Page 1

Owner’s Manual

Read this manual for complete instructions

FLEXSPRAY

HANDHELD

Model 0524093

Questions?

Call Titan Technical Service at:

1-800-526-5362

Register your product online at:

www.titantool.com

Contents

2 Important Safety Information

3 Introduction to Paint Spraying

4 Parts and Components

5 Quick Change System

6 Masking Guide

7 Setup

8 Setting the Spray Gun Controls

9 Spraying

10 Cleanup

12 Reassembly

13 Maintenance

14 Troubleshooting

44 Parts List

48 Warranty

0616 • Form No. 0529895B

Page 2

SafetySafety

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

Important Safety

Information

Read all safety information before operating

the equipment. Save these instructions.

9. Do not operate light switches, engines, or similar spark producing

products in the spray area.

10. Keep area clean and free of paint or solvent containers, rags, and other

ammable materials.

11. Know the contents of the paint and solvents being sprayed. Read all

Material Safety Data Sheets (MSDS) and container labels provided with

the paints and solvents. Follow the paint and solvent manufacture’s

safety instructions.

12. Fire extinguisher equipment shall be present and working.

WARNING - To reduce the risk of injury:

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

To reduce the risks of re or explosion, electrical shock

and the injury to persons, read and understand all

instructions included in this manual. Be familiar with the

controls and proper usage of the equipment.

Grounding Instructions

This product must be grounded. In the event of an electrical short circuit,

grounding reduces the risk of electric shock by providing an escape wire for

the electric current. This product is equipped with a cord having a grounding

wire with an appropriate grounding plug. The plug must be plugged into

an outlet that is properly installed and grounded in accordance with all local

codes and ordinances.

WARNING - Improper installation of the grounding plug

can result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary, do not connect the

green grounding wire to either at blade terminal. The wire with insulation

having a green outer surface with or without yellow stripes is the grounding

wire and must be connected to the grounding pin.

Check with a qualied electrician or serviceman if the grounding instructions

are not completely understood, or if you are in doubt as to whether the

product is properly grounded. Do not modify the plug provided. If the plug

will not t the outlet, have the proper outlet installed by a qualied electrician.

This product is for use on a nominal 120 volt circuit and has a grounding

plug that looks like the plug illustrated below. Make sure that the product is

connected to an outlet having the same conguration as the plug. No adapter

should be used with this product.

1. Always wear appropriate gloves, eye protection, clothing and a

respirator or mask when painting. Hazardous vapors – Paints, solvents,

insecticides, and other materials can be harmful if inhaled or come

in contact with body. Vapors can cause severe nausea, fainting or

poisoning.

2. Do not operate or spray near children. Keep children away from

equipment at all times.

3. Do not overreach or stand on an unstable support. Keep eective

footing and balance at all times.

4. Stay alert and watch what you are doing.

5. Do not operate the unit when fatigued or under the inuence of drugs

or alcohol.

6. Never aim spray gun at any part of the body.

7. Follow all appropriate local, state, and national codes governing

ventilation, re prevention, and operation.

8. The United States Government Safety Standards have been adopted

under the Occupational Safety and Health Act (OSHA). These standards,

particularly part 1910 of the General Standards and part 1926 of the

Construction Standards should be consulted.

9. Use only manufacturer authorized replacement parts. User assumes

all risks and liabilities when using parts that do not meet the minimum

specications and safety devices of the manufacturer.

10. Power cord must be connected to a grounded circuit.

11. Use only recommended Titan FlexSpray components.

12. Do not spray outdoors on windy days.

WARNING - To reduce the risk of electric shock:

1. Always remove turbine before cleaning.

2. Power cord must be connected to a grounded circuit.

3. Never submerge electrical parts, including the turbine.

4. Never expose the equipment to rain. Store indoors.

5. Keep electrical cord plug and spray gun trigger free from paint and

other liquids. Never hold the cord at plug connections to support the

cord. Failure to observe may result in an electrical shock.

1. Do not spray ammable or combustible materials near an open ame,

pilot lights or sources of ignition such as hot objects, cigarettes, motors,

electrical equipment and electrical appliances. Avoid creating sparks

from connecting and disconnecting power cords.

2. Exhaust and fresh air introduction must be provided to keep the air

within the spray area free from accumulation of ammable vapors.

3. Use extreme caution when using materials with a ashpoint below 100°

F (38°C). A uid’s ashpoint is the temperature at which vapors from the

uid could ignite if exposed to a ame or spark.

4. Verify that all containers and collection systems are grounded to

prevent static discharge.

5. Connect to a grounded outlet and use grounded extension cords

(electric models only). Do not use a 3 to 2 adapter.

6. Do not use a paint or solvent containing halogenated hydrocarbons.

Such as chlorine, bleach mildewcide, methylene chloride and

trichloroethane. They are not compatible with aluminum. Contact the

coating supplier about compatibility of material with aluminum.

7. Keep spray area well ventilated. Keep a good supply of fresh air

moving through the area to keep the air within the spray area free

from accumulation of ammable vapors. Keep turbine assembly in well

ventilated area. Do not the spray turbine assembly.

8. Do not smoke in the spray area.

WARNING - To reduce the risk of re or

explosion:

English

Important Electrical Information

Use only a 3-wire extension cord that has a 3-blade grounding plug and a

3-slot receptacle that will accept the plug on the product. Make sure your

extension cord is in good condition.

When using an extension cord, be sure to use one heavy enough to carry the

current your product will draw. An undersized cord will cause a drop in line

voltage resulting in loss of power, overheating and possible damage.

This unit is equipped with a 14 gauge power cord, therefore a 14 gauge or 12

gauge extension cord is required. Do not use more than 100 feet of extension

cord.

If an extension cord is to be used outdoors, it must be marked with the sux

W-A after the cord type designation. For example, a designation of SJTW-A

would indicate that the cord would be appropriate for outdoor use.

2

Page 3

Introduction

Start

Notice:

to Paint

Spraying

Introduction

Function description

The paint spraying system consists of a hand-held, motor-operated

turbine, which provides the spray gun with atomization air

In the spray gun, part of the air from the turbine is used to pressurize

the container. This pressure causes the coating material to be fed

through the suction tube to the uid nozzle where it is then atomized

as it exits the uid nozzle.

All settings necessary for operation (e.g. material volume, air volume)

can be conveniently adjusted directly on the gun, including start/stop

of the turbine by activating the trigger.

Coating material

Coating Materials Suitable for Use

Water-based and solvent based coatings.

Review this page to familiarize yourself with

some general information regarding FLEXSPRAY

paint spraying, including which spray materials

are suitable for use, and how to prepare the

spray material.

Coating Materials Not Suitable for Use

Materials that contain highly abrasive components, caustic solutions

and acidic coating substances. Use extreme caution when using

materials with a ashpoint below 100° F (38°C).

Preparing the coating material

Note: Observe the manufacturer’s instructions for the use of the

coating material on the material container or on the technical data

sheet.

Coating material purity

An absolute pre-condition for the trouble-free operation of the

FLEXSPRAY system is that the coating material is uncontaminated.

If you have doubts as to the purity of the coating material, we

recommend that you rst lter your coating material with a paint

strainer.

3

English

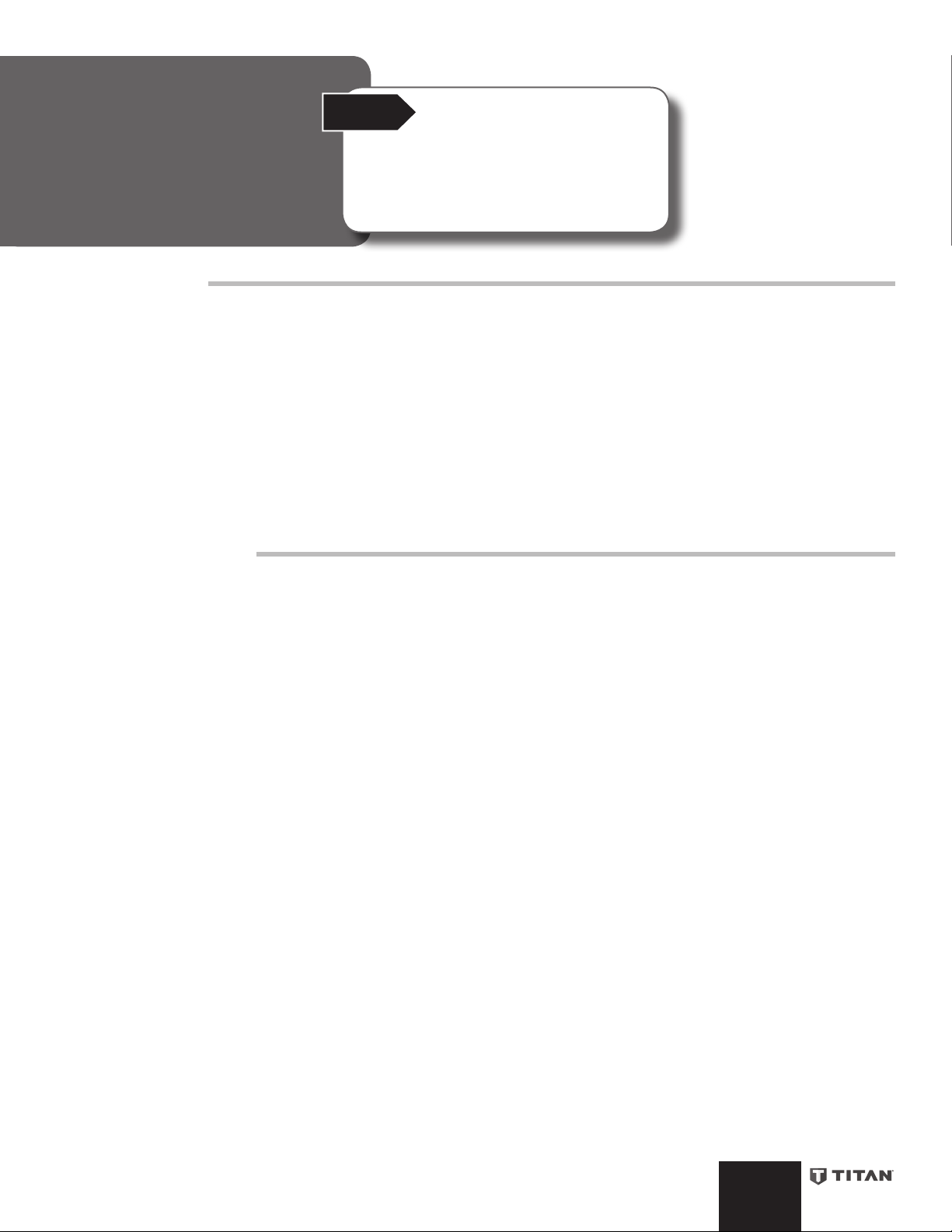

Page 4

Safety

Parts and

Start

Start

Notice:

Components

9

19

20

Review the information on this page to

familiarize yourself with the parts and

components of your unit.

10

11

8

22

23

24

7

6

5

3

# Description

1 Nozzle

2 Air cap

3 Adjustment lever (pattern width)

4 Adjustment ring (pattern direction)

5 Connecting nut

6 Front end assembly

7 Adjustable material ow control

8 Turbine

9 Variable speed air control knob

10 Air lter cover lock

21

16

15

# Description

11 Shoulder strap hook (can be mounted

on either side of the turbine)

12 Quick Change release lever

13 2-Stage trigger (activates turbine and

then uid needle in order to spray ma-

terial)

14 Material container, 1 Quart

15 Suction tube

16 Container seal

17 Check valve

18 Air tube

13

18

17

14

12

# Description

19 Air lter cover

20 Air lter

21 Power cable

22 Cleaning brush (2)

23 Carry case

24 Shoulder strap

Petroleum jelly, 2cc (not shown)

Velcro strap to wrap power cord (not

shown)

1

2

4

English

4

Page 5

Safety

1a

1b

c

Quick

Start

Start

Notice:

Change

System

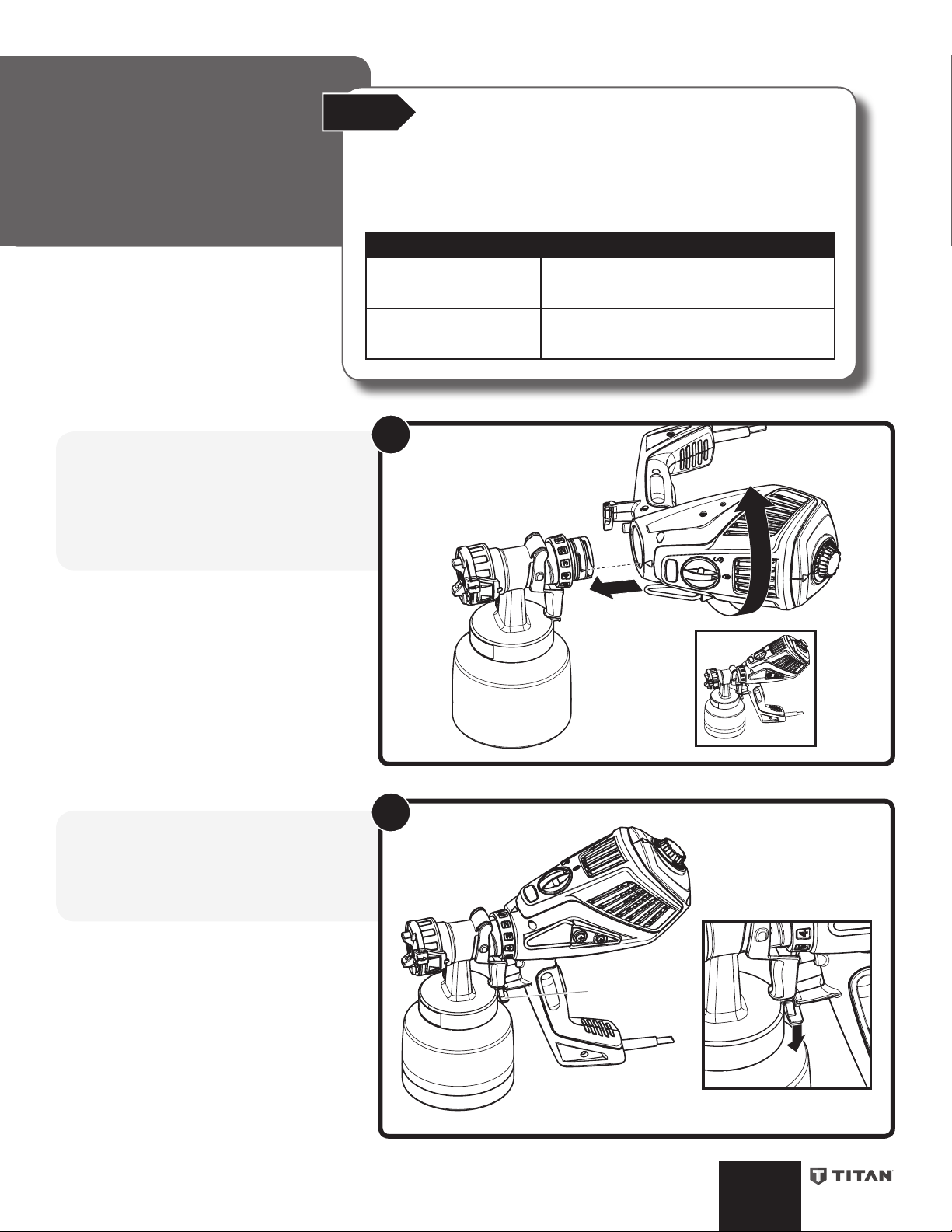

1) To assemble the spray gun:

a. For assembly, insert the front end

assembly into the turbine so that the two

arrows align with each other.

b. Turn the turbine 90° in the arrow direction

until it clicks into place.

With the Quick Change System, the front part of the gun (front end assembly) can

be replaced quickly and easily.

This enables a rapid material change for dierent coatings and larger jobs, and

ensures that the right tool is available for every material and application.

The following front end assemblies are available:

Front End Assembly Description

FlexFinish (white)

Part No. 0529009 (included

with this unit)

FineFinish (red)

Part No. 0529008 (sold

separately)

Spray attachment with slot nozzle and 1 Qt.

stainless steel container. Processes all standard

paints, stains, lacquers and multi-color coatings.

Spray attachment with round nozzle and 1 Qt

stainless steel container. Ideal for low-viscosity

paints, stains and lacquers.

1

2) To disassemble the spray gun:

Push the Quick Change lever below the

trigger (c), twist and separate the front end

assembly from the turbine.

2

5

English

Page 6

Masking

Start

Notice:

Guide

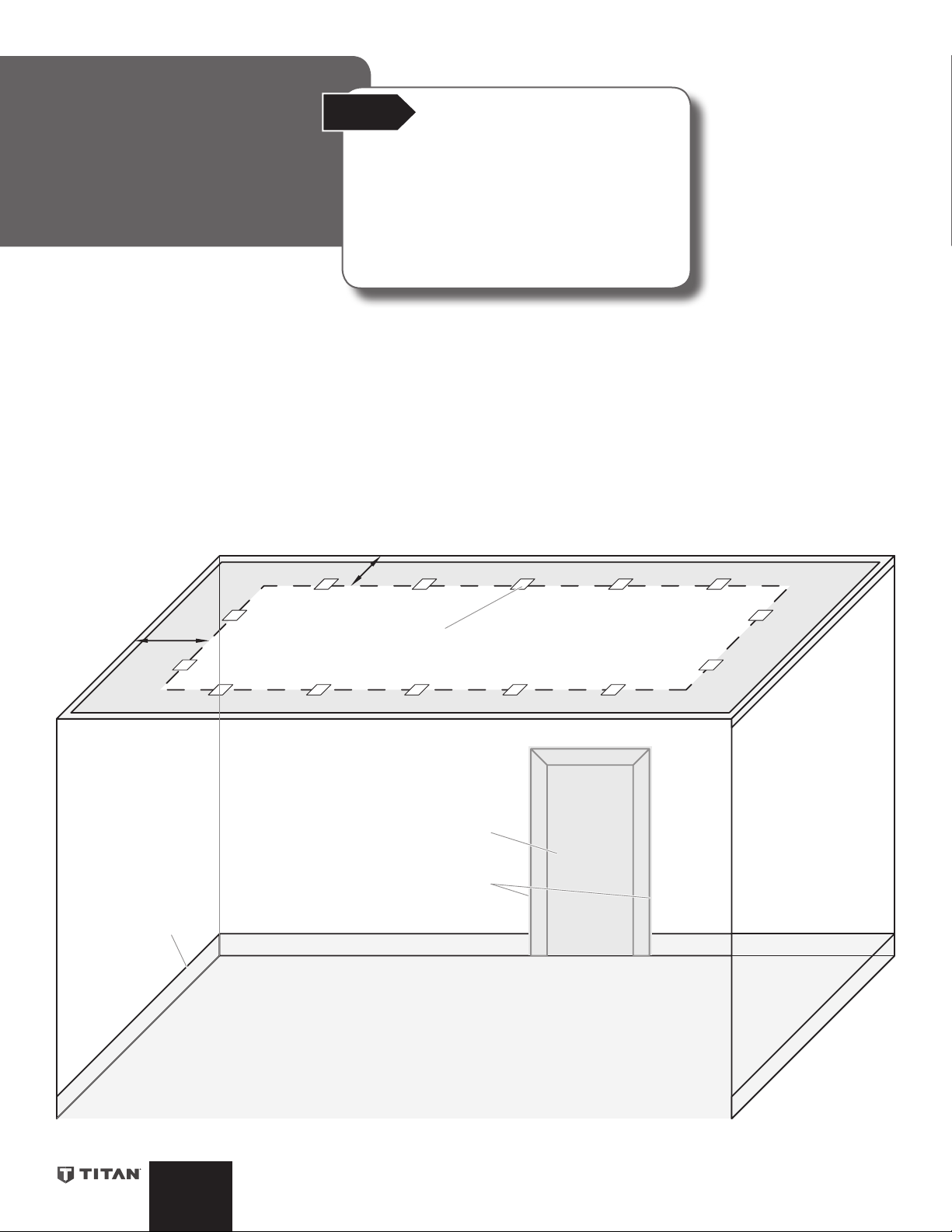

A. If spraying walls, make sure to cover the ceiling no less

than 24” from where the wall and ceiling meet.

B. Use a small piece of masking tape placed every few

feet to secure the covering to the ceiling.

C. Use drop covering to cover the oor and baseboards.

A

If spraying inside a room, follow the guidelines on

this page in order to properly mask anything that

should not be sprayed with paint.

You will need:

• Masking tape

• Plastic covering for walls

• Heavy drop cloth for oors

24”

D. Use masking tape to secure drop covering to

baseboards.

E. Cover any doors or windows with plastic covering.

F. Use masking tape to secure the covering to both sides

of the door or window.

A

24”

A

B

A

E

F

D

C

English

6

Page 7

Setup

1 Quart

b

a

b

Start

Additional instructional items are located inside

the carry case. These items are meant to be

supplements to this instruction manual.

Notice:

IMPORTANT: Before connecting to the

power source, make sure that the power

cord voltage corresponds to the operating

voltage on the rating label. The unit must

be connected with a properly grounded

socket.

To set up:

1. Unscrew the material container from the

front end assembly.

2. Align the suction tube:

a. If you are going to be spraying in an

upward direction, the angled end of the

suction tube should be pointing toward

the rear of the gun.

b. If you are going to be spraying in a

downward direction, the angled end

of the suction tube should be pointing

toward the front of the gun.

3. Pour in the prepared coating material

(maximum 1 quart).

4. Carefully screw the material container

back onto the front end assembly.

5. Connect front end and turbine.

Plug in the power cord.

The sprayer is now ready for

operation.

1

3

2

4

5

7

English

Page 8

Safety

a

b

1

12

2

d

c

1

2

3

4

5

6

7

8

9

10

11

12

e

f

Setting the

Spray Gun

Controls

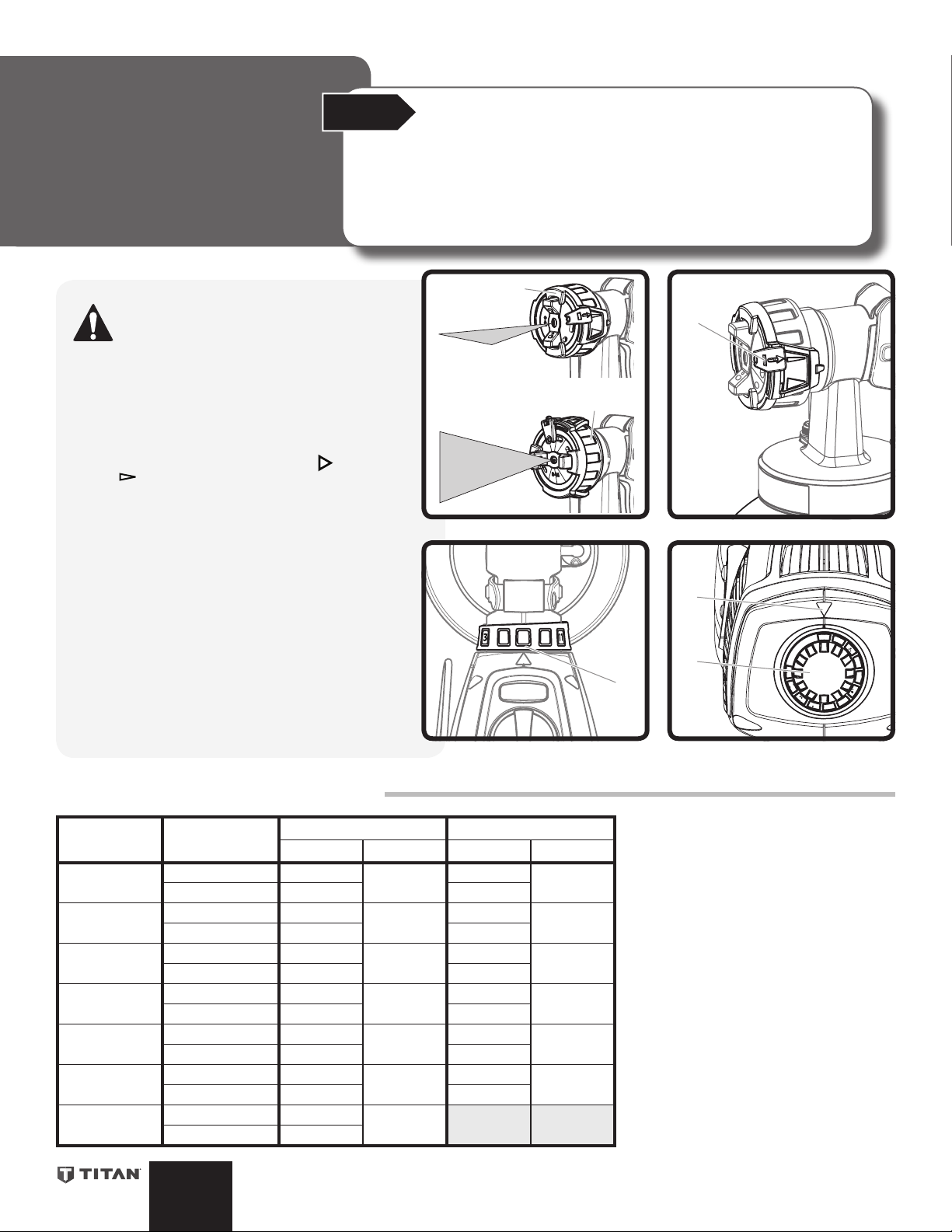

NEVER trigger the gun while adjusting the

adjustment ring. NEVER point the spray gun

at any part of the body.

Start

Start

Spray performance will depend upon a number of factors: material thickness, spray

pattern selected, material volume, and air volume. With any type of spray system,

desired spray results will be achieved through some trial and error while adjusting

some or all of these variables.

Review these pages to learn about the spray controls and how they can be used to

acheive the desired spray results.

To set the Spray Pattern: (width/direction)

The alignment of the spray pattern can be determined

by turning the adjustment ring (a).

