Page 1

INSTALLATION MANUAL

MATRIX SYSTEM SX-2000 SERIES

When an EN 54-16 compliant SX-2000 system has to be installed, then read "APPENDIX: ADDITIONAL

INSTALLATION INSTRUCTIONS FOR AN EN 54-16 COMPLIANT SYSTEM" in this document carefully

and follow up the installation and configuration requirements explained herein. This APPENDIX contains

the basic description of settings and installations, so please refer to the general instruction sections in

this document for more details.

Note

Refer to the Instruction Manual attached to the VX-2000DS for the installation of the the VX-2000DS

Emergency power supply, the VX-2000PF Power supply frame, and the VX-200PS Power supply unit.

Thank you for purchasing TOA's Matrix System.

Please carefully follow the instructions in this manual to ensure long, trouble-free use of your equipment.

1134

TOA Electronics Europe GmbH

Suederstrasse 282, 20537 Hamburg, Germany

The year when the CE mark was affixed on the product

is indicated by the first two digits of the serial number.

1134-CPD-102

EN 54-16: 2008

Fire detection and fire alarm systems

— Part 16: Voice alarm control and indicating equipment

Options:

Emergency microphone(s)

Manual reset of the voice alarm condition

Indication of faults related to voice alarm zones

Phased evacuation

Voice alarm condition output to CIE

Redundant power amplifiers

Page 2

2

TABLE OF CONTENTS

1. NOMENCLATURE AND FUNCTIONS

1.1. SX-2000SM System Manager .................................................................................. 6

1.2. SX-2000AI Audio Input Unit ................................................................................... 10

1.3. SX-2100AI Audio Input Unit ................................................................................... 15

1.4. SX-2000AO Audio Output Unit ............................................................................... 20

1.5. SX-2100AO Audio Output Unit ............................................................................... 26

1.6. SX-2000CI Control Input Unit ................................................................................. 32

1.7. SX-2000CO Control Output Unit ............................................................................ 34

1.8. RM-200SF Fireman's Microphone ......................................................................... 36

1.9. RM-200SA Remote Microphone ............................................................................ 39

1.10. RM-210 Remote Microphone Extension ................................................................ 42

1.11. RM-200RJ Terminal Unit ........................................................................................ 43

1.12. Optional Modules

1.12.1. SX-200RM Remote Microphone Interface Module .................................... 44

1.12.2. D-921E Microphone/Line Input Module ...................................................... 45

1.12.3. D-921F Microphone/Line Input Module ...................................................... 45

1.12.4. D-922E Microphone/Line Input Module ...................................................... 46

1.12.5. D-922F Microphone/Line Input Module ...................................................... 46

1.12.6. D-936R Stereo Input Module ..................................................................... 47

1.13. VP-2064, VP-2122, VP-2241, and VP-2421 Power Amplifiers .............................. 48

1.14. VP-200VX Power Amplifier Input Module ............................................................... 48

2. INSTALLATION

2.1. SX-2000SM

2.1.1. System reset enable/disable settings (DIP switch 3 operation) ................... 49

2.1.2. Failure reset operation method settings (DIP switch 4 operation) ............... 50

2.2. SX-2000AI and SX-2100AI

2.2.1. Module installation ....................................................................................... 51

2.2.2. Setting the device number ........................................................................... 52

2.2.3. Changing the type of control outputs (SX-2100AI only) ............................... 53

2.3. SX-2000AO and SX-2100AO

2.3.1. Setting the device number ........................................................................... 55

2.3.2. 24 V Emergency cutoff input settings (DIP switch 8 operation)

(SX-2000AO only) ........................................................................................ 56

2.3.3. Converting an output into a transformer-balanced output

(SX-2000AO only) ........................................................................................ 57

2.3.4. Changing the method of power supply for the control input signal

applied to the Local Audio Control Input Terminal (SX-2100AO only) ......... 60

2.4. SX-2000CO ............................................................................................................ 62

2.5. RM-200SF, RM-200SA, and RM-210

2.5.1. RM-200SF and RM-200SA device number settings

(DIP switches 1 – 3 operation) ..................................................................... 64

2.5.2. Adjusting microphone sensitivity (RM-200SF: DIP switch 5 operation

or RM-200SA: DIP switch 4 operation) ........................................................ 66

2.5.3. CPU OFF function (general urgency all-call) settings

(RM-200SF:DIP switch 6 operation or RM-200SA: DIP switch 5 operation)

..... 68

2.5.4. RM Communication function setting

(RM-200SF: DIP switch 4 operation or RM-200SA: DIP switch 6 operation)

.... 69

2.5.5. Using an external microphone (RM-200SA only) ......................................... 70

2.5.6. Compressor function setting ........................................................................ 72

2.5.7. Microphone fault detection function settings (RM-200SA only) ................... 74

Page 3

3

2.5.8. Installing the RM-200SF on a wall ............................................................... 75

2.5.9. RM-200SA expansion with the addition of the RM-210

(Installed on a flat surface) ........................................................................... 79

2.5.10. Installing the RM-200SA on a wall ............................................................. 80

2.5.11. Installing the RM-210 on a wall .................................................................. 81

2.5.12. Creating remote microphone name labels ................................................. 83

2.6. VP-2064, VP-2122, VP-2241 and VP-2421 Power Amplifiers

2.6.1. Removing the VP Power Amplifier's top panel ............................................. 87

2.6.2. Changing the speaker line voltage ............................................................... 87

2.6.3. Installing the VP-200VX Power Amplifier Input Module

in the VP Power Amplifiers ........................................................................... 89

2.6.4. Ground lifting using the VP-200VX Power Amplifier Input Module .............. 91

2.6.5. Replacing the blade fuse .............................................................................. 92

2.7. Rack Mounting ....................................................................................................... 93

3. SYSTEM CONFIGURATION EXAMPLE

3.1. System Configuration Example 1 ........................................................................... 94

3.2. System Configuration Example 2 ........................................................................... 95

4. CONNECTIONS

4.1. Removable Terminal Plug Connection ................................................................... 96

4.2. Input Equipment Connections

4.2.1. Connections of SX-2100AO's Local audio control input terminals ............... 97

4.2.2. Connecting the SX-200RM to the RM-200SF or RM-200SA

(via RM-200RJ as needed) .......................................................................... 99

4.2.3. Connecting other input equipment ............................................................. 104

4.3. Output Equipment Connections

4.3.1. Connecting the SX-2000AO to power amplifiers ........................................ 106

4.3.2. Connecting the SX-2100AO to power amplifiers and speakers ................. 107

4.3.3. Connecting the SX-2100AO to external attenuators .................................. 108

4.3.4. Connecting the SX-2100AO to standby amplifiers ..................................... 109

4.4. Control Input/Output Connections

4.4.1. SX-2000SM ................................................................................................ 110

4.4.2. SX-2100AI .................................................................................................. 112

4.4.3. SX-2000AO and SX-2100AO ..................................................................... 115

4.4.4. SX-2000CI .................................................................................................. 118

4.4.5. SX-2000CO ................................................................................................ 119

4.5. SX Link Terminal Connections ............................................................................. 120

4.5.1. Redundant configuration of switching hubs ............................................... 121

4.5.2. Non-redundant configuration of switching hubs ......................................... 122

4.6. CI/CO Link Terminal Connections

4.6.1. Connecting a single SX-2000CI or SX-2000CO ........................................ 123

4.6.2. Connecting one each of SX-2000CI and SX-2000CO ............................... 123

4.7. Analog Link Terminal Connections ...................................................................... 124

4.8. Connections to Use the Surveillance Function

4.8.1. Speaker line surveillance (SX-2100AO only) ............................................. 125

4.8.2. Control line surveillance ............................................................................. 129

5. SPEAKER LINE INITIAL SETTING

5.1. Setting Items ........................................................................................................ 130

5.2. OPEN/SHORT Criterion by Comparing the Current Value

with the Initial Value ............................................................................................. 130

5.3. Setting Procedures

5.3.1. Summary setting procedures ..................................................................... 131

Page 4

4

5.3.2. Screen display (Common) .......................................................................... 133

5.3.3. Impedance initialization setting flow ........................................................... 134

5.3.4. Setting an initial impedance value .............................................................. 135

5.3.5. Adjusting the speaker line's OPEN sensitivity ............................................ 137

5.3.6. Adjusting the speaker line's SHORT sensitivity ......................................... 138

5.3.7. Clearing the settings .................................................................................. 139

6. INSERTING A CF CARD

6.1. Using Settings Data ............................................................................................. 140

6.2. Inserting a CF Card (SX-2000SM: DIP switch 2 operation) ................................. 140

7. TIME SETTINGS ................................................................................................... 141

8. KEY LOCK SETTINGS AND CANCELLATION

8.1. SX-2000AI and SX-2100AI (DIP Switch 1 Operation) .......................................... 142

8.2. SX-2000AO and SX-2100AO (DIP Switch 1 Operation) ...................................... 143

9. OUTPUTTING LOG DATA

(SX-2000SM: DIP Switches 1 and 2 operations)

..................................... 144

10. FAILURE INDICATIONS

10.1. SX-2000SM ........................................................................................................ 145

10.2. SX-2000AI and SX-2100AI ................................................................................ 146

10.3. SX-2000AO and SX-2100AO ............................................................................. 148

10.4. SX-2000CI .......................................................................................................... 149

10.5. SX-2000CO ........................................................................................................ 150

10.6. RM-200SF and RM-200SA ................................................................................ 150

11. SPECIFICATIONS

11.1. SX-2000SM System Manager ............................................................................ 151

11.2. SX-2000AI Audio Input Unit ............................................................................... 153

11.3. SX-2100AI Audio Input Unit ............................................................................... 154

11.4. SX-2000AO Audio Output Unit ........................................................................... 155

11.5. SX-2100AO Audio Output Unit ........................................................................... 156

11.6. SX-2000CI Control Input Unit ............................................................................. 158

11.7. SX-2000CO Control Output Unit ........................................................................ 159

11.8. RM-200SF Fireman's Microphone ..................................................................... 160

11.9. RM-200SA Remote Microphone ........................................................................ 161

11.10. RM-210 Remote Microphone Extension ............................................................ 162

11.11. RM-200RJ Terminal Unit .................................................................................... 162

11.12. SX-200RM Remote Microphone Interface Module ............................................. 162

11.13. D-921E Microphone/Line Input Module .............................................................. 163

11.14. D-921F Microphone/Line Input Module .............................................................. 163

11.15. D-922E Microphone/Line Input Module .............................................................. 164

11.16. D-922F Microphone/Line Input Module .............................................................. 164

11.17. D-936R Stereo Input Module .............................................................................. 164

11.18. VP-2064 Power Amplifier 4 x 60 W ................................................................... 165

11.19. VP-2122 Power Amplifier 2 x 120 W ................................................................. 166

11.20. VP-2241 Power Amplifier 1 x 240 W ................................................................. 167

11.21. VP-2421 Power Amplifier 1 x 420 W ................................................................. 168

11.22. VP-200VX Power Amplifier Input Module ........................................................... 168

Page 5

5

1. GENERAL INFORMATION

1.1. Terms and Abbreviations ..................................................................................... 169

1.2. Access Levels

1.2.1. Access level 1 ............................................................................................ 169

1.2.2. Access level 2 ............................................................................................ 169

1.2.3. Access level 3 ............................................................................................ 170

1.2.4. Access level 4 ............................................................................................ 170

1.3. Declaration for the VACIE SX-2000 according to EN54-16 §13.1.2 .................... 170

2. INDICATIONS AND CONTROLS IN ACCESS LEVEL 1

2.1. Mandatory Indications and Controls in Access Level 1 ........................................ 171

2.2. Options Requiring Indications and Controls in Access Level 1 ............................ 172

2.3. Examples for the Mandatory Indications and Controls

2.3.1. Minimum configuration ............................................................................... 173

2.3.2. Configuration with indication of faults in VA zones .................................... 174

3. INDICATIONS AND CONTROLS IN ACCESS LEVEL 2

3.1. Mandatory Control in Access Level 2 ................................................................... 175

3.2. Options Requiring Controls in Access Level 2 ..................................................... 176

3.3. Proposal for the Installation and Setting of an Emergency Microphone

3.3.1. Installation place ........................................................................................ 177

3.3.2. Settings ...................................................................................................... 177

3.3.3. Example for a setting on an emergency microphone ................................. 177

4. OVERVIEW OF THE ACCESS LEVEL REQUIREMENTS

FOR THE EQUIPMENT AND RELATED FUNCTIONS

............................ 178

5. POWER SUPPLY .................................................................................................. 178

6. CABINETS .............................................................................................................. 179

7. STANDBY (RESERVE, REDUNDANT) AMPLIFIERS .............................. 179

8. SETTING ON THE SYSTEM MANAGER SX-2000SM ............................. 179

APPENDIX: ADDITIONAL INSTALLATION INSTRUCTIONS

FOR AN EN 54-16 COMPLIANT SYSTEM

Page 6

6

1. NOMENCLATURE AND FUNCTIONS

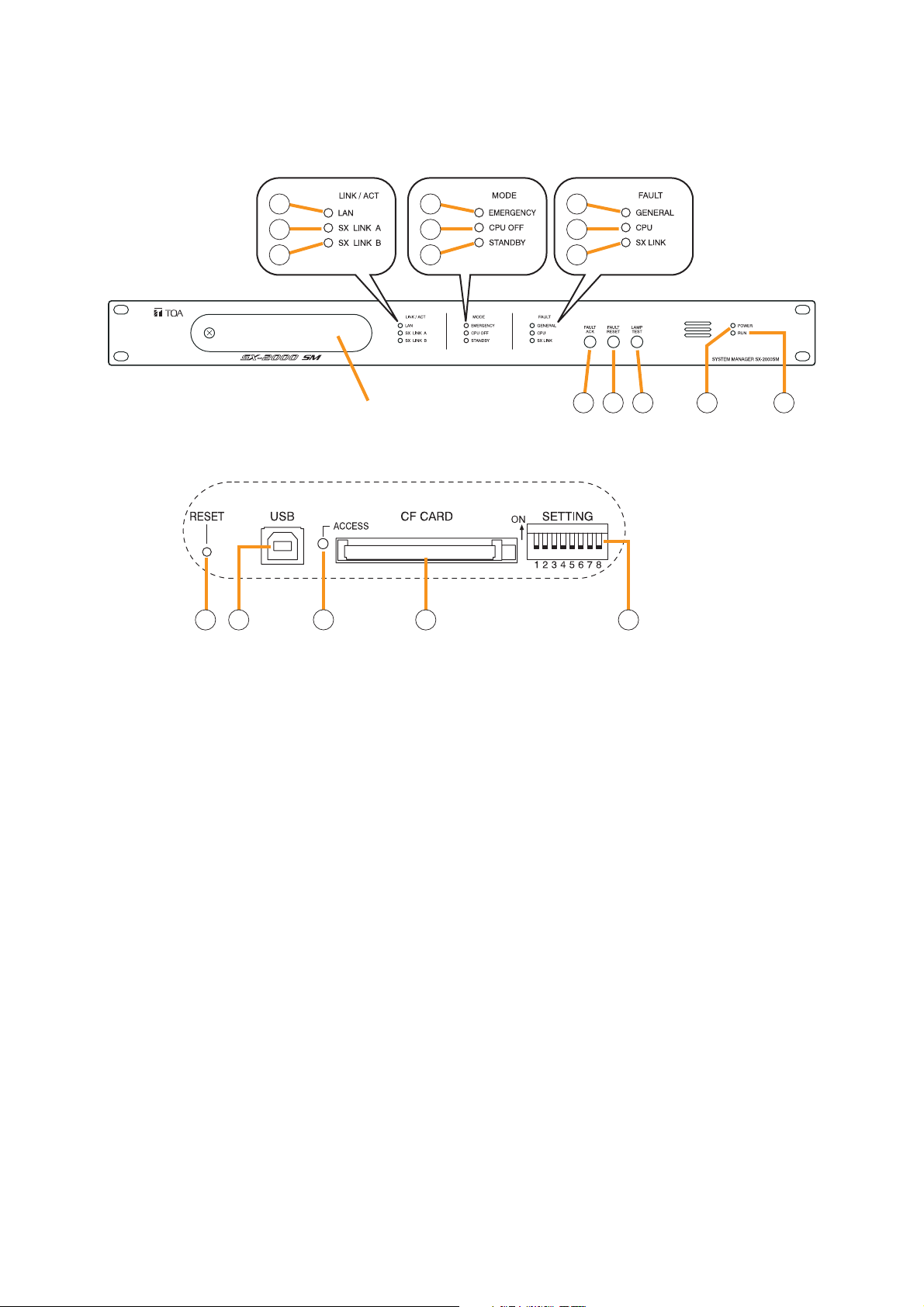

1.1. SX-2000SM System Manager

[Front]

1. LAN Indicator [LAN] (Green)

Lights when the LAN connection terminal (31) on

the rear panel is connected, and flashes during

LAN communications.

2. SX Link A Indicator [SX LINK A] (Green)

Lights when the SX Link A terminal (29) on the

rear panel is connected, and flashes while

communications are being performed via the SX

Link A terminal.

3. SX Link B Indicator [SX LINK B] (Green)

Lights when the SX Link B terminal (29) on the

rear panel is connected, and flashes while

communications are being performed via the SX

Link B terminal.

