Page 1

INSTRUCTION MANUAL

EMERGENCY POWER SUPPLY

POWER SUPPLY FRAME

POWER SUPPLY UNIT

VX-2000DS ER

VX-2000DS UK

VX-2000DS SA

VX-2000PF

VX-200PS ER

VX-200PS UK

VX-200PS SA

Thank you for purchasing TOA's Emergency Power Supply, Power Supply Frame, and Power Supply

Unit.

Please carefully follow the instructions in this manual to ensure long, trouble-free use of your equipment.

1134

TOA Electronics Europe GmbH

Suederstrasse 282, 20537 Hamburg, Germany

1134-CPR-083

14

DoP 1134-CPD-083

EN 54-4: 1997/A1: 2002 + A2: 2006

Power supply equipment for fire detection and fire alarm systems for buildings

VX-2000DS ER/UK, VX-200PS ER/UK

(Does not apply to VX-2000DS SA and VX-200PS SA)

Page 2

2

TABLE OF CONTENTS

1. SAFETY PRECAUTIONS ................................................................................. 3

2. NOMENCLATURE AND FUNCTIONS

2.1. VX-2000DS Emergency Power Supply .............................................................. 5

2.2. VX-200PS Power Supply Unit ............................................................................ 7

2.3. VX-2000PF Power Supply Frame ...................................................................... 8

3. INSTALLATION

3.1. Assembling the VX-2000PF Power Supply Frame ............................................ 9

3.2. Installing the VX-200PS Power Supply Unit in the VX-2000PF ....................... 10

3.3. Battery Installation ............................................................................................ 11

3.4. Affixing Declaration of Compliance (EN 54-4 Standard) .................................. 15

4. CONNECTIONS WHEN USING WITH THE VX-2000 SYSTEM

4.1. Connections between VX-2000DS and VX-200PS .......................................... 16

4.2. Connecting the VX-2000DS to VX-2000 System ............................................. 17

5. CONNECTIONS WHEN USING WITH THE SX-2000 SYSTEM

5.1. Connections between VX-2000DS and VX-200PS .......................................... 18

5.2. Connecting the VX-2000DS to SX-2000 System ............................................. 19

5.3. DS Link Terminal Connections ......................................................................... 21

6. CONNECTIONS WHEN USING WITH THE VM-3000 SYSTEM ....... 22

7. CABLE USAGE TABLE ................................................................................. 26

8. USING THE VX-2000DS EXCLUSIVELY AS A BACKUP

POWER SUPPLY

.............................................................................................. 27

9. SWITCHING OFF SYSTEM POWER (DC) ............................................... 28

10. BLOCK DIAGRAM ........................................................................................... 29

11. SPECIFICATIONS

11.1. VX-2000DS Emergency Power Supply .......................................................... 30

11.2. VX-200PS Power Supply Unit ........................................................................ 31

11.3. VX-2000PF Power Supply Frame ................................................................. 31

Page 3

3

1. SAFETY PRECAUTIONS

• Before installation or use, be sure to carefully read all the instructions in this section for correct and safe

operation.

• Be sure to follow all the precautionary instructions in this section, which contain important warnings and/or

cautions regarding safety.

• After reading, keep this manual handy for future reference.

When Installing the Unit

• Do not expose the unit to rain or an environment where it may be splashed by water or other liquids, as

doing so may result in fire or electric shock.

• Use the unit only with the voltage specified on the unit. Using a voltage higher than that which is specified

may result in fire or electric shock.

• (Applicable to VX-2000DS and VX-200PS only)

Do not cut, kink, otherwise damage nor modify the power supply cord. In addition, avoid using the power

cord in close proximity to heaters, and never place heavy objects -- including the unit itself -- on the power

cord, as doing so may result in fire or electric shock.

• Since the unit is designed for in-door use, do not install it outdoors. If installed outdoors, the aging of parts

causes the unit to fall off, resulting in personal injury. Also, when it gets wet with rain, there is a danger of

electric shock.

When the Unit is in Use

• Should the following irregularity be found during use, immediately switch off the main power (or circuit

breaker), and contact your nearest TOA dealer. Make no further attempt to operate the unit in this condition

as this may cause fire or electric shock.

· If you detect smoke or a strange smell coming from the unit.

· If water or any metallic object gets into the unit

· If the unit falls, or the unit case breaks

· (Applicable to VX-2000DS and VX-200PS only)

If the power supply cord is damaged (exposure of the core, disconnection, etc.)

· If it is malfunctioning (no tone sounds.)

• To prevent a fire or electric shock, never open the unit case nor modify the unit. Refer all servicing to

qualified service personnel.

• Do not place cups, bowls, or other containers of liquid or metallic objects on top of the unit. If they

accidentally spill into the unit, this may cause a fire or electric shock.

• (Applicable to VX-2000DS and VX-200PS only)

Do not insert nor drop metallic objects or flammable materials in the ventilation slots of the unit's cover as

this may result in fire or electric shock.

• (Applicable to VX-2000DS and VX-200PS only)

Do not touch a power supply plug during thunder and lightning, as this may result in electric shock.

• (Applicable to VX-200PS only)

When replacing the fuse, be sure to use the supplied one (3.15 A). Using any other fuse than supplied may

cause fire or electric shock.

Indicates a potentially hazardous situation which, if mishandled, could

result in death or serious personal injury.

WARNING

Page 4

4

When Installing the Unit

• (Applicable to VX-2000DS and VX-200PS only)

Never plug in nor remove the power supply plug with wet hands, as doing so may cause electric shock.

• (Applicable to VX-2000DS and VX-200PS only)

When unplugging the power supply cord, be sure to grasp the power supply plug; never pull on the cord

itself. Operating the unit with a damaged power supply cord may cause a fire or electric shock.

• (Applicable to VX-2000DS and VX-200PS only)

Do not block the ventilation slots in the unit's cover. Doing so may cause heat to build up inside the unit and

result in fire.

•

Avoid installing the unit in humid or dusty locations, in locations exposed to the direct sunlight, near the heaters,

or in locations generating sooty smoke or steam as doing otherwise may result in fire or electric shock.

• System units (except remote microphones) are designed exclusively to be mounted in an equipment rack.

Be sure to observe the following instructions when rack-mounting the unit. Failure to do so may cause a fire

or personal injury.

· Install the equipment rack on a stable, hard floor. Fix it with anchor bolts or take other arrangements to

prevent it from falling down.

· When connecting the power cord of the DC power supply panel for the units to an AC outlet, ensure that

the total load current never exceeds the AC outlet's allowable current capacity.

· The supplied rack-mounting screws can be used for the TOA equipment rack only. Do not use them for

other racks.

• (Applicable to VX-2000DS only)

Note correct polarity (positive and negative orientation) when connecting the power supply cord. Reversed

polarity connections will cause damage to the system.

When the Unit is in Use

• Use the specified power supply unit for the system. Note that the use of other power supply unit may cause

a fire.

• (Applicable to VX-2000DS only)

Make sure to observe the following handling precautions so that a fire or personal injury does not result from

leakage or explosion of the battery.

· Do not short, disassemble, heat nor put the battery into a fire.

· Avoid using both new and old batteries together.

· Never charge batteries of the type which are not rechargeable.

· Do not solder a battery directly.

· Be sure to use the specified type of batteries.

· Note correct polarity (positive and negative orientation) when connecting a battery to the unit.

· Avoid locations exposed to the direct sunlight, high temperature and high humidity when storing batteries.

• (Applicable to VX-200PS only)

Contact your TOA dealer as to the cleaning. If dust is allowed to accumulate in the unit over a long period of

time, a fire or damage to the unit may result.

Indicates a potentially hazardous situation which, if mishandled, could

result in moderate or minor personal injury, and/or property damage.

