Page 1

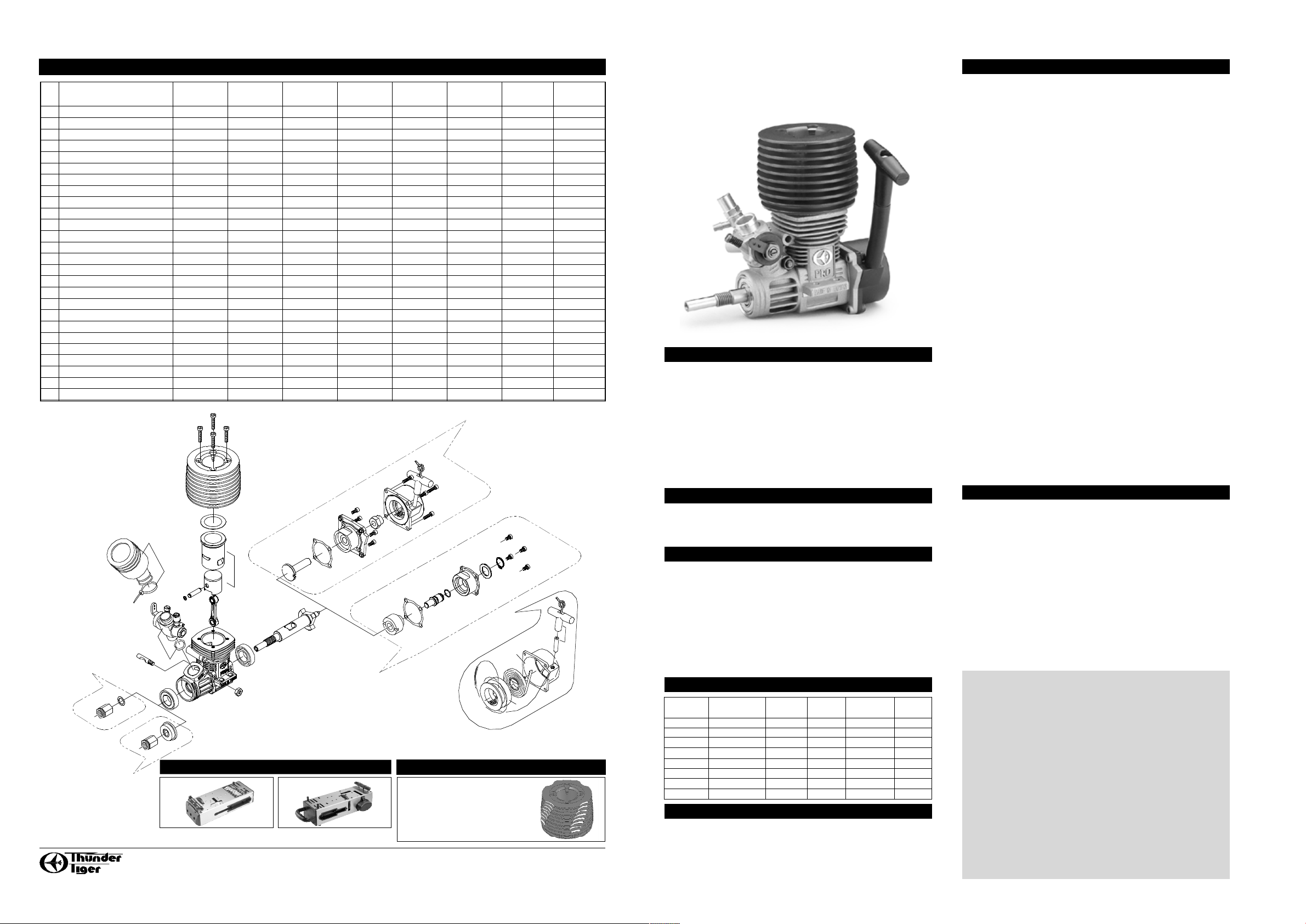

PARTS LIST / ENGINE

THUNDER TIGER CAR ENGINES

INSTRUCTIONS

PRO-18BX / 9442 SHOWN

INTRODUCTION

Congratulations on your purchase of a Thunder Tiger model engine. The

latest Thunder Tiger PRO-12/ 15/ 18 series car engines have been designed

for one tenth scale radio-controlled model cars to combine high performance

with easy handing and maintenanc e using modern CAD compu ter

technology. Majo r components of the engines are mac hined from the

highest quality materials using state-o f-the art CNC manufacturing

techniques, resulting in consistently high performance and reliability. The

PRO series engines are equipped with dual-ball bearings, Schnuerle

porting, ABC type piston and cylinder, and automatic mixture control

carburetors.

