Topcon America 5434 Installation Manual

8

$%XCAVATOR)NDICATE3YSTEM

)NSTALLATIONAND#ALIBRATION-ANUAL

POSITIONING SYSTEMS

X-22

Excavator Indicate System

Installation and Calibration

Manual

Part Number 7010-1019

Rev A

©Copyright Topcon Positioning Systems, Inc.

June, 2011

All contents in this manual are copyrighted by Topcon. All rights reserved.

The information contained herein may not be used, accessed, copied, stored,

displayed, sold, modified, published, distributed, or otherwise reproduced

without express written consent from Topcon.

Terms and Conditions

Thank you for buying this Topcon product. This manual has been prepared to assist

you with the care and operation of the product and its use is subject to these Terms

and Conditions and those more fully set forth in the Operator’s/User’s Manual.

Usage and Safety

This product is designed for use by professionals. Always use safety precautions

when operating this or any Topcon product.

Copyrights

All information contained in this Manual is the intellectual property of, and

copyrighted material of TPS. All rights are reserved. You may not use, access, copy,

store, display, create derivative works of, sell, modify, publish, distribute, or allow

any third party access to, any graphics, content, information or data in this Manual

without TPS’ express written consent and may only use such information for the care

and operation of your Product. The information and data in this Manual are a valuable

asset of TPS and are developed by the expenditure of considerable work, time and

money, and are the result of original selection, coordination and arrangement by TPS.

Trademarks

X-22, Topcon, and Topcon Positioning Systems are trademarks or registered

trademarks of TPS.

Other product and company names mentioned herein may be trademarks of their

respective owners.

Disclaimer of Warranty

EXCEPT FOR SUCH WARRANTIES AND LICENSES PROVIDED WITH THE PRODUCT,

THIS MANUAL AND THE PRODUCT ARE PROVIDED “AS-IS”. TOPCON AND ITS

DISTRIBUTORS SHALL NOT BE LIABLE FOR TECHNICAL OR EDITORIAL ERRORS OR

OMISSIONS CONTAINED HEREIN; NOR FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES RESULTING FROM THE FURNISHING, PERFORMANCE OR USE OF THIS

MATERIAL OR THE PRODUCT.

Please see the Operator’s/User’s Manual for detailed information on warranties and

the license agreement which may apply to the Product.

License Agreement

Use of any computer programs or software supplied by Topcon or downloaded from

the Topcon website in connection with the Product implies acceptance of the Terms

and Conditions here and in the Operator’s/User’s Manual.

Please see the Operator’s/User’s Manual for detailed information on warranties and

the license agreement which may apply to the Product.

ECO#4152

TOC

Table of Contents

Chapter 1

Introduction .......................................................... 1-1

System Components ........................................................ 1-1

Chapter 2

Installation and Calibration ................................. 2-1

Getting Started ................................................................. 2-1

Step 1: Charge the Sensors ........................................ 2-1

Step 2: Attach the Brackets ....................................... 2-2

Bracket for Boom Sensor ................................... 2-2

Bracket for Arm (Stick) Sensor with

Laser Detector ................................................. 2-5

Bracket for Bucket Sensor .................................. 2-6

Bracket for Tilt Bucket Sensor (Optional) ......... 2-10

Step 3: Attach the Mast for the PitchRollCompass ... 2-13

Step 4: Attach the X-22 Display ............................... 2-15

Step 5: Measure the Excavator .................................. 2-17

Step 6: Entering the Sensors on the X-22 Display .... 2-17

Step 7: Attach the Sensors to the Excavator ............. 2-19

Step 8: Calibrate the Sensors ..................................... 2-23

Calibrating the Boom Sensor .............................. 2-23

Calibrating the ArticBoom Sensor (Optional) .... 2-23

Calibrating the PitchRollCompass ...................... 2-23

Calibrating the Stick Sensor ............................... 2-24

Calibrating the Bucket Sensor ............................ 2-24

Calibrating the Tilt Bucket Sensor (Optional) .... 2-25

Step 9: Measure and Calibrate the Buckets ............... 2-25

Finding Your Way Around the Software ......................... 2-26

Tracking .................................................................... 2-26

Wizards ..................................................................... 2-26

How to Return to the Main Menu ............................. 2-27

Before You Start to Dig ................................................... 2-28

P/N 7010-1019

i

Table of Contents

Check that X-22 is Measuring Correctly ................... 2-28

Backup ....................................................................... 2-28

Applications ............................................................... 2-28

Arm (Stick) Sensor with Laser Detector ................... 2-29

Handling Damaged Sensors ....................................... 2-29

Important Information On Use ......................................... 2-30

Charger ...................................................................... 2-30

Sensors ....................................................................... 2-31

X-22 Display and Power Supply ............................... 2-32

Machine and Bucket Measurements ................................ 2-32

Measure Additional Buckets ............................... 2-42

Chapter 3

Troubleshooting .................................................. 3-1

Appendix A

Specifications ...................................................... A-1

X-22 Sensor ...................................................................... A-1

WEEE Directive ............................................................... A-2

Appendix B

Safety Warnings ................................................... B-1

General Warnings ............................................................. B-1

Sensor Warnings .............................................................. B-2

Usage Warnings ............................................................... B-3

Appendix C

Warranty Terms ................................................... C-1

ii

X22 Installation and Calibration Manual

Introduction

Congratulations on your new X-22 System.

