Page 1

Owner’s Manual

Notice d’utilisation

Manual del Propietario

Do not use this equipment before

reading this manual!

ED655

Airless Diaphragm Pump

Model

0508090

Register your product online at:

www.titantool.com

Serial Number* _ _ _ _ _ _ _ _ _ _

* See page 33 for location

NOTE: This manual contains important

warnings and instructions. Please read

and retain for reference.

1016 • © Titan Tool Inc. All Rights Reserved. Form No. 0528937H

Page 2

Important Safety Information

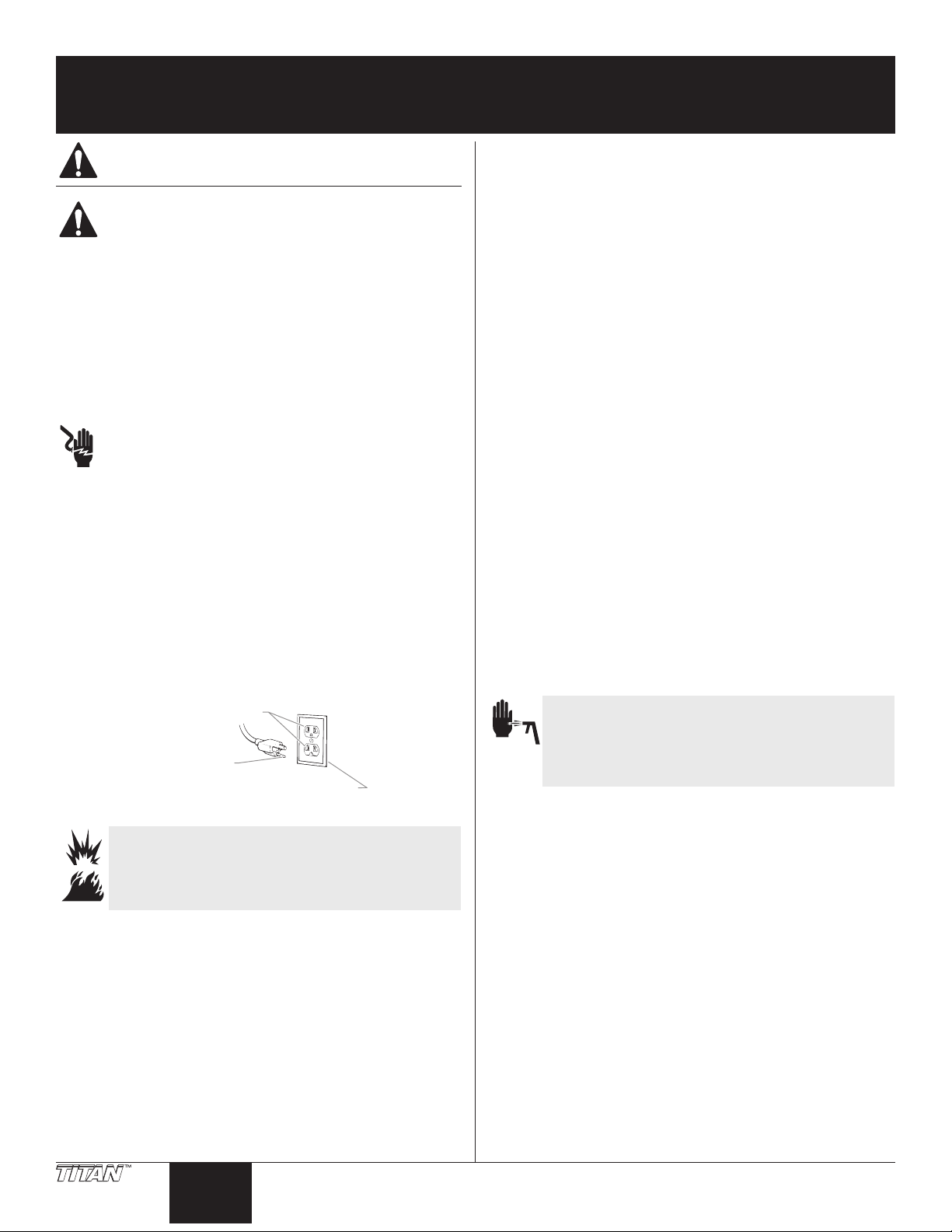

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

Read all safety information before operating the

equipment. Save these instructions.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

To reduce the risks of re or explosion, electrical shock

and the injury to persons, read and understand all

instructions included in this manual. Be familiar with the

controls and proper usage of the equipment.

Grounding Instructions

This product must be grounded. In the event of an electrical short

circuit, grounding reduces the risk of electric shock by providing an

escape wire for the electric current. This product is equipped with a

cord having a grounding wire with an appropriate grounding plug.

The plug must be plugged into an outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

WARNING - Improper installation of the grounding plug

can result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary, do not

connect the green grounding wire to either at blade terminal. The

wire with insulation having a green outer surface with or without

yellow stripes is the grounding wire and must be connected to the

grounding pin.

Check with a qualied electrician or serviceman if the grounding

instructions are not completely understood, or if you are in doubt as

to whether the product is properly grounded. Do not modify the plug

provided. If the plug will not t the outlet, have the proper outlet

installed by a qualied electrician.

This product is for use on a nominal 120 volt circuit and has a

grounding plug that looks like the plug illustrated below. Make

sure that the product is connected to an outlet having the same

conguration as the plug. No adapter should be used with this

product.

sparks. Use only conductive or grounded high-pressure airless

paint sprayer hoses specied by the manufacturer.

• Verify that all containers and collection systems are grounded

to prevent static discharge.

• Connect to a grounded outlet and use grounded extension

cords (electric models only). Do not use a 3 to 2 adapter.

• Do not use a paint or solvent containing halogenated

hydrocarbons. Such as chlorine, bleach mildewcide,

methylene chloride and trichloroethane. They are not

compatible with aluminum. Contact the coating supplier

about compatibility of material with aluminum.

• Keep spray area well ventilated. Keep a good supply of fresh

air moving through the area to keep the air within the spray

area free from accumulation of ammable vapors. Keep

pump assembly in well ventilated area. Do not spray pump

assembly.

• Do not smoke in the spray area.

• Do not operate light switches, engines, or similar spark

producing products in the spray area.

• Keep area clean and free of paint or solvent containers, rags,

and other ammable materials.

• Know the contents of the paint and solvents being sprayed.

Read all Material Safety Data Sheets (MSDS) and container

labels provided with the paints and solvents. Follow the paint

and solvent manufacture’s safety instructions.

• Place pump at least 25 feet (7.62 meters) from the spray

object in a well ventilated area (add more hose if necessary).

Flammable vapors are often heavier than air. Floor area must

be extremely well ventilated. The pump contains arcing parts

that emit sparks and can ignite vapors.

• Plastic can cause static sparks. Never hang plastic to enclose

spray area. Do not use plastic drop cloths when spraying

ammable material.

• Fire extinguisher equipment shall be present and working.

WARNING: EXPLOSION OR FIRE

Solvent and paint fumes can explode or ignite. Property

damage and/or severe injury can occur.

PREVENTION:

• Do not spray ammable or combustible materials near an

open ame, pilot lights or sources of ignition such as hot

objects, cigarettes, motors, electrical equipment and electrical

appliances. Avoid creating sparks from connecting and

disconnecting power cords.

• Do not spray materials with a ashpoint below 100ºF (38ºC).

Flashpoint is the temperature that a uid can produce enough

vapors to ignite.

• Paint or solvent owing through the equipment is able to

result in static electricity. Static electricity creates a risk of re

or explosion in the presence of paint or solvent fumes. All

parts of the spray system, including the pump, hose assembly,

spray gun and objects in and around the spray area shall be

properly grounded to protect against static discharge and

2 © Titan Tool. All rights reserved.

WARNING: INJECTION INJURY

A high pressure paint stream produced by this equipment

can pierce the skin and underlying tissues, leading to

serious injury and possible amputation. See a physician

immediately.

PREVENTION:

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge.

For example, do not try to stop leaks with any part of the

body.

• NEVER put your hand in front of the gun. Gloves will not

provide protection against an injection injury.

• ALWAYS keep the tip guard in place while spraying. The tip

guard provides some protection but is mainly a warning

device.

• Only use a nozzle tip specied by the manufacturer.

• Use caution when cleaning and changing nozzle tips. In the

case where the nozzle tip clogs while spraying, ALWAYS lock

gun trigger, shut pump o, and release all pressure before

servicing, cleaning tip or guard, or changing tip. Pressure

will not be released by turning o the motor. The PRIME/

SPRAY valve or pressure bleed valve must be turned to their

appropriate positions to relieve system pressure. Refer to

PRESSURE RELIEF PROCEDURE described in the pump manual.

• Do not leave the unit energized or under pressure while

unattended. When the unit is not in use, turn o the unit and

relieve the pressure in accordance with the manufacturer’s

instructions.

English

Page 3

Important Safety Information

• High-pressure spray is able to inject toxins into the body and

cause serious bodily injury. In the event that injection occurs,

seek medical attention immediately.

• Check hoses and parts for signs of damage, a leak can inject

material into the skin. Inspect hose before each use. Replace

any damaged hoses or parts. Only use TITAN original-high-

pressure hoses in order to ensure functionality, safety and

durability.

• This system is capable of producing 2800 PSI / 193 Bar. Only

use replacement parts or accessories that are specied by the

manufacturer and that are rated a minimum of 2800 PSI. This

includes spray tips, nozzle guards, guns, extensions, ttings,

and hose.

• Always engage the trigger lock when not spraying. Verify the

trigger lock is functioning properly.

• Verify that all connections are secure before operating the

unit.

• Know how to stop the unit and bleed pressure quickly. Be

thoroughly familiar with the controls. Pressure will not be

released by turning o the motor. The PRIME/SPRAY valve

or pressure bleed valve must be turned to their appropriate

positions to relieve system pressure. Refer to PRESSURE

RELIEF PROCEDURE described in the pump manual.

• Always remove the spray tip before ushing or cleaning the

system.

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic injury which can lead

to possible amputation. It is important to treat the injury as

soon as possible. DO NOT delay treatment to research toxicity.

Toxicity is a concern with some coatings injected directly

into the blood stream. Consultation with a plastic surgeon or

reconstructive hand surgeon may be advisable.

• Do not expose the hose to temperatures or pressures in excess

of those specied by manufacturer.

• Do not use the hose as a strength member to pull or lift the

equipment.

• Use lowest possible pressure to ush equipment.

• Follow all appropriate local, state and national codes

governing ventilation, re prevention and operation.

• The United States Government Safety Standards have been

adopted under the Occupational Safety and Health Act

(OSHA). These standards, particularly part 1910 of the General

Standards and part 1926 of the Construction Standards should

be consulted.

• Before each use, check all hoses for cuts, leaks, abrasion

or bulging of cover. Check for damage or movement

of couplings. Immediately replace hose if any of those

conditions exist. Never repair a paint hose. Replace with a

conductive high-pressure hose.

• Do not spray outdoors on windy days.

• Always unplug cord from outlet before working on equipment

(electric models only).

IMPORTANT: The diaphragm pump is provided with a thermally

protected automatic reset. If an overload occurs the thermally

protected automatic reset disconnects the motor from the power

supply.

• The motor will restart without warning when the protector

automatically resets.

• Always disconnect the motor from the power supply before

working on the equipment.

• When the thermally protected automatic reset disconnects

the motor from the power supply, relieve pressure by turning

the PRIME/SPRAY valve to PRIME.