IMPORTANT

Be certain to completely read all of the instructions su pplied with your

engine, and pay close attention to the "SAFETY INSTRUCTIONS AND

WARNINGS".

SPECIAL ATTENTION

When you rotate the crankshaft of your engine by hand, you may find that

it becomes rough or "notch" as the piston approaches TDC (Top Dead

Center). This is not a defect or manufacturing fault, indeed it is normal

for an engine of ABC type construction. When the engine runs, the cylinder

actually expands as it heats. The cylinder has been precision machined

so that (at optimum operating temperature) the cylinder walls are perfectly

aligned with the piston. A s the engine cools after a run, you will notice

that the tightness will actually return. This is normal and typical of an ABC

type engine.

LEARNING ABOUT YOUR ENGINE

Before actually operate your engine, the following information is for the

benefit of the newcomers with no previous experience of model engines.

Please put the engine near you and read this instruction. The model engine

is just like the engine of a motorcycle or a car that needs a key to start.

You have to prepare some accessories and knowledge. It is not hard to

operate your model engine by following the instructions properly.

RECOIL STARTING SYSTEM & SHAFT STARTING SYSTEM

The Thunder Tiger "X" type series engines feature a built-in recoil starting

system that eliminates the need for a separate electric starter and battery

or a starter box, and allows the engine to be started easily by simply

pulling the starter handle.

1) Pull the handle straight away from the starter housing so that it prevents

the cord from being damaged by rubbing against the starting wheel

cover or car body.

2) Let the cord recoil slowly while still holding the handle. Do not release

the handle abruptly.

3) It is recommended to keep the cord away from fuel, as fuel will weaken

the cord and cause it to break.

4) The recoil starter system is developed to operate in a counter clockwise

direction (when viewed from front of the engine). If you attempt to crank

the flywheel or force the engine in the opposite direction, the one-way

clutch set will be damaged.

5) The spring in the recoil system is under extreme tension! If it is necessary

to dismantle your engine, remove the starting wheel cover set gently

to prevent damage or injury.

The Thunder Tiger "K" type series engines feature a built-in hexagonal

shaft starting system that can be operated to start the engine as simple

as the "X" type series. Please refer to the instruction of your model

vehicle for the compatibility of installing the "K" type series engine on

your model vehicle.

1) To use the Hex Starting shaft, either a cordless drill or 12V DC handy

starter is required.

2) Install the extended 6mm hex starting tool into the cordless drill or a

12V DC starter.

3) BEFORE inserting the Hex Starting shaft into the back start output,

squeeze the trigger and verify that the drill is turning the same direction

as is shown on the sticker on the back start cover.

4) Attempting to start the motor by using a counter-clockwise direction

could damage the pull-start mechanism or possibly the engine internal

components. Insert the ball end of the Hex Start shaft into the Dual

Start output. Grasp the drill tightly and squeeze the trigger.

NECESSARY ACCESSORIES

The following items are necessary for operating the engine, these are

available at you hobby dealer.

FUEL

A good quality, commercially available fuel containing 25% lubricant and

75% methanol is recommended for break-in/run-in and general usage.

We also recommend castor oil or a castor/synthetic blend only for use

as a lubricant. Fuel containing 10%-30% nitromethane and 20% lubricant

is for use when more power is required. Most fuels containing synthetic

lubricants (only) are much less tolerant of a lean run compared to fuel

that contains castor oil. If availability or local conditions force you to use

a fuel that contains only synthetic lubricant, we suggest that you keep

your needle valve set to a slightly richer setting, allowing more lubricant

to flow through your engine to extend engine life and maintain optimum

reliability. Do not use fuel containing less than 20% lubricant.

CAUTION 1

Methanol and nitromethane are poisonous and highly flammable.

Keep out the reach of small children and keep away from heat

and open flame.

CAUTION 2

Excessive heat can great reduce the life of your engine. Most

of the heat generated by combustion is removed via the

lubricants that are contained in your fuel, and exits the engine

as exhaust vapor. As a precaution, you should periodically

remove the muffler from your engine and visually inspect the

exhaust port and piston. If the outer surface of the piston is

stained a very dark color, it can indicate that your engine may

be overheating. This can be caused by either an excessively

lean needle setting or a lack of airstream across the cylinder

and head.

