Page 1

TITAN DK 2500

English

OPERATOR'S MANUAL

NV. A. DE KONINCK

Avenue Sleeckx 84-86

B-1030 BRUSSELS -BELGIUM

Phone : ++32/2 216 31 40 Fax : ++32/2 242 41 89

E-mail : info@titansew.com Web : www.titansew.com

Page 2

DK 2500 MANUAL E PAGE 1

Chapter 1: Installation and lubrication

1. INSTALLATION ................................................................................................................................3

a. Complete machine - with motor and table.................................................................................3

b. Sewing head only .......................................................................................................................5

2. LUBRICATING THE SEWING HEAD....................................................................................................5

Chapter 2: Threading

1. TYPES OF YARNS.............................................................................................................................7

a. Needle yarn................................................................................................................................7

b. Chain yarn .................................................................................................................................7

HREADING ....................................................................................................................................7

2. T

a. Needle thread.............................................................................................................................7

b. Chain yarn .................................................................................................................................7

Chapter 3: Stitch formation

1. CHAIN YARN FEED ..........................................................................................................................9

2. Stitch density setting......................................................................................................................11

a. On standard equipment............................................................................................................

b With the stitch density regulator...............................................................................................11

Chapter 4: Mechanic adjustment of the sewing head

1. TYPES OF NEEDLES .......................................................................................................................13

a. How often are the needles to be replaced?..............................................................................13

b. Needle replacement..................................................................................................................13

c Needle height adjustment..........................................................................................................15

d. Replacing the needle bar and adjusting the needle height ......................................................15

2. UPPER LOOPER..............................................................................................................................17

a. Preparatory work.....................................................................................................................17

b. Replacing the upper looper .....................................................................................................17

11

c. Upper looper fine adjustment...................................................................................................17

3. THE LOWER LOOPER .....................................................................................................................19

a. Preparatory work.....................................................................................................................19

b. Replacing the lower looper......................................................................................................19

c. Adjusting the upper looper to the lower looper .......................................................................21

d. Adjusting the distance between needle and lower looper........................................................21

4. THE CUTTING MOTION...................................................................................................................23

a. Renewing the upper knife.........................................................................................................23

b. Renewing the lower knife.........................................................................................................23

c. Knife fine adjustment ...............................................................................................................23

d. Aligning the lower blade with the needle plate........................................................................23

5. THE PRESSER FOOT ................................................................................................................. 23-25

6. FEED-DOG.....................................................................................................................................26

7. CHAIN GUIDE ................................................................................................................................27

8. STITCH PLATE FINGER ...................................................................................................................27

Chapter 5: Maintenance schedule

Maintenance schedule........................................................................................................28

Page 3

TIT

DK 2500 MANUAL E PAGE 2

AN

DK2500

ADD

OIL

YARN

OIL

HERE

LEVEL

STAND

2587012P

i------------------------------.

