah),

Setting the threshold 2 (optional):

Computer→Scale: S H D1...DN CR LF (53h 48h D1...DN 0Dh 0Ah),

where: D1...DN – threshold value, up to 8 characters,

Scale→Computer: no response

Cable WK-1 Configuration

Cable WD-1 Configuration

17.2 Baud Rate

1. Press the MENU key, when the option “Port - 1” is displayed press the T key, and then select the option

“Baud” by press the T key once again.

rs -1

2. The scale will begin to display available baud rates: “4800”, “9600”, “19200”, “38400”, and “57600”. To

make a selection, press the T key when the desired setting is displayed.

bAUd

4800 9600 19200

38400 57600

- 34 -

17.3 Bites

1. Press the MENU key, when the option “Port - 1” is displayed press the T key, and then select the option

“Bites” by press the T key once again.

rs -1 bItS

2. The scale will display available Bits settings: “7-bit”,”8-bit”. To make a selection press the T key when

the desired setting is displayed.

7 - bIt

17.4 Parity

1. Press the MENU key, when the option “Port - 1” is displayed press the T key, and then select the option

“Parity” by press the T key once again.

8 - bIt

rs -1 PARITY

2. The scale will display available Parity settings: “none”,”odd”, “even”. To make a selection press the T key

when the desired setting is displayed.

none odd

- 35 -

evEN

(

)

Chapter 18: Receipt Printout

A detailed transaction receipt can be printed after weighing has been completed. The receipt can be

customized to include the following information:

Header

idOPER

pRINT

Header – includes unit information such as: Mode

number, Max Capacity, resolution and Unit Serial

number.

Operator Id – shows the ID number of the user

which performed the weighing transaction

DATE

Date – Date of the performed transaction

TIME

Time – Time at which the transaction was

performed

prn no

Printout number – Number of the receipt

prenticed in a given day

ID Prod

Product Id – ID number of the product or item

weighed

Count

Count – Result obtained in Parts Counting

APW – Average Piece weight of the counted parts

ApWW

in the Parts Counting Functions

NETTo

Net – Net result of the weighing transaction

tare

Tare – tared weight in the weighing transaction

brUTTo

Gross – gross weight of the weighing transaction

total

Total – grand total obtained in the totalizing

function

- 36 -

18.1 Enabling and Disabling Receipt Fields

1. Press the MENU key, when the option “Print” is displayed press the T key, and then select a desired field

by press the T key once again when the name is displayed.

PrINT

2. The scale will display options “ON” and” Off”. To enable the field press the T key when “On” displayed,

to disable the field press the T key when “Off” is displayed.

ON

18.2 Assigning Operator and Product ID numbers.

1. From the weighing mode press and hold the MENU key for 3 seconds or until the scales displays

“IDPROD” and “IOPER”. Select the desired option by pressing the T key.

OFF

HEADER

0.00 IDPRoD

2. A dashed line will be displayed indicating to manually enter ID number. To manually enter the ID

number, use the following keys: the C key to increment a digit, the T key to accept and go to the next

digit, the key to insert a decimal, and the MENU key to accept the entire setting.

To increment a digit To accept and go to

next digit

To insert a decimal To accept entered

- 37 -

value

(

)

Chapter 19: Dynamic and Animal Weighing

Function Options:

LOC Off

LOC On

LOC Prn

1. Hang a container or a hanging pan and press the T key to tare.

( LOC oFF)

(LOC on)

(LOC Prn)

Disables the LOC Dynamic Weighing Function

Enables and Starts the LOC Dynamic Weighing Function (Weight integration

initiates automatically)

- Enables and Starts the LOC Dynamic Weighing Function (Weight integration is

initiated manually with the press of the Data Transfer Key )

LOC

-------

2. Press the MENU key, when the option “LOC” is displayed press the T key, and then select the option

“LOC On” or “LOC Prn” by press the T key once again.

LOC

3. Place the animal or the moving object on the pan. Weight integration will begin automatically. If “LOC

Prn” was selected press the data transfer key to initiate weight integration manually

is integrating the weighing result the display flashes.

0

28

4. Final result will be automatically sent to a printer or a PC via the RS232 port. During data transmission

the word print will be displayed. The final result remains displayed for 30 seconds. To perform the next

weighing remove the animal, wait for the scale to display 0 and place the next animal on the pan.