SPECIFICATION

11

17

12

10

7

8

9

19

15

13

16a

12

1

5

13

16b

4

22

12

20

12

22

12

24

17

20

33

17

12

12

24

17

25

26

23

27

21

33

3

1

28

ITEMS DISPLACEMENT BORE STROKE PRACTIAL OUTPUT

(cc/cu.in.) (mm/in.) (mm/in.) R.P.M. RANGE (BHP/RPM)

PRO12-BK 2.11/ 0.129 13.85/ 0.545 14/ 0.551 3,000-30,000 0.6/ 29,000

PRO12-BX 2.11/ 0.129 13.85/ 0.545 14/ 0.551 3,000-30,000 0.6/ 29,000

PRO12-BXP 2.11/ 0.129 13.85/ 0.545 14/ 0.551 3,000-30,000 0.6/ 29,000

PRO15-BX 2.47/ 0.151 15/ 0.591 14/ 0.551 3,000-30,000 0.7/ 29,000

PRO15-BXP 2.47/ 0.151 15/ 0.591 14/ 0.551 3,000-30,000 0.7/ 29,000

PRO18-BX 2.97/ 0.181 16.2/ 0.638 14.4/ 0.567 3,000-32,000 0.8/ 31,000

PRO18-BKP 2.97/ 0.181 16.2/ 0.638 14.4/ 0.567 3,000-32,000 0.8/ 31,000

PRO18-BXP 2.97/ 0.181 16.2/ 0.638 14.4/ 0.567 3,000-32,000 0.8/ 31,000

No. DESCRIPTION 9442 9443 9444 9459 9486 9487 9488 9489

PRO-18BX PRO-12BX PRO-15BX PRO-12BK PRO-12BXP PRO-15BXP PRO-18BKP PRO-18BXP

1 PROP NUT AA0199B AA0199B AA0199B AA0199B AA0199B AA0199B AA0199B AA0199B

3 DRIVE WASHER SET ******* ******* ******* ******* AA0023 AA0023 AA0023 AA0023

4 CRANKSHAFT AA2024 AA0728 AA0728 AA0728 AA0022 AA0022 AA2176 AA2176

5 CRANKCASE AN2033 AN2020 AN2029 AN2020 AN2020 AN2029 AN2033 AN2033

7 CONNECTING ROD AN2025 AN0433 AN0433 AN0433 AN0433 AN0433 AN2025 AN2025

8 WRIST PIN ASSEMBLY AA2006 AA0134 AA0188 AA0134 AA0134 AA0188 AA2006 AA2006

9 CIRCLIP AA0722 AA0722 AA0722 AA0722 AA0722 AA0722 AA0722 AA0722

10 CYLINDER&PISTON AN2030 AN0918 AN0716 AN0918 AN0918 AN0716 AN2030 AN2030

11 CYLINDER HEAD AA2121-R AA2124-R AA2125-R AA2122 AA2124-R AA2125-R AA2121-R AA2121-R

12 GASKET SET PN0245 PN0250 PN0248 PN0247 PN0260 PN0261 PN0265 PN0266

13 CARB RETAINING BOLT PN0188 PN0188 PN0188 PN0188 PN0188 PN0188 PN0188 PN0188

15 CARBURETOR ASSEMBLY 9785 9784 9785 9784 9784 9785 9785 9785

16a BALL BEARING, FRONT AMV6800Z AMV6800Z AMV6800Z AMV6800Z AMV6800Z AMV6800Z AMV6800Z AMV6800Z

16b BALL BEARING, REAR AMV6800X AMV6800X AMV6800X AMV6800X AMV6800X AMV6800X AMV6800X AMV6800X

17 SCREW SET PN0196 PN0196 PN0196 PN0195 PN0196 PN0196 PN0195 PN0196

19 AIR CLEANER SET 9262 9262 9262 PD1212 9262 9262 9262 9262

20 ONE WAY CLUTCH SET AN0924 AN0924 AN0924 AN0315 AN0924 AN0924 AN0315 AN0924

21 HANDLE SET PN0050 PN0050 PN0050 ******* PN0050 PN0050 ******* PN0050

22 STARTING AXLE AA0923 AA0923 AA0923 AA2017 AA0923 AA0923 AA2017 AA0923

23 STARTING SPRING AA0735 AA0735 AA0735 ******* AA0735 AA0735 ******* AA0735

24 BACKPLATE AN0764 AN0764 AN0764 AN2018 AN0764 AN0764 AN2018 AN0764

25 STARTING WHELL WIRE AA0733 AA0733 AA0733 ******* AA0733 AA0733 ******* AA0733

26 STARTING WHELL AA0721 AA0721 AA0721 ******* AA0721 AA0721 ******* AA0721

27 STARTING WHELL COVER AN0720 AN0720 AN0720 ******* AN0720 AN0720 ******* AN0720

28 STARTING SET ******* ******* ******* PN0267 ******* ******* PN0267 *******

33 STARTING COVER SET PN0246 PN0246 PN0246 ******* PN0246 PN0246 ****** PN0246