I

@a,...___

25841E

25841VSC

·-........_

25882

2

5884

........._

25882V

........._

I

vsET

LOOPER

FIG

25884

YARN

1.1

25841R

I

I

T 16/12/04

Page 4

DK 2500 MANUAL E PAGE 3

Chapter 1: Installation and lubrication

1. Installation

a. Complete machine - with motor and table

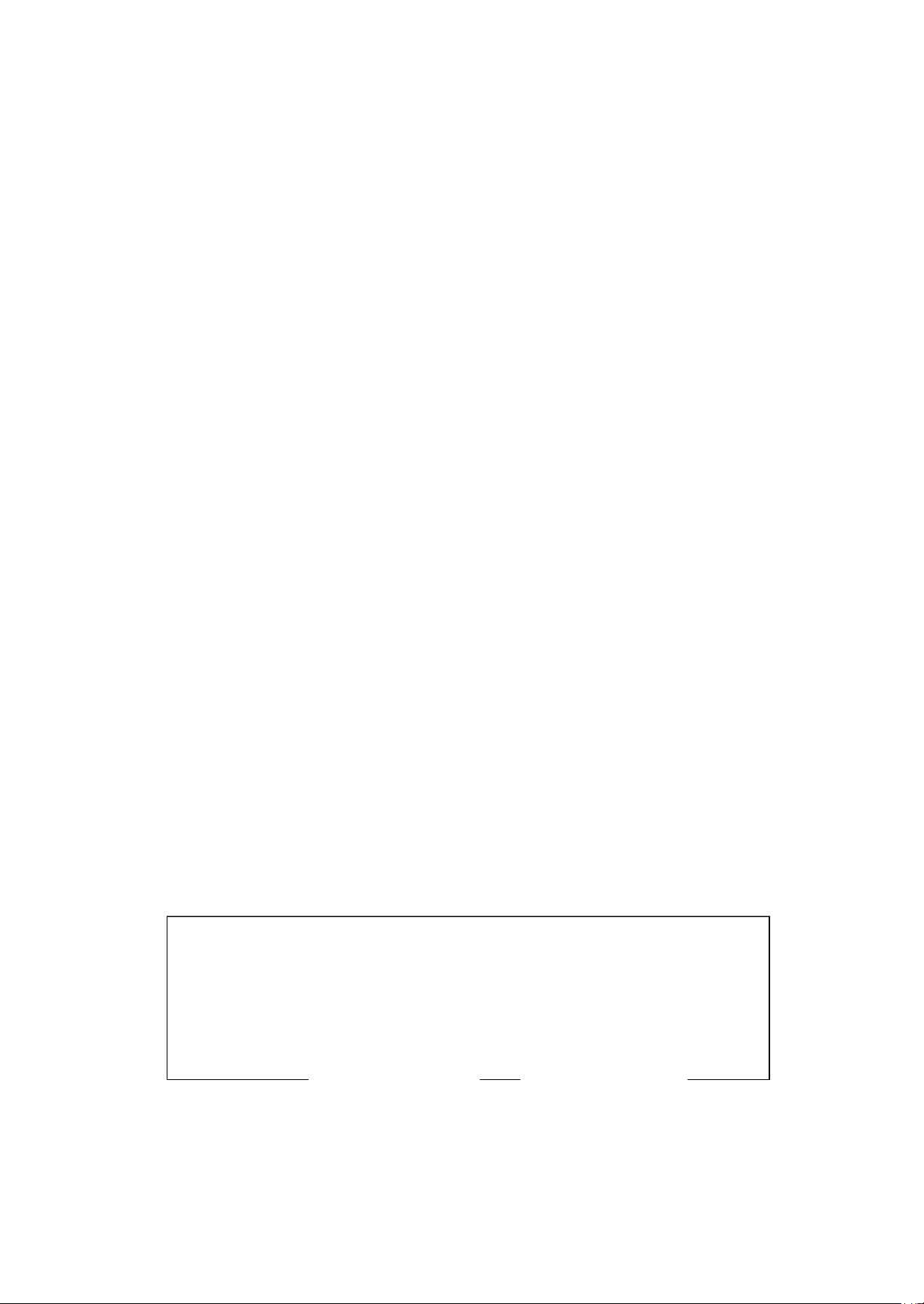

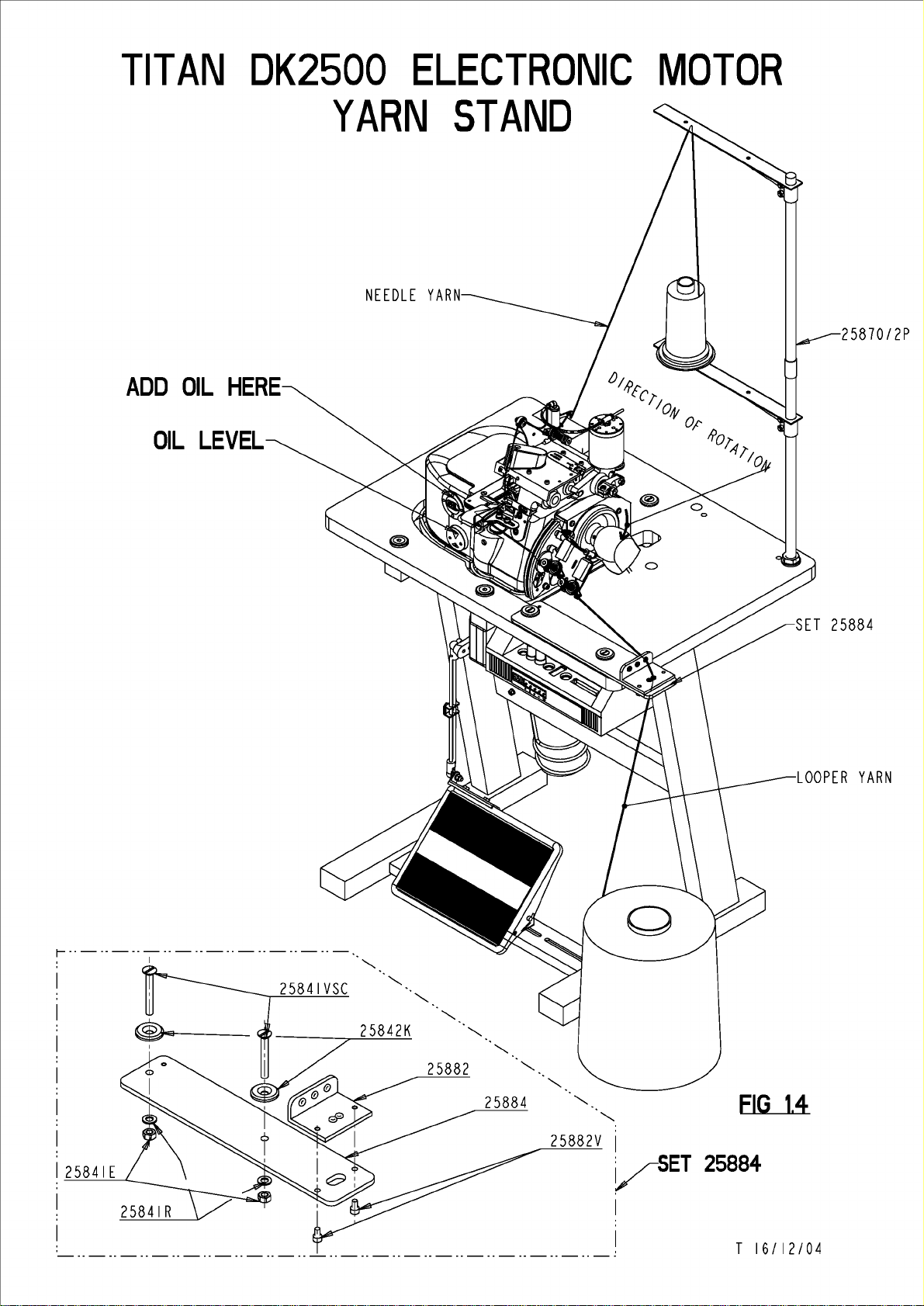

For units, supplied complete with motor and table, use FIG 1.1+1.4

1. Mount the yarn-stand 25850/2P en screw it on the table.

2. Mount the yarn guide plate SET 25884 on the table.

3. Place the black rubber anti-vibration blocks(25840) in the aluminium holders .

4. Take the TITAN DK 2500 machine out of its box. TAKE CARE NOT TO LIFT UP

the machine by holding the UPPER PARTS. Instead, place your hands

underneath the closing plate of the machine, and lift the machine. Place the 3

little feet attached at the lower plate, precisely in the black rubber blocks.

5. Look underneath the table, and loosen the nut of the motor, with a flat key of 24.

This allows the motor to rotate upwards or downwards .

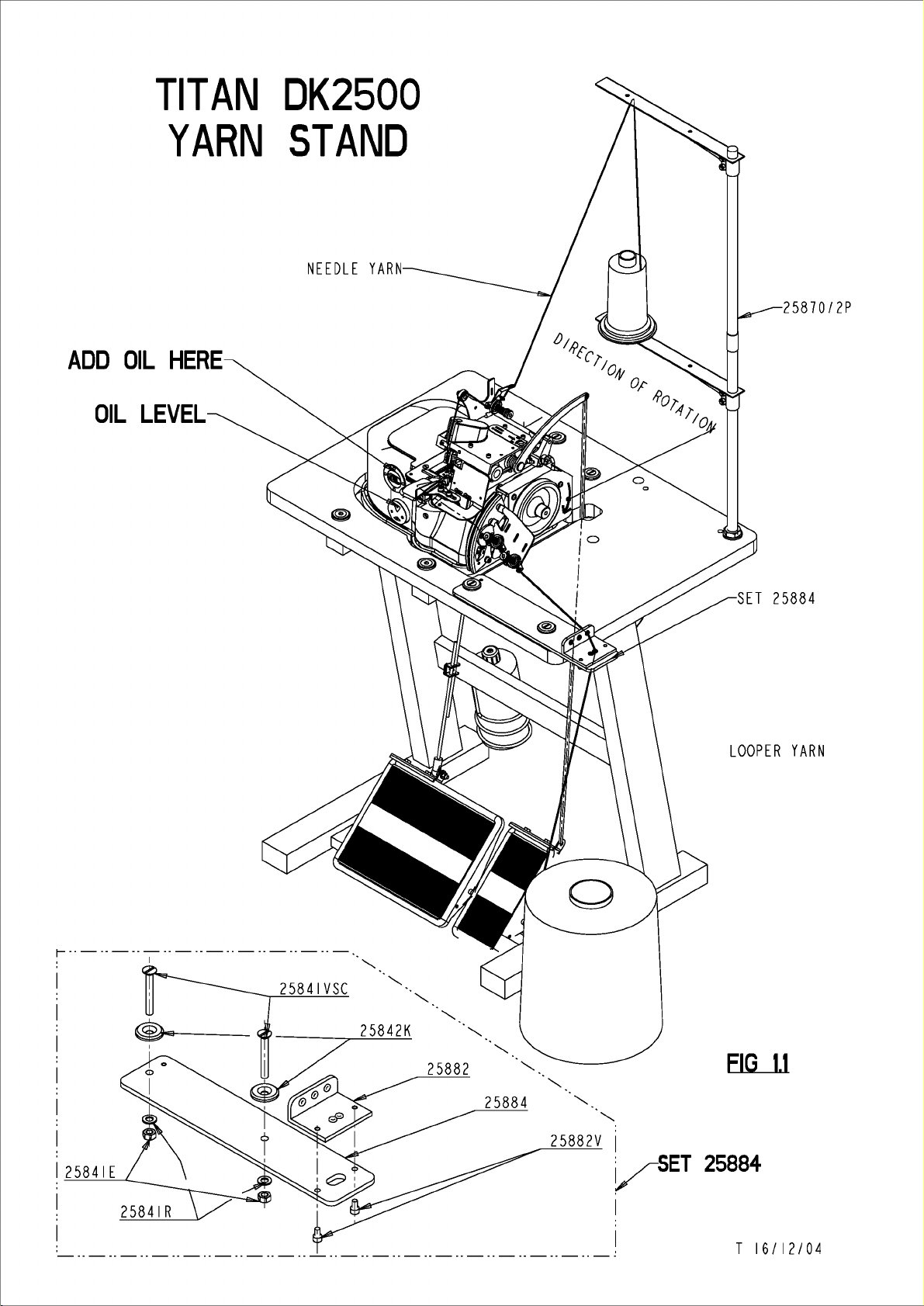

6. Push with one hand the motor upwards, and place the driving belt (attached to

the sewing machine) (M10012) around the pulley of the motor. Push the motor

down to stretch the belt slightly as seen in FIG 1.2.

