Page 1

Copyright © 2004, Tjernlund Products, Inc. All rights reserved. P/N 8504125

CPC-3 CONTROLLED START-UP MANUAL

FOR MODULATING DRAFT & COMBUSTION AIR SYSTEMS

FOR USE WITH AUTO-DRAFT® VSAD-SERIES

INDUCERS & VSUB-SERIES BLOWERS

THIS INSTALLATION GUIDE IS INTENDED AS AN AID TO QUALIFIED, LICENSED

SERVICE PERSONNEL FOR PROPER INSTALLATION, ADJUSTMENT AND

OPERATION OF THIS UNIT. READ THESE INSTRUCTIONS THOROUGHLY

BEFORE ATTEMPTING INSTALLATION OR OPERATION. FAILURE TO FOLLOW

THESE INSTRUCTIONS MAY RESULT IN IMPROPER INSTALLATION, ADJUSTMENT, SERVICE OR MAINTENANCE POSSIBLY RESULTING IN FIRE, ELECTRICAL SHOCK, CARBON MONOXIDE POISONING, EXPLOSION, OR PERSONAL

INJURY OR PROPERTY DAMAGE.

TJERNLUND PRODUCTS, INC.

1601 Ninth Street • White Bear Lake, MN 55110-6794

PHONE (800) 255-4208 • (651) 426-2993 • FAX (651) 426-9547

Visit our web site • www.tjernlund.com

Listings:

The Mechanical Draft System

is Listed to UL-378

The Mechanical Combustion Air

System is Listed to UL-1995

Page 2

TABLE OF CONTENTS PAGE

Descriptions

Induced Draft / Exhaust ..............................................................................................................................................1

Combustion Air............................................................................................................................................................1

Auxiliary Devices ............................................................................................................................................................2

Operation Modes

Automatic ....................................................................................................................................................................2

Manual.........................................................................................................................................................................2

Suggested Physical Placement of Components & Maximum Lead Lengths ..................................................................3

Transducer Sensing Tube Installation .............................................................................................................................3

Induced Draft...............................................................................................................................................................3

“Open” Combustion Air................................................................................................................................................3

“Sealed” Combustion Air .............................................................................................................................................3

CPC-3 Keypad Layout & Display ...................................................................................................................................4

CPC-3 Circuit Board Callouts .....................................................................................................................................5, 6

Wiring

Low Voltage VFD Control Cable Wiring to CPC-3......................................................................................................6

Low Voltage TD-Series Transducer & PSA-1 Manual Mode Fan Prover Wiring to CPC-3........................................7

Remote Alarm / Auxiliary Device Wiring .....................................................................................................................7

VFD to Inducer / C.A. Blower Wiring ......................................................................................................................8, 9

CPC-3 Main Power Input & Heater Interlock Wiring.................................................................................................10

Pre-start up Field Wiring Verification.........................................................................................................................10

Start Up of CPC-3

Powering & Initializing CPC-3 ...................................................................................................................................10

Default CPC-3 Program Settings ..............................................................................................................................11

Unlocking & Locking the CPC-3 Keypad...................................................................................................................11

Setting CPC-3 Time and Date...................................................................................................................................11

Activating the Draft or Combustion Air......................................................................................................................11

Testing the Operation of System components

Test Run Set Up ........................................................................................................................................................12

VFD and Pressure Transducer Response................................................................................................................12

Checking for Proper Rotation....................................................................................................................................12

Draft Adjustment

Draft Set Point Adjustment..................................................................................................................................12, 13

Balancing Draft..........................................................................................................................................................13

Combustion Air Adjustment

“Open” & “Sealed” Combustion Air Modes of Operation ....................................................................................13, 14

Combustion Air Set Point Adjustment .......................................................................................................................14

“Open” Mode System Start Up..................................................................................................................................14

“Sealed” Mode System Start Up ...............................................................................................................................14

Auxiliary Devices

Alarm Buzzer.............................................................................................................................................................15

Aux Sensor Set Up ...................................................................................................................................................15

Aux Device Set Up....................................................................................................................................................15

CPC-3 Options

Resetting VFD Drive(s) .............................................................................................................................................15

Setting Pressure Units of Measure ...........................................................................................................................15

Viewing & Resetting Fault History.............................................................................................................................16

Set Stages & Burner Interlock Verification ................................................................................................................16

Setting Pre and Post Purge ......................................................................................................................................16

Manual Mode Operation and PSA-1 Fan Prover Switch Adjustment......................................................................16, 17

Maintenance & How to Obtain Service Assistance .......................................................................................................17

INDUCED DRAFT EXHAUST & COMBUSTION AIR SYSTEMS

INDUCED DRAFT / EXHAUST

The automatic variable speed draft system consists of:

1. A Draft Inducer (either VSAD-Series or VSUB-Series)

2. A CPC-3 Constant Pressure Controller

3. A TD-Series Pressure Transducer

4. A VFD-Series Variable Frequency Drive

5. A PSA-1 Fan Prover for Manual Mode Operation (Included with VSAD & VSUB Series)

COMBUSTION AIR / MAKE-UP AIR

The automatic variable speed combustion air system consists of:

1. A VSUB-Series blower

2. A CPC-3 Constant Pressure Controller

3. A TD-Series Pressure Transducer

4. A VFD-Series Variable Frequency Drive

5. A PSA-1 Fan Prover for Manual Mode Operation (Included with VSAD & VSUB Series)

1

Page 3

The Patented CPC-3 Controller can simultaneously control both draft and combustion air so only one is needed when both Draft

Inducers and Combustion Air Blowers are installed in conjunction with the same heating system. For the remainder of this guide

Inducer will be synonymous to Induced Draft Exhaust and C.A. Blower will be synonymous to Combustion Air Blower.

AUXILIARY DEVICES

The CPC-3 auxiliary devices include an Audible Alarm Buzzer (circuit board mounted), an Auxiliary Device relay for activating a motorized damper in series with the draft and/or combustion function, and a sensor input for a damper end switch. The sensor input can

also be configured to accept a signal from a CO detector and lock out all interlocked burners.

CPC-3 AUTOMATIC / MANUAL MODE SEQUENCES OF OPERATION

CPC-3 AUTOMATIC MODE SEQUENCE OF OPERATION, SEE DIAGRAM A

An aquastat, sequencing control or building management system signals a call for heat. This signal is intercepted and routed

through the CPC-3.

The CPC-3 compares actual pressure levels in vent connector and/or mechanical room with previously entered set points.

The Inducer speeds up to achieve the vent pressure set point and/or the combustion air blower simultaneously speeds up

to achieve desired pressure set point. These separate functions happen in parallel but are based on software and tolerances unique to the respective draft or combustion air function and to the differential between actual and set point. When

the set point is reached the CPC-3 completes the circuit to the heaters allowing ignition sequence to begin.

Pressures are constantly monitored by the transducer during the heating cycle. The Inducer / C.A. Blower motor speeds

are independently and continuously adjusted to maintain set points entered into the CPC-3. Winds, outdoor temperatures,

natural chimney draft, flue gas temperatures, modulating firing rates and building pressure changes will all be compensated

for automatically.

The heaters will be disrupted for 1 minute if at any time the draft cannot be maintained within the times and tolerances of the software. After this restart delay the CPC-3 will once again try to reach the system set points. If successful, the system will sequence normally. If not successful, the CPC-3 will lock out the heaters until it is manually reset. Up to 5 fault codes will be stored memory.

CPC-3 MANUAL MODE SEQUENCE OF OPERATION

Manual Mode is a method of setting Draft and/or Combustion Air at a fixed speed. It was developed to be used in emergency cases

where a transducer is not operational. In Manual mode, the heaters are allowed to operate as long as the manual mode PSA-1 Fan

Prover Switch is closed. WARNING: Because Manual Mode is a method of setting a fixed speed for Draft and/or Combustion Air, consideration must be given to over-drafting and/or excessive combustion air supply, See “Manual Mode Operation and PSA-1 Fan

Prover Switch Adjustment”, page 16. Deactivate heaters not necessary in an emergency situation to reduce the chance for these conditions. To shut off heater calls from being processed, refer to the “SET STAGES” option, page 16 or shut off the service switch to

each heater.

4

3

2

1

2

DIAGRAM A

Page 4

SUGGESTED COMPONENT PHYSICAL PLACEMENT

Although it is not necessary to install the CPC-3 and related VFD(s) adjacent to each other it is highly recommended since both displays may need to be viewed simultaneously during system startup or servicing. A faulted VFD can be reset from either the CPC-3 or

the VFD.

MAXIMUM LEAD LENGTH FROM CPC-3 CONTROLLER:

Transducer: 150 feet with 18 AWG (3 leads required)

Manual Mode PSA-1 Proving Switch: 325 feet with 18 AWG (2 leads required)

VFD Control Signal: 220 feet with 18 AWG (10 leads required)*

*VFD comes with 10 foot set of leads terminated with a VFD quick connect

MAXIMUM LEAD LENGTH FROM VFD TO INDUCER/BLOWER:

230 VAC Models: 300 feet with 14 AWG, 600 VAC Insulation

460 VAC Models: 100 feet with 14 AWG, 600 VAC insulation

TRANSDUCER SENSING TUBE INSTALLATION

FOR MECHANICAL DRAFT INSTALLATIONS

The TD-2 Transducer sensing tube should be installed in

the cap of a tee or rear of a common manifold. The tee is

necessary so that only static pressure is measured. If the

transducer sensing tube is installed in the side of a vent

pipe it will also measure velocity pressure, giving an incorrect signal back to the CPC-3 Controller. If mounting on the

side of the pipe is unavoidable, the sensing tube should be

flush

to the interior wall of the vent pipe. Typically, draft

applications should sample at a point in back of the vent

connection that is farthest

from the inducer/blower, See

Diagram B.

FOR “SEALED” COMBUSTION AIR APPLICATIONS

The TD-2 Transducer sensing tube should be installed in

the capped end of a common supply manifold. This is necessary so that only static pressure is measured. If the

transducer sensing tube is installed in the side of a duct it

will also measure velocity pressure, giving an incorrect signal back to the CPC-3 Controller. If mounting on the side of

the duct pipe is unavoidable, the sensing tube should be

flush

to the interior wall of the duct. If a filter is installed it

must be positioned between the blower inlet and intake

opening, See Diagram C.