9442/ PRO-18BX

9443/ PRO-12BX

9444/ PRO-15BX

9486/ PRO-12BXP

9487/ PRO-15BXP

9489/ PRO-18BXP

9459/ PRO-12BK

9488/ PRO-18BKP

OPTIONAL CYLINDER HEAD

AA2034-R for PRO-18BX

AA2126-R for PRO-12BX/ 12BXP

AA2127-R for PRO-15BX/ 15BXP

9442/ PRO-18BX

9443/ PRO-12BX

9444/ PRO-15BX

9459/ PRO-12BK

9486/ PRO-12BXP

9487/ PRO-15BXP

9488/ PRO-18BKP

9489/ PRO-18BXP

2409 PRO STARTER BOX

OTHER ITEMS OF INTEREST

2408 PITMATE STARTER BOX

JA0460 V4

THUNDER TIGER CORP.

http://www.thundertiger.com

Page 2

CARBURETOR ITEM NO 9784 9785

NO. DESCRIPTION PART# PART#

A CARBURETOR BODY W/ROTOR PN1304 PN1303

B CARB. ROTOR ASSY PN1125 PN1128

C NEEDLE VALVE ONLY PN1035 PN1035

D SPRAY BAR ASSEMBLY PN1036 PN1036

E NEEDLE VALVE ASSY. PN1037 PN1037

F THROTTLE LEVER PN1038 PN1038

G BOLT&FUEL INLET PN1039 PN1039

H THROTTLE ROTOR SET PN1124 PN1127

I O RING SET PN1041 PN1041

J MIXTURE METERING SCREW SET PN1042 PN1042

PRO-12BX/ 12BK/ 12BXP/ 9784

PRO-15BX/ 15BXP/ 18BX/ 18BKP/ 18BXP/ 9785

GLOW PLUG

The type and quality of glow plug used

in your engine will have a maior impact

on overall performance and reliability.

All of the Thunder Tiger engi nes

operate best with a R/C long-type plug

such as Thunder Tiger, K&B, or O.S.

No.8. Fox plug s (while of excellent

quality) have a colder heat range and

may cau se idle or throttle transit ion

problems in smaller engines . Select

the best one by practical tests.

GLOW STARTER

The electric power source for heating

the glow plug.

PLUG WRENCH

Used for tight ing or screwing off the

glow plug. 4-way type (Thunder Tiger

4-way wrench) is preferred.

FUEL FILL BOTTLE OR FUE L

PUMP

Required to transfer fuel into the fuel

tank in your model. A Thun der Tiger

hand-crank pump or an electric pump

are available at your hobby dealer.

INSTALLATION

ENGINE

Locate your engine onto the engine mount on the chassis. Make sure the

gear mesh is smooth without excessive backlash. Set the clearance and

secure the engine mounting screw. Both the top and bottom surfaces of

the engine mount must be absolutely flat and parallel to avoid crankcase

distortion, stress and power loss.

MUFFLER/SILENCER

After the engine is mounted onto your model , secure the muffler to the

engine with two screws equipped with your engine. Be sure to tighten

them firmly. The rear half of the muffler can be rotated to direct the exhaust

residue away.

GLOW PLUG

Use 4-way wrench to screw the glow plug into your engine and do not

over tighten. Be sure to put the glow plug washer between the cylinder

head and glow plug to eliminate gas leakage.

AIR CLEANER

It preven ts damag ing dust an d dirt from being draw n into the engine

through the carburetor. Even minute foreign particles can easily damage

the engine and cause unreliable performance. It is necessary to chec k

the filter element periodly and replace it as required.

