Page 1

i

Page 2

ii

Thank you for purchasing the Signature Series Model OC-2300 Ophthalmic Chair. Please read this

User's Manual carefully and place it in a convenient location for future reference.

WARNING: The installation of the chair shall be performed only by a qualified

technician.

!

WARNING: The chair is designed for use with TOPCON equipment. If any other

equipment is used, it shall meet the same certifications.

!

WARNING: Any service and/or repairs (other than replacement of the two exter-

nal fuses) shall be performed only by a qualified technician.

!

Precautions for Operation

• Installation: Never position the chair where it will be exposed to moisture, direct sunlight, dust, salty

air, chemical storage areas, excessive temperature or humidity. Install the chair in a stable place, free

of uneven floors, vibration and shock.

• Prior to Operation: Check all cords and/or cabling for proper connections.

• Operation: Take appropriate action to stop the chair from moving (leaving the patient in a safe

condition) if a malfunction occurs.

• After Operation: Never disconnect any plugs by pulling on the cable. Doing so may cause damage to

the internal connections. If the chair has been idle for a period of time, check all functions and safety

features for normal operation prior to reuse.

Safety Precautions

• The OC-2300 exam chair conforms to UL 2601-1 and CAN/CSA-C22.2 No. 601.1-M90. There is no

disposal of any waste products associated with the OC-2300 exam chair provided that all damaged

components are returned to Topcon.

WARNING: Do not load the chair with more than the maximum specified

capacity listed in the specifications section.

!

WARNING: Do not sit on the chair armrests. Doing so may cause damage to

internal chair components.

!

WARNING: If the chair makes a strange noise, discontinue use of the chair

!

Precautions for Repair

• When disassembling, repairing, and reassembling the OC-2300, be very careful not to scratch or

damage the various mechanical and electrical components of the chair.

• Always disconnect the power cord when trouble-shooting or repairing electrical system components,

unless power is absolutely required to perform the repair.