FOR “OPEN” COMBUSTION AIR APPLICATIONS

In "Open" mode the mechanical room air is sampled and an adjacent space is referenced. Referencing an adjacent space within the

building typically provides a more stable reference pressure than referencing outdoor air. In both cases, the goal is to reference static

pressure. Don't sample pressures at locations that can be affected by frequently opened doors, elevator shafts, ventilation fans and

diffusers. The model IPS-1 includes a decorative cover, sampling tube and fittings and when used in conjunction with the TD-3

Transducer may be used to sample indoor reference pressure. It reduces the effects of air movement on the sampling tube and provides a finished look. Varying wind speeds will affect outdoor reference pressure and are difficult to neutralize. If sampling outdoor reference pressure, the model WW-1 may be used in conjunction with the TD-3 Transducer to help neutralize the effects of winds. For

best performance mount the WW-1 at least one foot away from an outside wall

3

D2D

FROM VENTER

HEATER FURTHEST

8054004 12/8/04

BACK FROM THE MANIFOLD.

BE 2 TIMES THE DIAMETER OF THE PIPE

IF POSSIBLE, THE SENSING TUBE SHOULD

BACK FROM THE LAST HEATER MANIFOLD.

BE 2 TIMES THE DIAMETER OF THE PIPE

IF POSSIBLE, THE SENSING TUBE SHOULD

2D

FIGURE 8054005 12/9/04

LAST HEATER

FIRST HEATER

COMBUSTION AIR

MANIFOLD

COMBUSTION

AIR INTAKE

INSTALLER-SUPPLIED

FILTRATION MUST BE ON

BLOWER INLET SIDE.

SENSING TUBE

DIAGRAM B

DIAGRAM C

Page 5

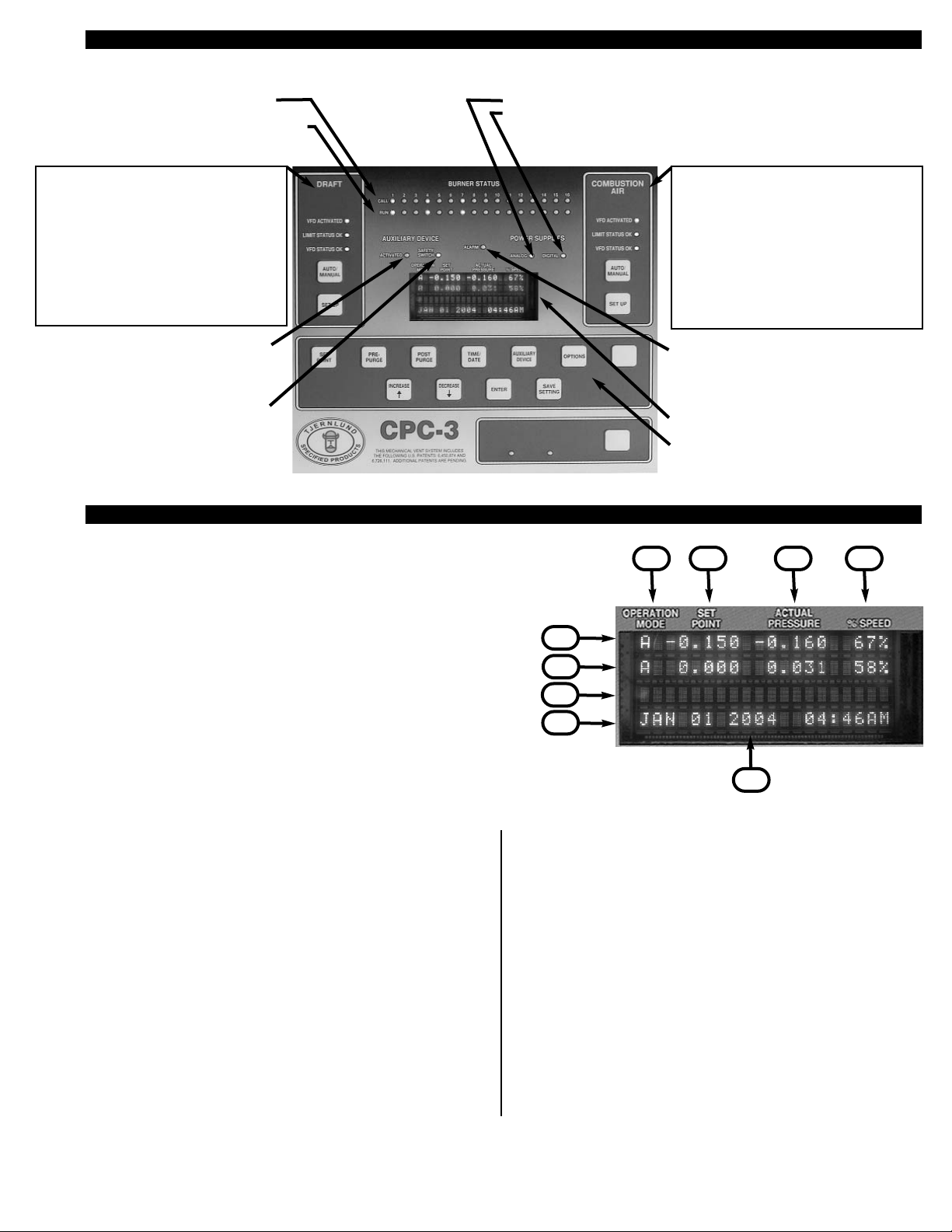

CPC-3 KEYPAD LAYOUT

CPC-3 DISPLAY

4

AUXILIARY DEVICE Green ACTIVATED LED

indicates AUX. CONTROL Relay contacts (C & O)

are closed to actuate auxiliary devices such as a

motorized louver.

AUXILIARY DEVICE Green SAFETY SWITCH

LED indicates Auxiliary device safety contacts

such as a damper end switch are in a closed

position within 90 seconds after a call for heat.

Red ALARM LED indicates a system fault is

detected. On board audible alarm buzzer can be

activated. Alarm relay contacts (NO, C & NC) can

be interlocked with building management system

or other device.

CPC-3 Display window

Additional Programming Keys

BURNER STATUS

Amber CALL LED indicates burner call for heat

Green RUN LED indicates burner approved to fire

after completing CPC-3 safety circuit

POWER SUPPLIES

ANALOG - 24 VDC CPC-3 on board power supply for check circuits and transducer

DIGITAL - 5 VDC CPC-3 on board power supply for CPC-3 microcontroller and logic

COMBUSTION AIR Setup portion of CPC-3

VFD ACTIVATED - Green LED shows VFD turned

on by CPC-3

LIMIT STATUS OK -Green LED shows all limits /

safeties closed (i.e. motor or freeze limits)

VFD STATUS OK -Green LED shows VFD is not

faulted, no LED indicates VFD fault

Auto / Manual mode and Setup for Combustion Air

Options

DRAFT Setup portion of CPC-3

VFD ACTIVATED- Green LED shows VFD turned

on by CPC-3

LIMIT STATUS OK - Green LED shows all limits /

safeties closed (i.e. motor limit, heat limits, tilt

switches)

VFD STATUS OK - Green LED shows VFD is not

faulted, no LED indicates VFD fault

Auto / Manual mode and Setup for Draft Options

A

B

C

D

E

F G H

I

A. The 1st display line is for the Draft System. If the Draft System is

not active, the top line will read "INDUCER INACTIVE" and will

not display an operation mode, set point, actual pressure or

motor operating speed %.

B. The 2nd display line is for the Combustion Air System. If

the Combustion Air System is not active, the second line will read

"COMBUS. AIR INACTIVE" and will not display an operation

mode, set point, actual pressure or motor operating speed %.

C. The 3rd display line is the "Message" line for different operating

phases such as, Start Up, Pre-Purge, Post Purge, Etc. This line

also displays faults that have been detected within the overall

operation of the control. A fault message displayed will be

specific to the fault type, the draft or combustion air system and

which operation phase the control was in when the fault occurred. If the key pad is unlocked, this line converts to a progammable menu line where options are displayed.

D. The 4th and last display line is for the Date and Time. Used

when the keypad is unlocked, as a programmable menu options

line. In short, when the keypad is unlocked, the bottom 2 lines

become menu information lines for the key functions and their

options.

E. The 1st column of the display is for the OPERATION MODE and

will display an "A" if the Draft or Combustion Air System is active

in “Automatic” mode or an "M" if in “Manual” mode.

F. The 2nd column of the display is for the SET POINT of the

Draft or Combustion Air system set by the installer. The pressure

units displayed (Inches of water column or Pascals) are set

under the "Options" key. The factory default set point is

-0.15" WC. for Draft and 0.00" WC. for Combustion Air.

G. The 3rd column of the display is for the ACTUAL PRESSURE of

the Draft or Combustion Air System, updated every second based

on the pressure sensed by the pressure transducer. If the Draft

or Combustion Air System is Active, the Actual Pressure will be

displayed 100% of the time. As with the set point, the units of

pressure measurement will change based on Inches of WC or

Pascals in "Options".

H. The 4th and last column of the display is for the %SPEED of the

Draft or Combustion Air System. This speed percentage is direct

ly rendered from the control voltage signal that is being provided

by the CPC-3 controller to the VFD. The scale is 1 VDC to 10 VDC.

1 VDC = 1% motor speed, 10 VDC = 100% motor speed. Anytime the control is telling the motor to run, the percentage speed

is illustrated here.

