Page 1

TJERNLUND PRODUCTS, INC.

1601 Ninth Street • White Bear Lake, MN 55110-6794

PHONE (800) 255-4208 • (651) 426-2993 • FAX (651) 426-9547

Visit our web site • www.tjernlund.com

Radon VACTMSide Wall Radon Mitigation System

READ OWNERS INSTRUCTIONS CAREFULLY PRIOR TO INSTALLATION.

THESE INSTRUCTIONS MUST REMAIN WITH EQUIPMENT. DO NOT DESTROY.

Model RMS160

DESCRIPTION

The Radon Vac

TM

Radon Mitigation System is designed to reduce radon levels in homes by removing radon gas from

beneath the home and discharging it to the outdoors. The Radon VacTMeliminates intrusive PVC pipe runs vertically through

living areas or ugly PVC runs up the home exterior. It reduces radon across a variety of sub-slab soil types (dirt, gravel,

etc.). It features a sealed, galvanized housing & PSC permanently lubricated, quiet-low watt motor. The corrosion-proof,

Variable Aspiration Control Hood dilutes radon gas with infused outdoor air & propels it away. Airflow velocity easily adjusts

for various pipe lengths and extraction point from a sump pit or below basement floor.

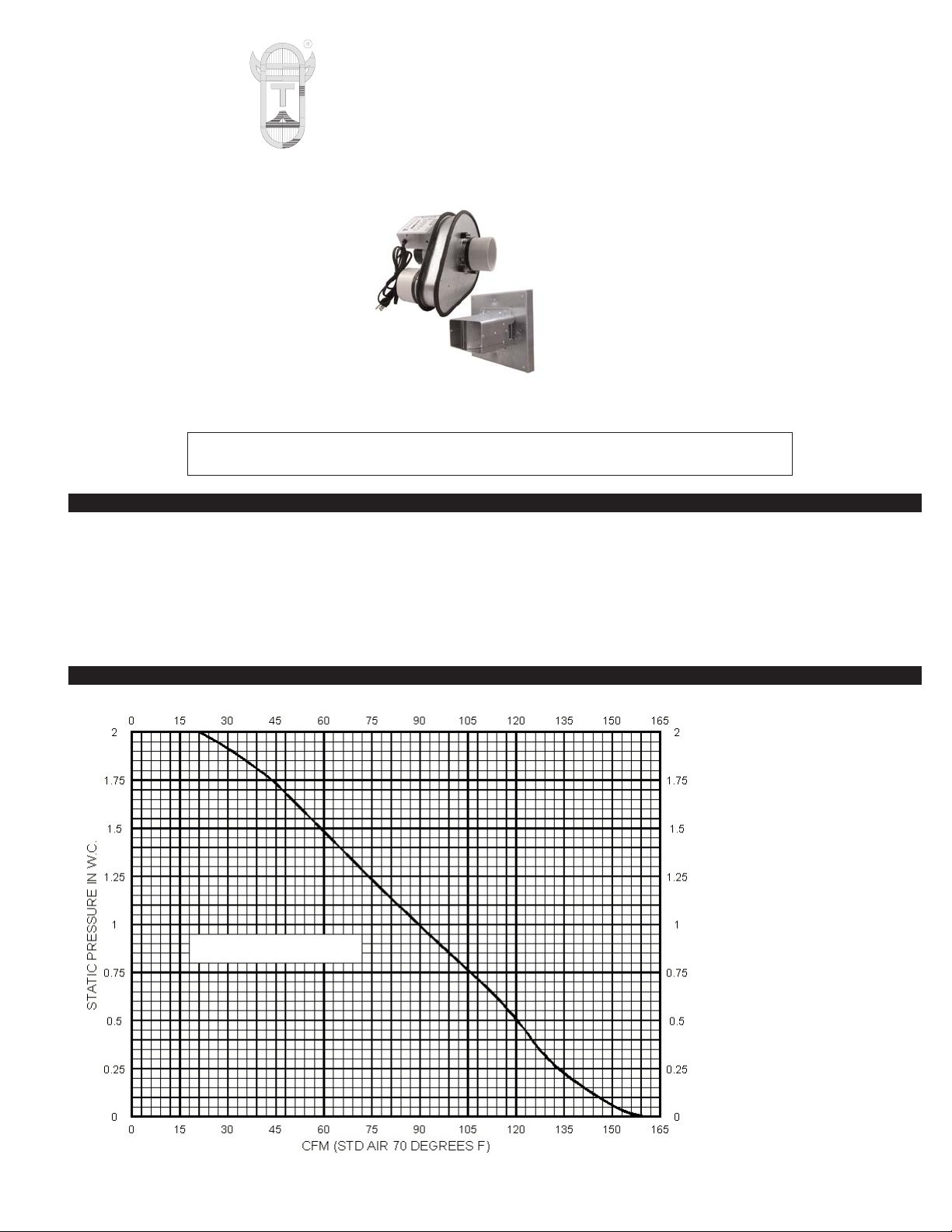

PERFORMANCE & SPECIFICATIONS

RMS160 Performance

MODEL RMS160

Motor: 115 Volts ~ 50/60 Hz

Watts: 50

Amps: 0.80 maximum

©2011 TJERNLUND PRODUCTS, INC. ALL RIGHTS RESERVED P/N: 8504183

Page 2

2

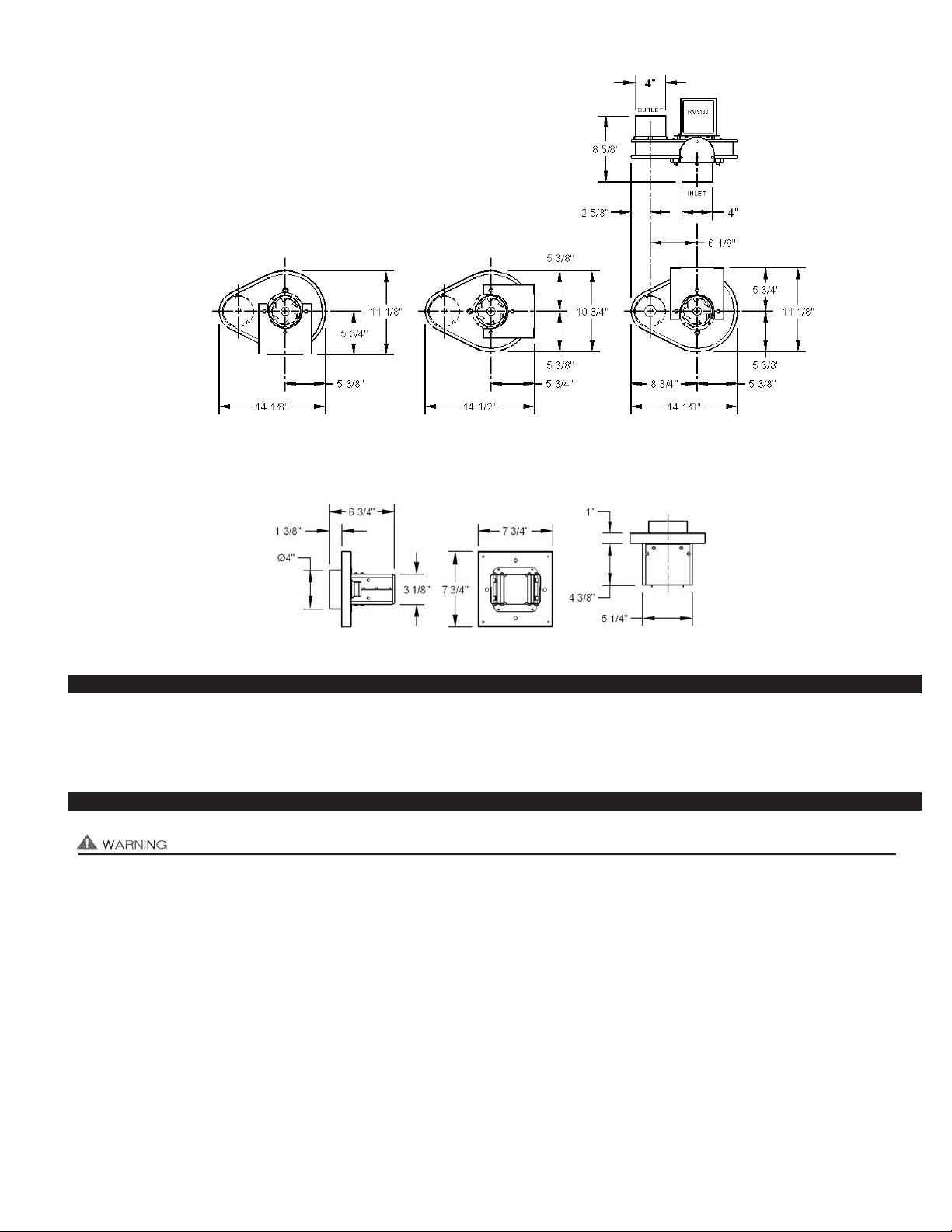

RMS160 FAN DIMENSIONS

RMS160 HOOD DIMENSIONS

GENERAL INFORMATION

Each Radon VACTMis factory line tested before shipment. After opening carton, inspect thoroughly for shipment damage.