IMPORTANT: Always make sure the connecting nut

(b) is fully tightened before spraying.

It is also possible to switch between a wide ( ) and a

narrow ( ) spray fan pattern with the adjustment lever (c).

To set the Material Flow:

The material ow can be adjusted incrementally from 1

(minimum) to 12 (maximum) by turning the adjustable

material ow control (d). Consult Quick Start Guide

below for a starting point.

Notice:

To set the Air Flow:

Turn the variable speed air control (e) clockwise to

increase the air ow or counter-clockwise to reduce

the air ow (note arrow (f) on body of gun for setting).

Consult Quick Start Guide below for a starting point.

Note: Observe the manufacturer’s instructions for the

use of the coating material on the material container or

on the technical data sheet.

FLEXSPRAY Quick Start Guide

Fan Pattern

Width

1-5 inches 3

5+ inches 6 10

1-5 inches 3

5+ inches 7 10

1-5 inches 2

5+ inches 5 9

1-5 inches 4

5+ inches 8 11

1-5 inches 5

5+ inches 9 11

1-5 inches 4

5+ inches 9 11

1-5 inches 7

5+ inches 10

English

Coating

Stain

Lacquers

Urethanes

Enamels

Acrylic Alkyds

Acrylic Latex

Multi-Color

FlexFinish front end FineFinish front end 1) Start with a fan pattern for painting

Material Air Material Air

5-8

(Medium)

5-8

(Medium)

5-8

(Medium)

9-12

(high)

9-12

(High)

9-12

(High)

5-8

(Medium)

7

7

6

9

9

8

NA NA

9-12

(High)

5-8

(Medium)

5-8

(Medium)

9-12

(High)

9-12

(High)

9-12

(High)

trim work (1-5” width) and larger

surfaces like doors and walls (>5”

width).

2) Adjust Material & Air Flow settings as

shown in chart based on coating, fan

pattern width, and Front End.

3) Fine tune the Material and Air Flow

settings to achieve the best results for

your application.

4) Use narrow pattern for detailed work,

touch up.

5) Recommended settings for Material

and Air Flow may change if the

coating is thinned.

8

Page 9

Safety

Spraying

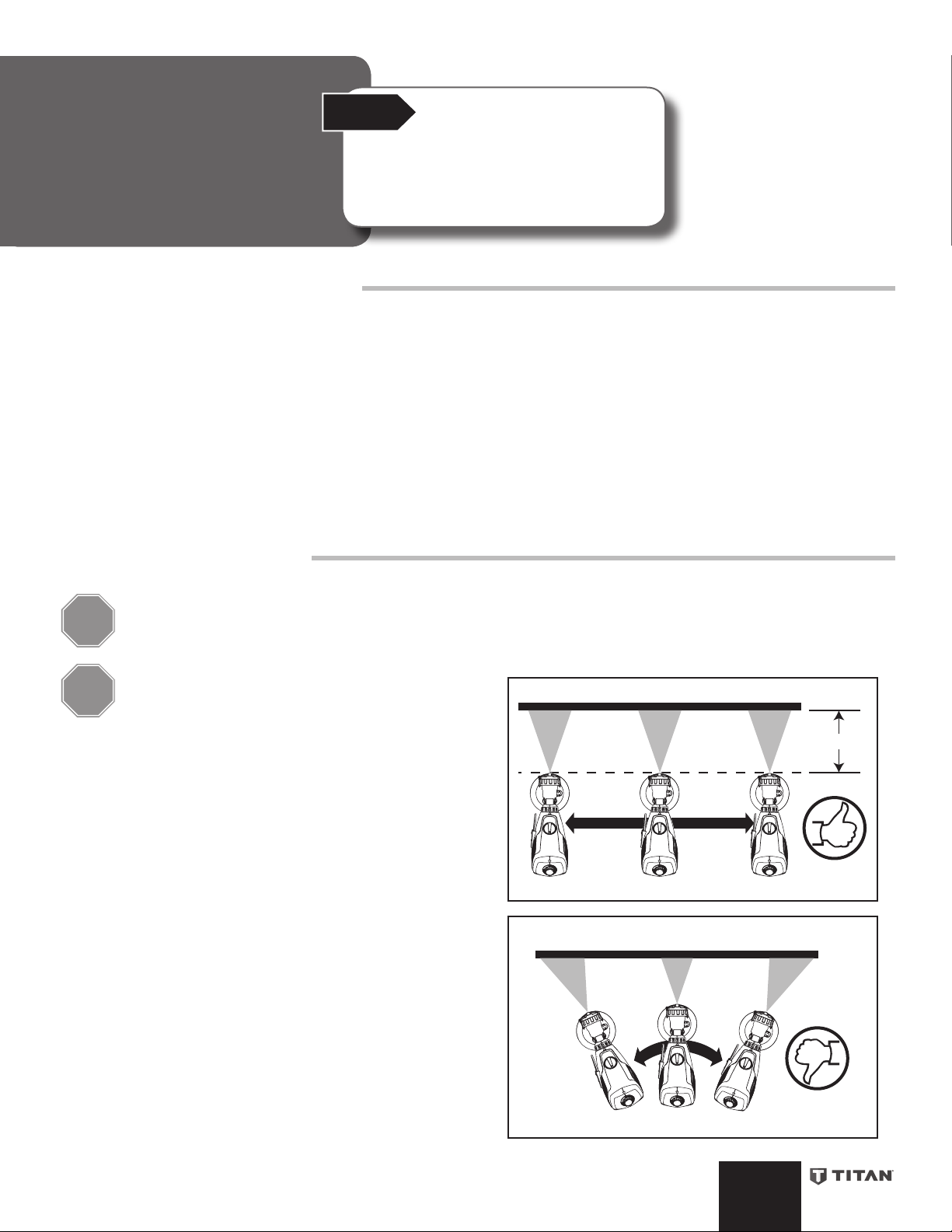

Before You Begin Spraying

Practice

It is advisable to practice on a piece of scrap wood or cardboard before beginning

on your intended workpiece. A spray poster is also available in the carry case that

can be referenced for additional guidance. Refer to the settings on the FLEXSPRAY

Quick Start Guide, previous page as reference for a starting point.

Surface Preparation

All objects to be sprayed should be thoroughly cleaned before spraying material on

them. Areas not to be sprayed may, in certain cases, need to be masked or covered.

Spray Area Preparation

The spray area must be clean and free of dust in order to avoid blowing dust onto

your freshly sprayed surface.

Start

Start

The room you are spraying must be properly

masked in order to prevent overspray from

coating woodwork, oors or furnishings. Make

sure you have properly masked the room per

the instructions on page 6.

Notice:

How to Spray Properly

It is important to keep your arm moving whenever the

STOP

STOP

• Position the spray gun perpendicular to and six (6) or more

Note: If spraying trim or some other surface that requires a very

narrow spray pattern, you may need to get closer than 6 inches from

the spray surface.

• Spray parallel to the surface with smooth passes at a consistent

• Always apply a thin coat of material on the rst pass and allow to

• When spraying larger surfaces, overlap each spray pass by at

• When spraying, always trigger the spray gun after spray pass

Note: Between passes, the trigger should be released only far enough

for material to stop spraying, but not enough to cause the turbine to

shut down.

gun is being triggered. If you pause or linger in one

spot too long, too much material will be sprayed to the

surface.

Partially pulling the trigger will start the turbine, but

no material will spray until the trigger is pulled fully.

It is recommended that the trigger rst be pulled

partially in order to start the turbine before a spray

pass is made.

inches from the spray surface, depending upon the spray pattern

size desired.

speed as illustrated, right. Doing this will help avoid irregularities

in the nish (i. e. runs and sags).

dry before applying a second, slightly heavier coat.

least 50% This will ensure full coverage.

has begun and release trigger before stopping the pass. Always

keep the gun pointed squarely at the spray surface.

Even coat throughout

6 -12 inches

1122 1122 1122

Keep stroke smooth and at an even speed

Light coat Heavy coat Light coat

12

1

2

1122

2

1

12

IMPORTANT: When using quick-drying or two-component

coating materials, make sure to clean the sprayer with a suitable

cleaning agent before the material dries or cures inside the spray

gun. Check the manufacturer’s technical data sheet for drying

times.

9

Do not ex wrist while spraying.

English

Page 10

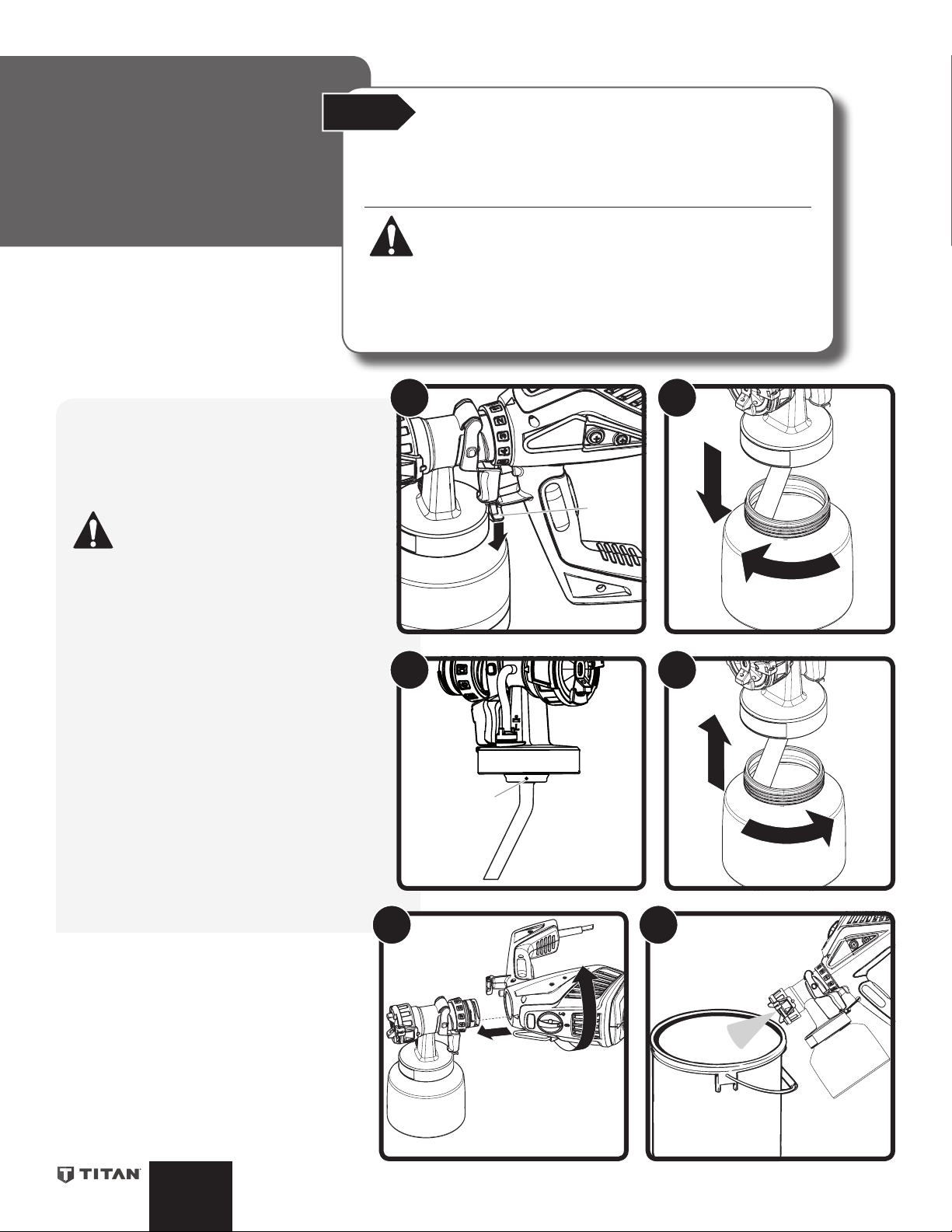

Cleanup

a

b

Start

When cleaning, use the appropriate cleaning solution (warm, soapy water

for latex materials; mineral spirits for oil-based materials)

IMPORTANT: Never clean nozzle or air holes in the spray gun with sharp

metal objects. Do not use solvents or lubricants containing silicone.

Before you begin:

Special cleanup instructions for use with flammable solvents

Use extreme caution when using materials with a flashpoint

below 100° F (38°C):

To clean:

1. Unplug the power cord.

Divide the spray gun. Push the Quick-Change

lever below the trigger (a), twist and separate

the front end from the turbine.

Never hold the turbine under water or

immerse it into liquids.

2. Unscrew the container and remove.

Empty any remaining material back into the

material container.

Pre-clean the container and suction tube using

a brush and appropriate cleaning solution.

3. Clean the air vent (b) on the suction tube.

4. Pour a small amount of the appropriate

cleaning solution into the container. Attach

the container to the gun.

5. Connect front end assembly and turbine.

6. Plug in the power cord. Spray the cleaning

solution into a safe area.

Note: If you are spraying into a waste container as

shown, have the spray pattern width set to narrow

to better direct cleaning solution into the waste

container.

Repeat the above procedure until the solvent

or water emerging from the nozzle is clear.

