Page 1

MODEL PS1503

The Tjernlund Duct Airstat senses positive pressure in a forced

air heating and/or cooling system. The single pole, single throw,

snap-acting switch is activated by a diaphragm with integral

pressure probe inserted directly into the duct or plenum.

The Duct Airstat can be used to initiate such auxiliary devices

as: Duct Boosters, Electronic Air Cleaners, Electrical Duct

Heaters, and Humidifiers. The electrical contacts of the switch

are closed upon sensing positive air pressure generated by the

blower.

Switch actuates air

cleaner by sensing

positive plenum pressure.

Switch activates humidifier

by sensing positive plenum

pressure.

Switch proves operation

of blower by sampling

positive pressure.

ELECTRONIC AIR CLEANERS

HUMIDIFIERS

FAN OPERATION

Switch activates Duct Booster by sensing positive pressure on either plenum, trunk, or branch lines as shown in Figures A and B above.

TYPICAL MOUNTING LOCATIONS & APPLICATIONS

A

B

Trunk Line

Plenum

115-120V

Duct

Airstat

Duct

Booster

Electronic

Air Cleaner

Electronic

Duct Heater

Humidifier

Duct Booster

Branch

Run

WIRING:

All wiring must agree with applicable electrical codes

and ordinances. Typical diagrams are shown below.

SWITCH MUST BE

MOUNTED WITH

DIAPHRAGM IN

VERTICAL POSITION

TJERNLUND PRODUCTS, INC.

1601 Ninth Street • White Bear Lake, MN 55110-6794

PHONE (651) 426-2993 • FAX (651) 426-9547

Visit our web site • www.tjernlund.com

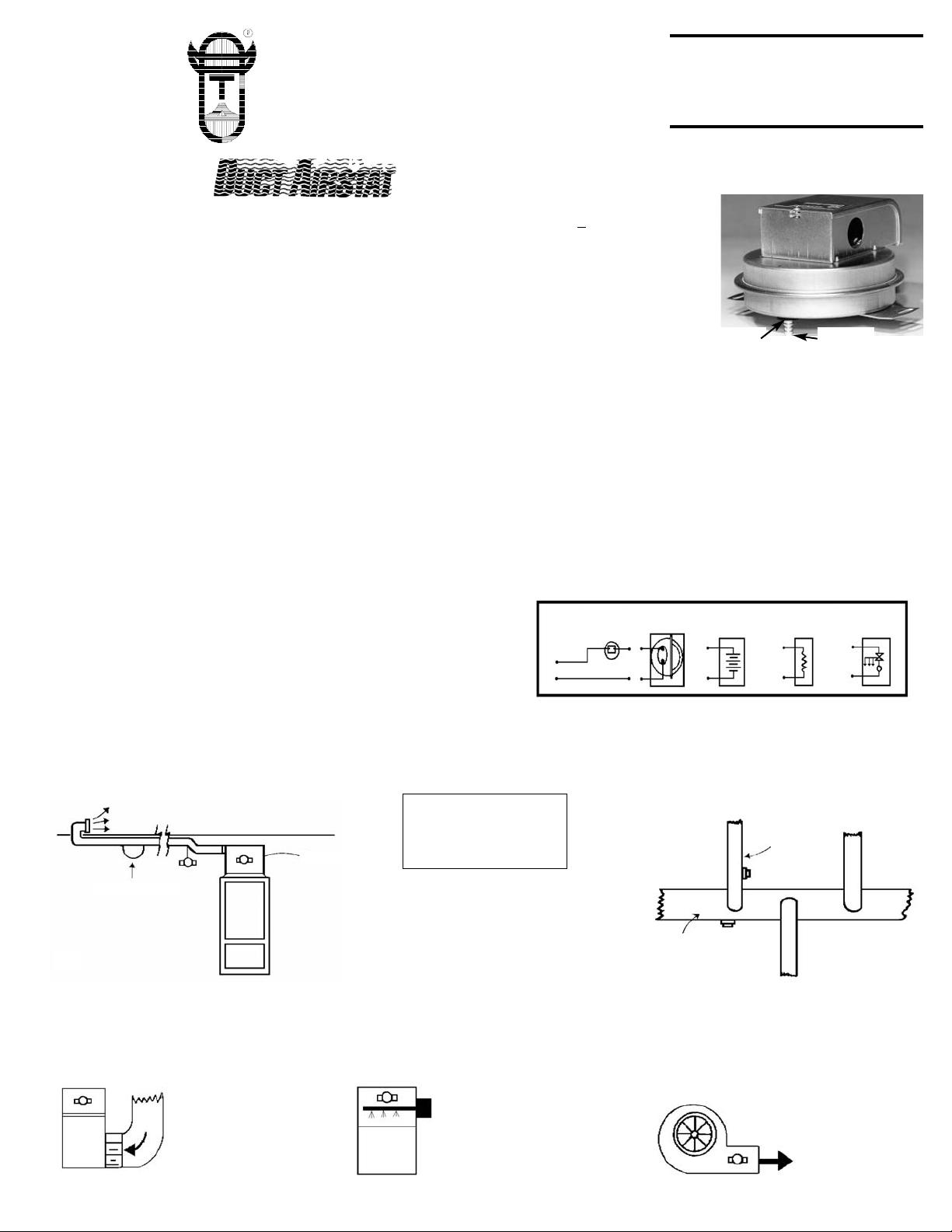

SIDE VIEW TOP VIEW

LOCATION AND MOUNTING:

1. The duct Airstat must be mounted in a vertical position.

2. Drill a 11/32” hole in the duct or plenum to permit the insertion the pressure probe. If furnace has central air-conditioning, care must be taken so as not to drill into the cooling

coil when mounting the Duct Airstat on the furnace plenum.