2001010038 Revision C, 9/04

Page 3

iii

CONTENTS

1.0 NOMENCLATURE 1

1.1 Model OC-2300 Main Components 1

2.0 PERFORMANCE AND SPECIFICATIONS 1

3.0 ASSEMBLY 3

3.1 Tools 3

3.2 Ophthalmic Chair / Stand Position 3

3.3 Electrical Connections 3

3.4 Alternate Connections 3

3.5 Power Up 4

4.0 OPERATION 4

4.1 Elevation Control 4

4.2 Motorized Recline Control 4

4.3 Auto-Return Control 4

4.4 Memory Controls 5

4.5 Cancel Button 5

4.6 Swivel Brake Operation 5

4.7 Armrest Retraction 5

4.8 Headrest Position 5

4.9 Footrest Retraction 5

5.0 ADJUSTMENTS 6

5.1 Headrest Locking Tension 6

5.2 Swivel Brake Adjustment 6

5.3 Armrest Adjustment 6

6.0 MAINTENANCE 7

6.1 Paint and Nonmetallic Parts 7

6.2 Upholstery 7

7.0 TROUBLE SHOOTING 7

Page 4

1

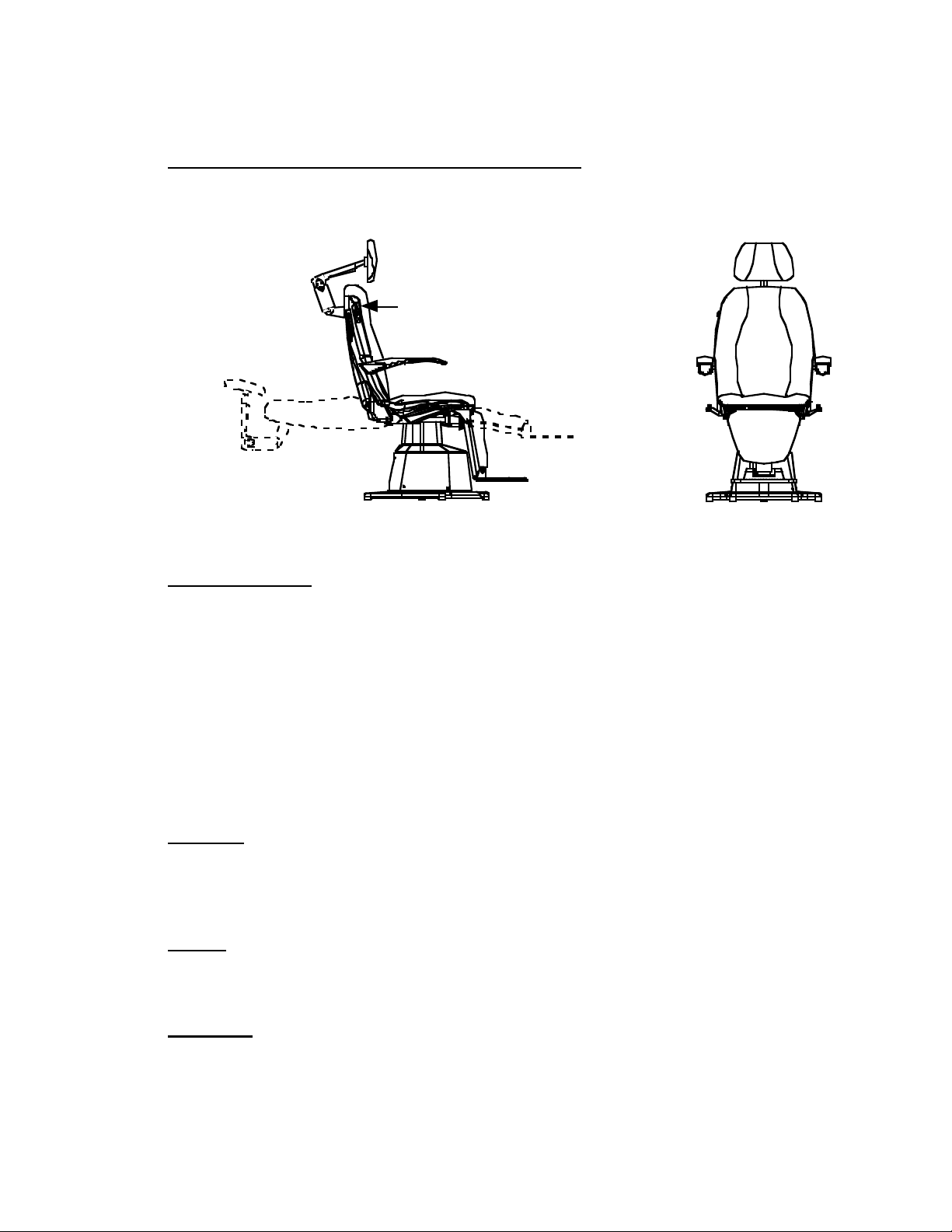

1.0 NOMENCLATURE

1.1 Signature Series Model OC-2300 Main Components

Figure 1 shows the primary features and key components of the OC-2300 Ophthalmic Chair.

Use the figure as a reference.

Recline

Position

Footrest

Headrest

Armrest

Brake

Handle

(both

sides)

Chair Controls

(both sides)

2.0 PERFORMANCE & SPECIFICATIONS

Chair Dimensions

• Overall: 55” (1397mm)/ 53” (1346mm)* (High) x 28 ” (711mm)

Wide x 40” (1016mm) Deep

• Seat Height (retracted): 22.5” (571mm)/ 20.0” (508mm)*

• Seat Height (full stroke): 35.0” (889mm)/ 29.0” (737mm)*

• Footrest Height: 3.5” (89mm)/ 1.5” (38mm)*

• Full Recline Length: 75” (1905mm)

• Mode of Operation: Continuous Use

• Type of Protection: Class 1 protection (Against Electrical Shock)

• Ingress of Water Protection: Ordinary Protection (IPX0)

• AP or APG: Not AP or APG equipment

Electrical

• Voltage, Current, Frequency:

US Versions: 120VAC (±10%), 7 A, 60 Hz

Non-US Versions: 240VAC (±10%), 3 A, 50Hz

Weight

• Chair Net Wt.: 286 lbs. (129 kg)

• Chair Capacity: 500 lbs. (227 kg)

Movement

• Elevation Stroke: 12.5” (318mm)/ 9” (229mm) *

• Range of Rotation: 355 degrees

• Recline Angle: 70 degrees

Page 5

2

Environmental Operating Conditions

• Ambient Temperature Range: 50 to 104 Degrees F (10 to 40 Degrees C)

• Relative Humidity Range: 30 to 75%

• Atmospheric Pressure Range: 10.1 to 15.4 psi (700 to 1060 hPa)

Environmental Storage/Transportation Conditions

• Ambient Temperature Range: -20 to 130 Degrees F (-23 to 54 Degrees C)

• Relative Humidity Range: 30 to 95%

• Atmospheric Pressure Range: 10.1 to 15.4 psi (700 to 1060 hPa)

• Acceptable Storage Time

(in operating environment): 5 years

(in extreme environment): 20 days

* Denotes dimensions for the High/Low lift configurations

SYMBOLS FOUND ON THE OC-2300 CHAIR

Protective Earth ground location

CAUTION: Electrical shock possibility

!

ATTENTION: Information provided in manual

Alternating Current (AC) Symbol

UP Symbol

DOWN Symbol

Forward Symbol

Backward Symbol

Direct Current (DC) Symbol

Page 6

3

3.0 ASSEMBLY

3.1 Tools

Phillips Screw Driver

5/32” and 3/16” Allen Wrench

3.2 Ophthalmic Chair / Stand Position

1) Place the chair next to the base of the ophthalmic stand or cabinet. Allow it to

come to room temperature.

2) Remove the red shipping bolt, which secures the chair seat to the base

assembly (Remove the seat upholstery if installed).

WARNING: Red shipping bolt must be removed before power up.

!

3) Install the upholstery set to the chair (if not already installed) with the

instructions included in the upholstery box.

3.3 Electrical Connections

1) Connect the chair power cable into the appropriate wall outlet or into the

ophthalmic stand.

2) Connect the chair control cable to the ophthalmic stand and check the vertical

movement of the ophthalmic chair.

3.4 Alternate Connections

When the Ophthalmic Chair model OC-2300 is not used in conjunction with a

Topcon ophthalmic stand, use the table below to configure the electrical inputs

correctly.

Stand Cable Wire Code

Pin

Number

Wire Function

Wire Color

1

Ground

Green

2

Neutral

White

3

Hot

Black

4

Up

Red

5

Down

Violet

6

Auto-Return

Orange

7

Relay Engage

Brown

8

Safety Switch

Yellow

9

Safety Switch

Blue

WARNING: If the chair is used with a Topcon IS-800 stand, the plastic base shroud (non-fuse

side) must be removed to make a configuration change on the circuit board. This

will make the IS-800 safety switch feature operable.

Page 7

4

1) If the chair has a 1st generation circuit board, remove the blue jumper pin

located between the transformer and the 9-pin connector. Re-install the base

shroud.

OR

2) If the chair has a 2nd generation circuit board, move the red jumper pin located

between the 9-pin connector and the 6-pin connector labeled ‘Stand Safety’

from the OFF position to the ON position. Re-install the base shroud.

3.5 Power Up

Plug the chair power cord into a wall receptacle or into the exam stand or cabinet

system. The chair control membrane switches should illuminate to indicate that the

chair is operational. Perform a test of all chair features to verify proper function.

Refer to the operation section of this document for details.

4.0 SYSTEM OPERATION

The OC-2300's sturdy design and motorized recline features make it an excellent choice for

Ophthalmic and Optometric exam rooms.

Each of the chair control membrane switch buttons performs a specific function. Refer to

Performance and Specifications for the button symbols and their corresponding functions.