1

3

2

4

Continued on next page

English

65

Empty waste

container

10

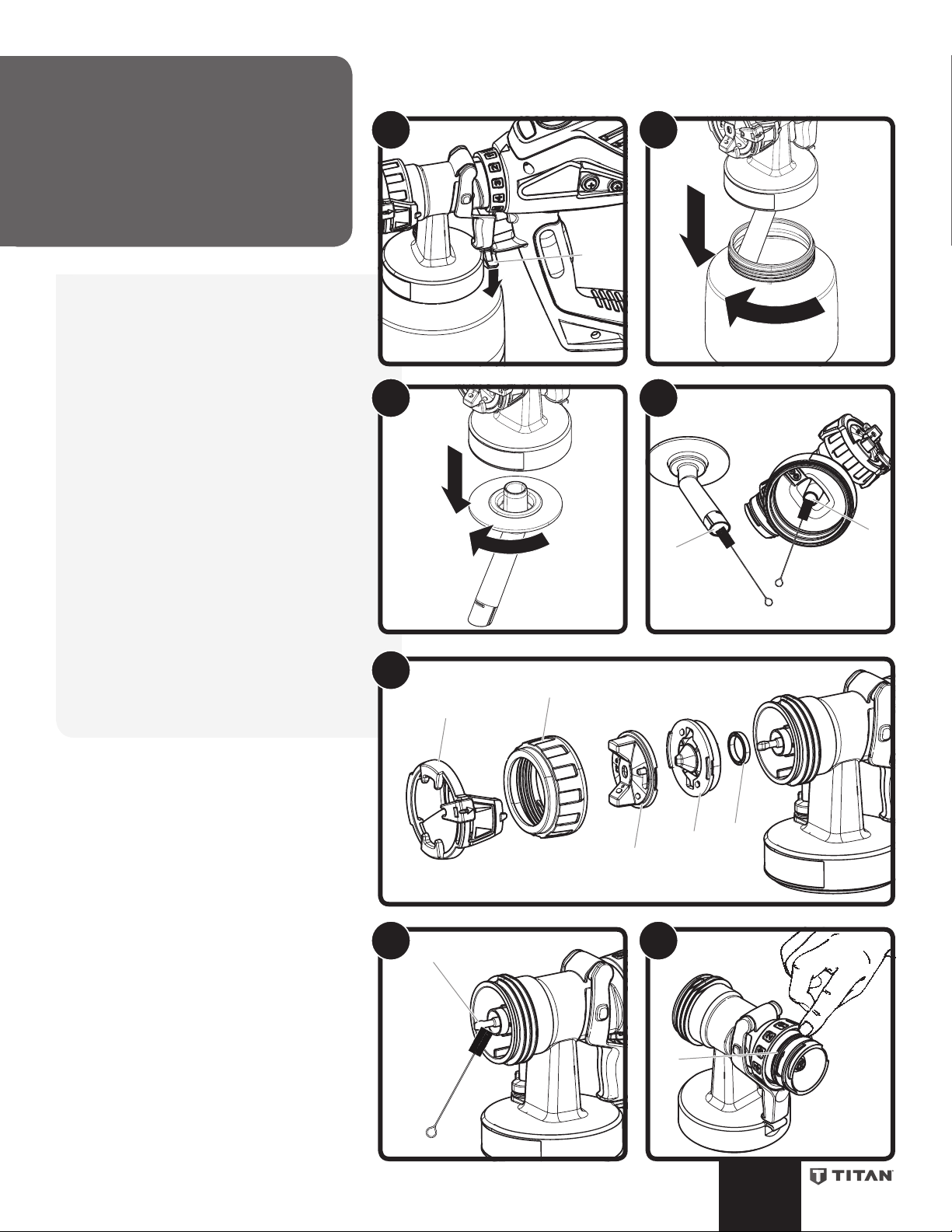

Page 11

SafetyCleanup

a

e

f

g

h

i

j

k

c

d

(continued)

7. Unplug the power cord.

Divide the spray gun. Push the Quick-

Change lever below the trigger (a), twist

and separate the front end from the

turbine.

8. Remove the 1 Qt. container and empty it.

9. Remove suction tube with container seal.

10. Clean suction tube (c) and suction nozzle

opening in front end assembly (d) with

cleaning brush.

11. Remove the adjustment ring (e) carefully

from the connecting nut (f). Unscrew

connecting nut (f), remove air cap (g),

nozzle (h) and nozzle seal (i).

Thoroughly clean all parts.

12. Gently clean the end of the needle (j) and

the needle opening with the cleaning

brush.

Wipe the outside of the front end

assembly and material container with a

damp cloth (be sure cloth is damp with

appropriate cleaning solution).

13. Lubricate the O-ring (k) on the rear of the

front end assembly with a thin layer of the

included petroleum jelly.

Move on to “Reassembly”, next page.

7 8

9

11

10

12 13

11

English

Page 12

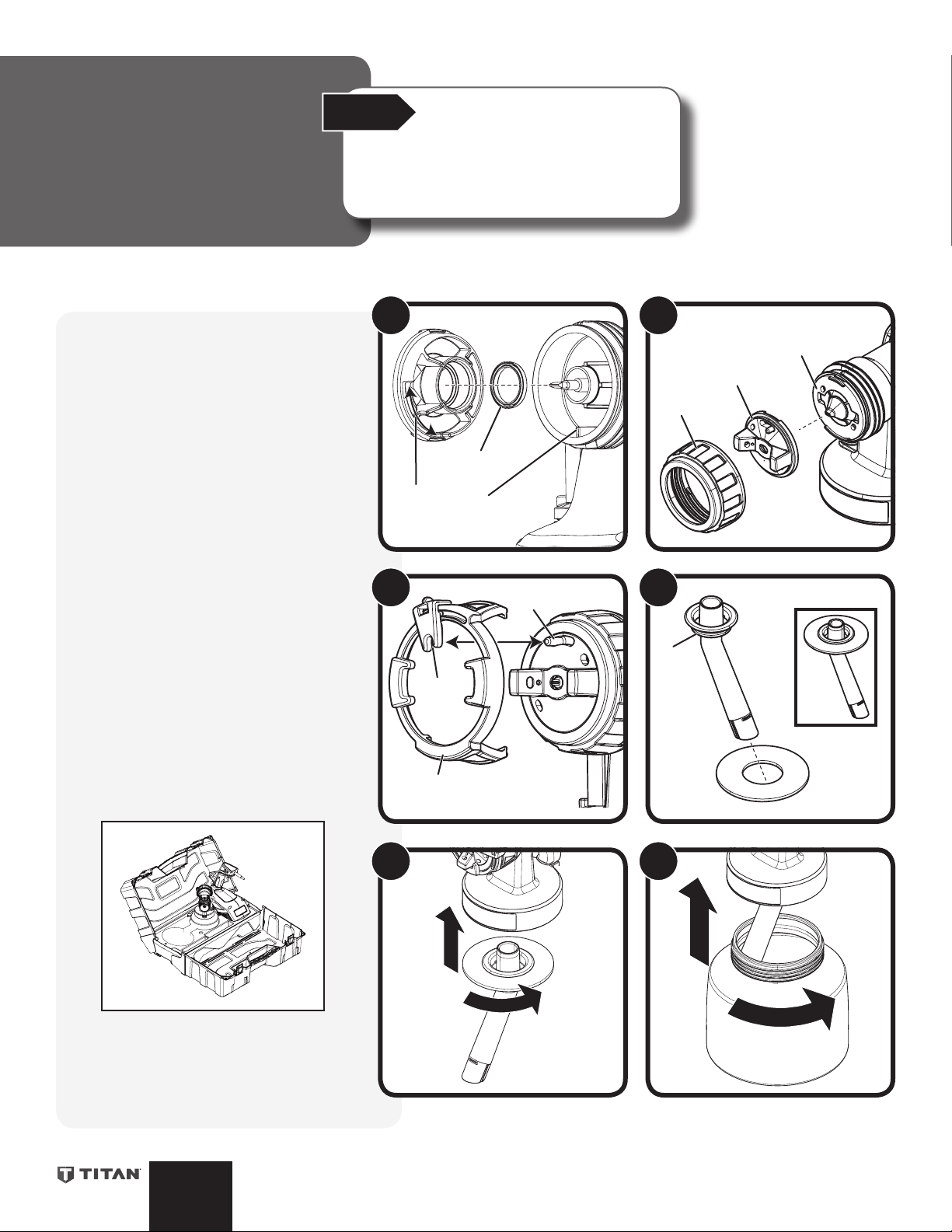

Reassembly

b

a

c

g

h

i

e

d

f

Start

Follow the steps described below for

reassembly. Improper reassembly can result in

damage to the spray gun assembly.

IMPORTANT:

To reassemble:

1. Install the nozzle seal with the groove (a)

(slot) facing toward the nozzle (away from

the front end assembly).

Insert the nozzle. Make sure to align the

groove (b) and notch (c) and align the

nozzle opening with the needle.

2. Put the air cap (d) on the nozzle (e) and

secure with the connecting nut (f).

3. Snap the adjustment ring (g) into the

connecting nut, enabling the adjustment

lever (h) on the peg (i) to be positioned in

the air cap.

Note: Make sure that the two recesses on the

adjustment ring are engaged in the air cap tabs.

4. Place the container seal on the suction

tube and slide it over the collar (j), while

turning the container seal slightly.

5. Insert the suction tube with the container

seal into the front end assembly.

6. Replace container.

Transportation / storage

1. Detach the strap from the sprayer and

secure it to the carry case (it can also be

stored inside the carry case).

2. Place the unit and accessories into the

carry case as shown below and secure with

the elastic straps.

1

3

2

4

j

3. Coil the power cord and use the provided

Note: Press the right and left inside of the case

lid outwards in order to open up the transport

case completely.

velcro strap to secure.

English

5 6

12

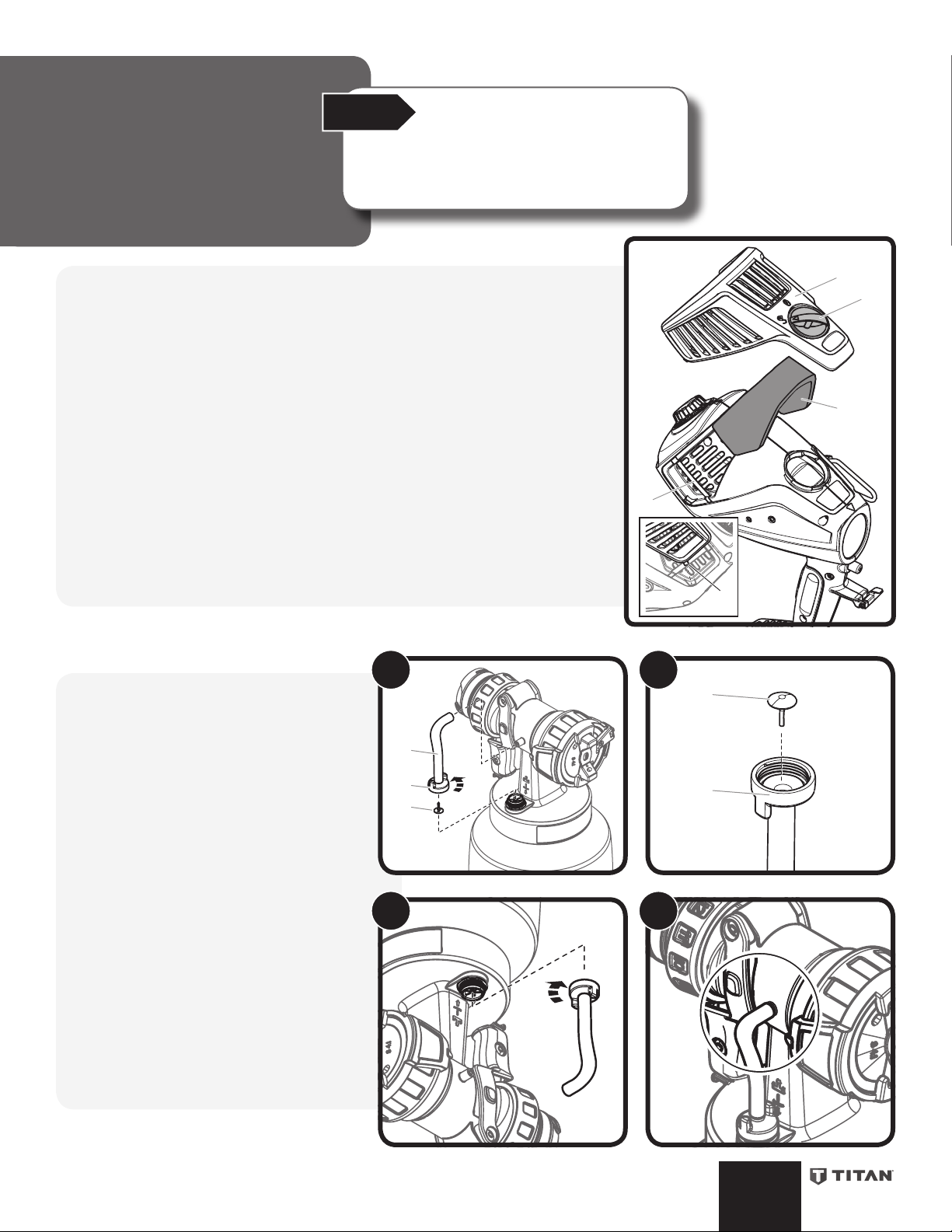

Page 13

Maintenance

a

b

d

e

c

a

b

c

c

b

Start

Review the information on this page to familiarize

yourself with the proper way to maintain your

paint sprayer.

