Page 1

GB

Operating manual

Betriebsanleitung ............p. 28

Mode d’emploi ................. p. 56

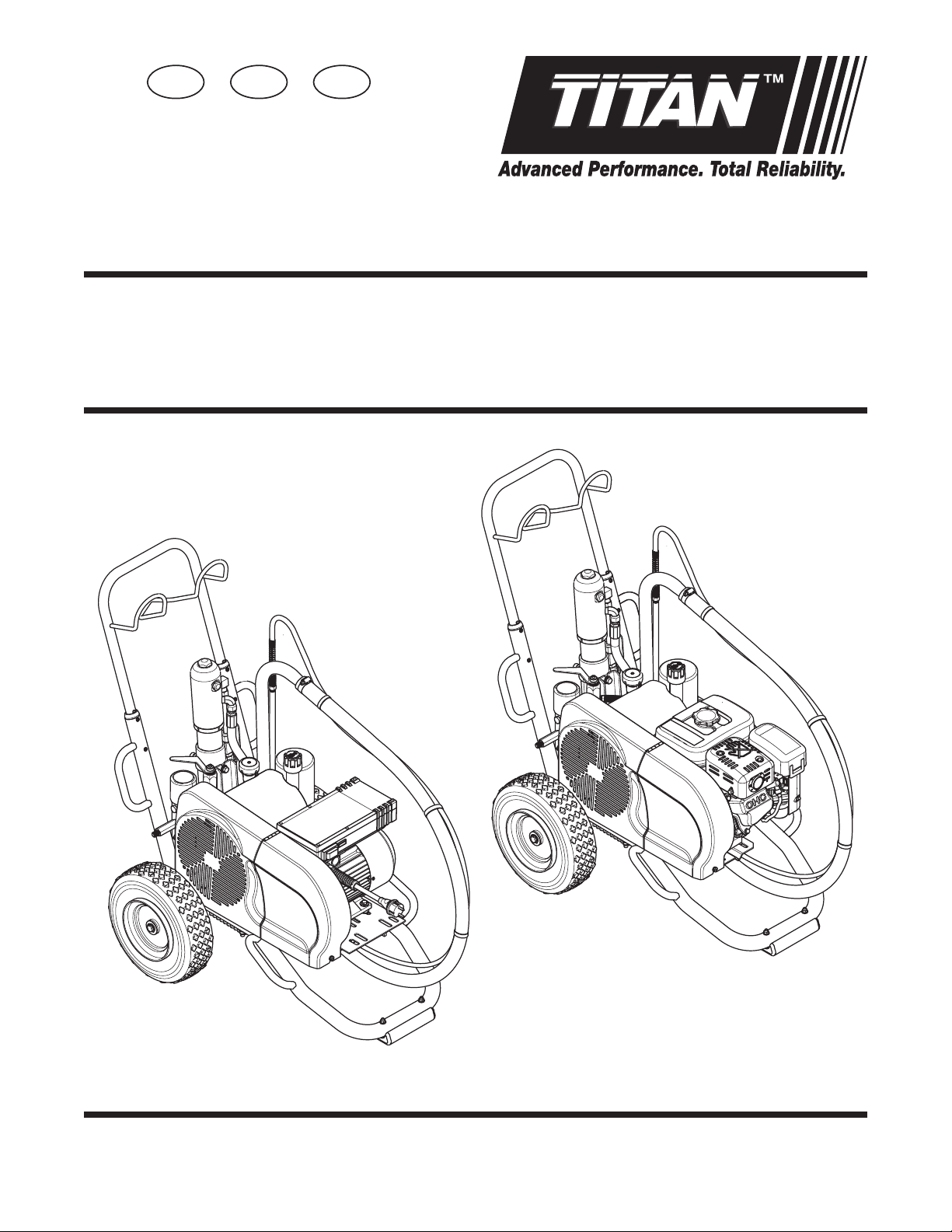

Airless high-pressure spraying unit

Airless Hochdruck-Spritzgerät

Groupe de projection à haute pression

D F

PowrTwin Plus

Model 0290012 (PT4900)

0290013 (PT6900)

0290018 (PT8900)

Model 0290032 (PT4900)

Edition 9 / 2016 0290 935L

Ausgabe

0290016 (PT12000)

Page 2

Original Operating Manual

Airless units develop extremely high spraying pressures.

Never put your ngers, hands or any other parts of the body into

the spray jet!

1

Never point the spray gun at yourself, other persons or animals.

Never use the spray gun without safety guard.

GB

Warning!

Attention: Danger of injury by injection!

2

3

Do not treat a spraying injury as a harmless cut. In case of injury

to the skin through coating materials or solvents, consult a doctor

immediately for quick and expert treatment. Inform the doctor

about the coating material or solvent used.

The operating instructions state that the following points must

always be observed before starting up:

1. Faulty units must not be used.

2. Secure Titan spray gun using the safety catch on the trigger.

3. Ensure that the unit is properly earthed.

4. Check allowable operating pressure of high-pressure hose and spray

gun.

5. Check all connections for leaks.

The instructions regarding regular cleaning and maintenance of

the unit must be strictly observed.

Before any work is done on the unit or for every break in work the

following rules must be observed:

1. Release the pressure from spray gun and hose.

2. Secure the Titan spray gun using the safety catch on the trigger.

3. Switch o unit.

Be safety conscious!

2 PowrTwin Plus

Page 3

GB

Contents

Contents

Page

1. Safety regulations for Airless spraying ...................................... 2

1.1 Explanation of symbols used .............................................................. 2

1.2 Electrical safety ......................................................................................... 3

1.3 Gasoline engine safety .......................................................................... 4

1.4 Fueling (gas engine) ............................................................................... 4

2. General view of application ............................................................. 5

2.1 Application ................................................................................................ 5

2.2 Coating materials .................................................................................... 5

3. Description of unit................................................................................ 5

3.1 Airless process .......................................................................................... 5

3.2 Functioning of the unit ......................................................................... 5

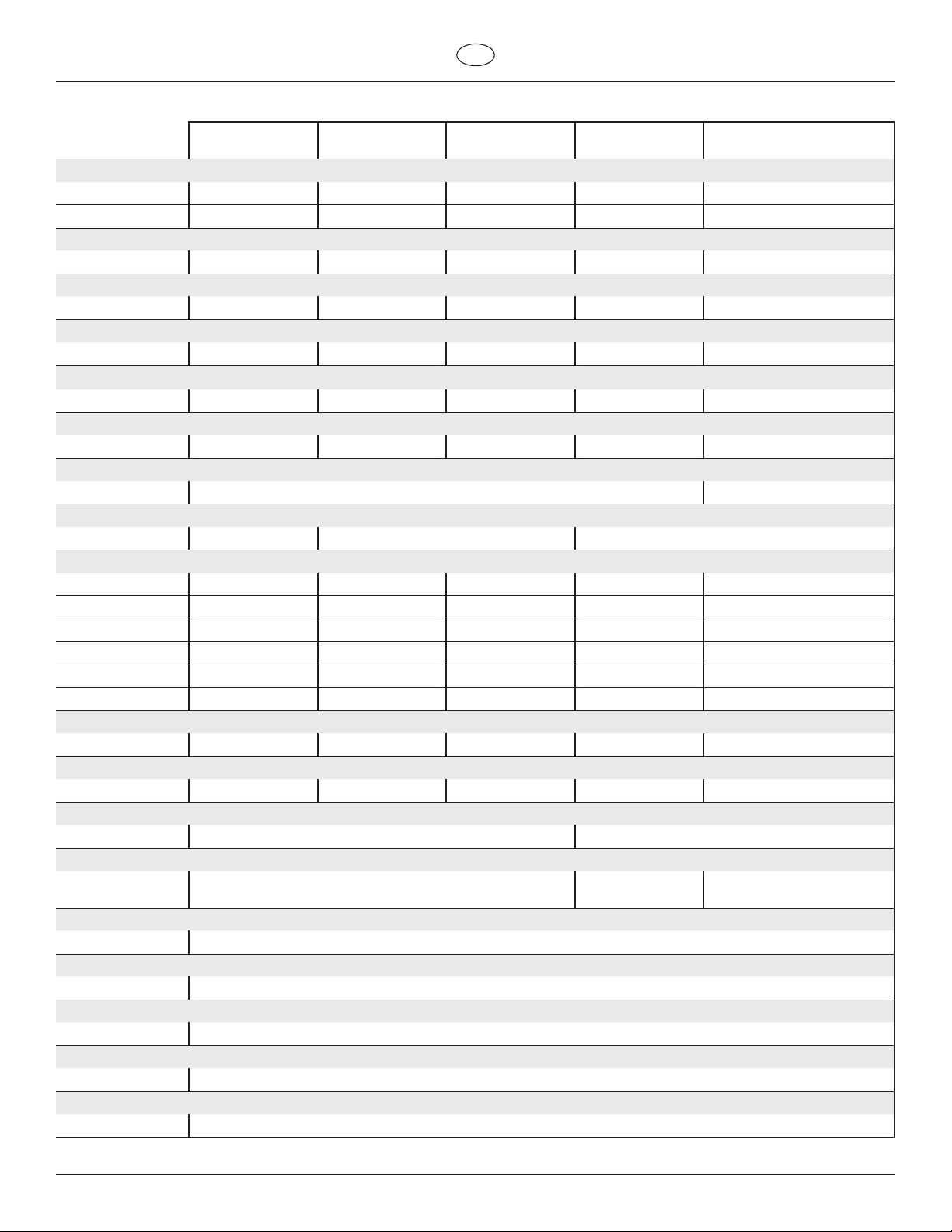

3.3 System diagram - gasoline PT units .................................................. 6

3.4 System diagram - electric PT units .................................................... 7

3.5 Technical data for PT units ................................................................... 8

3.6 Airless Spray Tip Recommendation Chart ...................................... 9

4. Operation ................................................................................................10

4.1 Setup .......................................................................................................... 10

4.2 Preparing a new sprayer ..................................................................... 11

4.3 Preparing to paint ................................................................................. 12

4.4 Painting ..................................................................................................... 13

4.5 Pressure relief procedure ...................................................................13

5. Cleanup .................................................................................................... 14

5.1 Special cleanup instructions for use with

ammable solvents ..............................................................................14

5.2 Cleaning the sprayer ............................................................................ 14

5.3 Cleaning a clogged tip ........................................................................ 14

Page

7. Troubleshooting .................................................................................25

7.1 Airless gun ...............................................................................................25

7.2 Fluid section ............................................................................................ 25

7.3 Hydraulic motors ................................................................................... 26

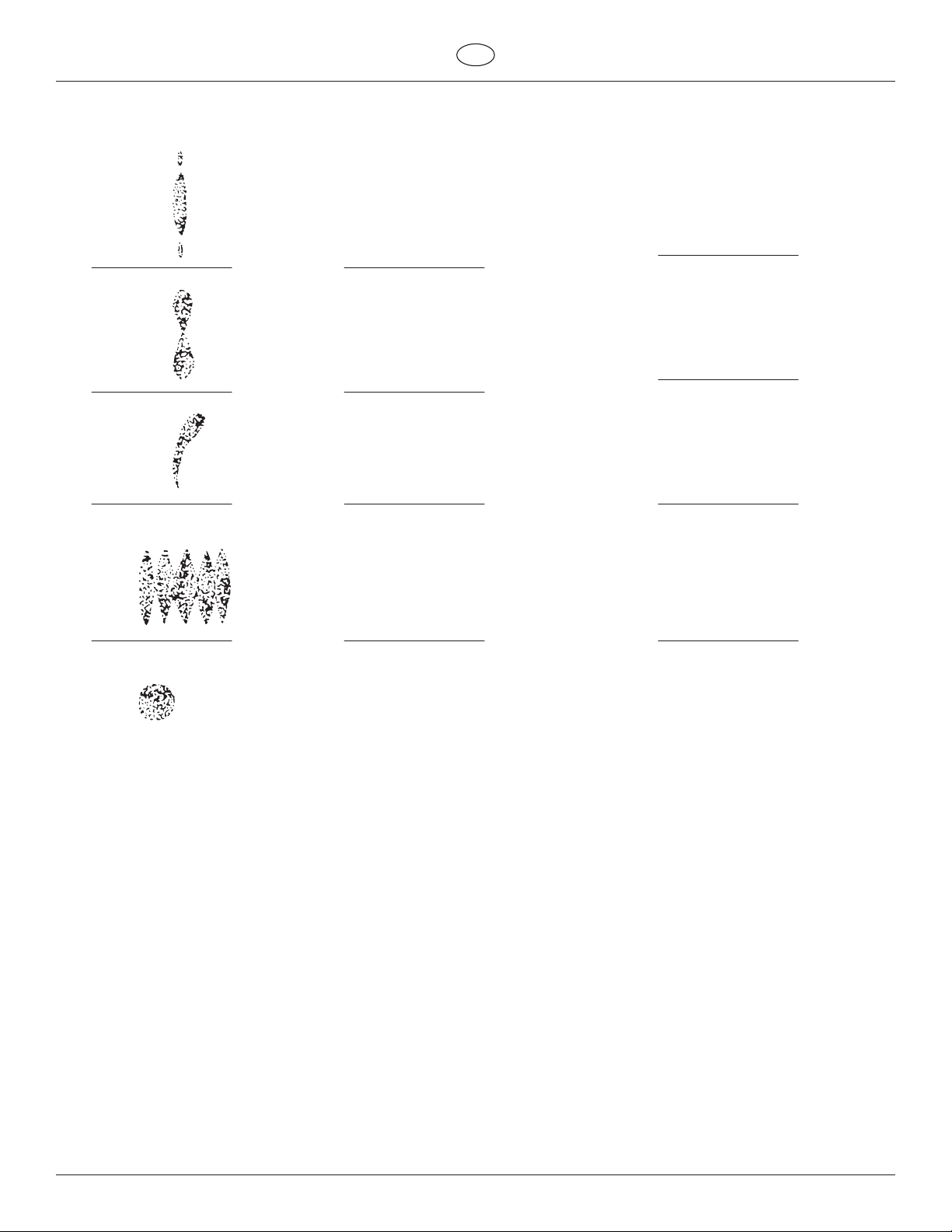

7.4 Spray patterns ........................................................................................27

Accessories and spare parts ........................................................................84

Spare parts list for the main assembly .................................................. 84/85

Spare parts list for the cart assembly .................................................... 86/87

Spare parts list for the hydraulic system .............................................. 88/89

Spare parts list for the hydraulic motor ............................................... 90/91

Spare parts list for the uid section • PT4900 ..................................... 92/93

Spare parts list for the uid section •

PT6900 / PT8900 / PT12000 ...................................................................... 94/95

Spare parts list for gas convertokit ........................................................ 96/97

Spare parts list for electric convertokit (230V) ................................... 98/99

Spare parts list for the high-pressure lter ..............................................100

Spare parts list for belt guard assembly ....................................................101

Spare parts list for bleed hose assembly with valve .............................102

Spare parts list for bleed valve .....................................................................103

Spare parts list fo siphon hose assembly ..................................................104

Connection diagram (230V) .......................................................................105

Accessories for PT units ...............................................................................106

Gun manifold assemblies (optional) ..........................................................108

Warranty .............................................................................................................109

6. Maintenance..........................................................................................15

6.1 Daily maintenance ................................................................................ 15

6.2 Maintaining the lter assembly........................................................15

6.3 Maintaining the hydraulic system ................................................... 17

6.4 Maintaining the uid section ............................................................ 17

6.5 Basic engine maintenance ................................................................. 17

6.6 Replacing the motor brushes (120V electric convertokit) ...... 18

6.7 Replacing the belt ................................................................................. 19

6.8 Servicing the hydraulic motor .......................................................... 20

6.9 Servicing the uid section .................................................................. 22

6.10 SAE O-ring tting installation ...........................................................24

PowrTwin Plus 1

Page 4

Safety precautions

At

i

1. Safety regulations for Airless spraying

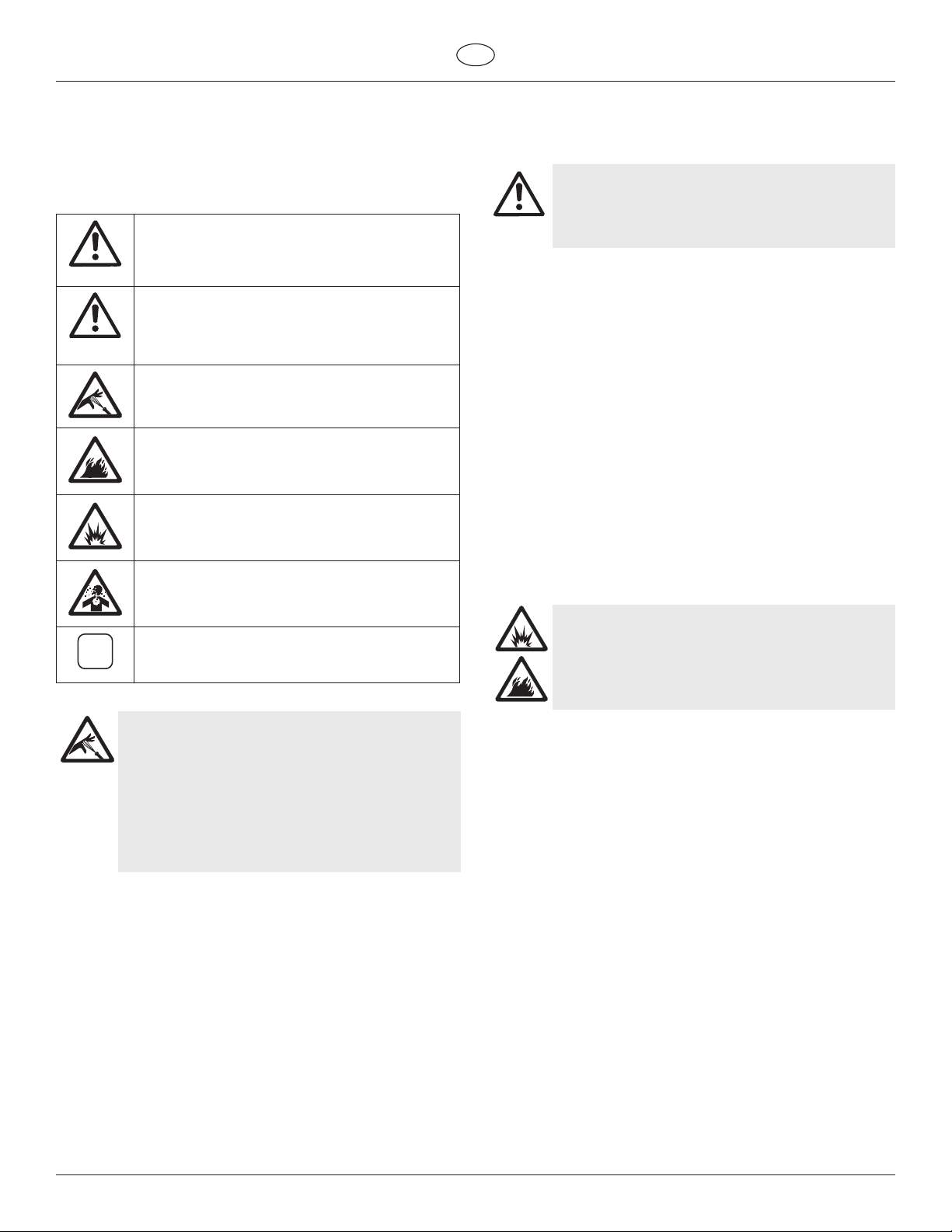

1.1 Explanation of symbols used

This manual contains information that must be read and understood

before using the equipment. When you come to an area that has one

of the following symbols, pay particular attention and make certain

to heed the safeguard.