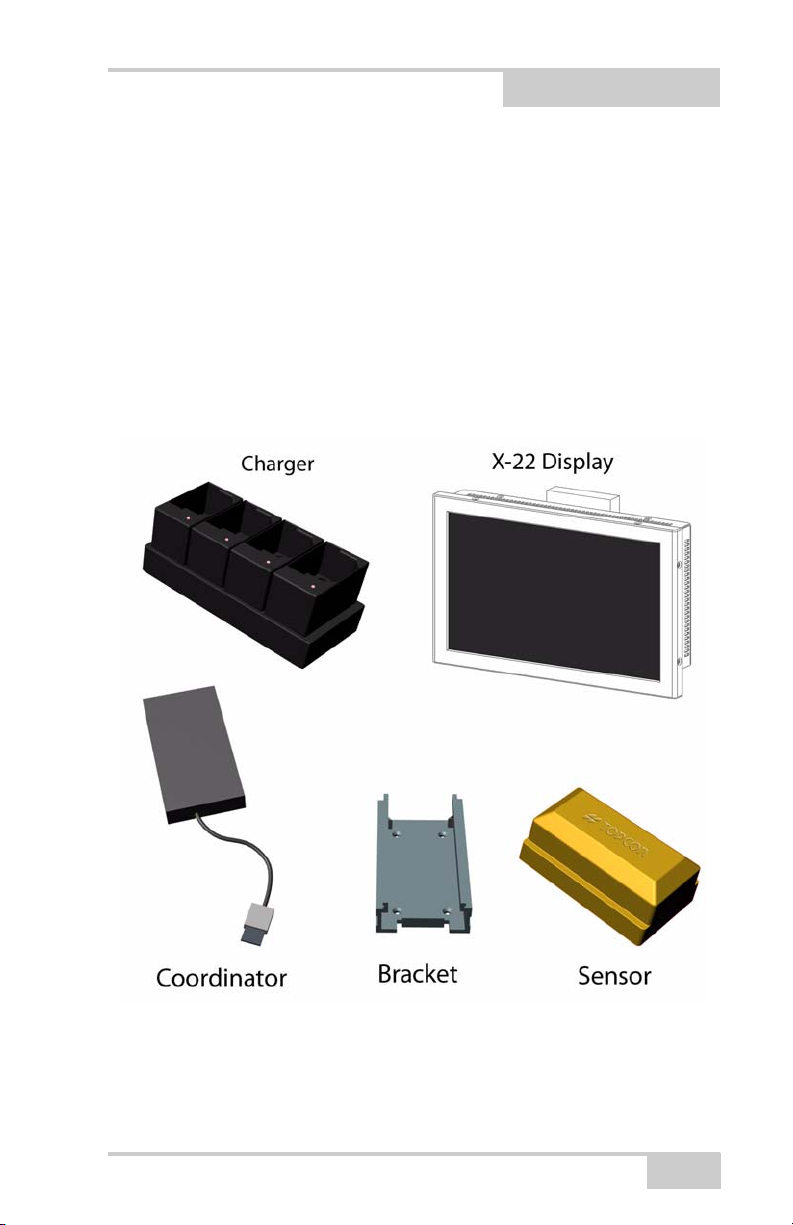

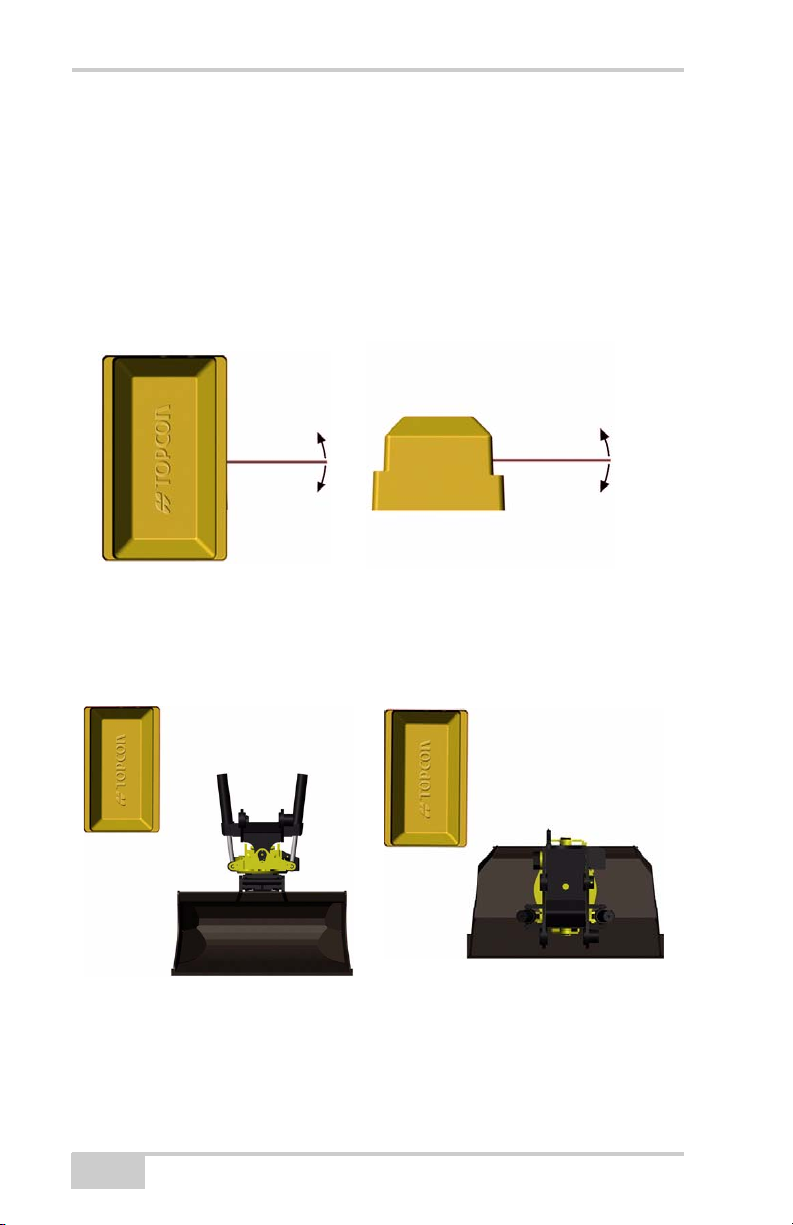

System Components

Chapter 1

Measuring and installation equipment is also available separately (not

shown).

P/N 7010-1019

1-1

Notes:

1-2

X-22 Installation and Calibration Manual

Chapter 2

Installation and Calibration

Getting Started

Before you can start using your X-22 System for excavation, you

need to set it up. Read on to find out how to install X-22 on your

excavator in nine simple steps.

