Page 1

TJERNLUND PRODUCTS, INC.

1601 Ninth Street • White Bear Lake, MN 55110-6794

PHONE (800) 255-4208 • (651) 426-2993 • FAX (651) 426-9547

Visit our web site • www.tjernlund.com

VP-2 For Millivolt Water Heaters up to

60,000 BTU/hr

Patented

MODELS

VP-3 For Millivolt Water Heaters from

60,000 to 120,000 BTU/hr

OWNERS INSTRUCTIONS

THESE INSTRUCTIONS MUST REMAIN

WITH EQUIPMENT

DO NOT DESTROY

ALWAYS FOLLOW WATER

HEATER MANUFACTURER’S

INSTRUCTIONS FOR PROPER

OPERATION OF HEATER AND

RE-LIGHTING OF PILOT

WATER HEATER VENT PACKAGE

For Natural Gas or LP

NOTE:

The VP-2 and VP-3 Water Heater Vent Packages use a solenoid valve as part

of the safety interlock circuit. The solenoid valve is installed in the gas supply piping

to the water heater’s thermostat/valve. To save installation time, do not pipe gas to

water heater before installing the gas solenoid valve.

OPTIONAL PILOT SAVER KIT AVAILABLE

The optional Pilot Saver Kit (P/N: 950-2061) allows for Solenoid Valve to be installed in

1/2” burner gas line from water heater gas valve to burner, eliminating pilot outages

caused by power interruptions.

Rev. A 01/00 Copyright © 2000, Tjernlund Products, Inc. All rights reserved. P/N 8504025

Page 2

Tjernlund Products welcomes your comments and questions. Address all correspondence to: Customer Service,

Tjernlund Products Inc., 1601 Ninth Street, White Bear Lake, MN 55110-6794 or email us at fanmail@tjfans.com.

TABLE OF CONTENTS

In The Event of a Pilot Outage ........................................................................................................................................1

Typical Installation...........................................................................................................................................................2

Sequence of Operation ...................................................................................................................................................2

Installation Restrictions....................................................................................................................................................3

Actuation and Safety Controls Installation ......................................................................................................................3

Gas Solenoid Valve...........................................................................................................................................3

Gas Pressure Switch ........................................................................................................................................4

Linear Limit Spillage Sensing Switch ..........................................................................................................4 - 5

Vent Hood .......................................................................................................................................................................5

Code Restrictions & Termination Clearances...................................................................................................5

Vent Hood Installation .......................................................................................................................................6

Power Venter Installation.................................................................................................................................................6

Code Requirements and Installation Restrictions............................................................................................ 6

Power Venter Installation .............................................................................................................................6 - 7

Electrical Connections.....................................................................................................................................................7

Control Cord Routing.................................................................................................................................. 7 - 8

Actuation and Safety Control Circuit Connections ............................................................................................8

Operation Circuit Check ..................................................................................................................................................8

Safety Interlock Test ...................................................................................................................................................8 - 9

Ladder Wiring Diagram ...................................................................................................................................................9

Combustion Air Test .................................................................................................................................................9 - 10

Performance Curves......................................................................................................................................................10

Troubleshooting Guide...........................................................................................................................................11 - 12

Maintenance..................................................................................................................................................................13

How to Obtain Service Assistance & Warranty.............................................................................................................13

Replacement Parts List .................................................................................................................................................13

Vent Hood Mounting Template ......................................................................................................................................14