4. Emergency Indicator [EMERGENCY] (Red)

Lights while the general urgency all-call is being

made (p. 68) or when the SX-2000 system is in an

emergency condition, and flashes when a 24 V

emergency cutoff* state occurs involving any SX2000AO within the system.

* In the SX-2000 system, a 24 V emergency cutoff

input terminal that allows control of an

emergency audio input is provided on the SX2000AO's rear panel. When the SX-2000 system

is combined with another emergency broadcast

system, a 24 V DC is normally kept being

supplied to this emergency cutoff input terminal

and is cut off (24 V emergency cutoff function) in

emergency situations. This interrupts the

general-purpose broadcast from the SX-2000,

allowing the emergency broadcast system to

override it. (For details, see p. 56.)

5. CPU OFF Indicator [CPU OFF] (Red)

Lights while the general urgency all-call (CPU

OFF state) is being made (p. 68).

6. Standby Indicator [STANDBY] (Yellow)

Lights when the SX-2000 system is operating on

the backup power supply during power failures.

It also lights when the system reset cannot be

performed using the SX-2000 Setting software.

Note that if the standby indicator lights, it is not

possible to restart your SX-2000SM using the

Setting software.

To perform system reset, press the Reset key (15)

inside the protective cover to restart.

7. General Indicator [GENERAL] (Yellow)

Lights while the general urgency all-call is being

made (p. 68) or when a failure is detected in the

SX-2000SM. Lights or flashes when a failure is

detected in the system.

SX-2000SM

1

2

3

Inside of the protective cover

15 16 18 1917

4

5

6

Protective cover

7

8

9

10 11 12 13 14

Page 7

7

8. CPU Indicator [CPU] (Yellow)

Lights while the general urgency all-call is being

made (p. 68) or when a failure is detected in the

SX-2000SM.

9. SX Link Indicator [SX LINK] (Yellow)

Flashes when a cable is connected to neither the

rear panel-mounted SX Link terminal A nor B.

10. Fault Ack Key [FAULT ACK]

The buzzer will sound when a failure is detected

in the SX-2000 system. Press this key to stop the

buzzer.

11. Fault Reset Key [FAULT RESET]

Pressing this key resets the failure information

(the buzzer and fault indicators) for the entire

SX-2000 system.

Set the mode for operation method using DIP

switch 4 (19).

12. Lamp Test Key [LAMP TEST]

Used to test each indicator on the front panel of

the SX-2000SM.

All Mode and Fault indicators (4) – (9) remain lit

and the buzzer sounds as long as this key is

pressed.

13. Power Indicator [POWER] (Blue)

Lights when the power is switched on.

14. RUN Indicator [RUN] (Green)

Normally flashes continuously.

Goes off while the general urgency all-call is

being made (p. 68).

15. Reset Key [RESET]

Pressing this key reactivates the SX-2000SM.

The entire system, including the SX-2000AI, SX2100AI, SX-2000AO, and SX-2100AO is

reactivated.

Notes

• Reactivating the system stops broadcasts

currently in progress.

• Do not keep pressing the key for over 1

second. The unit cannot operate.

If the unit operation is suspended, press the

Reset key for less than one second again.

16. USB Port [USB]

This port is not used.

17. CF Card Access Indicator [ACCESS] (Green)

Flashes while reading from or writing to a CF

card.

Note

Do not remove and reinsert the CF card nor

operate the DIP switch (19) while this indicator is

flashing.

18. CF Card Slot [CF CARD]

Use this slot to insert the CF card to operate

settings data or write log data to the card.

• For settings data operation, see p. 140.

• For the method of writing log data, see p. 144.

Note

Removing and reinserting the CF card requires

DIP switch settings. If the CF card is removed

and reinserted without performing correct DIP

switch settings, this may cause settings data loss

or damage the card.

19. DIP Switch [SETTING]

• Switch 1

Used to read log data (p. 144).

ON: Allows log data to be written into the CF

card.

OFF: Normally select this position.

• Switch 2

Used to perform CF card access settings

(p. 140).

ON: Stops access to the CF card.

OFF: Normally select this position.

• Switch 3

Set whether or not to enable online control

using the SX-2000 Setting Software (p. 49).

ON: Disables online writing of settings data

and system reset.

OFF: Normally select this position.

• Switch 4

Set the method of operation to reset the failure

information (the buzzer and fault indicators)

with the FAULT RESET key (11) (p. 50).

In the same manner as the FAULT RESET key

operation, the failure information can also be

reset by shorting the RES terminals of the Data

input terminals (26) at the timing set here.

ON: Sets to the accidental operation

prevention mode.

OFF: Sets to the one touch mode.

(For the operation methods in each individual

mode, see the separate Operating Instructions,

"Detecting Fault.")

• Switches 5 – 8

These switches are not used.

Note

Switches 1 – 8 are set to the OFF position by

default.

SX-2000SM

Page 8

8

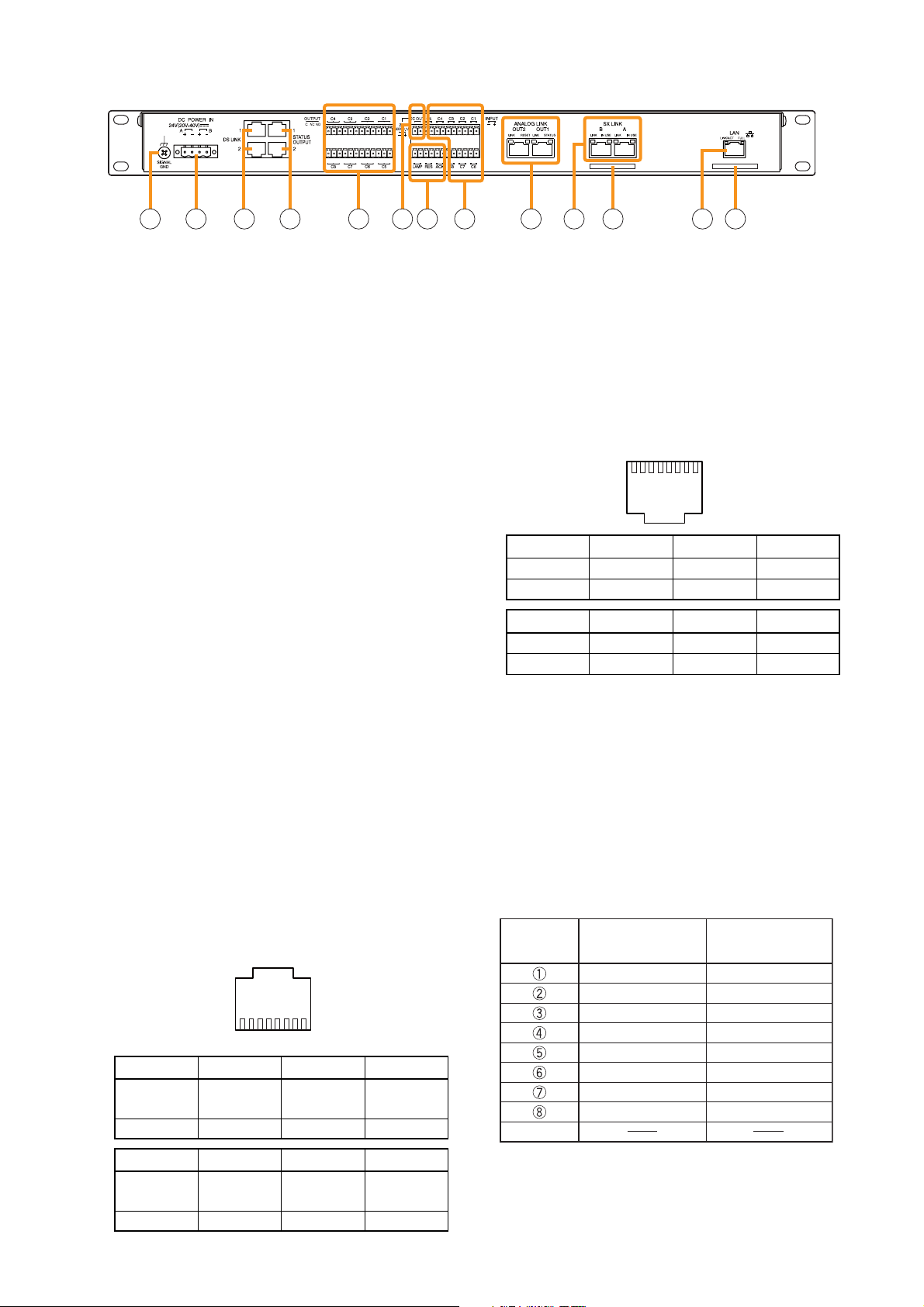

[Rear]

20. Functional Earth Terminal [SIGNAL GND]

Hum noise may be generated when external

equipment is connected to the unit. Connecting

this terminal to the functional earth terminal of

the external equipment may reduce the hum

noise.

Note: This terminal is not for protective earth.

21. DC Power Input Terminal [DC POWER IN]

Connect an optional DC power supply unit to this

terminal. Select the DC power supply source with

consideration given to the current power

consumption of the system the SX-2000SM is to

be connected to. When not using a redundant

power system*, connect the [+] terminal of input

A to the [+] terminal of input B, and the [–]

terminal of input A to the [–] terminal of input B.

(

Refer to the Instruction Manual attached to the

VX-2000DS.

)

* A method of connecting separate power

sources to each power input or connecting the

commercial power supply and backup power

supply separately to each power input to

prevent the system from going down when a

cable is broken or power fails.

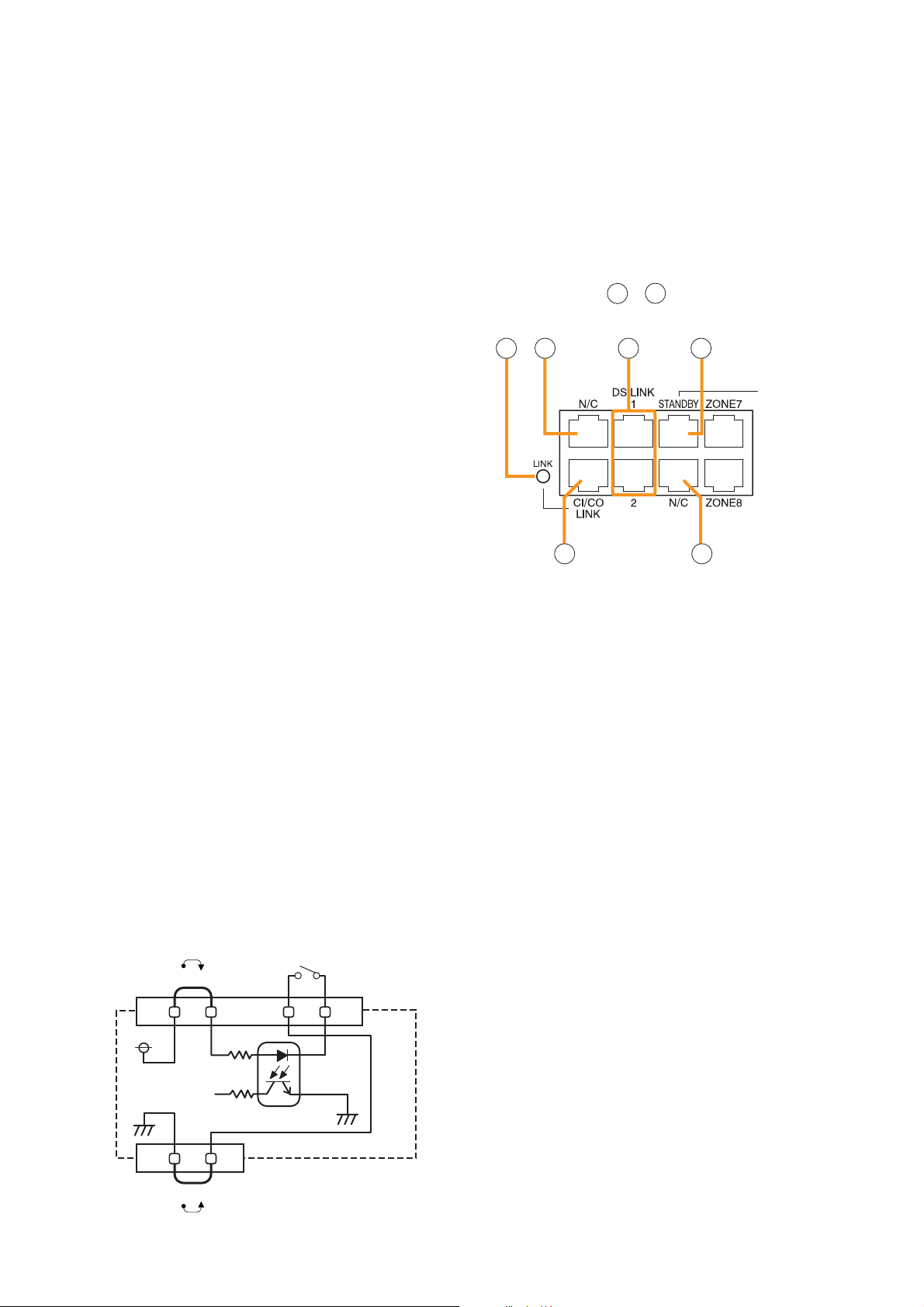

22. DS Link Terminals [DS LINK]

Connect either terminal to the DS-SF Link

terminal of the VX-2000DS.

23. Status Output Terminals [STATUS OUTPUT]

Relay make contact outputs. Each contact

capacity is rated at 40 V DC for withstand

voltage, and 2 mA – 300 mA for control current.

The number of outputs is 4. The RJ45

connector's pin arrangement is as follows:

[Upper row]

• CPU FAULT

CPU irregularity in progress:

Pin 1 – Pin 2 shorted

Normal: Pin 1 – Pin 3 shorted

• GENERAL FAULT

Some irregularity in progress:

Pin 5 – Pin 7 shorted

Normal: Pin 5 – Pin 8 shorted

[Lower row]

• BUZZER

Buzzer ON: Pin 1 – Pin 2 shorted

Buzzer OFF: Pin 1 – Pin 3 shorted

• CPU OFF

Remote microphone-initiated general urgency

all-call broadcasts in progress:

Pin 5 – Pin 7 shorted.

General urgency all-call broadcasts not initiated:

Pin 5 – Pin 8 shorted.

[RJ45 connector's pin No. vs. Cable color]

24. Control Output Terminals [OUTPUT C1 – C8]

Relay make contact outputs. Each contact

capacity is rated at 40 V DC for withstand

voltage, and 2 mA – 300 mA for control current.

Pin 8 Pin 7 Pin 6 Pin 5

GENERAL GENERAL Not used GENERAL

FAULT FAULT FAULT

NC NO COM

Pin 4 Pin 3 Pin 2 Pin 1

Not used CPU CPU CPU

FAULT FAULT FAULT

NC NO COM

Pin 5 Pin 6 Pin 7 Pin 8

CPU OFF Not used CPU OFF CPU OFF

COM NO NC

Pin 1 Pin 2 Pin 3 Pin 4

BUZZER BUZZER BUZZER Not used

COM NO NC

SX-2000SM

21 22 23 24 25 26 27 28 29 30 31 3220

112345678

87654321

2

RJ45's

pin No.

Shield

Cable color Cable color

(T568B type) (T568A type)

Orange/White

Orange

Green/White

Blue

Blue/White

Green

Brown/White

Brown

Green/White

Green

Orange/White

Blue

Blue/White

Orange

Brown/White

Brown

Page 9

9

These terminals are controlled by the SX-2000

Setting Software. (See the separate Setting

Software Instructions, "Pattern Settings.")

25. 24V DC Output Terminals [DC OUT]

These terminals can provide up to 100 mA of 24

V DC power to connected external equipment.

26. Data Input Terminals [ACK/RES/LAMP]

Photo coupler inputs. A current of approximately

2 mA flows when shorted, and the voltage

becomes approximately 24 V DC when opened.

• ACK

The buzzer may sound when a failure is

detected in the SX-2000SM.

Short the ACK terminals to stop the buzzer.

If a failure occurs while ACK is on, it is

automatically received.

These terminals serve the same function as the

front-mounted FAULT ACK key (10).

• RES

In accordance with the DIP switch 4 (19)

setting, shorting these terminals resets once

the failure information (the buzzer and fault

indicators) of the SX-2000SM.

These terminals serve the same function as the

front-mounted FAULT RESET key (11).

• LAMP

Used to test the indicators on the SX-2000SM's

front panel. All MODE and FAULT indicators (4)

– (9) remain lit and the buzzer sounds as long

as these terminals are set to ON.

27. Control Input Terminals [INPUT C1 – C8]

Photo coupler inputs. A current of approximately

2 mA flows when shorted, and the voltage

becomes approximately 24 V DC when opened.

Functions can be assigned to these terminals

using the SX-2000 Setting Software. (See the

separate Setting Software Instructions, "Event

Settings.")

28. Analog Link Output Terminals

[ANALOG LINK OUT 1/2]

Connect these terminals to the analog link input

terminals of the SX-2000AI, SX-2100AI, SX2000AO, or SX-2100AO.

29. SX Link Terminals [SX LINK A/B]

Use switching hubs to connect between the SX

link terminals of the SX-2000SM, SX-2000AI,

SX-2100AI, SX-2000AO, and SX-2100AO.

Connect each of the SX Links A and B to the same

switching hub*, or to different switching hubs* that

have been connected in star configuration.