Notice:

Air Filter:

IMPORTANT: Never operate the device with a dirty or missing air filter, as dirt

could be sucked in and affect the operation of the turbine and/or contaminate your

material. Always check the air filter before starting work.

1. Unplug the power cord.

2. Turn the lter cover lock (a) to the unlock position. Remove the lter cover (b) and

lter (c).

3. Clean, blow out, or replace the air lter (c).

IMPORTANT: DO NOT clean the filter with any solvent. Use only warm, soapy water

to clean.

4. Replace the cleaned or new lter into the turbine. Make sure the lter is tucked

underneath the housing (d) on both sides of the turbine. Reattach the lter cover

and turn the lter cover lock to the lock position.

Note: Make sure the tabs of the lter cover (e) snap into place on both sides of the

turbine (inset).

Note: When replacing, use only Titan FlexSpray HandHeld lters.

1

2

Air Tube:

Note: If paint has entered the air tube, proceed

as follows.

1. Pull the air tube (a) at the top from the

gun body. Screw o the valve cover (b).

Remove the valve seal (c). Clean all the

parts carefully.

IMPORTANT: The air tube and valve seal (c)

are only solvent-resistant to a limited extent.

Do not immerse in solvent, only wipe.

2. Place the valve seal (c) in the valve cover

(b) with the pin facing into the tube.

Note: Installing the valve seal into the valve

cover will be much easier if the valve cover is

inverted.

3. Turn the front end assembly upside down

and screw on the valve cover (with valve

seal inside) from underneath.

Note: Turning the front end assembly upside

down will prevent the valve seal from falling out

of the valve cover during reinstallation.

4. Place the air tube on the valve cover and

on the nipple at the gun body.

3

4

13

English

Page 14

Troubleshooting

Any attempt to open the motor housing or repair any electrical

parts within the unit by anyone other than an authorized repair

technician could cause serious injury and will void the warranty.

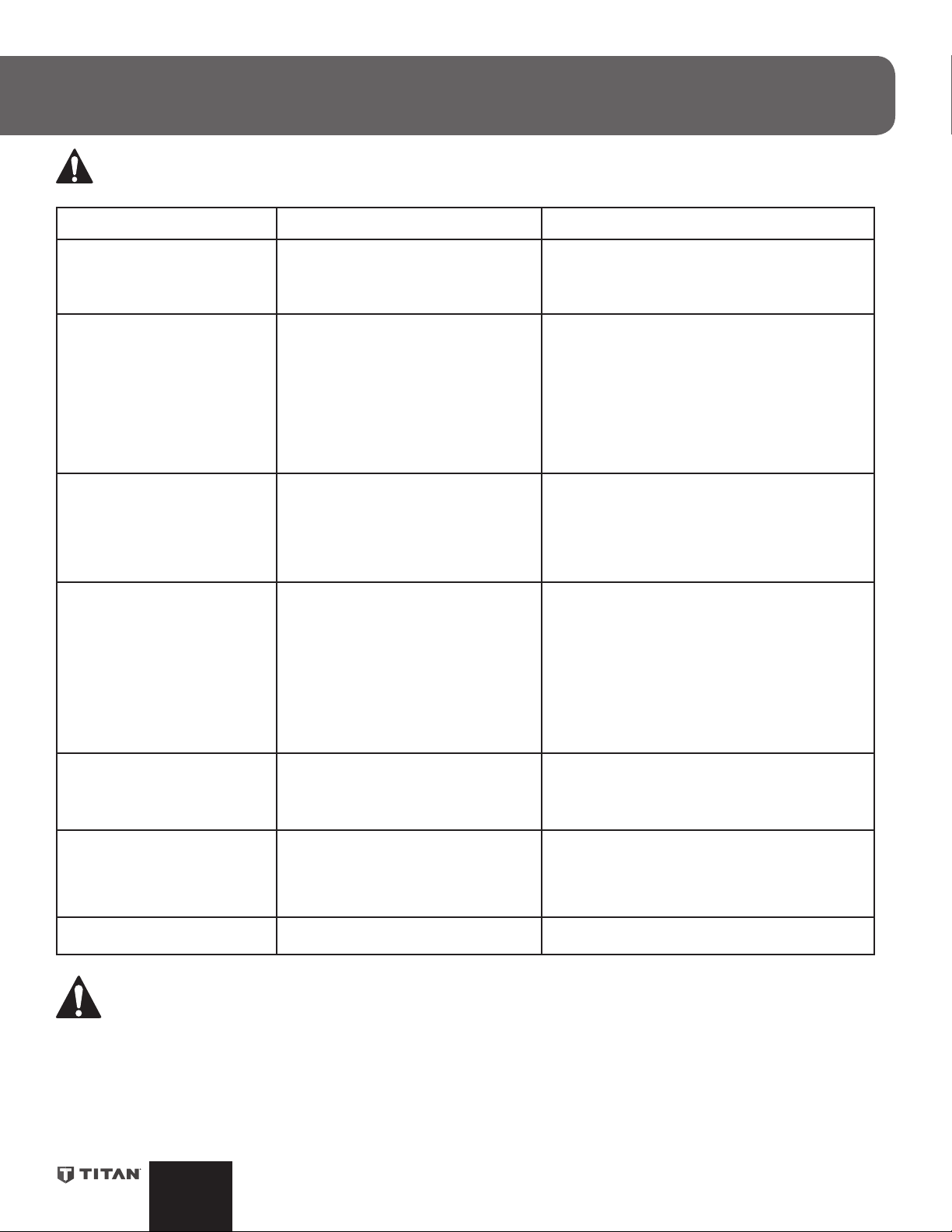

Problem Cause Solution

The unit will not run

Little or no material ow

Material leaking

Spray pattern too thick, runs, spits

and sags

Spray jet pulsates

1. The power cord is unplugged, or no power

in outlet

2. Device overheated

1. Nozzle clogged

2. Suction tube clogged

3. Material ow setting too low

4. Suction tube loose

5. No pressure build-up in container

6. Container empty

7. Suction tube lter clogged (if applicable)

8. Air tube loose/damaged

9. Paint container seal damaged

10. Air vent on suction tube blocked

11. Air tube valve seal stuck

12. Air lter clogged

1. Air cap, nozzle or needle dirty

2. Front end assembly attachment incorrectly

assembled

3. Nozzle loose

4. Nozzle seal worn

5. Nozzle worn

6. Needle worn

7. Material build-up on air cap and nozzle

1. Material ow setting too high

2. Air ow setting too low

3. Nozzle clogged

4. Air lter clogged

5. Too little pressure build-up in container

6. Viscosity of material too high

7. Air tube loose/damaged

8. Activating the trigger too quickly

9. Applying too much material

10. Distance from the spray object too small

11. Front end assembly not suitable for spray

material

1. Material in container running out

2. Air lter clogged

3. Nozzle seal worn

4. Suction tube loose

5. Suction tube / suction tube lter clogged

1. Plug the power cord into 120V outlet

2. Unplug the power plug, let the device cool down

approx. 30 minutes, check the air lter, do not cover the

intake slots

1. Clean

2. Clean

3. Increase ow

4. Insert

5. Tighten container

6. Rell

7. Clean or use another lter

8. Re-install or replace (see page 13)

9. Replace

10. Clean (see page 10)

11. Clean (see page 13)

12. Clean or replace

1. Clean

2. Assemble correctly (see page 12)

3. Tighten

4. Replace

5. Replace

6. Use new spray attachment

7. Clean

1. Decrease ow setting

2. Increase air ow setting

3. Clean

4. Clean or replace (see page 13)

5. Tighten container

6. Thin

7. Re-install or replace

8. Pull trigger partially until turbine reaches full power

9. Decrease volume setting or increase movement of spray

gun

10. Increase distance to spray object

11. Use a dierent front end assembly

1. Rell

2. Clean or replace (see page 13)

3. Replace

4. Insert

5. Clean or use another lter

Too much overspray

Paint in the air tube

This unit contains no servicable electrical parts. Do

not attempt to service yourself. Store indoors with

the power cord wrapped and secured with the velcro

strap.

English

1. Gun too far from spray object

2. Too much material applied

3. Air ow setting too high

4. Material has been over-thinned

5. Front end assembly not suitable for spray

material

1. Valve seal dirty

2. Valve seal defective

14

1. Reduce distance

2. Decrease material ow setting

3. Decrease air ow setting

4. Thicken the material by adding more material

5. Use a dierent front end assembly

1. Clean the valve seal (see page 13)

2. Replace the valve seal (see page 13)

Page 15

Manuel de

l’utilisateur

Lire ce manuel pour obtenir des directives complètes

FLEXSPRAY

HANDHELD

Modèle 0524093

Besoin d’aide?

Appelez le service technique Titan

1-800-526-5362

Enregistrement du produit en ligne

sur le site :

www.titantool.com

Table de matières

16 Consignes de sécurité importantes

17 Introduction à la pulvérisation de peinture

18 Pièces et composants

19 Système de changement rapide (Quick Change)

20 Guide pour appliquer du ruban

21 Montage

22 Réglage des commandes du pistolet pulvérisateur

23 Pulvérisation

24 Nettoyage

26 Remontez

27 Entretien

28 Dépannage

44 Liste de pièces

46 Garantie limitée

Français

Page 16

Importantes

Prise trilaire

Broche de mise à la terre

SafetySafety

consignes de sécurité

Lire toutes ces consignes avant d’utiliser

l’appareil. Garder ces consignes

8. Ne fumez pas dans la zone de pulvérisation.

9. N’actionnez pas d’interrupteurs électriques, de moteurs ou autres

dispositifs produisant des étincelles dans la zone de pulvérisation.

10. Maintenez la propreté de la zone et veillez à ce qu’elle ne contienne pas

de conteneurs de peinture ou de solvant, de chions et autres matières

inammables.

11. Sachez ce que contiennent la peinture et les solvants pulvérisés. Lisez

les ches de sécurité du matériel (MSDS) et les étiquettes apposées sur

les conteneurs de peintures et de solvants. Respectez les consignes de

sécurité du fabricant de peinture et de solvant.

12. Ayez un extincteur en bon état de fonctionnement à portée de main.

Indique une situation à risque, laquelle, si elle n’est pas

évitée, peut entraîner des blessures graves, voire la mort.

Pour réduire les risques d’incendie ou d’explosion,

de choc électrique et de blessure, vous devez lire et

comprendre les directives gurant dans ce manuel.

Familiarisez-vous avec les commandes et l’utilisation

adéquate de l’équipement.

Directives sur la mise à la terre

Ce dispositif doit être mis à la terre. En cas de court-circuit, ce procédé

permet de réduire le risque d’un choc électrique en fournissant un parcours

d’évacuation pour le courant. Ce produit est équipé d’un cordon comportant

un l de mise à la terre, et muni d’une che appropriée. Cette che doit être

connectée dans une prise adéquatement installée et mise à la terre selon les

codes et règlements en vigueur.

Une installation inadéquate de la fiche de

mise à la terre risque de provoquer un choc électrique.

S’il est nécessaire de réparer ou de remplacer le cordon ou la che, ne pas

connecter le l de mise à la terre vert à aucune des bornes à broches plates. Le

l comportant un isolant de couleur verte, avec ou sans lignes jaunes, est le l

de mise à la terre devant être connecté à la broche de mise à la terre.

Il est recommandé de consulter un électricien qualié ou un technicien si les

directives sur la mise à la terre ne sont pas entièrement comprises, ou si l’on

n’est pas sûr que le produit soit correctement mis à la terre. Ne pas modier la

che. Si la che ne peut être insérée dans la prise, demander à un électricien

qualié d’installer la prise appropriée.

Ce produit doit être utilisé sur un circuit d’une tension nominale de 120 volts

et comporte une che de mise à la terre semblable à celle illustrée ci-dessous.

Veuillez-vous assurer que le produit est connecté à une prise électrique ayant

la même conguration que la che mâle. Ne pas utiliser d’adaptateur avec ce

produit.

AVERTISSEMENT – Pour réduire le risque de blessure :

1. Portez toujours les gants, la protection oculaire, les vêtements et

un respirateur ou masque appropriés quand vous peignez. Vapeurs

dangereuses – Les peintures, solvants, insecticides et autres matières

peuvent être dangereux s’ils sont inhalés ou entrent en contact avec le

corps. Les vapeurs peuvent provoquer d’importantes nausées, une perte

de connaissance ou un empoisonnement.

2. Ne travaillez pas et ne pulvérisez pas près d’enfants. Éloignez toujours

les enfants de l’équipement.

3. Ne travaillez pas avec les bras au-dessus de la tête ni sur un support

instable. Appuyez-vous bien sur les deux pieds pour toujours conserver

l’équilibre.