This symbol indicates a potential hazard that

may cause serious injury or loss of life. Important

safety information will follow.

This symbol indicates a potential hazard to you

or to the equipment. Important information that

tention

tells how to prevent damage to the equipment or

how to avoid causes of minor injuries will follow.

Danger of skin injection

Danger of fire from solvent and paint fumes

Danger of explosion from solvent, paint fumes

and incompatible materials

Danger of injury from inhalation of harmful

vapors

GB

• All accessories must be rated at or above the maximum

operating pressure range of the sprayer. This includes spray

tips, guns, extensions, and hose.

HAZARD

The paint hose can develop leaks from wear, kinking

and abuse. A leak can inject material into the skin.

Inspect the hose before each use.

PREVENTION:

• Avoid sharp bending or kinking of the high-pressure hose. The

smallest bending radius amounts to about 20 cm.

• Do not drive over the high-pressure hose. Protect against

sharp objects and edges.

• Replace any damaged high-pressure hose immediately.

• Never repair defective high-pressure hoses yourself!

• Electrostatic charging of spray guns and the high-pressure

hose is discharged through the high-pressure hose. For this

reason the electric resistance between the connections of the

high-pressure hose must be equal to or lower than 1M.

• For reasons of function, safety and durability use only original

Titan high-pressure hoses.

• Before each use, check all hoses for cuts, leaks, abrasion

or bulging of cover. Check for damage or movement of

couplings. Immediately replace the hose if any of these

conditions exist. Never repair a paint hose. Replace it with

another earthed high-pressure hose.

• Make sure power cord, air hose and spray hoses are routed in

such a manner to minimize slip, trip and fall hazard.

: HIGH PRESSURE HOSE

Notes give important information which should

be given special attention.

HAZARD: INJECTION INJURY

A high pressure stream produced by this equipment

can pierce the skin and underlying tissues, leading to

serious injury and possible amputation.

Do not treat a spraying injury as a harmless cut. In

case of injury to the skin through coating materials

or solvents, consult a doctor immediately for quick

and expert treatment. Inform the doctor about the

coating material or solvent used.

PREVENTION:

• NEVER aim the gun at any part of the body.

• NEVER allow any part of the body to touch the uid stream.

DO NOT allow body to touch a leak in the uid hose.

• NEVER put your hand in front of the gun. Gloves will not

provide protection against an injection injury.

• ALWAYS lock the gun trigger, shut the uid pump o and

release all pressure before servicing, cleaning the tip guard,

changing tips, or leaving unattended. Pressure will not be

released by turning o the engine. The PRIME/SPRAY valve

or pressure bleed valve must be turned to their appropriate

positions to relieve system pressure.

• ALWAYS keep tip guard in place while spraying. The tip guard

provides some protection but is mainly a warning device.

• ALWAYS remove the spray tip before ushing or cleaning the

system.

• NEVER use a spray gun without a working trigger lock and

trigger guard in place.

HAZARD: EXPLOSION OR FIRE

Flammable vapors, such as solvent and paint vapors,

in work area can ignite or explode.

PREVENTION:

• Use equipment only in well ventilated area. Keep a good

supply of fresh air moving through the area to keep the air

within the spray area free from accumulation of ammable

vapors. Keep pump assembly in well ventilated area. Do not

spray pump assembly.

• Electric models only - Do not use materials with a ashpoint

below 38º C (100º F). Flashpoint is the temperature at which a

uid can produce enough vapors to ignite.

• Gas models only - Do not ll fuel tank while engine is running

or hot; shut o engine and allow to cool. Fuel is ammable

and can ignite or explode if spilled on a hot surface.

• Eliminate all ignition sources, such as pilot lights, cigarettes,

portable electric lamps and plastic drop cloths (potential static

arc).

• Keep work area free of debris, including solvent, rags and

gasoline.

• Do not plug or unplug power cords, or turn power or light

switches on or o when ammable vapors are present.

• Ground equipment and conductive objects in work area.

Make sure the grounding cable (not equipped) is connected

from the grounding lug to a true earth ground.

• Use only grounded hoses.

• Hold spray gun rmly to the side of a grounded pail when

triggering into pail.

• If there is static sparking or if you feel a shock, stop operation

immediately.

2 PowrTwin Plus

Page 5

GB

Safety precautions

• Know the contents of the paint and solvents being sprayed.

Read all Material Safety Data Sheets (MSDS) and container

labels provided with the paints and solvents. Follow the paint

and solvent manufacturer’s safety instructions.

• Do not use a paint or solvent containing halogenated

hydrocarbons. Such as chlorine, bleach, mildewcide,

methylene chloride and trichloroethane. They are not

compatible with aluminum. Contact the coating supplier

about compatibility of material with aluminum.

• Keep a re extinguisher in work area.

HAZARD: HAZARDOUS VAPORS

Paints, solvents, and other materials can be harmful

if inhaled or come in contact with body. Vapors can

cause severe nausea, fainting, or poisoning.

1.2 Electric Safety

Electric models must be earthed. In the event of an electrical short

circuit, earthing reduces the risk of electric shock by providing an

escape wire for the electric current. This product is equipped with

a cord having an earthing wire with an appropriate earthing plug.

Connection to the mains only through a special feed point, e.g.

through an error protection insallation with INF < 30 mA.

DANGER — Work or repairs at the electrical

equipment may only be carried out by a skilled

electrician. No liability is assumed for incorrect

installation. Switch the unit o. Before all repair

work, unplug the power plug from the outlet.

Danger of short-circuits caused by water ingressing into the electrical

equipment. Never spray down the unit with high-pressure or high-

pressure steam cleaners.

PREVENTION:

• Wear respiratory protection when spraying. Read all

instructions supplied with the mask to be sure it will provide

the necessary protection.

• All local regulations regarding protection against hazardous

vapors must be observed.

• Wear protective eyewear.

• Protective clothing, gloves and possibly skin protection cream

are necessary for the protection of the skin. Observe the

regulations of the manufacturer concerning coating materials,

solvents and cleaning agents in preparation, processing and

cleaning units.

HAZARD: GENERAL

This product can cause severe injury or property

damage.

PREVENTION:

• Follow all appropriate local, state, and national codes

governing ventilation, re prevention, and operation.

• Pulling the trigger causes a recoil force to the hand that is

holding the spray gun. The recoil force of the spray gun is

particularly powerful when the tip has been removed and

a high pressure has been set on the airless pump. When

cleaning without a spray tip, set the pressure control knob to

the lowest pressure.

• Use only manufacturer authorized parts. User assumes all

risks and liabilities when using parts that do not meet the

minimum specications and safety devices of the pump

manufacturer.

• ALWAYS follow the material manufacturer’s instructions for

safe handling of paint and solvents.

• Clean up all material and solvent spills immediately to prevent

slip hazard.

• Wear ear protection. This unit can produce noise levels above

85 dB(A).

• Never leave this equipment unattended. Keep away from

children or anyone not familiar with the operation of airless

equipment.

• Do not spray on windy days.

• The device and all related liquids (i.e. hydraulic oil) must be

disposed of in an environmentally friendly way.

Work or repairs at the electrical equipment:

These may only be carried out by a skilled electrician. No liability is

assumed for incorrect installation.

Operating Temperature

This equipment will operate correctly in its intended ambient, at a

minimum between +10°C and +40°C.

Relative Humidity

The equipment will operate correctly within an environment at 50%

RH, +40°C. Higher RH may be allowed at lower temperatures.

Measures shall be taken by the Purchaser to avoid the harmful eects

of occasional condensation.

Altitude

This equipment will operate correctly up to 2100 m above mean sea

level.

Transportation and Storage

This equipment will withstand, or has been protected against,

transportation and storage temperatures of -25°C to +55°C and for

short periods up to +70°C.

It has been packaged to prevent damage from the eects of normal

humidity, vibration and shock.

PowrTwin Plus 3

Page 6

Safety precautions

Attention

GB

1.3 Gasoline Engine Safety

1. Gas engines are designed to give safe and dependable service

if operated according to instructions. Read and understand

the engine manufacturer’s Owner’s Manual before operating

the engine. Failure to do so could result in personal injury or

equipment damage.

2. To prevent re hazards and to provide adequate ventilation,

keep the engine at least 1 meter (3 feet) away from buildings

and other equipment during operation. Do not place

ammable objects close to the engine.

3. People who are not operating the device must stay away from

the area of operation due to a possibility of burns from hot

engine components or injury from any equipment the engine

may be used to operate.

4. Know how to stop the engine quickly, and understand the

operation of all controls. Never permit anyone to operate the

engine without proper instructions.

5. Gasoline is extremely ammable and is explosive under

certain conditions.

6. Refuel in a well-ventilated area with the engine stopped. Do

not smoke or allow ames or sparks in the refueling area or

where gasoline is stored.

7. Do not overll the fuel tank. After refueling, make sure the

tank cap is closed properly and securely.

8. Be careful not to spill fuel when refueling. Fuel vapor or

spilled fuel may ignite. If any fuel is spilled, make sure the area

is dry before starting the engine.

9. Never run the engine in an enclosed or conned area. Exhaust

contains poisonous carbon monoxide gas; exposure may

cause loss of consciousness and may lead to death.

10. The muer becomes very hot during operation and remains

hot for a while after stopping the engine. Be careful not to

touch the muer while it is hot. To avoid severe burns or re

hazards, let the engine cool before transporting it or storing it

indoors.

11. Never ship/transport sprayer with gasoline in the tank.

1.4 Fueling (gas engine)

Gasoline is extremely flammable and is explosive

under certain conditions.

Do not overll the gas tank. Overlling can cause

the gas cap to become clogged with any particles

in the gasoline which can cause a vaccum. Read

Attention

Fuel Specications

• Use automotive gasoline that has a pump octane number of

i

• Unleaded fuel produces fewer engine and spark plug deposits

• Never use stale or contaminated gasoline or an oil/gasoline

the gas engine’s instruction manual for fueling

instructions.

86 or higher, or that has a research octane number of 91 or

higher. Use of a lower octane gasoline can cause persistent

“pinging” or heavy “spark knock” (a metallic rapping noise)

which, if severe, can lead to engine damage.

If “spark knock” or “pinging” occurs at a steady

engine speed under normal load, change brands of

gasoline. If spark knock or pinging persists, consult

an authorized dealer of the engine manufacturer.

Failure to do so is considered misuse, and damage

caused by misuse is not covered by the engine

manufacturer’s limited warranty.

Occasionally you may experience light spark knock

while operating under heavy loads. This is no

cause for concern, it simply means your engine is

operating eciently.

and extends the life of the exhaust system components.

mixture. Avoid getting dirt, dust, or water in the fuel tank.

DO NOT use this equipment to spray water or acid.

Do not lift by cart handle when loading or unloading.

Device is very heavy. Three-person lift is required.

Gasolines Containing Alcohol

If you decide to use a gasoline containing alcohol (gasohol), be

sure its octane rating is at least as high as that recommended by

the engine manufacturer. There are two types of “gasohol”: one

containing ethanol, and the other containing methanol. Do not use

gasohol that contains more than 10% ethanol. Do not use gasoline

containing methanol (methyl or wood alcohol) that does not also

contain co-solvents and corrosion inhibitors for methanol. Never

use gasoline containing more than 5% methanol, even if it has cosolvents and corrosion inhibitors.

Fuel system damage or engine performance

i

problems resulting from the use of fuels that contain

alcohol is not covered under the warranty. The

engine manufacturer cannot endorse the use of

fuels containing methanol since evidence of their

suitability is incomplete at this time.

Before buying gasoline from an unfamiliar station, try

to nd out if the gasoline contains alcohol. If it does,

conrm the type and percentage of alcohol used. If

you notice any undesirable operating characteristics

while using a gasoline that contains alcohol, or one

that you think contains alcohol, switch to a gasoline

that you know does not contain alcohol.

4 PowrTwin Plus

Page 7

GB

i

General view of application Description of unit

2. General view of application

2.1 Application

Priming and nal coating of large areas, sealing, impregnation,

construction sanitation, façade protection and renovation, rust

protection and building protection, roof coating, roof sealing,

concrete sanitation, as well as heavy corrosion protection.

Examples of objects to be sprayed

Large-scale construction sites, underground construction, cooling

towers, bridges, sewage treatment plants and terraces.

2.2 Coating materials

Processible coating materials

Pay attention to the Airless quality of the coating

materials to be processed.

Latex paint, dispersion paints, re protection and thick lm materials,

zinc dust and micaceous iron ore paints, Airless spray primer,

sprayable glue, anti-corrosive agents, thick coating materials and

bitumen-like coating materials.

No other materials should be used for spraying without Titan’s

approval.

Filtering

In spite of the high-pressure lter, ltering of the coating material is

to be recommended in general (except when processing airless joint

ller).

Stir coating material before commencement of work.

Make sure when stirring with motor-driven agitators

i

that no air bubbles are stirred in. Air bubbles disturb

when spraying and can, in fact, lead to interruption

of operation.

3. Description of unit

3.1 Airless process

The main area of application are thick layers of highly viscous coating

material for large areas and a high consumption of material.

A piston pump takes in the coating material by suction and conveys it

to the tip. Pressed through the tip at a pressure of up to a maximum

of 3300-3600 PSI (228-248 bar, 24.4-24.8 MPa), the coating material is

atomised. This high pressure has the eect of micro ne atomisation

of the coating material.

As no air is used in this process, it is described as an AIRLESS process.

This method of spraying has the advantages of nest atomisation,

cloudless operation and a smooth, bubble-free surface. As well as

these, the advantages of the speed of work and convenience must be

mentioned.

3.2 Functioning of the unit

The following section contains a brief description of the technical

construction for better understanding of the function.

TITAN PowrTwin Plus (PT) are high-pressure spraying units driven by

either a gasoline engine or electric motor.

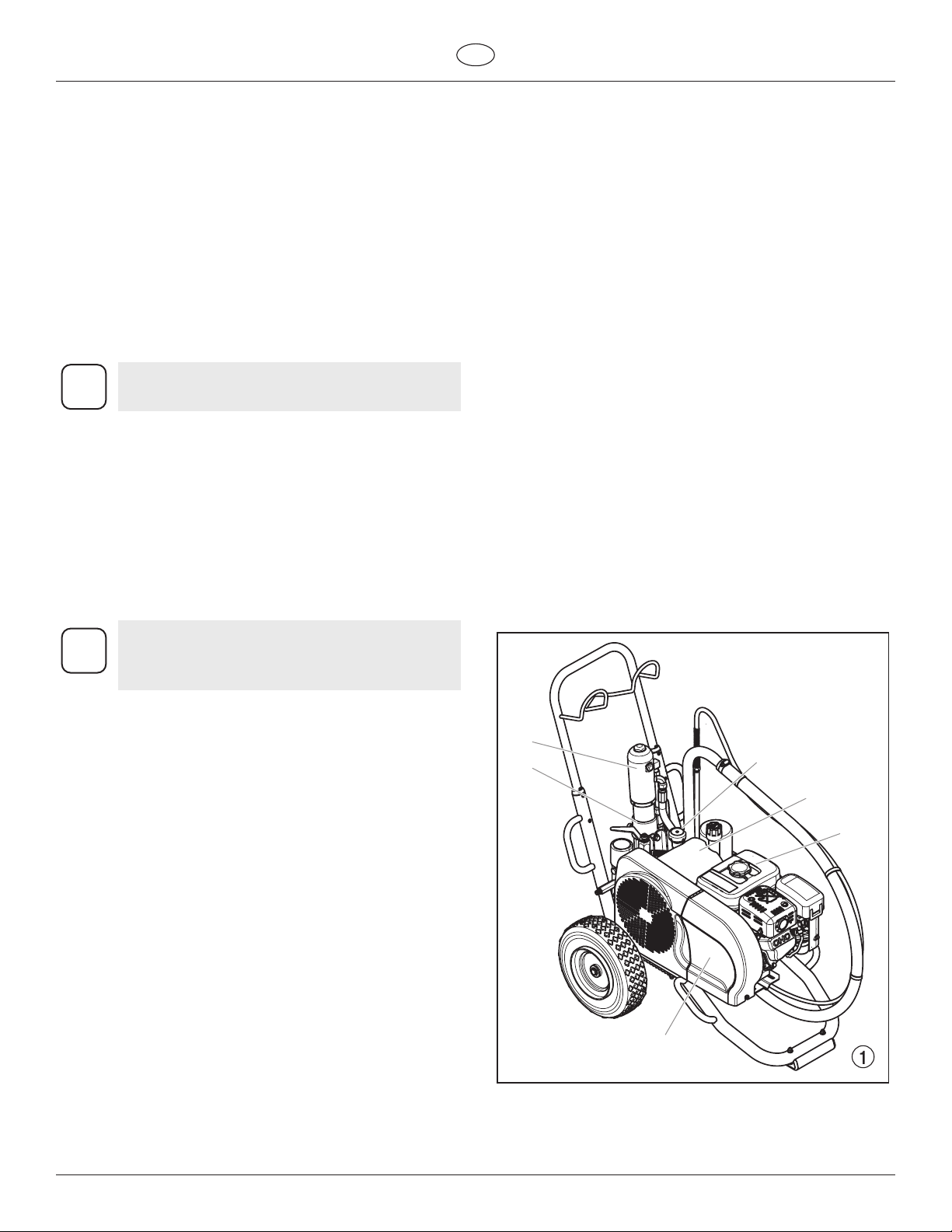

The gasoline engine or electric motor (g. 1, item 1) drives the

hydraulic pump (3) by means of a V-belt which is under the belt cover

(2). Hydraulic oil ows to the hydraulic motor (4) and then moves the

piston up and down in the material feed pump (5).

