TJERNLUND SS1 SIDESHOT WITH UC1 UNIVERSAL CONTROL (VERSION X.02) 8504102 REV 0702, SIDESHOT SS1 Installation Instructions Manual

Page 1

TJERNLUND PRODUCTS, INC.

1601 Ninth Street • White Bear Lake, MN 55110-6794

PHONE (800) 255-4208 • (651) 426-2993 • FAX (651) 426-9547

Visit our web site • www.tjernlund.com

INCLUDES NEW UC1

UNIVERSAL CONTROL

REV. 7/02

MODEL SS1

INSTALLATION INSTRUCTIONS

Recognize this symbol as an indication of important Safety Information!

!

OWNER INSTRUCTIONS, DO NOT DESTROY

NOTE: FLUE GAS TEMPERATURES MUST NOT EXCEED

650oF AT VENT SYSTEM INLET.

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO QUALIFIED, LICENSED

SERVICE PERSONNEL FOR PROPER INSTALLATION, ADJUSTMENT AND

OPERATION OF THIS UNIT. READ THESE INSTRUCTIONS THOROUGHLY

BEFORE ATTEMPTING INSTALLATION OR OPERATION. FAILURE TO FOLLOW

THESE INSTRUCTIONS MAY RESULT IN IMPROPER INSTALLATION, ADJUSTMENT, SERVICE OR MAINTENANCE POSSIBLY RESULTING IN FIRE, ELECTRICAL SHOCK, CARBON MONOXIDE POISONING, EXPLOSION, OR PERSONAL

INJURY OR PROPERTY DAMAGE.

DO NOT DESTROY. PLEASE READ CAREFULLY AND

KEEP IN A SAFE PLACE FOR FUTURE REFERENCE.

Copyright © 2002, Tjernlund Products, Inc. All rights reserved P/N 8504102

Page 2

Tjernlund Products welcomes your comments and questions. Address all correspondence to:

Customer Service • Tjernlund Products, Inc. • 1601 Ninth Street • White Bear Lake, MN 55110-6794

Call us toll free at 800-255-4208, visit our web site @ www.tjernlund.com or email us at fanmail@tjfans.com.

TABLE OF CONTENTS

Page (s)

Description and Specifications ....................................................................................................................................1, 2

Installation Restrictions .................................................................................................................................................2

Cautions .........................................................................................................................................................................3

Safety Inspection of a Previously Used Appliance .........................................................................................................3

SideShot Model SS1 Terminology ..................................................................................................................................3

SideShot®With Integral UC1 Universal Control Board Features ...................................................................................4

LED Status & Fault Indicators .........................................................................................................................................4

Pre / Post-Purge & Prover Status Check Settings...........................................................................................................5

Termination Clearances .................................................................................................................................................6

Installation

Tools Required .................................................................................................................................................7

Vent Hood Installation ..............................................................................................................................7, 8, 9

Installation of Rain Shield .................................................................................................................................8

Plenum Installation .................................................................................................................................8, 9, 10

Installation of Vent Pipe ............................................................................................................................10, 11

Electrical Wiring

Warnings, Sequence of Operation & Internal Schematic ...............................................................................12

Wiring to Oil Fired Equipment ............................................................................................................13, 14, 15

Wiring to Gas Fired Appliance .................................................................................................................16, 17

Draft Adjustment Procedure (Oil) ............................................................................................................................17, 18

Draft Adjustment Procedure (Gas) ..........................................................................................................................18, 19

Combustion Air............................................................................................................................................................. 19

System Operation Check Out .......................................................................................................................................19

Troubleshooting Oil Odors.......................................................................................................................................19, 20

Troubleshooting Electrical Problems.......................................................................................................................20, 21

Maintenance..................................................................................................................................................................21

Removal & Replacement of Motor/Wheel ......................................................................................................22

Warranty & Replacement Parts...............................................................................................................................22, 23

Mounting Templates

Template B Motor Notch ................................................................................................................................24

Template A Vent Hood Terminus....................................................................................................................25

SideShot® is a registered trademark of Tjernlund Products, Inc. for their Models SS1 & SS2 Vent Systems.

DESCRIPTION

The SS1 is a mechanical vent system designed and listed for use with natural draft oil or gas heating equipment. It is factory

assembled and wired. The SS1 automatically vents the flue gases from heating equipment to the outdoors. By combining outside

air with high-tech insulation, surrounding combustible materials and the Vent Hood exterior remain at safe temperatures. After

each burner cycle the SS1 will continue to operate in post-purge mode to purge the heater and vent of residual flue gases. A factory post-purge time is set at 2 minutes and is adjustable up 16 minutes, see “Pre / Post-purge Settings” on page 5. The SS1 features a safety system consisting of the integral UC1 Universal Control, a Fan Proving Switch and a High Limit temperature control.

These devices monitor the SS1’s performance and will interrupt the main burner if a venting malfunction is detected.

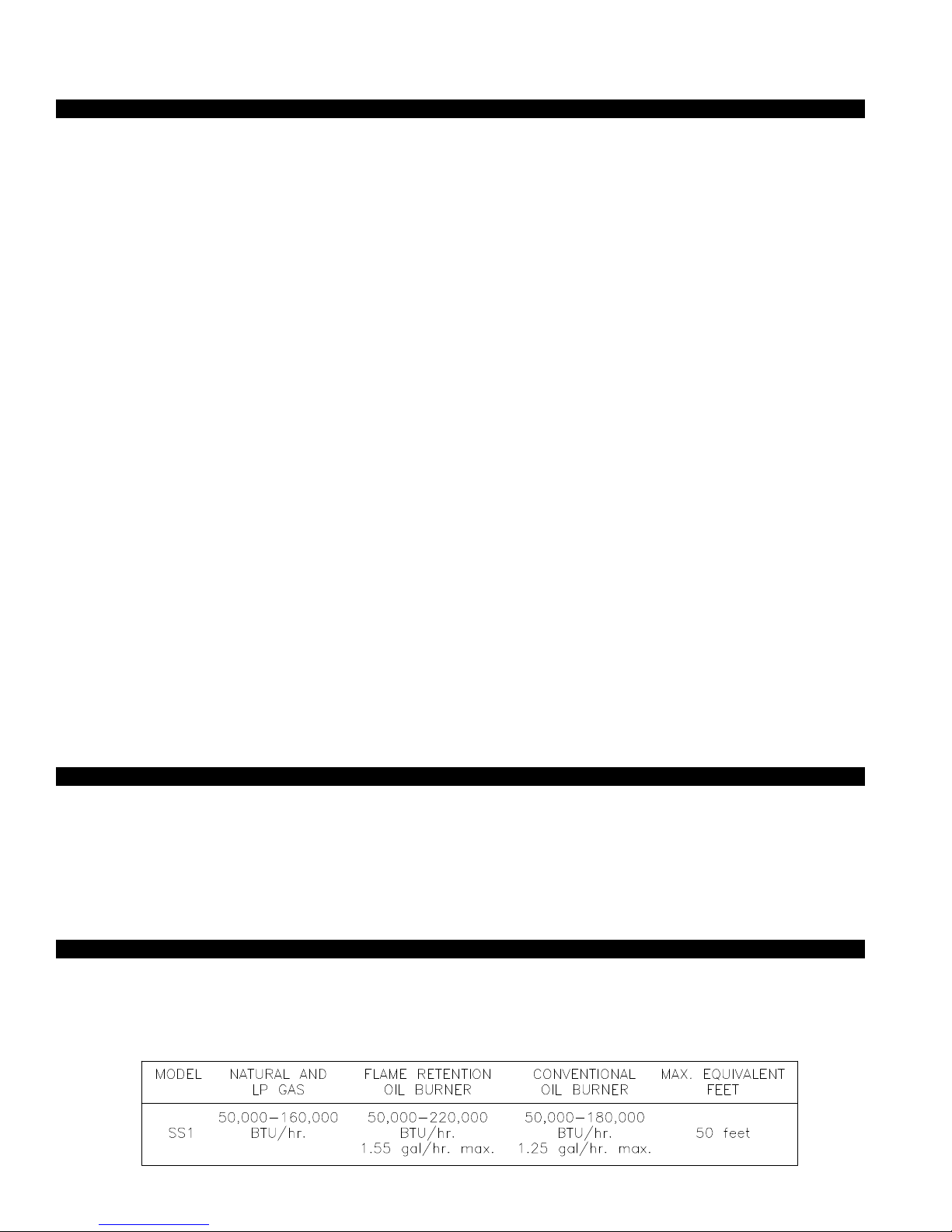

APPLICATION TABLE

Verify that the total BTU/hr. input of the heating appliance(s) fall within the proper category listed below. All BTU/hr. capacity

ranges are based on a maximum of 50 equivalent feet. To determine equivalent feet, add the total length of straight vent pipe plus

10 feet for each 90 degree elbow and 5 feet for each 45 degree elbow. Vent runs of over 15 linear feet should use an approved,

insulated vent connector to prevent problems related to sulfur condensation.

1

Page 3

2

SPECIFICATIONS

Motor: 115/1/60, 3300 RPM, 212 watts, 2.28 FLA

Fan Proving Switch: Non-adjustable, N/O with a set point of -.04" W.C.

High Limit: Manual reset, N/C contacts, open at 79oC (175oF) +

8oC (15oF)

UC1 Universal Control: See UC1 Universal Control Board Features on page 4.

Pre-Purge: Options (0, 15, 30, 60 seconds); Post-Purge: Factory set at 2 minutes, Options (0, 30 seconds or 1, 2, 4, 8, 16 minutes).

See Page 5 for Pre / Post-purge options.

GENERAL INFORMATION

These units have been factory tested and rated in accordance with the following Canadian Standards: CAN/CSA - B140.0-M87

General Requirements For Oil Burning Equipment; CAN/CSA - B139-M91 Installation Code For Oil Burning Equipment;

CAN3 - B255-M81 Mechanical Flue - Gas Exhausters.

Each SideShot is electrically factory line tested before shipment.

After opening carton, inspect thoroughly for hidden damage. Wheel should rotate freely. If any damage is found notify freight carrier and your distributor immediately and file a concealed damage claim.

INSTALLATION RESTRICTIONS

1. The SideShot may not be installed on condensing appliances, incinerators, incinerating toilets, or solid fuel burning appliances.

2. The SideShot Model SS1C is Listed for Oil Fired appliances only.

3. The SideShot may only be installed on appliances equipped with a barometric draft control.

4. The SideShot shall not be installed where flue gas temperatures exceed 301oC (575oF) at its inlet. Flue gas temperature

verification:

A) On oil fuel, verify flue gas temperature at SS1C inlet is at or above 250oF (121oC) after 5 minutes of operation during

setup. See “Oil Draft Adjustment Procedure” on page 17, step 10.

AND

B) Measure temperature of flue gases at the inlet to the SideShot at time of installation. Temperature should be

measured after appliance and SideShot have operated for at least 15 minutes, allowing flue gas temperature to stabilize.

5. The maximum recommended wall thickness is 39cm (15”).

6. Vent runs of over 4.5 linear meters (15 linear feet) should use an approved, insulated vent connector to prevent problems

related to sulfur condensation.

CAUTIONS

Improper installation, adjustment, alterations, service or maintenance can cause injury, property damage or death. Refer to this

manual. For assistance or additional information consult a qualified installer, service agency or the equipment supplier.

Do not exceed the recommended input range of the SideShot. Under no circumstances shall the minimum draft adjustment be

used for the larger input range of this product. Improper adjustment may result in the dispersion of flue products (carbon monoxide) into the building interior causing carbon monoxide poisoning or death.

If oil nozzle is changed or other equipment is added perform “Draft Adjustment Procedure” on pages 16, 17 again.

