Page 1

ADVANCING

SPRAY

TECHNOLOGY

DO

Owners

EPI[690gx

FOR

313=389

NOT USE EQUIPMENT BEFORE READING THIS SECTiON

PROFESSIONAl

USE

Mam1a~

ONlY

WARNING

HIGH PRESSURE SPRAY

CAN CAUSE SERIOUS INJURY,

Maximum Working Pressure 3000 psi, 210 BAR

An airless spray gun requires that fluid be introduced to it at very high pressure. Fluids under high pressure, from

spray or

and properly treated, the injury

disability

airless spray equipment.

SIMPLE CUTI

leaks,

can

penetrate the skin

or

amputation of the wounded part. Therefore, extreme caution must be exercised when using any

IF YOU ARE INJECTED, SEE A PHYSICIAN IMMEDIATELY.

and

inject substantial quantities of toxic fluid into the body. If not promptly

can

cause tissue death or gangrene and may result

in

serious, permanent

DO

NOT TREAT

REV

AS

1/93C

A

NOTE TO PHYSICIAN: Injection

surgically as soon as possible.

coatings injected directly into the blood stream. Consultation with a plastic surgeon or a reconstructive hand

surgeon may be advised.

1) Handle the spray gun carefully. NEVER point the gun at yourself or anyone else. NEVER permit any part

of your body to come

gun trigger safety lever

2)

NEVER attempt to force the flow of fluid backward through the gun with your finger, hand or hand-held ob-

ject

against the gun nozzle. This is NOT

3)

NEVER attempt to remove tip, disassemble or repair equipment without first doing the following:

PRESSURE RELEASE PROCEDURE

A. Set trigger safety

B. Shut off pump and unplug electrical cord.

C. Release fluid pressure from entire system and trigger gun.

D.

Reset trigger safety in a locked position.

4)

Before flushing system, always remove spray tip and adjust fluid pressure to lowest possible setting.

5)

Tighten all fluid connections before each use. NEVER exceed 3000 psi with this unit. Make sure that all accessory hoses, connections, swivels and

exceed the pressure rating of any component

6)

WARNING: The paint hose can develop leaks from wear, kinking, abuse, etc. A leal(

fluid into the

hose with any part of your body, adhesive tape or any other makeshift device.

spray hose, instead replace it with a new grounded hose. Use only with hoses that have spring guards.

NEVER use less than 50' of hose with this unit.

7)

Be

sure that the airless equipment being used and the object being sprayed are properly grounded to prevent static discharge or sparks which could cause fire or explosion. WARNING: ALWAYS hold the gun

against metal container when flushing system with tip removed,

8)

ALWAYS keep the working area around the pump well ventilated. Additionally, the pump itself should be a

minimum of

explosion with certain materials.

and warnings. Never spray flammable material near open flames, pilot lights or any source of ignition.

9)

ALWAYS wear spray masks and protective eyewear while spraying. Additional personal protective equipment may be required depending

Always contact supplier of material for recommendation.

1

0)

Keep all extension poles clear of electrical wires.

11) NEVER alter

12) NEVER leave equipment unattended. Keep away from children or anyone not familiar with the operation

airless equipment.

sldn, therefore the

25'

from the spray area. If these instructions are not followed there is the possibility of fire or

or

modify any part of this equipment; doing

into the skin is a serious, traumatic injury. It is important to treat the injury

Do

not delay

in

contact with the fluid stream of either the gun or any hose leak. ALWAYS keep the

in

a locked position when not spraying. ALWAYS use a tip safety guard.

in a locl1ed

trea~ment

position.

so

paint

hose should be inspected before each use. NEVER attempt to plug a

ALWAYS follow the coating or solvent manufacturers safety precautions

on

the type of material being sprayed and conditions of ventilation.

to research toxicity. Toxicity

AN

AIR SPRAY GUN.

forth can withstand the high pressures which develop. NEVER

in

the system.

to

prevent static discharge.

so

could cause it to malfunction.

is

a concern with some exotic

is

capable

Do

not attempt to repair a

of

injecting

of

1

Page 2

REPAIR AND SERVICE

GENERAL REPAIR &

SERVICE NOTES

WARNING: Before proceeding,

Relief Procedure outlined

follow all other

injection

shock. Always

The

following tools are needed when repairing this sprayer.

Complete Tool Kit Available. Product

Phillips Screwdriver 3/8" Allen Wrench

Needle Nose Pliers

Adjustable Wrench

Rubber

1. Before repairing any part

instructions carefully, including all warnings.

2.

