MEC 310

APPLICATION NOTES

M-Logic

Internal Logic Controller

r. 0556B

PM103 Rev 0 09/08/20

9087A – 198th Street, Langley, BC Canada V1M 3B1 Ÿ Telephone (604) 888-0110

Telefax (604) 888-3381 Ÿ E-Mail: info@thomsontechnology.com Ÿ www.thomsontechnology.com

This document covers the following products:

MEC 310 SW version 1.2X.X

Utility Software TPS300 version 3.10.1 and later.

Table of Contents

MEC 310 APPLICATION NOTES, M-Logic

1. ABOUT THIS DOCUMENT..........................................................................................................1

ENERAL PURPOSE

G

NTENDED USERS

I

2. WARNINGS AND LEGAL INFORMATION...............................................................................2

EGAL INFORMATION AND RESPONSIBILITY

L

LECTROSTATIC DISCHARGE AWARENESS

E

AFETY ISSUES

S

ACTORY SETTINGS

F

EFINITIONS

D

3. GENERAL DESCRIPTION ...........................................................................................................4

NTRODUCTION

I

4. CONFIGURATION ........................................................................................................................5

TARTING

S

EAD/WRITE

R

AVE/OPEN

S

ASIC FUNCTIONS

B

EFINITIONS

D

XAMPLES

E

5. LIST OF EVENTS AND COMMANDS.......................................................................................13

MEC 310 ............................................................................................................................................ 13

..............................................................................................................................................5

.............................................................................................................................................9

.................................................................................................................................1

....................................................................................................................................1

.............................................................................................2

................................................................................................2

.......................................................................................................................................2

................................................................................................................................2

..........................................................................................................................................2

......................................................................................................................................4

..........................................................................................................................................6

............................................................................................................................................6

...................................................................................................................................7

..........................................................................................................................................9

PM103 R0 09/08/20 THOMSON TECHNOLOGY

MEC 310 APPLICATION NOTES, M-Logic

Please make sure to read this handbook before working with the MEC 310

set to be controlled. Failure to do this could result in

1. About this document

General purpose

This document is the M-Logic handbook for Thomson Technology’s MEC 310 Generator

Controller. The document mainly includes a general description, information about programming,

overall configuration and relay configuration.

The general purpose of this handbook is to inform the intended users about programming and

configuration of the M-Logic tool.

Intended users

The handbook is mainly intended for the person responsible for the unit setup. In most cases, this

would be a panel builder designer. Naturally, other users might also find useful information in the

handbook.

controller and the gendamage to the equipment or human injury.

PM103 R0 09/08/20 Page 1 THOMSON TECHNOLOGY

MEC 310 APPLICATION NOTES, M-Logic

ll be helpful for the reader to

Be aware of the hazardous live currents and voltages. Do not touch any AC

2. Warnings and legal information

This chapter includes important information about general legal issues relevant in the handling of

Thomson Technology products. Furthermore, some overall safety precautions will be introduced

and recommended. Finally, the highlighted notes and warnings, which will be used throughout the

document, are presented.

Legal information and responsibility

Thomson Technology takes no responsibility for installation or operation of the generator set. If

there is any doubt about how to install or operate the generator set controlled by the unit, the

company responsible for the installation or the operation of the set must be contacted.

The units are not to be opened by unauthorized personnel. If opened anyway, the

warranty will be lost.

Electrostatic discharge awareness

Sufficient care must be taken to protect the terminals against static discharges during the

installation. Once the unit is installed and connected, these precautions are no longer necessary.

Safety issues

Installing the unit implies work with dangerous currents and voltages. Therefore, the installation

should only be carried out by authorized personnel who understand the risks involved in working

with live electrical equipment.

measurement inputs as this could lead to injury or death.

Factory settings

The unit is delivered with certain factory settings. Given the fact that these settings are based on

average values, they are not necessarily the correct settings for matching the individual engine.

Thus precautions must be taken to check the settings before running the engine.

Definitions

Throughout this document a number of notes and warnings will be presented. To ensure that these

are noticed, they will be highlighted in order to separate them from the general text.

Notes

PM103 R0 09/08/20 Page 2 THOMSON TECHNOLOGY

The notes provide general information which wi

bear in mind.

The warnings indicate a potentially dangerous situation, which could result

in death, personal injury or damaged equipment, if certain guidelines are not

Warnings

followed.