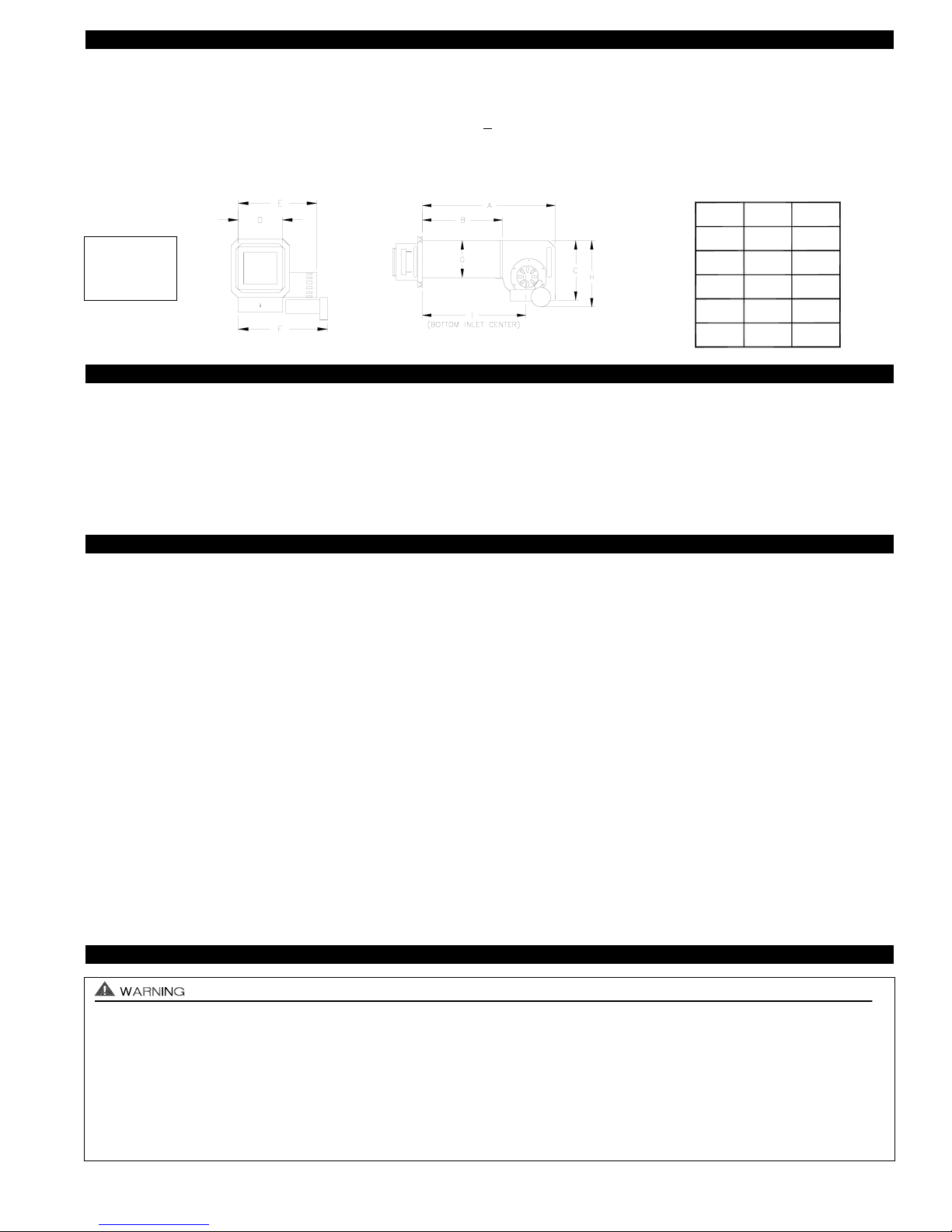

12 1/4"16 1/2"27 3/8"

ABC

15 1/8"

8"

D

13 3/4"

EF

7 3/4"G14 3/4"H23 1/4"

I

Rough-In

8” Height

8 3/8” Width

FRONT VIEW

SIDE VIEW

Page 4

CAUTIONS

The SS1 must be installed by a qualified installer (an individual properly licensed and/or trained) in accordance with all local

codes or, in their absence, in accordance with the appropriate National Fire Protection Association #31, #54, #211 and the

National Electrical Code.

Failure to install, maintain and/or operate the SS1 in accordance with manufacturer's instructions may result in conditions

which can produce bodily injury and property damage.

1. The installer must verify that the BTU/hr. input of the appliance does not exceed the recommended input of the SS1. See

“Application Table” on page 1 of these instructions for maximum input capacities.

2. Disconnect power supply from the SS1 and heating equipment when making wiring connections and servicing the SS1.

Failure to do so may result in personal injury and/or equipment damage. LED #5 (RED) should be off with power removed.

3. Plan the vent layout so that the code required clearances are maintained from plumbing, wiring and combustible materials.

4. The SideShot motor shaft must be mounted horizontally to ensure proper operation of the Fan Proving Switch and prevent

motor bearing wear.

5. Flue gas temperatures must not exceed 650oF at SideShot inlet. Ambient temperature must not exceed 104oF.

6. Oil fuel, flue gas temperature at vent system inlet must be at least 250oF during appliance steady state.

7. Make certain power source is adequate for the SideShot requirements. Do not add the SideShot to a circuit when the total

electrical load is unknown.

8. "Safety Inspection of a Previously Used Appliance", below must be completed when replacing a conventional chimney venting

system or when SideShot is installed on used heating equipment.

*SAFETY INSPECTION OF A PREVIOUSLY USED APPLIANCE

(Perform prior to SideShot installation)

The following procedure is intended as a guide to aid in determining that an appliance is properly installed and is in safe condition

for continuing use. This procedure is based on central furnace and boiler installations and it should be recognized that generalized procedures cannot anticipate all situations. Accordingly, in some cases deviation from this procedure may be necessary to

determine safe operation of the equipment.

a. This procedure should be performed prior to any attempt at modifications of the appliance or installation of the SS1.

b. If it is determined there is a condition which could result in an unsafe operation, the appliance should be shut off and the owner

advised of the unsafe condition.

The following steps should be followed in making the safety inspection:

1. Visually inspect the venting system and determine there is no blockage or restriction, leakage, corrosion or other deficiencies

which could cause an unsafe condition.

2a. Oil Installations: Inspect burner and primary control for proper operation.

2b. Gas Installations: Conduct a gas leakage test of the appliance piping and control system downstream of the shutoff valve

in the supply line to the appliance.

Inspect burners and cross overs for blockage and corrosion.

3. Applicable only to furnaces: Inspect heat exchanger for cracks, openings or excessive corrosion. Check both the limit control

and fan control for proper operation.

4. Applicable only to boilers: Inspect for evidence of water or combustion product leaks. Determine that the water pumps are in

operating condition. Test low water cutoffs, automatic feed controls, pressure and temperature limit controls and relief valves in

accordance with the manufacturer's recommendations to determine that they are in operating order.

*Excerpts from the National Fuel Gas Code (ANSI Z223.1/NFPA #54), Appendix H.