LOC oN

. While the scale

- 38 -

Chapter 20: Storing Tare Values

20.1 Storing a Tare Value Manually

1. Press the MENU key, when the option “Tare” is displayed press the T key, and then select the option “Tar

Set ” by press the T key once again.

tare tarset

2. The scale will begin to Display tare locations. Locations marked with a dot in the upper left corner of the

LED have a stored tare value assigned. To select a tare location or overwrite a current location press the T

key when a desired location is displayed, and then select the option “Manual ” by press the T key once

again.

tare 1

3. A dashed line will be displayed indicating to manually enter the Tare value. To manually enter tare value,

use the following keys: the C key to increment a digit, the T key to accept and go to the next digit, the

key to insert a decimal, and the MENU key to accept the entire setting.

To increment a digit To accept and go to

next digit

4. Once a tare value has been assigned, the scale will automatically store the value in the selected memory

location and return to the weighing mode with the tare value in use.

mmanual

To insert a decimal To accept entered

value

- 39 -

20.2 Storing a Tare Value Automatically

1. Hang a container or a hanging pan and press the MENU key to enter the main menu.

0

60

2. When the option “Tare” is displayed press the T key, and then select the option “Tar Set ” by pressing the

T key once again.

tare

3. The scale will begin to Display tare locations. Locations marked with a dot in the upper left corner of the

LED have a stored tare value assigned. To select a tare location or overwrite a current location press the T

key when a desired location is displayed, and then select the option “Pan ” by press the T key once again.

tare 1

4. The scale will automatically store the value of the pan on the in the selected memory location and return

to the weighing mode with the tare value in use.

tar set

PAn

- 40 -

20.3 Recalling a previously stored tare value.

1. Press the MENU key, when the option “Tare” is displayed press the T key, and then select the option “Tar

On ” by press the T key once again.

tare

2. The scale will begin to Display tare locations. Locations marked with a dot in the upper left corner of the

LED have a stored tare value assigned. To select a tare location press the T key when a desired location is

displayed.

tar on

tare 1

3. The scale will return to the weighing mode with the selected tare value in use.

- 41 -

(

)

Chapter 21: Min – Max Weighing

This function allows you to find the maximum (highest) or minimum (lowest) weight in a series of weights.

1. Press the MENU key, when the option “Up” is displayed press the T key, and then select the option

“High” or “Low” by press the T key once again.

up

2. The scale will return to weighing and it will begin to hold on the display the highest or the lowest weight.

When seeking the highest weight in a series make sure to remove the previous weight from the pan before

adding the new weight. When seeking the lowest value weight be sure to add the new weight before

removing the previous weight.

Note: Add and remove weights with care in order not to increase the weight unintentionally.

UP

LOWW HIGH

1.00

Note: Stability indicator and Auto-Zero is disabled during Min/Max weighing.

10.00

- 42 -

10.00

(

)

Chapter 22: Newton – Force Measurement

This function changes the unit of weight to Newton (N) - 1N ≈0.101971 kg

1. Press the MENU key, when the option “Newton” is displayed press the T key.

NEWWTO

newwtO

2. The scale will display options “ON” and” Off”. To enable Newton force measuring press the T key when

“New On” displayed, to disable Newton force measuring press the T key when “New Off” is displayed.

neww ON

nww oFF

- 43 -

(

)

Chapter 23: Filtering

This function is used when vibration is encountered during weighing. This may be the result of ground

vibration, or a vibrating live load on the pan. Increasing the filter setting will increase the time required for a

measurement. The integration time of the measurement is increased thereby eliminating higher frequency

vibration.

1. Press the MENU key, when the option “Filter” is displayed press the T key.

FILTER

fILTER

2. The scale will display options “Off” and available filter sensitivity levels “Fil 10, Fil 20, Fil 30 and Fil

40”. To select and enable Filtering press the T key when a desired filter level is displayed.