4.1 Elevation Control

Height adjustment of the full power recline ophthalmic chair, model OC-2300, is

made by pressing the appropriate arrow button on either membrane switch located on

the sides of the back or with an optional footswitch. The chair may also be controlled

by the UP, DOWN and AUTORETURN buttons on the exam stand.

4.2 Motorized Recline Control

The motorized recline buttons, located on the sides of the backrest, recline and

upright the backrest. To recline the patient, press the back arrow button on one of the

membrane switches. Release the button once the desired position is achieved. You

may also preset one or both of the memory buttons to a predetermined condition. To

return the patient to the upright position press the forward arrow button on one of the

membrane switches. Release the button once the chair is upright. You may also press

the AUTORETURN button to bring the chair fully upright and fully down. An

optional dual function footswitch may also be used to recline the chair.

4.3 Auto-Return Control

An AUTORETURN button is located on each membrane switch and on most exam

stands. Pressing the AUTORETURN button will automatically return the chair to the

fully down and fully upright position.

WARNING: Check all power cords and electrical connections for damage prior to

powering up the system.

!

Page 8

5

4.4 Memory Controls

4.4.1 Programming

1) Press the AUTORETURN button to position the chair in the fully down and

fully upright position (home position).

2) Using one of the membrane switches located in the sides of the chair backrest,

move the chair to a desired position.

3) Press and hold one of the memory buttons for 3 seconds. An audible 2-beep

sequence indicates that the position has been recorded in memory. Once

memory programming is complete, the settings will be retained even if power

is cut to the chair. Repeat steps 1 through 3 to set a new memory position.

4) Press and release the appropriate memory button to move the chair to the

desired position.

NOTE: Moving the chair up and down from the footswitch or stand console may

cause the chair to exhibit some inaccuracy in locating the memory position

settings. To correct this, press the auto-return button to “re-home” the

chair then continue to use the controls as normal.

4.5 Cancel Button

A CANCEL button is located on each membrane switch. Pressing either CANCEL

button will terminate any automatic motion, such as auto-return and/or movement to

memory positions. As an additional safety feature, pressing any button on either chair

membrane switch will also terminate any automatic motion.

4.6 Swivel Brake Operation

To rotate the chair, move the swivel brake handle to the released position

(perpendicular to the floor), rotate the chair to the desired position, then move the

swivel brake handle to the activated position (parallel to the floor) to secure the chair

in position.

4.7 Armrest Retraction

One or both of the armrests may be pivoted up out of the way if desired. Press the

latch release button in the middle underside of the armrest then lift up on the

armrest. To return the armrest to the horizontal position, simply pivot the armrest

back down until it latches.

4.8 Headrest Position

The headrest assembly consists of a 2 pivot-articulating clamp as well as a pivoting

pillow mount. The headrest assembly has a very wide adjustment range and can

accommodate any examination situation. The articulating headrest position may be

adjusted as desired by releasing the clamp-locking handle, pivoting the headrest into

position, then re-activating the clamp-locking handle.

4.9 Footrest Retraction

The footrest may be stowed for easier access to the patient, or for closer

examination or surgical purpose. Simply pivot the footrest up by lifting on the

front edge until it clicks into its stowed position.

Page 9

6

5.0 ADJUSTMENTS

5.1 Headrest Locking Tension

If the position of the chair headrest has begun to move with the clamp-locking

handle in the locked position, the headrest clamp may require an adjustment.

Follow the instructions below to adjust the headrest assembly.

Headrest Clamp Adjustment

5.1.1 Release the clamp-locking handle. Loosen the Phillips screw in the side of

the clamp body, and then turn the slotted adjustment screw in the end of

the clamp assembly to adjust the clamping tension. (Clockwise for more

tension, counter-clockwise for less tension). Adjust the clamp tension so

that the clamp-locking handle closes easily and the pivots at each end of

the clamp are secure. Repeat the adjustments until the proper adjustment is

achieved. Re-tighten the Phillips screw in the side of the clamp body to

secure the adjustment.