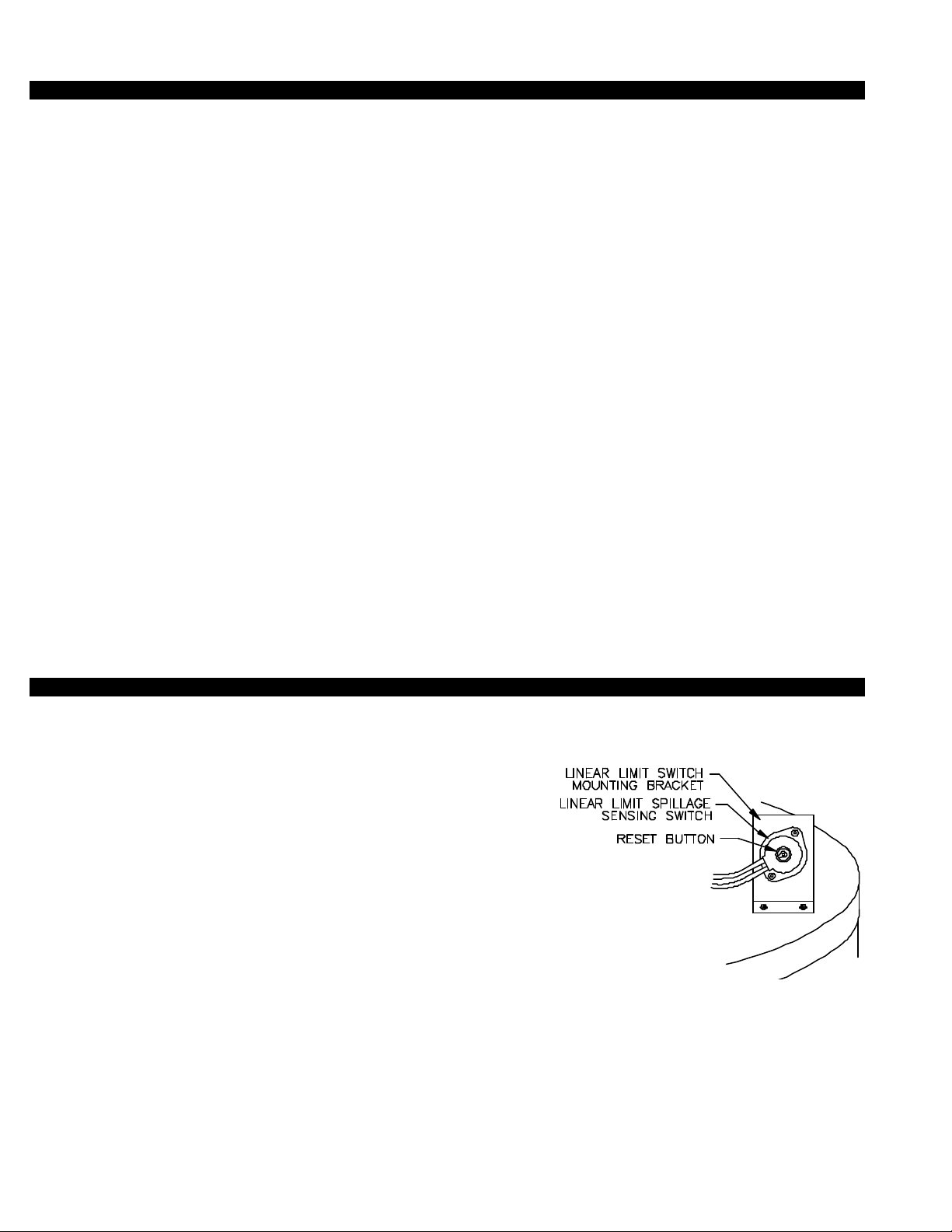

IN THE EVENT OF PILOT OUTAGE

1. Push the reset button in the center of the linear limit spillage sensing located on

the draft hood on the top of the water heater.

2. Turn the gas pilot knob at the top of water heater gas valve to “OFF” position.

WARNING: Gas pilot knob MUST REMAIN IN “OFF” POSITION FOR FIVE

MINUTES BEFORE PILOT IS RE-LIT. Perform steps 3 & 4 while waiting.

3. Visually verify that there is 115 volt power established to the Power Venter.

Check fuse or circuit breaker, wall plug and electrical connections.

4. Visually verify that all electrical connections of control cord circuit are intact.

5. Follow water heater manufacturer’s re-lighting instructions attached to water

heater or located in water heater owner’s manual.

USER NOTE:

Since the Power Venter cannot operate during a power outage, the safety interlock controls are designed to prohibit gas flow to the

water heater. Follow the above procedures and water heater manufacturer’s instructions for relighting the pilot when power has been

restored.

OPTIONAL PILOT SAVER KIT AVAILABLE

The optional Pilot Saver Kit (P/N: 950-2061) allows for Solenoid Valve to be installed in 1/2” burner gas line from water heater gas

valve to burner, eliminating pilot outages caused by power interruptions.

1

Page 3

INSTALLER NOTES

1. The installer must read and follow these instructions carefully to assure proper installation and operation of the water

heater vent package.

2. The installer must fill in the required information on the nameplate located on the Power Venter electrical box.

3. The installer must affix the wiring diagram label included with these instructions to the water heater casing adjacent to

its rating plate.

4. The water heater may only be installed on the suction side of Power Venter.

5. The installer must notify the homeowner of the maintenance (Page 13) required with the use of this product.

6. The installer must verify that the pilot safety controls on water heater are in good operating condition before

installation of the water heater vent package.

7. No more than 2 water heaters may be vented by either the VP-2 or VP-3.

8. The Power Venter must not be installed into any portion of a vent system which serves appliances other than the

one(s) vented by the VP-2 or VP-3.

