Page 1

HOT FOOD SERVERS

IL2087

FREE STANDING MODELS

3A81D

3B84D

3C84D, 3D8XD

BUILT-IN MODELS

3A20A, 3A80A

3B20A, 3B80A,3B84A

3C80A, 3C84A

Installation and

3B84D

Operation

Instructions

2M-3102301, Rev. B, September 9, 2013

3A20A

Page 2

2

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

UsinganypartotherthangenuineToastmasterfactorysuppliedpartsrelievesthe

manufacturer of all liability.

Toastmaster reserves the right to change specications and product design

withoutnotice. Suchrevisionsdonotentitlethebuyertocorrespondingchanges,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specications contained in this sheet are subject to change

without notice. While Toastmaster exercises good faith efforts to provide

information that is accurate, we are not responsible for errors or omissions

in information provided or conclusions reached as a result of using the

specications. By using the information provided, the user assumes all risks in

connection with such use.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance.

Please record the model number, serial number, voltage and purchase date in the area below and have it

ready when you call to ensure a faster service.

SAFETY SYMBOLS

Model No.

Serial No.

Voltage

Purchase Date

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (314) 678-6347

Fax: (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

The Service Help Desk

Authorized Service Agent Listing

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.toastmastercorp.com

E-mail Service@star-mfg.com

Telephone: (314) 678-6347

Mailing Address: Toastmaster

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

CAUTION

WARNING

2

Page 3

TABLE OF CONTENTS

Page

Electrical Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Features & Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation

Inspection for Shipping Damage . . . . . . . . . . . . . . . . . . . . 4

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation of Free-Standing Models . . . . . . . . . . . . . . . . . 5

Installation of Built-In Units . . . . . . . . . . . . . . . . . . . . . . . . 6

Initial Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation

Location of Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Function of Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pre-heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Capacity Per Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Recommended Temp & Humidity Setting . . . . . . . . . . . . .10

Daily Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Clean & Lubricate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Exploded View & Parts List