-----------

--------

---

--

Tightened

7. Unscrew the cover marked “OIL” on the machine. Take the two oil bottles out of

the box and fill the machine with 1.5 L oil. Check if sufficient oil has been added

by looking at the oil-level glass. The oil level should be exactly between the two

red arrows. Close the cover again.

The electric motor is supplied, connected for use on 380V/3 PHASE supplies. For use

on 220V/3PH supplies, use the connection diagram (FIG 1.3). Connect the cores of

the mains to the receptacles of a plug designed for local operation (not included).

Verify that the direction of rotation is correct (FIG 1.1).

too

strongly

Z Y X

~ ~

bl

bl

V u

w

FIG 1.2

f@1

bl

Well

y

z

(~

~

@ @ @

V

w

X

~

u

220

FIG 1.3

VOLT

380

VOLT

Page 5

TIT

AN

DK25OO

ELECTRONIC

MOTOR

ADD

OIL

OIL

HERE

LEVEL

YARN

STAND

2587012P

i------------------------------.

I

25841VSC

·-........_

@a,...___

25882

25841E

25841R

2

5884

........._

25882V

........._

I

vsET

I

I

FIG

25884

T 16/12/04

1.4

Page 6

b.

Sewing head only

The sewing

motor rating¾

Use a pulley

Verify direction of rotation (FIG 1.1)

Prior

the machine.

See previous paragraph for more information about this.

I

2.

Lubricating the sewing head

Utilising splash lubrication, the sewing head

the components concerned.

machine with oil level lower

determination of

ATTENTION: the machine should NEVER RUN WITHOUT

The machine will loose daily a small amount of

is

recommended. If required, refill the oil reservoir

marking OIL just above the sight-glass.

Very important: oil type SP68.

The type of

SP68.

Recommended

to

starting

head

requires a drive motor that must meet the following specifications:

HP

and

rated

load

speed 2.800

80

mm

in

oil

diameter

the

sewing machine, always make sure

the

oil level (see

to

be

used

oil

types: CASTROL-ALPHA SP68 or any similar

to

match the V

is

To

get the maximum performance, never

than

the minimum level

FIG

1.1+1.4).

in

this sewing machine should

rpm.

belt.

to

pour about 1,5 I of

designed for optimum lubrication of

line.

The sight-glass allows quick

OIL.

oil.

An

inspection at periodical intervals

by

unscrewing the filler

be

of following viscosity:

oil

grade.

run

the

plug

oil

into

all

ATTENTION:

excessive wear, which

Conversely, use of high-viscosity oils

necessitate early renewal of the spare parts from lack of lubrication.

VERY IMPORTANT:

I.)

( 1.5

Remove the

bucket. Replace the

If

the oil

machine

Change the gasket (25839J)

refill the machine with oil as described above.

Use

of low-viscosity oils

in

turn will necessitate early renewal of the internal parts.

OIL

should

ONCE A MONTH. This is best done after a

plug

for oil draining underneath the machine

plug

and add

is

strongly polluted, it

and

to

remove

all

excess deposit, which has accumulated

will

result

in

poor lubrication properties

will

lead

to

lines clogging, which

be

completely removed

new oil (1.5

is

recommended

and

close the cover. Place the machine

I)

through the

to

remove

few

and

new oil should

hours

of

and

let the oil leak

plug

marked

the

cover underneath the

and

in

turn will

operation

OIL.

on

the cover.