Filter Sensitivity

Fil 10 Low

Fil 20 Medium

Fil 30 High

Fil 40 Severe

FIL 10 FIL 20 FIL 30 FIL 40

3. To disable filtering select “Fil Off” from the filter menu.

- 44 -

(

)

Chapter 24: Date and Time

Function Options:

Dat On

Dat Off

Dat Set

Dat Pin

Dat For

24.1 Enabling and Disabling Date and Time stamping

1. Press the MENU key, when the option “Date” is displayed press the T key.

(DAT oN)

(DAToff)

(datset)

(datpIn)

(datfor)

Enables date and time printing with every weighing result.

Disables date and time printing.

Date configuration” allows to set the current date and time.

Enables PIN access to the Date Configuration.

Format selection (United States / Europe).

date

date

2. The scale will display options “Dat On, Dat Off, Dat Set, Dat Pin, Dat For” . To enable Date stamping

press the T key when “Dat On” is displayed, to disable press the T key when “Dat Off” is displayed.

dat ON dat oFF

24.2 Setting the current date and time

1. Press the MENU key, when the option “Date” is displayed press the T key, and then select the option “Dat

Set ” by press the T key once again.

Date DATSET

2. The current time will be displayed. To change or to set a new time press the T key

h03-25

h03-25

- 45 -

3. Use the following keys to change the current time

4. Once the time has been set the scale will display “PM” or “AM”. Press the T key when the desired setting

is displayed.

To increment a digit To accept and go to

next digit

5. Once the Time has been set, the scale will display the current date. To change or to set a new date press

the T key

d06-12

6. Use the following keys to change the date

7. Once the time has been set the scale will display the current year. To change the years press the T key.

To increment a digit To accept and go to

d06-12

next digit

y - 2010

- 46 -

24.3 Enabling PIN access to the Date Configuration Function.

Configuration of the current date and time can be protected with a PIN. Once set the user is prompted to enter

a pin number before time and date change is allowed.

1. To Set PIN for date configuration press the MENU key. When the option “Date” is displayed press the T

key, and then select the option “Dat PIN ” by press the T key once again.

Date

2. The scale will display a dashed line indicating to enter a desired PIN. To enter the PIN, use the following

keys: the C key to increment a digit, the T key to accept and go to the next digit, the key to insert a

decimal, and the MENU key to accept the entire setting.

To increment a digit To accept and go to

next digit

3. After setting the PIN, you will be asked to key in the pin in order to access the “Date and Time” feature.

To remove or disable PIN access, enter the “Date” function and key-in the current PIN. After accessing

the “Date” menu, select option “DatPin” and do not enter a new PIN number. Simply press the MENU

key with the dashed line displayed.

To insert a decimal To accept entered

DATPIN

PIN

_

- 47 -

(

)

Chapter 25: Threshold Check Weighing

Threshold check weighing is used to check whether a weight of an object falls within specified threshold

limits.

Function Options:

Thr Off

Thr On

Thr Prn

Dat Cfg

(throFF)

(thr on)

(thrPrn)

(thrCFG)

Disables threshold and check weighing.

Enables threshold weighing and sets function parameters.

Prints currently set parameters.

Sets output mode for the opto-isolator (Pulse Mode / Level Mode).

ThR

25.1 Enabling check weighing and setting threshold limits.

1. Press the MENU key, when the option “thr” is displayed press the T key, and then select the option

“thr On” by press the T key once again.

thr thr on

2. The scale will begin to display threshold limits. To set the Lower Limit waits for “Set-1” to display and

press the T key. To set the Upper Limit waits for “Set-2” to display and press the T key. To set the

minimum weight value that should be used in check weighing select “Set-3”.

set 0 set 1 set 2 set 3

3. The scale will display a dashed line indicating to enter the limit value. To enter the value, use the

following keys: the C key to increment a digit, the T key to accept and go to the next digit, the

insert a decimal, and the MENU key to accept the entire setting.

key to

To increment a digit To accept and go to

next digit

To insert a decimal To accept entered

value

- 48 -

4. After setting all limit sets, select “Set-0” in order to return to weighing with the limits enabled.

set - O

5. To perform check weighing places the weigh on the Pan. The result is indicated by a dashed line located

on the left side of the display.

LOW OK HIGH

0.50

6. To disable check weighing enter the “thr” menu and select “thr Off”

7. To view the threshold limits Press the MENU key, when the option “thr” is displayed press the T key, and

then select the option “thrPrn ” by press the T key once again.