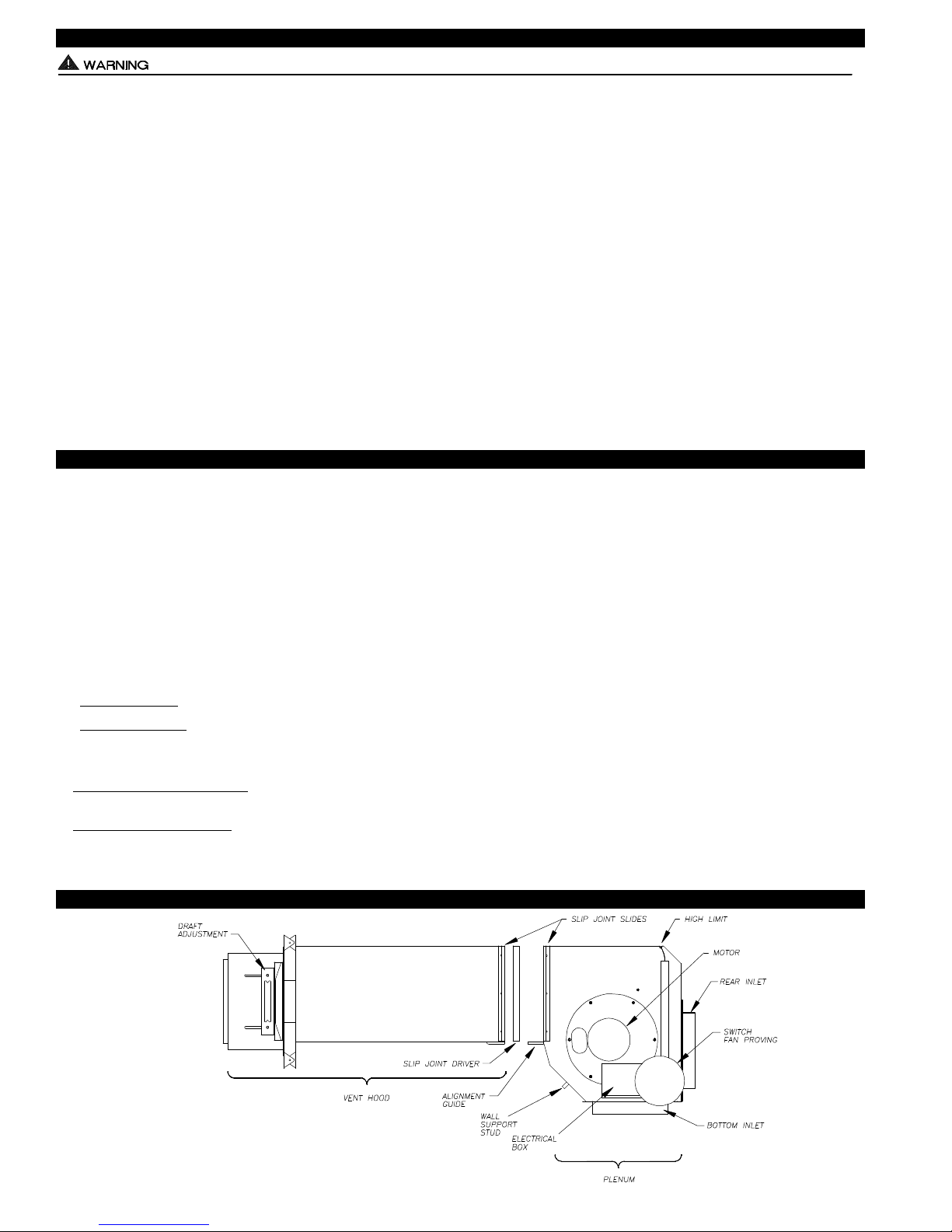

SIDESHOT®MODEL SS1 TERMINOLOGY

3

Page 5

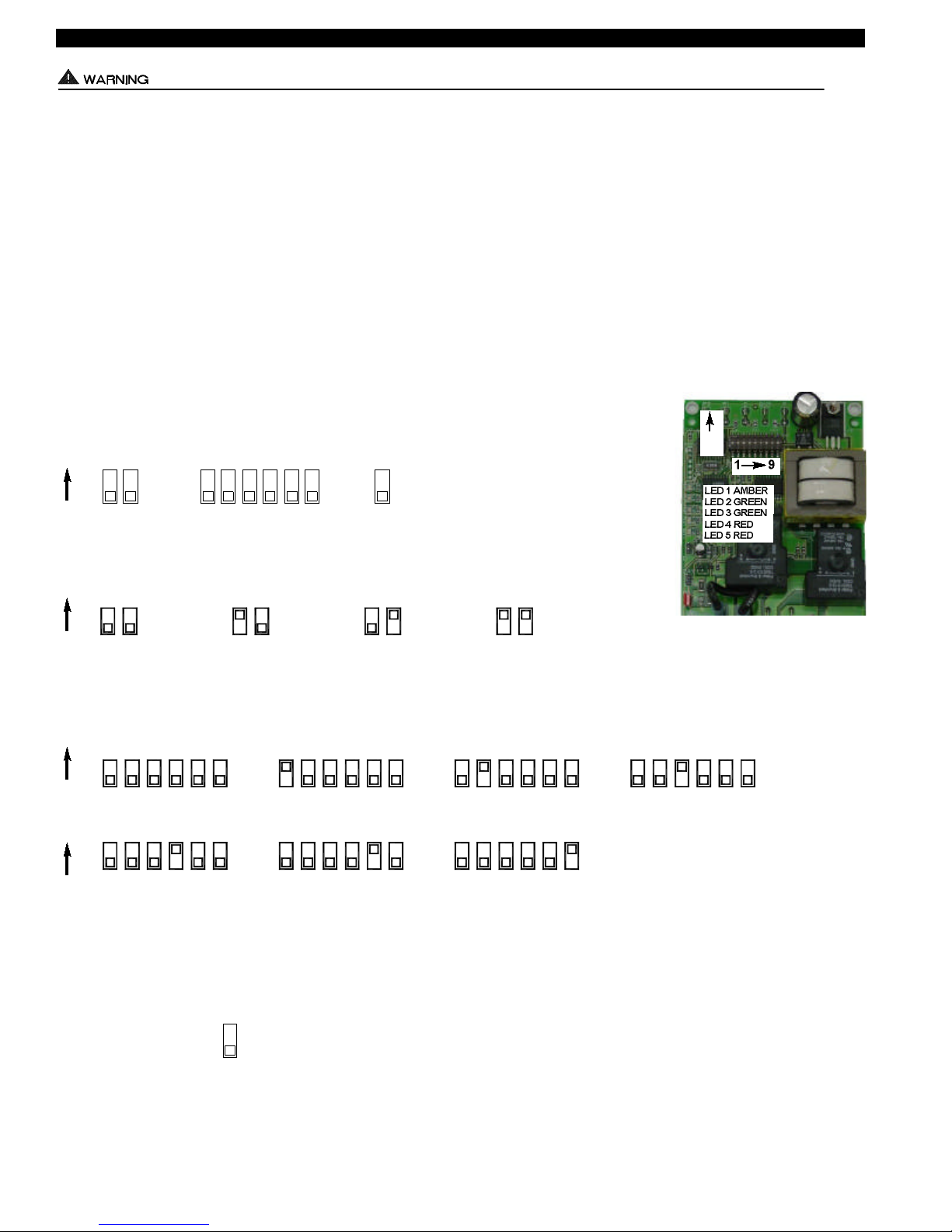

SS1 WITH INTEGRAL UC1 UNIVERSAL CONTROL BOARD FEATURES

P1 - P2 SAFETY CIRCUIT

TERMINALS

1 mA @ 5VDC.

SEE WARNING # 1.

DIP SWITCH SETTINGS

Pre-Purge (1-2)

Post-Purge (3-8)

Prover status check (9)

See “Pre / Post Purge &

Prover Status Check Dip

Switch Settings”.

LED STATUS LIGHTS

See “LED Status & Fault

Indicator Section” for details.

APPLIANCE CALL

VOLTAGE SELECTION

IMPORTANT

Place RED voltage jumper in

proper location based on

appliance call interlock voltage. SEE WARNING # 2.

J1- J2 CALL

JUMPER

Used when the call signal is

used as the “proven” return

signal to the appliance. See

wiring section for details.

APPLIANCE INTERLOCK

TERMINAL BLOCK (A-B, 1-4)

A - B - Dry Contact call. 3 mA @ 5VDC.

SEE WARNING # 1.

1 - 24 or 115 VAC intercepted call.

IMPORTANT: RED voltage jumper must

match intercepted call voltage.

2 - 24V common or 115V Neutral.

3 - Common terminal to appliance relay con-

tacts. IMPORTANT: J1-J2 jumper routes

call voltage at terminal 1 to 3. Remove

J1-J2 jumper if a different voltage source is

provided to terminal 3.

4 - Normally open terminal of appliance relay.

Will be energized from terminal 3 if safety

circuit is “proven”.

P1 P2 C GND F

LED 1 (AMBER)

LED 2 (GREEN)

LED 3 (GREEN)

LED 4 (RED)

LED 5 (RED)

DRY

24 V

115 V

A B 1 2 3 4 L N

C, GND, F AUXILIARY DEVICE

COMMUNICATION TERMINALS

2 mA @ 5VDC. For Tjernlund MAC1E or

MAC4E auxiliary devices. SEE WARNING # 1.

(1 9)

APPLIANCE

INTERLOCK

RELAY

J1 J2 XL XN

L / N - 115 VAC POWER

SUPPLY BLOCK

115 VAC / 50-60 Hz

Circuit protection provided by installer.

SEE WARNING # 3.

VENTER

MOTOR

RELAY

N M MTR

APPLIANCE INTERLOCK

RELAY

1 HP MAX LOAD across

terminals 3 & 4.

VENTER MOTOR RELAY

1 HP MAX LOAD from

terminals L to MTR & M.

XL / XN AUXILIARY DEVICE

POWER TERMINALS

115 VAC - Maximum of 0.15 Amps.

Only connect to Tjernlund auxiliary devices.

SEE WARNING # 1.

MTR & M LOAD TERMINALS

FROM VENTER MOTOR RELAY

Used to drive SS1 Motor.

1 HP MAX LOAD across terminals MTR & M / N.

# 1. Power supplied by board. Do not supply power to this area or control damage may result.

# 2. Do not supply power to the appliance interlock block with the call selector in the “DRY” position.

Control damage may result if power is supplied.

# 3. Circuit protection must be provided by the installer. 16 Amps is the maximum current allowed for this device at terminal L.

A 15 Amp circuit breaker is recommended.

I A

LED INDICATOR LIGHTS

LED #1 (Amber) Appliance call for heat.

LED #2 (Green) Safety circuit through P1 & P2 (SS1 Limit & Fan Prover) is verified “Open” upon start-up. Burner circuit is

energized with contact closure from terminal 3 to 4. Also verifies SS1 prover & limit are closed during run cycle.

LED #3 (Green) Power switched to SS1 Motor from L to MTR & M.

LED #4 (Red) Status indicator.

LED #5 (Red) 115 VAC power supplied to board. Also used as status indicator.

LED INDICATOR LIGHT STATUS & FAULTS

LED #4 & #5 Flashing Alternately = Prover start up fault. SS1 Prover contacts “Closed” across P1 & P2 upon appliance call

before SS1 is turned on. Prover status check must be activated, see page 5.

LED #4 & #5 Flashing in Unison = Fan Prover circuit is “Open” longer than 60 seconds on start-up or 10 seconds during run

cycle. Prover or Limit contacts are not staying “Closed” across P1 & P2 safety circuit.

LED #4 Flashing & #5 on Continuous = System in Pre-Purge. (Pre-Purge options 0, 15, 30, 60 seconds)

LED #5 Flashing & #4 on Continuous = System in Post-Purge. (Post-Purge options 0, 30 seconds or 1, 2, 4, 8, 16 minutes)

IMPORTANT: To reset faults, verify fault by checking the LEDs and then remove call for heat.

VETI

VETI

LED STATUS & FAULT INDICATORS

4

Page 6

PRE / POST PURGE AND PROVER STATUS CHECK DIP SWITCH SETTINGS

PRE-PURGE SETTINGS

Remove power to SS1 and heating equipment when installing, servicing or changing dip switch settings. Failure to do so may result in

personal injury and/or equipment damage. LED #5 (RED) should not be on if 115 VAC supply power is removed from the control.

Pre-purge

Used for a Venter with longer vent runs to get draft fully established throughout the vent system prior to burner ignition. Also beneficial for negative pressure prone environments. IMPORTANT: Pre-purge settings must be shorter than primary control lockout

time unless wired prior to primary control (i.e. aquastat / thermostat).

Post-purge

A Venter post-purge has been factory set at 2 minutes. Confirm that dip switch #5 is in the up or "on" position. Oil fired equipment

requires that the post-purge be long enough to eliminate post cycle nozzle drip odor. A longer post-purge may be necessary for

longer vent runs or high heat retention, refractory lined combustion chambers. A shorter post-purge may be desired for gas installations.

DIP SWITCH NUMBERING

Pre-Purge Post-Purge

Prover Status

Check Activated

ON

1

ON

ON

2 3 4 5 6 7 8 9

PRE-PURGE SETTINGS

1 2 1 2 1 2 1 2

0 Seconds 15 Seconds 30 Seconds 60 Seconds

POST-PURGE SETTINGS

ON

43 4865 7 3 5 6 7 8 3 4 5 6 7 8 3 754 6 8

1 Minute0 Seconds 30 Seconds 2 Minutes

ON

43 4865 7 3 5 6 7 8 3 4 5 6 7 8

4 Minutes 8 Minutes 16 Minutes

P1 & P2 FAN PROVER SAFETY CIRCUIT “OPEN” UPON APPLIANCE CALL

Prover Status

Check Activated

The Prover Status Check is activated from the factory. When activated the UC1 Universal Control

checks across P1 & P2 safety circuit (SS1 Prover & Limit) to verify that the Fan Prover switch is

“Open” upon a call for heat and not stuck “Closed”. IMPORTANT: This must always be in the

9

down “Activated” position when side wall venting.

5

Page 7

PLENUM AND VENT HOOD CLEARANCE FROM COMBUSTIBLES

With an inlet flue gas temperature of 650oF or below, the SideShot has been Listed for the following clearances from combustible

materials:

IMPORTANT

Vent Hood and top of Plenum: Zero Clearance

Plenum front and sides: 1/2 inch

Plenum rear: 3 inches

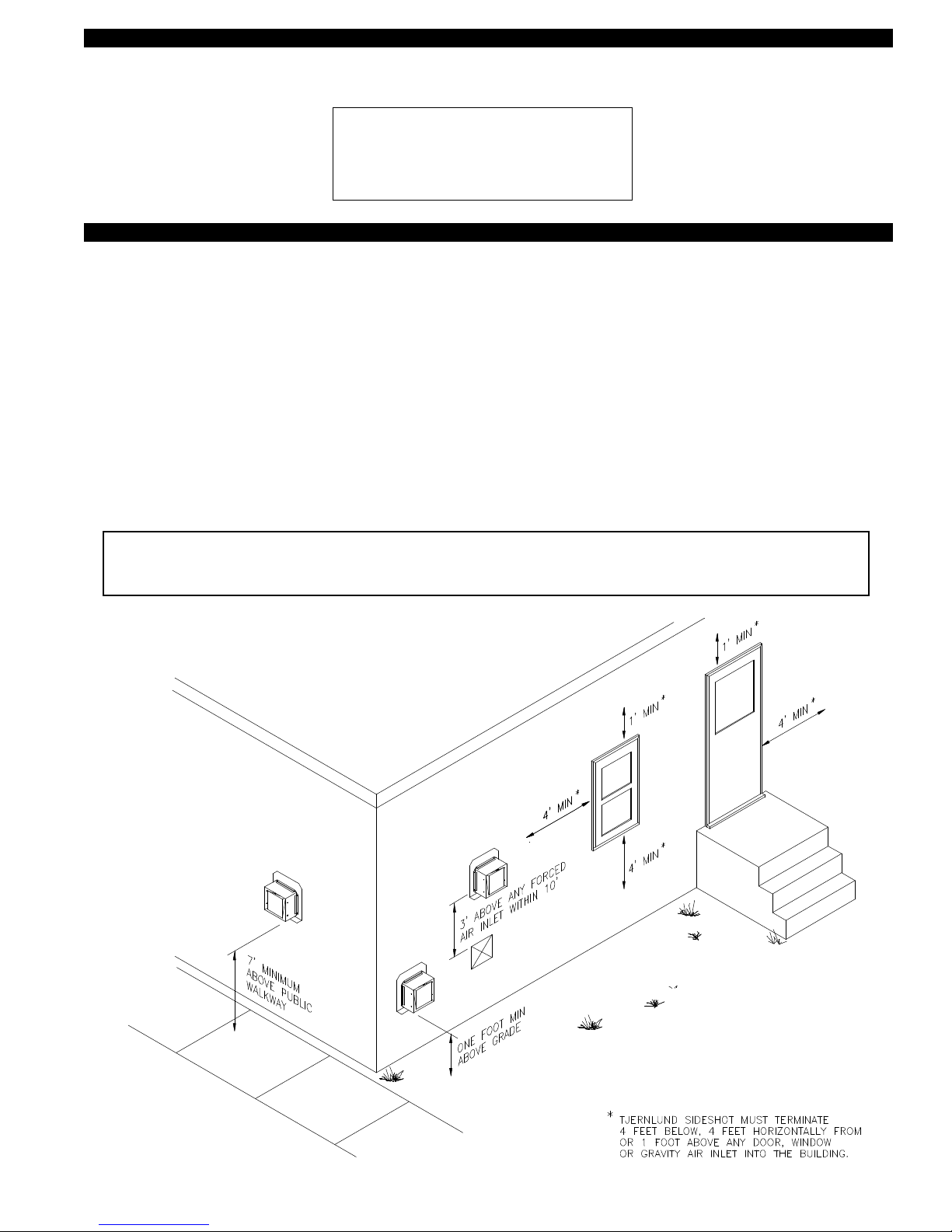

VENT HOOD TERMINATION CLEARANCES

The SideShot has been ETL Listed according to the requirements of the National Fire Protection Association #31, #54 and #211

as follows, (See Diagram A).