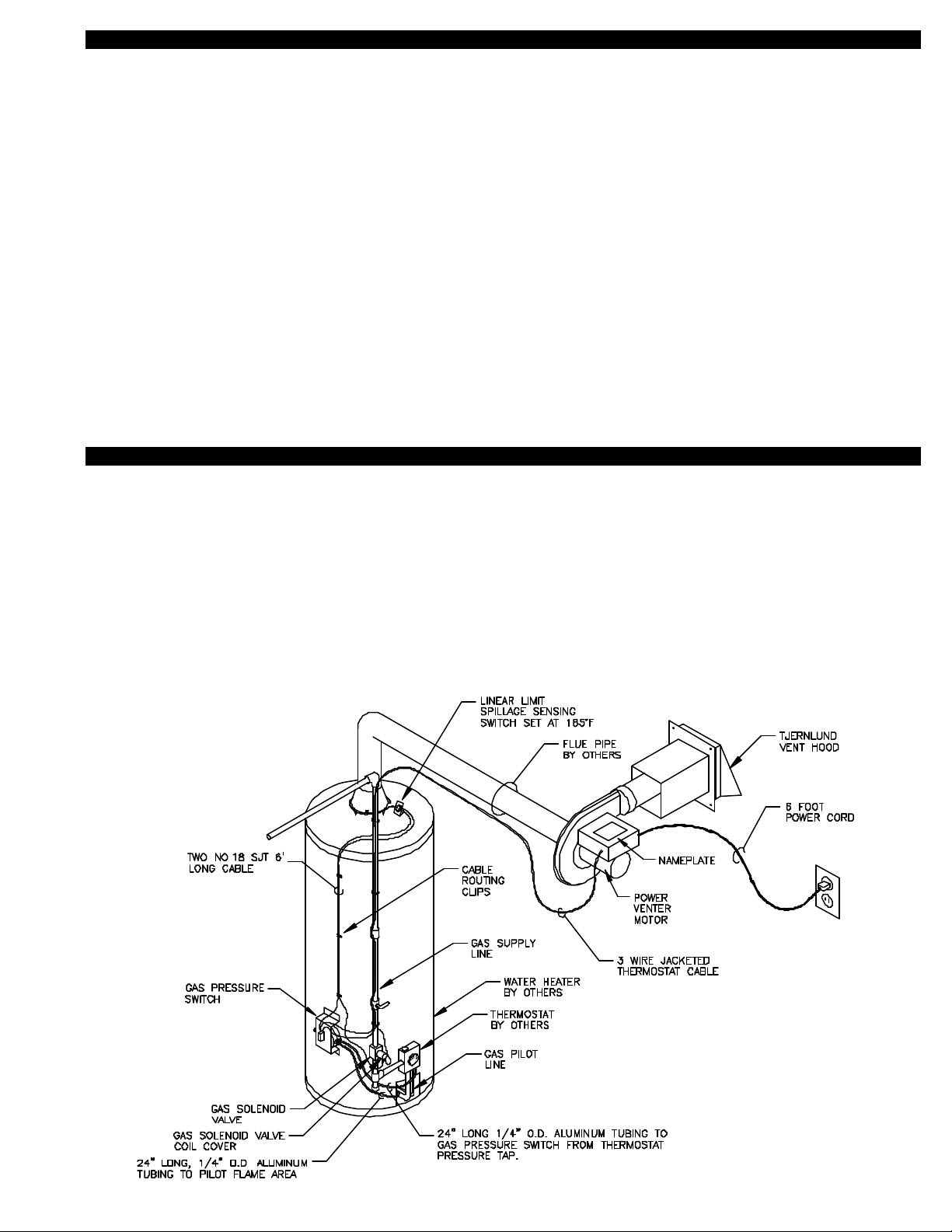

SEQUENCE OF OPERATION

1. Water heater thermostat calls for heat.

2. Simultaneously, the Power Venter is actuated by the gas pressure switch and the burner fires.

3. When the thermostat is satisfied the burner shuts down.

4. The Power Venter continues to operate for a non-adjustable time period of approximately 45 seconds to purge the

vent system of residual flue gases.

5. If, at any time, sustained flue gas spillage is detected by the linear limit spillage sensing switch the solenoid valve is

de-energized, disrupting the flow of gas to the burner and pilot. The reset button on the linear limit will need to be

pushed in and the pilot will need to be relit to establish water heater operation. NOTE: If optional Pilot Saver kit

(P/N: 950-2061) is installed pilot light should not have to be relit.

TYPICAL INSTALLATION

NOTE: The installer must install the Power

Venter downstream of the draft hood.

2

Page 4

INSTALLATION RESTRICTIONS

The Power Venter shall not be installed on incinerators, condensing type appliances or solid-fuel burning appliances.

The Power Venter may only be installed on appliances equipped with a draft hood, draft diverter or barometric draft control.

The Power Venter shall not be installed on an appliance with an automatic valve having a manual opener unless the manual opener

has been rendered inoperative or the automatic valve has been replaced with a valve not equipped with a manual opener.

CAUTION:

1. Failure to install, maintain and/or operate the Power Venter in accordance with manufacturer’s instructions

may result in conditions which can produce bodily injury and property damage.

2. The Power Venter must be installed by a qualified installer in accordance with these instructions and all local

codes or in their absence in accordance with the 1988 (or latest) Edition of the National Fuel Gas Code (NFPA #54), The

1987 (or latest) Edition of the National Electric Code (NFPA #70) and The Occupational Safety and Health Act (OSHA)

when applicable. If improperly installed a hazardous condition such as an explosion or carbon monoxide poison

accumulation could result.

3. “Qualified Installer” shall mean an individual properly trained and licensed.

4. The installer must write or imprint name, phone number, date of installation and sign in the appropriate space on the Power Venter

nameplate.

5. Plan the vent system so that Code required distances are maintained from plumbing and wiring.

6. The Power Venter motor shaft must be mounted horizontally to prevent motor bearing wear.

7. Flue gas temperature must not be exceed 5750F at Power Venter inlet. Ambient temperature must not exceed 1040F.

8. Disconnect power supply when making wiring connections or when working around the fan blade and motor. Failure

to do so may result in severe personal injury and equipment damage.

9. Make certain the power source is adequate for the fan motor requirements. Do not add the Power Venter to a circuit

where the total load is unknown.

10. The installer must verify that the BTU/hr input of the water heater does not exceed the recommended input of the

VP-2 (60,000) or VP-3 (120,000).

11. A safety inspection of the water heater must be performed before installation of the VP-2 or VP-3 as outlined in

ANSI Z223.1/NFPA #54, Appendix H.