Notes

• Be sure to connect both terminals of A and B.

• After connection completion, press the Reset

key to reactivate the SX-2000SM.

* Contact your TOA dealer for more information

on switching hubs.

30. MAC Address for SX Link Connections

MAC address to be used for SX link connection.

31. LAN Connection Terminal [LAN]

Used when setting times to be recorded in

operation logs.

Connect this terminal to a switching hub that

supports the 10BASE-T or 100BASE-TX

standard. Since time settings can also be

performed via a PC, connect the PC to the

switching hub as well.

Notes

• Do not connect the switching hub to the LAN.

• Avoid directly connecting the SX-2000SM to

the PC via a cross cable.

(See the separate Setting Software Instructions

"Basic Settings" for settings related to the SX2000SM's IP address, etc.)

31. MAC Address for LAN Connection

A 12-digit hexadecimal address number peculiar

to and assigned to the network-connected unit.

SX-2000SM

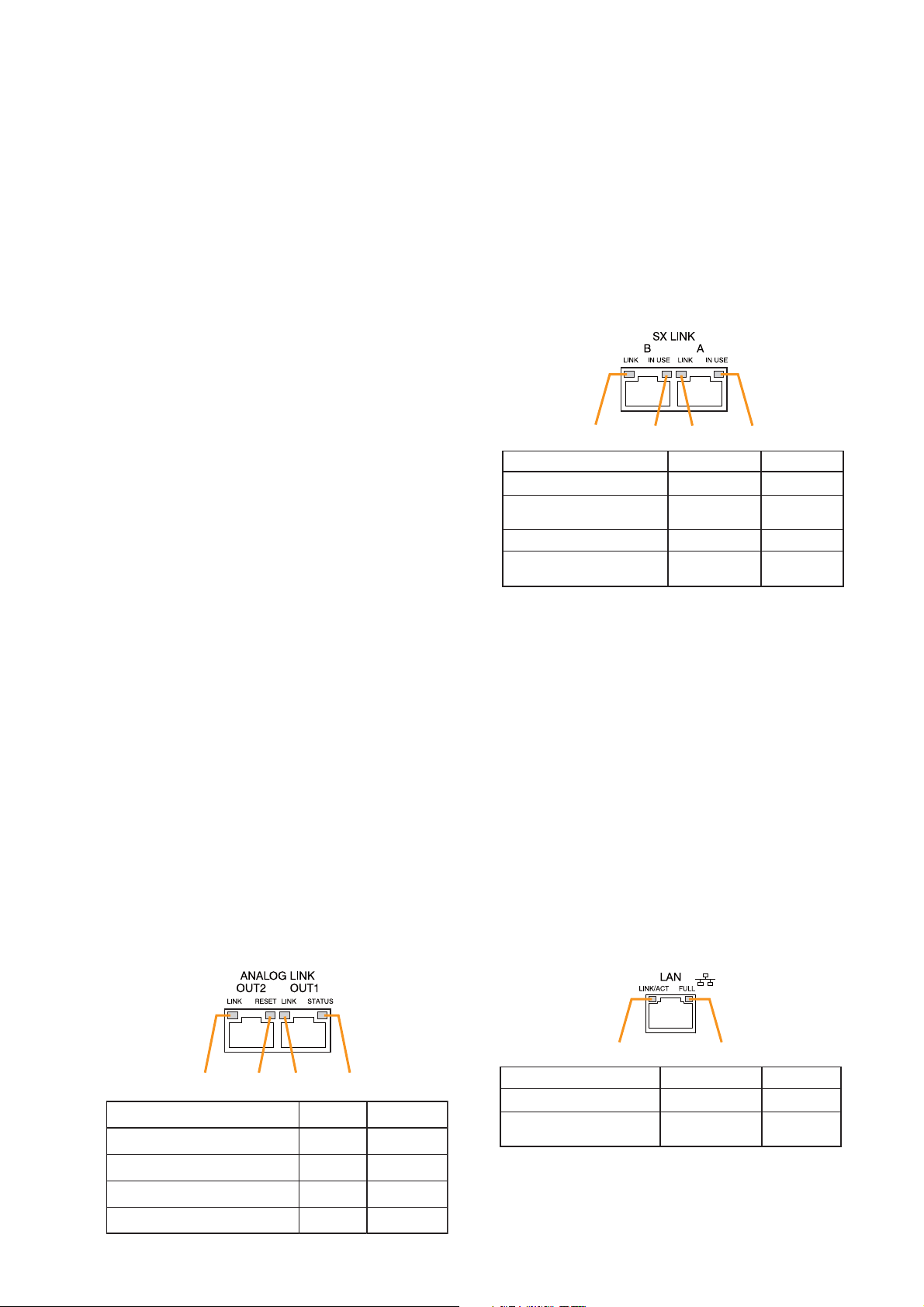

1234

Function

1. B connection confirmation

2. B operation in progress

indication

3. A connection confirmation

4. A operation in progress

indication

LED On/Flashing

Connected

Operating

Connected

Operating

LED Off

Unconnected

Not operating

Unconnected

Not operating

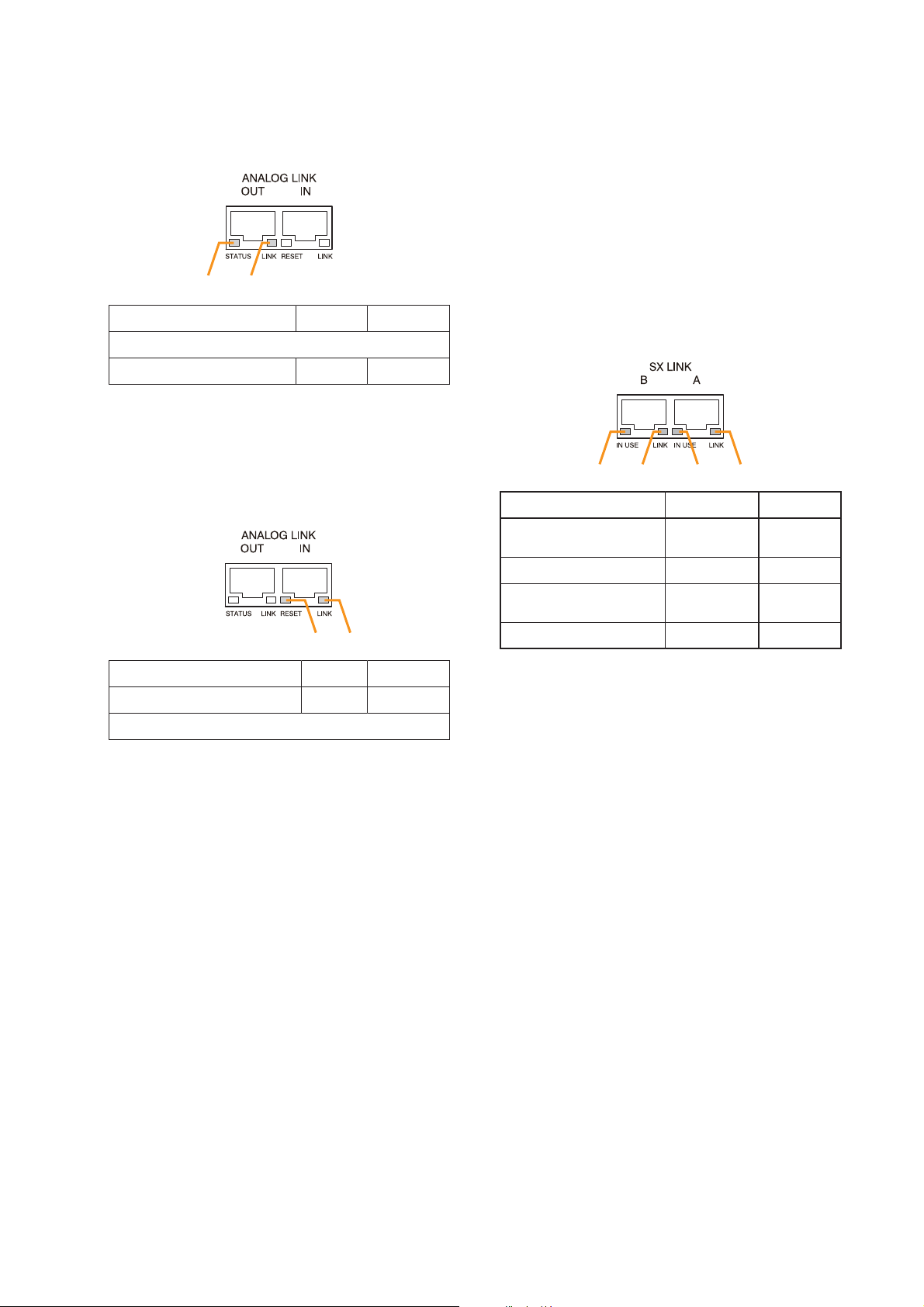

1234

Function LED On LED Off

1. OUT 2 connection confirmation

2. OUT RESET output

3. OUT 1 connection confirmation

4. OUT STANDBY start output

Connected

Resetting

Connected

Start

Unconnected

Normal

Unconnected

Normal

12

Function LED On/Flashing LED Off

1. Connection confirmation

2. Full duplex

communication detection

Connected

Detected

Unconnected

Undetected

Page 10

10

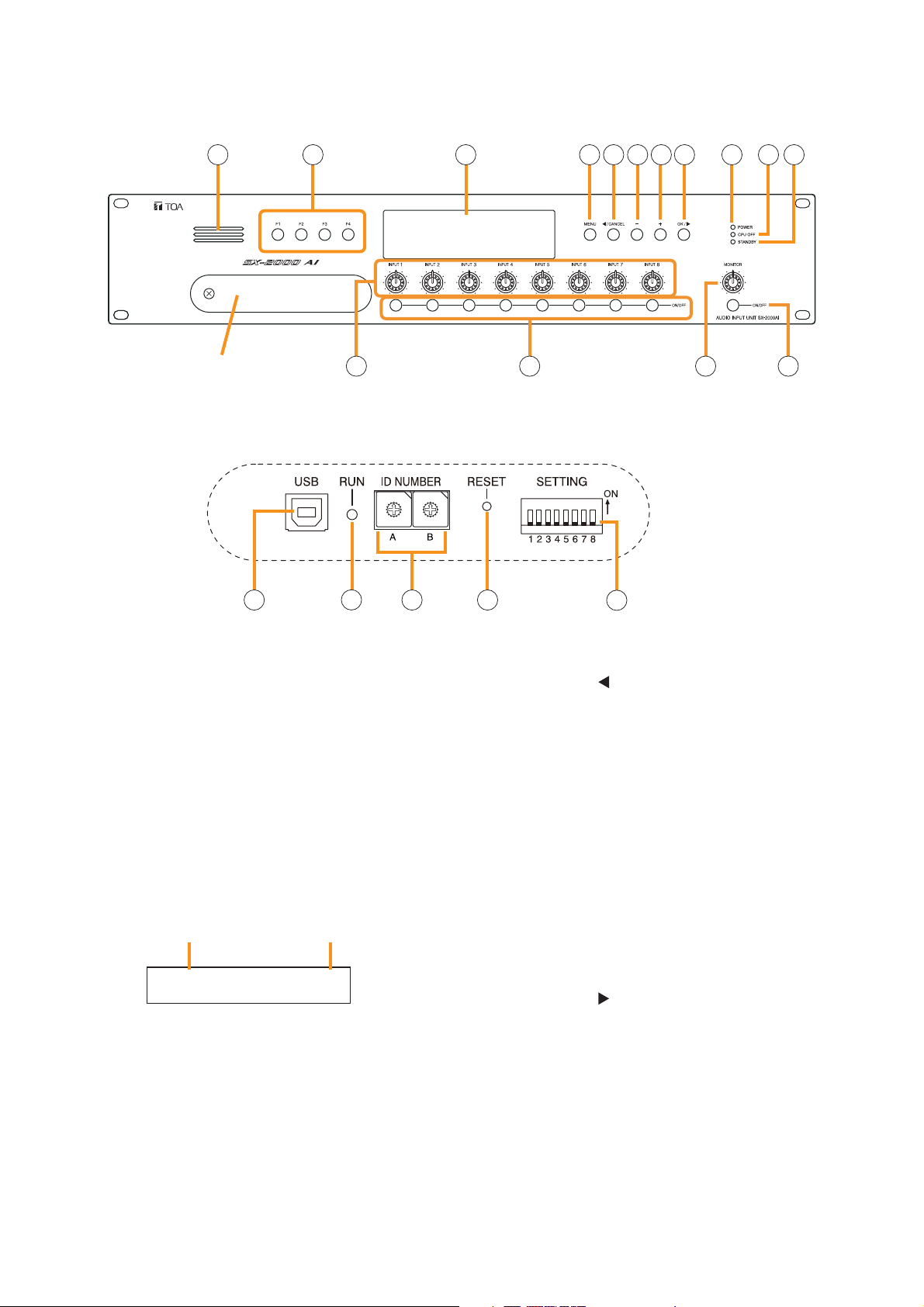

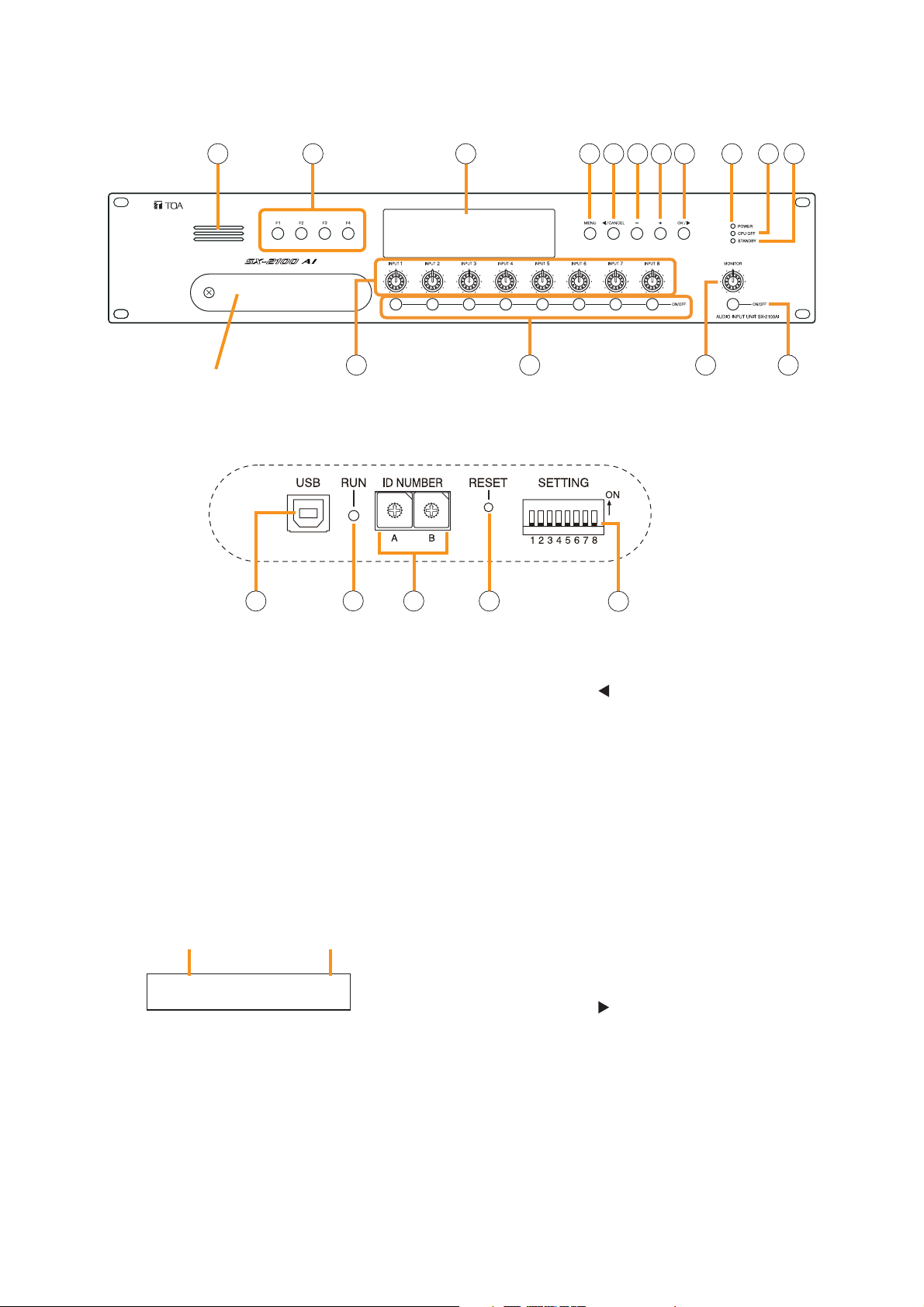

1.2. SX-2000AI Audio Input Unit

[Front]

1. Monitor Speaker

Allows any input channel to be monitored.

2. Function Keys [F1, F2, F3, F4]

Pressing a function key executes the function that

has been assigned to that key using the SX-2000

Setting Software.

(See the separate Setting Software Instructions,

"Event Settings.")

3. Fluorescent Display

The default display shows device numbers and

firmware versions.

Displays the SX-2000AI's current operation status,

input level, etc. (See the separate Operating

Instructions, "SX-2000AI Audio Input Unit.")