Step 1: Charge the Sensors

The first thing you must do is charge the sensors for several hours

(i.e. overnight). The charger’s LEDs may briefly turn on and off as

the sensors go through their charging cycle. This is normal. Leave the

sensors on the charger to ensure a full charge. If the batteries are

completely flat, it takes around 12 hours to charge them fully. Make

sure the contacts on the charger and the sensors are free of debris

before charging.

P/N 7010-1019

Figure 2-1. Battery Charger

2-1

Step 2: Attach the Brackets

NOTICE

NOTICE

Attach the aluminum brackets using the self-tapping screws provided.

The drill and bit for the screws are also included. The drill is 4.6 mm

and the screws Taptite M5x10 have a recessed head.

Rub a little grease or oil onto the screws before

screwing them in.

When determining the location of the sensor

brackets, make sure you allow room to install and

uninstall the sensors onto the brackets.

A weld plates can be purchased separately, if drilling is not possible.

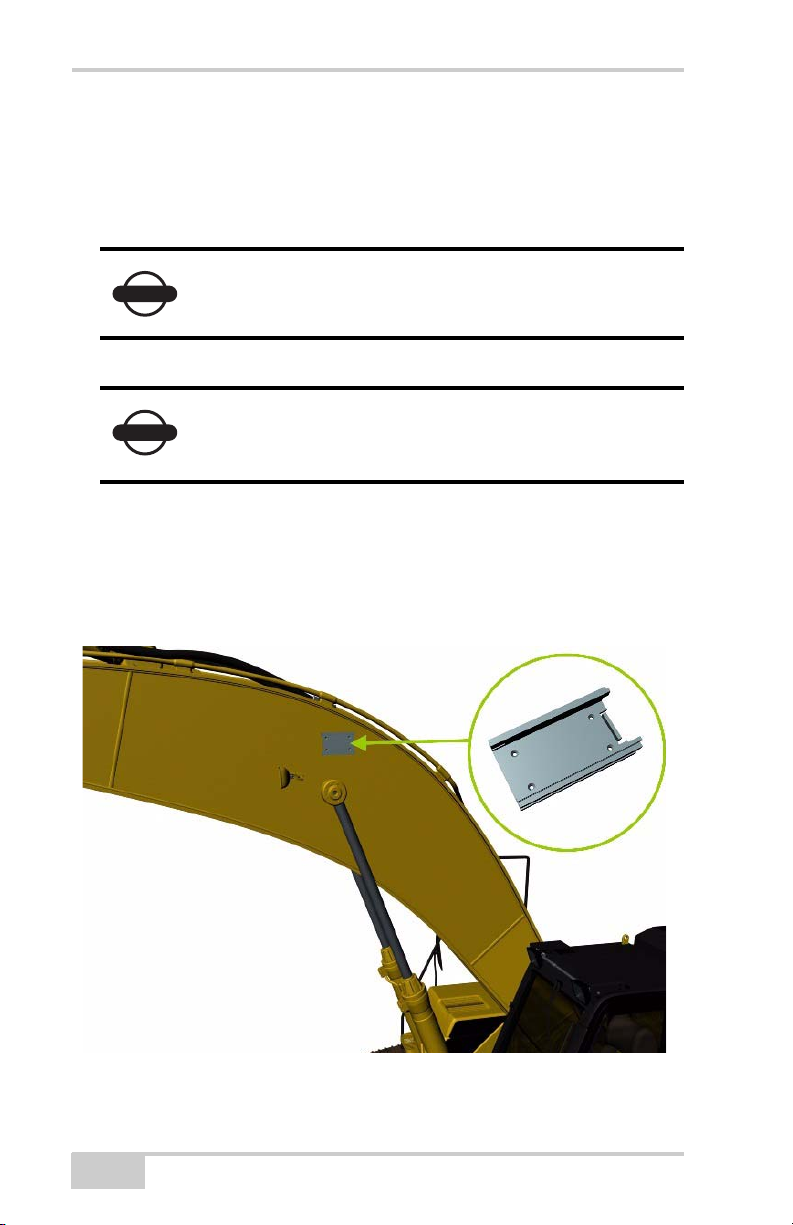

