Page 1

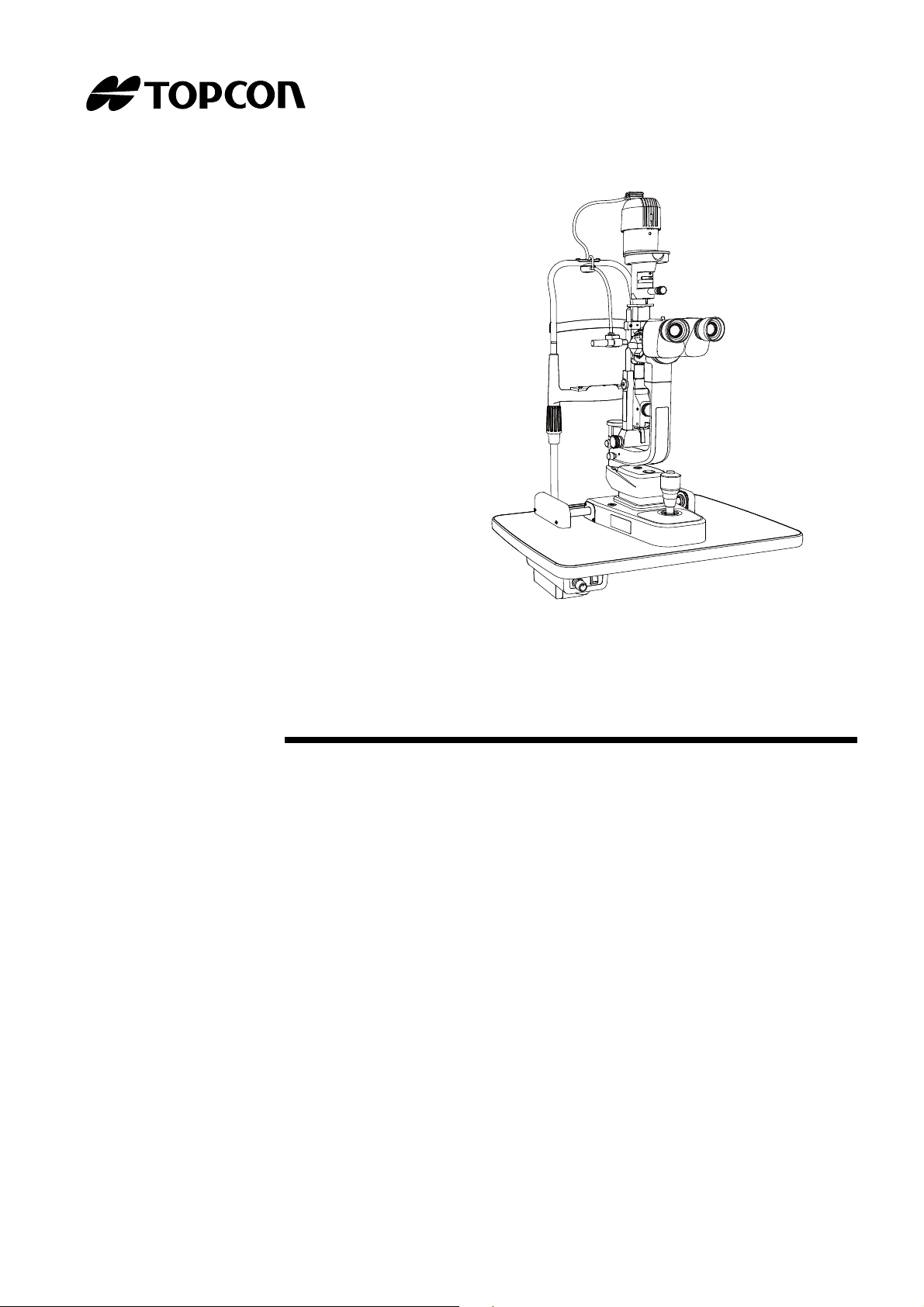

USER MANUAL

SLIT LAMP

SL-D301

Page 2

Page 3

INTRODUCTION

Thank you for purchasing the SLIT LAMP SL-D301.

INTENDED USE / INDICATIONS FOR USE

The Slit Lamp SL-D301 is an AC-powered slitlamp biomicroscope intended for use in eye examination of the anterior eye segment, from the cornea epithelium to the posterior capsule. It is used to

aid in the diagnosis of diseases or trauma which affect the structural properties of the anterior eye

segment.

FEATURES

This instrument has the following features:

• Various accessories to extend the system

• Ergonomic cable layout

• Clear fluorescent cornea observation and photography of cornea

• Clear eyeground observation and photography by color conversion filter

PURPOSE OF THIS MANUAL

To get the best usage from the instrument, please read DISPLAYS FOR SAFE USE and GENERAL

SAFETY INFORMATION.

Keep this manual with the instrument for future reference.

1

Page 4

2

1. No part of this manual may be copied or reprinted, in whole or in part, without prior written

permission.

2. The contents of this manual are subject to change without prior notice and without legal

obligation.

3. The contents of this manual are correct to the best of our knowledge. Please inform us of

any ambiguous or erroneous descriptions, missing information, etc.

4. Original Instructions

This manual was originally written in English.

©2016 TOPCON CORPORATION

ALL RIGHTS RESERVED

Page 5

CONTENTS

INTRODUCTION ......................................................................................................................... 1

DISPLAYS AND SYMBOLS FOR SAFE USE .................................................................... 5

GENERAL SAFETY INFORMATION .................................................................................... 6

HOW TO USE THIS MANUAL ................................................................................................ 8

GENERAL MAINTENANCE INFORMATION ...................................................................... 8

DISCLAIMERS ............................................................................................................................ 8

POSITIONS OF WARNING AND CAUTION INDICATIONS .......................................... 9

SYSTEM DIAGRAM .......................................................................................................................... 10

COMPONENT NAMES .................................................................................................................. 10

COMPOSITION OF PARTS THAT COME IN CONTACT WITH THE PATIENT ........................... 10

STANDARD ACCESSORIES ......................................................................................................... 11

COMPONENTS .................................................................................................................................. 12

COMPONENTS .............................................................................................................................. 12

ASSEMBLY PROCEDURE ............................................................................................................. 13

SECURING THE POWER UNIT .................................................................................................... 13

SECURING THE TABLETOP SO-TABLE06 (OPTIONAL ACCESSORY) ................................... 13

SECURING THE TABLETOP SO-TABLE07 (OPTIONAL ACCESSORY) .................................... 13

SECURING THE CHINREST ......................................................................................................... 14

SECURING THE BASE UNIT AND RAIL COVER ......................................................................... 15

SECURING THE BINOCULAR TUBES ......................................................................................... 15

SECURING THE ILLUMINATION UNIT ......................................................................................... 15

REMOVING THE ILLUMINATION UNIT PAD ................................................................................ 16

CONNECTING THE CABLES ........................................................................................................ 17

FITTING THE CHINREST TISSUE ................................................................................................ 17

FITTING THE CAP ......................................................................................................................... 17

FITTING THE DIFFUSION LENS SO-DFL01 (OPTIONAL ACCESSORY) ................................... 18

SECURING THE TONOMETER MOUNT SO-TM1 (OPTIONAL ACCESSORY) .......................... 19

PREPARATIONS ............................................................................................................................... 20

POWERING ON ............................................................................................................................. 20

ADJUSTING THE DIOPTER AND PUPILLARY DISTANCE (PD) ................................................. 20

OPERATION PROCEDURE ........................................................................................................... 22

FIXING THE PATIENT'S FACE AND FIXATION ........................................................................... 22

OPERATING THE MICROSCOPE UNIT ....................................................................................... 23

OPERATING THE BASE AND FOCUSING ................................................................................... 24

OPERATING THE ILLUMINATION UNIT ...................................................................................... 25

ENDING PROCEDURE ................................................................................................................. 29

MAINTENANCE AND CHECKUPS .............................................................................................. 30

PERIODIC MAINTENANCE ...........................................................................................................30

DAILY CARE .................................................................................................................................. 30

PLACING AN ORDER FOR CONSUMABLES .............................................................................. 30

USER MAINTENANCE ITEMS ...................................................................................................... 30

DEALER MAINTENANCE ITEMS .................................................................................................. 30

REPLACING ILLUMINATION LAMPS ........................................................................................... 31

REPLACING SOCKETS ................................................................................................................ 32

RESTOCKING CHINREST TISSUE .............................................................................................. 32

DAILY CARE .................................................................................................................................. 33

3

Page 6

CLEANING APPLIED PARTS ........................................................................................................ 33

CLEANING LENSES AND MIRRORS ........................................................................................... 33

TROUBLESHOOTING ................................................................................................................... 34

TROUBLESHOOTING GUIDE ....................................................................................................... 34

SPECIFICATIONS AND PERFORMANCE .................................................................................... 35

GENERAL INFORMATION ON USAGE AND MAINTENANCE ........................................... 36

INTENDED PATIENT POPULATION ............................................................................................. 36

INTENDED USER PROFILE ..........................................................................................................36

ENVIRONMENTAL CONDITIONS FOR USE ................................................................................ 36

STORAGE, USAGE PERIOD ........................................................................................................ 36

ENVIRONMENTAL CONDITIONS FOR PACKAGING IN STORAGE ........................................... 37

ENVIRONMENTAL CONDITIONS FOR PACKAGING IN TRANSPORTAION ............................. 37

ELECTRIC RATING ....................................................................................................................... 37

DIMENSIONS AND WEIGHT ......................................................................................................... 37

SYSTEM CLASSIFICATION ..........................................................................................................38

OPERATION PRINCIPLES ............................................................................................................ 38

CHECKPOINTS FOR MAINTENANCE .......................................................................................... 38

DISPOSAL ..................................................................................................................................... 39

PATIENT’S ENVIRONMENT ......................................................................................................... 40

REQUIREMENTS FOR THE EXTERNAL DEVICE ....................................................................... 40

ELECTROMAGNETIC COMPATIBILITY ....................................................................................... 41

OPTICAL RADIATION HAZARD .................................................................................................... 45

RELATIVE SPECTRAL DISTRIBUTION OF ILLUMINATION LIGHT ............................................ 45

TYPE OF PLUG ............................................................................................................................. 46

OPTIONAL ACCESSORIES ........................................................................................................... 47

SYSTEM CONFIGURATION ......................................................................................................... 47

DIGITAL CAMERA UNIT DC-4 ...................................................................................................... 48

BACKGROUND ILLUMINATION BG-2GN ..................................................................................... 48

YELLOW FILTER UNIT .................................................................................................................. 48

IRIS DIAPHRAGM SO-DF01 .........................................................................................................48

12.5X EYEPIECE ........................................................................................................................... 48

20X EYEPIECE .............................................................................................................................. 48

TONOMETER MOUNT SO-TM1 .................................................................................................... 49

HRUBY LENS ................................................................................................................................ 49

PARALLEL BINOCULAR TUBE PB-2 ............................................................................................ 49

ADAPT COVER SO-AC7 ............................................................................................................... 49

DIFFUSION LENS SO-DFL01 ....................................................................................................... 49

TABLETOP SO-TABLE06, 07 ........................................................................................................50