on

the table

be

in

added

a

and

Page 7

TIT

DK 2500 MANUAL E PAGE 6

AN

DK2500

25900

THREADING

25900A

25900B

FIG

DIAGRAM

SEE

DETAIL

2.1

A

DETAIL

SCALE

A

2/5

T

07/01/2005

Page 8

DK 2500 MANUAL E PAGE 7

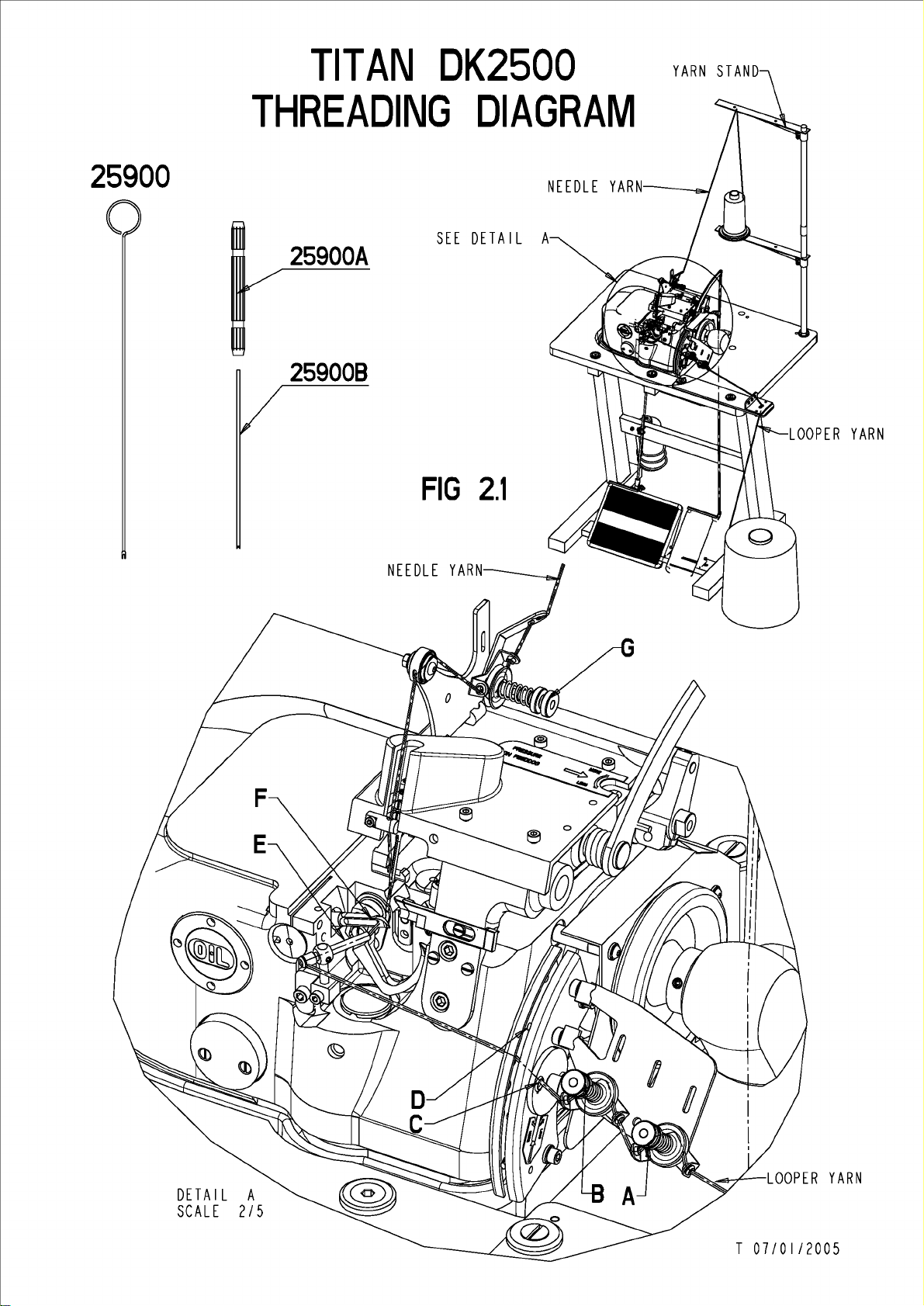

Chapter 2: Threading

1. Types of yarns

a. Needle yarn:

Many types of yarns can be used on the machine. Good results have been obtained

with following qualities : Nylon polyamide yarn of thickness 30 or 40,

Monofil (invisible) thread of 750 denier. (0,3 mm diameter) or

cotton (for example, mercerized cotton, thickness No.18).

b. Chain yarn (or “looper yarn”):

A wide range of threads can be used with DK 2500 machines.

Good results have been obtained with following qualities:

Polypropylene and Polyamide Nylon are most frequently used in thickness ranging

from 1800 detex till 5200 detex. The threads

gives better results after sewing, because the thread flattens out and covers the

carpet better.

Other qualities like wool, acrylic or cotton have also been used with success.

2. Threading

Remark: always switch off the motor prior to threading the yarns!

a. Needle thread

should be very lightly twined. This

Refer to FIG 2.1 THREADING DIAGRAM for the details.

b. Chain yarn

1. Turn the hand-wheel by hand and bring the take-up D in its topmost

2. Turn the hand-wheel by hand and bring the take-up D in its

3.

4. Tightly wrap the chain yarn around the point of the threading needle and push it

5. Gently remove the threading needle and push some more chain yarn into the

6. Turn the flying-wheel by hand to make sure the chain yarn extends above the

7. Make sure the needle thread remains threaded. The sewing machine is now

Note: For improved covering, use two or three thinner threads in the lower

looper.

position. Lead the yarn thru the tension-adjusters A and B and by hole C thru the

plates on both sides of the take-up D.

bottommost

position. In this position the eye of the lower looper faces the threading tube E

Thoroughly clean (if necessary, using the threading needle, part 25900) the

lower looper's eye.

all the way (as far as possible) into the threading tube and through the eye of the

lower looper

threading tube in order to obtain a small tangle of chain yarn behind the lower

looper's eye F

needle plate.

ready for use.

F.

EMARK: Remember : remove the THREADING NEEDLE ALWAYS.

. R

Page 9

TIT

DK 2500 MANUAL E PAGE 8

AN

DK25OO

STITCH

NEEDLE

CARPET

YARN

C:

A:

NOT

ADJUSTMENT

LOOPER

OK

OK

YARN

FIG

3.1

LOOPER

B:

NOT

D.

NOT

YARN

OK

OK

D

H

FIG

IMITATION

3.2

FIG

3-THREADSTITCH

3.4

C

FIG

J

3.3

T

25/11/04

Page 10

DK 2500 MANUAL E PAGE 9

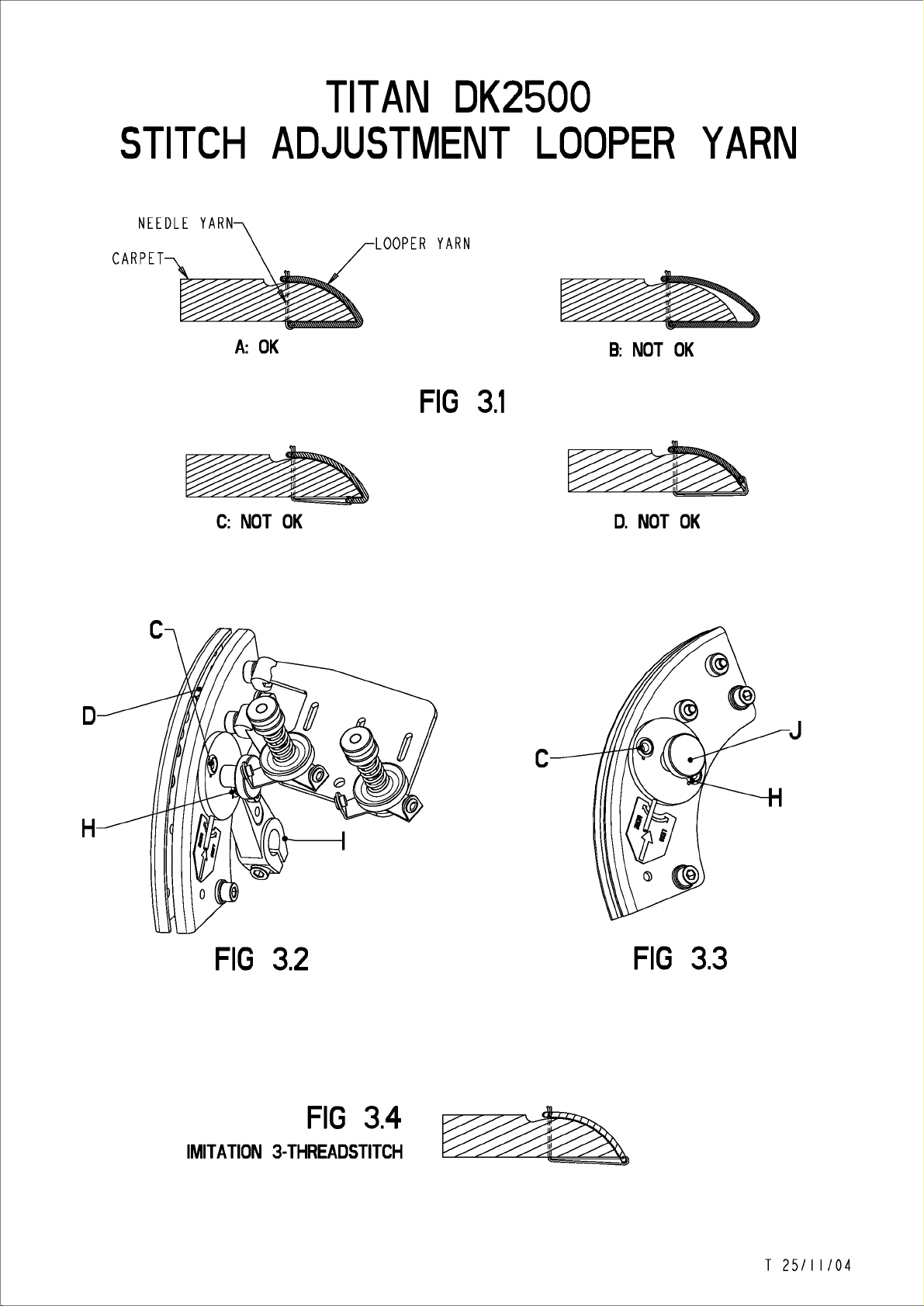

Chapter 3: Stitch formation

1. Chain yarn feed

It is recommended to keep the pressure on the springs to a minimum on the thread

tensioners A, B and G (FIG 2.1).