• The exit terminals of mechanical draft systems shall not be less than 7 feet above grade when located adjacent to public walk

ways.

• A venting system shall terminate at least 3 feet above any forced air inlet located within 10 feet.

• The venting system shall terminate at least 4 feet below, 4 feet horizontally from or 1 foot above any door, window or gravity air

inlet into any building.

• The bottom of the vent terminal shall be located at least 12 inches above grade.

• The exit terminal shall be so arranged that the flue gases are not directed so as to jeopardize people, overheat combustible

structures or enter buildings.

• Not to be less than 10 feet from an adjacent building.

The SideShot is also Listed to terminate a minimum of 12” below, above or horizontally from a soffit, deck or adjacent sidewall.

If possible, do not terminate the SS1 on a wall that faces the direction of the prevailing winds. Backdrafts by severe winds

can cause oil odors to remain in the structure and/or interrupt heating equipment operation.

DIAGRAM A

6

Page 8

INSTALLATION

Tools required:

• Reciprocating Saw • 1/2", 7/16",5/8" Wrench

• Drill and 1/8", 1/4", 1/2" Bits • 1/4" Masonry Drill Bit

• Blade Screwdriver • 1/4", 5/16”, 11/32" Nut Runner or Socket

• Wire Cutter/Stripper • Hammer

• Tube Cutter

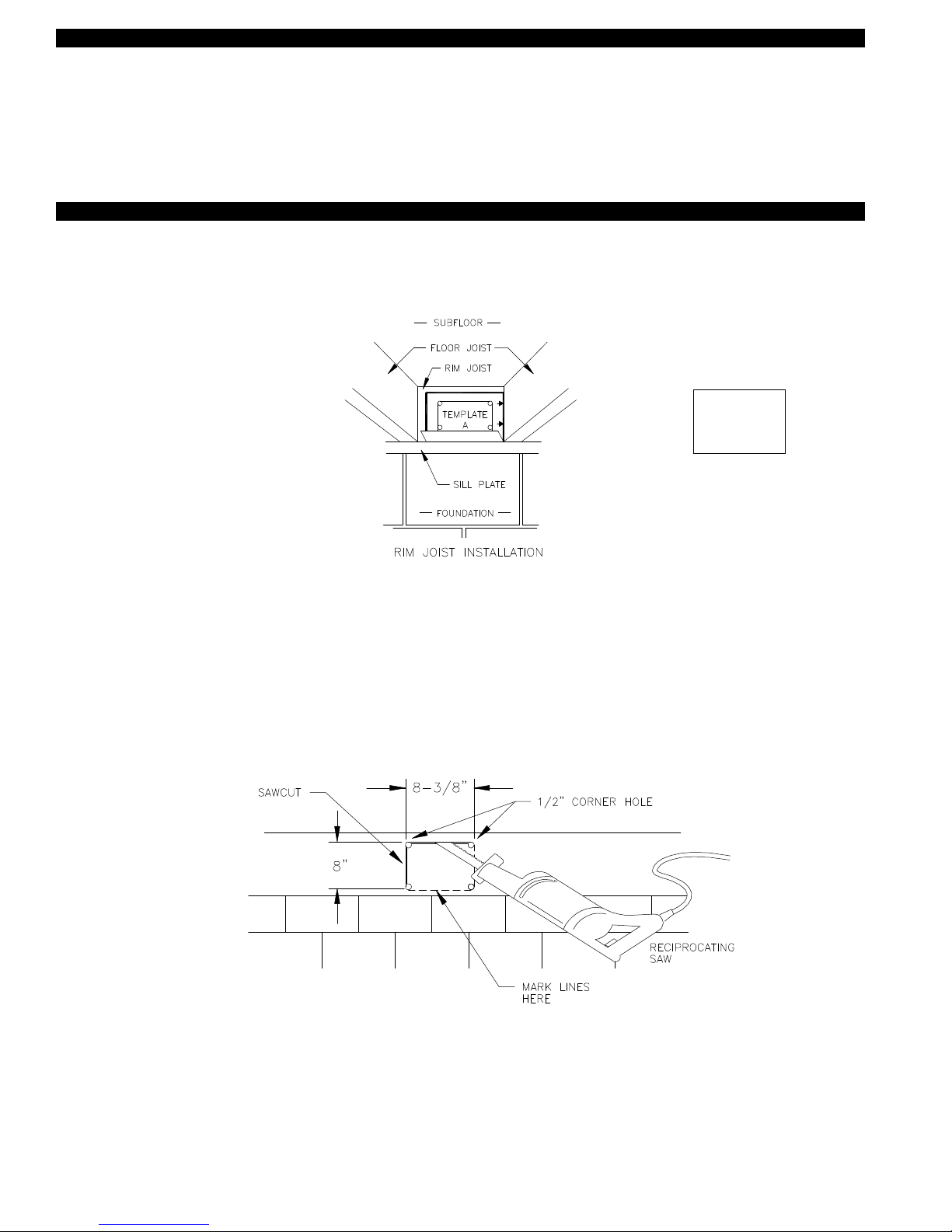

INSTALLING VENT HOOD TERMINUS

1. a) Fold template A (Page 25) along dashed line and attach in between the floor joists ensuring that it is snug against the sill

plate and right hand floor joist. Follow same procedure if floor trusses are used, (See Diagram B).

b) If the SideShot is not being installed between floor joists, attach the template to the wall it will be exiting ensuring it is level.

Rough-In

DIAGRAM B

8” Height

8 3/8” Width

2. Using 1/2" bit, drill pilot holes noted on each side of the template from inside through rim-joist, wall board, siding, etc., keeping

drill bit perpendicular to the wall. 1/2" bit must be long enough to penetrate through exterior.

3. Remove template from rim-joist and attach to building exterior, aligning pilot hole markings on template with holes previously

created in Step #2.

4. Drill the four corner holes noted on the template through the building exterior. Remove the template and mark lines from the

outside edge of the holes drilled, forming a rectangle.

5. Using reciprocating saw and appropriate blade, cut a rectangular opening through the rim joist, wall board, siding, etc., on the

lines marked in step 4. The rectangular opening should be no larger than 8-3/8" in width by 8" in height, (See Diagram C).

DIAGRAM C

6. Knock out block material exposing rectangular opening through the wall.

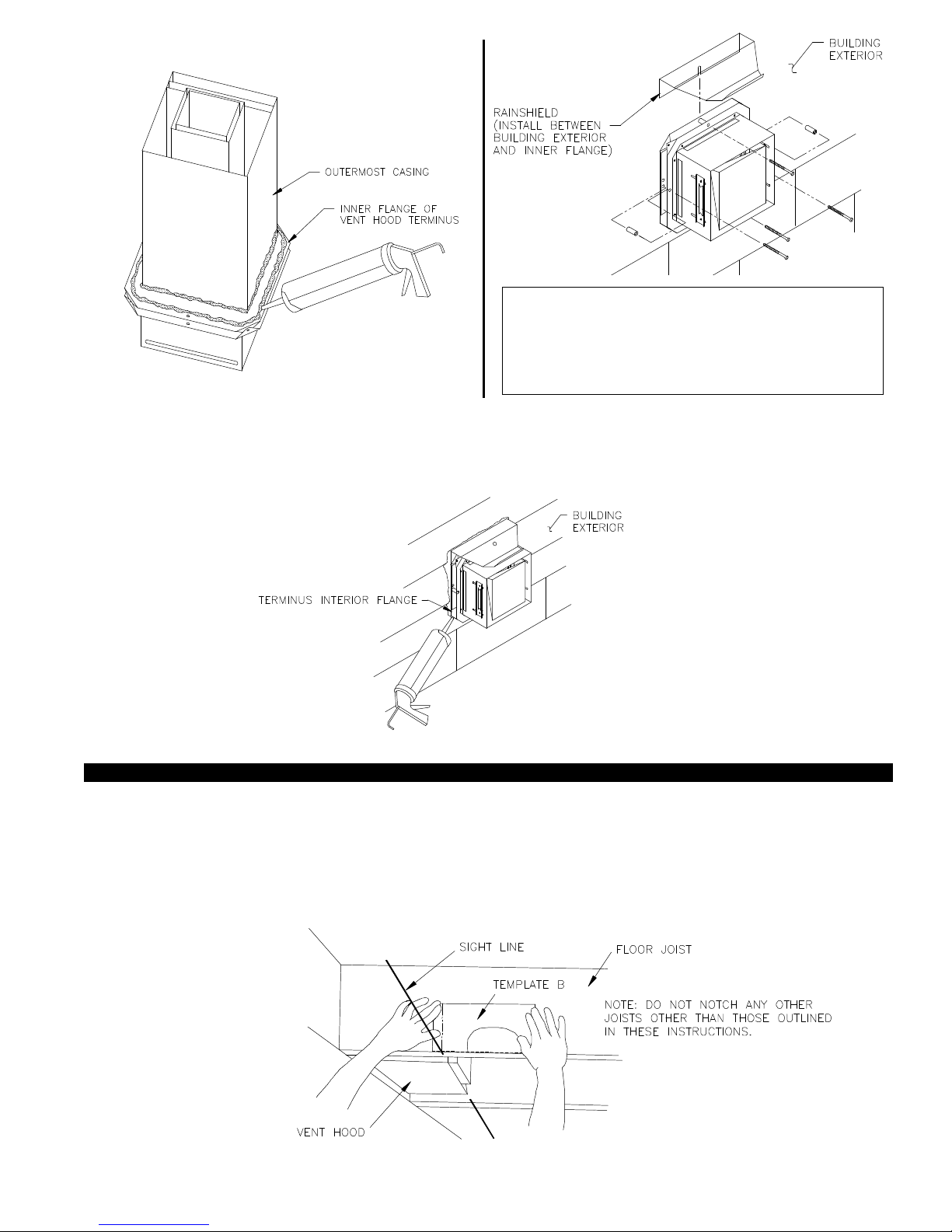

7. Apply two beads of exterior rated caulk approximately 3/8" in width at the seam of the outermost casing of the Vent Hood and

the inner flange of the Vent Hood Terminus, (See Diagram D).

8. Slide the Vent Hood through the wall while taking care installing the rain shield as shown, (See Diagram E). The nuts located on

the Vent Hood outermost casing should be facing up when sliding it through the wall. Mount Vent Hood to the exterior using

four #8 x 3" wood screws and spacers provided, (See Diagram E). Wall anchors are provided for installation into masonry wall.

7

Page 9

DIAGRAM D DIAGRAM E

NOTE: For mounting on vinyl or lap siding a wood frame

with 1” x 1 1/2” on the sides and top and 1” x 2” material on

bottom can be utilized on exterior wall. This will provide a

flush mounting surface for the hood and a nicely finished

look with “J” channel when siding. Inside of frame opening

should be 8 3/8” wide by 8” high.

9. Connect the Plenum to the Vent Hood of the SideShot following the steps on pages 8, 9 and 10.

10. After the SideShot is completely installed, apply a bead of exterior rated caulk between the Vent Hood Terminus inner flange

and the exterior of the building, (See Diagram F).

DIAGRAM F

INSTALLING PLENUM

Depending on building construction, it may be necessary to notch out a section of the floor joist to provide proper clearance for the

SideShot motor.

1. Attach Template B (Page 24) to the floor joist that is to be notched, aligning the sight line noted on the template with the end or

the outside casing of the vent hood.

2. Cut out notch on line shown on the template.

DIAGRAM G

8

Page 10

NOTCH BRACING

It is recommended and local codes may dictate that the joist be reinforced as outlined below. Bracing of the rim joist is not

necessary.