The inlet valve is opened automatically by the upwards movement

of the piston. The outlet valve is opened when the piston moves

downward.

The coating material ows under high pressure through the highpressure hose to the spray gun. When the coating material exits from

the tip it atomises.

The pressure control valve (6) controls the volume and the operating

pressure of the coating material.

Viscosity

It is possible to work with high-viscosity coating materials with the

devices.

If highly viscous coating materials cannot be sucked up, they must be

diluted in accordance with the manufacturer’s instruction.

Two-component coating material

The appropriate processing time must be adhered to exactly. Within

this time rinse through and clean the unit meticulously with the

appropriate cleaning agents.

Coating materials with sharp-edged additional materials

These have a strong wear and tear eect on valves, high-pressure

hose, spray gun and tip. The durability of these parts can be reduced

appreciably through this.

4

5

6

3

1

2

PowrTwin Plus 5

Page 8

Description of unit

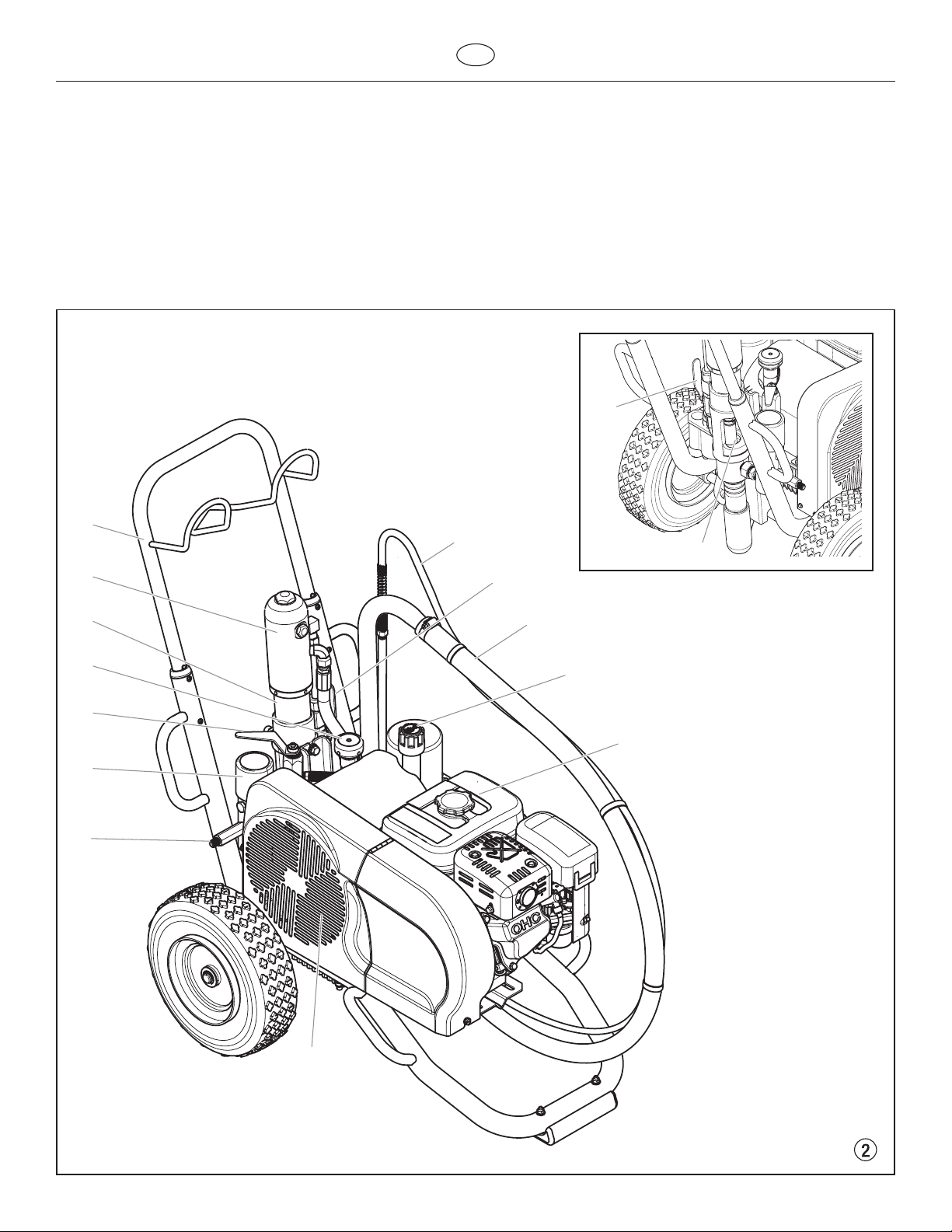

3.3 System diagram - gasoline PT units

GB

1 Extractable handle

2 Hydraulic motor

3 Oil cup for separating oil (separating oil prevents increased

wear and tear of the packings)

4 Pressure control knob

5 Relief valve handle: Turn left for circulation k

Turn right for spray p

6 High-pressure lter

1

2

7 High-pressure hose outlet

8 V-belt under the belt cover

9 Bleed hose

10 Ball valve: horizontal position – hydraulic motor switched o

vertical position – hydraulic motor switched on

11 Suction tube

12 Oil measuring stick

13 Gasoline engine

10

9

3

10

3

4

11

12

5

13

6

7

8

6 PowrTwin Plus

Page 9

GB

Description of unit

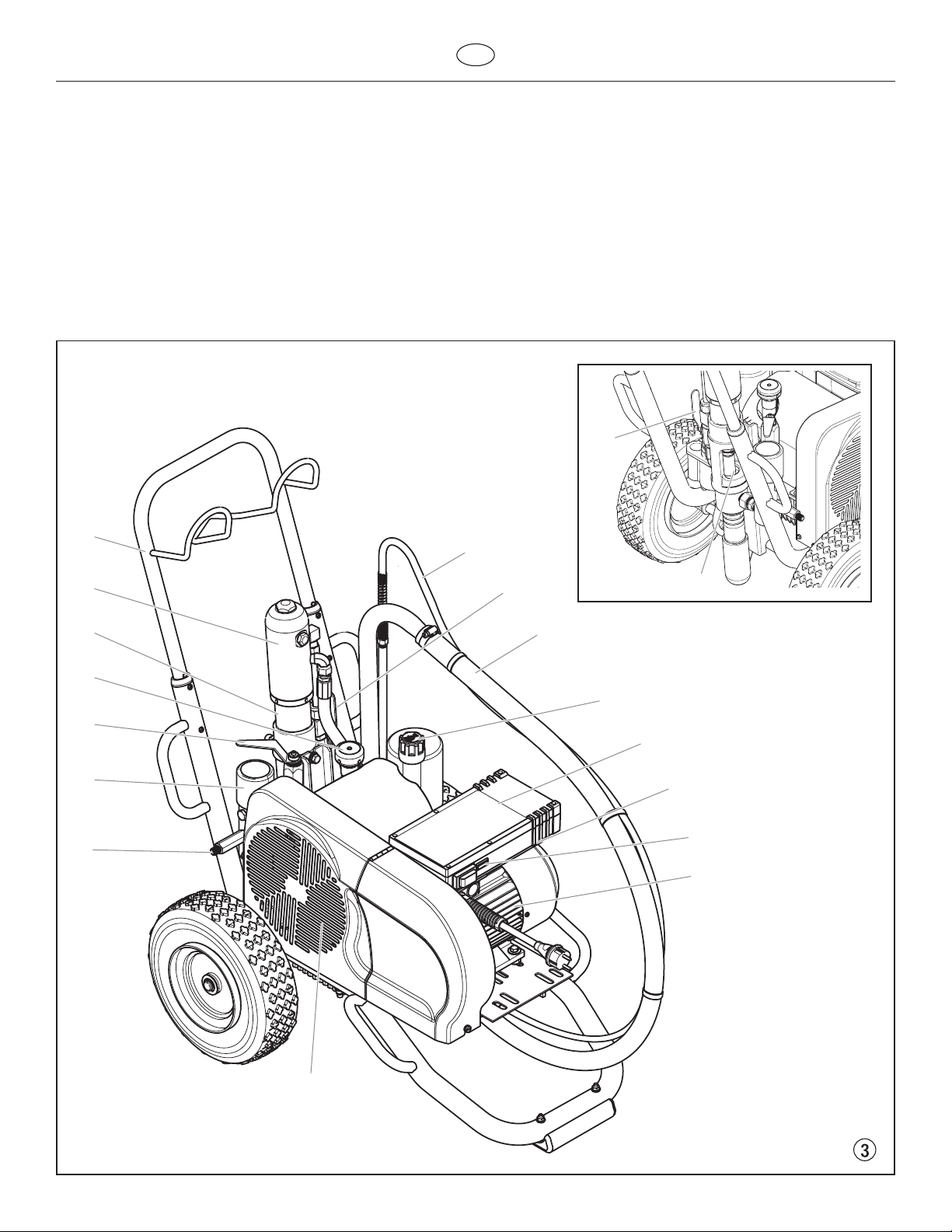

3.4 System diagram - electric PT units

1 Extractable handle

2 Hydraulic motor

3 Oil cup for separating oil (separating oil prevents increased

wear and tear of the packings)

4 Pressure control knob

5 Relief valve handle: Turn left for circulation k

Turn right for spray p

6 High-pressure lter

7 High-pressure hose outlet

8 V-belt under the belt cover

1

2

9 Bleed hose

10 Ball valve: horizontal position – hydraulic motor switched o

vertical position – hydraulic motor switched on

11 Suction tube

12 Oil measuring stick

13 Electric motor (230V)

14 ON/OFF switch

15 Control lamp that shows unit operational

16 Power Cord

10

9

10

3

3

11

4

12

5

13

6

14

15

7

16

8

PowrTwin Plus 7

Page 10

Description of unit

3.5 Technical data for PT units

GB

PT4900 Plus

(230V)

Gasoline engine, power

Subaru -------- 169cc, 5.7 Hp -------- -------- ------- Honda -------- -------- 163cc, 4.8 Hp 196cc, 5.5 Hp 270cc, 8.5 Hp

Fuel Capacity

-------- 0.95 US gal (3.6 l) 0.83 US gal (3.1 l) 0.83 US gal (3.1 l) 1.6 US gal (6.06 l)

Voltage

230 V~, 50 Hz -------- -------- -------- --------

Capacity

2.6 kW -------- -------- -------- --------

Power Cord

3 x 2.5 mm – 6 m -------- -------- -------- --------

Fuse Protection

16 A -------- -------- -------- --------

Max. operating pressure

Max. sound pressure level

80 dB (A)* 92 dB (A)* 98 dB (A)*

Max. size of tip with a spray gun

1-gun 0.031” – 0.79 mm 0.037” – 0.94 mm 0.050” – 1.27 mm 0.054” – 1.37 mm 0.059” – 1.50 mm

2-gun 0.028” – 0.71 mm 0.028” – 0.71 mm 0.033” – 0.84 mm 0.038” – 0.96 mm 0.040” – 1.01 mm

3-gun 0.022” – 0.56 mm 0.022” – 0.56 mm 0.023” – 0.58 mm 0.032” – 0.81 mm 0.034” – 0.86 mm

4-gun -------- -------- 0.019” – 0.48 mm 0.028” – 0.71 mm 0.030” – 0.76 mm

5-gun -------- -------- -------- 0.024” – 0.61 mm 0.026” – 0.66 mm

6-gun -------- -------- -------- -------- 0.024” – 0.61 mm

Max. volume ow

1.1 gal (4.2 l)/min 1.5 gal (5.7 l)/min 2.35 gal (8.9 l)/min 2.5 gal (9.5 l)/min 3.15 gal (11.9 l)/min

Weight

139 lbs. (63 kg) 132 lbs. (60 kg) 139 lbs. (63 kg) 154 lbs. (70 kg) 183 lbs. (83 kg)

Max. viscosity

Dimensions L x W x H

37.2” x 26.8” x 35” (946 x 680 x 890 mm)

Max. temperature of the coating material

Filter insert (standard equipment)

Hydraulic oil lling quantity

Max. tire pressure

Special high-pressure hose

PT4900 Plus

(gas)

22.8 MPa (228 bar, 3300 PSI) 24.8 MPa (248 bar, 3600 PSI)

50.000 mPa·s 65.000 mPa·s

DN 6 mm, 15 m (50’ x 1/4”), connection thread NPSM 1/4

PT6900 Plus PT8900 Plus PT12000 Plus

42.5” x 27” x 31” (1080

109ºF (43° C)

50 mesh, 18 in

5.9 l (1.56 gal) CoolFlo

0.2 MPa (2 bar, 30 PSI)

2

x 686 x 866 mm)

46” x 27” x 31” (1168 x 686 x

866 mm)

* Place of measurement: 1 m distance from unit and 1.60 m above reverberant oor, 120 bar (12 MPa) operating pressure.

8 PowrTwin Plus

Page 11

GB

Description of unit

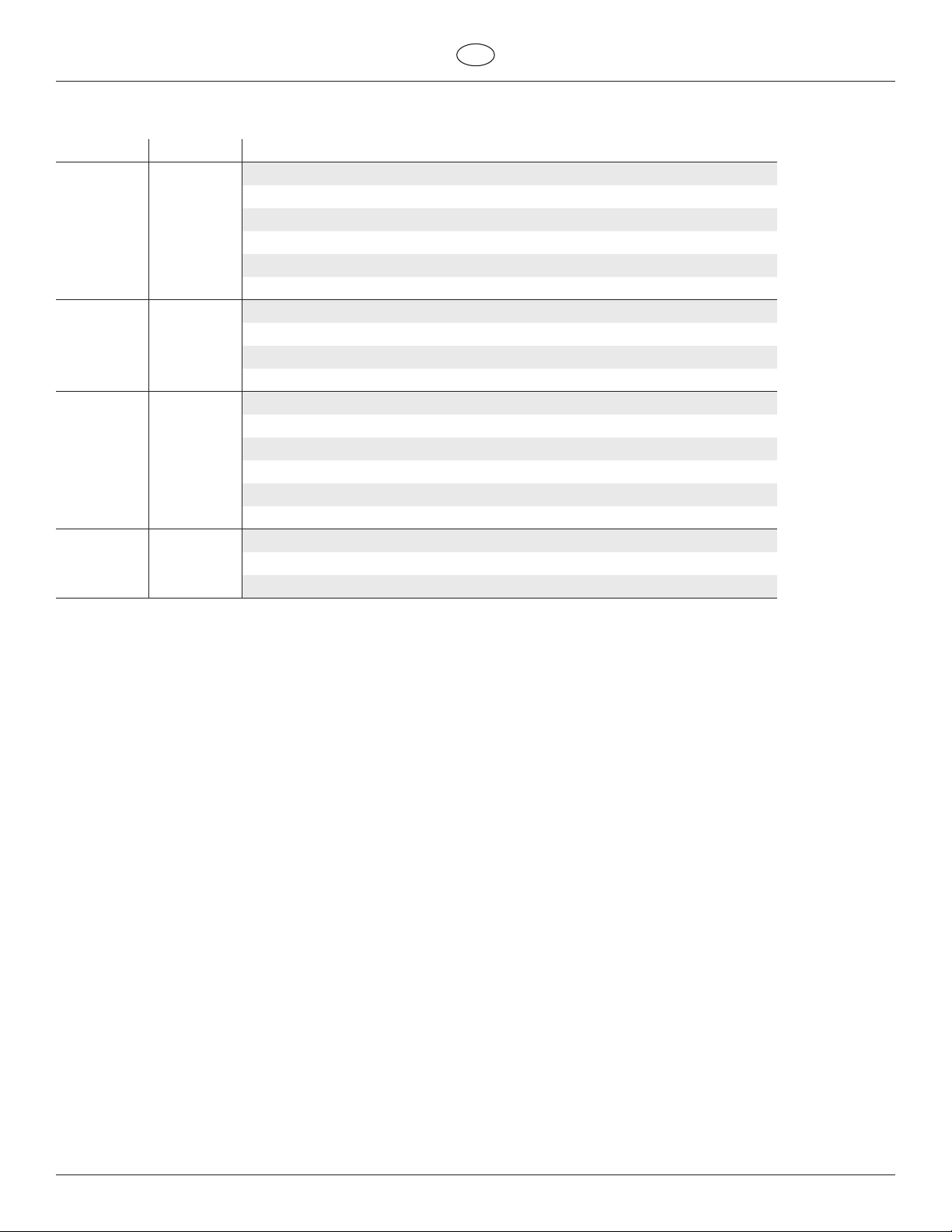

3.6 Airless Spray Tip Recommendation Chart

Viscosity Filter Mesh Coating Orice Range Synergy™ (Fine Finish)

Light 100-150 Varnishes .009 - .011 .008 - .010

Lacquer Finishes (clear) .009 - .011 .008 - .010

Sanding Sealers .009 - .011 .008 - .010

Shellac (clear) .009 - .013 .008 - .012

Transparent Stain .011 - .013 .010 - .012

Water Sealers (clear) .011 - .013 .010 - .012

Medium 60-100 Solid Stains .013 - .015

Exterior House Paints .013 - .017

Interior Wall Paints .013 - .017

Interior & Exterior Primers .017 - .019

Heavy 30-60 Commercial Grade

Architectural Coatings .017 - .019

Interior Wall Paints .017 - .019

Interior Wall Primers .017 - .019

Dry Fall (quick dry) .019 - .023

One Coat, Primer-Finish Paints .019 - .023

Extra Heavy 0 Elastomerics .021 - .031

Pigmented Waterproofers .021 - .027

Block Filler .025 - .031

Orice sizes recommended on this chart are based on fan widths between 8 inches (20 cm) and 12 inches (30 cm)

PowrTwin Plus 9

Page 12

Operation

Attention

GB

4. Operation

This equipment produces a fluid stream at extremely

high pressure. Read and understand the warnings

in the Safety Precautions section at the front of this

manual before operating this equipment.