I. Date and Time display when not used for programming options.

Page 6

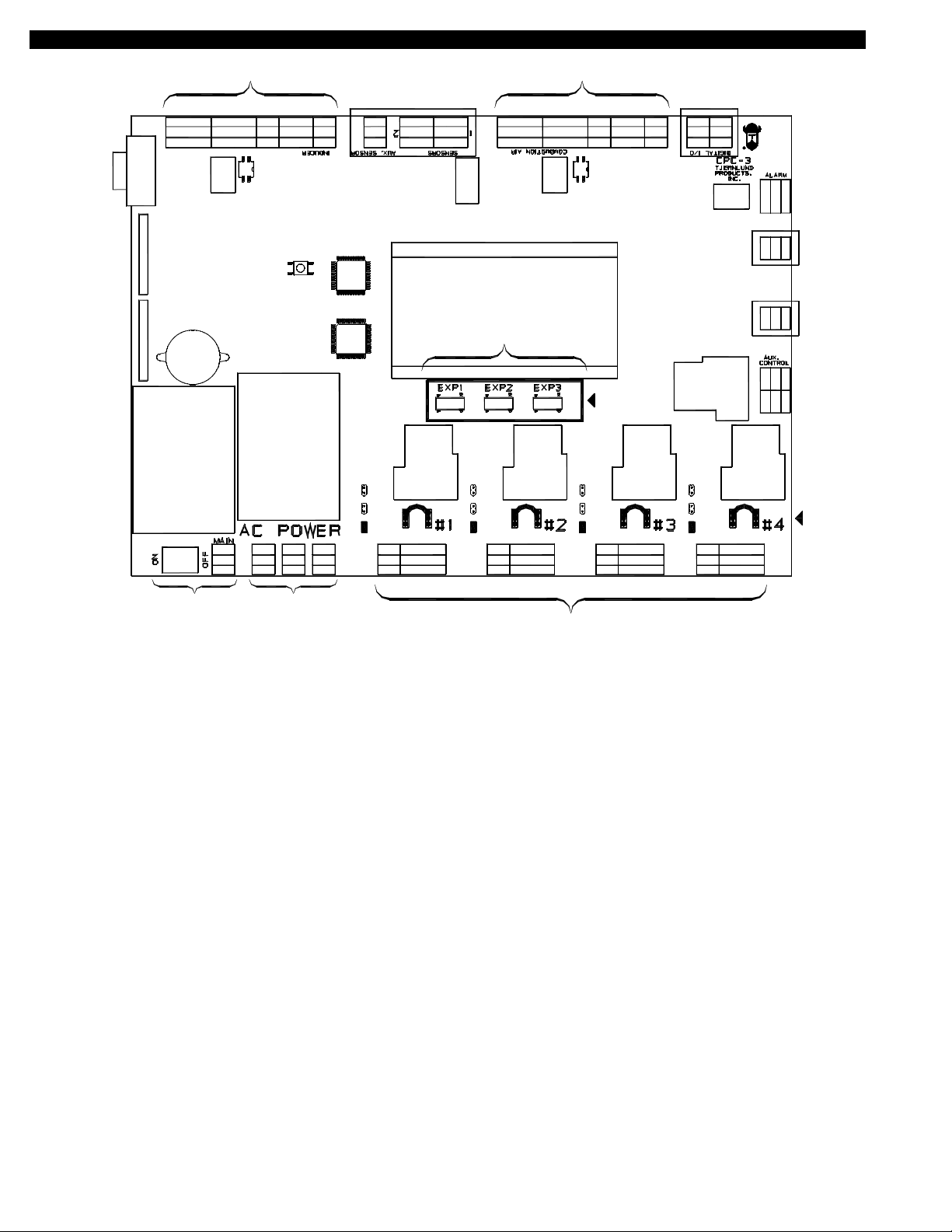

5

MBMCM1M2S1S2SCS3D-D+BRGP1P2S2S1S2S1 P2 P1 G R B D+ D- S3 SC S2 S1 M2 M1 MC MBB R G B R G S1 S2

OCS2S1 12 12 NCCNO

NLLN LN LN AB AB AB AB 21344

3

124

3

124

3

12

POWER TERMINAL

MAIN AC EXP-4E

POWER TERMINALS

HEATER 1 HEATER 2 HEATER 3 HEATER 4

INDUCER PORT COMBUSTION AIR PORT

BOARD

ALARM

POWER

DIGITAL

ANALOG AND

SUPPLIES

KEYPAD

CONNECTORS

CALL

RETURN

JUMPERS

PORT

DEVICE

AUXILIARY

PORT

ALARM

REMOTE

PORTS

SIGNAL

EXP-4E

MICROCONTROLLERS

SWITCH

RESET

SELECTOR

INDUCER

MOTOR

ROTATION ROTATION

MOTOR

COMBUSTION AIR

SELECTOR

CONTROLLER DISPLAY

DRY1

A24V

A115V

DC

B115V

B24V

DRY2

C115V

C24V

DRY3

D115V

D24V

DRY4

D1 D1 D1 D1

AB

I

C1

E

F

H1 G1

H

G

FUTURE USE FUTURE USE

FUTURE

USE

USE

FUTURE

FIGURE 8081005

CPC-3 BOARD CALLOUTS

A) CPC-3 Main Power Switch

B) Power Supply Input Terminals: Accepts either 115 or 230 VAC, 50/60 Hz. 230V power can be suppied from VFD L & L Terminals.

C) Power Supply Output Terminals: Supply power to accessory EXP-4E Expansion boards.

C1) EXP-4E Expansion Modules: Communications connections from EXP-4E Expansion boards.

D) Heater Interlock Terminal Blocks (Four):

Positions A & B are for dry contact actuation, with A outputting 5 VDC and B needing 5 VDC to activate the CPC-3. Positions 1 &

2 require either 24 or 115 VAC from a heater control circuit to activate the CPC-3. A factory installed call return jumper wire above

each terminal block routes the voltage connected from position 1 to position 3. When the CPC-3 safety circuit is made it switches

position 3 to position 4, where the intercepted heater control circuit is routed back to the heater. Positions 3 & 4 are used independent of positions 1 & 2. If the A & B dry contacts are used to activate the CPC-3 (Call return jumper wire must be removed).

D1) IMPORTANT: Each six position terminal block includes a RED jumper tab to select the heater interlock voltage that is

connected heater terminal block. Place RED jumper tab in Dry for positions A & B, 24V or 115V for positions 1 & 2 depening

upon heater interlock voltage)

E) Auxiliary Device Terminals:

Used to activate a motorized damper/louver in series with the inducer/blower activation by switching power to device through terminal C & O. Position S1 outputs 5 VDC to be switched through a damper end switch and returned to position S2. This incorporates the end switch closure into the overall CPC-3 safety circuit. Positions S1 & S2 may also be used to react to the contact closure of a carbon monoxide alarm. The functions of C & O and S1 & S2 are independently activated through the Auxiliary Device key.

F) Remote Alarm Terminals:

Used to activate a remote alarm through either normally open or normally closed contacts. A power source is routed to the C position and returned out of either the N/C or N/O positions if an alarm condition exists.

G & H) Draft and Combustion Air Terminals:

The CPC-3 can independently control mechanical draft and combustion air inducers/blowers. While the software that runs

these functions differs, the communications to the VFD's that control the inducer/blower is identical. The following information

is applicable to both the Inducer and Combustion Air terminal strips.

Page 7

6

Positions P1 & P2 are for the PSA-1, manual mode proving switch. Position P1 outputs a 5 VDC signal to the PSA-1 Proving

Switch. When the switch closes it returns the signal to position P2, allowing interlocked heaters to operate with the CPC-3 in

Manual Mode.

Positions G, R & B connect to a TD-Series transducer. Position G receives the 1-10 VDC output from the transducer. Position R is

the 24 VDC power supply to the transducer. Position B is the ground for the transducer.

Positions D+ & D- connect to the VFD through the included communications cable. Position D+ outputs a 1-10 VDC signal to the

VFD to modulate the inducer/blower. Position D- is the reference ground.

Positions S3, SC, S2 and S1 connect to the VFD through the included communications cable. These connections enable reset of

a faulted VFD and reverse the rotation of an inducer/blower from the CPC-3 controller.

Positions M1, M2, MC and MB connect to the VFD through the included communications cable. Position M1 outputs a 5 VDC signal to the inducer/blower limit circuits. This signal must return to position M2 or a mechanical fault will be posted on the display

and the Limit Status OK LED will not be lit. Position MC outputs a 5 VDC signal to a N/C fault relay within the VFD. This signal

must return to position MB or a VFD fault will be noted in the display and the VFD Status OK Green LED will not be lit.

G1 & H1) Inducer / C.A. Blower Rotation Selectors:

Below the Inducer (Draft) and Combustion Air terminal strips are two sets of dip switches. These dip switches determine the

rotation of the inducer/blower being controlled by that particular terminal strip. The two dip switches at each position must

always be switched opposite of each other or the VFD will receive simultaneous FWD/REV run commands, causing it to

fault. See "Checking Rotation", page 12.

I) CPC-3 Reset Button:

Pressing this button resets the CPC-3 controller with a "soft boot". It can be used in lieu of the power switch to "re-boot" the microcontrollers of the CPC-3 without power spiking the board.

LOW VOLTAGE VFD CONTROL CABLE WIRING TO CPC-3

FIGURE 8055010 8/30/04

D+ D- S3 SC S2 S1 M2 M1 MC MBB R G B R G S1 S2

CPC-3 CONTROL

SENSORS AUX. SENSOR INDUCER

21

BRGP1P2

SELECTOR

INDUCER

MOTOR

ROTATION

from the Inducer VFD to the CPC-3 Inducer terminal strip.

Be sure to route the communications cable in metal conduit1.

NOTES:

to route each wire from the Inducer VFD to the CPC-3

If a longer communication cable is required, make sure2.

Inducer terminal strip correctly. MB to MB, MC to MC, etc.

BLACK

VIOLET

ORANGE

GRN/YEL

BLUE

YELLOW

WHT/RED

RED

WHT/BRN

GRAY

WITH VFD

10 FOOT

COMMUNICATION

CABLE PROVIDED

NOT USED -

FOR FUTURE

DEVELOPMENT

NOT USED -

FOR FUTURE DEVELOPMENT

THE INDUCER

TERMINAL STRIP

INSERT PLUG INTO THE INDUCER

VFD RECEPTACLE

GRAY

WHT/BRN

RED

WHT/RED

YELLOW

GRN/YEL

BLUE

ORANGE

VIOLET

BLACK

TOP LEFT CORNER

CPC-3 CONTROL

BOARD

RS232

COM.