Single Drawer Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-16

Two, Three & Four Drawer, Single Controls . . . . . . . . . 18-21

Two, Three & Four Drawer, Individual Controls . . . . . . . 22-24

ELECTRICAL SPECIFICATIONS

ELECTRICAL SPECIFICATIONS

Model No Voltage Watts Phasee Hz Power Cord

7C-3A20AT09-120 3A20A 120 .45 KW 1 50/60

7C-3A80AT09-120 3A80A 120 .45 KW 1 50/60

7C-3A80AT72-240 3A80A 240 .4/.54 KW 1 50/60

7C-3A80AWC-120V 3A80A 120 .45 KW 1 50/60 5-15P

7C-3A81D-120KFC 3A81D-KFC 120 .45 KW 1 50/60

7C-3A81DT09-120 3A81D 120 .45 KW 1 50/60

7C-3A81DT72-240 3A81D 208/240 .45/.54 KW 1 50/60

7C-3B20AT09-120 3B20A 120 1.0 KW 1 50/60

7C-3B20AT72-240 3B20A 208/240 .9/1.2 KW 1 50/60

7C-3B80AT09-120 3B80A 120 1.0 KW 1 50/60

7C-3B80AT72-240 3B80A 208/240 .9/1.2 KW 1 50/60

7C-3B80AWC-120V 3B80A 120 1.0 KW 1 50/60 5-15P

7C-3B84AT09-120 3B84A 120 .9 KW 1 50/60

7C-3B84AT72-240 / -SA 3B84A 208/240 .85/.98 KW 1 50/60

7C-3B84DT09-120 3B84D 120 .9 KW 1 50/60

7C-3B84DT09-KFC 3B84D-KFC 120 .9 KW 1 50/60

7C-3B84DT72-240 3B84D 208/240 .85/.98 KW 1 50/60

7C-3C80AT09-120 3C80A 120 1.35 KW 1 50/60

7C-3C80AT72-240 3C80A 208/240 1.22/1.6 KW 1 50/60

7C-3C84AT09-120 3C84A 120 1.35 KW 1 50/60

7C-3C84AT72-240 3C84D 208/240 1.28/1.47 KW 1 50/60

7C-3C84DT09-120 3C84D 120 1.35 KW 1 50/60

7C-3C84DT72-240 3B84D 208/240 .85/.98 KW 1 50/60

7C-3D8XDT09-120 3D8XD 120 1.35 KW 1 50/60

7C-3D8XDT72-240 3D8XD 208/240 1.22/1.6 KW 1 50/60

1

Page 4

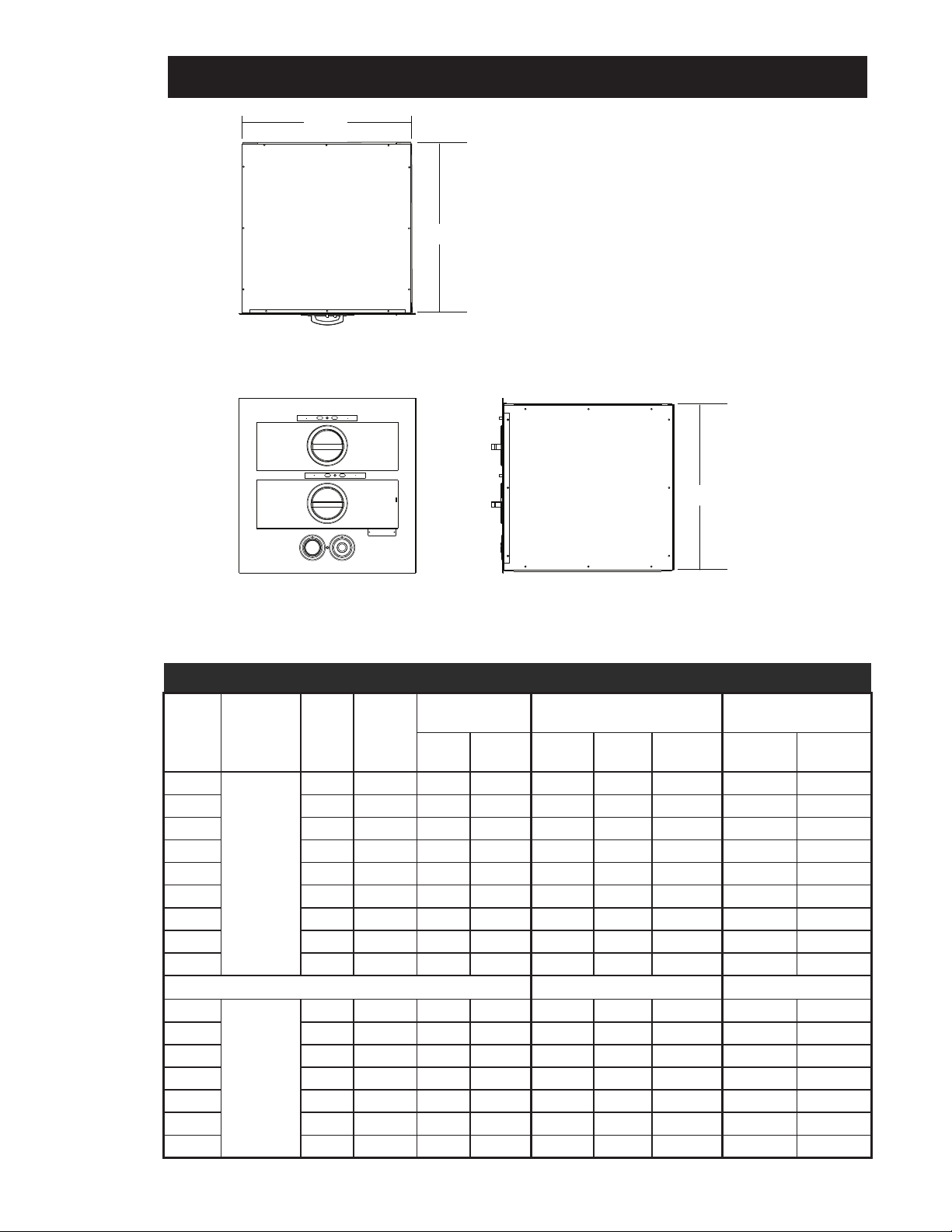

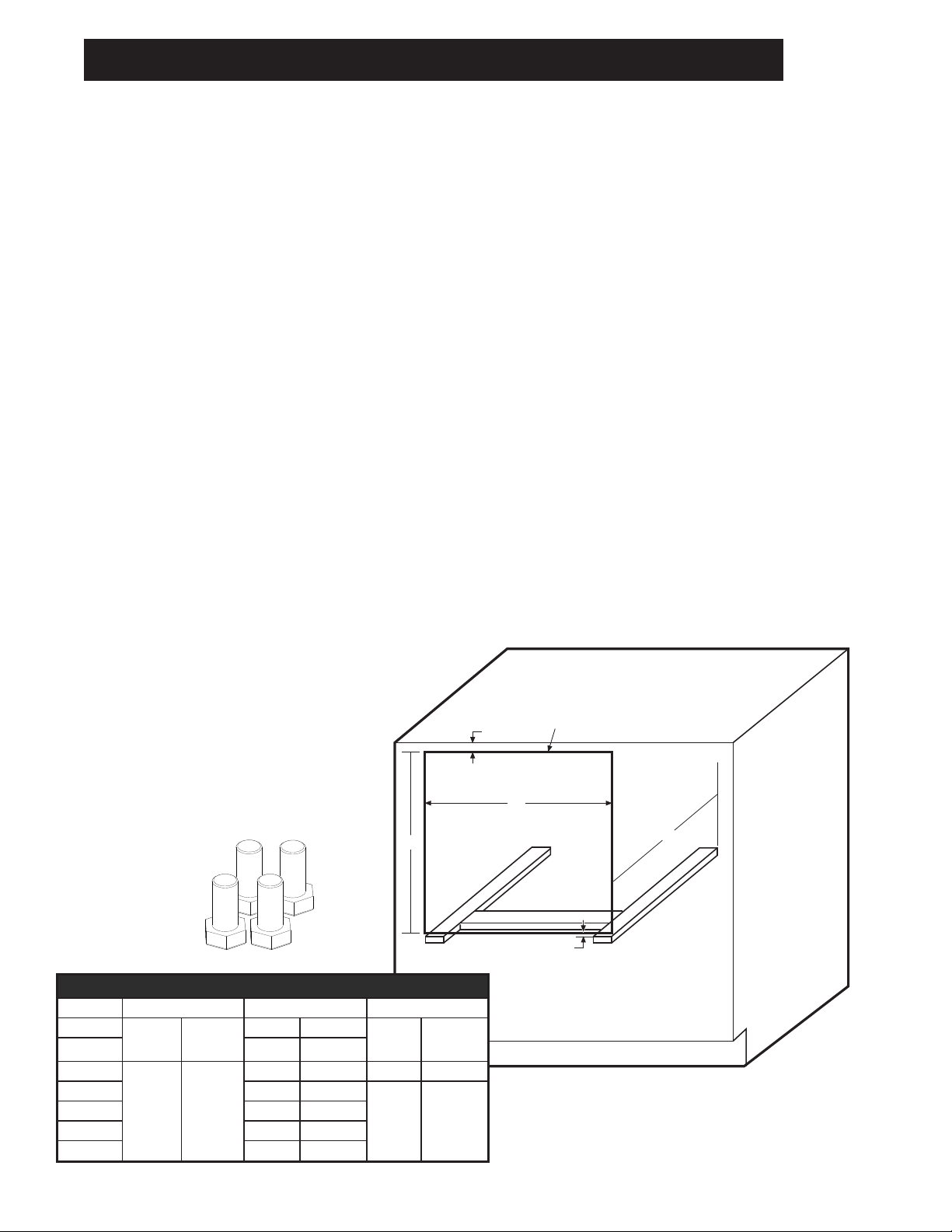

Height

Front View Side View

Top View

Width

Depth

IL2088

SPECIFICATIONS

MODEL CHART

Model

3A81D

3A20D 1 YES 18.8 26.2 24 1/16 22 9/16 12 1/4 84 lbs 94 lbs

3A21D 1 YES 18.8 26.2 24 1/16 22 9/16 12 1/4 84 lbs 94 lbs

3B22D 2 NO 17.2 24.8 23 1/16 24 1/4 22 1/8 129 lbs 144 lbs

3B82D 2 NO 18.8 26.2 29 1/16 20 5/16 21 1/8 120 lbs 139 lbs

3B84D 2 YES 18.8 26.2 29 1/8 20 7/16 21 5/8 120 lbs 139 lbs

3C8XD 3 NO 20.6 28.2 29 1/16 20 5/16 28 3/4 201 lbs 229 lbs

3C84D 3 YES 18.8 26.2 29 1/8 20 7/16 32 5/16 201 lbs 229 lbs

3D8XD 4 NO 22.3 29.7 29 1/16 20 5/8 36 5/16 237 lbs 252 lbs

3A20A

3A80A 1 YES 18.8 26.2 29 1/16 19 1/8 11 72 lbs 84 lbs

3B20A 2 NO 17.2 21.8 23 1/16 23 22 1/2 120 lbs 138 lbs

3B80A 2 NO 18.8 26.2 29 1/16 19 1/4 21 1/2 125 lbs 144 lbs

3B84A 2 YES 18.8 26.2 29 1/16 19 1/4 21 3/4 125 lbs 144 lbs

3C80A 3 NO 20.6 28.2 29 1/16 19 1/4 29 5/16 171 lbs 186 lbs

3C84A 3 YES 18.8 26.2 29 1/16 19 1/4 32 1/2 206 lbs 228 lbs

Built-In /

Free Standing

Free Standing

Built-In

Drawers

Individual

Drawer

Control

1 YES 18.8 26.2 29 1/16 20 3/8 11 84 lbs 94 lbs

1 YES 18.8 25.8 23 1/16 23 11 1/4 70 lbs 82 lbs

Preheat Times

(minutes)

150°F

(65°C)

175°F

(79°C)

Dimensions Weight

“W” “D” “H” w/o legs Installed Shipped

Body Dimensions

2

Page 5

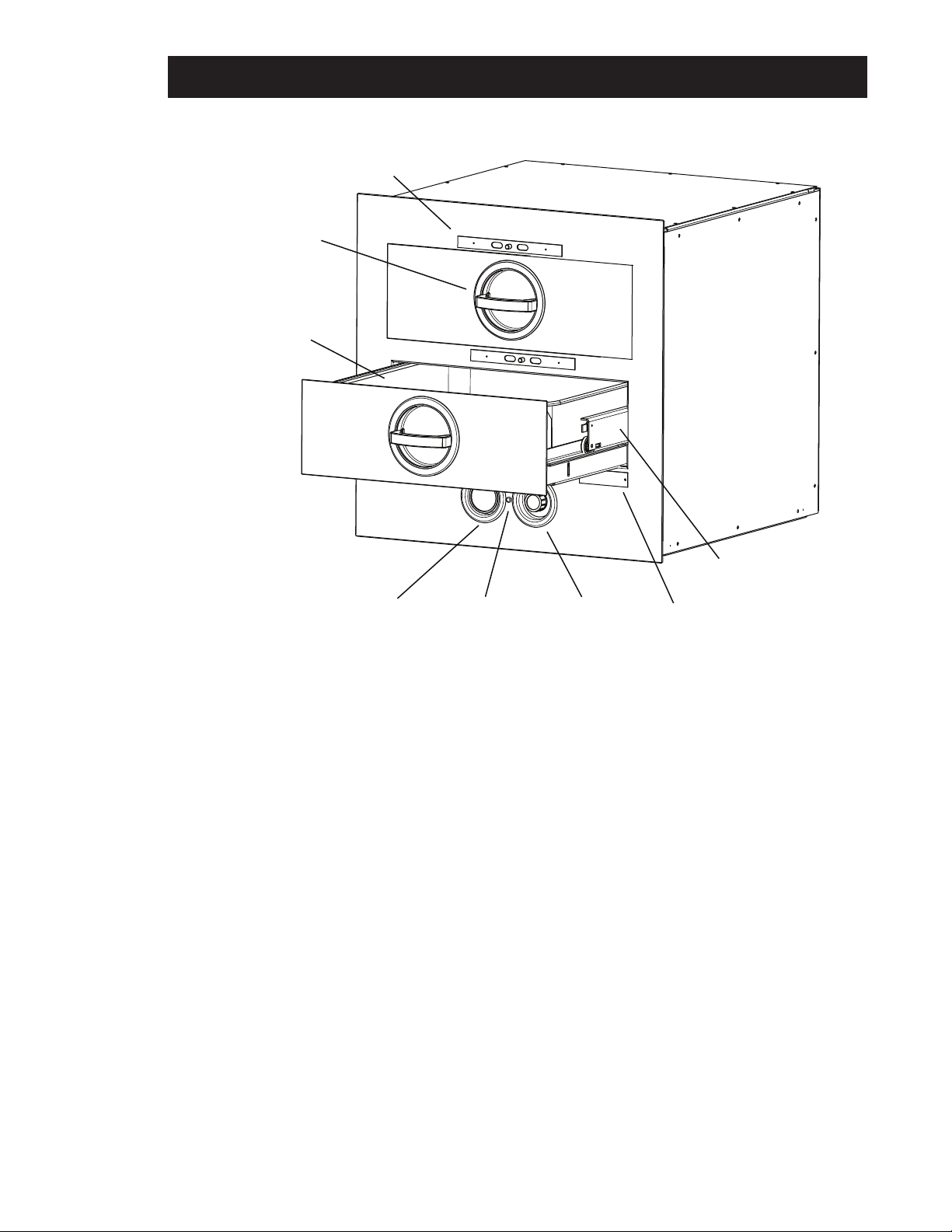

Moisture

Control Adjustment

Thermostat Knob

(Adj 100°F to 200°F)

Thermometer Indicator

Light

Handle Latching

Mechanism

Third Member

Drawer Rail

Drawer

Pan Insert

Nameplate

IL2089

FEATURES & DESCRIPTIONS

COMPONENT LOCATION & FUNCTION

Toastmaster Hot Food Servers are heated drawer-type cabinets designed to HOLD food cooked in

advance at serving temperature and proper moisture content.