CAUTION

Page 5

5

2. NOMENCLATURE AND FUNCTIONS

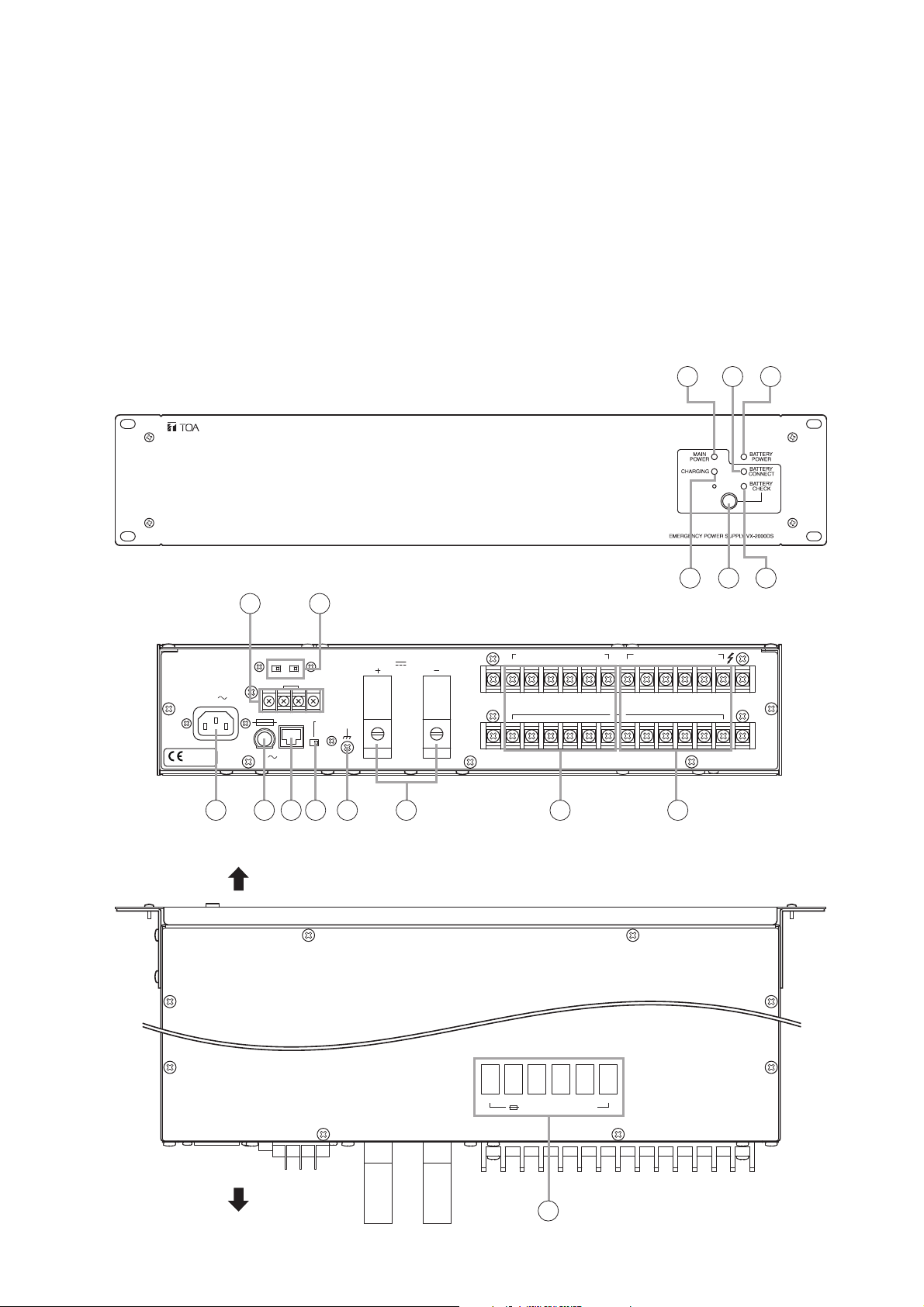

2.1. VX-2000DS Emergency Power Supply

• Up to 3 (6 ch) VX-200PS Power Supply units can be connected per VX-2000DS to supply backup DC power

to individual components.

• Automatically switches to the backup power supply when the DC power supply from the VX-200PS is

interrupted.

• Detects charging circuitry or battery failures, and transmits failure signals to the DS LINK of the TOA Voice

Evacuation Systems (VX-2000, SX-2000, and VM-3000).

• Keeps a 2 x 12 V sealed lead-acid battery charged while maintaining temperature compensation for the

charging voltage.

• Automatically disconnects the battery if its voltage reaches a discharge final level.

1

[Front]

2 3

[Rear]

[Top]

7 8

DC POWER OUT (+) MAX 25A (DC 20V-40V)

1134

50/60Hz 240W

EN 54-4

1134-CPD-083

230V

DETECT(VX-200PS)

PS3 PS2

THERMISTOR

FUSE

T3.15A L

250V

OFFONON OFF

DS – SF

LINK SETTING

DCAC

BATTERY POWER IN

24V MAX150A

( ) ( )

9 10 11 12 13 14 15 16

Note: This figure represents the VX-2000DS ER.

Front side

PS IN (+) MAX 25A (DC20V-40V)

615432615432

( )

5

4

6

PS IN

1,2:PS1

3,4:PS2

5,6:PS3

Rear side

654321

FUSE 40A (DC POWER OUT)

17

Page 6

6

1. Power indicator [MAIN POWER]

Lights green when both DC power from the VX200PS and AC power are supplied.

2. Battery connect indicator

[BATTERY CONNECT]

Lights green when the battery is connected.

3. Battery indicator [BATTERY POWER]

Indicates the state of battery usage. Lights red

when the DC power supply is interrupted and

switched over to the backup power supply.

4. Charging indicator [CHARGING]

Indicates battery charging status. Flashes green

while charging, and continuously lights green

after charging completion.

5. Battery check button

Used to check internal resistance state of the

backup battery.

Pressing the button permits measuring of the

internal resistance value. The Battery check

indicator goes off if the measurement exceeds

the specified value.

In automatic mode, the unit performs battery

check every 3 and a half hours.

When the DS-SF LINK is connected to the VX2000 system, SX-2000 system, or VM-3000

system, the resistance measurement is activated

by the equipment, not by the unit itself.

Note

Battery check cannot function for 1 minute after it

has been activated once. In this case, wait a few

minutes, then reactivate it.

6. Battery check indicator [BATTERY CHECK]

In the AC operated system, the internal

resistance value of the battery is measured

automatically or manually to check whether the

battery is faulty. The Battery check indicator

indicates the result.

• Before measurement:

Flashes green at 2-second intervals.

• During measurement:

Flashes green at 1-second intervals.

• Normal: Lights green.

• Abnormal: Remains unlit.

In the battery-operated system, the battery

voltage is constantly monitored and its level is

indicated by the indicator as shown below

without pressing the Battery check button.

• Lights green: 25 V or more

• Flashes green: 20 – 25 V

• OFF: 20 V or less

7. Thermistor connection terminal

[THERMISTOR]

Detects the ambient temperature of the backup

battery, and performs temperature compensation

for the charging voltage. For the installation

instructions, refer to p. 14.

8. PS detect switches

Always connect a power supply to the terminals

1 + 2 of the DC INPUT. When connecting a

power supply to the terminals 3 + 4 of the DC

INPUT, set the PS2 switch to ON. When

connecting a power supply to the terminals 5 + 6

of the DC INPUT, set the PS3 switch to ON.

9. AC inlet

Using the supplied power cord, connect this AC

line receptacle to a power source of 230 V AC

(ER/UK), 220 – 230 V AC (SA), 50/60 Hz.

10. Fuse holder

Requires an AC fuse.

Type: 250 V, T3.15 A L

11. Control connector [DS-SF LINK]

This RJ45 connector connects to DS-SF LINK

connector of the VX-2000 system, SX-2000

system, or VM-3000 system.

12. Setting switch [SETTING]

Select the DC position (factory set) when using

the unit in the VX-2000 system, SX-2000 system,

or VM-3000 system.

Select the AC position when using the unit as a

backup power supply in an AC-operated system.

Refer to p. 27 for the switch setting in the VM2000 series system or other systems.

13. Ground terminal

14. Battery connection terminal

[BATTERY POWER IN]

Connects to the backup battery.

Recommended battery: Panasonic LCX1265PG/APG sealed lead-acid battery

15. DC output terminal [DC POWER OUT]

Supplies the DC power to the DC-operated

devices.

16. DC input terminal [PS IN]

Connects to the DC output terminal of the VX200PS Power Supply unit or VM-3000 series

(Voice Alarm System Amplifier or VM Extension

Amplifier).

Be sure to connect the first VX-200PS unit or

VM-3000 amplifier to the terminals 1 and 2, the

second unit or amplifier to the terminals 3 and 4,

and the third unit or amplifier to the terminals 5

and 6.

17. Fuse

Provided in each DC output.