MEC 310 APPLICATION NOTES, M-Logic

PM103 R0 09/08/20 Page 3 THOMSON TECHNOLOGY

MEC 310 APPLICATION NOTES, M-Logic

3. General description

This chapter includes overall product information about the unit in general and its place in the

Thomson Technology product range.

Introduction

The M-Logic is a small logic controller incorporated in the MEC 310 controller. Even though it is a

logic controller, it must not be confused with a PLC. The M-Logic can be compared with a PLC

limited in functionality and can only be used for uncomplicated tasks.

The M-Logic can carry out binary control functions only; there are no possibilities for analogue

reading and/or control functions.

The M-Logic can be programmed from the free PC tool called TPS 300 Utility Software (ver. 3).

The TPS 300 software can be downloaded from:

www.thomsontechnology.com

M-Logic setting is done in command lines. There are 40 lines, and each line contains 3 events, 2

operators and one output with a possibility to make a time delay.

If 3 operators are not enough, a number of virtual events can be used to pass the control on to

another line and carry on there. This makes it possible to build larger event based controls.

PM103 R0 09/08/20 Page 4 THOMSON TECHNOLOGY

MEC 310 APPLICATION NOTES, M-Logic

4. Configuration

Starting

Once TPS 300 has been started, there will be an icon on the lower lefthand side to activate M-Logic.

Click the icon, and the following screen appears:

PM103 R0 09/08/20 Page 5 THOMSON TECHNOLOGY

MEC 310 APPLICATION NOTES, M-Logic

Read/write

When the M-Logic screen is shown, the M-Logic toolbar appears at the top of the screen. The

toolbar has two buttons which are used to write and read the M-Logic configuration to and from the

unit.

The M-Logic configuration can also be saved/opened to/from a file using the default save/open

buttons.

Read M-Logic settings from the unit

Activating this button will read all M-Logic settings from the unit to TPS 300.

Write M-Logic settings to the unit

Activating this button will write the M-Logic settings from TPS 300 to the unit.

Save/open

Save

Activating this button makes it possible to save the M-Logic configuration to file

(part of the general MEC 310 configuration file “.USW”).

Open

Activating this button makes it possible to open a previously saved logics file.