Thermostat: The thermostat

Thermometer: The thermometer

Note: On models with one drawer and on models with individual temperature controls for each drawer

the thermostat knob and thermometer are protected with either a wire guard, or the are recessed into the

front panel.

Moisture Control: The

Indicator Light: The light

from 100°F to 200°F (38°C to 93°C) holding temperature. Some

models are equipped with separate thermostat for each drawer. Refer

to Specications on the previous page.

at the desired setting. Chicken, beef, ribs, sh, potatoes, vegetables

and sauces can be held at temperatures with condence because you

can see that the actual holding temperature is safe. The thermometer

will tell at a glace if the holding temperature is high enough to retard

dangerous bacteria growth and low enough to prevent overcooking and

drying out food.

moisture control consist of a slide which is used to control the

amount of moisture allowed to escape form the foods being held.

will illuminate when the unit is calling for heat and will shut off

when it has reached the set temperature.

is graduated from 0 to 10 which makes is adjustable

is used to visually check if the holding temperature is

3

Page 6

DESCRIPTION continued

Accessories

3 & 4 Drawer Free Standing Models:

7C-3L6 Square legs 6” high, stainless steel, set of 4, leveling adj. up to 3/4”

7C-3L9 Square legs 9” high, stainless steel, set of 4, leveling adj. up to 3/4”

7C-3L12 Square legs 12” high, stainless steel, set of 4, leveling adj. up to 3/4”

7C-3L15 Square legs 15” high, stainless steel, set of 4, leveling adj. up to 3/4”

7C-3M3 Casters, 3”, set of four (swivel without brakes) adds 4-1/4” to unit height

7C-3M4 Casters, 3”, set of four (two swivel/lock, two xed), adds 4-1/4” to unit height

2 Drawer Free Standing Models:

7C-3M338STSB

Casters, 3” set of four swivel (two with brakes), 360lbs. Load capacity

INSTALLATION

INSTALLATION

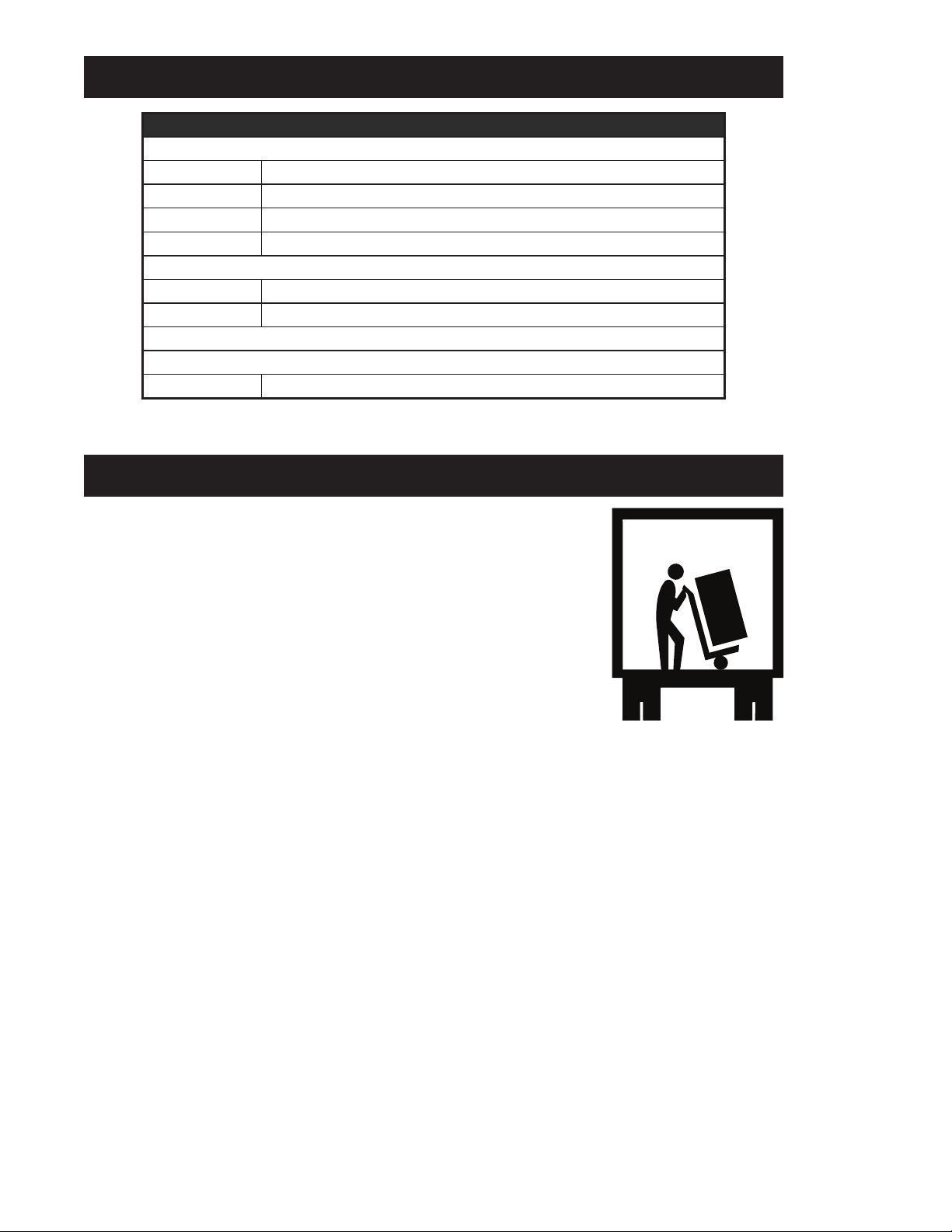

A. Inspect for Shipping Damage

All shipping containers should be examined for damage before and during

unloading. This equipment was carefully inspected and packaged at

the factory. The freight carrier has assumed responsibility for its safe

transit and delivery. If equipment is received in damage condition, either

apparent of concealed, a claim must be made with the delivery carrier.

1. Apparent Damage or Loss - If damage or loss is apparent it must be

noted on the freight bill or express receipt at the time of delivery, and

it must be signed by the carrier’s agent (driver). If this is not done, the

carrier may refuse the claim. The carrier will supply the necessary claim forms.

2. Concealed

unpacked, a request for inspection of concealed damage must be made with carrier within

15 days. The carrier will make an inspection and will supply necessary claim forms. Be

certain to retain all contents plus external and internal packaging materials for inspection.

B. Unpacking Hot Food Server

1. Open carton and remove it from around hot food server, then remove the empty carton from

the area.

2. Remove all tape from unit and set food server on its side on three 2x4’s (as shown in Figure

2-1) so the packing skid attached to the bottom of the unit is off the ground.

WARNING: DO NOT set the unit on its back, damage could be occur to the power cord or

conduit. Place unit on its side.

3. Remove 4 bolts attaching skid to bottom of unit.

Damage or Loss - If damage or loss is NOT apparent until after equipment is

4

Page 7

LEG

2” x 4”

BOLT

IL2094

Fig. 2-1, Leg / Caster Installation

INSTALLATION continued

C. Installation of Free-Standing Models

1. Counter top Models 3B22D, 3A81D, 3A20D, 3A21D , 3B82D AND 3B84D.

a. Countertop models are shipped with a set of four 4”(102mm) adjustable legs or an

optional set of 4 casters (see Accessories Chart on previous page) can be ordered.

Screw the legs or casters into the threaded holes in the corners of the unit bottom.

b. Hot food servers with legs can be set on the oor or on the counter. Units with

casters can only be set on the oor. Do not set the hot food server with casters

on a counter top.

c. Level unit with legs by turning the hexagonal adjustment feet located at the bottom

of the legs.

2. Floor Models 3C8XD, 3C84D AND 3D8XD are usually installed as oor models due to their

size. One of the available leg or caster accessory kits must be used in the installation.

a. Leg Installation using accessory kit (see chart for available leg or caster accessories,

sold separately)

Locate and open the accessory leg kit and the hardware package included with it.

With the

the square corner of a leg ange with a corner of the unit. Attach the leg ange using

5 of the bolts furnished. Refer to gure 2-2.

Repeat for remaining three legs.