• Turn the pump ON/OFF switch to OFF.

WARNING: HAZARDOUS VAPORS

Paints, solvents, insecticides, and other materials can

be harmful if inhaled or come in contact with the body.

Vapors can cause severe nausea, fainting, or poisoning.

PREVENTION:

• Use a respirator or mask if vapors can be inhaled. Read all

instructions supplied with the mask to be sure it will provide

the necessary protection.

• Wear protective eyewear.

• Wear protective clothing as required by coating manufacturer.

WARNING: GENERAL

Can cause severe injury or property damage.

PREVENTION:

• Always wear appropriate gloves, eye protection, clothing and

a respirator or mask when painting.

• Do not operate or spray near children. Keep children away

from equipment at all times.

• Do not overreach or stand on an unstable support. Keep

eective footing and balance at all times.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or under the inuence

of drugs or alcohol.

• Do not kink or over-bend the hose. Airless hose can develop

leaks from wear, kinking and abuse. A leak can inject material

into the skin.

© Titan Tool. All rights reserved. 3

NOTE: The cause of the overload should be corrected

before restarting. Refer to the Troubleshooting

section.

NOTE: Make sure to check for grounding continuity after

service is performed on any electrical components.

Use an ohmmeter to determine that there is

continuity between accessible dead-metal parts

of the product and the grounding blade of the

attachment plug.

Specications

Weight .....................................................27 lbs

Capacity ..................................................Up to .35 gallon (1.25 liters) per

minute

Power source ........................................Electric motor, totally enclosed, fan

cooled

Power requirement.............................15 amp minimum circuit on 115

VAC, 60 Hz current.

Generator ...............................................5000 Watts

Spraying pressure ...............................Up to 2800 PSI

Capabilities ............................................Sprays a variety of oil-based and

latex paints, primers, and stains

English

Page 4

Table of Contents

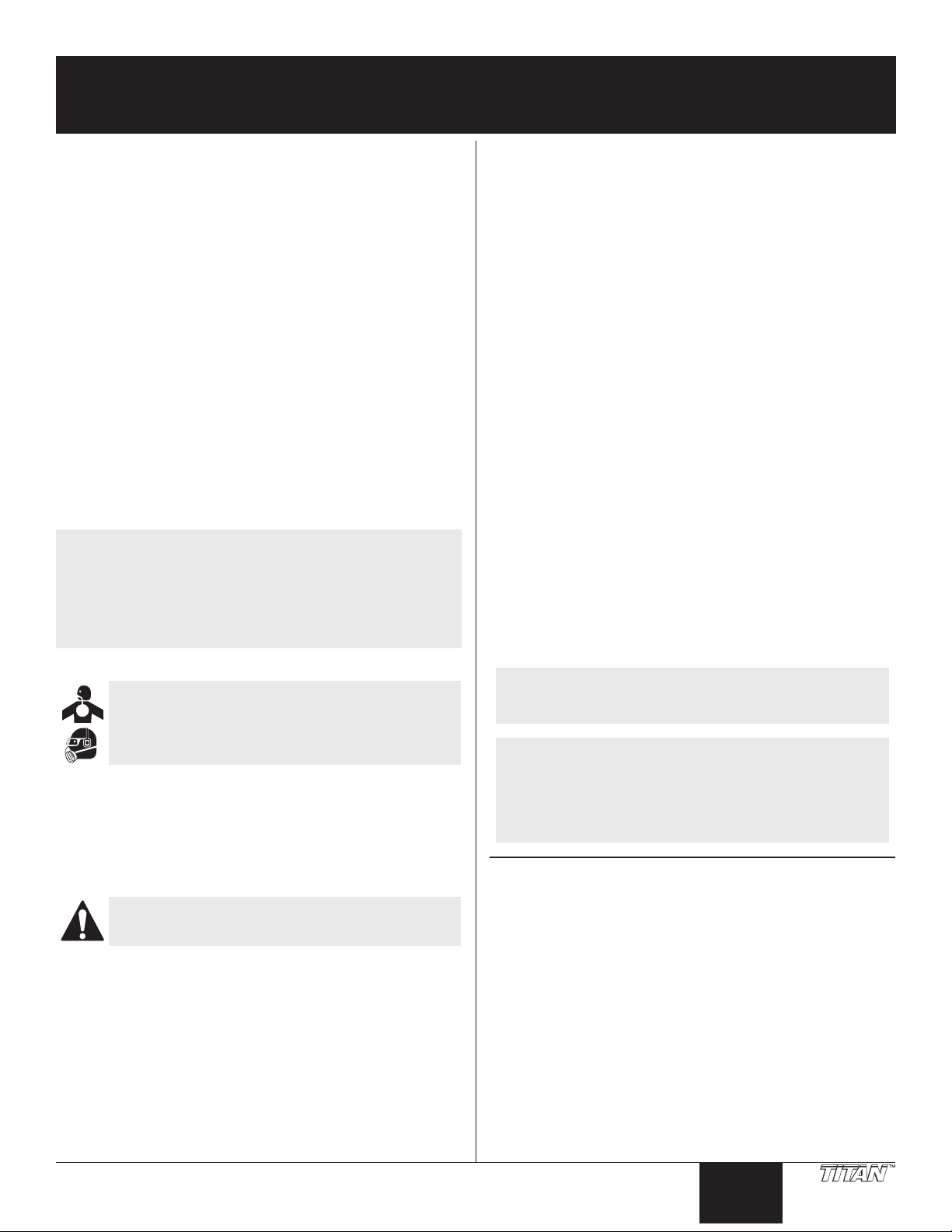

Pressure Control

Return Tube

Outlet Valve

the tip guard

Pusher Valve Button

Safety Precautions ........................................................................... 2

Grounding Instructions .............................................................................. 2

General Description ........................................................................ 4

Specications ................................................................................................. 4

Preparing to Paint ........................................................................... 4

Attaching the Tip to the Gun....................................................................4

Checking the Outlet Valve (optional) .................................................... 4

Attaching the Paint Hose ........................................................................... 5

Pressure Relief Procedure ............................................................... 5

Priming ............................................................................................. 5

Preparing to Prime ....................................................................................... 5

Mounting the Paint Hopper......................................................................6

Attaching the Return Tube........................................................................6

Priming the Pump ........................................................................................ 6

Spraying ........................................................................................... 7

Spraying Technique ..................................................................................... 7

Practice ............................................................................................................. 7

Cleanup ............................................................................................ 8

Overnight Storage ........................................................................................ 8

Long-Term Storage ...................................................................................... 8

Maintenance .................................................................................. 10

Removing and Cleaning the Inlet Valves ...........................................10

Removing and Cleaning the Outlet Valve .........................................10

Cleaning the Hopper Screen ..................................................................10

Troubleshooting ............................................................................ 11

Parts Listings .................................................................................. 32

Main Assembly ............................................................................................32

Diaphragm Pump .......................................................................................34

Pump Head Assembly ...............................................................................36

Hopper Assembly .......................................................................................37

Limited Warranty ........................................................................... 40

General Description

This high performance airless sprayer is a precision power tool used

for spraying many types of materials. Read and follow this instruction

manual carefully for proper operating instructions, maintenance and

safety information.

Preparing to Paint

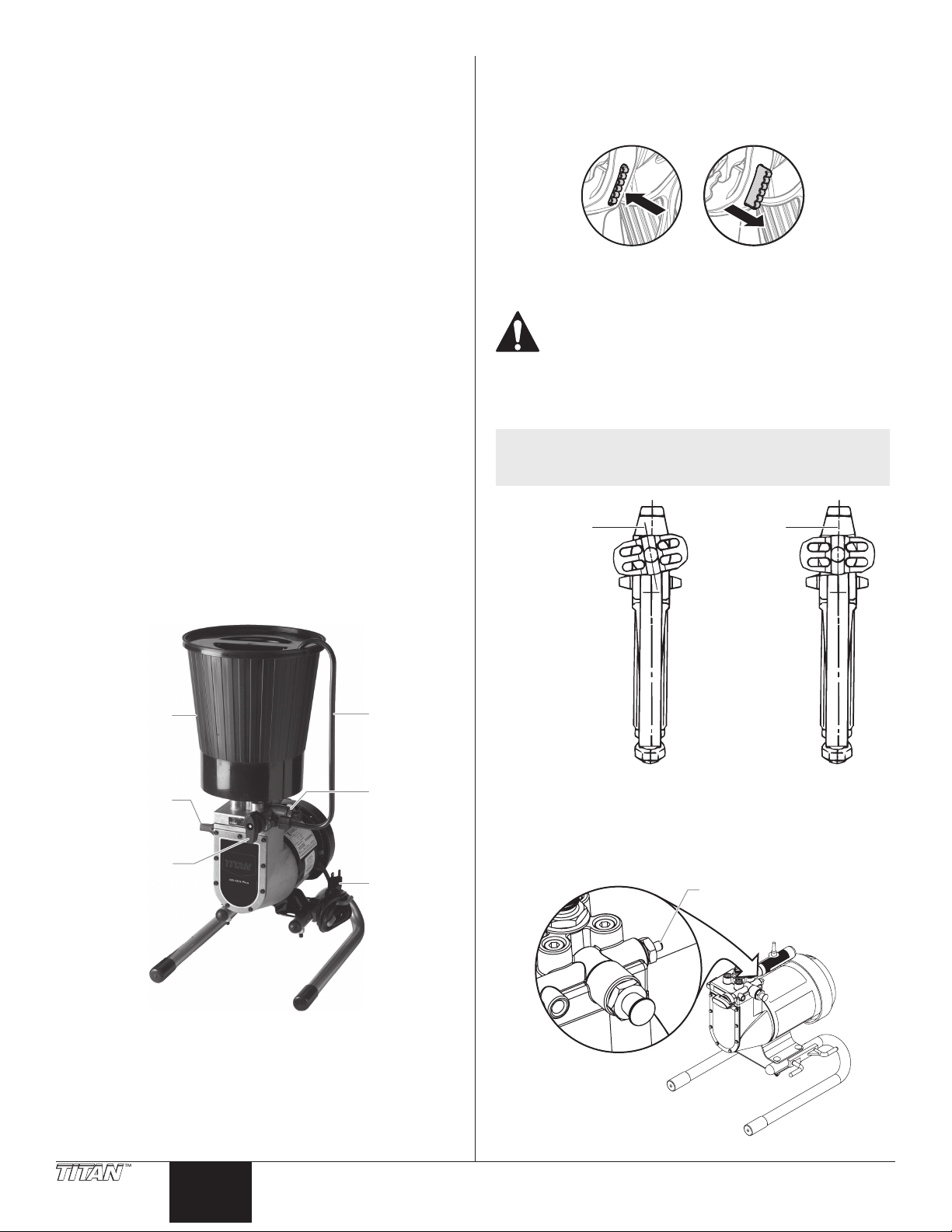

Attaching the Tip to the Gun

1. To lock the trigger, push in the trigger lock from left to right,

when looking at the rear of the gun.

Gun locked

(gun will not spray)

POSSIBLE INJECTION HAZARD. Do not spray without

the tip guard in place. Never trigger the gun unless the

tip is in either the spray or the unclog position. Always

engage the gun trigger lock before removing, replacing

or cleaning tip.

2. Thread the tip guard onto the gun. Tighten the nut rst by

hand, then tighten more rmly with a wrench.

NOTE: When attaching the tip guard to the gun, align the

tip guard as shown in the gure below, then tighten

with a wrench.