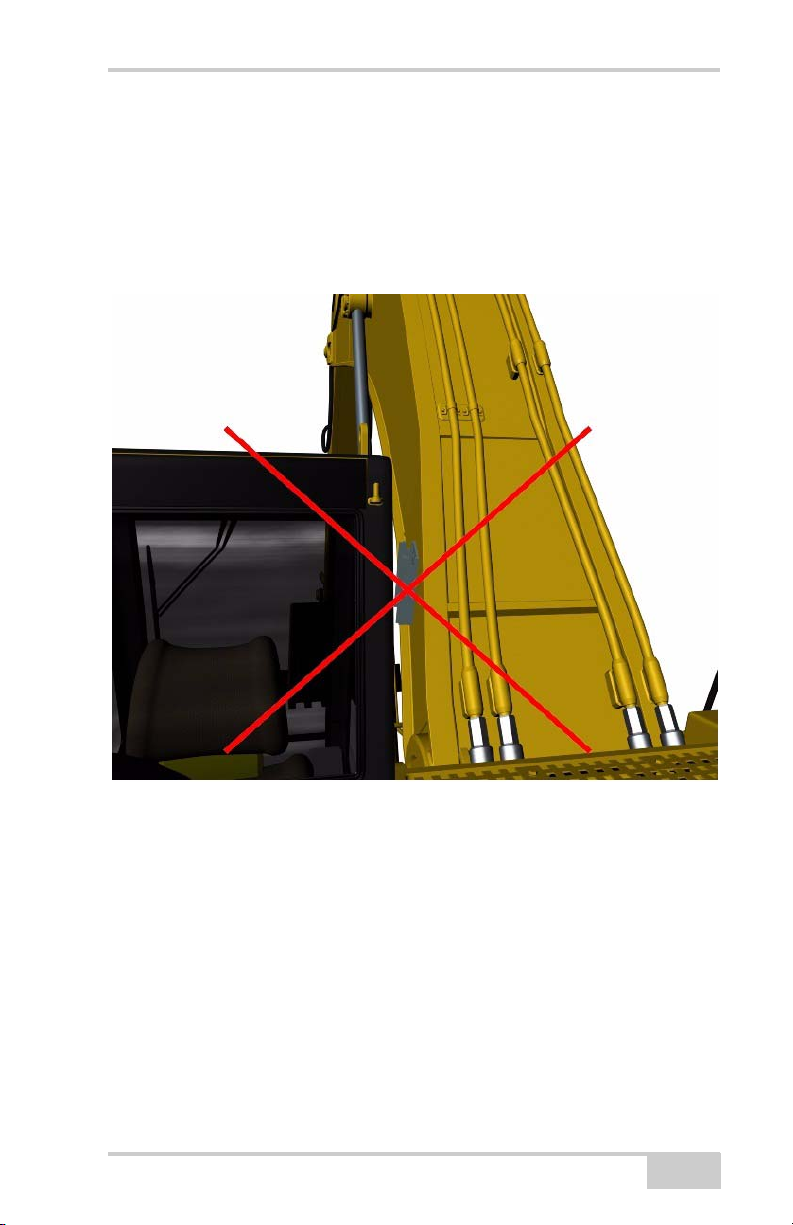

Bracket for Boom Sensor

The bracket for the boom sensor must be attached to the side of the

boom that faces the cab.

2-2

Figure 2-2. Boom Sensor Bracket Location

X-22 Installation and Calibration Manual

Installation and Calibration

The bracket for the boom sensor must be attached to a face of the

boom that does not slant in relation to the boom bolt. The following

picture shows how the boom is widest down by the boom bolt and

gets narrower towards the center. The bracket must not therefore be

attached in this area.

Figure 2-3. Do Not Install Bracket on Slanted Area of Boom

The bracket for the ArticBoom sensor should be attached to the

articulated (extended) boom, if the machine has one, in the same way.

P/N 7010-1019

2-3

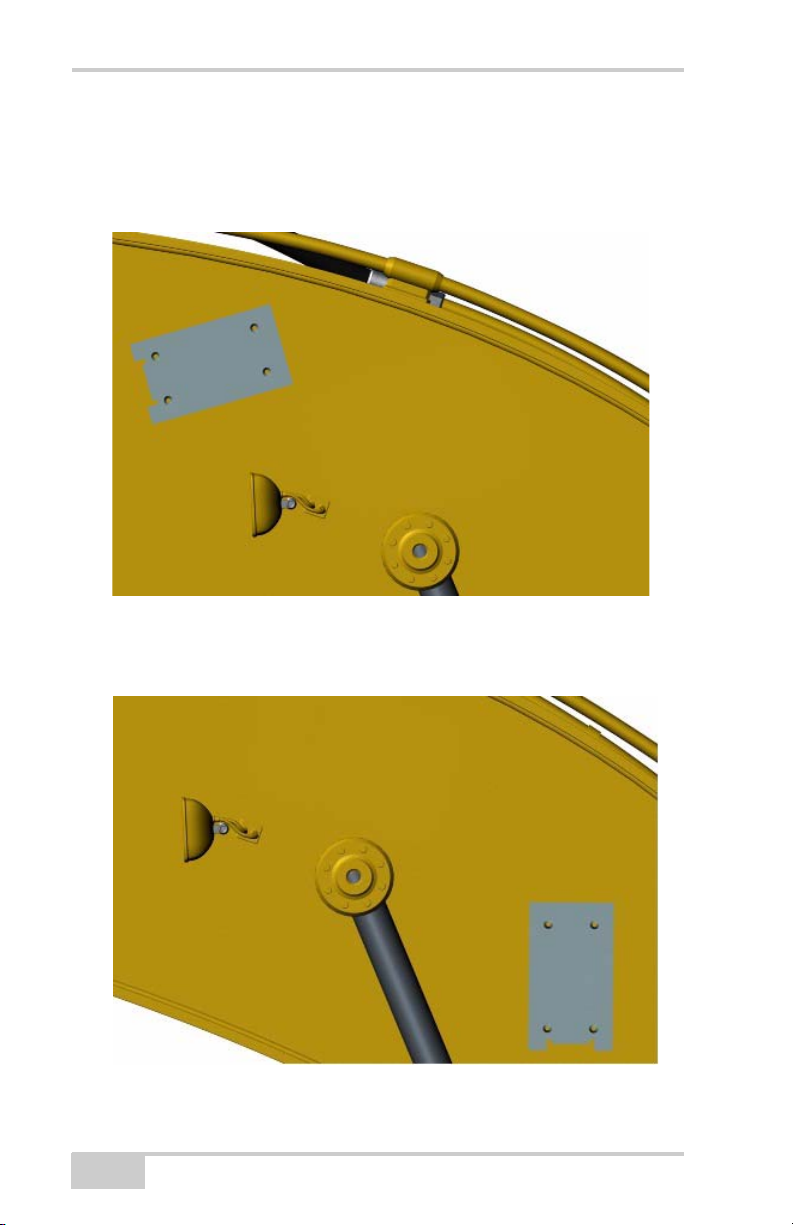

It makes no difference to the wireless communication or angle

measurements for the sensors whether the bracket for the boom

sensor is positioned as shown in Figure 2-4,

Figure 2-4. Boom Sensor Bracket Orientation

or as shown in Figure 2-5.