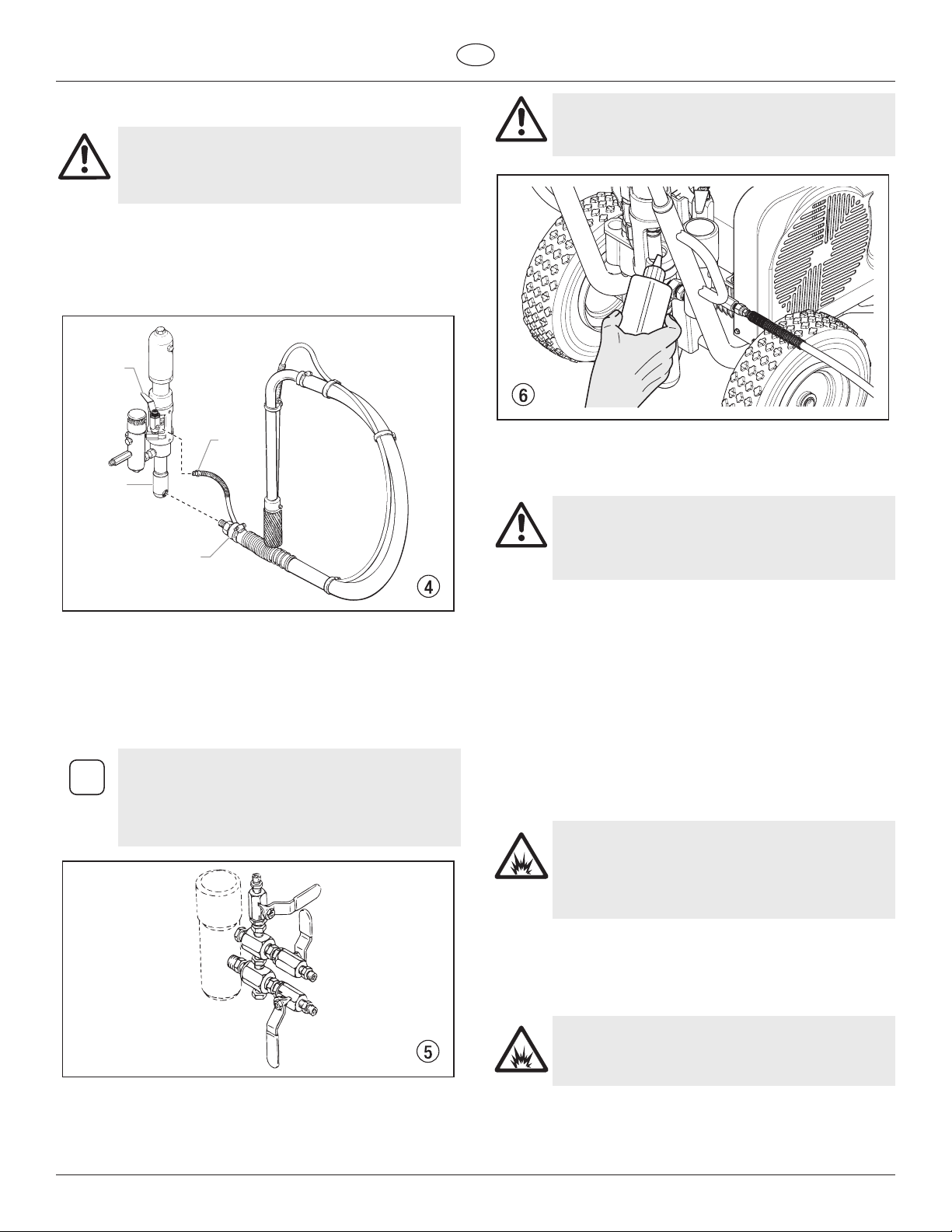

4.1 Setup

1. Make sure the siphon hose (g. 4, 1) is connected to the uid

section (2) and the bleed hose (3) is connected to the bleed

valve (4). They each have factory installed PTFE tape on the

male end of the hoses and should be wrench tight.

4

3

2

1

Piston Lube prevents increased wear and tear to the

packings.

5. Check the hydraulic uid level daily before starting the

sprayer. The hydraulic uid level should be at the “Full” mark

on the dipstick. Refer to the Maintenance section of this

manual for hydraulic system maintenance instructions.

Use of Titan’s Coolflo™ Hydraulic Fluid (P/N 430-361)

is mandatory in the hydraulic system. Do not use

any other hydraulic fluid. Use of any other hydraulic

Attention

fluid may seriously damage the hydraulic system

and will void the warranty.

2. Attach a minimum of 15m of nylon airless spray hose to the

sprayer. Do not use PTFE tape or thread sealant on the spray

hose connection.

3. Attach an airless spray gun to the spray hose. Do not attach

the tip to the spray gun yet. Remove the tip if it is already

attached.

a. To use two guns, remove the plug from the second gun outlet

4. Fill the oil cup 1/2 full with Piston Lube (P/N 314-480). This

on the lter assembly. Connect a hose and gun to the outlet.

For multiple gun operation, connect a multiple gun

i

manifold to the single gun outlet. Connect a hose

and gun to each outlet. Make sure the second gun

outlet remains plugged. See “Technical Data”,

Section 3.5 to determine number of guns and

maximum spray tip sizes.

extends packing life.

6. For gas models, check the engine oil level daily before starting

the sprayer. The gasoline engine oil level is determined by

the engine manufacturer. Refer to the engine manufacturer’s

service manual supplied with this sprayer.

7. For electric models, use a 20 amp service outlet. Always

locate the electric model within 10 to 15 feet of the service

outlet. Use a short electric cable and a long paint hose. Any

extension cord will create some voltage drop. If an extension

cord is necessary, use only a grounded 3-wire #12 extension

cord.

8. Make sure the sprayer is earthed. All sprayers are equipped

with a earthing lug. An earthing cable (not supplied) should

be used to connect the sprayer to a true earth ground.

Check your local electrical regulations for detailed earthing

instructions.

Proper earthing is important. This applies to both

gas and electric powered models. The passage of

some materials through the nylon uid hose will

build up a static electric charge, which if discharged,

could ignite solvent vapors present and create an

explosion.

9. Strain all paints with a nylon strainer to ensure trouble free

operation and freedom from frequent cleaning of the inlet

screen and gun lter.

10. Make sure the spray area is well ventilated to prevent

hazardous operation with volatile solvents or exhaust fumes.

If lacquer or other flammable materials are to be

sprayed, ALWAYS locate the sprayer outside the

immediate spraying area. Failure to do so may cause

an explosion.

11. Locate the sprayer outside the immediate spraying area to

avoid clogged air intake of the engine or electric motor with

overspray.

10 PowrTwin Plus

Page 13

GB

Operation

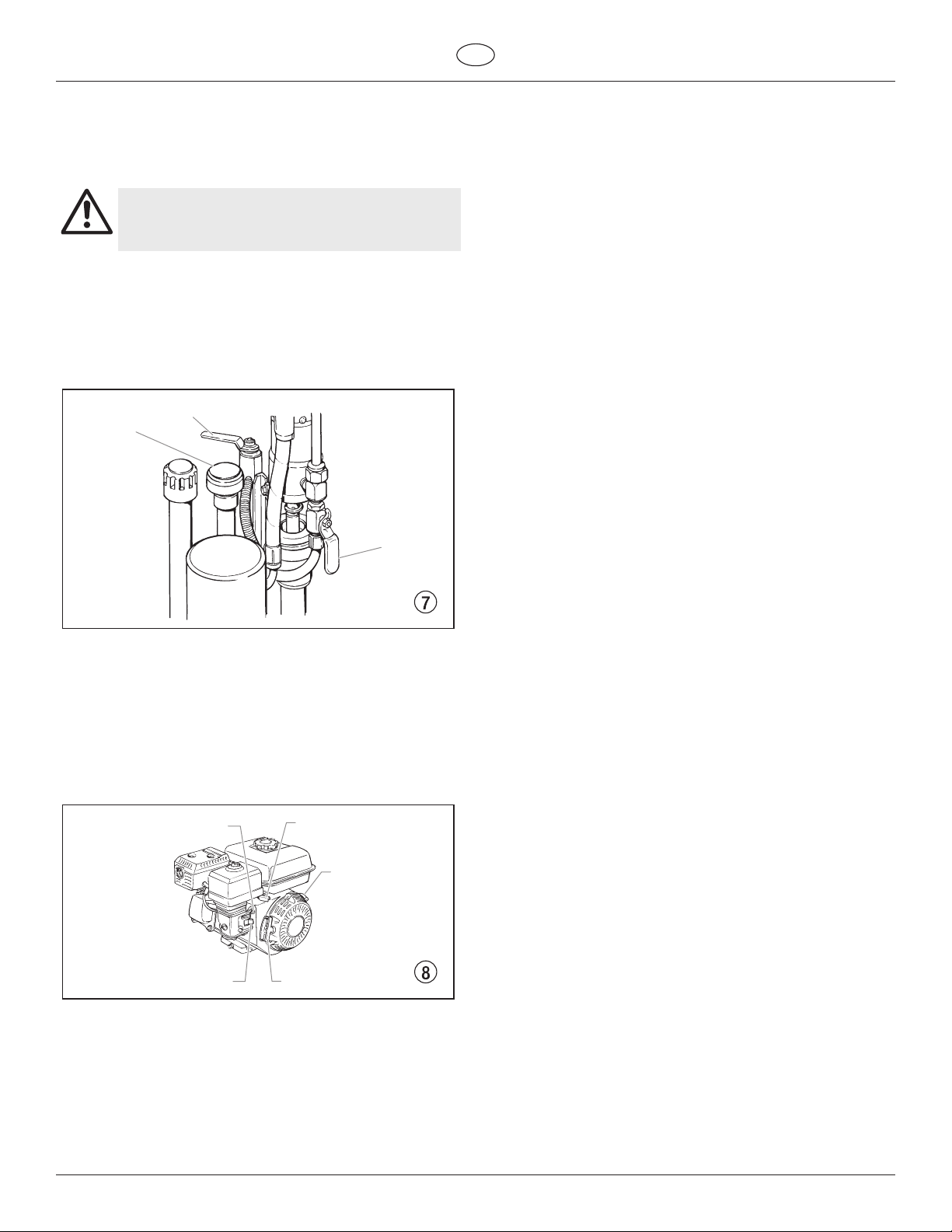

4.2 Preparing a New Sprayer

If this unit is new, it is shipped with test uid in the uid section to

prevent corrosion during shipment and storage. This uid must be

thoroughly cleaned out of the system with mineral spirits before you

begin spraying.

Always keep the trigger lock on the spray gun in the

locked position while preparing the system.

Attention

1. Place the siphon tube into a container of mineral spirits.

2. Place the bleed hose into a metal waste container.

3. Turn the pressure control knob fully counterclockwise to its

lowest pressure setting (g 7, 1).

4. Open the hydraulic shut-o valve (2) located on the hydraulic

pressure hose. The handle should be in line with the hose.

5. Open the bleed valve (3) by turning it fully counterclockwise.

9. Turn o the sprayer.

a. To turn o the gas engine,

• set the pressure to minimum by turning the pressure control

knob fully counterclockwise,

• move the throttle lever to the slow position, and

• turn the engine switch to the OFF position.

b. To turn o the electric motor,

• set the pressure to minimum by turning the pressure control

knob fully counterclockwise,

• move the ON/OFF switch to the OFF position.

3

1

2

6. Start the engine or turn on the electric motor.

a. To start the gas engine (g. 8),

• move the fuel valve lever (2) to the open position,

• move the throttle lever (3) to its middle point,

• move the choke lever (4) to the closed position for a cold

• turn the engine switch (1) to the ON position, and

• pull the starter rope (5) briskly until the engine starts.

b. To start the electric motor, move the ON/OFF switch to the ON

engine or to the open position for a warm engine,

position.

4

3

1

2

5

7. Turn the pressure control knob (g. 7, 1) clockwise

approximately 1/3 of the way down to increase pressure until

the sprayer cycles evenly and solvent ows freely from the

bleed hose.

8. Allow the sprayer to run for 15–30 seconds to ush the test

uid out through the bleed hose and into the waste container.

PowrTwin Plus 11

Page 14

i

Operation

GB

4.3 Preparing to Paint

Before painting, it is important to make sure that the uid in the

system is compatible with the paint that is going to be used.

Incompatible uids and paint may cause the valves

i

Attention

1. Place the siphon tube into a container of the appropriate

i

2. Place the bleed hose into a metal waste container.

3. Turn the pressure control knob fully counterclockwise to its

4. Open the hydraulic shut-o valve (2) located on the hydraulic

5. Open the bleed valve (3) by turning it fully counterclockwise.

6. Start the engine or turn on the electric motor.

a. To start the gas engine (g. 8),

• move the fuel valve lever (2) to the open position,

• move the throttle lever (3) to its middle point,

• move the choke lever (4) to the closed position for a cold

• turn the engine switch (1) to the ON position, and

• pull the starter rope (5) briskly until the engine starts.

b. To start the electric motor, move the ON/OFF switch to the ON

7. Turn the pressure control knob (1) clockwise approximately

8. Allow the sprayer to run for 15–30 seconds to ush the test

9. Turn o the sprayer.

a. To turn o the gas engine,

• set the pressure to minimum by turning the pressure control

• move the throttle lever to the slow position, and

• turn the engine switch to the OFF position.

b. To turn o the electric motor,

• set the pressure to minimum by turning the pressure control

• move the ON/OFF switch to the OFF position.

to become stuck closed, which would require

disassembly and cleaning of the sprayer’s uid

section.

Always keep the trigger lock on the spray gun in the

locked position while preparing the system.

solvent for the material being sprayed.

If you are spraying a water-based latex, ush with

warm, clean water. If you are using any other

material, check with the material manufacturer for a

compatible solvent.

lowest pressure setting (g 7, 1).

pressure hose. The handle should be in line with the hose.

engine or to the open position for a warm engine,

position.

1/3 of the way down to increase pressure until the sprayer

cycles evenly and solvent ows freely from the bleed hose.

uid out through the bleed hose and into the waste container.

knob fully counterclockwise,

knob fully counterclockwise,

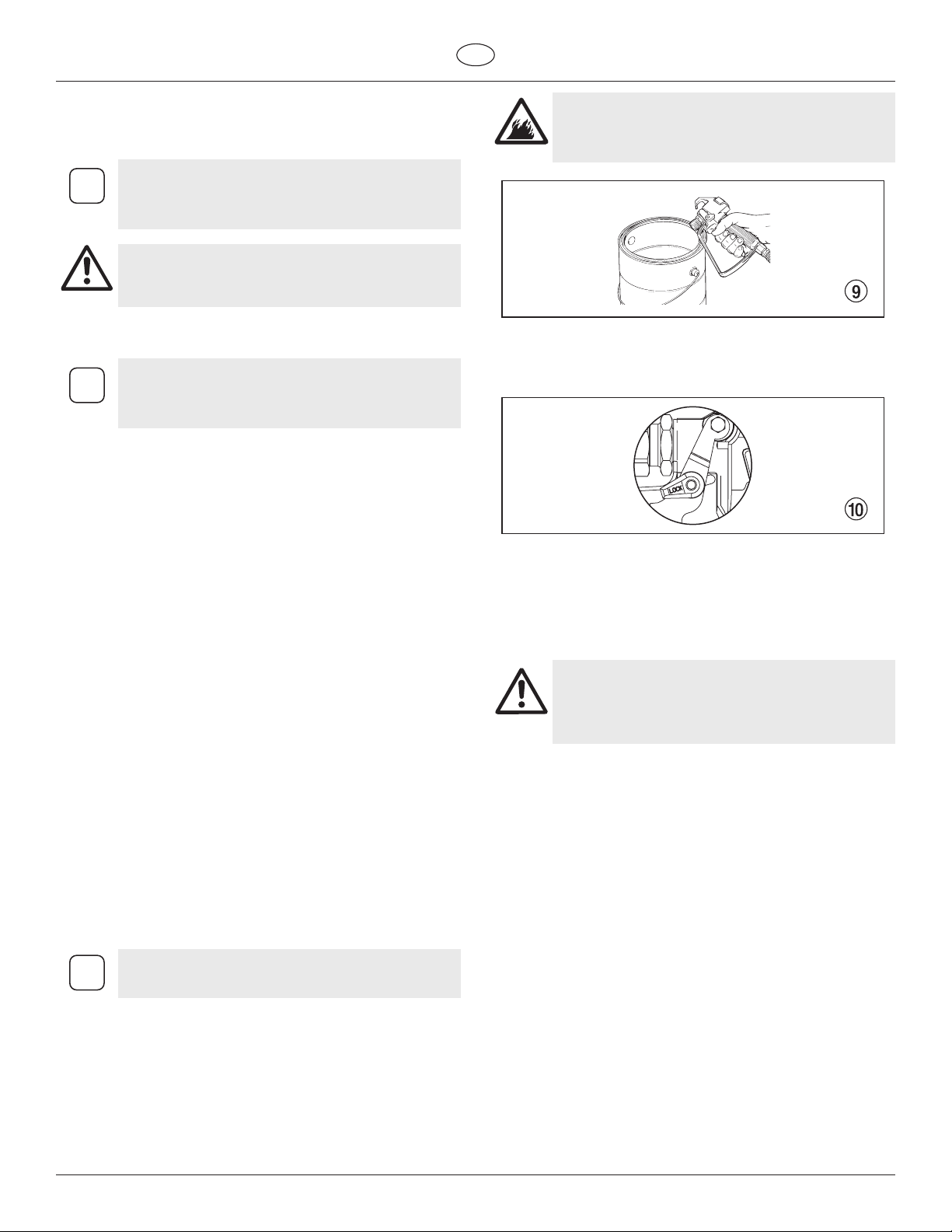

Earth the gun by holding it against the edge of the

metal container while flushing. Failure to do so may

lead to a static electric discharge, which may cause

a fire.

14. Trigger the gun into the metal waste container until the old

solvent is gone and fresh solvent is coming out of the gun.

15. Lock the gun by turning the gun trigger lock to the locked

position (g 10).

16. Set down the gun and increase the pressure by turning the

pressure control knob slowly clockwise to its highest setting.

17. Check the entire system for leaks. If leaks occur, turn the

sprayer o and follow the “Pressure Relief Procedure” in this

manual before tightening any ttings or hoses.