3. Insert the pressure probe into the drilled hole, position the

Duct Airstat and mark the mounting holes. If necessary,

bend the mounting feet with pliers to match the contour of

the duct or plenum.

4. Remove control and drill or punch two 1/8” holes for

mounting screws.

5. Using the two sheet metal screws furnished, fasten the Duct

Airstat to the duct or plenum. Sealing gasket must be

mounted on pressure probe to ensure minimal air leakage.

OWNERS

INSTRUCTIONS

DO NOT DESTROY

DUCT AIRSTAT INCLUDES:

1. A fixed “fan-on” setpoint

(+ .05 + .02” W.C.)

2. Integral pressure probe

3. Sealing gasket

4. Mounting hardware

INSTALLATION:

CAUTION

1. Disconnect power supply before making wiring

connections to prevent electrical shock and

equipment damage.

2. All wiring must comply with applicable codes and

ordinances.

3. Always conduct a thorough checkout when installation is complete.

SEALING

GASKET

PRESSURE

PROBE

Page 2

GENERAL SPECIFICATIONS:

ELECTRICAL RATING:

278 VA Pilot Duty at 24 Volts AC

300 VA Pilot Duty at 115 to 277 Volts AC

15 AMPS Non-Inductive to 277 Volts AC

ELECTRICAL SWITCH:

SPST, N/O, Snap Action Contacts, Non Adjustable

OPERATING PRESSURE / POSITION:

On pressure rise at +.05 + .02” W.C. (Diaphragm Vertical)

MAXIMUM PRESSURE:

1/2 PSI

OPERATING TEMPERATURE RANGE:

-40 to 190

0

F.

OPERATING POSITION:

Diaphragm must be vertical

PRESSURE PROBE:

Self-sealing, integral pressure probe

DIMENSIONS:

5” Diam., 5 1/2” Across Bracket, 3” High

To connect to screw-in terminals, use the following

procedures:

1. Remove electrical box cover.

2. No. 14, 16 or 18 solid or No. 14 or 16 stranded wire

may be connected to these terminals. Do not connect

aluminum wire to the screw-in terminals on this device.

3. Strip insulation from wires approximately 1/2”.

4. Bend each bare lead around its respective terminal in

a clockwise direction and tighten terminal screw.

5. Replace the electrical box cover when connections

are complete.

© 1999 Tjernlund Products, Inc. P/N 8504014 Rev. A 10/99

TJERNLUND LIMITED ONE YEAR WARRANTY

Tjernlund Products, Inc. warrants to the original purchaser of this product that the product will be free from defects due to faulty material or workmanship

for a period of (1) year from the date of original purchase or delivery to the original purchaser, whichever is earlier. Remedies under this warranty are

limited to repairing or replacing, at our option, any product which shall, within the above stated warranty period, be returned to Tjernlund Products, Inc. at

the address listed below, postage prepaid. THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF,

AND TJERNLUND PRODUCTS, INC. EXPRESSLY DISCLAIMS LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING FROM THE

USE OF THIS PRODUCT. THIS WARRANTY IS IN LIEU OF ALL OTHER EXPRESS WARRANTIES AND NO AGENT IS AUTHORIZED TO ASSUME

FOR US ANY LIABILITY ADDITIONAL TO THOSE SET FORTH IN THIS LIMITED WARRANTY. IMPLIED WARRANTIES ARE LIMITED TO THE STATED DURATION OF THIS LIMITED WARRANTY. Some states do not allow limitation on how long an implied warranty lasts, so that limitation may not

apply to you. In addition, some states do not allow the exclusion or limitation of incidental or consequential damages, so that above limitation or exclusion may not apply to you. This warranty gives you specific legal rights and you may also have other rights which may vary from State to State. Send

all inquiries regarding warranty work to Tjernlund Products, Inc. 1601 9th Street, White Bear Lake, MN 55110-6794. Phone (651) 426-2993 •

Fax (651) 426-9547.

TROUBLE-SHOOTING:

Installations in larger ducts or “dead spots” in duct work may not create enough positive pressure “impact” to activate the Duct

Airstat. Try locating pressure probe at several points. Contact Tjernlund Products customer service @ 1-800-255-4208 or email

us at fanmail@tjfans.com for further assistance.

OTHER TJERNLUND PRODUCTS

HIGH PRESSURE DUCT FANS

DUCT BOOSTER®DUCT & EXHAUST FANS

CONNECTING TO SCREW-IN

TERMINALS:

Loading...

Loading...