When

separate

CAUTION: Never pull

Pulling

wire.

warnings

injury,

injury

from

unplug

Mallet 1/8" Allen Wrench

Flatblade Screwdriver

disconnecting wires, use needle

mating

on

a wire could loosen the connector

the sprayer before servicing!

connectors.

follow

the Pressure

on

page

1.

Additionally,

to reduce the risk

moving

5/16" Allen Wrench

3/16" Allen Wrench

of

on

a wire to disconnect it.

the

parts,

No.

700-840

sprayer,

or

read

nose

of

electric

an

the

pliers

from

to

the

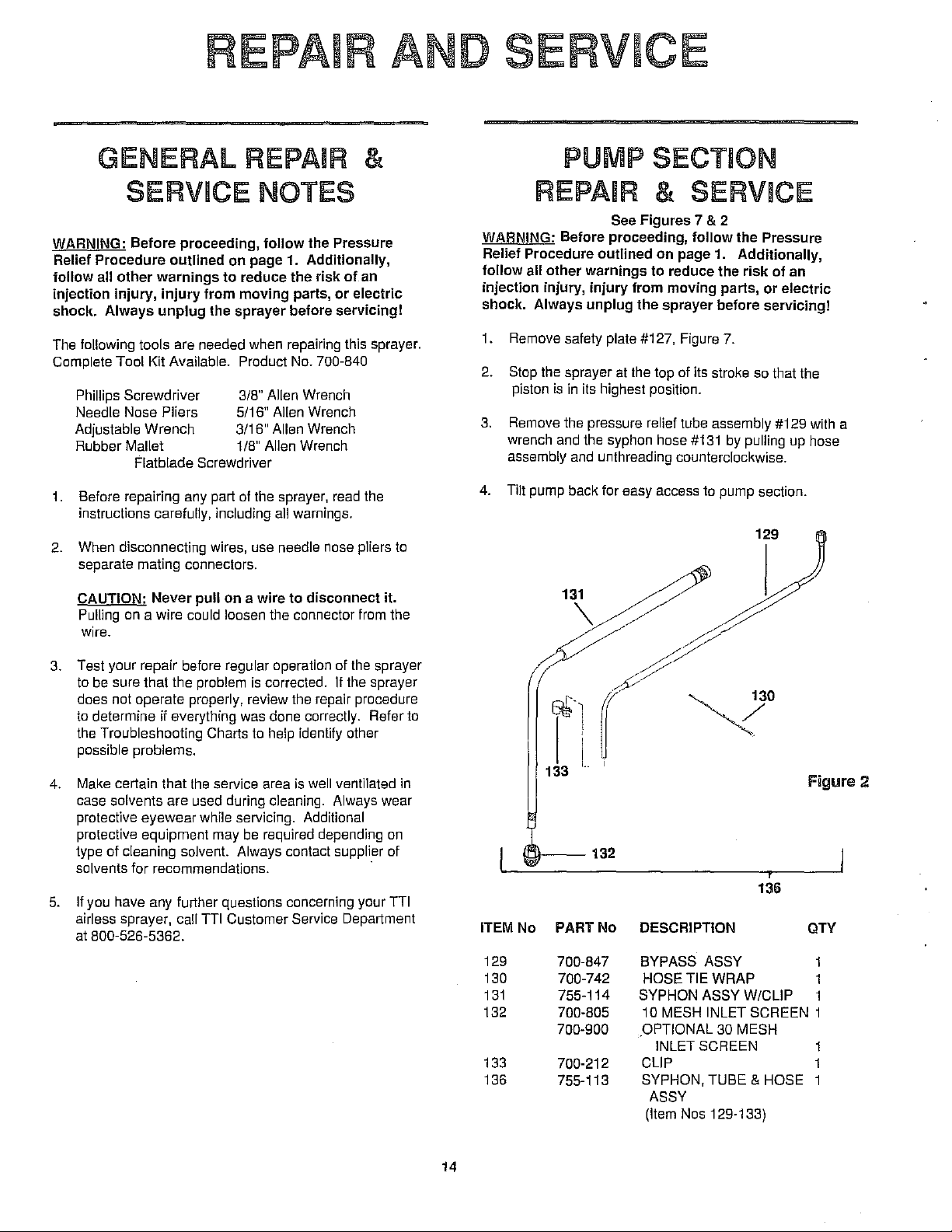

PUMP SECTION

REPAIR

WARNING: Before proceeding,

Relief Procedure outlined

follow all other warnings to reduce the

injection injury,

shock. Always unplug the sprayer before servicing!

1.

Remove safety plate #127, Figure

2. Stop

3.

4. Tilt pump back for easy access to pump section.

the

piston

Remove the pressure relief tube assembly #129

wrench

assembly

injury

sprayer at

is

in

its highest position.

and

the

syphon hose

and

unthreading counterclockwise.