2-4

Figure 2-5. Boom Sensor Bracket Orientation

X-22 Installation and Calibration Manual

Installation and Calibration

NOTICE

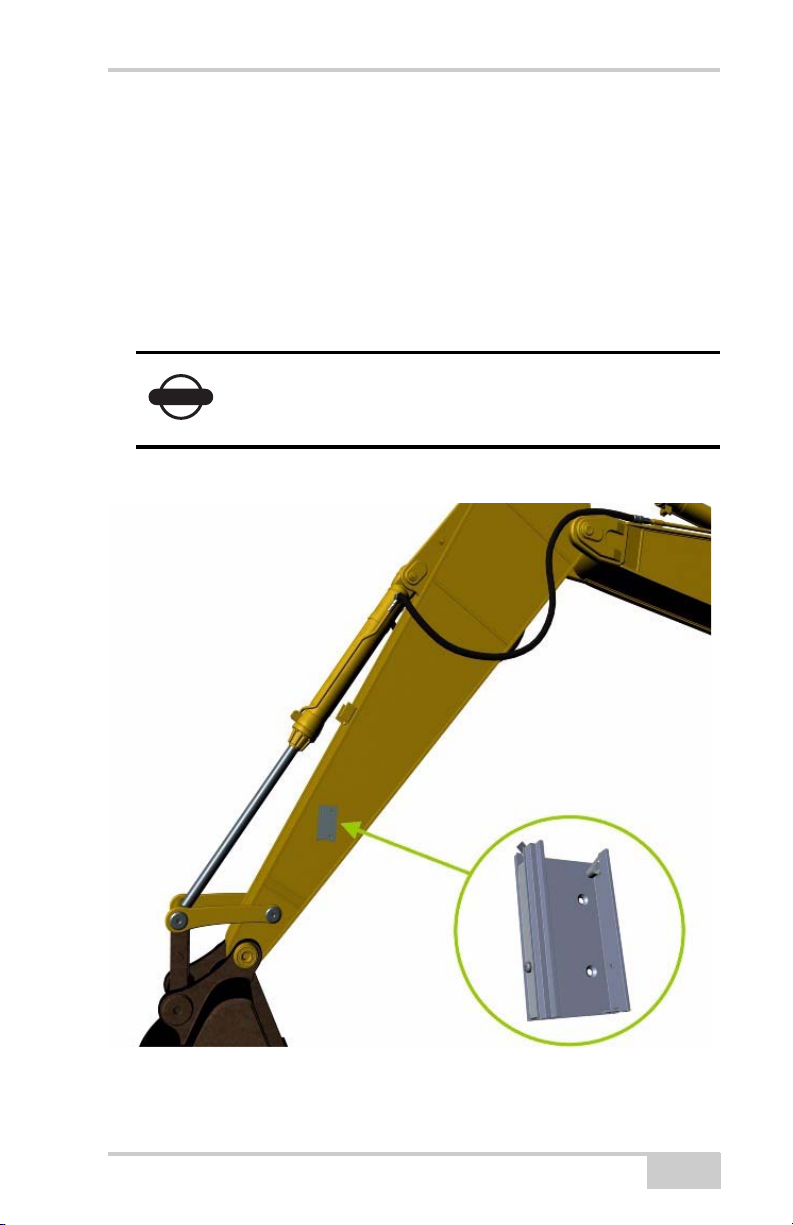

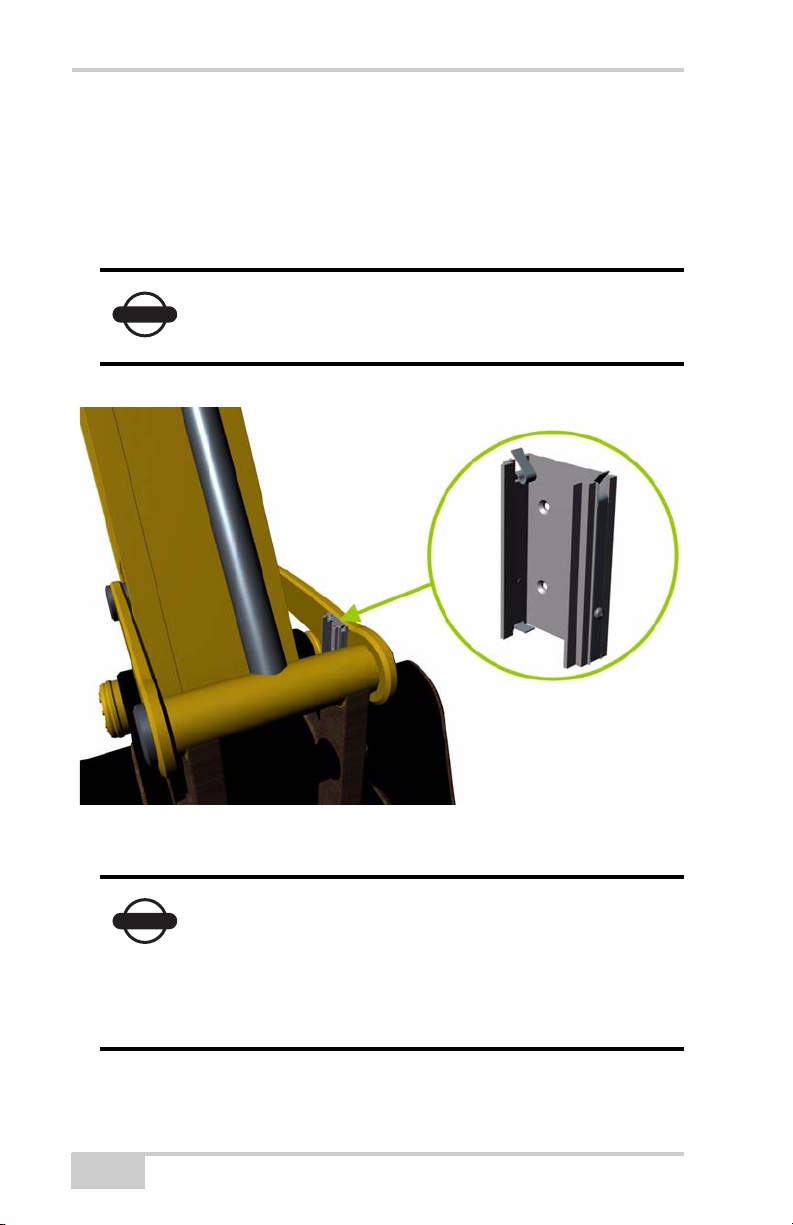

Bracket for Arm (Stick) Sensor with Laser Detector

The bracket for the arm (stick) sensor must be attached to the side of

the arm (stick) that faces the cab.

Position the bracket so that the sensor is roughly vertical when the

laser hits it. Take care not to attach the bracket too high on the arm

(stick) to avoid problems with getting the laser beam to hit the sensor.