Fan should rotate freely and all electrical wires and connections should be secured. If any damage is found, notify freight

carrier and your distributor immediately and file a concealed damage claim.

INSTALLATION GUIDELINES

The RMS160 must be installed by a qualified installer in accordance with these instructions and all local codes or in their

absence in accordance with the latest editions of the International Residential Code and International Electrical Code.

Improper installation can create a hazardous condition such as fire, electric shock or personal injury. To reduce these risks

significantly, use this unit only in the manner intended by the manufacturer. If you have questions, contact Tjernlund

Products. Always disconnect the RMS160 from its power source before installation and servicing.

CAUTION: For general ventilation use only. Do not use to exhaust hazardous or explosive materials and vapors. No maintenance is required for the RMS160, but regular radon testing is recommended to verify levels remain low.

WARNING: To reduce the risk of fire or electric shock, do not use this fan with any solid-state speed control device. Do not

plug in fan without PVC attached in order to avoid contact with rotating blower wheel.

The Radon VAC

TM

radon mitigation system is an important part of limiting the entry of radon gas into your home. However,

minimizing your home's exposure to radon requires a comprehensive approach and includes, but is not limited to:

Page 3

3

• Sealing cracks in foundation floors and walls

• Sealing ductwork that may create a negative pressure in basement or crawlspace

• Providing make-up air for combustion appliances and other exhaust sources to reduce the negative pressure

inside the home

• Diluting crawlspace or basement air with fresh air, (See Companion Products Section on page 7).

Radon fans work by actively depressurizing the soil under the foundation or crawl space vapor barrier. The lower pressure

created by the fan forces radon gas into the system's piping and to the outside rather than allowing it to leak into the home.

A fan can only effectively depressurize within a certain square foot range and this range is affected by many factors beyond

the performance of the fan (different soil types, densities, and foundation sizes). Note that some homes may require multiple

floor penetrations and/or fans. Use these guidelines to maximize the area covered by the fan:

• Minimize pipe run length and elbows

• Use larger diameter PVC pipe when practical

• Use appropriate PVC glue that matches PVC type to ensure sealed pipe joints & connections

• Seal all cracks in the foundation

• Seal PVC pipe penetration (around top of slab, sump pit, or vapor barrier)

• For sub-slab penetrations, provide 5-10 gallons of pea gravel under the slab to improve the air path area to the pipe

• Avoid structural restrictions to flow (e.g. foundation walls or footings)

• Avoid interfering with plumbing and heating pipes such as infloor heat or ductwork

Proper installation is critical at the point of penetration under the home. Below are general guidelines by penetration type.

Sub-membrane

Ensure that the entire sub-membrane is sealed and air tight. Seal penetration of PVC pipe into submembrane with commercial grade builder’s tape or other permanent means.

Sub-slab

Once penetration is made, promote proper flow by clearing out 5-10 gallons of dirt/clay from beneath foundation and replace

with pea gravel. IMPORTANT: PVC pipe should not "dead end" into dirt/clay, but rather should have some room to

"breathe" (the pea gravel allows this). Fittings are available so PVC is supported in the pea gravel and does not “dead end”

into the dirt. Use caulk or other means to seal the penetration around the pipe.

Sump Pit

Ensure that the sump pit cover is air tight and that pipe penetration is sealed. Some sump pit covers are available with

molded holes designed for PVC pipe. Install PVC pipe just inside the cover to avoid pulling water from the sump pit.

Page 4

RECOMMENDED DISCHARGE HOOD TERMINATION CLEARANCES

These recommendations are based on the National Fire Protection Association requirements for other sidewall discharge

devices. Always check local codes when installing this unit.

• Discharge should not be installed within 20 feet of another home or directed so as to jeopardize people or enter buildings.

• Discharge should be no less than 7 feet above grade when located adjacent to public walkways.

• Discharge should be no less than 3 feet above any air inlet located within 10 feet.

• Discharge should be at least 4 feet below or 4 feet horizontally from any door or window

• The bottom of the discharge should be located at least 12 inches above grade.

• If possible, do not locate discharge on a wall that faces the direction of the prevailing winds.