18. Follow the “Pressure Relief Procedure” (section 4.5) in this

manual before changing from solvent to paint.

Be sure to follow the Pressure Relief Procedure when

shutting the unit down for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray tips, or preparing for

cleanup.

Make sure that the spray gun does not have a tip or

tip guard installed.

10. Close the bleed valve by turning it fully clockwise.

11. Start the engine or turn on the electric motor.

12. Turn the pressure control knob clockwise approximately 1/3

of the way down to increase pressure.

13. Unlock the gun by turning the gun trigger lock to the

unlocked position.

12 PowrTwin Plus

Page 15

GB

Operation

4.4 Painting

1. Place the siphon hose into a container of paint.

2. Place the bleed hose into a metal waste container.

3. Turn the pressure control knob fully counterclockwise to its

lowest pressure setting (g 7, 1).

4. Open the hydraulic shut-o valve (2) located on the hydraulic

pressure hose. The handle should be in line with the hose.

5. Open the bleed valve (3) by turning it fully counterclockwise.

6. Start the engine or turn on the electric motor.

a. To start the gas engine (g. 8),

• move the fuel valve lever (2) to the open position,

• move the throttle lever (3) to its middle point,

• move the choke lever (4) to the closed position for a cold

engine or to the open position for a warm engine,

• turn the engine switch (1) to the ON position, and

• pull the starter rope (5) briskly until the engine starts.

b. To start the electric motor, move the ON/OFF switch to the ON

position.

7. Turn the pressure control knob (1) clockwise approximately

1/3 of the way down to increase pressure until the sprayer

cycles evenly and solvent ows freely from the bleed hose.

8. Turn o the sprayer.

a. To turn o the gas engine,

• set the pressure to minimum by turning the pressure control

knob fully counterclockwise,

• move the throttle lever to the slow position, and

• turn the engine switch to the OFF position.

b. To turn o the electric motor,

• set the pressure to minimum by turning the pressure control

knob fully counterclockwise,

• move the ON/OFF switch to the OFF position.

9. Remove the bleed hose from the waste container and place it

into the container of paint.

10. Close the bleed valve by turning it fully clockwise.

11. Start the engine or turn on the electric motor.

12. Turn the pressure control knob clockwise approximately 1/3

of the way down to increase pressure.

13. Unlock the gun by turning the gun trigger lock to the

unlocked position.

Earth the gun by holding it against the edge of the

metal container while flushing. Failure to do so may

lead to a static electric discharge, which may cause

a fire.

19. Increase the pressure by turning the pressure control knob

slowly clockwise and test the spray pattern on a piece of

cardboard. Adjust the pressure control knob until the spray

from the gun is completely atomized.

Turning the pressure up higher than needed to

i

atomize the paint will cause premature tip wear and

additional overspray.

4.5 Pressure Relief Procedure

Be sure to follow the Pressure Relief Procedure when

shutting the unit down for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray nozzles, or preparing for

cleanup.

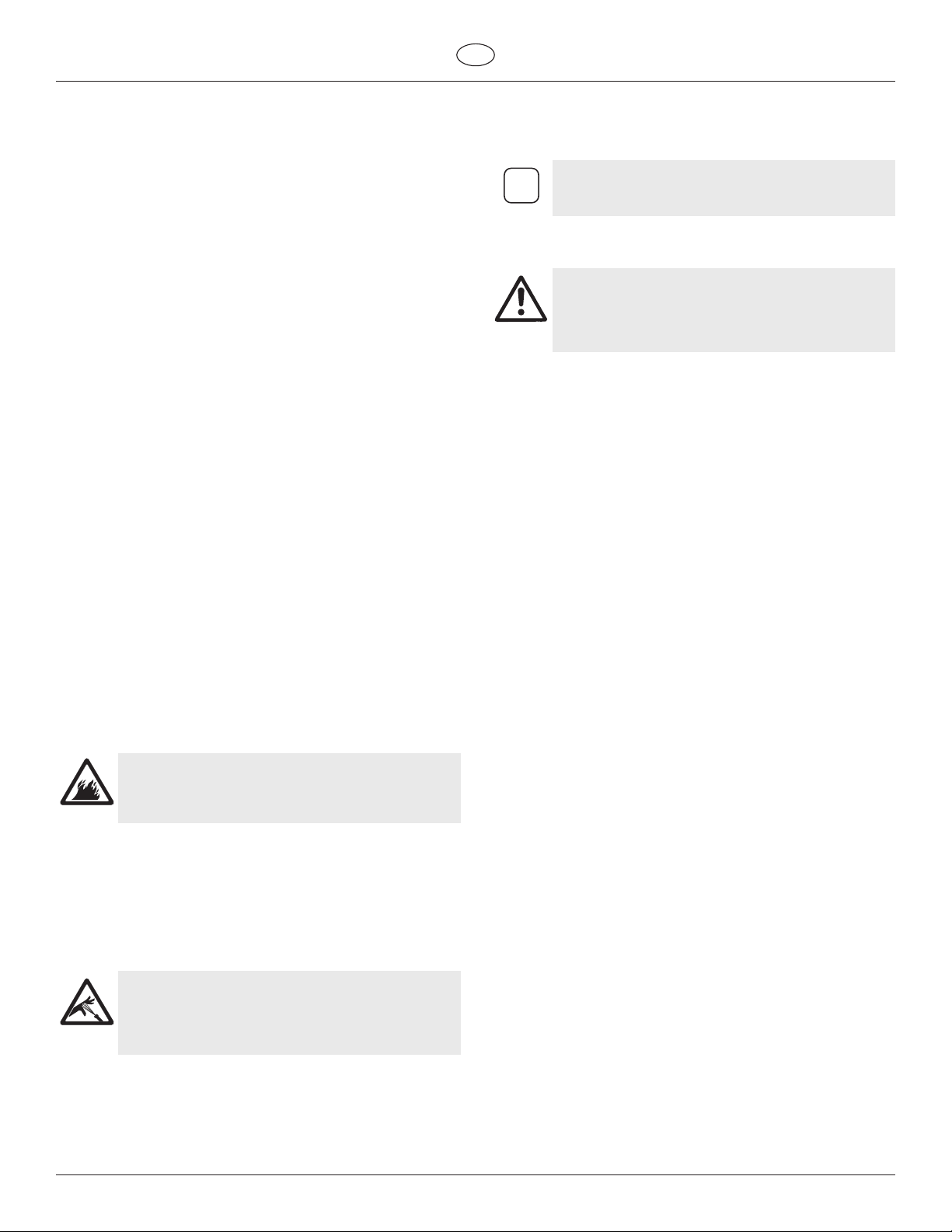

1. Lock the spray gun by turning the gun trigger lock to the

locked position.

2. Turn o the sprayer.

a. To turn o the gas engine,

• set the pressure to minimum by turning the pressure control

• move the throttle lever to the slow position, and

• turn the engine switch to the OFF position.

b. To turn o the electric motor,

• set the pressure to minimum by turning the pressure control

• move the ON/OFF switch to the OFF position.

3. Close the hydraulic shut-o valve on the hydraulic pressure

4. Unlock the gun by turning the gun trigger lock to the

5. Hold the metal part of the gun rmly to the side of a metal

6. Trigger the gun to remove any pressure that may still be in the

7. Lock the gun by turning the gun trigger lock to the locked

8. Place the bleed hose into the metal waste container.

9. Open the bleed valve by turning it fully counterclockwise.

knob fully counterclockwise,

knob fully counterclockwise,

hose.

unlocked position.

waste container to earth the gun and avoid a build up of static

electricity.

hose.

position.

14. Trigger the gun into the metal waste container until all air and

solvent is ushed from the spray hose and paint is owing

freely from the gun.

15. Lock the gun by turning the gun trigger lock to the locked

position (g 10).

16. Turn o the sprayer.

17. Attach tip guard and tip to the gun as instructed by the tip

guard or tip manuals.

POSSIBLE INJECTION HAZARD. Do not spray

without the tip guard in place. Never trigger the

gun unless the tip is in either the spray or the unclog

position. Always engage the gun trigger lock before

removing, replacing or cleaning tip.

18. Start the engine or turn on the electric motor.

PowrTwin Plus 13

Page 16

Cleanup

i

5. Cleanup

GB

12. Start the engine or turn on the electric motor.

The sprayer, hose, and gun should be cleaned

thoroughly after daily use. Failure to do so permits

material to build up, seriously aecting the

Attention

performance of the unit.

Always spray at minimum pressure with the gun

nozzle tip removed when using mineral spirits or

any other solvent to clean the sprayer, hose, or

gun. Static electricity buildup may result in a re or

explosion in the presence of ammable vapors.

5.1 Special cleanup instructions for use with

ammable solvents

• Always ush spray gun preferably outside and at least one hose

• If collecting ushed solvents in a one gallon metal container,

• Area must be free of ammable vapors.

• Follow all cleanup instructions.

length from spray pump.

place it into an empty ve gallon container, then ush solvents.

5.2 Cleaning the sprayer

1. Follow the “Pressure Relief Procedure” found in the Operation

section of this manual, section 4.5.

2. Remove the gun tip and tip guard and clean with a brush

using the appropriate solvent.

3. Place the siphon tube into a container of the appropriate

solvent.

Earth the gun by holding it against the edge of the

metal container while flushing. Failure to do so may

lead to a static electric discharge, which may cause

a fire.

13. Trigger the gun into the metal waste container until the paint

is ushed out of the hose and solvent is coming out of the

gun.

14. Continue to trigger the spray gun into the waste container

until the solvent coming out of the gun is clean.

For long-term or cold weather storage, pump

mineral sprits through the entire system.

15. Follow the “Pressure Relief Procedure” found in the Operation

section of this manual.

16. Store the sprayer in a clean, dry area.

Do not store the sprayer under pressure.

Attention

5.3 Cleaning a Clogged Tip

1. Follow the “Pressure Relief Procedure” in the Operation

section of this manual.

2. If the tip clogs, rotate the tip handle 180° until the arrow on

the handle is facing the opposite of the spray direction and

the handle clicks in the reverse position.

Use only compatible solvents when cleaning

out oil based enamels, lacquers, coal tar, and

epoxies. Check with the uid manufacturer for the

Attention

4. Place the bleed hose into a metal waste container.

5. Set the pressure to minimum by turning the pressure control

6. Open the hydraulic shut-o valve located on the hydraulic

7. Open the bleed valve (3) by rotating the bleed valve handle

recommended solvent.

knob (1) fully counterclockwise.

pressure hose (2). The handle should be in line with the hose.

fully counterclockwise.

3

1

3. Trigger the gun once so that the pressure can blow the clog

out. NEVER use the tip in the reverse position for more than

ONE trigger pull at a time. This procedure can be repeated

until the tip is free of clogging.

The flow from the spray tip is at very high pressure.

Contact with any body part may be dangerous. Do

not place finger on gun outlet. Do not point the gun

at any person. Never operate the spray gun without

the proper tip guard.

2

8. Start the engine or turn on the electric motor.

9. Allow the solvent to circulate through the sprayer and

ush the paint out of the bleed hose into the metal waste

container.

10. Turn o the sprayer.

11. Close the bleed valve by rotating the bleed valve handle fully

clockwise.

14 PowrTwin Plus

Page 17

GB

i

i

i

Maintenance

6. Maintenance

Before proceeding, follow the Pressure Relief

Procedure outlined previously in this manual.

Additionally, follow all other warnings to reduce the

risk of an injection injury, injury from moving parts

or electric shock. Always unplug the sprayer before

servicing!

6.1 Daily Maintenance

Two daily procedures are required for routine operator maintenance

on this sprayer:

A. Lubricating the upper packings.

B. Cleaning the lter screen

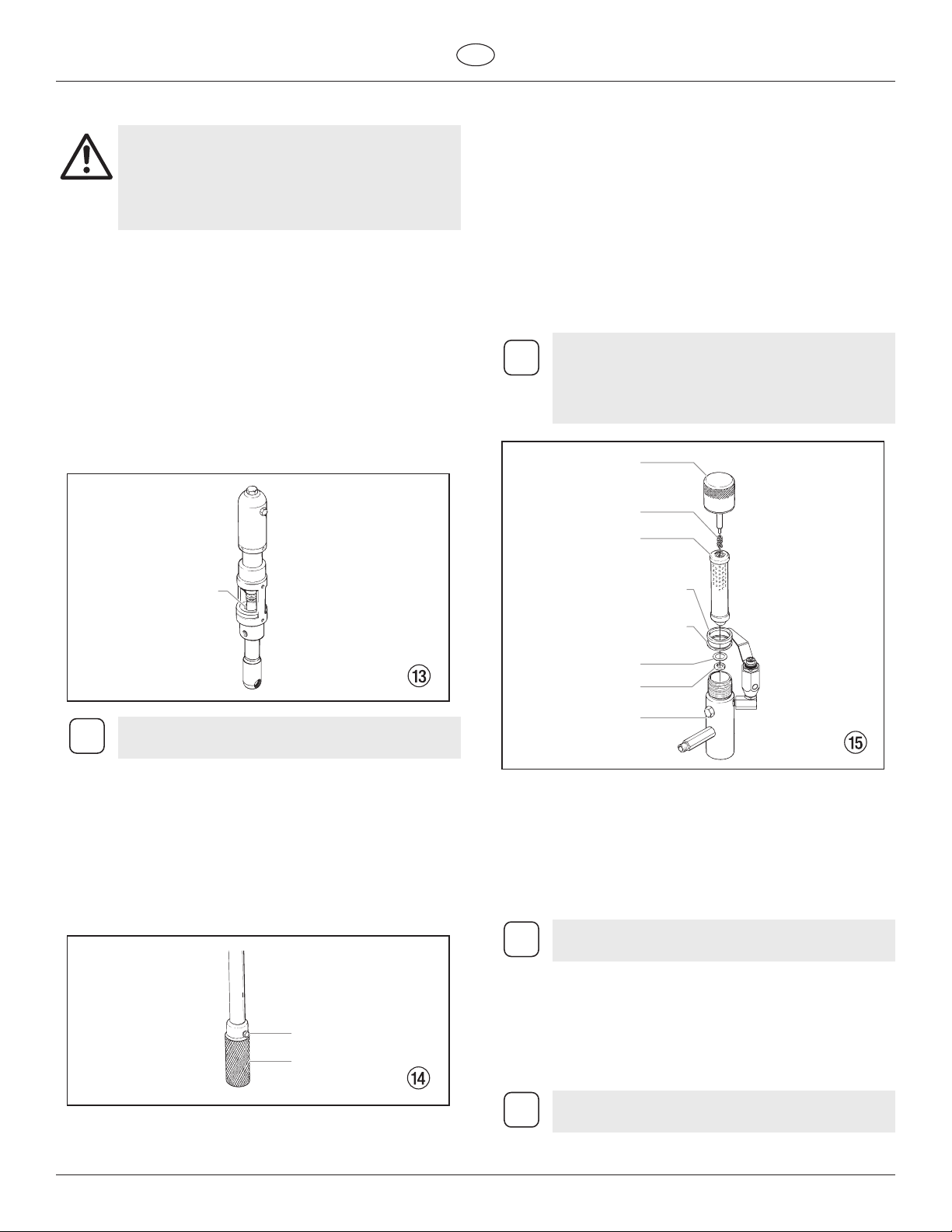

A) Lubricating the Upper Packings

1. Clean out the paint that has seeped past the upper packings

into the packing oil reservoir (g. 13, item 1) above the uid

section.

2. Fill the packing oil reservoir 1/2 full with Piston Lube (P/N 314-

480) supplied by the factory. This will extend packing life.

6.2 Maintaining the Filter Assembly

Clean the lter regularly. Dirty or clogged lters can greatly reduce

ltering ability and cause a number of system problems including

poor spray patterns, clogged spray tips, etc.