1. Cut two 2 x 4 pieces of wood 28 inches in length.

2. Center both pieces on each side of the floor joist above the notch and drive 8 16D or larger nails into each piece, (See Diag. H)

DIAGRAM H

CONNECTING THE PLENUM TO THE VENT HOOD

NOTE: Cut any nails which are protruding downward from the subfloor that may come in contact with the SideShot. Place both

slip joint drivers in your pocket before continuing.

Minimum clearances from the Plenum to any combustible materials must be maintained as listed on page 6.

NOTE: Blower - Motor/Wheel assembly can be removed to make Plenum section lighter & easier to install. Refer to Removal

and Replacement of Motor/Wheel Assembly, Page 22.

1. Connect the Plenum to the Vent Hood by aligning both grooves on the bottom of Plenum with both grooves on the bottom of the

Vent Hood. The Plenum is designed to slide into the Vent Hood, (See Diagram I).

2. Gently slide the Plenum into the Vent Hood until the slip joint guides located on each side of the Plenum are in contact with

each other.

3. Slide the slip joint drivers from the bottom upward over the the slip joint guides as far as possible by hand. A hammer may be

used to tap the slip joint drivers to their final position. Start the slip joint drivers on the slip joint guides with the embossed end

facing down. Do not force slip joint drivers past embossing.

DIAGRAM I

INSTALLATION OF WALL SUPPORT BRACKET

1. To prevent damage to the SideShot, temporarily support the bottom of the plenum (prop on ladder top) while assembling the

wall support bracket. Assemble the wall support bracket as shown, (See Diagram J).

2. Using the prepunched holes, adjust the wall support bracket so that a slight pitch is maintained for water drainage, (See

Diagram J).

3. Use the prepunched holes on the wall bracket as a template to mark holes to be drilled into the side wall for mounting screws.

4. a) If installing the bracket into a wood wall, drill 2 pilot holes at each point established in step 3 with a 1/8" drill bit

approximately 1" deep and install the screws provided to secure the bracket to the wall.

b) If installing the bracket into a masonry wall, drill 2 holes at each point established in step 3 with a 1/4" masonry drill bit

approximately 1" deep. Tap the masonry anchors into the holes drilled in step 4. Screw the wall bracket onto the wall.

5. Connect the other end of wall support bracket to the stud on the plenum using the supplied 1/4"-20 keps nut. (See Diagram J).

9

Page 11

DIAGRAM J

IMPORTANT:

Adjust SS1 mounting bracket

for a slight downward pitch

towards exit terminal.

INSTALLATION OF VENT PIPE

If installing the SideShot Vent System on an oil or gas appliance which is not equipped with a draft hood or draft diverter, a barometric draft control must be used. Install the barometric draft control as shown, (See Diagram K). The SideShot Vent System is

designed to accept all brands of 6" single wall, Type "B", Class "A" or Type "L" vent pipe. The vent pipe used must be in compliance with local codes and the listing of the vent pipe manufacturer. When necessary, install tapered reducers and increasers as

shown below.

Determine which inlet of the SideShot Vent System will allow for the least amount of elbows to the appliance. DO NOT USE

BOTH INLETS. Calculate the equivalent vent pipe footage from the appliance to the SideShot Vent System by adding the straight

vent pipe length and the equivalent elbow lengths together. Each 90 degree elbow is equal to 10 feet of straight vent pipe, each

45 degree elbow is equal to 5 feet of straight pipe. The equivalent vent pipe length must not exceed 50 feet from the appliance to

the SideShot Vent System. Vent runs of over 15 linear feet should use an approved, insulated vent connector to prevent problems

related to sulfur condensation. It is not necessary to maintain a 1/4" rise per every foot of horizontal when Side Wall Venting.

The SideShot Vent System is shipped from the factory with the plug connected to the rear and the vent pipe inlet collar connected

to the bottom. If using the bottom inlet, skip to the section entitled "Vent Pipe Clamp Assembly". If your installation requires the

use of the rear inlet, follow the steps in the section entitled "Vent Pipe Inlet Collar Conversion" to move the vent pipe inlet collar

from the bottom to the rear.

DIAGRAM K

1. Remove the plug from rear inlet port by unfastening the 6 nuts that secure it to the Plenum. Keep the plug & nuts for later use,

(See Diagram M).

2. Remove the sensing tube from the Fan Proving Switch by loosening the plastic compression fitting.

3. Remove the vent pipe inlet collar from the bottom port by unfastening the 6 nuts. Keep the nuts for later use.

IMPORTANT: Oil installations

must have a barometric draft

control. Gas installations must

have a draft hood, diverter or

barometric draft control.

VENT PIPE INLET COLLAR CONVERSION

10

Page 12

4.

Using a tube cutter, cut the sensing tube 2" from the elbow directed at the vent pipe inlet collar, (See Diagram L). Discard

the cut off section of metal tube.

5. Attach the vent pipe inlet collar to the rear inlet port making sure that the sensing tube is orientated as shown, (See Diagram M).

NOTE: Alignment marks on the inlet collar and plenum casing must match.

DIAGRAM L DIAGRAM M

6. Attach 90ocompression fitting to the short tube on the inlet collar.

7. Using the "soft" aluminum tubing, connect the Fan Proving Switch to the inlet collar. Take care not to crimp the tubing.

8. Install the plug removed in step 1 over the bottom inlet port, tightening securely.

VENT PIPE CLAMP ASSEMBLY

1. Attach the three vent pipe clamps to the inlet collar, (See Diagram N).

NOTE: The following diagrams show the use of the rear inlet. The same steps will apply if using the bottom inlet.

2. Bend each vent pipe clamp so it conforms to the outside diameter of the vent pipe being used, (See Diagram O).

DIAGRAM N

3. Route the adjustable clamp through the openings at the opposite end of the legs.

4. Slide the vent pipe over the inlet collar of the SideShot.

5. Tighten the adjustable clamp around the vent pipe, (See Diagram O).

DIAGRAM O

11

Page 13

ELECTRICAL WIRING

All wiring from the SS1 to the appliance must be appropriate Class 1 wiring as follows: installed in rigid metal conduit, intermediate

metal conduit, rigid non-metallic conduit, electrical metallic tubing, Type MI Cable, Type MC Cable, or be otherwise suitably protected

from physical damage.

SS1 SEQUENCE OF OPERATION WITH INTEGRAL UC1 UNIVERSAL CONTROL:

Control signal from thermostat, aquastat, primary control or gas valve is intercepted and routed to terminal “1” on UC1 terminal

strip. When terminal “1” is energized with either 24 VAC or 120 VAC, the SS1 motor is energized. After draft is established, the

Fan Proving Switch closes within 5 to 10 seconds energizing terminal “4”, which completes the circuit allowing burner to fire.

NOTE: If a venter pre-purge is selected, the burner will not fire until the pre-purge time is finished. The SS1 will continue to run

after the burner has finished firing for the set post-purge time cycle. The SS1 is set for a 2 minute post-purge time period from the

factory. See “Pre / Post-Purge Settings” on page 5 for details.

The "1" input terminal on the SideShot can accept either a 24 VAC or 120 VAC control signal. IMPORTANT: The RED

jumper must be positioned based on appliance interlock voltage. For most furnace applications it may be easier to interlock with

the 24 VAC thermostat circuit. For most boiler applications it may be easiest to interlock with the 120 VAC aquastat or primary

control circuit to the burner motor. Choose the interlock method that best fits your application.

The steps listed under each diagram are intended as a supplement to the diagram. Wiring colors or designations may vary by

manufacturer. If you are unable to wire the SS1 as outlined in these instructions, call Tjernlund’s Customer Service Department

toll free at 1-800-255-4208 for assistance.

IMPORTANT: To reset faults, verify fault by checking the LEDs and then remove call for heat.

SS1 WITH INTEGRAL UC1 UNIVERSAL CONTROL

(THE SS1 MOTOR, LIMIT & PROVER ARE ALL FACTORY PREWIRED)

"DRY"

LINE

115 VAC

DO NOT SUPPLY VOLTAGE

TO "A" OR "B".

USER-PROVIDED

CALL SWITCH

OR

HOT

24 VAC

OR

COMMONNEUTRAL

APPROVED

SUPPLY

115 VAC

50/60 Hz

R

PRODUCTS,

INC.

SS1 MOTOR

1 H.P. MAX @ 115 VAC

LEGEND:

115 VAC

24 VAC

5 VDC BOARD-GENERATED POWER

DO NOT SUPPLY POWER!

IMPORTANT:

RED JUMPER POSITION MUST BE THE SAME

AS APPLIANCE INTERLOCK VOLTAGE.

115V

24V

DRY

LED5 LED4 LED2LED3

RED

CALL

J2

J1

JUMPER

COM

INTERLOCK

XL

RELAY

NO

XN

TJERNLUND

9183006

N

COM

K2

MOTOR

MTRM

NO

RELAY

RED

GREEN

GREEN

PRE-PURGE SETTINGS

POST-PURGE SETTINGS

OPEN PROVER OPTION

K1

LED1

AMBER

(1 - 2)

(3 - 8)

115 OR 24 VAC FROM CALL JUMPER

OR USER-PROVIDED VOLTAGE

FROM TERMINAL 3 TO 4 WITH CALL

JUMPER REMOVED

ON

2 431

CP1P2

5

FOR TJERNLUND

97 86

(9)

FGND

MAC1E OR MAC4E

AUXILIARY

DEVICES. DO NOT

CONNECT POWER

TO P1, P2, C, GND

OR F. DOING SO

WILL DAMAGE THE

CONTROL.

SS1 LIMIT

SS1 PROVER

1303960-1

WARNING: Disconnect power supply from the SS1 and heating equipment when making wiring connections and servicing the

SS1.Failure to do so may result in personal injury and/or equipment damage. LED #5 (RED) should be off with

power removed.

12

Page 14

SIDESHOT WITH INTEGRAL UC1 UNIVERSAL CONTROL CONNECTED TO A

HONEYWELL R8184 SERIES OR EQUIVALENT PRIMARY CONTROL

HONEYWELL

R8184 SERIES

OR EQUIVALENT

LEGEND:

115 VAC

D/N 9183046-2

BLACK

ORANGE

WHITE

L1

RED JUMPER POSITION MUST BE THE SAME

AS APPLIANCE INTERLOCK VOLTAGE.

IGNITION TRANS

WHITE

WHITE

BURNER MOTOR

IMPORTANT:

CRIMP GROUND WIRE TO GROUNDING

SPADE TERMINAL IN ELECTRICAL BOX.

BLACK

SUPPLY

115 VAC

50/60 Hz

GROUND

IMPORTANT:

R

115V

J2

UNIVERSAL CONTROLLER

J1

XL

XN

DRY

24V

CALL

JUMPER

1. Separate the Black burner motor wire from the Orange wire of R8184 Primary Control.

NOTE: Do not separate the ignition transformer wire from the Orange.

2. Connect Orange wire of R8184 to #1 on UC1 terminal block.

3. Connect #2 on UC1 terminal block to White on R8184.

4. Connect Black of burner motor to #4 on UC1 terminal block.

5. Connect 115 VAC supply voltage to L & N terminals on UC1. Installer must supply overload and disconnect protection.

6. Crimp ground wire to grounding spade in SS1 electrical box.

7. Make sure RED voltage jumper on UC1 is on 115V.

SIDESHOT WITH INTEGRAL UC1 UNIVERSAL CONTROL CONNECTED TO A HONEYWELL R7184

SERIES OR EQUIVALENT PRIMARY CONTROL WITH A LINE VOLTAGE THERMOSTAT OR AQUASTAT

SUPPLY

Limit

115 VAC

60 Hz

SUPPLY

115 VAC

50/60 Hz

GROUND

LEGEND:

115 VAC

D/N 9183046-6

IMPORTANT:

RED JUMPER POSITION MUST BE THE SAME

AS APPLIANCE INTERLOCK VOLTAGE.

115V

UNIVERSAL CONTROLLER

J1J2

XL

R

XN

DRY

24V

CALL

JUMPER

T

Low Voltage

Jumper

T

A

Alarm

A

R7184

L1

Limit

L2

Oil Valve

Burner

Motor

Interrupted

Ignitor

Intermittant

Cad Cell

Line Voltage Thermostat

or Aquastat Control

OIL VALVE

BURNER MOTOR

IGNITION TRANS

IMPORTANT:

CRIMP GROUND WIRE TO GROUNDING

SPADE TERMINAL IN ELECTRICAL BOX.