4

Page 7

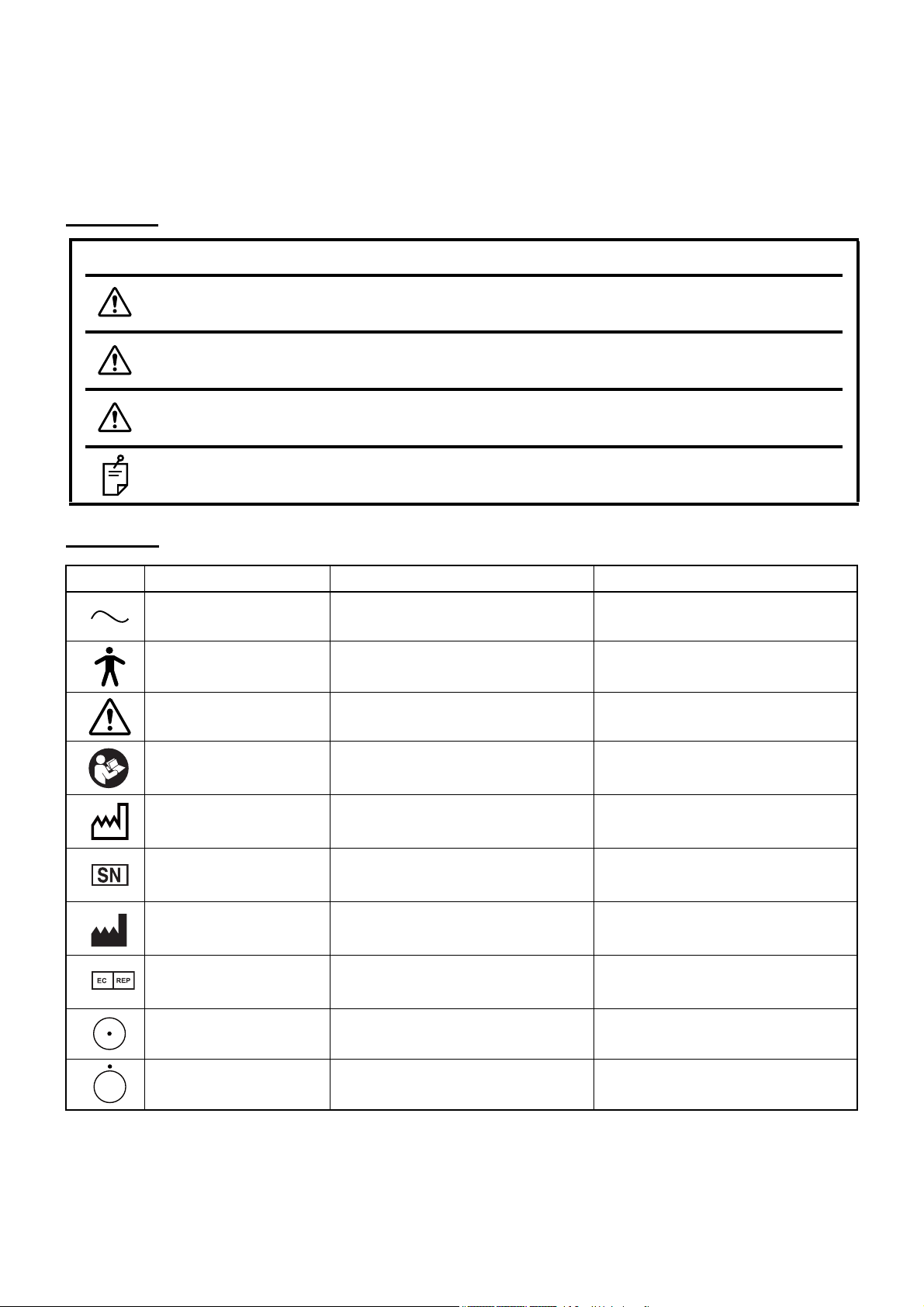

DISPLAYS AND SYMBOLS FOR SAFE USE

To encourage safe and proper use and to prevent injury to the operator and others or potential damage to

property, important messages are put on the instrument body and inserted in this manual.

We suggest that everyone understand the meaning of the following displays, icons and text before reading the GENERAL SAFETY INFORMATION and observe all listed instructions.

DISPLAY

Display Meaning

Situations in which the device should not be used because the

CONTRAINDICATION

WARNING

CAUTION

NOTE

risk of use clearly outweighs any possible benefit.

Incorrect handling by ignoring this display may lead to a risk of

death or serious injury.

Incorrect handling by ignoring this display may lead to

personal injury or physical damage.

Useful functions to know. Paying attention to these will

prevent the noted problems.

SYMBOL

Symbol IEC/ISO Publication Description Description (French)

IEC 60417-5032 Alternating Current Courant alternatif

IEC 60878-02-02 Type B applied part Partie appliquée du Type B

ISO 7010-W001 General warning sign

ISO 7010-M002

ISO 7000-2497 Date of manufacture Date de fabrication

ISO 7000-2498 Serial number Numéro de série

ISO 7000-3082

ISO 15223-1

Refer to instruction manual/

booklet

Manufacturer Fabricant

Authorised Representative in

the European Community

Symbole d'avertissement

général

Voir le manuel/la brochure

Représentant autorité pour

l’Union européenne

IEC 60417-5264

IEC 60417-5265

“On” (only for a part of EQUIPMENT)

“Off” (only for a part of EQUIPMENT)

Mise en service d'une partie

d'appareil

Mise hors service d'une partie

d'appareil

5

Page 8

GENERAL SAFETY INFORMATION

CONTRAINDICATION

This instrument must not be used for the following patients:

• Patients who are hypersensitive to light.

• Patients who recently underwent photodynamic therapy (PDT).

• Patients taking medication that causes photosensitivity.

WARNING

Ensuring the Safety of Patients and Operators

Use this instrument carefully on the following patients.

• Patients who have epidemic corneitis, conjunctivitis or any other infectious disease.

• Patients who are taking medications that cause light hypersensitivity.

To avoid injury to the patient’s eye and nose, pay particular attention while operating the instrument

body. (The patient may be injured.)

The Topcon SL-D301 is a medical device. The software and hardware has been designed in accordance with U.S., European and other international medical device design and manufacturing standards. Unauthorized modification of the Topcon SL-D301 software or hardware, or any addition or

deletion of any application in any way can jeopardize the safety of operators and patients, the performance of the instrument, and the integrity of patient data.

Because prolonged intense light exposure can damage the retina, the use of the device for ocular

examination should not be unnecessarily prolonged, and the brightness setting should not exceed

what is needed to provide clear visualization of the target structures.

The retinal exposure dose for a photochemical hazard is a product of the radiance and the exposure

time. If the value of radiance were reduced in half, twice the time would be needed to reach the maximum exposure limit.

While no acute optical radiation hazards have been identified for direct or indirect ophthalmoscopes, it

is recommended that the intensity of light directed into the patient's eye be limited to the minimum level

which is necessary for diagnosis. Infants, aphakes and persons with diseased eyes will be at greater

risk. The risk may also be increased if the person being examined has had any exposure to the same

instrument or any other ophthalmic instrument using a visible light source during the previous 24 hours.

This will apply particularly if the eye has been exposed to retinal photography.

Equipment is not suitable for use in the presence of a Flammable Anesthetic Mixture with Air, Oxygen,

or Nitrous Oxide.

The Topcon SL-D301 has no special protection against harmful ingress of water or other liquids (classified IPX0). To avoid damage to the instrument and cause a safety hazard, the cleaning solutions,

including water, should not be directly applied to the device. Using a dampened cloth (without dripping), is a good method to clean the exterior surface of the enclosure.

Handling the cord on this product or cords associated with accessories sold with this product, will expose

you to lead, a chemical known to the State of California to cause birth detects or other reproductive harm.

Wash hands after handling.

6

Page 9

Preventing Electric Shock and Fire.

To avoid fire in the event of an instrument malfunction, immediately turn off the power switch and

remove the power plug from the outlet if you see smoke coming from the instrument or if you detect

other problems. Don't install the instrument where it is difficult to disconnect the power plug from the

outlet. Ask your dealer for repairs.

CAUTION

Ensuring the Safety of Patients and Operators

Be careful not to let the patient touch this instrument. The patient's hand may be pinched by a movable

part.

To avoid burns caused by heat, do not replace the lamp with a new one immediately after it goes off.

To avoid injury to the patient's head, incline the illumination unit slowly while holding the base unit.

When operating the base unit, please note the following:

•Beware of catching fingers in the moving parts.

•Avoid hitting the patient's eyes or nose.

Preventing Electric Shock and Burn

To avoid injury or fire caused by electric shock, turn off the power switch and unplug the power cord

when not in use.

To avoid injury caused by electric shock, turn off the power switch when replacing the lamp.

Electromagnetic Compatibility (EMC)

This instrument has been tested (with 100/120/230V) and found to

2007as class B(classified according to CISPR11).

This instrument radiates radio frequency energy within standard and may affect other devices in the

vicinity.

If you have discovered that turning on/off the instrument affects other devices, we recommend you

change its position, keep a proper distance from other devices, or plug it into a different outlet.

Please consult your authorized dealer if you have any additional questions.

comply with IEC60601-1-2 Ed.3.0:

7

Page 10

HOW TO USE THIS MANUAL

• Read the instructions on pages 1 to 9 before using the machine.

• If you would like an overview of the system, begin by reading OPERATION PROCEDURE (page 22).

GENERAL MAINTENANCE INFORMATION

USER MAINTENANCE

To maintain the safety and performance of the instrument, unless done by an authorized service engineer, never attempt to do maintenance of items other than those specified here in.

For details about maintenance, read the description of this manual.

Replacing the Illumination Lamp

The illumination lamp can be replaced if necessary. For specific instructions, see page 30.

DISCLAIMERS

•TOPCON is not responsible for damage due to fire, earthquakes, actions or inactions of third

persons or other accidents, or damage due to negligence and misuse by the user and any use

under unusual conditions.

•TOPCON is not responsible for damage derived from inability to properly use this equipment,

such as loss of business profits and suspension of business.

•TOPCON is not responsible for damage caused by operations other than those described in this

user manual.

•The device does not provide a diagnose of any condition or lack thereof or any recommendation

for appropriate treatment. The relevant healthcare provider is fully responsible for all diagnose

and treatment decisions and recommendations.