& SERVICE

See Figures 7 & 2

follow

on

page 1. Additionally,

from moving parts,

the

top of its stroke

#131

the Pressure

risk

of

or

electric

7.

so

that the

by

pulling

129

an

up

with

hose

13~/

a

3. Test your repair before regular operation of

to

be

sure that the problem

does not operate properly, review

to

determine if everything

the

Troubleshooting Charts

possible problems.

Make

4.

5.

certain that

case solvents are used during cleaning. Always wear

protective eyewear while servicing. Additional

protective equipment may

type of cleaning solvent. Always contact supplier of

solvents

If

airless sprayer, call

at

for

you have

800-526-5362.

the

recommendations.

any

further questions concerning your

Til

is

corrected. If

the

was

done correctly. Refer to

to

help identify other

service area

be

Customer Service Department

is

required depending

the

repair procedure

well

ventilated

the

sprayer

sprayer

in

on

Til

//~

il(

133 I ·

!--132

ITEM No PART No DESCRIPTION

129

130

131

132

133

136

700-847

700-742

755-114

700-805

700-900

700·212

755-113

BYPASS ASSY

SYPHON ASSY W/CLIP 1

OPTIONAL

y

HOSE TIE

10

MESH

INLET SCREEN

CLIP 1

SYPHON, TUBE & HOSE 1

ASSY

(Item

WRAP

INLET SCREEN 1

30

Nos 129·133)