4. Menu Key [MENU]

Pressing this key displays the fluorescent display's

menu screen. Whenever this key is pressed, the

screen returns to the default display for whatever

portion of the menu screen is displayed.

5. Cancel Key [ /CANCEL]

Used to switch the menu screen.

6. Minus Key [–]

Used to switch the menu screen. When the

Monitor ON/OFF Key (15) is set to ON, use this

key to select which channel to monitor.

The selected channel number decreases by one

each time this key is pressed.

7. Plus Key [+]

Used to switch the menu screen. When the

Monitor ON/OFF Key (15) is set to ON, use this

key to select which channel to monitor.

The selected channel number increases by one

each time this key is pressed.

8. OK Key [OK/ ]

Used to switch the menu screen.

9. Power Indicator [POWER] (Blue)

Lights when the power is switched on.

10. CPU OFF Indicator [CPU OFF] (Red)

Lights while the general urgency all-call (CPU

OFF state) is being made (p. 68).

SX-2000AI

1 2 3 114 5 6 7 8 9 10

Protective cover

12 13 14 15

Inside of the protective cover

1

0

2

F

3

E

D

C

6

B

7

A

8

9

16 18 1917

1

0

2

F

3

E

4

4

D

5

5

C

6

B

7

A

8

9

20

Device No.

AI– 1 VER300

Firmware version

..

Page 11

11

11. Standby Indicator [STANDBY] (Green)

Lights while the unit is being initialized at poweron or at reset.

Flashes when the fluorescent display is in light

shutoff mode and the light stays unlit.

Lights when the SX-2000 system is operating on

the backup power supply during power failures.

12. Input Volume Controls [INPUT 1 – 8]

Adjust the input volume of each input channel.

Rotating the control fully counterclockwise mutes

the input sound source connected to that

channel and causes the input ON/OFF indicator

(28) on the fluorescent display to turn off.

When an input channel's "Type" is set to

"Emergency" on the SX-2000 Setting software,

the input signal source is made to bypass this

Input volume control. (See the separate Setting

Software Instructions, "System Settings.")

13. Channel Keys [ON/OFF]

Turn each input channel on or off. The input

channel alternates between on and off each time

this key is pressed.

Other functions can also be assigned to each

key by using the SX-2000 Setting Software. (See

the separate Setting Software Instructions,

"Event Settings.")

When an input channel's "Type" is set to

"Emergency" on the SX-2000 Setting software,

the input signal source is made to bypass this

Channel key. (See the separate Setting Software

Instructions, "System Settings.")

14. Monitor Volume Control [MONITOR]

Adjusts the sound volume of the monitor speaker

(1).

15. Monitor ON/OFF Key [ON/OFF]

Enables or disables the audio monitor function

for the selected input channel. The monitor

function alternates between on and off each time

this key is pressed.

16. USB Port [USB]

This port is not used.

17. RUN Indicator [RUN] (Green)

Normally flashes continuously.

18. ID Switch [ID NUMBER]

Sets the SX-2000AI's device number.

(See p. 52.)

19. Reset Key [RESET]

Pressing this key resets the SX-2000AI.

Notes

• Resetting the SX-2000AI stops broadcasts in a

part of or all zones currently in progress via the

reset SX-2000AI.

• Do not keep pressing the key for over 1

second. The unit cannot operate.

If the unit operation is suspended, press the

Reset key for less than one second again.

20. DIP Switch [SETTING]

Performs key lock function settings.

(See p. 142.)

• Switch 1

ON: Disables operation of the front panel input

volume controls and channel keys.

OFF: Cancels key lock status.

• Switches 2 – 8

These switches are not used.

Note

Switches 1 – 8 are set to the OFF position by

default.

SX-2000AI

Page 12

12

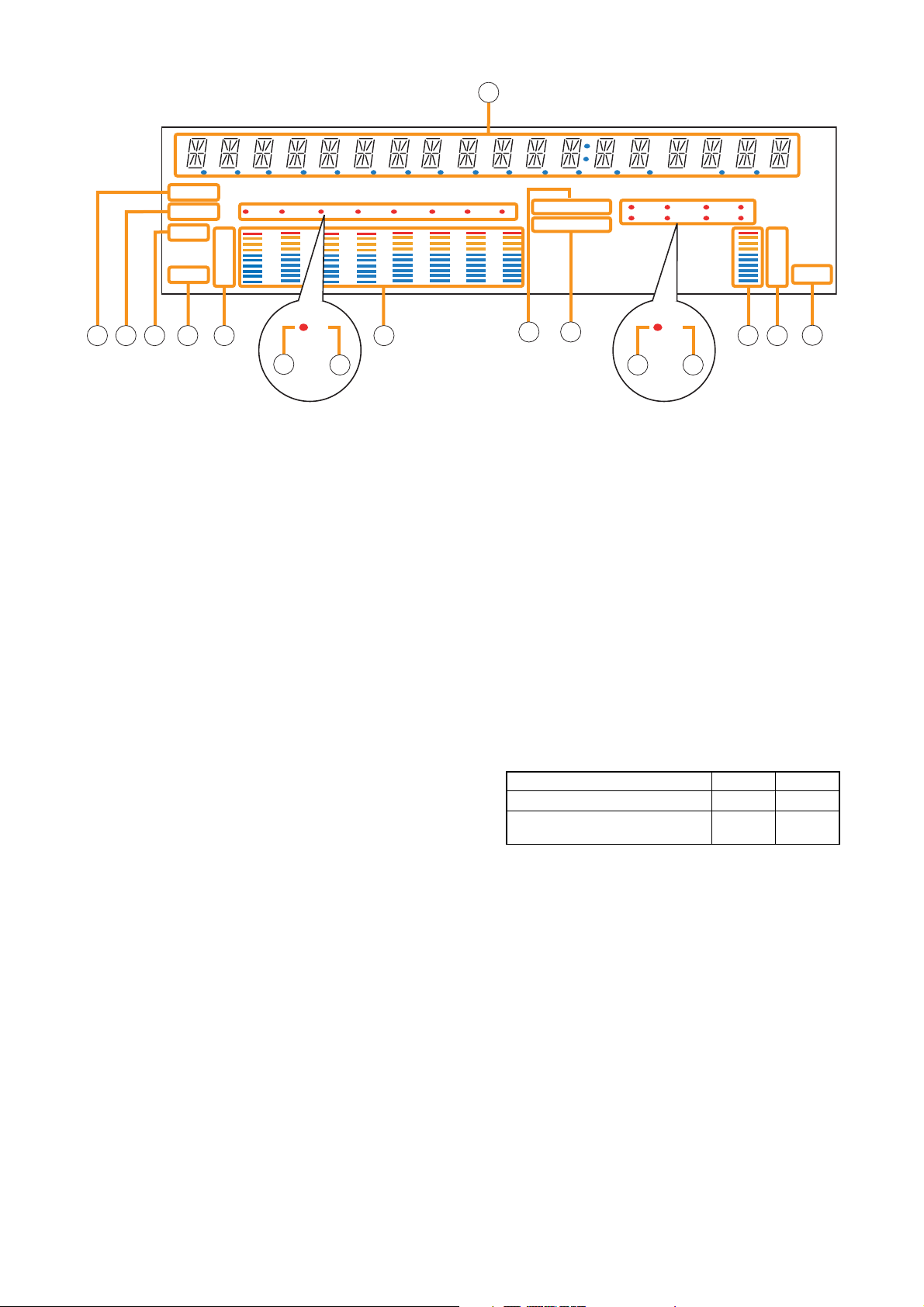

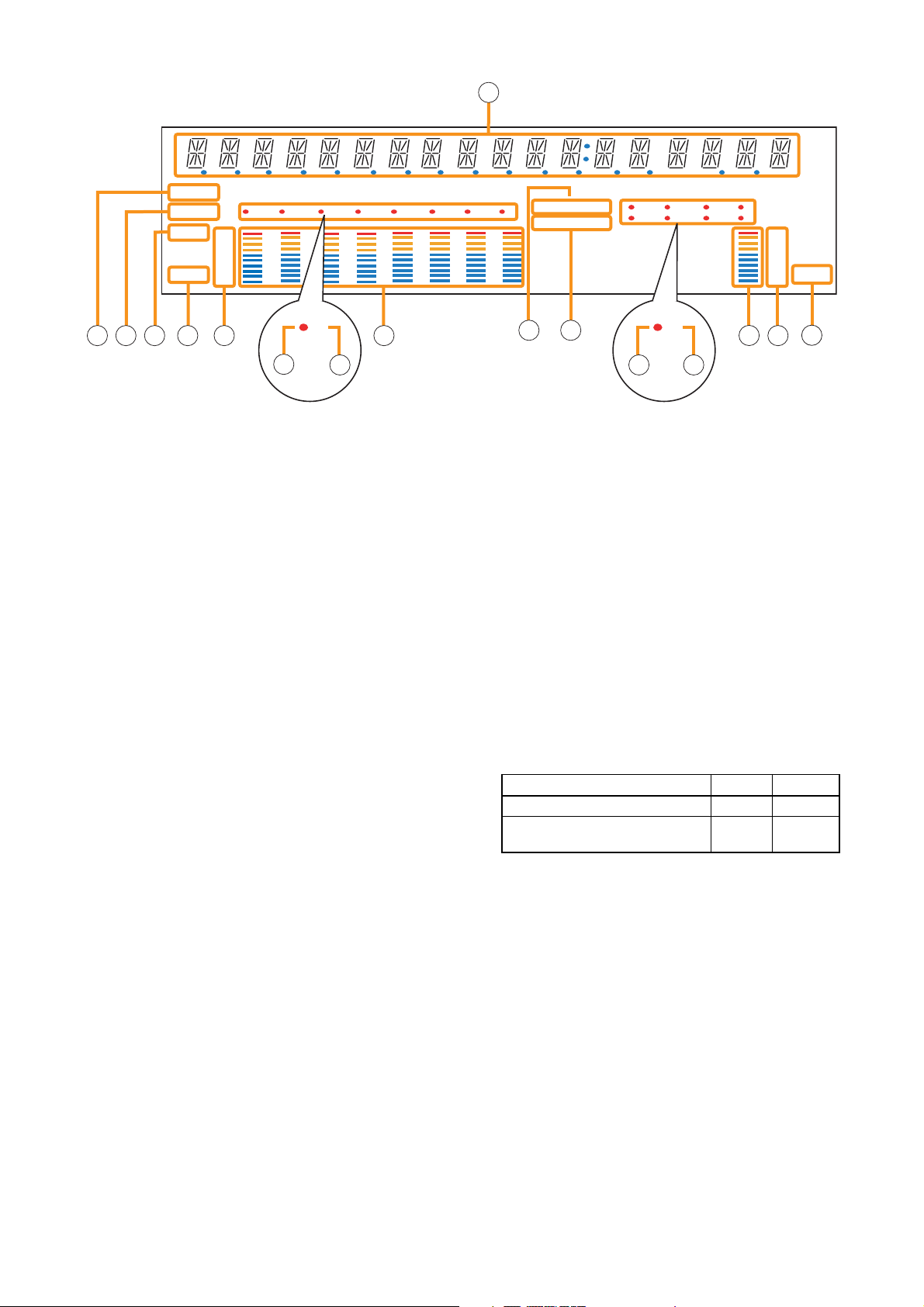

[Fluorescent Display]

21. Text Display Area

Displays the menu screen information when the

corresponding function key is pressed.

22. COM Indicator [COM]

Flashes to indicate a communications error.

23. Fault Indicator [FAULT]

Flashes when a system failure, incorrect system

configuration* or communications error is

detected. This indicator continues to flash until

failure conditions return to normal.

* When the system or module configuration

differs from the contents set by the SX-2000

Setting Software.

24. Input Level Meter Fader Indicator [FADER]

Lights when the input level meter indicates the

sound volume set using the SX-2000 Setting

Software or input volume control.

25. Input Level Meter Level Indicator [LEVEL]

Lights when the input level meter indicates the

level being input to the SX-2000AI.

26. Input Level Meter Scale

27. Input Indicator

The input channel to be monitored lights red.

28. Input ON/OFF Indicator

Indicates the unit's operating status when the

corresponding channel key is pressed.

The indicator state differs depending on the

function assigned to each channel key as

follows.

* The indicator state is "Unlit" when the input volume is muted.

29. Input Level Meter

Indicates the actual level or a set volume value

on each input channel.

30. Key Lock Indicator [KEY LOCK]

Lights when the input volume controls and

channel keys are locked. (See p. 142, "Key Lock

Settings and Cancellation.")

31. Emergency Indicator [EMERGENCY]

Lights when the SX-2000 system is in an

emergency condition.

32. Remote Microphone Output Status Indicator

Lights red continuously as long as announcements

are made from the RM-200SF, RM-200SA, or RM210 Remote Microphone.

Notes

• A timer-activated light shutoff function can be set for the fluorescent display using the SX-2000 Setting

Software. (See the separate Setting Software Instructions, "Basic Settings.")

When the light shutoff function has been set, if the SX-2000AI is not operated for 5 minutes or more, the

fluorescent display's light goes off and the standby indicator (11) begins to flash. Pressing any keys other

than the function keys on the front panel resets the screen display.

• Normally, the fluorescent display's light goes off at the time of the power failure.

• While the SX-2000 system is in an emergency condition, the fluorescent display's light does not go off even

if the power fails.

SX-2000AI

Function assigned to the channel key When ON When OFF

Input ON/OFF Lights* Unlit

General-purpose pattern broadcast's Flashes Lights

activation and termination

21

COM

FAULT

FADER

LEVEL LEVEL

–10

–20

–30

–40

OL

0

22 23 26

12 345678

27

33

2924 25

28

30

KEYLOCK

EMERGENCY

31

12 34

56 78

66

34 35

32 33

–10

–20

–30

–40

OL

0

36

Page 13

13

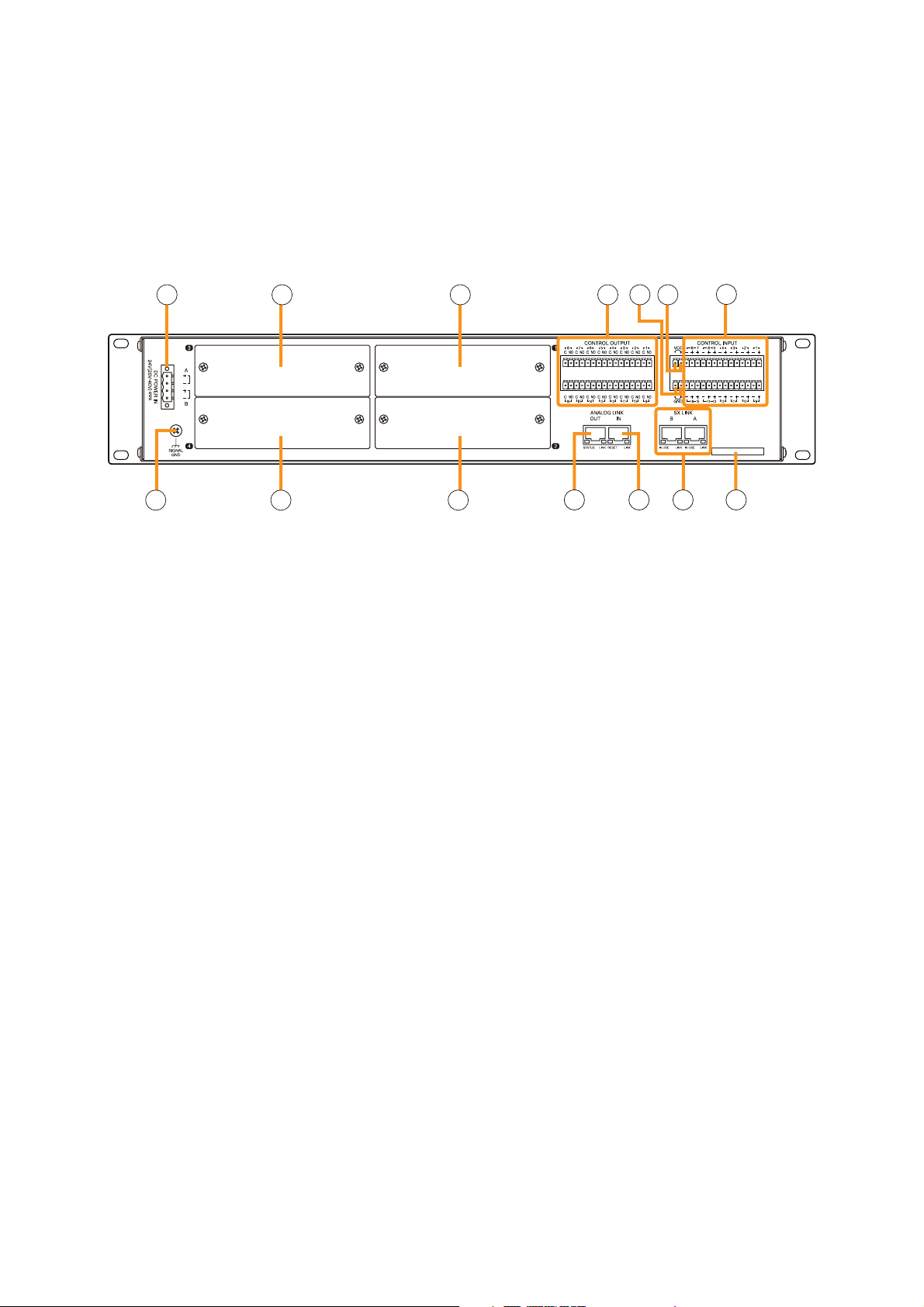

[Rear]

37. DC Power Input Terminal [DC POWER IN]

Connect an optional DC power supply unit to this

terminal. Select the DC power supply source with

consideration given to the current power

consumption of the system the SX-2000AI is to

be connected to. When not using a redundant

power system*, connect the [+] terminal of input

A to the [+] terminal of input B, and the [–]

terminal of input A to the [–] terminal of input B.