PREPARATION FOR STARTING YOUR ENGINE

PRE-ADJUST NEEDLE VALVE

Turn the needle valve clockwise until you begin to feel resist ance. This

is the fully closed position. Do not force the needle valve or you ma y

damage your carburetor! It may be convenient to remember the position

of the mark on the end of the needle valve. Now turn the needle valve

counter-clockwise about 2 1/2-3 turns. This will be a good place to start.

(Turn the needle valve clockwise is to "close" for leaner mixture, while

counter-clockwise is to "open" for richer mixture.)

CHOKING/PRIMING YOUR ENGINE

Turn on your control system and shift the throttl e full to test. Press fuel

pump in your fuel tank twice to prime your engine. The quanti ty of fuel

drawn into the engine by priming is an important factor for starting your

engine successfully. It needs more choke for the first starting and when

the engine is cold.

HEATING GLOW PLUG

Fit the glo-starter or conn ect the 1.2 volt ignition battery onto the glow

plug. The glow plug is made to keep the engine turning after removing

the glow-starter or cutting off the ignition battery. The platinum alloy coil

inside the glow plug is heated by the starter battery current, and remains

hot to keep the engine running even after the electric power is cut off.

STARTING

1) Pull Start/ Starter Box- Turn the flywheel by using an electric starter/starter

box or pull the handle of the recoil starting system to start the engine

with the throttle opening slightly (appro ximately 1m/m). The engine

should fire after one or two tries.

2) Hex Starter- Make sure that your drill/ starter is set to the clockwise

or forward position. Fit the extension starting shaft to the drill/starter

tight. Insert the shaft into the starting output on th e engine and then

power on the drill/starter. The engine should fire after one or two tries.

If the engine becomes flooded: turn off your vehicle, and then the radio.

Remove the glow plug using a glow wrench and then remove the air filter.

Turn the vehicle over to allow any excess fuel in the engine to run out.

Turn the vehicle right side up. Reinstal l the air cleaner. Slowly pull the

start cord about 8 inches, 5 to 7 times. Reinstall the glow plug with the

glow plug wrench. And return to the normal starting procedure.

CAUTION 1

Do not open the throttle beyond the setting position described

above before starting. It can develop enou gh power to injure

people seriously and do substantial property damage.

CAUTION 2

Never operate your engine at high R.P.M without a "load", that

is, with the wheels off the ground. Otherwise, your engine may

be damaged in a few seconds!

STOP YOUR ENGINE

Cut off the f uel supply to the carburetor by pinching the fuel line closed

or disconnect the fuel line at idle.

BREAK-IN/RUN-IN PROCEDURES

Because your Thunder Tiger engine has been precision-made from quality

materials and is an ABC-type engine, a prolonged break-in period is not

necessary. In fact, your engine can be run in your car to break it in.

1) We strongly recommen ded a fu el containing 20 % caster oil or

castor/synthetic blend with no more than 10% nitromethane be used

for break-in. We strongly discourage using fuel containing only synthetic

lubricants during the initial break-in period.

2) Turn the needle valve clockwise to the fully closed position and back

counter-clockwise about 3-3 1/2 turns. Start your engine as described

above.

3) Use the thro ttle-stop screw to set the idle position (with the throttle

opening approximately 1m/m) where the engine runs at a fast idle but

without engaging the clutch. Then, disconnect the battery from the glow

plug.

4) Let the car run down the longest available straight, or at least, around

a wide curve of sufficient radius to permit full-throttle driving and allow

the engine to consume the entire tank of fuel at this needle setting. If

it stops from being over-rich (i.e. dense smoke coming from the exhaust),

close the needle valve 1/8 turn and re-start the engine.

5) All adjustments during break-in will be made to the high speed needle

valve. If your engine stops in the mid-range or does not accelerate

smoothly (when the thrott le is opened fro m any setting above idle),

ple ase adju st the mixture metering screw as describe d in the

CARBURETOR ADJUSTMENT paragraph after break-in.

6) After the first tank full, allow the engine to cool for a few minutes before

re-filling the tank. Then close the needle valve 1/8 turn an d restart .

During the second tank of fue l, run the engine at alternate throttle

settings (i.e.1/2 throttle for 30 seconds, then full throttle for 30 seconds,

etc.) for about half the tank. Advance the throttle to full, and slowly lean

the needle setting (about 1/8 turn at a time) until the highest speed is

obtained (the smoke has thinned to a light gray).

7) At this point, richen the needle setting about 1/8 turn (counter clockwise)

and run a third tank of fuel at this needle setting. After 4-5 runs, your

engine will be completely broken-in and ready for consistent performance.