Figure 2

136

QTY

MESH

1

14

Page 3

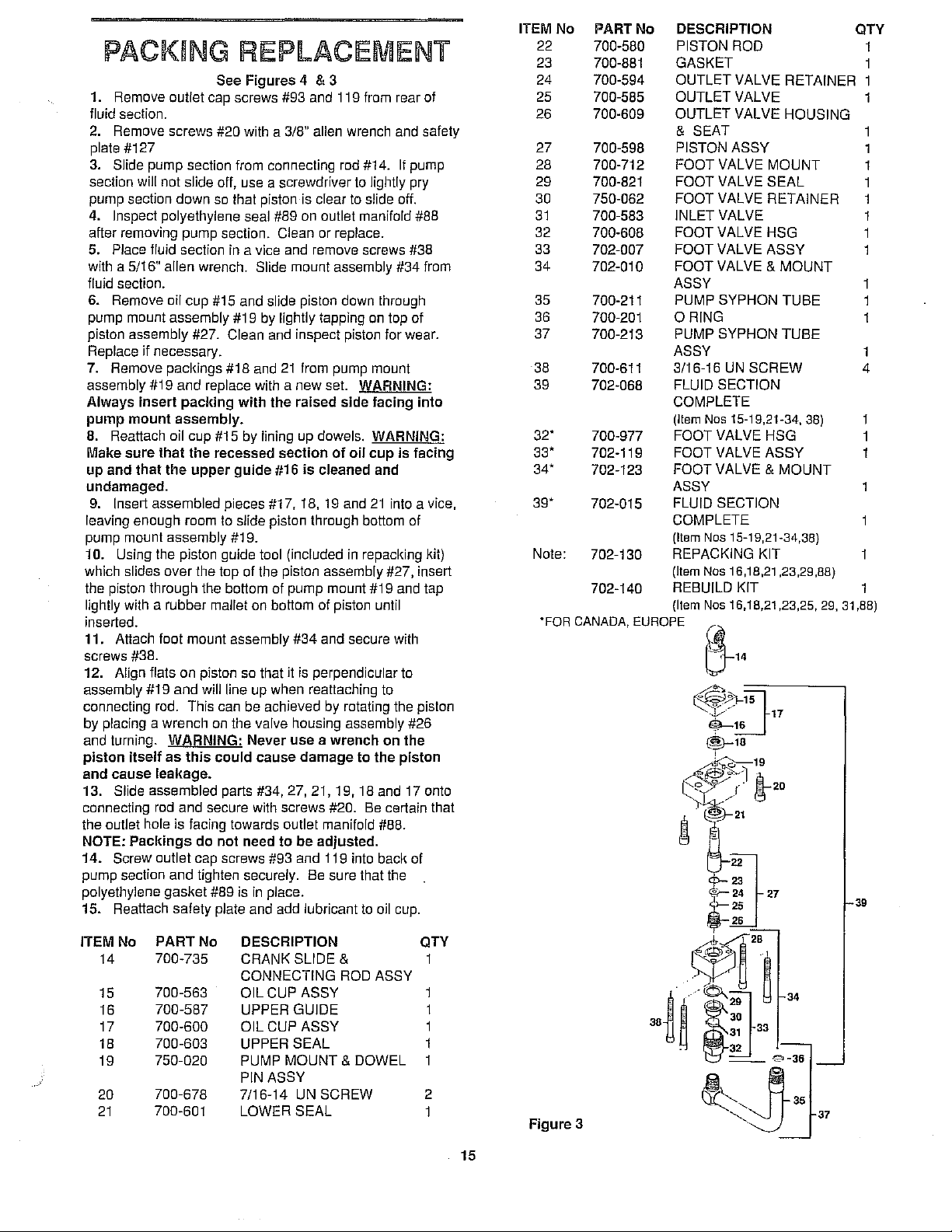

PACKING REPLACEMENT

See

Figures

1. Remove

fluid section.

2.

Remove screws #20 with a 3/8" allen wrench and safety

plate #127

3.

Slide pump section from connecting rod #14. If pump

section

pump section

outlet cap screws #93 and 119 from rear of

will

not

slide off, use a screwdriver to lightly pry

down

so that piston is clear to slide off.

4. Inspect polyethylene seal #89 on outlet manifold #88

after removing pump section.

5. Place

with a 5/16" allen wrench. Slide

fluid section.

6. Remove

pump mount

piston

Replace

fluid

section

oil cup #15 and slide piston down through

assembly #19 by lightly tapping on top of

assembly #27. Clean and inspect piston for wear.

if

necessary.

in

a vice and remove screws

7. Remove pacl<ings #18 and

assembly

Always

pump

8. Reattach oil cup #15 by lining up dowels.

Make

up

undamaged.

9.

leaving enough room to slide piston through bottom of

pump mount

10. Using the piston guide tool (included

which

the piston through the bottom of pump mount #19 and tap

lightly with a rubber mallet on bottom of piston until

inserted.

11. Attach foot mount

screws

12. Align flats on piston so that it is perpendicular to

assembly

connecting rod. This can be achieved by rotating the piston

placing a wrench on the valve housing assembly #26

by

and turning.

piston

and

13. Slide assembled parts #34, 27, 21, 19, 18 and 17 onto

connecting rod

the

NOTE:

14.

pump section

polyethylene

15.

1119

and

replace with a

insert

pacl<ing

mount

sure

and

Insert assembled pieces #17, 18, 19 and

slides

cause

outlet hole is facing towards outlet manifold #88.

Screw outlet cap screws #93 and 119 into

Reattach

assembly.

that

that

the

assembly #19.

over

1138.

1119

and

WARNING:

itself

as

leakage.

and

Pacl<ings

and

gasket

safety

the

this

with

recessed

upper

guide

the top of the piston assembly #27, insert

assembly

will line up when reattaching to

Never

could

secure with screws #20. Be certain that

do

not

need

tighten securely. Be sure that the

#89 is

in

plate and add lubricant to oil cup.

4 & 3

Clean or replace.

mount

21

from pump mount

new

set.

the

raised

section

1116

is

cleaned

1134

and secure with

use a wrench

cause

damage

to

be

adjusted.

place.

#38

assembly #34 from

WARNING:

side

facing

into

WARNING:

of

oif

cup

is

facing

and

21

into a vice,

in

repacking kit)

on

the

to

the

piston

bacl<

of

ITEM

No

PART

No

DESCRIPTION

22 700-580 PISTON ROD

23

24

25

26

27

28

29 700-821 FOOT VALVE

30

31

32

33

34

35

36

37

38

39

32"

33'

34"

39'

Note:

"FOR

700·881

700·594

700-585 OUTLET

700-609

700-598

700-712

750-062

700-583 INLET VALVE

700-608 FOOT VALVE

702-007

702-010

700-211 PUMP SYPHON

700-201

700-213

700-611 3/16-16 UN

702-068 FLUID

700-977 FOOT VALVE

702-119 FOOT VALVE

702-123 FOOT

702-015

702-130

702-140

CANADA,

GASKET

OUTLET

OUTLET

&

PISTONASSY

FOOT

FOOT

FOOT

FOOT

ASSY

ORING

PUMP

ASSY

COMPLETE

(Item

ASSY

FLUID SECTION

COMPLETE

(Item

REPACKING KIT

(Item

REBUILD KIT

(Item

EUROPE

SEAT

VALVE

VALVE

VALVE

VALVE &

SYPHON

SECTION

Nos

VALVE &

Nos

Nos

Nos

~14

VALVE RETAINER 1

VALVE

VALVE

15-19,21·34, 38)

15-19,21·34,38)

16,18,21 ,23,29,88)

16,18,21 ,23,25, 29.