Begin

tightening

at this angle

Gun unlocked

(gun will spray)

to achieve

the desired

spray angle

when tight.

Paint Hopper

Knob

PRIME/SPRAY

Knob

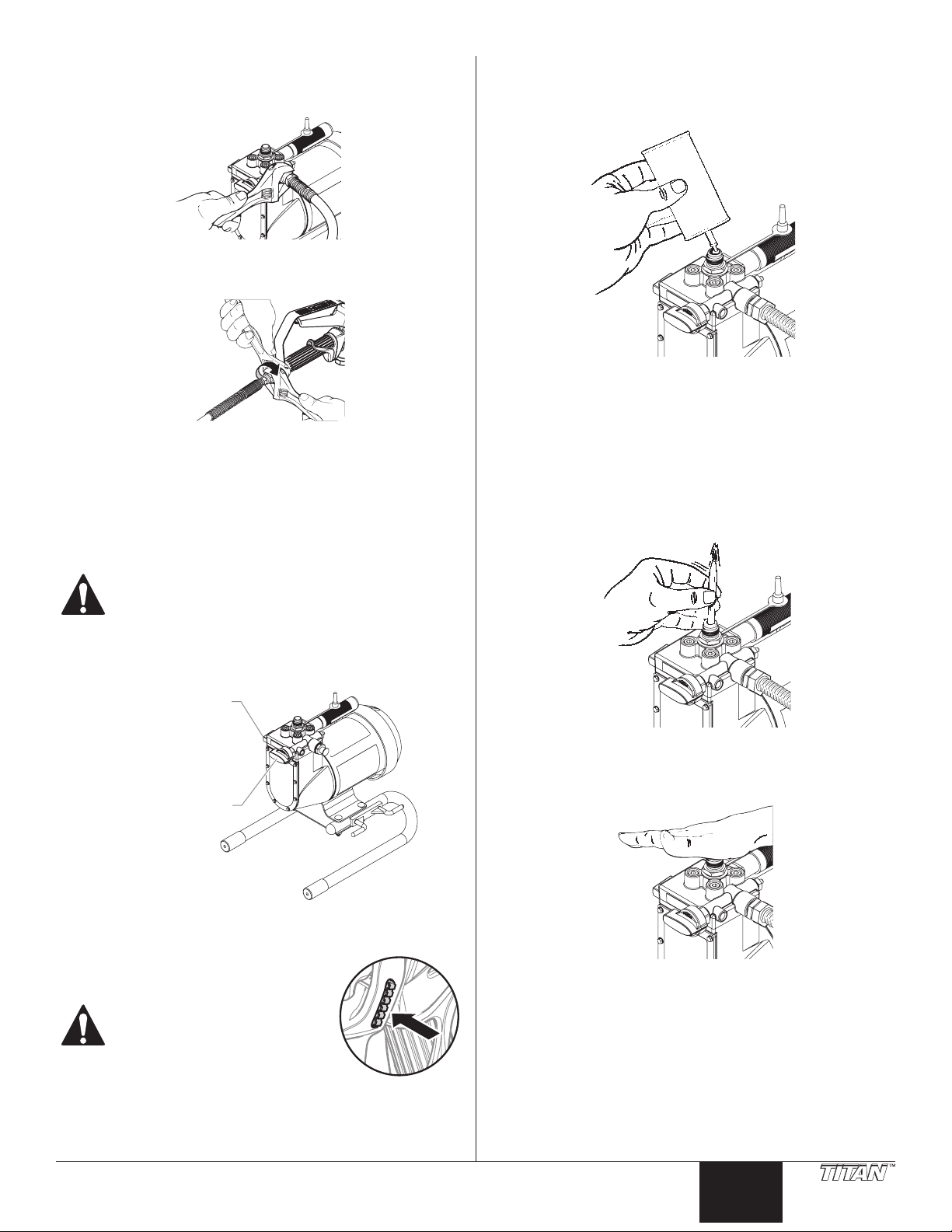

Checking the Outlet Valve (optional)

1. Firmly press the optional pusher valve button on the side of

the pump housing to make sure the outlet ball valve moves

freely.

Power Cord

(optional)

4 © Titan Tool. All rights reserved.

English

Page 5

Attaching the Paint Hose

Pressure Control Knob

1. Attach the high pressure hose to the paint sprayer. Use a

wrench to tighten the paint hose securely.

2. Attach the spray gun to the other end of the high pressure

hose. Tighten the hose securely to the gun using two

wrenches.

3. Plug the sprayer into a properly grounded outlet or heavy

duty grounded extension cord. Do not use more than 100

feet of cord. If you must spray a long distance from a power

source, use more paint hose, not more extension cords. Use a

minimum size of 16 gauge extension cord for up to 50 feet in

length, or 12 to 14 gauge for extension cords between 50 and

100 feet in length.

Priming

Preparing to Prime

1. Fill the inlet valve with water or with a light household oil.

2. Make sure the PRIME/SPRAY knob is set to PRIME and that

the pressure control knob is turned counterclockwise to the

lowest pressure setting.

3. Turn the motor switch to ON.

4. Increase the pressure by turning the pressure control knob

clockwise 1/2 turn.

5. Force the inlet valve to open and close by pushing on it with

a screwdriver or the eraser end of a pencil. It should move up

and down about 1/16 of an inch. Continue until water or oil

is sucked into the sprayer. This will wet the moving parts and

break loose any old paint residue.

Pressure Relief Procedure

Be sure to follow the pressure relief procedure when

shutting the unit down for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray tips, or preparing for

cleanup.

1. Turn the pressure control knob counterclockwise to its lowest

setting.

PRIME/SPRAY Knob

2. Turn the PRIME/SPRAY knob to PRIME.

3. Trigger the gun to remove any pressure which may still be in

the hose.

4. Lock the gun by pushing the gun trigger

lock to the locked position.

INJECTION HAZARD. Do not spray

without the tip guard in place.

NEVER trigger the gun unless the

tip is completely turned to either

the spray or the unclog position.

ALWAYS engage the gun trigger

lock before removing, replacing or

cleaning tip.

6. Put the palm of your hand over the inlet. Turn the pressure

control knob clockwise to its maximum setting. You should

feel suction coming from the inlet valve. If you do not, see the

section on cleaning and servicing the outlet valve.

7. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

8. Turn the motor switch to OFF.

© Titan Tool. All rights reserved. 5

English

Page 6

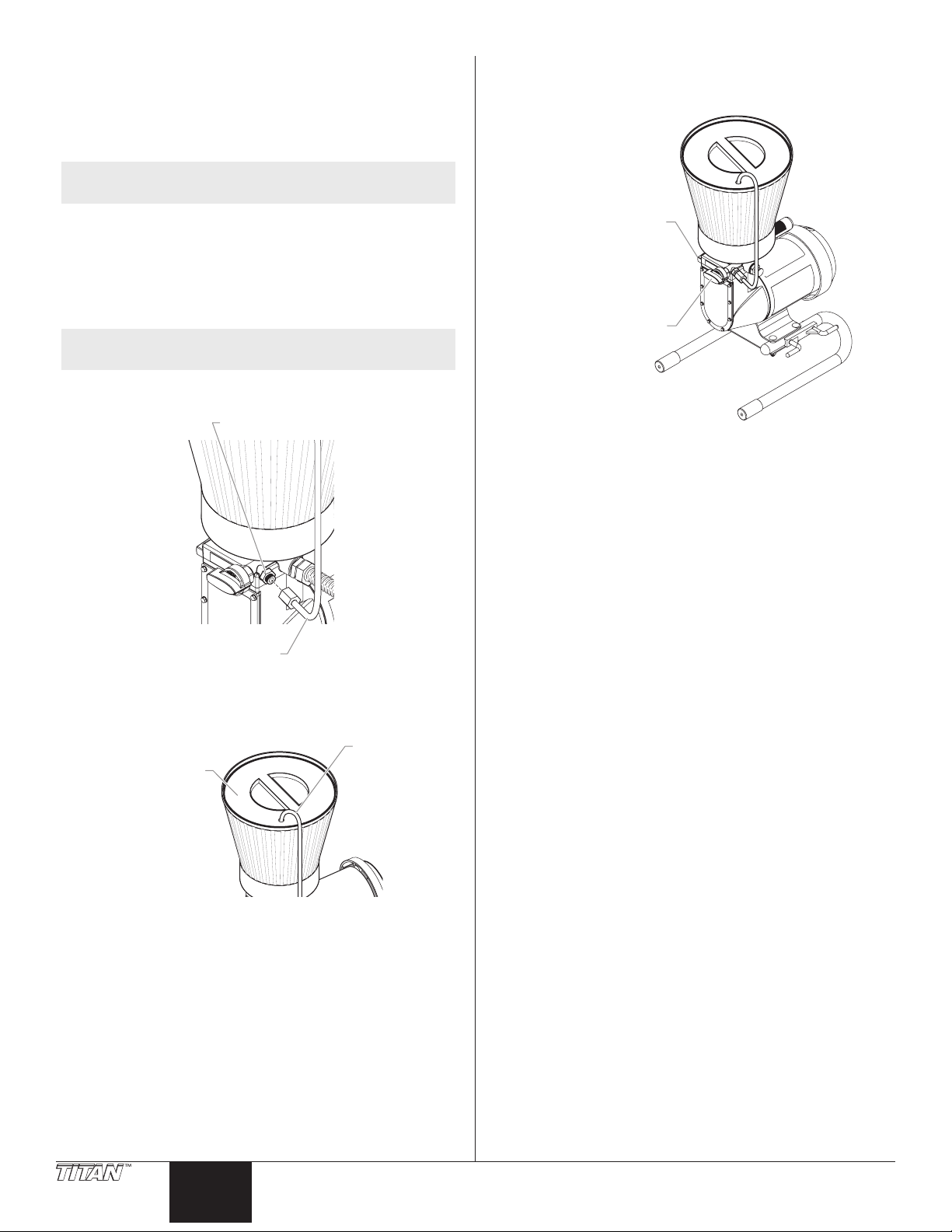

Mounting the Paint Hopper

Return Tube Fitting

Return Tube

E

Return Tube

P

Pressure Control Knob

1. Align the bottom of the paint hopper with the threaded inlet

valve on the paint pump block.

2. Turn the paint hopper clockwise to thread it onto the inlet

valve. Continue to turn the paint hopper until it is secure on

the inlet valve.

Priming the Pump

1. Turn the pressure control knob counterclockwise to its lowest

pressure setting.

NOTE: Make sure the threads are straight and the hopper

turns freely on the inlet valve. Do not cross-thread.

3. Place the lter screen into the bottom of the paint hopper and

snap it in position.

Attaching the Return Tube

1. Make sure that the motor switch is turned to OFF.

2. Screw the return tube tting found in the literature set into

the return tube port on the side of the pump.

NOTE: Do not over-tighten. Hand-tighten only. Some

threads will be visible even when fully tightened.

3. Place the straight end of the return tube into the return tube

tting.

4. Thread the nut on the return tube onto the return tube tting

and tighten until the return tube is secure.

5. Place the hook end of the return tube into the hole in the

paint hopper cover.

PRIME/SPRAY Knob

2. Remove the paint hopper cover and ll the paint hopper with

material.

3. Turn the PRIME/SPRAY knob to PRIME.

4. Turn the motor switch to ON.

5. Turn the pressure control knob clockwise to between half and

full pressure. Let the unit prime 1 to 2 minutes after material

begins to ow through the return tube.