(

Refer to the Instruction Manual attached to the

VX-2000DS.

)

* A method of connecting separate power

sources to each power input or connecting the

commercial power supply and backup power

supply separately to each power input to

prevent the system from going down when a

cable is broken or power fails.

38. Module Slot 3 [3]

Slot for input channels 5 and 6.

39. Module Slot 1 [1]

Slot for input channels 1 and 2.

40. Functional Earth Terminal [SIGNAL GND]

Hum noise may be generated when external

equipment is connected to the unit. Connecting

this terminal to the functional earth terminal of

the external equipment may reduce the hum

noise.

Note: This terminal is not for protective earth.

41. Module Slot 4 [4]

Slot for input channels 7 and 8.

42. Module Slot 2 [2]

Slot for input channels 3 and 4.

43. Analog Link Output Terminal [ANALOG LINK

OUT]

Connect this terminal to the analog link input

terminal of the SX-2000AI, SX-2100AI, SX2000AO, or SX-2100AO.

44.

Analog Link Input Terminal [ANALOG LINK IN]

Connect this terminal to the analog link output

terminal of the SX-2000SM, SX-2000AI, SX2100AI, SX-2000AO, or SX-2100AO.

SX-2000AI

33.

Remote Microphone Connection Status Indicator

The device number of the Remote Microphone

connected to the SX-2000AI lights.

34. Monitor Level Meter

Indicates the sound volume level of the input

channel being monitored.

35. Monitor Level Meter Scale

Lights when the monitor ON/OFF key (15) is set

to ON.

36. Monitor ON/OFF Indicator [LEVEL]

Lights when the monitor ON/OFF key (15) is set

to ON.

3837

40 41 42 43 44 45

39

46

1 2

Function LED On LED Off

1. Not used

2. OUT connection confirmation Connected Unconnected

34

Function LED On LED Off

3. RESET input Resetting Normal

4. Not used

Page 14

14

45. SX Link Terminals [SX LINK A/B]

Use switching hubs to connect between the SX

link terminals of the SX-2000SM, SX-2000AI, SX2100AI, SX-2000AO, and SX-2100AO. Connect

each of the SX Links A and B to the same

switching hub*, or to different switching hubs* that

have been

connected in star configuration.

Notes

• Be sure to connect both terminals of A and B.

• After connection completion, press the Reset

key to reactivate the SX-2000AI.

* Contact your TOA dealer for more information

on switching hubs.

46. MAC Address

MAC address to be used for SX link connection.

SX-2000AI

1 234

Function

LED On/Flashing

LED Off

1. B operation in progress

indication

2. B connection confirmation Connected Unconnected

3. A operation in progress

indication

4. A connection confirmation Connected Unconnected

Operating Not operating

Operating Not operating

Page 15

15

1.3. SX-2100AI Audio Input Unit

[Front]

1. Monitor Speaker

Allows any input channel to be monitored.

2. Function Keys [F1, F2, F3, F4]

Pressing a function key executes the function that

has been assigned to that key via the SX-2000

Setting Software.

(See the separate Setting Software Instructions,

"Event Settings.")

3. Fluorescent Display

The default display shows device numbers and

firmware versions.

Displays the SX-2100AI's current operation status,

input level, etc. (See the separate Operating

Instructions, "SX-2100AI Audio Input Unit.")

4. Menu Key [MENU]

Pressing this key displays the fluorescent display's

menu screen. Whenever this key is pressed, the

screen returns to the default display for whatever

portion of the menu screen is displayed.

5. Cancel Key [ /CANCEL]

Used to switch the menu screen.

6. Minus Key [–]

Used to switch the menu screen.

When the Monitor ON/OFF Key (15) is set to ON,

use this key to select which channel to monitor.

The selected channel number decreases by one

each time this key is pressed.

7. Plus Key [+]

Used to switch the menu screen.

When the Monitor ON/OFF Key (15) is set to ON,

use this key to select which channel to monitor.

The selected channel number increases by one

each time this key is pressed.

8. OK Key [OK/ ]

Used to switch the menu screen.

9. Power Indicator [POWER] (Blue)

Lights when the power is switched on.

10. CPU OFF Indicator [CPU OFF] (Red)

Lights while the general urgency all-call (CPU

OFF state) is being made (p. 68).

SX-2100AI

1 2 3 114 5 6 7 8 9 10

12 13 14 15

Protective cover

Inside of the protective cover

1

0

2

F

3

E

D

C

B

7

A

8

9

16 18 1917

Device No.

AI– 1 VER300

Firmware version

..

1

0

2

F

3

E

4

4

D

5

5

C

6

6

B

7

A

8

9

20

Page 16

16

11. Standby Indicator [STANDBY] (Green)

Lights while the unit is being initialized at poweron or at reset.

Flashes when the fluorescent display is in light

shutoff mode and the light stays unlit.

Lights when the SX-2000 system is operating on

the backup power supply during power failures.

12. Input Volume Controls [INPUT 1 – 8]

Adjust the input volume of each input channel.

Rotating the control fully counterclockwise mutes

the input sound source connected to that

channel and causes the input ON/OFF indicator

(28) on the fluorescent display to turn off.

When an input channel's "Type" is set to

"Emergency" on the SX-2000 Setting software,

the input signal source is made to bypass this

Input volume control. (See the separate Setting

Software Instructions, "System Settings.")

13. Channel Keys [ON/OFF]

Turn each input channel on or off. The input

channel alternates between on and off each time

this key is pressed.

Other functions can also be assigned to each

key by using the SX-2000 Setting Software. (See

the separate Setting Software Instructions,

"Event Settings.")

When an input channel's "Type" is set to

"Emergency" on the SX-2000 Setting software,

the input signal source is made to bypass this

Channel key. (See the separate Setting Software

Instructions, "System Settings.")

14. Monitor Volume Control [MONITOR]

Adjusts the sound volume of the monitor speaker

(1).

15. Monitor ON/OFF Key [ON/OFF]

Enables or disables the audio monitor function

for the selected input channel. The monitor

function alternates between on and off each time

this key is pressed.

16. USB Port [USB]

This port is not used.

17. RUN Indicator [RUN] (Green)

Normally flashes continuously.

18. ID Switch [ID NUMBER]

Sets the SX-2100AI's device number.

(See p. 52.)

19. Reset Key [RESET]

Pressing this key resets the SX-2100AI.

Notes

• Resetting the SX-2100AI stops broadcasts in a

part of or all zones currently in progress via the

reset SX-2100AI.

• Do not keep pressing the key for over 1

second. The unit cannot operate.

If the unit operation is suspended, press the

Reset key for less than one second again.

20. DIP Switch [SETTING]

Performs key lock function settings.

(See p. 142.)

• Switch 1

ON: Disables operation of the front panel input

volume controls and channel keys.

OFF: Cancels key lock status.

• Switches 2 – 8

These switches are not used.

Note

Switches 1 – 8 are set to the OFF position by

default.

SX-2100AI

Page 17

17

[Fluorescent Display]

21. Text Display Area

Displays the menu screen information when the

corresponding function key is pressed.

22. COM Indicator [COM]

Flashes to indicate a communications error.

23. Fault Indicator [FAULT]

Flashes when a system failure, incorrect system

configuration* or communications error is

detected. This indicator continues to flash until

failure conditions return to normal.

* When the system or module configuration

differs from the contents set by the SX-2000

Setting Software.

24. Input Level Meter Fader Indicator [FADER]

Lights when the input level meter indicates the

sound volume set using the SX-2000 Setting

Software or input volume control.

25. Input Level Meter Level Indicator [LEVEL]

Lights when the input level meter indicates the

level being input to the SX-2100AI.

26. Input Level Meter Scale

27. Input Indicator

The input channel to be monitored lights red.

28. Input ON/OFF Indicator

Indicates the unit's operating status when the

corresponding channel key is pressed.

The indicator state differs depending on the

function assigned to each channel key as

follows.

* The indicator state is "Unlit" when the input volume is muted.

29. Input Level Meter

Indicates the actual level or a set volume value

on each input channel.

30. Key Lock Indicator [KEY LOCK]

Lights when the input volume controls and

channel keys are locked. (See p. 142, "Key Lock

Settings and Cancellation.")

31. Emergency Indicator [EMERGENCY]

Lights when the SX-2000 system is in an

emergency condition.

32. Remote Microphone Output Status Indicator

Lights red continuously as long as announcements

are made from the RM-200SF, RM-200SA, or RM210 Remote Microphone.

Notes

• A timer-activated light shutoff function can be set for the fluorescent display using the SX-2000 Setting

Software. (See the separate Setting Software Instructions, "Basic Settings.")

When the light shutoff function has been set, if the SX-2100AI is not operated for 5 minutes or more, the

fluorescent display's light goes off and the standby indicator (11) begins to flash. Pressing any keys other

than the function keys on the front panel resets the screen display.

• Normally, the fluorescent display's light goes off at the time of the power failure.

• While the SX-2000 system is in an emergency condition, the fluorescent display's light does not go off even

if the power fails.

SX-2100AI

Function assigned to the channel key When ON When OFF

Input ON/OFF Lights* Unlit

General-purpose pattern broadcast's Flashes Lights

activation and termination

21

COM

FAULT

FADER

LEVEL LEVEL

22 23 26 2924 25

12 345678

OL

0

–10

–20

–30

–40

33

27

28

KEYLOCK

EMERGENCY

30

31

12 34

56 78

32

66

33

34 35

–10

–20

–30

–40

OL

0

36

Page 18

18

[Rear]

37. DC Power Input Terminal [DC POWER IN]

Connect an optional DC power supply unit to this

terminal. Select the DC power supply source with

consideration given to the current power

consumption of the system the SX-2100AI is to

be connected to. When not using a redundant

power system*, connect the [+] terminal of input

A to the [+] terminal of input B, and the [–]

terminal of input A to the [–] terminal of input B.

(

Refer to the Instruction Manual attached to the

VX-2000DS.

)

* A method of connecting separate power

sources to each power input or connecting the

commercial power supply and backup power

supply separately to each power input to

prevent the system from going down when a

cable is broken or power fails.

38. Module Slot 3 [3]

Slot for input channels 5 and 6.

39. Module Slot 1 [1]

Slot for input channels 1 and 2.

40. Functional Earth Terminal [SIGNAL GND]

Hum noise may be generated when external

equipment is connected to the unit. Connecting

this terminal to the functional earth terminal of

the external equipment may reduce the hum

noise.

Note: This terminal is not for protective earth.

41. Module Slot 4 [4]

Slot for input channels 7 and 8.

42. Module Slot 2 [2]

Slot for input channels 3 and 4.

43. Control Output Terminals

[CONTROL OUTPUT 1 – 16]

Relay make contact outputs.

All the contact outputs are of normally open type

when shipped from the factory.

Each output can be converted into normally

closed type by changing the internal jumper

setting. (See "Operation of Power Feed Jumper

and Isolation Jumper" on the next page.)

Each contact capacity is rated at 40 V DC for

withstand voltage, and 2 mA – 300 mA for

control current. These terminals are controlled by

the SX-2000 Setting Software. (See the separate

Setting Software Instructions, "Pattern Settings.")

44. Isolation Jumper [GND]

The supplied removable terminal plug is

equipped with a jumper. When the jumper is

attached, the [–] terminals of all inputs (1 – 16)

are connected to the internal power supply.

Removing the jumper disconnects and isolates

these [–] terminals from this unit. (See

"Operation of Power Feed Jumper and Isolation

Jumper" on the next page.)

45. Power Feed Jumper [VCC]

The supplied removable terminal plug is

equipped with a jumper. When the jumper is

attached, the circuits of all control inputs (1 – 16)

are powered from inside the SX-2100AI.

Removing the jumper disconnects this internal

power supply and thus requires that power be

supplied externally to the circuit. (See "Operation

of Power Feed Jumper and Isolation Jumper" on

the next page.)

SX-2100AI

33. Remote Microphone Connection Status

Indicator

The device number of the Remote Microphone

connected to the SX-2100AI lights.

34. Monitor Level Meter

Indicates the sound volume level of the input

channel being monitored.

35. Monitor Level Meter Scale

Lights when the monitor ON/OFF key (15) is set

to ON.

36. Monitor ON/OFF Indicator [LEVEL]

Lights when the monitor ON/OFF key (15) is set

to ON.

3837 39

40 41 42

43 445045

46

47 48 49

Page 19

46. Control Input Terminals

[CONTROL INPUT 1 – 16]

Photo coupler inputs. A current of approximately

2 mA flows when shorted, and the voltage

becomes under 40 V DC when opened.

The input of 100 msec or greater is required to

operate. These contact inputs can be isolated

from the SX-2100AI unit by cutting the power

feed jumper (45) and the isolation jumper (44).

Each contact input when isolated is 40 V DC for

maximum applied voltage and approximately 2

mA for the loop current. Since each terminal is

equipped with a current limiter employing

constant current circuitry, there is no need to limit

current on the external equipment side. The [–]

terminals of all control inputs are common. Use

the SX-2000 Setting Software to assign functions

to these terminals. (See the separate Setting

Software Instructions, "Event Settings.")

47. Analog Link Output Terminal

[ANALOG LINK OUT]

Connect this terminal to the analog link input

terminal of the SX-2000AI, SX-2100AI, SX2000AO, or SX-2100AO.

48. Analog Link Input Terminal

[ANALOG LINK IN]

Connect this terminal to the analog link output

terminal of the SX-2000SM, SX-2000AI, SX2100AI, SX-2000AO, or SX-2100AO.

49. SX Link Terminals [SX LINK A/B]

Use switching hubs to connect between the SX

link terminals of the SX-2000SM, SX-2000AI, SX2100AI, SX-2000AO, and SX-2100AO. Connect

each of the SX Links A and B to the same

switching hub*, or to different switching hubs* that

have been

connected in star configuration.

Notes

• Be sure to connect both terminals of A and B.

• After connection completion, press the Reset

key to reactivate the SX-2100AI.

* Contact your TOA dealer for more information

on switching hubs.

50. MAC Address

MAC address to be used for SX link connection.

19

SX-2100AI

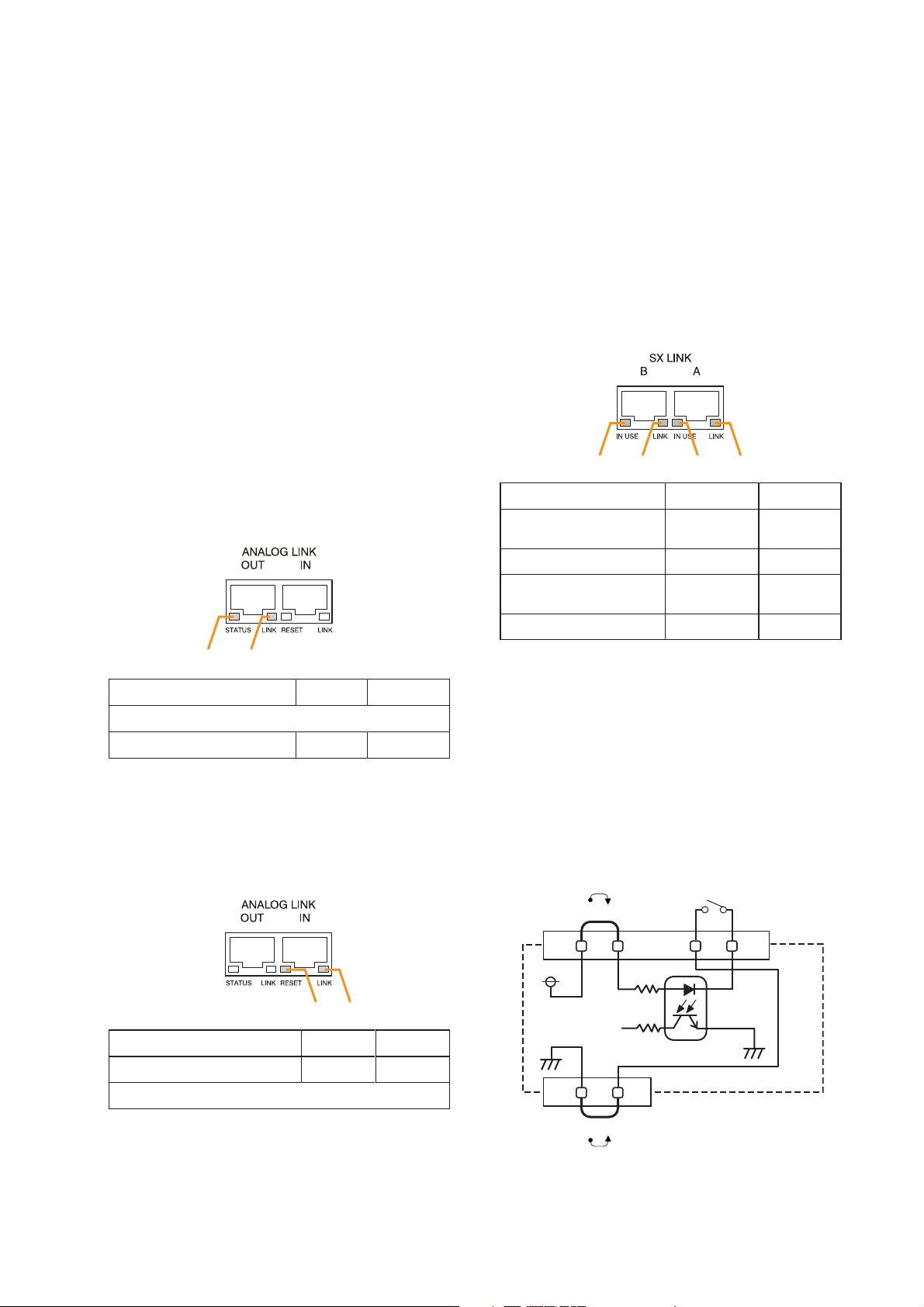

[Operation of Power Feed Jumper and

Isolation Jumper]