8

Page 11

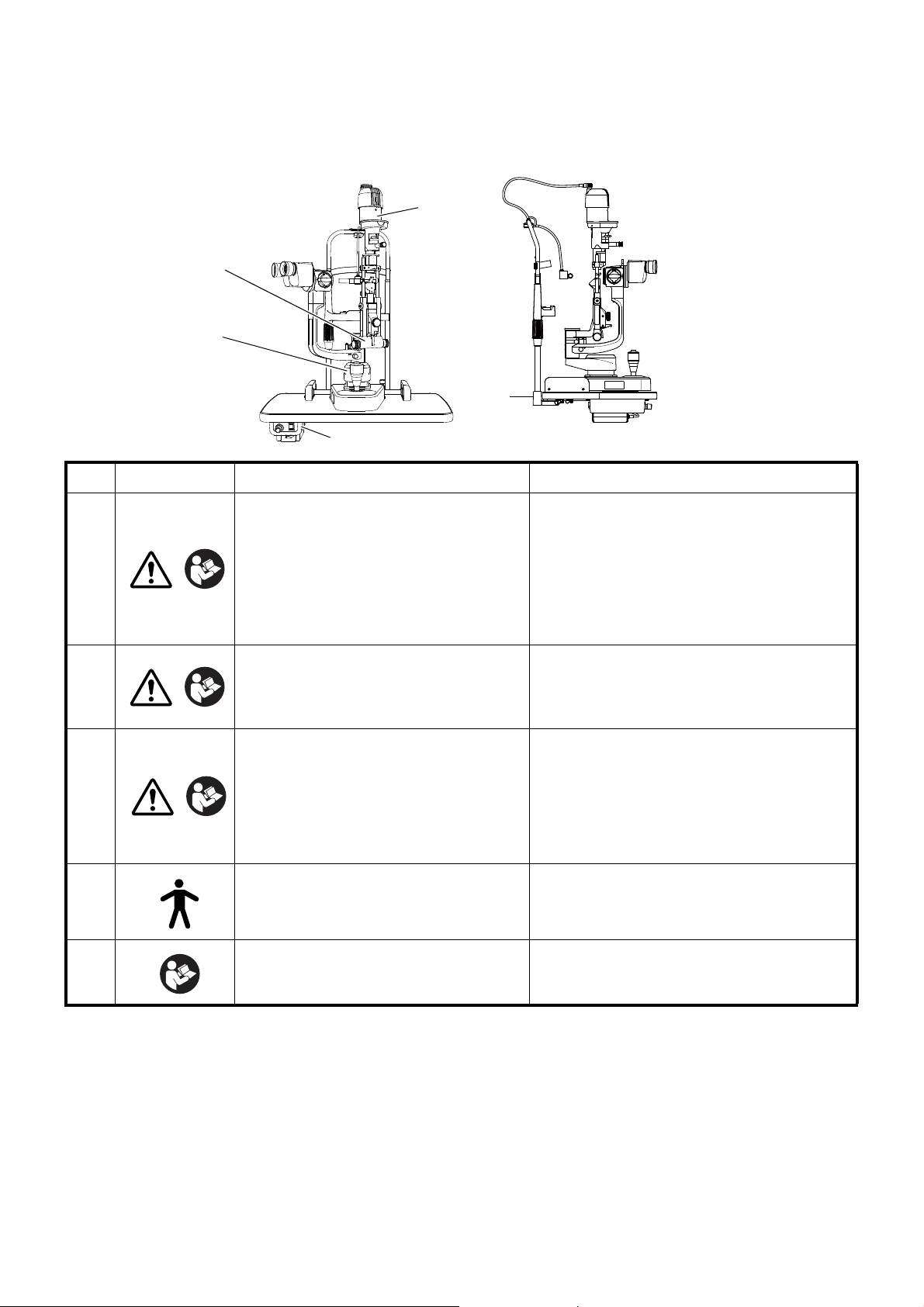

POSITIONS OF WARNING AND CAUTION INDICATIONS

2

1

3

4

5

To ensure safety, warning labels are provided on the instrument body.

Use the instrument following these warning instructions. If any of the following labels are missing, contact your dealer or TOPCON (see the back cover).Fabricant

No. Label Meaning Signification

CAUTION

・To prevent electric shocks, switch off

the power supply and remove the

1

power cord before replacing the lamp.

・Do not replace the lamp immediately

after switching it off: the high temperatures could cause burns.

• Afin d’éviter les chocs électriques, coupez

l’alimentation électrique et débranchez le

câble d’alimentation avant de remplacer la

lampe.

• Ne pas remplacer la lampe immédiatement

après l’avoir éteinte: la température élevée

peut provoquer des brûlures.

CAUTION

2

To avoid injury to the patient’s head,

incline the illumination unit slowly while

holding the base unit.

Afin d’éviter de blesser le patient à la tête,

inclinez lentement l’élément lumineux tout en

maintenant la base de l’appareil.

CAUTION

When operating the base unit, please

3

4

5

note the following:

・Beware of catching fingers in the

moving parts.

・Avoid hitting the patient’s eyes or

nose.

Degree of protection against electric

shock

: TYPE B APPLIED PART

AC adapter

Model :BPM050S18F03

Manufacturer :Bridge Power Corporation

Lorsque vous maniez la base de l’appareil,

veuillez noter les points suivants:

• Faites attention à ne pas vous coincer les

doigts dans les parties en mouvement.

• Évitez de heurter les yeux ou le nez du

patient.

Degré de protection contre les chocs

électriques

: TYPE B PARTIE D'APPLICATION

Adaptateur secteur

Modèle :BPM050S18F03

Fabricant :Bridge Power Corporation

PRÉCAUTION

PRÉCAUTION

PRÉCAUTION

9

Page 12

SYSTEM DIAGRAM

Plug

Lamp house cover

Aperture/slit length

display window

Filter selector lever

Aperture/slit-length

selector knob

Canthus marker

Mirror

Centering knob

Inclination lever

Slit width controls

Photography button

Control lever

Base locking knob

Base

Forehead rest

Chinrest

Objective lens

Magnification selector handle

Fixing knob

Diopter adjusting ring

12.5× eyepiece

Magnification index mark

Chinrest adjuster

Microscope arm

Illumination arm locking knob

Power switch

Microscope arm locking knob

Illumination Unit

Tabletop

Power Supply

Microscope Unit

Base Unit

Chinrest Unit

Bightness adjustment knob

Fixation target

Tabletop*

Illumination arm

COMPONENT NAMES

COMPOSITION OF PARTS THAT COME IN CONTACT WITH THE PATIENT

* Tabetop is opptional accessory.

Forehead rest: Polyamide resin

Chinrest : Polyamide resin

10

SYSTEM DIAGRAM

Page 13

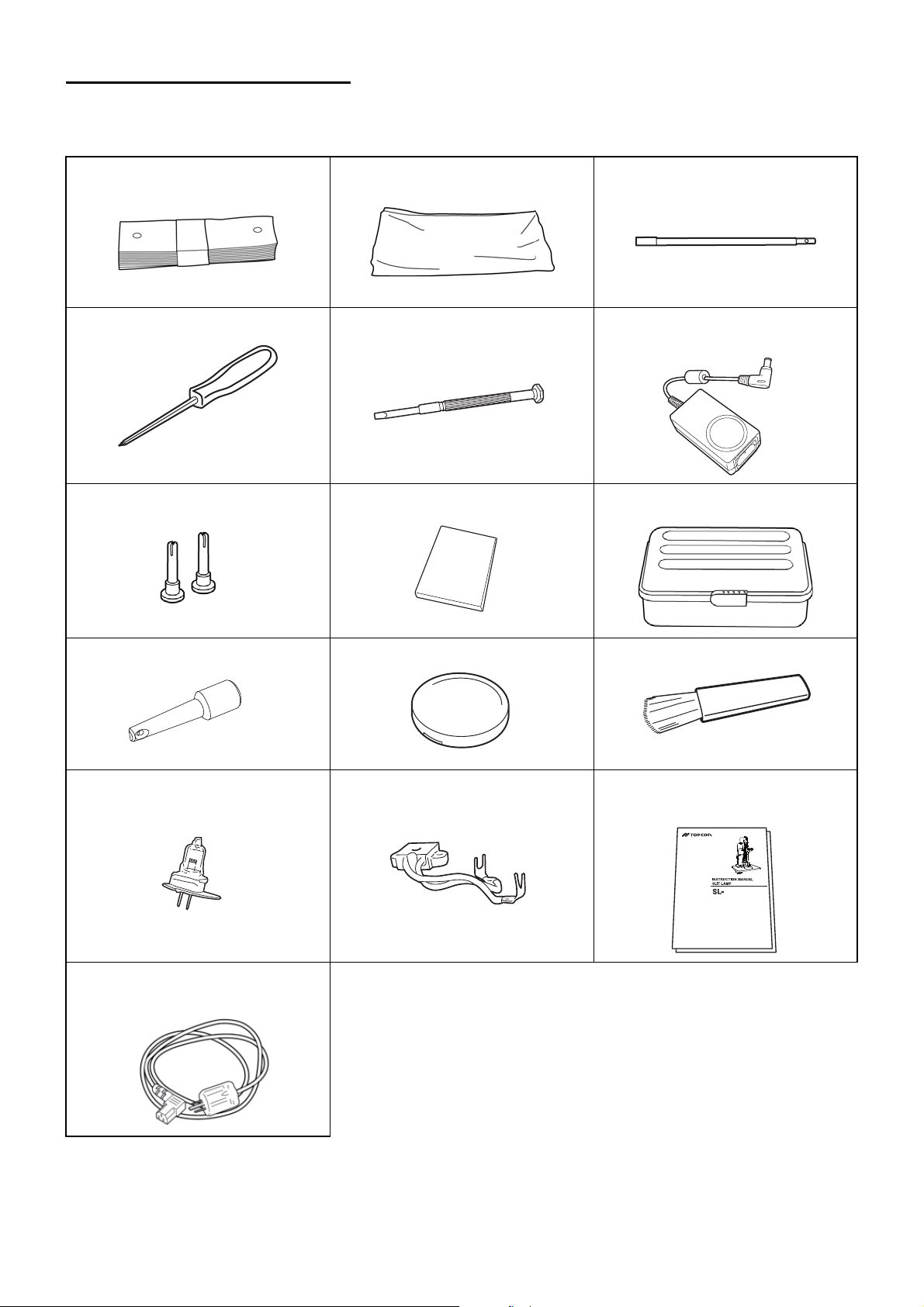

STANDARD ACCESSORIES

D301

Make sure that all the following standard accessories are included.

Figures in parentheses are the quantities.

Chinrest tissue (1) Dust cover (1) Test rod (1)

Crosshead screwdriver (1) Screwdriver (1) AC adapter (1)

(model:BPM050S18F03)

Chinrest tissue pin (2) Square mirror (1)

Luminous fixation target (1) Cap (1) Cleaning brush (1)

Illumination lamp (1) Socket (1) User manual (1),

Accessory case (1)

Instruction manual (1)

Power cord (1) *

* More than one power cord can be included on certain occasions.

For optional accessories, see “Optional Accessories” on page 47.