Carefully set unit upright, using a level, level the server by turning the adjustable

feet.

b. Caster Installation using accessory kit (see chart for available leg or caster

accessories, sold separately)

The casters kits are installed the same as the leg kits above, except 2 of the casters

are xed and should be installed at one end or at the rear. The other 2 swivel casters

with brakes are installed opposite the xed casters.

hot food server on it side and the 2x4’s still positioned under the unit, align

5

Page 8

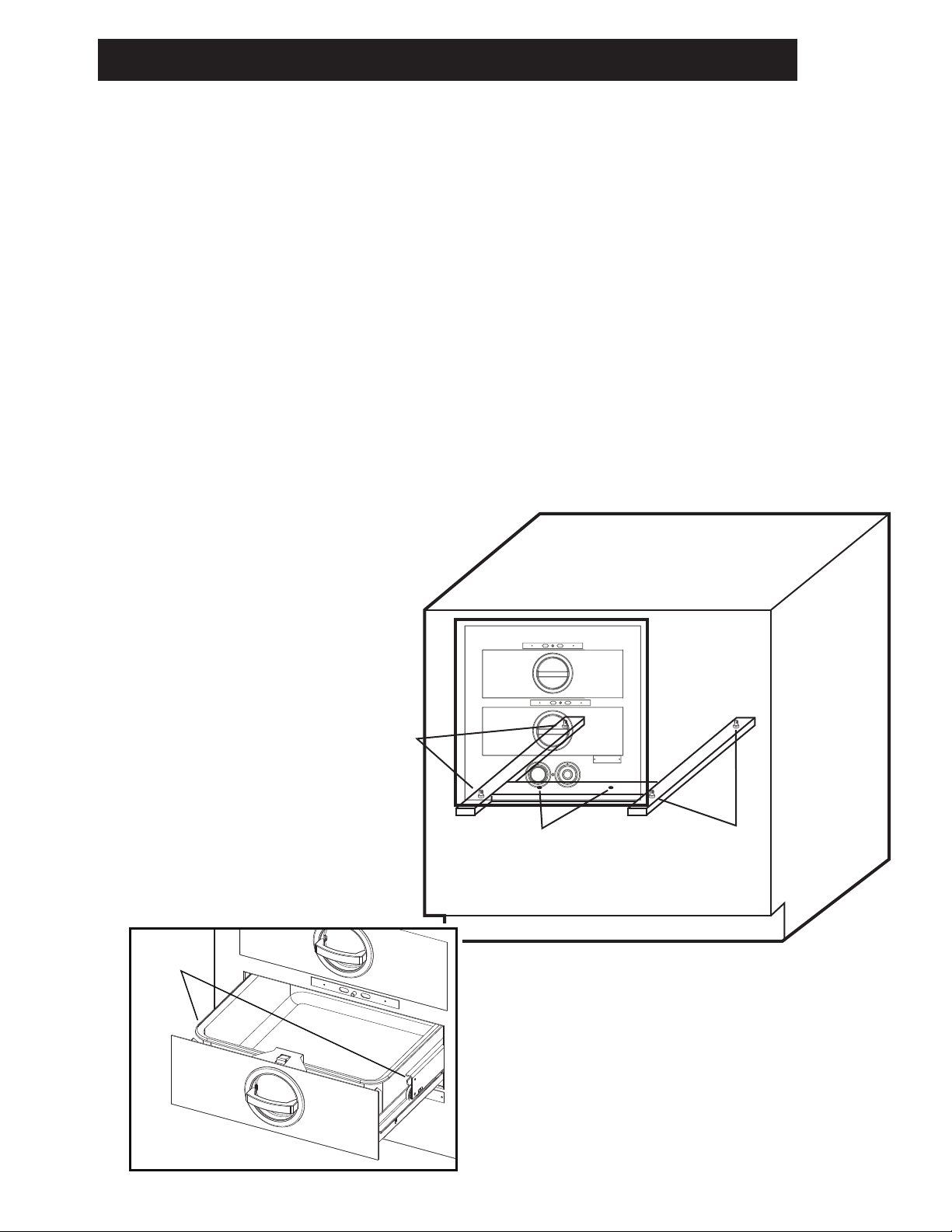

INSTALLATION continued

B

A

C

1/2” Minimum

Cut Opening for

Hot Food Server

1/2” Minimum

IL2090-01

Figure 2-5, Cabinet Mounting

IL2100

3. Electrical Connections:

FREE STANDING UNITS: All free standing hot food servers are quipped with a factory installed 36”

(914mm) cord and plug.

• 120V models: Plug conforms to NEMA Standard 5-15P

• 208/240V models: Plug conforms to NEMA

BUILT-IN UNITS: Most units are provided with a 48” exible metal conduit for electrical connections

(see electrical specications for specics).

D. Installation of Built-In Units:

All of these units are true built-in models and are designed to be installed into the front face of a counter xture.

Front of units extends beyond the body to form a self-trimming ange that covers the cut out in the xture.

1. Cabinet Cut Out and Support. Cut out the face of the counter xture according to the drawing that is

provided with your hot food server. Figure 2-5 can also be used for the cut out drawing of your model

number. As shown in the drawing allow 1/2” (13mm) minimum cabinet face material above top of cut out

opening. This allows unobstructed seating of hot food server ange.

Be sure

Minimum depths are shown for each model in Figure 2-5.

counter xture has adequate depth from front face to inside of back to accept the hot food server.

a. The

hot food server body must be supported from the bottom. This can be accomplished by

installing metal support angles of wooden support blocks as shown in Figure 2-5. The supports

are not supplied and must be furnished using a suitable strength metal or wood. The top surface

of these supports must be 1/16” (3mm) below the bottom edge of the face cut out. A metal or

wood crossbrace approximately 2-1/2” (64mm) wide should be securely mounted between the

supports as shown. The center line of the crossbrace must be 4” (102mm) from the face of the

cut out and its top surface must be ush with the side supports.

b. An

alternate support method is to install a solid at platform in lieu of the side supports and

crossbrace. The top surface of the platform must be 1/16” (3mm) below the bottom edge of the

cut out.

Standard 6-15P

I

nstall Leveling Feet (shown

2.

below). Open the top drawer

and remove the small cloth bag

containing four hex head cap

screws & two mounting screws.

Thread these four screws hand

tight up into the four holes in

the bottom of the unit. Refer to

2-6.

Right: Leveling Feet for

Built-in Units.

(pn: 2C-1513D8805)

BUILT-IN MODELS OPENING DIMENSIONS

Model “A” Width “B” Height “C” Depth

3A20A

3B20A 22 3/4” 578 mm

23 3/8” 594 mm

3A80A

3B80A 21 3/4” 552 mm

3C80A 29 1/2” 749 mm

29 3/8” 746 mm

3B84A 22” 559 mm

11 1/2” 292 mm

24 1/2” 622 mm

11 1/4’ 286 mm 20 5/8” 524 mm

20 3/4” 527 mm

3C84A 32 3/4” 832 mm

6

Page 9

INSTALLATION continued

Bolts used as

leveling feet

Bolts used as

leveling feet

Drill starter holes and attach

hot food server to support through

these two holes.

Use flat head screws.

IL2090-02

Drawer

Release Tabs

IL2101

3. Electrical Connection. All electrical connections required for this unit must be performed by a certied

electrician. Built-in models are equipped with a 3/4” (19mm) diameter x 4ft. (122cm) long exible conduit

containing power lead pigtails and a ground wire. It is necessary that this conduit and the wiring leads

connect at a junction box in accordance with local codes. Be sure to check the data plate on the front of

the unit to be sure the power supply is correct. 115V units operate on voltage ranging from 110V to 125V.

220V units operate on voltage ranging from 208V to 240V.

4. Mount Unit in Cabinet.

a. Remove the drawer(s) from the unit, pull the drawer(s) out to the stop. Grasp the entire drawer

assembly at the sides as if to lift it and locate your thumbs on the tabs of the drawer slide (gure

2-7). Press down on these tabs with your thumbs and simultaneously pull out on the drawer. Set

drawer assembly aside.

b. Lift

c. Place

d. Secure

e. Replace the drawers. NOTE: The drawers of multiple drawer units are individually identied

the unit form both sides and start its backside into the cut out. Push back until the trim ange

meets the face of the xture.

a level on the oor of the unit and check from side to side and front to back. If adjustments

are necessary, slide the entire unit out of the xture and adjust the leveling feet as required.

the unit into position after leveling. There are two holes in the unit bottom for this purpose

(See Figure 2-6). Place a drill bit down through these two holes and bore two pilot holes into the

crossbrace beneath. Tighten a pair of at head sheet metal screws down through these holes

and into the crossbrace. The unit is now installed.

(ex: “TOP”, “2” AND “3”). They should be reinstalled in their respective positions.

E. Initial Start-up

1. Turn on the branch line circuit

breaker

2. Set the thermostat control dial

at “10” the indiactor light will

come on indicating that unit is

calling for heat.

3. After a few minutes have

elapsed, open a drawer and

check that the unit is heating.

NOTE:

4. If unit fails to heat, recheck to

If your unit is equipped with

a separate thermostat for each

drawer, complete Steps 2 & 3

for each drawer individually.

be sure circuit breakers are

on and electrical connections

are properly made. If it still

fails to heat, call a

Toastmaster

Authorized Service Agent.