ACTUATION AND SAFETY CONTROLS INSTALLATION

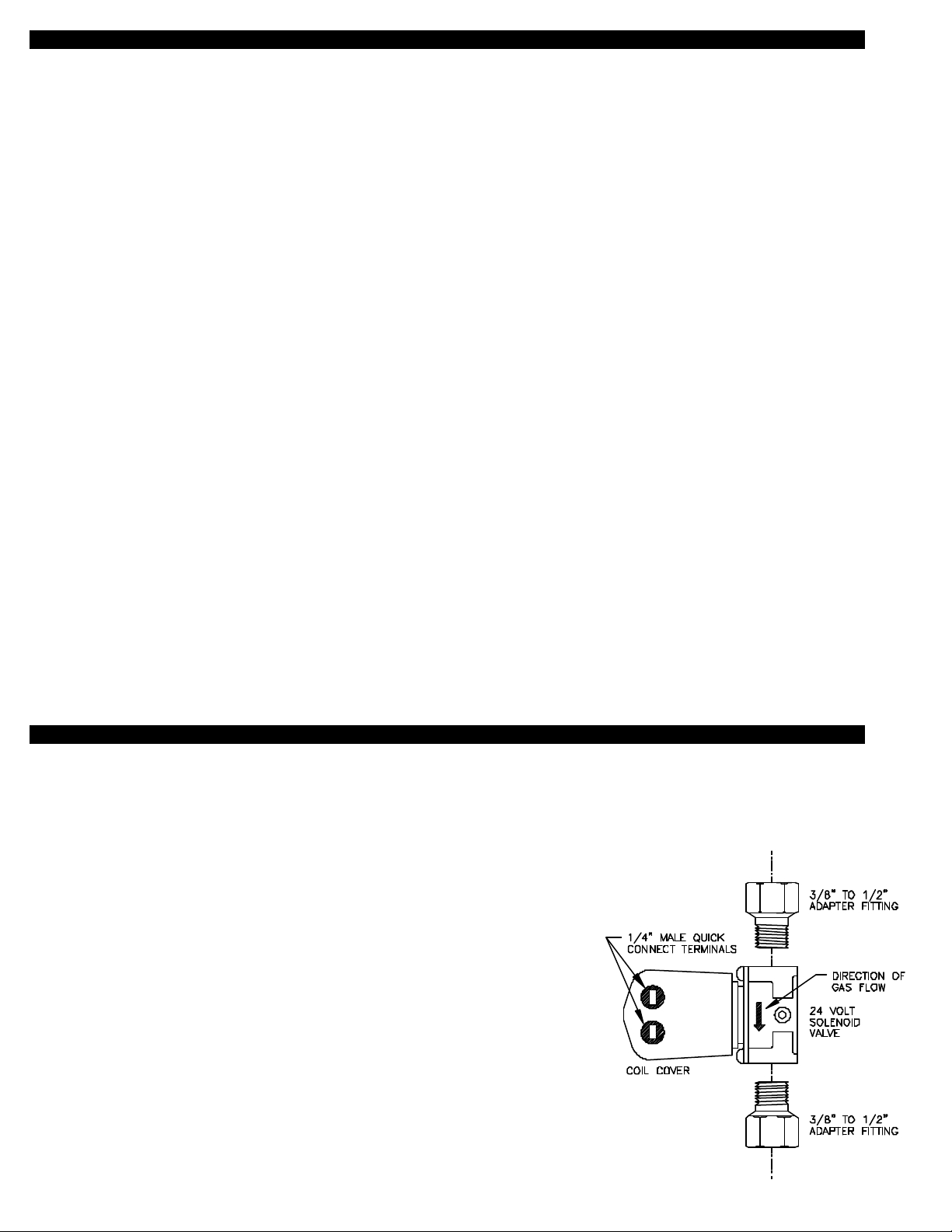

GAS SOLENOID VALVE INSTALLATION

After opening carton, inspect thoroughly for hidden damage. Fan blade should rotate freely. If any damage is found notify freight

carrier and your distributor immediately and file a concealed damage claim.

1. Remove the carton labeled “Actuation and Safety Controls.”

2. Open this carton and remove the gas solenoid valve. Make sure that the black coil guard

is covering the coil of the solenoid valve as shown, (See Diagram A).

3. Remove the 3/8” to 1/2” adapters and install as shown. Use thread sealant to ensure a

gas-tight seal. NOTE: 3/8” to 1/2” adapters are not used if using Pilot Saver kit

(P/N: 950-2061).

4. Turn off the gas supply line to the water heater using the shutoff valve in the supply line

to the water heater.

5. Install the solenoid valve between the manual shut off valve and the water heater

thermostat/valve. NOTE: If using Pilot Saver kit (P/N: 950-2061), Solenoid Valve is

installed in 1/2” burner gas line from water heater gas valve to burner.

6. Verify that the arrow on the solenoid valve points in the direction of gas flow to the water

heater. The solenoid valve should be positioned so the top of the coil cover is on top of

or horizontal to the solenoid valve. The top of the solenoid cover must not be pointing

downward.

7. After installation of the solenoid valve conduct a gas leakage test of the appliance piping

and control system down stream of the shutoff valve in the supply line to the appliance

as outlined in the 1988 (or latest) Edition of NFPA 54, ANSI Z223.1, part 4. Any leaks

detected must be repaired and retested.