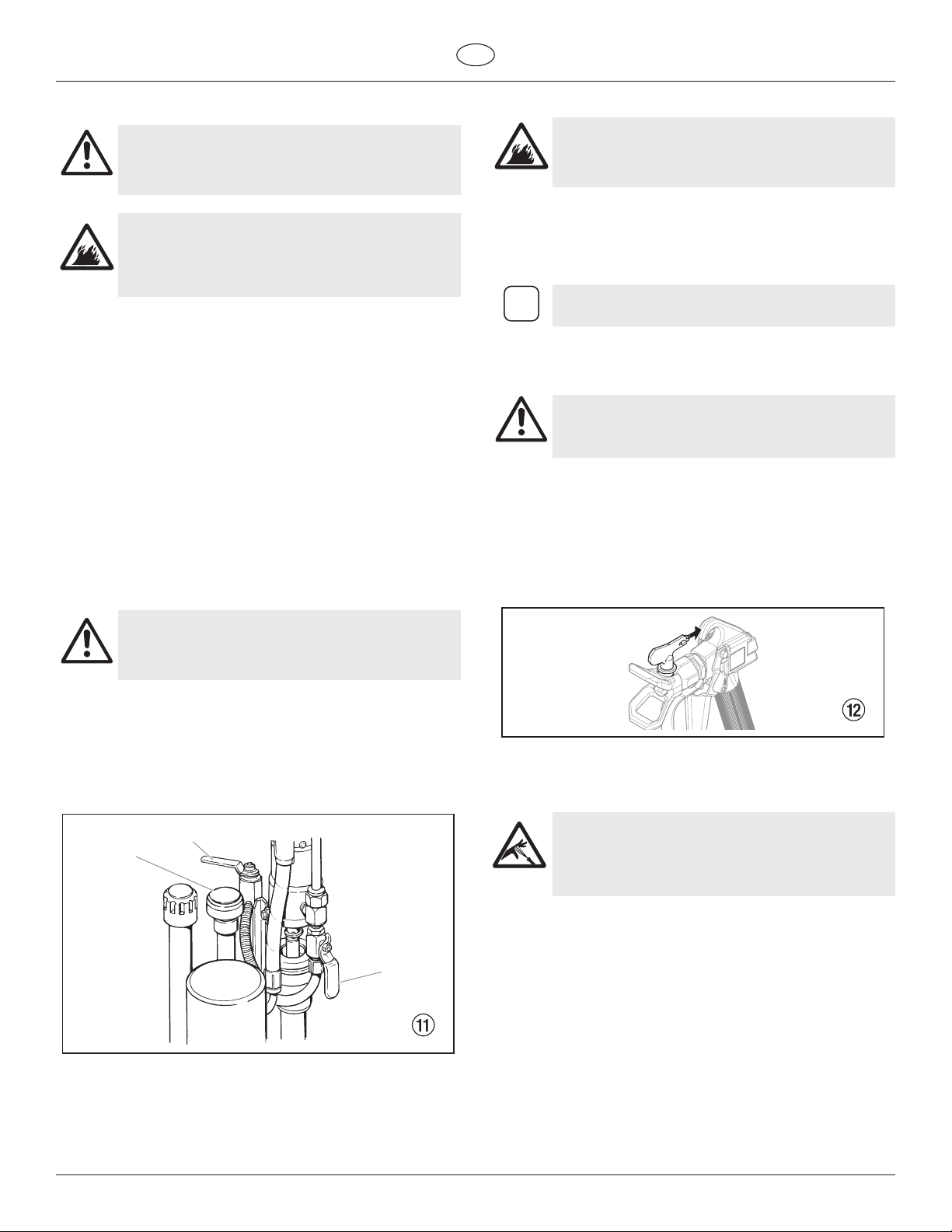

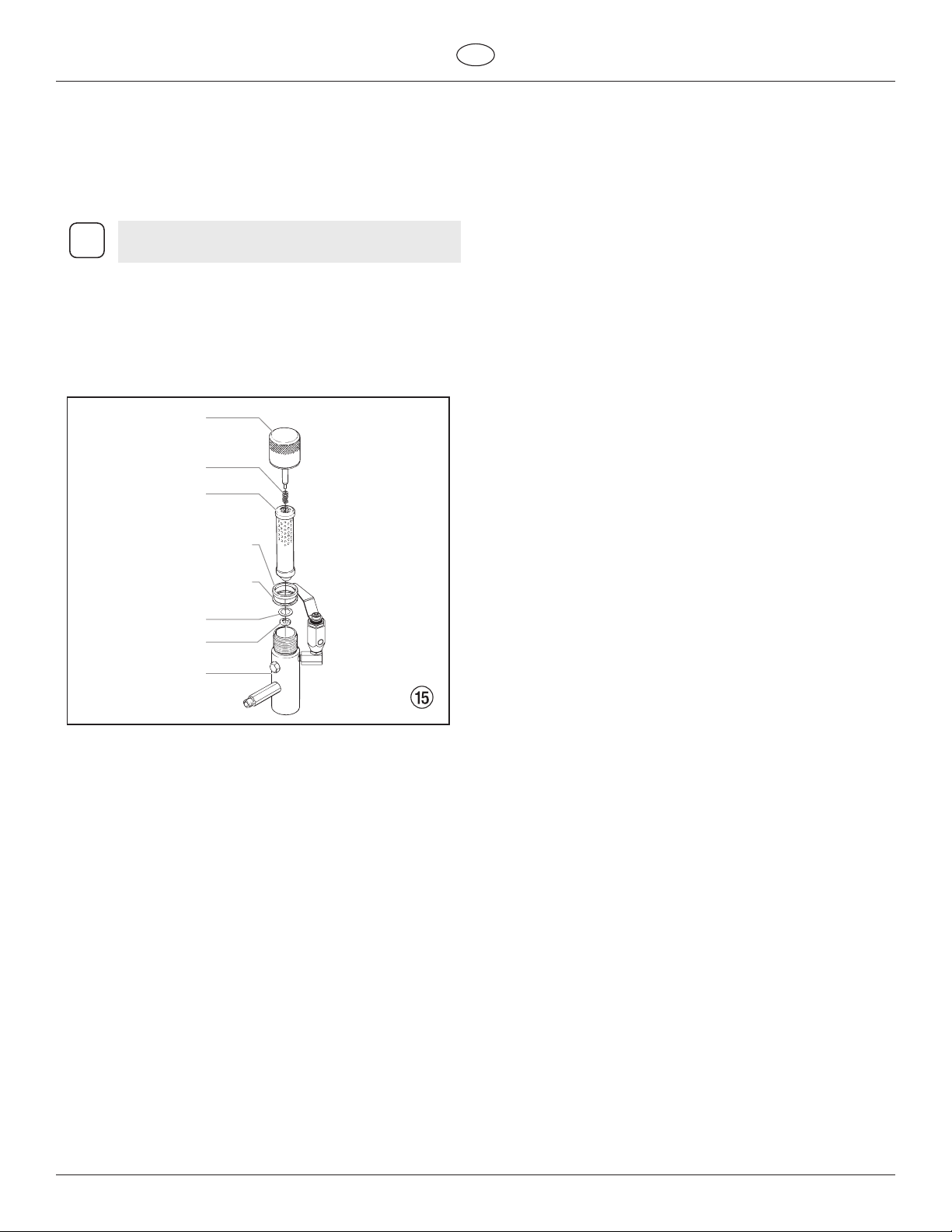

Cleaning (Fig. 15)

To clean the lter, perform the following procedure.

1. Follow the “Pressure Relief Procedure” found in the Operation

section of this manual.

2. Remove the lter cap assembly (1) and spring (2).

3. Pull the lter element with ball straight (3) out of the lter

body (4).

4. Clean inside the lter body, lter element with ball, and lter

cap assembly using the appropriate solvent.

Use care in handling parts as dirt, debris, scratches,

i

or nicks may prevent o-rings or gaskets from sealing.

This lter element lters from the inside out. Be sure

to clean the lter element thoroughly on the inside.

Soak in solvent to loosen hardened paint or replace.

1

1

Do not over-ll the reservoir so that it overows and

drips into the paint.

B) Cleaning the Filter Screen

1. The lter screen will clog and must be cleaned at least once a

day.

2. Loosen the hex nut (g. 14, item 1) that secures the lter

screen to the siphon tube.

3. Remove the lter screen (2) from the bottom of the siphon

tube.

4. Clean thoroughly with the appropriate solvent.

2

3

7

8

5

6

4

Inspection (Fig. 15)

Inspect all parts of the lter assembly before reassembly.

1. Inspect the ball inside the lter element. If the ball has

pressure cuts or scratches, replace the lter element.

a. If the ball is cut, remove the PTFE o-ring (5) using an o-ring pick

and remove the carbide seat (6).

b. Check the seat for nicks or grooves. If the seat is damaged,

replace.

Removal of the PTFE o-ring will damage the o-ring

and require replacement.

1

2

PowrTwin Plus 15

2. Remove the spring (2) from the spring guide on the lter cap.

a. Measure the length of the spring uncompressed. If it measures

less than 3/4” from end to end, replace.

b. Push the spring back onto the spring guide until it “snaps” back

into position.

3. Inspect the two PTFE gaskets (7,8) and the PTFE o-ring (5) for

deformity, nicks, or cuts. Replace, if needed.

The PTFE gaskets, PTFE o-ring, and spring are

packaged in Filter Service Kit P/N 930-050.

Page 18

Maintenance

i

Reassembly (Fig. 15)

After cleaning and inspecting all parts, reassemble the lter.

1. Place the carbide seat (6) into the lter body (4). Make sure

the beveled side of the seat is facing up.

2. Place the PTFE o-ring (5) into the groove on the outer

diameter of the carbide seat (6).

3. Place the lter element with ball (3) into the lter body (4).

The top and bottom of the lter element with ball

are identical.

4. Push the spring (2) back onto the spring guide of the lter cap

(1) until it “snaps” back into position, if not already done.

5. Place the thin PTFE gasket (8) onto the step at the top of the

lter body (4).

6. Place the thick PTFE gasket (7) onto the top of the thin gasket

(8).

7. Tighten the lter cap assembly (1) onto the lter body (4).

1

2

3

GB

7

8

5

6

4

16 PowrTwin Plus

Page 19

GB

Maintenance

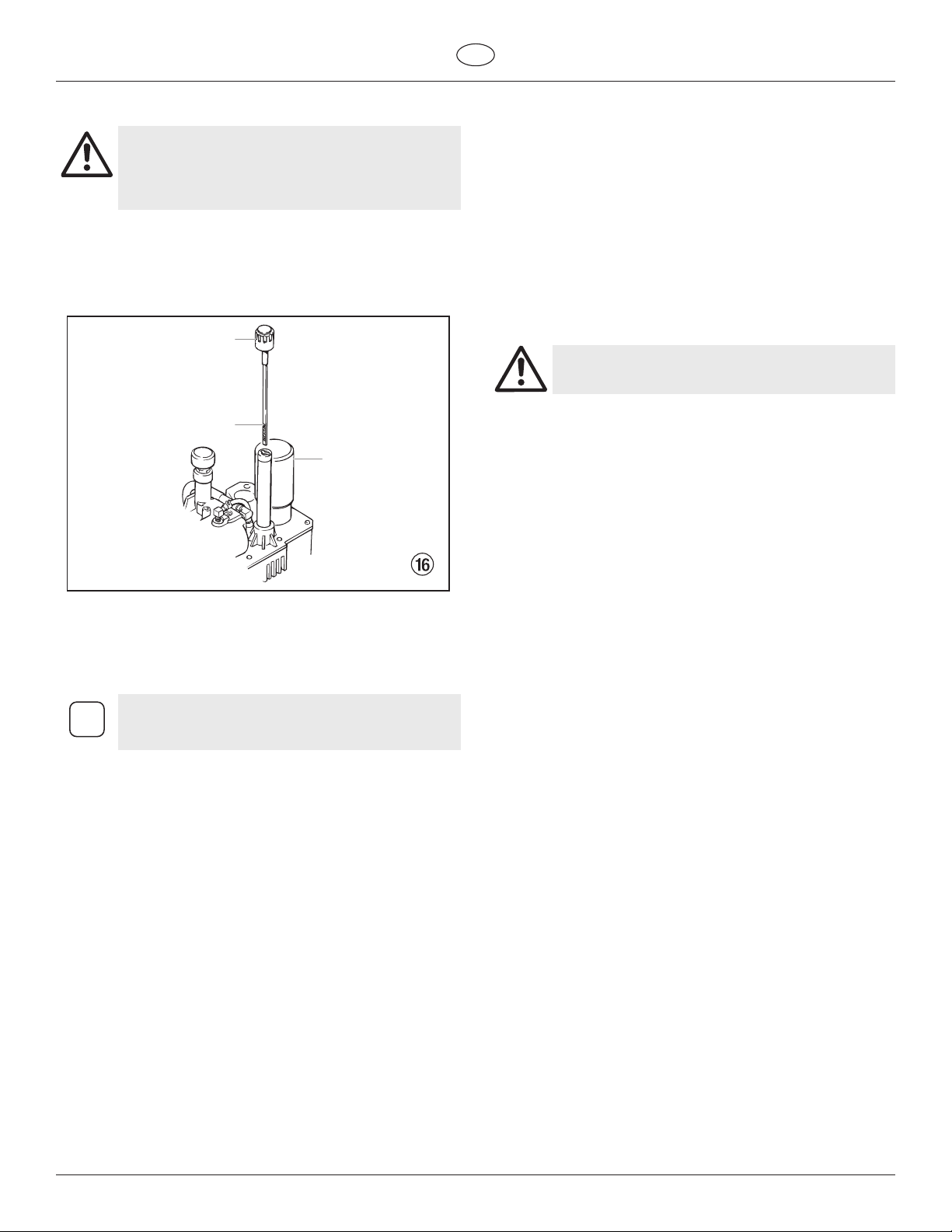

6.3 Maintaining the Hydraulic System

Use of Titan’s Coolflo™ Hydraulic Fluid is mandatory

in the PowrTwin Plus hydraulic system. Do not use

any other hydraulic fluid. Use of any other hydraulic

Attention

1. Check the hydraulic uid daily. It should be at the “Full”

fluid may seriously damage the hydraulic system

and will void the warranty.

mark (g. 16, item 1) on the dipstick (2). If it is low, add only

Titan Coolo™ Hydraulic Fluid (P/N 430-361). Never add

or change hydraulic uid except in a clean, dust-free area.

Contamination of the hydraulic uid will shorten hydraulic

pump life and may void warranty.

2

1

3

2. Change the hydraulic uid every twelve months. Drain the

old uid from the tank and ll with 6.25 quarts of hydraulic

uid. Start the sprayer at just enough pressure to operate the

uid section. Run the sprayer at this low pressure for at least

5 minutes. This removes air from the system. Check the uid

level after this procedure. Do not over-ll.

When replacing the hydraulic filter (3) during a

i

3. The hydraulic system has an external, replaceable hydraulic

4. The hydraulic pump should not be serviced in the eld. If

6.4 Maintaining the Fluid Section

If the sprayer is going to be out of service for an extended period of

time, it is recommended that following cleanup, a kerosene and oil

mixture be introduced as a preservative. Packings may tend to dry

out from lack of use. This is particularly true of the upper packing

set for which upper packing lubricant Piston Lube (P/N 314-480) is

recommended in normal usage.

If the sprayer has been out of service for an extended period of time,

it may be necessary to prime the pump with solvent. It is extremely

important that the threads on the siphon hose coupling are properly

sealed. Any air leakage will produce erratic operation of the sprayer

and may damage the system. The up and the down strokes should

be approximately equal in time (one should not be faster than the

other). A fast up or down stroke may indicate air in the system or

malfunctioning valve or seats (see the Troubleshooting section).

fluid change, it may be necessary to add up to one

additional quart of hydraulic fluid.

lter. Change the lter every twelve months.

service on the hydraulic pump is required, it must be returned

to Titan.

6.5 Basic Engine Maintenance (gas engine)

• For detailed engine maintenance and technical specications

refer to the separate gasoline engine manual.

• All service to the engine should be performed by a dealer

authorized by the engine manufacturer.

• Use a premium quality motor oil. 10W30 is recommended for

general all temperature use. Other viscosities may be required

in other climates.

• Use only a (NGK) BR-6HS (PT4900), or (NGK) BP6ES / BPR6E

spark plug (PT6900/PT8900/PT12000). Gap the plug to 0.028

to 0.031 In. (0.7 to 0.8 mm) Always use a spark plug wrench.

Daily

1. Check engine oil level, and ll as necessary.

2. Check gasoline level, and ll as necessary.

Always follow the fueling procedure outlined earlier

in this manual.

First 20 Hours

1. Change engine oil.

Every 100 Hours

1. Change engine oil.

2. Clean the sediment cup.

3. Clean and re-gap the spark plug.

4. Clean the spark arrestor.

Weekly

1. Remove the air lter cover and clean the element. In very

dusty environments, check the lter daily. Replace the

element as needed. Replacement elements can be purchased

from your local engine manufacturer dealer.

Engine Operation and Service

1. Clean and oil air lter pad on gasoline engine every 25 hours

or once weekly. Do not permit the air intake screen around

the y wheel of the gas engine to load up with paint or

trash. Clean it regularly. The service life and eciency of

the gas engine model depends upon keeping the gasoline

engine running properly. Change the oil in the engine

every 100 hours. Failure to observe this may result in engine

overheating. Consult the engine manufacturer’s service

manual provided.

2. To conserve fuel, service life, and eciency of the sprayer,

always operate the gasoline engine at the lowest RPM at

which it runs smoothly without laboring and delivers the

amount required for the particular painting operation.

Higher RPM does not produce higher working pressure. The

gasoline engine is connected to the hydraulic pump by a

pulley combination designed to produce full paint delivery at

maximum RPM.

3. The warranty on gasoline engines or electric motors is limited

to the original manufacturer.

PowrTwin Plus 17

Page 20

Maintenance

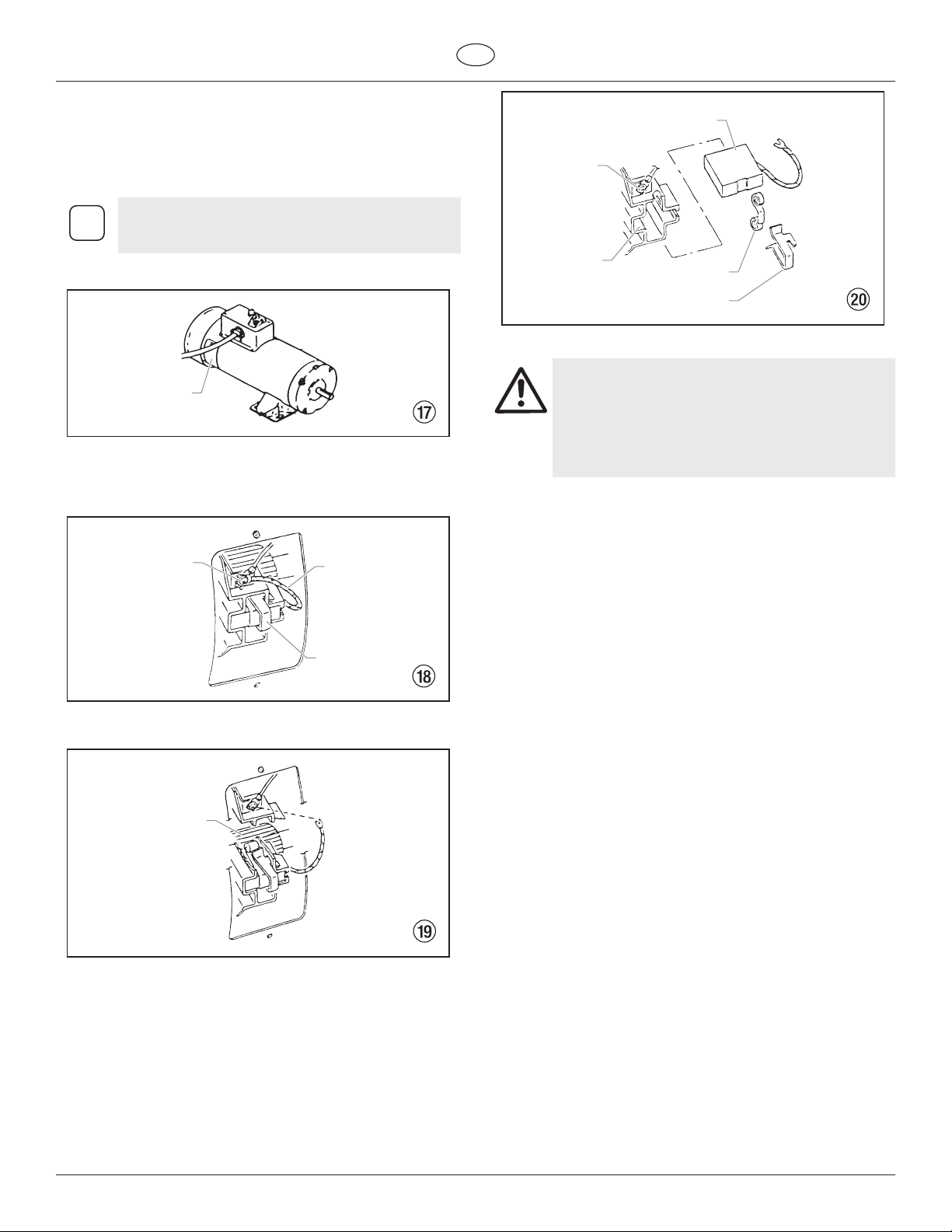

6.6 Replacing the Motor Brushes (optional 120V

electric motor)

The 120V electric Convertokit is available for separate purchase.