PORT

NOTE: The diagram below is suitable for both the Inducer or Combustion Air side of the the CPC-3 board. While the software that

runs draft or combustion air differs, the communication to the VFD's that control the Inducer / C.A. Blower is identical. The following

information is applicable to both the CPC-3 Inducer and Combustion Air terminal strips.

WIRING

All wiring from the Inducer / C.A. Blower to the heater must be in compliance with the local codes or in their absence, the National

Electric Code (NFPA 70).

All wiring from the Inducer/blower to the heater must be appropriate class 1 wiring installed in rigid metal conduit or intermediate metal

conduit. This installation manual does not contain any system design documentation. Installation and use of Tjernlund controls like the

EXP-4E Heater Interlock Expansion boards or VFD-Series Variable Frequency Drives are not covered by this manual. Please refer to

those installation manuals for details.

INDUCER OR

COMBUSTION AIR

MOTOR ROTATION

SELECTOR

NOTES:

1. Be sure to route the communications cable in metal conduit

from the Inducer or C. A. Blower to the respective CPC-3

Inducer or Combustion Air terminal strip.

2. If a longer communication cable is required, make sure to route

each wire from the Inducer or C.A. Blower VFD to the respective CPC-3 Inducer or Combustion Air terminal strip.

Page 8

7

LOW VOLTAGE TD-SERIES TRANSDUCER & PSA-1 MANUAL MODE FAN PROVER WIRING TO CPC-3

MAXIMUM WIRE LENGTH TABLE

WARNING:

Failure to wire the Transducer

Make sure to wire G - G, R - R

correctly will destroy the

and B - B before activating the

THE INDUCER

MANUAL MODE

PRESSURE SWITCH

PRESSURE TRANSDUCER

(PSA-1)

THE INDUCER

Transducer!

the CPC-3.

TD-___

900' (274m)

12 AWG

FIGURE 8055011 9/3/04

D+ D- S3 SC S2 S1 M2 M1 MCMBB R G B R G S1 S2

CPC-3 CONTROL

SENSORS AUX. SENSOR INDUCER

21

BRGP1P2

SELECTOR

INDUCER

MOTOR

ROTATION

NOT USED -

FOR FUTURE

DEVELOPMENT

NOT USED -

FOR FUTURE DEVELOPMENT

THE INDUCER

TERMINAL STRIP

TOP LEFT CORNER

CPC-3 CONTROL

BOARD

RS232

COM.

PORT

Wire Gage

Max. Distance

600' (183m)

14 AWG

390' (119m)

220' (67m)

16 AWG

18 AWG

22 AWG

20 AWG

110' (34m)

165' (50m)

CAUTION:

These wires must be

metal conduit.

routed in their own

RBG

NOTE: The diagram below is suitable for both the Inducer or Combustion Air side of the the CPC-3 board. While the software that

runs draft or combustion air differs, the wiring to the Transducer and PSA-1 manual mode fan prover is identical. The following information is applicable to both the CPC-3 Inducer and Combustion Air terminal strips.

REMOTE ALARM / AUXILIARY DEVICE WIRING

FOR FUTURE

SYSTEM USE

LOAD

SYSTEM O.K.

SIGNAL POWER IN

REMOTE ALARM

TERMINAL BLOCK

AUXILIARY

LOAD

AUXILIARY DEVICE

POWER IN

5 VDC SIGNAL

ALARM AND AUXILIARY

RELAY SPECIFICATIONS:

40 AMPS @ 240 VAC / 30 VDC

30 AMPS @ 277 VAC

2 HP @ 250 VAC

1 HP @ 125 VAC

ALARM RELAY

APPLIANCE 4

INTERLOCK BLOCK

USER-PROVIDED

SWITCH

TOP RIGHT CORNER

CPC-3 CONTROL BOARD

FOR FUTURE

SYSTEM USE

OCS2S1 12 12 NCCNO

34

CALL

RETURN

JUMPERS

P2S2S1S2S1

DIGITAL I/O

TJERNLUND

PRODUCTS,

CPC-3

CONTROL

AUX.

ALARM

12AB4

#3 #4

FOR FUTURE

SYSTEM USE

SYSTEM FAULTED

LOAD

AUXILIARY SENSING

CIRCUIT

AUXILIARY DEVICE

TERMINAL BLOCK

NOTE:

INDUCER OR

COMBUSTION AIR

MOTOR ROTATION

SELECTOR

Page 9

8

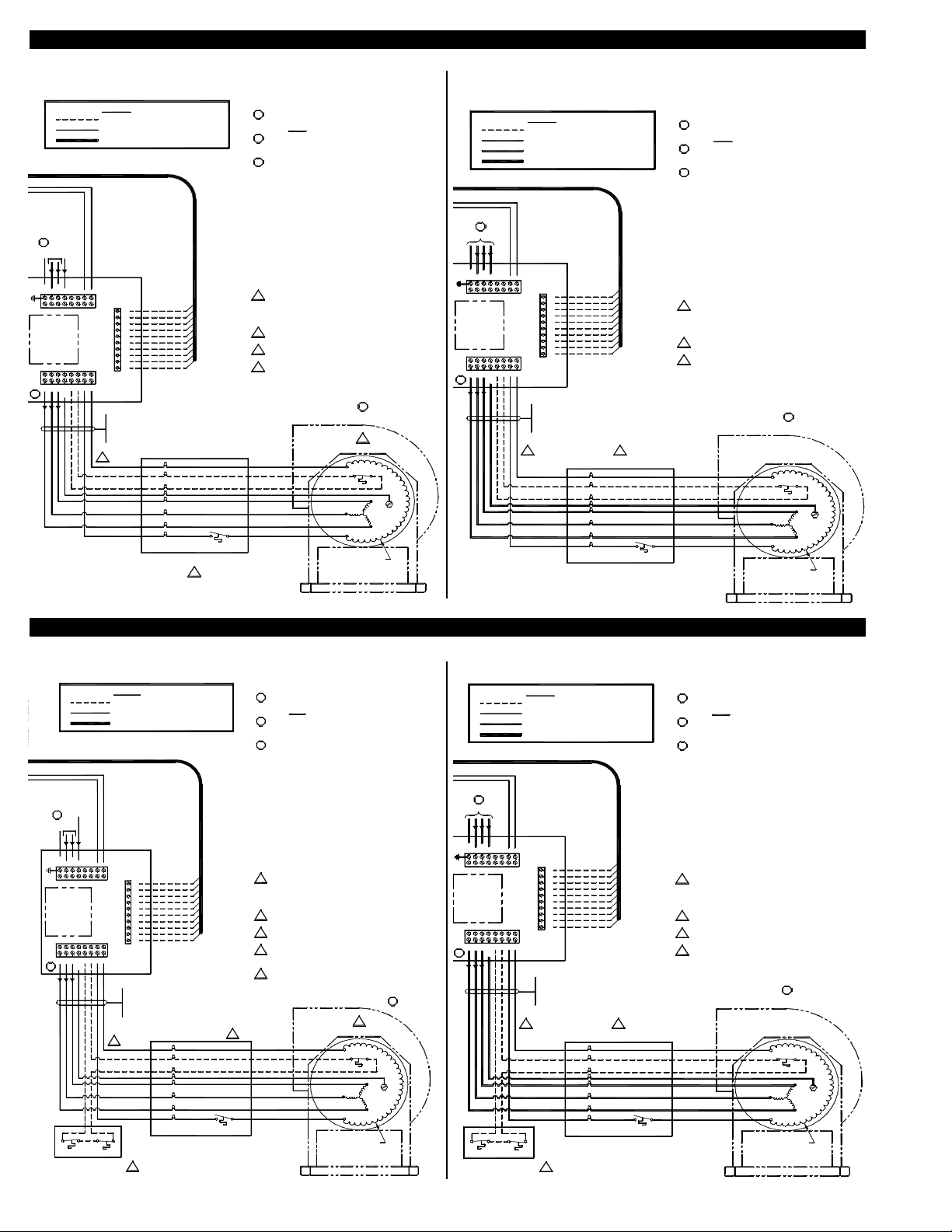

230 VOLT VSAD SERIES WIRING

460 VOLT VSAD SERIES WIRING

plate rating before applying power. Improper supply voltage

Verify that the input power voltage matches the VFD's name-

All wiring must be in metal conduit (best) or shielded cable.

the same conduit. Undesired VFD operation could result.

Do not run the VFD's input power and output power wir ing in

Verify that the venter (VSAD 8/10/12-230) is rated for the

output voltage from the VFD. If not correct, severe damage to

3.

2.

1.

3.

2.

WARNINGS:

CAUTIONS:

1.

to the VFD could damage the VFD.

the venter and/or the VFD could result.

When the system is completely installed, perform the safety

interlock and operational test as outlined in the installation

4.

manuals. Failure to do these tests could result in an unsafe

and/or incorrectly operating system.

NOTES:

"C" means "Closed Loop"

"3" means "CPC-3 Contro l"

3

3

BLACK

VIOLET

ORANGE

GRN/YEL

BLUE

YELLOW

WHT/RED

RED

GRAY

WHT/BRN

VFD COMMUNICATIONS CABLE

ADD FOR 208-230 VAC 3Ø

208-230 VAC 1Ø / 60 HZ

Route transducer wiring in metal conduit or use Belden Shield

Cable #9939 or equivalent. Make sure the transducer wiring

does not contain or cross line voltage wiring or undesired

Use caution to ensure that the wiring to the transducer is

Improper wiring to the transducer will destroy the transducer.

correct before activating the CPC-3 controller.

transducer performance may result.

4

For vertical termination of the VSAD venter, connect the S2

position to the orange wire and cap off the gray wire as shown.

For horizontal termination of the VSAD venter, connect the S2

position to the gray wire and cap off the orange wire.

4.

If the provided 10-foot, 10-wire VFD control cable is not long1.

enough to meet the application needs, use caution to ensure

that the connections from the VFD to the CPC-3 controller

are correctly located. MB to MB, MC to MC, etc. In addition,

Use caulking to seal the electrical box cover to the electrical2.

box, and to seal the conduit holes to hole plugs.

2

reference the Wire Length Table.

If required, non-fused disconnects are to be supplied by the3.

installer.