1 234

Function

1. B operation in progress

indication

2. B connection confirmation Connected Unconnected

LED On/Flashing

Operating Not operating

LED Off

1 2

Function LED On LED Off

1. Not used

2. OUT connection confirmation Connected Unconnected

34

3. A operation in progress

indication

4. A connection confirmation Connected Unconnected

Operating Not operating

VCC

Power feed jumper

Control input

-

+

Function LED On LED Off

3. RESET input Resetting Normal

4. Not used

Photo coupler

Internal circuit

Isolation jumper

GND

Page 20

20

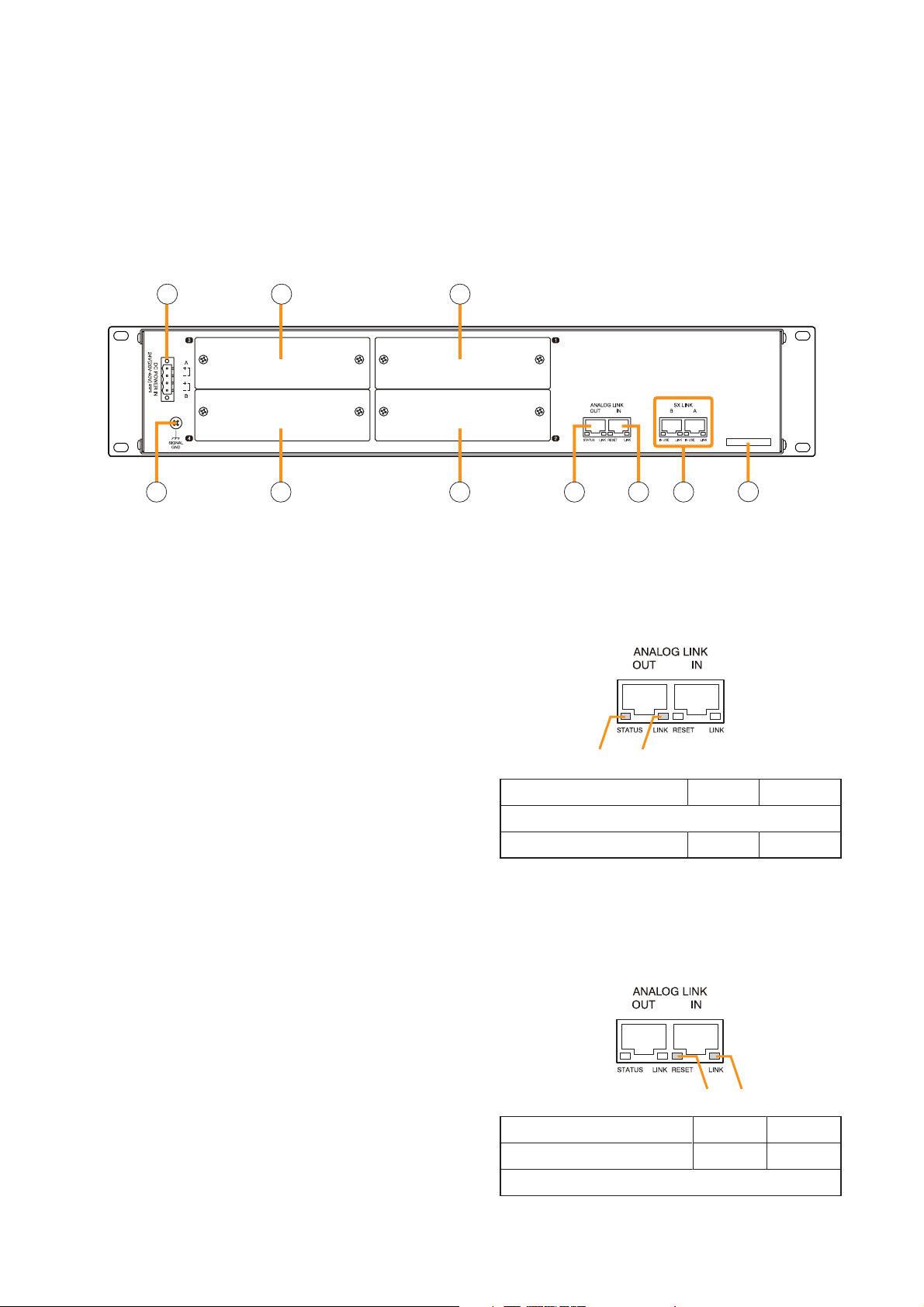

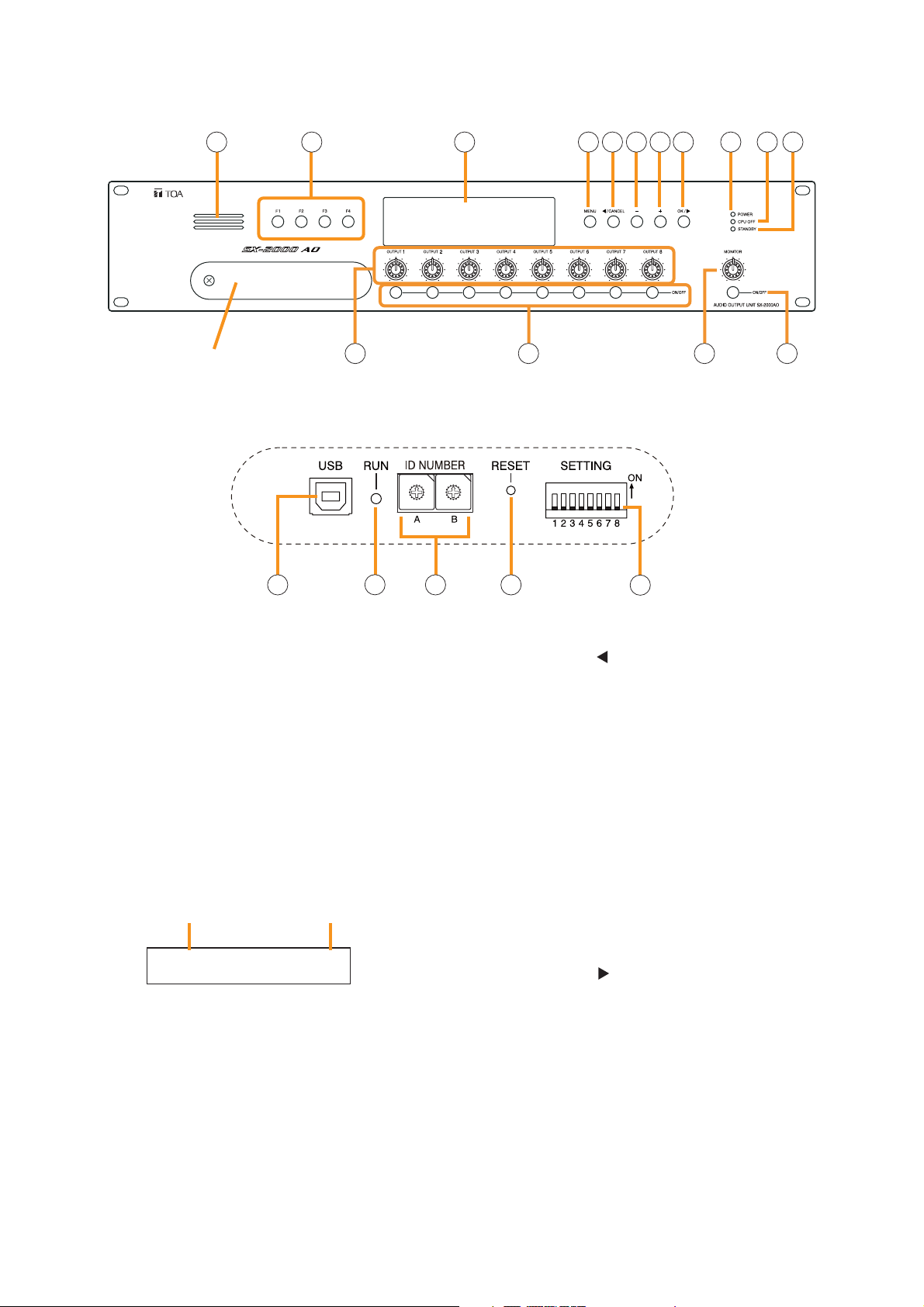

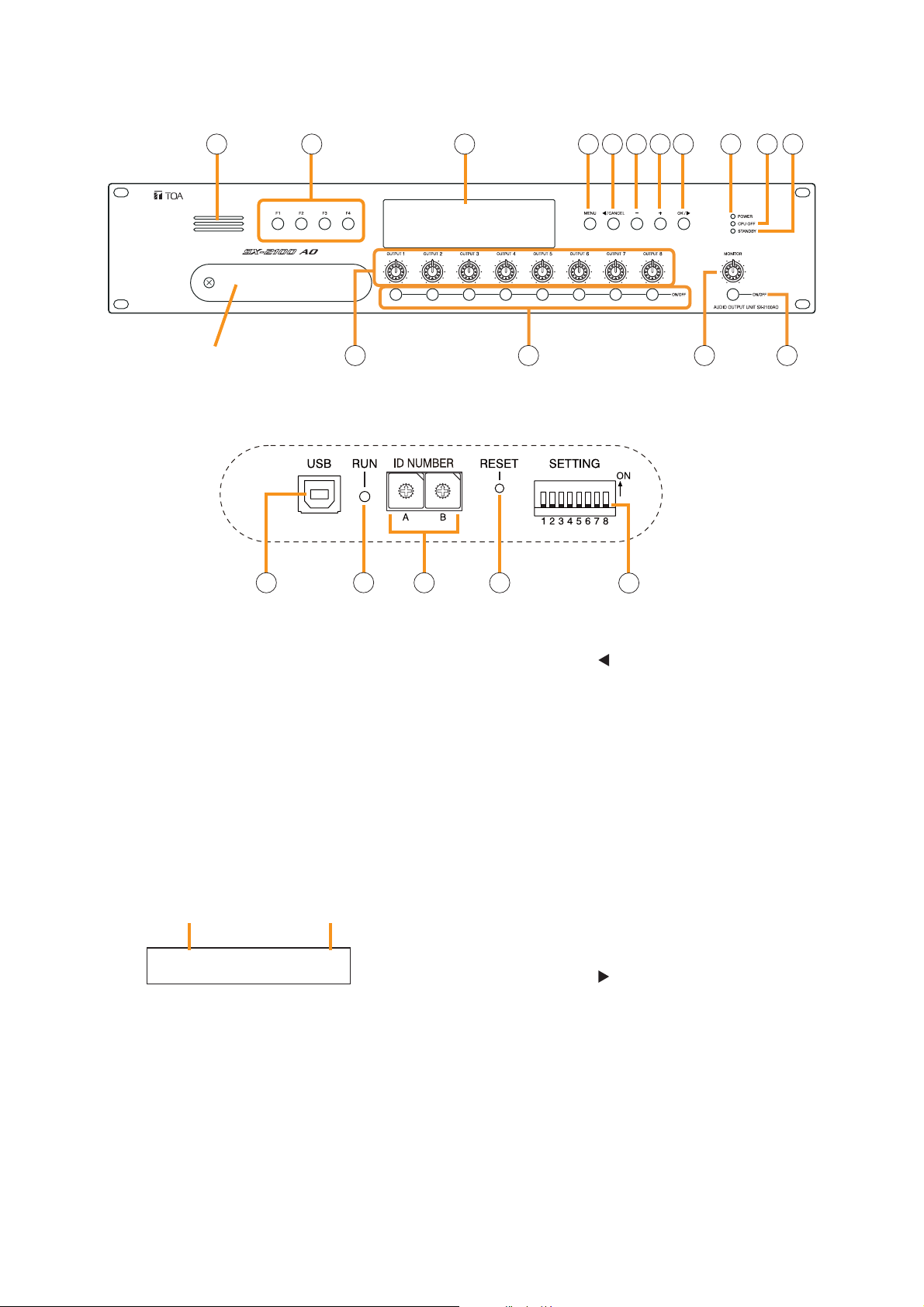

1.4. SX-2000AO Audio Output Unit

[Front]

1. Monitor Speaker

Allows any output channel to be monitored.

2. Function Keys [F1, F2, F3, F4]

Pressing a function key executes the function that

has been assigned to that key via the SX-2000

Setting Software.

(See the separate Setting Software Instructions,

"Event Settings.")

3. Fluorescent Display

The default display shows device numbers and

firmware versions.

Displays the SX-2000AO's current operation

status, output level, etc. (See the separate

Operating Instructions, "SX-2000AO Audio Output

Unit.")

4. Menu Key [MENU]

Pressing this key displays the fluorescent display's

menu screen. Whenever this key is pressed, the

screen returns to the default display for whatever

portion of the menu screen is displayed.

5. Cancel Key [ /CANCEL]

Used to switch the menu screen.

6. Minus Key [–]

Used to switch the menu screen. When the

Monitor ON/OFF Key (15) is set to ON, use this

key to select which channel to monitor. The

selected channel number decreases by one each

time this key is pressed.

7. Plus Key [+]

Used to switch the menu screen. When the

Monitor ON/OFF Key (15) is set to ON, use this

key to select which channel to monitor. The

selected channel number increases by one each

time this key is pressed.

8. OK Key [OK/ ]

Used to switch the menu screen.

9. Power Indicator [POWER] (Blue)

Lights when the power is switched on.

10. CPU OFF Indicator [CPU OFF] (Red)

Lights while the general urgency all-call (CPU

OFF state) is being made (p. 68).

SX-2000AO

1 2 3 114 5 6 7 8 9 10

Protective cover

12 13 14 15

Inside of the protective cover

16 18 1917

1

1

0

0

2

2

F

F

3

E

D

C

B

A

3

E

4

4

D

5

5

C

6

6

B

7

7

A

8

8

9

9

20

AO– 1 VER300

Device No. Firmware version

..

Page 21

21

11. Standby Indicator [STANDBY] (Green)

Lights while the unit is being initialized at poweron or at reset.

Flashes when the fluorescent display is in light

shutoff mode and the light stays unlit.

Lights when the SX-2000 system is operating on

the backup power supply during power failures.

12. Output Volume Controls [OUTPUT 1 – 8]

Adjust the output volume of each output channel.

Rotating the control fully counterclockwise mutes

the output volume and causes the output

ON/OFF indicator (28) on the fluorescent display

to turn off.

Signals on the output channel being used for

emergency broadcast are made to bypass this

Output volume control.

13. Channel Keys [ON/OFF]

Turn each output channel on or off. The output

channel alternates between on and off each time

this key is pressed.

Other functions can also be assigned to each

key by using the SX-2000 Setting Software. (See

the separate Setting Software Instructions,

"Event Settings.")

Signals on the output channel being used for

emergency broadcast are made to bypass this

Channel key.

14. Monitor Volume Control [MONITOR]

Adjusts the sound volume of the monitor speaker

(1).

15. Monitor ON/OFF Key [ON/OFF]

Enables or disables the audio monitor function

for the selected output channel. The monitor

function alternates between on and off each time

this key is pressed.

16. USB Port [USB]

This port is not used.

17. RUN Indicator [RUN] (Green)

Normally flashes continuously.

18. ID Switch [ID NUMBER]

Sets the SX-2000AO's device number.

(See p. 55.)

19. Reset Key [RESET]

Pressing this key resets the SX-2000AO.

Notes

• Resetting the SX-2000AO stops broadcasts

currently in progress via the reset SX-2000AO.

• Do not keep pressing the key for over 1

second. The unit cannot operate.

If the unit operation is suspended, press the

Reset key for less than one second again.

20. DIP Switch [SETTING]

• Switch 1

Performs key lock function settings.

(See p. 143.)

ON: Disables operation of the front panel

output volume controls and channel keys.

OFF: Cancels key lock status.

• Switches 2 – 7

These switches are not used.

• Switch 8

Enables or disables the 24 V emergency cutoff

input on the rear panel. (See p. 56.)

Note

Switches 1 – 8 are set to the OFF position by

default.