DIAGRAM A

3

Page 5

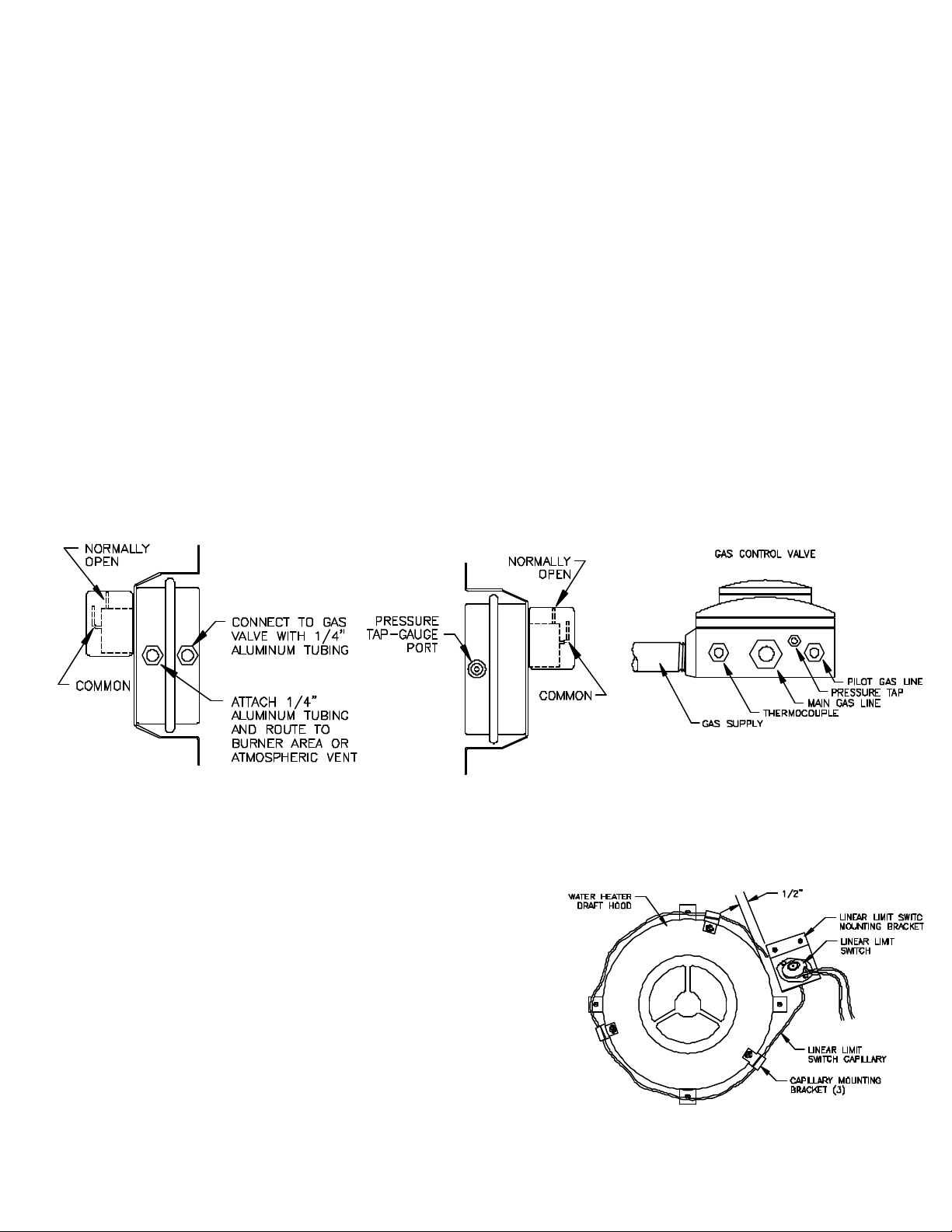

GAS

PRESSURE

SWITCH

INSTALLATION

Remove the gas pressure switch from the carton also remove the 1/8” compression fitting, the four 1/2” x #10 self tapping screws and

the 2 sections of 1/4” diameter aluminum tubing from the master carton liner.

The gas pressure switch is mounted on the casing of the water heater adjacent to the heater’s thermostat/valve. It should be mounted

close enough so that the supplied 1/4” tubing will reach from the gas pressure switch fittings to the burner. The four provided screws

are self tapping and drilling. They do not require the use of a drill. Their 1/2” length assures that the inner tank will not be penetrated.

1. Mount the gas pressure switch by securing it to the heater casing with a screw in each of the four mounting holes.

2. Using a tube cutter, cut the appropriate length of 1/4” tubing to reach from the fitting marked “connect to gas valve” to the pressure

tap port of the thermostat/valve, (See Diagram B). NOTE: DO NOT alter the heater’s PILOT GAS LINE, (See Diagram B, Gas

Control Valve).

3. Remove the pressure tap plug from the underside of the thermostat/valve and install the supplied compression fitting. Use thread

sealant, do not over tighten.

4. Use 1/4” tubing to connect the fitting installed in step #3 to the fitting marked “connect to gas valve” on the gas pressure switch.

Make sure each end of the tubing is not pinched closed.

5. Measure and cut an appropriate length of tubing to reach from the fitting marked “warning” to the burner of the water

heater. Connect tubing to gas pressure switch and route to pilot/burner area. NOTE: DO NOT locate the tubing in the

pilot/burner flame.

6. Conduct a gas leakage test of the aluminum tubing as outlined in the 1988 (or latest) edition of NFPA 54, ANSI Z223.1, part 4.

NOTE: The gas pressure switch has a built in pressure tap marked “gauge port”.

DIAGRAM B

LINEAR LIMIT SPILLAGE SENSING SWITCH INSTALLATION

PURPOSE:

To provide a means for appliance shut-down in the event of flue blockage

or Power Venter failure.

OPERATION:

When concentrated spillage of the products of combustion occurs from the

draft hood, the linear limit sensing switch circuit will open preventing burner

operation.

NOTE: Do not alter pilot gas line

DIAGRAM C

1. Attach the linear limit sensing switch mounting bracket to the top of the

water heater using the sheet metal screws provided. The linear limit

bracket should be approximately 1/2” from the draft hood.

2. Attach the three linear limit capillary mounting brackets around the draft

hood, equally spaced.

3. Insert the linear limit spillage sensing switch capillary into the “U” of the

linear limit brackets outlining the perimeter of the draft hood. The linear limit capillary may be overlapped if necessary,

(See Diagram C). IMPORTANT: DO NOT CUT THE CAPILLARY, it will be destroyed and water heater will be disabled.