1.10

3.20

thr thrprn

8. Current limit sets will be displayed and transmitted via the RS-232 port. To view all limits use the T key.

LOW HIGH Min

1.00

- 49 -

3.00

0.20

(

)

Chapter 26: Totalizing

Function Options:

Tot Prn

Tot Off

Tot o

Tot -

1. Hang a container or a hanging pan and press the T key to tare.

(totPRN)

(totoff)

(tot o)

(tot -)

Displays and prints transaction total. (Does not reset the sum value)

Displays and disables the transaction total. (Resets the sum Value)

Prints measurement weigh before adding.

Adds measurement weigh to the total without printing

ToTAl

-------

2. Press the MENU key, when the option “Total” is displayed press the T key, and then select the option

“Tot o ” or “Tot –“ by press the T key once again.

total tot -

3. The display will read 0 indicating that you may place the first object into the container. Once the weight of

the object stabilized press the data transfer key

0

to accept and add the object weight to the total.

22

- 50 -

4. Once the weight has been added, remove the object from the weighing pan.

0

00

5. Wait for the scale to return to 0 and place the second object on the pan. . Once the weight of the object

stabilized press the data transfer key to accept and add the second object weight to the total.

0

55

6. Follow steps 3 through 6 until all object have been added. To view the total of the transaction press the

MENU key, when the option “Total” is displayed press the T key, and then select the option “Tot Prn“ by

press the T key once again.

total

7. The total will be displayed. To view the number of measurements added and the average press the MENU

key.

Total Number of measurements

totprn

Transaction Average

0.77 0.39

- 51 -

(

)

(

)

Chapter 27: RF Channel Setup for Remote Control

In order to use the Crane Scale with the remote control, both the BAS Crane Scale as well as the remote

control must be set to the same RF Channel. To set or change an RF Channel follow the steps below:

1. Press the MENU key, when the option “RF Chan” is displayed press the T Key.

rf chan

rf CHan

2. The scale will display available channels. To set a desired channel presses the T Key.

CHan 01

…

Chapter 28: LCD Back Light

Function Options:

B_L OFF

B_L On

B_L ECO

B_L BAT

To configure or disable the LCD back light follow the steps below:

1. Press the MENU key, when the option “B_Light” is displayed, press the T Key.

(B_L OFF)

(B_L On)

(B_L ECO)

(B_L BAT)

Disables LCD back light.

Enables LCD back light.

Disables the LCD back light after 30 second inactivity “no weight applied to the

pan or the pressed keys.”

Disables back light after 30 second inactivity when operating the unit on batteries

“no weight applied to the pan or the pressed keys.”

b_LIGHT

b_LIgHT

2. The scale will display available back light settings: “B_L On”, B_L Off, “B_L ECO” and “B_L BAT”.

b_L on B_L oFF b_L ECO

3. To make a selection press the T key when desired back light setting is displayed.

- 52 -

b_L BAt

(

)

Chapter 29: Auto OFF

Function Options:

AUT OFF

AUT On

AUT BAT

To configure or disable the LCD back light follow the steps below:

1. Press the MENU key, when the option “Aut Off” is displayed, press the T Key.

(AOF oFF)

(aOF on)

(aOF BAT)

Disables the Auto OFF Function. Scale is always on.

Enables the Auto Off Function. Scale automatically turns OFF after 5min.

inactivity (no weight applied or keys depressed).

Enables the Auto Off Function. Scale automatically turns OFF after 5min.

inactivity (no weight applied or keys depressed).

autoOFF

AUToFF

2. The scale will display available back light settings: “AOF Off”, AOF On, and “AOF BAT”.

AOF on AOF oFF AOF bat

3. To make a selection press the T key when desired Auto Off setting is displayed.

- 53 -

(g)

(

)

Chapter 30: Changing to Grams

The function “lb bal” is used to configure the unit to weigh in grams (g) or pounds (lb). “Lb Bal” optimize

the scale’s accuracy and resolution disabling or enabling ponds (lb) as a default unit of measure.

1. To disable lb (pounds) as default unit of measure and set the scale weigh in grams (g) .Press the MENU

key, when the option “lb_bal” is displayed press the T key.

or Pounds (lbs)

LB_BAL

LB_BAL

2. The scale will display options “Lb Off” and” Lb On”. To select disables pounds and select grams as the

default unit of measure press the T key when “Lb Off” is displayed, to disables grams and select pounds

and the default unit of measure press the T key when “Lb Ob” is displayed.