IMPORTANT: Always reduce the pressure to zero before

changing the position of the PRIME/SPRAY knob. Failure to do so

may cause damage to the paint pump diaphragm.

IMPORTANT: If the pressure control knob is reduced to zero

and the PRIME/SPRAY knob is still on SPRAY while the sprayer is

operating, there will be high pressure in the hose and spray gun

until the PRIME/SPRAY knob is turned to PRIME or until the spray

gun is triggered to relieve the pressure.

aint Hopper Cover

6 © Titan Tool. All rights reserved.

English

Page 7

Spraying

Keep stroke smooth and at an even speed.

Even coat throughout

Heavy Coat

Do not ex wrist while spraying.

Light CoatLight Coat

Approximately

Proper way to trigger the spray gun

Start stroke End strokePull trigger Release triggerKeep steady

Pressure Control Knob

Spraying Technique

The key to a good paint job is an even coating over the entire surface.

This is done by using even strokes. Keep your arm moving at a

constant speed and keep the spray gun at a constant distance from

the surface. The best spraying distance is 10 to 12 inches between

the spray tip and the surface.

Approximately

10 to 12 inches

Keep the spray gun at right angles to the surface. This means moving

your entire arm back and forth rather than just exing your wrist.

Keep stroke

even

Aproximately

10 to 12 inches

Overlap each stroke by about 50%. This will ensure an even coating.

When you stop painting, lock the gun trigger lock, turn the pressure

control knob counterclockwise to its lowest setting and set the

PRIME/SPRAY knob to PRIME. Turn the motor switch to OFF and

unplug the sprayer.

If you expect to be gone more than 1 hour, follow the short term

clean up procedure described in the CLEANUP section of this manual.

Practice

1. Be sure that the paint hose is free of kinks and clear of objects

with sharp cutting edges.

2. Turn the pressure control knob counterclockwise to its to its

lowest setting.

Keep the spray gun perpendicular to the surface, otherwise one end

of the pattern will be thicker than the other.

10 to 12 inches

Right way

Wrong way

The spray gun should be triggered by turning it on and o with each

stroke. This will save paint and avoid paint buildup at the end of the

stroke. Do not trigger the gun during the middle of a stroke. This will

result in an uneven spray and splotchy coverage.

PRIME/SPRAY Knob

3. Turn the PRIME/SPRAY knob to SPRAY.

4. Turn the pressure control knob clockwise to its highest

setting. The paint hose should stien as material begins to

ow through it.

5. Unlock the gun trigger

lock by turning the

switch so that it is

parallel to the handle.

6. Trigger the spray gun

Good spray pattern

to bleed air out of the

hose.

7. When paint reaches the

spray tip, spray a test

area to check the spray

pattern.

Paint tailing pattern

8. Use the lowest pressure

setting necessary to get a good spray pattern. If the pressure

is set too high, the spray pattern will be too light. If the

pressure is set too low, tailing will appear or the paint will

spatter out in gobs rather than in a ne spray.

© Titan Tool. All rights reserved. 7

English

Page 8

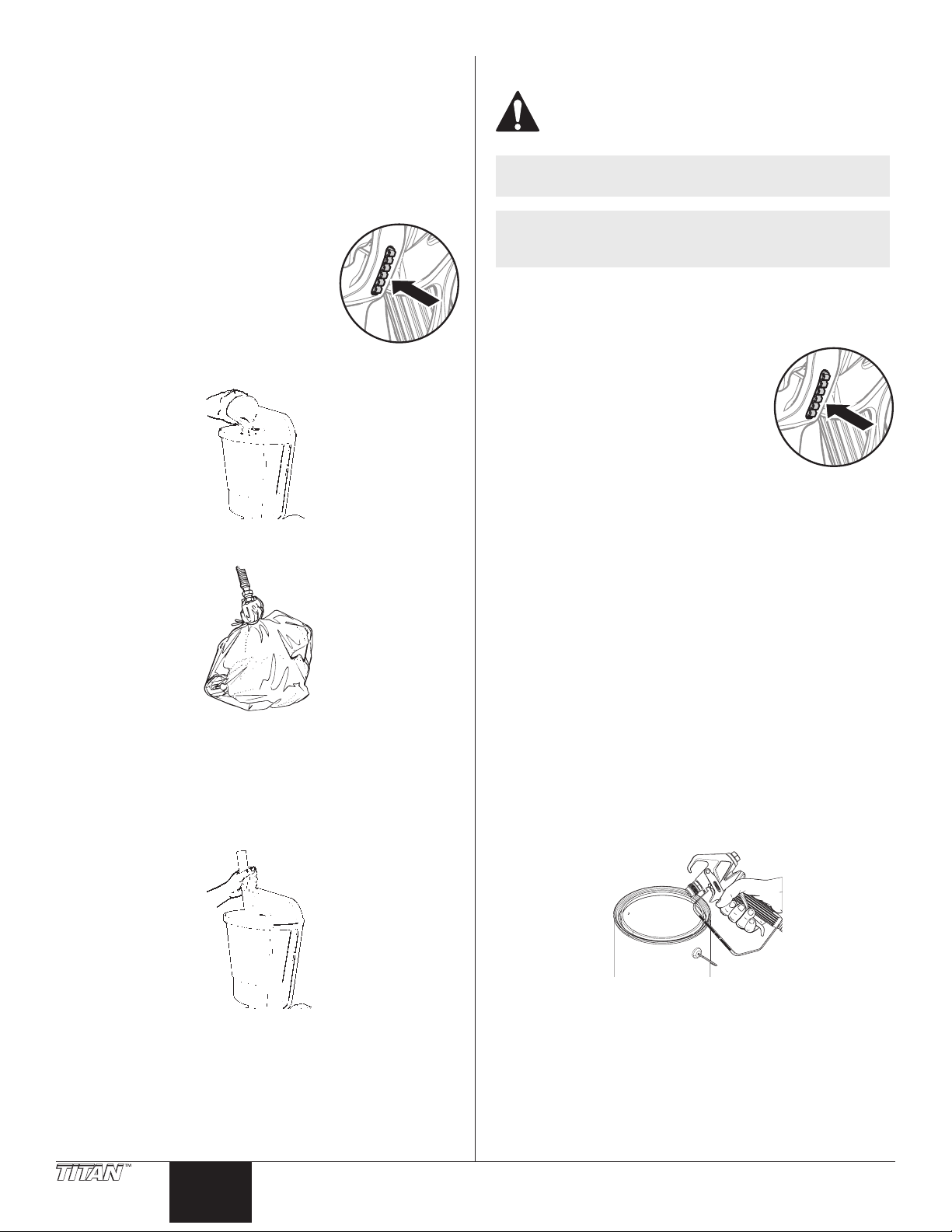

Cleanup

Long-Term Storage

Overnight Storage

Shutdown

1. Turn the pressure control knob counterclockwise to the

minimum setting.

2. Turn the PRIME/SPRAY knob to PRIME to release system

pressure.

3. Trigger the gun to remove any pressure that may still be in the

hose.

4. Lock the gun by pushing the gun trigger

lock to the locked position.

5. Turn the motor switch to OFF and

unplug the sprayer.

6. For latex materials only, pour 1/2 cup

water slowly on the top of the paint to

prevent the paint from drying. For other

materials, seal the paint hopper with the

hopper cover keeping the return tube in

the paint.

7. Wrap the spray gun assembly in a damp cloth and place it in a

plastic bag. Seal the bag shut.

8. Place the sprayer in a safe place out of the sun for short-term

storage.

Startup

1. Remove the gun from the plastic bag.

2. Stir the water into the paint for latex materials. Remove the

hopper cover from the paint hopper and stir the paint for all

other materials.

Do not allow paint to build up on the motor or the

motor will overheat. Do not allow flammable solvents

to come in contact with the motor or they could ignite.

NOTE: You will need a bucket, cleaning solution, a

toothbrush, a wrench and cleaning rags.

NOTE: If spraying with latex paint, use warm soapy water

for cleaning. If using oil or alkyd-based paints, use

mineral spirits or paint thinner.

IMPORTANT: Do not use mineral spirits or paint thinner on latex

paint, or the mixture will turn into a jelly-like substance which is

difficult to remove.

Clearing the Paint Hopper

1. Lock the gun by pushing the gun trigger

lock to the locked position.

2. Turn the pressure control knob

counterclockwise to the minimum

setting.

3. Turn the PRIME/SPRAY knob to PRIME.

4. Turn the motor switch to OFF.

5. Direct the return tube into the original

paint bucket.

6. Turn the motor switch to ON.

7. Turn the pressure control knob to 1/2 maximum pressure.

This will draw the remaining paint in the paint hopper

through the pump, up the return tube, and into the paint

bucket.

8. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

9. Trigger the gun to relieve pressure and lock the gun.

10. Remove the spray tip and guard and place them into a

container of water or appropriate solvent for the type of

material with which you are painting.

11. Fill the paint hopper with water or an appropriate solvent for

the type of material with which you are painting.

12. Direct the return tube into a waste bucket.

13. Increase the pressure to 1/2 the maximum pressure. Let the

water or solvent circulate for 2-3 minutes to ush paint out of

the pump, the paint hopper, and the return tube.

Clearing the Paint Hose

1. To save paint left in the hose, release the gun trigger lock and

carefully trigger the gun with the spray tip removed against

the inside of the paint container.

2. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

3. Check to be sure that the PRIME/SPRAY knob is set to PRIME

and that the pressure is completely reduced.

4. Plug sprayer in and turn the motor switch to ON.

5. After the sprayer is primed, turn the PRIME/SPRAY knob to

SPRAY and gradually turn the pressure control knob clockwise

to increase the pressure.

6. Test the sprayer on a practice piece and begin spraying.

8 © Titan Tool. All rights reserved.

English

3. Turn the PRIME/SPRAY knob to SPRAY.

4. Turn the pressure control knob slowly until paint starts to

ow into the bucket. As soon as the water or solvent starts to

come into the bucket, release the trigger.

5. Change to clean water or solvent, point the gun to the side

of the waste bucket, and continue circulating for another 5

minutes to thoroughly clean the hose, pump and spray gun.

6. Turn the pressure control knob counterclockwise to its lowest

setting.

Page 9

7. Turn the PRIME/SPRAY knob to PRIME.

8. Trigger the gun to remove any pressure which may still be in

the hose.

9. Lock the gun trigger by rotating the trigger lock forward until

it stops.

10. Turn the motor switch to OFF.

Clearing the Gun

1. Remove the spray gun from the paint hose using two

adjustable wrenches.

2. Remove the lter housing from the gun. Place the gun and

the lter assembly into a container of water or solvent to soak.

3. Clean the spray tip and gun lter with a soft brush.

4. Reassemble the gun and lter. Assemble the spray tip in the

cleaning position with the arrow pointing to the back of the

gun.

5. Attach the paint hose to the gun and tighten using two

wrenches.

Final Cleanup

1. Remove the tip assembly.

2. Turn the motor to ON.

3. Turn the PRIME/SPRAY knob to SPRAY.

4. Turn the pressure control knob clockwise to 1/2 power.

5. Trigger the gun into the cleaning bucket until the hopper is

empty.

6. Rell the hopper and continue ushing the system until the

solution coming out of the gun appears clean.

7. Lock the gun and turn the pressure control knob

counterclockwise to its lowest setting.

8. Turn the PRIME/SPRAY knob to PRIME.

9. Remove the hopper from the inlet valve.

10. Clean the threads of the inlet valve with a damp cloth.

11. Fill the inlet valve with a light household oil.

6. Turn the motor switch to ON.

7. Unlock gun trigger by turning the gun trigger lock so that it is

parallel to the gun handle.