Above: Figure 2-6, Cabinet Mounting

Left: Figure 2-7, Drawer Release Tabs

7

Page 10

OPERATION

A. Location of Controls

The following information provides a basic description of the hot food server components, their location and function

they perform.

B. Function of Controls

Hot food server models are either equipped with one set of controls for the complete unit of a separate set of controls

for each drawer. Units with one set of controls have a thermostat control, indicator light and thermometer located

below the drawer(s). Units with separate drawer controls have them under each drawer.

1. Thermostat Control Knob - The thermostat control knob is used to set the temperature to your requirements.

The control knob is graduated from “0” to “10” with “OFF” position. The maximum temperature setting is 10

(200°F [93°C]), the minimum temperature setting is 0 (100°F [38°C]).

2. Indicator Light -

3. Thermometer -

4. Moisture

and with proper moisture content. Because hot food servers produce dry heat, moisture loss from the food

must be controlled. The moisture control allows the operator to control the rate at which the natural moisture

of the food escapes.

Slide the moisture control for the desired opening:

Crisp:

Partially Open: Adjust slide for the desired amount of moisture retention.

Moist: Slide is fully closed to retain all of the moisture in the food.

Control - Hot food servers operate on a principle of holding food at proper and safe temperatures

hot food server will not get soggy.

An indicator light cycles on and off as the thermostat calls for heat.

The thermometer indicates the actual holding temperature within the unit.

Slide is fully opened to allow rapid escape of moisture so crisp foods placed in the

C. Operation

1. Turn the main power disconnect switch (circuit breaker) ON.

2. Turn the thermostat control knob to the desired setting. Allow the unit to preheat for the time shown in the

following chart. The indicator light will cycle ON and OFF as it heats.

3. Read

4. Place cooked food into hot food server drawer(s) WHILE HOT. Do not allow to cool.

5. Close

6. Open drawers as required to remove and/or replenish food.

IMPORT

Rolls that have been heated once and then cooled have lost most of their moisture while setting in the open air,

the thermometer after the preheat time has elapsed. If the indicated temperature is above or below

the desired (set) temperature adjust the thermostat up of down unit the desired holding temperature is

reached.

drawer and set moisture control slide to the desired position appropriate for the food being held. Refer

“FUNCTION CONTROLS” for moisture control settings.

ANT: When holding bread and rolls it is important to rotate product. Rolls already in the drawer should

be moved to the front and rolls being added should be placed at the rear.

they can not be reheated with satisfactory results.

8

Page 11

OPERATION continued

D. Shutdown

1. Turn the thermostat control knob to “OFF”.

E. Pre-heating

Model

3A21D

3A20D

3B20A

3B22D 24.8

3A80A/3A81D

3B80A/3B82D

3B84A/3B84D

3C84A/3C84D

3C80A/3C8XD 20.6 28.2

3D8XD 22.3 29.7

Preheat Time in Minutes

150°F (66°C) 175°F (79°C)

18.5 25.83A20A

17.2

18.8 26.2

21.8

CAPACITY PER PAN

Model No

3A20A, 3B20A, 3B22D, 3A20D, 3A21D 35 7 25 5 6

3A80A, 3B80A, 3C80A, 3A81D, 3B82D, 3C8XD, 3D8XD

3B84A, 3C84A, 3B84D, 3C84D

Baked Potatoes Vegetables Ribs Hamburger Buns Dinner Rolls

(120 count) (#10 Can) (lbs.) (doz.) (doz.)

40 8 30 6-1/2 7

9

Page 12

OPERATION continued

G. Recommended Temperature & Humidity Settings

Recommended Temperature and Humidity Settings

Soft Rolls: Clover Leaf, Cinnamon Rolls, Corn Bread, Doughnuts,

Gingerbread, Hamburger & Frankfurter Buns, Mufns, Parker House, Soft

Oval and Sweet Rolls.

Temperature Humidity

150°F to 175°F

Moist

(66°C to 79°C)

Hard Rolls: French, Kaiser, Swiss & Poppy Seed Rolls and Salt Sticks

Vegetables: Asparagus, Beans, Beets, Boiled or Mashed Potatoes,

Braised Celery, Broccoli, Brussel Sprouts, Carrots, Corn Dutch Potato

Salad, Peas, Spinach & Tomatoes

Meat, Fish & Eggs: Bacon, Baked Fish, Barbecued Spareribs,

Beef or Pork Roasts, Chicken Croquettes, Chicken-Whole or Sliced,

Frankfurters, Ground Steak Patties, Ham, Hash, Lamb and Pork Chops,

Liver, Lobster and Shrimp, Meat Loaf, Roast Duck, Sausage, Scrambled

Eggs, Swiss Steak and Veal Cutlets

Casserole Dishes, Chicken Pot Pie, Cod Fish Cakes, Fried Chicken, Fried

Fish, Hamburgers and Scallops

Pies & Desserts: Apple Brown Betty, Plum Pudding and Steamed

Raisin Puddings

Miscellaneous Foods: Cream of Wheat, Farina, Macaroni &

Cheese, Oatmeal, Spaghetti and Spanish Rice

IMPORTANT: There are three main causes for rolls and foods to loose their moisture. The temperature is too high;

the moisture control is not properly adjusted’ or the length of time the rolls are in the drawer is too long. Investigate

these causes if foods or rolls tend to loose moisture.

150°F to 175°F

(66°C to 79°C)

175°F to 185°F

(79°C to 85°C)

165°F to 185°F

(74°C to 85°C)

150°F to 175°F

(66°C to 79°C)

160°F to 185°F

(71°C to 85°C)

165°F to 175°F

(74°F to 79°C)

3/4 to Crisp

Moist

Moist

Moist

Moist

Moist

H. Daily Cleaning

CAUTION: BEFORE CLEANING BE SURE TO TURN OFF THE HOT FOOD SERVER’S MAIN DISCONNECT

SWITCH.

1. Drawer Pans

a. Open the drawer(s) and lift the pan(s) out.

b. Empty contents of pan and wash pan in hot soapy water.

c. Rinse with hot water and let air dry.

or

d. If desired pan can be pre-rinsed and then run through dishwasher and air dried.

2. Exterior Surface (Stainless Steel)

a. Wash with a damp cloth or sponge wrung out of detergent and hot water solution.

b. Rinse with a damp cloth or sponge wrung out of hot clean water.

c. Dry and polish with a soft cloth

or

d. Clean the exterior using a good stainless steel cleaner/polish. Spray on and wipe off.

e. For best results always polish in the direction of the nish grain of the metal.

10

Page 13

OPERATION continued

IL2095

Fig. 3-3, Drawer Removal

Press down on tabs

here to remove drawer

CAUTION

CAUTION

CAUTION: DO NOT USE SCOURING POWDERS OR ABRASIVE PADS TO CLEAN

THE EXTERIOR AS THEY WILL SCRATCH AND MAR THE FINISH.

3. Interior Surfaces (Aluminized Steel)

a. Use a stiff non-metallic bristle brush to loosen food soil and crumbs. Let them fall to the oor

of the unit.

b. Wipe

c. Wash interior with a damp cloth or sponge wrung out of detergent and hot water solution.

d. Rinse with a damp cloth or sponge wrung out of hot clear water.

e. Dry with a clean cloth plus allow time to air dry.

CAUTION: BE CAREFUL NOT TO ALLOW WATER TO RUN INTO ELECTRICAL

COMPARTMENTS AS DAMAGED COULD RESULT.

I. Clean and Lubricate as Necessary

1. Drawer Carriages & Third Rail Members

a. Remove drawer by pulling drawer open until it stops, grasping the carriage on both sides and

b. W

or vacuum accumulated loose soil from the unit paying particular attention to areas around

heating elements.

pressing down on the tabs at the front of the third rail members and then removing drawer.

ash food residue from the carriage with hot detergent and water solution, rinse with clean

hot water and wipe dry.

11

Page 14

OPERATION continued

CAUTION

CAUTION

WARNING

Third Rail Member

Rail Stud

Stud Groove

IL2096

Fig. 3-5, Third Rail Removal

CAUTION: DO NOT SUBMERGE DRAWER FRONTS. THEY ARE INSULATED AND

THE INSULATION BE DAMAGED BY THE LIQUIDS.

c. The third rail members ride in channels welded to the interior sides of the unit. Remove them by

pushing back as far as possible, grasping the member and tilting it inward from the top. (Fig 3-5).

d. Use a stiff bristle brush to loosen food soil and crumbs.

e. Wash with a damp cloth or sponge wrung out of detergent and hot water solution.

f. Rinse with a damp cloth or sponge wrung out of hot clean water.

g. Dry with a clean cloth plus allow time to air dry.

h. Periodically lubricate the third rail members and examine the rollers. They should all turn freely.

i. Lubricate the large rollers with high temperature food grade machine grease. Using your ngers,

j. The small rollers should also be lubricated periodically with high temperature grease. Using your

k. Reinstall the third rail members.

l. Reinstall the drawers. The placement of each drawer is identied near the front of the right side

m. Place the ats of the drawer carriage sides on the bottom rollers of the third rail members and push

CAUTION: DO NOT SUBMERGE. KEEP EXCESS LIQUID OUT OF BEARING

RACES.

force grease into the bearings through the small crack formed at the at spot on the mounting

stud.

ngers, force a small amount of grease into the crack where bearing meets shaft.