11

SYSTEM DIAGRAM

Page 14

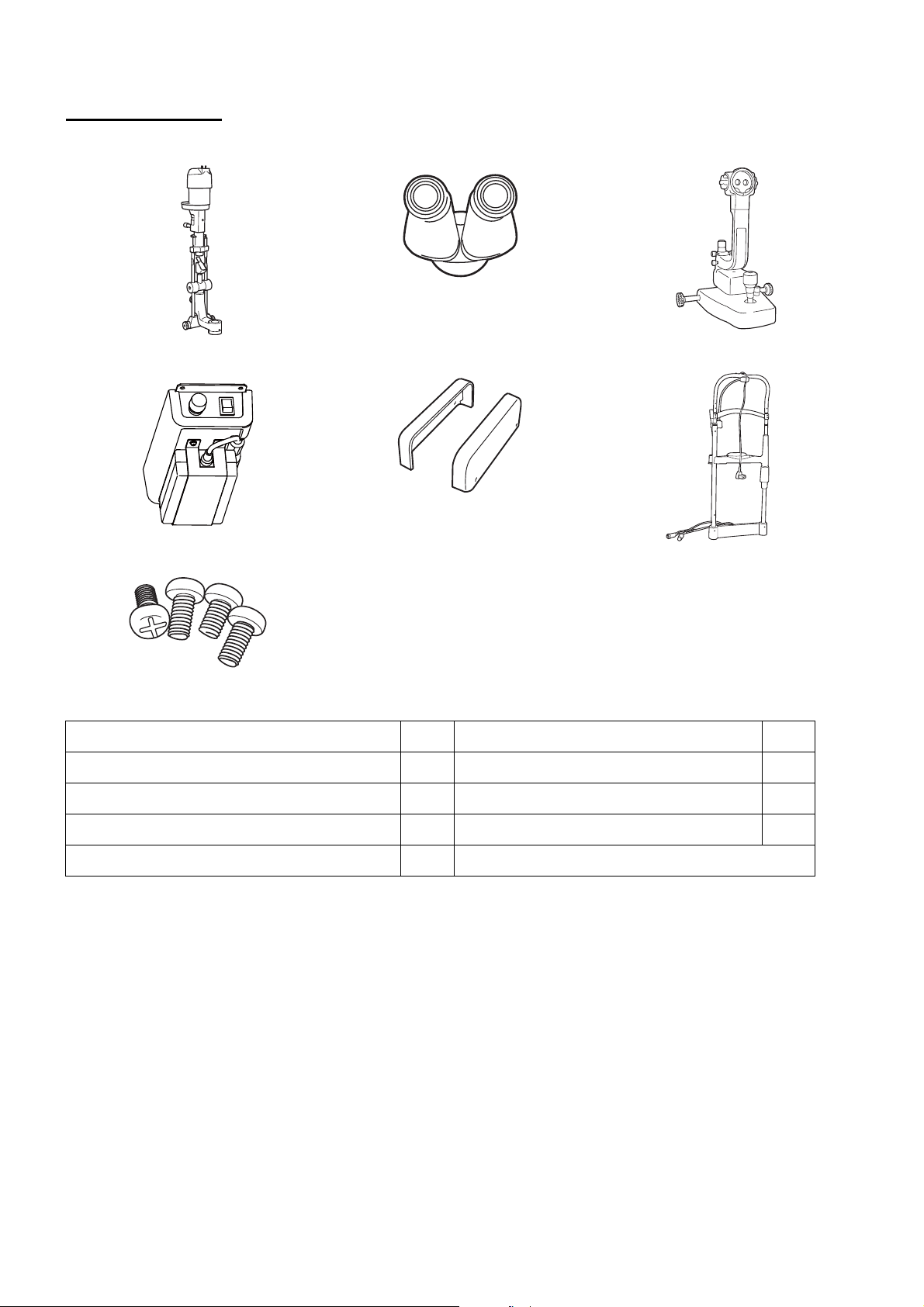

COMPONENTS

COMPONENTS

(1) Illumination unit (2) Binocular tubes (3) Base unit

(4) Power Supply (5) Rail cover (6) Chinrest unit

(7) Rail cover fixing screw

Article name Qty Article name Qty

(1) Illumination unit 1 (5)Rail cover 2

(2) Binocular tubes 1 (6)Chinrest unit 1

(3) Base unit 1 (7) Rail cover fixing screw 4

(4) Power Supply 1

12

COMPONENTS

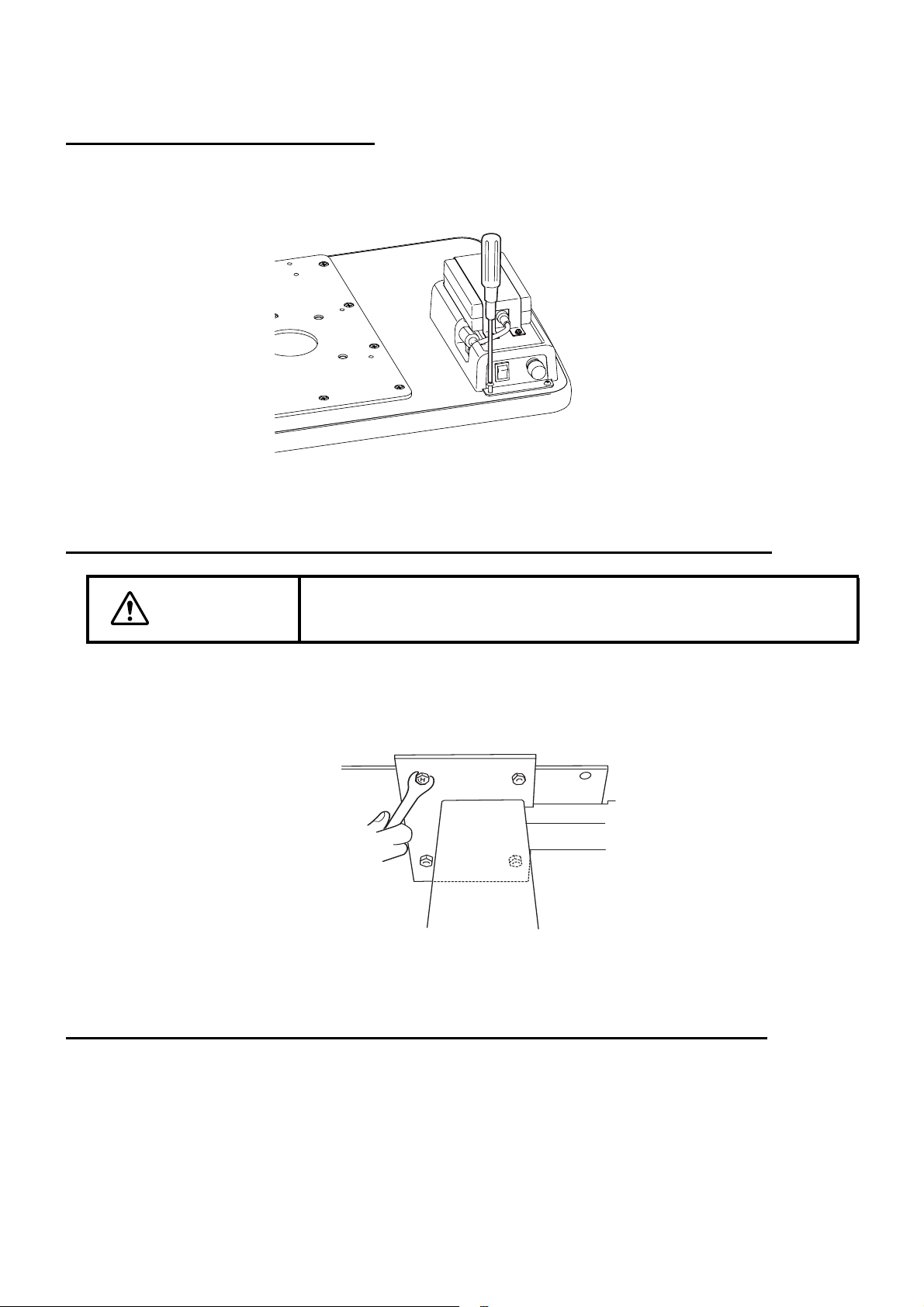

Page 15

ASSEMBLY PROCEDURE

* The illustration depicts the SO-TABLE06.

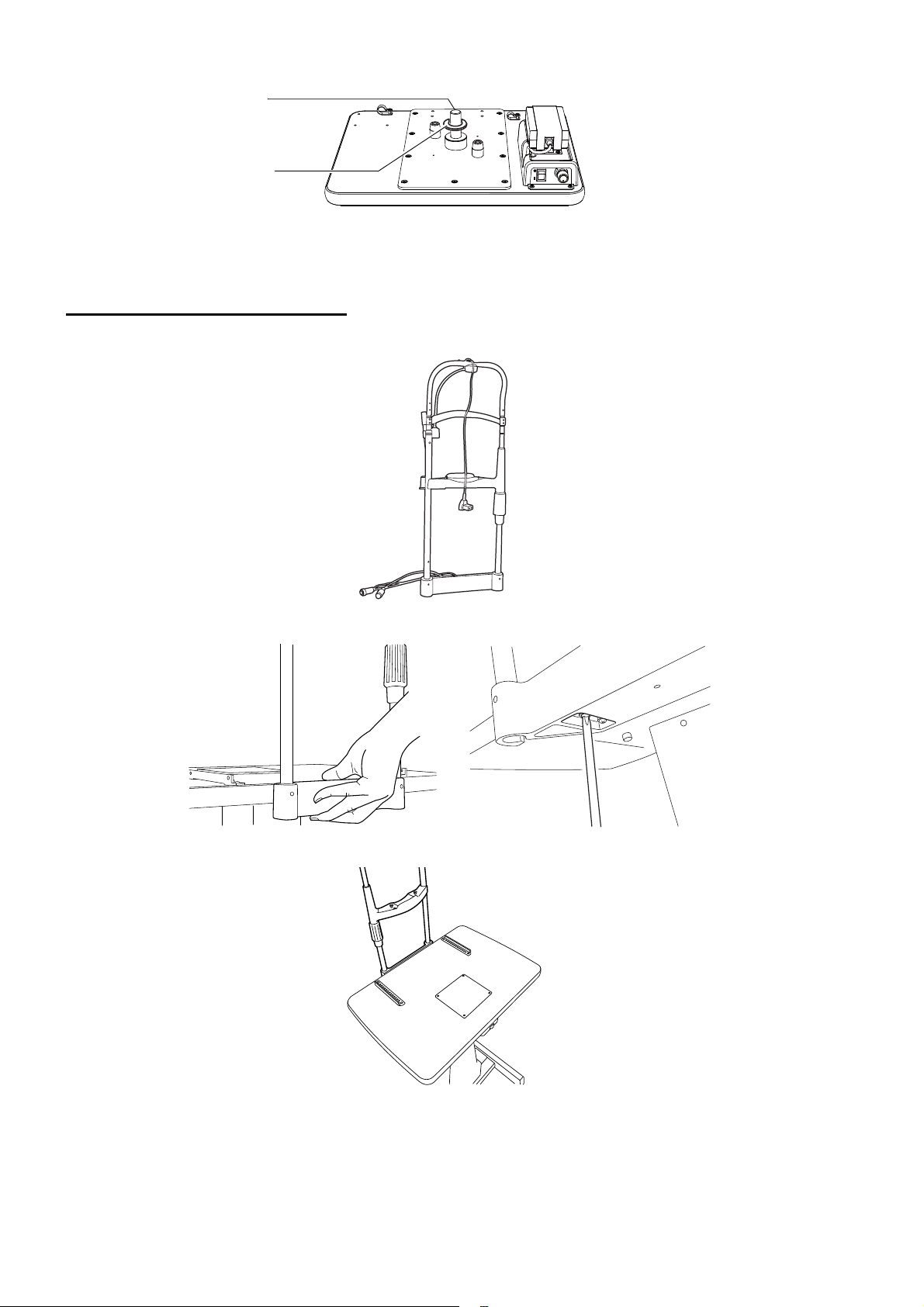

SECURING THE POWER UNIT

• The tabletop SO-TABLE06 and SO-TABLE07 is optional accessory.

1 Affix the power supply to the back of the tabletop with 4 screws.

SECURING THE TABLETOP SO-TABLE06 (OPTIONAL ACCESSORY)

CAUTION

FITTING TO AUTOMATIC INSTRUMENT TABLE AIT-16

To prevent falling during use and movement, secure each unit.

1 Place the tabletop on the instrument table, and secure it with the 4 bolts attached to the instru-

ment table.