PM103 R0 09/08/20 Page 6 THOMSON TECHNOLOGY

MEC 310 APPLICATION NOTES, M-Logic

Basic functions

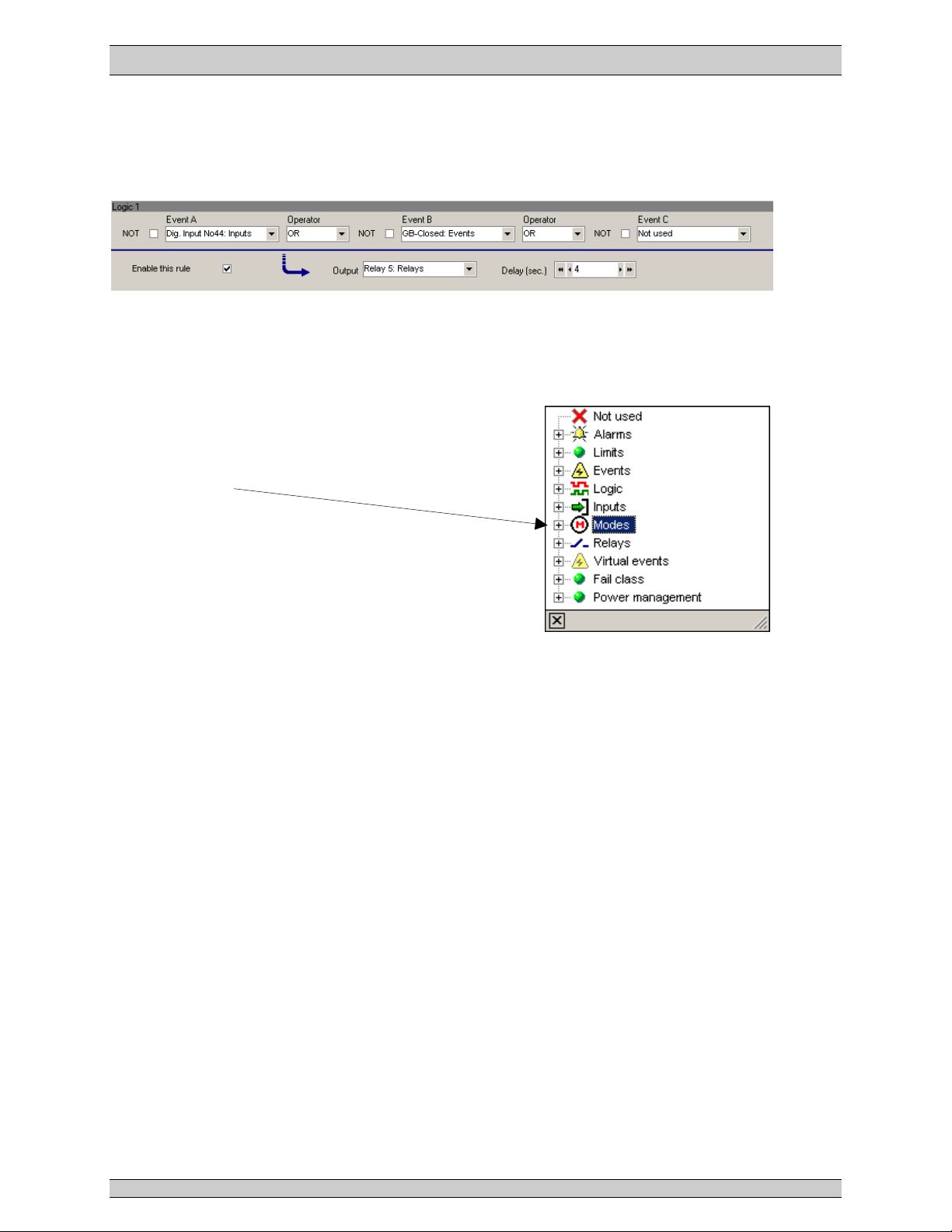

The M-Logic consists of a number of “lines”, Logic 1, Logic 2 and so on. Each of these lines have

3

The available functions are:

Events A, B and C

These are used to trigger the logic.

Note that for each event the function “NOT” can be selected

to get an inverted function.

When opening the roll-down window of the events, this

window appears:

Alarms: Use an alarm to activate.

Limits: Same as alarms, only with no time delay.

Events: Events that are not alarms, e.g.

Logic: Can be TRUE or FALSE. TRUE means always, FALSE means never.

Inputs: Direct activation of a binary input. The availability of binary inputs is

Modes: Are running modes and plant modes, e.g. “AUTO”.

Relays: Activation when a relay activates. The availability of relay outputs is

Virtual

events: Is a number of internal (virtual) events that can be activated from another logic

Fail class: The event activates upon activation of any alarm with the chosen fail class,

Command

timers

1 s pulse: If the activating (triggering) event is required to be a pulse, these can be used.

Power Manage-

ment: Status related to power management, e.g. “Engine 1 running”.

event

settings, 2

operator

settings, an

enable

tick box and one

output

setting.

“Engine running”.

option dependent.

option dependent.

line. By using these virtual events, the number of activating (triggering) events

can be expanded from the 3 available in each logic line to, in theory, an

unlimited number of events.

e.g. “Shutdown”.

PM103 R0 09/08/20 Page 7 THOMSON TECHNOLOGY

MEC 310 APPLICATION NOTES, M-Logic

If a relay output is chosen, the relay in question must be set up to be an

Operators

2 operators are available, and they can be:

“OR” (any operator activates the function output),

“AND” (all activated operators must have status ON to activate the function output).

Enable the rule

If this tick box is not ticked, the logic in question will not operate.

Output

This is the selection of the reaction of the system upon activation of the function. Note that the

output has a delay function. If set to 0 s (default), there is no delay.

Relays: Selection of a relay output. The selection of

these is option-dependent.

Commands: Command to the Multi-line unit, e.g. select

AUTO running mode.

Virtual events: Is a number of internal (virtual) events that

can be activated and used in another logic

line. By using these virtual events, the number

of activating (triggering) events can be

expanded from the 3 available in each logic

line to, in theory, an unlimited number of

events.

Virtual events can also be trigged from Modbus.

Alarm LED: The availability of the alarm LEDs is dependent on the module in question. The

above example comes from a MEC 310 where 4 LEDs are mounted on the display

front.

Inhibits: A selection of inhibit functions for the alarms.

Buzzer: Incorporated buzzer (MEC 310) or buzzer in the additional operator panel (MEC

310/EAP 300). Control of activation and deactivation of the buzzer (e.g. with

alarms).

alarm/limit output (input/output settings, icon in the top of TPS 300).

PM103 R0 09/08/20 Page 8 THOMSON TECHNOLOGY

MEC 310 APPLICATION NOTES, M-Logic

Definitions

The TRUE and FALSE states are explained below.