4. Soyez attentif et regardez ce que vous faites.

5. N’utilisez pas l’appareil quand vous êtes fatigué ou sous l’inuence de

drogues ou d’alcool.

6. Ne pas pointer le pistolet vers une partie du corps.

7. Observer tous les codes locaux, provinciaux, d’état et nationaux

régissant la ventilation, la prévention des incendies et le

fonctionnement de l’appareil.

8. Aux États-Unis, le gouvernement a adopté des normes de sécurité en

vertu de l’Occupational Safety and Health Act (OSHA). Le cas échéant, on

doit les consulter, notamment les parties 1910 des normes générales et

1926 des normes de construction.

9. N’utiliser que les pièces autorisées par le fabricant; les utilisateurs qui

choisiront d’utiliser des composants dont les caractéristiques techniques

et les exigences en matière de sécurité sont inférieures devront en

assumer tous les risques et responsabilités.

10. Le cordon d’alimentation doit être branché à un circuit trilaire.

11. Utiliser que des piéces recommandée de Titan FlexSpray.

12. Ne pas pulvériser à l’extérieur par grands vents.

AVERTISSEMENT – Pour réduire le risque de de choc électrique :

Plaque murale de la prise

AVERTISSEMENT – Pour réduire le risque

d’incendie ou d’explosion :

1. Ne pulvérisez pas de matières inammables ou combustibles près d’une

amme nue, de voyants lumineux ou de sources d’ignition telles que

des objets chauds, cigarettes, moteurs, matériel et appareils électriques.

Évitez de produire des étincelles en connectant et en déconnectant les

cordons électriques.

2. Veiller à éviter toute accumulation de vapeurs inammables en vous

assurant que la zone où la pulvérisation a lieu est susamment ventilée.

3. S’entourer de toutes les précautions possibles lorsqu’on utilise des

produits ayant un point d’éclair inférieur à 38 °C (100 °F). Le point

d’éclair d’un uide est la température à laquelle les vapeurs émanant du

uide peuvent s’enammer au contact d’une amme ou d’une étincelle.

4. Vériez que tous les conteneurs ou systèmes de stockage sont reliés à la

terre pour éviter les décharges d’électricité statique.

5. Connectez à une prise électrique avec prise de terre et utilisez des

rallonges électriques reliées à la terre. N’utilisez pas d’adaptateur 3 à 2.

6. N’utilisez pas de peinture ou de solvant contenant du halon, par

exemple, le chlore, les agents antimoisissure à l’eau de Javel, le chlorure

de méthylène et le trichloroéthane. Ils ne sont pas compatibles avec

l’aluminium. Contactez le fournisseur de revêtements pour connaître la

compatibilité du matériau avec l’aluminium.

7. La zone de pulvérisation doit toujours être bien aérée. Une bonne

quantité d’air frais doit constamment traverser la zone de pulvérisation

pour éviter les accumulations de vapeurs inammables. Le turbine doit

être placé dans une zone bien aérée. Ne pulvérisez pas le turbine.

1. Retirez toujours la turbine avant le nettoyage.

2. Le cordon d’alimentation doit être branché à un circuit doté d’une mise

à la terre.

3. N’immergez pas les pièces électriques, y compris le turbine.

4. Ne laissez jamais l’appareil sous la pluie. Entreposez-le à l’intérieur.

5. Garder la che du cordon électrique et la détente de l’appareil libres de

toute produits ou de tout autre liquide. Ne jamais exercer de contrainte

sur le raccordement de la che. Le défaut de suivre toutes les directives

énoncées peut provoquer un choc électrique.

Informations importantes sur le

système électrique

Utilisez seulement une rallonge électrique trilaire pourvue d’une prise avec

mise à la terre (trois tiges) et d’une connexion femelle à trois trous convenant au

cordon de l’appareil. Assurez-vous que la rallonge électrique est en bon état.

Lorsque vous utilisez une rallonge électrique, assurez-vous qu’elle a un calibre

assez élevé pour transmettre le courant nécessaire au fonctionnement de

l’appareil. L’utilisation d’une rallonge de calibre trop faible entraîne une chute

de tension sectorielle se traduisant par une perte de courant, une surchaue

de l’appareil et dommage possible.

Cet appareil est équipé d’un cordon d’alimentation de calibre 14, donc un

calibre 14 ou 12 rallonge électrique est nécessaire. Ne pas utiliser plus de 31m

de rallonge électrique.

Si vous devez utiliser une rallonge à l’extérieur, la mention W-A doit y gurer

suivant la désignation du type de rallonge. Par exemple, SJTW-A représente

une rallonge appropriée pour une utilisation à l’extérieur.

Français

16

Page 17

Introduction à la

pulvérisation de

peinture

Introduction

Description de la fonction

Le système de pulvérisation de peinture se compose d’une turbine

motorisée portative qui fournit de l’air de pulvérisation au pistolet de

pulvérisation.

Dans le pistolet de pulvérisation, une partie de l’air de la turbine est

utilisée pour mettre le réservoir en pression. Cette pression alimente le

matériau de revêtement dans le tube d’aspiration à l’embout de liquide

où il est ensuite pulvérisé en sortant.

Tous les réglages nécessaires au fonctionnement (p. ex., volume de

produit, volume d’air) peuvent facilement être réglés directement sur

le pistolet, y compris le démarrage/l’arrêt de la turbine en activant la

détente.

Démarrer

Passez cette page en revue an de vous

familiariser avec certains renseignements

généraux concernant la pulvérisation de

peinture FLEXSPRAY, y compris les produits à

pulvériser convenables et la façon de préparer le

produit à pulvériser.

Avis :

Matériau de revêtement

Matériaux de revêtement appropriés

Revêtements à eau et avec solvant.

Matériaux de revêtement non appropriés

Les matériaux qui contiennent des composantes très abrasives, des

solutions caustiques et des matières de revêtement acides. S’entourer

de toutes les précautions possibles lorsqu’on utilise des produits

ayant un point d’éclair inférieur à 38 °C (100 °F).

Préparation du matériau de revêtement

Remarque : Suivez les consignes du fabricant pour l’utilisation du

matériau de revêtement sur le contenant du matériau ou sur la che

technique.

Pureté du matériau de revêtement

Une condition préalable absolue du fonctionnement sans problème

du système de FLEXSPRAY est que le matériau de revêtement ne

soit pas contaminé. Si vous doutez de la pureté du matériau de

revêtement, nous vous recommandons de ltrer le matériau de

revêtement à l’aide d’un tamis à peintures.

17

Français

Page 18

Pièces et

Démarrer

Avis :

composants

9

19

20

Examinez l’information gurant dans

cette page pour vous familiariser avec

les pièces et les composants de votre

appareil.

10

11

8

22

23

24

7

6

5

3

# Description

1 Embout

2 Chapeau d’air

3

Levier de tarage (largeur de la répartition)

4

Anneau de tarage (direction de la

répartition)

5 Écrou d’assemblage

6 Ensemble avant

7 Réglage du débit de produit

8 Turbine

9 Réglage de l’air à vitesse variable

10 Système de verrouillage de couvercle

de ltre à air

21

16

15

# Description

11 Crochet de la courroie d’épaule (peut

être monté d’un côté ou de l’autre de

la turbine)

12 Levier de dégagement pour le change-

ment rapide

13 Détente à deux étages (active la turbine

et ensuite le pointeau an de pulvériser

le produit)

14 Réservoir de liquide, 1 Qt.

15 Tube d’aspiration

16 Joint d’étanchéité de réservoir

17 Clapet antiretour

13

18

17

14

12

# Description

18 Tube d’air

19 Couvercle de ltre d’air

20 Filtre d’air

21 Cordon d’alimentation

22 Brosse de nettoyage (2)

23 Boîtier de transport

24 Courroie d’épaule

1

2

4

Pétrolatum, 2 cc (non illustré)

Courroie Velcro pour enrouler le cordon

d’alimentation (non illustré)

Français

18

Page 19

Système de

1a

1b

c

changement

rapide (Quick

Change)

1) Montage

a. Pour le montage, insérez l’ensemble avant

dans la turbine an que les deux èches

s’alignent.

b. Tournez la turbine de 90° dans la direction

de la èche jusqu’à ce qu’elle clique en

place.

Démarrer

Grâce au système de changement rapide, la partie avant du pistolet (ensemble avant)

peut être remplacée rapidement et facilement.

Cela permet le changement rapide de produit pour diérents revêtements et les

plus gros travaux. Cela assure également que le bon outil est disponible pour chaque

produit et application.

Les ensembles avant suivants sont vendus :

Ensemble avant Description

FlexFinish (blanc)

Nº de pièce 0529009

(incluse avec cet appareil)

FineFinish (rouge)

Nº de pièce 0529008

(vendue séparément)

1

Avis :

Accessoire de pulvérisation avec embout à fente et

un réservoir en acier inoxydable de 0,9 litre. Pulvérise

toutes les peintures, les teintures, les laques et tous

les revêtements multicolores standards.

Accessoire de pulvérisation avec embout rond et

un réservoir en acier inoxydable de 0,9 litre. Idéal

pour les peintures, les teintures et les laques à faible

viscosité.

2) Démontage

Poussez le levier de changement rapide

sous la détente (c), tournez et séparez

l’ensemble avant de la turbine.

2

19

Français

Page 20

Guide pour

Démarrer

Avis :

appliquer

du ruban

A. Si vous pulvérisez les murs, assurez-vous de couvrir

le plafond au moins 60 cm à partir du bord où se

joignent le mur et le plafond.

B. Utilisez un petit morceau de ruban-cache placé

chaque quelques pieds pour xer le revêtement au

plafond.

C. Utilisez une toile de protection pour couvrir le

plancher et les plinthes.

Si vous pulvérisez à l’intérieur d’une pièce, suivez les

directives gurant sur cette feuille an de masquer

correctement les choses qui ne devraient pas être

peintes.

Vous aurez besoin de ce qui suit :

• Ruban-cache

• Revêtement en plastique pour les murs

• Toile de protection résistante pour les planchers

A

24”

D. Utilisez du ruban-cache pour xer la toile de

protection aux plinthes.

E. Couvrez les portes ou les fenêtres d’un revêtement en

plastique.

F. Utilisez du ruban-cache pour xer le revêtement aux

deux côtés de la porte ou de la fenêtre.

A

24”

A

B

A

E

F

D

C

Français

20

Page 21

Montage

1 Quart

b

a

b

Démarrer

Des instructions supplémentaires se trouvent à

l’intérieur du boîtier de transport. Ces directives

constituent un complément de ce manuel

d’instructions.

Avis :

IMPORTANT : Avant de brancher l’appareil

à la source d’alimentation, s’assurer

que la tension du cordon d’alimentation

correspond à la tension de fonctionnement

gurant sur l’étiquette de tension.

L’appareil doit être branché à une prise

correctement mise à la terre.

Montage :

1. Dévisser le réservoir de peinture de

l’ensemble avant.

2. Aligner le tube d’aspiration.

a. Si vous prévoyez diriger le jet vers

le bas, il faut alors pointer la partie

angulaire du tube d’aspiration vers

l’avant du pisolet.

b. Par contre, si vous prévoyez diriger

le jet vers le haut, vous devez alors

pointer le bout angulaire du tube

d’aspiration vers l’arrière du pistolet.

3. Vider le revêtement préparé (maximum

de 0,9 livre) dans le réservoir.

4. Visser soigneusement le réservoir de

peinture sur l’ensemble avant.

5. Raccorder l’ensemble avant et la turbine.

Brancher le cordon d’alimentation.

Le pistolet de pulvérisation est maintenant

prêt à être utilisé.

1

3

2

4

5

21

Français

Page 22

Réglage des

a

b

1

12

2

d

c

1

2

3

4

5

6

7

8

9

10

11

12

e

f

Démarrer

commandes

du pistolet

pulvérisateur

N’APPUYEZ JAMAIS sur la gâchette du pistolet

pendant que vous êtes en train de régler le

anneau de tarage. NE POINTEZ JAMAIS le

pistolet pulvérisateur vers l’une ou l’autre des

parties de votre corps.

Régler la répartition de pulvérisation :

(largeur/direction)

On peut déterminer l’orientation de la répartition de

pulvérisation en tournant l’anneau de tarage (a).

IMPORTANT : Toujours veiller à ce que l’écrou de

connexion (b) soit bien serré avant la pulvérisation.

Il est également possible de passer d’une répartition de

peinture en forme d’éventail large (

du levier de réglage (c).

Régler le débit du produit :

On peut régler le débit du produit progressivement de 1

(minimum) à 12 (maximum) en tournant le réglage du débit

de produit (d). Consulter le guide de démarrage rapide pour

établir un point de départ.

) et étroite ( ) à l’aide

Le rendement dépendra d’un certain nombre de facteurs: l’épaisseur du produit,

la répartition de pulvérisation sélectionnée, le volume du produit et la volume de

l’air. Avec n’importe quel type de systeme de pulvérisation, on peut obtenir les

résultats désirés par essais et erreurs pendant le réglage de certaines ou de toutes

ces variables.

