Page 1

When using the WMK-Series mounting kit on a combustible wall, it is recommended to

use vent pipe rated for reduced clearances to combustibles. Vent pipe manufacturer’s

clearances must be adhered to.

WMK mounting location must be based on “Termination Clearances” found in the

Auto-Draft instruction manual for U.S. and Canadian installations.

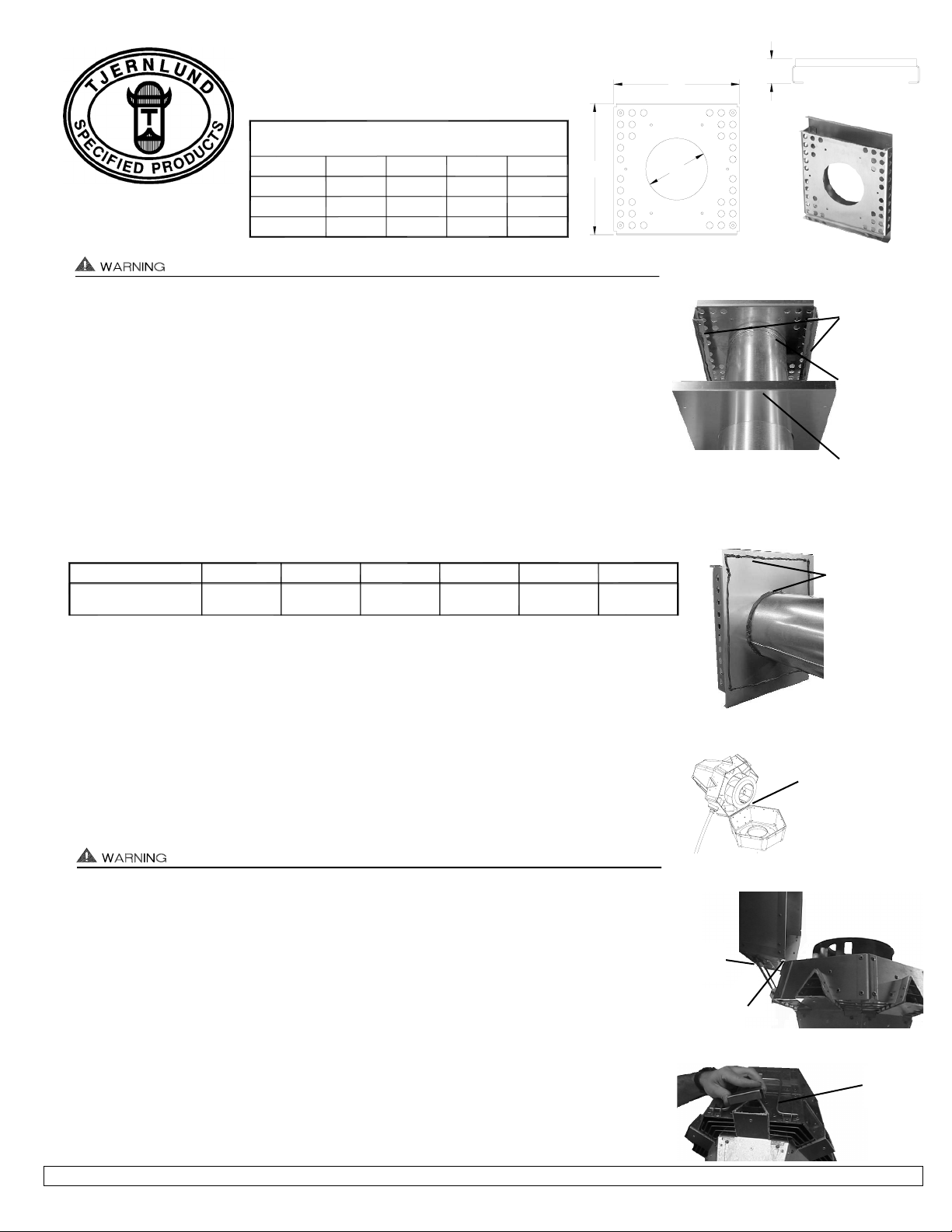

IMPORTANT: The diameter of hole in the Backing Plate for each kit is 9 1/8” for WMK-8, 11 1/8”

for WMK-10, 13 1/8” for WMK-12. The Backing Plate hole may be trimmed out for larger pipe

diameters.