Lb off Lb on

- 54 -

(

)

(

)

Chapter 31: Menu Customization

The Active function is used to customize the scale’s Main Menu. This feature should be used to deactivate

functions or features that are not used. Deactivated functions will not appear in the Main Menu which will

simplify its use. To activate or deactivate features or function follow the steps below.

1. Press the MENU key, when the option “Active” is displayed press the T key, and then select a desired

function or feature by press the T key once again when the name is displayed.

ACTIU

ACTIu Avtota

2. The scale will display options “ON” and” Off”. To disable a function from appearing in the Main Menu

press the T key when “Off” is displayed, to enable a function to have it appear in the Main Menu press the

T key when “On” is displayed.

ON OFF

Chapter 32: Restoring Default Settings

To restore the scale’s factory settings follow the steps below

1. Press the MENU key, when the option “Default” is displayed press the T key.

DEFAUL

DefauL

2. The scale will display options “Yes” and” No”. To restore the scale’s factory setting press the T key when

“Yes” is displayed. To cancel press the T key when “No” is displayed.

YES NO

- 55 -

Chapter 33: Common Errors and Troubleshooting

Error or Indicator Cause Explanation / Solution

- - - - Below zero Re-zero the scale by pressing the

Æ0Å key.

- - Taring is not allowed Place a weight on the pan before

taking a tare.

- - Re-zeroing is not allowed Remove weight from pan and clear

stored tare values.

L Pan error Make sure that pan is properly

seated on the pan support.

H Exceeded capacity The scale has exceeded its

weighing capacity. Reduce the

weight.

Err - b Pan not cleared on power-up The pan was not empty while the

scale was initiating at startup.

Clear the pan and restart the scale.

Sapl LO (Parts Counting) Average piece weight is too low The average piece weight is lower

than 3e. Be sure that individual

piece weight is greater than 3e.

Sapl LO (Percent Weighing) Sample reference weight is too low The sample reference weight is

lower than 100d. Increase the

sample weight.

The scale will not turn on Possible power failure Check the power AC adapter

connection.

Weighing results are not accurate Inaccurate calibration Calibrate the scale.

Weighing result will not stabilize Irregular environment Eliminate drafts or vibrations.

Chapter 34: Maintenance

Cleaning and maintaining your Scale:

• Before cleaning the scale always unplug the A/C adapter from the electrical outlet.

• Use a soft, slightly damp cloth to clean the exterior housing of your scale,.

• Wipe the scale gently. Do not allow any liquid to enter into the scale.

• Do not apply extensive pressure to the LCD or the LED display.

• Do not use chemicals or benzene when cleaning the surface. Corrosive chemicals may damage the

finish.

• Alcohol may be used only to clean the scale’s stainless steel pan or the draft ring.

- 56 -

Chapter 35: Limited Warranty

PURCHASER’S 12-MONTH WARRANTY

Warranty is valid only if the attached warranty registration card is completed and returned within 30 days.

This product is a precision device made to exacting standards of scientific accuracy. It is guaranteed to have

been adjusted and inspected for proper workmanship and performance, and certified for its currently

advertised specifications before shipment.

Fulcrum Products are warranted against defects in material and workmanship under normal use and service.

This warranty is extended only to the first purchaser. This limited warranty will not apply if, upon inspection,

it is found that the product was tampered with, misused, overloaded, or abused, mishandled, placed in an

improper environment, improperly installed or adjusted, used for a purpose other than that for which it was

designed, or repaired by unauthorized personnel.

Fulcrum’s liability under this warranty is limited to furnishing labor and parts necessary to remedy the defect

covered by this warranty and restore the product to normal operating condition. Purchasers may be charged a

minimum repair fee for in-warranty products returned for repair if those products are determined to be

problem-free.

To make a claim under this limited warranty, obtain an RMA number from Fulcrum and return the product,

carefully packed in its original packaging, shipping prepaid, with the RMA number written on the return

package.

- 57 -

Fulcrum Inc.

100 Delawanna Ave.,#120

Clifton, NJ 07014

(973) 473 6900

(973) 777 8302

http://www.fulcruminc.net

Loading...

Loading...