1. Disconnect burner motor wire off the R7184.

2. Connect burner motor terminal of R7184 to #1 on UC1 terminal block.

3. Connect #2 on UC1 terminal block to L2 or N.

4. Connect #4 on UC1 terminal block to burner motor wire removed from R7184.

5. Connect 115 VAC supply voltage to L & N terminals on UC1. Installer must supply overload and disconnect protection.

6. Crimp ground wire to grounding spade in SS1 electrical box.

7. Make sure RED voltage jumper on UC1 is on 115V.

13

Page 15

SIDESHOT WITH INTEGRAL UC1 UNIVERSAL CONTROL CONNECTED WITH AN AQUASTAT

AQUASTAT

C1

L1

C2

L2

B1

B2

N

L1

LINE VOLTAGE OIL BURNER

PRIMARY CONTROL, BURNER

RELAY OR GAS VALVE

IMPORTANT:

CRIMP GROUND WIRE TO GROUNDING

SPADE TERMINAL IN ELECTRICAL BOX.

CAUTION:

WHEN INTERLOCKING WITH AQUASTAT DO NOT DISCONNECT BURNER MOTOR

FROM PRIMARY CONTROL / CAD CELL RELAY.

RED JUMPER POSITION MUST BE THE SAME

AS APPLIANCE INTERLOCK VOLTAGE.

SUPPLY

115 VAC

50/60 Hz

GROUND

IMPORTANT:

R

J1J2

XL

XN

LEGEND:

115 VAC

115V

UNIVERSAL CONTROLLER

DRY

24V

CALL

JUMPER

D/N 9183046-7

1. Disconnect B1 from L1 of oil burner primary control, burner relay or hot of gas valve and reconnect to #1 on UC1 terminal block.

2. Connect #2 on UC1 terminal block to B2 or N.

3. Connect #4 on UC1 terminal block to the L1 on line voltage oil burner primary control, burner relay or gas valve.

4. Connect 115 VAC supply voltage to L & N terminals on UC1. Installer must supply overload and disconnect protection.

5. Crimp ground wire to grounding spade in SS1 electrical box.

6. Make sure RED voltage jumper on UC1 is on 115V.

NOTE: If burner primary control goes out on lockout, the SideShot will continue to run as long as a call for heat is present.

SIDESHOT WITH INTEGRAL UC1 UNIVERSAL CONTROL CONNECTED WITH A CARLIN

40200, 42230, 48245, 50200, 60200 SERIES OR EQUIV. AND A LINE VOLTAGE THERMOSTAT OR AQUASTAT

SUPPLY

115 VAC

60 Hz

Red/WhiteT

Low Voltage

Jumper

T Black

F White

OrangeF

A Blue

Alarm

A Violet

1. Disconnect burner motor wire off the Orange on Carlin.

2. Connect burner motor terminal Orange of Carlin to #1 on UC1 terminal block.

3. Connect #2 on UC1 terminal block to L2 or N

4. Connect #4 on UC1 terminal block to burner motor wire removed from Orange of Carlin.

5. Connect 115 VAC supply voltage to L & N terminals on UC1. Installer must supply overload and disconnect protection.

6. Crimp ground wire to grounding spade in SS1 electrical box.

7. Make sure RED voltage jumper on UC1 is on 115V.

Line Voltage Thermostat

or Aquastat Control

10 FLA / 60 LRA

500 VA

0.3 A, AC

IMPORTANT:

CRIMP GROUND WIRE TO GROUNDING

SPADE TERMINAL IN ELECTRICAL BOX.

Limit

BURNER MOTOR

IGNITION TRANS

OIL VALVE

SUPPLY

115 VAC

50/60 Hz

GROUND

14

IMPORTANT:

RED JUMPER POSITION MUST BE THE SAME

AS APPLIANCE INTERLOCK VOLTAGE.

115V

J2

UNIVERSAL CONTROLLER

J1

R

XNXL

DRY

24V

CALL

JUMPER

LEGEND:

115 VAC

D/N 9183046-3

Page 16

SIDESHOT WITH INTEGRAL UC1 UNIVERSAL CONTROL CONNECTED WITH A HONEYWELL R8184

SERIES OR EQUIVALENT PRIMARY CONTROL AND A BURNER MOTOR POST-PURGE

BURNER

L1

BLACK

ORANGE

IGNITION

TRANS

B

O

WHITE

W

HONEYWELL R8184

SERIES OR EQUIVALENT

OIL VALVE

MOTORMOTOR

SS2

THERMOSTAT

T

T

F

F

COOLING

SS2

FAN

SUPPLY

115 VAC

50/60 Hz

GROUND

J1J2

XL

XN

N MTRM

IMPORTANT:

RED JUMPER POSITION MUST BE THE SAME

AS APPLIANCE INTERLOCK VOLTAGE.

115V

DRY

24V

CALL

JUMPER

UNIVERSAL CONTROL

IMPORTANT:

CRIMP GROUND WIRE TO GROUNDING

SPADE TERMINAL IN ELECTRICAL BOX.

LEGEND:

115 VAC

D/N 9183046-4

1. Separate the burner motor wire and ignition transformer from the Orange wire of R8184.

2. Connect the Orange of R8184 to #1 on UC1 terminal block.

3. Connect #2 on UC1 terminal block to White on R8184 or N.

4. Connect the HOT wire of oil solenoid valve to #4 on UC1 terminal block and neutral wire to White or N.

5. Connect burner motor and ignition transformer HOT wires to M terminal on UC1 and neutrals to White or N.

6. Connect 115 VAC supply voltage to L & N terminals on UC1. Installer must supply overload and disconnect protection.

7. Crimp ground wire to grounding spade in SS1 electrical box.

8. Make sure RED voltage jumper on UC1 is on 115V.

SIDESHOT WITH INTEGRAL UC1 UNIVERSAL CONTROL CONNECTED

WITH A SINGLE ZONE 24 VAC THERMOSTAT

RED JUMPER POSITION MUST BE THE SAME

AS APPLIANCE INTERLOCK VOLTAGE.

THERMOSTAT

Y

R

W

GG

R

C

Y

W

INTERNAL CONTROL

OF FURNACE

SUPPLY

115 VAC

50/60 Hz

GROUND

IMPORTANT:

CRIMP GROUND WIRE TO GROUNDING

SPADE TERMINAL IN ELECTRICAL BOX.

1. Connect W from t-stat to #1 on terminal block of UC1.

2. Connect #2 on UC1 terminal block to C on internal control terminal strip of furnace/boiler.

3. Connect #4 on UC1 terminal block to W on internal control terminal strip of furnace/boiler.

4. Connect 115 VAC supply voltage to L & N terminals on UC1. Installer must supply overload and disconnect protection.

5. Crimp ground wire to grounding spade in SS1 electrical box.

6. Make sure RED voltage jumper on UC1 is on 24V.

IMPORTANT:

J1J2

XL

R

XN

115V

24V

DRY

CALL

JUMPER

UNIVERSAL CONTROLLER

LEGEND:

115 VAC

24 VAC

D/N 9183046-5

15

Page 17

SIDESHOT WITH INTEGRAL UC1 CONTROL CONNECTED WITH A 24 VAC ELECTRONIC IGNITION MODULE

RED JUMPER POSITION MUST BE THE SAME

IMPORTANT:

AS APPLIANCE INTERLOCK VOLTAGE.

SPARK (9)

(8)

OR

115V

24V

CALL

DRY

JUMPER

UNIVERSAL CONTROLLER

(7)

24V (6)

24V GND (5)

BNR GND (4)

PV (3)

MV / PV (2)

MV (1)

HONEYWELL IGNITION

CONTROL

PI

YE

GR

YE

WH

OR

YE

PV

WH

PV

MV

OR

MV

GR

GAS VALVE

SUPPLY

115 VAC

50/60 Hz

R

GROUND

IMPORTANT:

CRIMP GROUND WIRE TO GROUNDING

SPADE TERMINAL IN ELECTRICAL BOX.

J1J2

XL

XN

LEGEND:

115 VAC

24 VAC

D/N 9183046-8

1. Remove the wire on MV at gas valve and connect it on #1 on UC1 terminal block.

2. Connect #2 on UC1 terminal block to MV/PV.

3. Connect #4 on UC1 terminal block to MV on gas valve.

4. Connect 115 VAC supply voltage to L & N terminals on UC1. Installer must supply overload and disconnect protection.

5. Crimp ground wire to grounding spade in SS1 electrical box.

6. Make sure RED voltage jumper on UC1 is on 24V.

SIDESHOT WITH INTEGRAL UC1 UNIVERSAL CONTROL CONNECTED

WITH A 24 OR 115 VAC STANDING PILOT

IMPORTANT:

RED JUMPER POSITION MUST BE THE SAME

INTERNAL CONTROLS

OF FURNACE/BOILER

B2

COM

Aquastat

T-stat

B1

HOT

J1J2

SUPPLY

XL

115 VAC

COM

TR

HOT

TH

50/60 Hz

GROUND

XN

IMPORTANT:

CRIMP GROUND WIRE TO GROUNDING

24V OR 115V GAS VALVE

SPADE TERMINAL IN ELECTRICAL BOX.

1. Remove the wire on TH or HOT of gas valve and connect it on #1 on UC1 terminal block.

2. Connect #2 on UC1 terminal block to TR or Common.

3. Connect #4 on UC1 terminal block to TH or HOT on gas valve.

4. Connect 115 VAC supply voltage to L & N terminals on UC1. Installer must supply overload and disconnect protection.

5. Crimp ground wire to grounding spade in SS1 electrical box.

6. Make sure RED voltage jumper on UC1 is on 24V or 115V depending on control voltage.

AS APPLIANCE INTERLOCK VOLTAGE.

115V

24V

DRY

CALL

JUMPER

UNIVERSAL CONTROLLER

LEGEND:

115 VAC

24 OR 115 VAC

D/N 9183046-1

16

Page 18

DRAFT ADJUSTMENT PROCEDURE

NOTES: All draft adjustments are approximate. This

chart is to be used for initial draft adjustment only.

Subsequent draft adjustments may be required to compensate for various field conditions: wind, vent pipe

resistance, building pressure, multiple appliances, etc.

BTU/HR input ratings assume 30% or less excess air

for flame retention burners and 50% to 100% excess

air for conventional oil burners.

Do not exceed the recommended BTU/HR input range

of the SideShot.

Under no circumstances shall the minimum draft

adjustment be used for the larger input range of this

product.

Improper draft adjustment may result in the dispersion

of flue products/carbon monoxide into the building interior.

DIAGRAM P

DRAFT ADJUSTMENT PROCEDURE FOR OIL EQUIPMENT

The SideShot Vent system will properly vent a wide range of BTU/hr. input capacities. To compensate for different burner capacities, vent connector lengths and wind conditions it features a draft adjustment located on the outside of the Vent Hood. In general,

positioning the draft adjustment inward will cause the SideShot to operate at lowest capacity. Positioning the draft adjustment

outward will cause the SideShot to operate at highest capacity.

IMPORTANT:

The following paragraph describes the initial draft adjustment. It may be necessary to make a slight readjustment to compensate

for various conditions: wind, vent connector resistance, negative building pressure and multiple appliances.

ASHRAE lists the average design factor for wind loads in North America at 15 MPH. Refer to the Draft Adjustment Chart above.

We recommend that the 25 MPH category be used to allow for excursions beyond the 15 MPH average. It is not recommended

for the SideShot to be terminated on a wall that faces the direction of the prevailing winds. Backdrafts by severe winds can cause

oil odors to remain in the structure and/or interrupt heating equipment operation. If the SideShot is terminated in a direction prone

to higher winds, or if higher winds are common in your geographic area, use the 40 MPH category to determine the proper draft

adjustment setting. If the draft adjustment is set at the 25 MPH category and sustained winds exceeding 25 MPH are present, the

Fan Proving Switch will disrupt the burner until the wind load drops below 25 MPH. Wind loads referenced are based on straight

line winds directed against the Vent Hood.