Capacity: Blade-Type Fuse 40 A

Page 7

7

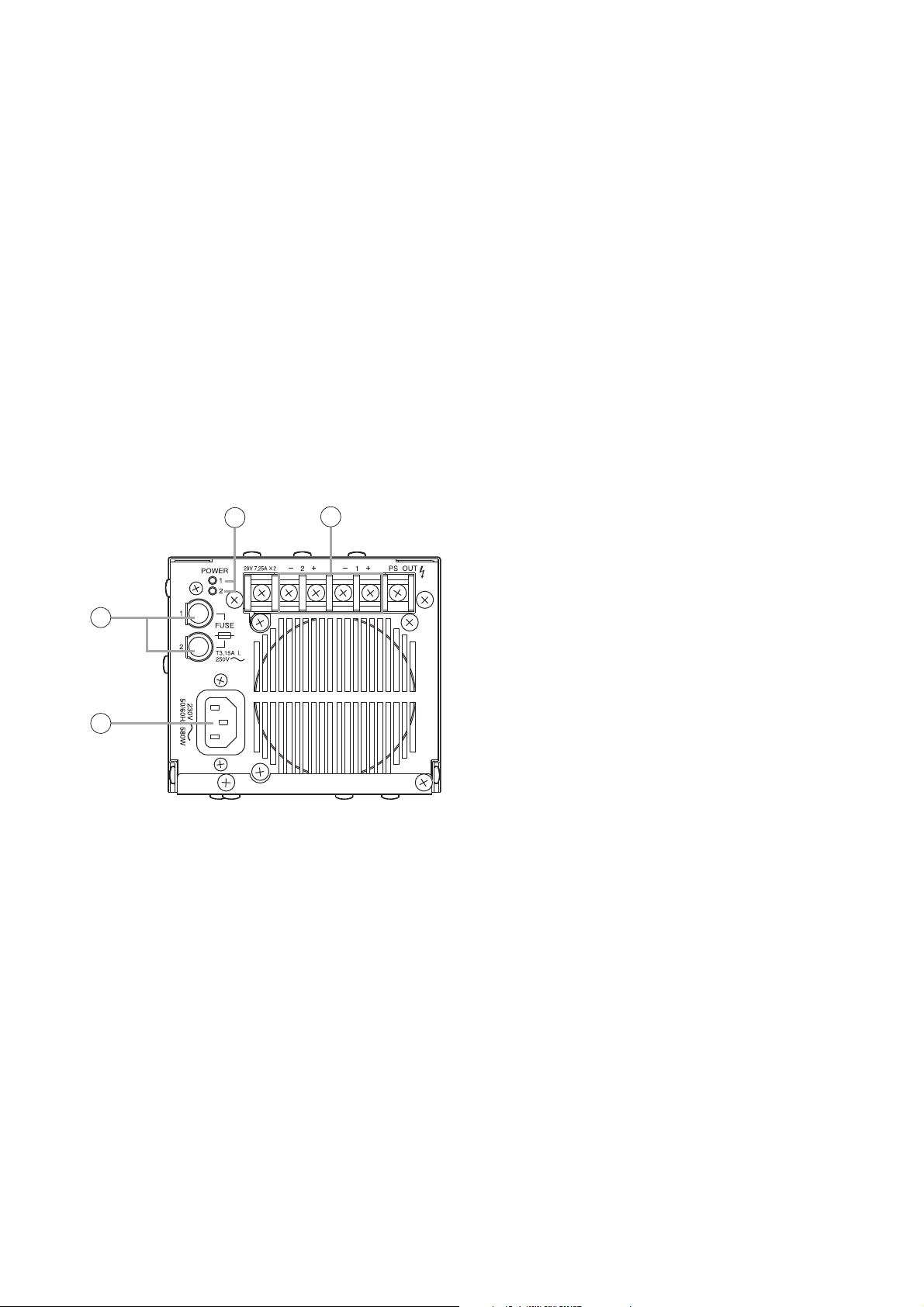

2.2. VX-200PS Power Supply Unit

1. Power indicator [POWER]

These indicators (one for each channel) light

green when DC power is output.

2. DC output terminal 1, 2 [PS OUT]

Connects to the PS IN terminals of the VX2000DS Emergency Power Supply.

3. AC fuse 1, 2

Type: 250 V, T3.15 A L

4. AC inlet

Using the supplied power cord, connect this

AC line receptacle to a power source of 230 V

AC (ER/UK), 220 – 230 V AC (SA), 50/60 Hz.

Note

The VX-200PS Power Supply unit is designed for exclusive use with the VX-2000 system, SX-2000 system,

and VM-3000 system.

Up to 3 VX-200PS Power Supply units can be mounted in the V-2000PF Power Supply Frame. The VX200PS unit has 2 DC output channels, and up to 3 units (6 ch) can be connected to one VX-2000DS

Emergency Power Supply. Use the VX-200PS in the number suited to the required total system power.

[Fault indication]

If any of the Power indicator [MAIN POWER], Battery connect indicator [BATTERY CONNECT], Charging

indicator [CHARGING], or Battery check indicator [BATTERY CHECK] on the front panel remains unlit, the

unit is judged failed. In such cases, remove the cause of the failure, and restore the unit to normal operation.

Note

Even if any of these indicators flashes, this does not indicate malfunction.

[Rear]

1

2

3

4

Page 8

8

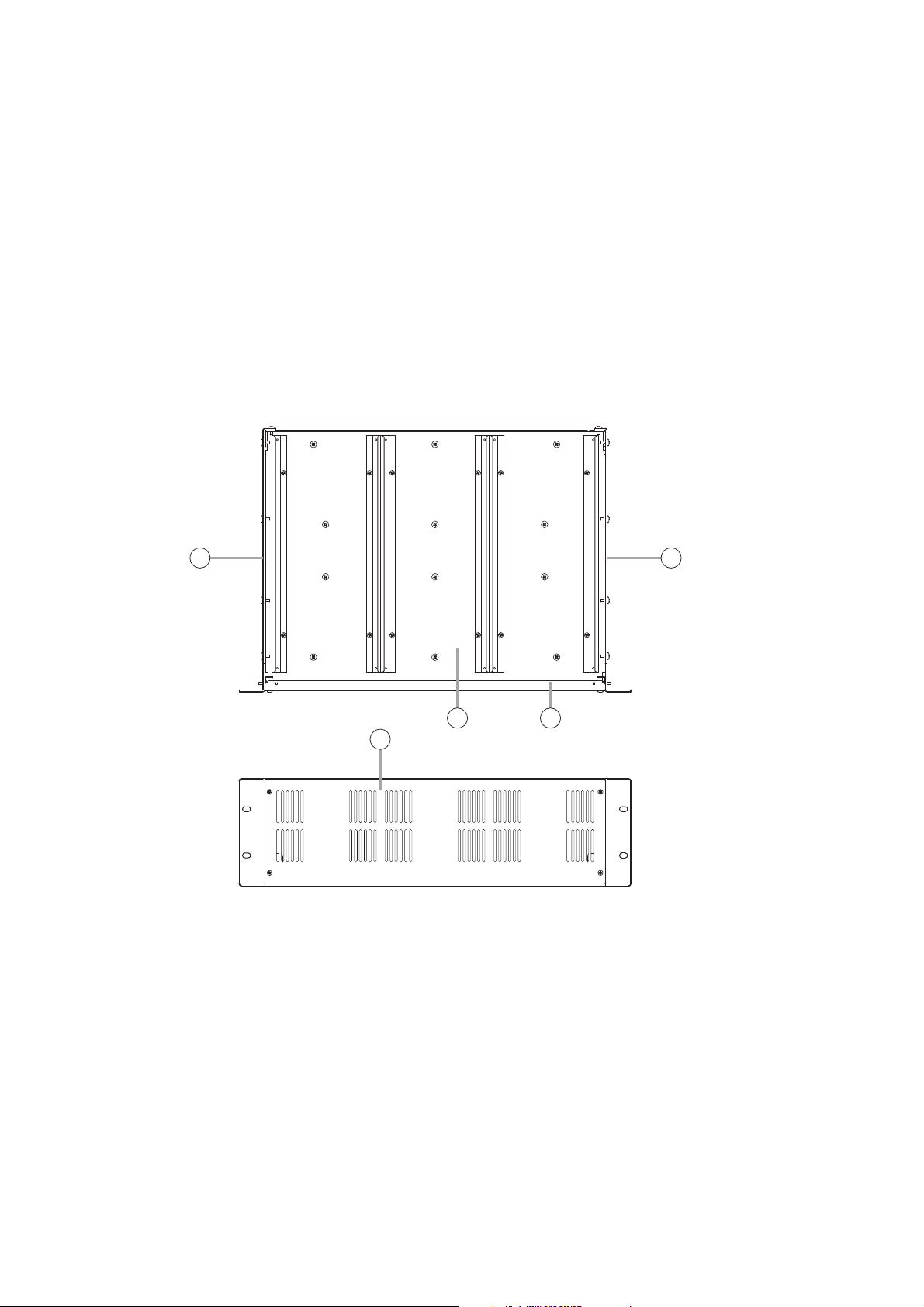

2.3. VX-2000PF Power Supply Frame

[VX-2000PF Components]

This unit is comprised of the following components. For the component assembly, refer to p. 9.

1. Front panel .................................................................. 1

2. Side panel ................................................................... 2

3. Chassis (VX-200PS guide rails pre-mounted) ..............1

4. Fixing bracket* ..............................................................1

* The Fixing bracket is not supplied with the previous VX-2000PF.

(Refer to p. 9, "Installation Precautions.")

The VX-2000PF permits the VX-200PS Power Supply to be mounted in an equipment rack.

Up to 3 VX-200PS units can be installed in the VX-2000PF. Refer to p. 10 for the VX-200PS mounting

procedure.