SECURING THE TABLETOP SO-TABLE07 (OPTIONAL ACCESSORY)

1 Peel off the tape which secures the plastic washer to the mounting bracket’s shaft.

ASSEMBLY PROCEDURE

13

Page 16

2 Insert the plastic washer, together with the shaft, into the cavity for the ophthalmic unit arm.

Washer

Shaft

SECURING THE CHINREST

1 Take out the chinrest from the upper section of the container box.

2 Attach the chinrest to the bottom face of the table, and affix it to the table using 4 screws.

3 Chinrest fitted to the tabletop.

14

ASSEMBLY PROCEDURE

Page 17

SECURING THE BASE UNIT AND RAIL COVER

Rail cover

Fixing knob

Microscope unit

30° - 60°

Indices

1 Align the wheel of the base unit with the rail of the tabletop.

2 Secure the rail covers with 4 screws (7): (2 screws each on the right and left sides).

SECURING THE BINOCULAR TUBES

1 Align the pin of the microscope unit with the groove on the binocular tubes, and fit the binocular

tubes with the fixing knob.

NOTE

Make sure you do not touch the lens surfaces.

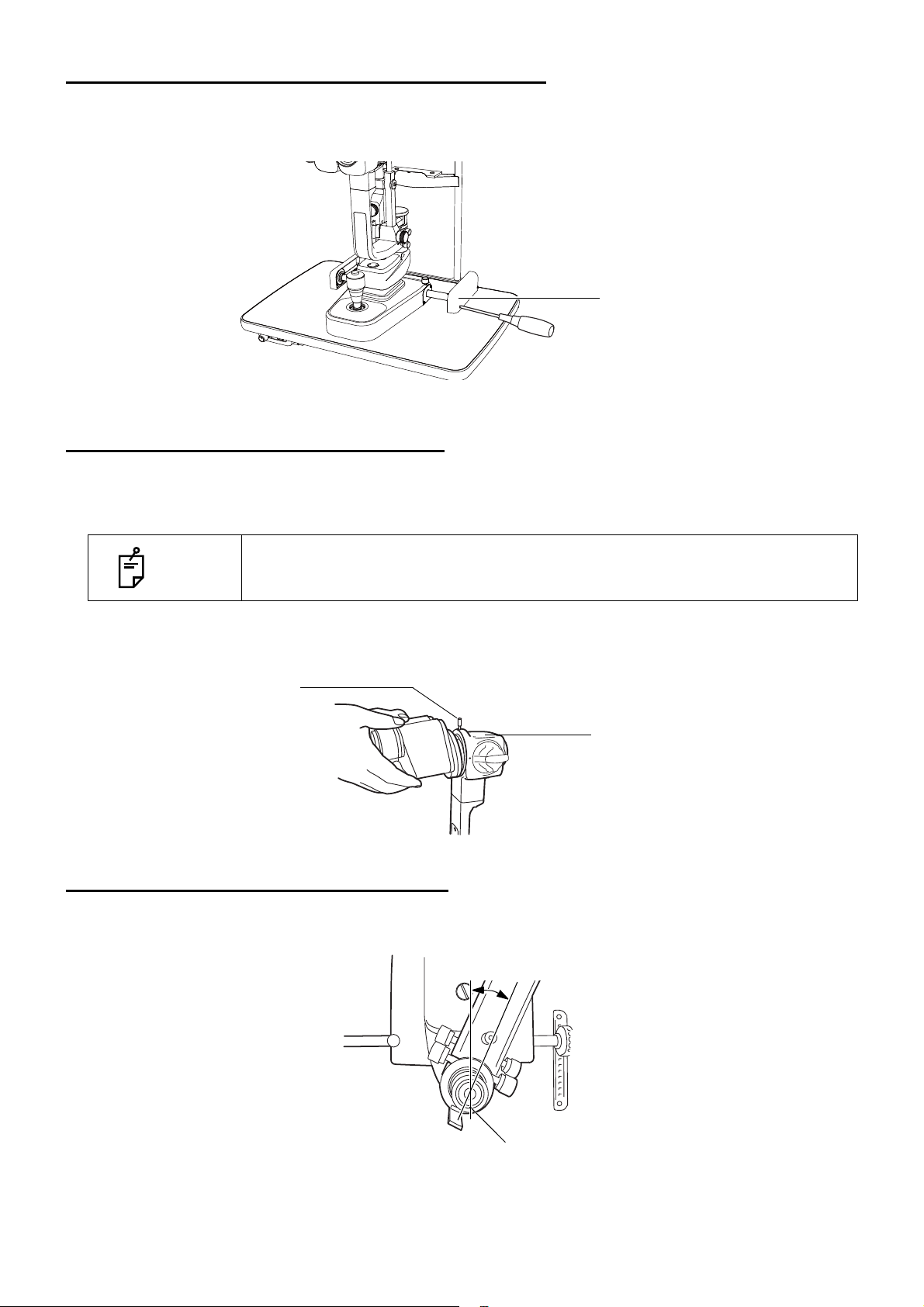

SECURING THE ILLUMINATION UNIT

Loosen the microscope arm locking-knob of the base unit, manually turn the shaft and tilt the guide rodshaft index 30-60°, then refasten the microscope-arm locking-knob.

15

ASSEMBLY PROCEDURE

Page 18

2 Loosen the fixing screw on the outside of the fitting cavity of the illumination unit with a screw-

Indices

Protection pad (for transportation)

driver. Align indices and slowly lower the illumination unit onto the shaft of the base unit.

NOTE

While assembling the illumination unit, take care not to get your fingers caught.

3 Firmly tighten the fixing screw with a screwdriver.

REMOVING THE ILLUMINATION UNIT PAD

1 Remove the rubber band and slowly withdraw the protection pad from the slit operation mecha-

nism of the illumination unit.

16

ASSEMBLY PROCEDURE

Page 19

CONNECTING THE CABLES

Plug

Illumination cable

power cord

Fixation target cable

• Use the power cord applicable to the voltage of the commercial power

supply being used. Using a power cord improper to the commercial

CAUTION

power supplymay cause the instrument to malfunction.

• The power cable in standard accessories for this instrument cannot

use besides this instrument.

1 Remove the tape from the lamp house cover of the illumination unit. Plug the cable from the

upper part of the chinrest into the illumination unit.

2 Connect the cable from the lower part of the chinrest unit and the power cord to the power supply.

3 Pull the base assembly toward the operator's side fully. Attach the cables to the rear side of the

table with the cable clip to adjust the loosening of the cord.

4 Move the base assembly and illumination assembly and make sure there is enough cable to

allow free movement of the base assembly in all directions.

FITTING THE CHINREST TISSUE

1 Remove the chinrest tissue pins.

2 Take approximately one-fifth of the pad of chinrest tissues and secure this at each end with the pins.

FITTING THE CAP

1 Fit the cap to the shaft aligning the guide rod with the groove in the cap.

17

ASSEMBLY PROCEDURE

Page 20

FITTING THE DIFFUSION LENS SO-DFL01 (OPTIONAL ACCESSORY)

Mirror stopper

Frame

Hole

Pivot

DIFFUSION LENS

SO-DFL01

Flat side

Concave side

Concave side

Hole

Pivot

1 Insert one pivot of frame of SO-DFL01 into the hole of mirror stopper.

Be careful not to make mistake of the flat side / concave side of SO-DFL01.

NOTE

Set the concave side as shown below.

2 Insert another pivot into the opposite hole of mirror stopper.

• Be careful not to extend the frame excessively.

The frame may be deformed and, if so, it cannot be attached.

• Make sure you do not touch the mirror surface,If you touch the mirror surface,

please clean this according to the process on page 33 Cleaning Lenses and

Mirrors.

NOTE

18

ASSEMBLY PROCEDURE

Page 21

SECURING THE TONOMETER MOUNT SO-TM1 (OPTIONAL ACCESSORY)

Screw

Locating Pin

The holes

Screw

Fixing knob

1 Align the locating pin of SO-TM1 into the holes of the microscope, and fasten the screw.

2 Remove the fixing knob of the microscope, and secure the eyepieceunit, etc with the packaged

screw.

3 Applanation tonometer R900 type, Photokeratoscope attachment, etc could be mounted on SO-

TM1.

19

ASSEMBLY PROCEDURE

Page 22

PREPARATIONS

Tes t ro d

Magnification selector handle

Slit adjustment knob

Aperture/slit-length selector knob

Eyepiece

POWERING ON

To avoid fire and electric shock in case of leakage, be sure to use a

WARNING

CAUTION

1 Connect the power cord.

2 Turn ON the POWER switch.

ADJUSTING THE DIOPTER AND PUPILLARY DISTANCE (PD)

grounded outlet. Do not connect to outlets that are not grounded.

• Use the power cord applicable to the voltage of the commercial power

supply being used. Using a power cord improper to the commercial

power supplymay cause the instrument to malfunction.

• The power cable in standard accessories for this instrument cannot

use besides this instrument.

NOTE

In case that no test rod is provided, set the diopter scale to your diopter by turning the diopter adjustment ring.

To ensure sharp observation of slit images, always carry out the diopter and PD

adjustments.

1 Insert the test rod into the rotation shaft cavity, and set the black face square with the micro-

scope.

2 Place the brightness adjustment knob (see page 25) in at the 2/3.

3 Adjust the illumination to φ9mm by adjusting the slit width control knob and aperture/slit length

control knob.

4 Turn the diopter adjusting ring of the eyepiece at one side fully counter-clockwise.

5 Turn the diopter adjusting ring clockwise and stop when the test rod can be clearly seen.

6 Adjust the diopter of another eyepiece in the same way as above.

20

PREPARATIONS

Page 23

7 After adjusting the diopter, turn the slit width control knob until the slit width is about 1mm, then

Diopter adjusting ring

Prism box

check if the slit image projected on the test rod is properly in focus.

8 Holding the prism box, look through the eyepiece with both eyes, and adjust the pupillary dis-

tance so that the image projected on the test rod can be seen without diplopia (double vision),

and appear to be three dimensional.

21

PREPARATIONS

Page 24

OPERATION PROCEDURE

Forehead rest

Canthus marker

Chinrest

Chinrest adjuster

(A) Fixation target with

diopter adjustment

(B) Luminous fixation target

Diopter adjusting

ring

Fixation target unit

Fixation target

lever

FIXING THE PATIENT'S FACE AND FIXATION

1 Place the patient's chin on the chinrest with his forehead against the forehead rest.

2 By rotating the chinrest adjuster, align the patient's eye with the canthus marker on the chinrest

frame.

3 Ask the patient to look at the fixation target with the eye that is not being examined.To change the

patient's fixation point, hold the fixation target at the end opposite to the target and adjust accordingly.

• When using the fixation target with diopter adjustment (A), slide the diopter

adjustment knob so that the patient can see the following target ( ).

NOTE

• The ring target can be adjusted within a range of -15D to +10D.

• The luminous fixation target is used for myopia of -15D or more.

• When replacing targets, remove the target by pulling gently whilst supporting

the opposite end.

22

OPERATION PROCEDURE

Page 25

OPERATING THE MICROSCOPE UNIT

Magnification selector

handle

Magnification index mark

Turn the magnification selector to set a magnification value against the magnification index mark.

For the overall magnification in conjunction with magnification marks of the

NOTE

magnification selector handle, see page 35.

23

OPERATION PROCEDURE

Page 26

OPERATING THE BASE AND FOCUSING

Base locking knob

Base

Control lever

• To avoid injury to the eye and nose whilst moving the base unit, make

sure that you have a clear view of the slit lamp and the patient's face.

CAUTION

• To prevent dropping the base locking knob from the base, do not loosen the

NOTE

• Rough focusing is carried out with major movements, following step 1-3.