Attach the bracket for the arm sensor with the

spring clips at the top so that the sensor slides in

from above.

P/N 7010-1019

Figure 2-6. Arm (Stick) Sensor Bracket Location

2-5

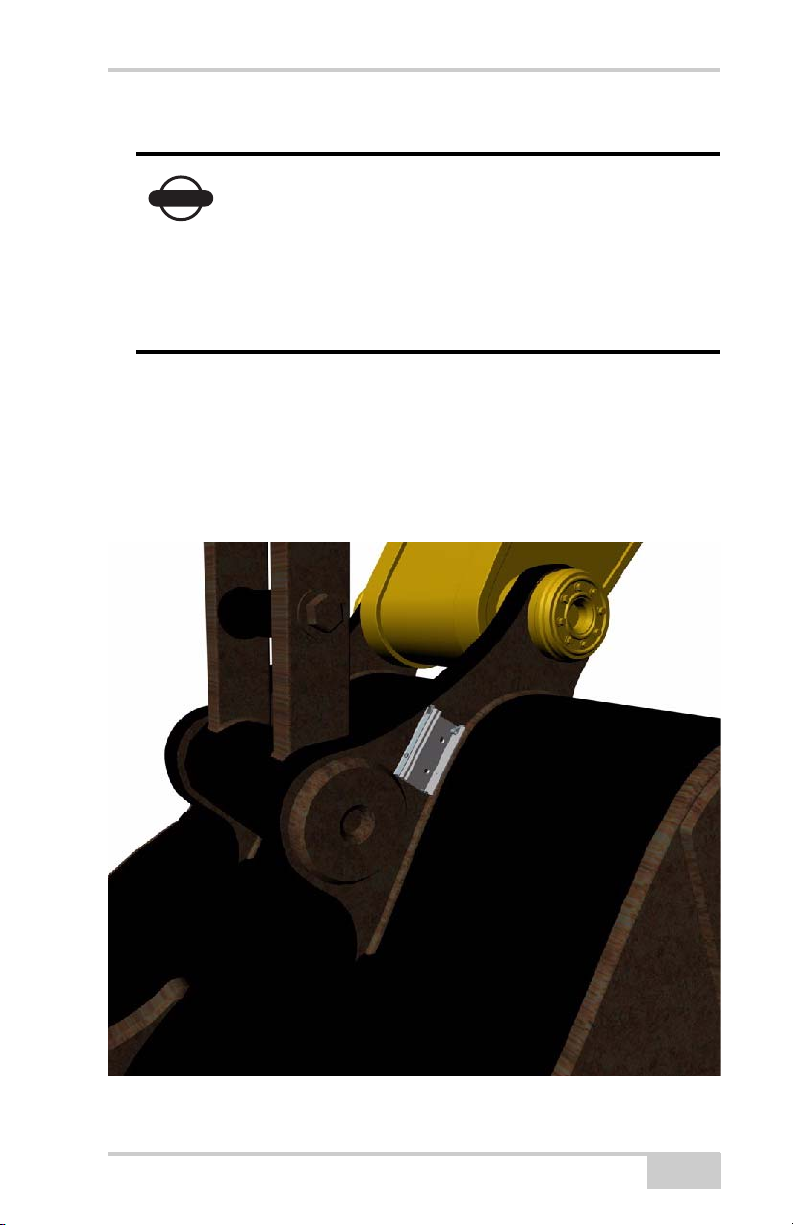

Bracket for Bucket Sensor

NOTICE

The best place to attach the bracket for the bucket sensor depends on

the size of the excavator and if the joints are tight or loose.

It is easiest to make X-22 measure accurately if the bucket sensor is

attached directly on the bucket/quick coupler. This is especially the

case if the joints are loose.

Alternative 1: The inside of the quick coupler/bucket

If the excavator is large enough, the bracket for the bucket sensor can

be attached on the inside of the quick coupler/bucket. Attach the

bracket on the part of the quick coupler/bucket closest to the cab.

2-6

Figure 2-7. Quick Coupler/Bucket Bracket Location - Inside

Fully extend and retract the bucket cylinder before

fitting and make sure that the bracket and the sensor

do not meet any obstructions.

X-22 Installation and Calibration Manual

Installation and Calibration

NOTICE

If the bucket sensor is attached on the inside of the

quick coupler/bucket, the sensor direction of the

bucket sensor must be changed from Normal to

Reverse. Select Main Menu Setup

Hardware Sensors and mark the bucket

sensor. Then select Details. Select Sensor

direction and press Edit.

Alternative 2: The outside of the quick co upler/bucket

The bracket for the bucket sensor can also be attached on the outside

of the quick coupler / bucket. Attach the bracket on the part of the

quick coupler/bucket closest to the cab.