IMPORTANT:

Before proceeding, close all windows, doors and fireplace dampers. Turn on all appliances in the structure that exhaust indoor air

such as clothes dryer, exhaust fans, range hoods, bathroom and whole house exhaust fans. Failure to perform the draft adjustment procedure may cause a poor vent system installation possibly resulting in fire, carbon monoxide poisoning, explosion, personal injury or property damage.

1. Set the draft adjustment on SS1 Vent Hood to the appropriate setting based on the above instructions and the Draft Adjustment

Chart. Adjustment is accomplished by loosening both nuts on each side of the Vent Hood and centering both indicators to the

desired setting. Tighten the four nuts to secure the draft adjustment at desired setting.

2. Insert a stack thermometer into the vent pipe as close as possible to the SS1 inlet. NOTE: plug hole when finished with installation.

3. Adjust barometric draft control to the minimum or least draft setting.

4. Place the heating system into operation. NOTE: There will be a slight pause between the venter operation and the burner operation.

A Venter pre-purge of up to a minute may also be selected. See “Pre / Post-Purge Settings” on page 5.

5. Continuously monitor the over fire draft and adjust the barometric damper to maintain a reading of -.02 to -.03” W.C..

When the flue gas temperature at the venter inlet has stabilized make any final draft adjustment necessary to maintain a

17

Page 19

reading of -.02 to -.03” W.C..

IMPORTANT:

If a minimum of -.02” W.C. cannot be obtained by adjusting the barometric

damper closed (more draft), the SS1 draft control on the vent hood should be pushed out (more draft) and the barometric

damper readjusted to reach -.02 to -.03” W.C..

6. Perform a smoke test and make any adjustments to the burner air shutter, SS1 draft control on the vent hood or the barometric

draft control to arrive at a trace of smoke (between 0 and 1) at a minimum over fire draft of -.02” W.C..

7. Perform a CO2 test at the same location as the smoke test. Reduce the CO2 1% to 2% by opening the burner air shutter.

Recheck over fire draft and increase venter draft or adjust barometric damper closed (more draft) if necessary to maintain a

minimum of -.02” W.C..

Do not allow heating system to run at less than a -.02” W.C. over fire draft or at a CO2 level that is less than a 1% reduction from

the value measured at a trace of smoke and a -.02” W.C. over fire draft. If these parameters are unobtainable, contact Tjernlund at

1-800-255-4208 for Technical Assistance.

8. Remove the call for heat from the heating system. NOTE: The SS1 will run in post-purge mode which is factory set at 2

minutes and adjustable up to 16 minutes. Allow the system to cool down to ambient room temperature.

9. Restart the heating system.

10. At 5 minutes into the restart, read and record the inlet temperature ________F. If this temperature is above 2500F, continue to

step 11. If this temperature is below 2500F, use an approved insulated pipe / vent connector. Verify that the over fire draft and

CO2 have not changed, If they have, redo the adjustment steps. With insulated pipe / vent connector, redo the 5 minute temperature test and record the new value here ________F. If insulated pipe / vent connector did not increase the inlet temperature above 2500F. within 5 minutes of the heating system call for heat, call 800-255-4208 for technical support.

11. Lock down the burner primary air adjustment, the barometric adjustment knob and the SS1 draft adjustment with four lock nuts

on adjustment cone brackets, (See Diagram P). Verify the over fire draft and CO2 readings have not changed from the earlier values.

DRAF

DRAFT ADJUSTMENT PROCEDURE FOR GAS EQUIPMENT

The SideShot Vent System will properly vent a wide range of BTU/hr. input capacities. To compensate for different burner capacities, vent connector lengths and wind conditions it features a draft adjustment located on the outside of the Vent Hood. In general,

positioning the draft adjustment inward will cause the SideShot to operate at lowest capacity. Positioning the draft adjustment

outward will cause the SideShot to operate at highest capacity.

IMPORTANT:

The following paragraph describes the initial draft adjustment. It may be necessary to make a slight readjustment to compensate

for various conditions: wind, vent connector resistance, negative building pressure and multiple appliances.

ASHRAE lists the average design factor for wind loads in North America at 15 MPH. Refer to the Draft Adjustment Chart on Page

17. We recommend that the 25 MPH category be used to allow for excursions beyond the 15 MPH average. It is not recom-

mended for the SideShot to be terminated on a wall that faces the direction of the prevailing winds. Backdrafts by severe winds

can interrupt heating equipment operation. If the SideShot is terminated in a direction prone to higher winds, or if higher winds are

common in your geographic area, use the 40 MPH category to determine the proper draft adjustment setting. If the draft adjustment is set at the 25 MPH category and sustained winds exceeding 25 MPH are present, the Fan Proving Switch will disrupt the

burner until the wind load drops below 25 MPH. Wind loads are based on straight line winds directed against the Vent Hood.

IMPORTANT:

Before proceeding, close all windows, doors and fireplace dampers. Turn on all appliances in the structure that exhaust indoor air

such as clothes dryer, exhaust fans, range hoods, bathroom and whole house exhaust fans. Failure to perform the draft adjustment procedure may cause a poor vent system installation possibly resulting in fire, carbon monoxide poisoning, explosion, personal injury or property damage.

DRAFT ADJUSTMENT PROCEDURE

1. Set the draft adjustment on SS1 Vent Hood to the appropriate setting based on the above instructions and the Draft Adjustment

Chart. Adjustment is accomplished by loosening both nuts on each side of the Vent Hood and centering both indicators to the

desired setting. Tighten the four nuts to secure the draft adjustment at desired setting.

2. Place the heating system into operation. NOTE: there will be a slight pause between venter operation and burner operation. A

Venter pre-purge of up to a minute may also be selected. See “Pre / Post-Purge Settings” on page 5. If installation uses a

barometric draft control adjust it to the minimum or least draft setting. Allow heater to operate for 5 minutes.

3. PREFERRED METHOD: MUST HAVE DRAFT GAUGE AVAILABLE

Sample draft one foot after draft hood, diverter or barometric draft control using a draft gauge. If the draft reading is in excess of

-0.05” W.C. adjust SS1 Vent Hood cone in (less draft) or adjust barometric for (less draft) so that a draft reading of -0.02” to

-0.05” W.C. is obtained. Never adjust draft to a setting of less than -0.02” W.C. If the vent system is terminated on a wall

subject to prevailing winds a -0.05” W.C. draft setting is recommended.

4. If a draft gauge is not available test for spillage at the draft hood, diverter or barometric draft control using the flame from a

match, lighter or candle and determine the following:

A. The flame or smoke is being drawn into the draft hood, diverter or barometric draft control.

B. The main burner is burning properly, i.e. no floating, lifting or flash back.

18

Page 20

C. If the heater has a two stage or modulating gas valve verify that burner operates properly at both low and high fire.

If the draft appears excessive adjust SS1 Vent Hood cone in (less draft) or adjust barometric for (less draft) repeat steps A

through C.

5. Lock down the he SS1 draft adjustment with four lock nuts on adjustment cone brackets and barometric damper adjustment knob

if a barometric is installed, (See Diagram P).

6. Turn off appliances and exhaust fans activated for draft adjustment procedure.

COMBUSTION AIR

Adequate combustion air is vital for proper combustion and for safe venting. Likewise, for proper SS1 performance, adequate

combustion air must be available to the appliance. Many installers assume adequate combustion air is present, especially in older

homes. In some cases this is a false assumption, because many older homes have been made "tight" due to weatherization. Size

the combustion air opening(s) into the appliance room as outlined NFPA 54/NFPA 211. When installing a SS1, it is not necessary

to supply any more combustion air than normally required when conventional venting. Common symptoms of inadequate combustion air include: Fan Proving Switch short cycling, odor present at the end of burner cycle, outside air enters the structure through

the SS1 Vent System on SS1/Appliance off cycle.

FINAL SYSTEM OPERATION CHECK-OUT

1. Adjust thermostat or appliance controls to call for heat.

2. Verify that the SS1 operates first, prior to burner ignition.

Allow heating equipment and SS1 to operate continuously while performing steps 3-5.

3. Close all doors and windows of the building. If heating equipment is installed in utility room or closet, close the entrance door to

this room. Close fireplace dampers.

4. Turn on all appliances in the structure that exhaust indoor air during their operation, e.g. turn on clothes dryer and exhaust fans

such as range hoods, bathroom exhaust and whole house fans.

5. Allow SS1 and equipment to operate for at least 15 minutes. Tripping of the burner circuit by the Fan Prover Switch or High

Limit during the 15 minute operation indicates an unsafe operating condition. Turn fuel supply off to appliance and DO NOT

OPERATE UNTIL UNSAFE VENTING CONDITION IS INVESTIGATED BY QUALIFIED SERVICE PERSONNEL.

6. Turn thermostat or equipment controls to the "off" position. Verify that the venter operates for the post-purge time period set

after the burner stops firing. See “Pre / Post-Purge Settings” on page 5.

7. Return all windows, doors and exhaust fans to their original conditions of use.

TROUBLESHOOTING OIL ODORS

Many problems can be eliminated quite easily by having the equipment properly set up by a professional oil-heat service contractor. The sophistication of today's heating equipment and instrumentation needed for efficient operation requires proper training.

There is no substitute for the work of a qualified oil-heat service professional. All trouble shooting recommendations that follow

assume the equipment is installed and maintained by a qualified service person.

Post-purge: A post-purge is always necessary on oil installations. The factory default post-purge time period is 2 minutes. Just

as a chimney continues to draft after the burner has shut-down, the SS1 will continue to run to clear the vent system of residual

gases. The duration of the post-purge cycle is adjustable from 0 to 16 minutes. We recommend a minimum of 2 minutes postpurge on oil.

Draft Adjustment: The SideShot Draft Adjustment, located outdoors on the Vent Hood, has two functions: A) It allows the installer

to fine-tune the amount of draft that the SideShot must develop to vent the specific appliance, and B) It prevents air infiltration

caused by strong winds and gusts. Air infiltration back through the vent system will bring with it the odors from the flue gas residue

on the inside of the vent pipe. When the Draft Adjustment is at an inward setting (lower number) the Vent Hood will deflect a

greater volume of wind than at a higher setting.

REMINDER : The most significant preventer of wind-induced air infiltration is choosing a proper termination location of

the SideShot before installation, see requirements on page 6, under "Vent Hood Termination Clearances."

V

Verify that the Draft Adjustment is appropriate for the BTU/hr input, as shown on the "Draft Adjustment Chart," page 17 . If necessary, change setting by loosening both nuts on each side of the Vent Hood and center both indicators to the desired setting.

Tighten the four nuts to secure new draft adjustment.

IMPORTANT

Any adjustment to the draft setting must be followed by an over-fire draft measurement and necessary adjustments to the

primary air intake on the burner and barometric draft control. See “Draft Adjustment Procedure”, page 17.

Burner Adjustment: Verify that the over-fire draft matches that recommended by the heating equipment manufacturer. Adjust the

combustion efficiency and smoke characteristics to optimum levels of performance.

19

Page 21

Combustion Air:

Modern construction methods and materials have reduced natural air infiltration rates to extremely low levels.

Even older homes can lack adequate air for combustion, when insulation upgrades and other weatherization methods have been

installed. It is recommended that fuel burning appliances have dedicated sources of outside air for combustion. This may be simply accomplished by running a properly sized duct from outdoors and terminating it near the burner air intake. Accessory air

intakes are available that connect to the burner motor, using it to pull in the outdoor air. The Tjernlund IN-FORCERTMCombustion

Air Intake tempers the raw outdoor air as it is delivered to the burner. Without a source of outdoor air for combustion, a tight

home's negative pressures will draw odors back through the venting system during the appliance off cycle.

Chronic Oil Odor Conditions: Certain features of the specific appliance and installation, e.g. high heat-retention combustion

chamber; low-mass, dry-base; piping system design; oil impurities; air in lines, can all contribute to an increased production of oil

odor and cannot always be anticipated. For extreme cases of oil odor nuisance Tjernlund recommends the practice of post-purging the burner during the vent system post-purge. A burner post-purge cycle can eliminate any shortcomings of compatibility

between the specific installation and the SideShot. Burner post-purge kits, such as, Tjernlund's P/N 950-2043, are available from

most oil equipment distributors. Burner post-purge kits should be used on installations where the combustion air is being adequately supplied, yet oil odors continue.