1. Using Backing plate as a template, center over opening on wall to mark bolt hole locations on

wall. There are (4) for the WMK-8 and (8) for the WMK-10 & WMK-12. Flanges of Backing

Plate must face top and bottom. IMPORTANT: Flanges of backing plate must be level when

marking bolt hole locations on wall, (See Diagram A). Drill out and tap holes as necessary for

appropriate lag bolts to support the weight of the Auto-Draft® unit as shown below.

2. Insert Inlet Collar through WMK and secure the Inlet Collar with self tapping stainless steel

screws to a length of vent pipe required to get through wall. Make sure the screws are long

enough to penetrate vent pipe to adequately secure Inlet Collar. Slide Backing Plate

over vent pipe with flanges facing towards WMK. Place a bead of hi-temp silicone on WMK

back flange and slide Backing Plate up to WMK, (See Diagram A).

3. With Backing Plate pushed against WMK hi-temp siliconed flange, place a bead of hi-temp

silicone on the Backing Plate back side around perimeter of pipe opening and perimeter of

Backing Plate and firmly push assembly against wall with flanges facing top and bottom, (See

Diagram B). WMK and Backing Plate must be level. Secure WMK and Backing Plate to wall

with appropriate stainless steel lag bolts, washers and lock nuts, installer supplied. Hardware

utilized must support Auto-Draft® weight as shown above.

Auto-Draft® motor side is heavy. Housing hinge pin should be removed for easier installation. Support Venter base when removing hinge pin. When removing motor side, use

extreme caution so internal parts such as the impeller are not damaged, (See Diagram C).

4. IMPORTANT: Housing hinge must face down when mounting on a side wall, (See Diagram D).

Align WMK studs with holes in Auto-Draft® Inducer base, insert stainless steel washers

and secure the Auto-Draft® to the WMK with provided stainless steel keps nuts.

5. Seal around the Inducer base and the WMK with hi-temp silicone. Make sure it is watertight

so water can’t slip in between the Inducer base and WMK.

6. Reattach Auto-Draft® motor side to Base making sure that hinge pin is fully inserted in

hinges, (See Diagram C).

7. Apply a bead of hi-temp silicone on the cooling air inlet on top of Auto-Draft® and firmly

adhere triangle shaped cooling air inlet cover to cooling air inlet, (See Diagram E). This

procedure will prevent rain and/or snow from entering Inducer.

DIAGRAM E

TOP

COOLING

AIR INLET

DIAGRAM D

HOUSING

HINGE MUST

POINT DOWN.

SUPPORT

HANDLE

BRACKET

DIAGRAM C

HINGE PIN & MOTOR

SIDE SHOULD BE

REMOVED FOR

EASIER INSTALLATION.

SUPPORT VENTER

BASE AND MOTOR SIDE

WHEN REMOVING PIN.

DIAGRAM B

Centrifugal Impeller

FSAD-8 FSAD-10 FSAD-12 VSAD-8 VSAD-10 VSAD-12

MODEL

Fan Type

47

21.32

97

43.99

138

62.59

48

21.77

101

45.80

140

63.49

kgs

lbsWeight

WMK SERIES WALL MOUNT KIT DIMENSIONS

WMK-8

WMK-10

WMK-12 29.00

24.00

17.00

28.38

23.25

16.25

3.25

3.38

3.25

12.00

10.00

8.00

DCBA

(ALL DIMENSIONS ARE IN INCHES)

DA

B

FIGURE WMK 1b

C

WMK SERIES WALL MOUNTING KITS

Constructed out of rugged 5052 Aluminum.

ETL Recognized for zero - clearance

termination on combustible walls.

Tjernlund Products, Inc. • 1601 Ninth Street • White Bear Lake, MN 55110 • (651) 426-2993 • (800) 255-4208 • FAX (651) 426-9547 • www.tjernlund.com

P/N 8504097 11/01

DIAGRAM A

BACKING PLATE

FLANGES MUST

FACE TOP &

BOTTOM AND

BE LEVEL.

CAULK BACK

FLANGES OF

WMK WITH RTV.

RTV BACKING

PLATE PERIMETER

& AROUND VENT

PIPE BEFORE

ATTACHING TO

WALL.

SLIDE INLET

COLLAR

THROUGH WMK

AND ATTACH TO

VENT PIPE.

Loading...

Loading...