3

FIGURE 8052017 11/18/04

INCLUDED

39" (1m) CABLE

BLACK

BLACK

ORANGE

BLUE

GREEN

VIOLET

RED

YELLOW

VSAD MOTOR ENCLOSURE

COOLING FAN

THERMOSTAT

FAN

GND

VERTICAL

TILT SWITCH

MOTOR

LIMIT

HIGH

LIMIT

L3

L2

L1

GRAY

BLK

BLK

BLK

BLK

BLK

BLUE

BLUE

WHT/BRN

HORIZONTAL

TILT SWITCH

BLK

WEATHERPROOF

BOX AND WHIP

MOTOR

Max. length:

dedicated metal conduit.

Wiring is to be in

230 VAC SUPPLY / LOAD W IRING

LEGEND:

LOW VOLTAGE / DC CONTROL WIRING

300' (91m) @ 230 VAC

TJERNLUND DRIVE MODEL

VFD- _ _ _ _ _ _ _ 2C3

"2" means "230 VAC"

2

VFD

CONTROL

BOX

M1M2M3

MGND

S1

S2

F1

F2

GNDL1L2/NL3NCNCL

L

MB

MC

M1

M2

S1

S2

SC

S3

D-

D+

INCLUDED

39" (1m) CABLE

BLACK

BLACK

ORANGE

BLUE

GREEN

VIOLET

RED

YELLOW

VSAD MOTOR ENCLOSURE

COOLING FAN

THERMOSTAT

FAN

GND

VERTICAL

TILT SWITCH

MOTOR

LIMIT

HIGH

LIMIT

L3

L2

L1

GRAY

BLK

BLK

BLK

BLK

BLK

BLUE

BLUE

WHT/BRN

HORIZONTAL

TILT SWITCH

BLK

WEATHERPROOF

BOX AND WHIP

MOTOR

Max. length:

dedicated metal conduit.

Wiring is to be in

230 VAC SUPPLY / LOAD W IRING

LEGEND:

LOW VOLTAGE / DC CONTROL WIRING

100' (30m) @ 460 VAC

TJERNLUND DRIVE MODEL

VFD- _ _ _ _ _ _ _ 4C3

"4" means "460 VAC"

2

4

VFD

CONTROL

BOX

M1M2M3

MGND

S1

S2

F1

F2

GNDL1L2/NL3NCNCL

L

MB

MC

M1

M2

S1

S2

SC

S3

D-

D+

460 VAC SUPPLY / LOAD W IRING

plate rating before applying power. Improper supply voltage

Verify that the input power voltage matches the VFD's name-

All wiring must be in metal conduit (best) or shielded cable.

Route transducer wiring in metal conduit or use Belden Shield

the same conduit. Undesired VFD operation could result.

Do not run the VFD's input power and output power wir ing in

Verify that the venter (VSAD 8/10/12-460A) is rated for the

output voltage from the VFD. If not correct, severe damage to

3.

2.

1.

3.

2.

WARNINGS:

Cable #9939 or equivalent. Make sure the transducer wiring

CAUTIONS:

does not contain or cross line voltage wiring or undesired

Use caution to ensure that the wiring to the transducer is

Improper wiring to the transducer will destroy the tr ansducer.1.

correct before activating the CPC-3 controller.

to the VFD could damage the VFD.

the venter and/or the VFD could result.

When the system is completely installed, perform the safety

interlock and operational test as outlined in the installation

4.

manuals. Failure to do these tests could result in an unsafe

and/or incorrectly operating system.

For vertical termination of the VSAD venter, connect the S2

position to the orange wire and cap off the gray wire as shown.

For horizontal termination of the VSAD venter, connect the S2

position to the gray wire and cap off the orange wire.

4.

NOTES:

If the provided 10-foot, 10-wire VFD control cable is not long1.

enough to meet the application needs, use caution to ensure

that the connections from the VFD to the CPC-3 controller

are correctly located. MB to MB, MC to MC, etc. In addition,

"C" means "Closed Loop"

"3" means "CPC-3 Contro l"

460 VAC / 3Ø / 60 HZ

3

3

BLACK

VIOLET

ORANGE

GRN/YEL

BLUE

YELLOW

WHT/RED

RED

GRAY

WHT/BRN

transducer performance may result.

Use caulking to seal the electrical box cover to the electrical2.

box, and to seal the conduit holes to hole plugs.

2

VFD COMMUNICATIONS CABLE

reference the Wire Length Table.

If required, non-fused disconnects are to be supplied by the3.

installer.

3

FIGURE 8052016 11/18/04

VSAD DRAFT INDUCER INTERLOCK WITH VFD

VFD & INDUCER / C.A. BLOWER WIRING

WARNINGS:

1. Verify that the input power voltage matches the VFD's nameplate rating before applying power. Incorrect supply voltage can

damage VFD.

2. Verify that the Inducer/Blower is rated for the same voltage as the VFD. Incorrect voltage can damage motor and VFD.

3. Maximum wire lengths between the VFD and the inducer/blower are:

230 VAC Models: 300 feet with 14 AWG, 600 VAC Insulation

460 VAC Models: 100 feet with 14 AWG, 600 VAC insulation

CAUTIONS:

1. All wiring must be in metal conduit.

2. Do not route the VFD's input and output wiring in the same conduit. Undesired system operational effects could occur.

NOTES:

1. If the provided 10-foot, 10-wire VFD control cable is not long enough, use caution to ensure that the wires from

the VFD control cable are correctly extended. Route in metal conduit. All connections between the VFD and the

CPC-3 must alpha/numerically match.MB to MB, MC to MC, etc. See maximum lead length chart to right.

2. Use caulk to seal the exterior electrical box cover and to seal any conduit hole plugs.

3. If required, use only non-fused disconnects.

4. Wire proper Vertical or Horizontal Tilt Switch on VSAD-Series Inducers. For vertical

termination of VSAD-Series inducers, connect

the S2 position to the Orange wire and cap off the Grey wire. For horizontal terminations of VSAD-Series inducers, connect the S2

position to the Grey wire and cap off the Orange wire.

5. VSUB-Series Blowers are shipped from the factory internally wired for 460 VAC. For 230 VAC applications reconfigure the motor’s

internal wiring for 230 VAC by following the diagram on motor label.

6. VSUB-Series Blowers used to provide combustion air must

install the FFP-1. The FFP-1 will disable the C. A. Blower when exces-

sively hot or cold temperatures are detected in the mechanical room. Refer to FFP-1 instructions for details.

Wire Gage

Max. Distance

600' (183m)

14 AWG

390' (119m)

220' (67m)

16 AWG

18 AWG

22 AWG

20 AWG

110' (34m)

165' (50m)

900' (274m)

12 AWG

Max. VFD to CPC-3

Lead Length

Page 10

9

VSUB INDUCER OR COMBUSTION AIR BLOWER INTERLOCK WITH VFD

VSUB DRAFT INDUCER INTERLOCK WITH VFD

230 VOLT VSUB DRAFT INDUCER WIRING

460 VOLT VSUB DRAFT INDUCER WIRING

RED

ORANGE

BLUE

GREEN

BLACK

BLACK

BLACK

VSUB BLOWER

TSTAT

MOTOR HEATER

GROUND

MOTOR LIMIT

MOTOR

Max. length:

dedicated metal conduit.

Wiring is to be in

230 VAC SUPPLY / LOAD W IRING

LEGEND:

LOW VOLTAGE / DC CONTROL WIRING

300' (91m) @ 230 VAC

TJERNLUND DRIVE MODEL

VFD- _ _ _ _ _ _ _ 2C3

"2" means "230 VAC"

VFD

CONTROL

BOX

M1M2M3

MGND

S1

S2

F1

F2

GNDL1L2/NL3NCNCL

L

MB

MC

M1

M2

S1

S2

SC

S3

D-

D+

plate rating before applying power. Improper supply voltage

Verify that the input power voltage matches the VFD's name-

All wiring must be in metal conduit (best) or shielded cable.

the same conduit. Undesired VFD operation could result.

Do not run the VFD's input power and output power wir ing in

Verify that the blower (VSUB 8/12/16/20) is w ired for the

output voltage from the VFD. If not correct, severe damage to

3.

2.

1.

3.

2.

WARNINGS:

CAUTIONS:

1.

to the VFD could damage the VFD.

the blower and/or the VFD could result.

When the system is completely installed, perform the safety

interlock and operational test as outlined in the installation

4.

manuals. Failure to do these tests could result in an unsafe

and/or incorrectly operating system.

"C" means "Closed Loop"

"3" means "CPC-3 Contro l"

3

3

BLACK

VIOLET

ORANGE

GRN/YEL

BLUE

YELLOW

WHT/RED

RED

GRAY

WHT/BRN

VFD COMMUNICATIONS CABLE

& 30 WATTS FOR VSUB20)

ARCTIC-DUTY

MOTOR HEATER

(15 WATTS FOR VSUB8,12,16

RED

WINDINGS

MOTOR

2

ADD FOR 208-230 VAC 3Ø

208-230 VAC 1Ø / 60 HZ

4 x 4 WEATHERPROOF

BOX AND WHIP

2

This blower is shipped from the factory wired for 460 VAC .4.

Reconfigure the motor wiring at the motor for 230 VAC.

See the Motor Label for details.

4

Route transducer wiring in metal conduit or use Belden Shield

Cable #9939 or equivalent. Make sure the transducer wiring

does not contain or cross line voltage wiring or undesired

Use caution to ensure that the wiring to the transducer is

Improper wiring to the transducer will destroy the transducer.

correct before activating the CPC-3 controller.

transducer performance may result.

INCLUDED CABLE

NOTES:

If the provided 10-foot, 10-wire VFD control cable is not long1.

enough to meet the application needs, use caution to ensure

that the connections from the VFD to the CPC-3 controller

are correctly located. MB to MB, MC to MC, etc. In addition,

Use caulking to seal the electrical box cover to the electrical2.

box, and to seal the conduit holes to hole plugs.

reference the Wire Length Table.

If required, non-fused disconnects are to be supplied by the3.

installer.