Perform this procedure using Motor Brush Kit P/N 978-050. The kit

consists of two brushes, two springs, and two clips.

Brushes should be replaced when they are worn to

i

1. Remove both inspection covers (1) on the motor.

less than 1/2 inch. Check and replace both brushes

at the same time.

1

2. Push in the spring clip (2) to unhook it, then pull it out.

3. Loosen the terminal screw (3). Pull the brush lead (4) away,

but leave the motor lead in place. Remove the brush and

spring.

GB

8

7

7. Reinstall both inspection covers.

If electric motor overloads and stops running,

IMMEDIATELY turn the motor off and follow

the Pressure Relief Procedure in the Cleanup

section of this manual. Wait until the motor cools

(approximately 30 minutes). Then push in the

bubble top, manual reset button, turn the motor on

and pressurize the system.

6

9

2

3

4

2

4. Inspect the commutator (5) for burning, excessive pitting or

gouging. A black color on the commutator is normal.

5

5. Install the new brush (6) so its lead slides in the long slot of the

brush holder (7). Push the terminal under the terminal screw

washer (8). Ensure the motor lead is still connected at the

screw. Tighten the screw.

6. Place the spring (9) on the brush (6) as shown above. Push

in and hook the spring clip (2). Repeat this procedure for the

other side.

18 PowrTwin Plus

Page 21

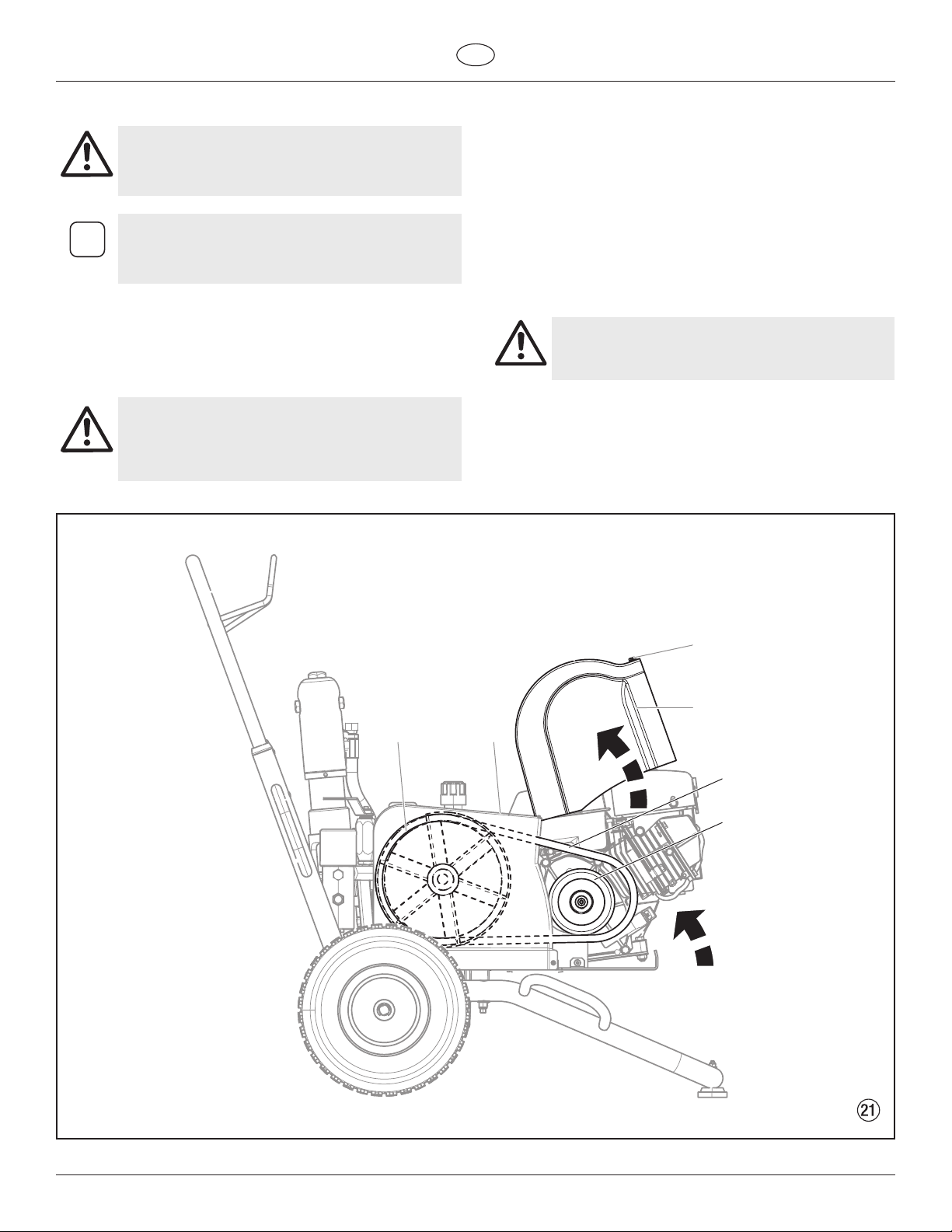

GB

Attention

Maintenance

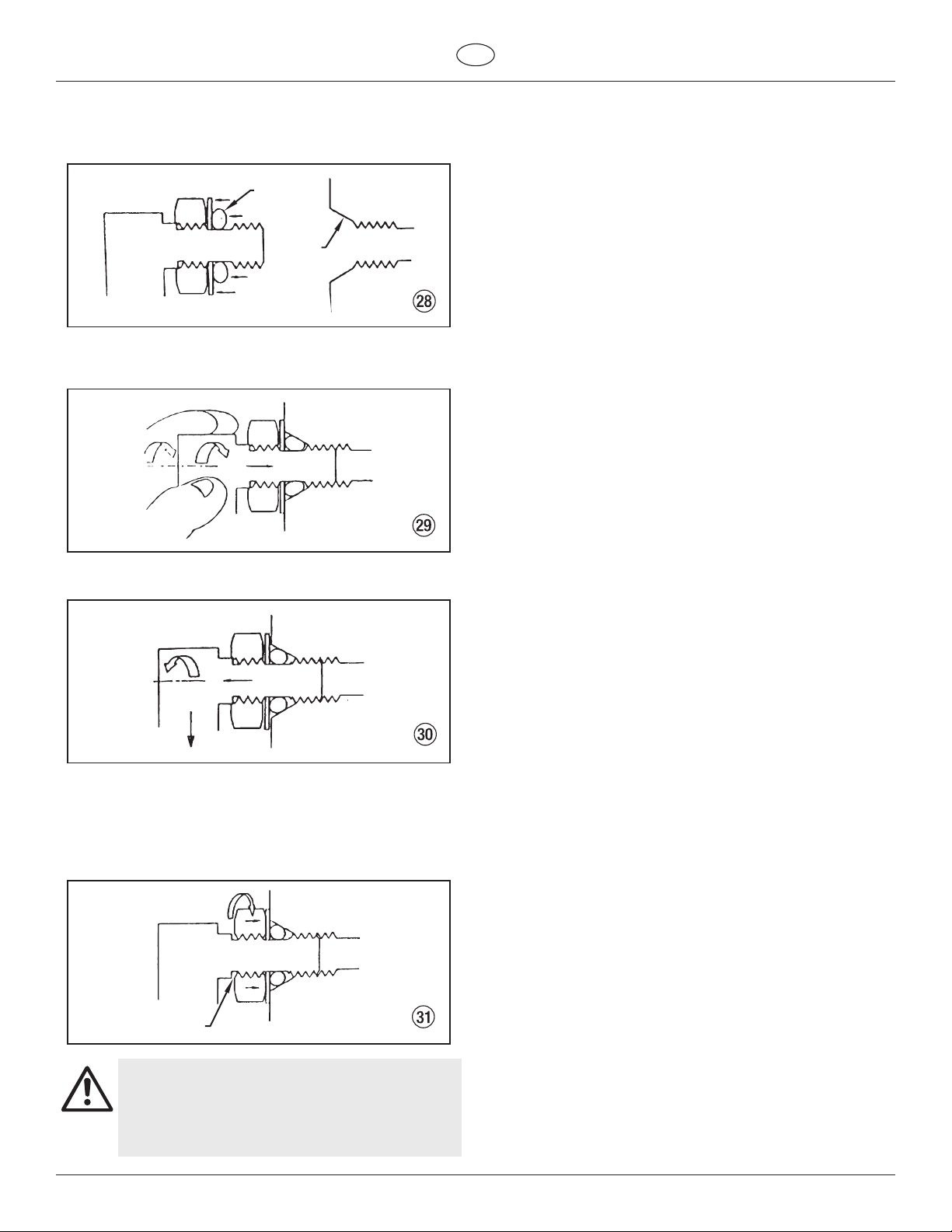

6.7 Replacing the Belt (Fig. 21)

Before replacing the belt on your unit, make sure

you have performed the “Pressure Relief Procedure”

as illustrated in the Operation section of this manual.

DO NOT attempt this repair while the unit is running.

The graphics below show a unit with a gas engine.

All instructions given in this section will apply to

i

both gas engine models and electric motor models

except where noted.

1. Loosen the bolt (1) on the front of the belt guard. Lift open

the front end of the belt guard (2) so that the front end of the

belt (3) is exposed.

2. Gently lift the front end of the gas engine / electric motor.

This will loosen the tension on the belt and make it easier to

remove.

PINCH HAZARD. Make sure your fingers remain clear

of the gas engine / electric motor mounting plate.

BURN HAZARD. Make sure the gas engine has had

time to sufficiently cool before touching it.

3. While the gas engine / electric motor is lifted up, remove the

belt from the front (4) and rear (5) pulleys.

4. Install the new belt:

a. Insert the belt into the xed section of the belt guard (6). Loop

the belt over the rear pulley (5) until the belt engages the

pulley groove.

b. Gently lift the front end of the gas engine / electric motor.

c. With the front end of the gas engine / electric motor lifted, loop

the other end of the belt around the front pulley (4).

d. Gently set the the gas engine / electric motor down. The

weight of the gas engine / electric motor will create tension in

the belt and prevent it from coming o.

Make sure the belt is not pinched or twisted in any

way once you have set the gas engine / electric

motor back into place.

e. Close the belt guard (2) and tighten the belt guard bolt (1).

5 6

1

2

3

4

PowrTwin Plus 19

Page 22

Maintenance

GB

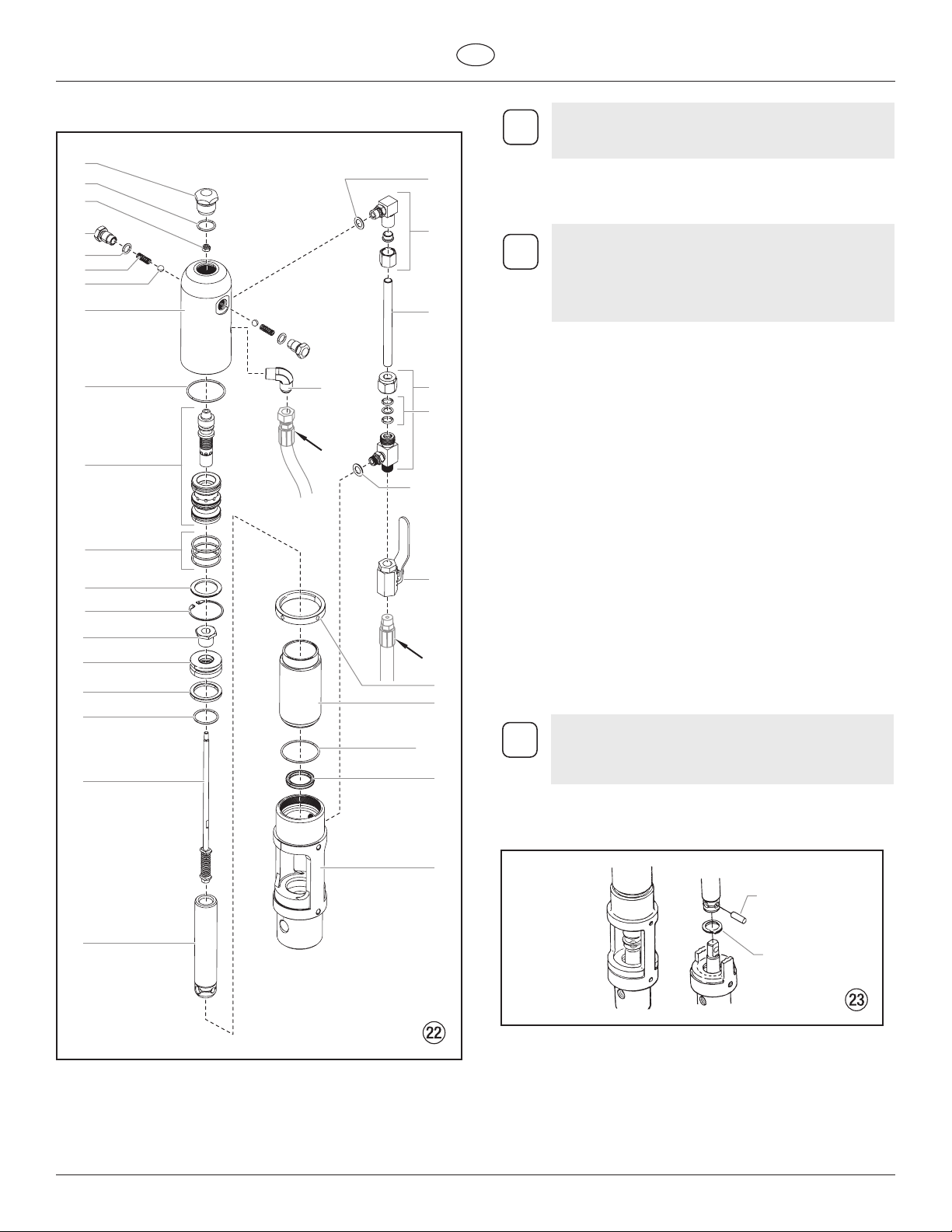

6.8 Servicing the Hydraulic Motor (Fig. 22)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

20

(A)

21

9

(B)

21

22

23

24

25

26

28

29

30

Refer to the ”SAE O-Ring Fitting Installation”

i

Perform this procedure using the necessary parts from Motor Service

Kit — Minor (P/N 235-050). If the hydraulic motor is operable, start

the machine and jog the piston rod (19) into its top position.

i

procedure at the end of this section for installation

instructions for item 22.

Servicing of the hydraulic motor should be carried

out in a clean, dust free area only. Any dust or

metallic particles left in the motor or entering it on

reassembly may damage the critical parts and aect

its service life and warranty. All parts should be

inspected for absolute cleanliness.

Disassembling the Hydraulic Motor

1. Disconnect the pressure hose assembly (B) from the elbow

(34 and 35 in Hydraulic System parts list) on the back of the

hydraulic pump.

2. Remove the two mounting screws and two lock washers (17

and 16, in Cart Assembly parts list) that attach the motor/

pump assembly to the cart.

3. Place the motor/pump assembly in a vise, holding it securely

by the motor/pump block (31).

4. Remove cylinder head plug (1).

5. Loosen lock ring (28) with a spanner wrench and unthread

tube retaining nut on tee (24). Loosen tube retaining nut on

elbow (22). Slide the nut down. Push motor tube (23) into tee

(24) far enough to clear elbow (22). Slowly unthread cylinder

head (8) and Iift it just high enough above the cylinder (29) to

reach the valve rod assembly (18) with vise grip pliers.

6. The piston rod (19) should be near the top of its stroke for

disassembly. It may be necessary to use a wood or nylon driver

to push the piston rod up to its top position.

7. Grip the valve rod securely with vise grip pliers and then

remove the FlexLoc nut (3) from the top of the valve rod

assembly (18). Be careful that spool (10) does not fall. The

cylinder head (8) can now be lifted o. Unthread the cylinder

(29) from the motor/pump block (31).