Note:

Always make sure the chain yarn is positioned underneath the yarn drawing lever D

(or “take-up”) (see FIG. 2.1-3.2). Failure to do so, will result in improper stitch

formation. To avoid this, check if the machine has been threaded properly (see

chapter 2b).

FIG 3.1A:

absolutely uniform tensions.

FIG 3.1B:

FIG 3.1C&D:

Correct stitch formation, the chain yarn and the needle thread have both

Either insufficient chain yarn tension, or excessive needle thread tension

Either excessive chain yarn tension, or insufficient needle thread tension

With the take-up lever D correctly set, the amount of thread thus fed will assure

successful overlocking of the carpet.

In the event of insufficient thread feed (or with thicker carpets), however, undue

tension will be placed on the chain yarn along the edges of the carpets, which in turn

will pull the needle thread from the carpet backing (see figure 3.1C).

To remedy: adjust the take-up lever D slightly in the direction of C3 (see figure 3.5).

Conversely in the event of excessive thread feed (or with thin carpets), the chain yarn

will be found to be slack around the carpet edges (see figure 3.1B).

To remedy: adjust the take-up lever D slightly in the direction of C1 (see figure 3.5).

If the machine isn’t equipped with RFR fine adjustment gear (see figure 3.3), the

position of take-up lever D is to be changed as follows:

Untighten the screw of the arm I (figure 3.2) and place the take-up lever D into the

wanted position (higher=less thread, lower=more thread) afterwards, tighten the

screw of arm I again.

RFR fine adjustment assembly: standard in the new machines (from 2004 on)

To adjust the thread feed : loosen the screw J (FIG 3.3). Push the bar (lever)

towards “+” to increase thread feed, towards “-“ to decrease thread feed.

Note: For the typical two-thread overlock stitch, insert the chain yarn in the C eye as

illustrated in figure 3.2 and 3.3

For special stitch formation similar to a three-thread stitch (see figure 3.4), pass the

chain yarn through the H eye (see figure 3.2 and 3.3) and then adjust thread feed so

that the stitch thus formed is similar to the one shown in figure 3.4.

Page 11

TIT

DK 2500 MANUAL E PAGE 10

AN

DK2500

STITCH

FIG

3.6

ADJUSTMENT

STITCH

WIDTH

STITCH

STANDARD

STITCH

ADJUSTEMENT

FIG

WITH

3.7

ADJUSTEMENT

RPR

K

M

L

T

25/11/04

Page 12

DK 2500 MANUAL E PAGE 11

FIG 3.5

2. Stitch density setting (per cm)

I

a. On standard equipment

• Unscrew and remove the big knurled screw to allow access to nut K

(FIG 3.6).

• Turn the hand-wheel by hand to secure the needle in its bottommost position.

• Holding the hand-wheel in position with your right hand, unscrew (counter

clockwise) the nut K by ½ a turn using a M10 hex key.

• Place the nut K either forward or backward as appropriate. Thus you will

increase/reduce stitch density per cm (see figure 3.6).

• Retighten the nut K and replace the knurled screw on the sewing head!

b. With the stitch density regulator (RPE/DK 2500 SEE OPTIONAL ATTACHMENTS)

The RPE option as illustrated in figure 3.7 is fitted on to the left-hand side of the

sewing machine.

• Loosen both L screws.

• Turn the disc M counter clockwise.

• By turning the adjuster screw N clockwise,

By turning the adjuster screw N counter clockwise,

• For best results, we recommend to sew first on a small piece of carpet to see if

the correct amount of stitches per cm has been obtained.

• To secure the adjuster screw N into position, turn disc M clockwise until it can

not move further.

• Slightly tighten both L bolts to lock the settings.

you increase stitch density.

you decrease stitch density.

,

The RPE option is designed to guarantee optimum sewing result with any carpet

quality and/or yarn thickness.

Page 13

TIT

DK 2500 MANUAL E PAGE 12

AN

DK2500

NEEDLE

PLACE

NEEDLEBAR

REPLACEMENT

IN

HIGHEST

POSITION.

D

&

ADJUSTMENT

X

R

FIG

4.1

T

26/11/04

Page 14

Chapter 4: Mechanic adjustment of the sewing

DK 2500 MANUAL E PAGE 13

head.

!! Remark: Always switch off the motor before adjusting wh

1. The needle

The table below is a breakdown of typical needle types.

Type: Description Suitable for:

7713/230T Standard needle Medium carpets

7713-99/230T Square pointed needle Heavy car carpets

7713-99/230TP Needle with flat holder Heavy Car carpets

7713-99/230TPC Golden needle For automatic systems DK 4600

7713-200T Medium thick needle Light carpets

7713/180T Medium thin needle Light carpets

7713/160T Thin needle Blankets

7713/130T Ultra thin needle Fabrics (butt-seamer DK 2500E

and 2510E series)

atever part of the machine !!

For special purposes, please contact our service department for additional information.

tel.: ++32/2-216.31.40

a. How often are the needles to be replaced?

Considering the typical up and down movement of needles on DK 2500 series sewing

machines is about 2.800 movements per minute, needles will need replacing after a

couple of days as they become blunt, thin, and the groove disappears, thus result :

false stitches.

Assuming the machine is used for one 8-hour shift, the needle will have pierced the

carpet approximately 6 million times in one week (40h). Depending on carpet quality,

we advise to replace the needle at least once a week.

b. Needle replacement

While sewing, a circle of dust will be built up around the needle holder. It is

important to remove first any dust that may have accumulated, prior to fitting a

replacement needle! If not, dust accumulation in the needle holder may probably

modify the exact movement of the needle, which will result in false or bad stitch

formation and may drastically decrease the life time of internal parts.

very

Page 15

PART

NR.

NEEDLE

NR.

Needle

DK

2500.

guide.

- 25559-230

- 25559-200

-7713/230

- 7713-99/230

-

7713 / 200

I

HEAVY C ARPETSI

25559A

PART

-

25559A

25559B

NR.

NEEDLE

-

7713 / 110

-7713/130

-

7713 / 160

- 7

713 / 180

- 7713 /

NR.

200

.

!NORMAL

CARPETS!

Page 16

SET 25559A

Afstelling

- Stukken 25559A

worden

bevestigd

- Stukken 25559A

maximaal

-

De

.

met

-

We

onderste

-

We

25559B

er

achterwaartse

-

We

vast.

Adjustment

van

los

op

met

openschuiven,

afstelling

een

nieuwe

zetten

sluiten

geen

schroeven,

de

dode

stukken·25559A

rond

voorwaartse

of

de

naaldgeleiding.:..

en

25559B

de

naaldplaat

schroef

en

gebeurt

naald.

risald

punt.

de

naald

speling

schroef

the

25559V.

25559B

steeds

in

haar

zodat

of

meer

25559V

needle-g~

en

is.

Reglage

-

Pieces

fixees

aiguille

-

Ouvrir

25559B

-

L'ajustement

avec

Positioner

point

- Fermer

25559B

si

j

eu en

-

Serrer

une

bien

du

guide-aiguille.