Étudiez ces pages pour vous renseigner sur les commandes de pulvérisation et la

façon dont elles peuvent être utilisées pour obtenir les résultats désirés.

Avis :

Régler le débit d’air :

Tourner le réglage de l’air à vitesse variable (e) dans le sens

des aiguilles d’une montre an d’augmenter le débit d’air ou

dans le sens inverse des aiguilles d’une montre an de réduire

le débit d’air (remarquer la èche (f) sur le corps du pistolet

pour le réglage). Consulter le guide de démarrage rapide pour

établir un point de départ.

Remarque : Suivre les directives du fabricant quant à

l’utilisation du matériau de revêtement sur le réservoir de

peinture ou sur la che de données techniques.

Guide de démarrage rapide FLEXSPRAY

Largeur de la

Revêtement

Teinture

Lacques

Uréthanes

Émails

Teintures

Acryliques/Alkydes

Émulsion

Acrylique

Multicolores

Répartition en

forme d’éventail

2,5 à 12,5 cm 3

Plus de 12,5 cm 6 10

2,5 à 12,5 cm 3

Plus de 12,5 cm 7 10

2,5 à 12,5 cm 2

Plus de 12,5 cm 5 9

2,5 à 12,5 cm 4

Plus de 12,5 cm 8 11

2,5 à 12,5 cm 5

Plus de 12,5 cm 9 11

2,5 à 12,5 cm 4

Plus de 12,5 cm 9 11

2,5 à 12,5 cm 7

Plus de 12,5 cm 10

Français

Application Frontale FlexFinish Application Frontale FineFinish

Produit Air Produit Air

5-8

(Moyen)

5-8

(Moyen)

5-8

(Moyen)

9-12

(Élevé)

9-12

(Élevé)

9-12

(Élevé)

5-8

(Moyen)

7

7

6

9

9

8

NA NA

22

9-12

(Élevé)

5-8

(Moyen)

5-8

(Moyen)

9-12

(Élevé)

9-12

(Élevé)

9-12

(Élevé)

(1) Commencez avec une répartition

en forme d’éventail pour peindre les

garnitures (largeur de 2,5 à 12,5 cm)

et les plus grandes surfaces comme

les portes et les murs (largeur de >

12,5 cm).

(2) Réglez les paramètres du produit

et du volume d’air comme illustré

dans le tableau, en fonction du

revêtement, de la largeur de la

répartition en forme d’éventail et

l’application frontale.

(3) Réglez les paramètres du produit

et du volume d’air an d’obtenir les

meilleurs résultats pour votre projet.

(4) Optez pour la répartition circulaire

pour le travail détaillé ou les

retouches.

(5) Les paramètres recommandés pour

le produit et le volume d’air peuvent

changer si le revêtement est dilué.

Page 23

Pulvérisation

Démarrer

La pièce à pulvériser doit être bien masquée an

de prévenir que la surpulvérisation ne couvre la

boiserie, les planchers ou les meubles. Assurezvous de bien masquer la pièce conformément

aux directives du « Guide pour appliquer un

ruban »., page 20.

Avis :

Avant de commencer la pulvérisation

Practiquer

Si vous suggérons de vous pratiquer sur un bout de bois ou de carton avant de commencer à pulvériser la surface ou

l’objet proprement dit. Une ache de pulvérisation est également inclusse dans le boîtier de transport. Cette ache

peut être consultée pour obtenir des conseils supplémentaires. Consulter les réglages du guide de démarrage rapide

FLEXSPRAY à la page précédente pour établir un point de départ.

Préparation de la surface

Tous les objets à pulvériser doivent être nettoyés à fond avant de recevoir une première couche. Dans certains cas, il

faudra recouvrir d’un rubancache les parties ne devant pas être pulvérisées.

Préparation de la zone de pulvérisation

Si les travaux de pulvérisation doivent avoir lieu à l’intérieur, la zone de pulvérisation doit alors être propre et exempte

de poussière pour éviter que cette dernière ne se retrouve sur la surface fraîchement peinte à cause du jet d’air.

Méthode de pulvérisation conseillée

Il est important de garder votre bras en mouvement

STOP

STOP

• Placez le pistolet perpendiculairement par rapport à la surface

Remarque : Il peut être nécessaire de se rapprocher à moins de 15 cm

de la surface à pulvériser pour la pulvérisation de garnitures ou d’autres

surfaces exigeant une répartition de pulvérisation très étroite.

• Il faut maintenir le jet parallèle à la surface et le mouvement du bras

• Le premier jet doit toujours servir à l’application d’une mince couche

• Pendant la pulvérisation de plus grandes surfaces, chevaucher

• Lors de l’application, appuyez toujours sur la gâchette après avoir

Remarque : Entre les coups de peinture, il faut seulement libérer la

détente susamment pour arrêter la pulvérisation du produit, mais pas

assez pour arrêter la turbine.

lorsque vous appuyez sur la détente du pulvérisateur. Si

vous arrêtez à un endroit trop longtemps, trop de produit

sera pulvérisé à la surface.

Activation partielle du gâchette va commencer la turbine,

mais pas la matière se vaporiser jusqu’à ce que la gâchette

est appuyez complètement. il est recommandé que la

gâchette intially être activé partiellement de manière à

démarrer la turbine avant une passe de pulvérisation est

eectué.

à pulvériser, à une distance de 15 cm (6 po) ou plus selon la

conguration de jet souhaitée.

doit être uniforme et constant, comme le montre sur la droite. On

évitera ainsi les irrégularités du ni telles que les dégoulinades et la

formation de rideaux.

qu’on laisse ensuite sécher avant de passer une deuxième fois pour

appliquer une couche un peu plus épaisse.

chaque pulvérisation par au moins 50 %. Cela assurera une

couverture complète.

amorcé le mouvement, et relâchez-la avant la n du mouvement.

Un balayage de 50 cm (20 po) produira de meilleurs résultants.

Maintenez toujours le pistolet bien droit par rapport à la surface à

pulvériser.

Couche uniforme partout

De 15 à 30 cm

1122 11221122

Mouvement régulier à vitesse constante

Couche minceCouche épaisse Couce mince

12

1

2

1122

2

1

12

Ne pas échir le poignet

IMPORTANT : Lorsqu’on utilise des matériaux de revêtement

à séchage rapide ou à deux composantes, s’assurer de

nettoyer le pulvérisateur avec un produit de nettoyage

convenable avant que le matériau sèche ou durcisse à

l’intérieur du pistolet de pulvérisation. Vérier la che de

données techniques du fabricant pour le temps de séchage.

23

Français

Page 24

Nettoyage

a

b

Démarrer

Pour le nettoyage, utilisez la solution de nettoyage appropriée (eau chaude, savonneuse

pour les peintures aux latex; essences minérales pour les peintures à l’huile)

IMPORTANT : Ne jamais nettoyer la buse ou l’alésage d’air du pistolet avec des

objets métalliques pointus. N’utilisez pas de solvants ou de lubriants au silicone.

Avant de commencer :

Directives spéciales pour le nettoyage au moyen de solvants

inflammables. S’entourer de toutes les précautions possibles lorsqu’on

utilise des produits ayant un point d’éclair inférieur à 38 °C (100 °F) :

Nettoyage :

1. Debrancher le cordon d’alimentation.

Diviser le pistolet de pulvérisation. Poussez le

levier de changement rapide sous la détente

(a), tournez et séparez l’ensemble avant de la

turbine.

Ne jamais tenir la turbine sous l’eau ou

les immerger dans des liquides.

2. Dévisser le réservoir et retirez.

Vider le reste du matériel dans le contenant du

produit.

Nettoyer le réservoir et le tube d’aspiration à

l’aide d’une brosse et la solution de nettoyage

appropriée.

3. Nettoyer l’ouverture d’aération (b) sur le tube

d’aspiration.

4. Vider une petite quantité de la solution

appropriée de nettoyage dans la réservoir.

Fixer le réservoir au pistolet.

5. Raccorder l’ensemble avant et la turbine.

6. Brancher le cordon d’alimentation. Vaporiser la

solution en utilisant le pistolet dans un endroit

sécuritaire.

Remarque : Il est préférable de régler la

pulvérisation à un mode de répartition étroite an

de mieux diriger la solution de nettoyage dans le

contenant de vidange.

Répéter la procédure ci-dessus jusqu’à ce que

le solvant ou l’eau qui sort de l’embout soit

propre.

Suite à la page suivante

1

3

2

4

65

Français

24

Récipient à

déchets vide

Page 25

SafetyNettoyage

a

e

f

g

h

i

j

c

d

k

(suite)

7. Debrancher le cordon d’alimentation.

Diviser le pistolet de pulvérisation.

Poussez le levier de changement rapide

sous la détente (a), tournez et séparez

l’ensemble avant de la turbine.

8. Retirer le réservoir de 0,9 litre et le vider.

9. Retirer le tube d’aspiration avec le joint

d’étanchéité du réservoir.

10. Nettoyer le tube d’aspiration (c) et

l’ouverture de l’embout d’aspiration de

l’ensemble avant (d) à l’aide de la brosse

de nettoyage.

11. Retirer l’anneau de réglage (e)

soigneusement de l’écrou de connexion

(f). Dévisser l’écrou de connexion (f), retirer

le chapeau d’air (g), l’embout (h) et le joint

d’étanchéité de l’embout (i).

Bien nettoyer toutes les pièces.

12. Nettoyer doucement le bout du pointeau

(j) et l’ouverture du pointeau à l’aide de la

brosse de nettoyage.

Essuyer l’extérieur de l’ensemble avant

et du réservoir de peinture à l’aide d’un

linge humide (s’assurer que le linge

est humidié en utilisant la solution de

nettoyage appropriée).

13. Lubrier le joint torique (k) à l’arrière de

l’ensemble avant d’une couche mince du

pétrolatum inclus.

7 8

9

11

10

Passer à la section « Remontage » à la

prochaine page.

12

25

13

Français

Page 26

Remontez

b

a

c

g

h

i

e

d

f

Démarrer

Suivre les étapes décrites ci-dessous pour le

remontage. Un mauvais remontage risque

d’endommager le pistolet de pulvérisation.

IMPORTANT :

Remontez :

1. Insérer d’abord l’embout d’étanchéité

(a)avec rainure (fente) dans l’embout

(éloigné de l’ensemble avant).

Insérer l’embout. S’assurer d’aligner la

gorge (b) et l’encoche (c) et d’aligner

l’embout avec le pointeau.

2. Disposer le chapeau à air (d) sur l’embout

(e) et xer en serrant à fond l’écrou

d’assemblage (f).

3. Clipser la anneau de tarage (g) sur l’écrou

d’assemblage en veillant à disposer

l’oeillet sur le téton (i) du chapeau à air.

Remarque : S’assurer que les deux gorges sur

l’anneau de réglage sont engrenées dans les

onglets du chapeau d’air.

4. Placer le joint d’étanchéité du réservoir

sur le tube d’aspiration et le glisser sur la

bague (j), tout en tournant légèrement le

joint d’étanchéité du réservoir.

5. Insérer le tube d’aspiration avec le joint

d’étanchéité du réservoir dans l’ensemble

avant.

6. Replacer le réservoir.

Transport/entreposage

1. Détachez la courroie du pulvérisateur et

xez-la au boîtier de transport (elle peut

également être entreposée dans le boîtier

de transport).

2. Placez l’appareil et les accessoires dans

le boîtier de transport tel qu’illustré cidessous et xez-les à l’aide d’élastiques.

1

3

2

4

j

3. Enroulez le cordon d’alimentation et

Remarque : Appuyez à l’intérieur du couvercle

du boîtier à droite et à gauche vers l’extérieur

an d’ouvrir complètement le boîtier de

transport.

utilisez la courroie Velcro pour le xer.

Français

5 6

26

Page 27

Entretien

a

b

c

c

b

a

b

d

e

c

Démarrer

Passer en revue l’information gurant sur cette

page an de vous familiariser avec la bonne façon

d’entretenir votre pulvérisateur.

Avis :

Filtre d’air:

IMPORTANT : Ne jamais utiliser l’appareil avec un ltre d’air sale ou manquant,

étant donné que la saleté peut être aspirée et peut avoir une incidence sur le

fonctionnement de la turbine et/ou contaminer le produit. Il faut toujours vérier

le ltre d’air avant de commencer la pulvérisation.

1. Débrancher l’appareil.

2. Tournez le verrou du couvercle de ltre (a) à la position de déverrouillage. Retirez le

couvercle de ltre (b) et le ltre (c).

3. Nettoyer, souer ou remplacer le ltre d’air (c).

IMPORTANT : NE PAS nettoyer le ltre avec un solvant. Nettoyez avec de l’eau

chaude et savonneuse seulement.

4. Replacez le ltre nettoyé ou le nouveau ltre dans la turbine. Assurez-vous que

le ltre est glissé sous le logement (d) des deux côtés de la turbine. Raccordez

le couvercle de ltre et tournez le verrou du couvercle de ltre à la position de

déverrouillage.

Remarque : Assurez-vous que les onglets du couvercle de ltre (e) s’enclenchent sur la

turbine (schéma en médaillon).

Remarque : Lors du remplacement, utiliser uniquement des ltres de TITAN FLEXSPRAY

HANDHELD .