4

Page 6

4. Route the linear limit spillage sensing switch cable down the water heater casing locating the end near the solenoid

valve. Secure it with the cable clamps and self drilling screws provided.

VENT HOOD TERMINATION CLEARANCES

CODE REQUIREMENTS

Failure to follow these installation instructions may violate applicable national and/or local codes. Terminate the vent system so that

proper minimum clearances are maintained as cited in the latest edition of the National Fuel Gas Code (NFPA # 54) and the latest edition of Chimneys, Fireplaces, Vents, and Solid Fuel Burning Appliances (NFPA #211), or as follows:

• Not be less than 7 feet above grade when located adjacent to public walk ways.

• At least 3 feet above any forced air inlet located within 10 feet.

• At least 4 feet below, 4 feet horizontally from or 1 foot above any door, window or gravity air inlet into any building.

• At least 12 inches above grade.

• So that the flue gases are not directed so as to jeopardize people, overheat combustible structures or enter buildings, and

• Not less than 2 feet from an adjacent building.

The vent terminal shall also not be installed closer than 3 feet from the inside corner of an L shaped structure.

1. Check vent pipe system for leakage. All vent system leaks must be sealed prior to installation of a power venter.

2. A vent system incorporating a Tjernlund VH1 Series vent hood should not exceed 575o F.

3. Termination of a sidewall vent system with a device other than the Tjernlund VH1 Series vent hood could affect system

performance and result in a possible safety hazard.

4. Plan the vent system layout to avoid the possibility of accidental contact with wiring or plumbing inside of walls.

5. Installation must be done by one experienced and familiar with venting of combustion appliances.

5

Page 7

VENT HOOD INSTALLATION

1. Verify that proposed Vent Hood location will conform to “Vent Hood Termination Clearances” on page 5.

2. Use scissors to detach Vent Hood Mounting Template on page 14. Follow instructions on Vent Hood template.

POWER VENTER INSTALLATION

CODE REQUIREMENTS

Power Venter installation must be in accordance with the following requirements of the National Fuel Gas Code: (ANSI Z223.1)

• All portions of the vent system under positive pressure during operation (on the outlet side of the Power Venter) shall be designed

and installed so as to prevent leakage of flue or vent gases into a building.

• All appliances must enter the vent system on the inlet side of the Power Venter.

• Provision shall be made to interlock the appliance(s) to prevent the flow of gas to the main burners when the draft system is not

performing so as to satisfy the operating requirements of the equipment for safe performance.

INSTALLATION RESTRICTIONS

1. Power Venter should be installed as close to the termination of the vent system as possible to prevent flue gas leakage.

2. Power Venter must be installed with the motor shaft horizontal to prevent motor bearing wear.

3. Power Venter housing is single wall. Six inch clearance must be maintained to combustible materials.

4. If installing the VP-2, 3” vent pipe may be used from the water heater to the Power Venter. If the flue outlet is larger

than 3”, install a tapered reducer directly after the draft hood of the water heater.

If installing the VP-3, 4” vent pipe may be used from the water heater to the Power Venter. If the flue outlet is larger

than 4”, install a tapered reducer directly after the draft hood of the water heater.

NOTE: All reducers and vent pipe are to be supplied by the installer and are available from your local heating wholesaler.

5. The equivalent vent pipe length of elbows and straight pipe must be calculated. The total equivalent length must not

exceed 75 feet with no more than 25 equivalent feet in elbows.

TAPERED REDUCER

6” CLEARANCE

FROM VENTER HOUSING

6

Page 8

MOUNTING POWER VENTER

1. To facilitate installation and reduce vibration, we have included 2 mounting brackets, 2 rubber isolators and 2 rubber

grommets. One of the brackets may be used temporarily as a “third hand” to support the Power Venter while

positioning it for permanent installation. Install the brackets as shown below.

NOTE: The Power Venter may be mounted in any position as long as the shaft of the motor remains horizontal.

VP-2 MOUNTING VP-3 MOUNTING

2. Connect outlet of Power Venter to inner sleeve of vent hood. Sections of vent pipe are

permitted between Power Vent and Vent Hood but all connections after the Power Venter will

be under a positive pressure during operation. These connections must be sealed with high

temperature silicone sealant or aluminum vent pipe tape supplied by installer.

3. Using the holes as a guide, attach vent pipe to inlet collar using sheet metal screws. Install

properly sized vent pipe sections from Power Venter inlet to appliance outlet avoiding elbows

wherever possible and using only tapered transitions.

4. Support vent pipe in accordance with vent manufacturer’s instructions.

ELECTRICAL

Route the 25’ control cable supplied with the Power Venter back to the water heater controls along the ceiling joists, taking care not to

come closer than 6” to the vent pipe or any other potentially hot surface. In most cases, the gas supply line may be used as a routing

path from the ceiling to the water heater controls, the supplied nylon straps may be used to secure the cable.

NOTE: If the distance between the Power Venter and the heater controls is greater than the length of the cable, splice a section of 3

conductor PVC sheathed, 105 degree C thermostat cable to the supplied cable. Make sure the color coded leads remain consistent.

An NEC approved accessible junction box must be used to contain the splice. Splices shall be made mechanically secure and insulat ed with tape or fixture type splicing connectors may be employed. Strain relief hardware contained within the NEC approved junction

box shall be utilized.