HOUSING

MOUNT

SEAL

RETAINER

HSG

ASSY

MOUNT

TUBE

TUBE

SCREW

HSG

ASSY

MOUNT

31

QTY

1

1

1

1

1

1

1

1

1

1

1

1

4

,88)

39

ITEM

14

15

16

17

18

19

20

21

PART

No

No

700-735

700-563

700-587

700-600

700-603

750-020

700-678

700-601 LOWER

DESCRIPTION

CRANK

CONNECTING

OIL

UPPER

OIL

UPPER

PUMP

PIN

7/16-14 UN

SLIDE

CUP

ASSY

GUIDE

CUPASSY

SEAL

MOUNT & DOWEL

ASSY

SCREW

SEAL

QTY

& 1

ROD

ASSY

1

1

1

1

2

1

15

Figure

3

Page 4

SERVICE I REPLACEMENT

OF CLUTCH ASSEMBLY

See Figure 4

WARNING: Before proceeding, follow the Pressure

Relief Procedure outlined on page 1. Additionally,

follow all other warnings to reduce the

injection injury, injury from moving parts, or electric

shoe!<.

Removal of Clutch Plate Assembly

Always unplug the sprayer before servicing!

1. Remove engine/motor assembly #81 by removing allen

screws

#54.

2. Slide fan assy #73 and clutch plate #72 from engine.

3. Inspect clutch plate #72 and clutch rotor assy

wear. Replace if necessary.

Removal of Clutch Rotor Assembly

Follow steps 1-3 and remove rear mounting bolts #92

4.

and 93 from rear of fluid section.

5. Remove front cover #41 and (4) socket head screws

#42

located

in

pump housing assy #43.

6. Slide entire pump housing assy #43 from motor housing

assy #53.

Remove crank shaft

7.

from motor housing assy.

#45

and output pinion assy #48

8. Remove snap ring #51 from clutch rotor assy #67 and

slide rotor assy

Removal of Clutch Coil Assembly

#67

from housing assy #53.

9. Follow steps 1-8 and remove switch cover plate #60.

Disconnect wires from clutch starter #58

1 0.

clutch starter.

11.

Remove (4) screws #51 from coil assy #65 and slide

assy from motor assy #53.

12. To reassemble, reverse the procedures described

above.

ITEM No

40 700-653

41

42

43 750-008

44

45

46

47

48

49

50

51

52 750-015

53

PART

No

DESCRIPTION

SCREW 10

700-562

COVER

700-681 SCREW

PUMP HSG ASSY 1

700-680

730-360

730-088

700-688

THRUST WASHER

CRANK SHAFT

THRUST WASHER

THRUST WASHER

730-167 OUTPUT PINION ASSY

700-514

730-144

750-016

755-115

THRUST WASHER 1

SNAP RING 1

SNAP RING 1

BALL BEARING 1

MOTOR HSG ASSY 1

54 730-148 SCREW 4

56 710-127

57

58

59

60

61

730-145

730-060

730-146

710-147

700-748 SWITCH

SETSCREW

SCREW 2

CLUTCH STARTER 1

5 AMP FUSE 1

SWITCH COVER PLATE 1

TO

WIRE

risl<

of an

#67

for

as

indicated on

QTY

STARTER 1

1

4

1

1

1

1

1

1

ITEM No PART No DESCRIPTION

62 700-646

63 700-775

64

700-645 RUBBER BOOT

65 730-149

TOGGLE SWITCH

ON/OFF PLATE

COILASSY

66 730-150 SCREW

67 730-152 CLUTCH ROTOR ASSY

68 730-151 ELECTRICAL CONNECTOR

69 730-155 THRUST WASHER

70

71

72

730-154 THRUST BEARING

730-153

THRUST WASHER

RETAINER

730-140 CLUTCH PLATE ASSY

73 730-157 CLUTCH FAN ASSY

74

75

730-184

ELECTRICAL CONNECTOR

750-051 SCREW

76 750-086 ENGINE MOUNT

(Incl. 78,79)

77

78

750-018 SCREW

750-043 ENGINE OIL SEAL

79 750-044 ENGINE BEARING

80 750-042 GASKET

81

82

83

755-117

ENGINEASSY

(Incl. 74-80)