[Top]

[Front]

2 2

3

4

1

Page 9

9

3. INSTALLATION

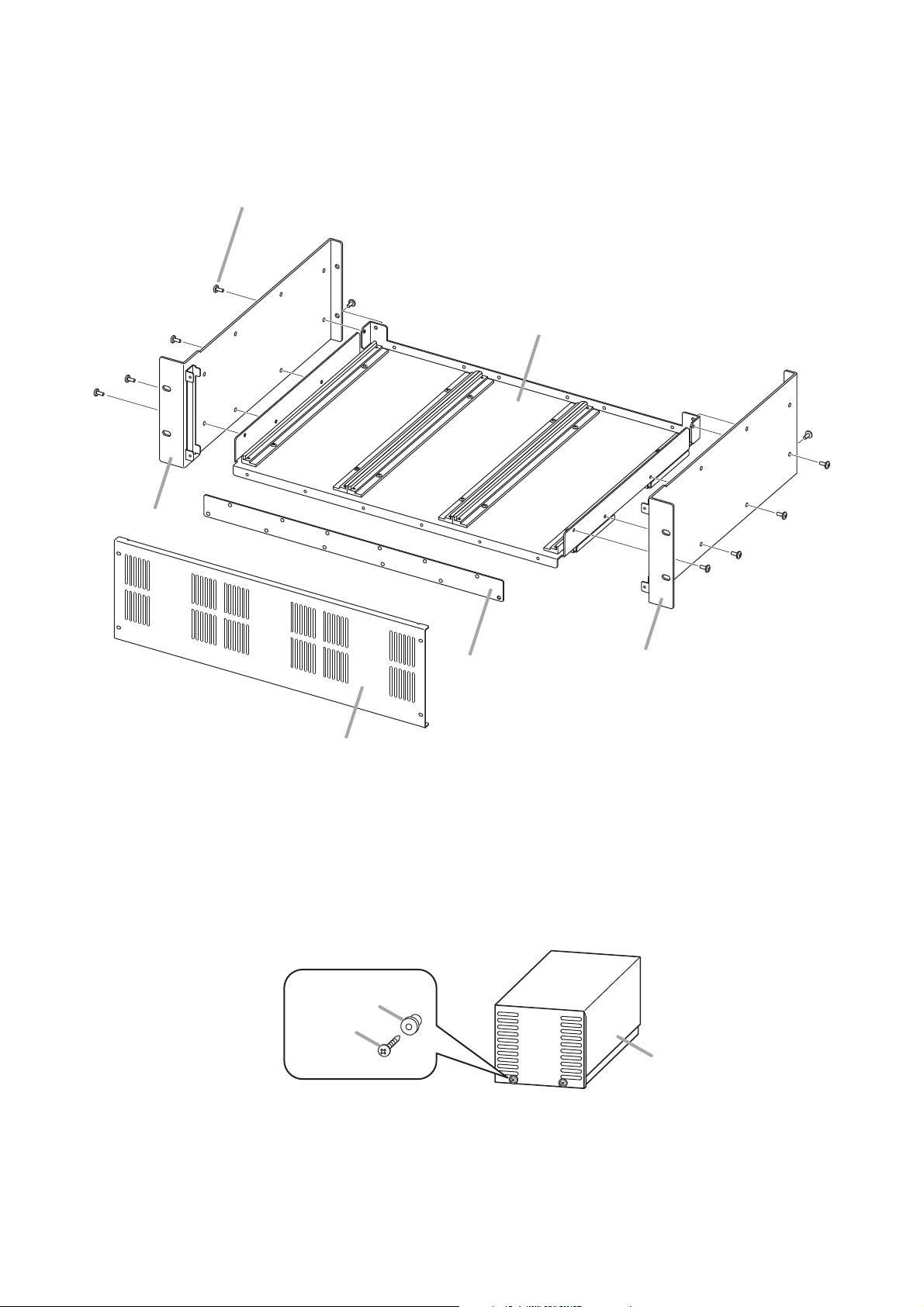

3.1. Assembling the VX-2000PF Power Supply Frame

Note: Mount the front panel and fixing bracket after installing the VX-200PS units on the chassis.

[Installation Precautions]

The VX-2000PF and VX-200PS units are slightly different in specifications between the previous and current

production lots.

The previous unit differs from the product explained in this manual in the following points.

Previous VX-2000PF: A Fixing bracket is not supplied.

Previous VX-200PS: A spacer is placed between the front panel and screw. (See the figure below.)

The mounting method for the combination of the current unit and previous unit differs from the steps shown on

the next page.

• When mounting the previous VX-200PS in the current VX-2000PF;

Use only the removed screws without using the spacers removed from the VX-200PS's front panel in Step 3.

• When mounting the VX-200PS (previous or current unit) in the previous VX-2000PF;

There is no need to secure the VX-200PS units using the screws in Steps 2, and 3.

Self-tapping screw 4 x 10

(supplied with the VX-2000PF)

Chassis

Side panel

Fixing bracket

Front panel

Spacer

Screw

Side panel

Previous VX-200PS

Page 10

10

Step 3. Fit the VX-2000PF's fixing bracket and front panel in place.

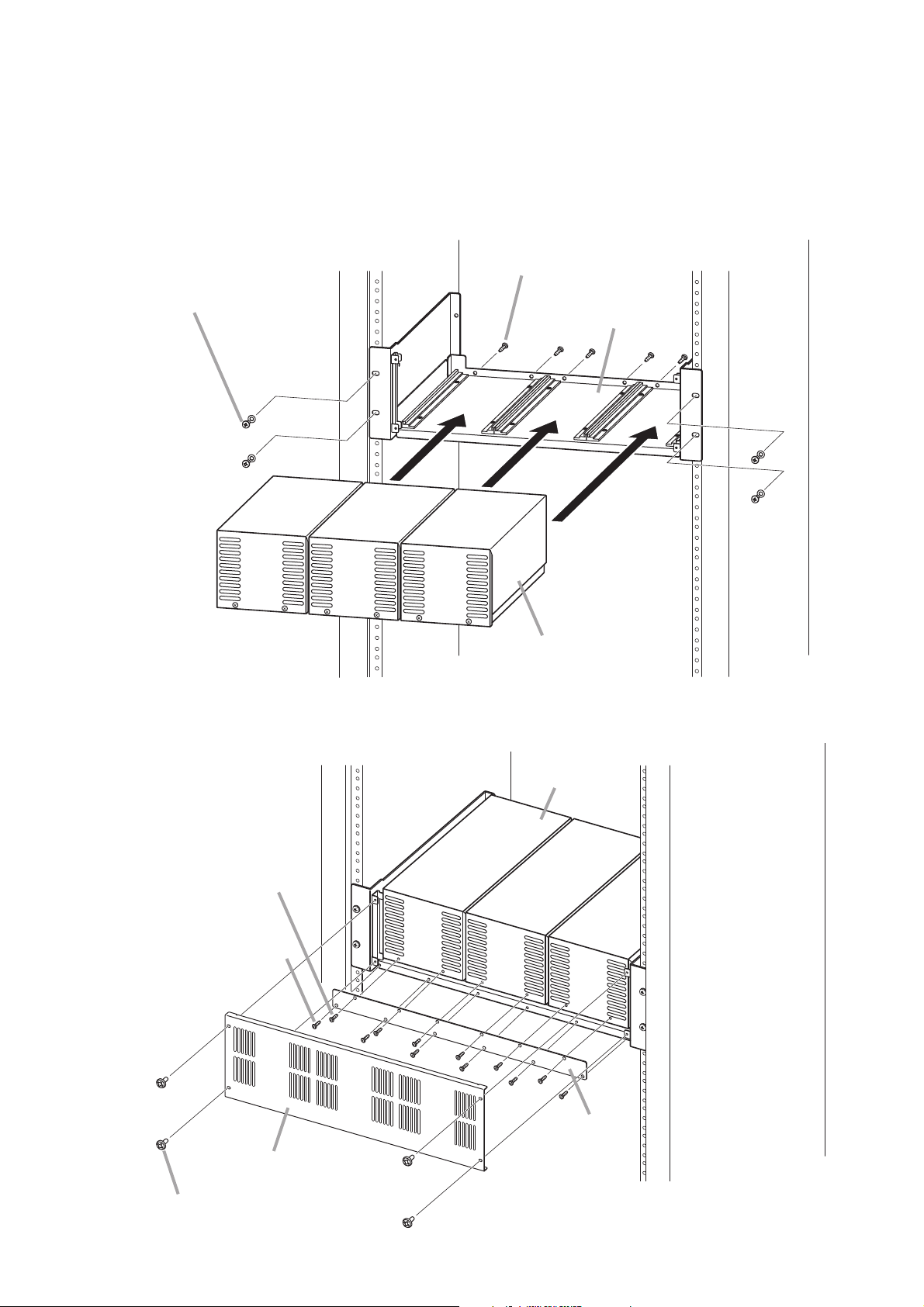

3.2. Installing the VX-200PS Power Supply Unit in the VX-2000PF

To be compliant with EN 54-4, install the VX-2000DS and VX-2000PF in the CR cabinet rack series CR-15,

CR-22, CR-27, CR-35, CR-40, and CR-44.

Step 1. Mount the VX-2000PF in an equipment rack.

Step 2. Mount the VX-200PS in the VX-2000PF.

Self-tapping screw 4 x 10

(remove from VX-200PS'

rear panel)

Supplied with the VX-2000PF

or other appropriate screw

VX-2000PF

1

1

VX-200PS

Self-tapping screw 4 x 10

(remove from the VX-200PS'

front panel)

Self-tapping screw 4 x 10

(supplied with the VX-2000PF)

2

Rack

VX-200PS

Rack

VX-2000PF's

Fixing bracket

VX-2000PF's Front panel

Machine screw M3 x 6

(supplied with the VX-2000PF)

Page 11

11

3.3. Battery Installation

• Take special care to prevent the battery from being shorted by misconnection of the battery cable.