A TRUE state of an input/event will be detected, if the condition defined in the input/event is met.

Examples given:

Digital input is TRUE when activated (12/24V DC applied)

Alarm condition is TRUE when the alarm is present

Mode condition is TRUE when the mode is selected

A FALSE state of an input event will be detected, if the condition defined in the input event is

met.

Examples given:

Digital input is FALSE when deactivated (12/24V DC not applied)

Alarm condition is FALSE when the alarm is not present

Mode condition is FALSE when the mode is not selected

not

Examples

By using the events, rules can be made for the use of the M-Logic.

Virtual events

Virtual events are used to expand the number of events in a logic sequence.

The following shows how the output of Logic 1 is used to continue the sequence in Logic 2.

The Logic 1 output is set to Virtual Event 1.

The Event A in Logic 2 is Virtual Event 1.

This gives a total of 5 events that can be used in this logic sequence (A + B + C in Logic 1 and B

+ C in Logic 2).

Set/reset function

If you use a single binary input for e.g. selection of AUTO/MANUAL, you need a SET/RESET

function, since 2 binary inputs are normally required for this.

In the following example, binary input no. 10 is used to switch between AUTO (input ON) and

PM103 R0 09/08/20 Page 9 THOMSON TECHNOLOGY

MEC 310 APPLICATION NOTES, M-Logic

MANUAL (input OFF).

First line: If input 10 = ON and AUTO = OFF (NOT Auto operation mode), then set

AUTO mode command.

Second line: If input 10 = OFF and MANUAL = OFF (NOT Manual operation), then set

MANUAL mode command.

In M-Logic, it looks like this:

Toggle function

Using a single button to toggle between 2 running modes.

In this example, the button no. 1 on the EAP-2 (configured in a separate tool) is used to activate

Virtual event 1. Logic 1 selects AMF if the mode is NOT AMF, and Logic 2 selects LTO mode if

the mode is NOT LTO. In this way, one single button can be used for toggling between AMF and

LTO modes.

EAP 300 configurator

The window below appears.

Read the present setting by clicking here:

PM103 R0 09/08/20 Page 10 THOMSON TECHNOLOGY

MEC 310 APPLICATION NOTES, M-Logic

Click button 1 and you select this:

The item text can be written freely and printed, so it can be put in the EAP-2 front pockets.

Click OK and close the EAP-2 window.

Select M-Logic (bottom left-hand side).

PM103 R0 09/08/20 Page 11 THOMSON TECHNOLOGY

MEC 310 APPLICATION NOTES, M-Logic

Controlling a relay output with one single EAP button

In this example, the relay can be replaced by any other output, and the EAP button can be

replaced by e.g. a binary input.

The button of the EAP-2 must be set to activate Virtual Event 1 (VE 1) (in this case).

In Logic 1, the VE 1 will activate the relay output (26). At the same time, the relay output (26) will

remain ON, unless Virtual Event 2 (VE 2) is activated (AND NOT VE 2).

In Logic 2, the VE 1 will activate VE 2 if the relay output (26) is ON (AND Relay output (26)).

The result is that the relay changes position every time the EAO button is activated.

Power up in a specific mode

In the above example, the unit will always power up in manual mode. The timer in Logic 1 sets the

output for 5 s, and this is used to set manual mode in event 2. When the timer expires, you can

freely select any mode since the virtual event 1 turns ON and the Logic 2 says NOT virtual event

1.

PM103 R0 09/08/20 Page 12 THOMSON TECHNOLOGY

MEC 310 APPLICATION NOTES, M-Logic

lists are those used in the Designer’s Reference

Handbook and the description of options. Please refer to these documents for

5. List of events and commands

The terms used in the

detailed explanations.

If there are no references to the function in question, the reference can be

found in the Designer’s Reference Handbook.

MEC 310

Events

Event Description Notes

Alarms All alarms available in the alarm list are

Events

Logic TRUE (= always)

available as events. Note that the list

will show all alarms, also those that are

not available in the present

configuration of basic unit and options.

Mains failure Mains failure relates to option A.

Diesel generator V/Hz OK

Engine running

Ready to auto start

Cranking

Service timer 1

Service timer 2

Engine heater active

Fuel pump active

Lamp test

Nominal settings 1

Nominal settings 2

Nominal settings 3 (single phase) 1 phase + Neutral.