710-069 PLUG

730-006 MAXI FILTER HSG

84 730-083 FILTER SPRING

85 730-067 FILTER CARTRIDGE

86

87

88

730-018 FILTER CORE

730-005

702-081

FILTER GASKET

FILTER

HSG

89 700-804 PUMP OUTLET GASKET

90

91

730-195 3/8" PLUG

490-006 1/4" NIPPLE

92 700-685 SOCKET HEAD SCREW

93

94

700-681 CAP HEAD SCREW

700-699 PRESSURE RELEASE

FITIING

95 755-135 CLIP

96 225-002 SCREW

97 700-537 GASKET

98

99

100

101

102

103

104 700-698

105

106 700-731

107

108

109

110

111

112

113

114 700-499

115

116

221-012

0-RING

222-012 0-RING

700-755

700-721

700-752

700-706

700-705

700-754

700-759

700-697

700-757

BY-PASS

0-RING

BY-PASS VALVE STEM

WASHER

SPRING

WASHER

BY-PASS VALVE

RETAINER

BY-PASS CAM BASE

DOWEL

BY-PASS VALVE HANDLE

BY-PASS VALVE ASSY

(Item Nos 97-109)

HSG

PIN

700-784 SCREW

700-771 ADJUSTMENT KNOB

710-049 PRESSURE CONTROL

0-RING

700-483

GASKET 1

730-172 CLUTCH SEAL

117 730-165 GROUND WIRE 1

OTY

1

1

1

1

4

1

2

1

1

1

1

1

1

6

1

2

1

1

2

1

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

2

1

1

1

1

2

1

1

1

1

16

Page 5

"'

43

110

17

ITEM No

118

119

121

122

125

126

127

PART No

730-158

730-234

702-082

730-261

730-223

700-841

700-791

DESCRIPTION

QTY

DIPSTICK

SCREW

FILTER BLOCK ASSY

(Excludes Item Nos 92,119, 93,89)

THRUST WASHER ASSY 1

(Item Nos 69,70,71,125)

THRUST WASHER

INSULATOR JACKET

SAFETY

PLATE

1

1

1

1

1

1

Page 6

SERVICE /REPLACEMENT

OF INLET

See Figure 3

1. Remove lower foot valve and mount assembly #34

removing screws

2. Place lower valve mount assembly

remove foot valve assembly

3. Remove valve retainer #30 and inlet valve #31. if

unable to remove, unscrew pump syphon tube assembly

#37

and poke valve and retainer free

housing assembly

hammer

4. Clean and inspect valve #31, reverse or replace if

showing wear or damage. Rubbing lightly

sandpaper can remove any dried paint.

5. Clean valve housing assembly #32, check for wear or

damage. Replace if necessary.

6. Reattach fool valve assembly #33 to #28 and secure

tightly with a wrench. Reattach syphon tube assembly

if

#38

#32, using screw #38. Tap screw with a

necessary.

with

VALVE

a 5/16" allen wrench.

#34

in

a vice and

#33 with a wrench.

Jrom

bottom of

on

fine

by

#96.

tighten securely with a wrench.

washers

lubricate with grease. Line up cam

#88.

handle

pin

#105 and 103 are properly

7. Install bypass cam

8.

Using dowel pin, line up stem

#1

09. Secure handle with dowel pin

9.

Important:

on

cam

#1

07.

If

handle

Mal<e

sure that both

in

place.

#1

07 over bypass retainer

#1

07 with filter block

#1

02 with hole

#1

08.

#1

09 rotates 360 degrees, check

#1

on

SERVICE/REPLACEMENT

OF FILTER

See Figure 5

WARNING: Before proceeding,

Relief Procedure

follow

all

other

injection injury,

shock. Always

The

pump

after each use.

and

outlined

warnings

injury

unplug

gun

filter

from

the

should

follow

on page 1.

to

reduce the risl<

moving

sprayer

parts

before

be cleaned

the

Pressure

Additionally,

of

an

or

electric

servicing!

or

reolaced

06,

SERVICE/REPLACEMENT

OF UPPER (OUTLET)

VALVE

See Figure 3

1. To clean or replace upper valve, remove valve housing

assembly

pump. This

2. Remove valve retainer

and inspect along with housing

worn or damaged. Use fine sandpaper to remove dried

paint.

3. Reattach assemblies #32, #25 and #26

and secure tightly wit, 1 a wrench.

#26 while piston assembly

will prevent the piston from rotating.

#24

#27

is still attached to

and outlet valve #25. Clean

#26. Reverse or replace if

to

piston #22

SERVICE/REPLACEMENT

PRESSURE RELIEF

PRIME VALVE

See Figure 5

WARNING:

Relief

follow

injection

shock.

Before

Procedure

all

other

warnings

injury,

Always

proceeding,

outlined

injury

unplug

on

to

from

the

follow

page

1.

reduce the

moving

sprayer

before

the

Pressure

Additionally,

risk

of

parts

or

electrical

servicing!

an

NOTE: If

blockfiller, remove

PUMP

1. Unscrew filter housing #83.

2.

3.

4.