If the short occurs, the unit may fail.

Follow the instructions in this section for safe and secure connection.

• Be sure to switch off the system power before battery connection. For the procedure, refer to p. 28

"SWITCHING OFF SYSTEM POWER."

• After completing the battery connection, be sure to attach a terminal cover onto each battery

terminal to prevent shorts between positive and negative terminals.

WARNING

[Cable end treatment]

To secure the connection between the battery terminal and cable, be sure to use the cable of specified

diameter and treat its end as follows.

[Cautions on cable connection to the battery terminal]

• Before connecting the battery cable to the battery

terminal, be sure to fully open the cable clamp by

turning the terminal screw counterclockwise.

• Insert the battery cable into the correct position in the battery terminal referring to the terminal's cross

sectional diagrams below.

Usable cable diameter: AWG 6 – AWG 0 (1/0)

(Line resistance should be within 4 mΩ in total.)

Stripped length: 30 mm ± 5 mm

Cross sectional area: 16 – 50 mm

Battery terminal

Cable clamp

Terminal screw

Fully open. Too narrow to

2

Incorrect

clamp the cable

Correct position of the cable insertion Incorrect position of the cable insertion

Wrong insertion position of the cable or a forked

Cable conductor

Cable clamp

cable insertion causes poor contact or insufficient

connection tightness, making the cable come off

to possibly cause short-circuit accident.

Page 12

12

• Strip the cable end long enough (30 mm ± 5 mm) to

be fully clamped. Otherwise, its outer jacket

prevents the cable conductor from being tightly

secured, causing poor contact.

[Attaching the insulating sheet]

To prevent the battery cable from being shorted to the rear panel due to misconnection, attach the supplied

insulating sheet in place following the procedures below.

Step 1. Remove the screw indicated by the arrow.

Step 2. Put the supplied insulating sheet over the

battery terminals, and fix it with the removed

screw.

Note

Attach the supplied Attention label (German) onto the

current English label as required.

Note correct polarity (positive and negative orientation) when

connecting the power supply cord. Reversed polarity connections will

cause damage to the system.

CAUTION

[Connecting the Battery]

Notes

To avoid battery failure and charger failure, take care of the following points.

• If batteries not recommended by the manufacturer are used and a charger failure occurs, connect a resistor

of 18 kΩ (1/4 W) parallel to the batteries.

• Use the specified type of batteries and capacity.

Correct Incorrect

VX-2000DS

BATTERY POWER IN

24V MAX150A

WARNING

Take special care to prevent the battery from

being shorted by misconnection of the battery

cable. If the short occurs, the unit may fail.

Insulating sheet

Attention label

18 kΩ (1/4 W)

Battery Battery

Page 13

13

• Use the battery connection cables as short in length and as large in diameter as possible.

• Total resistance of the battery connection path should be less than 4 mΩ, which includes resistance of all of

wire, terminal, fuse, and terminal points.

For reference, refer to each resistance as follows.

Resistance of terminal, fuse (if provided): 1 – 2 mΩ

Resistance of terminal point: 0.1 – 0.5 mΩ

• Fasten the bolts, nuts, and screws of the unit's battery connection terminals and battery terminals with the

torque as shown below.

Step 1. Allow more than 10 seconds to elapse after removing the power cord from the VX-2000DS' rear-

mounted AC inlet.

Step 2. Insert the positive battery cable into the VX-2000DS' rear-mounted BATTERY POWER IN positive

terminal from the bottom side of the connector, then tighten the terminal screw with a flat screwdriver.

Note

Never connect the negative cable first to avoid battery short-circuit that occurs if the positive cable

should contact the unit chassis or equipment rack.

Step 3. Connect the negative battery cable to the negative terminal in the same manner as Step 2.

Tightening torque: 6 – 8 Nm

VX-2000DS

230V

50/60Hz 240W

DETECT(VX-200PS)

PS3 PS2

THERMISTOR

DS – SFFUSE

LINK

BATTERY POWER IN

24V MAX150A

OFFONON OFF

( ) ( )

DC POWER OUT (+) MAX 25A (DC 20V-40V)

PS IN (+) MAX 25A (DC20V-40V)

615432615432

( )

PS IN

1,2:PS1

3,4:PS2

5,6:PS3

Battery connnection terminals

Cable A

AWG 6

AWG 4

AWG 2

AWG 0 (1/0)

Battery

Cable cross

sectional area

2

16 mm

2

25 mm

2

35 mm

2

50 mm

Cable B

Battery

Length (2 mΩ)AWG

180 cm

280 cm

400 cm

570 cm

Cable C

Example of wire length

Cable A, Cable C Cable B

80 cm each

130 cm each

190 cm each

275 cm each

20 cm

20 cm

20 cm

20 cm

VX-2000DS’ Battery connection terminals

Battery terminals

6 – 8 Nm

4.1 – 5.6 Nm (M6)

8.2 – 5.6 Nm (M8)

VX-2000DS

B

A

TT

E

R

Y

P

O

W

E

R

I

N

2

4V M

A

X

15

0A

1

2

Page 14

14

[Installing a thermistor]

The thermistor located on the VX-2000DS' rear panel is designed to compensate for temperature changes

when charging the battery. It should be mounted on the side of one battery in between 2 batteries using

thermal insulating sheet to avoid ambient temperature change, thereby maintaining the temperature of the

thermistor relatively constant.

Step 1. Clean the exterior surface of the battery using a soft damp cloth.

Note

Avoid using chemical cleaners and solvents that may cause the battery cases to crack or leak.

Step 2. Follow the procedure shown above to attach the thermistor to the adhesive side of thermal insulating

sheet, then attach the sheet to the side of the battery.

Note

The thermal insulating sheet is extremely difficult to remove after attached.

Step 1. Confirm that battery power is not in use by means of the VX-2000DS' front-mounted BATTERY

POWER LED, which is unlit in this case.

Step 2. Loosen the VX-2000DS' BATTERY POWER IN negative terminal screw, then pull out the negative

battery cable.

Notes

• Never remove the positive cable first to avoid battery short-circuit that occurs if the positive cable

should contact the unit chassis or equipment rack.

• Insulate the exposed end of the removed cable with insulating tape to avoid shorting to the other

cable.

Step 3. Remove the positive battery cable from the positive terminal in the same manner as Step 2.

Note

Insulate the exposed end of removed cable with insulating tape to avoid shorting to the other cable.

[Disconnecting the Battery]

Thermistor

Thermal insulating sheet

(supplied with the VX-2000DS)

VX-2000DS

Rack

Batteries

Page 15

15

[Fixing the battery] (ER/UK version only)

To comply with EN 54-4, fix the battery at the bottom plate surface of the rack as shown below.

Attach hook fasteners to the bottom surface of each battery, and loop fasteners to the bottom plate surface of

the rack.

3.4. Affixing Declaration of Compliance (EN 54-4 Standard, ER/UK version only)

To declare that the VX-2000DS, VX-2000PF, and VX-200PS comply with EN 54-4, affix the sticker supplied

with the VX-2000DS visible to the front panel of the equipment (e.g. at the upper right side as shown below).

Bottom of battery

[Viewed from the battery's bottom surface side]

Hook fasteners

(supplied with the VX-2000DS)

When replacing the batteries, 4 each of fastener hooks and loops, and a thermal insulating sheet listed

below are also required. Consult your nearest TOA dealer on how you can obtain them.

Part code Part name

135-01-075-2

135-01-076-3

131-27-891-2 VX-2000DS THERMAL INSULATING SHEET

VX-2000DS FASTENER HOOK (A)

VX-2000DS FASTENER LOOP (B)

Rack

VX-2000PF and

VX-200PS

VX-2000DS

EN 54-4

Sticker (supplied with the VX-2000DS)

Affix only the upper part of the

sticker to the equipment rack.

EN 54-4

Paste this sticker on the outside

of the cabinet rack containing

the so certified equipment.

Page 16

16

4. CONNECTIONS WHEN USING WITH THE VX-2000 SYSTEM

4.1. Connections between VX-2000DS and VX-200PS

(–)

DETECT(VX-200PS)

PS3

PS2

OFFONON OFF

VX-200PS VX-200PS

230V

50/60Hz

230 V AC

220 V AC

50/60 Hz

e

f

––

+

PS OUT

+

230V

50/60Hz

230 V AC

220 V AC

50/60 Hz

Turn the PS2 switch on when the

second VX-200PS unit is connected,

and the PS3 switch on when the

third unit is connected.

VX-200PS

c

d

––

PS OUT

+

+

230V

50/60Hz

230 V AC

220 V AC

50/60 Hz

Cable:

AWG 14 – AWG 10

(line resistance within

10 mΩ/pair)

a

b

––

+

PS OUT

+

VX-2000DS

230V

50/60Hz 240W

230 V AC

220 V AC

50/60 Hz

Cat. 5 STP

To VX-2000SF

DS–SF LINK 1, 2 connectors

Lead-acid

Battery

DETECT(VX-200PS)

PS3 PS2

OFFONON OFF

THERMISTOR

DS – SFFUSE

LINK

BATTERY POWER IN

24V MAX150A

( ) ( )

Lead-acid

Battery

DC POWER OUT (+) MAX 25A (DC 20V-40V)

( )

To DC inputs of the following units.