SX-2000AO

Page 22

22

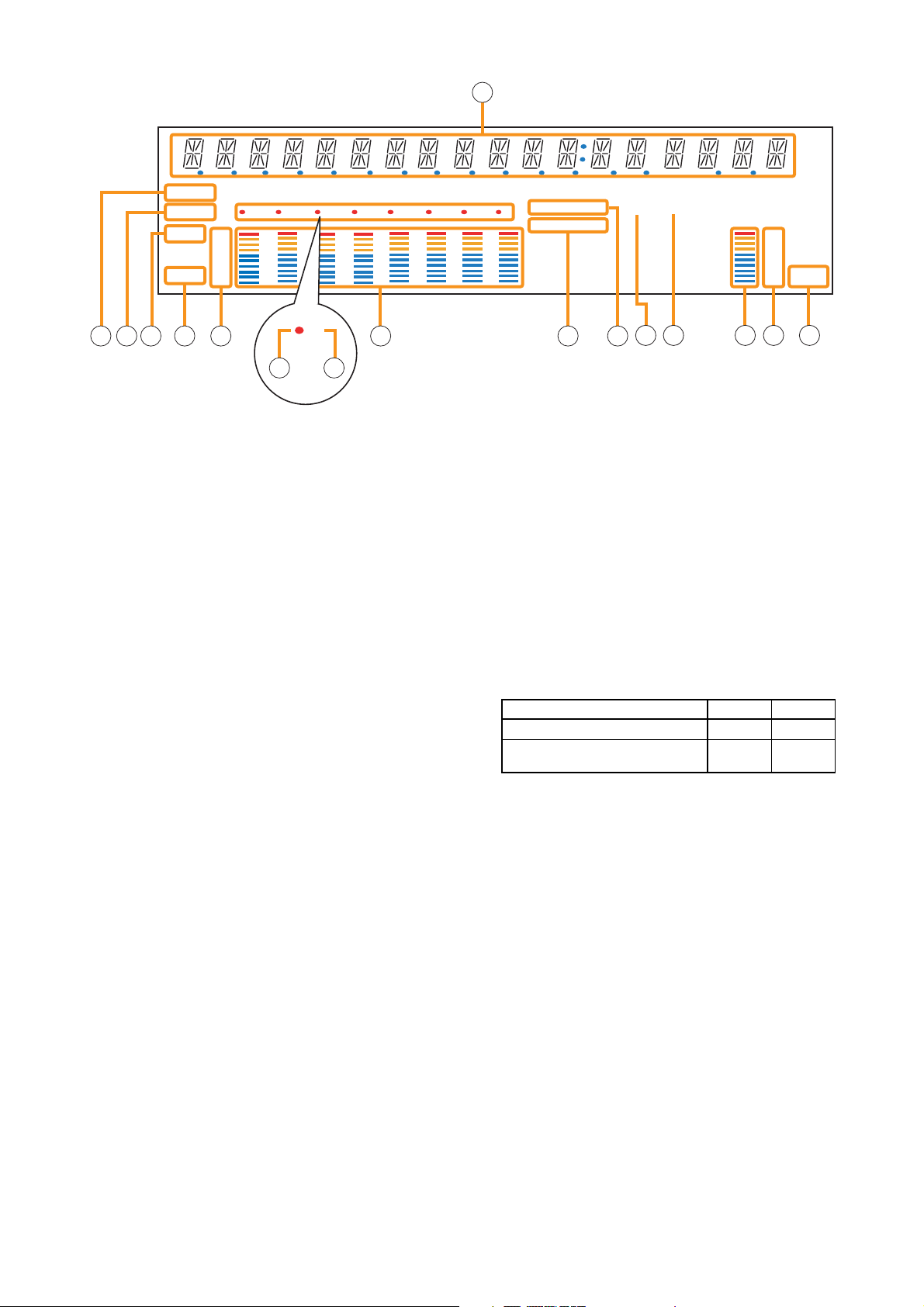

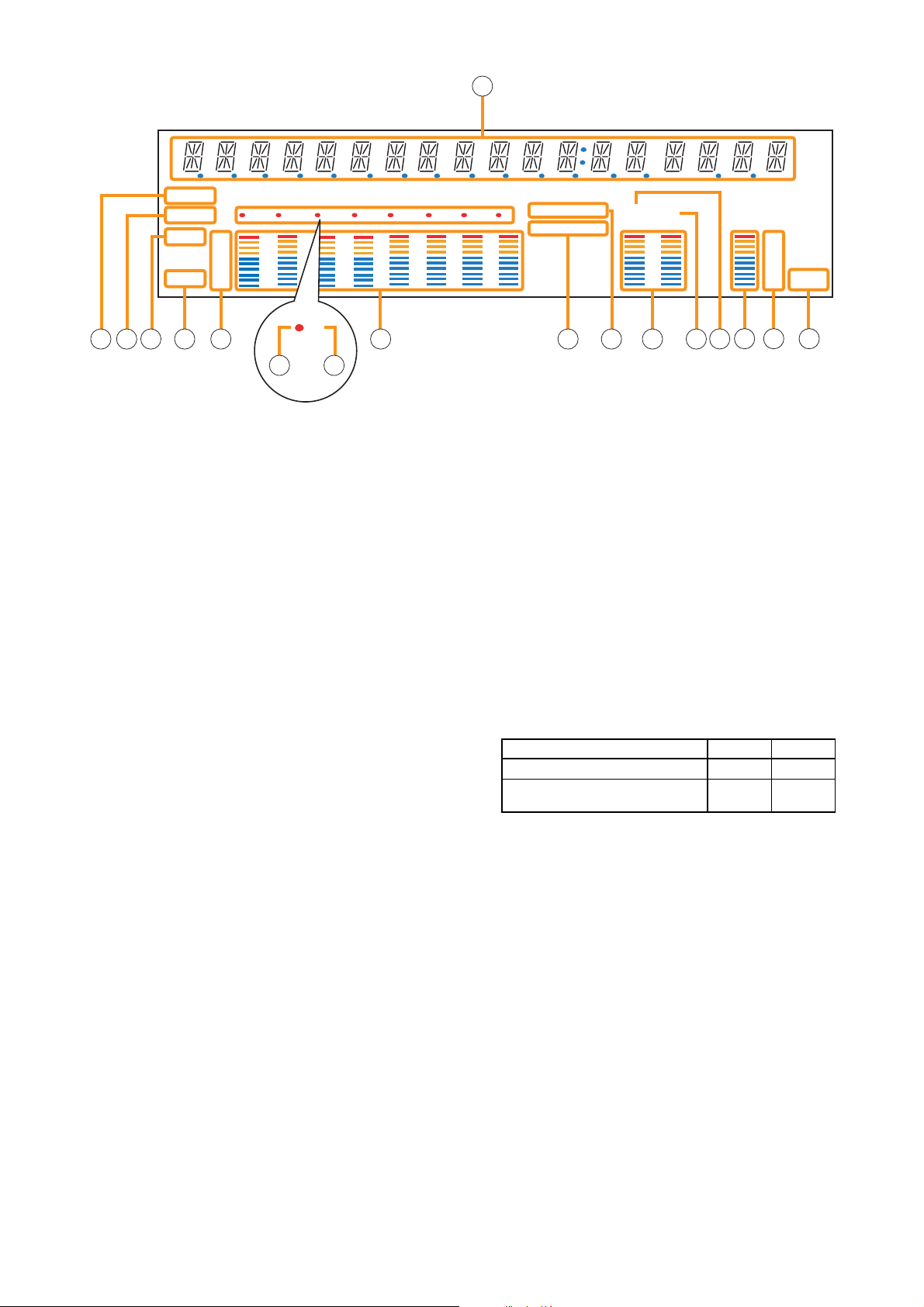

[Fluorescent Display]

21. Text Display Area

Displays the menu screen information when the

corresponding function key is pressed.

22. COM Indicator [COM]

Flashes to indicate a communications error.

23. Fault Indicator [FAULT]

Flashes when a system failure, incorrect system

configuration*1or communications error is

detected. This indicator continues to flash until

failure conditions return to normal.

*

1

When the system or module configuration

differs from the contents set by the SX-2000

Setting Software.

24. Output Level Meter Fader Indicator [FADER]

Lights when the output level meter indicates the

sound volume set using the SX-2000 Setting

Software or output volume control.

25. Output Level Meter Level Indicator [LEVEL]

Lights when the output level meter indicates the

level being output from the SX-2000AO.

26. Output Level Meter Scale

27. Output Indicator

The output channel to be monitored lights red.

28. Output ON/OFF Indicator

Indicates the unit's operating status when the

corresponding channel key is pressed.

The indicator state differs depending on the

function assigned to each channel key as

follows.

* The indicator state is "Unlit" when the output volume is muted.

29. Output Level Meter

Indicates the actual level or a set volume value

on each output channel.

30. Emergency Indicator [EMERGENCY]

Lights when the SX-2000 system is in an

emergency condition.

When the 24 V emergency cutoff input*2is

enabled, this indicator flashes if the input

receives an emergency signal.

*

2

The SX-2000AO has a 24 V emergency cutoff

input terminal (49) on the rear panel, allowing

control of an emergency audio input. When the

SX-2000 system is combined with an

emergency broadcast system, a 24 V DC is

normally kept being supplied to this

emergency cutoff input terminal and is cut off

(24 V emergency cutoff function) in emergency

situations. This interrupts the general-purpose

broadcast from the SX-2000 system, allowing

the emergency broadcast system to override it.

(For details, see p. 56.)

Notes

• A timer-activated light shutoff function can be set for the fluorescent display using the SX-2000 Setting

Software. (See the separate Setting Software Instructions, "Basic Settings.")

When the light shutoff function has been set, if the SX-2000AO is not operated for 5 minutes or more, the

fluorescent display's light goes off and the standby indicator (11) begins to flash. Pressing any keys other

than the function keys on the front panel resets the screen display.

• Normally, the fluorescent display's light goes off at the time of the power failure.

• While the SX-2000 system is in an emergency condition, the fluorescent display's light does not go off even

if the power fails.

SX-2000AO

Function assigned to the channel key When ON When OFF

Output ON/OFF Lights* Unlit

General-purpose pattern broadcast's Flashes Lights

activation and termination

21

COM

FAULT

FADER

LEVEL LEVEL

22 23 24 25 26 29 30 31

12 345678

OL

0

–10

–20

–30

–40

33

KEYLOCK

EMERGENCY

12

OL

0

–10

–20

–30

–40

32 33 34 35 36

27 28

Page 23

23

Note

When the 24 V Emergency cutoff input is set to

be disabled (not usable) with the DIP switch 8

inside the protective cover, the Emergency

indicator will not flash even if 24 V DC supply to

this input terminal is cut off.

31. Key Lock Indicator [KEY LOCK]

Lights when the output volume controls and

channel keys are locked. (See p. 143, "Key Lock

Settings and Cancellation.")

32. Control Input Unit Connection Indicator [1]

Indicates "1" when the SX-2000CI is connected

to the SX-2000AO.

33. Control Output Unit Connection Indicator [2]

Indicates "2" when the SX-2000CO is connected

to the SX-2000AO.

34. Monitor Level Meter

Indicates the sound volume level of the output

channel being monitored.

35. Monitor Level Meter Scale

Lights when the monitor ON/OFF key (15) is set

to ON.

36. Monitor ON/OFF Indicator [LEVEL]

Lights when the monitor ON/OFF key (15) is set

to ON.

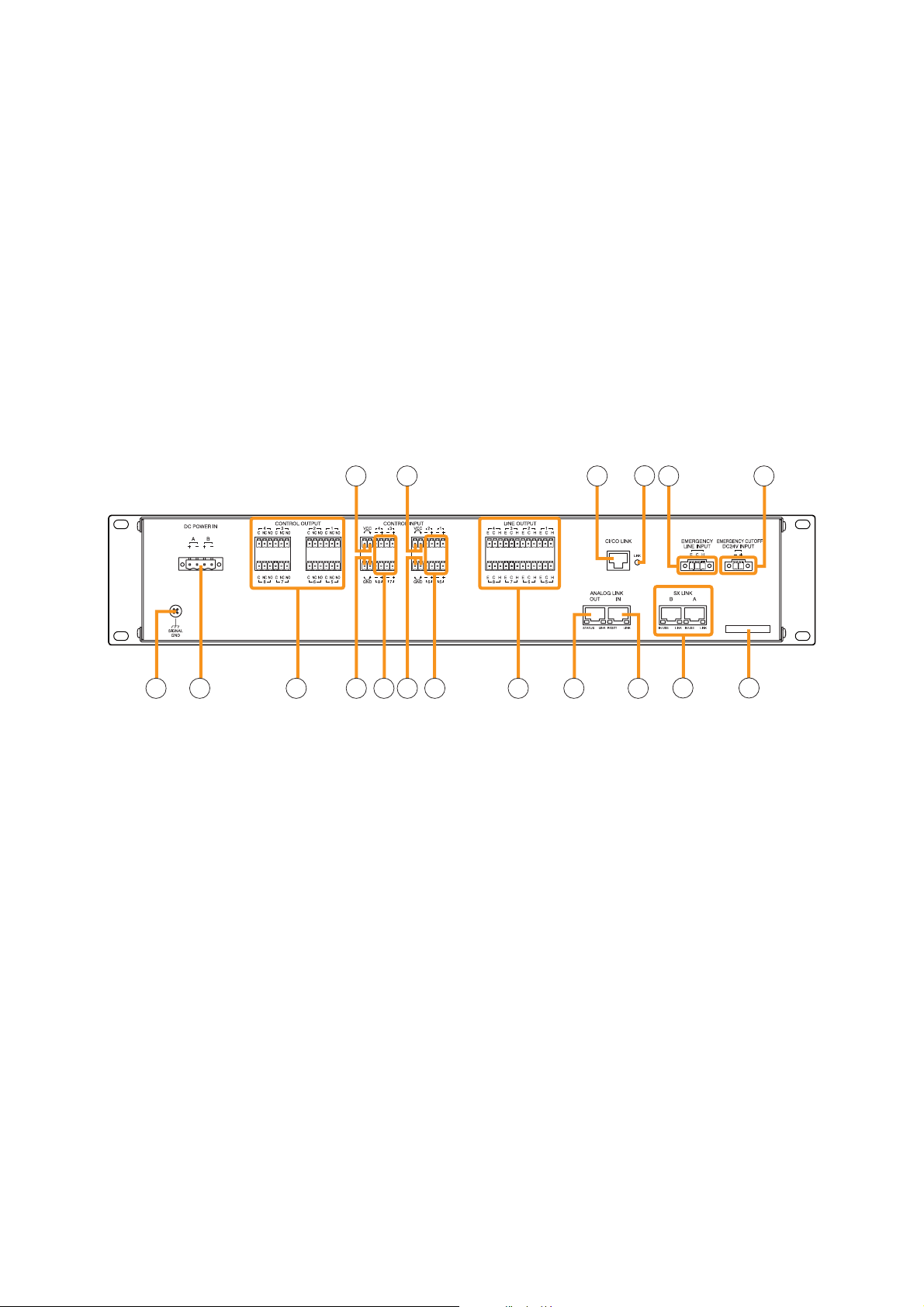

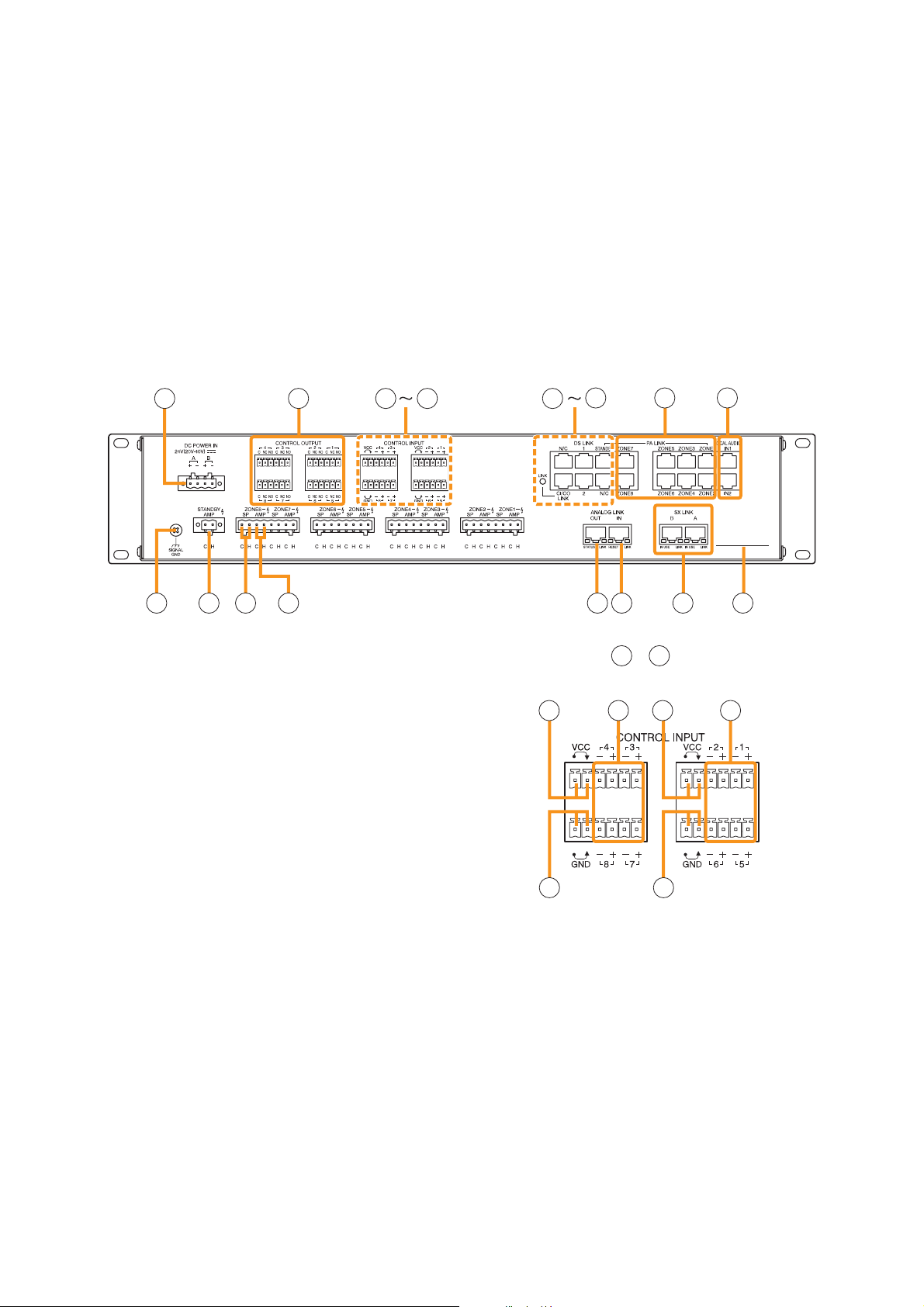

[Rear]

37. Functional Earth Terminal [SIGNAL GND]

Hum noise may be generated when external

equipment is connected to the unit. Connecting

this terminal to the functional earth terminal of

the external equipment may reduce the hum

noise.