GUN

WARNING:

in high pressure

your

release the

damaged

Replacement

1.

First pull down

away from handle.

2.

Unscrew handle

3.

Unscrew filter

(NOTE: Left handed thread, turn the filter clockwise to

remove.)

4.

Screw new or cleaned filler into the head. (Turn counter

clocl<wise.)

5.

Reattach handle to head and secure safety trigger

guard.

wood

spraying

Fll

Remove filter cartridge #85. Clean or replace.

Inspect seal #87. Clean or replace.

Reattach filter housing #83. Secure with a wrench.

Fll

Follow

spray

gun

trigger,

or

dirty

(NOTE: if filter

screw

to

heavy-bodied materials

all

filters

from

TEFI

TER

or

remove.)

--See

Figure 5

--

all safety precautions as

warning

leaks

and

Removal

on

Jrom

from

section before proceeding.

or

spits

at

the

the

needle

must

trigger safety guard and swing

spray head.

breal<s

or

be

replaced

of

Filter:

spray head.

off

in

such

system.

described

tip

when

you

seat

is

worn

or

or

cleaned.

the head, use a small

-~

as

If

1. Remove dowel

#109. Push out pin as shown

2.

Remove handle

3.

Using a wrench, loosen bypass housing

unscrew.

bypass valve stem #1 02.

5.

bypass housing

Inspect D-Ring

6.

assembly into filter block except

Inspect

4.

Unscrew bypass valve retainer

Inspect ball on

When reinstalling, screw completely assembled

0-Rings

#1

00.

#1

01.

pin

#1

08 from bypass valve handle

in

Figure 5.

#1

09 and bypass cam #107.

#99 and 98.

#1

06 and remove

end

of

stem

#1

02 and seat, located

Clean or replace, if damaged.

#107, 109 and 108 and

#1

DO

and

in

18

Page 7

ITEM No PART No

PTFE

82 710-069

83

84

85 730-067

86

87

88

89 700-804

90

91

92 700-685

93 700-681

94

97 700-537

98

99 222-012

100

1

01"

102

103

104

105

106

107

108

109

11

0

113 761-140

114

115

119

121

730-006

730-083

730-018

730-005

702-081

730-195

490-006

700-699

221-012

700-755

700-721

700-752

700-706

700-698

700-705

700-731

700-754

700-759

700-697

700-757

700-499

700-483

730-234

702-082

700-897

700-890

DESCRIPTION QTY

PLUG 2

MAXI FILTER

FILTER SPRING 1

FILTER CARTRIDGE 1

FILTER CORE

GASKET

FILTER

PUMP OUTLET GASKET

3/8" PLUG

1/4" NIPPLE

1/4-20

UN

1/4-20

UN

PRESSURE RELEASE

FITIING

GASKET

0-RING

0-RING

BY-PASS

#005 0-RING

BY-PASS VALVE SYSTEM

WASHER

SPRING

WASHER

BY-PASS VALVE 1

RETAINER

BY-PASS

DOWEL

BY-PASS VALVE HANDLE

BY-PASS VALVE ASSY

PRESSURE CONTROL

0-RING

GASKET

1/4-20 UN SCREW

FILTER HSG ASSY

(Excludes

OPTIONAL TEFLON 1

0-RING

BY-PASS 0-RING TOOL

HSG

HSG

SCREW 2

SCREW 1

HSG

CAM BASE

PIN

llem

Nos

89,92,

93,11

2

9)

1

1

1

'

1

1

1

1

l_j

I

o'=---

L j b

-82

-83

,

-as

121

--88

0--89

110

I

I

91

! I

/

92

Figure 5 ,

19

Page 8

PRESSURE SWiTCH

REPLACEMENT

See Figure 6

WARNING: Before proceeding, follow the Pressure

Relief Procedure outlined on page 1. Additionally,

follow

all other warnings to reduce the risk of

injection injury, injury from moving parts or electric

shock. Always unplug the sprayer before servicing!

1. Remove head cap screws #93 and 119 from rear of fluid

section and bottom of filter block.

2.

Remove filter block #87.

3.

Remove switch cover plate #60, located near pressure

switch and disconnect two red wires from clutch starter #58.

4.

Remove screw

knob and slide knob off.

5.

Remove screw

housing #53 and using a

screw #56, until pressure switch

through. Feed electrical wires down at the same time.

6.

Insert new switch assembly #113 into housing while

carefully working the wires into the switch box. Using

needle

nose

7. Making sure that

tighten set screw #56 with a

switch assembly is secure. Reattach adjustment knob

#112.

B.

Inspect

properly

dowels.

sure that the pump outlet gasket #89 is properly

before installing filter block #88.