Figure 2-8. Quick Coupler/Bucket Bracket Location - Outside

P/N 7010-1019

2-7

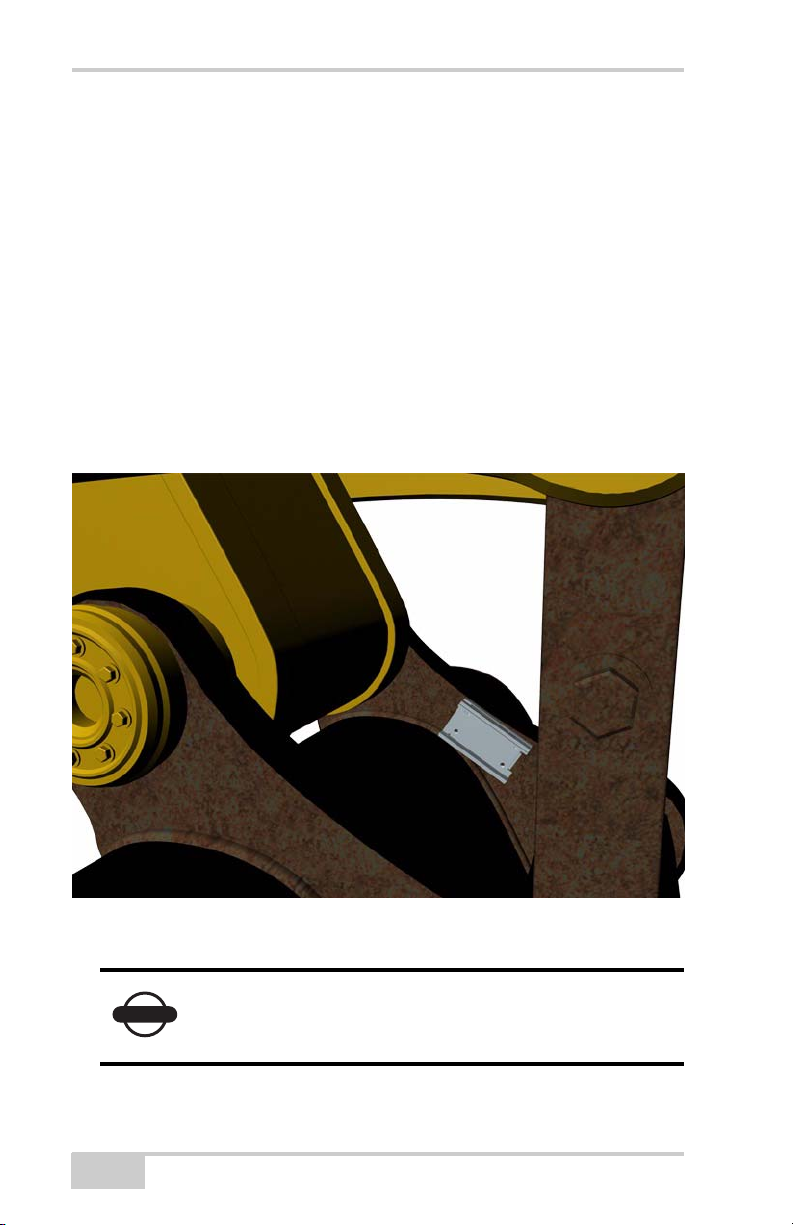

Alternative 3: The inside of the control arm (dog-bone)

NOTICE

NOTICE

If the excavator is large enough and the joints are tight, the bracket for

the bucket sensor can be attached on the inside of the control arm

(dog-bone). Attach the bracket on the control arm closest to the cab.

Fully extend and retract the bucket cylinder before

fitting and make sure that the sensor do not meet

any obstructions.

2-8

Figure 2-9. Inside of Control Arm (Dog-bone)

If the bucket sensor is attached on the inside of the

control arm (dog-bone), the direction of the bucket

sensor must be altered from Normal to Reverse.

Select Main Menu Setup Hardware

Sensors and mark the bucket sensor. Then select

Details. Select Sensor direction, and press Edit.

X-22 Installation and Calibration Manual

Installation and Calibration

NOTICE

NOTICE

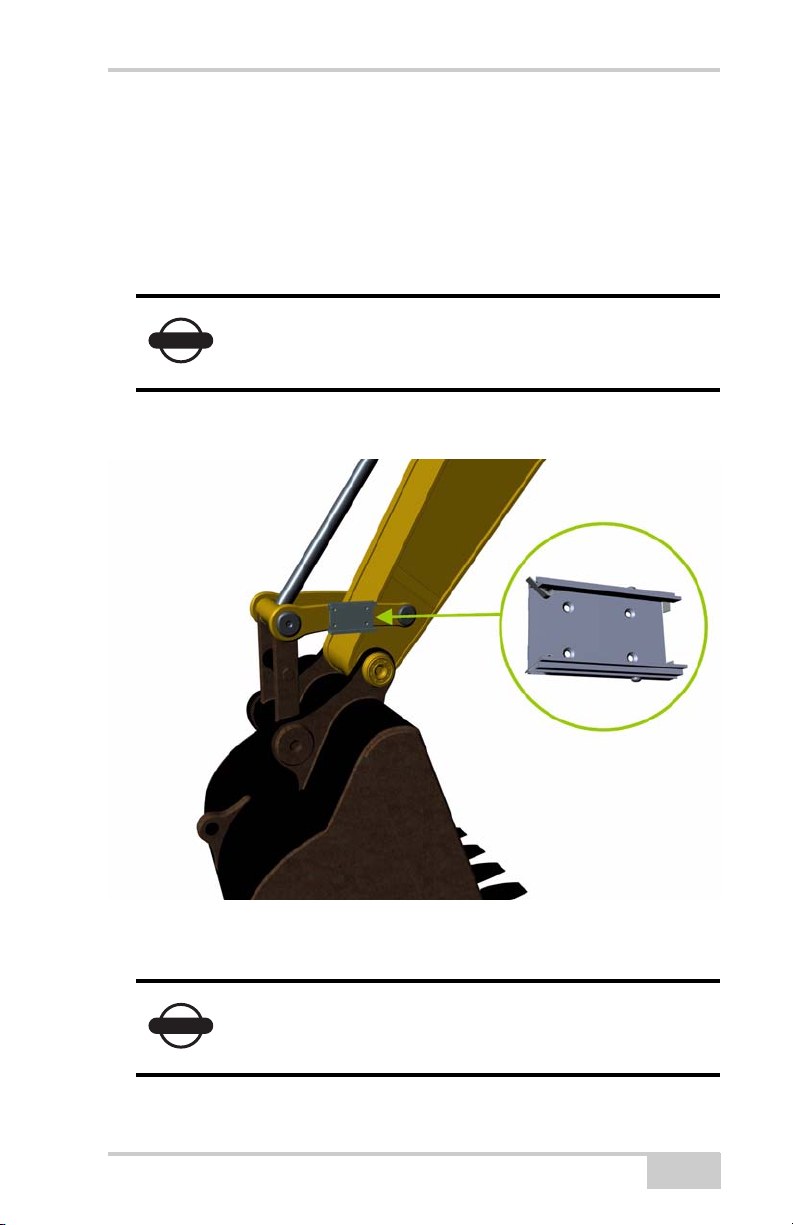

Alternative 4: The outside of the control arm (dog-bone)

If the excavator is too small to fit the bracket with the bucket sensor

on the inside of the control arm and the joints are tight, the bracket

can be attached on the outside of the control arm. Attach the bracket

on the control arm closest to the cab.