The Power Venter operates on 110/115 VAC, therefore a grounded outlet must be within reach of the six foot power cord supplied with

Power Venter. The flexible power cord supplied with the unit may only be used where local codes permit. If local codes do not permit

the use of flexible power cord, follow steps below.

1. Remove the electrical box cover, flexible cord and strain relief from the enclosure.

2. Install suitable conduit fitting in enclosure and splice field wiring into existing wiring using code authorized method (wire nuts, etc.).

3. Replace electrical box cover.

7

Page 9

ACTUATING AND SAFETY CONTROL CIRCUIT CONNECTIONS

TYPICAL INSTALLATION

1. Push the black lead from the 6’ 18/2 cable onto the common terminal of the gas pressure switch.

2. Push the remaining black lead from the 6’ 18/2 cable onto one of the terminals on the solenoid valve.

3. Push the yellow lead from the 25’ control cable onto the remaining terminal on the solenoid valve.

4. Push the red lead from the 25’ control cable onto the piggyback terminal joined with common on the gas pressure switch.

5. Push the blue lead from the 25’ control cable onto the normally open terminal on the gas pressure switch.

6. Plug the power cord from the Power Venter into a grounded 115 VAC outlet. Verify that the outlet is powered through

a 15 amp circuit breaker.

NOTE: The installer must ensure that all electrical connections are tight.

1. Place water heater in operation.

A. The Power Venter should operate.

2. Turn gas pilot knob to “pilot”.

B. The Power Venter should continue to operate for approximately 45 seconds to purge the vent system of any residual flue gases.

3. Repeat steps 1 and 2 twice to assure operation.

1. Remove the blue lead from the normally open contact of the gas pressure switch. This will disable the Power Venter.

2. Adjust the heater’s thermostat or run hot water until full burner operation occurs.

3. Within 3 minutes the linear limit spillage sensing switch circuit should disrupt power to the gas solenoid valve, stopping the supply

of gas to water heater.

NOTE: The Power Venter May operate for approximately 45 seconds when power is first

established. Wait until the Power Venter shuts off before continuing.

OPERATION CIRCUIT CHECK

SAFETY INTERLOCK TEST

8

Page 10

4.

IMPORTANT

: Wait 4 minutes and push the reset button on linear limit spillage sensing switch.

5. Reconnect the blue lead to the normally open terminal of the gas pressure switch.

6. Light pilot following the heater manufacturer’s instructions. NOTE: Pilot should not have to be relit if using optional Pilot Saver Kit

(P/N 950-2061).

7. Extinguish the pilot with the burner off. Determine after 3 minutes that there is no gas flow to the main burner. If gas flow to the

main burner is detected, replace the water heater gas valve immediately.

VP-2 / VP-3 WATER HEATER VENT PACKAGE LADDER WIRING DIAGRAM

COMBUSTION AIR TEST

WARNING:

The linear limit spillage sensing switch is designed to alert the user to a potentially hazardous condition. It is not designed to, and cannot replace, regular vent system inspection, appliance servicing and combustion testing. DO NOT USE IT AS A SUBSTITUTE FOR

PROFESSIONAL APPLIANCE MAINTENANCE.

1. Close all doors and windows of the building. If the appliance is installed in a utility room or closet, close the entrance door. Close fire

place dampers.

2. Turn on clothes dryer. Turn on all exhaust fans, such as range hoods, bathroom exhaust and whole house fans to maximum speeds.

Do not operate a fan used strictly for summer exhausting.

9

Page 11

3. Following the water heater manufacturer’s instructions, place the appliance in operation, set thermostat for continuous operation.

4. Allow fans and appliance to operate for 5 minutes.

5. Tripping of the Linear LImit spillage sensing switch during the 5 minutes indicates an unsafe operating condition. Turn off fuel supply

to appliance and DO NOT OPERATE UNTIL UNSAFE VENTING CONDITION IS INVESTIGATED BY PROFESSIONAL

CONTRACTOR OR UTILITY SERVICE PERSONNEL.

6. Return all windows, doors and fans to their previous conditions of use.

7. Sign and date these instructions to verify that the Sign:

combustion air and safety interlock test have been

completed. These instructions must remain on Date:

premises.

PERFORMANCE CURVES

VP-2 PERFORMANCE CURVE

VP-3 PERFORMANCE CURVE

10

Page 12

VP-2 / VP-3 TROUBLESHOOTING GUIDE

NOTE: If the pilot light is extinguished, follow the steps under “IN THE EVENT OF

A PILOT OUTAGE” on page 1 of these instructions before continuing.

Note: For further assistance contact the Tjernlund

Products, Inc. Technical Customer Service

Department at 1-800-255-4208, 7:30 - 4:30 CST.

11

Page 13

NOTE:

If the pilot light is extinguished, follow the steps under “IN THE EVENT OF

A PILOT OUTAGE” on page 1 of these instructions before continuing.

Note: For further assistance contact the Tjernlund

Products, Inc. Technical Customer Service

Department at 1-800-255-4208, 7:30 - 4:30 CST.

12

Page 14

MAINTENANCE

1. Oil motor every six months with 2 drops of S.A.E. #20. The oil ports are located on the top ends of the motor. NOTE: The model

VP-3 motor does not need to be oiled if it is a Magnetek motor.

2. The Homeowner must semiannually inspect the vent hood and vent pipe for blockage, corrosion and leaks.

3. A vent system inspection must be performed annually by a qualified service agency. The inspection should include the

operation circuit check, safety interlock test, combustion air test and a visual inspection of the complete vent system for

corrosion, blockage and leaks. Any corrosion, blockage or leaks detected, must be replaced or repaired immediately.