• Fine focusing is done with the microscope, following steps 2 and 3.

• For the safety of the operator and the patient, do not place fingers

between moving parts.

knob too much.

1 For major horizontal movements, hold the control lever in the upright position and move the

entire base.

2 For fine adjustments, move the control lever in the required direction.

3 The base can be raised by turning the control lever clockwise, and lowered by turning the control

lever counter-clockwise.

4 To fix the base, fasten the base locking knob.

24

OPERATION PROCEDURE

Page 27

OPERATING THE ILLUMINATION UNIT

Brightness adjustment

knob

Slit-width control knob

• To avoid injury to the patient’s head, incline the illumination unit holding the base unit.

CAUTION

• Adjust the slit width according to the results of the investigation.

NOTE

ADJUSTING THE BRIGHTNESS

Turn the brightness adjustment knob.

The brightness of the illumination light can be adjusted to the preferred illumination setting.

• The slit-width scale should be used as a guideline.

• When using the square mirror, incline the illumination unit at least 10º.

• To avoid causing discomfort to the patient or any damage to the

patient's eye, keep the illumination at its minimum during adjustment.

The surrounding number of the brightness adjustment

NOTE

knob indicate the ratio of brightness, where 1 is the

maximum value.

ADJUSTING THE SLIT WIDTH

Turn the slit-width control knob.

The slit width can be changed gradually between 0 and 9mm (9mm=circle).

25

OPERATION PROCEDURE

Page 28

CHANGING THE APERTURE/SLIT LENGTH

Aperture/slit-length

display window

Aperture/slit-length

control knob

Aperture/slit-length

control knob

Slit-angle scale

Centering knob

Turn the aperture/slit-length control knob.

When the slit is fully opened, 7 types of spot illumination (φ9, φ8, φ5, φ3, φ2, φ1, φ0.2mm) are availa-

ble. The slit width can be changed gradually from 1mm to 8mm.

NOTE

The spot illumination size and slit length are displayed on the aperture/slitlength display window.

TURNING THE SLIT

Horizontally rotate the aperture/slit-length control knob.

This directly changes the slit image from vertical to horizontal. In this mode, the slit angle can be

read off the angle scale.

SWINGING THE SLIT SIDEWAYS

Loosen the centering knob and swing the illumination unit right and left.

This provides indirect illumination displacing the slit light from the microscope center.

By fastening the centering knob, the slit light returns to the center of the vision field.

NOTE

26

OPERATION PROCEDURE

This function is used for scanning observation and observation with indirect illumination.

Page 29

INCLINED ILLUMINATION

Inclination lever

Square mirrorBattledore mirror

Press to unlock the inclination lever and pull.

The illumination unit is inclined for inclined illumination up to 20° in 5° steps.

NOTE

This function is used for observing a horizontal cross section, and for corner

angle and fundus observation.

REFLECTION MIRROR

For this instrument, a battledore mirror and a square mirror are available. For normal observation,

the battledore mirror is used.

However, if the arm angle scale, which represents the angle formed by the illumination arm and

microscope arm, reads approx. 3° to 10° and the observation light flux is disturbed by the battledore

mirror, then the square mirror should be used.

The square mirror is to be used when the arm angle is opened to more than 10°

.

NOTE

The square mirror is standard accessory.

27

OPERATION PROCEDURE

Page 30

REPLACING REFLECTION MIRRORS

Square mirrorBattledore mirror

Green-colored

No filter

ND filter

(13%transmission)

Blue filter

Red-free filter

Blue-colored

Filter selector lever

Replace mirrors as follows, taking care not to touch the mirror and lens surfaces:

1 Open the microscope arm and illumination arm 30° or more.

2 Incline the illumination unit 10° or more.

3 Pull out the battledore mirror, holding the slender part on both sides. To reinsert the battledore

mirror, hold the slender part on both sides and insert.

4 Insert the square mirror from the side recessed on the back.

5 To pull out the square mirror, which has no handle, push the square mirror up as illustrated

below.

NOTE

CHANGING FILTERS

Move the filter selector lever right and left to select the required filter from the 4 types.

If you touch the mirror or lens surface, please clean this according to the process on page 33 "Cleaning Lenses and Mirrors".

28

OPERATION PROCEDURE

Page 31

DIFFUSION LENS SO-DF 01 (OPTIONAL ACCESSORY)

Diffusion lens

When in use, the diffusion lens is set vertically in front of the reflection mirror.

When not in use, remove the diffusion lens from the light path.

When using the diffusion lens, open the microscope arm and illumination arm

NOTE

30°to avoid friction of the diffusion lens or illumination support.

Also, fully open the slit; otherwise this prevents sufficient light from entering.

ENDING PROCEDURE

Turn OFF the Power switch.

29

OPERATION PROCEDURE

Page 32

MAINTENANCE AND CHECKUPS

PERIODIC MAINTENANCE

Before using, confirm the following:

•Adjust the diopter and eye width following ADJUSTING THE DIOPTER AND PUPILLARY DISTANCE (PD) on page 20 and turn the Slit width controls and make the slit width about 1mm: The

slit image projected on the test rod is seen clearly.

•Move the base forward-backward and right-left: The base moves smoothly.

•Component parts, including the eyepiece unit, are fitted in place.

•The chinrest base is firmly fitted to the table.

•Cables and plugs are firmly connected.

•The slit width doesn't narrow by disengaging a hand from the Slit width control knob.

•The illumination unit smoothly swings.

Daily Care

This instrument may be affected adversely by dust. Apply the dust cover when not using.

PLACING AN ORDER FOR CONSUMABLES

When ordering consumable items, contact your dealer or TOPCON (see the back cover).

Specify the article name, product code and quantity.

Article name Product code

Light source

Chinrest tissue 403104082

Halogen lamp 447032530

Socket 405261249

USER MAINTENANCE ITEMS

Item Inspection time Contents

Inspection Before using • Adjusting the diopter and pupillary distance

• Focus of slit image

• The base unit must move smoothly.

• The components must be fitted in place correctly.

• The chinrest unit must be fitted to the table unit correctly.

• The cables and plugs must be connected correctly.

• The objective lens, eyepiece and mirror must not be stained or

damaged.

Cleaning When the part is

stained

Replacement As required • Halogen lamp

Supply As required • Chinrest tissue

• Objective lens

• Eyepiece

•Mirror

• Sliding plate, rail and wheel shaft unit

• Forehead rest and chinrest unit

• Socket

DEALER MAINTENANCE ITEMS

Item Inspection time Contents

Adjustment

Within 12

months from the

last maintenance

• Slit width control knob torque

• Inclination torque of illumination unit

30

MAINTENANCE AND CHECKUPS

Page 33

REPLACING ILLUMINATION LAMPS

Lamp house cover

Plug

Socket fixing

Lamp unit

lever

L

Pin

• When replacing the lamp, switch off the power supply and remove the

CAUTION

• To ensure perfect illumination, make sure that the socket flange and notch are

NOTE

• Use a soft cloth and do not touch the illumination lamp with bare fingers: fin-

firmly fitted to the lamp house.

gerprints and stains may affect illumination and cause premature failure of the

lamp.

power cord to avoid electric shock.

• Beware of high temperatures when replacing the lamp immediately

after switching it off: these could cause burns.

1 Turn OFF ( ) the POWER switch and remove the cable

plug.

Pull out the plug from the lamp house cover. Turn the lamp

house cover counterclockwise and remove upward.

2 Lightly pull the socket fixing lever and turn in the direction indicated

by the arrow.

3 Pull out the lamp unit.

4 Remove the illumination lamp from the socket and fit the new lamp.

When fitting the new lamp, make sure the direction of the illumination

lamp and socket is correct.

∗ For the article name and product code of the illumination lamp,

refer to PLACING AN ORDER FOR CONSUMABLES on P.30.

Check the marked "L" on the illumination lamp.

If "L" is not marked, it can not use.

NOTE

5 Fit the pin into the groove on the lamp house cover as shown below. Turn the lamp house cover clockwise

to fix it.

6 Connect the plug.

NOTE

Unless the pin is fitted into the groove correctly, the plug is not connected properly and the illumination is not turned on.

31

MAINTENANCE AND CHECKUPS

Page 34

REPLACING SOCKETS

Cable-fixing terminal

NOTE

The socket may deteriorate due to the constant heat: therefore, it should be

replaced after the lamps have been changed two or three times.

1 Remove the lamp following steps 1 - 4 of REPLACING ILLUMINATION LAMPS.

2 Loosen the cable-fixing terminal by turning it counterclockwise, remove the cable and replace the

socket with a new one.

*For the article name and product code of the socket, refer to PLACING AN ORDER FOR CONSUMABLES on P.

30.

3 Turn the cable-fixing terminal clockwise to fix the cable securely.

NOTE

Unless the cable-fixing terminal is fixed securely, the illumination may not be

turned on.

4 Install the lamp house cover and plug following steps 5 - 6 of REPLACING ILLUMINATION

LAMPS.

RESTOCKING CHINREST TISSUE

When the chinrest tissue supply is depleted, pull out the chinrest tissue pins and replace tissue.

32

MAINTENANCE AND CHECKUPS

Page 35

DAILY CARE

• Before carrying out daily care, remove the power cord (to avoid elec-

CAUTION

• To prevent the chinrest, forehead rest and other plastic parts from discolora-

NOTE

• Wipe parts with a cloth moistened with a tepid solution of neutral kitchen detergent.

tion and deterioration, do not use volatile solvents for cleaning, including benzine, thinner, ether, gasoline, etc.

tric shocks) and wait until the lamp house has cooled (to avoid burns).

• Do not touch parts inside the lamp house cover during operation and

immediately after switching off the power supply: this could cause burns.

CLEANING APPLIED PARTS

Wipe the forehead rest, the chinrest with a cloth moistened with a tepid solution of neutral detergent

for kitchenware.

CLEANING LENSES AND MIRRORS

REMOVING STAINS

NOTE

To prevent damaging lens surfaces, do not hold gauze with tweezers.

1 Prepare a solution of ethyl alcohol 20% and ether 80%.

2 Remove dust from lens and mirror surfaces with the cleaning brush, or a blower.

3 Using clean gauze or lint-free tissue, lightly clean with a rotating movement from the center of the

lens/mirror outwards.

4 If the stain remains, repeat this 2 to 3 times.

5 If stains are persistent, call your dealer or TOPCON (see the back cover).

33

MAINTENANCE AND CHECKUPS

Page 36

TROUBLESHOOTING

TROUBLESHOOTING GUIDE

To avoid electric shocks, do not attempt overhauling, rebuilding or

CAUTION

If you suspect a problem, check the possible cause by means of the check list below.

If the check list below does not solve the problem, or if the problem is not included in the list, contact

your dealer or TOPCON (see the back cover).

Problem Possible cause Check Page

Plug of lamp house cover is switched off Insert plug. 17

Cable connection is disconnected Check cable connection. 20

POWER switch is OFF Turn ON POWER switch. 20

Illumination lamp

does not work

Illumination field is

not uniform/is shady/

is dark

Brightness adjustment knob is the minimum

Illumination lamp is broken Replace it with a new illumination lamp. 30

Socket has deteriorated Replace it with a new socket. 32

Slit width is the minimum Rotate the Slit width controls

Filter selector lever is out of position Click filter selector lever. 28

repairs. Ask your dealer for repair.