VX-2000/2000SF, VP-2064/2122/2241/2421

Cable:

AWG 6 – AWG 0 (1/0)

PS IN (+) MAX 25A (DC20V-40V)

615432615432

e

c

d

f

(–)

PS IN

1,2:PS1

3,4:PS2

5,6:PS3

a

b

RJ45 male connector

Caution

The charging current from VX-2000DS is 5 A maximum.

Applicable Batteries: Panasonic LC-X1265PG/APG

Page 17

17

4.2. Connecting the VX-2000DS to VX-2000 System

VX-2000

DATA LINK

a

From VX-2000DS

From VX-2000DS

From VX-2000DS

(+)

(–)

(+)

(–)

(+)

(–)

b

DC POWER IN

VX-2000SF

1

DS-SF

LINK

2

a

b

DC POWER IN

VP-2064, VP-2122, VP-2241, or VP-2421

DC POWER IN

28 V 4.8 A

a

b

CH4

CH

PA OUT (SP LINE)

CH3

CH

CH2

CH

CH1

CH

AUDIO LINK

OUT

CH3 CH1

CH4 CH2

From VX-2000DS

(+)

(–)

VP-2064, VP-2122, VP-2241, or VP-2421

DC POWER IN

28 V 4.8 A

CH4

CH

PA OUT (SP LINE)

CH3

CH

CH2

CH

CH1

CH

a

b

VX-2000DS (No. 1)

DS – SF

LINK

Cat. 5 STP

VX-2000DS (No. 2)

DS – SF

LINK

DC power

output terminals

(–)

CH3 CH1

CH4 CH2

a

DC POWER OUT (+) MAX 25A (DC 20V-40V)

615432615432

( )

b

PS IN (+) MAX 25A (DC20V-40V)

PS IN

1,2:PS1

3,4:PS2

5,6:PS3

Cat. 5 STP

RJ45 male connector

Page 18

18

5.1. Connections between VX-2000DS and VX-200PS

5. CONNECTIONS WHEN USING WITH THE SX-2000 SYSTEM

(–)

DETECT(VX-200PS)

PS3

PS2

OFFONON OFF

e

f

VX-200PS VX-200PSVX-200PS

PS OUT

+

+

230V

50/60Hz

230 V AC

220 V AC

50/60 Hz

230V

50/60Hz

230 V AC

220 V AC

50/60 Hz

––

Turn the PS2 switch on when the

second VX-200PS unit is connected,

and the PS3 switch on when the

third unit is connected.

c

d

––

PS OUT

+

+

230V

50/60Hz

230 V AC

220 V AC

50/60 Hz

Cable:

AWG 14 – AWG 10

(line resistance within

10 mΩ/pair)

a

b

––

+

PS OUT

+

VX-2000DS

230V

50/60Hz 240W

230 V AC

220 V AC

50/60 Hz

Cat. 5 STP

To SX-2000SM or SX-2100AO

DS LINK 1, 2 connectors

Lead-acid

Battery

Caution

The charging current from VX-2000DS is 5 A maximum.

Applicable Batteries: Panasonic LC-X1265PG/APG

DETECT(VX-200PS)

PS3 PS2

OFFONON OFF

THERMISTOR

DS – SFFUSE

LINK

BATTERY POWER IN

24V MAX150A

( ) ( )

Lead-acid

Battery

DC POWER OUT (+) MAX 25A (DC 20V-40V)

( )

To DC inputs of the following units.

SX-2000SM/2100AI/2000AO/2100AO

/2000CI/2000CO,

VP-2064/2122/2241/2421

Cable:

AWG 6 – AWG 0 (1/0)

PS IN (+) MAX 25A (DC20V-40V)

615432615432

e

c

d

f

(–)

PS IN

1,2:PS1

3,4:PS2

5,6:PS3

a

b

RJ45 male connector

Page 19

19

5.2. Connecting the VX-2000DS to SX-2000 System

[When using a redundant power system*]

In this connection example, 2 power supply units are used. Even if one of the 2 units fails or its power supply

line is broken, power is still supplied from the other unit, preventing the system from going down.

* A method of connecting separate power sources to each power input or connecting the commercial power

supply and backup power supply separately to each power input to prevent the system from going down

when a cable is broken or power fails.

4P removable terminal plug

(supplied with the SX-2000SM, SX-2100AI, SX-2000AO

SX-2100AO, SX-2000CI, and SX-2000CO)

(DC power input terminal)

Cable: AWG 18 – AWG 14

VX-2000DS

230V

50/60Hz 240W

DETECT(VX-200PS)

PS3 PS2

THERMISTOR

DS– SFFUSE

LINK

SX-2100AO or SX-2000AO

(The figure below shows the SX-2100AO.)

(DC power input terminal)

SX-2000SM

SX-2100AI

SX-2000CI

SX-2000CO

Power line B (+)

DC POWER OUT (+) MAX 25A (DC 20V-40V)

BATTERY POWER IN

24V MAX150A

( ) ( )

OFFONON OFF

DC POWER OUT (+) MAX 25A (DC 20V-40V)

PS IN (+) MAX 25A (DC20V-40V)

615432615432

( )

PS IN (+) MAX 25A (DC20V-40V)

615432615432

PS IN

1,2:PS1

3,4:PS2

5,6:PS3

( )

VX-2000DS

DETECT(VX-200PS)

230V

50/60Hz 240W

PS3 PS2

THERMISTOR

Power line B (–)

Power line A (+)

DC POWER OUT (+) MAX 25A (DC 20V-40V)

BATTERY POWER IN

24V MAX150A

( ) ( )

OFFONON OFF

DS– SFFUSE

LINK

DC POWER OUT (+) MAX 25A (DC 20V-40V)

PS IN (+) MAX 25A (DC20V-40V)

615432615432

( )

PS IN (+) MAX 25A (DC20V-40V)

615432615432

PS IN

1,2:PS1

3,4:PS2

5,6:PS3

( )

Power line A (–)

Page 20

20

[When not using a redundant power system]

Required power is supplied to the system from a single power supply unit. Connect the [+] terminal of Input A

to the [+] terminal of Input B, and the [–] terminal of Input A to the [–] terminal of Input B.

Note

When connecting 2 power cables to a single terminal of the removable

terminal plug, use a ferrule terminal with an insulation sleeve to crimp the

cables because such cable conductors could become loose.

Recommended "Phoenix Contact" ferrule terminals for power supply

cables

Crimping tool: CRIMPFOX UD6-4 (made by Phoenix Contact)

4P removable terminal plug

(supplied with the SX-2000SM, SX-2100AI,SX-2000AO,

SX-2100AO, SX-2000CI, and SX-2000CO)

(DC power input terminal) (DC power input terminal)

Cable: AWG 18 – AWG 14

DC POWER OUT (+) MAX 25A (DC 20V-40V)

SX-2100AO or SX-2000AO

(The figure below shows the SX-2100AO.)

SX-2000SM

SX-2100AI

SX-2000CI

SX-2000CO

PS IN (+) MAX 25A (DC20V-40V)

615432615432

VX-2000DS

230V

50/60Hz 240W

DETECT(VX-200PS)

PS3 PS2

THERMISTOR

DS – SFFUSE

LINK

BATTERY POWER IN

24V MAX150A

OFFONON OFF

( ) ( )

DC POWER OUT (+) MAX 25A (DC 20V-40V)

DC POWER IN

28 V 4.8 A

PS IN (+) MAX 25A (DC20V-40V)

615432615432

( )

VP-2064, VP-2122, VP-2241, or VP-2421

Model Number a

AI 1,5-8 BK

a

3.4 mm

1

AI-TWIN 2 x 1,5-8 BK 6.6 mm

2

a

3.6 mm

b

1.8 mm

1

l

14 mm

16 mm2.3 mm

2

l

8 mm

8 mm

PS IN

1,2:PS1

3,4:PS2

5,6:PS3

( )

DC POWER IN

28 V 4.8 A

PA OUT (SP LINE)

CH

CH1CHCH2CHCH3CHCH4

CH3 CH1

CH4 CH2

Insulation sleeve

Contact section

a

2

l

1

l

bb

Insulation sleeve

1

a

Contact section

2

a

2

l

1

l

Page 21

21

5.3. DS Link Terminal Connections

Connect the DS-SF LINK terminal of the VX-2000DS to the DS Link terminal of the SX-2000SM or SX2100AO. The figure below shows a connection example when the VX-2000DS units are connected to the SX2100AO. This connection also applies to the SX-2000SM.