FAN INSTALLATION

1. Determine the centerline exit point for the PVC discharge pipe based on the orientation of the surface that the mounting

bracket will be attached to, (See Diagrams A, B, & C). Dimensional diagram on page 2 can also be referenced.

2. Mark centerline and drill small pilot hole to outside to verify that the termination hood is favorably positioned on the

home’s exterior, (See Diagrams D & E).

3. Using a 4" hole saw drill through to exterior. NOTE: When hole saw reaches back of siding it may be preferable to finish

cut from outside, (See Diagram F).

4

Diagram A Diagram B Diagram C

Page 5

4. Install mounting bracket in orientation used to determine exit point centerline leaving at least 1 foot from bracket to the

foundation wall or other vertical obstruction. This will allow room in the future to service the fan without detaching it from

the PVC piping, (See Diagram G).

5. Line up vibration isolation studs on back of fan housing to holes in bracket and secure with provided ¼" nuts,

(See Diagram H).

6. Cut a piece of 3" Schedule 40 PVC long enough to connect to the fan discharge and extend about 1 foot beyond the

home’s exterior. Push PVC pipe through hole to outside and insert it firmly in fan discharge - IMPORTANT: Do not glue to

fan at this time. This section of PVC will be cut to the finished length in Step 13 after performing the inflation test required

for adjustment of the VAC termination hood.

7. Connect PVC from the slab or sump pit to the inlet of the fan. Glue each section with adhesive approved for your type of

PVC, (See Diagram I). Schedule 40 PVC is most commonly used for radon exhaust. The inlet and outlet on the RMS160

fan is Schedule 40 PVC. Make sure that connection through slab or sump pit is completely sealed.

8. Sub-slab mitigation professionals would generally drill sample holes

in the corners of the slab to validate with the fan operating that the

system can create a suction throughout the entire sub-slab area. For

those points that a suction cannot be established additional PVC suction points should be installed and PVC piped to the existing Radon

VAC fan or exhausted separately with another fan.

5

Diagram I

Diagram H

Diagram G

Diagram D Diagram E Diagram F

ALLOW 12” BETWEEN

BRACKET AND WALL

FOR SERVICE

Page 6

BAG TEST (Determining optimal discharge hood blade settings)

By determining the amount of time the RMS160 radon fan takes to inflate the included 55 gallon garbage bag you can optimize the settings of the internal blades of the exhaust hood to create maximum dilution and discharge velocity. The outer

right and left blades adjust the dilution and the inner right and left blades adjust the velocity of the discharge.

9. NOTE: Operate fan for 10 minutes before proceeding to evacuate any built up moisture and soil gases below sub-slab

area. Turn fan off and secure included garbage bag to the end of the PVC exhaust pipe by pulling draw-strings tight and

duct taping to seal off the end of the pipe, (See Diagram J).

10. Squeeze air out of the bag, (See Diagram K).

11. Using an extension cord or working with a partner plug in the radon fan. As soon as power is supplied start to time how

many seconds it takes to fully inflate the 55 gallon bag and record here (Seconds ______). The bag should extend horizontally away from the PVC pipe when fully inflated, (See Diagram L). If you don't get a good time trial, unplug fan,

squeeze air out of bag and repeat time test.

12. After time test, assemble discharge hood by sliding the included PVC Flange onto the studs of the discharge hood and

secure with included nuts. Note that either set of 4 round holes on the flange can be used.

13. Mark the discharge PVC where it meets the lowest outside surface of wall, remove and cut to length, (See Diagram M).

Firmly insert and glue pipe into fan discharge. Insert discharge hood onto PVC pipe to test fit prior to gluing. Next glue the

discharge hood to the PVC stub on the home’s exterior making sure that it is right side up and level. The seams

on the side of the hood should point down. Fasten to exterior through the 4 corner holes using provided hardware.

Caulk around exterior of discharge hood with exterior rated caulk, (See Diagram N).

14. Reference the time recorded in Step 11 on the Radon Vac

TM

Bag Inflation Test chart to determine the suggested blade

settings. Set outer tips of left and right sides of each set of blades to line up with the scale on hood label and tighten

screws on both top and bottom to lock settings in place. NOTE: To tighten screws a second screwdriver may be needed

to prevent the opposite screw from rotating as the screw is tightened, (See Diagram O).