(i.e. “TOP” “BOTTOM” “2” “3”). Be sure to re-install the drawers in their proper position.

the drawer all the way closed. Then open the drawer to check that the stops are engaged.

WARNING: NEGLECTED THIRD RAIL MEMBERS MAY EVENTUALLY FAIL TO

FUNCTION PROPERLY. ROLLERS MAY CEASE TO TURN. THIS COULD RESULT

IN EXCESSIVE WEAR TO ROLLERS, MOUNTING CHANNELS AND DRAWER

FRAMES.

12

Page 15

Warranty Statement

Toastmaster warrants equipment that it manufactures to be free from defects in material and

workmanship. Toastmaster’s obligation is limited to repairing or replacing, at Toastmaster’s option, without

cost to the customer, any part found to be defective, as well as any labor or material expense required to

replace the part.

Length of Warranty

This warranty is effective for a period of 12 months from the date the equipment is placed in service.

Exceptions

• This warranty is valid only for the original end user owner/operator of the equipment.

• This warranty does not apply to normal maintenance functions, including (but not limited to)

improper operation, installation or the use of an improper utility supply.

• This warranty is valid only if the equipment is used in a commercial setting. The equipment

is designed and constructed for commercial use by trained professionals only. Any use of the

equipment in private or domestic applications immediately voids this warranty.

• This warranty does not apply to any parts, labor and material expenses for service that is not

pre-approved and performed by a Toastmaster authorized service agent. Any such service

immediately voids this warranty.

• This warranty does not apply to any parts, labor and material expenses associated with the

installation of parts that are not factory-approved for use in the equipment. Any use of such

parts immediately voids this warranty.

• This warranty is not valid if terms of payment have not been met.

Parts Warranty

Parts that are sold to repair our of warranty equipment are warranted for ninety (90) days. The part

only is warranted, the labor to replace the parts is NOT warranted.

Portable Equipment

Toastmaster will not honor service bills that include travel time and mileage charges for servicing any

products considered “Portable”. These products should be taken to the Service Agency for repair.

A portable unit is a unit thats designed to sit on a countertop, has a powercord & is less than 50lbs

installed.

Toastmaster reserves the right to change the design and specications of this equipment or any related

documentation at any time. The end user is not entitled to upgrades resulting from these changes.

This warranty is exclusive and supersedes all other warranties for the equipment, both expressed and

implied. There are no implied warranties of merchantability or of tness for a particular purpose.

The foregoing is Toastmaster’s sole and exclusive obligation and the end user sole and exclusive remedy

for any action including breach of contract or negligence. In no event shall Toastmaster be liable for a sum

in excess of the purchase price of the equipment, or for any prospective or lost prots of the end user.

is a registerd trademark of Toastmaster, A Middleby Company. All rights reserved.

13

Page 16

Hot Food Server

Single Drawer Models

Model: 3A20A, 3A80A, 3A81D

IL2097, Rev. - 10/11/2010

12

11

10

9

1

2

3

4

5

6

7

8

1413

15

16

17

18

31

30

28

29

24

20

19

23

21

22

27

26

25

32

(Items 23 thru 31)

Third Members

Sold as Assemlby Only

2M-3102301; Hot Food Server

Page 17

PARTS LIST September 9, 2013, Rev. B

ONE DRAWER HOT FOOD SERVER MODELS: 3A20A, 3A80A, 3A81D

Fig No Part No. Description Qty Application

1 C9-7005899 COVER,T’STAT 1

2 2R-1523B8301 LEG, 4INBLACK PLASTIC 4 3A81D-120KFC, 3A81DT09-120, 3A81DT72-240

3 2T-3B70A8929 THERMOSTAT,100-200F 1

4 2R-2100087 KNOB,TSTAT OFF & 0-10 1

C9-TC0069 LIGHT,SIGNAL ASSY RED-115

5

C9-3B82D0181 ASSY,LIGHT SIGNAL RED 250 3A80AT72-240, 3A81DT72-240

6 2T-3004112 THERMOMETER 1

7 C9-3A80A3007 GUARD,KNOB CONTROL 2

8 2C-K1DS195 KNOB GUARD SCREW 4

9 2C-B102851 RING,RETAINING 4

9 2C-B102851 RING,RETAINING 6 3A81D-120KFC

10 2C-2001748 WASHER, SPRING #10 4

11 2C-3B82D8827 WASHER,FLAT 7/16 4

12 2R-7610283 ASSY,VENT SLIDE HFS 1

C9-3B22D0045 ASSY,CHANNEL THIRD MEMBER LF

13

C9-3B82D0069 ASSY,CHANNEL THIRD MEMBER LF

C9-3B22D0041 ASSY,CHANNEL THIRD MEMBER RT

14

C9-3B82D0067 ASSY,CHANNEL THIRD MEMBER RT

2D-3B22D8411 PAN 17-5/8 X 17-5/8 X 5-1

15

2D-3B82D8411 PAN 23-3/4 X 14-38 X 5-1

16 C9-7007086 COVER,CATCH HFS DRAWER 1

C9-3B22D0143 DRAWER CARRIAGE ASSY w/FRONT

17

C9-3B82D0179 ASSY, DRAWER & CARRIAGE

2N-3A20A8701 ELEMENT,HEATING 115V 450W

18

2N-3A81D8701 ELEMENT,HEATING 115V 450W 3A80AT09-120, 3A80AWC-120V, 3A81DT09-120

2N-3A81D8703 ELEMENT, HEATING 220V 450W 3A80AT72-240, 3A81DT72-240

2W-3B22D0079 WLDMT, CARIAGE

19

2W-3B82D0151 WLDMT, CARIAGE

20 2C-32259 WELD NUT 1/4-20 SS 4

21 2C-A27469 WASHER,FLAT 1/4IN 7/8OD 1 4

22 2C-A6153 SCR,MS HH 1/4-20X1/2 18-8 4

23 C9-3B82D4065 DRAWER,FRT BRKT-LT 1

24 C9-3B82D4063 BRACKET,DRAWER FRONT RT 1

25 2C-2001347 NUT,KEPS 8-32 ZP 3

26 C9-3B82D0175 ASSY,CATCH BRACKET & TRUS 1

27 2P-3B82D8401 SPRING,DRAWER CATCH 1

28 2A-3B82D8311 SPACER,DRAWER FRONT,3/16X 3

29 C9-7608910 ASSY,DRAWER CUP HANDLE 1

31 2R-3101758 HANDLE,DRAWER 1

2M-3102301; Hot Food Server

30 2C-3023A8811 SCR,MS SLT FH 8-32X1/2 NP 2

3A20AT09-120, 3A80AT09-120, 3A80AWC-120V,

3A81D-120KFC, 3A81DT09-120

1

3A20AT09-120

1

3A80AT09-120, 3A80AT72-240, 3A80AWC-120V,

3A81DT09-120, 3A81DT72-240

3A20AT09-120

1

3A80AT09-120, 3A80AT72-240, 3A80AWC-120V,

3A81DT09-120, 3A81DT72-240

3A20AT09-120

1

3A80AT09-120, 3A80AT72-240, 3A80AWC-120V,

3A81D-120KFC, 3A81DT09-120, 3A81DT72-240

3A20AT09-120

1

3A80AT09-120, 3A80AT72-240, 3A80AWC-120V,

3A81D-120KFC

3A20AT09-120

1

3A20AT09-120

1

3A80AT09-120, 3A80AT72-240, 3A80AWC-120V,

3A81D-120KFC, 3A81DT09-120, 3A81DT72-240

is a registered trademark of Toastmaster, A Middleby Company. All rights reserved.