8. Turn the PRIME/SPRAY knob to SPRAY and point the gun to

the side of the waste bucket.

9. Trigger the gun and gradually turn the pressure control knob

clockwise to 1/2 pressure. Continue to trigger the gun for

approximately 30 seconds.

10. Turn the pressure control knob counterclockwise to its lowest

setting.

11. Turn the PRIME/SPRAY knob to PRIME.

12. Trigger the gun to remove any pressure which may still be in

the hose.

13. Lock the gun trigger by rotating the trigger lock forward until

it stops.

14. Turn the motor switch to OFF.

12. Turn the PRIME/SPRAY knob to SPRAY to distribute the oil.

NOTE: Proper cleaning and oiling of the pump after use

are the most important steps you can take to insure

proper operation after storage.

13. Turn the pressure control knob counterclockwise to its lowest

setting.

14. Turn the PRIME/SPRAY knob to PRIME.

15. Trigger the gun to remove any pressure that may still be in the

hose.

16. Lock the gun trigger by rotating the trigger lock forward until

it stops..

17. Turn the motor switch to OFF.

18. Remove the hopper lter and clean in clean water or the

appropriate solvent. Use a soft brush.

19. Return the hopper lter to its position in the hopper and

replace the hopper on the inlet valve.

20. Wipe the entire unit, hose and gun with a damp cloth to

remove accumulated paint.

© Titan Tool. All rights reserved. 9

English

Page 10

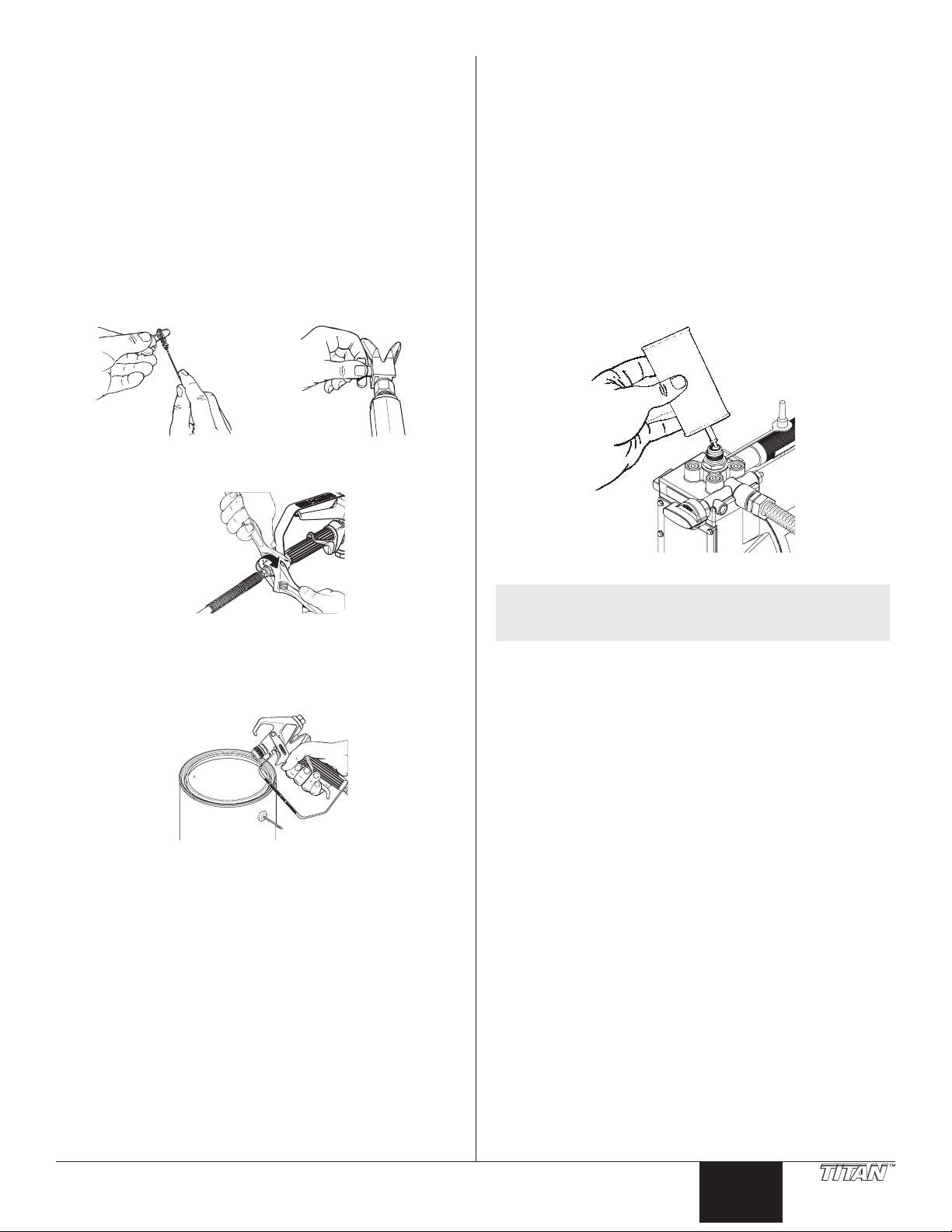

Maintenance

Valve Body

Seal

Follow these procedures when encountering problems indicated in

the troubleshooting section.

Removing and Cleaning the Inlet Valves

1. Be certain that the sprayer is o.

2. Remove the inlet valve assembly using a 27 millimeter socket

or box end wrench.

NOTE: This spring is manufactured to a very specic

tension. Do not put in an unauthorized substitute.

See the paint pump assembly parts diagram for the

proper replacement part number.

3. Remove the seat and ball assembly.

4. Clean all parts thoroughly. If the ball or seat show any sign of

wear or damage, replace them with new parts. This carbide

ball must seal tightly against its seat for the valve to function

properly.

5. Cover all parts with a thin coat of light oil before reassembling.

3. Test movement of the valve by pushing on it from the open

end of the valve housing with a screwdriver or the eraser end

of a pencil. It should move about 1/16 of an inch. If it does

not move, it should be cleaned or replaced.

NOTE: The inlet valve must be oiled after every job. This

will reduce or eliminate priming problems the next

time the sprayer is used.

4. Thoroughly clean the valve assembly with water or the

appropriate solvent. Use a small brush.

5. If you have properly cleaned the valve and water drips out of

the bottom, the valve is worn and needs to be replaced. A

properly seated valve lled with water and held vertically will

not drip.

6. Install a new or cleaned valve in the pump block and then ll

the valve with light oil or solvent.

NOTE: You will need to align the ridge on the seat with the

groove in the pump housing when reassembling.

6. Drop in the valve ball.

7. Insert the ball stop and spring and replace the valve body. Be

sure that the o-ring is positioned properly and that the tongue

on the cap ts inside the spring.

8. Tighten the valve body securely with an adjustable wrench.

Do not over-tighten.

Seat

Ball

Spring

Ball Stop

O-ring

Cleaning the Hopper Screen

The screen at the bottom of the paint hopper may need cleaning

periodically. Check it every time you add paint. Remove the screen

by pulling it out of the hopper with a pliers. Clean the screen with

water or solvent and a soft-bristle brush, if necessary.

Removing and Cleaning the Outlet Valve

It may be necessary to remove and clean the outlet valve or to

replace parts inside the valve worn out through normal use.

1. Remove the outlet valve body with a wrench.

2. Remove and clean the ball stop and small spring inside the

valve using a wire hook or tweezers. Replace the spring if it is

broken or worn.

10 © Titan Tool. All rights reserved.

English

Page 11

Troubleshooting

Problem

A. The sprayer does not start up.

B. The sprayer starts up but does

not draw in paint when the

PRIME/SPRAY knob is set to

PRIME.

C. The sprayer draws up paint but

the pressure drops when the

gun is triggered.

D. The sprayer will not build

pressure.

Cause

1. The sprayer is not plugged in.

2. The ON/OFF switch is set to OFF.

3. Low or no voltage is coming from the wall

plug.

4. The sprayer was turned o while still under

pressure.

5. The extension cord is damaged or has too low

a capacity.

6. The thermal overload on the sprayer is

tripped.

7. There is a problem with the motor.

1. The unit will not prime properly or has lost

prime.

2. The paint hopper is empty

3. The hopper lter is clogged.

4. The inlet valve is stuck.

5. The outlet valve is stuck.

6. The PRIME/SPRAY valve is plugged.

7. The inlet valve is worn or damage.

8. There is a problem with the diaphragm.

9. The hydraulic oil level is low or empty.

1. The spray tip is worn.

2. The hopper lter is clogged.

3. The gun or spray tip lter is plugged.

4. The paint is too heavy or coarse.

5. The outlet valve assembly is dirty or worn.

6. The inlet valve assembly is damaged or worn.

1. The inlet or outlet valve ball or ball seat is

worn.

2. Foreign matter or paint has built up between

the ball and the seat.

3. Foreign matter or paint has built up in PRIME/

SPRAY valve

Solution

1. Plug the sprayer in.

2. Turn the ON/OFF switch to ON.

3. Properly test the power supply voltage.

4. Turn the PRIME/SPRAY knob to PRIME.

5. Replace the extension cord.

6. Allow the motor to cool and move the sprayer to a

cooler spot.

7. Take the sprayer to a Titan Authorized Service Center.

1. Try to prime the unit again.

2. Fill the paint hopper with paint.

3. Clean the hopper lter.

4. Clean the inlet valve.

5. Clean the outlet valve and replace any worn parts.

6. Take the sprayer to a Titan Authorized Service Center.

7. Replace the inlet valve.

8. Take the sprayer to a Titan Authorized Service Center.

9. Take the sprayer to a Titan Authorized Service Center.

1. Replace the spray tip with a new tip.

2. Clean the hopper lter.

3. Clean or replace the proper lter. Always keep extra

lters on hand.

4. Thin or strain the paint.

5. Clean or replace the outlet valve assembly.

6. Replace the inlet valve.

1. Take the sprayer to a Titan Authorized Service Center.

2. Take the sprayer to a Titan Authorized Service Center.

3. Replace PRIME/SPRAY valve or take the sprayer to a Titan

Authorized Service Center.

E. The spray gun leaks.

F. The tip assembly leaks.

G. The spray gun will not spray.

H. The paint pattern is tailing.

I. The thermal overload tripped

and shut o the sprayer.

1. Internal parts of the gun are worn or dirty.

1. The tip was assembled incorrectly.

2. A seal is worn.

1. The spray tip, the gun lter or the tip lter is

plugged.

2. The spray tip is in the CLEAN position.

1. The pressure is set too low.

2. The gun, the tip, or the hopper lter is

plugged.

3. The tip is worn.

4. The paint is too thick.

1. The motor overheated.

2. The extension cord is too long or is too small

a gauge.

3. Paint has built up on the motor.

4. The motor was started while the sprayer was

under pressure.

5. The sprayer was sitting in the hot sun.

NOTE: The electric motor should always be kept clean and

dry. Paint acts as an insulator. Too much paint on the

motor will cause the motor to overheat.

NOTE: Make sure to check for grounding continuity after

service is performed on any electrical components.

Use an ohmmeter to determine that there is

continuity between accessible dead-metal parts

of the product and the grounding blade of the

attachment plug.