9.

Install switch plate #60.

10.

adjustment is required.

0-Rings

in

place, then install filter block #88 by lining up

Secure with screws #93 and 119. Note: Make

The pressure switch is factory calibrated so

#111

from pressure switch adjustment

#111

located

pliers,

reconnect

the

switch assembly is fully inserted,

#114 and 115 on switch assembly. If

on

side of gear box

1/8"'

allen wrench remove set

#113 is able to slide down

wires

to

motor

1/8'"

allen wrench until the

an

starter.

in

no

place

"'

ITEM No

53

54

56

57

58 730-060

59

60

61

62

63

64

82

83

84

85

86

87

PART

755-115

730-148

710-127

730-145

730-146

710-147

700-748

700-646

700-775

700-645

710-069

730-006 MAXI FIL TEA HSG

730-083

730-067

730-018 FILTER CORE

730-005

DESCRIPTION

No

MOTOR HSG ASSY

SCREW

SETSCREW

SCREW

CLUTCH STARTER

5 AMP FUSE

SWITCH COVER

SWITCH TO STARTER 1

WIRE

TOGGLE SWITCH 1

ON/OFF

RUBBER BOOT

PLUG

FILTER SPRING

FILTER CARTRIDGE

FILTER GASKET

PLATE 1

PLATE 1

1

2

1

1

1

1

1

QTV

1

4

1

2

1

1

20

Figure 6

PART

No

ITEM No

88

89

90

9t

92

93

94 700·699 PRESSURE RELEASE

111

112

113 761-140

114

115 700-483

119

121

126

702-081 FILTER HSG

700·804 PUMP OUTLET

730-195

490-006

700·685 SOCKET HEAD SCREW 2

700-681 CAP HEAD SCREW

700·784 SCREW

700-771 ADJUSTMENT KNOB 1

700·499

730·234 SCREW

702·082 FILTER BLOCK ASSY 1

(Excludes

700·841 INSULATOR JACKET 1

DESCRIPTION

GASKET

3/8'"

PLUG

1/4'"

NIPPLE

FITIING

PRESSURE CONTROL 1

0-RING

GASKET

Item

Nos

89,92,93,119)

QTY

2

2

1

1

1

Page 9

GEAR REPLACEMENT

See Figure 7

WARNING: Before proceeding,

Relief Procedure

follow

all

other

injury,

injury

Always

unplug

outlined

warnings

from

moving

the

sprayer

on

to

reduce

parts,

before

follow

page 1.

or

servicing!

the Pressure

Additionally,

risk

electric

of

an

injection

shock.

1. Remove safety plate

2. Remove front cover #41.

3. Remove mounting bolts #93 and 119, from rear of pump.

4.

Remove

housing

5.

Inspect gears beginning with crank shaft assembly #45.

Then output pinion gear #48.

6. Reassemble

reassembling, make sure that

that gears and bearings are

(4)

socket head screws #42 and slide pump

assembly #43 from gear box housing #53.

by

11127,

from front of pump.

reversing the above order. When

all washers are

properly lubricated.

in

place and

111

r

W®r"2

! 53

~~~·

6

/~

6,]

54

46

43

40

ITEM No PART

40 700-653

41

42 700-681

43

44

45

46

47 700-688

48

49

50

51

52 750-015 BALL BEARING 1

53 755-115

54

No

DESCRIPTION

SCREW 10 56

700-562

750-008

700-680

730-360 CRANK

730-088

730-167

700-514

730-144

750-016

730-148

COVER

SCREW 4

PUMP HSG ASSY

THRUST WASHER

THRUST WASHER

THRUST WASHER 1

OUTPUT PINION ASSY

THRUST WASHER 1

SNAP RING 1

SNAP RING

MOTOR HSG ASSY

SCREW

SHAFT

QTY ITEM No

1

1 59

1

1

1

1

1 96

1 112

4 127

21

57

58

60

61

62

63

64

95

111

.

.

'8".

-~~

Figure

PART No DESCRIPTION

710-127

730-145

730-060 CLUTCH

730-146

710-147

700-748

700-646

700-775

700-645

755-135

225-002

700-784

700-771

700-791

SETSCREW

SCREW

5

AMP FUSE

SWITCH COVER PLATE

SWITCH TO STARTER 1

WIRE

TOGGLE SWITCH

ON/OFF PLATE

RUBBER

CLIP

SCREW

SCREW

ADJUSTMENT

SAFETY PLATE

·-,

·-,

7

STARTER

BOOT

·-,/

-~-

·-......

QTY

1

2

1

1

1

1

1

1

1

2

2

KNOB

1

1

127

.......

Loading...

Loading...