3

FIGURE 8052019 11/18/04

460 VAC SUPPLY / LOAD W IRING

plate rating before applying power. Improper supply voltage

Verify that the input power voltage matches the VFD's name-

All wiring must be in metal conduit (best) or shielded cable.

the same conduit. Undesired VFD operation could result.

Do not run the VFD's input power and output power wir ing in

Verify that the blower (VSUB 8/12/16/20) is w ired for the

output voltage from the VFD. If not correct, severe damage to

3.

2.

1.

3.

2.

WARNINGS:

CAUTIONS:

1.

to the VFD could damage the VFD.

the blower and/or the VFD could result.

When the system is completely installed, perform the safety

interlock and operational test as outlined in the installation

4.

manuals. Failure to do these tests could result in an unsafe

and/or incorrectly operating system.

NOTES:

If the provided 10-foot, 10-wire VFD control cable is not long1.

enough to meet the application needs, use caution to ensure

that the connections from the VFD to the CPC-3 controller

are correctly located. MB to MB, MC to MC, etc. In addition,

"C" means "Closed Loop"

"3" means "CPC-3 Contro l"

460 VAC / 3Ø / 60 HZ

3

RED

ORANGE

BLUE

GREEN

BLACK

BLACK

BLACK

VSUB BLOWER

TSTAT

MOTOR HEATER

GROUND

MOTOR LIMIT

4 x 4 WEATHERPROOF

BOX AND WHIP

MOTOR

Max. length:

dedicated metal conduit.

Wiring is to be in

230 VAC SUPPLY / LOAD W IRING

LEGEND:

LOW VOLTAGE / DC CONTROL WIRING

100' (30m) @ 460 VAC

TJERNLUND DRIVE MODEL

VFD- _ _ _ _ _ _ _ 4C3

"4" means "460 VAC"

2

VFD

CONTROL

BOX

M1M2M3

MGND

S1

S2

F1

F2

GNDL1L2/NL3NCNCL

L

MB

MC

M1

M2

S1

S2

SC

S3

D-

D+

3

BLACK

VIOLET

ORANGE

GRN/YEL

BLUE

YELLOW

WHT/RED

RED

GRAY

WHT/BRN

Use caulking to seal the electrical box cover to the electrical2.

box, and to seal the conduit holes to hole plugs.

2

VFD COMMUNICATIONS CABLE

reference the Wire Length Table.

& 30 WATTS FOR VSUB20)

ARCTIC-DUTY

MOTOR HEATER

(15 WATTS FOR VSUB8,12,16

RED

WINDINGS

MOTOR

Route transducer wiring in metal conduit or use Belden Shield

Cable #9939 or equivalent. Make sure the transducer wiring

does not contain or cross line voltage wiring or undesired

Use caution to ensure that the wiring to the transducer is

Improper wiring to the transducer will destroy the tr ansducer.

correct before activating the CPC-3 controller.

transducer performance may result.

INCLUDED CABLE

If required, non-fused disconnects are to be supplied by the3.

installer.

3

FIGURE 8052018 11/18/04

230 VOLT VSUB COMBUSTION AIR BLOWER WIRING

460 VOLT VSUB COMBUSTION AIR BLOWER WIRING

plate rating before applying power. Improper supply voltage

Verify that the input power voltage matches the VFD's name-

All wiring must be in metal conduit (best) or shielded cable.

the same conduit. Undesired VFD operation could result.

Do not run the VFD's input power and output power wir ing in

Verify that the blower (VSUB 8/12/16/20) is w ired for the

output voltage from the VFD. If not correct, severe damage to

3.

2.

1.

3.

2.

WARNINGS:

CAUTIONS:

1.

to the VFD could damage the VFD.

the blower and/or the VFD could result.

When the system is completely installed, perform the safety

interlock and operational test as outlined in the installation

4.

manuals. Failure to do these tests could result in an unsafe

and/or incorrectly operating system.

NOTES:

If the provided 10-foot, 10-wire VFD control cable is not long1.

enough to meet the application needs, use caution to ensure

that the connections from the VFD to the CPC-3 controller

are correctly located. MB to MB, MC to MC, etc. In addition,

"C" means "Closed Loop"

"3" means "CPC-3 Contro l"

3

3

BLACK

VIOLET

ORANGE

GRN/YEL

BLUE

YELLOW

WHT/RED

RED

GRAY

WHT/BRN

RED

ORANGE

BLUE

GREEN

BLACK

BLACK

BLACK

VSUB BLOWER

TSTAT

MOTOR HEATER

GROUND

MOTOR LIMIT

4 x 4 WEATHERPROOF

BOX AND WHIP

FFP-1

Max. length:

dedicated metal conduit.

Wiring is to be in

230 VAC SUPPLY / LOAD W IRING

LEGEND:

LOW VOLTAGE / DC CONTROL WIRING

300' (91m) @ 230 VAC

TJERNLUND DRIVE MODEL

VFD- _ _ _ _ _ _ _ 2C3

"2" means "230 VAC"

VFD

CONTROL

BOX

M1M2M3

MGND

S1

S2

F1

F2

GNDL1L2/NL3NCNCL

L

MB

MC

M1

M2

S1

S2

SC

S3

D-

D+

Use caulking to seal the electrical box cover to the electrical2.

box, and to seal the conduit holes to hole plugs.

2

VFD COMMUNICATIONS CABLE

reference the Wire Length Table.

& 30 WATTS FOR VSUB20)

ARCTIC-DUTY

MOTOR HEATER

(15 WATTS FOR VSUB8,12,16

RED

WINDINGS

MOTOR

Route transducer wiring in metal conduit or use Belden Shield

Cable #9939 or equivalent. Make sure the transducer wiring

does not contain or cross line voltage wiring or undesired

Use caution to ensure that the wiring to the transducer is

Improper wiring to the transducer will destroy the transducer.

correct before activating the CPC-3 controller.

transducer performance may result.

The FFP-1 will disable the combustion air blower when5.

excessively hot or cold room air is detected. Refer to the

FFP-1 installation instructions for details.

REFER TO FFP-1 INSTALLATION

INSTRUCTIONS FOR DETAILS

HEAT LIMIT FREEZE LIMIT

5

This blower is shipped from the factory wired for 460 VAC .4.

Reconfigure the motor wiring at the motor for 230 VAC.

See the Motor Label for details.

2

ADD FOR

208-230 VAC

MOTOR

4

INCLUDED CABLE

3

FIGURE 8052021 11/18/04

8052021 SHEET 2

If required, non-fused disconnects are to be supplied by the3.

installer.

208-230 VAC 3Ø

1Ø / 60 HZ

460 VAC SUPPLY / LOAD W IRING

plate rating before applying power. Improper supply voltage

Verify that the input power voltage matches the VFD's name-

All wiring must be in metal conduit (best) or shielded cable.

the same conduit. Undesired VFD operation could result.

Do not run the VFD's input power and output power wir ing in

Verify that the blower (VSUB 8/12/16/20) is w ired for the

output voltage from the VFD. If not correct, severe damage to

3.

2.

1.

3.

2.

WARNINGS:

CAUTIONS:

1.

to the VFD could damage the VFD.

the blower and/or the VFD could result.

When the system is completely installed, perform the safety

interlock and operational test as outlined in the installation

4.

manuals. Failure to do these tests could result in an unsafe

and/or incorrectly operating system.

NOTES:

If the provided 10-foot, 10-wire VFD control cable is not long1.

enough to meet the application needs, use caution to ensure

that the connections from the VFD to the CPC-3 controller

are correctly located. MB to MB, MC to MC, etc. In addition,

"C" means "Closed Loop"

"3" means "CPC-3 Contro l"

460 VAC / 3Ø / 60 HZ

3

230 VAC SUPPLY / LOAD W IRING

LEGEND:

LOW VOLTAGE / DC CONTROL WIRING

100' (30m) @ 460 VAC

TJERNLUND DRIVE MODEL

VFD- _ _ _ _ _ _ _ 4C3

"4" means "460 VAC"

2

VFD

CONTROL

BOX

M1M2M3

MGND

S1

S2

F1

F2

GNDL1L2/NL3NCNCL

L

MB

MC

M1

M2

S1

S2

SC

S3

D-

D+

3

BLACK

VIOLET

ORANGE

GRN/YEL

BLUE

YELLOW

WHT/RED

RED

GRAY

WHT/BRN

Use caulking to seal the electrical box cover to the electrical2.

box, and to seal the conduit holes to hole plugs.

2

VFD COMMUNICATIONS CABLE

reference the Wire Length Table.

& 30 WATTS FOR VSUB20)

ARCTIC-DUTY

MOTOR HEATER

(15 WATTS FOR VSUB8,12,16

RED

WINDINGS

MOTOR

Route transducer wiring in metal conduit or use Belden Shield

Cable #9939 or equivalent. Make sure the transducer wiring

does not contain or cross line voltage wiring or undesired

Use caution to ensure that the wiring to the transducer is

Improper wiring to the transducer will destroy the transducer .

correct before activating the CPC-3 controller.

transducer performance may result.

The FFP-1 will disable the combustion air blower when4.

excessively hot or cold room air is detected. Refer to the

FFP-1 installation instructions for details.

REFER TO FFP-1 INSTALLATION

INSTRUCTIONS FOR DETAILS

HEAT LIMIT FREEZE LIMIT

4

MOTOR

INCLUDED CABLE

If required, non-fused disconnects are to be supplied by the3.

installer.

3

FIGURE 8052020 11/18/04

RED

ORANGE

BLUE

GREEN

BLACK

BLACK

BLACK

VSUB BLOWER

TSTAT

MOTOR HEATER

GROUND

MOTOR LIMIT

4 x 4 WEATHERPROOF

BOX AND WHIP

FFP-1

Max. length:

dedicated metal conduit.

Wiring is to be in

Page 11

PRE-START UP FIELD WIRING VERIFICATION

The CPC-3 has two sets of terminal strips across the top of its circuit board. All mechanical draft related connections are made on the

"INDUCER" terminal strip located on the top left side of the circuit board. All mechanical combustion air related connections are made

on the "COMBUSTION AIR" terminal strip located on the top right side of the circuit board. IMPORTANT: It is critical that wiring con-

nections below are correct.