SX-2100AO

VX-2000DS (No. 1)

230V

50/60Hz 240W

T3.15A L

Control connector

VX-2000DS (No. 2)

230V

50/60Hz 240W

T3.15A L

DETECT(VX-200PS)

PS3 PS2

OFFONON OFF

THERMISTOR

DS – SF

LINK

DS – SFFUSE

DS – SF

LINK SETTING

DETECT(VX-200PS)

PS3 PS2

OFFONON OFF

THERMISTOR

DS – SF

LINK

DS – SFFUSE

DS – SF

LINK SETTING

DCAC

DCAC

BATTERY POWER IN

24V MAX150A

( ) ( )

BATTERY POWER IN

24V MAX150A

( ) ( )

DS Link Terminals

DC POWER OUT (+) MAX 25A (DC 20V-40V)

( )

DC POWER OUT (+) MAX 25A (DC 20V-40V)

( )

PS IN (+) MAX 25A (DC20V-40V)

615432615432

PS IN (+) MAX 25A (DC20V-40V)

615432615432

Applicable cable: Cat. 5 STP

(Category 5 shielded twisted pair cable)

PS IN

1,2:PS1

3,4:PS2

5,6:PS3

PS IN

1,2:PS1

3,4:PS2

5,6:PS3

Control connector

Page 22

22

6. CONNECTIONS WHEN USING WITH THE VM-3000 SYSTEM

230 V AC

220 V AC

50/60 Hz

From VX-2000DS

230 V AC

220 V AC

50/60 Hz

VM-3240VA/3360VA

VP-2241

(+)

c

(–)

d

VM-3240E/3360E

DC POWER IN

28 V 4.8 A

(–)(–)(+)(+)

PA OUT (SP LINE)

CH

(–)(–)(+)(+)

Cable: AWG 10 – AWG 8

From VX-2000DS

c

d

d

Note

a

Remove the short bar attached at the factory.

PA LINK VP-200VX

From VX-2000DS

c

d

d

Cable: AWG 10 – AWG 8

b

VP-2241

DC POWER IN

From VX-2000DS

(+)

(–)

28 V 4.8 A

c

d

PA OUT (SP LINE)

CH

See “Note” below.

VX-2000DS

DETECT(VX-200PS)

PS3 PS2

OFFONON OFF

THERMISTOR

DS – SFFUSE

LINK

230 V AC

220 V AC

230V

50/60Hz 240W

50/60 Hz

Cat. 5 STP

Cable:

Caution

AWG 6 – AWG 0 (1/0)

The charging current from the

VX-2000DS is 5 A maximum.

Applicable Batteries:

Panasonic LC-X1265PG/APG

Note

Make PS2 and PS3 switch settings according to the total number of

connected power supply units VX-200PS and VM-3240VA/3360VA

(power supply unit incorporated); set PS2 to ON for 2 units, and PS2

and PS3 to ON for 3 units.

Note that these power supply units should be connected to the PS IN

(+) terminals 1 and 2 for the 1st unit, 3 and 4 for the 2nd unit, and 5

and 6 for the 3rd unit.

Lead-acid Battery

DC power

output terminals

BATTERY POWER IN

24V MAX150A

( ) ( )

c

DC POWER OUT (+) MAX 25A (DC 20V-40V)

( )

(–)

d

Cable:

AWG 14 – AWG 10

(line resistance within

10 mΩ/pair)

230 V AC

220 V AC

50/60 Hz

PA LINK VP-200VX

DC power

a

b

PS IN (+) MAX 25A (DC20V-40V)

615432615432

input terminals

VX-200PS

RJ45 male connector

PS IN

1,2:PS1

3,4:PS2

5,6:PS3

Page 23

23

Below is an example showing that one VX-2000DS is used in a system including 3 VM amplifiers.

Number of VM amplifiers 1 2 3 4 5 6 7 8 9 10

Number of VX-2000DS units 1 2 3 4

[Required number of VX-200PS and VX-2000DS units]

The required number of the VX-2000DS Emergency Power Supply units and VX-200PS Power Supply Units

are determined depending on the application of the system configured with the VM-3240VA, VM-3360VA, VM3240E, and VM-3360E (hereinafter called "VM amplifier"), and/or the VP-2241 and VP-2421 (hereinafter

called "VP amplifier").

•

Required number in a 1-channel broadcasting system

System including VM amplifiers only

One VX-2000DS is required every 3 VM amplifiers. The VX-200PS is not needed in this system.

VM-3240VA

VX-2000DS

Lead-acid Battery

VM LINK

VM-3240E

VM LINK

DS LINK

VM-3240E

DC POWER

Page 24

24

System including one VP amplifier connected as a standby amplifier

One VX-2000DS is required every 3 VM amplifiers.

Note

Connect the VX-200PS to the VX-2000DS to

which the VP amplifier is connected.

Number of VM amplifiers 1 2 3 4 5 6 7 8 9 10

Number of VX-2000DS units 1 2 3 4

Number of VX-200PS units 0 1

Below is an example showing that 2 VX-2000DSs and 1 VX-200PS are used in a system including 4 VM

amplifiers.

VM-3240VA

VX-2000DS

Lead-acid Battery

VX-2000DS

Lead-acid Battery

VX-200PS

DS LINK

DC POWER

DS LINK

DC POWER

EXT. AMP

INPUT

EXT. AMP

INPUT

EXT. AMP

INPUT

VM LINK

EXT. PA LINK

DC POWER

VM LINK

VM LINK

EXT. AMP INPUT

PA OUT

VP-2241

PA OUT

VM-3240E

VM-3240E

VM-3240E

Page 25

25

Number of VM amplifiers 1 2 3 4 5 6 7 8 9 10

Number of VX-2000DS units 1 2 3 4 5

Number of VX-200PS units 1 2 3 4 5

Below is an example showing that 2 each of VX-2000DSs and VX-200PSs are used in a system including 3

VM amplifiers.

Notes

•

A pair of the VM amplifier and VP amplifier should be connected to the same VX-2000DS.

•

One VX-200PS should be connected to each VX-2000DS.

•

Required number of VX-2000DS and VX-200PS units in a BGM/Paging system

One each of the VX-2000DS and VX-200PS is required every 2 VM amplifiers.

VM-3240VA

VX-2000DS

Lead-acid Battery

VX-200PS

VX-200PS

DS LINK

DC POWER

VM LINK

EXT. PA LINK

DC POWER

VM LINK

EXT. PA LINK

DC POWER

EXT. AMP INPUT

PA OUT

VM-3240E

EXT. AMP INPUT

PA OUT

VM-3240E

VP-2241

VP-2241

EXT. AMP INPUT

VX-2000DS

Lead-acid Battery

DS LINK

DC POWER

EXT. PA LINK

DC POWER

PA OUT

VP-2241

Page 26

26

[VX-2000DS]

AC IN 3P inlet

–

Supplied cable

–

230 V AC, 50/60 Hz

220 V AC, 50/60 Hz

––

[VX-200PS]

AC IN 3P inlet

–

Supplied cable

–

230 V AC, 50/60 Hz

220 V AC, 50/60 Hz

––

DS-SF LINK RJ45 (female) RJ45 (male) Cat. 5 STP RJ45 (male) VX-2000SF DS-SF LINK RJ45 (female)

BATTERY

POWER IN

Screw terminal

Unprocessed cable

end

AWG 6 – AWG 0 (1/0)

16 – 50 mm

2

(line resistance

within 4 mΩ/total)

Unprocessed cable

end

Lead-acid battery

Electrode

(+, –)

–

PS IN Screw terminal

Round terminal

AWG 14 – AWG 10

2.0 – 5.5 mm

2

(line resistance

within 10 mΩ/pair)

Round terminal

VX-200PS PS OUT Screw terminal

PS OUT Screw terminal

Round terminal

AWG 14 – AWG 10

2.0 – 5.5 mm

2

(line resistance

within 10 mΩ/pair)

Round terminal

VX-2000DS PS IN Screw terminal

DC POWER

OUT

Screw terminal

Round terminal

–

Round terminal

VX-2000

VX-2000SF

VP-2064/2122/2241

/2421

DC POWER

IN

2P screw terminal

Terminal

Name

Equipment

Receptacle

Plug Cable Type Plug Equipment

Terminal

Name

Equipment

Receptacle

Terminal to Connect Cable Type Equipment to be Connected to

Terminal

Name

Equipment

Receptacle

Plug Cable Type Plug Equipment

Terminal

Name

Equipment

Receptacle

Terminal to Connect Cable Type Equipment to be Connected to

DC plug

(Outer diameter:

F5.5 mm

Inner diameter:

F2.1 mm

Length: 9.5 mm)

RM-200X

RM-200SA

RM-200M

DC IN

DC jack

AWG 24 – AWG 12

0.2 – 3.5 mm

2

Unprocessed cable

end

RM-200XF

LINK

(DC Power

In +/)

9P plug-in screw

terminal

7. CABLE USAGE TABLE

AWG 18 – AWG 14

0.8 – 2.0 mm

2

AWG 18 – AWG 14

0.8 – 2.0 mm

2

Round terminal

SX-2000SM

SX-2100AI

SX-2000AO

SX-2100AO

SX-2000CI

SX-2000CO

DC POWER

IN

4P removable

terminal plug

Round terminal

VM-3240VA

VM-3360VA

VM-3240E

VM-3360E

DC POWER

IN

2P screw terminal

AWG 10 – AWG 8

5.5 – 8.0 mm

2

AWG 24 – AWG 12

0.2 – 3.5 mm

2

Round terminal

RM-200SF

RM-300MF

DC IN 24 V Screw terminal

• VX-2000DS

Connector Name

DS-SF Link

'

DS-SF LINK Connections

RJ45 Pin No.