1. Take the sprayer to a Titan Authorized Service Center.

1. Check the tip assembly and assemble properly.

2. Replace the seal.

1. Clean the spray tip, gun lter or tip lter.

2. Put the tip in the SPRAY position.

1. Increase the pressure.

2. Clean the lters.

3. Replace the spray tip.

4. Thin the paint.

1. Allow to cool for 30 minutes.

2. Allow to cool for 30 minutes and replace the extension

cord with a shorter extension or a thicker gauge cord.

3. Clean the paint from the motor.

4. Restart the sprayer in the PRIME mode.

5. Move the sprayer out of the sun.

© Titan Tool. All rights reserved. 11

English

Page 12

Consignes de sécurite important

Prise trilaire

Lire toutes ces consignes avant d’utiliser l’appareil.

Garder ces consignes.

Indique une situation à risque, laquelle, si elle n’est pas

évitée, peut entraîner des blessures graves, voire la mort.

Pour réduire les risques d’incendie ou d’explosion,

de choc électrique et de blessure, vous devez lire et

comprendre les directives gurant dans ce manuel.

Familiarisez-vous avec les commandes et l’utilisation

adéquate de l’équipement.

Directives de mise à la terre

Cet appareil doit être mis à la terre. En cas de court-circuit, cette

précaution réduit les risques de choc en procurant un parcours

au courant électrique. Le cordon de l’appareil est doté d’un l de

terre relié à la troisième broche de sa che. Cette dernière doit être

branchée dans une prise correctement câblée et mise à la terre

conformément aux codes et règlements locaux.

MISE EN GARDE - Le fait de ne pas brancher

correctement la che trilaire de l’appareil peut

entraîner des risques de choc électrique.

Si on doit réparer ou remplacer le cordon ou la che, ne pas raccorder

le l de terre à la borne des broches plates (lames) de cette dernière.

Ce l, normalement vert (avec ou sans rayures jaunes), doit être relié

à la broche de terre.

Consulter un technicien ou un électricien qualié à défaut de

comprendre l’ensemble des présentes directives ou en cas

d’incertitude quant à la mise à terre de l’appareil. Ne pas modier la

che de l’appareil; si elle ne s’adapte pas dans la prise voulue, la faire

remplacer par un électricien qualié.

Conçu pour les circuits de 120 V, cet appareil est doté d’une che

ressemblant à celle illustrée ci-dessous. S’assurer que le produit est

connecté à une prise électrique ayant la même conguration que la

che mâle. Ne pas utiliser d’adaptateur avec ce produit.

Broche de mise à la terre

Plaque murale de la prise

MISE EN GARDE : EXPLOSION OU INCENDIE

Les émanations de certains produits peuvent exploser

ou s’enammer, et risquent d’entraîner des dommages

matériels ou de graves blessures.

MESURES PRÉVENTIVES :

• Ne pulvérisez pas de matières inammables ou combustibles

près d’une amme nue, de voyants lumineux ou de sources

d’ignition telles que des objets chauds, cigarettes, moteurs,

matériel et appareils électriques. Évitez de produire des étincelles

en connectant et en déconnectant les cordons électriques.

• Ne pulvérisez pas et ne les nettoyez pas avec des liquides

ayant un point d’éclair inférieur à 38°C (100°F). Le point

d’éclair est la température à laquelle le liquide peut créer

susamment de vapeurs et s’enammer.

• L’écoulement de peinture ou de solvant dans l’équipement

peut produire de l’électricité statique. L’électricité statique

crée un risque d’incendie ou d’explosion en présence de

fumées de peinture ou de solvant. Toutes les pièces du

système du pulvérisateur, y compris la pompe, l’ensemble

du tuyau, le pistolet de pulvérisation et les objets dans et

autour de la zone de pulvérisation doivent être correctement

reliés à la terre pour protéger contre les décharges

d’électricité statique et les étincelles. N’utilisez que des

12 © Titan Tool Inc. Tous droits réservés.

Français

tuyaux conducteurs ou reliés à la terre pour pulvérisateurs de

peinture sous vide à haute pression, spéciés par le fabricant.

• Vériez que tous les conteneurs ou systèmes de stockage sont

reliés à la terre pour éviter les décharges d’électricité statique.

• Connectez à une prise électrique avec prise de terre et utilisez

des rallonges électriques reliées à la terre. N’utilisez pas

d’adaptateur 3 à 2.

• N’utilisez pas de peinture ou de solvant contenant du halon,

par exemple, le chlore, les agents antimoisissure à l’eau

de Javel, le chlorure de méthylène et le trichloroéthane.

Ils ne sont pas compatibles avec l’aluminium. Contactez le

fournisseur de revêtements pour connaître la compatibilité du

matériau avec l’aluminium.

• La zone de pulvérisation doit toujours être bien aérée. Une

bonne quantité d’air frais doit constamment traverser la zone

de pulvérisation pour éviter les accumulations de vapeurs

inammables. Le système de pompage doit être placé dans une

zone bien aérée. Ne pulvérisez pas le système de pompage.

• Ne fumez pas dans la zone de pulvérisation.

• N’actionnez pas d’interrupteurs électriques, de moteurs ou

autres dispositifs produisant des étincelles dans la zone de

pulvérisation.

• Maintenez la propreté de la zone et veillez à ce qu’elle ne

contienne pas de conteneurs de peinture ou de solvant, de

chions et autres matières inammables.

• Sachez ce que contiennent la peinture et les solvants

pulvérisés. Lisez les ches de sécurité du matériel (MSDS) et

les étiquettes apposées sur les conteneurs de peintures et de

solvants. Respectez les consignes de sécurité du fabricant de

peinture et de solvant.

• Placez la pompe à une distance minimum de 7,62 mètres

(25 pieds) de l’objet à pulvériser, dans une zone bien aérée

(ajoutez de la longueur de tuyau si besoin est). Les vapeurs

inammables sont souvent plus lourdes que l’air. La zone près

du sol doit être très bien aérée. La pompe contient des pièces

qui produisent des arcs et émettent des étincelles pouvant

enammer les vapeurs.

• Le plastique peut causer des étincelles d’électricité statique.

N’accrochez aucun plastique dans une zone de pulvérisation

fermée. N’utilisez pas de toiles de protection en plastique

quand vous pulvérisez une matière inammable.

• Ayez un extincteur en bon état de fonctionnement à portée de main.

MISE EN GARDE : INJECTION CUTANÉE

Le jet de haute pression produit par cet appareil peut

transpercer la peau et les tissus sous-jacents, causant des

blessures graves pouvant entraîner l’amputation.

MESURES PRÉVENTIVES :

• Ne dirigez pas le pistolet sur et ne pulvérisez pas les personnes

ou les animaux.

• N’approchez pas les mains ni d’autres parties du corps de la

sortie du produit. Par exemple, ne tentez pas d’arrêter une

fuite avec une partie du corps.

• NE JAMAIS mettre la main, même gantée, devant le pistolet

(les gants n’orent aucune protection contre les blessures par

injection).

• TOUJOURS s’assurer que le protège-embout est en place avant

de pulvériser. Il est cependant à noter que, s’il assure une

certaine protection, ce dispositif joue surtout un rôle préventif.

• Utilisez exclusivement un embout de buse spécié par le fabricant.

• Prenez garde quand vous nettoyez ou que vous changez les

embouts de buse. Si l’embout se bouche pendant que vous

pulvérisez, verrouillez TOUJOURS la détente du pistolet, arrêtez

la pompe et libérez toute la pression avant de réparer ou

de nettoyer l’embout ou le protecteur ou avant de changer

d’embout. La pression n’est pas libérée par l’arrêt du moteur.

La poignée du robinet-valve PRIME/SPRAY doit être placée sur

PRIME pour libérer la pression. Consultez la PROCÉDURE DE

DÉCOMPRESSION décrite dans le manuel de la pompe.

Page 13

Consignes de sécurite important

• Ne laissez pas l’appareil sous tension ou sous pression

quand vous vous en éloignez. Quand vous n’utilisez pas

l’appareil, éteignez-le et libérez la pression conformément aux

instructions du fabricant.

• La pulvérisation à haute pression peut injecter des toxines dans

le corps et causer de graves blessures corporelles. Si une telle

injection se produisait, consultez immédiatement un médecin.

• Vériez les tuyaux et les pièces pour détecter des signes

d’endommagement : une fuite peut injecter le produit dans la peau.

Inspectez le tuyau avant chaque emploi. Changez tous les tuyaux

ou pièces endommagés. Pour des raisons de fonctionnement,

de sécurité et de durée de vie, utiliser exclusivement des tuyaux

exibles à haute pression d‘origine de TITAN.

• Ce système peut produire une pression de 2 800 PSI / 193

Bar. N’utilisez que les pièces de rechange ou les accessoires

spéciés par le fabricant et ayant une pression nominale

minimum de 2 800 PSI. Ceci est valable pour les embouts

de pulvérisation, les protecteurs de buse, les pistolets, les

rallonges, les raccords et le tuyau.

• Verrouillez toujours la détente quand vous ne pulvérisez pas.

Vériez que le verrou de la détente fonctionne correctement.

• Vériez que toutes les connexions sont bien serrées avant

d’utiliser l’appareil.

• Sachez comment arrêter l’appareil et le dépressuriser

rapidement. Soyez bien familiarisé avec les commandes. La

pression n’est pas libérée lorsque le moteur est arrêté. La

poignée du robinet-valve PRIME/SPRAY doit être placée sur

PRIME pour libérer la pression. Consultez la PROCÉDURE DE

DÉCOMPRESSION décrite dans le manuel de la pompe.

• Retirez toujours l’embout de pulvérisation avant de rincer ou

de nettoyer le système.

REMARQUE À L’INTENTION DES MÉDECINS : Les injections

cutanées sont des lésions traumatiques; il importe donc de

les traiter sans délai. On NE DOIT PAS retarder ce traitement

sous prétexte de vérier la toxicité du produit en cause, celle-ci

n’étant conséquente que dans le cas d’injection directe de

certains produits dans le système sanguin. Il pourrait s’avérer

nécessaire de consulter un plasticien ou un spécialiste en

chirurgie reconstructive de la main.

MISE EN GARDE : ÉMANATIONS DANGEREUSES

Certains produits (peintures, solvants, insecticides ou

autres) peuvent être nocifs s’ils sont inhalés ou entrent en

contact avec l’organisme. Les émanations de ces produits

peuvent provoquer de graves nausées, évanouissements

ou empoisonnements.

MESURES PRÉVENTIVES :

• Se servir d’un masque ou d’un respirateur s’il y a risque

d’inhalation (lire toutes les directives concernant ces

dispositifs an de s’assurer qu’ils orent la protection requise).

• Porter des lunettes de protection.

• Porter les vêtements de protection prescrits par le fabricant

du produit utilisé.

MISE EN GARDE : GÉNÉRALITÉS

D’autres dangers peuvent entraîner des dommages

matériels ou des blessures graves.

MESURES PRÉVENTIVES :

• Portez toujours les gants, la protection oculaire, les vêtements

et un respirateur ou masque appropriés quand vous peignez.

• Ne travaillez pas et ne pulvérisez pas près d’enfants. Éloignez

toujours les enfants de l’équipement.

• Ne travaillez pas avec les bras au-dessus de la tête ni sur un

support instable. Appuyez-vous bien sur les deux pieds pour

toujours conserver l’équilibre.

• Soyez attentif et regardez ce que vous faites.

© Titan Tool Inc. Tous droits réservés. 13

• N’utilisez pas l’appareil quand vous êtes fatigué ou sous

l’inuence de drogues ou d’alcool.