Nominal settings 4 (split phase) 2 phases + Neutral with 180o phase

angle between phases.

Parameter group 1

Parameter group 2

Parameter group 3

Simple test function Simple test relates to option A.

Idle mode

Alarm buzzer on EAP-2-1

Alarm buzzer on EAP-2-2

Access lock

Mute horn button

LTO with AMF active LTO (Load Take Over) relates to option

EAP-300 (Additional Operator Panel)

relates to feature EAP 300.

A.

PM103 R0 09/08/20 Page 13 THOMSON TECHNOLOGY

MEC 310 APPLICATION NOTES, M-Logic

Event Description Notes

Inputs

FALSE(= never)

MB closed MB (Mains Breaker) relates to option A.

MB open

GB closed GB = Generator Breaker.

GB open

Digital input terminal 10-15

Multifunctional input terminal 1-3

Ext. I/O dig. in. 1-16 External I/Os relate to feature EXP.

Modes

Manual operation

Test sequence Test sequence relates to option A.

Auto operation

Island mode

AMF (Automatic Mains Failure) mode AMF mode relates to option A.

LTO mode LTO mode relates to option A.

Relays

Relays no. 21-24

Relay no. 26

Relay no. 45

Relay no. 47

External I/O dig. out. 1-16 External I/O relates to feature EXP.

Virtual

events

Virtual event 1-10

These are used as interconnection

between multiple logics to enhance the

possible number of events in one

sequence.

Fail class

Warning

Trip GB

Trip and stop

Shutdown

Command

timers

Command timer 1-8

The command timers will issue a 1 s

pulse, enough to trigger an event.

Operators

Operator Description Notes

OR Using OR between 2 events means that

the output will activate when one of

these activates.

AND Using AND between 2 operators means

that the output will only activate if both

events are activated.

Outputs

Output Description Notes

Relays Selectable number of relays are option

dependent

The list will show all relays possible

including optional ones. Make sure that

a selected relay is actually present.

PM103 R0 09/08/20 Page 14 THOMSON TECHNOLOGY

MEC 310 APPLICATION NOTES, M-Logic

Output Description Notes

Command

s

AUTO operation

MANUAL operation

Island mode

AMF mode AMF mode relates to option A.

LTO mode

Lamp test

Ack. all alarms

Switch to nominal settings 1

Switch to nominal settings 2

Switch to nominal settings 3

Switch to nominal settings 4

Mute horn relay

Start gen-set Reacts in MANUAL mode only.

Stop gen-set Reacts in MANUAL mode only.

Open GB Reacts in MANUAL mode only.

Close GB Reacts in MANUAL mode only.

Open MB Reacts in MANUAL mode only.

Close MB Reacts in MANUAL mode only.

Virtual

events

Virtual event 1-10

These are used as interconnection

between multiple logics to enhance the

possible number of events in one

sequence.

Alarm LED

Alarm LED 1

Alarm LED 2

Alarm LED 3

Alarm LED 4

The alarm LEDs are placed to the right

of the display on the unit front. Possible

choices are:

- red + blink

- red (steady)

- yellow + blink

- yellow (steady)

- green + blink

- green (steady)

Inhibits

Deactivate mode selection

Deactivates the AUT and MAN mode

buttons on the MEC 310.

Inhibit alarm ack. in auto Prevents the use of the binary input

“alarm ack.” when in AUTO running

mode.

Inhibit ext. comm. Inhibits alarms related to engine

communication (option J).

Buzzer

Inhibit 1

Inhibit 2

Inhibit 3

Activate buzzer on main unit

Inhibit 1, 2 and 3 are used for alarm

inhibit. Remember to activate inhibit in

the alarm in question.

Main unit is the MEC 310 unit.

Deactivate buzzer on main unit

Activate buzzer on EAP-2-1

Deactivate buzzer on EAP-2-1

Activate buzzer on EAP-2-2

Deactivate buzzer on EAP-2-2

Ack. alarm buzzer on EAP-2-1

EAP 300 units are external Additional

Operator Panels. The setup of these is

made in a separate M-Logic-like setting

(EAP-2 configuration icon on top of the

USW screen).

Ack. alarm buzzer on EAP-2-2

PM103 R0 09/08/20 Page 15 THOMSON TECHNOLOGY

MEC 310 APPLICATION NOTES, M-Logic

Thomson Technology reserves the right to change any of the above.

PM103 R0 09/08/20 Page 16 THOMSON TECHNOLOGY

Loading...

Loading...