CARBURETOR ADJUSTMENT

These Thunder Tiger carburetors are specially designed for use with the

high performance Thunder Tiger engines. The y are able to provi de a

proper air-fuel mixture automatically at all throttle ranges from idle to full

speed. The carburetor has been pre-adjusted at the factory, which should

give excellent engine performance in most cases. Large adjustments of

the carbur etor should not be re quired. However, different operation

conditions (such as your choice of fuel, glow pl ug, gear ratio, clutch

engagement point and climate) may make further adjustments necessary

Model fuel contains alcohol, which is hydroscopic (meaning that it attracts

moisture from the atmosphere). This can cause corrosion to the internal

engine parts. After each running session, run all the fuel out from inside

the engine and disconnect the fuel line from the carburet or. Put 4 or 5

drops of after-run oil (Marvel Mystery Oil, Prather, Pacer, etc.) into the

carburetor and turn the engine over by hand several times to protect the

engine bearings and internal parts from corrosion.

The use of after-run oil is also important during periods of prolonged

storage (such as winter). We suggest removing the engine from the model,

and liberally applying oil into the carburetor and glow plug hole, wrap your

engine in a soft cloth and store in a sealed plastic bag.

Do not dismantle your engine unnecessarily, as this may upset precision

fits such as piston/cylinder and crank pin/connecting rod assembly. If it

is necessary to clean your engine completely, remove only the carb. (do

no disassemble), muffler, backplate, and cylinder head . Flush the entire

engine with fresh fuel and reassemble. Apply after-run oi l to the engine

and store or re-install into the model. Do not disassembl e your engine

further than described above.

SERVICE PROCEDURES

Thunder Tiger strives to bring you the highest level of

quality and service we can provide. We race and test

our products around the world to bring you state-of-theart items. Thunder Tiger guarantees that you should

enjoy many hours of trouble free use from our R/C

products. Thunder Tiger products have been sold

worldwide through the authorized distributors that are

supported directly and rapidly from Thunder Tiger. You

may find that Thunder Tiger is always pursuing to explore

new items creatively with highest quality. To update the

latest product information and to get the best technical

support, please feel free to contact your local hobby

shops or Thunder Tiger authorized distributor.

NEEDLE VALVE ADJUSTMENT

This is use d to adjust the high speed fuel mixture. Opti mum setting is

described in the BREAK-IN/RUN-IN PROCEDURES.

MIXTURE METERING SCREW ADJUSTMENT

This is used to obtain a smooth transition and stable idle.

1) After the needle valve has been set, keep running at the highest speed

for about 10 seconds the n abruptly close the throttle to the lowest

speed. Run at idle for about 5 seconds. Then quickly open the throttle.

2) If the engine hesitates before picking up speed, and there is plenty of

smoke and un-burned fuel coming out from the exhaust, the mixture

is too rich. Screw in (clockwise) the mixture metering screw about 1/8

turn.

3) On the other hand, if it speeds up before qu itting, the mixture is too

lean. Screw it out about 1/8 turn.

4) If this is difficult to observe, then allow the engine to idle slightly longer

before opening the throttle. Repeat procedure 1) patiently for few times

to ensure the best running is obtained.

THROTTLE-STOP SCREW ADJUSTMENT

This is used to set the minimum idle speed. If the engine runs too fast at

the lowest throttle opening, turn the throttle stop screw counter-clockwise

to reduce the throttle opening.

ENGINE CARE

Always keep the outside of your engine clean. Use clean, fresh fuel and

keep your fuel can, pump, and fueling system free from dirt particles.

Install a fresh fuel filter between the fuel tank and carburetor, and between

your fuel pump and filling line to prevent any potential of dirt entering your

engine.

B

I

D

G

C

E

J

H

F

A

NO.9281

GLOW PLUG

NO.2150/ 2151/ 2152

GLOW STARTER

NO.1102

PLUG WRENCH

NO.1645

FUEL PUMP

PARTS LIST / CARBURETOR

NOTE 1

The m ix ture m et ering scre w of yo ur

carburetor has been pre-adjusted at the

factory. If it is screwed in or out too far, reset

it as follow:

Screw in or out the mixture metering screw

until its end is flush with the throttle. Then

screw the mixture metering screw out about

1 turn. Now it is the standard position.

1 turn

Mix. Metering Screw

Loading...

Loading...