• Ne faites pas de nœuds avec le tuyau et ne le tordez pas trop.

Le tuyau à vide peut présenter des fuites suite à l’usure, les

nœuds ou les mauvais traitements. Une fuite risque d’injecter

du produit dans la peau.

• N’exposez pas le tuyau à des températures ou des pressions

supérieures à celles spéciées par le fabricant.

• N’utilisez pas le tuyau pour tirer ou soulever l’équipement.

• Utilisez la plus basse pression possible pour rincer l’équipement.

• Respectez tous les codes locaux, étatiques et nationaux

qui régulent la ventilation, la prévention d’incendies et le

fonctionnement.

• Les normes de sécurité du gouvernement des États-Unis ont

été adoptées dans la loi Occupational safety and Health Act

(OSHA). Ces normes, en particulier la partie 1910 des Normes

générales et la partie 1926 des Normes de construction,

doivent être consultées.

• Avant chaque emploi, vériez tous les tuyaux pour détecter

d’éventuelles coupures, fuites, abrasion ou couvercle bombé.

Vériez l’état ou le mouvement des accouplements. Changez

immédiatement le tuyau si l’une de ces conditions est vériée.

Ne réparez jamais un tuyau de peinture. Remplacez-le par un

tuyau conducteur à haute pression.

• Ne pulvérisez pas à l’extérieur par temps venteux.

• Débranchez toujours le cordon électrique de la prise avant de

travailler sur l’équipement.

IMPORTANT: La pompe à diaphragme est dotée d’un dispositif

de remise en marche automatique avec protection thermique.

En cas de surcharge, ce dispositif débranche le moteur du bloc

d’alimentation.

• Le moteur se remet en marche sans avertissement lorsque le

protecteur est réarmé automatiquement.

• Débranchez toujours le moteur du bloc d’alimentation avant

d’utiliser l’équipement.

• Lorsque le dispositif de remise en marche automatique débranche

le moteur du bloc d’alimentation, libérez de la pression en

tournant la soupape de PRIME/SPRAY à la position PRIME.

• Placez l’interrupteur MARCHE/ARRÊT (ON/OFF) de la pompe

en position ARRÊT (OFF).

NOTA : Il faut remédier à la cause de la surcharge avant

de faire redémarrer la pompe. Voir la section

Dépannage.

NOTA : Assurez-vous de vérier la continuité du terre après

le service est eectuée sur tous les composants

électriques. Utilisez un ohmmètre pour déterminer

s’il y a une continuité entre les pièces de métal

inerte accessibles du produit et la lame de mise à la

terre de la che de branchement.

Caractéristiques techniques

Poids .........................................................11,3 kg

Débit maximum ...................................1,25 liters/min

Source de puissance...........................Moteur électrique, totalement

fermé, refroidi par un ventilateur

Tension ....................................................Circuit d’une intensité minimale de

15 A, sous tension de 115 V c.a., à

fréquence de 60 Hz

Génératrice ............................................5000 W

Pression de service maximale .........2800 PSI (193 bar)

Capacités ................................................Pulvériser une grande variété

de peintures à huile ou au latex,

d’apprêts et de teintures

Français

Page 14

Table des matières

PRIME/SPRAY

d'alimentation

Commencer

Bouton du clapet de poussée

Consignes de sécurité ................................................................... 12

Directives de mise à la terre ....................................................................12

Description générale ..................................................................... 14

Caractéristiques techniques ...................................................................14

Installation ..................................................................................... 14

Fixation de l’embout sur le pistolet .....................................................14

Vérication du robinet de sortie (en option) ....................................14

Assemblage du exible de peinture ....................................................15

Procédure de décompression ....................................................... 15

Amorçage ....................................................................................... 15

Préparation à l’amorçage .........................................................................15

Assemblage de la trémie de peinture .................................................16

Fixation de tube de retour ......................................................................16

Amorçage de la pompe ............................................................................16

Pulvérisation .................................................................................. 17

Technique de pulvérisation ....................................................................17

Pratique ..........................................................................................................17

Nettoyage ...................................................................................... 18

Rangement pour la nuit ...........................................................................18

Rangement à long terme .........................................................................18

Maintenance .................................................................................. 20

Démontage et nettoyage de la soupape d’admission ..................20

Démontage et nettoyage de la soupape de sortie ........................20

Nettoyage du tamis ...................................................................................20

Dépannage ..................................................................................... 21

Liste de pièces ................................................................................ 32

Ensemble principal ....................................................................................32

Pompe à membrane ..................................................................................34

Ensemble tête de pompe ........................................................................36

Ensemble de trémie ...................................................................................37

Garantie Limitée ............................................................................ 38

Installation

Fixation de l’embout sur le pistolet

1. Pour verrouiller la détente, appuyez sur le verrou de la détente

de gauche à droite, en regardant l’arrière du pistolet.

Détente bloquée (le

pistolet ne pulvérise pas)

RISQUE ÉVENTUEL D’INJECTION. Ne vaporisez pas si la

protection d’embout n’est pas montée. Ne déclenchez

jamais le pistolet si l’embout n’est pas en position

de vaporisation ou débouché. Engagez toujours

le verrouillage de la gâchette du pistolet avant de

démonter, de remplacer ou de nettoyer l’embout.

2. Fileter l’embout sur le pistolet. Serrer d’abord l’écrou

manuellement, puis plus fermement au moyen d’une clé.

NOTA : Lorsqu’on xe l’embout au pistolet, il faut en

aligner le dispositif de protection tel qu’illustré à la

gure ci-dessous, puis le serrer au moyen d’une clé.

Détente débloquée

(le pistolet pulvérise)

Description générale

Ce pulvérisateur sous vide à hautes performances est un outil

électrique de précision utilisé pour pulvériser de nombreux types

de peintures. Lisez ce manuel et respectez-en les instructions

d’utilisation et de maintenance ainsi que l’information relative à la

sécurité.

Ensemble

de trémie

Bouton de

commande

de pression

Robinet

Tube de

retour

Soupape

de sortie

Cordon

à serrer le

protection

à l'angle

indiqué

pour pulvériser

dans la direction

voulue une fois

l'embout serré

Vérication du robinet de sortie (en option)

1. Appuyez fortement sur le bouton du clapet de poussée,

fourni en option, placé sur le côté du logement de la pompe,

pour vous assurer que le robinet à bille de sortie bouge sans

problème.

(en option)

14 © Titan Tool Inc. Tous droits réservés.

Français

Page 15

Assemblage du exible de peinture

Bouton de

PRIME/SPRAY

1. Fixez le exible à haute pression sur le pulvérisateur de peinture.

Utilisez une clé pour bien serrer le exible de peinture.

2. Fixez le pistolet de pulvérisation à l’autre extrémité du exible

à haute pression. Serrez fermement le tuyau sur le pistolet en

utilisant deux clés.

3. Branchez le pulvérisateur à une prise correctement reliée à la

terre ou à une rallonge pour service intensif reliée à la terre.

N’utilisez pas plus de 100 pieds (3 m) de cordon. Si vous devez

pulvériser loin d’une source d’électricité, utilisez un exible de

peinture plus long et non pas des rallonges plus longues. Utilisez

une rallonge d’un calibre minimum de 16 pour une longueur

maximum de 50 pieds (1,5 m) ou d’un calibre de 12 à 14 pour des

rallonges de longueur comprise entre 50 et 100 pieds (1,5 et 3 m).

Procédure de décompression

Assurez-vous de bien suivre la procédure de limitation

de pression lorsque vous arrêtez l’appareil pour une

raison quelconque, y compris lors de l’entretien ou

du réglage d’une pièce du circuit de vaporisation,

du remplacement ou du nettoyage des embouts de

vaporisation ou lors de la préparation au nettoyage.

1. Tournez le bouton de commande de pression dans le sens

contraire des aiguilles d’une montre jusqu’au réglage le plus bas.

Amoçage

Préparation à l’amorçage

1. Remplissez le soupape d’admission avec de l’eau ou avec une

huile ménagère uide.

2. Assurez-vous que le robinet PRIME/SPRAY est réglé sur PRIME

et que le bouton de commande de pression est tourné dans

le sens contraire des aiguilles d’une montre sur le réglage de

pression le plus bas.

3. Placez l’interrupteur ON/OFF du moteur sur ON.

4. Augmentez la pression en tournant le bouton de commande

de pression dans le sens des aiguilles d’une montre d’1/2 tour.

5. Forcez l’ouverture le soupape d’admission et fermez en

poussant dessus avec un tournevis ou le côté gomme d’un

crayon. Il doit s’enfoncer et ressortir d’environ 1/16 de pouce

(1,5 mm). Continuez jusqu’à ce que l’eau ou l’huile soit aspirée

par le pulvérisateur, ce qui humidiera les pièces mobiles et

détachera tout résidu de vieille peinture.

2. Tournez le robinet de PRIME/SPRAY sur PRIME.

3. Appuyez sur la détente du pistolet pour éliminer toute

4. Verrouiller le pistolet en mettant

© Titan Tool Inc. Tous droits réservés. 15

commande

de pression

Robinet

pression éventuellement restante dans le tuyau.

le verrou de détente à la position

appropriée.

RISQUE ÉVENTUEL D’INJECTION.

Ne vaporisez pas si la protection

d’embout n’est pas montée. Ne

déclenchez jamais le pistolet si

l’embout n’est pas en position de

vaporisation ou débouché. Engagez

toujours le verrouillage de la gâchette

du pistolet avant de démonter, de

remplacer ou de nettoyer l’embout.

6. Placez la paume de votre main sur l’entrée. Tournez le bouton

de commande de pression dans le sens des aiguilles d’une

montre jusqu’au réglage maximum. Vous devez sentir une

aspiration provenant du soupape d’entrée. Si ce n’est pas le

cas, reportez-vous au chapitre sur le nettoyage et la réparation

du soupape de sortie.

7. Tournez le bouton de commande de pression dans le

sens contraire des aiguilles d’une montre jusqu’au réglage

minimum de pression.

8. Placez l’interrupteur ON/OFF du moteur sur OFF.

Français

English

Page 16

Assemblage de la trémie de peinture

Raccord du tube de retour

Tube de retour

Tube de retour

C

PRIME/SPRAY

1. Alignez le bas de la trémie de peinture avec le soupape

d’admission leté du bloc de la pompe à peinture.

2. Tournez la trémie dans le sens des aiguilles d’une montre

pour la visser sur le soupape d’admission. Continuez à tourner

la trémie jusqu’à ce qu’elle soit bloquée sur le soupape

d’admission.

Amorçage de la pompe

1. Tournez le bouton de commande de pression dans le sens

contraire des aiguilles d’une montre jusqu’au réglage de

pression le plus bas.

NOTA : Vériez que les lets sont droits et que la trémie est

libre de tourner sur le robinet d’entrée. Veillez à ne

pas visser de travers.

3. Placez le tamis dans le bas de la trémie de peinture. Il se met

en place par un coup sec.

Fixation de tube de retour

1. Assurez-vous que l’interrupteur ON/OFF du moteur est placé

sur OFF.

2. Vissez le raccord du tube de retour fourni avec les manuels

dans l’orice du tube de retour, sur le côté de la pompe..

NOTA : Ne serrez pas trop. Serrez seulement à la main.

Certains lets seront visibles même après avoir

serré à fond.

3. Placez l’extrémité droite du tube de retour dans le raccord du

tube.

4. Vissez l’écrou du tube de retour sur le raccord du tube de

retour et serrez jusqu’à ce que le tube soit xé.