1

2

3

4

5

6

7

8

Shield

Orange/white

Orange

Green/white

Blue

Blue/white

Green

Brown/white

Brown

Shield

Colour Pair Assignment Direction/Level

Connection Check

Battery Failure

Charging Circuitry Failure

Output/0 – 3.3 V

DC Off

AC Off

3.3 V DC Input

Input (DC)/3.3 V

NC

Battery Check Activation

Input/0 – 3.3 V

Chassis GND

Page 27

27

The VX-2000DS can be used with the VM-2000 series system or other systems as a backup power supply

unit which supplies battery power to the system when AC mains fail.

To permit the VX-2000DS operation in this system configuration, shift the VX-2000DS' rear-mounted Setting

switch to the AC position (factory-preset to the DC position).

[Setting and connection example for the VX-2000 system]

8. USING THE VX-2000DS EXCLUSIVELY AS A BACKUP POWER SUPPLY

Note: Internal setting change is required. Leave this work to service personnel. Contact your TOA dealer.

VM-2240

230 V AC

220 V AC

50/60 Hz

230 V AC

220 V AC

50/60 Hz

VX-2000DS

230V

50/60Hz 240W

SETTING

DCAC

Setting switch

To DC (+) inputs of the VM-2000 series

system or other systems

SETTING

BATTERY POWER IN

24V MAX150A

( ) ( )

DETECT(VX-200PS)

PS3 PS2

OFFONON OFF

THERMISTOR

DS – SFFUSE

LINK

Note

Be sure to leave these

terminals unconnected.

PS IN

1,2:PS1

3,4:PS2

5,6:PS3

( )

To DC (–) inputs of the VM-2000 series

system or other systems

Lead-acid

Battery

Lead-acid

Battery

Caution

The charging current from VX-2000DS is 5 A maximum.

Applicable Batteries: Panasonic LC-X1265PG/APG

Page 28

28

When the system power (DC) needs to be switched off in such cases as maintenance or unit configuration

change, shift the Setting switch on the VX-2000DS to the "AC" position following the procedure below.

9. SWITCHING OFF SYSTEM POWER (DC)

Step 1. Terminate all current broadcasts to stop system operation.

Step 2. Shift the Setting switch on the VX-2000DS rear panel to the "AC" position.

Step 3. Stop the AC power supply to the VX-200PS.

This permits the system power to be switched off without switching over to battery operation.

Note

Never stop the AC power supply to the VX-2000DS as doing so causes the system power source to

be maintained by the battery.

[To restore the power supply to the system]

Step 1. Restore the AC power supply to the VX-200PS.

The DC power is supplied from the VX-200PS to the VX-2000DS.

Step 2. Shift the Setting switch on the VX-2000DS rear panel back to the "DC" position.

Step 3. Operate the system normally.

[To switch off the system power]

VX-2000DS

230V

50/60Hz 240W

DETECT(VX-200PS)

PS3 PS2

OFFONON OFF

THERMISTOR

DS – SFFUSE

DS – SF

LINK SETTING

BATTERY POWER IN

24V MAX150A

( ) ( )

DC POWER OUT (+) MAX 25A (DC 20V-40V)

PS IN (+) MAX 25A (DC20V-40V)

615432615432

( )

PS IN

1,2:PS1

3,4:PS2

5,6:PS3

T3.15A L

DCAC

SETTING

DCAC

Setting switch

Page 29

29

10. BLOCK DIAGRAM

Control Connector

[DS-SF LINK]

AC Mains

50/60 Hz

Fuse

250 V AC

T3.15 A L

Voltage

Checker

BATTERY

CONNECT Indicator

MAIN

POWER

Charging

NO

NC

NC

NO

Circuit

Delay

NC

CHARGING

Battery

Check Switch

NO

BATTERY

POWER

Control Circuit

NC

NC

NO

Fuse

7.5 A

DC Detect

NO

NO

NO

NO

NO

NO

Fuse

40 A

Fuse

40 A

Fuse

40 A

Fuse

40 A

Fuse

40 A

Fuse

40 A

DC Input [PS IN]

(150 A max.)

DC Input 1

DC Input 2

DC Input 3

DC Input 4

DC Input 5

DC Input 6

Battery Connection

Terminal

[BATTERY POWER IN]

[DC POWER OUT]

DC Output 1

DC Output 2

DC Output 3

DC Output 4

DC Output 5

DC Output 6

When battery voltage drops

below the reference voltage

BATTERY

CHECK Indicator

CPU

Page 30

30

11. SPECIFICATIONS

11.1. VX-2000DS Emergency Power Supply

230 V AC (ER/UK), 220 – 230 V AC (SA), 50/60 Hz

240 W max.

Panasonic LC-X1265PG/APG (65 Ah)

Trickle charging

5 A max.

27.3 V ±0.3 V (at 25°C)

Temperature correction coefficient: –40 mV/°C

6, M4 screw terminal, distance between barriers: 11 mm

6 (25 A max. each), M4 screw terminal, distance between barriers: 11 mm

RJ45 female connector for connecting the VX-2000SF Surveillance Frame

Twisted-pair straight cable (TIA/EIA-568A standard)

Type of control signal: Battery check, AC power status, DC power status,

charging circuit failure, and battery failure

1 pair of positive and negative terminals

Applicable cable diameter: AWG 6 – AWG 0 (1/0) (Line resistance within

4 mΩ/total)

Cross sectional area: 16 – 50 mm

2

0 to +40°C

Panel: Surface-treated steel plate, black (30% gloss), paint

482 (w) x 88.4 (h) x 377.6 (d) mm

10.5 kg

Power Source

Power Consumption

Applicable Battery

Charging Method

Charging Current

Charging Output Voltage

Power Supply Input

DC Power Output

Control Connector

Battery Connection

Operating Temperature

Finish

Dimensions

Weight

• Accessories

Rack mounting screw (5 x 12) .................... 4

Fiber washer .............................................. 4

Blade fuse (40 A) ....................................... 3

Fuse (T3.15 A L) ........................................ 1

Insulating sheet .......................................... 1

Attention label (German) ............................ 1

Thermal insulating sheet ............................ 1

Power cable (2 m) ...................................... 1

(ER/UK version only)

Fastener hook ............................................ 4

Fastener loop ............................................. 4

Sticker (Declaration of compliance) ........... 1

Note: The design and specifications are subject to change without notice for improvement.

Blade fuse (40 A), Blade fuse (7.5 A), Fuse (7.5 A)

43.5 A

50 mΩ

43.5 A

43.5 A

0 A

Twisted-pair straight cable (TIA/EIA-568A standard)

Fuse ratings

Maximum output current draw from the battery

Maximum internal resistance of the battery and its

associated circuitry, Ri max

Rated maximum continuous output current, I max a

Rated maximum short duration output current, I

max b

Rated minimum output current, I min

Recommended cable parameter for DS-SF Link

Page 31

31

11.3. VX-2000PF Power Supply Frame

Panel: Surface treated steel plate, black (30% gloss), paint

483 (w) x 132.6 (h) x 324.8 (d) mm

5.5 kg

Side Panel ..... 2, Front panel .....1, Chassis ..... 1, Fixing bracket* ..... 1

VX-200PS (up to 3)

Finish

Dimensions

Weight

Product Composition

Usable Unit

• Accessories

Self-tapping screw (4 x 10) ...................... 16

Machine screw M3 x 6 ............................... 4

Rack mounting screw (5 x 12) .................... 4

Fiber washer .............................................. 4

11.2. VX-200PS Power Supply Unit

230 V AC (ER/UK), 220 – 230 V AC (SA), 50/60 Hz

580 W

Rated output: 210 W (29 V, 7.25 A) x 2

Peak output: 400 W x 2

M4 screw terminal, distance between barriers: 11 mm

Applicable cable diameter: AWG 14 – AWG 10 (line resistance within

10 mΩ/pair)

Cross sectional area: 2.0 – 5.5 mm

2

Max. 4 V

0 to +40°C

VX-2000PF

Surface-treated steel plate

135 (w) x 118.2 (h) x 333.8 (d) mm

13.2 kg

Power Source

Power Consumption

DC Power Output

Ripple Voltage at Imax B

(at VX-2000DS's DC Output)

Operating Temperature

Applicable Frame

Finish

Dimensions

Weight

• Accessories

Fuse (T3.15 A L) ........................................ 1

Power cable (2 m) ...................................... 1

Note: The design and specifications are subject to change without notice for improvement.

* The Fixing bracket is not supplied with the previous VX-2000PF. (Refer to p. 9, "Installation Precautions.")

Note: The design and specifications are subject to change without notice for improvement.

Page 32

133-02-00147-00

URL: http://www.toa.jp/

Traceability Information for Europe

Manufacturer:

TOA Corporation

7-2-1, Minatojima-Nakamachi, Chuo-ku, Kobe, Hyogo,

Japan

Authorized representative:

TOA Electronics Europe GmbH

Suederstrasse 282, 20537 Hamburg,

Germany

Loading...

Loading...