25559A

mobile

lea

maximum.

mort

les

auteur

qu1il

avant

la

et

sur

avec

la

pieces

se

nouvelle

l'aiguille

inferieur.

pieces

de

n'y a plus

ou

vis

25559V,

25559B

la

plaque

vis

25559V.

25559A

fait

toujours

aiguille

a

25559A

l'aiguille

en

arriere

sont

a

et

•

son

et

de.

~

Einstellung der nadelfuhrung.

-

Fix

parts

·mobile o~

with

- Push

25559B

- Adjustment

done

-

Put

the·

death

-

Close

around

way

that

backward

-

Fix

the

25559A

the

screw

the

with

25559V. ·

parts

maximum

must

a new

needle

point,

parts

25559A and

the

needle

there

or

forward

screw 25559V.

and

25559B

needle

25559A and

open.

in

is

plate

always

needle.

her

in

such

no more

play.

be

lowest

25559B

a

_.,,

-

Teile

milssen Mobil

Platte

Schraube

-

Teile

maximal

-

Die

unterste

-

Schlieszen

und 25559B rund

-

25559A und 25559B

befestigt

25559A und 25559B

aufschieben.

Einstellung

geschehen

Setzen

sodasz

ri.i.ckwarts

Schraube

schrauben.

Sie

es

auf

25559V

mit

die

Tode

Sie

kein

Spiel

25559V

die

Nadel-·

werden

•.

musz immer

einer

Funkt.

neue

Nadel

Teile

vorwarts

die

mehr

fest

in

25559A

Nadel

gibt.

mit

Nadel

Ihre

oder

Page 17

TIT

AN

DK2500

NEEDLE

FLAT

SIDE

NEEDLE

WITH

LOWER

5

REPLACEMENT

H

PARALLEL

LOOPER

FIG

4.2

&

ADJUSTMENT

w

.!!!

SEE

5

FIG

DETAIL

4.3

A

DETAIL

SCALE

LOWEST

OF

NEEDLE

A

3/

I

POSITION

POINT

T

07/01/2005

Page 18

DK 2500 MANUAL E PAGE 15

To replace worn out or broken needles, proceed as follows:

• Loosen the screw H (see figure 4.1) and remove the needle.

• Remove accumulated dust in the needle-holder.

• Fit in a replacement needle. Make sure to position and push the new needle

fully home into the needle-holder.

• Be sure the groove of the needle faces the front and that the flat side on the

back of the needle is mounted parallel to the flat face of the lower looper S (FIG

4.2). To check this, turn the hand-wheel by hand and have the lower looper and

the needle cross.

• Retighten the screw H.

• Check the needle position according to chapter 4.1c .

c. Needle height adjustment

With the needle having reached the top of its stroke, distance between the needle

point and the needle plate must be exactly 23 mm (see figure 4.1).

For fine adjustment of the needle height:

• Loosen the screws H first while holding the needles by hand (see figure 4.1).

• Push the needle against the screw F.

• If adapting screw F, you first have to unscrew the screw G

• By turning the screw F, the needle height will be increased or reduced

(clockwise/counter-clockwise).

.

• Retighten the screw G and also screw H

!! The following instructions are restricted to qualified personnel only !!

d. Replacing the needle bar and adjusting the needle height.

Replacing the needle bar

• Loosen the screws A and remove the worn out needle bar B (figure 4.1) from

clamp C.

• Loosen the screw X and recuperate the needle holder W.

• Fit the needle holder W into the new needle bar and tighten screw X to secure

the needle bar.

• Place a new needle in the needle holder W.

• Check the parallelism between the needle and the needle bar. If these 2 parts

are not parallel, it is strongly advised to replace the needle holder W

• Fit the new needle bar into the holder C and lightly tighten the screws A.

• Turn the hand-wheel by hand to place the needle at the top of its stroke

(highest position).

• In this position, the distance between the needle point and the needle plate

(25558) must be exactly 23 mm (figure 4.1).

Adjusting the needle height

• Loosen the screws A in FIG 4.1. By doing this, the holder C will loose its grip

on needle bar B (figure 4.1).

• The position of the needle can be adjusted to the top dead point being 23 mm.

• Retighten the screws A.

• Verify, by turning the hand-wheel by hand, if the needle is moving up and down

right in the centre of the needle plate (Fig.4.1 Detail).

Optimum needle thread loop formation setting

To achieve optimum needle thread loop formation, make sure the position of the

needle with respect to the lower looper S, is correct.

• Turn the hand-wheel by hand and bring the needle to reach the bottom of its

stroke (lowest position)

• Turn the hand-wheel a little further (see figure 4.3) until the needle has travelled

1,2mm on the upward stroke.

• In this position, the point of the lower looper should just pass behind the needle

as seen in Fig. 4.3 + Detail A.

Page 19

TITAN

DK 2500 MANUAL E PAGE 16

DK25OO

UPPER

LOOPER

ADJUSTMENT

5mm

T

FIG

V

4.4

T

29/11/04

Page 20

DK 2500 MANUAL E PAGE 17

2. Upper looper

a. Preparatory work

In order to replace the upper looper, the cover and some other parts have to be

removed. We strongly advise to proceed as follows:

• Loosen the two screws 25833V and remove the protective plate (25833).

• Release the pressure on the pressure foot.

• Loosen the two screws 25556V and remove the needle (7713/230T).

• Loosen the two screws 25558V and remove the needle plate (25558).

• Loosen the screw 25804VL and remove the threader unit (25804).

• Loosen the screw 25655V and remove the lower blade (25655).

• Loosen the screw 25744V and remove the feed dog (25744).

• Loosen the two screws 25700V and remove the upper looper (25705).

b. Replacing the upper looper

• Turn the handwheel by hand and push the lower looper to its furthermost

backward position. This action will give the operator access to the screws T

(FIG 4.4).

• Unscrew these and replace the worn out upper looper with a new one (25705).

• Retighten the screws T

• Turn the hand-wheel by hand for the upper looper to reach its top of its stroke.

• Make sure the outer end of the upper looper extends for 5mm beyond the edge

of the needle, as illustrated in figure 4.4.

If this is not the case, adjust correct position via the screws T

c. Upper looper fine adjustment

Our sewing machines are factory-set to sewing medium quality carpets with medium

quality yarn

When using thicker/finer yarns deviating from the factory-set typical yarn thickness,

we recommend that the position of the upper looper be adjusted as follows:

Loosen the T screws (figure 4.4) and turn the hand-wheel by hand for the upper

looper to reach the top of its stroke (highest position).

s.

.

as in figure 4.4.

In the event of thick yarns, move the point of the upper looper a little to the left

(0,5mm maximum), so that the distance between the outer end of the upper looper

and the edge of the needle is 5,5mm.

In the event of fine yarns, move the outer end of the upper looper a little to the right

(0,5mm maximum), so that the distance between the outer end of the upper looper

and the edge of the needle is 4,5mm.

Note: With every change of the upper looper, check the following points while turning

the hand-wheel by hand:

When the upper looper V and the lower looper S (figure 4.5) cross one another on the

upper looper upward stroke, the end of the upper looper S must travel right in the

centre of the recess of the lower looper S.