1

2

Tube d’air:

Remarque : Si de la peinture s’est introduite

dans le tube d’air, suivre les étapes suivantes.

1. Tirer le tube d’air (a) sur le dessus du

corps du pistolet. Dévisser le couvercle de

soupape (b). Retirer le joint de soupape (c).

Nettoyer soigneusement toutes les pièces.

IMPORTANT : Le tube d’air et le joint de

soupape (c) résistent aux solvants dans

une mesure limitée uniquement. Ne pas

les immerger dans du solvant, les essuyer

uniquement.

2. Placer le joint de soupape (c) dans le

couvercle de soupape (b) avec le goujon

face au tube.

Remarque : Installer le joint de soupape dans le

couvercle de soupape sera beaucoup plus facile

si ce dernier est inversé.

3. Retourner l’ensemble avant et visser le

couvercle de soupape (avec le joint de

soupape à l’intérieur) du dessous.

Remarque : Retourner l’ensemble avant

empêchera le joint de soupape de tomber du

couvercle de soupape pendant le remontage.

4. Placer le tube d’air sur le couvercle de

soupape et sur le raccord du corps du

pistolet.

3

4

27

Français

Page 28

Dépannage

Toute tentative par une personne autre qu’un technicien autorisé

d’ouvrir le carter du moteur ou de réparer un composant électrique

pourrait entraîner des blessures graves et annulerait la garantie.

Probleme Cause Solution

La turbine ne dèmarre pas

Débit de produit faible ou

inexistant

Fuite du produit

La répartition de pulvérisation

est trop épaisse et coule

Pulsation du jet

Surpulvérisation excessive

Peinture dans le tube d’air

1. Le cordon d’alimentation n’est pas branché ou la

prise n’est pas alimentée

2. L’appareil s’est surchaué

1. Buse est encrassé

2. Tube d’aspiration est encrassé

3. Débit matériel plaçant si bas (-)

4. Tube d’aspiration est desserré.

5. Il n’y a pas de pression d’air dans le réservoir.

6. Le réservoir est vide

7. Le ltre du tube d’aspiration est bouché (s’il y a lieu)

8. Le tube d’air est desserré/endommagé

9. Le joint d’étanchéité du réservoir de peinture est

endommagé

10. L’ouverture d’aération du tube d’aspiration est

bloquée

11. Le joint de soupape du tube d’air est coincé

12. Filtre à air est encrassé.

1. Le chapeau d’air, l’embout ou le pointeau est sale

2. L’accessoire de l’ensemble avant est mal installé

3. Buse deserré

4. Le joint d’étanchéité de la buse est usé

5. Buse usée

6. Le pointeau est usé

7. Accumulation de produit sur le chapeau d’air et

l’embout

1. Débit de produit trop élevé

2. Débit d’aire trop basse

3. Buse est encrassé

4. Filtre à air est encrassé

5. Il n’y a pas de pression d’air dans le réservoir.

6. Viscosité trop élevée du produit de revêtement.

7. Le tube d’air est desserré/endommagé

8. Le déclencheur est activé trop rapidement

9. L’application du produit est trop abondante

10. Le pistolet n’est pas assez loin de l’objet à pulvériser

11. L’ensemble avant ne convient pas au produit à

pulvériser

1. Épuisement du produit dans le réservoir.

2. Filtre à air est encrassé.

3. Le joint d’étanchéité de la buse est usé

4. Tube d’aspiration est desserré.

5. Le tube d’aspiration/ltre du tube d’aspiration est

bloqué

1. Le pistolet pulvérisateur est trop éloigné de la

surface

2. Apport excessif de produit

3. Débit d’aire trop élevé

4. Le produit a été trop dilué

5. L’ensemble avant ne convient pas au produit à

pulvériser

1. Le joint de soupape est sale

2. Le joint de soupape est défectueux

1. Brancher le cordon d’alimentation dans une prise de 120 V

2. Débrancher l’appareil. Laisser l’appareil se refroidir

pendant environ 30 minutes, ne pas plier le tuyau,

vérier le ltre d’air, ne pas couvrir les fentes d’entrée

1. La nettoyer

2. La nettoyer

3. Augmenter l’arrangement matériel de débit (+)

4. Insérer

5. Bien visser le réservoir

6. Remplir le réservoir

7. Nettoyer ou remplacer le ltre

8. Installer à nouveau ou remplacer le tube d’air (voir la page 27)

9. Remplacer le réservoir de peinture

10. Nettoyer l’ouverture (voir la page 24)

11. Nettoyer le pistolet (voir la page 27)

12. La nettoyer ou remplacer

1. Nettoyer les pièces

2. Installer l’accessoire correctement (voir la page 26)

3. La serrer

4. La remplacer

5. La remplacer

6. Utiliser un nouvel accessoire de pulvérisation

7. Nettoyer les pièces

1. Diminuer l’arrangement matériel de débit (-)

2. Augmenter le réglage d’aire.

3. La nettoyer

4. La nettoyer ou remplacer (page 27)

5. Bien visser le réservoir

6. Le diluer

7. Installer à nouveau ou remplacer le tube d’air (voir la page 27)

8. Appuyer sur la gâchette jusqu’à ce que partiellement

atteint turbine à pleine puissance

9. Réglez le débit du liquide (-) ou encore augmentez le

mouvement du pisolet pulvérisateur.

10. Éloigner le pulvérisateur de l’objet à pulvériser

11. Utiliser un diérent ensemble avant

1. Remplissez

2. La nettoyer ou remplacer (page 27)

3. La remplacer

4. Insérer

5. Nettoyer ou remplacer le ltre

1. Réduire la distance

2. Diminuer l’arrangement matériel de débit (-)

3. Diminuer le débit d’aire

4. Épaissir le produit en en ajoutant plus

5. Utiliser un diérent ensemble avant

1. Nettoyer le joint de soupape (voir la page 27)

2. Remplacer le joint de soupape (voir la page 27)

Cet appareil n’a aucune pièce électrique utilisable. Ne tentez pas

d’effectuer vous-même l’entretien. Rangez, à l’intérieur, avec le

cordon d’alimentation enroulé et fixez-le à l’aide d’une courroie

Velcro.

Français

28

Page 29

Manual de usario

Lea este manual para obtener las instrucciones

completas

FLEXSPRAY

HANDHELD

Modelo 0524093

¿Necesita ayuda?

Llame Titan Technical Service al:

1-800-526-5362

Regístrelo del producto en línea en:

www.titantool.com

Tabla de contenido

30 Información importante sobre seguridad

31 Introducción a la pulverización de pintura

32 Piezas y componentes

33 Sistema de cambio rápido (Quick Change)

34 Guía de protección con cinta adhesiva

35 Preparación

36 Ajuste de los controles de la pistola pulverizadora

37 Rociado

38 Limpieza

40 Reensamblaje

41 Mantenimiento

42 Solución de problemas

44 Lista de piezas

47 Garantía Limitada

Page 30

Información Importante

Receptáculo conectado a tierra

Espiga de conexión a tierra

Tapa de la caja de receptáculo conectada a tierra

SafetySafety

sobre Seguridad

Lea toda la información de seguridad

antes de operar el equipo. Guarde estas

insturcciones.

Indica una situación peligrosa que, de no evitarse, puede

causar la muerte o lesiones graves.

Para reducir los riesgos de incendios, explosiones,

descargas eléctricas o lesiones a las personas, lea y

entienda todas las instrucciones incluidas en este

manual. Familiarícese con los controles y el uso adecuado

del equipo.

Instrucciones para la conexión a tierra

Este producto debe conectarse a tierra. En caso de un cortocircuito eléctrico,

la conexión a tierra reduce el riesgo de choque eléctrico al aportar un alambre

de escape para la corriente eléctrica. Este producto está equipado con un cable

que tiene alambre a tierra con un enchufe a tierra adecuado. Debe usarse el

enchufe para conectar a un receptáculo que esté debidamente instalado y

conectado a tierra en conformidad con los códigos y las ordenanzas locales.

ADVERTENCIA - La instalación incorrecta del enchufe a

tierra puede ocasionar un riesgo de choque eléctrico.

Si es necesario reparar o cambiar el cable o el enchufe, no conecte el cable

verde a ninguna de las dos puntas planas. El cable con aislamiento de color

verde por fuera con o sin rayas amarillas es el alambre de conexión a tierra y

debe conectarse a la espiga de conexión a tierra.

Consulte a un electricista o técnico de servicio capacitado si las instrucciones

para la conexión a tierra no se entienden claramente o si tiene dudas en

cuanto a que el producto esté debidamente conectado a tierra. No modique

el enchufe que se incluye. Si el enchufe no encaja en el receptáculo, pida a un

electricista capacitado que instale un receptáculo adecuado.

Este producto es para utilizarse en un circuito de 120 voltios nominales y

tiene un enchufe a tierra que tiene un aspecto similar al ilustrado más abajo.

Asegúrese que el producto esté conectado a un tomacorriente que tenga la

misma conguración que el enchufe. No deben utilizarse adaptadores para

este producto.

7. Mantenga la zona de pulverización bien ventilada. Asegúrese de que

circula aire fresco por la zona para evitar que se acumulen vapores

inamables en el aire de la zona de pulverización. Ponga el conjunto

de la turbina en una zona bien ventilada. No pulverice el conjunto de la

turbina.

8. No fume en la zona de pulverización.

9. No encienda interruptores de luces, motores ni productos similares que

puedan producir chispas en la zona de pulverización.

10. Mantenga la zona limpia y despejada de botes de pintura y disolventes,

trapos y otros materiales inamables.

11. Infórmese del contenido de la pintura y de los disolventes que pulverice.

Lea las hojas de datos sobre seguridad de los materiales (MSDS) y las

etiquetas en los botes de pintura y disolvente. Siga las instrucciones de

seguridad del fabricante de la pintura y del disolvente.

12. Deberá contar con equipos extintores de incendios que funcionen

correctamente.

ADVERTENCIA – Para reducir el riesgo de lesiones:

1. Cuando pinte, lleve siempre guantes, protección para los ojos, ropa y

un respirador o máscara adecuados. Vapores peligrosos: Las pinturas,

disolventes, insecticidas y otros materiales pueden ser perjudiciales

si se inhalan o entran en contacto con el cuerpo. Los vapores pueden

producir nauseas intensas, desmayos o envenenamiento.

2. Nunca utilice el aparato ni pulverice cerca de niños. Mantenga el equipo

alejado de los niños en todo momento.

3. No se estire demasiado ni se apoye sobre un soporte inestable.

Mantenga los pies bien apoyados y el equilibrio en todo momento.

4. No se distraiga y tenga cuidado con lo que hace.

5. No utilice el aparato si está fatigado o se encuentra bajo la inuencia del

alcohol o de las drogas.

6. NUNCA apunte la pistola a ninguna parte del cuerpo.

7. Siga todos los códigos locales, estatales y nacionales correspondientes

que rijan la ventilación, prevención de incendios y operación.

8. Se han adoptado las normas de seguridad del Gobierno de los Estados

Unidos según la Ley de seguridad ocupacional y salud (Occupational

Safety and Health Act, OSHA). Deben consultarse estas normas,

particularmente el apartado 1910 de las Normas generales y el apartado

1926 de las Normas de construcción.

9. Utilice solamente componentes autorizados por el fabricante. El

usuario asume todos los riesgos y responsabilidades cuando usa piezas

que no cumplen con las especicaciones mínimas y los requisitos de

dispositivos de seguridad del fabricante de la turbina.

10. Debe conectarse el cable eléctrico a un circuito a tierra.

11. Utilice sólo peizas recomendadas de Titan FlexSpray.

12. No pinte en exteriores en días con viento.

ADVERTENCIA – Para reducir el riesgo de

incendio o explosión:

1. No pulverice materiales inamables ni combustibles cerca de llamas

desnudas, pilotos o fuentes de ignición como objetos calientes,

cigarrillos, motores, equipos eléctricos o electrodomésticos. Evite

producir chispas al conectar y desconectar los cables de alimentación.

2. Se deberá contar con un escape y entrada de aire fresco para mantener

el aire del área de atomización libre de acumulaciones de vapores

inamables.

3. Tenga muchísimo cuidado al usar materiales cuyo punto de ignición sea

inferior a 100° F (38° C). El punto de ignición es la temperatura a la cual

pueden encenderse los vapores emanados por un uido al exponerlos a

llamas o chispas.

4. Compruebe que todos los recipientes y sistemas de recogida están

conectados a tierra para evitar descargas eléctricas.

5. Conecte a una salida con toma a tierra y utilice cables alargadores puestos a

tierra. No utilice un adaptador de 3 a 2.

6. No utilice pintura o disolvente que contenga hidrocarburos

halogenados, como cloro, fungicida blanqueador, cloruro de metileno y

tricloroetano. No son compatibles con el aluminio. Póngase en contacto

con el proveedor del material para conocer su compatibilidad con el

aluminio.

Español

ADVERTENCIA – Para reducir el riesgo de electrocución:

1. Retire siempre la turbina antes de la limpieza.

2. El cable de alimentación debe estar conectado a un circuito con toma a

tierra.