Pillow Mount Pivot Adjustment

5.1.2 Turn the small adjustment screw in the pillow mount clamp to adjust the

pillow mount clamp tension (Clockwise for more tension, counterclockwise for less tension. The clamp is properly adjusted when the

headrest pillow position can be adjusted easily, but has enough bind to

remain in the position that it is set to after adjustment.

5.2 Swivel Brake Adjustment

If the chair can be rotated while the swivel brake handle is in the activated

position (parallel to the floor) an adjustment may be required. The swivel brake

adjustment screw is located behind the lift assembly on the underside of the metal

chair seat. If the swivel brake clamping tension is too loose, move the swivel

brake handle to the released position (perpendicular to the floor) and turn the

adjustment screw with an Allen wrench (Clockwise for more tension, counterclockwise for less tension) until the proper adjustment is achieved. The swivel

brake is properly adjusted when the chair rotates freely with the swivel brake

released but does not rotate when the brake is activated.

5.3 Armrest Adjustment

The armrests may require periodic adjustment to maintain proper function.

Remove the three arm upholstery mounting screws, and then remove the arm

upholstery to gain access to the arm adjustment screw. Turn the flat head

adjustment screw in the back side of the armrest casting with an Allen wrench to

adjust the amount of play in the armrest latching mechanism (clockwise for more

play, counter-clockwise for less play). The armrest latching mechanism is

adjusted properly when the mechanism engages properly when the armrest is

down, but has minimal vertical play once engaged. Reinstall the arm upholstery

after performing the adjustment.

The armrest height and relative position can be adjusted. Remove the backrest

upholstery to gain access to the adjustment screws. Tighten/loosen the opposing

Page 10

7

set screws in the appropriate armrest stop to align the armrests with one another.

Reinstall the backrest upholstery after performing the adjustment.

6.0 MAINTENANCE

It is recommended that the exterior surfaces of the OC-2300 chair be cleaned periodically

to preserve the chair's appearance. Cleaning should be performed at least every six

months.

6.1 Cleaning Painted and Nonmetallic Parts

Dirt and oils can be easily removed from painted or nonmetallic chair components

with a mild soap and water solution and a clean damp cloth. Use a soft, clean,

cloth to wipe the chair dry after cleaning.

6.2 Upholstery Cleaning

Use the same procedure as described above.

7.0 TROUBLE SHOOTING

If the chair malfunctions or is inoperative, perform the following checks prior to seeking

assistance.

1. Check to see that all connector cords and/or cables are securely connected.

2. Replace any blown fuses.

Fuse Replacement

WARNING: Do not attempt fuse replacement without first disconnecting the

chair from the power source.

!

WARNING: Any service and/or repairs (other than replacement of the two exter-

nal fuses) shall be performed only by a qualified technician.

!

The main power fuses are located in the rear of the base assembly in the LH side plastic shroud.

Unplug the chair from the AC power source. Twisting the fuse cap counter-clockwise and

simultaneously pressing down easily replace the fuses. Carefully remove the fuse and check for

breaks in the filament or for any corrosion at the ends. If in doubt, test the fuses with an

Ohmmeter. Obtain replacement fuses at a hardware/electronics store if it they are damaged or

blown. Once the fuse has been properly inspected or replaced, place it into the cap and re-install

it by turning the cap clockwise and pressing down simultaneously. Note: If the fuse cap is not

fully inserted the unit will not function.

Fuse Rating Table

Location

Fuse

100~120 Volt

220~240 Volt

Base Shroud

Primary

7A 250 v - SB

3A 250 v - SB

Base Shroud

Secondary

7A 250 v - SB

3A 250 v - SB

WARNING: Do not expose painted or nonmetallic parts or upholstery to any

volatile solvents such as benzene or paint thinner as these agents

may cause permanent damage.

!

Page 11

8

If problems persist, call your dealer or Topcon for assistance.

Topcon Medical Systems, Inc.

37 West Century Road

Paramus, NJ 07652

800-223-1130

www.topconmedical.com

Loading...

Loading...