On its upward stroke towards the needle, the end of the upper looper V, mus

touch the lower looper S and needle (no contact is allowed). Should this occur

anyway, follow the steps below. After having adjusted the upper looper, put back all

parts and put back again the pressure on the pressure foot.

t not

Page 21

TITAN

DK25OO

LOWER

LOOPER

0

ADJUSTMENT

0

w

u

M

0

N

II

POINT

V

IN

V

OF

MIDDLE

LOWER

UPPER

OF

LOOPER S II

LOOPER

CUTOUT

IN

FIG

4.5

T

30/11/04

Page 22

DK 2500 MANUAL E PAGE 19

!! The following instructions are restricted to qualified

personnel only !!

With the upper looper in its bottom dead centre, make sure the outer end of the upper

looper aligns with the centre of the screw (25557V) that fixes the needle bar bushing

(Fig. 4.3).

Should this not be the case, loosen the two 25698VL screws (see part list – Upper

looper mechanism) and bring the upper looper in the right position as described in

previous paragraph 4.2b.

Turn the hand-wheel by hand for the upper looper to reach its upper position and

make sure the outer end of the upper looper extends for 5 mm beyond the edge of

the needle (see figure 4.5).

Should this not be the case, loosen the two 25698VL screws and bring the upper

looper in the right position as described in previous paragraph -

b. replacing the upper looper

3. The lower looper

a. Preparatory work

To gain access to the lower looper, proceed as follows:

• Turn to figure 2.1, titled ‘Threading Diagram’, and locate the screw-on/off fitting

cap with the wording OIL marked on it.

• Loosen and remove the cap. This will give the operator access to the lower

looper.

b. Replacing the lower looper

To replace a worn out lower looper, proceed as follows:

• Use an open ended spanner n° 6 to retain the base W (Fig. 4.5) of the lower

looper into position while using an open ended spanner n° 10, loosening the nut

K for ½ a turn (MAXIMUM).

• Gently unscrew the worn out lower looper and remove it.

• Fit in the replacement lower looper.

Note: Prior to fixing the lower looper into position, perform positioning of the lower

looper relative to the recess on the rear of the needle as described below (see figure

4.2-4.3-4.5).

Turn the hand-wheel by hand while making sure that when the lower looper is

passing beyond the needle, both flat faces on both parts are parallel. The lower

looper can under no condition touch the needle !

In the event of exact parallelism as shown in figure 4.2, retain the lower looper S in

position using an open ended spanner n° 6, while screwing the block nut K (figure

4.5) through ½ a turn, using an open ended spanner n° 10.

Page 23

TITAN

DK 2500 MANUAL E PAGE 20

DK25OO

LOWER

LOOPER

0

ADJUSTMENT

0

w

u

M

0

N

II

POINT

V

IN

V

OF

MIDDLE

LOWER

UPPER

OF

LOOPER S II

LOOPER

CUTOUT

IN

FIG

4.5

T

30/11/04

Page 24

DK 2500 MANUAL E PAGE 21

!! The following instructions are restricted to qualified personnel only !!

c. Adjusting the upper looper to the lower looper

Prior to adjusting, perform the steps detailed in previous paragraphs.

On the upper looper upward stroke and with the lower looper moving to its forward

dead point, as illustrated in figure 4.5, the outer end of the upper looper V must pass

right in the centre of the recess of the lower looper S.

In other words, when both loopers cross each other, the end of the upper looper V

must pass right in the centre of the recess of the lower looper S.

Should this not be the case, follow the steps below to adjust the position of the lower

looper inside

• Loosen the screw R, therefore enabling the lever M to move freely on the shaft

(Fig. 4.1).

• Turn the hand-wheel whilst making sure that the outer end of the upper looper

passes right in the centre of the recess located at the rear of the lower looper,

when both loopers cross one another.

• If necessary, adjust the position of the lever M.

• Retighten the screw R thus securing the lever M position.

d. Adjusting the distance between needle and lower looper

Prior to adjusting, perform the steps detailed in previous paragraphs.

the sewing machine.

Turn the hand-wheel such that the outer end of the lower looper S passes the rear of

the needle. Make sure that the distance between the needle and the lower looper is in

the range 0.2mm to 0.3mm (Fig. 4.2).

(These measures apply to machines equipped with standard needles, size 230.

When using different needles, contact our Service Department at +32/2.216.31.40).

If the distance measured above is either inferior to 0.2mm or superior to 0.3mm,

proceed as follows.

• Loosen the screw Q of figure 4.5.

• Manually move the part N forward or backward, so that the distance between

the needle and the lower looper is in the range 0.2mm to 0.3mm (figure 4.2).

Gently turn the flying wheel by hand while making sure that the distance between the

outer end of the upper looper V and the flat face of the recess on the rear of the lower

looper S is 1mm (see figure 4.5).

Should this not be the case, follow the steps below.

Unscrew the screw U (see figure 4.5) by 1/4 of a turn maximum

to move freely in the holder M. Manually move the part L a little forward or backward

whilst ensuring the distance between the outer end of the upper looper and the rear

of the lower looper is approximately 1 to 2 mm (see figure 4.5). Retighten the screw

U.

Note: After every change, it is essential to check the position of the outer end of the

upper looper in relation to the rear of the needle and if necessary to adjust as

described in the previous chapters.

Upon completion of any such adjustment, turn the handwheel and re-check the

position of the upper looper relative to the lower looper. Adjust, if necessary.

For each adjustment, remember to re-check all the positions and adjust until the

positions of the three parts are concordant.

, to enable the part L

Page 25

TITAN

DK2500

KNIFE

ADJUSTMENT

A

VIEW

A >

~--------------------

------------------------

~·-~-·-~-·-~-·-~-·-~-·-~-·--

_-

0

0

C

FIG

LOWER

KNIFE

4.6

IN

HIGHEST

B

POSITION

VIEW

A

- I

,Q

I

EE

EE

-=

=-

:z: ><

-<C

:a;;: :a;;:

E

E

Lt")

-

Lt")

f-

EE

.....JEE

::::, <.D

<C

u...

><:Z:

u..J<C-

c:,

:a;;: :a;;:

(")

T

30/11/04

Page 26

DK 2500 MANUAL E PAGE 23

4. The cutting motion

For an extended operational life, the lower knife (25655) and the upper knife (25656)

of TITAN DK 2500 series machines are equipped with special hardened steel.

a. Renewing the upper knife

• Loosen the screw C (see figure 4.6).

• Entirely remove the screw A retaining the upper knife.

• Replace the worn upper knife with a new item (25656) and retighten screw A.

b. Renewing the lower knife

• Unscrew the screw B (see figure 4.6) retaining the lower knife.

• Replace the worn lower knife with a new one (25655) and retighten the screw

B.

c. Knife fine adjustment

Upon completion of knife renewal, take great care to align both knifes by turning the

screw C.

Note: Do not over-tighten the screw C as this will put both knifes too close to one

another thus leading to their early wear. (The mobile under knife will produce a cut in

the upper knife.)

Secondly, as the knifes experience trouble sliding because too tightly screwed,

extreme pressure should be produced by the internal parts to drive the cutting motion,

which in turn will promote early wear or jam the internal parts.

d. Aligning the low

With the needle having reached its lowest stroke, ensure that the lower knife

protrudes 6 to minimum 3 mm above the needle plate (see figure 4.6). If this is not

the case renew both knives

er blade with the needle plate

5. The presser foot

For optimum sewing performance, a good control of presser foot pressure is very

important.