Note: This terminal is not for protective earth.

38. DC Power Input Terminal [DC POWER IN]

Connect an optional DC power supply unit to this

terminal. Select the DC power supply source with

consideration given to the current power

consumption of the system the SX-2000AO is to

be connected to. When not using a redundant

power system*, connect the [+] terminal of input

A to the [+] terminal of input B, and the [–]

terminal of input A to the [–] terminal of input B.

(

Refer to the Instruction Manual attached to the

VX-2000DS.

)

* A method of connecting separate power

sources to each power input or connecting the

commercial power supply and backup power

supply separately to each power input to

prevent the system from going down when a

cable is broken or power fails.

39. Control Output Terminals

[CONTROL OUTPUT 1 – 8]

Relay make contact outputs.

Each contact capacity is rated at 40 V DC for

withstand voltage, and 2 mA – 300 mA for

control current.

These terminals are controlled by the SX-2000

Setting Software. (See the separate Setting

Software Instructions, "Pattern Settings.")

40. Power Feed Jumper 2 [VCC]

The supplied removable terminal plug is

equipped with a jumper.

When the jumper is attached, the circuits of

control inputs 3, 4, 7, and 8 are powered from

inside the SX-2000AO.

Removing the jumper disconnects this internal

power supply and thus requires that power be

supplied externally to the circuit. (See "Operation

of Power Feed Jumper and Isolation Jumper" on

the next page.)

SX-2000AO

40

43

46

47 48 49

37 38 39

41 42 42

44 45

50 51

52 53

Page 24

41. Isolation Jumper 2 [GND]

The supplied removable terminal plug is

equipped with a jumper.

When the jumper is attached, the [–] terminals of

control inputs 3, 4, 7, and 8 are connected to the

internal power supply.

Removing the jumper disconnects and isolates

these [–] terminals from this unit. (See

"Operation of Power Feed Jumper and Isolation

Jumper" shown below.)

42. Control Input Terminals

[CONTROL INPUT 1 – 8]

Photo coupler inputs.

A current of approximately 2 mA flows when

shorted, and the voltage becomes under 40 V

DC when opened. The input of 100 msec or

greater is required to operate.

These contact inputs can be isolated from the

SX-2000AO unit by cutting power feed jumpers 1

(43) and 2 (40) and isolation jumpers 1 (44) and

2 (41). Each contact input when isolated is 40 V

DC for maximum applied voltage and

approximately 2 mA for the loop current.

Since each terminal is equipped with a current

limiter employing constant current circuitry, there

is no need to limit the current on the external

equipment side.

The [–] terminals of 1, 2, 5, and 6 are common,

while those of 3, 4, 7, and 8 are common.

Use the SX-2000 Setting Software to assign

functions to these terminals. (See the separate

Setting Software Instructions, "Event Settings.")

43. Power Feed Jumper 1 [VCC]

The supplied removable terminal plug is

equipped with a jumper.

When the jumper is attached, the circuits of

control inputs 1, 2, 5, and 6 are powered from

inside the SX-2000AO.

Removing the jumper disconnects this internal

power supply and thus requires that power be

supplied externally to the circuit. (See "Operation

of Power Feed Jumper and Isolation Jumper"

shown below.)

44. Isolation Jumper 1 [GND]

The supplied removable terminal plug is

equipped with a jumper.

When the jumper is attached, the [–] terminals of

control inputs 1, 2, 5, and 6 are connected to the

internal power supply.

Removing the jumper disconnects and isolates

these [–] terminals from this unit. (See

"Operation of Power Feed Jumper and Isolation

Jumper" shown below.)

45. Audio Output Terminals [LINE OUTPUT]

Output audio signals to be broadcast.

These outputs are electronically balanced, but

can be converted into transformer-balanced type

using optional IT-450 transformers. (See p. 57,

"Converting an output into a transformerbalanced output.")

Note

Each output cannot be converted into

unbalanced type as it is electronically balanced.

To convert each output into unbalanced type,

use an optional IT-450 transformer.

46. CI/CO Link Terminal [CI/CO LINK]

Connect this terminal to the CI/CO Link Data

Terminal of the SX-2000CI or SX-2000CO.

47.

CI/CO Link Connection Indicator [LINK] (Green)

Lights when the SX-2000CI or the SX-2000CO is

connected.

48. Emergency Audio Input Terminal

[EMERGENCY LINE INPUT]

Connect a voice evacuation system equipment to

this terminal. The input signal is routed to all

audio output terminals when the SX-2000AO is

turned off or 24 V DC is not applied to the 24 V

Emergency cutoff input terminal (49).

49. 24 V Emergency Cutoff Input Terminal

[EMERGENCY CUTOFF DC24 V INPUT]

Controls the Emergency audio input.

Input current is under 5 mA.

24

SX-2000AO

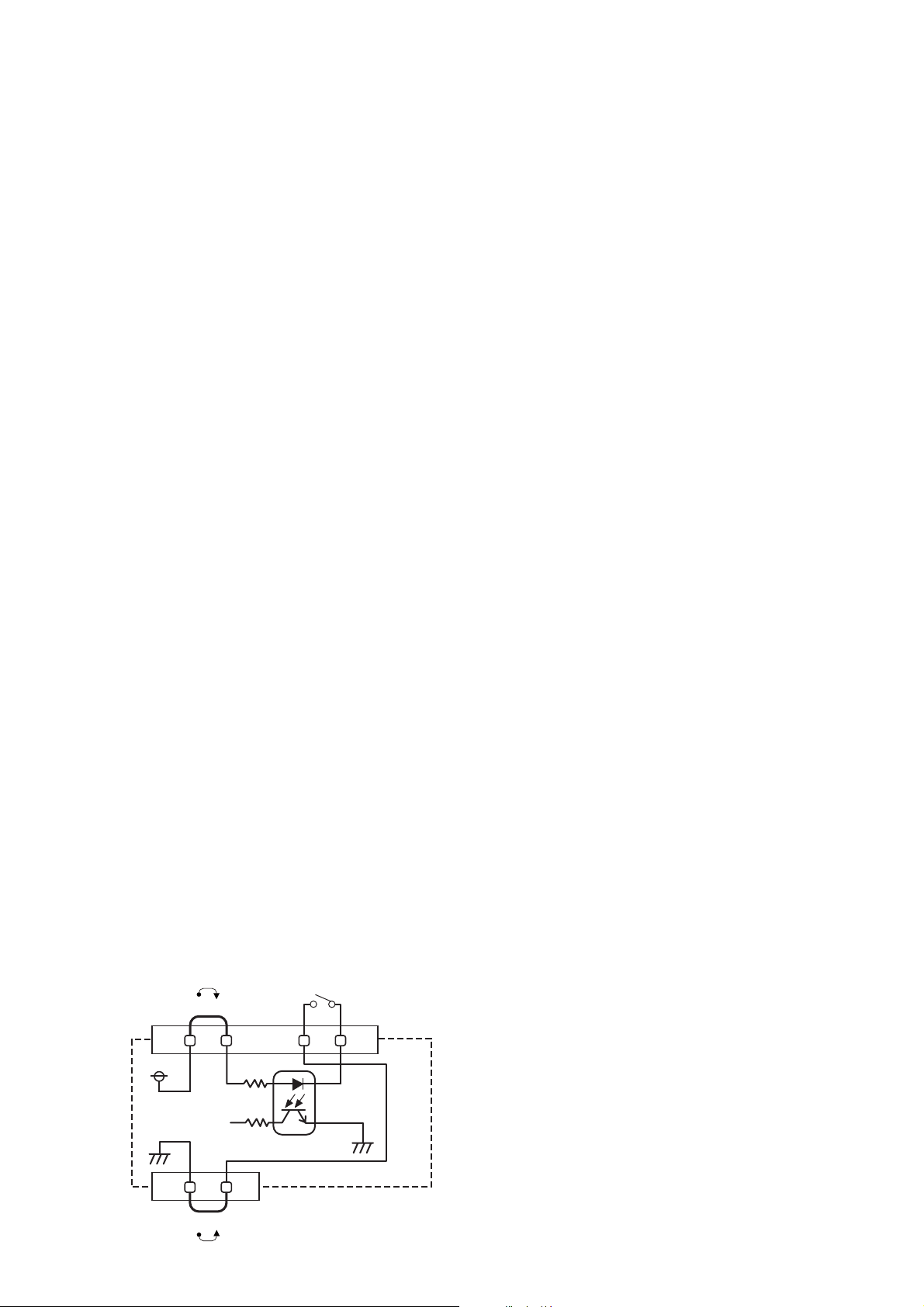

[Operation of Power Feed Jumper and Isolation Jumper]

VCC

Power feed jumper

Isolation jumper

GND

Control input

-

Photo coupler

+

Internal circuit

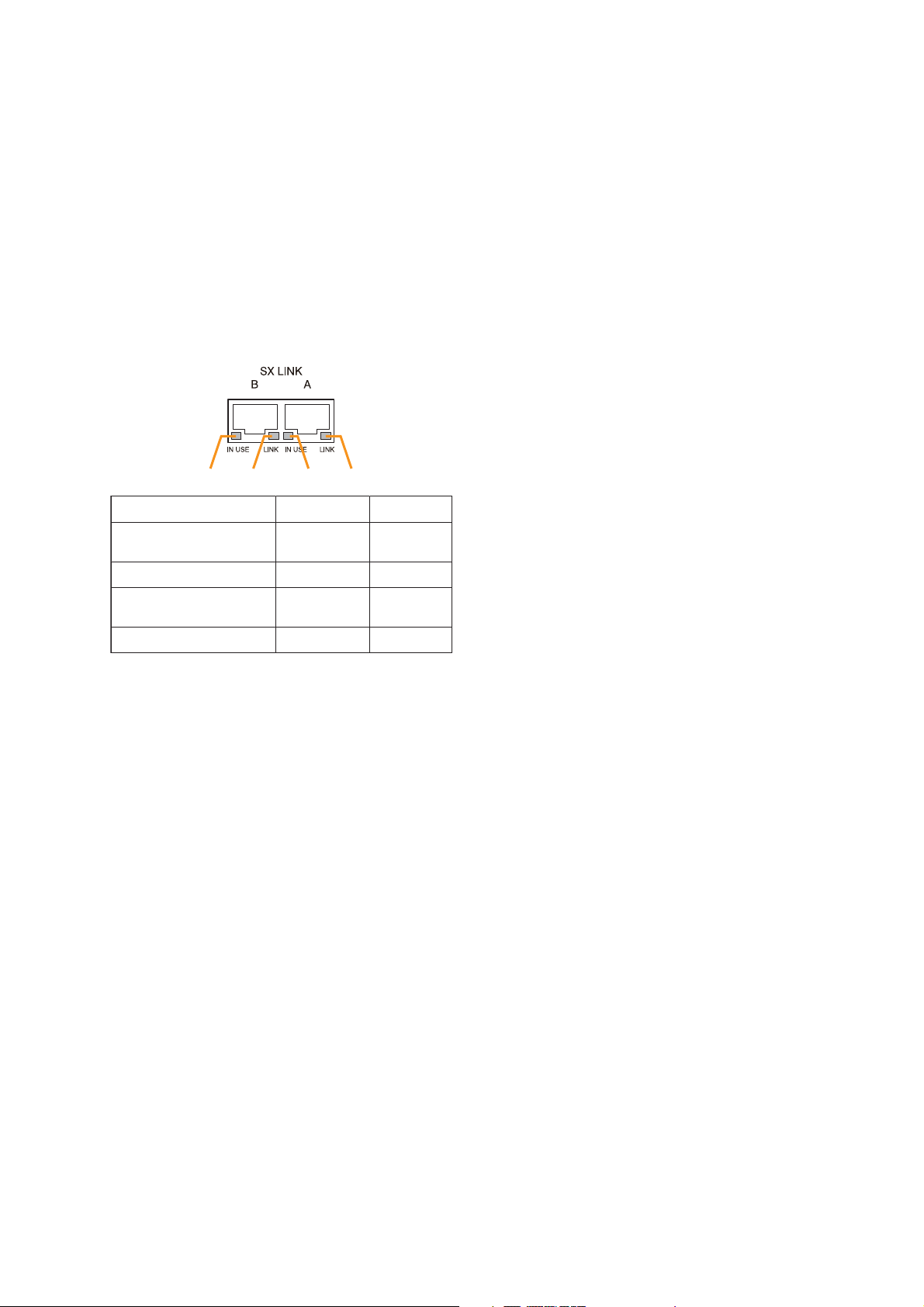

Page 25

25

50. Analog Link Output Terminal

[ANALOG LINK OUT]

Connect this terminal to the analog link input

terminal of the SX-2000AI, SX-2100AI, SX2000AO, or SX-2100AO.

51. Analog Link Input Terminal

[ANALOG LINK IN]

Connect this terminal to the analog link output

terminal of the SX-2000SM, SX-2000AI, SX2100AI, SX-2000AO, or SX-2100AO.

52. SX Link Terminals [SX LINK A/B]

Use switching hubs to connect between the SX

link terminals of the SX-2000SM, SX-2000AI, SX2100AI, SX-2000AO, and SX-2100AO. Connect

each of the SX Links A and B to the same

switching hub*, or to different switching hubs* that

have been

connected in star configuration.

Notes

• Be sure to connect both terminals of A and B.

• After connection completion, press the Reset

key to reactivate the SX-2000AO.

* Contact your TOA dealer for more information

on switching hubs.

53. MAC Address

MAC address to be used for SX link connection.

SX-2000AO

1 2

Function LED On LED Off

1. Not used

2. OUT connection confirmation Connected Unconnected

1 234

Function

LED On/Flashing

LED Off

34

Function LED On LED Off

3. RESET input Resetting Normal

4. Not used

1. B operation in progress

indication

2. B connection confirmation Connected Unconnected

3. A operation in progress

indication

4. A connection confirmation Connected Unconnected

Operating Not operating

Operating Not operating

Page 26

26

1.5. SX-2100AO Audio Output Unit

[Front]

1. Monitor Speaker

Allows any output channel to be monitored.

2. Function Keys [F1, F2, F3, F4]

Pressing a function key executes the function that

has been assigned to that key using the SX-2000

Setting Software.

(See the separate Setting Software Instructions,

"Event Settings.")

3. Fluorescent Display

The default display shows device numbers and

firmware versions.

Displays the SX-2100AO's current operation

status, output level, etc. (See the separate

Operating Instructions, "SX-2100AO Audio Output

Unit.")

4. Menu Key [MENU]

Pressing this key displays the fluorescent display's

menu screen. Whenever this key is pressed, the

screen returns to the default display for whatever

portion of the menu screen is displayed.

5. Cancel Key [ /CANCEL]

Used to switch the menu screen.

6. Minus Key [–]

Used to switch the menu screen.

When the Monitor ON/OFF Key (15) is set to ON,

use this key to select which channel to monitor.

The selected channel number decreases by one

each time this key is pressed.

7. Plus Key [+]

Used to switch the menu screen.

When the Monitor ON/OFF Key (15) is set to ON,

use this key to select which channel to monitor.

The selected channel number increases by one

each time this key is pressed.

8. OK Key [OK/ ]

Used to switch the menu screen.

9. Power Indicator [POWER] (Blue)

Lights when the power is switched on.

10. CPU OFF Indicator [CPU OFF] (Red)

Lights while the general urgency all-call (CPU

OFF state) is being made (p. 68).

SX-2100AO

1 2 3 114 5 6 7 8 9 10

Protective cover

12 13 14 15

Inside of the protective cover

F

E

D

C

B

A

16 18 1917

1

1

0

0

2

2

F

3

3

E

4

4

D

5

5

C

6

6

B

7

7

A

8

8

9

9

20

AO– 1 VER300

Device No. Firmware version

..

Page 27

27

11. Standby Indicator [STANDBY] (Green)

Lights while the unit is being initialized at poweron or at reset.

Flashes when the fluorescent display is in light