5. Placez l’extrémité en forme de crochet du tube de retour dans

le trou du couvercle de la trémie de peinture.

Bouton de

commande

de pression

Robinet

2. Retirez le couvercle de la trémie de peinture et remplissez la

trémie.

3. Tournez le robinet de PRIME/SPRAY sur PRIME.

4. Placez l’interrupteur ON/OFF du moteur sur ON.

5. Tournez le bouton de commande de pression dans le sens

des aiguilles d’une montre sur la position intermédiaire entre

demi-pression et pression totale. Laissez l’unité s’amorcer

pendant 1 à 2 minutes après que la peinture commence à

s’écouler dans le tube de retour.

IMPORTANT : Abaissez toujours la pression à zéro avant de

modifier la position du robinet de PRIME/SPRAY. Vous pourriez

sinon endommager la membrane de la pompe à peinture.

IMPORTANT : Si le bouton de commande de pression est placé

sur zéro et que le robinet dde PRIME/SPRAY est encore sur

SPRAY pendant que le pulvérisateur est en marche, il y aura une

pression élevée dans le tuyau et dans le pistolet de pulvérisation

jusqu’à ce que le robinet de PRIME/SPRAY soit placé sur la

position PRIME ou jusqu’à ce que la pression soit dégagée sur le

pistolet.

ouvercle de la trémie

16 © Titan Tool Inc. Tous droits réservés.

E

Français

Page 17

Pulvérisation

Revêtement également répartit

régulier et à vitesse constante.

Couche épaisse

Ne échissez pas votre poignet pendant la pulvérisation.

Couche légèreCouche légère

Environ 25 à 30 cm

Manière correcte d'enclencher le pistolet de pulvérisation

Début du

assage

du passage

sur la gâchette

la gâchette

itesse constante

PRIME/SPRAY

Technique de pulvérisation

Pour obtenir une peinture d’un ni impeccable il est essentiel que le

produit soit également réparti sur toute la surface. Pour y parvenir,

procédez par applications régulières. Déplacez votre bras à vitesse

constante et gardez toujours le pistolet de pulvérisation à une

distance constante de la surface. Placez votre pistolet de telle sorte

que la tête de pulvérisation soit à une distance d’environ 25 à 30 cm

(10 à 12 po) de la surface.

Environ 25 à 30 cm

(10 à 12 po)

Déplacez votre bras d’un mouvement

Gardez le pistolet de pulvérisation à angle droit par rapport à la

surface. Il vous faut pour cela déplace tout votre bras de haut en bas

et non pas seulement échir votre poignet.

Déplacez votre

bras d’un

mouvement régulier

Appuyez

Environ 25 à 30 cm

Gardez une

(10 à 12 po)

Relâchez

Fin

Chevauchez chaque passage d’environ 50 %. Vous obtiendrez ainsi

un revêtement uniforme.

Lorsque vous avez terminé de peindre, bloquez le pistolet, tournez le

bouton de commande de pression dans le sens contraire des aiguilles

d’une montre sur la pression la plus faible et placez le robinet de PRIME/

SPRAY sur PRIME. Placez l’interrupteur du moteur en position ARRÊT

(OFF) puis débranchez le pulvérisateur.

Si vous pensez être absent pendant plus d’une heure, suivez la

procédure de nettoyage rapide décrite dans la section Nettoyage du

présent manuel.

Pratique

1. Assurez-vous que le exible de peinture ne comporte pas de

nœuds et n’est pas près d’objets coupants.

2. Tournez le bouton de commande de pression dans le sens

contraire des aiguilles d’une montre jusqu’au réglage le plus bas.

Placez le pistolet de pulvérisation perpendiculaire à la surface, an

d’éviter qu’une extrémité de chaque passage soit plus épaisse que

l’autre.

(10 à 12 pi)

Bonne

technique

Mauvaise

technique

Appuyez sur la gâchette au début et à la n de chaque passage. Vous

éviterez de gaspiller de la peinture ou d’avoir une accumulation de

peinture à l’extrémité du passage. N’enclenchez pas le pistolet au

milieu d’un passage. Ceci entraînerait une pulvérisation inégale et un

revêtement irrégulier.

© Titan Tool Inc. Tous droits réservés. 17

Bouton de

commande

de pression

Robinet

3. Tournez le robinet de PRIME/SPRAY sur SPRAY.

4. Tournez le bouton de commande de pression (2) dans le

sens des aiguilles d’une montre jusqu’au réglage maximum.

Le exible de peinture doit se raidir quand la peinture

commence à s’écouler.

5. Débloquez le verrou de

la détente du pistolet en

tournant le commutateur

de sorte qu’il soit parallèle

Forme de pulvérisation correcte

à la poignée.

6. Appuyez sur la détente

du pistolet pour purger le

tuyau d’air.

7. Quand la peinture

arrive dans l’embout de

pulvérisation, faites un

Traînées de peinture

test pour en vérier les résultats.

8. Utilisez le réglage de pression le plus bas possible pour

obtenir une bonne pulvérisation. Si la pression est trop élevée,

la pulvérisation sera trop ne. Si la pression est trop basse, des

traînées apparaîtront ou alors la peinture s’étalera en faisant

des taches au lieu d’une ne pulvérisation.

Français

English

Page 18

Nettoyage

Rangement pour la nuit

Arrêt

1. Tournez le bouton de commande de pression dans le sens

contraire des aiguilles d’une montre jusqu’au réglage minimum.

2. Tournez le robinet de PRIME/SPRAY sur PRIME pour enlever la

pression du système.

3. Appuyez sur la détente du pistolet pour éliminer toute

pression éventuellement restante dans le exible.

4. Verrouiller le pistolet en mettant

le verrou de détente à la position

appropriée.

5. Placez l’interrupteur ON/OFF du moteur

sur OFF et débranchez le pulvérisateur.

6. Pour les peintures au latex, versez

lentement tasse d’eau sur la peinture

pour éviter qu’elle ne sèche. Pour les

autres types de peintures, scellez le

récipient ou la trémie (avec son couvercle) de peinture en

laissant le tube de retour dans la peinture.

7. Enveloppez le pistolet pulvérisateur dans un chion humide

et placez-le dans un sac en plastique. Fermez bien le sac

hermétiquement.

8. Placez le pulvérisateur dans un endroit sûr à l’abri du soleil

pour un rangement à court terme.

Reprise du travail

1. Retirez le pistolet du sac en plastique.

2. Remuez l’eau dans la peinture pour les peintures au latex.

Retirez le couvercle de la trémie ou du récipient de peinture et

remuez la peinture pour tous les autres types de peinture.

6. Testez le pulvérisateur sur une chute et commencez à

pulvériser.

Stockage à long terme

Ne laissez pas la peinture s’accumuler sur le moteur,

sous peine de le faire surchauer. Ne mettez pas de

solvants inammables en contact avec le moteur car ils

pourraient s’enammer.

NOTA : Vous aurez besoin d’un seau, d’une solution de

nettoyage, d’une brosse à dents, d’une clé et de

chions.

NOTA : Si vous pulvérisez avec de la peinture au latex,

utilisez de l’eau tiède savonneuse pour le

nettoyage. Si vous utilisez une peinture alkyde

ou à l’huile, utilisez des essences minérales ou un

produit diluant pour peinture.

IMPORTANT : N’utilisez pas d’essences minérales ni de diluants

avec une peinture au latex car le mélange se transformerait en

une substance gélatineuse difficile à enlever.

Nettoyage de la trémie de peinture

1. Verrouiller le pistolet en mettant

le verrou de détente à la position

appropriée.

2. Tournez le bouton de commande de

pression dans le sens contraire des

aiguilles d’une montre jusqu’au réglage

minimum.

3. Tournez le robinet de PRIME/SPRAY sur

PRIME.

4. Placez l’interrupteur ON/OFF du moteur sur OFF.

5. Dirigez le tube de retour dans le récipient de peinture

d’origine.

6. Placez l’interrupteur ON/OFF du moteur sur ON.

7. Tournez le bouton de commande de pression sur la moitié

de la pression maximum. De cette manière, la peinture

restante dans la trémie de peinture est aspirée dans la pompe

et remonte dans le tube de retour et dans le récipient de

peinture.

8. Tournez le bouton de commande de pression dans le

sens contraire des aiguilles d’une montre jusqu’au réglage

minimum de pression.

9. Actionnez le pistolet pour supprimer la pression et verrouillez-le.

10. Retirez le protège-embout et l’embout de pulvérisation et

placez-les dans un récipient d’eau ou de solvant approprié

pour le type de peinture utilisée.

11. Remplissez la trémie de peinture d’eau ou d’un solvant

approprié pour le type de peinture que vous utilisez.

12. Dirigez le tuyau de retour dans un seau pour résidus.

13. Augmentez la pression à la moitié de la pression maximale.

Laissez l’eau ou le solvant circuler pendant 2-3 minutes pour

évacuer la peinture hors de la pompe, de la trémie et du tuyau

de retour.

Nettoyage du tuyau de peinture

1. Pour économiser la peinture restée dans le tuyau, débloquez

le verrou de la détente du pistolet et actionnez le pistolet avec

précautions, avec l’embout enlevé, à l’intérieur du récipient de

peinture.

3. Vériez que le robinet de PRIME/SPRAY est réglé sur PRIME et

que la pression est réduite au maximum.

4. Branchez le pulvérisateur et placez l’interrupteur ON/OFF du

moteur sur ON.

5. Une fois le pulvérisateur amorcé, tournez le robinet de PRIME/

SPRAY sur SPRAY et tournez progressivement le bouton

de commande de pression dans le sens des aiguilles d’une

montre pour faire monter la pression.

18 © Titan Tool Inc. Tous droits réservés.

Français

Page 19

2. Tournez le bouton de commande de pression dans le

sens contraire des aiguilles d’une montre jusqu’au réglage

minimum de pression.

3. Tournez le robinet de PRIME/SPRAY sur SPRAY.

4. Tournez lentement le bouton de commande de pression

jusqu’à ce que la peinture commence à couler dans le seau.

Dès que l’eau ou le solvant commence à arriver dans le seau,

lâchez la détente.

5. Remplacez l’eau ou le solvant par de l’eau ou du solvant

propre, dirigez le pistolet sur la paroi du seau pour résidus

et continuez à faire circuler le liquide pendant 5 minutes

pour bien nettoyer le tuyau, la pompe et le pistolet de

pulvérisation.

6. Tournez le bouton de commande de pression dans le sens

contraire des aiguilles d’une montre jusqu’au réglage le plus bas.

7. Tournez le robinet de PRIME/SPRAY sur PRIME.

8. Appuyez sur la détente du pistolet pour éliminer toute

pression éventuellement restant dans le exible.

9. Bloquez la détente du pistolet en tournant le verrou de la

détente à fond vers l’avant.

10. Placez l’interrupteur ON/OFF du moteur sur OFF.

Nettoyage du pistolet

1. Retirez le pistolet de pulvérisation du tuyau de peinture en

vous servant de deux clés réglables.

2. Retirez le logement de ltre du pistolet. Placez le pistolet et le

ltre dans un récipient rempli d’eau ou de solvant.

3. Nettoyez l’embout de pulvérisation et le ltre du pistolet avec

une brosse douce.

4. Remontez le pistolet et le ltre. Assemblez l’embout de

pulvérisation dans la position de nettoyage avec le èche

dirigée vers l’arrière du pistolet.

10. Tournez le bouton de commande de pression dans le sens