Insufficient presser foot pressure will lead feed-dog to skid, which will endanger the

continued health of the feed-dog on the one hand, and will result in irregular stitch

formation on the other hand. When overlocking soft foam rubber backed carpets, the

carpet backing will be damaged.

However, carpet backings will show only small, virtually invisible signs of wear when

presser foot pressure is correct.

Conversely, when the presser foot pressure is too high, the feed-dog will break!

Typical rated torque setting is 80 N/m. Use a torque wrench for correct presser foot

setting (see figure 4.8).

Following is a breakdown of the presser feet available (for schematic representations

refer to fig. 14A).

Page 27

TITAN

DK 2500 MANUAL E PAGE 24

DK2500

PRESSURE

ON

PRESSUREFOOT

BON

FIG

4.8

"<I"

E

E

T 01/12/04

Page 28

DK 2500 MANUAL E PAGE 25

Part Suited for…

25583 Standard presser foot

25583 BIS Presser foot for fine delicate fabrics

30583K Presser foot for blankets; used in conjunction with

guides.

25583EEK Presser foot for carpets fine overlocking, typical

stitch width 5,5mm

25583B Buttseamer presser foot

25583E

BIS

Buttseamer presser foot for fine delicate fabrics.

25280 For car carpets DK 2500Ag

Page 29

DK 2500 MANUAL E PAGE 26

6. Feed-dog

With every up and down movement of the feed dog, some dust will accumulate. To

avoid excessive dust accumulation, we recommend to blow carefully the space

underneath the needle plates with compressed air at the end of each shift.

Furthermore, remove the stitch plate every two weeks, to thoroughly remove any

compressed dust built up underneath.

Failure to do so will result in dust mixing with the machine’s oil. The sticky black

mixture formed will act as abrasive paper and score critical components, resulting in

a premature wearing out of internal components such as bearings.

Available feed-dog types:

Part Suited for…

25744 Standard, for medium quality carpets

25744K With fine teeth, for light or delicate

materials

25744CAR Heavy duty

25744KPCAR Heavy duty, with pyramid shaped teeth

Page 30

DK 2500 MANUAL E PAGE 27

7. Chain guide

For optimum stitch formation, it is recommended for the chain guide to be adjusted to

the carpet thickness.

Find hereunder the available chain guides :

Part Number Suited for…

25560 Normal carpets

25560B High pile carpets

25560H Heavy carpets

25560EE Normal carpets with small-sized over locking (2500 EEK)

30560GR Normal carpets with tape insertion

25560C Blankets (DK 2500C type)

25560K Butt-seamer (DK 2500 E type)

8. Stitch plate finger

The type of stitch plate finger used will depend on different factors such as :

• Thickness of yarn

• Thickness of needle

• Stitch width

Phone our technical department for advice or mail : +32-2-216.31.40

Page 31

DK 2500 MANUAL E PAGE 28

CHAPTER 5 : MAINTENANCE SCHEDULE

MAINTENANCE SCHEDULE : to prolong the life time of your TITAN Machine.

TO DO EVERY 8 HOURS (+/- DAY)

• Blow clear the machine with compressed air at the end of each shift!

TO DO EVERY 40 HOURS (WEEK)

• Change needle every 40 working hours .

• Before replacement of the needle, thoroughly remove any dust that may have

accumulated round the needle holder.

• Remove dust beneath both the stitch plate and the feed-dog

once a week!

• Check oil level every week + add oil accordingly.

TO DO EVERY 200 HOURS (MONTH)

• Change the oil once a month minimum! OIL TYPE : 15W30

• Check and if necessary replace any worn out parts such as

loopers, knives, needle guide, chain guide with new ones.!

TO DO EVERY YEAR

• Check if the parts are still mounted tight

lower looper – needle bar – knifes and other parts. Open up the machine and

replace necessary parts such as bearings, and others

ly, if there is no play on the upper and

• If you have no maintenance engineer, you can send back your sewing head,

and the company DE KONINCK will give se

or sales department at TEL +32-2-216.31.40 or by email at :

info@titansew.com

rvice to you. Consult our technical

Page 32

PARAMETER SETTINGS ON THE EFKA MOTOR

PLEASE NOTE

As the Controller is programmed with a memory key from Titan and you want to

change some parameters. It is necessary to erase the settings from the memory key by

changing the parameter 399 cFP.

To activate this parameter you have to do following steps :

1. Enter Code 3112

2. Go to parameter 399 and push ENTER

3. Push on the arrow and ENTER again CODE 3112

4. Press two (2) times on P

5. Power off, wait for one second

6. Power on.

ELECTRONIC MOTOR SETTINGS EFKA :DC 1500/1550 SERIES

USE SETTINGS ONLY FOR DK 2500 OVEREDGING MACHINES!!

- POWER OFF

- POWER ON AND PRESS P KEY

- PRESS >> KEY

- SET SUPPLIER LEVEL CODE NUMBER 3112

- PRESS E KEY

- PARAMETER .2.0.0. IS DISPLAYED

- PRESS KEY >> AND CHANGE PARAMETER .2.0.0. TO .1.1.1.

- PRESS E KEY

- SET VALUE ON 2800 BY PRESSING + OR – KEY

- PRESS E KEY

- PARAMETER .1.1.2. IS DISPLAYED

- PRESS >> KEY AND CHANGE PARAMETER .1.1.2. TO .1.1.9.

- PRESS E KEY

- SET VALUE ON 3 WITH + OR – KEY

- PRESS E KEY

- PARAMETER .1.2.1. IS DISPLAYED

- PRESS >> KEY AND CHANGE PARAMETER .1.2.1. TO .1.5.3.

- PRESS E KEY

- SET VALUE ON 15 WITH + OR – KEY

- PRESS E KEY

- PARAMETER .1.5.5. IS DISPLAYED

- PRESS >> KEY AND CHANGE PARAMETER .1.5.5. TO .5.0.0.

- PRESS E KEY

- SIR- IS DISPLAYED

- PRESS >> KEY

- PARAMETER .2.9.0. IS DISPLAYED

- PRESS E KEY AND SET VALUE TO 05WITH + OR – KEY

- PRESS E KEY

- PARAMETER .1.6.1. IS DISPLAYED

- PRESS E KEY AND SET VALUE TO 0 WITH + OR – KEY

- PRESS E KEY

- PARAMETER .2.7.2. IS DISPLAYED

- PRESS E KEY AND SET VALUE TO 0739 WITH + OR – KEY

- PRESS E KEY

Page 33

- PARAMETER .2.7.0. IS DISPLAYED

- PRESS E KEY ANDSET VALUE TO 3 WITH + OR – KEY

- PRESS E KEY

- PARAMETER .4.5.1. IS DISPLAYED

- PRESS E KEY AND TURN HANDWHEEL CLOCKWISE AND

- SET NEEDLE ON LOWEST POINT

- PRESS E KEY

- PARAMETER .4.5.3. IS DISPLAYED

- PRESS E KEY AND TURN HANDWHEEL CLOCKWISE AND

- SET NEEDLE ON TOP POINT

- PRESS E

- PARAMETER .2.9.0. IS DISPLAYED

- PRESS TWO TIMES P KEY

- RUN THE MACHINE FOR ONE (1) SECOND

- POWER OFF

- POWER ON

Loading...

Loading...