1. Verify Transducer connections (Red terminal blocks of Inducer or Combustion Air terminal strip) G, R & B are wired to

the corresponding letter on the TD-Series transducer terminal strip. Failure to maintain proper polarity may damage transducer.

IMPORTANT: These wire leads must be enclosed within dedicated metal conduit. Do not

run any other power leads in the same

conduit or share a junction box with any other leads.

2. The inducer or combustion air manual mode proving switch, model PSA-1 should be connected to terminals P1 and P2 of the

Inducer or Combustion Air terminal strip. These leads may share conduit with other circuits within the mechanical room.

3. The free end of the CPC-3/VFD communications cable should be wired to the blue, black and green terminal blocks of the CPC-3

inducer or combustion air terminal strip. It is critical that the colored leads be connected to the exact terminals as depicted on the

wiring schematic. If the cable has been extended in the field wire labels should have been affixed indicating the terminal block designations. IMPORTANT: These wire leads must be enclosed within dedicated metal conduit. Do not

run any other power leads in

the same conduit or share a junction box with any other leads.

START UP OF VSAD-SERIES AND VSUB-SERIES VARIABLE SPEED SYSTEMS WITH THE CPC-3

POWERING UP THE CPC-3

Switch the Power switch on lower left of board to the left. After a brief moment, the display will come on and display will read "CPC-3

CPC-3" on all 4 lines. This indicates that the CPC-3 is functioning and going through it's power-up routine.

INITIALIZING & PROGRAM SETTINGS

When the CPC-3 is powered up, it retrieves the saved system settings from memory and loads them into the program. During the initializing process, the control will display the saved system settings as well as other useful information.

10

CPC-3 MAIN POWER INPUT WIRING & HEATER INTERLOCK WIRING

FIGURE 8055017

CPC-3 POWER SUPPLY WIRING

SUPPLY POWER HERE FROM A TJERNLUND VFD,

"L" AND "L" TERMINALS, OR FROM ANOTHER

GROUND LUG

WITH NUT

NLLN LN LN

POWER INPUT

MAIN AC EXP-4E

POWER OUTPUT TERMINALS

HEATER 1

POWER

DIGITAL

ANALOG AND

SUPPLIES

3412AB3412AB

AC POWER

MAIN

ON

OFF

#1 #2

TERMINAL

INTERLOCK

CPC-3 MAIN POWER SPECIFICATIONS:

THE CPC-3 HAS BUILT-IN CIRCUIT PROTECTION.

12/10/04

ON / OFF

SWITCH

DRY1

A24V

A115V B115V

B24V

DRY2

OR

24 VAC

OR

115 VAC

OR

230 VAC

OR

CALL METHOD

"DRY"

CALL HOT

NEUTRAL

CALL METHOD

"VOLTAGE"

22

3

RELAY

SAFETY

RELAY

SAFETY

BLOCK

WIRE ANY ADDITIONAL

REQUIRED INTERLOCK

BLOCKS THE SAME AS

THE HEATER 1 INTER-

LOCK BLOCK.

HEATER 2

INTERLOCK

BLOCK

0.50 AMP MAXIMUM @ 95-265 VAC.

120 / 208-230 VAC POWER SOURCE.

INTERLOCKED

HEATER

RUN SIGNAL

CALL VOLTAGE FROM INTERLOCKED

HEATER CONTROL CIRCUIT

USER-PROVIDED

CALL SWITCH

WIRE

CALL

JUMPER

WIRE

CALL

JUMPER

11

HEATER INTERLOCK

CALL METHODS

If using the “Dry” call method,

place the RED jumper tab in

the “DRY” position. Remove the

Wire Call Jumper that routes

voltage from terminal 1 to 3.

If using the “Voltage Call

Method”, place the RED jumper

tab in either the 24V or 115V

position depending upon heater

interlock voltage.

The Wire Call Jumper routes

the “voltage” hot call signal

form the #1 position to the #3

position. When the CPC-3 safety relay closes, this voltage is

routed to position #4 and the

interlocked burner.

If activating the CPC-3 with a

different call voltage than that

of the interlocked burner run

signal, remove the Wire Call

Jumper and provide the controlled voltage to position #3.

Page 12

11

The Factory Default Settings for the CPC-3 are as follows:

FACTORY DEFAULT

Software Version: XX.XX.XX

Pressure Unit Variables: Inches of Water Column

Pre-Purge Time Setting: 0 Minutes, 0 Seconds

Post Purge Time Units: 0 Minutes, 0 Seconds

Fault History: No Faults

Auxiliary Device Options:

Alarm Buzzer: Off

Auxiliary Sensor Type: None

Auxiliary Device Type: None

Induced Draft Condition: Inactive

Combustion Air Condition: Inactive

Heater Set Stages: All On

Once the settings have loaded, the initializing process is complete. The control is now ready to be set for operation.

UNLOCKING AND LOCKING THE KEYPAD

No Settings within the CPC-3 Control can be changed until the keypad is unlocked. This safety feature keeps unauthorized personnel

from changing settings. Any key that is pressed while the Key Pad is Locked will result in a “!! KEY PAD LOCKED !!” message.

Unlocking and Locking the Keypad To unlock the keypad, press the SAVE SETTING Key for 5 seconds. When the keypad is

unlocked, the “!! KEY PAD LOCKED !!” message on the bottom line of the display will change to “….KEY PAD OPEN….” with the Key

Pad Open, settings can be adjusted. If the Inducer and Combustion Air are inactive as indicated by the first 2 lines of the display, only

the TIME / DATE, AUXILIARY DEVICE, and OPTIONS settings will be adjustable. The SET POINT, PRE-PURGE, and POST

PURGE settings are specific to the Draft Inducer and / or Combustion Blower operation and will not be available until the Inducer and

/ or Combustion Air systems have been activated, See “Activating the Draft or Combustion Air” below.

To unlock the keypad, press the SAVE SETTING Key for 5 seconds.

The keypad can be locked any time the "Keypad Open" message is displayed by pressing the ENTER key and then pressing SAVE

SETTING. The keypad stays open for 30 minutes after the last key is pressed and then automatically locks.

SETTING TIME AND DATE

With the keypad unlocked, press the TIME / DATE key. NOTE: The "month" is displayed on the right side of the 3rd line of the display.

This is the time / date parameter that is ready to be adjusted. Pressing the ENTER key will toggle the adjustable time / date settings.

To change any of the month, day, year, hour, minute, and am/pm settings press the ENTER key until the parameter to adjust is shown

on the display and use the INCREASE and DECREASE keys to adjust. Press the ENTER key until the next desired parameter is displayed and again use the INCREASE and DECREASE keys to adjust. Once all of the time / date settings have been adjusted, press

the SAVE SETTING key to save. To exit the Time / Date screen, press the TIME / DATE key. NOTE: Any time power is removed from

the control, the time / date settings will need to be reset.

ACTIVATING THE DRAFT OR COMBUSTION AIR

To activate the Draft or Combustion Air the keypad must be unlocked. Press the SET UP key under the appropriate side (Draft or

Combustion Air) of the CPC-3 keypad. The display text will indicate that you are in the Set Up mode. All functions and settings can be

set while the SETUP is open and the Draft or Combustion Air function is active. Pressing the SAVE SETTING key will activate the

Draft or Combustion Air portion of the CPC-3 control.

The top line of the display has been assigned to the Draft information. The second line of the display has been assigned to the

Combustion Air information. With either the Draft or Combustion Air portion active, and in “AUTOMATIC” mode reading from left to

right an (“A” will be displayed in the first column under either the 1st line Draft or 2nd line Combustion Air). The CPC-3 will self regulate the speed of the Inducer / C.A. Blower to equal the CPC-3 set point(s) when a call for heat is recognized.

If the AUTO / MANUAL key is pressed while setup is active, the Inducer / C.A. Blower will be in the “MANUAL” mode (“M” will be displayed in the first column under either the 1st line Draft or 2nd line Combustion Air). The CPC-3 will run the fan at a constant speed

that is set manually by the user. WARNING: Because Manual Mode is a method of setting a fixed speed for Draft and/or Combustion

Air, consideration must be given to over-drafting and/or excessive combustion air supply, See “Manual Mode of Operation and PSA-1

Fan Prover Switch Adjustment”, page 16.

Next piece to the right on the display is the SET POINT. This is the pressure value that is used by the CPC-3 when in the

“AUTOMATIC” mode. Further right is the ACTUAL PRESSURE. This is the vent pressure as sensed by the pressure transducer. The

last information on the display is the % SPEED that the Inducer / C.A. Blower is operating at. To deactivate the Inducer / C.A. Blower

press the SAVE SETTING key again. NOTE: All settings made while in setup and saved will be defaulted when the Inducer / C.A.

Blower is made active.

Press the SET UP key under the Draft or the Combustion Air side of the CPC-3 keypad.

Press the SAVE SETTING key to activate the Draft or the Combustion air portion of the CPC-3 control.

Page 13

TESTING THE OPERATION OF THE SYSTEM COMPONENTS

TEST RUN SET UP

Test run can be used to test several aspects of the Inducer / C.A. Blower. While in Test Run mode, the communication between the

CPC-3 control and the VFD can be confirmed, a response from the pressure transducer can be confirmed and the Inducer / C.A.

Blower rotation can be checked and reversed if necessary. Test Run can not

be operational while a heater call is recognized by the

CPC-3 control. To operate Test Run, make sure all interlocked heater calls have been removed or refer to the SET STAGES, page 15

to lock out heater calls from being processed.

Test Run is a manually driven test where the user adjusts the speed of the Inducer / C.A. Blower. In order to perform Test Run, the

Key Pad must be unlocked and the Set Up menu for Draft or Combustion Air must be open. Press the INCREASE key until "TEST

RUN OFF" appears in the bottom line of the display. To activate test run, press the ENTER key. Note that the Test Run message

changed to "TEST RUN ON". The factory default setting for test run is 0%. Using the INCREASE key, adjust the Test Run percentage

to 50%.

Press the SET UP key under the Draft or Combustion Air side of the CPC-3 keypad to open SET UP menu.

Press the INCREASE key until "TEST RUN OFF" appears in the bottom line of the display.

Press the ENTER key to change display to "TEST RUN ON".