Check List

Turn up brightness adjustment knob. 25

25

34

MAINTENANCE AND CHECKUPS

Page 37

SPECIFICATIONS AND PERFORMANCE

Specifications and Performance

Microscope unit

Type Galileo type

Magnification Drum, 3-step magnification

Magnification steps 10/16/25

10.00 (φ22.5mm)

Overall magnification (actual vision field)

Eyepiece lens

PD adjustment range

Illumination unit

Illumination field

Aperture diameter φ9, 8, 5, 3, 2, 1, 0.2mm

Slit direction Vertical to horizontal, can be altered gradually

Inclination

Filter

Illumination lamp Halogen type: 6V 20W

Base unit

Forward-backward movement

Right-left movement length 100mm

Vertical movement length 30mm

Fine adjustment in all directions length 12mm

length 90mm

Chinrest unit

Adjustable range of the vertical direction 80mm

Fixation target

15.98 (φ14.1mm)

25.53 (φ8.8mm)

Magnification: 12.5x

Diopter adjustment range: -5D to +5D

55 to 78mm

Slit width: 0 to 9mm, can be altered gradually (9mm=circle)

Slit length: 1 to 8mm, can be altered gradually

5°, 10°, 15,° 20° from below

Available for use side swing

Blue filter, red-free filter, ND filter (13% transmission), UV cut

filter (normal use), IR cut filter (normal use)

Fixation target with diopter adjustment

Light source for fixation target: LED (red)

• The specification and design of the product can be altered for improvements without prior notice.

The following statement is the Essential performance provided for by IEC60601-1.

NOTE

The halogen lamp is not to be turned off.

There are no component failures.

MAINTENANCE AND CHECKUPS

35

Page 38

GENERAL INFORMATION ON USAGE AND MAINTENANCE

INTENDED PATIENT POPULATION

The patient who undergoes an examination by this instrument must maintain concentration for a few

minutes and keep to the following instructions:

To fix the face to the chinrest, forehead rest.

To keep the eye open.

To understand and follow instructions when undergoing an examination.

INTENDED USER PROFILE

The SL-D301 SLIT LAMP is an electric instrument for medical use.

Use this instrument under a doctor's guidance.

ENVIRONMENTAL CONDITIONS FOR USE

Temperature : 10°C to 40°C

Humidity : 30% to 90% (non-condensing)

Air pressure : 700hPa to 1060hPa

STORAGE, USAGE PERIOD

1. Environmental conditions (without package)

* Temperature : 10°C to 40°C

Humidity : 10% to 95% (without dew condensation)

Air pressure : 700hPa to 1060hPa

*THIS INSTRUMENT DOES NOT MEET THE TEMPERATURE REQUIREMENTS OF ISO 15004-1

FOR STORAGE. DO NOT STORE THIS INSTRUMENT IN CONDITIONS WHERE THE TEMPERATURE MAY RISE ABOVE 40°C OR FALL BELOW 10°C.

2. When storing the instrument, ensure that the following conditions are met:

(1) The instrument must not be splashed with water.

(2) Do not store the instrument in an environment where air pressure, temperature, humidity, venti-

lation, sunlight, dust, salty/sulfurous air, etc. could cause damage.

(3) Do not store or transport the instrument on a slanted or uneven surface or in an area where it is

subject to vibrations or instability.

(4) Do not store the instrument where chemicals are stored or gas is generated.

3. Normal life span of the instrument:

8 years from delivery providing regular maintenance is performed (according to the self-certification

[TOPCON data])

36

GENERAL INFORMATION ON USAGE AND MAINTENANCE

Page 39

ENVIRONMENTAL CONDITIONS FOR PACKAGING IN STORAGE

Temperature : -20°C to 50°C

Humidity : 10% to 95%

Air pressure : 700hPa to 1060hPa

ENVIRONMENTAL CONDITIONS FOR PACKAGING IN TRANSPORTAION

Temperature : -40°C to 70°C

Humidity : 10% to 95%

Air pressure : 700hPa to 1060hPa

ELECTRIC RATING

Source voltage : AC100 - 240V

Frequency : 50 - 60Hz

Power input : 80VA

DIMENSIONS AND WEIGHT

Dimensions, Weight

Dimensions:

w/o Table

w/ Unit Table 440mm(W) x 410mm(D) x 760 to 790mm(H)

w/ AIT Table 550mm(W) x 430mm(D) x 760 to 790mm(H)

Weight: w/o Table 12kg

w/ Unit Table 17kg

w/ AIT Table

Height from the top to patient’s eye 375mm

312mm(W) x 296mm(D) x 646 to 676mm(H)

17.5kg

37

GENERAL INFORMATION ON USAGE AND MAINTENANCE

Page 40

SYSTEM CLASSIFICATION

• Type of protection against electric shocks: Class Ι equipment

Class Ι equipment does not depend on basic insulation only for protection against electric shocks. It can

also be earthed; therefore, the metal parts with which one comes into contact do not become conductive if the basic insulation fails.

• Degree of protection against electric shocks: Type B applied part

Type B applied part is the applied part complying with the specified requirements of the Standard IEC

60601-1 to provide protection against electric shock, particularly regarding allowable LEAKAGE CURRENT.

• Degree of protection against harmful ingress of water: IPx0

SL-D301 has no protection against ingress of water. (The degree of protection against harmful ingress

of water defined in IEC 60529 is IPx0)

• Classification according to the methods of sterilization or disinfection recommended by the manufacture: not applicable.

SL-D301 has no part to be sterilized or be disinfected.

• Not AP or APG equipment

• Classification according to the degree of safety of application in the presence of a flammable anaesthetic mixture with air or with oxygen or nitrous oxide: Equipment not suitable for use in the presence of

a flammable anaesthetic mixture with air or with oxygen or nitrous oxide.

SL-D301 should be used in environments where no flammable anesthetics and/or flammable gases are

presents.

• Classification according to the mode of operation: Continuous operation.

Continuos operation is the operation under normal load for an unlimited period, without the specified

limits of temperature being exceeded.

OPERATION PRINCIPLES

Illuminates the observed part by the illumination light emitted from the illumination optical system and allows

enlargement observation by binocular stereoscopic microscope.

CHECKPOINTS FOR MAINTENANCE

1. Regularly maintain and check the instrument and its parts.

2. When using the instrument after a prolonged period of inactivity, confirm normal and safe operation

beforehand.

3. To take a good picture, be careful not to stain the objective lens with fingerprints or dust.

4. When this instrument is not in use, cap the objective lens and cover the instrument with the dust

cover.

5. When the objective lens is stained, clean it according to Cleaning Lenses and Mirrors in this manual.

38

GENERAL INFORMATION ON USAGE AND MAINTENANCE

Page 41

DISPOSAL

This symbol is applicable for EU member countries only.

To avoid potential damage to the environment and possibly human

health, this instrument should be disposed of (i) for EU member countries - in accordance with WEEE (Directive on Waste Electrical and

Electronic Equipment), or (ii) for all other countries, in accordance with

local disposal and recycling laws.

The base contains strong springs. Do not attempt to disassemble or

CAUTION

• When disposing of SL-D301 parts, follow the local regulations for disposal and recycling.

burn the base, as the springs could cause injury by shooting out of it.

NOTE

GENERAL INFORMATION ON USAGE AND MAINTENANCE

39

Page 42

PATIENT’S ENVIRONMENT

Do not use the power strip in the

patient's environment. Connect the

power supply of the device to the

commercial power supply.

Radius 1.5m

1.5m

2.5m

1.5m

Devices applicable to the

•Digital camera

patient’s environment

When the patient or inspector may touch the devices (including the connecting devices) or

when the patient or inspector may touch the person that comes into contact with the devices

(including the connecting devices), the patient's environment is shown below.

In the patient's environment, use the device conforming to IEC60601-1. If you are compelled to

use any device not conforming to IEC60601-1, use an insulation transformer.

Requirements for the EXTERNAL DEVICE

The external device connected to the analog and digital interfaces must comply with the

respective IEC or ISO standards (e.g. IEC 60950-1 for data processing equipment and IEC

60601-1 for medical equipment).

Anybody connecting additional equipment to medical electrical equipment configures a medical

system and is therefore responsible that the system complies with the requirements for medial

electrical systems. Attention is drawn to the fact that local laws take priority over the above

mentioned requirements. If in doubt, contact your dealer or TOPCON (see the back cover).

40

GENERAL INFORMATION ON USAGE AND MAINTENANCE

Page 43

ELECTROMAGNETIC COMPATIBILITY

This product conforms to the EMC standard (IEC 60601-1-2 Ed.3: 2007).

a) MEDICAL ELECTRICAL EQUIPMENT needs special precautions regarding EMC and needs to be

installed and put into service according to the EMC information provided in the ACCOMPANYING

DOCUMENTS.

b) Portable and mobile RF communications equipment can affect MEDICAL ELECTRICAL EQUIPMENT.

c) The use of ACCESSORIES, transducers and cables other than those specified, with the exception of

transducers and cables sold by the manufacturer of the EQUIPMENT or SYSTEM as replacement

parts for internal components, may result in increased EMISSIONS or decreased IMMUNITY of the

EQUIPMENT or SYSTEM.

d) The EQUIPMENT or SYSTEM should not be used adjacent to or stacked with other equipment. If adja-

cent or stacked use is necessary, the EQUIPMENT or SYSTEM should be observed to verify normal

operation in the configuration in which it will be used.

e) The use of the ACCESSORY, transducer or cable with EQUIPMENT and SYSTEMS other than those

specified may result in increased EMISSION or decreased IMMUNITY of the EQUIPMENT or SYS-

TEM.

Item

ACCESSORIES

DIGITAL CAMERA UNIT DC-4 - - BACKGROUND ILLUMINATION BG-2GN - - CABLES

AC Power cord (for AC adapter) Not Used Not Used 3.0

DC-4 TRIGGER cable Used Used 1.0

LAN cable Used Used 3.0

ILLUMINATION cable Used Not Used 1.6

AC adapter cable Not Used Used 0.15

Cable

shield

Ferrite

core

Length(m)

Guidance and manufacturer's declaration - electromagnetic emissions

The SL-D301 is intended for use in the electromagnetic environment specified below. The customer or

the user of the SL-D301 should assure that it is used in such an environment.

Emissions test Compliance Electromagnetic environment - guidance

RF emissions

CISPR 11

Group 1

The SL-D301 uses RF energy only for its internal function.

Therefore, its RF emissions are very low and are not likely

to cause any interference in nearby electronic equipment.

RF emissions

CISPR 11

Harmonic emissions

IEC61000-3-2

Voltage fluctuations/

flicker emissions

IEC61000-3-3

Class B

Class A

Complies

The SL-D301 is suitable for use in all establishments including domestic and those directly connected to the public lowvoltage power supply network that supplies buildings used

for domestic purposes.

41

GENERAL INFORMATION ON USAGE AND MAINTENANCE

Page 44

Guidance and manufacturer's declaration - electromagnetic immunity

The SL-D301 is intended for use in the electromagnetic environment specified below. The customer or

the user of the SL-D301 should assure that it is used in such an environment.