Page 18

PARTS LIST September 9, 2013, Rev. B

ONE DRAWER HOT FOOD SERVER MODELS: 3A20A, 3A80A, 3A81D

Fig No Part No. Description Qty Application

C9-3B72D0147 ASSY,FRONT & CATCH DRAWER

32

C9-3B82D0177 ASSY, DRAWER FRONT & CATCH

NI 2K-3002648 BUSHING, HEYCO STRAIGHT 1 3A81D-120KFC

NI 2K-B212E8717 BUSHING, STRAIN RELIEF 1 3A81DT09-120

NI C9-3A80A3009 COVER,BOTTOM 1

NI C9-7605845 ASSY, CORDSET (5-15P) 125V15 1 3A81D-120KFC, 3A81DT09-120

NI C9-7610652 ASSY, CORDSET(6-15P) 250V15 1 3A81DT72-240

NI C9-TC0049 CORD ASSY 120V 5-15P 8FT 1 3A80AWC-120V

WIRING DIAGRAMS

NI C9-3A20A8905 DIAGRAM,WIRING 115V 1 3A20AT09-120, 3A80AT09-120, 3A80AWC-120V

NI C9-3A20A8907 DIAGRAM, WIRING 230V 1 3A80AT72-240

NI C9-3A81D8901 DIAGRAM, WIRING 115V 1 3A81D-120KFC

NI C9-3A81D8905 DIAGRAM, WIRING 220V 1 3A81DT72-240

INSTALL INSTRUCTIONS

NI C9-3200085 INST,INSTALL 3A20 HFS AR 3A20AT09-120, 3A80AT09-120

3A20AT09-120

1

3A80AT09-120, 3A80AT72-240, 3A80AWC-120V,

3A81DT09-120, 3A81DT72-240

3A20AT09-120, 3A80AT09-120, 3A80AT72-240,

3A80AWC-120V

is a registered trademark of Toastmaster, A Middleby Company. All rights reserved.

2M-3102301; Hot Food Server

Page 19

2M-3102301; Hot Food Server

Page 20

Hot Food Server

Two, Three & Four Drawer,

Single Control Models

Model: 3B20A, 3B80A, 3C80A, 3D8XD

IL2098, Rev. A 5/6/2011

16

Third Members

Sold as Assemlby Only

19

15

14

13

11

12

7

6

5

8910

4

3

2

1

20

21

22

25

26

30

31

32

33

34 (items 25 thru 33)

27

28

29

23

24

18

17

2M-3102301; Hot Food Server

Page 21

PARTS LIST September 9, 2013, Rev. B

Single Controls, Hot Food Server Models: 3B20AT, 3B80AT, 3C80AT, 3D8XDT

Fig No. Part Number Description Quantity Application

8 3B20AT09-120, 3B20AT72-240

1 2C-B102851 RING,RETAINING

2 2C-3B82D8827 WASHER,FLAT 7/16

3 2C-2001748 WASHER, SPRING #10

4 2R-7610283 ASSY,VENT SLIDE HFS

5 2T-3B70A8929 THERMOSTAT,100-200F 1 ALL

6 C9-1523B0001 WLDMT,CONTROL CUP 1 ALL

7 2R-2100087 KNOB,TSTAT OFF & 0-10 1 ALL

C9-3B82D0181 ASSY, LIGHT SIGNAL 230V

8

C9-TC0069 LIGHT,SIGNAL ASSY RED-115

9 C9-7609086 WLDMT,CUP THERMOMETER MTG 1 ALL

10 2T-3004112 THERMOMETER 1 ALL

C9-7007051

11

C9-7007053 3B80AT, 3B80AWC, 3C80AT, 3D8XDT

C9-3B22D0029

12

C9-3B82D0047 3B80AT, 3B80AWC, 3C80AT, 3D8XDT

C9-3B22D0031

13

C9-3B82D0049 3B80AT, 3B80AWC, 3C80AT, 3D8XDT

2N-3B82D8701

14

2N-3D8XD8701 3C80AT, 3D8XDT

15 2C-30397 CLIP ELEM M P 8 ALL

C9-3B22D0041 ASSY,CHANNEL THIRD MEMBER

16

C9-3B82D0067 ASSY,CHANNEL THIRD MEMBER

C9-3B22D0045 ASSY,CHANNEL THIRD MEMBER

17

C9-3B82D0069 ASSY,CHANNEL THIRD MEMBER

2D-3B22D8411 PAN 17-5/8 X 17-5/8 X 5-1

18

2D-3B82D8411 PAN 23-3/4 X 14-3/8 X 5-1

19 C9-7007086 COVER,CATCH HFS DRAWER

2M-3102301; Hot Food Server

GUARD,WIRE (FRT-BACK) 1

ASSY,SHEATH ELEMENT RIGHT 1

ASSY,SHEATH ELEMENT LEFT 1

ELEMENT,HEATING 110V 500W 2

12 3B80AWC-120V, 3C80AT

16 3B80AT, 3D8XDT09-120

24 3D8XDT72-240

4 3B20AT, 3B80AT

6 3C80AT

8 3D8XDT

4 3B20AT, 3B80AT

6 3C80AT

8 3D8XDT

2 3B20AT, 3B80AT

3 3C80AT

4 3D8XDT

3B20AT72-240, 3B80AT72-240, 3C80AT72-240,

3D8XDT72-240

1

3B20AT09-120, 3B80AT09-120, 3B80AWC120V, 3C80AT09-120, 3D8XDT09-120

3B20AT09-120, 3B20AT72-240

3B20AT

3B20AT

3B20AT, 3B80AT, 3B80AWC-120V

3B20AT

2

3B80AT, 3B80AWC

3 3C80AT

4 3D8XDT

3B20AT

2

3B80AT, 3B80AWC

3 3C80AT

4 3D8XDT

3B20AT

2

3B80AT, 3B80AWC

3 3C80AT

4 3D8XDT

2 3B20AT, 3B80AT, 3B80AWC

3 3C80AT

4 3D8XDT

is a registered trademark of Toastmaster, A Middleby Company. All rights reserved.

Page 22

PARTS LIST September 9, 2013, Rev. B

Single Controls, Hot Food Server Models: 3B20AT, 3B80AT, 3C80AT, 3D8XDT

Fig No. Part Number Description Quantity Application

C9-3B22D0143 DWR CARROAGE ASSY W/FRONT 2 3B20AT

20

C9-3B82D0179 ASSY, DRAWER CARRIAGE

2W-3B22D0079 WLDMT, CARIAGE

21

2W-3B82D0151 WLDMT, CARIAGE

22 2C-32259 WELD NUT 1/4-20 SS

23 2C-A6153 SCR,MS HH 1/4-20X1/2 18-8

24 2C-A27469 WASHER,FLAT 1/4IN 7/8OD 1

25 C9-3B82D4063 BRACKET,DRAWER FRONT RT

26 C9-3B82D4065 DRAWER,FRT BRKT-LT

27 2P-3B82D8401 SPRING,DRAWER CATCH

28 C9-3B82D0175 ASSY,CATCH BRACKET & TRUS

29 2C-2001347 NUT,KEPS 8-32 ZP

30 2A-3B82D8311 SPACER,DRAWER FRONT,3/16X

31 C9-7608910 ASSY,DRAWER CUP HANDLE

32 2C-3023A8811 SCR,MS SLT FH 8-32X1/2 NP

33 2R-3101758 HANDLE,DRAWER

2 3B80AT

3 3C80AT

4 3D8XDT

3B20AT09-120, 3B20AT72-240

2

3B80AT09-120, 3B80AT72-240, 3B80AWC-120V

3 3C80AT

4 3D8XDT

8 3B20AT, 3B80AT

12 3C80AT

16 3D8XDT

8 3B20AT

16 3B80AT

24 3C80AT

8 3B20AT, 3C80AT

16 3B80AT, 3B80AWC

32 3D8XDT

2 3B20AT, 3B80AT, 3B80AWC

4 3C80AT

6 3D8XDT

2 3B20AT, 3B80AT, 3B80AWC

4 3C80AT

6 3D8XDT

2 3B20AT, 3B80AT

3 3C80AT

4 3D8XDT

2 3B20AT, 3B80AT, 3B80AWC

3 3C80AT

6 3B20AT, 3B80AT

9 3C80AT

12 3D8XDT

6 3B20AT, 3B80AT

9 3C80AT

12 3D8XDT

2 3B20AT, 3B80AT, 3B80AWC

3 3C80AT

4 3D8XDT

4 3B20AT, 3B80AT

6 3C80AT

8 3D8XDT

2 3B20AT, 3B80AT

3 3C80AT

4 3D8XDT

is a registered trademark of Toastmaster, A Middleby Company. All rights reserved.

2M-3102301; Hot Food Server

Page 23

PARTS LIST September 9, 2013, Rev. B

Single Controls, Hot Food Server Models: 3B20AT, 3B80AT, 3C80AT, 3D8XDT

Fig No. Part Number Description Quantity Application

C9-3B72D0147 ASSY,FRONT & CATCH DRAWER

34

C9-3B82D0177 ASSY,DRAWER FRONT CATCH

NI 2K-31040 BUSHING HEYCO 7/8 OD 1 3B80AWC-120V

NI 2K-B212E8717 BUSHING, STRAIN RELIEF 1 3D8XDT

NI C9-1511E0029 ASSY, CORDSET(5-15P)125V15 1 3D8XDT09-120

NI C9-1511E0031 ASSY, CORDSET-250V15A 3’ 6I 1 3D8XDT72-240

NI C9-TC0048 CORD SET ASSY 16-3 HSJO 1 3B80AWC-120V

WIRING DIAGRAMS

AR C9-3B20A8905 DIAGRAM,WIRING 115V 1

AR C9-3B20A8911 DIAGRAM, WIRING 220V 1 3B20AT72-240, 3B80AT72-240, 3C80AT72-240

AR C9-3B22D8911 DIAGRAM, WIRING 220V 1 3D8XDT72-240

AR C9-3B72D8913 DIAGRAM, WIRING 115V 1 3D8XDT09-120

INSTALL INSTRUCTIONS

AR C9-3200084 INST,INSTALL 3B20 HFS AR 3B20AT09-120, 3B20AT72-240

3B20AT

2

3B80AT

3 3C80AT

4 3D8XDT

3B20AT09-120, 3B80AT09-120, 3B80AWC-

120V, 3C80AT09-120

2M-3102301; Hot Food Server

is a registered trademark of Toastmaster, A Middleby Company. All rights reserved.