Fully extend and retract the bucket cylinder before

fitting and make sure that the sensor do not meet

any obstructions.

P/N 7010-1019

Figure 2-10. Outside of Control Arm (Dog-bone)

Attach the bracket with the spring clips on the left

so that the sensor slides into the bracket from the

left.

2-9

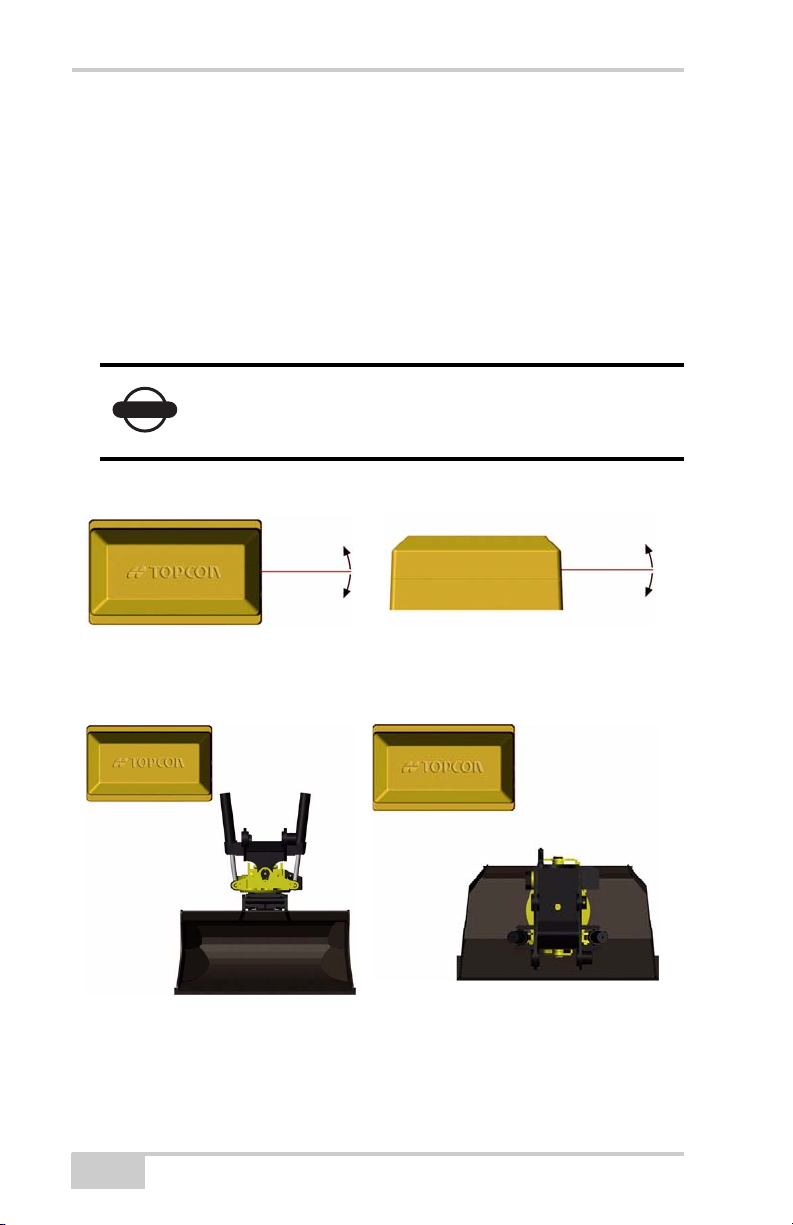

Bracket for Tilt Bucket Sensor (Optional)

NOTICE

The bracket for the tilt bucket sensor must be attached so that the

sensor rotates sideways or lengthways.

Alternative 1: Sideways

When the tilt bucket sensor is installed sideways, the long axis of the

sensor is used to measure how much the bucket is tilted to the side.

The long axis must move as shown in the pictures

below when the bucket is tilted to the side, or else

the sensor will not measure correctly.

Figure 2-11. Sideways Installation

2-10

Figure 2-12. Sideways Installation

X-22 Installation and Calibration Manual

Installation and Calibration

Example of sideways installation on a tilt bucket:

P/N 7010-1019

Figure 2-13. Sideways Installation

2-11

Alternative 2: Lengthways

When the tilt bucket sensor is installed lengthways, the short axis of

the sensor is used to measure how much the bucket is tilted to the

side. Note that the short axis must move as shown in the pictures

below when the bucket is tilted to the side, or else the sensor will not

measure correctly.

Figure 2-14. Lengthways Installation

2-12

Figure 2-15. Lengthways Installation

X-22 Installation and Calibration Manual

Example of lengthways attachment:

Installation and Calibration

Figure 2-16. Lengthways Installation

Step 3: Attach the Mast for the PitchRollCompass

A mast is supplied with X-22 for the PitchRollCompass sensor. We

recommend mounting the mast on the back of the machine’s

counterweight. Position the bracket on top of the mast, parallel with

the tracks of the machine.

The optional welding mast ring (sold separately) is to be welded to

the machine. Bolts and nuts are supplied with the mast. When the

P/N 7010-1019

2-13

mast ring is in place, attach the aluminium bracket firmly to the

NOTICE

mounting ring with the M8x30 Allen screws provided.

2-14

Figure 2-17. Mast and Mast Ring Installation

Position the mast (or mast ring) so that it holds the

mast steady and vertical on the excavator.

X-22 Installation and Calibration Manual

Installation and Calibration

NOTICE

Step 4: Attach the X-22 Display

You can easily attach the X-22 Display to the side window in the cab

using the suction cup provided. Clean the glass before attaching the

suction cup. This prevents air from getting into the suction cup.

P/N 7010-1019

Figure 2-18. X-22 Display - Side View

Check regularly that the suction cup is firmly

attached and take it off when it is not being

watched.

2-15

Loading...

Loading...