Press the INCREASE key, adjust the Test Run percentage to 50%.

VFD RESPONSE

With the control in Test Run and operating at 50%, the VFD should be displaying an output frequency and the Inducer / C.A. Blower

should be running. If no response from the VFD or the Inducer / C.A. Blower is realized, verify that the VFD ACTIVATED LED is solid

Green, the VFD has not faulted (solid red ALARM LED if faulted) and that the VFD has supply power at the correct voltage.

PRESSURE RESPONSE

While in Test Run, the Actual Pressure displayed on 3rd column of CPC-3 should be a negative pressure. Increasing the Test Run %

should increase this negative value. Decreasing the Test Run % should decrease the negative. If the pressure does not change,

check the wiring between the control and the pressure transducer, verify the transducer is pneumatically connected to the vent pipe

manifold and the front fitting on the transducer, and check to make sure the pressure transducer is operating correctly.

CHECKING ROTATION

While in Test Run and operating at 50%, record the Actual Pressure displayed on the top line of

the display_______. Press the ENTER key to shut off the Test Run option and wait 60 seconds.

Open the door to the CPC-3 control and reference the 2 dip switches under the Inducer or

Combustion Air terminal blocks at the top of the circuit board. These switches are used to reverse

the rotation of the Inducer / C.A. Blower. Switch both switches on the appropriate Inducer or

Combustion Air side to the opposite position they are currently in. Close the cover to the control

and activate Test Run again by pressing the ENTER key. Remember that no heater can be calling

for heat while performing this test. Adjust the Inducer / C.A. Blower speed to 50% again and record

the Actual Pressure displayed_______. The test that resulted in the greatest negative pressure is

the correct rotation. If the second half of the test resulted in a lower negative pressure the rotation

will need to be reversed to the original condition. Press ENTER to shut off the Test Run, wait 60

seconds, and reverse the 2 dip switch settings.

CAUTION: Systems that use multiple VFD's and/or multiple Inducers / C.A. Blowers will need to

visually verify each fan’s rotation. Changing the rotation as described above will change the rotation of all connected VFD's and fans. In multiple configurations, some rotations may be correct

while others may not. Switch any 2 of the 3 motor leads of the offending Inducer / C.A. Blower to

change the direction of its rotation. VSAD Series impellers must rotate counter-clockwise as

viewed through the discharge grill. VSUB Series impellers must rotate counter-clockwise as viewed

from the end bell/cooling fan of the motor. Failure to insure correct rotation may result in higher

power usage and significantly reduced inducer/blower performance.

Press the ENTER key to shut off the Test Run option and wait 60 seconds.

Change rotation dip switches as described above.

Press ENTER key to activate new Test Run, press Increase key to adjust Inducer / C.A. Blower

speed to 50% and record the Actual Pressure as displayed on the top line of the display.

The test that resulted in the greatest negative pressure is the correct rotation. If the second half of the test resulted in a lower negative pressure the rotation will need to be reversed to the original condition by changing the dip switches to the opposite positions.

ADJUSTING DRAFT

Reference the heater manufacturer's instructions for its specified draft range and for where the draft should be sampled. In general

most heaters will operate efficiently with a draft of -0.02 to -0.05" w.c. measured in the vent riser between the flue outlet and barometric draft control (if present). The CPC-3 has a default draft set point of -0.15" w.c. This vent manifold pressure may need to be adjusted up or down to meet the draft requirements of the interlocked heating equipment.

12

VSUB ROTATION 2/27/04

I

M

P

E

L

L

E

R

R

O

T

A

T

I

O

N

VSAD-SERIES ROTATION

VSUB-SERIES ROTATION

Page 14

13

DRAFT SET POINT ADJUSTMENT:

Once the Inducer is active and the “INDUCER SETUP” screen is visible, simply press the SET POINT key and the Set Point window

will open on the bottom line of the display. Use the INCREASE and DECREASE keys to make the new Set Point adjustment and

press the SAVE SETTING key. The new set point will be displayed on the top line under the SET POINT field. To exit from the Set

Point option back to the setup menu, simply press the SET POINT key again

Press the SET POINT key.

(Set Point window will open on the bottom line of the display.)

Press the INCREASE and DECREASE keys to make the Set Point adjustment

Press the SAVE SETTING key to save the new set point.

Press SET POINT to exit back to setup menu.

BALANCING DRAFT OF HEATER(S)

1. Turn ON the service switch to all of the heaters.

2. Momentarily cycle each heater to verify that the Amber BURNER STATUS CALL LED on CPC-3 for each heater illuminates. If not

verify that wiring conforms to appropriate heater interlock wiring diagram.

3. Verify that all balancing baffles or blast gates are in the closed position. Adjust barometric controls (if present) to the most closed

position.

4. Fire each heater individually, starting with the heater farthest from the Inducer / C.A. Blower. Slowly open balancing baffle or blast

gate until the specified draft is achieved. Barometric draft controls should be closed when the heater is operating within its specified

draft range. Adjust weight on barometric draft control so that it does not open until the manufacturer’s recommended maximum

draft is reached. If additional draft is needed increase the set point on the CPC-3 , See “Draft Set Point Adjustment”, above.

5. After adjusting draft levels on all connected heaters fire heaters in random order and simultaneously to verify draft levels remain

within the manufacturer’s specified range prior to ignition and during operation. Note: The CPC-3 will stage the firing of interlocked

heaters when more than one call for heat signal is simultaneously received by the CPC-3. In general, each successive heater will

be released after the CPC-3 set point has been reached and a 10 second time delay has occurred.

COMBUSTION AIR MODES OF OPERATION

The CPC-3 features two combustion air software modes. The "Open" mode is for maintaining the pressure within the mechanical

room. The "Sealed" program is for maintaining pressure within a common duct connected to sealed combustion heating equipment.

In general, the "Open" software allows room pressure to be maintained over a smaller scale and has features that diminish overshoot

and short cycling. The "Sealed" mode operates in a more reactive manner; similar to that of the variable speed Inducer software.

The Default combustion air program is the “Open” system. Combustion Air Systems used in the "Sealed" mode must use the TD-2

pressure transducer. Combustion Air Systems used in the "Open" mode must use the TD-3 pressure transducer.

“OPEN” COMBUSTION AIR MODE:

The “Open” mode is the most common method of supplying combustion air to the heaters by ducting combustion air directly into the

mechanical room. The transducer references a pressure outside of the mechanical room, such as an adjacent room or in rare cases,

outdoors. In both cases the goal is to reference static pressure so do not sample pressures at locations that can be affected by frequently opened doors, elevator shafts or ventilation fans and diffusers. The model IPS-1 may be used to sample indoor reference

pressure. It reduces the effects of air movement on the sampling tube and provides a finished look. Varying wind speeds will affect

outdoor reference pressure and are difficult to neutralize. The model WW-1 may be used to help neutralize the effects of winds. For

best performance mount the WW-1 at least one foot away from an outside wall.

If the pressure in the mechanical room drops below the set point due to the air consumed by the heaters, combustion air will be supplied. WARNING: Make sure the mechanical room is sealed from the rest of the building. Leakage of the supplied air to the rest of the

building may result in combustion air faults due to the pressure not being maintainable. Don't sample pressures at locations that can

be affected by frequently opened doors, elevator shafts, ventilation fans and diffusers. The CPC-3 set point pressure range for the

“Open” Combustion air system is +0.05" WC to -0.05" WC. The default setting is 0.00". NOTE: “Open” systems must use the TD-3

Transducer.

The Combustion Air Mode is defaulted to the “Open” Mode, or room pressure. Ducted outdoor air directly to burner air inlet(s) requires

the “Sealed” mode of operation.

Press the SET UP key under the Combustion Air side of the CPC-3 keypad to open SET UP menu.

Press the INCREASE key until "SET MODE" appears in the bottom line of the display.

Press the SAVE SETTING key to change display to "SEALED".

Press the SET UP key to escape out of the SET Up menu.

Page 15

“SEALED” COMBUSTION AIR MODE:

The “Sealed” mode supplies combustion air to a Combustion Air Manifold. Heaters with a combustion air inlet collar may be connected to a Combustion Air Manifold. The pressure is measured between the manifold and the mechanical room space. As heaters consume combustion air from the manifold, the “Sealed” mode recognizes the negative pressure and communicates to the Combustion

Air Blower to provide Combustion Air. The CPC-3 Set Point pressure range for the Sealed mode is +0.05" WC to -0.50" WC. The

default setting is 0.00" WC. NOTE: “Sealed” systems must use the TD-2 Transducer.

COMBUSTION AIR SET POINT: Once the Combustion Air is active and the COMBUSTION AIR SETUP screen is visible, press the

SET POINT key and the Set Point window will open on the bottom line of the display. Use the INCREASE and DECREASE keys to

make the Set Point adjustment and press the SAVE SETTING key to save. The new set point will be displayed on the second line

under the SET POINT field. To exit from the Set Point option back to the setup menu, press the SET POINT key again. WARNING:

The SET POINT pressure is the reference pressure the control will maintain the system static pressure at. Make sure an acceptable

static pressure is defined and used. Make sure to test fire each heater and all combination of heaters while monitoring the draft pressure at each heater. In most cases, a Combustion Air Set Point of 0.00" is acceptable. Make sure the reference side of the Pressure

Transducer is in a non-turbulent area and is an acceptable reference area outside of the Mechanical Room. Tjernlund Products, Inc. is

not responsible for a Set Point pressure that results in misapplied Combustion Air pressures to the heaters, mechanical room, or any

other location that could cause damage. If needed, consult Tjernlund Products, Inc. for more details.

"OPEN" COMBUSTION AIR MODE SYSTEM START-UP

Mechanical room pressure CPC-3 set points are +0.05 to -0.05” WC. If a positive pressure set point is desired extra care must be

taken to insure that the mechanical room is tightly sealed to outside spaces. Based on mechanical room size and leakage factor C.A.

Blower performance may not be adequate unless a positive pressure set point was factored into original computations.

1. Turn ON the service switch to all of the heaters.

2. Momentarily cycle each heater to verify that its CPC-3 Amber CALL LED illuminates. If not, verify that wiring conforms to appropriate heater interlock wiring diagram.