Page 24

Hot Food Server

Two, Three & Four Drawer,

Individual Drawer Control Models

Model: 3B84A, 3B84D, 3C84A, 3C84D

IL2099, Rev. - 10/11/2010

1

2

3

4

5

6

7

8

9

10

11

12

13

15

16

17

18

20

21

23

25

24

28

29

30

31

26

27

22

19

14

32 (items 21 thru 31)

Third Members

Sold as Assemlby Only

Includes;

Items 19 thru 31

2M-3102301; Hot Food Server

Page 25

PARTS LIST September 9, 2013, Rev. B

SEPARATE DRAWER CONTROLS, HOT FOOD SERVER MODELS: 3B84A, 3B84D, 3C84A, 3D84D

Fig No. Part No Description Quantity Application

1 2R-7610283 ASSY,VENT SLIDE HFS

2 2C-2001863 WASHER,FLAT .203X.63OX.05

3 2C-2001748 WASHER,SPRING #10

4 2C-B102851 RING,RETAINING 12 3B84AT09-120

5 2T-3B70A8929 THERMOSTAT,100-200F

6 2R-2100087 KNOB,TSTAT OFF & 0-10

C9-TC0069 LIGHT,SIGNAL ASSY RED-115

7

C9-3B82D0181 ASSY,LIGHT SIGNAL RED 250

8 2T-3004112 THERMOMETER

9 2R-2600068 BLANK,GUARD KNOB CONTROL

10 2C-K1DS195 KNOB GUARD SCREW

11 C9-7005899 COVER,T’STAT

12 2C-35487 SCREW 8-32X5/16 PH TR HD

13 C9-3B82D0067 ASSY,CHANNEL THIRD MEMBER

14 C9-3B82D0069 ASSY,CHANNEL THIRD MEMBER

15 2D-3B82D8411 PAN 23-3/4 X 14-3/8 X 5-1

16 C9-7007086 COVER,CATCH HFS DRAWER

17 C9-3B82D0179 ASSY,DRAWER CARRIAGE

2N-3A81D8701 ELEMENT,HEATING 115V 450W

18

2N-3A81D8703 ELEMENT,HEATING 220V 450W

19 2W-3B82D0151 WLDMT,CARRIAGE

20 2C-32259 WELD NUT 1/4-20 SS

21 2C-A6153 SCR,MS HH 1/4-20X1/2 18-8

2M-3102301; Hot Food Server

22 2C-A27469 WASHER,FLAT 1/4IN 7/8OD 1

2 3B84A, 3B84D

3 3C84A, 3C84D

4 3B84A, 3B84D

6 3C84A, 3C84D

4 3B84A, 3B84D

6 3C84A, 3C84D

2 3B84A, 3B84D

3 3C84A, 3C84D

2 3B84A, 3B84D

3 3C84A, 3C84D

2 3B84AT09-120, 3B84DT09-120, 3B84DT09-KFC

3 3C84AT09-120, 3C84DT09-120, 3C84DT09-120

2 3B84AT72-240 / -SA, 3B84DT72-240

3 3C84DT72-240, 3C84AT72-240

2 3B84A, 3B84D

3 3C84A, 3C84D

4 3B84A, 3B84D

6 3C84A, 3C84D

8 3B84A, 3B84D

12 3C84A, 3C84D

2 3B84A, 3B84D

3 3C84A, 3C84D

4 3B84A, 3B84D

6 3C84A, 3C84D

2 3B84A, 3B84D

3 3C84A, 3C84D

2 3B84A, 3B84D

3 3C84A, 3C84D

2 3B84A, 3B84D

3 3C84A, 3C84D

2 3B84A, 3B84D

3 3C84A, 3C84D

2 3B84A, 3B84D

3 3C84A, 3C84D

2 3B84AT09-120, 3B84DT09-120, 3B84DT09-KFC

3 3C84AT09-120, 3C84AT09-120, 3B84DT09-120

2 3B84AT72-240 / -SA, 3B84DT72-240

3 3C84AT72-240, 3C84DT72-240

2 3B84A, 3B84D

3 3C84A, 3C84D

8 3B84A, 3B84D

12 3C84A, 3C84D

16 3B84A, 3B84D

24 3C84A, 3C84D

16 3B84A, 3B84D

24 3C84A, 3C84D

is a registered trademark of Toastmaster, A Middleby Company. All rights reserved.

Page 26

PARTS LIST September 9, 2013, Rev. B

Separate Drawer Controls, Hot Food Server Models: 3B84A, 3B84D, 3C84A, 3D84D

Fig No. Part No Description Quantity Application

23 C9-3B82D4065 DRAWER,FRT BRKT-LT 2 3B84AT09-120

24 C9-3B82D4063 BRACKET,DRAWER FRONT RT 2 3B84AT09-120

25 2P-3B82D8401 SPRING,DRAWER CATCH

26 C9-3B82D0175 ASSY,CATCH BRACKET & TRUS

27 2C-2001347 NUT,KEPS 8-32 ZP

28 2A-3B82D8311 SPACER,DRAWER FRONT,3/16X

29 C9-7608910 ASSY,DRAWER CUP HANDLE

30 2C-3023A8811 SCR,MS SLT FH 8-32X1/2 NP

31 2R-3101758 HANDLE,DRAWER

32 C9-3B82D0177 ASSY,DRAWER FRONT & CATCH

NI 2A-Z0314 FOOT, 4” DIE CAST 4 3B84DT09-120, 3B84DT72-240

NI 2B-55036 RACK,DIVIDER 15 SECTION 2 3B84DT09-KFC

NI 2K-45609 BUSHING HEYCO 3/8 ID .500 1 3B84DT09-120

NI 2K-B212E8717 BUSHING,STRAIN RELIEF 1 3B84AT09-120

NI C9-45005 KIT, KFC SWVL CASTER W/BRK 1 3B84DT09-KFC

NI C9-7605845 ASSY,CORDSET(5-15P)125V15 1 3B84DT09-120

NI C9-7610652 ASSY,CORDSET(6-15P)250V15 1 3B84DT72-240, 3C84DT72-240

WIRING DIAGRAMS

AR C9-8000358 DIAGRAM, WIRING 120 3C84A 1 3C84AT09-120

AR C9-8000358-1 DIAGRAM, WIRING 208/240V 1 3C84AT72-240

AR C9-8000358-2 DIAGRAM, WIRING 120V 3C84D 1 3C84DT09-120

AR C9-8000358-3 DIAGRAM, WIRING 208/240V 1 3C84DT72-240

AR C9-8000361 DIAGRAM, WIRING 120V 1 3B84AT09-120

INSTALL INSTRUCTIONS

C9-3102206 INST,INSTALL,3B84 & 3C84

NI

ACCESSORIES

7C-3L6 LEG SET 6” ADJ FOOT HFS

7C-3L9 LEG SET 9” ADJ FOOT HFS

7C-3L12 LEG SET 12” ADJ FOOT HFS

7C-3L15 LEG SET 15” SDJ FOOT HFS

7C-3M3 CASTER KIT 3” SWIVEL

7C-3M4 CASTER SET (2 SWVL, 2 RDG)

7C-3M338STSB CASTER SET (4) 2 w/BRK

2 3B84A, 3B84D

3 3C84A, 3C84D

2 3B84A, 3B84D

3 3C84A, 3C84D

6 3B84A, 3B84D

9 3C84A, 3C84D

6 3B84A, 3B84D

9 3C84A, 3C84D

2 3B84A, 3B84D

3 3C84A, 3C84D

4 3B84A, 3B84D

6 3C84A, 3C84D

2 3B84A, 3B84D

3 3C84A, 3C84D

2 3B84A, 3B84D

3 3C84A, 3C84D

AR 3B84AT, 3C84AT

is a registered trademark of Toastmaster, A Middleby Company. All rights reserved.

2M-3102301; Hot Food Server

Page 27

Page 28

STAR INTERNATIONAL HOLDINGS INC. COMPANY

Star - Holman - Lang - Wells - Bloomeld - Toastmaster

10 Sunnen Drive, St. Louis, MO 63143 U.S.A.

(314) 678-6303

www.star-mfg.com

Loading...

Loading...