TROUBLESHOOTING ELECTRICAL PROBLEMS

The following guide is intended to be used if a problem occurs during the use of the SS1 side wall vent system. It may be necessary to measure voltage during troubleshooting.

Extreme caution must be exercised to prevent injury. If you are unable to determine the defective part with the use of this

guide, call your Tjernlund distributor or Tjernlund Products direct at 1-800-255-4208 for further assistance.

IMPORTANT: To reset faults, verify fault by checking the LEDs and then remove call for heat.

LED STATUS & FAULT INDICATORS

LED INDICATOR LIGHTS

LED #1 (Amber) Appliance call for heat.

LED #2 (Green) Safety circuit through P1 & P2 (SS1 Limit & Fan Prover) is verified “Open” upon start-up. Burner circuit is

energized with contact closure from terminal 3 to 4. Also verifies SS1 prover & limit are closed during run cycle.

LED #3 (Green) Power switched to SS1 Motor from L to MTR & M.

LED #4 (Red) Status indicator.

LED #5 (Red) 115 VAC power supplied to board. Also used as status indicator.

LED INDICATOR LIGHT STATUS & FAULTS

LED #4 & #5 Flashing Alternately = Prover start up fault. SS1 Prover contacts “Closed” across P1 & P2 upon appliance call

before SS1 is turned on. Prover status check must be activated, see page 5.

LED #4 & #5 Flashing in Unison = Fan Prover circuit is “Open” longer than 60 seconds on start-up or 10 seconds during run

cycle. Prover or Limit contacts are not staying “Closed” across P1 & P2 safety circuit.

LED #4 Flashing & #5 on Continuous = System in Pre-Purge. (Pre-Purge options 0, 15, 30, 60 seconds)

LED #5 Flashing & #4 on Continuous = System in Post-Purge. (Post-Purge options 0, 30 seconds or 1, 2, 4, 8, 16 minutes)

SYMPTOM 1: SS1 OPERATES CONTINUOUSLY

Verify that Venter is not in post-purge mode which could last up to 16 minutes. A factory post-purge has been set for 2 minutes.

LED #4 (Red) will be on continuously and LED #5 will be flashing during post-purge. A Venter pre-purge could also be set for up

to 1 minute. LED #4 (Red) will be flashing and LED #5 will be on continuously during a Venter pre-purge. See “Pre / Post-Purge

Settings” on page 5.

Verify that LED #1 (Amber) is not lit.

Yes, LED #1 (Amber) is lit: Check interlock wiring. UC1 control is receiving constant call for heat signal.

LED #1 (Amber) is not lit: Replace UC1 circuit board part number 950-8801.

SYMPTOM 2: SS1 MOTOR DOES NOT OPERATE

Verify that UC1 control has power, LED #5 (Red) should be lit.

No: Check circuit breaker, disconnect switches and wiring.

Yes, LED #5 (Red) is lit: Verify that the interlocked burner is calling for heat, LED #1 (Amber) should be lit.

No, LED #1 (Amber) is not lit: Verify interlock wiring and that thermostat/aquastat is adjusted to call for heat. Verify that the RED

voltage selection jumper is installed so that it matches the voltage of the interlocked burner.

20

Page 22

Yes, LED #1 (Amber) is lit: Verify Prover safety circuit fault does not exist. See LED indicator light status & faults, on page 20.

If faults exist check Prover P1 & P2 safety circuit.

If no faults exist, check for 115 VAC across terminals N and MTR.

Voltage present: Replace SS1 motor part number 950-0625.

No voltage present: Replace UC1 circuit board part number 950-8801.

SYMPTOM 3: SS1 OPERATES, BUT BURNER DOES NOT

NOTE: Prover status check must be activated, see page 5. For any newly established call for heat the SS1 will run for 60 seconds to try to close the fan prover circuit (P1 to P2). If circuit can not be made after 60 seconds LED's 4 & 5 (Red) will flash in unison, indicating a prover check circuit fault on SS1 start up. The SS1 will shut down and LED's 4 & 5 (Red) will flash in unison, indicating a prover check circuit fault on SS1 start up. NOTE: If primary control of oil burner locks out during the 1 minute period the

UC1 safety circuit and LED’s 4 & 5 will be reset. If the fan prover makes on start up, but breaks for more than 10 seconds during

the burner cycle, LED's 4 & 5 (Red) will flash in unison indicating a prover circuit fault. The SS1 will continue to run for 10 minutes

to try to make the prover circuit as long as a call for heat exists. After 10 minutes the SS1 will shut down and LED's 4 & 5 (Red)

will flash in unison indicating a prover circuit fault. Remove the call for heat and then reestablish to reset the UC1 prover safety

circuit (P1 to P2) & LED’s.

Verify that LED #2 (Green) is lit.

Yes, LED #2 (Green) is lit: Verify that "call jumper" is connected from J1 to J2 on UC1 circuit board. With call for heat established,

verify that wiring is correct by measuring voltage between terminals 1 & 2 and 2 & 4 of UC1 terminal strip. Voltage should be the

same in both cases, if not rewire per appropriate diagram. NOTE: If using the “Dry Contact” interlock method, make sure that the

RED voltage selection jumper is installed on the dry contact tabs.

No, LED #2 (Green) is not lit: Remove call for heat and reestablish a call for heat to reset control. Within 1 minute of call for heat,

carefully jump a wire between P1 & P2 on UC1 control. LED #2 (Green) should light.

No, LED #2 (Green) does not light: Replace UC1 circuit board, part number 950-8801.

Yes, LED #2 (Green) lights up: Remove supply power to UC1. Remove Jumper from P1 & P2. The SS1 high limit is open, the fan

proving switch is not closing, or wiring connections are incorrect/broken. Disrupt call for heat. Push reset button on SS1 high limit

inside electrical box. NOTE: Insufficient post-purge may cause limit to trip. If the limit switch trips, verify that the post-purge setting

is long enough to remove residual heat from the combustion chamber. If high limit trips repeatedly, do not operate the heater until

the source of excessive heat has been determined and repaired. If high limit will not reset and has an open circuit, replace high

limit part number 950-0640.

Initiate call for heat. With SS1 running, verify that venter performance is sufficient to close fan prover. Draft gauge should read a

minimum of -0.05" w.c. at SS1 Prover sampling port.

No, measured draft is less than -0.05" w.c.: Verify that SS1 vent hood draft adjustment is at proper setting, see “Draft Adjustment

Procedure”, page 17. Visually inspect system for blockages. Confirm that maximum BTU/hr. input and vent pipe lengths are not

exceeded. See “Application Table” on page 1 for capacities. Check fan proving switch sensing tube for blockage.

Yes, measured draft is at least -0.05" w.c.: Replace fan proving switch part number 950-0650.

MAINTENANCE

SERVICE TECHNICIAN AND USER REQUIREMENTS

1. SS1 must be visually inspected annually.

2. On oil, verify over-fire draft, CO2 and smoke readings are all correct. See “Draft Adjustment Procedure” on page 16.

3. Annually inspect vent pipe for evidence of corrosion. If any corrosion is found replace vent pipe and inspect venter.

4. The SideShot blower wheel must be inspected annually. Particulates, such as soot, oil impurities and sheet rock dust, can

prevent proper venting and will cause noise and vibration. Follow instructions, on page 22 for motor/wheel assembly removal.

5. Clean all particulate from wheel with a soft metal wire brush and soot cleaner. Clean the pocket of each blade, as well as the

rest of the wheel.

6. A wheel that exhibits large amounts of particulate or appears to be out of round should be replaced with a new wheel.

Instructions for wheel replacement are listed on page 22.

21

Page 23

DIAGRAM N

REMOVAL AND REPLACEMENT OF MOTOR/WHEEL ASSEMBLY (DIAGRAM N)

Disconnect power supply from the SS1 and heating equipment when making wiring connections and servicing the SS1.

Failure to do so may result in personal injury and/or equipment damage. LED #5 (RED) should be off with power removed.

1. Remove electrical box cover.

2. Disconnect the two motor leads from the MTR & N terminals.

3. Remove motor bracket screw from electrical box.

4. Holding the motor, apply firm pressure towards the plenum of the SideShot and remove the six motor mount nuts. Note: Hold

the assembly firmly; failure to do so could damage internal parts.

5. Slide motor/wheel assembly from Plenum. Grasp only the motor casing; do not damage wheel, shaft or other components on

Plenum. Do not rest assembly on wheel.

WHEEL REPLACEMENT (DIAGRAM N)

1. Loosen set screw from wheel hub by using a 5/32” allen wrench.

2. Twist wheel to loosen and pull off of motor shaft. Do not pull too hard; wheel may bend. Wheels “fused” to shaft may require

penetrating oil and/or a wheel puller to facilitate removal.

3. Slide new wheel on to flat of shaft and firmly tighten set screw.

MOTOR OILING

The SideShot motor is permanently lubricated and requires no oiling.

HOW TO OBTAIN SERVICE ASSISTANCE

1. If you have any questions about your Power Venter or if it requires adjustment, repair or routine maintenance, we suggest

that you contact your installer, contractor or service agency.

2. If you require technical information contact Tjernlund Products, Inc. at 1-800-255-4208.

When contacting Tjernlund Products, Inc., please have the following information available:

1. Model of the Power Venter as shown on the label attached to Power Venter.

2 Name and address of installer and any service agency who performed work on Power Venter.

3. Date of original installation and dates any service work was performed.

4. Details of the problem as you can best describe them.

22

Page 24

LIMITED PARTS WARRANTY AND CLAIM PROCEDURE

Tjernlund Products, Inc. warrants the components of the SideShot for two years from date of installation. This warranty covers

defects in material and workmanship. This warranty does not cover normal maintenance, transportation or installation charges for

replacement parts or any other service calls or repairs. This warranty DOES NOT cover the complete SS1 if it is operative, except

for the defective part.

Tjernlund Products, Inc. will issue credit or provide a free part to replace one that becomes defective during the two year warranty

period. Proof of date of the installation in the form of the contractor sales/installation receipt is necessary to prove the unit has

been in service for under two years. All receipts should include the date code of the SideShot to ensure that the defective component corresponds with the complete unit. This will help preclude possible credit refusal.

1.) Follow troubleshooting guide to determine defective component. If unable to determine faulty component, contact your

Tjernlund distributor or Tjernlund Products Technical Customer Service Department at 1-800-255-4208 for troubleshooting

assistance.

2.) After the faulty component is determined, return it to your Tjernlund distributor for replacement. Please include SideShot date

code component was taken from. The date code is located on the Electrical Box coverplate. If the date code is older than 2

years, you will need to provide a copy of the original installation receipt to your distributor. Credit or replacement will only be

issued to a Tjernlund distributor after the defective part has been returned prepaid to Tjernlund.

WHAT IS NOT COVERED

Product installed contrary to our installation instructions

Product that has been altered, neglected or misused

Product that has been wired incorrectly

Product that has been damaged by a malfunctioning or mistuned burner

Any freight charges related to the return of the defective part

Any labor charges related to evaluating and replacing the defective part

REPLACEMENT PARTS

Component Part Number

Motor w/Wheel 950-0625

Proving Switch 950-0650

Wheel 950-0635

High Limit Switch 950-0640

Universal Control Circuit Board 950-8801

TJERNLUND LIMITED TWO YEAR WARRANTY

Tjernlund Products, Inc. warrants to the original purchaser of this product that the product will be free from defects due to faulty

material or workmanship for a period of (2) years from the date of original purchase or delivery to the original purchaser,

whichever is earlier. Remedies under this warranty are limited to repairing or replacing, at our option, any product which shall,

within the above stated warranty period, be returned to Tjernlund Products, Inc. at the address listed below, postage prepaid.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF, AND TJERNLUND

PRODUCTS, INC. EXPRESSLY DISCLAIMS LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING FROM

THE USE OF THIS PRODUCT. THIS WARRANTY IS IN LIEU OF ALL OTHER EXPRESS WARRANTIES AND NO AGENT IS

AUTHORIZED TO ASSUME FOR US ANY LIABILITY ADDITIONAL TO THOSE SET FORTH IN THIS LIMITED WARRANTY.

IMPLIED WARRANTIES ARE LIMITED TO THE STATED DURATION OF THIS LIMITED WARRANTY. Some states do not allow