Immunity test

Electrostatic

discharge (ESD)

IEC 61000-4-2

Electrical fast

transient/burst

IEC 61000-4-4

Surge

IEC 61000-4-5

Voltage dips, short

interruptions and

Voltage variations

on power supply

input lines

IEC 61000-4-11

IEC 60601

test level

± 6 kV contact

± 8 kV air

± 2 kV for power

supply lines

± 1 kV for

input/output lines

± 1 kV

line(s) to line(s)

± 2 kV

line(s) to earth

<5% U

t

(>95% dip in Ut)

for 0.5 cycle

40% U

t

(60% dip in Ut)

for 5 cycles

70% U

t

(30% dip in Ut)

for 25 cycles

<5% U

t

(>95% dip in Ut)

for 5 sec

Compliance

level

± 6 kV contact

± 8 kV air

± 2 kV for power

supply lines

± 1 kV for

input/output lines

± 1 kV

line(s) to line(s)

± 2 kV

line(s) to earth

<5% U

t

(>95% dip in Ut)

for 0.5 cycle

40% U

t

(60% dip in Ut)

for 5 cycles

70% U

t

(30% dip in Ut)

for 25 cycles

<5% U

t

(>95% dip in Ut)

for 5 sec

Electromagnetic environment -

guidance

Floors should be wood, concrete or

ceramic tile. If floors are covered with

synthetic material, the relative humidity

should be at least 30%.

Main power quality should be that of a

typical commercial or hospital environment.

Main power quality should be that of a

typical commercial or hospital environment.

Main power quality should be that of a

typical commercial or hospital environment. If the user or the SL-D301

requires continued operation during

main power interruptions, it is recommended that the SL-D301 be powered

from an uninterruptible power supply or

battery.

Power frequency

(50/60 Hz)

magnetic field

3 A/m 3 A/m

IEC 61000-4-8

NOTE U

is the a.c. main voltage prior to application of the test level.

t

42

GENERAL INFORMATION ON USAGE AND MAINTENANCE

Power frequency magnetic fields

should be at levels characteristic of a

typical location in a typical commercial

or hospital environment.

Page 45

Guidance and manufacturer's declaration - electromagnetic immunity

PPP

The SL-D301 is intended for use in the electromagnetic environment specified below. The customer or

the user of the SL-D301 should assure that it is used in such an environment.

Immunity test IEC 60601

test level

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

3 Vrms

150kHz to 80MHz

3 V/m

80MHz to 2.5GHz

Compliance

level

3 V

3 V/m

Electromagnetic environment -

guidance

Portable and mobile RF communications

equipment should be used no closer to any

part of the SL-D301, including cables, than

the recommended separation distance calculated from the equation applicable to the frequency of the transmitter.

Recommended separation distance

d = 1.2

d = 1.2 80MHz to 800MHz

d = 2.3 800MHz to 2.5GHz

where P is the maximum output power rating

of the transmitter in watts (W) according to

the transmitter manufacturer and d is the rec-

ommended separation distance in meters

(m).

Field strengths from fixed RF transmitters, as

determined by an electromagnetic site sur-

a

vey,

should be less than the compliance

level in each frequency range.

Interference may occur in the vicinity of

equipment marked with the following symbol:

NOTE 1

NOTE 2

abField strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones

and land mobile radios, amateur radio, AM and FM radio broadcast and TV broadcast cannot be predicted theoretically with accuracy. To assess the electromagnetic environment due to fixed RF transmitters, an electromagnetic site survey should be considered. If the measured field strength in the

location in which the SL-D301 is used exceeds the applicable RF compliance level above, the SLD301 should be observed to verify normal operation. If abnormal performance is observed, additional

measures may be necessary, such as reorienting or relocating the SL-D301.

At 80 MHz and 800 MHz, the higher frequency range applies.

These guidelines may not apply in all situations. Electromagnetic propagation is affected by

absorption and reflection from structures, objects and people.

b

Over the frequency range 150 kHz to 80 MHz, field strengths should be less than 3 V/m.

43

GENERAL INFORMATION ON USAGE AND MAINTENANCE

Page 46

Recommended separation distance between

PPP

portable and mobile RF communications equipment and the SL-D301

The SL-D301 is intended for use in an electromagnetic environment in which radiated RF disturbances

are controlled. The customer or the user of the SL-D301 can help prevent electromagnetic interference

by maintaining a minimum distance between portable and mobile RF communications equipment

(transmitters) and the SL-D301 as recommended below, according to the maximum output power of the

communications equipment.

Rated maximum output

power of transmitter

W

0.01 0.12 0.12 0.23

0.1 0.38 0.38 0.73

1 1.2 1.2 2.3

10 3.8 3.8 7.3

100 12 12 23

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in meters (m) can be estimated using the equation applicable to the frequency of the transmitter, where P is the maximum output power rating of the transmitter in watts (W) according to the

transmitter manufacturer.

NOTE 1

NOTE 2

At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

These guidelines may not apply in all situations. Electromagnetic propagation is affected

by absorption and reflection from structures, objects and people.

Separation distance according to frequency of transmitter

m

150kHz to 80MHz

d = 1.2

80MHz to 800MHz

d = 1.2

800MHz to 2.5GHz

d = 2.3

44

GENERAL INFORMATION ON USAGE AND MAINTENANCE

Page 47

OPTICAL RADIATION HAZARD

• The light radiated from the instrument is potentially hazardous. The

longer the exposure time is, the higher the risk of causing disorder to

CAUTION

RELATIVE SPECTRAL DISTRIBUTION OF ILLUMINATION LIGHT

the eye is.

• When operating with the maximum intensity, the light radiation

reaches values exceeding the safety guideline in about 309 sec.

Because prolonged intense light exposure can damage the retina, the use of the device for ocular examination

should not be unnecessarily prolonged, and the brightness setting should not exceed what is needed to provide

clear visualization of the target structures.

The retinal exposure dose for a photochemical hazard is a product of the radiance and the exposure time. If the

value of radiance were reduced in half, twice the time would be needed to reach the maximum exposure limit.

While no acute optical radiation hazards have been identified for slit lamps, it is recommended that the intensity

of light directed into the patient's eye be limited to the minimum level which is necessary for diagnosis. Infants,

aphakes and persons with diseased eyes will be at greater risk. The risk may also be increased if the person

being examined has had any exposure with the same instrument or any other ophthalmic instrument using a visible light source during the previous 24 hours. This will apply particularly if the eye has been exposed to retinal

photography.

45

GENERAL INFORMATION ON USAGE AND MAINTENANCE

Page 48

TYPE OF PLUG

Country Voltage/frequency Type of plug

Mexico 110V/50Hz Type C&E

Argentina 220V/60Hz Type A

Peru 220V/60Hz Type A

Venezuela 110V/50Hz Type C&E

Bolivia & Paraguay 220V/60Hz Type A (Most common)

Type H (Infrequently)

Chile 220V/60Hz Type A

Colombia 110V/50Hz Type C

Brazil 220V/60Hz

127V/60Hz

Ecuador 110V/50Hz Type C&E

USA 120V/60Hz Type A (Hospital Grade)

Canada 120V/60Hz Type A (Hospital Grade)

Type A

Type C

46

GENERAL INFORMATION ON USAGE AND MAINTENANCE

Page 49

OPTIONAL ACCESSORIES

TOPCON SLIT LAMP SL-D301 provides the following optional accessories for imaging.

For inquiries, please call your dealer or TOPCON (see the back cover)

To prevent falling during use and movement, secure optional accesso-

CAUTION

•For details, please refer to the instruction manuals of each product.

SYSTEM CONFIGURATION

CAUTION

System Chart

TOPCON product

Products of other

ries.

To avoid electric shock, do not touch the external connection terminal

and the patient at the same time.

Background Illumination

BG-2GN

Diffusion Lens

SO-DFL01

Hruby

Lens

Applanation

Tonometer

Model R900

Tonometer Mount

SO-TM1

Iris Diaphragm

Yellow Filter

Parallel

binoculer Tubes

PB-2

SO-DF01

Adapt Cover

SO-AC7

Digital Camera Unit

DC-4

Trigger cable

SO-TRIG01

12.5X

Eyepiece

The one there is no click but

with measurement scale.

12.5X

Eyepiece

The one there is click, and

without scale.

12.5X

Eyepiece

The one there is click, and

with scale.

12.5X

Eyepiece

The one there is click, and

with measurement scale.

20X

Eyepiece

LAN cable

SO-LAN01

insulating transformer

Tabletop SO-TABLE06

For AIT-16

Tabletop SO-TABLE07

For Unit table

47

OPTIONAL ACCESSORIES

Page 50

DIGITAL CAMERA UNIT DC-4

FEATURES

• Simple operation and high-quality digital image.

• Optimized functions for slit lamp photography.

• Compact body and internal cabling for a neat look.

• All DC-4 functions are software driven.

BACKGROUND ILLUMINATION BG-2GN

FEATURES

• Used for background illumination.

YELLOW FILTER UNIT

FEATURES

• Combines with the blue filter prepared in the main body for a

high-contrast fluorescence observation.

• Easy switching between filter insertion & removal.

IRIS DIAPHRAGM SO-DF01

FEATURES

When taking picture, you can adjust the light intensity and the depth according to the

need.

12.5x Eyepiece

FEATURES

There are four types as below:

• One with internal measurement scale and no click stops.

• One without internal scale and click stops on each adjustment step.

• One with internal scale and click stops on each adjustment step.

• One with internal measurement scale and click stops on each adjustment step.

20X EYEPIECE

FEATURES

• Replaces the normal eyepiece for high magnification observation.

48

OPTIONAL ACCESSORIES

Page 51

TONOMETER MOUNT SO-TM1

FEATURES

• For the measuring of the intraocular pressure, models R900 type and T900

type, Haag-Streit, are available.

* If the R900 type is being used for the SL-D301, the tonometer mount SO-

TM1 is required.

(Depending on specification, SO-TM1 may be included in standard accesso-

ries.)

* If the T900 type is in use, the tonometer guide plate (for T-900 type) is

required.

HRUBY LENS

FEATURES

Normally, observation is possible only up to the anterior vitreous body due to the

refractive power of the cornea and lens. With the Hruby lens, the posterior vitreous

body and the retina can be observed.

PARALLEL BINOCULAR TUBE PB-2

FEATURES

• Can observe a parallel view of the object.

ADAPT COVER SO-AC7

FEATURES

Used to cover the gaps with the microscope arm and hide cables when attaching

the digital camera unit DC-4.

SO-AC7: For SL-D301 + DC-4 +SO-DF01

DIFFUSION LENS SO-DFL01

FEATURES

Large area can be illuminated with diffuse illumination.

49

OPTIONAL ACCESSORIES

Page 52

TABLETOP SO-TABLE06, 07

FEATURES

• The tabletop to support the base unit, the chinrest unit and the power supply.

SO-TABLE06 For AIT-16

SO-TABLE07 For Unit table

50

OPTIONAL ACCESSORIES

Page 53

Page 54

52

OPTIONAL ACCESSORIES

Page 55

Please provide the following information when contacting us regarding questions

about this instrument:

• Model name: SL-D301

• Serial No.: This is printed on the rating nameplate on the right side of the

power supply unit.

• Period of use: Please inform us of the date of purchase.

• Defective condition: Please provide us with as much detail as possible on the

problem.

SLIT LAMP

SL-D301

USER MANUAL

Rev.0 June 1, 2016

Published by TOPCON CORPORATION

75-1 Hasunuma-cho, Itabashi-ku, Tokyo, 174-8580 Japan.

Page 56

SLIT LAMP

0

SL-D301

Printed in Japan 1606100TH

44703 95850

Loading...

Loading...