HOW TO OBTAIN SERVICE ASSISTANCE

1. If you have any questions about your Power Venter or if it requires adjustment, repair or routine maintenance, we suggest that

you contact your installer, plumbing contractor or service agency.

2. If you require technical information contact Tjernlund Products, Inc. at 1-800-255-4208.

When contacting Tjernlund Products, Inc., please have the following information available:

1. Model number of the Power Venter

2. Name and address of installer and service agency

3. Date of original installation and dates any service work was performed

4. Details of the problem

LIMITED PARTS WARRANTY AND CLAIM PROCEDURE

Tjernlund Products, Inc. warrants the components of its products for one year from date of installation. This warranty covers defects

in material and workmanship. This warranty does not cover normal maintenance, transportation or installation charges for replacement parts or any other service calls or repairs. Products that are tampered with, damaged, installed improperly, wired incorrectly or

defective due to malfunctioning appliances are not covered under this warranty. This warranty DOES NOT cover the complete Power

Venter if it is operable, except for the defective part.

Tjernlund Products, Inc. will issue credit to the original distributor or provide a free part to replace one that becomes defective during

the one year warranty period. If the part is over 18 months old, proof of date of the installation in the form of the contractor sales /

installation receipt is necessary to prove the unit has been in service for under one year. All receipts should include the date code of

the Power Venter to ensure that the defective component corresponds with the complete unit. This will help preclude possible credit

refusal.

1.) Follow troubleshooting guide to determine defective component. If unable to determine faulty component, contact your Tjernlund

distributor or Tjernlund Products Technical Customer Service Department at 1-800-255-4208 for troubleshooting assistance.

2.) After the faulty component is determined, return it to your Tjernlund distributor for replacement. Please include Power Venter date

code component was taken from. The date code is located on the Electrical Box coverplate. If Power Venter date code is older

than 18 months you will need to provide a copy of the original installation receipt to your distributor. Credit or replacement will only

be issued to a Tjernlund distributor after the defective part has been returned prepaid to Tjernlund.

REPLACEMENT PARTS LIST

TJERNLUND LIMITED ONE YEAR WARRANTY

ITEM PART NUMBER

VP-2 Vent Hood VH1-3

VP-3 Vent Hood VH1-4

VP-2 Venter Motor 950-2020

VP-3 Venter Motor 950-1020

24V Solenoid Valve 950-2040

Gas Pressure Switch 950-2080

24V Transformer 950-2030

Post Purge Relay/Timer

(approx. 45 second non-adjustable delay) 950-0014

Post Purge Relay/Timer

(1 to 10 minute adjustable delay) 950-1067

Linear Limit Spill Switch 950-2064

25’ Control Cable 950-2060

Tjernlund Products, Inc. warrants to the original purchaser of this product that the

product will be free from defects due to faulty material or workmanship for a period

of (1) year from the date of original purchase or delivery to the original purchaser,

whichever is earlier. Remedies under this warranty are limited to repairing or replacing, at our option, any product which shall, within the above stated warranty period,

be returned to Tjernlund Products, Inc. at the address listed below, postage prepaid.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION

ON THE FACE HEREOF, AND TJERNLUND PRODUCTS, INC. EXPRESSLY DISCLAIMS LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING

FROM THE USE OF THIS PRODUCT. THIS WARRANTY IS IN LIEU OF ALL

OTHER EXPRESS WARRANTIES AND NO AGENT IS AUTHORIZED TO ASSUME

FOR US ANY LIABILITY ADDITIONAL TO THOSE SET FORTH IN THIS LIMITED

WARRANTY. IMPLIED WARRANTIES ARE LIMITED TO THE STATED DURATION

OF THIS LIMITED WARRANTY. Some states do not allow limitation on how long an

implied warranty lasts, so that limitation may not apply to you. In addition, some

states do not allow the exclusion or limitation of incidental or consequential damages,

so that above limitation or exclusion may not apply to you. This warranty gives you

specific legal rights and you may also have other rights which may vary from State

to State. Send all inquiries regarding warranty work to Tjernlund Products, Inc. 1601

9th Street, White Bear Lake, MN 55110-6794. Phone (651) 426-2993 •

(800) 255-4208 • Fax (651) 426-9547.

Pilot Saver Kit (Optional) 950-2061

13

Page 15

VENT HOOD MOUNTING TEMPLATE FOR VP-2 & VP-3

1. Use scissors to detach template. Verify “Vent Hood Installation Clearances”on page 5 are adhered to. Attach the Vent Hood

Mounting Template to the interior of the wall the vent hood will be penetrating.

2. Verify that wall penetration will not come in contact with concealed wiring or plumbing. Use VH1-3 template for the model VP-2

and VH1-4 template for the model VP-3. Using a 1/2” drill bit, drill two pilot holes where noted on the template. The drill bit

must be long enough to penetrate to the building exterior.

3. Attach the template to the building exterior aligning the pilot holes on the template with the pilot holes drilled in step 2.

4. Using a reciprocating saw, cut an opening through the building siding, wall board, etc., following the appropriate lines of the template.

5. Slide the Vent Hood through the opening and fasten to exterior wall using provided screws.

6. Once Power Venter is completely installed and secured, apply a bead of exterior rated caulk between Vent Hood flange and

exterior of building.

CUT OUT THIS SQUARE IF INSTALLING THE VP-3 (VH1-4” VENT HOOD)

CUT OUT THIS SQUARE IF INSTALLING THE VP-2 (VH1-3” VENT HOOD)

14

Loading...

Loading...