6

Diagram J Diagram K Diagram L

Diagram M

Diagram N Diagram O

HOOD SEAM SHOULD POINT DOWN

CAULK

HOOD

SCREWDRIVER

SCREWDRIVER

INNER

BLADES

OUTER

BLADES

Page 7

** If inflating the bag takes more than 25 seconds reference the Installation Guidelines on Page 2 to optimize volume cre-

ated by the mitigation system. NOTE: Although uncommon, some installations require more than one suction point or fan.

POST INSTALLATION RADON TESTING

We recommend a radon test after installation of the Radon Vac

TM

to confirm radon levels are reduced. Radon testing should

be performed periodically thereafter.

COMPANION PRODUCTS

Tjernlund offers other products that improve conditions under your home and reduce radon concentrations in basements

and crawl spaces through dilution with fresh outdoor air.

REPLACEMENT PARTS & WARRANTY

Component Part Number

Motor 950-9101

Radon Vac Hood 950-8700

7

Radon VACTMBag Inflation Test

Time to Fill Bag

(Seconds)

Velocity Blades Adjustment

(Inner Blades)

Dilution Blade Adjustment

(Outer Blades)

Less than 6 1 3/8" Left and Right of Center 1 1/2" Left and Right of Center

6 to 6.5 1 1/4" Left and Right of Center 1 3/8" Left and Right of Center

6.5 to 7 1 1/8" Left and Right of Center 1 1/4" Left and Right of Center

7 to 7.5 1" Left and Right of Center 1 1/8" Left and Right of Center

7.5 to 8 7/8" Left and Right of Center 1" Left and Right of Center

8 to 9 3/4" Left and Right of Center 7/8" Left and Right of Center

9 to 10 5/8" Left and Right of Center 3/4" Left and Right of Center

10 to 12 1/2" Left and Right of Center 5/8" Left and Right of Center

12 to 16 3/8" Left and Right of Center 1/2" Left and Right of Center

16 to 20 1/4" Left and Right of Center 1/2" Left and Right of Center

20 to 25 1/8" Left and Right of Center 1/2" Left and Right of Center

Over 25** 1/16" Left and Right of Center 3/4" Left and Right of Center

TJERNLUND LIMITED TEN YEAR WARRANTY

Tjernlund Products, Inc. warrants to the original purchaser of this product that the product will be free from defects due to faulty material or workmanship for a period of (10) years from the date of original

purchase or delivery to the original purchaser, whichever is earlier. Remedies under this warranty are limited to repairing or replacing, at our option, any product which shall, within the above stated warranty period, be returned to Tjernlund Products, Inc. at the address listed below, postage prepaid. If claim is filed within first (5) years of warranty period, Tjernlund will repair or replace at our option in consideration of the details expressed elsewhere in this warranty policy. Claims filed beyond the first 5 years, but still within the 10 year warranty period will be credited, repaired, or replaced at a 50% discount from the current LIST PRICE of the item at the time of the claim. THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF, AND TJERNLUND

PRODUCTS, INC. EXPRESSLY DISCLAIMS LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF THIS PRODUCT. THIS WARRANTY IS IN LIEU OF ALL

OTHER EXPRESS WARRANTIES AND NO AGENT IS AUTHORIZED TO ASSUME FOR US ANY LIABILITY ADDITIONAL TO THOSE SET FORTH IN THIS LIMITED WARRANTY. IMPLIED WARRANTIES ARE LIMITED TO THE STATED DURATION OF THIS LIMITED WARRANTY. Some states do not allow limitation on how long an implied warranty lasts, so that limitation may not apply to you.

In addition, some states do not allow the exclusion or limitation of incidental or consequential damages, so that above limitation or exclusion may not apply to you. This warranty gives you specific legal

rights and you may also have other rights which may vary from State to State. Send all inquiries regarding warranty work to Tjernlund Products, Inc. 1601 9th Street, White Bear Lake, MN 55110-6794.

Phone (651) 426-2993 • (800) 255-4208 • Fax (651) 426-9547 • Email fanmail@tjfans.com.

XchangeR™ Basement Fan

Many homes have basements

that are stale musty or smelly

because of seasonal water

issues, sump pits, floor drains or

general lack of air exchange.

The XchangeR™ Basement Fan

is the economical and simple

way to automatically ventilate

your basement to reduce odors,

humidity and radon levels.

UnderAire™ Crawl Space Fans

Tjernlund UnderAire™

crawl space fans ventilate excess moisture; a

cause of mold, mildew

and wood rot. Increases

air circulation to fight

condensation. Constant

operation helps vent

radon, treated wood off-gassing and odors that

might otherwise migrate into living areas.

Loading...

Loading...