An extra lock ring (28) can be used to jam the two

i

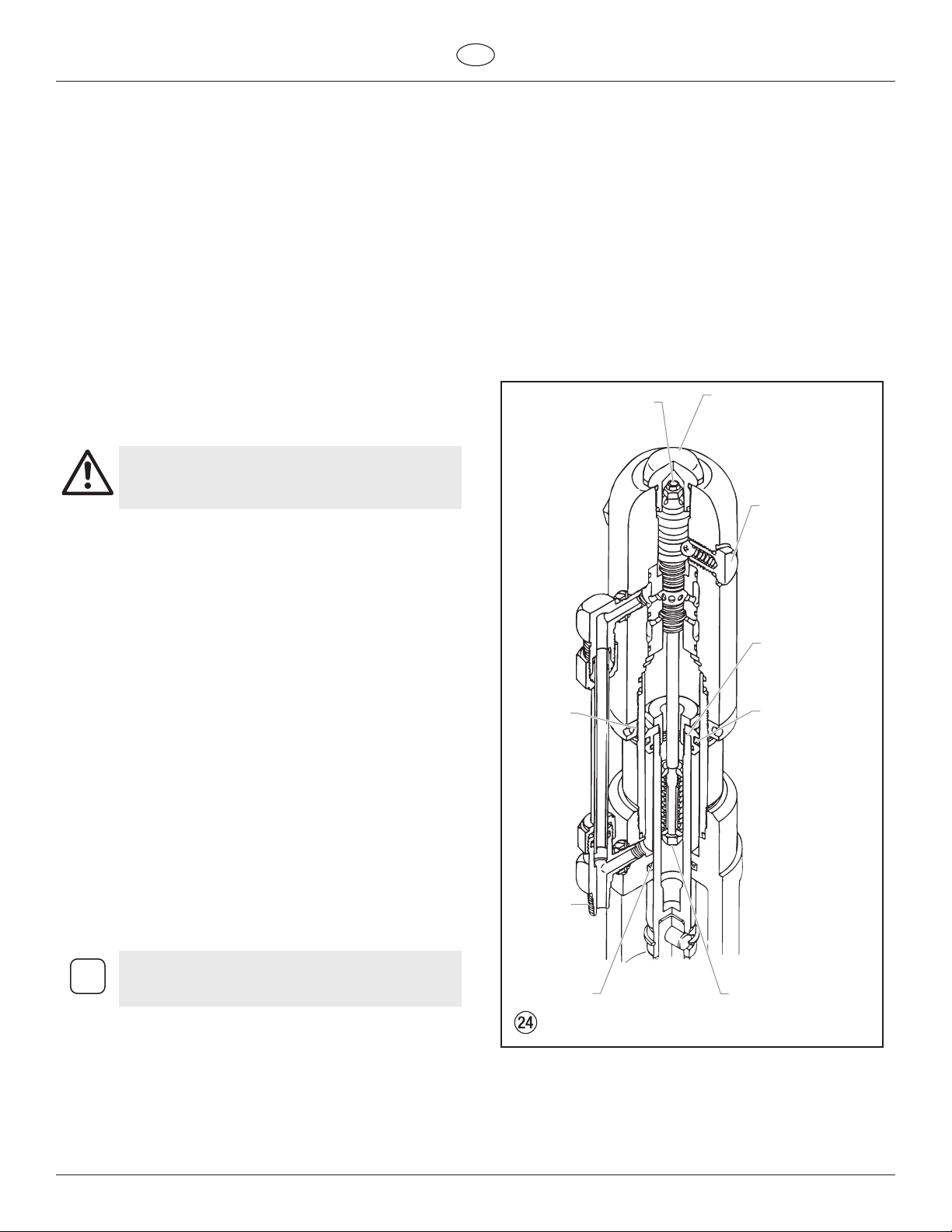

8. To remove the connecting pin (Fig. 23, 1), slide the retaining

lock rings together on the cylinder and a pipe

wrench can be used to unthread the cylinder (29)

from the motor/pump block.

ring (2) down with a small screwdriver, and then push the

connecting pin out.

31

1

19

9. Remove the piston rod assembly from the motor/pump block

(31).

10. Remove rod seal (30), being extremely careful not to scratch

the seal groove in the motor/pump block (31).

11. Place the piston retainer screw (14) on the piston rod assembly

in a vise. Slide a long bar through the hole at the base of the

piston rod for leverage, and unthread the piston rod from the

piston retainer screw.

12. Remove piston (19) and lift out valve rod assembly (18).

20 PowrTwin Plus

2

Page 23

GB

Attention

Maintenance

13. Remove piston seal (16) and o-ring (17).

14. Remove trip retainers (4), trip springs (6), and balls (7) from

cylinder head (8). Remove o-rings (5) from trip retainers.

15. Remove retaining ring (13) and sleeve retainer (12). Gently tap

spool/sleeve set (10) out of cylinder head (8) using a wood or

nylon rod.

16. Inspect piston rod (19) and cylinder (29) for wear, scratches,

and dents. Replace if damaged.

17. Inspect spool valve (10) for wear. Replace if necessary. spool

valve should move smoothly and freely with no force by

holding in a vertical position. If it does not, it can cause the

motor to stall.

Reassembling the Hydraulic Motor

1. Separate spool/sleeve set (10). Place o-rings (11) onto sleeve.

Lubricate o-rings with hydraulic oil. Gently push the sleeve

into cylinder head (8) with the atter side of the sleeve facing

out. Use a nylon rod to tap sleeve down until it reaches its full

depth. Do not use any other type of tool that might damage

or leave particles or residue on the sleeve. Install the spool

through the top of the cylinder head, down into the sleeve.

Do not use Piston Lube pump packing lubricant. It is

a solvent and will severely damage seals and O-Rings

of the hydraulic motor.

2. Install o-rings (5) on trip retainers (4). Install trip retainer balls

(7) followed by springs (6) which, when installed, will hold

spool/sleeve set (10) in proper place for assembly.

3. Install sleeve retainer (12) followed by retainer ring (13) into

cylinder head (8), which will hold valve sleeve in place. Install

o-ring (9) in the o-ring groove of the cylinder head.

4. Replace rod seal (30) in motor/pump block (31). Be sure the

open portion of the seal is facing upward (V). This seal requires

no special tool.

5. Place piston rod (19) in vise. Inspect valve rod assembly (18)

for any damage. Make sure the lock nut at the bottom of the

valve rod assembly is secure. DO NOT remove. Then, place into

piston rod as illustrated. Install o-ring (17), lubricating it well

and replacing piston (15) onto piston rod (19). Put one drop of

blue Loctite on the piston retainer screw (14). Tighten piston

retainer screw until piston is locked into place. Check valve rod

assembly for normal spring action at this time.

6. Install piston seal (16) with lips facing downward. Carefully

install o-ring (17). Expand the ring and stretch it suciently for

installation.

7. With motor/pump block (31) still in vise, install rod seal (30)

by pushing it towards its groove with a properly sized blunt

rod. Then complete installation with the ngers. No tool is

necessary. Do not twist the seal.

8. Pre-lubricate the piston and valve rod assembly with Coolo™

hydraulic uid (P/N 430-361). Install piston rod (19) into

motor/pump block (31) with a gently pushing and rotating

motion to work the piston rod in through the rod seal (30).

rod pass through the top of the spool/sleeve set (10). The

valve rod threads must be clean and free of oil. Place one drop

of blue Loctite on threads of ex lock nut (3) and thread nut

onto valve rod to full tight position (do not over-tighten) while

holding valve rod below with vise grip pliers.

13. Thread cylinder head (8) down onto the cylinder (29) and

then back o just enough to reassemble hydraulic ttings and

motor tube (23). Tighten lock ring with spanner wrench to

hold cylinder head in position.

14. The tee assembly (24) and the elbow (22) use an o-ring (25) to

seal on the outer diameter (O.D.) of the motor tube (23). The

O.D. of the motor tube should be free of scratches or sharp

edges. The lock nuts on these ttings rst should be hand

tightened, then wrench tightened another half turn.

15. Install o-ring (2) onto cylinder head plug (1). Tighten.

Hydraulic Motor Cut-Away

Torque ex locknut to

40 in./lbs. (4.5 Nm).

Use blue Loctite.

Use blue

Loctite on

lock ring.

Use

hydraulic

sealant.

Torque head plug to

15 ft./lbs. (22 Nm).

Do not over-tighten

o-ring seal.

Torque trip

retainers to

8 ft./lbs. (10.8 Nm).

Do not over-tighten

o-ring seal.

Torque piston

retainers to

40 ft./lbs. (55 Nm).

Use red Loctite.

Seal lip must

face down.

Inspect the bottom of piston rod (19) for nicks or

sharp areas that could damage the piston seal during

i

installation through the motor/pump block (31).

9. Replace the connecting rod pin and retainer ring.

10. Install o-ring (9) on cylinder wall. Lubricate ring and inner wall.

With the piston rod held rmly, the cylinder should be gently

driven over the piston seal with a rubber mallet. Tightly thread

the cylinder into motor/pump block (31).

11. Raise piston rod (19) to top position and thread lock ring (28)

all the way up on upper threads of cylinder (29).

12. Pull valve rod assembly (18) up as far as it will travel and grasp

it with vise grip pliers. Then install cylinder head (8), already

assembled, over valve rod until the top threads of the valve

PowrTwin Plus 21

Seal lip must

face up.

Valve rod assembly

is factory set and

permanently Loctited.

Do not disassemble.

Page 24

GB

Maintenance

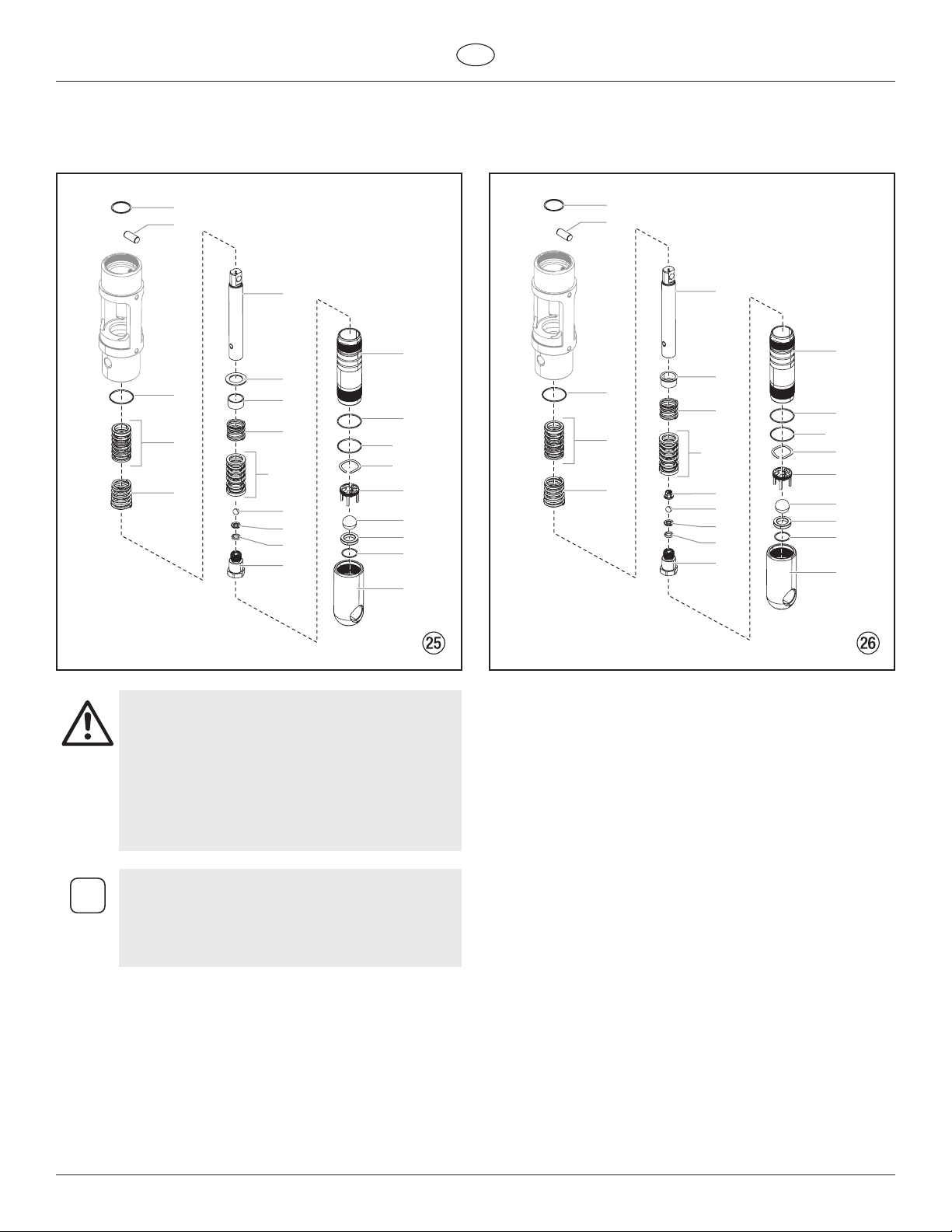

6.9 Servicing the Fluid Section

PT4900 Plus PT6900 Plus / PT8900 Plus / PT12000 Plus

1

2

6

14

7

3

4

5

8

9

4

10

11

12

13

15

3

21

16

17

18

19

20

1

2

6

14

7

3

8

4

5

4

9

10

11

12

13

15

3

16

17

18

19

20

21

Attention

i

Use of non-Titan service parts may void warranty.

Ask for original parts made by Titan for best services.

This pump should receive a routine servicing after

approximately 1,000 hours of use. Earlier servicing

is required if there is excessive leakage from the top

packing or if pump strokes become faster on one

stroke or the other. The use of Titan Piston Lube

(P/N 314-480) is recommended as an upper packing

lubricant. Do not substitute oil, water, or solvent for

an upper packing lubricant.

Numbers in parentheses refer to the item numbers

in the fluid section illustrations. If there are two

numbers, the first number represents the item

number for the PT4900 Plus and the second number

represents the item number for the PT6900 Plus /

PT8900 Plus / PT12000 Plus.

Disassembling the Fluid Section

1. Remove the siphon hose assembly. Unthread the foot valve

housing (20,21) and the pump cylinder (14) with a strap

wrench.

2. Slide the retainer ring (1) up with a small screwdriver, then

push the connecting pin (2) out.

3. Pull the displacement rod (6) through the lower cavity of the

motor/pump block.

4. Remove the PTFE o-ring (3), upper packing spring (5), and

upper packing set (4) from the motor/pump block.

5. Hold the displacement rod (6) in a vise by the ats at the top

of the displacement rod and remove the outlet valve housing

(13) with a wrench while holding the displacement rod

horizontal with wooden support, if necessary. Remove the

seal washer (12), outlet valve seat (11), outlet valve ball (10),

outlet valve cage (9, PT6900/PT8900/PT12000) lower packing

set (4), lower packing spring (9,8), sleeve (8, PT4900 only), and

spring retainer (7).

6. Using a 1/2” extension bar attached to a 1/2” drive ratchet,

insert the end of the extension bar into the square opening

of the foot valve cage (16,17) inside the foot valve housing

(20,21). Unscrew and remove the foot valve cage along with

the wave washer (21,16) from the foot valve housing.

7. Remove the PTFE o-ring (3), foot valve ball (17,18), foot

valve seat (18,19), and seat o-ring (19,20) from the foot valve

housing (20,21).

8. Remove the o-ring (15) from the pump cylinder (14)

22 PowrTwin Plus

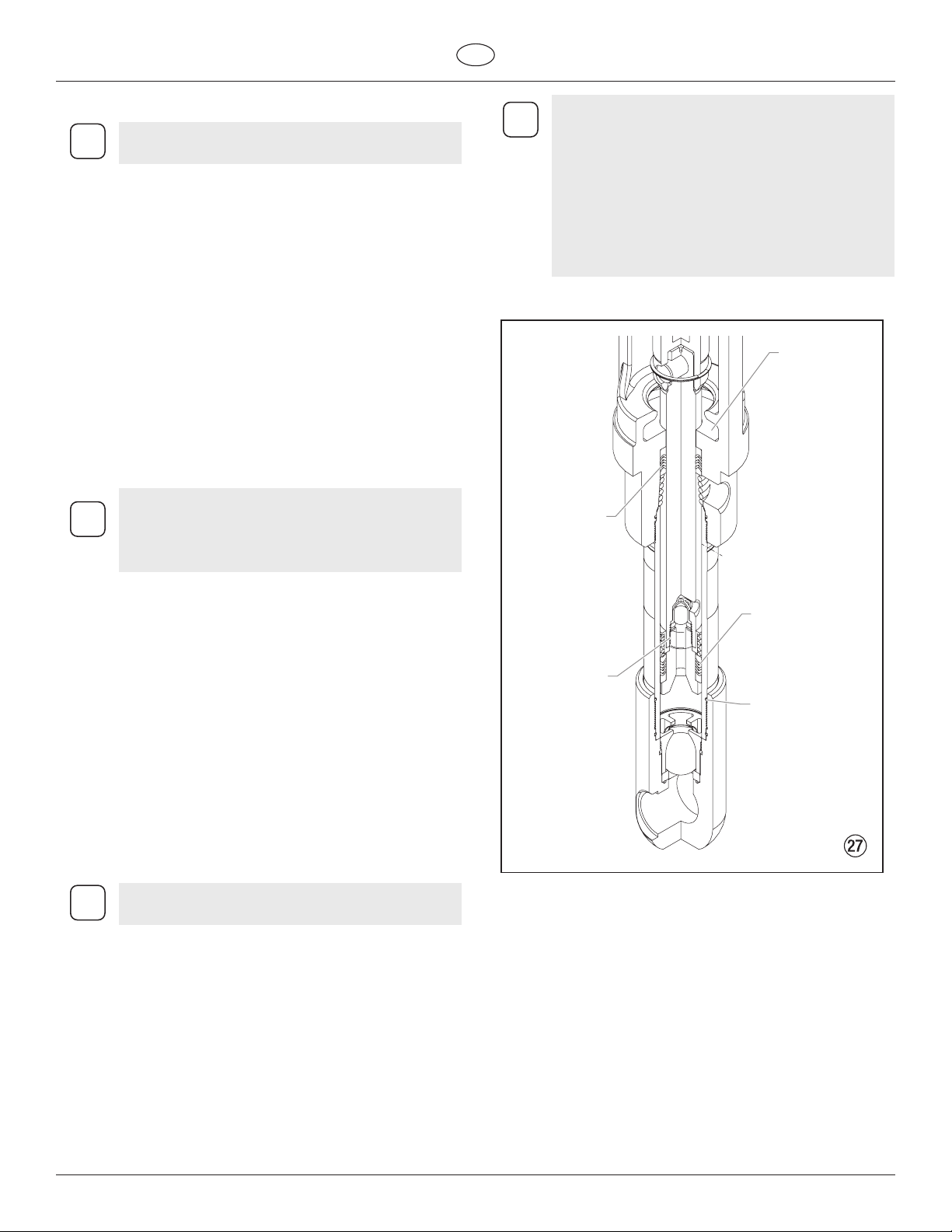

Page 25

GB

i

i

Maintenance

Reassembling the Fluid Section

Use PTFE tape on all threaded pipe connections.

1. Place a new seat o-ring (19,20) into the groove in the bottom

of the foot valve housing (20,21).

2. Inspect the foot valve seat (18,19) for wear. If one side is worn,

ip the seat to the unused side. If both sides are worn, install a

new seat. Place the new or ipped seat (worn side down) into

the bore at the bottom of the foot valve housing (20,21).

3. Place a new foot valve ball (17,18) onto the foot valve seat

(18,19). Using a 1/2” extension bar attached to a 1/2” drive

ratchet, insert the end of the extension bar into the square

opening of the foot valve cage (16,17) and screw the foot

valve cage into the foot valve housing (20,21). Torque the

cage to 240 in./lbs. (20 ft./lbs.).

4. Place the wave washer (21, 16) on top of the foot valve cage

(16,17).

5. Insert a new PTFE o-ring (3) into the groove of the foot valve

housing (20,21). Lubricate the o-ring using oil or grease.